Air-Con ABXEM4H4S09, ABXEM4H4S12, ABXEM4H4S18, ABXEM4H4S24 Service Manual

Service Manual

MODEL:

ABXEM4H4S09/ABXCI4H4S09 ABXEM4H4S12/ABXCI4H4S12 ABXEM4H4S18/ABXCI4H4S18 ABXEM4H4S24/ABXCI4H4S2

4

1

Contents

1. Safety Considerations ............................................................................................................................................................ 3

2. Product Specifications ........................................................................................................................................................... 5

3. Product Picture and Drawing ................................................................................................................................................. 9

3-

1. Product dimensions .................................................................................................................................................... 9

4. Installation Instruction ......................................................................................................................................................... 10

4-1. Installation Place and Condition ............................................................................................................................... 11

4-2. Electric Wiring Diagram ............................................................................................................................................ 14

4-3. Refrigerant Flow System .......................................................................................................................................... 16

4-4. Air Purging and Leakage Test ................................................................................................................................... 17

4-5. Test Running ............................................................................................................................................................. 18

5. Function Operation .............................................................................................................................................................. 19

5-1. Operation Range (cooling and heating) ................................................................................................................. 19

5-2. Remote Controller Operation & Function ................................................................................................................ 19

5-3. Special Function Instruction ..................................................................................................................................... 27

6. Electrical Characteristics ...................................................................................................................................................... 29

6-1. Print Circuit Board (Indoor & Outdoor) .................................................................................................................... 29

6-2. Fan Motor ................................................................................................................................................................. 34

6-3. Temperature Sensor ................................................................................................................................................. 36

6-4. Compressor .............................................................................................................................................................. 39

6-5. Electric Reactor ........................................................................................................................................................ 39

6-6.Room Card Control, Fire Protection, ON/OFF Function ........................................................................................... 40

6-6-1.Instructions for the function setting of room card control, fire protection, ON/OFF function. ... 40

6-6-2.Instructions for the function setting of room card control, fire protection, ON/OFF function. ... 43

6-7.Wiring Remote Controller ......................................................................................................................................... 46

7.Trouble Shooting ................................................................................................................................................................... 47

7-1. Error Code Table ....................................................................................................................................................... 47

7-2. Test the

jumper terminals ...................................................................................................................................... 59

7-3. Trouble Diagnosis of Protection ............................................................................................................................... 59

7-4. Trouble Diagnosis of Compressor ............................................................................................................................ 61

7-5. Trouble Diagnosis of Electric Filter Board ................................................................................................................ 61

7-6. Trouble Diagnosis of Electric Communication.......................................................................................................... 61

2

1. Safety Considerations

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating standards. As the installer or service

person, it is an important part of your job to install or service the system, so it operates safely and

efficiently.

For safe installation and trouble-free operation, you must:

● Carefully read this instruction booklet before beginning.

● Follow each installation or repair step exactly as shown.

● Observe all local, state, and national electrical codes.

● Pay close attention to all warning and caution notices given in this manual.

This symbol refers to a hazard or unsafe practice which can result in severe

personal injury or death.

This symbol refers to a hazard or unsafe practice which can result in personal

injury or product or property damage.

If Necessary, Get Help

These instructions are all you need for most installation sites and maintenance conditions. If you

require help for a special problem, contact our sales/service outlet or your certified dealer for

additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for improper installation or maintenance service,

including failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

When Wiring

ELECTRICAL SHOCK CAN CAUSE SEVERE PERSONAL INJURY OR DEATH. ONLY A

QUALIFIED, EXPERIENCED ELECTRICIAN SHOULD ATTEMPT TO WIRE THIS SYSTEM.

● Do not supply power to the unit until all wiring and tubing are completed or reconnected and

checked.

● Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram

and these instructions when wiring. Improper connections and inadequate grounding can cause

accidental injury or death.

3

● Ground the unit following local electrical codes.

● Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible

fire hazard.

When Transporting

Be careful when picking up and moving the indoor and outdoor units. Get a partner to help, and bend

your knees when lifting to reduce strain on your back. Sharp edges or thin aluminum fins on the air

conditioner can cut your fingers.

When Installing

● In a Ceiling or Wall

Make sure the ceiling/wall is strong enough to hold the unit’s weight. It may be necessary to

construct a strong wood or metal frame to provide added support.

● In a Room

Properly insulate any tubing run inside a room to prevent“sweating” that can cause dripping and

water damage to walls and floors.

● In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a solid, level foundation for the outdoor unit.

This prevents water damage and abnormal vibration.

● In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a metal frame. Provide a suitable air baffle.

● In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

△ Use the flare method for connecting tubing.

△ Apply refrigerant lubricant to the matching surfaces of the flare and union tubes before connecting

them, then tighten the nut with a torque wrench for a leak free connection.

△ Check carefully for leaks before starting the test run.

When Servicing

△ Turn the power OFF at the main power box (mains) before opening the unit to check or repair

electrical parts and wiring.

△ Keep your fingers and clothing away from any moving parts.

△ Clean up the site after you finish, remembering to check that no metal scraps or bits of wiring have

been left inside the unit being serviced.

Others

△ Ventilate any enclosed areas when installing or testing the refrigeration system. Escaped

refrigerant gas, on contact with fire or heat, can produce dangerously toxic gas.

△ Confirm upon completing installation that no refrigerant gas is leaking. If escaped gas comes in

contact with a stove, gas water heater, electric room heater or other heat source, it can produce

dangerously toxic gas.

NOTE:

The figure

、

size and parameter of the product may not be identical with the service manual, please

take the actual product as the standard.

