Page 1

TSX Series

High Current DC Power Supplies

INSTRUCTION MANUAL

Page 2

Table of Contents

Introduction 2

Specification 3

Safety 4

Installation 5

Operation 6

Maintenance and Repair 7

Instructions en Francais

Sécurité 8

Installation 9

Fonctionnement 10

Entretien et réparation 11

Bedienungsanleitung auf Deutsch

Sicherheit 12

Installation 13

Betrieb 14

Wartung und Instandsetzung 15

Istruzioni in Italiano

Sicurezza 16

Installazione 17

Funzionamento 18

Manutenzione 19

Instrucciones en Español

Seguridad 20

Instalación 21

Funcionamiento 22

Maintenimiento 24

1

Page 3

Introduction

This series of bench power supplies offer high power outputs (in excess of 350 Watts) in a casing

which is both compact and lightweight when compared with conventional designs. Their high

performance is derived from a r egulator design which combines switch-mode and linear

techniques to achieve high efficiency with excellent regulation, transient r espons e and very low

noise.

The supplies feature high accuracy voltage and current metering on bright 0.5" LEDs,

overvoltage and thermal protection, and remote sense t er m inals. The output operates in

constant voltage or constant current mode with automatic cross over and mode indicat ion.

Coarse and fine controls permit the out put voltage t o be set within 10 mV and the current limit

control is logarithmic to give good res olution at low current settings.

The supplies have a robust steel case which is half-rack width (3U height). They are Saf et y

Class I, Installation Category II instruments which meet EN61010-1 s afety requirements and

comply with EN61326-1 EMC standard.

2

Page 4

Output Voltage Setting:

By coarse and fine controls; 10mV setting r esolut ion.

Sensing:

Remote via rear panel screw terminals or direct via shorting strip ( supplied) .

>5kΩ in constant current mode (voltage limit at max.).

Temperature Coefficient:

Typically <100 ppm/°C.

Meter Resolution:

10mV, 10mA

Environmental:

Indoor use at altitudes up to 2000m, Pollution Degr ee 2.

Specification

OUTPUT SPECIFICATIONS

Voltage Range: Nominally 0-35V (35V/10A), Nomin a lly 0-18V ( 18V/ 20A)

Current Range: Nominally 0-10A (35V/10A), Nominally 0-20A (18V/20A)

Output Current Setting: By single semi-logarithmic control; 10mA setting resolution.

Output Mode: Constant voltage or constant current with automatic crossover.

Output Switch: Electronic. Preset voltage and current displayed when off.

Output Terminals: 4mm terminals on front panel, scr ew term inals at r ear.

Output Impedance:

Output Protection: Forward protection by Over-Voltage-Protection (OVP) trip; maximum voltage

OVP Range: 10% to 110% of maximum output voltage set by fr ont panel screwdriver

OVP Delay: <200µs

Load & Line Regulation: <0.01% of maximum output for 90% load change or 10% line change.

Ripple & Noise: <1mV rms typical in constant voltage

HF Common Mode

Noise:

Transient Response: 20µs to within 50mV of setting for a 5% to 95% load change.

Protection Functions: Overvoltage trip. Regulator overtemperatur e. Sense m iswiring.

Status Indication: Output off lamp. Constant voltage mode lamp

<1mΩ in constant voltage mode.

that should be applied to the terminals is 50V.

Reverse protection by diode clamp for reverse currents up to 3A.

adjustment.

<3mA rms typical in constant current.

Typically <3mV rms, <10mV peak.

Constant current mode lamp. Trip message on display.

METER SPECIFICATIONS

Meter Types: Dual 4 digit meter s with 12.5m m ( 0.5") LEDs. Reading rate 4Hz.

Meter Accuracy: Voltage 0.2% of reading ± 1 digit, current 0.5% of reading ± 1 digit.

GENERAL

AC Input Voltage: 110V-120V AC or 220V-240V AC ± 10%, 50/60Hz. Installation Category II.

Power Consumption: 600VA max.

Operating Range: 5°C to +40°C, 20% to 80% RH.

Storage Range: –40°C to +70°C.

Size: 210 x 140 x 385mm (W x H x D), half rack width x 3U height

(optional rack mounting k it available)

Weight: 5kg.

Safety & EMC: Complies with EN61010-1 & EN61326-1.

For details, request the EU Declaration of Conformity for this instrument via

http://www.aimtti.com/support (serial no. needed).

3

Page 5

l

Safety

This power supply is a Safety Class I instrument according t o I EC classification and has been

designed to meet the requirem ents of EN61010-1 (Safety Requirements for Electr ical Eq uipm ent

for Measurement, Control and Laborator y Use). It is an Installation Category II instrument

intended for operation fr om a nor m al single phase supply.

This instrument has been tested in accordanc e with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to r etain the inst r um ent in a safe condition.

This instrument has been designed f or indoor use in a Pollution Degree 2 environment in the

temperature range 5°C t o 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures bet ween +5°C and –10°C without deg r adation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not spec ified by these instructions may impair the safety

protection provided. Do not operate the instrum ent outside its rat ed supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conduct or inside or outside t he inst r um ent will make the

instrument dangerous. Int ent ional inter ruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, m aint enance or repair. Capacitors inside the power supply may still be

charged even if the power supply has been disconnected from all voltage sources but will be

safely discharged about 10 minutes after s witching off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be

avoided as far as possible and, if inevitable, shall be carried out only by a skilled person who is

aware of the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive

moisture or chemical corrosion the safety protection may be impaired and the apparatus should

be withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated c ur r ent and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited. Do

not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this m anual:-

Earth (ground) terminal.

mains supply OFF.

mains supply ON.

alternating current (ac)

direct current (dc)

4

Page 6

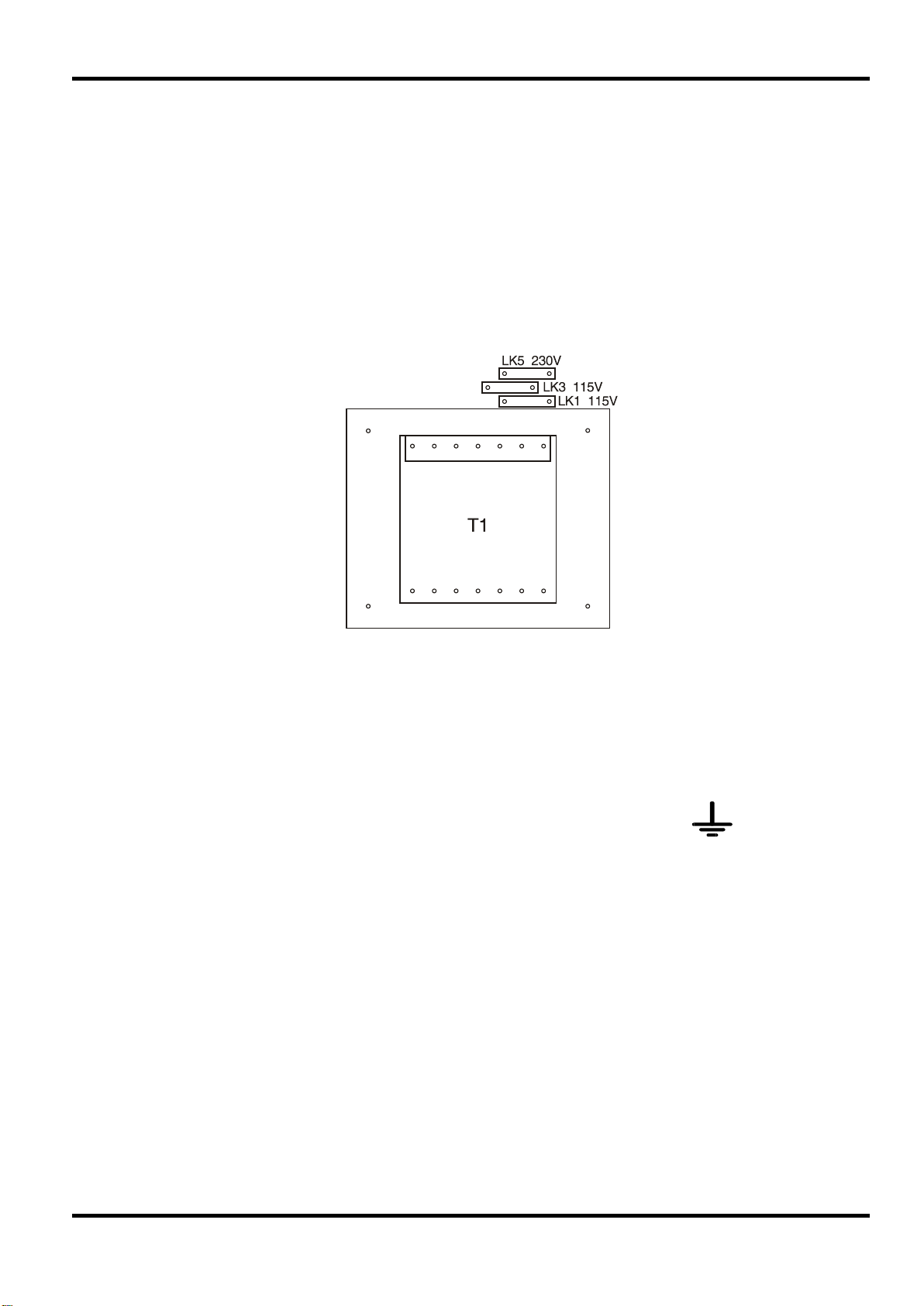

Mains Operating Voltage

Check that the instrument oper at ing voltage marked on the rear panel is suitable for the local

supply. Should it be necessary to change the operating voltage, proceed as follows:

1. Ensure that the instrument is disconnected from the AC supply.

2. Remove the 6 screws holding the case upper and lift off the cover.

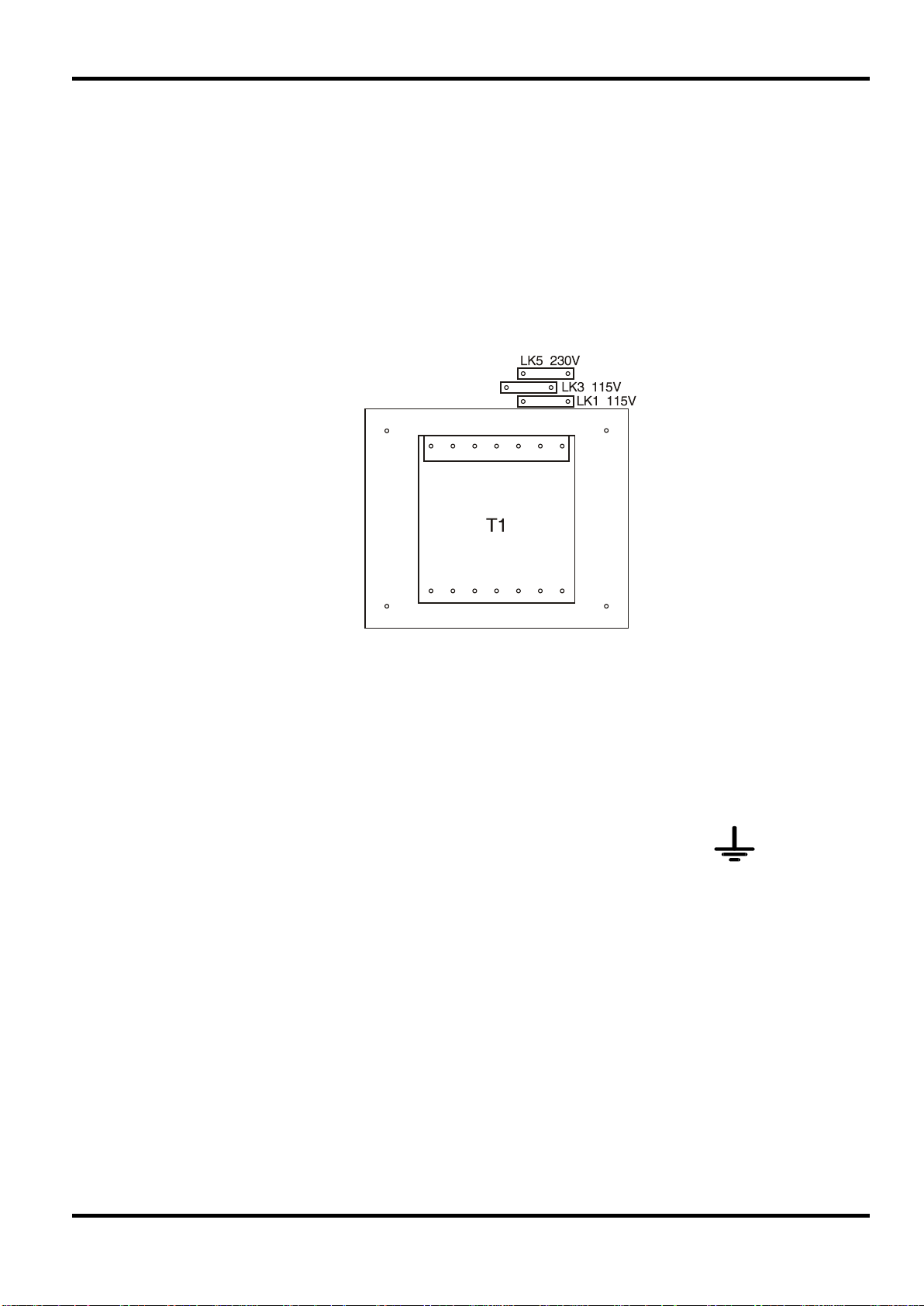

3. Change the appropriate zero-ohm links beside the t r ans former on the pcb:

Link LK5 only for 230V operation

Link LK1 and LK3 only for 115V operation

Installation

4. Re-assemble in the reverse order.

5. To comply with safet y standard requirements the operating voltage on the rear panel must be

changed to clearly show the new voltage setting.

Mains Lead

When a three core mains lead with bare ends is provided this should be connected as follows:

GREEN/YELLOW - EARTH

Safety Earth Symbol

When f it t ing a fused plug a 5 amp fuse should be fit t ed inside t he plug . As the colours of the

wires in the mains lead of this apparatus may not correspond with the coloured markings

identifying the terminals in your plug proceed as follows:

The wire which is coloured green-and-yellow must be connected to the terminal in the plug which

is marked by the letter E or by the safety earth symbol shown above or coloured green or greenand-yellow.

The wire which is coloured blue must be connected to the terminal which is marked with the letter

N or coloured black.

The wire which is coloured brown must be connected to the terminal which is marked with the

letter L or coloured red.

BROWN - MAINS LIVE

BLUE - MAINS NEUTRAL

WARNING! THIS APPARATUS MUST BE EARTHED.

Any interruption of the protective conductor inside or outside the apparatus or disconnec t ion of

the protective earth terminal is likely to mak e t he apparat us dangerous. Intentional interruption is

prohibited.

5

Page 7

Output Setting

With the PO WER switch on (l) and the OUTPUT push-button switch off ( out ) the output voltage

and current limit can be accurately set using the t hree output controls; the left-hand meter

indicates set voltage and the right-hand meter set current.

When the OUTPUT is switched on, the ON LED and the CV (constant voltage) LED will light; the

left-hand meter continues to s how the set voltage but the right-hand meter now shows actual

current drawn. Alternate presses of the I METER DAMPING button will switch current meter

damping in and out; with damping switched in the DAMPED LED will be lit and the average value

of a varying load current will be read.

If the output goes int o cur r ent limit the CI (constant current) LED will light instead of the CV LED

and the left-hand meter will now show the actual voltage at the output terminals; the r ight-hand

meter will continue to show the set current limit.

At any time, the set voltage and set current levels can be reviewed by pressing the CHECK V /I

button.

Outputs from several supplies may be connected in series or parallel to produce hig her voltages

or higher currents respectively. Care must be taken when connecting supplies in series to ensure

that the maximum voltage rating of any output terminal (300V peak maximum with respect to true

ground) is not exceeded.

Operation

Connection to the Load

Connection to the front panel output term inals c an be m ade with 4mm plugs, spade terminals or

wire ends. To minimise voltage drop, the connecting leads to the load should be of an adequate

wire gauge and be kept short. Load wires should also be twisted tog et her t o minimise

inductance.

To overcome er r or s introduced by connecting lead resistance at higher currents the remote

sensing facility should be used (10 mΩ of lead resistance will drop 0.2 Volt at 20 Amps). Remove

the two shorting links made between the rear output and sens e t er minals and connect the sense

terminals directly to the load; the power connections may be made f r om eit her the front or the

rear terminals.

To ensure good coupling between the output and sense, the sense wires should be twisted with

their corresponding output leads bef ore the output leads are twisted together.

The voltage drop in each output lead must not exceed 1 Volt.

The shorting links should be re-m ade bet ween the rear sens e and out put terminals when remote

sensing is not being used. However, the sense connection is also made internally through a low

value resistor and only a small error between the set and actual voltage will result if the links are

left disconnected.

The output is fully floating and eit her t er m inal can be connec t ed t o ground or raised by up to

300V peak above true ground; however, such voltages are hazardous and great care should be

taken.

6

The current limit control can be set t o lim it the continuous output current to levels down to 10mA.

However, in common with all precision bench power supplies, a capacitor is connected across

the output to maintain stability and good transient response. This capacitor char ges to the output

voltage, and short circuiting of t he out put will produce a short cur r ent pulse as the capacitor

discharges which is independent of the current limit s et t ing.

Page 8

Protection

Overvoltage protection (OVP) is fully variable within the range 10% to 110% of the supply's

maximum output level. The OVP limit is set via the screwdriver adjustable SET OVP preset

potentiometer, accessible through a hole in the front panel. Rotating the preset clockwise

increases the limit, which can be read directly on the left-hand display by pressing the READ

OVP button. If the voltage on the output exceeds the set O VP for any reason, including an

externally forced voltage, the output will be tripped off.

The output will also be tripped off if the therm al sens ing detects overheating of any of the power

semiconductors, or if the sens e wires are wired to the wrong out put or if an attempt is made to

draw power from the sense wires.

In all the above cases, the 'TRIP' message will be shown in both displays. Once the cause of the

trip has been removed, normal operation can be restor ed by switching the PO WER switch off

(

) then on (l) again.

The output is protected f r om r everse voltages by a diode; the continuous reverse current must

not exceed 3 Amps, although transients can be much higher.

Ventilation

These instruments are very efficient but nevertheless can g ener ate significant heat at full power.

The supplies rely on convection cooling only and it is therefore important that ventilation is never

restricted if perf ormance and safety are to be maintained. If the supplies ar e m ount ed in a

restricted space, eg. a 19 inch rack , then adequate ventilation must be ensured by using, for

example, a fan tray.

Fuse

Maintenance and Repair

The Manufacturers or their ag ents overseas will provide repair for any unit developing a f ault .

Where owners wish to undertake t heir own maintenance work , this should only be done by skilled

personnel in conjunction with the service manual which may be purchased directly from the

Manufacturers or their agents overseas.

The correct fuse type for all models and AC supply ranges is:

10 Amp 250V HBC time-lag, 5 x 20 mm

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse-holders is prohibited.

To replace t he fuse, first disconnect the instrum ent from the AC supply. Remove the 6 cover

securing screws and lift off the cover. Replace the fuse with one of the correct t ype and refit the

cover.

