Page 1

MN-525

m

by

(14604)

ECR 5656

Single rear wheel applications with a 3.5” axle require an additional spacer kit

*See Page 3 for Details.

Please read these instructions completely

before proceeding with installation

Failure to read these instructions can result in mis-installation

Introduction to the RoadTamer System

What You Need to Know About RoadTamer ...................... 2

V ehicle Requirements ....................................................... 3

RoadT amer W arranty and Return Policy ........................... 3

Installing the RoadTamer System

Getting Started .................................................................. 4

Inspecting Axle Spring Perch Uniformity ........................... 5

Attaching the Axle Beams ................................................. 5

Attaching the Frame Brackets ........................................... 6

Attaching and Adjusting the Panhard Rod......................... 7

Hardware List .................................................................... 9

*Kit Installation Diagram ................................................... 10

Installing the Rolling Lobe Air Sleeves ............................. 11

Installing the Air Lines ...................................................... 12

Final Adjustments............................................................. 13

.

F250-F350 Kit No. 39010

www.airliftcompany.co

Checking Driveline Angles

Checking Driveline Angles ............................................... 14

Checking Angles in Various Conditions ............................ 14

Installation Checklist

Installation Checklist......................................................... 15

T r oubleshooting Guide

Troubleshooting Guide ..................................................... 16

Checking for Leaks........................................................... 17

Fixing Leaks ..................................................................... 17

Maintaining and Servicing the System

Maintenance Guidelines................................................... 17

Servicing the RoadT amer System.................................... 18

Technical Support

1-800-248-0892

Ext. 2

1

Page 2

What You Need to Know About RoadTamer

About RoadTamer

The RoadTamer suspension system and your

vehicle’ s original equipment steel spring suspension

operate differently . RoadTamer allows your vehicle to

ride “on air.” It lowers air pressure for lighter loads,

meaning you will have a softer ride when you don’t

need the heavy factory springs.

RoadTamer lowers your vehicle to be approximately

level with the front suspension. The result is a vehicle

altitude very similar to that of a fully loaded vehicle.

The air management system then maintains that rear

suspension height regardless of the load you carry .

Ride Height

This will give you optimum ride performance,

regardless of the load. RoadTamer’s air management

system will maintain the vehicle’s ride height within

½”. You will enjoy a much more comfortable,

controllable and safer ride. The design of RoadT amer

is carefully considered to give you “The Ultimate

Suspension Upgrade. ”

V ehicle Leveling, Side-to-Side

V ehicles are not alwa ys lev el when they are deliv ered

from the factory . Installing RoadTamer on your vehicle

does not correct this non-level condition. Before you

install RoadTamer, measure for vehicle levelness on

a flat surface. After the factory springs have been

removed, use a level to verify that the axle spring

perches are level from side-to-side. If the perches are

not level, y ou will need to apply a wedge shim to one

side or the other to correct this condition. The wedge

shim is provided with each RoadTamer kit. More

information is provided later in the instruction manual.

Install your RoadTamer kit and make sure the axle is

level and square with the v ehicle frame. Snug, but DO

NOT TORQUE, all fasteners per the directions provided

in this installation manual. Check again to see if the

vehicle is lev el. If it is not close to as level as its f actory

levelness, re-read the installation man ual concerning

the use of the wedge shim. Y ou may also hav e to loosen

all beam connecting bolts, u-bolts, etc. Re-level the

axle to the frame before re-torquing all fasteners.

Driveline Angles

Driveline angles are factory-set to cancel vibrations

caused by the u-joints. RoadTamer takes this into

consideration when lowering the vehicle to a level

height. How ever , the factory does not set up all vehicles

to be identical. Many different axle, suspension, and

wheelbase combinations are possible. You will need

to measure the driveline angles and make a calculation

to verify that the driveline cancels correctly. See the

section toward the back of the installation manual that

covers this operation in detail.

Introduction to the RoadTamer System

Technical Support

1-800-248-0892

Ext. 2

2

Page 3

V ehicle Requirements

Vehicle Type

Ford F-250 Ford F-350

NOTE: Single rear wheel applications with a 3.5”

axle require spacer kit #26024 to be purchased

separately . If you do not already have this kit, y ou

can purchase it by calling Air Lift’s Customer

Service Department at 800-248-0892 extension 1.

Vehicle Y ears

See the application guide for specific years.

5th Wheel Hitch

The installation of this RoadT amer kit will fit onto most

vehicles with a fifth wheel hitch. Some fifth wheel

hitches may require modifications to make the kit fit

properly.

See page 5 for further instructions.

Muffler Modifications

Modifications will need to be made to the muffler after

the completion of this kit.

Gross Vehicle Weight Rating

(GVWR)

IMPORTANT: The installation of this kit does not

alter the GVWR or payload of the vehicle. Check

your vehicle owner’ s manual and do not e xceed the

maximum load listed for y our vehicle.

Gross Vehicle Weight Rating - The maximum allowab le

weight of the fully loaded vehicle (including passengers

and cargo). This number - along with other weight limits ,

as well as tire, rim size and inflation pressure data - is

shown on the vehicle’ s Saf ety Compliance Certification

Label.

Payload - The combined, maximum allowable weight

of cargo and pasengers that the truck is designed to

carry . It is GVWR minus the Base Curb W eight.

Introduction to the RoadTamer System

Air Lift Company recommends taking your vehicle to

a muffler repair shop upon completion of the kit

installation.

RoadTamer Warranty and Return Polic y

Air Lift Company warranties its RoadT amer

product against quality and workmanship defects

to the original retail purchaser as follows; Main

Structural components defined as; beams,

brackets, and links for 24 months or 24,000 miles,

whichever occurs first. All other components for

12 months or 12,000 miles, whichever occurs

first. Air Lift Company provides no warranty on

the vehicle’s original equipment or other

aftermarket products. This warranty does not

apply to products that have been improperly

applied, installed, used in racing applications or

maintained in accordance with installation

instructions furnished with the product. A $10.00

minimum shipping and handling charge will apply

to all warranty claims. Before returning any

defective product, you must call Air Lift Company

(800) 248-0892 ext 2 for an RGA (Returned

Goods Authorization) number. Product failures

resulting from abnormal use or misuse are

excluded from this warranty. The loss of use of the

product, loss of time, inconvenience, commercial

loss, or consequential damages is not covered. The

Air Lift Company reserves the right to change the

design of any product without assuming any

obligation to modify any product previously

manufactured. Dated proof of purchase is

required.

