Page 1

MX100T & MX100TP

Triple Output Multi-Range DC Power Supply

INSTRUCTION MANUAL

Page 2

CONTENTS

1 Product Description ......................................................................................................4

2 Safety .............................................................................................................................5

3 Installation .....................................................................................................................6

3.1 Mains Operating Voltage ..........................................................................................6

3.2 Mains Lead ...............................................................................................................6

3.3 Mounting ...................................................................................................................6

3.4 Ventilation .................................................................................................................6

4 Connections ..................................................................................................................7

4.1 Front Panel Connections ..........................................................................................7

4.2 Rear Panel Connections (MX100TP) .......................................................................7

4.3 Terminal Voltages and Safe ty...................................................................................7

4.4 Output Protection ......................................................................................................7

5 Initial Operation .............................................................................................................8

5.1 AC Power On/Off ......................................................................................................8

5.2 DC Output On/Off .....................................................................................................8

6 The Display and Soft Key Control ...............................................................................9

6.1 The Home Screen ....................................................................................................9

6.2 Individual Output Screens ........................................................................................9

6.3 Setting with the Keypad .......................................................................................... 10

6.4 Setting with the Spin Wheel .................................................................................... 10

6.4.1 Spin Wheel Action Options ...................................................................................10

7 Power Supply Settings ............................................................................................... 11

7.1 CV and CC modes, Viewing Settings (Limits)......................................................... 11

7.2 Setting with Individual Output Screens ................................................................... 11

7.3 Power Display (VxA) ............................................................................................... 12

7.4 Selecting Current Meter Averaging ......................................................................... 12

7.5 Setting Over-Voltage and Over-Current protection ................................................. 12

7.6 Setting the Voltage/Current Range ......................................................................... 13

7.7 Store and Recall of Settings ................................................................................... 13

7.8 The System Menu Screen ...................................................................................... 14

7.9 Voltage Tracking ..................................................................................................... 14

7.10 Locking the Front Panel ...................................................................................... 14

8 Display Symbols ......................................................................................................... 15

9 Menu - Advanced Functions ...................................................................................... 16

9.1 Setting Voltage Tracking ........................................................................................ 16

9.2 Current Meter Averaging Setup .............................................................................. 17

9.3 Store and Recall of Settings for All Outputs ........................................................... 17

9.4 Multi-On / Multi-Off Operation and Sequencing ...................................................... 17

9.4.1 Emergency Off ......................................................................................................18

9.5 Pass Code Locking of the Front Panel ................................................................... 18

9.6 System Preferences ............................................................................................... 19

9.7 Setting to Factory Defaults ..................................................................................... 19

9.8 Adjusting LCD Contrast .......................................................................................... 19

9.9 Calibration .............................................................................................................. 19

9.10 Remote Control Interfaces (MX100TP only) ........................................................ 19

Page 1

Page 3

10 Changing System Preferences ............................................................................... 20

10.1 Status at Power-up .............................................................................................. 20

10.2 Alert Sound (Beep) .............................................................................................. 20

10.3 Spin Wheel Action ............................................................................................... 20

11 Notes on Operation .................................................................................................. 21

11.1 Accuracy and Resolution ..................................................................................... 21

11.2 Remote Sense .................................................................................................... 21

11.3 Parallel Wiring of Outputs .................................................................................... 21

11.4 Series Wiring of Outputs ..................................................................................... 22

11.5 Instantaneous Current Output ............................................................................. 22

11.6 Output On/Off and Response Speed ................................................................... 22

11.7 Using OVP and OCP ........................................................................................... 23

11.7.1 OCP Trip at Output On .........................................................................................23

11.8 Over-temperature Trip (OTP) .............................................................................. 23

12 Remote Interface Operation (MX100TP only) ........................................................ 24

12.1 MX100TP Rear Panel Connections..................................................................... 24

12.2 Remote Interface Configuration .......................................................................... 24

12.2.1 GPIB Interface ......................................................................................................25

12.2.2 RS232 Interface ....................................................................................................25

12.2.3 USB Interface and Devic e Driver Installation ........................................................26

12.2.4 LAN Interface ........................................................................................................26

12.2.5 LAN IP Address and Hostname ............................................................................27

12.2.6 Interface Locking ..................................................................................................28

12.2.7 Status Reporting ...................................................................................................29

13 Remote Commands (MX100TP only) ...................................................................... 34

13.1 General ............................................................................................................... 34