Note that the main function of the fuse is to make the instrum ent s afe and limit damage in the

event of failure of one of the switching devices. If a fuse fails it is t her efore very likely that the

replacement will also blow, because the supply has developed a fault; in such circumstances the

instrument will need to be returned to t he m anufacturer for service.

Cleaning

If the PSU requires cleaning use a clot h t hat is only lightly dampened with water or a mild

detergent. Polish the display window with a soft dry cloth.

WARNING! TO AVOID ELECTRIC SHOCK, OR DAMAGE TO THE PSU, NEVER ALLOW

WATER TO GET INSIDE THE CASE. TO AVOID DAMAGE TO THE CASE OR DISPLAY

WINDOW NEVER CLEAN WITH SOLVENTS.

7

Page 9

l

Sécurité

Ce système alimentation est un instrument de classe de sécurit é 1 conforme à la classification

IEC et il a été conçu pour satisfaire aux exigences de la norme EN61010-1 ( Exigences de

sécurité pour les équipements électriques de mes ur e, de c ont r ôle et d' utilisation en laboratoire).

Il s'agit d'un instrument de Cat égorie II d'installation devant être exploité depuis une alimentation

monophasée standard.

Cet instrument a été testé conformément à la norme EN61010-1 et il a été fourni en t out état de

sécurité. Ce manuel d'instructions contient des informations et des avertissements qui doivent

être suivis par l'utilisateur afin d'assurer un fonctionnement et un état en toute sécurité.

Cet instrument a été conçu pour être ut ilisé en intér ieur, en environnement de pollution de

deuxième degré (Pollution degree 2) à des plages de tem pératures de 5°C à 40°C, et à des taux

d'humidité compris entre 20% et 80% ( sans c ondensation). Il peut être soumis de temps à autre

à des températures comprises entr e + 5° C et –10° C sans dégradation de sa sécurité. Ne pas

l'utiliser en conditions de condensation.

Toute ut ilisation de cet instrument de manière non spécifiée par ces instructions risq ue d'affecter

sa protection de sécurité. Ne pas utiliser l'instrument hors des plages de tension d'alimentation

nominale recommandées ni hors de ses tolérances d'environnement .

AVERTISSEMENT ! CET INSTRUMENT DOIT ETRE RELIE A LA TERRE

Toute int er r upt ion du conducteur de la terre du secteur à l'intérieur ou à l'extérieur de l'inst r um ent

rendra l'instrument dangereux. I l est absolument interdit de priver intentionnellement l'instrument

de son branchement à la terre. La sécurité de l' inst r um ent ne doit pas être annulée par

l'utilisation de rallonge sans conducteur de protect ion.

Lorsque l'instrument est r elié au sect eur, il est possible que les bornes soient sous tension :

l'ouverture des couvercles ou la dépose de pièces (à l'exception des pièces accessibles

manuellement) risque de mettr e à découvert des pièces s ous tension. L'instrument doit être

débranché du secteur et de toute source d' alimentat ion avant tout réglage, remplacement,

travaux d'entretien ou de réparations.

Les condensateurs qui se trouvent dans le bloc d'alimentation risq uent de rester chargés, même

si le bloc d'alimentation a été déconnecté de toutes les sources d'alimentation, m ais ils se

déchargeront en toute sécurité environ 10 minut es après extinction de l'alimentation.

Eviter dans la mesure du possible d'effectuer des rég lages, travaux de réparations ou d'entretien

lorsque l'instrument ouvert est br anché au secteur. Si cela s'avère toutefois indispensable, seul

un technicien compétent connaissant les risques encour us doit effectuer ce genre de travaux.

S'il est évident que l'instrument est défectueux, qu'il a été soumis à des dégâts mécaniques, à

une humidité excessive ou à une corrosion chimique, la protection de sécurité est affaiblie :

l'instrument doit être retir é de l'exploitation et renvoyé vérifications et de r éparat ions.

Ne remplacer les fusibles que par des fusibles d' int ensit é nom inale requise et du type spécifié. Il

est interdit d'utiliser des fusibles "maison" et de court-circuiter des porte-fusibles.

8

Ne jamais humidifier l'instrument lors du net t oyag e.

Les symboles suivants se trouvent sur l'instrument, ainsi que dans ce m anuel.

Borne de terre (masse)

alimentation secteur ON (allumée)

alimentation secteur OFF (éteinte)

courant continu (c.c.)

courant alternatif (c.a.)

Page 10

Tension de fonctionnement

Vérifier que la tension de fonct ionnem ent de l' inst r um ent indiquée sur le panneau arrière

convient à l'alimentation locale. S'il s'avère nécessaire de la modifier, procéder comme suit :

1. S'assurer que l'instrument es t débr anc hé de l' alimentation c. a.

2. Retirer les 6 vis qui maintiennent le couvercle du boîtier et démonter celui-ci en le

soulevant.

3. Changer les liaisons zéro-Ohm appropriées de la carte à circuits impr imés , sit uée à c ôt é

du transformateur:

Relier LK5 pour la seule alimentation à 230 V

Relier LK1 et LK3 pour la seule alimentation à 115 V

Installation

4. Effectuer le remontage dans l'ordr e inverse.

5. Afin de respecter les impératifs des normes de sécurité, modifier l'indication de tension de

fonctionnement sur le panneau arrière, pour indiq uer clairement la nouvelle tension

d'alimentation.

Câble secteur

Lorsqu'un câble secteur à trois conducteurs et aux extrémités dénudées est fourni, il doit être

branché comme suit :

MARRON - SECTEUR-TENSION

BLEU - SECTEUR-NEUTRE

VERT/JAUNE - TERRE Symbole de prise de terre de sécurité

Lors de l'installation d'une prise à fusible, un fusible de 5 ampèr es doit êt r e ut ilisé. Les couleur s

des fils du câble secteur de cet appareil ne correspondant pas f or cément aux couleurs utilisées

pour identifier les bornes de la prise, aussi il est recom m andé de s uivre la procédur e ci -dessous :

Le fil vert et jaune doit être connecté à la bor ne de la prise près de laquelle figure la lettre E ou le

symbole de terre ci-dessus ou de couleur verte ou verte/jaune.

Le fil bleu doit être connecté à la prise de la borne près de laquelle figure la lettre N ou de

couleur noire.

Le fil marron doit être connecté à la bor ne pr ès de laquelle figure la lettre L ou de couleur rouge.

ATTENTION ! CET APPAREIL DOIT ETRE RELIE A LA TERRE

Toute int er r upt ion du conducteur de la terre du secteur à l'intérieur ou à l'extérieur de l'inst r um ent

rendra l'instrument dangereux. I l est absolum ent int er dit de pr iver intent ionnellement l' inst rument

de son branchement à la terre.

9

Page 11

Réglage de la sortie

Lorsque l'interrupteur POWER (Alimentation) est sur ON (act if) et que le bouton OUTPUT

(sortie) est relâché (inactif ) la tension de sortie et la limite de courant peuvent être réglées avec

précision à l'aide des trois commandes de sortie ; l' affichage de gauche indique la tension et

l'affichage de droite indique le courant appliqué.

Lorsque le bouton OUTPUT est enfoncé (act if) , la DEL ON et la DEL CV (Constant Voltage tension constante) s'allument ; l'affichage de gauche continue d'indiquer la tension appliquée,

tandis que l'affichage de droite indique maintenant le courant réellement utilisé. Le fait d'enf onc er

puis de relâcher le bouton I METER DAMPING active puis inhibe l'amortissement de

l'ampèremètre ; lorsq ue l' am or tissement est actif, la DEL DAMPED s'allume et la valeur moyenne

d'un courant de charge variable s'affiche.

Si la puissance de sortie passe dans la limite de courant, la DEL CI s'allume au lieu de la DEL

CV, et l' affichage de gauche indique la tension réelle aux bornes de sortie ; l'affichage de droite

continue d'indiquer la limite de courant appliquée.

A t out m oment, la tension et le courant appliqués peuvent être contrôlés en appuyant sur le

bouton CHECK V/I.

Les sorties de plusieurs sources peuvent être connectées en sér ie ou en parallèle af in de

produire respectivement des tensions ou des courants plus élevés. Il convient de s'assur er, lors

du branchement d'appareils en série, que la tension nominale maximale de toute bor ne de sortie

(crête de 300 V maximum par rapport à la masse réelle) n'est pas dépassée.

Fonctionnement

Connexion à la charge

La connexion aux bornes de sortie du panneau avant peut s'effectuer à l'aide de prises de 4 mm,

des cosses ou des extrémités de fils. Pour minimiser la chute de tension, les fils de connexion à

la charge doivent être des fils de calibre suffisant et doivent rester courts. Les fils de charge

doivent être torsadés ensemble pour minimiser l'inductance.

Pour prévenir les erreurs introduites par la connexion d'une résistance à des courants plus

élevés, le dispositif de télédétection doit être utilisé (10 mΩ de résistance de fil cause une de

baisse de 0,2 Volt à 20 A). Retirer les deux contacts court-circuitants entre la sortie arrière et les

bornes de détection et connecter les bornes de détection directement à la charge ; les

connexions d'alimentation peuvent s'effectuer des bornes avant ou arrière.

Pour assurer le branchement correct ent r e la sor t ie et la bor ne de dét ec t ion, les fils de détection

doivent être torsadés ensemble avec leurs fils de sortie res pectifs avant de torsader ensemble

les fils de sortie.

La chute de tension de chaque fil de sortie ne doit pas dépasser 1 Volt.

Les contacts court-circuitants doivent être rétablis entre les bornes arrière de détection et de

sortie lorsque la télédétection n'est pas utilisée. Cependant, la connexion de la borne de

détection se fait également de l' intérieur par le biais d'une résistance de faible valeur, et seule

une erreur mineure entre la tension appliquée et la tens ion réelle en r ésult e si les contacts ne

sont pas branchés.