Technical Support

1-800-248-0892

Ext. 2

3

Page 4

Getting Started

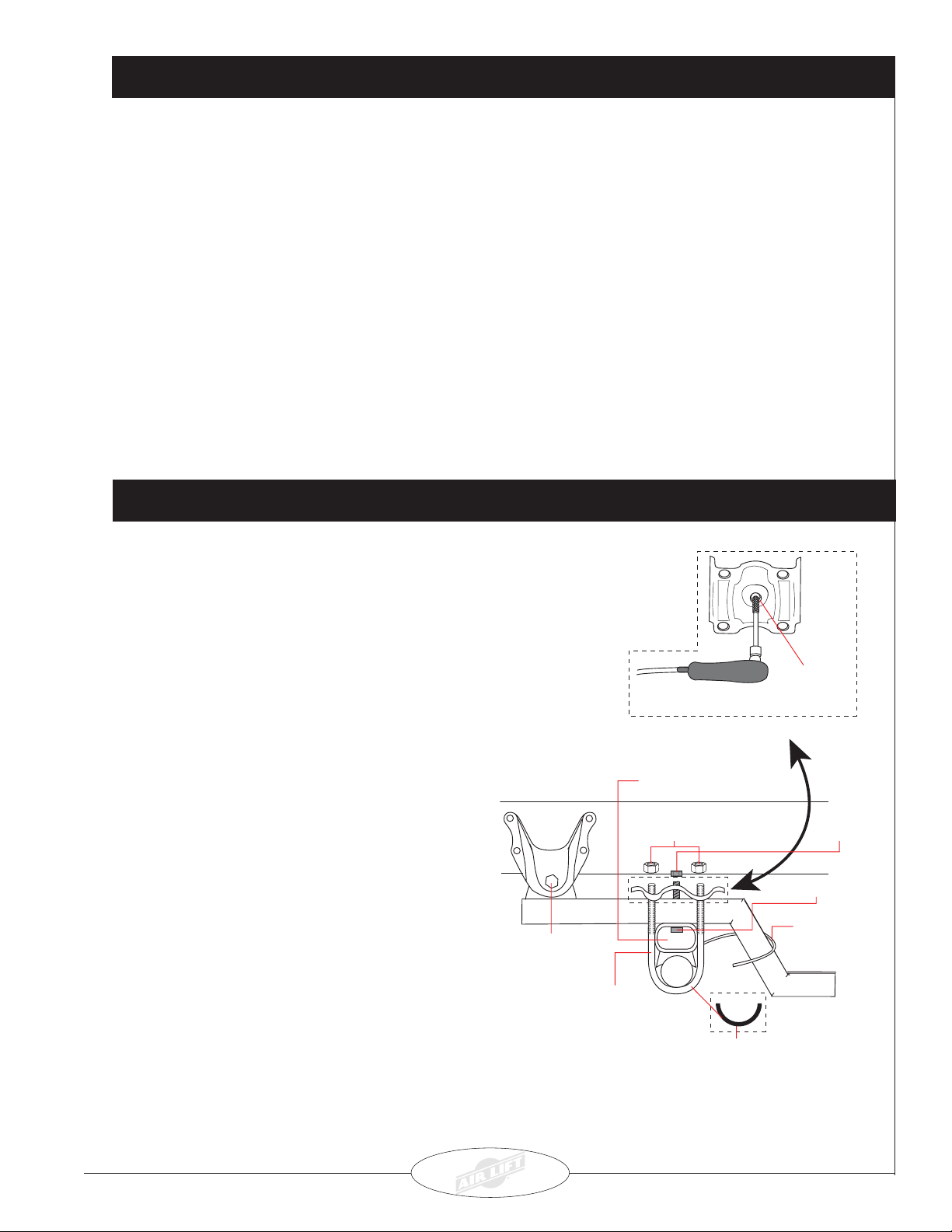

Driver-Side View

REMOVE Frame

Contact Overload

Upper Bracket

if Equipped.

REMOVE

Spare Tire.

Axle

REMOVE

Leaf Spring.

DANGER: Compressed air can cause injury and

damage to the vehicle and parts if it is not handled

properly. For your saf ety, do not try to inflate the air

springs until they have been properly secured to the

vehicle.

IMPORT ANT : Me asure and record the driveline angles

in the chassis as first received (Figure 19).

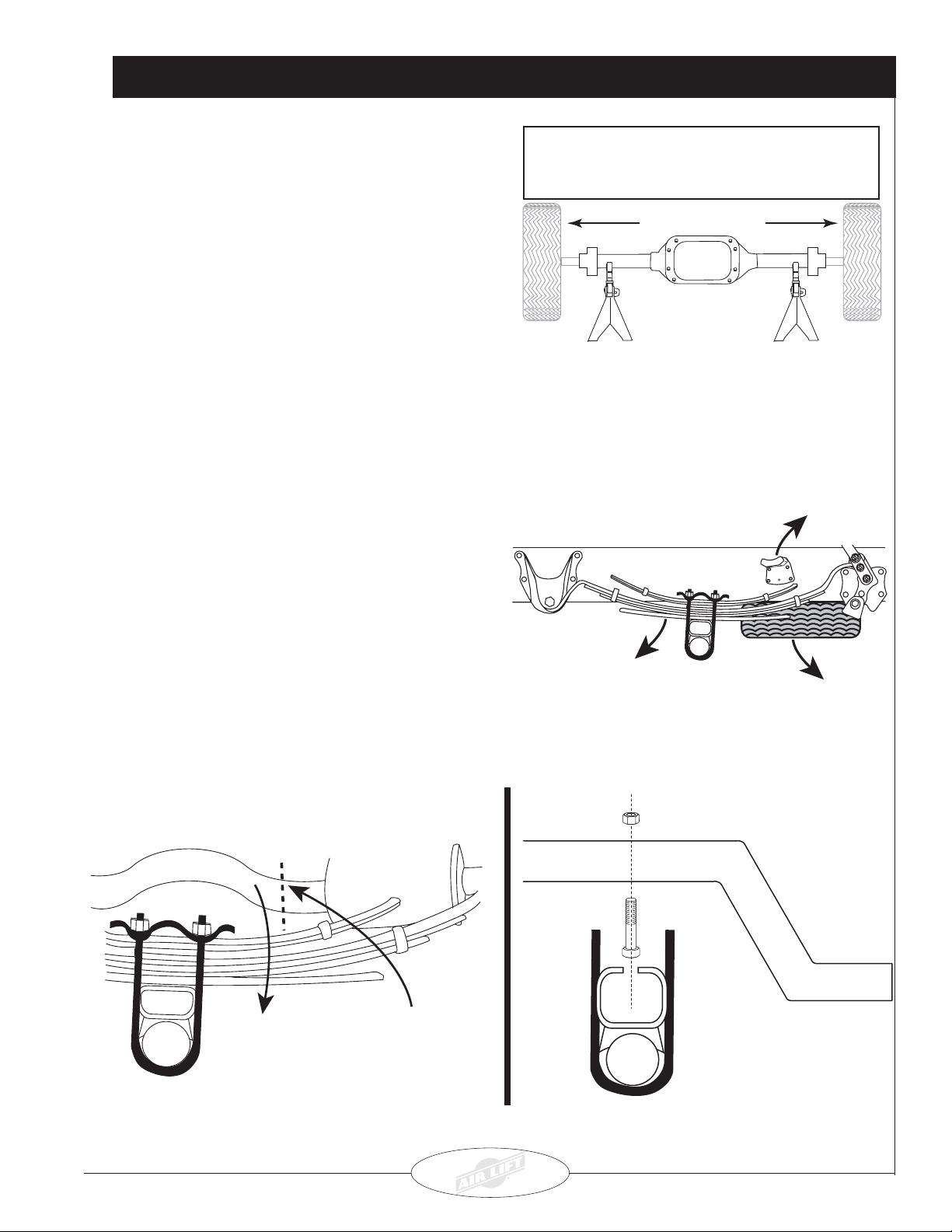

1. Elevate the rear of the vehicle and secure the frame

with jack stands or a frame-contact hoist. Support the

axle (Figure 1).

2. Remove the spare tire, both leaf springs, and the

rear frame contact ov erload brack ets, if equipped, from

the frame (Figure 2).

NOTE: It may be necessary to remove the trailer

hitch in order to remove the bolts fr om the spring

hanger.

NOTE: After removing the factory steel springs,

check the axle spring perches for side-to-side

angle uniformity. Refer to the Inspecting Axle

Spring Perc h Uniformity section for information

on installing the supplied 1° wedge shim.

No Load in Truck

Remove Wheel Remove Wheel

Support the axle with jack

stands and raise or lower

to Normal Ride Height

Figure 1

Installing the RoadTamer System

3. Cut off the tailpipe behind the muffler and remove.

4. Install the centering pin into the beam assembly.

Leave enough room on the muffler to install a

replacement pipe (Figure 3).

Install the pin so that the head is facing down and

the nut is at the top of the beam (Figure 4).

Passenger-Side Vie w

CUT OFF tailpipe behind

muffler. Leave enough

room to attach a

replacement pipe.

Axle

REMOVE

excess tailpipe.