13.1.1 Remote and Local Operati on ................................................................................34

13.1.2 Remote Command Handling .................................................................................34

13.1.3 Remote Command Formats ..................................................................................34

13.1.4 Command Timing..................................................................................................35

13.1.5 Response Formats................................................................................................35

13.2 Command List ..................................................................................................... 35

13.2.1 Instrument Function Com mands ...........................................................................35

13.2.2 Common Commands ............................................................................................37

13.2.3 Status Commands ................................................................................................38

13.2.4 Interface Management Commands .......................................................................39

14 Maintenance ............................................................................................................. 40

14.1 Cleaning .............................................................................................................. 40

14.2 Fuse .................................................................................................................... 40

14.3 Calibration ........................................................................................................... 40

14.4 Firmware Update ................................................................................................. 40

15 Technical Specifications ......................................................................................... 41

16 Default Values .......................................................................................................... 44

Page 2

Page 4

1 Using this Manual

This manual includes cr os s references which are shown as fol lows - see section X.X.

Within a PDF file, the shaded number is a hyperlink to that section number which enables the

user to jump rapidly to the sect i on r eferred to and then jump back to c ontinue reading the

original section.

(N.B. for hyperlink navigation within Acrobat Reader , enable “show all page navigati on tools” or

use the keyboard shortcut s Alt+Left-Arrow and Alt+Right -Arrow).

The Table of Contents is also fully hyperlinked and is replicated within the Bookmarks pane.

Note: The latest revisio ns of this manual, device drivers and s oftware tools can be

downloaded from: http://www.aimtti.com/support or http://www.aimtti.us/support

This manual is 48511-1610 Issue 5

(USA).