La sortie est isolée de la terre et l'une ou l'autr e des bor nes peut êt r e reliée à la terre ou

augmentée de 300 V maximum au-dessus de la masse réelle ; cependant, ces tensions sont

dangereuses et il une extrême prudence s'impose.

10

La commande de limite de courant peut être appliquée pour limit er le cour ant de sortie continu à

des niveaux aussi faibles que 10 mA. Tout efois, comme pour toutes les sources d'alimentation de

précision, un condensateur est connecté en parallèle à la sortie, afin de maintenir la stabilité et

une bonne réponse transitoire. Ce condensateur transfère la charge à la tension de sortie, et

lorsque le condensateur se décharge, un c our t-circuit de la sortie produit une courte impulsion de

courant, indépendante de la limite de courant adoptée.

Page 12

Protection

La protection contre les surtensions est ent ièr em ent variable dans la plage de 10% à 110% du

niveau maximal d'alimentation en sortie. Cette limite s'applique à l'aide du potentiomètre

préréglé SET OVP réglable par tournevis et accessible par une ouverture dans le panneau

frontal. Tourner le pot ent iomètre en sens horaire pour augmenter la limite. Cett e limit e s ' affiche

sur le compteur de gauche par pression sur le bouton READ OVP (Lire la surtension). Si la

tension de la sortie dépasse la protection de surtension appliquée, pour quelque raison que ce

soit, y compris une tension externe forcée, la sor t ie disj onc t e.

La sortie disjoncte également si le détect eur t her mique rélève une surchauffe de l'un des semiconducteurs, si les fils de détection sont c onnect és à la m auvaise sort ie ou en cas de t entat ive

de prélèvement d'alimentation des fils de détection.

Dans tous ces cas, le message TRIP (Interruption) s'affiche sur les deux affichages. Une fois la

raison de l'interruption éliminée, le fonctionnem ent nor m al peut r epr endre en plaçant

l'interrupteur POWER alternativement sur (

La sortie est protégée des tensions inverses par une diode ; le cour ant inverse cont inu ne doit

pas dépasser 3 A, bien que les courants transitoires puissent être beaucoup plus importants.

Ventilation

Ces appareils sont extrêmement efficaces, mais ils peuvent néanmoins g énér er une c haleur

importante à plein régime. Les appareils ne sont refroidis que par convection. Il est donc

important, pour garantir les performances et la sécurité, de s'assurer que la ventilation ne soit

jamais gênée. Si les appareils sont installés dans un espace réduit, tel qu'un châssis de 19

pouces, une ventilation adéquate doit être assurée, par l'ut ilisation, par exemple, de ventilateur s.

) puis (l).

Le constructeur ou ses agents à l'étr anger répareront toute unité qui tombe en panne. Si le

propriétaire de l'appareil décide d'effectuer ses propres r éparations, c elles -c i doivent êtr e

effectuées exclusivement par un personnel spécialisé qui doit se référ er au m anuel de

maintenance disponible directement auprès du construct eur ou de s es agents à l'étranger.

Fusible

Le fusible qui convient pour tous les modèles et toutes les plag es de CA est :

S'assurer que seuls les fusibles du courant nom inal et du t ype spécifiés sont utilisés. Il est

interdit d'utiliser des fusibles "maison" ou de cour t-circuiter les porte-fusibles.

Pour remplacer le fusible, débrancher tout d'abord l'instrument de la source d'alimentation CA.

Retirer les 6 vis de fixation du couvercle et déposer ce der nier. Remplacer le fusible par un

fusible approprié puis remettre le couvercle en place.

Il convient de noter que la fonction principale d'un fus ible est d'assurer la sécurité de l'appareil, et

de limiter les dégâts en cas de panne de l'un des dispositifs de commutation.

Si un fusible saute il est donc très probable que le fusible de remplacement sautera aussi, en

raison d'une défectuosité dans l'alimentation ; dans ce cas l'instrument devra être renvoyé au

constructeur pour réparation.

Nettoyage

Entretien et réparation

10 Amp 250V HBC à action retardée, 5 x 20 mm

S'il faut nettoyer le bloc d'alimentation, utiliser un chiff on légèrement imbibé d'eau ou d'un

détergent doux. Nettoyer le cadran d'aff ichage au moyen d'un chiffon sec et doux.

AVERTISSEMENT ! EMPECHER TOUTE INTRODUCTION D'EAU DANS LE BOITIER AFIN

D'EVITER TOUT CHOC ELECTRIQUE ET DEGATS AU BLOC D'ALIMENTATION. NE JAMAIS

UTILISER DE SOLVANTS POUR NETTOYER LE BLOC, AFIN D'EVITER D'ENDOMM AGER LE

BOITIER OU LE CADRAN D'AFFICHAGE.

11

Page 13

l

Sicherheit

Diese Stromversorgung wurde nach der Sicherheitsklasse (Schutzart) I der IEC-Klassifikation

und gemäß den europäischen Vorschriften EN61010-1 (Sicherheitsvorschriften für Elekt r ische

Meß-, Steuer, Regel- und Laboranlagen) entwickelt. Es handelt sich um ein Gerät der

Installationskategorie II, das für den Betrieb von einer normalen einphasigen Versorgung

vorgesehen ist.

Das Gerät wurde gemäß den Vorschriften EN61010-1 geprüft und wurde in sicherem Zustand

geliefert. Die vorliegende Anleitung enthält vom Benutzer zu beachtende Informationen und

Warnungen, die den sicheren Betrieb und den sicheren Zus tand des Gerätes gewährleisten.

Dieses Gerät ist für den Betrieb in Innenr äumen der Umgebungsklass 2 , für einen

Temper at ur ber eich von 5° C bis 40° C und 20 - 80 % relative Feuchtigkeit (nicht kondensierend)

vorgesehen. Gelegentlich kann es Temperaturen zwischen +5° und –10°C ausgesetzt sein, ohne

daß seine Sicherheit dadurch beeinträchtigt wird. Betreiben Sie das Gerät jedoch auf keinen Fall,

solange Kondensation vorhanden ist.

Ein Einsatz dieses Geräts in einer Weise, die für diese Anlage nicht vorgesehen ist, kann die

vorgesehene Sicherheit beeinträchtigen. Auf keinen Fall das Gerät außerhalb der angegebenen

Nennversorgungsspannungen oder Umgebung sbedingungen betreiben.

WARNUNG! - DIESES GERÄT MUSS GEERDET WERDEN!

Jede Unterbrechung des Netzschutzleiters innerhalb oder außerhalb des Ger äts m acht das

Gerät gefährlich. Eine absicht liche Unter br echung ist verboten. Die Schutzwirkung darf durch

Verwendung eines Verlängerungskabels ohne Schutzleiter nicht aufgehoben werden.

Ist das Gerät an die elektrische Versorgung angeschlossen, so können die Klemmen unter

Spannung stehen, was bedeutet, daß beim Entfernen von Verkleidungs- oder sonstigen Teilen

(mit Ausnahme der Teile, zu denen Zugang mit der Hand möglich ist) höchstwahrscheinlich

spannungsführende Teile bloßgelegt weden. Vor jeglichem Öffnen des Ger äts zu Nachstell-,

Auswechsel-, Wartungs- oder Reparatur zwecken, G er ät s t ets von sämt lichen Spannungsquellen

abklemmen. Kondensatoren in der Stromversorgung k önnen auch noc h nach Abschalten

sämtlicher Stromversorgung Spannung führen, sie entladen sich jedoch innerhalb von etwa 10

Minuten nach Spannungsabschaltung.

Jegliche Nachstellung, Wartung und Reparatur am geöffneten, unter Spannung stehenden

Gerät, ist nach Möglichkeit zu vermeiden. Falls unvermeidlich, sollten solche Arbeiten nur von

qualifiziertem Personal ausgef ühr t werden, das sich der G efahren bewußt ist.

Ist das Gerät eindeutig fehlberbehaftet, bzw. wurde es mechanisch beschädigt, übermäßi ger

Feuchtigkeit oder chemischer Korrosion ausgesetzt, so können die Schutzeinrichtungen

beeinträchtigt sein, weshalb das Gerät aus dem Verkehr zurückgezogen und zur Überprüfung

und Reparatur eingesandt werden sollte.

Sicherstellen, daß nur Sicherungen der vorgesc hr iebenen Stromstärke und des vorgesehenen

Typs als Ersatz verwendet werden. Provisorische “Sicherungen” und der Kurzschluß von

Sicherungshaltern ist verboten.

12

Beim Reinigen darauf achten, daß das Gerät nicht naß wird.

Am Gerät werden folgende Symbole verwendet:

Erdungsklemme

Netz ON (ein)

Netz OFF (aus)

Gleichstrom

Wechselstrom

Page 14

Netzbetriebspannung

Sicherstellen, dass die auf der Geräter ückwand angegebene Betriebsspannung mit der

Versorgungsspannung am Ort übereinstimmt. Falls es erforderlich ist, die Betriebsspannung zu

ändern, wie folgt vorgehen:

1. Sicherstellen, dass das Gerät vom W echselstromnetz getrennt ist.

2. Die 6 Schrauben entfernen, mit denen die obere Gehäusehälfte befestigt ist, und den

Deckel abheben.

3 Die in Frage kommenden Null-Ohm-Drahtbrücken neben dem Transformator auf der

Platine nach Bedarf umstecken.

Drahtbrücke LK5 nur für 230 V-Betrieb

Drahtbrücke LK1 und LK3 nur für 115 V-Betrieb

Installation

4. Gerät in umgekehrter Reihenfolge wieder zusammenbauen.

5. Die Sicherheitsvorschriften werden nur dann erfüllt, wenn auch die Angabe der

Betriebsspannung auf der Geräter ückwand geändert wird, so dass die neue

Spannungseinstellung deutlich angezeigt ist.