Figure 2

Axle

Figure 3

Technical Support

1-800-248-0892

Ext. 2

Figure 4

4

Page 5

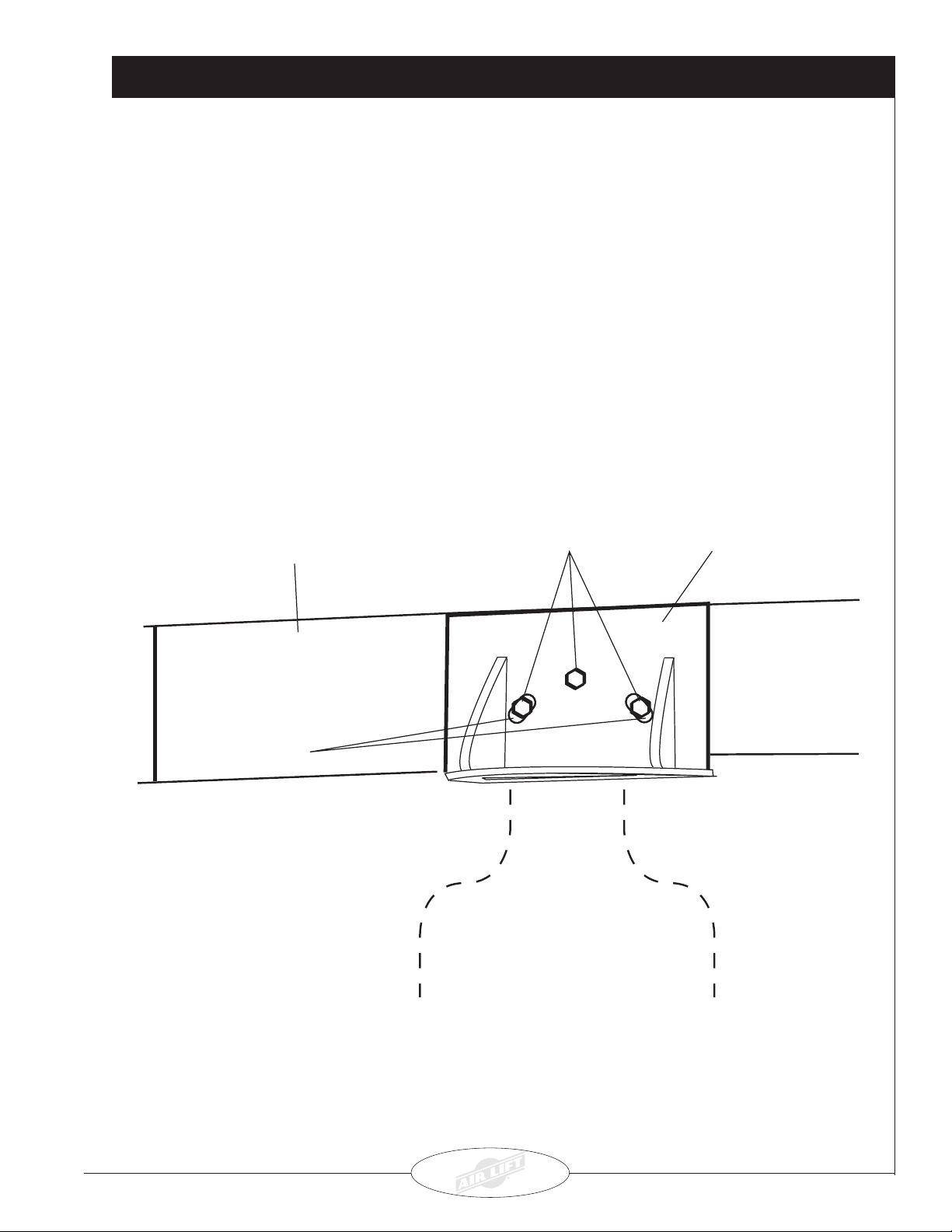

Inspecting Axle Spring Per ch Unif ormity

1. After removing the factory steel springs, check the

axle spring perches for side-to-side angle

uniformity. Without disturbing the axle position,

place a magnetic angle protractor on one perch

and note the angle. Next, place the angle protractor

on the other perch and note the angle there as

well. A difference of less than 1° is normal and

does not require a shim. If the diff erence between

the two angles exceeds 1°, use the supplied 1°

wedge shim to correct the difference.

2. Place the 1° wedge shim on one axle spring perch

and re-measure the angles to verify that they equal

less than 1°. Use the centering pin to attach the

wedge to the correct beam and install the beams

as directed in the section titled

Beams

. DO NO T TIGHTEN F ASTENERS until you

Attaching the Axle

Attaching the Axle Beams

1. Install the driver-side beam assembly to the front spring

eye hanger using the pre viously removed stock bolt and

nut. Be sure to index the centering pin into the stock

spacer block (4x4 only) or spring perch (2WD) in order

to properly locate the axle and the beam. Leav e loose

at this time (Figure 5).

NOTE: The emergency brake cable should go over

the beam assembly .

have chec ked the driveline angles as instructed in the

section dealing with that topic toward the back of this

manual.

NOTE: You must check the driveline angles for

cancellation before completing the installation (see the

Driveline Angles section toward the back of the

manual). It ma y be necessary to reverse the shim and

place it on the opposite side to maintain correct

driveline angles.

3. Measure from the top of each frame rail (at the rear of

the frame) to the ground. The measurement must be

made at vehicle ride height with the vehicle on level

ground and with equal tire pressures. The vehicle

levelness is acceptab le if the two measurements from

side-to-side are within 3/8”. If the vehicle is not level

within 3/8”, check that the 1° shim is placed properly.

Grind out to

provide clearance

for centering pin.

Stock Spring Retainer

Installing the RoadTamer System

NOTE: If a block or spacer was used between the

stock spring and axle, it is necessary to replace the

block or spacer between the axle and the beam.

2. Drill or grind the spring retainer center hole out to

provide clearance for the centering pin nut on the

beam assembly (Figure 5).

NOTE: Draw the nuts down evenly on the retainer

by using a criss-cross tightening pattern.

NOTE: On models with a 3.50” axle, use spacer

kit #26024.

Technical Support

1-800-248-0892

Stock Bolt

Figure 5

Ext. 2

U-Bolt

& Mounting

Hardware

Replace the

stock spacer

DO NOT

TIGHTEN

Centering Pin

Emergency

Brake Cable

Axle

Axle Spacer for

3.50" Diameter Axles

(Not Included In This Kit)

*See Page 1 for Details

Centering

Pin Nut

5

Page 6

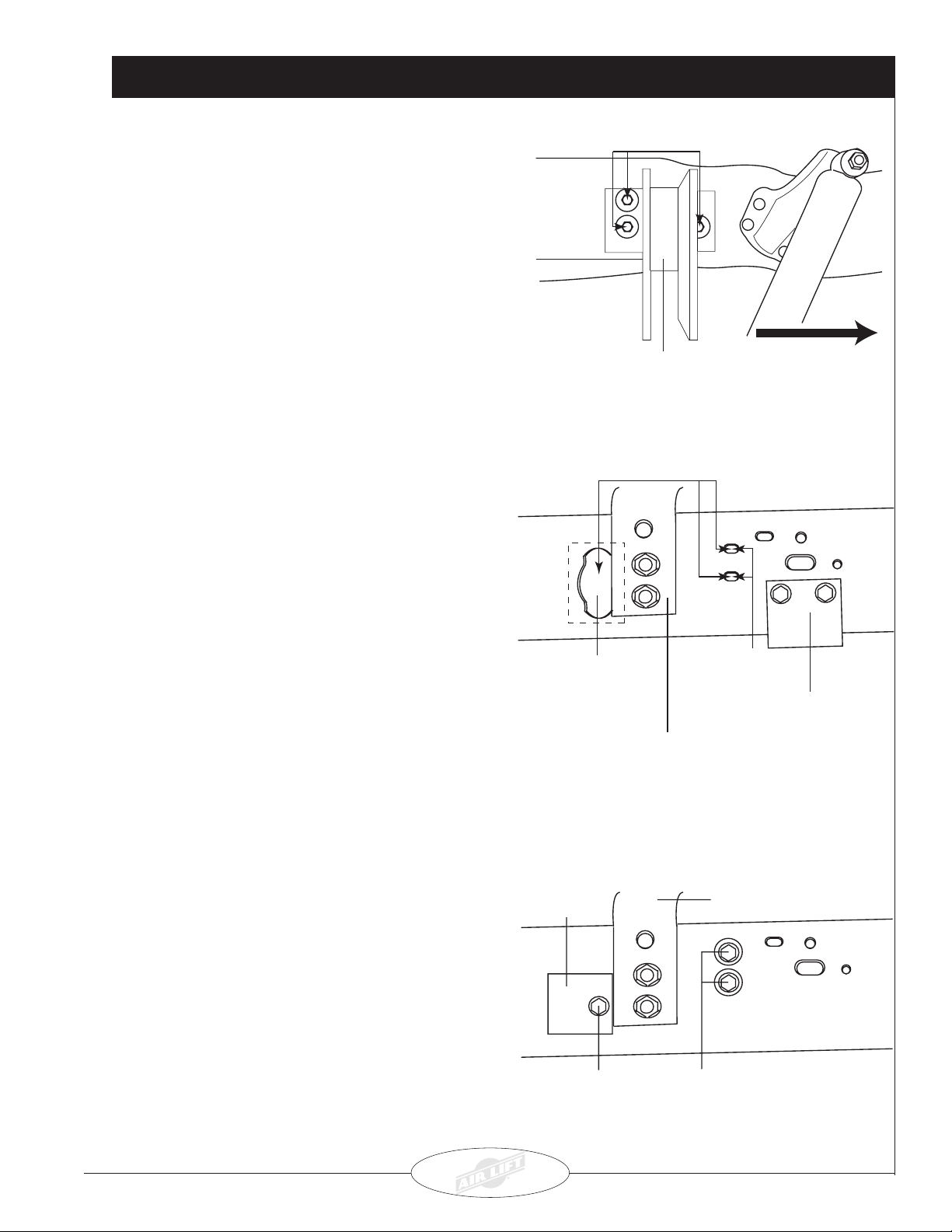

Attaching the Frame Brackets

1. Install the driver-side frame brac ket. Line up the lower

set of holes in the side of the frame brack et with the

slotted holes that are angled in the side of the frame.