Page 3

Page 5

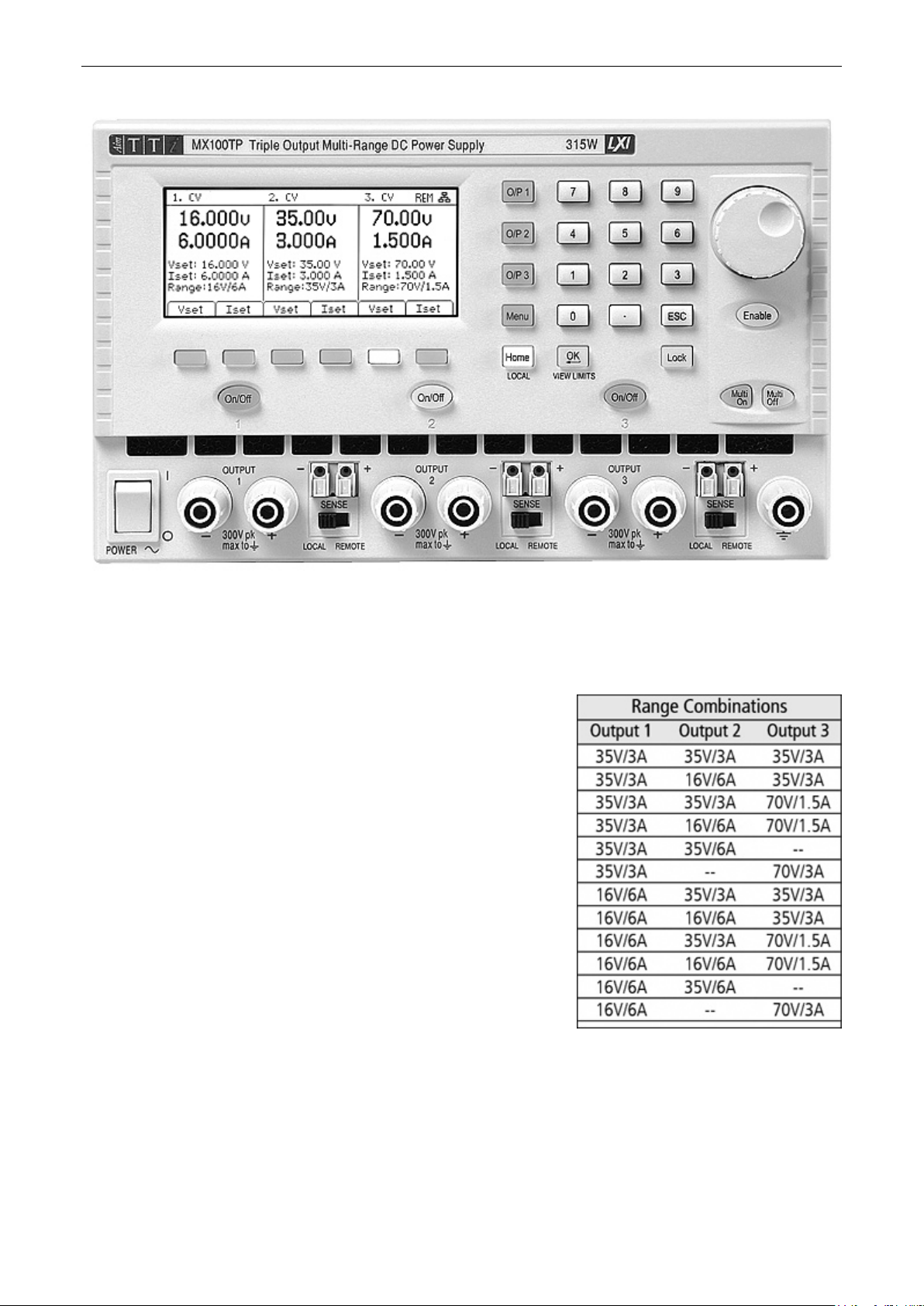

2 Product Description

The MX100T is a triple output l aboratory power supply incorp or ating three outputs of similar

power and features.

Each output can provide 0 to 35 volts at 0 to 3 amps (105 watts) with range switching extending

its capabilities to prov ide voltages up to 70V and currents up to 6A. Twelve range combinations

are available as shown in t he c har t.

Mixed-mode r egulation is used which com bines switchmode power conversion with linear final regulation to give

good noise and transient performance.

All information is displayed on a large backlit graphic LCD

and control is via soft keys together with a numeric keypad

and spin wheel.

Advanced features inclu de 50 settings memories for each

output plus 50 further memories that record the settings for

all three outputs together.

Multi-On and Multi-Off keys supplement the individual output

On/Off keys and can be programmed to turn the outputs on

or off in a timed sequence.

The front panel can be locked t o pr ev ent accidental changes

to settings.

The power supply is housed in a compact half-rack width, 3U high c as e with front input

ventilation. An intelligent fan is used to minimise coolin g nois e.

The MX100TP has the sam e manual control features and adds USB, RS232, GPIB and LXI

compliant LAN interfaces together with duplicate power and sense terminals at the rear.

Page 4

Page 6

3 Safety

meaning Caution. In this manual this symbol is used to highl ight situations where

Earth (ground) terminal.

mains supply OFF.

l

mains supply ON.

alternating current (ac )

This power supply is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use). It is an Installation Category II instrument intended for

operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environm ent in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be subjected

to temperatures between +5°C an d –10°C without degradation of its safety. Do not oper ate while

condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live parts.

The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair. Capacitors inside the power supply may still be

charged even if the power supply has been disconnected from all voltage sources but will be safely

discharged about 10 minutes after switching off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a sk illed person who is aware of the

hazard involved.

If the instrument is clearly defective, has been subj ect t o mechanical damage, excessive moisture or

chemical corrosion the safety protection may be impaired and the apparatus should be withdrawn

from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:-

incorrect use may either damage the instrument or cause a potential hazard to the

user.

Page 5

Page 7

4 Installation

4.1 Mains Operating Voltage

This instrument has a univers al input range and will operate from a nominal 115V or 230V

mains supply without adjustment. Check that the local supply meets the AC Input requirement

given in the Specification see section 17.

4.2 Mains Lead

Connect the instrum ent to the AC supply using the mains lead pro vid ed. Should a mains plug

be required for a different mains outlet socket, a suitably rated and approved mains lead set

should be used which is f itted with the required wall plug and an IE C60320 C13 connector for

the instrument end. To determine the minimum current rating of the lead-set for the intended

AC supply, refer to the power rating information on the equipment or in the Specification.

WARNING! THIS INSTRUMENT MUST BE EARTHED.

Any interruption of the mains earth conductor inside or outsid e the instrument will make the

instrument dangerous. I ntentional interruption is prohibited.

4.3 Mounting

This instrument is s ui table both for bench use and rack mounting. It is delivered with feet for

bench mounting. The f ront feet include a tilt mechanism for optimal panel angle.

A rack kit for mounting in a 19” rack i s available from the manufacturers, or their agents and

distributors overseas.

4.4 Ventilation

The power supply is cooled by an intelligent multi-speed fan which vents at the rear. Cooling

air is drawn in through slots in t he front panel directly above the terminals, and by slots in the

base of the unit close to the front.

