OPERATING MANUAL

INSTRUCTION MANUAL

FOR

VACUUM PRESSURE PUMP

MODEL 400-1903

Barnant Company

28W092 Commercial Avenue

Barrington, Illinois U.S.A.60010-2392

(847) 381-7050

(847) 381-7053 (Fax)

800-637-3739

www.barnant.com

e-mail: barnant@barnant.com

A-1299-0341

Edition 03

WARRANTY

The Manufacturer warrants this product to be free from significant deviations from published specifications. If repair or adjustment is necessary

within the warranty period, the problem will be corrected at no charge if it

is not due to misuse or abuse on your part as determined by the

Manufacturer. Repair costs outside the warranty period, or those resulting

from product misuse or abuse, may be invoiced to you.

The warranty period for this product is noted on the Warranty Card.

PRODUCT RETURN

To limit charges and delays, contact the seller or Manufacturer for authorization and shipping instructions before returning the product, either within or outside of the warranty period. When returning the product, please

state the reason for the return.For your protection, pack the product carefully and insure it against possible damage or loss. Any damages resulting from improper packaging are your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the

Manufacturer or authorized seller.

NOTE

We reserve the right to make improvements in design, construction and

appearance of our products without notice.

FLUOREL - Reg TM Minnesota Mining and Manufacturing Co.

NORYL - Reg TM General Electric Co.

TEFLON - Reg TM E.I. DuPont de Nemours & Co.

Trademarks bearing the ® symbol in this publication

are registered in the U.S. and in other countries.

Printed in U.S.A.

030697

4

32

OPERATING INSTRUCTIONS

Model 400-1903 comes with two leads which are eight inches in length,

with a half inch stripped at the ends.

Wrap TEFLON sealing tape supplied with the fitting thread (to eliminate

any possible leakage) and assemble into the port.Instead of the standard

fittings supplied with the pump, any other appropriate system can be

attached to the pump.

A muffler can be used at the outlet to decrease the noise level if desired.

Usually, three feet lengths of tubing at both ends is more than adequate

for quiet operation.If the air or gas being pumped is relatively dirty, use of

an air filter is desirable. Otherwise excessive amounts of dust and other

particles will collect at the valve seats.This may interfere with the proper

seating of the valves and will decrease flow, pressure and vacuum characteristics and may make the flow values erratic.

Sudden changes in the diameter of system tubes, fittings, bends, and

other obstructions will increase pressure and/or vacuum in the system and

will decrease the available flow. Intentional reduction in flow can be

achieved by a simple valve or pinching of the tube at inlet (preferred for

the diaphragm life) or outlet systems.

MAINTENANCE

For diaphragm replacement, disassemble top part of pump head. Then

unscrew the diaphragm, and install the new diaphragm and pump head

per instructions with Service Kit.

Do not disassemble the pump housing from the motor. Proper assembly

(factory-adjusted) is critical for proper pump performance.