Insert two 1/2” bolts, four flat washers and two 1/2”

nylock nuts. Secure the nylock nuts until snug, but

do not overtighten at this time (Figure 6).

2. Line the top hole up with the existing hole in the frame.

NOTE: Do not use the hole that does not line up with

the existing hole in the frame.

Driver-Side Shown

Frame

3. Drill a 1/2” hole through the frame using the top hole in the

bracket as a template .

4. Drill two 1/2” holes in the bottom on the frame flange.

5. Insert the remaining 1/2” hardw are and tighten all bolts to

107 ft.lbs. (Figure 6).

6. The spare tire can be reinstalled at this time.

Upper

1/2" Bolts

Bracket

Installing the RoadTamer System

Existing Slots

in Frame

Drill out 1/2" holes

in the underside of

the frame rail using

the bracket as a template

Figure 6

Technical Support

1-800-248-0892

Ext. 2

6

Page 7

Attaching and Adjusting the Panhar d Rod

This hole may

be a square on

your vehicle.

Drill out

to 1/2"

5th Wheel

Hitch Bracket

Use these holes for mounting.

Jounce

Bumper

Bracket

NOTE: If you have a fifth-wheel hitch with a

bracket that hangs down to the side of the frame,

it may be necessary to modify the bracket and/

or the Air Lift bracket in order to mount the

panhard bracket to the inside of the frame.

NOTE: One large round washer and one large

square washer are supplied in this kit. Use the

square washer if you have a fifth wheel bracket.

It may be necessary to weld the square bracket

to the leg of the fifth-wheel hitch bracket to make

the bracket work properl y (Figure 8, Figure 9).

1. On the passenger’ s side frame r ail, drill out the two

oval holes that are behind the jounce bumper with a

1/2” drill bit (Figure 8).

2. Insert the panhard bracket into the inside of the

frame rail (Figure 7). Line up the front holes with

the previously drilled holes (Figure 8).

3. Place a flat washer onto each of the two 1/2” bolts.

Insert the bolts through the frame and the bracket and

then fasten each bolt with another flat washer and a

nyloc nut (Figure 9).

1/2" Flat Washers

1/2" Nylock Nuts

Inside View of

Frame-Rail on

Passenger-Side

Panhard Rod Bracket

REAR

Inside of Passenger-Side Framerail

Figure 7

Installing the RoadTamer System

4. Using the 1/2”-13 x 2.5” bolt, attach the rear of the

bracket through:

A) the large square washer, if using on v ehicles with

a fifth-wheel bracket.

B) the large round washer , if no fifth wheel bracket

is present.

Insert the bolt through the frame inside the panhard

rod bracket and use a 1/2” flat w asher and nylock nut

to attach. Tighten the front and rear bolts at this time,

making sure the two center holes on the panhard

bracket line up with the oval holes in the side of the

frame. Drill the two holes out to 1/2” and insert the

remaining 1/2” hardware (Figures 8 and 9). T orque all

bolts to 107 ft.lbs.

Large

Square

Washer

Figure 8

5th Wheel

Bracket

Technical Support

1-800-248-0892

Ext. 2

1/2" Bolt

1/2" Bolts

1/2" Washer s

Figure 9

7

Page 8

Attaching and Adjusting the Panhar d Rod

e

5. Attach the the rubber bushing end of the panhard

rod assembly to the driver-side beam assembly

using one 9/16” bolt, two flat washers and one nyloc k

nut (Figure 10). Leave loose at this time.

6. Raise or lower the axle to create a space of 12.5

inches between the rolling lobe upper and lower

mounting brackets (Figure 14). Measure the

distances between the passenger and driver sides

of the beam to the frame. Adjust the heim so both

beam-to-frame distances are equal. Y ou ma y have

to use a pry bar between the beam and frame to

adjust the heim.

CAUTION: There m ust be no more than 1-1/2” of

thread showing on the heim joint (Figure 11).

7. Attach the heim to the passenger side frame bracket.

Refer to Figure 12 for an installation diag ram. Tighten

both ends of the panhard rod securely.

Jam Nut

Heim Joint

8. Turn the heim joint so the cage is parallel with the

bracket to prevent suspension travel from

interfering. Tighten the lock nut on the heim.

9. Refer to figure 19 and the Checking Driveline

Angles section at this time. If angles are

acceptable, proceed with torquing the U-bolts and

pivot bolts.

10. Tighten the beam U-bolts to 170 ft/lbs. using a crisscross pattern to tighten evenly (Figure 13). Using

a hacksaw, grinder, or cut-off wheel, trim off the

excess U-bolt so it is 1” above the retaining nuts.

Torque the front stock beam pivot bolts to 185 ft/

lbs. (Figure 5).

No more than 1-1/2" of thread

showing on heim joint

Installing the RoadTamer System

Rubber Bushing

Driver-Side Passenger-Side

Figure 10

Flat Washer

Jam Nut

Flat Washer

Front of Vehicl

Bolt

Spacers

Nut

Frame

Bottom View P assenger-Side

0" to 1-1/2"

Figure 11

Torque to 170 ft/lbs.