Netzanschlußkabel

Ein mitgeliefertes dreiadrig es Anschlußkabel mit abisolierten Enden ist wie folgt anzuschließen:

BRAUN - STROMFÜHREND

BLAU - NEUTRAL

GRÜN/GELB - ERDE Schutzerdesymbol

Beim Anbau eines abgesicherten Steckers ist eine 5 A Sicherung im Stecker anzubringen. Da die

Farben der Adern im Netzkabel des Geräts unter Umständen nicht mit den Farben der

Steckerklemmen übereinstimmen, wie folgt vorgehen:

Die grün/gelbe Ader ist an die Steckerklemme anzuschließen, die mit dem Buchstaben E, dem

oben angegebenen Schutzerdesymbol oder grün oder g r ün/ gelber Farbe versehen ist.

Die blaue Ader ist mit der Klemme zu verbinden, die mit dem Buchstaben N oder schwarzer

Farbe gekennzeichnet ist.

Die braune Ader ist mit der Klemme zu verbinden, die mit dem Buchstaben L oder roter Farbe

gekennzeichnet ist.

Jegliche Unterbrechung des Schutzleiters innerhalb oder außer halb des G er äts oder ein

Abschließen des Schutzleiteranschlusses kann dazu führen, daß das Gerät gefährlich wird. Eine

absichtliche Unterbrechung ist unzulässig.

WARNUNG! DIESES GERÄT MUSS GEERDET WERDEN.

13

Page 15

Ausgangseinstellung

Bei eingeschaltetem LEISTUNGSSCHALTER (l) und ausgeschaltetem AUSGANGSDRUCKSCHALT ER ist es möglich, mit Hilfe der drei Ausgangsverstellungen die

Ausgangsspannung und Strombegrenzung genau einzustellen. Die linke Anzeige läßt die

Spannung, die rechte die Stromstärke erkennen.

Nach dem Einschalten des AUSGABESCHALTERS leuchten die Netz-LED und die CV-LED

(konstante Spannung). Die linke Anzeige zeigt weiterhin die eingestellte Spannung; auf der

rechten Anzeige erscheint jetzt jedoch der aufgenommene Istst r om . Durch Drücken der Taste I

METER DAMPING (ANZEIGEDÄMPFUNG) wird die Dämpfung der Stromanzeige ein- und

ausgeschaltet. Während des Einschaltens leuchtet die Lampe DAMPED (GEDÄMPFT) und auf

der Anzeige erscheint der Mittelwert der schwankenden Stromaufnahme.

Wenn die Ausgabe auf Strombegrenzung geht, leuchtet die Lampe CI (konstanter Strom)

anstelle der Lampe CV und auf der linken Anzeige erscheint jetzt die Istspannung an den

Ausgangsklemmen. Auf der rechten Anzeige erscheint weiterhin die eingestellte

Strombegrenzung. Durch Drücken der Tast e CHECK V/I ( PRÜFUNG V/I) können jederzeit

Sollspannung und Sollstrombegrenzung angezeigt werden.

Die Ausgänge verschiedener Stromversorgungen können in Reihe oder parallel geschaltet

werden, um höhere Spannungen oder höhere Stromstärken zu erzeugen. Bei einer

Reihenschaltung der Versorgungsquellen ist darauf zu achten, daß die max. Nennspannung

irgendeiner Ausgangsklemme nicht überschritten wird (Spitzenspannung 300 V gegen Erde).

Anschluß des Verbrauchers

Der Anschluß an die Ausgang sklemmen der Fronttafel kann durch Stecker 4 mm, Flachstecker

oder Drahtenden durchgeführt werden. Um den Spannungsabfall zu minimieren, müssen die

Anschlußkabel der Verbraucher einen ausreichenden Querschnitt haben und kurz gehalten

werden. Verbraucherdrähte sind zu verdrallen, um die Selbstinduktion zu mindern.

Betrieb

Um Fehler durch den Leitungswiderstand bei größeren Stromstärken zu vermeiden, ist die

Fernerfassungseinrichtung zu verwenden (10 mΩ Leitungswiderstand führt zu einem Abfall von

0,2 V bei 20 A). Die beiden kurzen Brücken zwischen den hinteren Ausgangs- und

Erfassungsklemm en entfernen und die Erfassungsklemmen direkt mit dem Verbraucher

verbinden. Die Leistungsanschlüsse können an die vorderen oder hinteren Klemmen angelegt

werden.

Um eine gute Verbindung zwischen Ausgang und Abtastung herzustellen, sind die Abtastdrähte

mit den entsprechenden Ausgangsleitungen zu verdrallen, bevor die Ausgangsleitungen

zusammen verdrallt werden. Der Spannungsabfall in jeder Ausgangsleitung darf 1 V nicht

überschreiten. Wird die Fernerfassung nicht mehr verwendet, müss en die Brüc ken zwischen den

hinteen Erfassungs- und Ausgangsklemmen wieder eingesetzt werden. Der Abtastanschluß wird

jedoch auch intern über einen niedrigohmigen Widerstand hergestellt, und ohne Einsatz der

Brücken entsteht nur ein kleiner Fehler zwischen Soll- und Istspannung.

Der Ausgang ist vollständig ungeerdet, und jede Klemme kann an Erde angeschlossen oder mit

einer Spitzenspannung von 300 V gegen Erde erhoben werden. Derartige Spannungen sind

jedoch gefährlich und erf ordern große Vorsicht.

Mit Hilfe der Strombegrenzungsverstellung kann der Ausgangsstrom bis herunter auf eine Höhe

von 10 mA begrenzt werden. Wie jedoch in allen Präzisionsstromversorgungseinheiten ist ein

Kondensator über dem Ausgang vorgesehen, um Stabilität und gutes Einschwingverhalten zu

gewährleisten. Dieser Kondensator wird durch die Ausgangsspannung geladen, und ein

Kurzschluß der Ausgangsspannung erzeugt einen kurzen Stromimpuls während des Entladens

des Kondensators; dieser ist unabhängig von der Einstellung der Strombegrenzung.

14

Page 16

Schutz

Der Überspannungsschutz ist im Bereich von 10 % bis 110 % der höchsten

Versorgungsspannung einstellbar. Die Einstellung erfolgt dur ch Schraubendreher mit Hilfe des

Potentiometers SET OVP (ÜBERSPANNUNGSSCHUTZ EINST ELLEN), der durch ein Loch in

der Frontplatte zugänglich ist. Durch ein Drehen im Uhrzeiger s inn (nac h r echts) wird die Grenze

vermindert. Nach Drücken der Taste READ OVP (ÜBERSPANNUNGSSCHUTZ LESEN)

erscheint die Begrenzung direkt auf der linken Anzeige. Sollte die Ausgangsspannung den

eingestellten Überspannungsschutz aus irgendeinem Gr unde oder dur ch eine exter ne Spannung

überschreiten, wird der Ausgang abgeschaltet.

Das Abschalten des Ausgangs erfolgt ebenfalls, wenn ein Thermistor die Übertemper atur eines

Leistungshalbleiters erkennt, wenn die Abtastdrähte mit dem falschen Ausgang verbunden sind

oder wenn es versucht wird, den Verbraucher an die Abtastleitungen anzuschließen.

Unter allen obigen Bedingungen erscheint die Meldung “TRIP” (AUSGELÖST) auf beiden

Anzeigen. Nachdem der Grund für die Auslösung entfernt wurde, kann der norm ale Betr ieb nach

dem AUS- (

schützt den Ausgang im Fall von Gegenspannungen. Ein kontinuierlicher Gegenstrom darf 3 A

nicht überschreiten, obgleich geleg ent liche Spitzen viel höher liegen können.

Belüftung

Diese Geräte sind besonders leistungsvoll, können jedoc h bei Volleistung eine erhebliche Wär m e

erzeugen. Das Stromversorgungsgerät wird nur durch Konvektion g ekühlt, deshalb darf die

Belüftung niemals behindert werden, um eine hohe Leistung und Sicherheit zu erhalt en. Wenn

das Stromversorgungsgerät in beschränktem Raum angeordnet ist, z.B. einem 19" Gestell, muß

für ausreichende Belüftung zum Beispiel durch Verwendung eines Fremdlüfters gesorgt werden.

) und EINSCHALTEN (l) des Leistungsschalters fortgesetzt werden. Eine Diode

Die Hersteller bzw. deren Vertretungen im Ausland bieten die Instandsetzung von Geräten an, bei

denen eine Störung aufgetreten ist. W enn der Eig entümer die Wartungsarbeiten selbst

durchfuhren möchte, hat er dafür Sorge zu tragen, daß diese Arbeiten ausschließlich von

entsprechend qualifiziertem Personal und gemäß den Vorgaben im Wartungshandbuc h

ausgeführt werden, das direk t bei den Herstellern oder deren Vertretungen im Ausland bezogen

werden kann.

Sicherung

Die korrekte Sicherung für alle Modelle und Wechselstrombereiche ist:

Bitte darauf achten, daß nur Sicher ungen mit der richtigen Amperezahl und des angegebenen

Typs zum Auswechseln verwendet werden. Der Gebrauch von provisorischen Sicherungen und

das Kurzschließen von Sicherungshaltern ist verboten.

Zum Ersatz der Sicherung zunächst das Gerät von der Netzversorg ung abschließen. Sechs

Befestigungsschrauben am Deckel abschrauben und Deckel abheben. Die Sicherung gegen eine

der korrekten Art austauschen und Deckel wieder anbauen.

