Page 1

INSTRUCTION MANUAL

EN

SMU4000 SERIES

SOURCE MEASURE UNITS

Page 2

CONTENTS

CONTENTS ............................................................................................................................................................ 1

Product description ..................................................................................................................................... 4

Safety ............................................................................................................................................................. 5

Symbols .......................................................................................................................................................................... 5

Safety notices ................................................................................................................................................................. 6

Installation .................................................................................................................................................... 7

Mounting ......................................................................................................................................................................... 7

Ventilation ....................................................................................................................................................................... 7

Handle/stand .................................................................................................................................................................. 7

Electrical Requirements .................................................................................................................................................. 8

Switching On .................................................................................................................................................................. 9

Instrument overview .................................................................................................................................... 10

Front Panel ................................................................................................................................................................... 10

Rear Panel .................................................................................................................................................................... 12

Introduction .................................................................................................................................................. 14

Using this Manual ......................................................................................................................................................... 14

Navigation Controls ...................................................................................................................................................... 15

Home screen ................................................................................................................................................................ 17

Getting Started ............................................................................................................................................. 19

Connections .................................................................................................................................................................. 19

High Voltage Interlock [SMU4201 only] ........................................................................................................................ 20

Basic operation ............................................................................................................................................................. 21

Selecting a Range ........................................................................................................................................................ 23

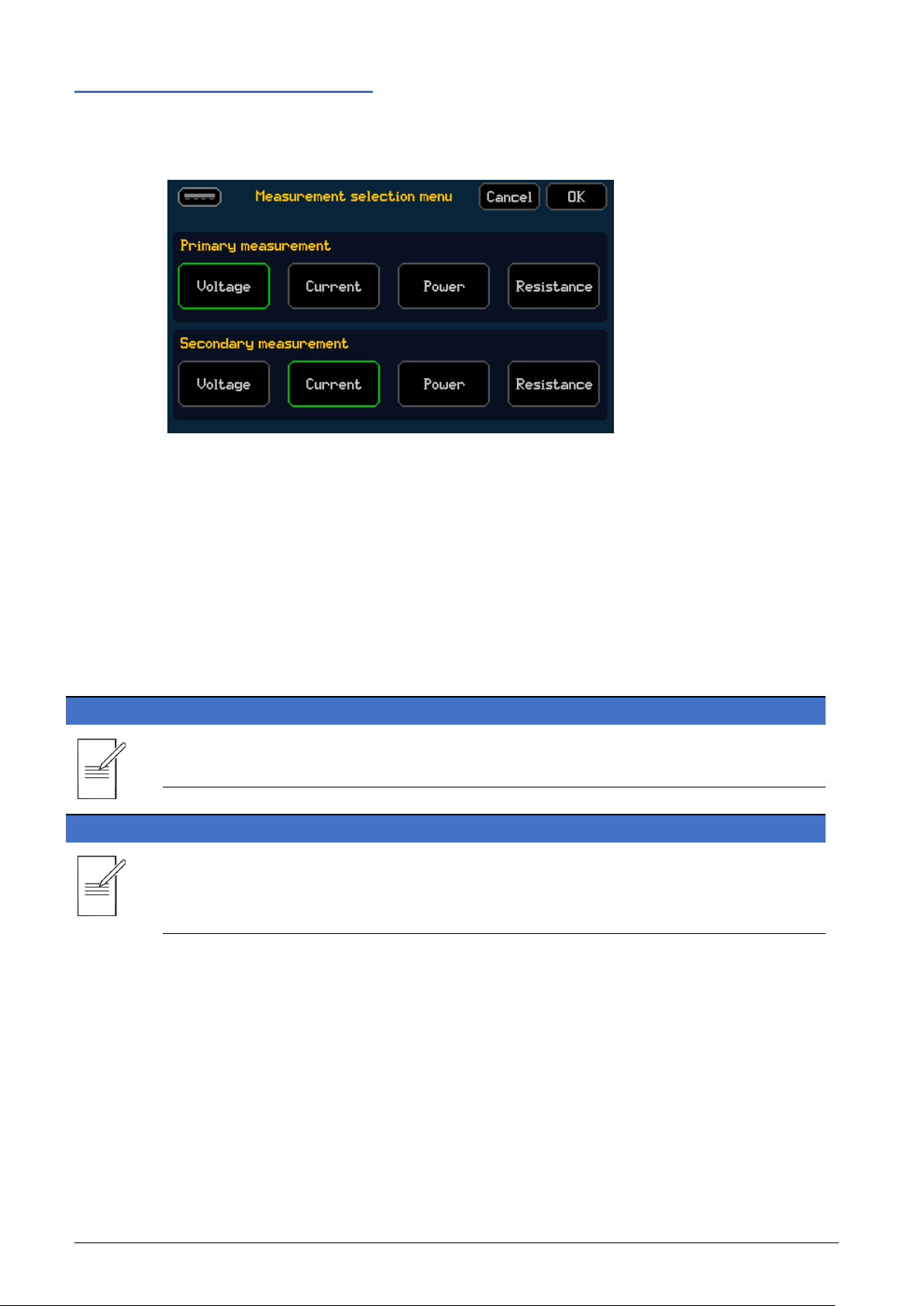

Measurement selection................................................................................................................................................. 25

Saving Data .................................................................................................................................................................. 26

Sample table ................................................................................................................................................................. 28

Measure Statistics ........................................................................................................................................................ 29

Graph............................................................................................................................................................................ 30

Graph Menu .................................................................................................................................................................. 31

Page 3

CONTENTS

Graph view Menu ......................................................................................................................................................... 36

Storing and Loading Setup Files ................................................................................................................................... 37

Event log....................................................................................................................................................................... 40

Easy setup .................................................................................................................................................... 41

Overview....................................................................................................................................................................... 41

Manual setup ................................................................................................................................................ 42

Overview....................................................................................................................................................................... 42

Operating Mode ............................................................................................................................................................ 43

Source Modes .............................................................................................................................................................. 44

Load Modes .................................................................................................................................................................. 45

Measure Modes ............................................................................................................................................................ 48

Terminal selection ......................................................................................................................................................... 49

Measurement count ...................................................................................................................................................... 50

Source shape ............................................................................................................................................................... 51

Output off state ............................................................................................................................................................. 60

Source Control .............................................................................................................................................................. 62

Limits and Protection .................................................................................................................................................... 64

Source Level ................................................................................................................................................................. 66

Timing options .............................................................................................................................................................. 67

Sequence mode ........................................................................................................................................................... 70

Digital I/O ....................................................................................................................................................... 77

Overview....................................................................................................................................................................... 77

Math Functions ......................................................................................................................................... 79

Applying calculations to measurements ....................................................................................................................... 79

Measure........................................................................................................................................................................ 79

Result sorting ........................................................................................................................................... 80

Tolerance ...................................................................................................................................................................... 80

Application notes ..................................................................................................................................... 81

Source- Measure considerations .................................................................................................................................. 81

2 SMU4000 Series Instruction Manual

Page 4

CONTENTS

PowerFlex ..................................................................................................................................................................... 83

System management ............................................................................................................................... 84

Maintenance .............................................................................................................................................. 88

Cleaning ....................................................................................................................................................................... 88

Remote interfaces .................................................................................................................................... 89

Overview....................................................................................................................................................................... 89

Calibration ................................................................................................................................................. 90

Measurement Zero and Self Calibration ....................................................................................................................... 90

Routine Calibration ....................................................................................................................................................... 90

Factory Default settings .......................................................................................................................... 91

Specification ............................................................................................................................................. 93

Specification Conditions ............................................................................................................................................... 93

Key Specifications of SMU4000 series ......................................................................................................................... 93

Output Power, Voltage and Current Capability ............................................................................................................. 96

Protection ..................................................................................................................................................................... 97

Measurement Result Buffer .......................................................................................................................................... 97

Digital Input/Output (DIO) ............................................................................................................................................. 98

Remote Control Interfaces ............................................................................................................................................ 98

System Speeds ............................................................................................................................................................ 98

Environmental ............................................................................................................................................................... 99

Mechanical ................................................................................................................................................................... 99

3 SMU4000 Series Instruction Manual

Page 5

1 - Product description

PRODUCT DESCRIPTION

e SMU4000 (Source Measure Unit) Series provides class leading performance at a new and

Th

affordable price point for a four quadrant SMU. Combining touch screen technology with an

intuitive graphical user interface provides a clear and natural flow through the test and

measurement process.