Axle

Figure 12

Technical Support

1-800-248-0892

Ext. 2

Figure 13

8

Page 9

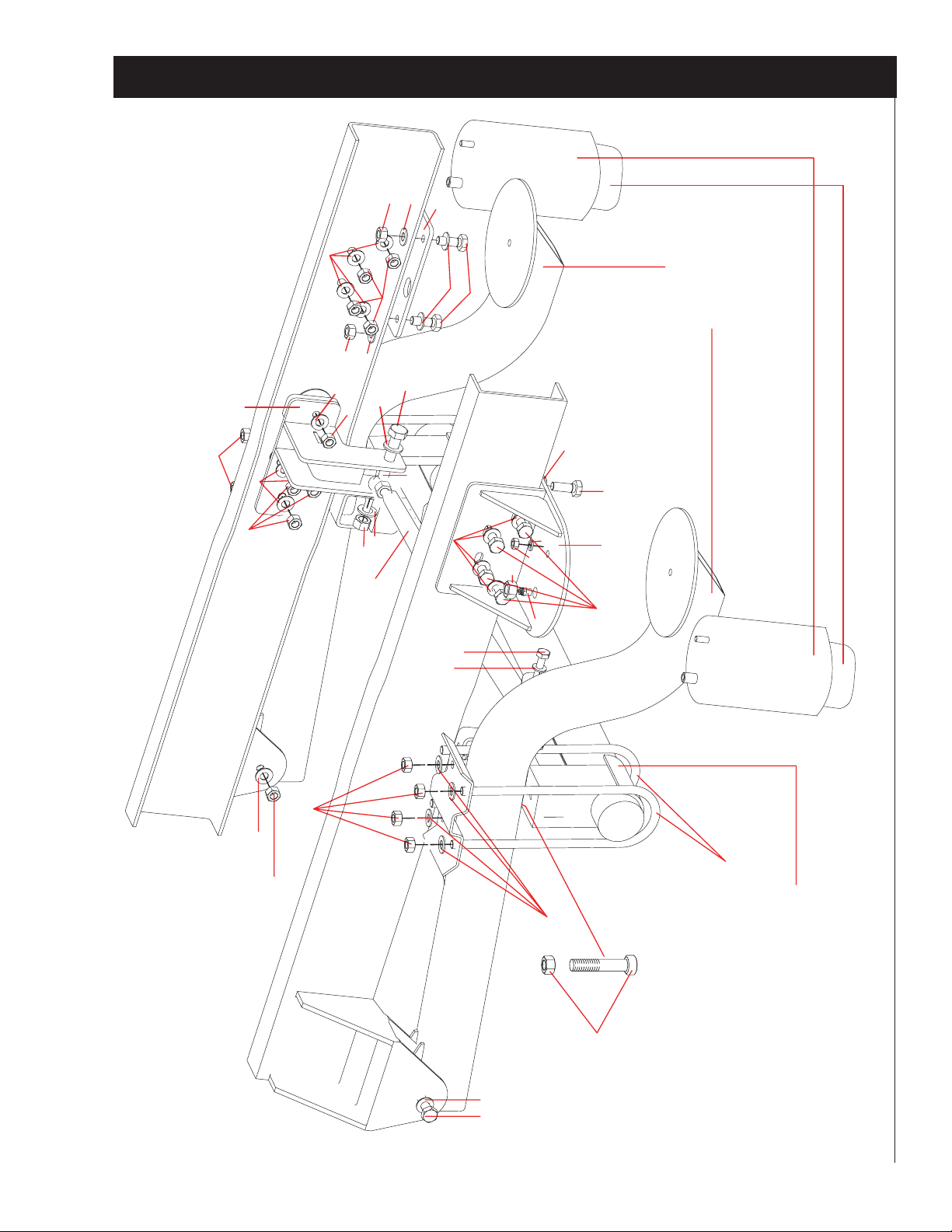

Kit Diagram

Hardware List

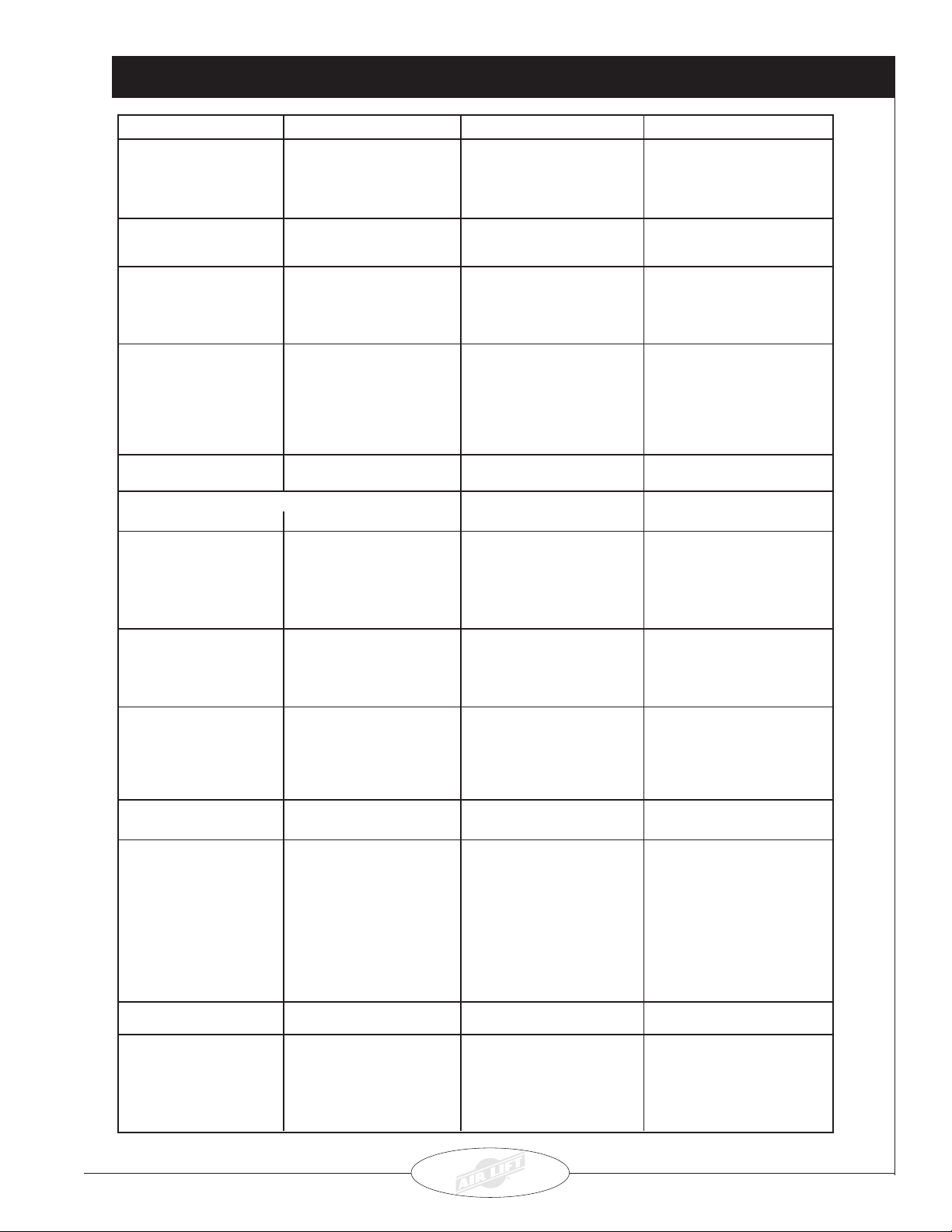

Item Part No. Description Quantity

A 26456 Passenger-Side Beam Assembly 1

B 26517 Driver-Side Beam Assembly 1

C 26404 Panhard Rod Assembly 1

D 10021 Panhard Rod Brac k et 1

E 58225 Rolling Lobe Slee ve 2

G 07001 Driver-Side F rame Brac k et 1

H 07002 Passenger-Side F rame Brac ket 1

J 18017 5/8”-18 x13” U-Bolt 4

K 18509 1.25” Flat Washer 8

L 18508 5/8”-18 Nylock Nut 8

M 18451 3/4”-16 Jam Nut 2

N 18484 1/2”-20 Hex Nut 4

O 18429 1/2” Lock Washer 4

P 21745 1/4” x 1/4” Air Fitting 2

Q 10466 8” Zip Tie 6

R 18405 5/16” x 5/8 x .032 Flat Washer 2

S 18411 5/16” Ext. Tooth Lock Washer 2

T 21230 Poly Cap 2

U 21233 He x Nut 4

V 21234 Rubber Washer 2

W 17219 9/16”-12 x 5 Bolt 1

X 18485 1/2” Flat Washer 28

Y 18480 9/16”-12 Nylock Nut 1

Z 13227 3/4” x 1/2” Spacer 2

AA 17269 3/4”-16 x 4 Bolt 1

BB 18518 3/4” Flat Washer 2

CC 18470 3/4”-16 Nylock Nut 1

DD 17247 1/2”-13 x 1.75 Bolt 12

EE 18460 1/2”-13 Nylock Nut 13

JJ 10035 3” Square W asher 1

KK 10008 2.5” Flat Washer 1

LL 17285 1/2”-13 x 2.5 Bolt 1

MM 17286 Centering Pin and Nut 2

NN 10049 Piston 2

Installing the RoadTamer System

I 20086 Air Line Assembly 16 ft.