Es ist zu beachten, daß es die Hauptfunktion der Sicherung ist , das Gerät zu schützen und beim

Ausfall einer Schalteinrichtung jeglichen Schaden zu begr enzen. Wenn deshalb eine Sicherung

durchbrennt, brennt sehr wahrscheinlich auch die Ersatzsicherung durch, da ein Fehler in der

Versorgung vorliegt. Unter diesen Umständen ist das Gerät den Herstellern zwecks Wartung

einzusenden.

Reinigung

Falls die Stromversorgung der Reinigung bedarf, eine mit Wasser oder einem milden Detergens

angefeuchteten Lappen benutzen. Anzeigefenster mit einem weichen, trockenen Lappen

polieren.

WARNUNG! ZUR VERMEIDUNG EINES ELEKTRISCHEN SCHLAGS BZW. BESCHÄDIGUNG DER

STROMVERSORGUNGSEINHEIT, DAFÜR SORGEN, DASS KEIN WASSER INS GEHÄUSE EINDRINGT.

UM SCHADEN AM GEHÄUSE BZW. AM ANZEIGEFENSTER ZU VERMEIDEN, KEINE

LÖSUNGSMITTEL ZUR REINIGUNG VERWENDEN!

Wart ung und I ns tands et z ung

10 A, 250V, träge HBC Sicherung, 5 x 20 mm

15

Page 17

l

Sicurezza

Questo alimentatore appartiene alla Categoria di Sicurezza 1 secondo la classifica IEC ed è stato

progettato in modo da soddisfare i crit er i EN61010-1 (requisiti di Sicurezza per Apparecchiature

di misura, controllo e per uso in laboratorio). È uno st r um ento di Categoria II di installazione e

inteso per funzionamento con un’alimentazione normale monofase.

Questo strumento ha superato le prove previste da EN61010-1 e viene fornito in uno stato di

sicurezza normale. Questo manuale contiene informazioni e avvertenze che devono essere

seguite per assicurarsi di un’operazione sicura e mantenere lo str umento in condizioni di

sicurezza.

Questo strumento è progettato per uso all’interno e in un ambiente d’inquinamento Grado 2,

entro la gamma di temperat ur a da 5° C a 40°C con um idità relativa (non condensante) di

20% - 80%. Può occasionalmente essere assoggettato a temperature fra + 5° C e –10°C senza

comprometterne la sicurezza. Non usare in presenza di condensazione.

L’uso dello strumento in maniera non conforme a quanto specificato in quest e istruzioni potrebbe

pregiudicare la protezione di cui è dotato. Non usare lo strumento per misurare tensioni al di

sopra dei valori nominali o in condizioni ambientali al di fuori di quelle specificate.

ATTENZIONE! QUESTO STRUMENTO DEVE ESSERE COLLEGATO A TERRA

Una qualsiasi interruzione sia interna che esterna del collegamento a terra lo rende pericoloso.

È proibito interrompere questo colleg am ent o deliberatam ent e. La pr otezione non deve essere

negata attraverso l’uso di un cavo di prolunga privo del filo di collegamento a ter ra.

Quando lo strumento è alimentato, alcuni morsett i sono s ot t o tensione e l’apertura dei coperchi o

la rimozione di parti (eccetto quei componenti accessibili senza l’uso di attrezzi) può lasciare

scoperti dei morsetti sotto tensione. L’apparecchiatura deve essere staccata da tutte le sorgenti

di tensione prima di aprirla per regolazioni, manutenzione o riparazioni.

I condensatori collegati all’alimentazione interna possono essere carichi anche dopo aver

staccato l’alimentazione ma si scaricano in circa 10 minuti dopo aver levato la corrente.

È consigliabile evitare, per quanto possibile, qualsiasi operazione di regolazione e di riparazione

dello strumento sotto tensione e, q ualora fosse inevitabile, dette operazioni devono essere

eseguite da una persona specializzata in materia, che sia pienamente conscia del pericolo

presente.

Quando sia chiaro che lo strumento è difettoso, o che ha subito un danno meccanico, un

eccesso di umidità, o corrosione a mezzo di agenti chimici, la sicurezza potrebbe essere stata

compromessa e lo strumento deve essere ritir at o dall’uso e rim andat o indiet r o per le pr ove e le

riparazioni del caso.

Assicurarsi di usare solo fusibili della portata giusta e del tipo corretto durante eventuali

sostituzioni. Sono proibiti sia l’uso di fusibili improvvisati che il corto circuito deliberato dei

portavalvole.

Non bagnare lo strumento quando si pulisce.

Sullo strumento e in questo manuale si fa uso dei seguenti simboli.

16

Terminale di Terra

alimentazione ON (accesa)

alimentazione OFF (spenta)

Corrente Continua

Corrente Alternata

Page 18

Tensione d’esercizio

Controllare che la tensione d’esercizio dello strumento segnata sul pannello posteriore sia uguale

a quella della rete elettrica locale. Se dovesse rendersi necessario cambiare la t ensione

d'esercizio, osservare il seguente procedimento:

1. Controllare che lo str um ent o sia sc olleg at o dall'alim entazione a c.a.

2. Rimuovere le 6 viti che tengono la parte superiore del cor po e sollevare il coperchio.

3. Cambiare il collegamento vicino al trasformatore sul circuito stampato:

Collegare soltanto LK5 per tensione d’esercizio di 230V.

Collegare solo LK1 e LK3 per tensione d’esercizio di 115V.

Installazione

4. Riassemblar e invertendo la pr ocedur a di sm ontaggio.

5. Per soddisfar e le nor m e di ant infortunistica, la tensione segnata sul pannello posteriore

deve essere opportunamente modificata per most r ar e c hiaramente la nuova impostazione di

tensione.

Cavo d’Alimentazione

Quando viene fornito un cavo tripolare ad estremità scoper te per il collegamento a rete, questo

dovrebbe essere connesso nel modo seguente:

MARRONE - RETE FASE

BLU - RETENEUTRO

VERDE/GIALLO - TERR

Simbolo di Sicurezza di Terra

Quando si monta una spina con fusibile, un fusibile a 5 amp dovrebbe essere inserito nella spina.

Dato che i colori dei fili nel cavo di collegamente a rete di questo apparecchio potr ebber o non

corrispondere ai segni colorati che identificano i morsetti nella vostra presa, procedete come

segue:

Il filo di colore verde e giallo deve essere connesso al morsetto nella presa che è m ar chiat o c on

la lettera E o con il simbolo della terra mostrato sopra o di color e verde o verde e g iallo.

Il filo di colore blu deve essere connesso al morsetto marc hiat o con la lettera N o di colore nero.

Il filo di colore marrone deve essere connesso al morset t o m ar c hiat o con la lettera L o di colore

rosso.

AVVERTENZA! QUESTO APPARECCHIO DEVE ESSERE MESSO A TERRA.

Qualsiasi interruzione del conduttore all'interno o all'esterno dell'apparecchio o sconness ione del

morsetto protettivo della terra può verosimilment e r endere l'apparecchio pericoloso.

L'interruzione intenzionale è proibita.

17

Page 19

Regolazione dell'Output [Livello d'Uscita].

Quando l’interruttore POWER [alimentazione] è acceso e il pulsante OUTPUT [livello d'uscita] è

spento, il voltaggio d'uscita e il limite della corrente possono venire regolati accuratam ent e

usando i tre controlli dell'uscita: il contatore sulla sinistra indica il voltaggio e quello sulla destra la

corrente prescelti.

Quando l'OUTPUT è acceso, il LED ON e il LED CV (voltaggio costante) si accendono; il

contatore sulla sinistra continua a mostrare il voltaggio scelto m a il contator e sulla dest r a m os t ra

ora la reale corrente ricevuta. Premendo alternativamente il tasto I METER DAMPING [lettura

fissa del contatore I] si attiverà e disattiverà la lett ur a fissa del contatore di corrente; con la lettura

fissa attivata il DAMPED LED [fissato] sarà acceso e il valore medio di un carico di corrente

variabile verrà letto.

Se il livello d'uscita rientra nel limite di corrente il LED CI (corrente costante) si accenderà invece

del LED CV ed il contatore sulla sinistra mostrerà ora il valore reale del voltaggio che arriva ai

morsetti d'uscita; il contatore sulla destra continuer à a m os t r ar e il limite di cor rente fissato. Il

voltaggio e il livello di corrente prescelti possono venire rivisti schiacciando il tasto CHECK V/I

[controllo V/I]. Delle uscite da diversi alimentatori possono venire connesse in serie o in parallelo

per produrre rispettivamente dei voltaggi più alti o delle correnti più alte. Q uando s i connet t ono

degli alimentatori in serie ci si deve assicurare che il valore massimo di voltaggio di ogni morsett o

d'uscita (300 V picco massimo rispetto alla massa reale) non venga superato.

Funzionamento

Connessione al Carico

La connessione con i morsetti d'uscita del pannello frontale può essere eseguita con degli

spinotti da 4 mm, dei terminali a lancia o con le estremità dei fili. Per ridurre al minimo la caduta

di voltaggio, i cavi di connessione al carico dovrebbero essere di diametro adeguato e

dovrebbero essere tenuti corti. I cavi di carico dovrebbero inoltre esser e int r ec ciat i fra di loro per

ridurre al minimo l'induttanza.

Per superare delle malfunzioni provocate dalla connessione della resistenza del cavo a delle

correnti più alte si dovrebbe usare la funzione di rilevamento a distanza (10 mΩ di resistenza del

cavo faranno perdere 0,2 Volt a 20 amp). Rimuovete i due contatti di corto fra i morsett i

dell'uscita e i morsetti di rilevamento sul retro e collegate i mor s et t i del r ilevamento diret tam ent e

al carico; le connessioni di potenza possono essere fatte sia dai morsetti frontali che da quelli

posteriori.