Integrating a fast and agile, high power four quadrant voltage/ current source and advanced

precise voltage/ current meters in a compact half rack 2U casing, capable of precisely supplying

positive and negative voltages, sourcing or sinking power, while simultaneously measuring both

current and voltage for I-V characterising.

With high current and power combined with fast measurements and low glitch auto ranging

speed, it is the ideal solution for industrial development as well as educational environments,

identifying the SMU as the all-in-one solution for simplifying test applications such as battery

charging/discharging, I-V characterising, semiconductor testing and much more.

4 SMU4000 Series Instruction Manual

Page 6

2 - Safety

Caution, possibility of electric shock

UKCA ‘UK Conformity Assessed’ marking is a

certification mark that affirms conformity

with the applicable requirements for

products sold within Great Britain.

Caution, possibility of

Earth (ground) terminal

‘CE’ marking is a certification mark that

affirms the good's conformity with

European health, safety, and environmental

protection standards.

Protective Earth terminal

Standby supply. Instrument is not

disconnected from AC mains power when

switch is off.

WEEE (do not dispose in household waste)

Alternating current.

Symbols

SAFETY

WARNING

Symbols

This document provides safety information and warnings which must be followed by the user to

ensure safe operation of the SMU4001 and SMU4201 and to keep the instrument in a safe

condition. The Source Measure Units described in this document are designed to be used as

general purpose test and measurement equipment

Category II or higher mains circuits (as defined in IEC 60364)

User manuals, additional support and service information can be found at:

www.aimtti.com/support

The following symbols are displayed on the instrument and throughout the manual, to ensure

the safety of the user and the instrument, all information must be read before proceeding.

. Must not be used for measurements of

CAUTION

NOTE

EXAMPLE

Indicates a hazard that, if not avoided, could result in injury or death.

Indicates a hazard that could damage the product that may result in loss of important data or

invalidation of the warranty.

Indicates a helpful tip.

Indicates an example to show further details.

damage

5 SMU4000 Series Instruction Manual

Page 7

2 - Safety

Safety notices

WARNING

Safety notices

This instrument is:

· A safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 and EN61010-2-030 (Safety

Requirements for Electrical Equipment for Measurement, Control and

Laboratory Use).

· An Installation Category II instrument intended for operation from a normal

single-phase supply.

· Supplied in a safe condition and tested in accordance with EN61010-1.

· Designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing) and less than

2000m altitude.

Do not operate while condensation is present.

Do not operate outside its rated supply voltages or environmental range.

THIS INSTRUMENT MUST BE EARTHED.

Any interruption of the mains earth connector, inside or outside, will make the instrument

dangerous. Intentional interruption is prohibited.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided

If any adjustment or repair of the opened power supply under voltage is inevitable it shall be

carried out only by a skilled person who is trained to perform such adjustments and is aware of

the hazards involved.

When connected, terminals may be live and opening the covers or removal of parts (except

those that can be accessed by hand) may expose live parts.

To avoid electric shock, or damage to the instrument, never allow water to get inside the case.

If the instrument is clearly defective, has been subject to mechanical damage, excessive

moisture, or chemical corrosion the safety protection may be impaired and it must be

withdrawn from use and returned for checking and repair.

Voltages above 60VDC are hazardous live according to EN 61010-1 and great care must be taken

when using the SMU at voltages above this level.

Capacitors inside the SMU may still be charged even if it has been disconnected from all voltage

sources, these will be safely discharged a few minutes after switching off. LEDs on the HV rail to

indicate that charge is still present, as such it’s not safe to dismantle until all LEDs have gone

out.

This instrument is protected by three internal fuses which are user serviceable (refer to the

Service Manual).

CAUTION

6 SMU4000 Series Instruction Manual

Do not wet when cleaning, use only a soft dry cloth to clean the screen.

Do not use sharp or pointed objects to operate the touch screen.

Take care not to restrict the inlet vents at the front, rear, sides or underneath the instrument. In

rack-mounted situations, allow adequate space around the instrument.

Page 8

3 - Installation

Mounting

INSTALLATION

Mounting

This instrument is suitable both for bench use and rack mounting.

For rack mounting the protective bezels and handle/stand should be removed such that the

instrument can be fitted beside any other standard 2U half-rack instrument in a 19” rack. A

suitable 2U 19” rack kit is available from the manufacturers or their overseas agents.

See rack mount instructions for details on how to remove the protective bezel and handle.

Ventilation

The instrument uses a fan fitted to the rear panel. Take care not to restrict the rear air exit or

the inlet vents at the front (sides and underneath). In rack-mounted situations allow adequate

space around the instrument and/or use a fan tray for forced cooling. If the air inlet vents are

restricted for any reason, the fan can be set to ‘fast’ to compensate for minimal restrictions, see

‘Air vents’ for more details.

