Air King AIK24Y, AIF8X, AIF6Y, AIK26Y, AIK16X User Manual

...

IMPORTANT INSTRUCTIONS -

OPERATING MANUAL

Models: AIK14X, AIK16X, AIK24Y, AIK26Y,

AIF4X, AIF6Y, AIF8X, AIF10X,

AIG4, AIG6

In-Line Exhaust Fan

READ AND SAVE THESE INSTRUCTIONS

READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE OR MAINTAIN THE PRODUCT DESCRIBED. PROTECT

WARNING: DO NOT CONNECT POWER SUPPLY UNTIL FAN

IS COMPLETELY INSTALLED. MAKE SURE ELECTRICAL SERVICE

TO THE FAN IS LOCKED IN OFF POSITION.

1. Read all instructions before installing or using exhaust fan.

2. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer.

YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH

INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE!

RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

GENERAL SAFETY INFORMATION

When using electrical appliances, basic precautions

should always be followed to reduce the risk of fire,

electric shock and injury to person, including the following:

6. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

7. Ducted fans must always be vented to the outdoors.

8. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off

power unit.

3. Before servicing or cleaning the unit, switch power off at

service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When

the service disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag, to the

service panel.

4. Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable codes

and standards, including fire-related construction.

5. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment

to prevent back drafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA)

and the American Society for Heating, Refrigeration, and Air

Conditioning Engineers (ASHRAE), and the local code authorities.

CAUTION: FOR GENERAL VENTILATING USE ONLY. DO

NOT USE TO EXHAUST HAZARDOUS OR EXPLOSIVE MATERIALS

AND VAPORS.

9. Acceptable for use over a bathtub or shower when installed

in a GFCI protected branch circuit.

10. Suitable for use with solid-state speed control.

11. This unit has rotating parts and safety precautions should be

exercised during installation, operation and maintenance.

12. Guards must be installed when fan is within reach of personnel

or within seven (7) feet of working level or when deemed

advisable for safety.

13. NEVER place a switch where it can be reached from a tub or

shower.

14. Do not insert or allow fingers or foreign objects to enter the

motor.

WARNING: DO NOT USE IN KITCHENS

5S7635036 New 9-06

SAVE THESE INSTRUCTIONS

www.airkinglimited.com

1 of 12

INSTALLATION INSTRUCTIONS

CAUTION:

SERVICE PANEL BEFORE STARTING INSTALLATION.

MAKE SURE POWER IS SWITCHED OFF AT

SECTION 1

Preparing for Fan Installation

1. When selecting fan mounting location, the following criteria

should be considered:

a) Mounting to minimize noise generated by fan operation:

Mounting the fan as far as possible from the intake

point will minimize fan operating noise from being

transmitted back through the duct work. If the fan is to

be used as a booster for moving the air between two

rooms, a central point along the duct may be optimal.

Insulated flexible type duct work (recommended for all

bathroom exhaust applications) will result in much

quieter operation. It is recommended that a minimum

8' of insulated flexible ducting be used between any

exhaust grill and fan for low noise level.

b) Service accessibility: Fan location should allow

sufficient access for service.