4

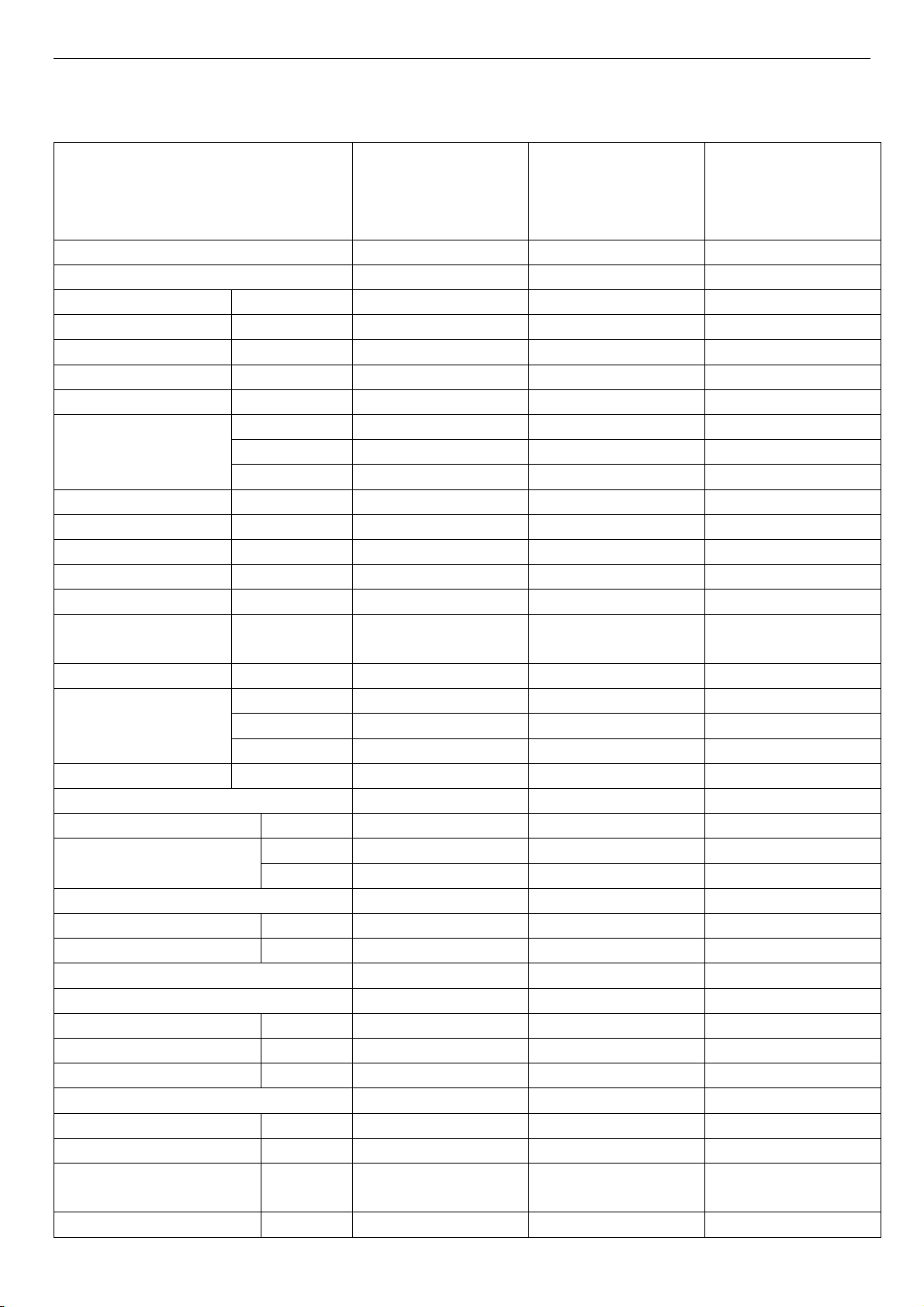

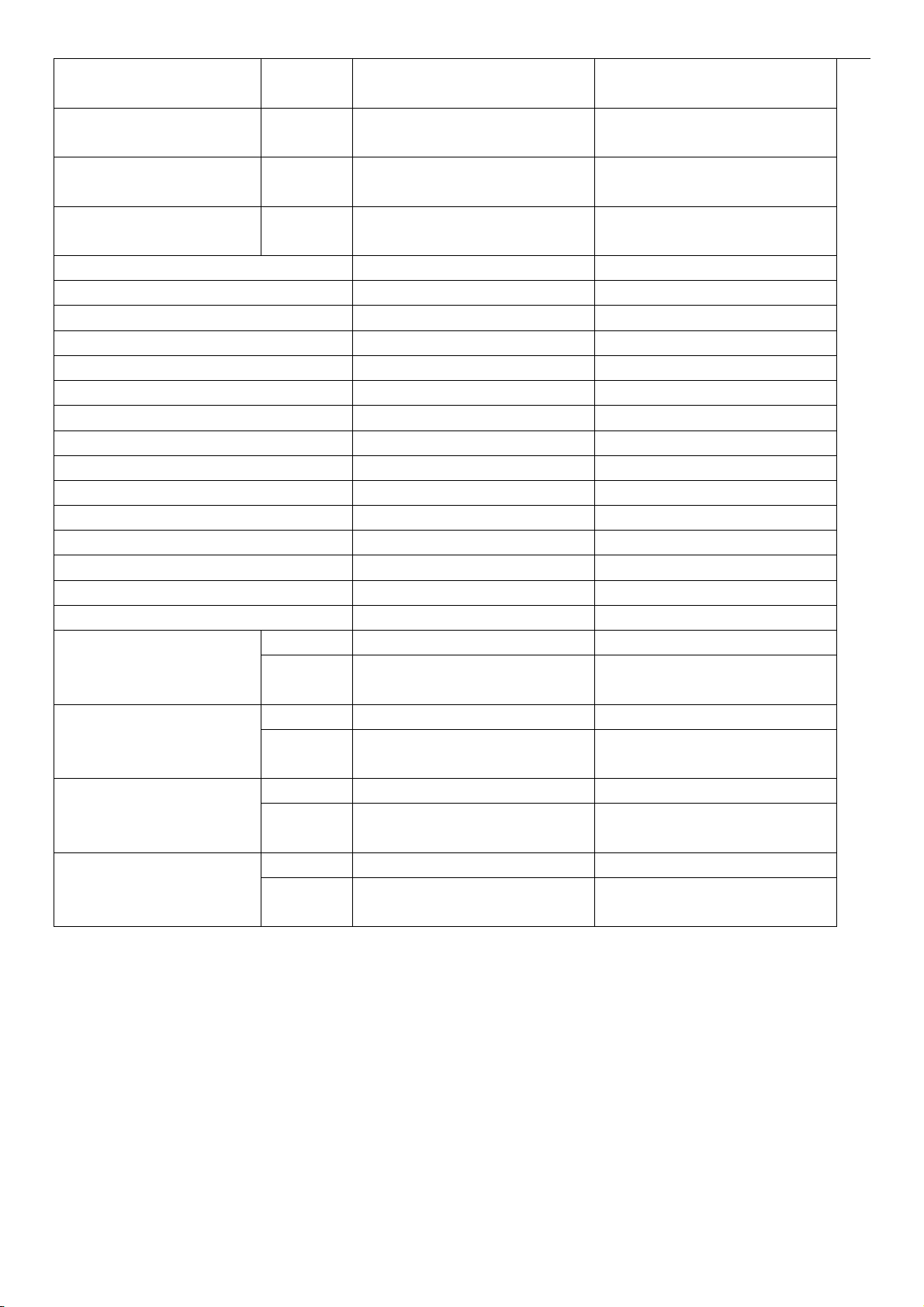

2. Product Specifications

ABXEM4H4S09/ABX

Model No.

Type

Ratings

Cooling Capacity W

Heating Capacity W

Rated Input-Cooling W

Rated Input-Heating W

Moisture Removal L/h

High m3/h

Air Circulation

EER for Cooling W/W

COP for Heating W/W

Energy Class Cooling

Energy Class Heating

Refrigerant

Refrigerant charge

volume (5M)

Additional ref. Volume g

Indoor Unit Noise Level

Outdoor Unit Noise Level dB (A)

Power Supply

Voltage, Frequency, Phase V

Rated Current

System pressures in cooling rated conditions

Max suction pressure MPa

Max discharge pressure MPa

System

Compressor

Compressor type

Compressor Model No.

Compressor MFG

Connecting Pipe Diameter

Liquid Pipe inch

Gas Pipe inch

Cooling Setting Temperature

Range

Heating Setting Temperature

Mid m3/h

Low m3/h

g

High(dB (A))

Mid(dB (A))

Low(dB (A))

Cooling (A)

Heating (A)