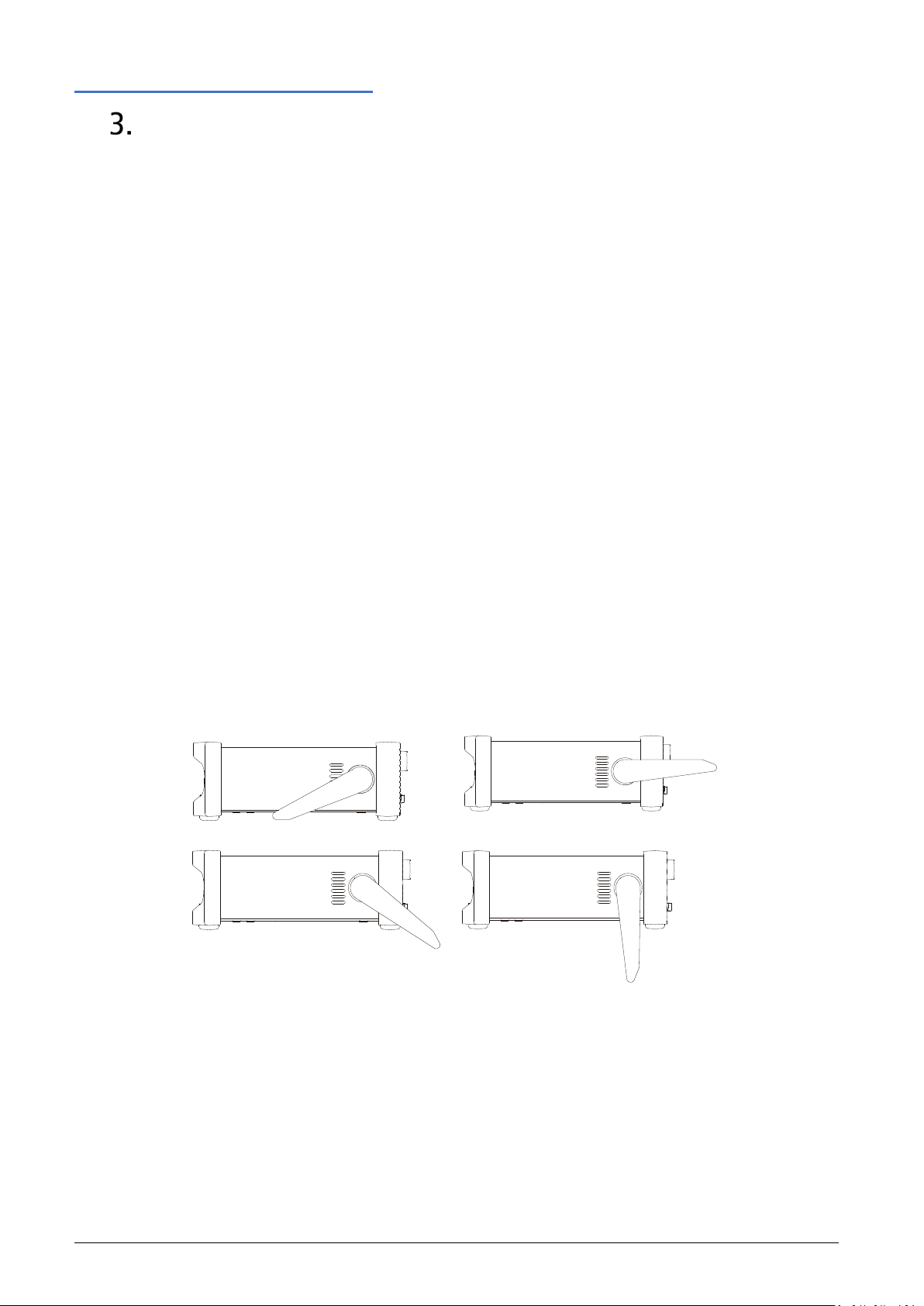

Handle/stand

The instrument is fitted with a 4-position handle/stand. Pull out both sides of the handle at the

case pivot points to free the position locking pegs and rotate the handle from the stowed

position to the required stand or handle position. Release the sides of the handle to lock it in

the new position.

7 SMU4000 Series Instruction Manual

Page 9

3 - Installation

A switch is located in the highlighted postiton (SW1).

Electrical Requirements

Electrical Requirements

Mains operating voltage

CAUTION

The operating voltage is switch selectable between 115Vac or 230Vac. You must check that the

local supply meets the AC input printed on the rear panel before connecting the unit to the

supply.

Changing the mains operating voltage

Should it be necessary to change the operating voltage from 230V to 115V or vice-versa, follow

the instructions below:

WARNING

The apparatus must be disconnected from all voltage sources before it is opened for any

adjustment. Capacitors inside the SMU may still be charged even if it has been disconnected

from all voltage sources, these will be safely discharged a few minutes after switching off. LEDs

on the HV rail to indicate that charge is still present, as such it’s not safe to dismantle until all

LEDs have gone out.

Remove the case:

① Position the handle as shown.

③ Slide and lift the case clear.

Mains supply voltage selection:

Select the required value with the switch

and replace the case.

CAUTION

② Remove 2x screws from the rear panel.

The set AC input voltage MUST be clearly

labeled on the rear panel.

8 SMU4000 Series Instruction Manual

Page 10

3 - Installation

Switching On

Mains lead

Connect the instrument to the AC supply using the mains lead provided.

Should a mains plug be required for a different mains outlet socket, a suitably rated and

approved 3 core mains lead with protective earth conductor should be used which is fitted with

the required wall plug and an IEC60320 C13 connector for the instrument end.

The minimum current rating of the lead-set for the intended AC supply is 6A or more.

WARNING

THIS INSTRUMENT MUST BE EARTHED.

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited.

Before use, inspect provided mains lead for any signs of damage. Do not use if lead is damaged.

Before use, inspect the instrument for any signs of damage. Do not use if damaged.

WARNING

Switching On

Connect the instrument to the AC supply using the mains lead provided.

Press the standby button; the button will illuminate to indicate start up. At power-up the

instrument will display a start-up message whilst initialising the application.

Loading takes a short while as the SMU will carry out self-testing and a self-calibration (at every

power cycle), after which the home screen is displayed.

To sw itch off, press the standby button. When powered down into standby mode the LED is

dimly lit, indicating mains power is still present.

To fully disconnect from the AC supply, unplug the mains cord from the back of the instrument

or switch off at the AC supply outlet; make sure that the means of disconnection is readily

accessible. Disconnect from the AC supply when not in use.

9 SMU4000 Series Instruction Manual

Page 11

4 - Instrument overview

②

⑧

Front Panel

INSTRUMENT OVERVIEW

CAUTION

Front Panel

④

⑤

⑥

③

⑩

⑦

⑨

①

① Standby button

When pressed to power up the instrument, the button will illuminate to indicate start up.

When powered down into standby mode, mains power is still present.

Alternative power up options are available, see ‘Power Control’ for more details.

② Remote Indicator LEDs

When the instrument is being controlled remotely, the remote indicator will be illuminated,

either the LAN, USB or GPIB indicator will also be illuminated, depending on the communication

type.

③ Flash Drive

This is a USB Host port for the connection of flash drives which conform to the Mass Storage

Class specification and are formatted as FAT3 2.

Setups, sequences, and lists can be imported and exported via the flash drive port, see ‘Storing

and Loading Setup Files’ for more details.

Measurement data can be automatically recorded to the flash drive on completion of a test run,

see ‘Saving Data’ for more details.

Images of the display can be captured and exported using the flash drive port see ‘Icons/

indicators on the status bar’ for more details

④ Rotary Knob

The rotary knob is used to navigate the user interface and scroll through values - it features a

‘press’ function to select an option, see ‘

Basic operation’ for more details.

⑤ Menu Keys

- HOME - Returns to the home screen, see ‘Home screen’ for more details.

- CNFG- Accesses the main menu configuration screen

10 SMU4000 Series Instruction Manual

Page 12

4 - Instrument overview

Front Panel

⑥ Run Key

The Run key enables the output and executes the present configuration.

⑦ Test Key

The Test key performs a quick internal self-calibration and measurement zero. See ‘Zero

Calibration’ for more details.

⑧ Help Key

The context sensitive help key provides direct assistance with menus, settings, and parameters.

⑨ Terminals

The front input terminals are 4mm safety sockets on a 19mm pitch designed to accept 4mm

safety plugs with fixed or retractable shrouds.

WARNING

CAUTION

Only ever use either the front or rear terminals, never use both at once. Hazardous voltages

will appear on both sets of terminals.

SMU4201 Front and Rear Terminal Blocks, Main/ Force(F), Sense(S) and Guard(G) can be set

and operate at voltages up to 210Vpeak. Voltages greater than 60V are deemed hazardous

voltages.

Only use test leads conforming to IEC61010-031.

Always make connections to the instrument with the OUTPUT off and in the Open off state;

this is the only output state that completely isolates the external circuitry from the

instrument.

All terminals are rated to 300Vpeak with respect to earth ground. Safety will be maintained if

voltages up to 21Vpeak for SMU4001 or 210Vpeak for SMU4201, are accidentally applied

between inappropriate terminals in excess of their marked ratings. The maximum differential

between MAIN HI and SENSE HI and MAIN LO and SENSE LO should be < 2Vpeak. The SENSE

terminals are protected against accidental connection of up to 21Vpeak for SMU4001 or

210Vpeak for SMU4201 between HI & LO.

Main- Main Terminals source or sink voltage or current.

Sense- Sense terminals measure voltage. The HI Sense terminal can be used as a guard in 2 Wire

+ Guard setups. 4 Wire setups use the HI & LO Sense plus the HI & LO Main terminals.

Ground- chassis ground for ground reference purposes only. See ‘Terminal selection’ for more

details.

⑩ CV / CC LED indicator

When the output is running, the CV/ CC indicators show whether the instrument is in Constant

Voltage or Constant Current.

11 SMU4000 Series Instruction Manual

Page 13

4 - Instrument overview

②

③

Rear Panel

Rear Panel

④

WARNING

①

⑤

⑥

⑦

⑧

① Terminal Block

The terminal block provides rear access to the Main and Sense connections with the addition of

Guard connections.

To connect a wire, press the orange actuators of the screwless terminals, insert the connecting

wire and release the actuator to secure the connection.