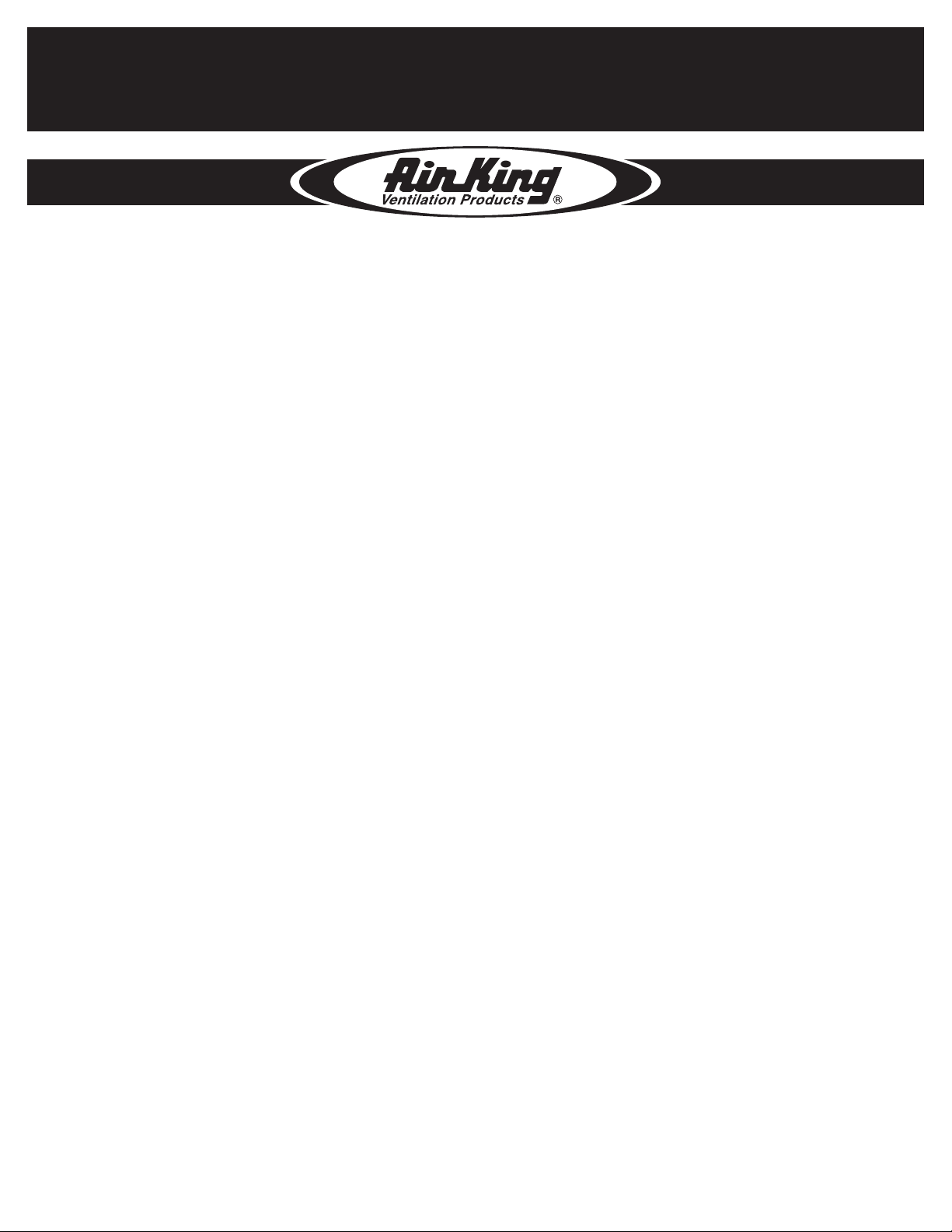

Fan

Stud

Screws

Figure 2

NOTE: Bracket is provided with rubber vibration isolation grommets

to prevent the transmission of sound through the structure. Be

careful not to over tighten. Also, care should be taken not to strip

the plastic housing. Screws are self tapping and do not require

pilot holes. Pilot holes no larger than 1/16" can be used to ease

the installation however.

Bracket

SECTION 3

Installing Supply/Exhaust Grill

SECTION 2

Installing the Fan

1. Using the 1" wood screws provided, attach the fan mounting

bracket to a support beam at the selected location

Vertical Mounting

Horizontal Mounting

Bracket

Bracket

or

Stud

Figure 1

NOTE: Fan mounting can be at any point along the duct and in

any angle, however, vertical mounting is recommended to reduce

condensation buildup in the fan. If a horizontal installation is

necessary and condensation buildup may pose a problem, wrap

insulation around the fan to minimize buildup.

2. Attach fan to the mounting bracket with the three 7/16" sheet

metal screws provided, making sure the wiring box is

positioned for easy access

(Figure 2).

(Figure 1).

Joist

1. Select the grill mounting point within the area to be ventilated

that does not interfere with a ceiling joist. To ease installation,

locations of framing beams within the walls or joists supporting

the ceiling should be considered. Collar/damper is provided

with a perforated hanging strap for attachment directly to a

beam or joist. Allow sufficient space between the collar/damper

and the beam to attach the duct work. If the location of the

grill does not allow direct attachment, a cross-member mounted

to the framing should be used.

2. Bend the mounting straps attached to the collar outward so

they are straight across (Figure 3).

Mounting

Strap

Mounting

Strap

Figure 3

Collar/Damper

SECTION 4

New Construction

1. Install the collar/damper in the selected location using the

provided 1" wood screws

mounting height is determined by the thickness of the final

wall/ceiling material. Ensure that the edge of the collar/damper

will be flush with the finished wall/ceiling material (Figure 4).