℃

℃

CI4H4S09

T1, H/P, INVERTER T1, HP, INVERTER T1, HP, INVERTER

2600 3517

2750 3810

655 920

720 1120

0.9 1.2

580

/

/

22.50 3.82

10.70 3.40

SEER20

SEER20

R410A R410A

950 1160

20 20

39 39

32

29

53 53

220-240V~,60Hz,1P 230/208V~,60Hz,1P 230/208V~,60Hz,1P

2.9 4.1

3.2 5.0

1.6 1.6

4.15 4.15

Rotary Rotary

ASD088RKQA6JT6 ASN108D32UFZ

HITACHI

1/4 1/4

3/8 3/8

16-30

16-30

ABXEM4H4S12/ABX

CI4H4S12

620

/

/

SEER22.0

HSPF10.5

GMCC

16-30

16-30

ABXEM4H4S18/ABX

CI4H4S18

5275

5569

1385

1595

1100

21.5

10.0

R410A

1550

20

45

41

37

6.3

7.2

1.65

3.79

Rotary

ATM150D43UFZ

GMCC

1/4

1/2

16-30

16-30

/

/

/

/

/

55

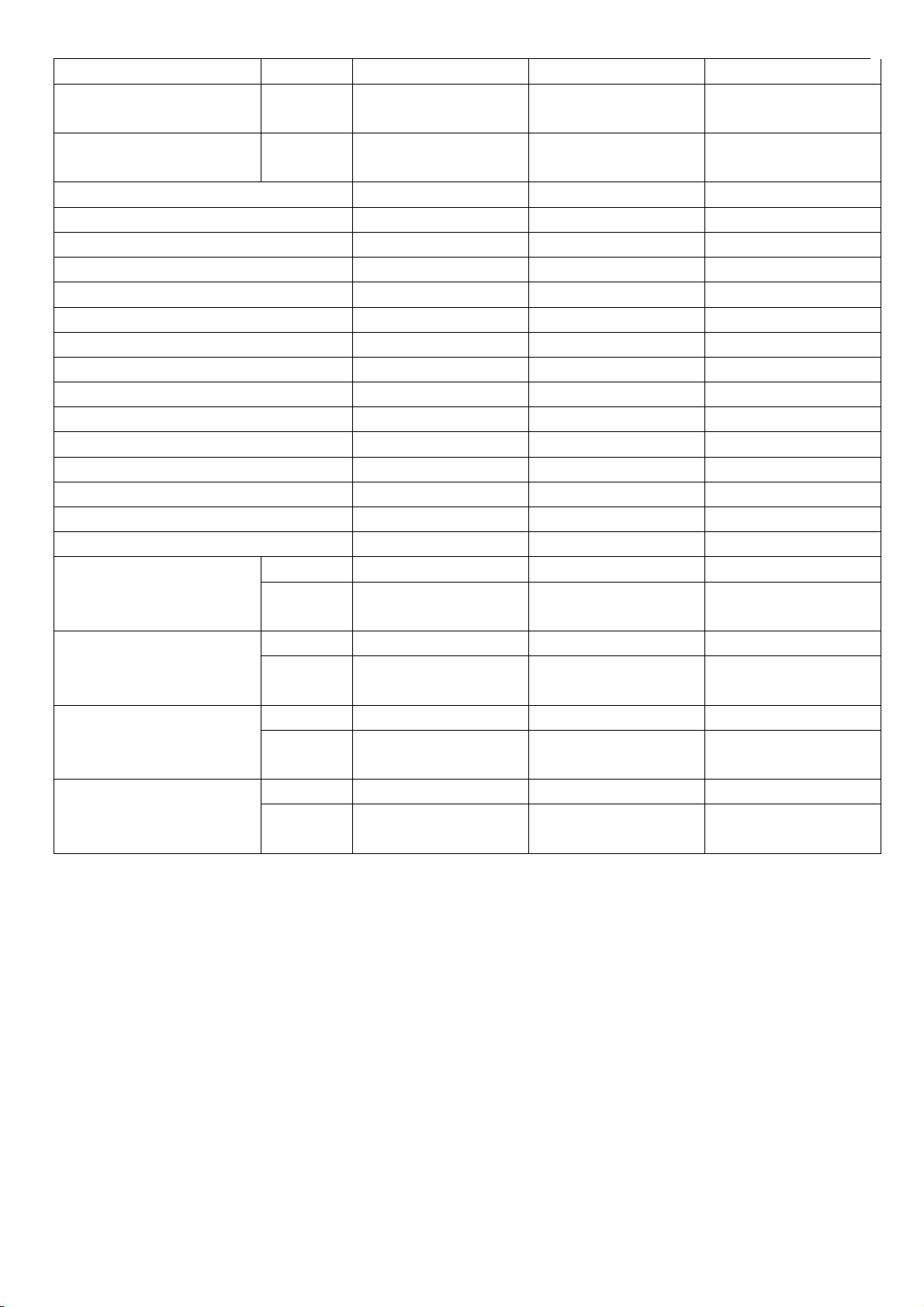

5

Range

Cooling Operating

Temperature Range

Heating Operating

Temperature Range

Features

Display on Front Panel

LCD Wireless Remote Controller

Removable and washable Panel

Washable PP Filter

24 Hours Timer

3 Speed and Auto Indoor Fan Control

Vertical Auto Swing Louver

Manual Adjustable Horizontal Swing Louver

Sleep Operation

Smart Function

Super Function

Auto Restart

Dimmer

Other

Net Dimensions

WxHxD (mm)

Net Weight (Kg)

Packing Dimensions WxHxD

(mm)

Gross Weight (Kg)

℃

℃

Indoor Unit

Outdoor

Unit

Indoor Unit

Outdoor

Unit

Indoor Unit

Outdoor

Unit

Indoor Unit

Outdoor

Unit

16-43 -15-46

-15--46 -15-32

LED LED LED

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

/ /

715×240×486 810×585×280

/ /

27 33

/ /

830×315×530

940×630×385

/ /

29.5 36

-15-24

860×650×310

995×720×420

6

21-46

/

/

45

/

/

49

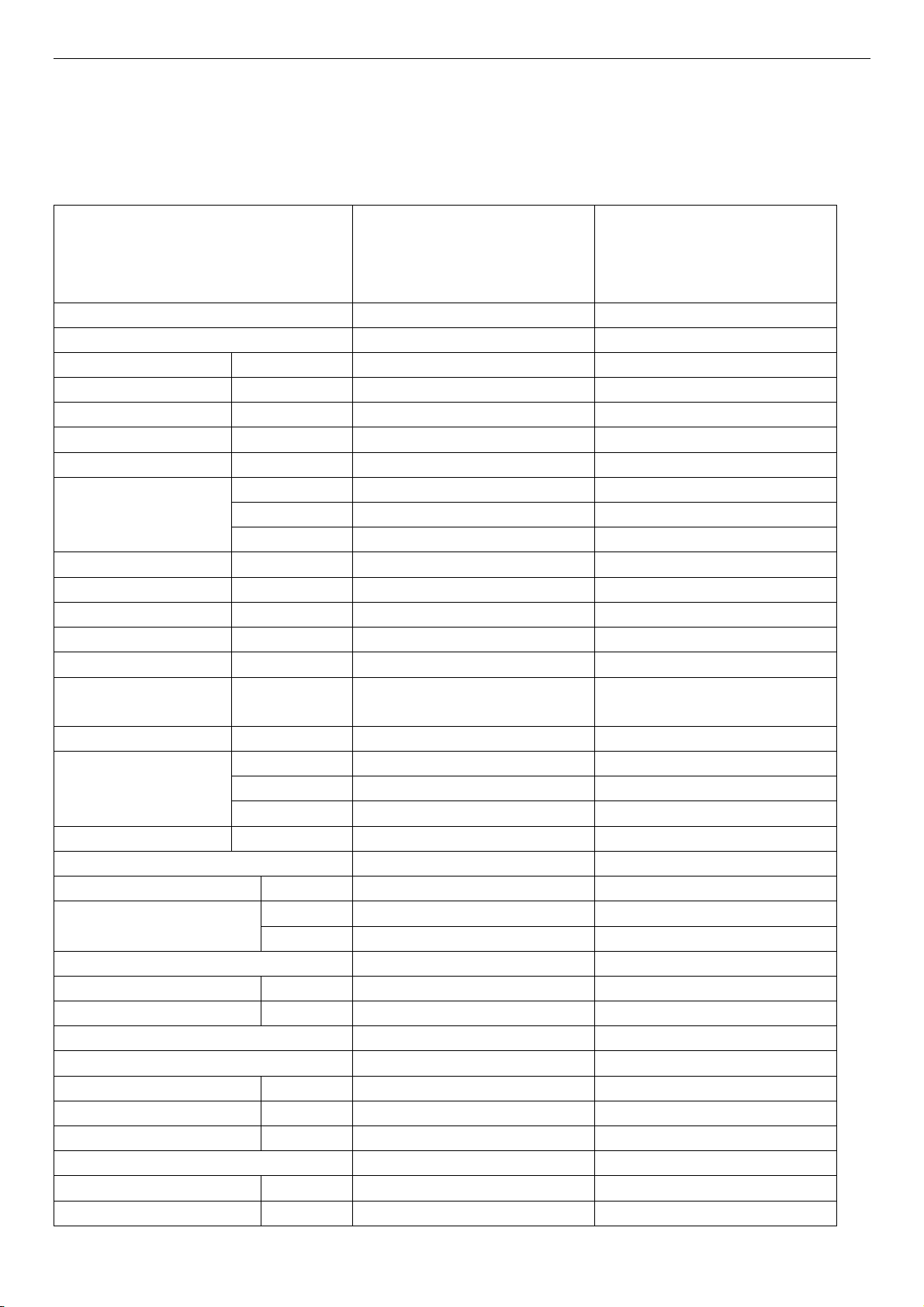

ABXEM4H4S24/ABXCI4H4S2

Model No.

Type

Ratings

Cooling Capacity W

Heating Capacity W

Rated Input-Cooling W

Rated Input-Heating W

Moisture Removal L/h

High m3/h

Air Circulation

EER for Cooling W/W

COP for Heating W/W

Energy Class Cooling

Energy Class Heating

Refrigerant

Refrigerant charge

volume (5M)

Additional ref. Volume g

Indoor Unit Noise Level

Outdoor Unit Noise Level dB (A)

Power Supply

Voltage, Frequency, Phase V

Rated Current

System pressures in cooling rated conditions

Max suction pressure MPa

Max discharge pressure MPa

System

Compressor

Compressor type

Compressor Model No.

Compressor MFG

Connecting Pipe Diameter

Liquid Pipe inch

Gas Pipe inch

Mid m3/h

Low m3/h

g

High(dB (A))

Mid(dB (A))

Low(dB (A))

Cooling (A)

Heating (A)

4

T1, HP, INVERTER

6850

7620

1874

2500

2.4

1200

/

/

3.66

3.05

SEER21

HSPF10.5

R410A

2150

30

47

/

/

58

230V~,60Hz,1P

8.3

11.1

1.6

4.15

Rotary

ATF135D22UMT

GMCC

3/8

5/8

7

Cooling Setting Temperature

Range

Heating Setting Temperature

Range

Cooling Operating

Temperature Range

Heating Operating

Temperature Range

Features

Display on Front Panel

LCD Wireless Remote Controller

Removable and washable Panel

Washable PP Filter

24 Hours Timer

3 Speed and Auto Indoor Fan Control

Vertical Auto Swing Louver

Manual Adjustable Horizontal Swing Louver

Sleep Operation

Smart Function

Super Function

Auto Restart

Dimmer

Other

Net Dimensions

WxHxD (mm)

Net Weight (Kg)

Packing Dimensions WxHxD

(mm)

Gross Weight (Kg)