In a rack-mounted situation no additional space is required above or to the sides of the unit.

Some air space below the unit will ensure the best possible airflow and the lowest fan speeds

for a given power, but is not required.

Ensure that the ventilation slots and rear fan exhaust are not obstructed. In the event of

overheating, a temper ature trip will turn all of the outputs off – see section 11.8.

Page 6

Page 8

5 Connections

5.1 Front Panel Connec tions

For each output, the load should b e connected to the positive (red) and negative (black)

terminals marked OUTPUT.

Both are fully floating and either can be connected to ground or t o a terminal of another output.

Remote sense connections to the load, if required, are made from the positive (+) and negati v e

(-) SENSE terminals. Switch the SE N S E switch to REMOTE when remote s ens ing i s r equired.

Switch back to LOCAL when remote sensing is not in use. See section 11.2 for more

information.

The grey terminal marked with an Earth symbol is connected to the chassis and safety

earth ground.

5.2 Rear Panel Connections (MX100TP)

The MX100T has only an AC power connection socket on t he r ear panel. The MX100TP has

duplicate power and sense terminals on the rear panel and offers full remote control capabilities

through USB, RS232, GPIB and LAN interfaces.

All interfaces are full y isolated from the power supply output terminals. USB, RS232 and G PIB

interfaces are connected to chassis ground. The LAN interface is isolated by standard network

transformers.

Rear connections for t he MX100TP are detailed in section 12.1.

5.3 Terminal Voltages and Safety

The outputs of the power supply are fully floating and may connected to other equipment resulting in

the voltage appearing at a terminal being greater than the output voltage alone.

The maximum permissible voltage between any terminal and earth ground ( ) is 300VDC;

the maximum permissible voltage between either terminal of one output and either terminal

of another output on the same power supply is also 300VDC.

WARNING! Such voltages are exceedingly hazardous and great care should be taken by the user.

The front terminals are intrinsically touch proof, but hazard may still exist depending upon the type

of connection made to the terminal. On no account should the connections be touched under such

use.

For the MX100TP only, voltages appearing on the front terminals will als o appear on the

rear terminals. The rear terminals have protective walls but are not intrinsically touch proof,

and additional precautions must be taken if voltages above 70 volts DC could be present.

If any hazardous voltages could exist, all connections to the front or rear terminals must be m ade

with the power switched off on all voltage sources.

5.4 Output Protect ion

Each output is protected agains t the application of external forward voltages up to 50 volts

(outputs 1 and 2) and 90 volts (output 3). Each output is protected agai ns t the application of

reverse voltages by a clamp diode with a maximum conti nuous c urrent capability of 3 amps.

Further protection is provided by OVP and OCP trips and an over-temperature trip.

Page 7

Page 9

6 Initial Operation

6.1 AC Power On/Off

Power ~ O/I

The AC power switch is located at the bottom left of the front panel.

At power-up a screen is displa ye d that shows the firmware revis i on number and a brief

description of the starting conditions. These can be changed from System Pref er enc es if

required – see section 10.1.

6.2 DC Output On/Off

On/Off

Each output has its own DC On/Off key. These are positioned direc tly above

each set of output terminals and are numbered 1, 2 and 3 from left to ri ght.

Alternate presses of the key turns the output on or off. The on stat e is

indicated by the key being illuminated in red.

At power-up the default beha viour is for all the outputs to be s et to off.

However, the user can change thi s default setting such that t he outputs are

restored to their condition when the instrument was switched off. This change is made from

System Preferences - see section 10.1.

Multi-O n / Multi-Off

It is also possible to turn all three outputs on or off simult aneously

using the Multi-On and Multi-Off keys. By default these keys operate

on all three outputs simult aneously but the behaviour can be changed

to turn the outputs on or off i n a timed sequence or to remove an

output from either Mult i-On or Multi-Off control, see section 9.4.

Page 8

Page 10

7 The Display and Soft Key Control

With the exception of output On/Off, the primary control of the

power supply is via the six ke ys dir ec tly below the display.

These are referred to as “soft keys” because their function is not

fixed but is annotated by legends on the display directly above.

The function of the keys depends upon the type of screen selec ted. There are five

main screens which are s el ec ted by the keys to the right of the di s play. The

selected key is illuminated.

The main screen (Home) displays all t hr ee outputs simultaneously, the system

menu screen (Menu) provides ac c es s to advanced functions, and the individual output screens

(O/P n) show more detailed inform ation for each individual output.