5S7635036 New 9-06 2 of 12

www.airkinglimited.com

through the mounting strap. The

Joist/Stud

Joist/Stud

SECTION 6

Ducting

Collar/Damper

Screws

Collar/Damper

Figure 4

2. Once the wall/ceiling material is in place, install the grill into

the collar by pushing it firmly inward towards the collar until

it fits flush against the wall/ceiling material

Wall/Ceiling Material

(Figure 5).

Collar/Damper

Grill

Figure 5

CAUTION: ALL DUCTING MUST COMPLY WITH LOCAL

AND NATIONAL BUILDING CODES.

NOTE: Insulated ducting is required for bathroom exhaust

applications, where ducting passes through unconditioned space

or where noise is a factor. Failure to use insulation could result

in excessive condensation buildup within the duct, and

undesirable sound levels within the room. Duct runs should have

as few bends as possible.

NOTE: Flexible insulated ducting may be used where allowed

by local code. For the quietest possible installations, it is

recommended a minimum of 8' of insulated flexduct be used

between any exhaust grill and fan. When using flexible type

duct work, duct should be stretched as tight and straight as

possible. Failure to do so could result in dramatic loss of system

performance. Flexible duct should be connected to the fan with

screw clamps or duct tape. All connections should be as airtight

as possible to maximize system performance.

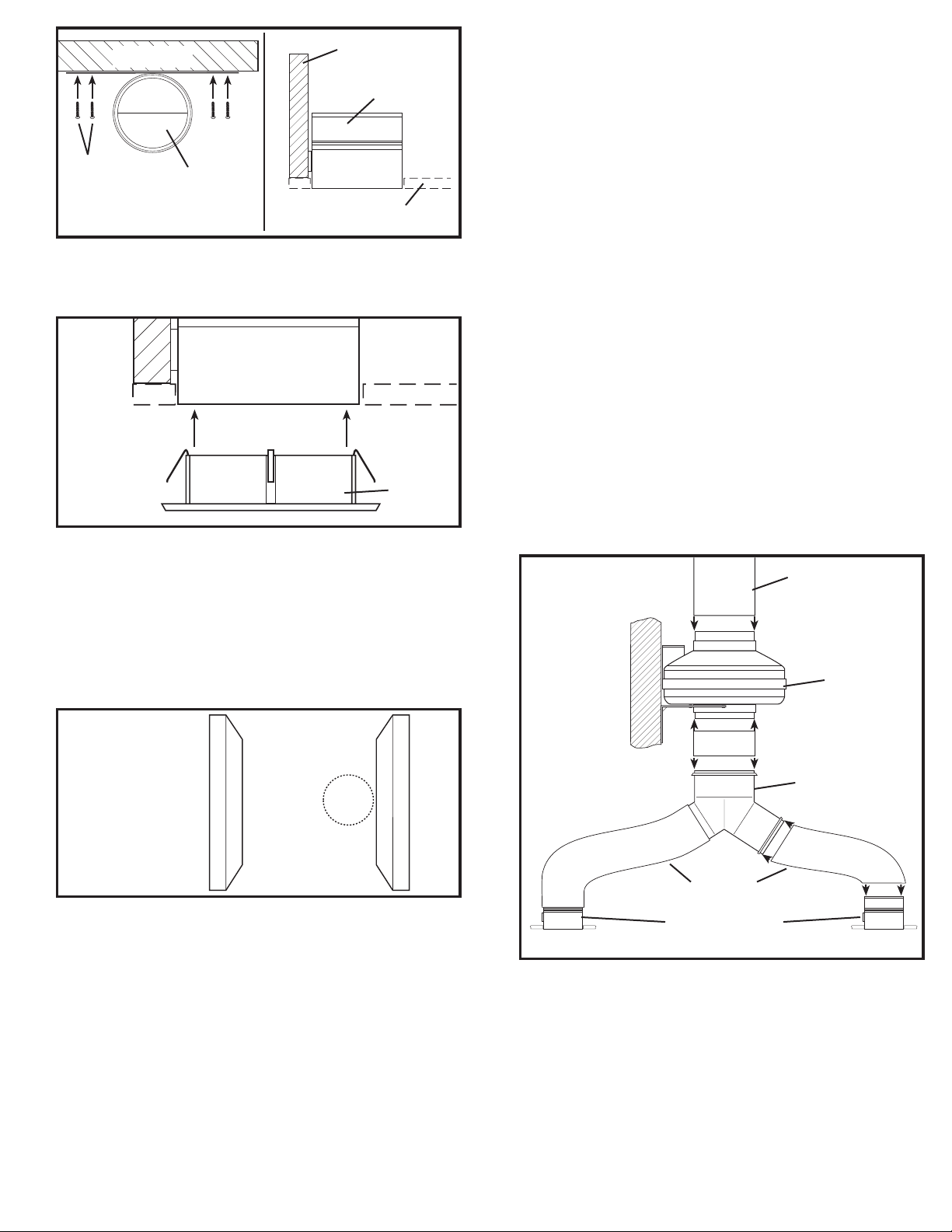

1. Connect one end of the ducting (not included) to the room

level collar/damper and the other end to the “Y” transition.