℃

℃

℃

℃

Indoor Unit

Outdoor

Unit

Indoor Unit

Outdoor

Unit

Indoor Unit

Outdoor

Unit

Indoor Unit

Outdoor

Unit

18-30

18-30

-15~46℃

-20~24℃

LED

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

/

885×365×793

/

61

/

1050×500×890

/

69

8

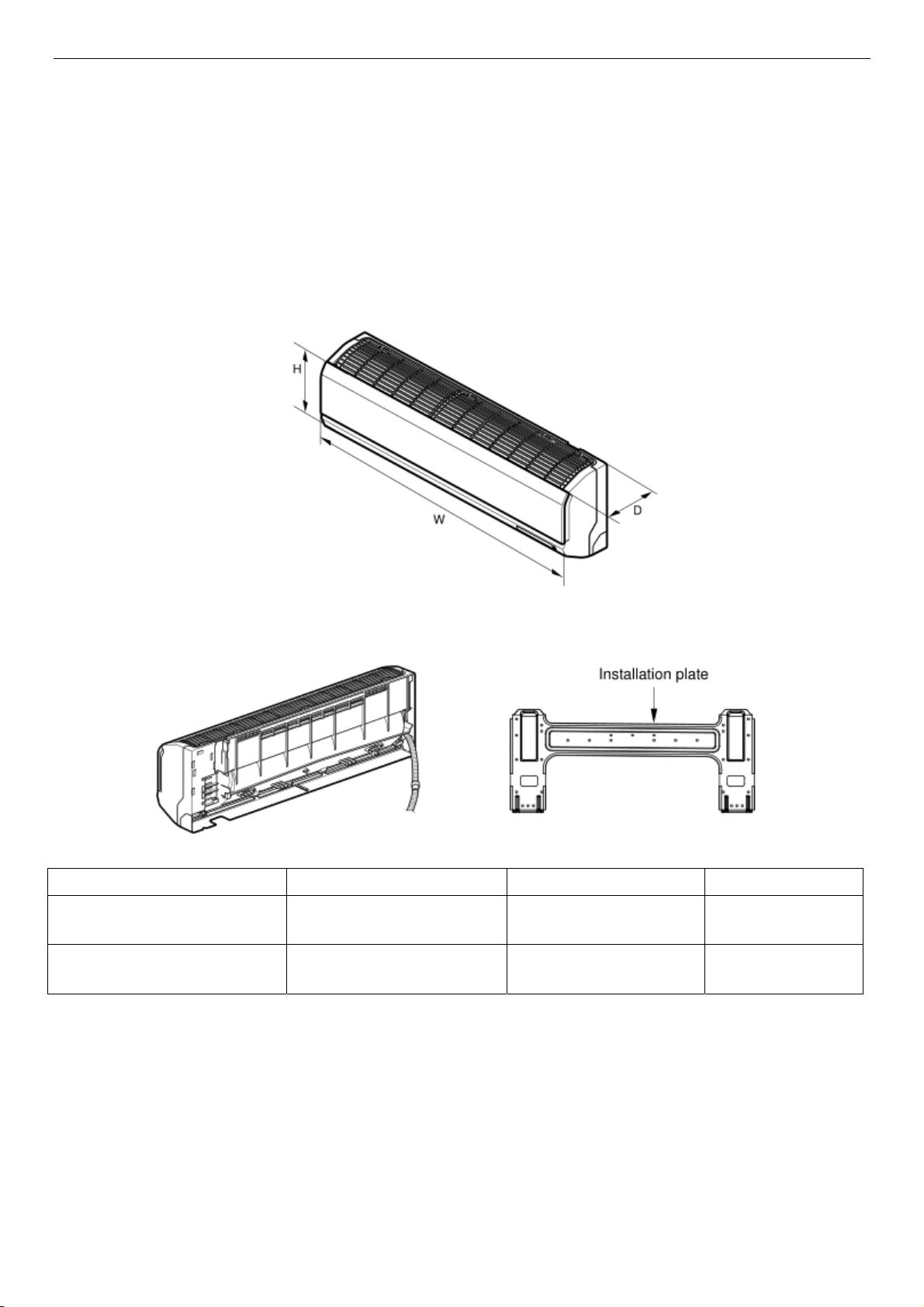

3. Product Picture and Drawing

3-1. Product dimensions

Indoor units:

Model W (mm) H (mm) D (mm)

ABXEM4H4S09

ABXEM4H4S12

ABXEM4H4S18

ABXEM4H4S24

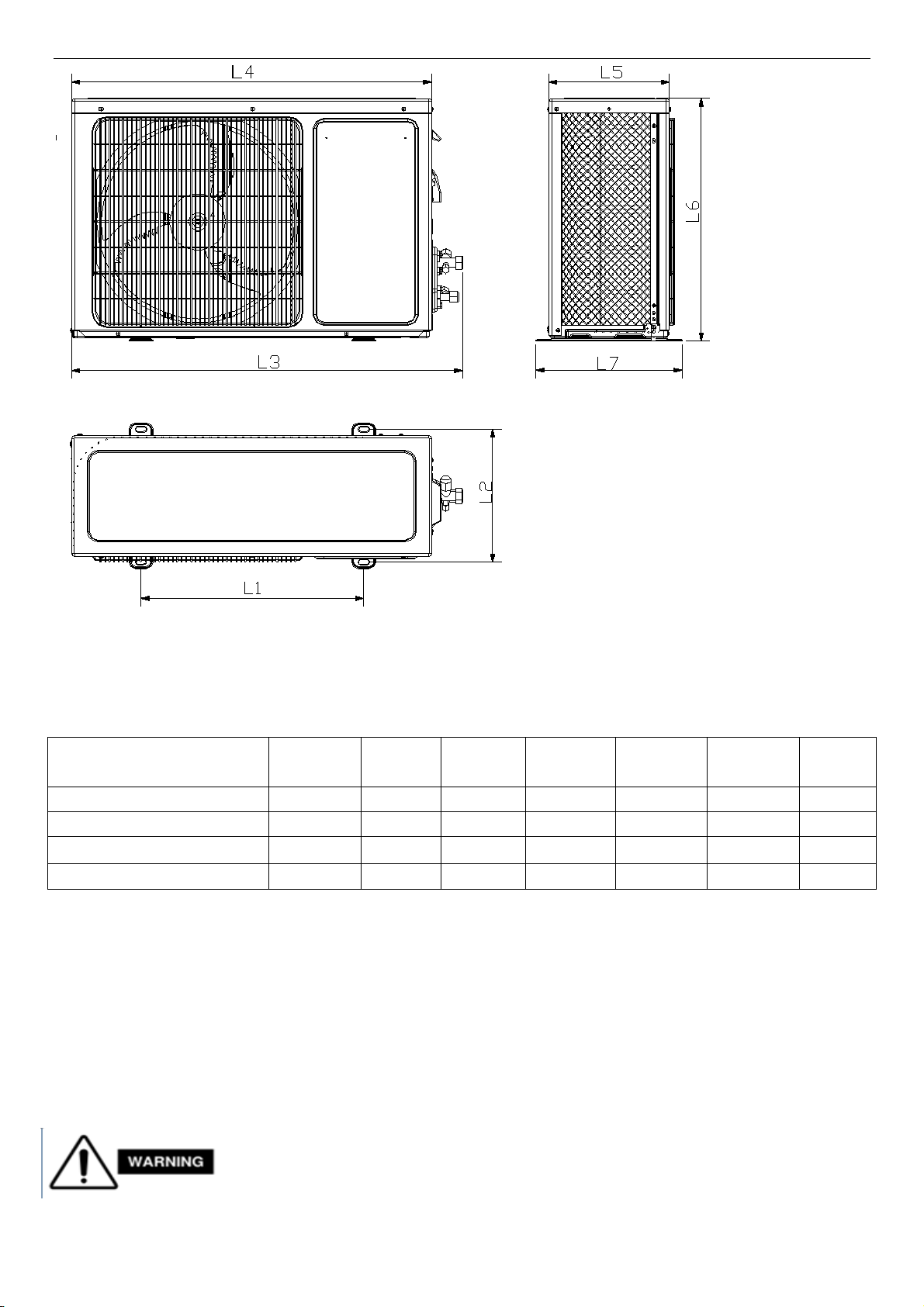

Outdoor units:

850 270 206

1131 315 228

9

Model L1

ABXCI4H4S09

ABXCI4H4S12

ABXCI4H4S18

ABXCI4H4S24

(mm)

L2

(mm)

L3

(mm)

L4

(mm)

L5

(mm)

L6

(mm)

L7

(mm)

443 264 776 715 240 486 290

510 320 886 810 280 585 330

542 341 935 878 310 667 368

662 390 959 884 365.5 793 414

4. Installation Instruction

To prevent abnormal heat generation and the possibility of fire, do not place

obstacles, enclosures and grilles in front of or surrounding the air conditioner in a

way that may clock air flow. And, more than 1 meter away from any antenna or

10

power lines or connecting wires used for TV, radio, telephone, security system, or intercom. Electrical

noise from any of these sources may affect operation.