Use insulated wire (solid or stranded, 0.5mm2 to 1.5mm2 (21 to 16AWG), strip length 9mm to

10mm) suitable to meet local safety standard for 300Vpeak, i.e. tri-rated 600V equipment wire

with uninsulated ferrule. Ensure there are no loose strands.

Only ever use either the front or rear terminals, never use both at once. Hazardous voltages

will appear on both sets of terminals.

CAUTION

SMU4201 Front and Rear Terminal Blocks, Main/ Force(F), Sense(S) and Guard(G) can be set

and operate at voltages up to 210Vpeak Voltages greater than 60V are deemed hazardous

voltages.

Only use test leads conforming to IEC61010-031.

Always make connections to the instrument with the OUTPUT off and in the Open off state;

this is the only output state that completely isolates the external circuitry from the

instrument.

All terminals are rated to 300Vpeak with respect to earth ground. Safety will be maintained if

voltages up to 21Vpeak for SMU4001 or 210Vpeak for SMU4201, are accidentally applied

between inappropriate terminals in excess of their marked ratings. The maximum differential

between FORCE HI and SENSE HI and FORCE LO and SENSE LO should be < 2Vpeak. The SENSE

terminals are protected against accidental connection of up to 21Vpeak for SMU4001 or

210Vpeak for SMU4201 between HI & LO.

F +/- [Force] - Force terminals source or sink voltage or current, they are permanently wired in

parallel with the front panel Main HI and LO terminals.

12 SMU4000 Series Instruction Manual

Page 14

4 - Instrument overview

Rear Panel

S +/- [Sense]- Sense terminals measure voltage and are permanently wired in parallel with the

front panel SENSE HI and LO terminals. 4 Wire setups use the HI & LO Sense plus the HI & LO

FORCE terminals.

WARNING

G [Guard] terminals

Dedicated Guard terminals only feature on the rear panel.

The Guard signal driven to the same potential as the FORCE HI. As such, if the FORCE HI is at a

hazardous voltage, the same hazardous voltage level will also be present at the Guard.

See ‘Terminal selection’ for more details.

② AC power inlet

The instrument must be connected to AC mains using the power lead provided. When the

power lead is connected this lead provides the necessary protective earth connection to an

external protective earth system. See ‘Electrical Requirements’ for more details.

③GPIB (optional)

For GPIB connection the SMU Requires a GPIB 1A user retrofittable option, available from the

manufacturers or their agents. The default GPIB address is 10. See ‘Remote interfaces’ for more

details.

④ USB

The USB device port accepts a standard USB cable. The Windows plug-and-play functions should

automatically recognise that the instrument has been connected. See ‘Remote interfaces’ for

more details.

⑤ K Lock

The Kensington slot is a standard slot that can be paired with a security cable lock.

⑥ LAN

The LAN interface is designed to meet 1.5 LXI (LAN extensions for Instrumentation) Core

2016.Remote control using the LAN interface is possible using a TCP/IP Socket protocol. See

‘Remote interfaces’ for more details.

⑦ Chassis earth M4

The M4 threaded screw marked provides a connection point to safety earth ground. An M4 Ring

tab must be used, with an appropriate washer.

⑧ Digital I/O [DIO]

The DIO is an input/output port that receives, and outputs signals through digital I/O lines. See

‘Digital I/O’ for more details.

+5.25Vpk Max. (diode clamped to +5V). The 5V supply is internally fused (resettable fuse) to

500mA, see the SMU4000 Series Service Manual for more information.

13 SMU4000 Series Instruction Manual

Page 15

5 - Introduction

Using this Manual

INTRODUCTION

Using this Manual

This manual is a general introduction to the organisation of the instrument and is intended to be

read before using the instrument for the first time.

In this manual:

The descriptions in this manual relate to using the instrument via the touch screen,

alternatively; the hard keys and rotary knob can be used. See Navigation Controls for details on

how to use the rotary knob to control the instrument.

Throughout this manual, the navigation through menus will be shown at the top of a section

using the following format: MENU>Sub Menu>Option

· Front panel keys and sockets are shown in capitals, e.g., HOME, CNFG;

· Text, entry fields and messages displayed on the LCD are shown in a different

font, e.g., Source, Limit, Results.

· Hyperlinks are shown in italics, e.g., ‘Using this Manual’

Other Manuals are available to download for this product series including:

· Safety Documentation and Quick Start Guide [English, French, German, Italian

& Spanish]

· Programming Manual [English]

· Service Guide [English] available on request.

Available from www.aimtti.com/support.

14 SMU4000 Series Instruction Manual

Page 16

5 - Introduction

Navigation Controls

Navigation Controls

Hard Keys

There are two main menus: HOME and CNFG (configuration)- These are accessed using the hard

keys on the front panel. The items within these menus can be selected using the following

options:

· Touch Screen

Direct selection and entry using touch. Simply touch the item with your finger

to select.

· Rotary Knob

Turn the knob clockwise to initiate, once the desired button has been selected,

press to engage the button. The knob can also be used to modify home screen

parameters once they have been selected.

Menu Scrolling

Some menus contain more than one page of options, when this is the case, arrows ① are

available to scroll the page up or down.

OK / Cancel

The OK and Cancel ② keys are available on all screens where changes can be made; pressing

OK will apply any changes and return the previous menu., Cancel will return to the previous

screen without making any changes.

②

①

Back Button

The Back button is available on sub menus, when pressed it will return to the previous menu.

15 SMU4000 Series Instruction Manual

Page 17

5 - Introduction

①

② ③ ④

Navigation Controls

Numeric Keypad / Keyboard Pop-up

Depending on where the keypad pop-up appears, the following options will be available to

select from on the keypad.

① Non-numeric Options:

Auto / Disabled etc.

② Numeric Selection

Numeric selection is 0-9, decimal point and minus sign (if negative values can be entered)

③ Unit Selection

④ Actions:

Bksp- Remove the previous number.

Revert- Revert the value back to the original; before the value was amended with the keypad.

Rev Pol- Available when a positive or negative value is to be accepted, toggles between plus

and minus symbol.

A full QWERTY keyboard is available for text entry.

16 SMU4000 Series Instruction Manual

Page 18

5 - Introduction

Home screen

Home screen

①

②

③

① Status bar

• USB flash drive status (connected/disconnected) and touch to capture screen image, if

connected.

④

• Logged Event; a Warning, Caution or Information pop up has occurred and been logged.

Touch to see the Event Log.

• LAN Status. Touch to edit in the Interfaces menu.

• Present Mode and selected shape (if other than steady), Output status, terminal

configuration and selected OFF state. See ‘Icons’ for more details. Touch to edit in the

Manual Setup menu.

• Operating voltage limit [SMU4201 only]. LV (low voltage mode) for up to ±42V working

mode, HV (high voltage mode) for up to ±210V working mode. Touch to change

between LV and HV. By default, the unit is locked into LV mode and password protected,

see ‘Password protection’ for more details.

• Date and time, touch to edit, see ‘Date and Time’ for more details.

② Source and Limits

User defined source/sink level and imposed limits, depending upon the selected mode.

Values can be modified by direct touch keypad entry, simply press on the relevant

parameter to bring up the numeric entry screen. Alternatively, the selected values can

be modified by using the rotary knob.

③ Results

Results box contains the real time measurements and, if enabled, the measurement

reference and math formula applied to the readings. When in Sequence mode the

active step and operating mode will be shown.

④ Buttons:

See ‘Measurement selection, ’Selecting a Range’, ‘Graph view Menu’ or ‘Sample table’

for more information.

17 SMU4000 Series Instruction Manual

Page 19

5 - Introduction

Icon

Variations

Description

Not Connected

Reading

USB Connected, Press to capture screen image

USB not supported.

③

Event log

LAN

LAN detected

↑↓

Data Transfer detected

LAN IP Error

LAN IP Address Error

Press to edit the setup.