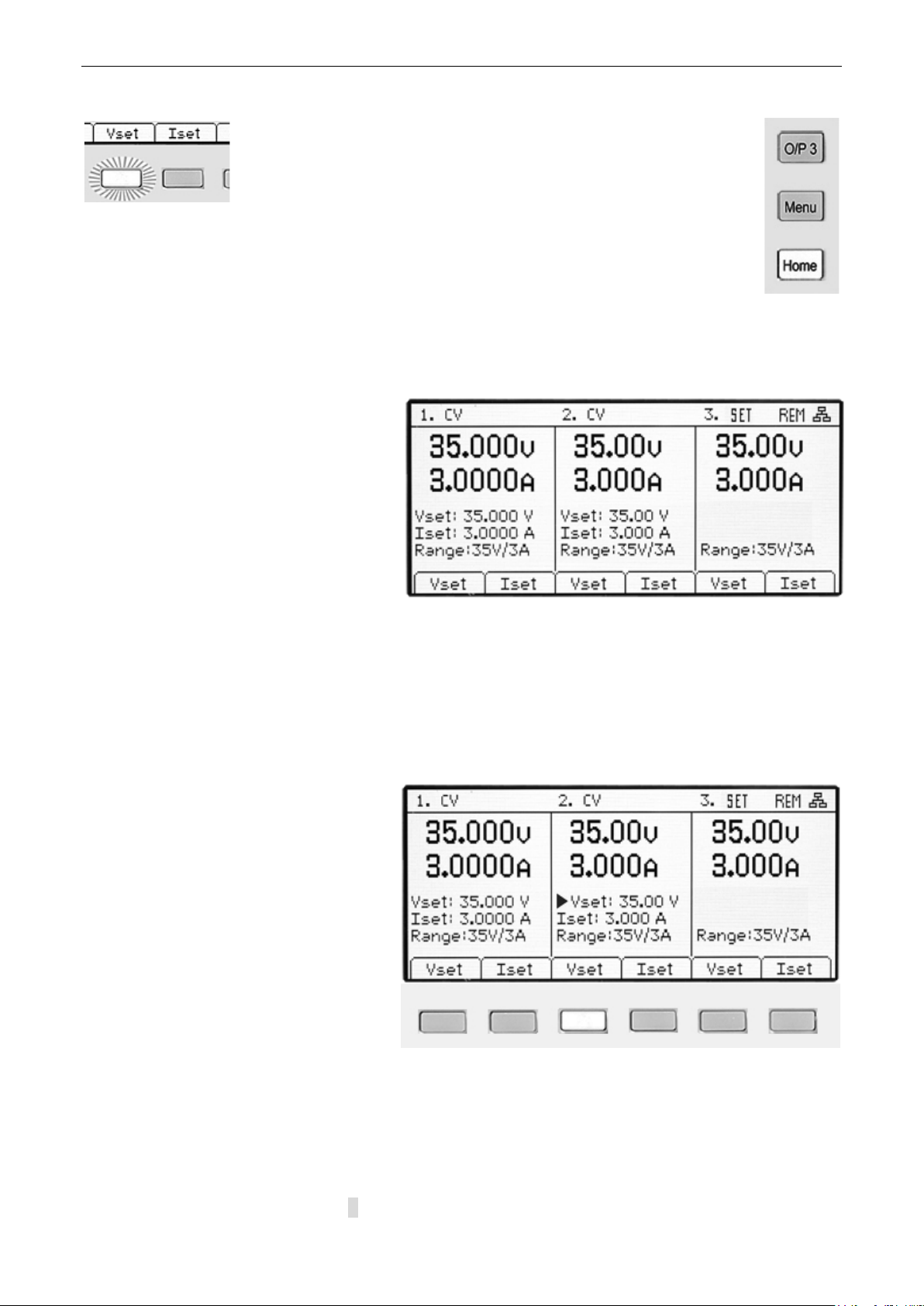

7.1 The Home Screen

The main (Home) screen is selected

with the key marked Home and shows

the primary information for all three

outputs simultaneousl y whilst enabling

voltage and current to be set for any

output.

The display is divided in to three

sections representing outputs 1, 2 and

3 from left to right. For each output

the display shows operat ing mode on

the top line as CV (constant voltage), CC (constant curr ent) or SET (Settings). SET is

displayed when the output is off.

The two meters directly below show the set values for voltage and current when the output is

off, and the voltage and cur r ent being supplied to the load when the output is on.