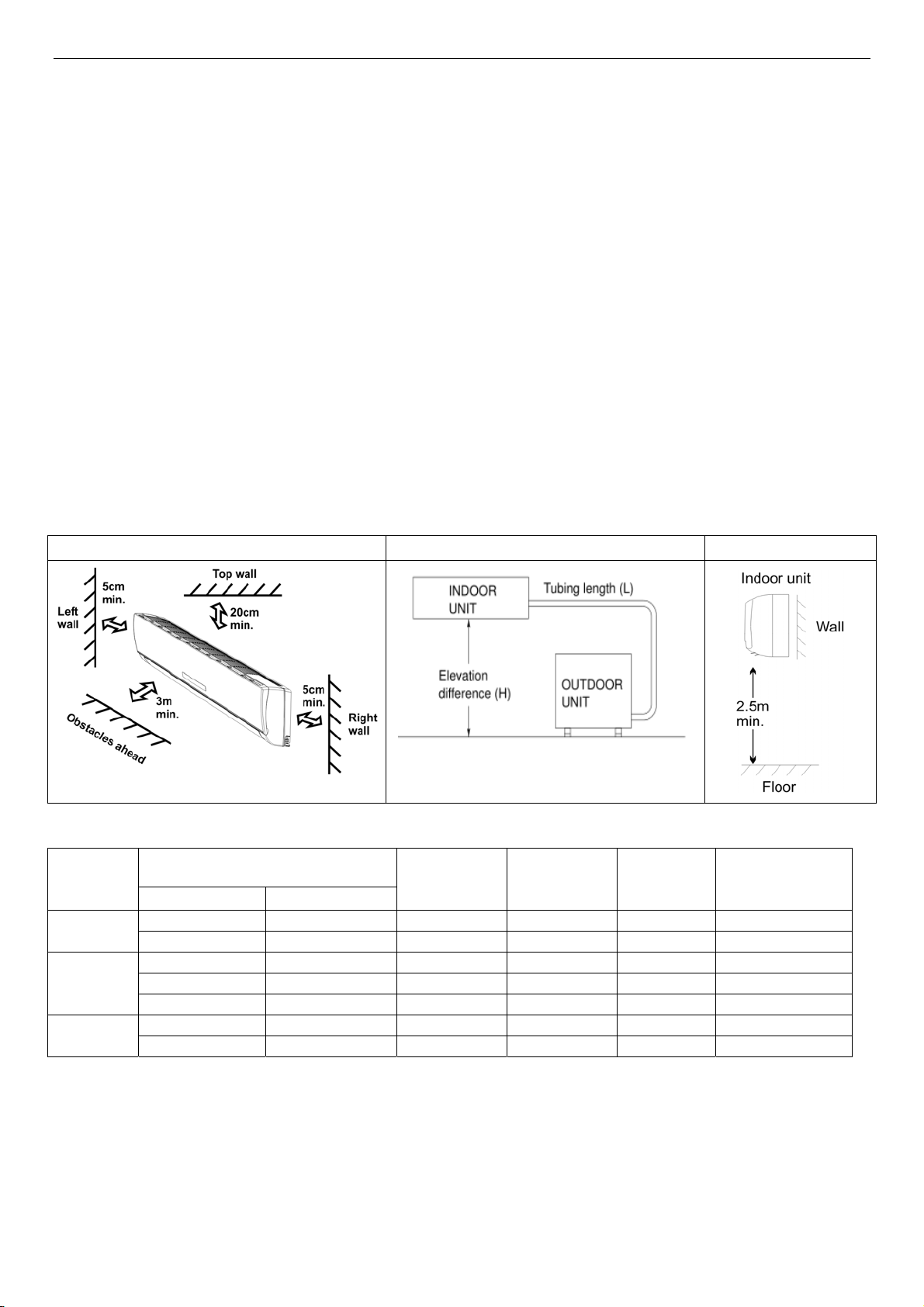

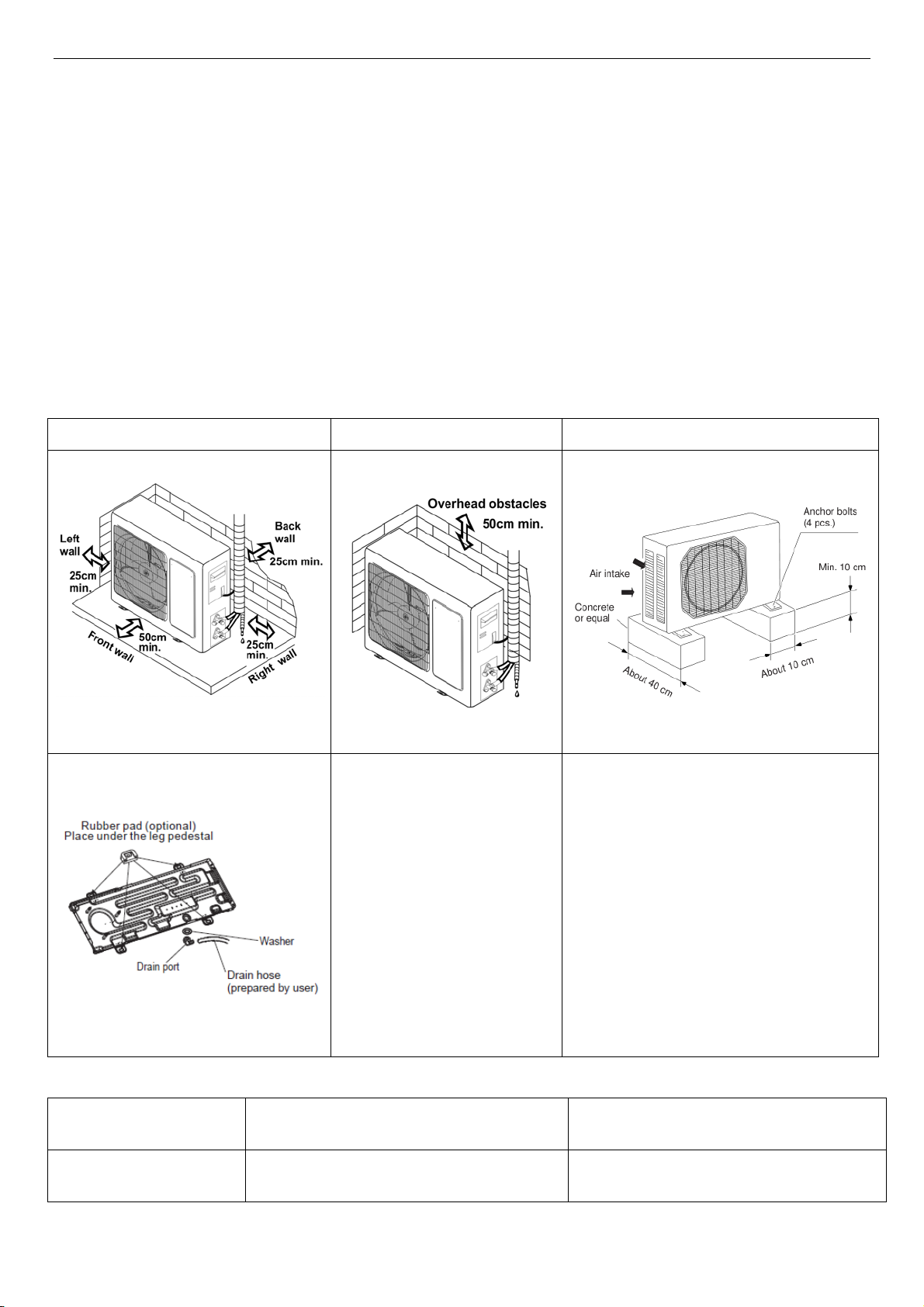

4-1. Installation Place and Condition

Indoor unit

Avoid:

△ direct sunlight.

△ nearby heat sources that may affect performance of the unit.

△ areas where leakage of flammable gas may be expected.

△ places where large amounts of oil mist exist.

Do:

△ Select an appropriate position from which every corner of the room can be uniformly cooled.

△ Select a location that will hold the weight of the unit.

△ Select a location where tubing and drain hose have the shortest run to the outside. (See a)

△ Allow room for operation and maintenance as well as unrestricted air flow around the unit. (See b)

△ Install the unit within the maximum elevation difference (H) above or below the outdoor unit and

within a total tubing length (L) from the outdoor unit as detailed (See table 1 and c)

a b c

table 1

Capacity

(Btu/h)

5k~14k

18k~28k

30k~38k

* If total tubing length becomes 7.5 to 15 m (max.), charge additional refrigerant as the table1 for

reference. And no additional compressor oil is necessary.

3/8"(Ø9.52) 1/4"(Ø6.35) 7.5 10 15 20

1/2"(Ø12.7) 1/4"(Ø6.35) 7.5 10 15 20

1/2"(Ø12.7) 1/4"(Ø6.35) 7.5 10 15 20

5/8"(Ø15.88) 1/4"(Ø6.35) 7.5 10 15 20

5/8"(Ø15.88) 3/8"(Ø9.52) 7.5 10 15 30

5/8"(Ø15.88) 3/8"(Ø9.52) 7.5 10 15 30

3/4"(Ø19.05) 3/8"(Ø9.52) 7.5 10 15 50

Pipe Size

GAS LIQUID

Standard

Length

(m)

Max.

Elevation

B (m)

Max.

Length

A (m)

Additional

Refrigerant

(g/m)

Outdoor unit

Avoid:

△ Heat sources, exhaust fans, etc.

△ Damp, humid or uneven locations.

11

DO:

△ Choose a place as cool as possible.

△ Choose a place that is well ventilated.

△ Allow enough room around the unit for air intake or exhaust and possible maintenance. (see a1,

b1 & c1)

△ Provide a solid base (level concrete pad, concrete block, 10 × 40 cm beams or equal), a minimum

of 10 cm above ground level to reduce humidity and protect the unit against possible water damage

and decreased service life.

△ If the installation bag has rubber pads, it is strongly recommended for use to reduce vibration and

noise.