Per assicurare un buon accoppiamento fra l' uscita e il rilevamento, i cavi del rilevamento

dovrebbero venire intrecciati con i loro corrispondenti cavi dell'uscita prima che i cavi dell'uscita

siano intrecciati assieme. La perdita di voltaggio in ogni singolo cavo d'uscita non deve superare

1 Volt.

I collegamenti di corto fra i m or s et t i del r ilevamento sul retro ed i morsetti dell'uscita devono

venire rifatti quando il controllo a distanza non viene più usato. In ogni caso, la connessione del

rilevamento è anche fatta internamente all'apparecchio tramite una resistenza di basso valore e

solo un piccolo errore risulterà fra il voltaggio pres celt o e quello reale se i contatti vengono

lasciati sconnessi.

18

L'uscita è completamente fluttuante ed uno q ualsiasi dei due mor s et t i può ess er e m ess o a

massa o alzato di un valore fino a 300 V di picco al di sopra della massa reale; comunque tali

voltaggi sono pericolosi e si deve usare grande cautela.

Il controllo del limite della corrente può venire regolato in modo tale da limitare il flusso cont inuo

della corrente d'uscita a dei livelli minimi fino a 10 mA. Comunque, com e per t utte le

alimentazioni da banco di precisione, un condensatore è connesso trasversalmente all'uscita per

mantenere la stabilità ed una buona risposta ai transistori. Questo c ondensat or e s i car ica al

voltaggio d'uscita, ed un corto circuito dell'uscita produrrà un br eve impulso di corr ent e m entre il

condensatore si scarica, il quale è indipendente dai valori fissati del limite della corrente.

Page 20

Protezione

La protezione di sovratensione (OVP) è completamente variabile nei limiti dal 10% al 110% del

livello massimo d'uscita dell'alimentazione. Il limite di OVP viene fissato tramite il potenziometro

preimpostato SET OVP regolabile per mezzo di un cacciavite ed accessibile da un'apertura sul

panello frontale. Girando in senso orario dalla posizione preimpostata si aumenta il limite, che

può essere letto direttamente sul display di sinistra premendo il tasto READ OVP [leggi OVP]. se

il voltaggio all'uscita è superiore al valore di OVP prefissato per qualsiasi motivo, includendo un

voltaggio forzato dall'esterno, l'interruzione dell'uscita verrà fatta scattare.

L'uscita verrà pure interrotta se il sensore termico r iscont ra il surriscaldamento di uno dei

semiconduttori di potenza, o se i cavi di rilevamento vengono collegati all'uscita sbagliata, o se si

cerca di prendere tensione dai fili del rilevamento

In tutti i casi esposti sopra il messaggio TRIP [interruzione] verrà mostrato su ambedue i display.

Una volta che la causa dell'interruzione è stata rimossa, il funzionamento normale può essere

ripreso spegnendo (

tensione inversa da un diodo; la tensione inversa continua non deve eccedere i 3 amp, anche se

dei picchi transitori possono essere molto più alti.

Ventilazione

Questi apparecchi sono molto efficienti ma a piena potenza possono comunque s viluppare un

notevole calore. Gli alimentatori si basano unicamente sul raffreddament o per convezione ed è

quindi importante che la ventilazione non sia mai limitata se si vogliono salvaguardare le

prestazioni e la sicurezza. Se gli alimentatori sono montati in uno spazio angusto, per esempio

un rack da 19 pollici, si deve assicurare una ventilazione adeguata usando, per esempio, un

piatto di ventilazione.

) e poi riaccendendo l'interruttore POWER (l). L'uscita è protet ta dalla

Il Fabbricante, od il suo Rappresentante all'estero, fornirà un servizio di riparazione per gli

strumenti che si guastino. Se il proprielario desidera esequire la manutenzione per proprio

conto, questo deve essere fatio unicam ent e c on l'ausilio del Manuale di Assistenza che può

essere acquistato diretiamente dal fabbricante o dai suoi agenti all'estero.

Fusibile

Il tipo di fusibile corretto per tut t i i m odelli e tut t e le diverse fonti di corrente alternata è:

Assicuratevi che i fusibili vengano sostituiti solo con altri che abbiano la corrente nom inale

richiesta e che siano del tipo specificato. E` proibito l'uso di fusibili di fortuna ed il mettere in corto

i porta fusibili.

Per cambiare il fusibile, come prima cosa sconnettere lo strumento dalla presa di corrente

alternata. Togliere le 6 viti che assicurano il pannello, alzarlo e toglierlo. Sostit uir e il fusibile con

un fusibile del tipo corretto e rif issar e il pannello.

Si noti che la funzione principale del fusibile è quella di rendere lo strumento sicuro e di limitare i

danni nel caso che una dei dispositivi di commutazione si guasti. E`quindi molto probabile che se

un fusibile viene meno anche il sostituto fonda, perché l'alim entator e s i è g uas tato; in questo

caso lo strumento dovrà essere rimandato alla f abbr ica per la r iparazione.

Pulizia

Se si deve pulire il dispositivo di alimentazione, usare uno strofinaccio appena bagnato con

acqua o con un detergente ad azione dolce. Pulire la finestrella della visualizzazione con uno

straccio asciutto e morbido.

ATTENZIONE! PER EVITARE LA SCOSSA ELETTRICA ED EVENTUALI DANNI AL

DISPOSITIVO DI ALIMENTAZIONE, NON PERMETTERE MAI ALL’ACQUA DI ENTRARE

ALL’INTERNO DELL’ALLOGGIAMENTO. PER EVITARE DANNI ALL’ALLOGGIAMENTO E

ALLA FINESTRELLA DELLA VISUALIZZAZIONE, NON PULIRE MAI CON SOLVENTI.

Manutenzione

10 Amp 250V ritardo HBC, 5 x 20 mm

19

Page 21

l

Seguridad

Esta fuente de alimentación es un dispositivo de Clase de Seguridad I según la clasificación del

IEC y ha sido diseñado para cumplir con los requisitos de la norma EN61010-1 (Requisitos de

Seguridad para Equipos Eléctricos para la Medición, Control y Uso en Laboratorio). Es un

instrumento de Categoría de Instalación II propuesto para ser usado c on un sum inist r o

monofásico normal.

Este instrumento ha sido comprobado según la nor m a EN61010-1 y ha sido suministrado en una

condición segura. El manual de instrucciones contiene información y advertencias que deben

seguirse para asegurar el empleo seguro por el usuario y para mantener al instrumento en una

condición segura.

Este instrumento ha sido diseñado para ser utilizado en el interior en un ambiente de Gr ado de

Polución 2 a temperaturas de entre 5ºC y 40ºC y una humedad relativa de entre el 20% y el 80%

(sin condensación). De manera ocasional puede someterse a tem per aturas de entre +5ºC y

−10ºC sin que ello afecte a su segur idad. No hay que poner lo en funcionamiento mientras haya

condensación.

El uso de este instrumento en una manera no especif icada por estas inst r ucc iones puede afectar

la seguridad protectora provista. El instrum ent o no debe s er ut ilizado fuer a de s u clasificación de

voltaje o de su gama ambiental.

ADVERTENCIA! ESTE INSTRUMENTO DEBE CONECTARSE A TIERRA

Cualquier interrupción del conductor a tierra dent r o o fuera del instrumento implicaría que el

instrumento resultará peligroso. Está pr ohibida cualq uier int er r upc ión intencional. La acción

protectora no debe negarse por el uso de una extensión de cable sin conductor pr otector.

Cuando el instrumento está conectado a su suministro es posible que queden sin protección

elementos bajo tensión y la abertura de tapas o el retiro de piezas (salvo las accesibles por la

mano) pueden dejar expuestos a elementos bajo tensión. Si se tuviera que efectuar alguna

operación de ajuste, cambio, mantenimient o o r eparación es nec esario desconectar al

instrumento de todas las fuentes de t ens ión. Los capacitor es dent ro del aparato pueden

permanecer cargados aún cuando las fuentes de tensión hayan sido desconectadas, pero

quedarán seguramente descargadas a 10 minutos de haber desconectado la corriente.

Todo ajuste, mantenimiento o reparación del instrumento abierto bajo tens ión debe ser evitado

en lo posible, pero si fuera ineludible, estos trabajos deben s er r ealizados exclusivamente por un

personal cualificado consciente del riesgo que implican.

Si el instrumento fuera claramente defectuoso, hubiera sido sometido a un daño mecánico, a

humedad excesiva o a corrosión química, su protección de seguridad puede f allar y el aparato

debe dejarse de usar y devolverse para su comprobación y reparación.

Asegurar que sólo se empleen fusibles de la clasificación y tipo especificados para todo

recambio. Está prohibido utilizar fusibles improvisados así como cortocircuitar el portafusibles.

El instrumento no debe humedecerse al ser limpiado. Los símbolos que aparecen a cont inuación

se utilizan en el instrumento y en este manual:-

20

Term inal a tier r a

alimentación principal ON (conectada)

alimentación principal OFF (desconectada)

corriente contínua (cc)

corriente alterna (ca)

Page 22

Instalación

Voltaje de trabajo de alimentación

Verificar que el voltaje de trabajo de alimentación que figura en el panel posterior concuerde con

el suministro local. Si fuese necesario cambiar la gama de voltajes de trabajo, proceda de la

siguiente manera:

1. Cerciorar se de que el instrumento esté desconectado del suministro de CA.

2. Retirar los 6 tor nillos q ue sujetan la parte superior de la caja y separar la tapa.

3. Cambiar el puente de 0 ohmios adecuado, j unto al transformador en la tarjeta de circuito

impreso:

Puente LK5 sólo para funcionamiento a 230 V

Puente LK1 y LK3, sólo para funcionamiento a 115 V

4. Volver a montar en el orden inverso.

5.