With an output on, the three lines below the meters show the set volt age (Vset), the set current

(Iset) and the output range (Range). If the output is off, the Vset and Iset lines do not appear

(because the meters are showing the set values).

The six soft keys are used to set

voltage (Vset) or current (Iset) for

each of the outputs. The presently

selected output and parameter (V or I)

is indicated by illuminat i on of the soft

key and by a flashing arrow in front of

the parameter to be adjusted. The

user can move freely between setting

voltage or current for any out put by

pressing the appropriate k ey.

Pressing the same key again or

pressing ESC (Escape) cancels the

key and disables all sett ing capability.

7.2 Individual Output Screens

Each output has its own display screen selected with t he keys O/P 1, O/P 2 and O/P 3. The

selected key is illuminated.

These enable additional parameters and functions to be controlled for that output including

Range, OVP & OCP, memory store & recall (Stores), and current meter averaging (Iavg).

These are detailed withi n s ection 7.

Page 9

Page 11

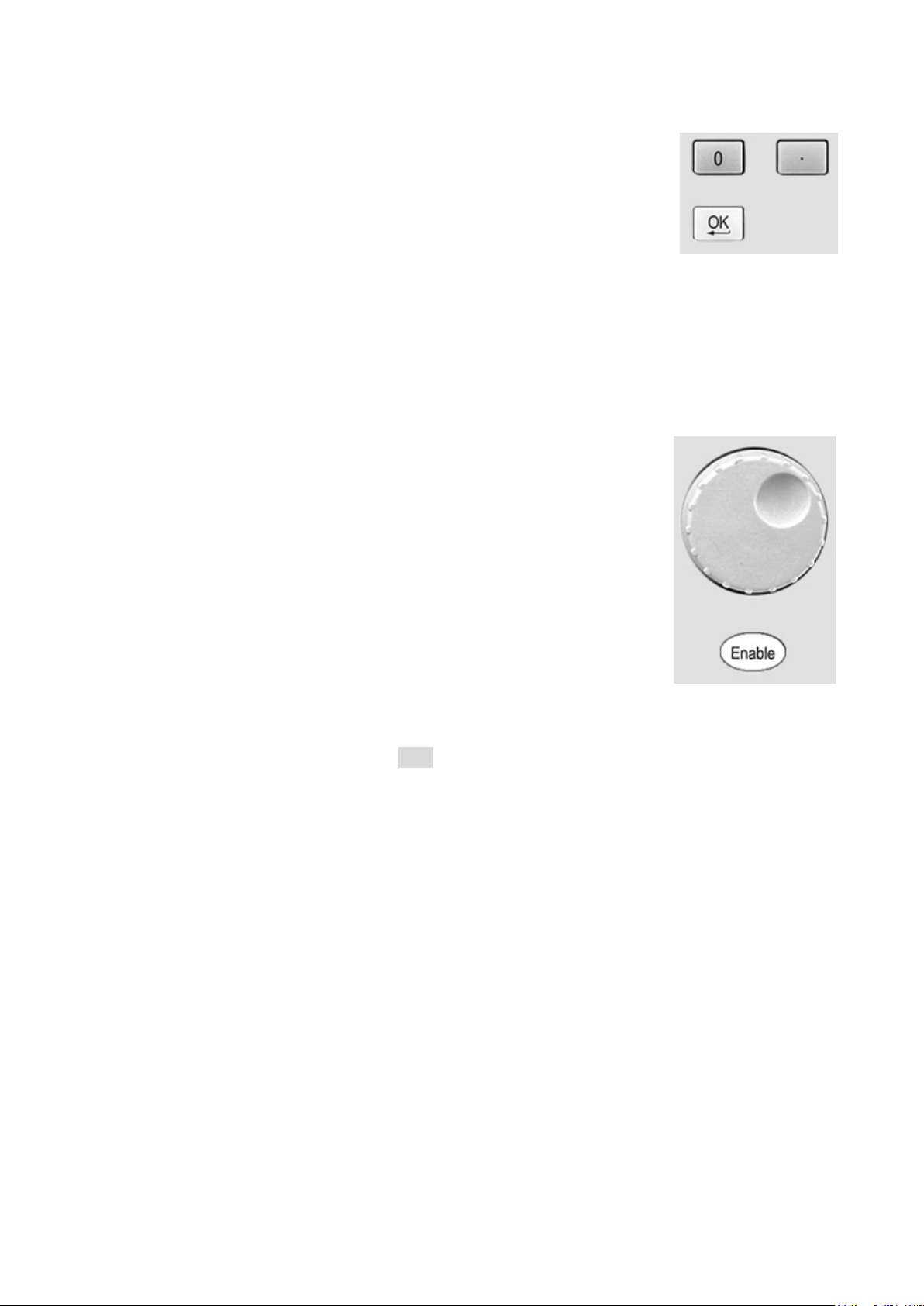

7.3 Setting with the Keypad

Vset & Iset

Voltage or current can be set using the numeric keypad.