Secure both ends in place using tape or a screw clamp to

create as air tight a seal as possible. Repeat this step for the

other room level grill housing (Figure 7).

SECTION 5

Existing Construction

1. Place the collar/damper in the selected location and trace

a circle onto the surface. From the interior side of the room,

cut through the surface. Please note: Take care not to damage

the ceiling and make a smooth cut (Figure 6).

Figure 6

2. Position the collar/damper in the previously cut hole so that

it is flush with the finished ceiling and secure to the joist/stud

using the provided 1" wood screws through the mounting

strap (Figure 4).

3. Install the grill

towards the collar until it fits flush against the wall/ceiling

material

into the collar by pushing it firmly inward

(Figure 5).

Exhaust to

Wall/Roof Cap

Fan

“Y” Transition

Ducting

Collar/Damper

Figure 7

NOTE: Units that include only one collar do not utilize the “Y”

transition. Follow the same instructions as in step 1, except

connect the one end of the ducting directly to the fan.

2. Connect one end of the ducting to the top of the “Y” transition

and the other end to the intake of the fan (Figure 7).

3. Connect one end of the ducting to the exhaust of the fan and

the other end to a wall or ceiling cap (Figure 7). Always duct

the fan to the outside through a wall or roof cap.

5S7635036 New 9-06 3 of 12

www.airkinglimited.com

NOTE: When using insulated flex duct, it is recommended that

the inner vinyl core be screw clamped or taped to the inlet and

outlet and that the vapor barrier surrounding the insulation be

taped to the fan housing.

NOTE: When attaching flex duct to the collar/damper combination

and an immediate elbow is necessary, be certain that the elbow is

installed with a "soft" bend to allow damper blades to operate properly.

Screws

SECTION 7

Installing Optional Balancing Damper

Some kits include an optional balancing damper to allow for

adjustment of the system. The damper may be used where the

grills will be connected using branches of unequal length or

where the flow will need to be balanced for any reason. To Install

the optional damper:

1. The damper must be installed on the branch with the least

restriction. This is generally the duct that is shortest or has

the fewest bends.

2. Drill a 5/16" hole approximately 1-1/2" from the edge on the

flat side of the “Y” transition.

3. Insert the shaft of the damper into the hole drilled in step 2. Place

the washer, handle, then wing nut onto the shaft (Figure 8).