SV

Source Voltage

SC

Source Current

LC

Load Current

LR

Load Resistance

LP

Load Power

MV

Measure Voltage

MC

Measure Current

MR

Measure Resistance- Voltage Limited

MHR

Measure Resistance- Current Limited

SEQ

Sequence Mode

Note: If Sequence Mode is running it will show the Active Mode in the step.

OFF

Output Off

ON

Output On

CC

Output On - Constant Current

CV

Output On - Constant Voltage

CMV

Output On- Constant Maximum Voltage

2 Wire

Main terminals- Source and Sense

2W+Guard

Main terminals- Source and Sense. HI Sense terminal - Guard

4 Wire

Main terminals- Source and Sense. Sense Terminals- Sense

0V/100µA

Source 0V/ 100uA current limit

Hi Z

Terminals are high impedance

Zero

Source 0V

Open

Terminals are open circuit

Steady

Source is steady

Pulse

Source is pulsed between two levels

Sweep

Source is swept in steps between start and end levels

List

Source is defined by a custom list of levels

Pulsed sweep

Source is swept in pulsed steps between start and end levels.

⑤

Press to activate/deactivate the High Voltage Interlock. Note: To access the High Voltage

*SMU4201

LV

Low Voltage Mode

HV

High Voltage Mode.

⑥Time

and Date

①

④

②

③

⑤

⑥

Home screen

Icons/ indicators on the status bar

The following icons or indicators may appear on the status bar.

①

USB Flash

Drive

②

LAN

status

④

Setup

Status

Active Mode

Output

status

Event logged, Press to see logged event/s

Press to edit Interface setup

Terminal

configuration

Off State

(Output Off)

Shape

(Output On,

in place of

Off State)

Operating

Voltage

Limit *

Interlock, the password protection may need to be removed first.

only.

Press to edit Time and Date

18 SMU4000 Series Instruction Manual

Page 20

6 - Getting Started

Connections

GETTING STARTED

Connections

Connections can be made to the front or rear terminals on the instrument. The front and rear

terminals are connected in parallel and must never be used simultaneously.

Front/Rear connections

Front and rear terminals are always active, there is no need to select between the two.

The terminals on the front panel are 4mm banana jack connectors, and the rear-panel contains

a terminal block. The rear terminals offer additional Guard connections for screening, see

‘Terminal selection’ for more details.

Front panel Main HI and LO terminals are permanently wired in parallel with the rear panel F +/[Force] terminals.

Front panel SENSE HI and LO terminals are permanently wired in parallel with the rear panel S

+/- [Sense] terminals

WARNING

Only ever use either the front or rear terminals, never use both at once. Hazardous voltages

will appear on both sets of terminals.

Hazardous voltages will appear on both sets of terminals.

Always make connections to the instrument with the OUTPUT off and in the Open off state;

this is the only output state that completely isolates the external circuitry from the

instrument.

19 SMU4000 Series Instruction Manual

Page 21

6 - Getting Started

High Voltage Interlock [SMU4201 only]

High Voltage Interlock [SMU4201 only]

The instrument contains a high voltage interlock to prevent accidental access to potentially

dangerous high voltages.

By default, the instrument is set to Low Voltage operation, restricting the maximum permitted

voltage to ±42V DC. Source level and limit settings are restricted to a maximum of ±42V DC. If

for whatever reason this voltage limit is exceeded whilst the output is running, the output will

either continue to run and limit the voltage to the maximum of ±42V DC (Limited), or the

output will trip to the OPEN off state condition (Trip). This feature can be set in the Interlock

Behaviour menu:

CNFG > [System] Manage > [Security] Interlock Behaviour.

The status of the interlock is shown in the form of a HV/LV icon on the status bar of the user

interface home screen and can also be queried remo tely.

There are three ways in which the interlock state can be changed between Low voltage

operation and full voltage operation:

1. Password Protection: A password entry is required to enable full voltage operation. See

‘

Password protection’. Once the password is entered correctly the interlock status can be

changed by touching the LV symbol on the status bar of the home screen.

WARNING

2. External DIO control: This allows for the controlling of the interlock via external circuitry.

This is primarily designed for helping to ensure the safe operation and safety of users of the

equipment when embedded into a test system or test fixture. For safety reasons, test

fixtures that may contain hazardous voltages often utilize a safety cover, a form of lid or

even complete doors to protect the user from hazardous voltage exposure. Installing a

switch on any of these and linking to the external DIO interlock control allows for the

limiting of hazardous voltages (Low voltage operation) whenever the switch is opened. For

more information on the DIO interlock control see ‘

Digital I/O’.

3. Remote interface control: The state of the interlock can be controlled directly without

password protection. The status of the interlock can also be queried remotel y. See the

SMU4000 Series Programming Manual for more information.

Enabling full voltage operation (asserting the interlock) could expose the user to potentially

hazardous voltages that could result in injury or death.

Potentially hazardous voltages of up to ±210 V may be present at the MAIN HI, F+/-, Sense HI,

S+/- and Guard terminals.

These terminals should be considered hazardous even if set to a non-hazardous voltage or

current level.

NOTE

Whenever the interlock setting is changed via the front panel or remote command, the output

is disabled for safety purposes.

20 SMU4000 Series Instruction Manual

Page 22

6 - Getting Started

Basic operation

Basic operation

Sourcing voltage and recording measurements

When set to default settings, the source voltage configuration settings will be loaded. To set the

source level:

· Touch the source setting.

· Enter the required value and press OK.

· Press the RUN hard key to activate the output.

The default measurement count is infinite; therefore, measurements will be recorded up to the

maximum amount of 100,000. Once reached, the output will remain on but measurements will

no longer be recorded.

The default measurement period is 1 PLC. One Power Line Cycle (PLC) for 50Hz is 20ms and one

PLC for 60Hz is 16.67ms. Mains input frequency is automatically monitored and applied by the

instrument.

21 SMU4000 Series Instruction Manual

Page 23

6 - Getting Started

Basic operation

Live adjusting source and limits from the home screen

The source and limit parameters can be adjusted in real time using the rotary knob when the

output is active. To adjust the source level in real time:

· Press the RUN hard key to activate the output.

· Highlight the source value using the rotary knob.

· Press the knob to enter the editing state, the knob will now scroll through the

source values.

NOTE

· Scrolling left and right will change the value resolution. Press again to edit the

numeric value.

A green digit indicates the encoder is in an active state, any adjustments using the encoder are

live and will be actioned at the terminals immediately (when the SMU is running).

· Double press the knob or press the HOME key to exit the live editing mode.

22 SMU4000 Series Instruction Manual

Page 24

6 - Getting Started

Selecting a Range

Selecting a Range

HOME > Ranges

Before considering a range selection it is important to understand the concept of manual setup

modes that are used in the SMU; see ‘Operating Mode’ for more details. Configuration settings,

including the selected ranges, are linked to the selected mode of operation.

NOTE

Range selection is ‘Manual setup’ specific.

Ranges can be set for current and voltage, the available ranges are determined by the selected

mode of operation.

A range can be set to Auto, or a manual value.

Most applications will require Auto Range, however if high accuracy or speed is required it may

be necessary to select a manual range.

The automatic range selection determines and selects the most suitable ranges based upon the

measured readings and source settings.

Timing considerations

Faster Response Speeds

Selecting a manual range can assist with faster response speed. Auto ranging changes the range

whilst the output is running, this can lead to increased rise/measurement/settling times whilst

the instrument selects the appropriate range; selecting a manual range overcomes this potential

timing penalty.

NOTE

The fastest response speeds can only be achieved when a manual range is selected.

Reduced settling times

Settling times can be reduced when in auto range by selecting a minimum range value. This

defines the minimum range that the instrument can select during auto-ranging. Setting this to

the lowest range that is required for the given test/application may help to reduce the settling

time, as the lower ranges have generally longer settling times.