Upon pressing a numeric k ey, the OK key will start to flash. When the

numeric value entry is completed, pressing OK causes the va l ue to be

accepted and actioned. E ntry can be abandoned at any point by

pressing ESC (Escape). The new value being entered is shown directly

below the meters in a sm aller font size.

Entry is in volts or amps to a res olution of 0.001 volts and 0.0001 amps for output 1, and 0.01

volts and 0.001 amps f or out puts 2 and 3.

Entries need only to be completed as far as the desired digit of resolution, e.g. to enter 5.000

volts it is only necessary to ent er 5 followed by OK.

7.4 Setting with the Spin Wheel

Vset & Iset

Voltage or current can alternatively be set using the spin wheel. The

wheel is disabled by default but can be enabled by pressing the ke y

below it which toggles its action on or off. When enabled the key is

illuminated. The wheel changes the output settings immediately, no OK

confirmation is required.

The wheel has a non-linear action. If it is moved slowly the value is

incremented in minimum steps (1mV/0.1mA for output 1, or 10mV/1mA

for outputs 2 or 3). When the wheel is r otated more rapidly the rate of

increment is increased enab li ng the value to be changed quickl y.

7.4.1 Spin Wheel Action Options

The action of the spin wheel can be c hanged from System Prefer enc es

to reduce the speed-related increment rate if preferred. Three choices are available: Normal

(default), Reduced acceleration, or Single Digit Increment.

Making changes is described in section 10.3.

Page 10

Page 12

8 Power Supply Settings

The procedures for set ting voltage and current, either numerically or via the spin wheel, have

been explained in the previous s ec tion.

8.1 CV and CC modes, Vi ewing Settings (Limits)

Depending upon the load conditions, the actual voltage and ac tual current applying t o the load

will not both be equal to t hei r s et values.

Output On – CV Mode

When in constant voltage mode the output voltage is equal to t he set value and CV is shown on

the top line of the display. The c urrent setting represents the limiting value of current that coul d

flow (the current limit).

Output On – CC Mode

When in constant current mode the output current is equal to the set value and CC is shown on

the top line of the display. The volt age setting represents the limiting value of voltage that could

be applied (the voltage limit).

Switch-over between CV and CC modes oc c urs automatically dependent upon t he l oad

conditions and the settings. The voltage and current settings may also be described as limits

since they represent the maximum values that can apply at the loa d.

To draw attention to the CC s ymbol and make it clear at a glance, a f lashing arr ow is

placed next to it. It is also possible to set an audible aler t – see section 10.2.

Output Off

When an output is off, the meters show these set values and SET is shown on the top line of

the display. When an output is on, the values of voltage generate d and current flowing are

shown together with CV or CC.

View Settings/ View Limits

It is also possible to view the set values for all three outputs at any time. Pressing the OK key

(also marked View Limits or V iew Settings) causes the display to change so that the meters all

show the limits values for a period of about 2 seconds.