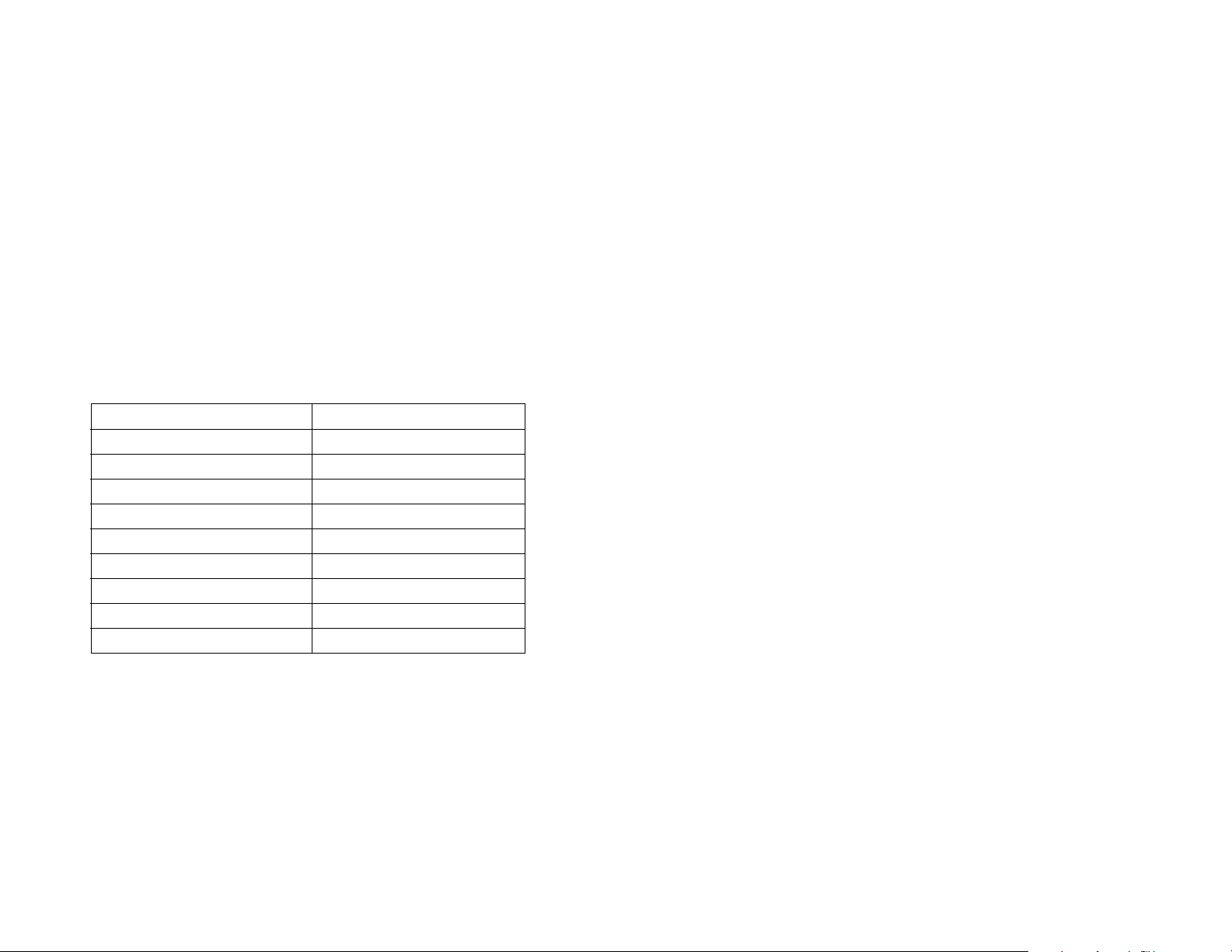

REPLACEMENT PARTS LIST

Part Description Part No.

Service Kit (nitrile diaphragm, two retainers, 401-0050

two valves and plastic head)

Service Kit (FLUOREL®diaphragm, two retainers, 7530-04

two valves and plastic head)

Eccentric Assembly (eccentric and bearing) 7530-75

Set Screw for Eccentric Assembly B-1079-0121

12V DC Motor B-1779

Diaphragm Clamp B-1352-0012

DESCRIPTION

The diaphragm-operated pump is designed for pressure, suction and gas

circulated applications. The convoluted diaphragm and the unique pump

cavity are designed to provide extended diaphragm life by minimizing

stress, wear, and heat buildup. This has been done while ensuring and

optimizing pressure and vacuum characteristics.

The media being pumped will come in contact with NORYL®, nitrile, and

TEFLON®PTFE. Polyethylene fittings are supplied. This provides much

better chemical resistance than conventional aluminum or stainless steel

pumps.

The polyethylene fittings provided with the pump will accept 3/8 in I.D.flexible tubing.

Figure 1 shows the typical flow characteristics of the pump as related to

pressure and vacuum.

SPECIFICATIONS

MODEL NO. 400-1903

Voltage 12V DC

Current 3.5 A

Air Capacity 1380 cu. in/min

Max. Pressure 18 psig

Max.Vacuum 20 in Hg

Motor 1/30 hp at 2200 rpm

Pump-Motor Dimensions 73⁄4 in L x 31⁄2 in W x 41⁄2 in

Motor Dimensions 41⁄2 in L x 21⁄2 in Diameter

Port Connections 3/8 in (F) NPT

Loading...

Loading...