23 SMU4000 Series Instruction Manual

Page 25

6 - Getting Started

Selecting a Range

In order to bypass this functionality, simply set the minimum range to the smallest range

available.

To set the minimum range, press the Auto (Min.Range xxx) Button. Set the minimum required

range and press Back to return to the Range Menu.

Stability Considerations

NOTE

NOTE

Auto ranging can, in some specific cases (where there may be a significantly highly reactive load)

lead to potential instability or oscillations. If this occurs, selecting the appropriate manual ranges

can alleviate the issue. When using the most sensitive current ranges i.e.200nA and 2µA ranges

potentially instability could occur, in this case try a higher current range.

Limit considerations

The source and limit level settings cannot exceed 105% of the selected associated range. The

limit setting is restricted to a minimum of 10% of the manually selected range.

If a lower manual range is selected that causes the existing source or limit level setting to exceed

the selected range maximum, the associated level is set to 105% of the new range. Likewise, if a

higher manual range is selected that causes the existing limit level setting to exceed the selected

range maximum, the limit level is set to 10% of the new range.

In SC and MR modes (see ‘Operating Mode’ for more details) where the current source is

utilized, the 3A range can only be accessed via manual range selection, the auto current range

will stop at the 1A range.

Noise pickup, leakage and instability issues may arise when testing within certain manual

ranges, see ‘Application notes’ for tips to overcome these issues.

24 SMU4000 Series Instruction Manual

Page 26

6 - Getting Started

Measurement selection

Measurement selection

HOME > Measure

The measurement selection configures the primary and secondary measurements. The primary

and secondary measurements can be set to measured voltage, measured current or the

computed power or resistance.

Only the selected primary and secondary measurements appear on the home screen results

section, within the sample table measurement buffer and within the measurement statistics

menu.

The primary measurement is used for setting the live and custom measurement reference math

operations (See ‘Math’), and defining the measurement that is displayed on the YT graphical

view (See ‘Graph’).

NOTE

The exported .CSV files contain all four measurement types.

NOTE

Alternative primary and secondary measurement types can be selected after the test is

complete. The selected measurement data can be viewed in the sample table or the YT graph

(primary measurements).

25 SMU4000 Series Instruction Manual

Page 27

6 - Getting Started

Saving Data

Saving Data

CNFG > [Files] Data Store

The buffer records all the information displayed in the sample table. Up to 100,000 points can

be recorded at any time.

NOTE

The buffer data is cleared each time the output is run, ready for the next set of measurement

data to be collected. The buffer data is also automatically cleared when the instrument is power

cycled.

Buffered data can be saved as a .CSV file to a USB flash drive connected via the front panel,

either manually or automatically.

The .CSV file will contain the following information:

· Index

· Active Mode

· Output state

· Measurement results (V and A)

· Calculated results (R and W)

· System Date

· System Time

· Measurement Timestamp

· Sequence Mode Step and Iteration

NOTE

To store all measurement data, the measurement buffer should be exported over remote or to

an external flash drive after completion of each run (automatically).

26 SMU4000 Series Instruction Manual

Page 28

6 - Getting Started

Saving Data

Save Data Automatically

To automatically save the data to USB after every run, press the Auto Store function. The file

name will be highlighted with a green border and the data will be saved to the flash drive when

the SMU has completed a run.

Save Data Manually

To manually save data, press the USB Store button. A .CSV file will be saved to the USB Flash

drive each time the USB Store button is pressed.

Buffer status

The buffer status is displayed as a percentage within the Clear button, when pressed the data

will be cleared and set to 0%.

View buffer data

Buffered Data can be viewed in three different formats from the front panel:

· Individually indexed measurements, see ‘Sample table’ for more details.

· Graphically plotted data, see ‘Graph’ for more details.

· Statistically, see ‘Measure Statistics’ for more details.

27 SMU4000 Series Instruction Manual

Page 29

6 - Getting Started

Sample table

Sample table

CNFG > [Files] Sample Table

The Sample Table displays the contents of the buffered measurement data in a table format. The

contents of the table include the index, primary measurement, secondary measurement, date,

and time. Results are stored sequentially from the first index number and will be stored until the

buffer limit is reached, at 100,000 measurements.

The time is recorded as HH:MM: SS.

The date is recorded as DD/MM/YYYY (Default), MM/DD/YYYY or YYYY/MM/DD, depending on

the format selected, see ‘Date and Time’ for more details .

All exported data from the sample table to the .csv file will be formatted as YYYY/MM/DD.

The up and down arrow keys can be used to scroll through the results in the sample table. Using

the touch screen, pressing, and holding the button will scroll through the results faster.

A single result can be selected and used as a reference point for a math function. To set the

reference point, use the encoder to select the required primary measurement and press to

activate. See ‘Math’ for more details.

NOTE

The sample table will only display the primary and secondary measurement data; however, the

internal buffer contains all four measurements which can be exported or can be accessed via

changing the primary and secondary measurements. Changing the primary and secondary

measurements can be done live or even after the test is complete to access all four

measurement data sets.

28 SMU4000 Series Instruction Manual

Page 30

6 - Getting Started

Measurement Statistics

Measurement Statistics

CNFG > [Files] Measure Statistics

The measurement statistics menu provides statistical measurement information based upon the

primary and secondary measurement data. With a large 100k measurement buffer it can be

very difficult to pick out key information from the sample table alone. The measurement

statistics menu provides details of:

· Minimum sample value

· Maximum sample value

· Total measurement span (min to max)

· Average (mean)

· Standard deviation of the measurements for both the primary and secondary

measurements.

The measurement statistical data is based on the data that is in the sample table and is updated

accordingly, as new data is recorded.

NOTE

Changes to the primary and secondary measurements can be actioned live or even after the test

is complete to access all four sets of measurement statical data (V, I, W & Ω).

29 SMU4000 Series Instruction Manual

Page 31

6 - Getting Started

Feature

Graph

Graph View

Graph

Graph

The Graph provides a graphical representation of the buffered results. This may be real time

data or previous test data already stored in the buffer. The real time / buffered data is always

shown in yellow. Any saved ‘Tra c e’ data is shown in blue- see ‘Trace’ for more details.

There are two separate graphing menus; graphing options with full manual control that is

accessed from the Configuration (CNFG) menu, and a view of the graph that is accessed from

the home screen.

NOTE

The two graph menus are linked; changes made in the Graph menu will be reflected in Graph

view and vice-versa.

(Blue background)

CNFG > [Files] Graph

(Black Background)

HOME > Graph View

Auto-Scale •

Auto-Fit •

Graph Type • •

Graph Style • •

Minimum Position • •

Markers • •

Save/Load Trace • •

Panning •

Zooming •

30 SMU4000 Series Instruction Manual

Page 32

6 - Getting Started

Graph Menu

Graph Menu

The graph uses an Auto-Scaling function to best fit the data onto the graph, the difference

between the Auto-Scaling and the Auto-Fit of the Graph View is that the Auto-Scaling is

designed like a traditional oscilloscope with standard 1,2,5 scaling applied to the X and Y axis.

Auto-Scaling also applies no offset compensation.

Auto -Scaling is activated by pressing a Graph Type button ①

Graph Type

Measurement data can be displayed in two formats, as two different graph types:

YT Graph (Default): The primary measurement data is plotted against time on the X axis.

①

NOTE

Voltammogram (I/V Scatter): A plot of voltage against current. This graph type is ideal for I/V

curve tracing.

Select the graph type using the Voltammogram and YT Graph buttons positioned above the

graph display.

Pressing either the Voltammogram or YT Graph buttons will cause the graph to auto-scale; any

manual scaling changes will be lost.

31 SMU4000 Series Instruction Manual

Page 33

6 - Getting Started

Graph Menu

Graph Settings

The following settings are available by pressing the Settings button:

Graph Style

Line (Default): Show the measured points connected in a linear format with a single line.