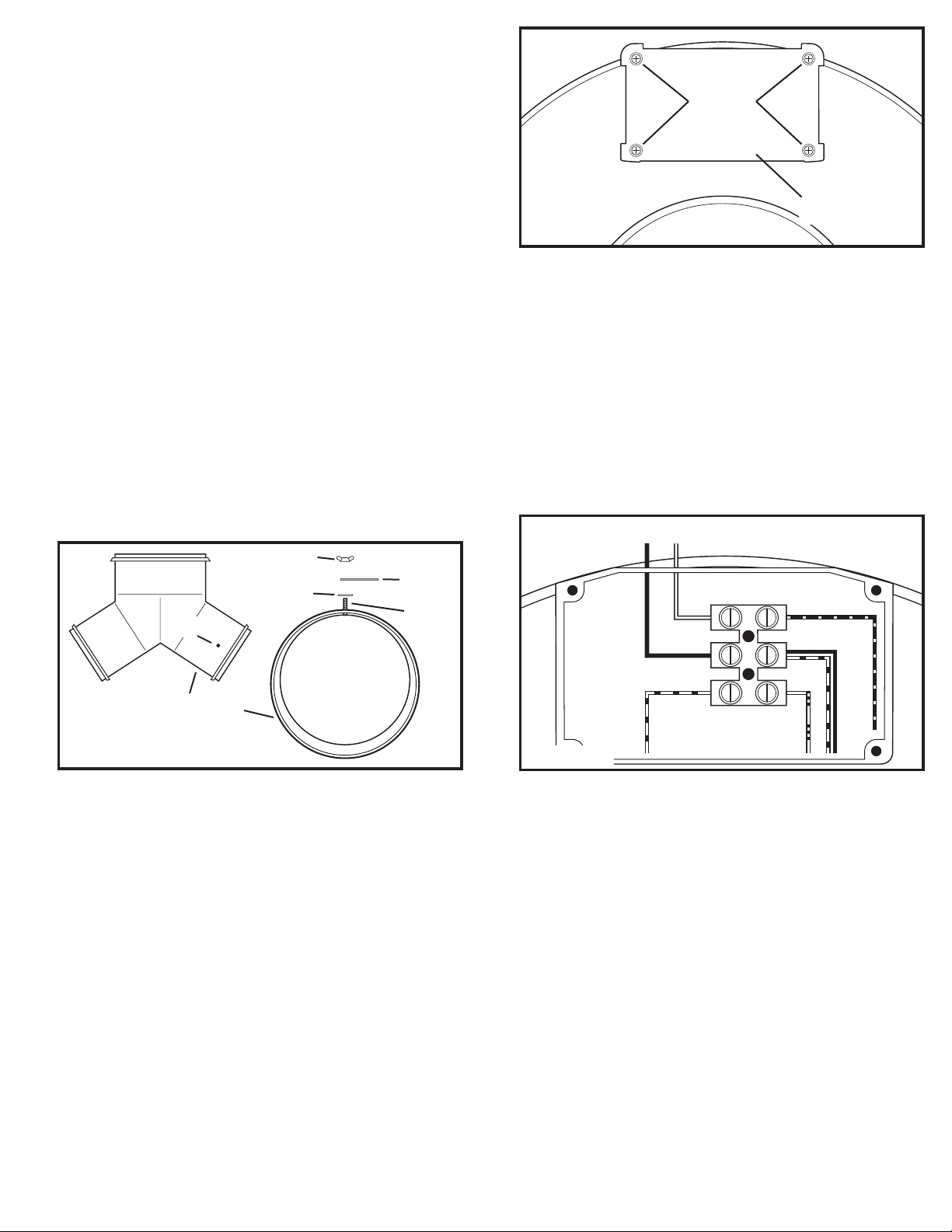

Wing Nut

Handle

Washer

Shaft

Hole

Terminal Box

Figure 9

2. Run wiring from an approved wall switch carrying the

appropriate rating. One neutral (white) and one hot (black

lead connected to the switch). Secure the electrical wires

to the housing with an approved electrical connector. Make

sure you leave enough wiring in the terminal box to make the

connections to the fan’s pre-wired electrical terminal strip.

3. Insert the white wire from the house into the terminal strip port

labeled “N” and tighten using a small regular screwdriver. Insert

the black wire from the wall switch into the terminal strip port

labeled “L” and tighten using a small regular screwdriver. Since

the motor is isolated within a plastic housing, grounding is not

necessary

(Figure 10).

Supply from house

White

N

Black

L

Blue

Black/Red

Damper

“Y” Transition

Figure 8

4. Adjust the damper to balance airflow and tighten the wing

nut to secure.

SECTION 8

Wiring the Fan

CAUTION: MAKE SURE POWER IS SWITCHED OFF AT

SERVICE PANEL BEFORE STARTING INSTALLATION.

CAUTION: ALL ELECTRICAL CONNECTIONS MUST BE MADE

IN ACCORDANCE WITH LOCAL CODES, ORDINANCES, OR

NATIONAL ELECTRICAL CODE. IF YOU ARE UNFAMILIAR WITH

METHODS OF INSTALLING ELECTRICAL WIRING, SECURE THE

SERVICES OF A QUALIFIED ELECTRICIAN.

1. Remove the screws securing the terminal box cover plate

located on the side of the motor

(Figure 9).

Red

Brown

Figure 10

4. Check to make sure all wire connections are securely fastened

to the terminal strip and replace the fan terminal box cover.

5. Restore power and test your installation.

SECTION 9

Use and Care

CAUTION: MAKE SURE POWER IS SWITCHED OFF AT

SERVICE PANEL BEFORE SERVICING THE UNIT.

1. Cleaning the Grill: Remove grill and use a mild detergent,

such as dishwashing liquid, and dry with a soft cloth. NEVER

USE ANY ABRASIVE PADS OR SCOURING POWDERS.

Completely dry grill before reinstalling. Refer to instructions

in Step 2 of Section 4, to reinstall grill.

The fan’s bearings are sealed and provided with an internal

2.

lubricating material, no additional lubrication is necessary.

5S7635036 New 9-06 4 of 12

www.airkinglimited.com

Loading...

Loading...