△ Use lug bolts or equal to bolt down unit, reducing vibration and noise.

a1 b1 c1

Recommended Wire Diameter:

Capacity size Wire Diameter(mm2) Fuse or Circuit Breaker Capacity

5K~12k 1.0(Power wire)/1.0(Connect wire) 3.15A or 5A(indoor)/15A(outdoor)

12

18k 2.5(Power wire)/1.5(Connect wire) 3.15A or 5A(indoor)/20A(outdoor)

22K~30K 2.5(Power wire)/2.5(Connect wire) 3.15A or 5A(indoor)/30A(outdoor)

13

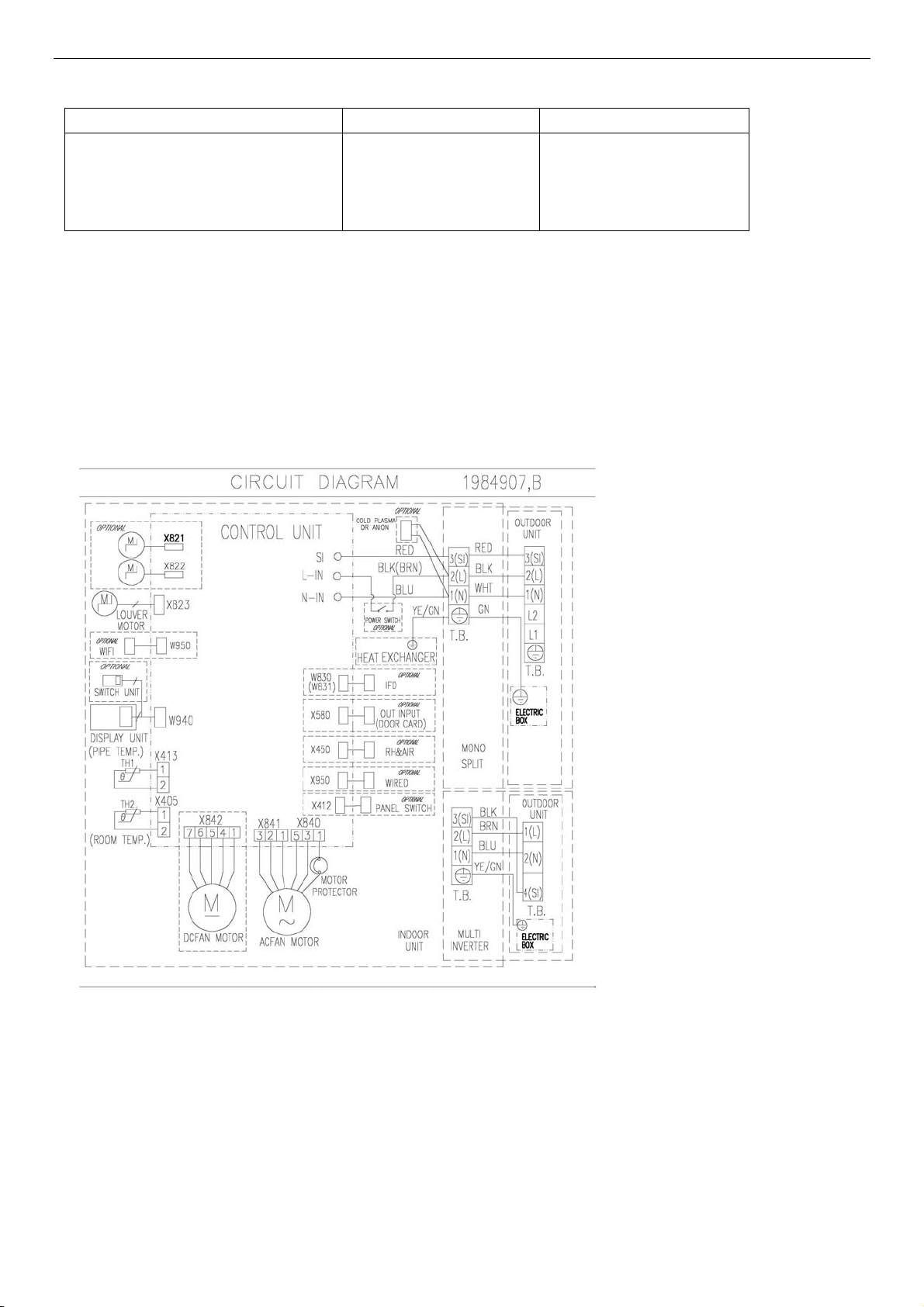

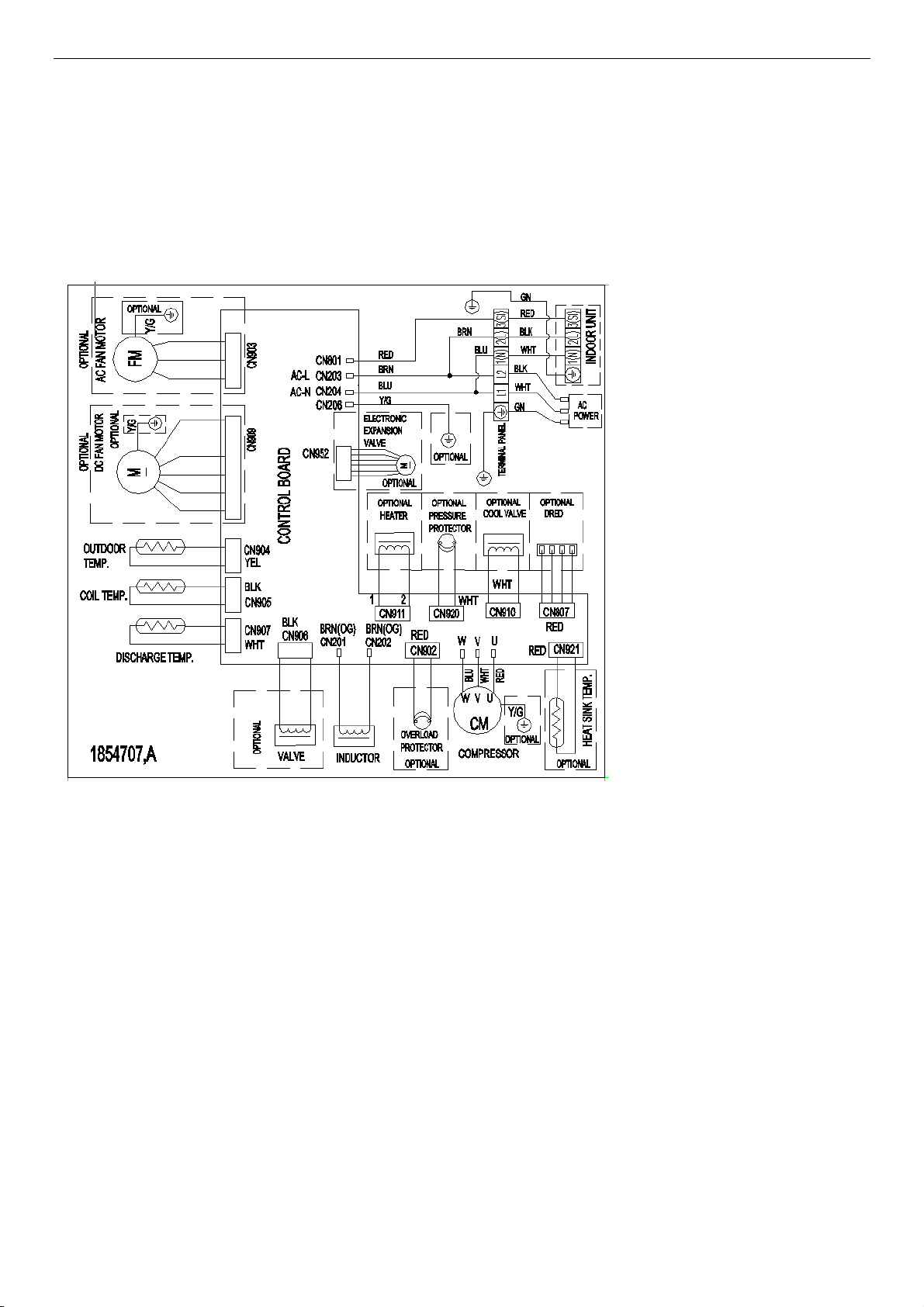

4-2. Electric Wiring Diagram

Model Indoor Unit DIAGRAM Outdoor Unit DIAGRAM

ABXEM4H4S09/ABXCI4H4S09

ABXEM4H4S12/ABXCI4H4S12

ABXEM4H4S18/ABXCI4H4S18

ABXEM4H4S24/ABXCI4H4S24

Indoor:

1984907

1984907 1854707

14

Outdoor:

1854707

15

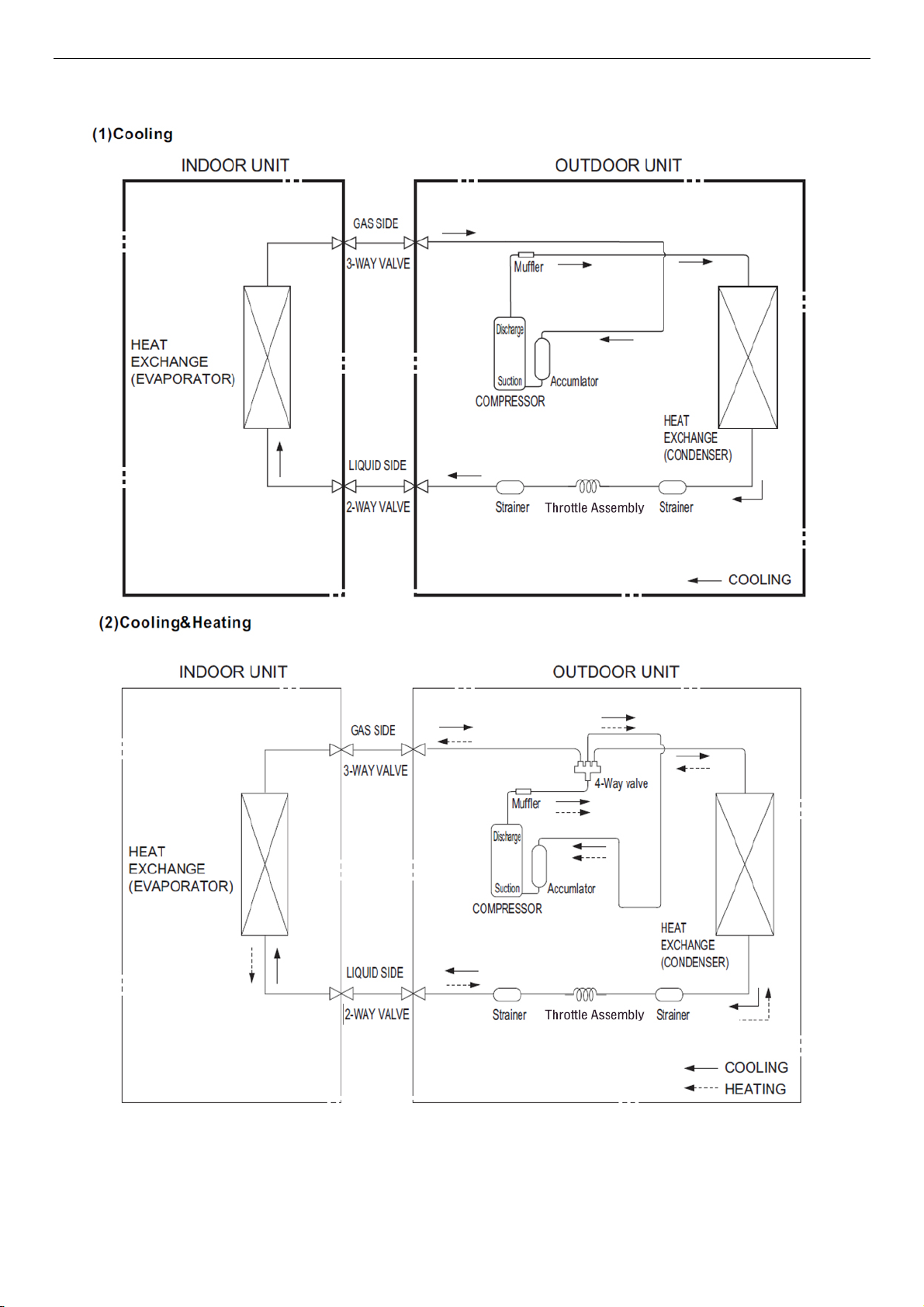

4-3. Refrigerant Flow System

NOTE: In different models, the throttle assembly may be Capillary or Electronic expansion valve.

16

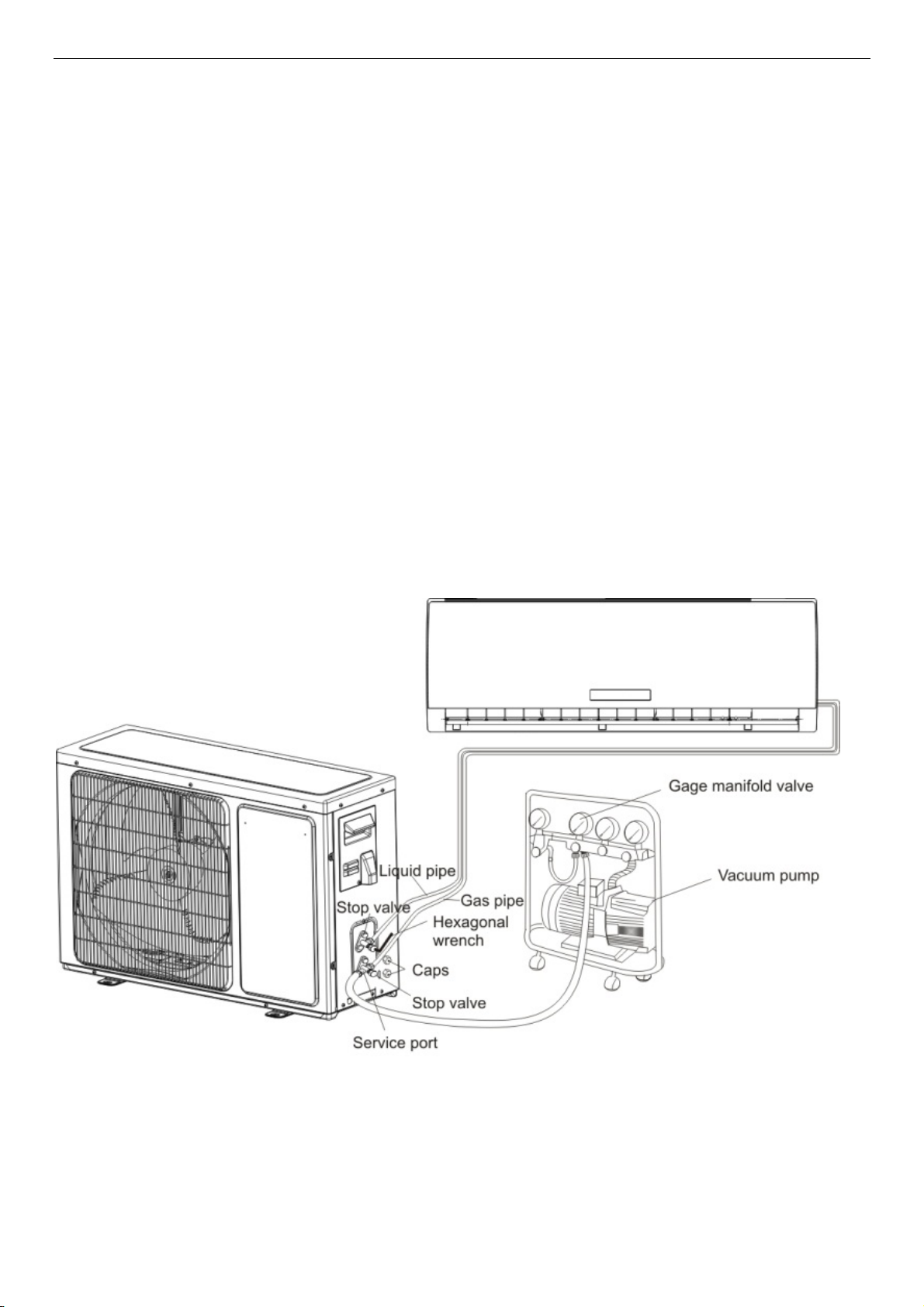

4-4. Air Purging and Leakage Test

1. Connect charging hose of manifold valve to charge end of low pressure valve (both high/low

pressure valves must be tightly shut).

2. Connect joint of charging hose to vacuum pump.

3. Fully open the handle of Lo manifold valve.

4. Open the vacuum pump to evacuate. At the beginning, slightly loosen joint nut of low pressure

valve to check if there is air coming inside. (If noise of vacuum pump has been changed, the reading

of multimeter is 0) Then tighten the nut.

5. Keep evacuating for more than 15mins and make sure the reading of multi-meter is -1.0 X105 pa

(-76cmHg).

6. Check the vacuum with the gage manifold valve, then close the gage manifold valve, and stop the

vacuum pump.

7. Leave it for one or two minutes. Make sure the pointer of the gage manifold valve remains in the

same position.

8. Remove the gage manifold valve quickly from the service port of the stop valve.

After refrigerant pipes are connected and evacuated, fully open all stop valves on gas and liquid pipe

sides.

9. Opening without fully opening lowers the performance and cause dangerous.

10. Tighten the cap to the service port to obtain the initial status.

11. Retighten the cap

12. Leak test

17

4-5. Test Running

△ Check after Installation

Items to be checked Possible malfunction

Has it been fixed firmly? The unit may drop, shake or emit noise.

Have you done the refrigerant leakage test?

Is heat insulation sufficient? It may cause condensation and dripping.

Is water drainage satisfactory? It may cause condensation and dripping.

Is the voltage in accordance with the rated

voltage marked on the nameplate?

Is the electric wiring and piping connection

installed correctly and securely?

Has the unit been connected to a secure earth

connection?

Is the power cord specified?

Are the inlet and outlet openings blocked?

Is the length of connection pipes and

refrigerant capacity been recorded?

It may cause insufficient

cooling(heating)capacity

It may cause electric malfunction or damage the

product.

It may cause electric malfunction or damage the

part.

It may cause electrical leakage.

It may cause electric malfunction or damage the

part.

It may cause insufficient

cooling(heating)capacity.

The refrigerant capacity is not accurate.

△Operation Test

1. Before Operation Test

(1)Do not switch on power before installation is finished completely.

(2)Electric wiring must be connected correctly and securely.