25425 SmartAir Automatic Leveling System 1

10349 1° Wedge Shim 1

Technical Support

1-800-248-0892

Ext. 2

9

Page 10

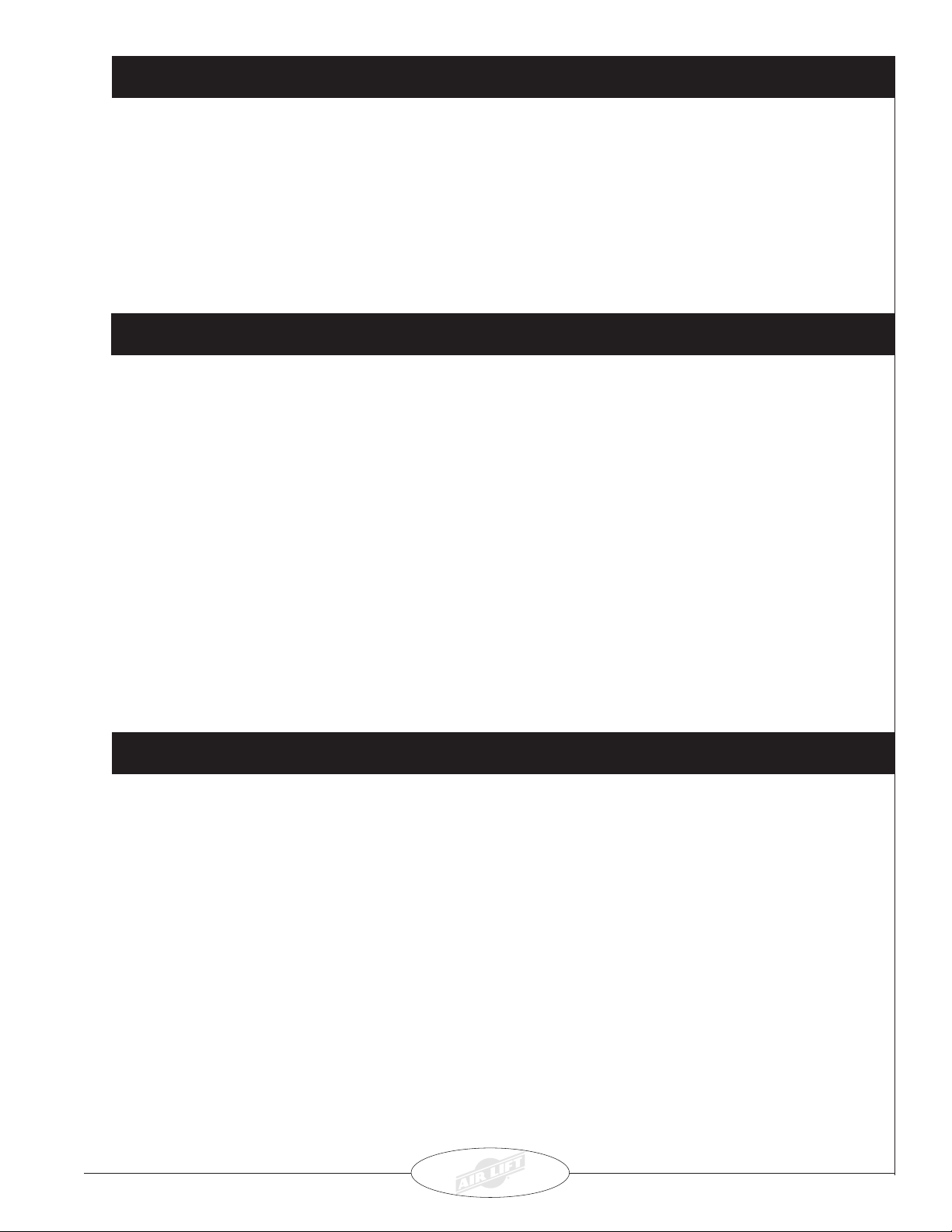

Kit Diagram

EE

E

NN

X

H

CC

D

EE

X

A

X

EE

DD

B

EE

X

BB

AA

Installing the RoadTamer System

BB

EE

X

X

Z

DD

CC

BB

X

M

O

G

N

C

P

DD

W

X

L

O.E.M.

J

K

*See Page 1 for Details

MM

Spacer for 3.5" Axles (Kit #26024)

O.E.M.

Technical Support

1-800-248-0892

Ext. 2

10

Page 11

Installing the Rolling Lobe Air Sleeves

Refer to Figure 14 f or the fo llowing instructions.

1. Install the fitting into the large top stud of the rolling

lobe air sleeve. Tighten the fitting finger-tight plus

11/2 turns, being careful to tighten on the metal hex

nut only.

NOTE: It may be necessary to raise the chassis

to provide adequate space to install the rolling

lobe air sleeves.

2. Insert the piston on the bottom the rolling lobe air sleev e.

3. Insert the studs of both rolling lobe air sleeves into the

bottom mounting hole of the beam assemblies on both

sides of the vehicle. Attach finger-tight using a 1/2”

lock washer and nut.

4. Lower the fr ame while guiding both studs on top of

the rolling lobe air sleeves through the holes in the

upper mounting bracket.

Installing the RoadTamer System

Lock

Washer

1/2" Nut

5. Attach the air sleeves using a 3/4” jam nut on the

large stud. Use a lock washer and 1/2” nut on the

smaller stud. Tighten the top mounts securely.

Leave the bottom loose at this time .

Driver-Side View

Inside of Beam

GUIDE rolling lobe bottom stud through

hole in center of beam. Attach with

hardware shown.

Air Fitting

3/4" Jam Nut

Large

Stud

1/2" Nut

Lock Washer

Small

Stud

Mounting

Height 12.5"

Figure 14

Technical Support

1-800-248-0892

Ext. 2

Beam

GUIDE rolling lobe top studs through

holes in upper mounting bracket

while lowering the frame.

Attach with hardware shown.

11

Page 12

Installing the Air Lines

Frame Rail

Air

Line

Tie Strap

Exhaust Pipe

Muffler

Keep air lines

secured at least 6"

away from all

heat sources

Good Cut

Air Line Cutting

Poor Cut

1. Choose a convenient location for mounting the inflation

valves. Popular locations for the inflation valve are:

the wheel well flanges, the license plate recess in the

bumper, under the gas cap access door, or through

the license plate itself.

NOTE: Whatever the chosen location is, make

sure there is enough clearance for an air chuc k

around the inflation valves.

2. Drill a 5/16 " hole to install the inflation valves.

3. Cut the air line assembly in two equal lengths .

CAUTION: When cutting or trimming the air line,

use a razor blade or a very sharp knife. A clean,

square cut will ensure against leaks. DO NOT

USE WIRE CUTTERS OR SCISSORS T O CUT THE

AIR LINE. These tools may flatten or crimp the

air line, causing it to leak around the O-ring seal

inside the elbow fitting (Figure 16).

4. Refer to Figure 15 to assist with air valve installation.

5. Route the air line along the frame to the air fitting on

the air spring. K eep at least 6" of clearance between

the air line and heat sources, such as the exhaust

pipes, muffler, or catalytic converter (Figure 17).

Avoid shar p bends and edges. Use the plastic tie

straps to secure the air line to fixed, non-moving

points along the chassis. Be sure that the tie straps

are tight, but do not pinch the air line. Leav e at least

2" of slack to allow for an y movement that might pull

on the air line.

6. Cut off air line leaving appro ximately 12" of extr a air

line. A clean square cut will ensure against leaks.

Insert the air line into the air fitting. This is a pushto-connect fitting. Simply push the air line into the

straight fitting until it bottoms out (9/16" of air line

should be in the fitting).