Con el fin de cumplir con los requisitos de las normas de seguridad es necesario cambiar el

voltaje de trabajo de alimentación marcado en el panel posterior para indicar claramente el nuevo

ajuste de tensión.

Cable de Red

Cuando se suministra un cable de tres conductores con puntas peladas, se deber á conec tar

como sigue:

MARRO - CORRIENTE DE RED

AZUL - NEUTRO DE RED

VERDE/AMARILLO - TIERRA

Símbolo de Seguridad de Tierra

Al montar un enchufe con fusible incorporado se debe emplear un fusible de 5 amp. Como los

colores de los conductores del cable de red del aparato pueden no corresponder a los colores

marcados en su enchufe, se debe proceder c om o se indica seguidamente:

El conductor de color verde y amarillo debe conectarse a la terminal del enchufe marcada c on la

letra E o con el símbolo de seguridad de tierra mostrado arr iba o color eado verde o verde y

amarillo.

El conductor de color azul debe conectarse a la terminal marcada con la letra N o de color

negro.

El conductor de color marrón debe conectarse a la terminal marcada con la letra L o de color

rojo.

AVISO! ESTE INSTRUMENTO DEBE PONERSE A TIERRA

Cualquier interrupción del conductor de protección dentr o o fuera del instrumento o cualquier

interrupción de la terminal de tierra implicaría un peligro problable para el usuario del

instrumento. Está prohibida toda interr upción intenc ional.

21

Page 23

Ajuste de la Salida

La salida de tensión y el límite de corriente pueden fijarse con precisión mediante el interr upt or

POWER (de fuerza) en la posición on (I) (conectado) y el pulsador OUTPUT (de salida) en la

posición off (desconectado), usando los tres c ont r oles de salida; el medidor izquier do indica la

tensión fijada y el medidor derecho la corriente fijada.

Cuando el OUTPUT está en la posición on, se encenderán el LED ON (diodo emisor de luz

salida conectada) y el LED CV (diodo emisor de luz voltaje constante) se encenderá; el medidor

izquierdo seguirá mostrando la tensión f ij ada per o el m edidor der ec ho m ostrará la cantidad de

corriente tomada. Al presionar el botón I METER DAMPING (Amortiguación del Medidor de

Corriente) alternativamente se conseguirá que la amortiguación del medidor se conecte o

desconecte; si la amortiguación está conectada, el DAMPED LED (diodo emisor de luz de

amortiguación) se encenderá y el valor promedio de una carga de cor r ient e variante será leído.

Si la salida llega al límite de corriente el CI LED (diodo em isor de luz de corrient e c onstant e) se

encenderá en vez del CV LED (diodo emisor de luz de voltaje constante) y el medidor izquierdo

mostrará el voltaje corriente de las terminales de salida; el medidor der ec ho seguirá mostrando

el límite de corriente fijado.

Funcionamiento

Los niveles de voltaje y de corriente fijados pueden verificarse en cualquier instante presionando

el botón CHECK V/I (Verificar Voltaje/ Corriente).

Las salidas de varios suministros pueden conectarse en serie o en paralelo para producir

voltajes más altos o corrientes más altas respectivamente. Se debe t ener cuidado al conectar a

suministros en serie para asegurar que la capacidad de voltaje máximo de la terminal (300V

cresta máxima con respecto a la tierra real) no sea superada.

Conexión a la Carga

La conexión a las terminales de salida del panel frontal puede realizarse mediante enchufes de

4mm, terminales planas o puntas de alambres. Para minimizar la caída de tensión es necesario

que los conductores de conexión a la carga sean de un calibre adecuado y de poca longitud. Los

cables de la carga deben retorcerse junt os para minimizar la inductancia.

Para superar los errores introducidos por la resistencia del conductor conector a altas corrientes

se debe emplear la prestación de detección remota (10 mΩ de resistencia del cable caerá de 0,2

Voltios a 20 Amps). Retirar los dos acoplam ient os de c or t ocir cuit o s ituados ent r e la salida t r aser a

y las terminales detectoras y conectar los detectores directament e a la car ga; las conexiones a

la fuerza pueden realizarse tanto mediante los terminales delanteros como los t raseros. Para

asegurar un buen acoplamiento entre la salida y el detector, los cables del detector tienen que

retorcerse con los conductores corr espondient es de la salida ant es de r etorcer entre sí a los

conductores de salida.

La caída de tensión en cada conductor de salida no debe superar 1 Voltio.

22

Los acoplamientos de cortocircuito deben volver a realizarse entre el detector t r asero y las

terminales de salida cuando no se utilice la detección remota. La conexión de detectores

también puede efectuarse internamente con una r esistencia de poco valor y un error muy

pequeño entre el voltaje fijado y el corriente podrá resultar si el acoplamient o se deja

desconectado.

La salida es totalmente flotante y cualquier terminal puede conectarse a t ierra o elevarse hasta

una cresta de 300V sobre tierra real; tales tensiones son, no obstante, peligrosas y se deben

tomar las precauciones debidas.

El control de límite de corriente puede fijarse de m odo que se limite la salida de corriente

contínua a niveles de hasta 10mA. Sin embargo, como sucede con todos los suministros de

fuerza de precisión para mesas de trabajo, se debe conectar a un c apacitor a t ravés de la

Page 24

salida para mantener buena estabilidad y una buena respuesta en estado transitorio. Este

capacitor se carga a la tensión de salida y el cortocircuito de la salida producirá un pulso corto

de corriente cuando el capacitor se descarga que es independiente del límite de corriente fijado.

Protección

La protección contra la sobrecarga de tens ión (OVP) es totalmente variable dentro de la gama

10% a 110% del nivel de salida máximo del suministro. El límite de OVP se fija mediante el

potenciómetro prefijado SET OVP (fijar protección contra sobrecarga de tensión), ajus table por

destornillador, al que se accede a través de un orificio en el panel frontal. Al rotar el prefijado a

la derecha se aumenta el límite, que puede leerse directamente en el visualizador de la izquierda

al presionar el botón READ OVP (leer protección contra sobrecarga de tensión) . Si el voltaje de

la salida supera al OVP fijado por cualquier motivo, incluyendo un voltaje forzado internamente,

la salida se “disparará”, cortándose.

La salida también se “disparará” si el detector térmico encuent r a el r ecalentamient o de

cualquiera de los semiconductores de fuer za, o si los cables detec t or es est án c ableados a la

salida equivocada o si se tratara de extraer fuerza de los cables detectores . En t odos los casos

anteriores el mensaje 'TRIP' (disparo) aparecerá en ambas pantallas. Una vez se corrija la

causa del disparo , se restaurará el funcionamiento normal al desconectar el interruptor de

fuerza POWER y volver a conectarlo en posición on (I) nuevamente.

La salida está protegida contra tensiones inversas por un diodo; la cor r ient e contínua inversa no

debe superar 3 Amps, aunque los estados transitorios pueden ser mucho más altos.

Ventilación

Estos aparejamientos son muy eficaces pero pueden g ener ar m uc ho calor a fuerza plena. Los

suministros dependen del enfriamiento por convección solamente y por lo tanto es m uy

importante que la ventilación no esté restringida si se quier en m antener el rendimiento y la

seguridad. Si los suministros están montados en un espacio restr ing ido, p. ej. un estante de 19

pulgadas, se debe asegurar una ventilación adecuada usando, por ej em plo, un ensam ble

ventilador.

23

Page 25

Los fabricantes o sus représentantes en el extraniero ofrecen un servicio de asistencia que se

encarga de reparar las averias que pudieran producirse en estos instrumentas. Si los usuarios

desearan establecer su propio servicio de mantenimiento, esto solo deberià ponerse en pr àc t ica

en combinacion con el Manual de Servicio que se puede adquirir directamente al fabricante o a

sus representantes en el extranjero.

Fusible

El tipo correcto de fusible para todos los modelos y para toda gama de sum inist r o de CA es:

Asegurarse que al efectuar un cambio sólo se usen fusibles de clasificación adecuada y del tipo

especificado. Está prohibido usar fusibles improvisados así como el cortocircuito de los

portafusibles. Para cambiar un fusible, pr imero se debe desconectar al instrumento de su

suministro de CA. Retirar los 6 tornillos que aseg ur an la tapa y sacar a ésta. Cambiar al fusible

por uno del tipo correcto y volver a poner la tapa.

Se debe observar que la función principal del fusible es la de hacer que el instrum ent o s ea

seguro y el limitar daños en el caso de la falla de uno de los dispositivos interruptores.

Si uno de los fusibles fallare es probable que su reemplazo también se funda puesto a que el

suministro ha desarrollado una falla; en tal caso será necesario devolver al instrument o al

fabricante para su reparación.

Limpieza

Si necesita limpiarse la unidad de suministro de fuerza, utilizar un paño húmedo en agua o en un

detergente suave. La ventana de visualización debe limpiarse con un paño suave y seco.

Maintenimiento

10 Amp 250V HBC retardado, 5 x 20 mm

ADVERTENCIA! PARA EVITAR CHOQUES ELÉCTRICOS O DAÑAR A LA UNIDAD DE SUMINISTRO

DE FUERZA, NUNCA DEJE ENTRAR AGUA EN LA CARCASA. PARA EVITAR QUE LA CARCASA O LA

VENTANA DE VISUALIZACIÓN SEAN DAÑADOS, NUNCA LIMPIE CON SOLVENTES.

24

Page 26

Thurlby Thandar Instruments

Ltd

.

Glebe Road • Huntingdon • Cambridgeshire • PE29 7DR • England (United Kingdom

)

Telephone: +44 (0)1480 412451 • Fax: +44 (0)1480 450409

International web site:

www

.aimtti.com • UK web site:

www

.aimtti.co.uk

Email: info@aimtti.com

Aim Instruments and Thurlby Thandar Instruments

Loading...

Loading...