(3)Cut-off valves of the connection pipes should be opened.

(4)All the impurities such as scraps and thrums must be cleared from the unit.

2. Operation Test Method

(1)Switch on power and press “ON/OFF” button on the remote controller to start the operation.

(2)Press MODE button to select the COOL, HEAT (Cooling only unit is not available), FAN to check

whether the operation is normal or not.

18

5. Function Operation

5-1. Operation Range (cooling and heating)

North America SEER 20 Model(9k-24k)&SEER16 Model(30k、36k):

Temperature Indoor Air Intake Temp. Outdoor Air Intake Temp

COOLING

Maximum

Minimum

Maximum

HEATING

Minimum /

North America SEER 28 Model:

Temperature Indoor Air Intake Temp. Outdoor Air Intake Temp

Maximum

COOLING

Minimum

Maximum

HEATING

Minimum /

30℃(86°F) 46 ℃(115°F)

16℃ (61°F) -15℃(5°F)

30℃ (86°F) 24℃ (75°F)

-15℃ (5°F)

30℃(86°F) 46 ℃(115°F)

16℃ (61°F) -18℃(-0.4°F)

30℃ (86°F) 24℃ (75°F)

-25℃ (5°F)

Note: The parameters for generic only, the exact value please refer to the product

specification.

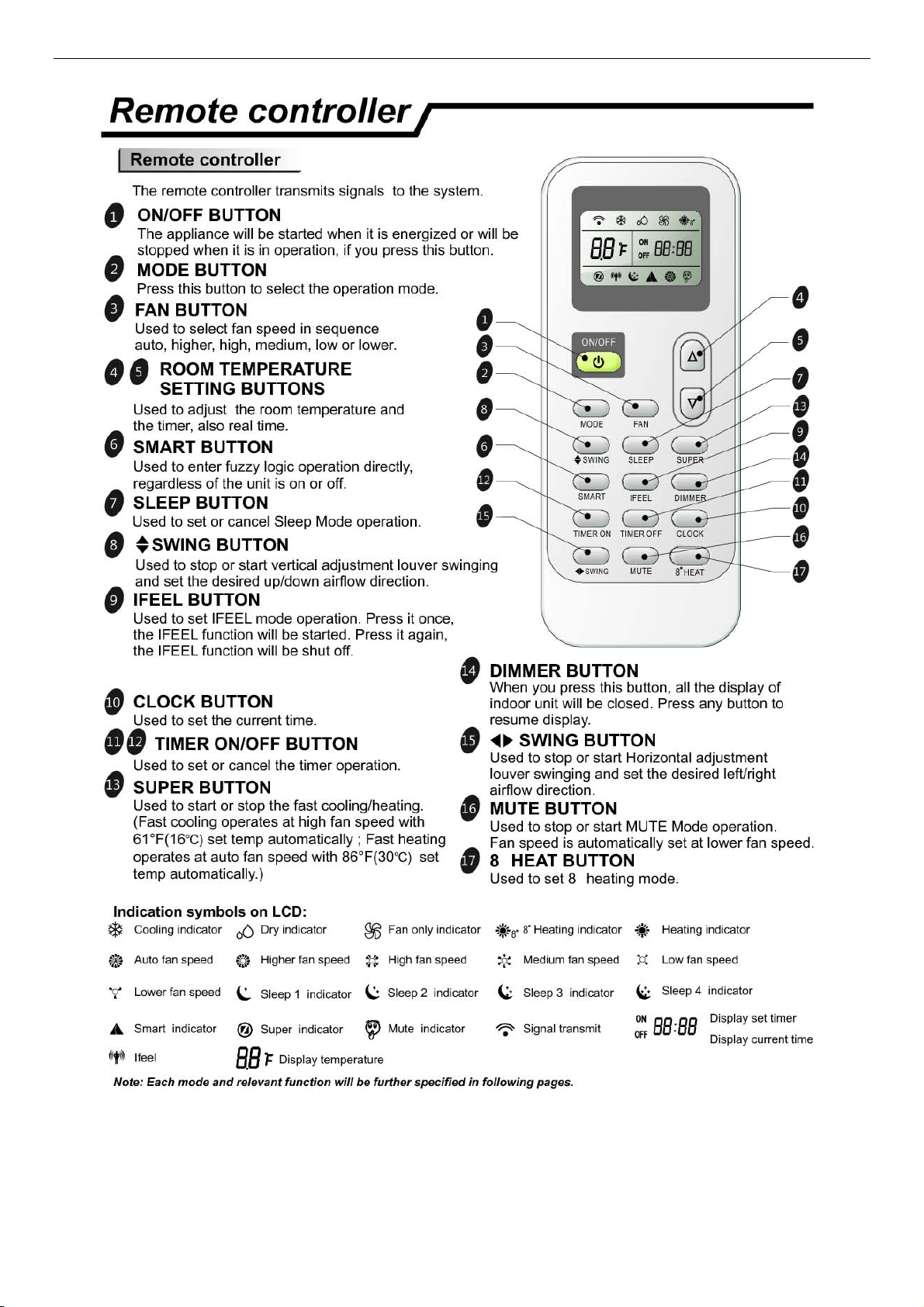

5-2. Remote Controller Operation & Function

△Remote Controller Instruction

J1-72

19

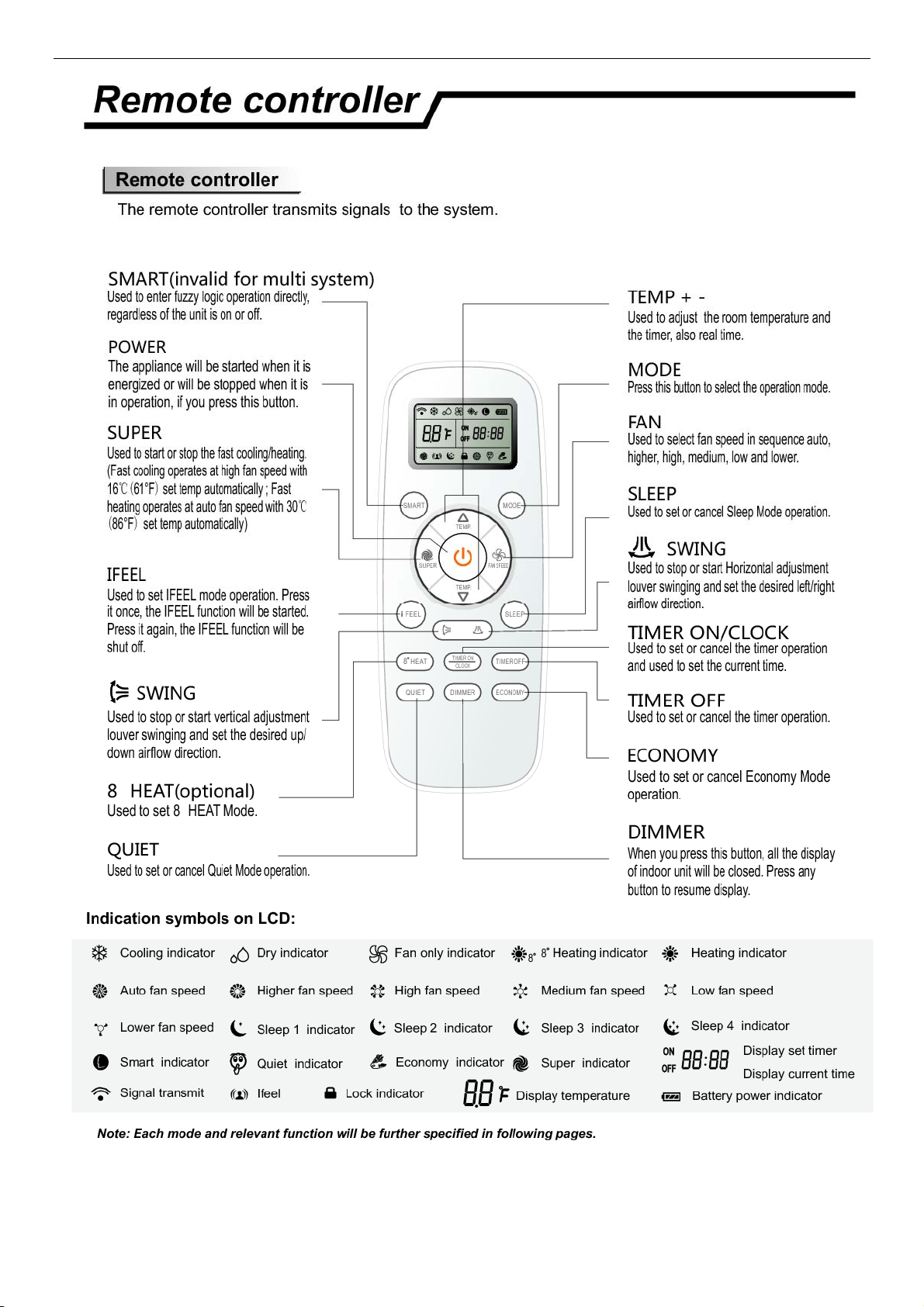

L1-04

20

Function Instruction

△

1.Major general technical parameters

21

Loading...

Loading...