Valve

Cap

Flat

Washer

Hex Nut

Figure 15

Vehicle body

or bumper

Rubber

Washer

Figure 16

Installing the RoadTamer System

Air Line to

Bellows

Hex Nut

Star

Washer

Technical Support

1-800-248-0892

Ext. 2

Figure 17

12

Page 13

Final Adjustments

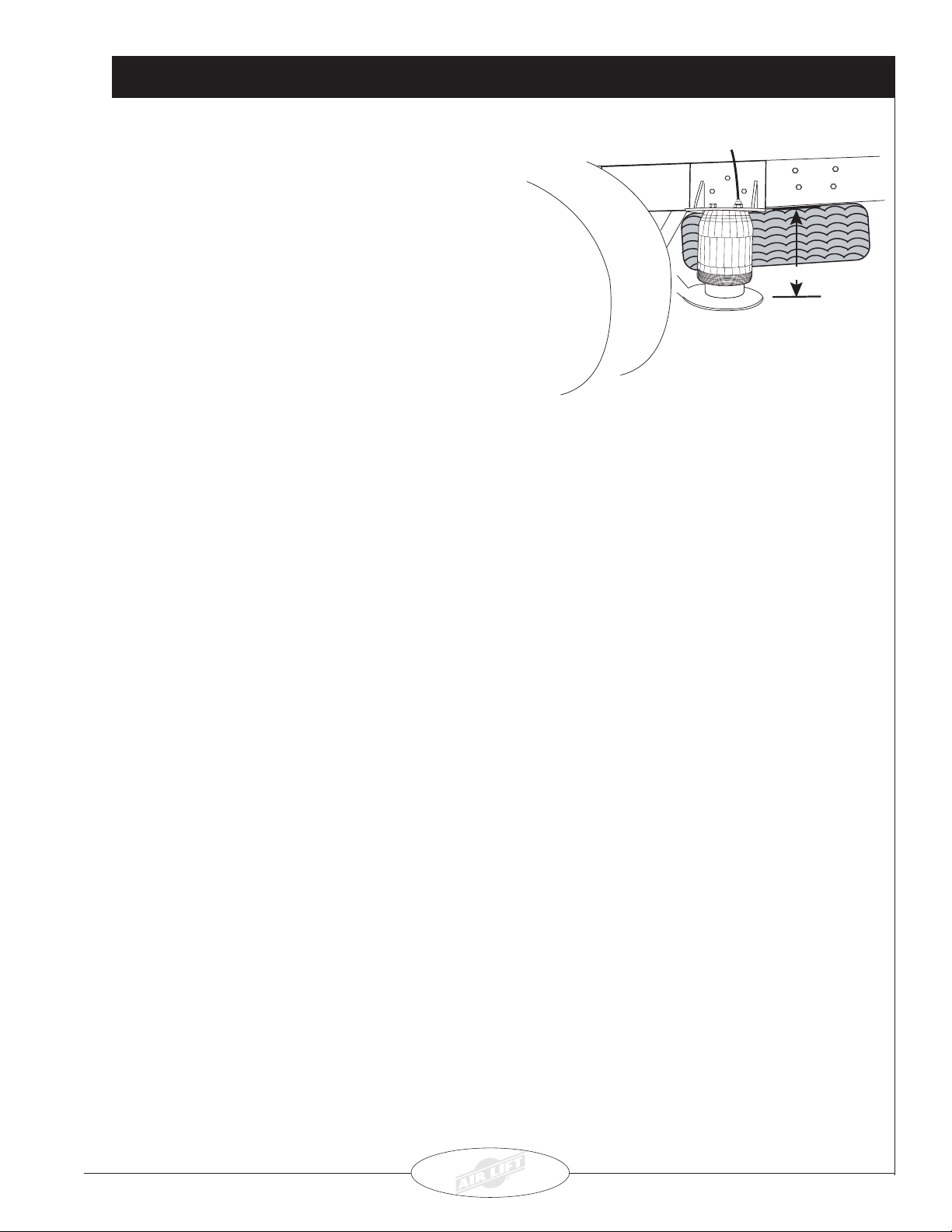

1. Inflate both rolling lobe air sleeves to 20 p.s.i and

check for leaks.

2. Tighten both bottom rolling lobe mounts

securely at this time. Torque to 50 ft/lbs.

3. You are now ready to install the SmartAir Automatic

Leveling System. Refer to the SmartAir instruction

manual to proceed with the installation.

Once the SmartAir system is installed it will

automatically maintain the rolling lobe air springs’

installed height of 12 - 13 inches within their mounts

(Figure 18).

4. Routing the e xhaust out of the side of the vehicle in

front of the rear wheel on the passenger side is

recommended.

NOTE: It may be necessary to have a custom

bent pipe made if routing the exhaust out the

back behind the rear wheels is desired.

5.

IMPORTANT: Check and re-torque all mounting

hardware, especiall y the beam U-bolts, after 100

and 3,000 miles.

Driver-Side Shown

12 - 13 inches

Keep a distance of 12 - 13

inches for operation of vehicle.

Installing the RoadTamer System

Figure 18

Technical Support

1-800-248-0892

Ext. 2

13

Page 14

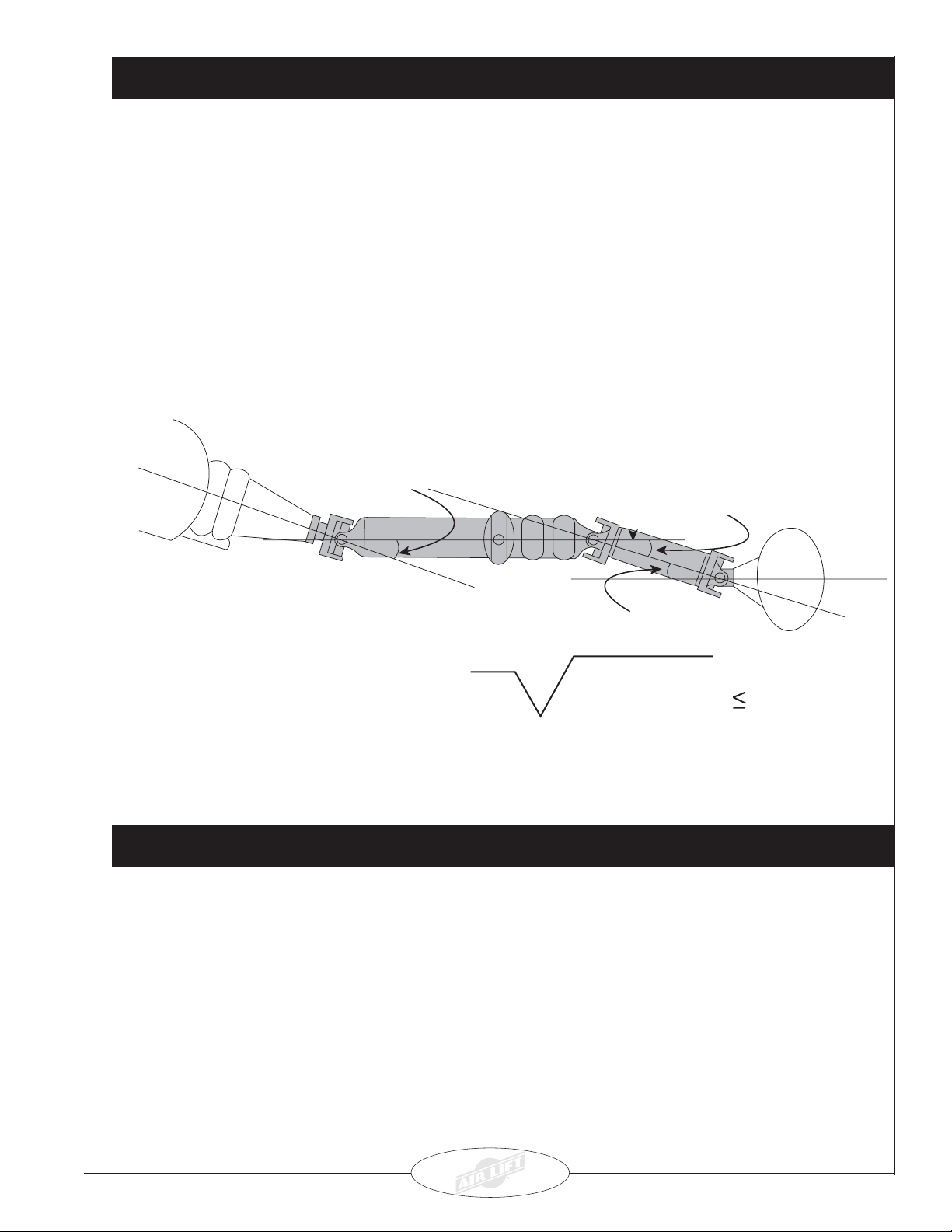

Checking Driveline Angles

1. After the RoadTamer kit is installed, the following

conditions must be true for the driveline angles, both at

unloaded and fully loaded ride heights:

a. Condition #1: The operating angle at an y individual

joint must be between 0.1° and 4°. The pref erred

maximum angle is 2°.

b. Condition #2: When added together, the operating

angles throughout the driveline MUST cancel. The

operating angles at either end of a shaft should

be within 1° of each other or at least satisfy the

following formula in order to provide adequate

cancellation (Figure 19).

angle-a

2. Wedge shims may be placed between the beams

and axle to correct driveline angles that fall outside

this requirement. Re-chec k all driveline angles after

installing the shims.

3. A minimum operating angle of 0.1° at each universal

joint is required to prevent dents from forming on

the bearing surfaces.

Checking Driveline Angles

DRIVESHAFT

angle-b

SIDE VIEW

For a 3-joint, 2-shaft driveline:

(as shown above)

angle-c

22 2

a - b + c 4.0˚

Figure 19

Checking Angles in Various Conditions

1. Measure and record the driveline angles in each of the

following conditions f or later comparison:

a. The chassis as first received (note that the driveline

angles may not conform e xactly to this bulletin in

this incomplete condition).

b. The completed v ehicle, unloaded.

c. The completed vehicle loaded to Gross

Vehicle Weight Rating (GVWR) with

maximum front Gross Axle Weight

Requirement (GAWR).

d. The completed vehicle loaded to GVWR with

maximum rear GAWR.

Technical Support

1-800-248-0892

Ext. 2

14

Page 15

Installation Checklist

This Installation Checklist must be completely filled out to ensure proper installation:

❏ Have you checked the mounted height of the air springs and is it correct?

❏ Have the axle U-bolts been torqued per the specification?

❏ Have the beam pivot bolts been torqued per the specification?