Point: Show each measured point on the graph as a single pixel.

Minimum position

A minimum X and Y position can be defined, starting the plotted results at a defined point.

32 SMU4000 Series Instruction Manual

Page 34

6 - Getting Started

Not Active (Default)

Active and Selected

Active, not Selected

Graph Menu

Markers

Markers are based on the display position and are not linked to measurement data points.

Marker selection is a multi-stage process:

To enable the markers, select the Marker 1 or Marker 2 button located at the bottom of the

graph.

Upon the first press the marker will appear as a red line across the span of the graph and a

green outline will appear to show the marker can now be moved, use the encoder to move the

marker.

The Marker Button shows the marker value, which is shown to a resolution of up to four digits,

to see the full resolution of the marker reference point, use the Stats button.

Once a marker has been selected, the markers menu ① will be active.

①

Marker orientation can be set to horizontal using the H.pos button or vertical using the V.p os

Button. When both X and Y markers are set to the same orientation, the difference between the

two is displayed in the bottom right-hand corner of the display in the marker’s menu. To see the

full resolution, use the Stats button.

33 SMU4000 Series Instruction Manual

A reference point based on the selected marker (used in the math function) can be set directly

from the graph using the Set Ref button. See ‘Math’ for more details.

Pressing the Marker button whilst the marker is active will disable the movement of the marker

via the encoder; however, the marker value and marker menu will still be displayed. This allows

for selection switching between the two markers, only one marker position can be adjusted at

any given time.

Page 35

6 - Getting Started

Graph Menu

A final consecutive press of the marker button disables the marker completely, the marker menu

will still be displayed if the either marker is still active.

Trace

The trace functionality enables a reference trace to be stored and recalled, allowing for a

previously stored trace to be compared against the latest measurement trace. Data in the buffer

will be displayed in yellow, the trace will be blue.

Once Trace has been selected, the trace menu ① will be active.

①

NOTE

This can be very useful when comparing two DUTs (device under test) to see the difference in

performance between the two. One reference trace can be stored at any given time.

The trace menu gives the following options –

Save – Store the existing latest measurement graphical waveform as the reference trace.

Load – Recall and display the previously saved reference trace.

Disable – Stop viewing the loaded reference trace.

The loaded reference trace appears in blue on the same graph as the latest measurement trace.

NOTE

When recalling a trace, the graph auto-scale will ensure both the recalled trace and the latest

measurement trace are visible on the display regardless of difference in levels.

34 SMU4000 Series Instruction Manual

Page 36

6 - Getting Started

Graph Menu

X & Y Axis Scaling

The X and Y Axis scale can be altered to effectively ‘zoom’ in or out of the displayed data on the

graph – this method will force the scaling into manual mode.

To change the scale, select the X (xxx/div) or Y (xxx/div) button located at the bottom of the

graph. The X and Y axis will remain in the automatically selected ranges until modified. A green

outline will appear to show the range can now be changed, use the encoder to change the

range, the scale will then be adjusted using units per division.

Press the button again to disable the movement via encoder and return to navigation.

NOTE

To familiarise a new user with the graph navigation; using the Auto-Scale (Type button) to define

the best suited ranges for the data, then using the manual scale to ‘zoom’ in and out on specific

areas of the measurement data by increasing and decreasing the scale as needed.

Panning

Panning can be set to horizontal using the H.Pan button or vertical using the V.Pan button

located in the Main menu section of the graph, this function will force the scaling into manual

mode. Once selected a green outline will appear to show that the graph can now be moved

either vertically or horizontally (dependant on selection). Use the encoder to pan the graph.

Press the button again to disable the movement via encoder and return to navigation.

35 SMU4000 Series Instruction Manual

Page 37

6 - Getting Started

Graph view Menu

Graph view Menu

HOME > Graph View

Graph View uses Auto-fit scaling- displaying the results in an automatically scaled view to best fit

the display; all the results will be shown at once. Graph view utilizes no standard range scaling,

the scaling is entirely arbitrary, allowing the results to fill the graphical area. The auto-fit scaling

also deals with any offsets within the measurement data, offsetting the graphical view

accordingly. This provides an instant graphical view of all the buffered measurement data, scaled

to fit perfectly within the graphical window area. The Graph View menu has a darker (black)

background than the Graph menu, to assist with recognition.

NOTE

Scaling or panning functions are not available in Graph Vie w.

Although scaling or panning options are not available, one method that can be implemented for

focusing in on an area of interest can be to re-run a specific test within the window of interest.

Graph view allows for the quick and easy view of the full measurement buffer data, which

means that a specific area of interest is very easy to find, especially with the use of the markers.

As an example, re-running an I/V trace curve sweep of a DUT around the area of interest can be

potentially quicker and provide greater measurement resolution than trying to pan and zoom

into a specific area of a graph under manual control.

The Graph View menu allows the use of Markers and the reference Trace function to view,

assess, and compare the results. The graph type can be set to

graph style to

Point or Line see ‘Graph Menu’ for more details on these functions.

NOTE

When a USB Flash Drive is present, screen captures of the graph can be stored by pressing the

flash Drive symbol in the top left corner.

YT Graph or Voltammogram, and

36 SMU4000 Series Instruction Manual

Page 38

6 - Getting Started

①

②

Storing and Loading Setup Files

Storing and Loading Setup Files

CNFG > [Source Measure Action] Store Setup

Setup Files are managed in the Store Setup menu, from here Setups can be:

· Stored to an Internal Memory.

· Recalled from the Internal Memory.

· Deleted from the Internal Memory.

· Exported to a USB Flash Drive.

· Imported from a USB Flash Drive.

Store a Setup to the Internal Memory

To store a Setup to the Internal Memory, select the item Empty block ① followed by Store

Internal ②. A keyboard will appear on screen, type the required file name- up to 7 characters,

and press OK.

NOTE

The file type will vary depending on the set mode, there are two types of files that will be

stored:

.STP – Manual Setup file type

.STP files contain all the set parameters from the Manual Setup when one of the following

Manual Modes are selected: SV, SC, LC, LR, LP, MV, MC, MR, or MHR.

.STP files stored in the internal memory can be added to a Sequence. See ‘Sequence mode’ for

more details.

.SEQ - Sequenced Setup file type

.SEQ files contain the contents of the sequence setup when ‘Sequence’ is the selected Manual

Mode.

Up to 20 manual setup files and 20 sequenced setup files can be stored at one time between

the internal memory and USB flash drive.

The files stored on the Internal memory will take priority. If a USB flash drive is connected and

internal max file limit is reached, no external files will be shown until an internal file is deleted.

37 SMU4000 Series Instruction Manual

Page 39

6 - Getting Started

①

②

③

Storing and Loading Setup Files

Load a Setup from the Internal Memory

To recall a Setup from the Internal Memory, select the required setup ①, followed by Load ②.

A pop-up box will appear to confirm the action.

NOTE

Recalling any stored setup will overwrite the existing configuration.

④

Delete a Setup from the Internal Memory

To delete a Setup from the Internal Memory, select the required setup ①, followed by Delete

④. A pop-up box will appear requesting to confirm the action.

Export a file to a USB Flash Drive

Once a setup has been stored as an internal file, it can be exported to a USB Flash Drive.

To export a file, select the file to be transferred ①, once selected the file name will be

highlighted with a green border, press Store USB to export.

The file will appear in the available setups list, with USB as the location.

38 SMU4000 Series Instruction Manual

Page 40

6 - Getting Started

②

①

Storing and Loading Setup Files

Import a file from a USB Flash Drive

USB files can be imported into the Internal Memory.

NOTE

Files must be imported into the Internal Memory before they can be loaded, external USB Files

cannot be loaded or deleted using the store setup menu.

To import a file, select the file ① to be imported, once selected the file name will be

surrounded with a green box, press Store Internal ② to import.