❏ Was the suspension at ride height and even from side-to-side

when the fasteners were torqued?

RoadTamer Installation Checklist

❏ Have the upper bracket bolts been torqued per the specification?

❏ Does the heim joint have the proper amount of thread showing?

❏ Have you tightened the heim joint jam nut?

❏ Was the axle centered in the chassis within

3

/8”?

❏ Have all remaining fasteners and fittings been torqued per the specification?

❏ Have the pinion angles been check and are they within specification?

❏ Has the panhard bar heim joint been properly greased?

❏ Is there a adequate clearance around all par ts of the panhard bar?

❏ Is there a minimum clearance of ½” around all par ts of the air spring?

❏ Has the system been leak checked and found free of leaks?

❏ Are all wires and hoses routed correctly and away from heat sources?

❏ Has the vehicle been road tested?

❏ Has the owner been infor med of the maintenance requirements?

❏ Has the owner been informed of the operation of the system?

❏ Does the owner have the correct instruction manual?

Technician’s Signature _____________________________

Technical Support

1-800-248-0892

Ext. 2

15

Page 16

Tro ubleshooting Guide

Problem Possible Problem Check Procedure Solution

Air System leaks.

Vehicle is not level sideto-side within 3/8".

Truck sits too low or too

high.

Suspension rides rough.

Rear end "jacks" when

vehicle is accelerated.

Pneumatic Control System

Problem

Compressor doesn't run.

Compressor runs all the

time.

System will not kneel.

Possible Problem Check Procedure Solution

SmartAir Control System

Problem

Compressor doesn't run.

Compressor runs all the

time.

System will not kneel.

Possible Problem Check Procedure Solution

• leaky airbag

• leaky pneumatic fittings

(i.e.: drain valve, Height

Control Valv e [HCV])

• cut or pinched air line

• OEM axle perch is not

level side-to-side.

• Air spring mounting height

is not correct.

• Air bag is mounted too

high or too low.

• OE shocks are too stiff or

worn out.

• Shocks are not compatible

with air suspension.

• blown fuse

• loose wire or ground

• bad pressure switch

• HCV or height sensor is

mounted incorrectly.

• Bad pressure switch

• Stuck or clogged solenoid

• Damaged or improperly

connected switch.

• blown fuse

• loose wire or ground

• Relay/ECU

• Magnet to ECU distance

• Magnet direction/180˚ off

• Possible major leak. • Check system for leaks.

• Stuck or clogged solenoid

• Damaged or improperly

connected switch.

• Spray air bag with a soapy

water solution.

• Spray fittings with a soapy

water solution.

• Conduct visual inspection.

• Refer to

Spring Perch Uniformity

the manual.

• Measure the distance

between the upper and

lower air bag mounting

surfaces.

• Measure the mounted height.

• Bounce the rear of the truck.

If there are more than two

oscillations, the shocks are

too worn. If less than two

oscillations, shocks are too stiff.

• Truck lurches when

accelerating.

• Check fuse.

• Inspect wiring connections.

• Jumper pressure switch.

• Check manual for mounting

location and adjustment

instructions.

• Disconnect switch.

• Inspect the exhaust port or

energize the solenoid.

• Ensure that switch wiring is

correct by referencing the

wiring diagram in the SmartAir manual.

• Check fuse.

• Inspect wiring connections.

• Ground terminals #85 if

compressor runs.

• Magnet may be too close or

too far from ECU

• Magnet not facing ECU

properly .

• Inspect the exhaust port or

energize the solenoid.

• Ensure that switch wiring is

correct by referencing the

wiring diagram in the SmartAir manual.

Inspecting Axle

in

• If leaking, replace air bag.

• Tighten fittings.

• Repair or replace as

necessary.

• Add a 1˚ shim per the

Inspecting Axle Spring Perch

Uniformity

• Change the ride height as

necessary to within

specifications given in the

manual for rolling lobe

mounting heights.

• Adjust mounted height as

necessary.

• Install Air Lift Select-A-Ride

shocks.

• Install Air Lift Select-A-Ride

shocks.

• Replace fuse.

• Tighten loose wires or grounds.

• If compressor runs, replace

switch.

• If compressor does not run,

replace compressor.

• Move HCV or height sensor

further towards the pivot

bushing.

• If compressor stops, replace

switch.

• Replace solenoid.

• Replace switch if found faulty.

• Replace fuse.

• Tighten loose wires or grounds.

• If compressor runs, replace ECU

• If compressor does not run,

replace compressor.

• Refer to SmartAir manual for

proper distance between magnet

and ECU

• Make sure dot on magnet

points towards the ECU

• Repair as necessary.

• Replace solenoid.

• Replace switch if found faulty.

section.

Trou bleshooting Guide

Technical Support

1-800-248-0892

Ext. 2

16

Page 17

Checking for Leaks

1. Spray all connections and the inflation v alves with

a solution of 1/5 liquid dish soap and 4/5 water to

check for leaks. You should be able to spot leaks

easily by looking for bub b les in the soap y w ater.

2 . After the test, deflate the springs to the minimum

pressure required to restore the Normal Ride

Height, but not less than 10 p.s .i.

Fixing Leaks

1. If there is a problem with the air fitting:

a. Check the air line connection by deflating the

spring and removing the line by pulling the

collar against the fitting and pulling firmly on

the air line. Trim 1" off the end of the air line.

Be sure the cut is clean and square. Reinsert

Minimum Air Pressure

the air line into the push-to-connect fitting.

b. Check the threaded connection by tightening

the swivel fitting another 1/2 turn. If it still leaks,

deflate the air spring, remove the fitting, and

re-coat the threads with thread sealant.

Reinstall by hand tightening as much as

possible, then use a wrench for an additional

two turns.

3.

IMPORT ANT : Check the air pressure a gain after

24 hours. A 2 to 4 p.s.i. loss after initial

installation is normal. Retest for leaks if the

loss is more than 5 lbs.

2. If there is a problem with the inflation v alv e:

a. Check the valve core b y tightening it with a valve

core tool.

b. Check the air line connection by removing the

air line from the barbed fitting.

not cut it off. This will usually nick the barb

and render the fitting useless.

a few inches in front of the fitting and use a pair

of pliers or vise-grips to pull/twist the air line off

the fitting.

3. If the preceding steps have not resolv ed the problem,

call Air Lift Technical Service at 1-800-248-0892 for

assistance.

CAUTION: Do

Cut air line off

Trou bleshooting Guide

Maintenance Guidelines

By following the steps below, vehicle owners will obtain the longest life and best results

from their air springs.

1. Fulfill all Installer Responsibilities:

The installer is solely responsible for checking the

installation for safe oper ation before the vehicle is

placed in service. This includes all fastener torques,

proper control system operation, and driveline

angles.

This instruction manual includes specifications for

fastener torques. Tighten fastening hardware as

instructed by the specifications.

Technical Support

1-800-248-0892

Ext. 2

Retorque the fasteners in intervals as

specified below under “Servicing the

RoadT amer System.”

Check driveline angles as shown in the

section titled “Checking Driveline Angles .”

2. If you dev elop an air leak in the system, use a

soapy water solution to check all air line

connections and the inflation valve core bef ore

deflating and removing the air spring.

17

Page 18

Servicing the RoadTamer System

1. At 150 miles and every 10,000 miles thereafter, check

and retorque (per the fastener torques specified in

this manual): the beam front hardw are and pivot bolts,

the axle U-bolts, and the panhard rod pivot bolts.

2. Every 3,000 miles:

Check the air spring install height and adjust the

height control valve as necessary.

Check all fittings for air leaks and reseal if

necessary.

Grease the panhard rod end fitting.

Check the compressor air filter and replace

as necessary.

3. Perf orm DAILY maintenance by releasing the

moisture from the air tank. To do this, pull

on the release cable attached to the drain

valve. Excess moisture in the system can

lead to component failure or freeze up in cold

weather.

Maintaining and Servicing the System

Thank you for purchasing Air Lift Products

Mailing Address: Street Address:

AIR LIFT COMPANY AIR LIFT COMPANY

P.O. Box 80167 2727 Snow Rd.

Lansing, MI 48908-0167 Lansing, MI 48917

Local Phone: (517) 322-2144

Fax: (517) 322-0240

www.airliftcompany.com

For Technical Assistance call 1-800-248-0892

Technical Support

“The Choice of the Professional Installer”

1-800-248-0892

Ext. 2

Printed in the USA

18

Loading...

Loading...