The file will appear in the available setups list, with Internal as the location.

File type- colour

File names may appear in the following colours:

Yellow: Compatible.

White: Incompatible with the current firmware version or model.

Red: Corrupted- Unable to be used or recovered.

To load an arbitrary list of set levels for a sweep (.CSV), see ‘Loading a List’.

To store buffer measurements (.CSV), see ‘Saving Data ’.

39 SMU4000 Series Instruction Manual

Page 41

6 - Getting Started

Event log

Event log

CNFG > [System] Event Log

The Event Log displays a record of events that have occurred whilst the instrument has been

operational, these include warning, er ro r, and information alerts.

Whenever a new warning, error or information event occurs, a warning symbol

appears on the status line of the home screen, this is often accompanied by a pop-up.

Pop-ups are colour coded based on the type of event that has occurred.

The duration that the pop-up is displayed can be changed using the Message Time button; this

can be set to a duration in seconds, or infinite. When set to infinite, touch the pop-up to remove

it.

Selecting the Event Log symbol on the status bar will open the event log menu, this menu can

also be accessed through the System menu: CNFG > [System] Event Log. Within the Event log

menu, the events are colour coded and include a Warning or Error number alongside the time

and date of when the error occurred.

40 SMU4000 Series Instruction Manual

Page 42

7 - Easy setup

Easy setup

Manual Mode

Easy setup

Manual Mode

Power Supply

SV

Ammeter

MC

Current Source

SC

Ohmmeter

MR

Load

LC

LC Meter

SV

Voltmeter

MV

IR Meter

MHR

Overview

EASY SETUP

Overview

CNFG > [Source Measure Action] Easy Setup

The Easy Setup menu contains a number of pre-configured setups, providing instant

configuration for basic operational use of the SMU, these include:

· Power Supply

· Current Source

· Load

· Voltmeter

· Ammeter

NOTE

· Ohmmeter

· IR Meter [Insulation Resistance Meter ]

· LC Meter [Leakage Current Meter]

Selecting any of the pre-configured ‘Easy Setups’ will reset the settings to the default for the

related manual setup mode. However, if the manual setup is set to anything other than the

mode related to the easy set, the settings will still be available when returning to that mode.

See ‘Factory Default settings’ for more details.

Once an easy setup has been selected, further settings can be configured using the Manual

Setup menu.

To activate a pre-configured setup, select the required option and press OK. If no option is

selected, pressing OK will return to the Configuration menu and no change will be made.

For more details, see SMU4000 Series Safety Documentation and Quick Start Guide, available to

download from: www.aimtti.com/support.

41 SMU4000 Series Instruction Manual

Page 43

8 - Manual setup

Overview

MANUAL SETUP

Overview

CNFG > [Source Measure Action] Manual Setup

The Manual Setup menu contains options and settings for source and measurement

configurations.

NOTE

All options and settings in the Manual Setup menu are saved to the selected source and

measurement mode , or ‘Operating Mode’.

Manual Setup options and settings are as follows:

· ‘Operating Mode’ (Source / Load / Measurement/ Sequenced Mode)

· ‘Terminal selection’

· ‘Measurement count’

· ‘Source shape’

· ‘Output off state’

· ‘Source Level’

· ‘Limits and Protection’

· ‘Timing options’

· ‘Result sorting’

· ‘Math Functions’

When the manual setup is complete, it can be stored in non-volatile memory or exported via a

USB Flash Drive using the Store Setup menu, see ‘Storing and Loading Setup’ for more details.

42 SMU4000 Series Instruction Manual

Page 44

8 - Manual setup

Operating Mode

Operating Mode

CNFG > [Source Measure Action] Manual Setup > [Overall] Mode

The Mode menu contains options for the source and measurement operating functionality.

NOTE

All options and settings in the Manual Setup menu are saved to the selected ‘Operating Mode’.

Operating Mode options are as follows:

· ‘Source Voltage' [Default]

· ‘Source Current’

· ‘Load Current’

· ‘Load Resistance'

· ‘Load Power'

· ‘Measure Voltage’

· ‘Measure Current’

· ‘Measure Resistance and High Resistance’

NOTE

· ‘Sequence mode’

Changing the mode whilst the instrument output is running will disable the output to the given

Off State defined for that mode.

43 SMU4000 Series Instruction Manual

Page 45

8 - Manual setup

Source Modes

Source Modes

Source Voltage (SV)

CNFG > [Source Measure Action] Manual Setup > [Overall] Mode > SV Mode

When set to source voltage, the SMU will perform as a low-impedance dual polarity voltage

source with a single user defined current limit for both polarities.

Current, Voltage, Resistance and Power can be simultaneously measured whilst sourcing

voltage. The sense circuit constantly monitors the output Voltage, and the in-built voltmeter

measures the voltage and compares it to the configured value, adjusting where necessary.

NOTE

In SV mode, the SMU will sink current if a voltage is set below that of the external source.

For example, if a 5 V battery is connected as a voltage source (HI to battery +ve) and the SMU is

set to source +4 V, in SV mode the SMU will sink current from the external battery (source +V

and measure –I).

Source Current (SC)

CNFG > [Source Measure Action] Manual Setup > [Overall] Mode > SC Mode

When set to source current, the SMU will perform as a dual polarity current source with a single

user defined voltage limit for both polarities. The current source can be used to source and sink

a constant current.

Current, voltage, resistance and power can be simultaneously measured whilst sourcing current.

The sourced current is constantly monitored and compared to the configured value, adjusting

where necessary.

44 SMU4000 Series Instruction Manual

Page 46

8 - Manual setup

LC

Load Current

The current is the Level setting, independent of voltage.

LP

Load Power

Implements I = W / V where W is the Level setting.

LR

Load Resistance

Implements I = V / R where R is the Level setting.

Load Modes

Load Modes

The selected load mode determines how the current drawn by the SMU varies with the applied

voltage.

When set to a load (or sink) mode, the power dissipating stage in the SMU is fundamentally an

adjustable current sink, which conducts a current that does not depend on the voltage presently

applied from the source being investigated. This is known as Constant Current operation.

The SMUs fast digital feedback loop is used to offer other operating modes in which the current

does depend on the applied voltage in a known way, providing the additional choices of

Constant Power and Constant Resistance characteristics.

The SMU load modes can only be used in one single quadrant, with positive external source

voltages and negative load currents.

When sinking high currents, it is always recommended to use the 4-wire terminal configuration

to sense the voltage directly at the external source terminals.

Dropout voltage

Resistive discharge with voltage dropout.

The primary purpose of the dropout facility is to protect batteries from being excessively

discharged.

When the source voltage falls below the Dropout threshold voltage setting, the load will reduce

the current it draws to zero. This is a dynamic limit, not a latched state, so if the source voltage

recovers above the threshold (as batteries often do) then the load will conduct current again.

To help avoid dropout oscillations, a 5% hysteresis is applied by the SMU on the limit. As such

the external source voltage has to increase to above 5% of the dropout level in order to conduct

current once more.

If the dropout facility is not required, set the Dropout Voltage to 0 Volts.

Load mode selection

The following sections give a brief description of the way each mode is implemented and give

some guidance of the effect that has on the application of the load.

45 SMU4000 Series Instruction Manual

Page 47

8 - Manual setup

Load Modes

Load Current (LC)

CNFG > [Source Measure Action] Manual Setup > [Overall] Mode > LC Mode

This is the fundamental operating Load mode of this instrument and has the simplest feedback

loop.

When set to Load Current, the SMU provides rapid measurement of power source regulation

(V/I characteristics). The sensed voltage signal is only used for the meters and protection.

Load current mode is normally used in conjunction with low impedance power supplies and will

be quite stable unless there is significant inductance in either the interconnections or the

source. It is critical to have low inductance connections in this mode.

NOTE

The load cannot be used in constant current mode to test a constant current power supply, as