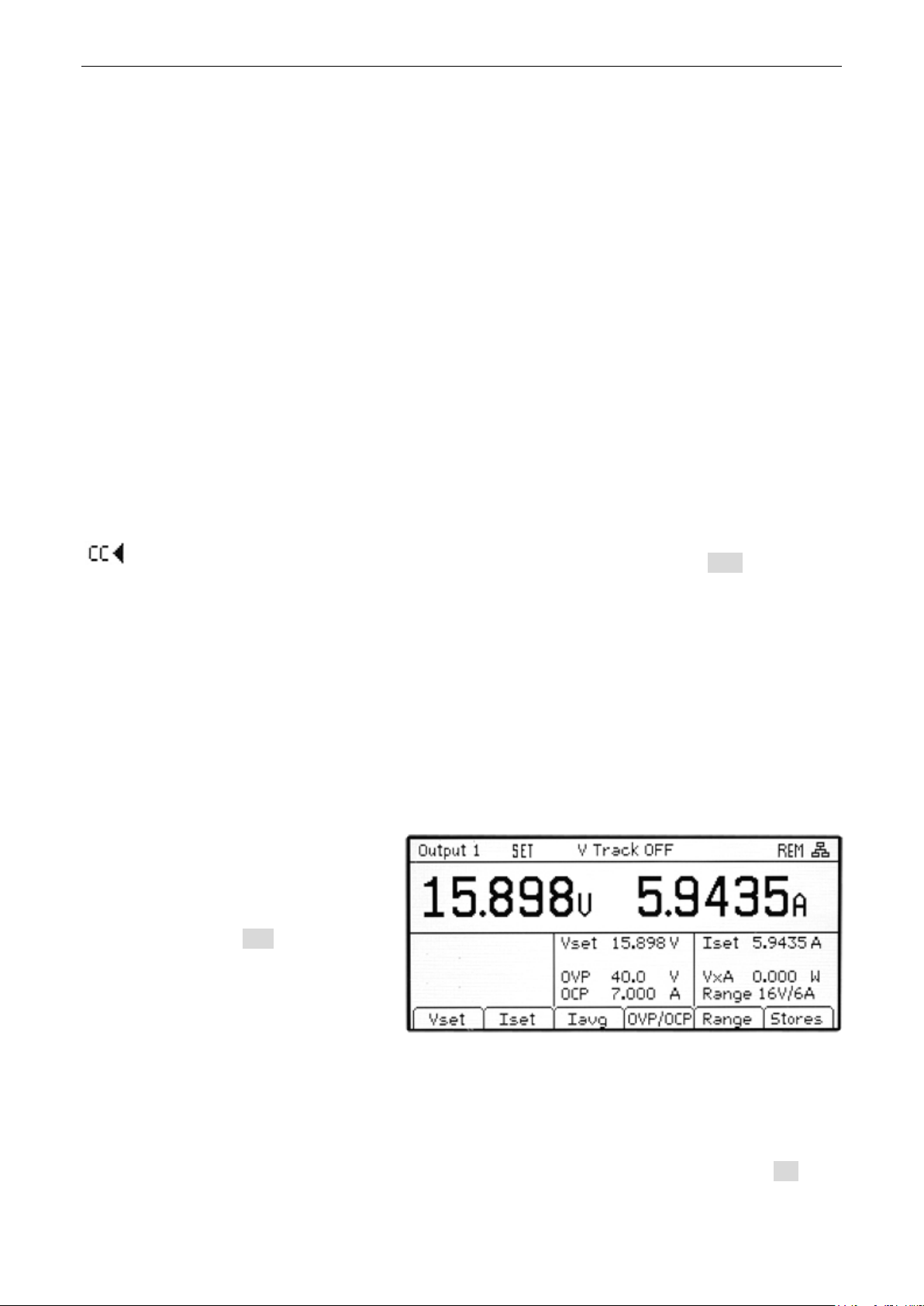

8.2 Setting with Individual Output Screens

The three illuminated k eys marked

O/P 1, O/P 2 and O/P 3 select a

screen that controls only the chosen

output. This screen provides more

information than the main (Home)

screen (see section 6.1), and allows

additional param eters to be set.

The top line shows the operating

mode (CV, CC or SET) together with

the voltage tracking status . The

meters are displayed in a larger font, and the complete sett ings status for the output is shown

below them.

The six soft keys are used to set voltage and current (Vset and Iset), over-voltage and overcurrent protection levels (OVP & OCP), current meter averaging (Iavg), range selection (Range)

and store or recall of settings (Stores).

Setting voltage or current is as previously described for the Home screen – see section 6.1.

Page 11

Page 13

8.3 Power Display (VxA)

The power being supplied to the load (VxA) is displayed in watts on the lower right hand side.

The value is calculated from the metered values of voltage and current and is displayed with a

maximum resolution of 0.001 watts f or output 1 and 0.01 watts for outputs 2 and 3.

8.4 Selecting Current Meter Averaging

Iavg

Current meter averaging is us eful when the load current is varying rapidly. It can help to reduce

the variation in the reading and make the display easier to foll ow.

Selection is done from each individual output screen. Pr es s i ng the soft key

marked Iavg toggles curr ent meter averaging on or off. The pres ent status is

shown in the area above the key and by a n asterisk ( s symbol) appearing

directly after the curr ent meter. This symbol is also displayed on the Home

screen.

Three levels of averaging representing low, medium or hi gh c an be s el ected from the System

Menu - see section 9.2. The default value is medium.

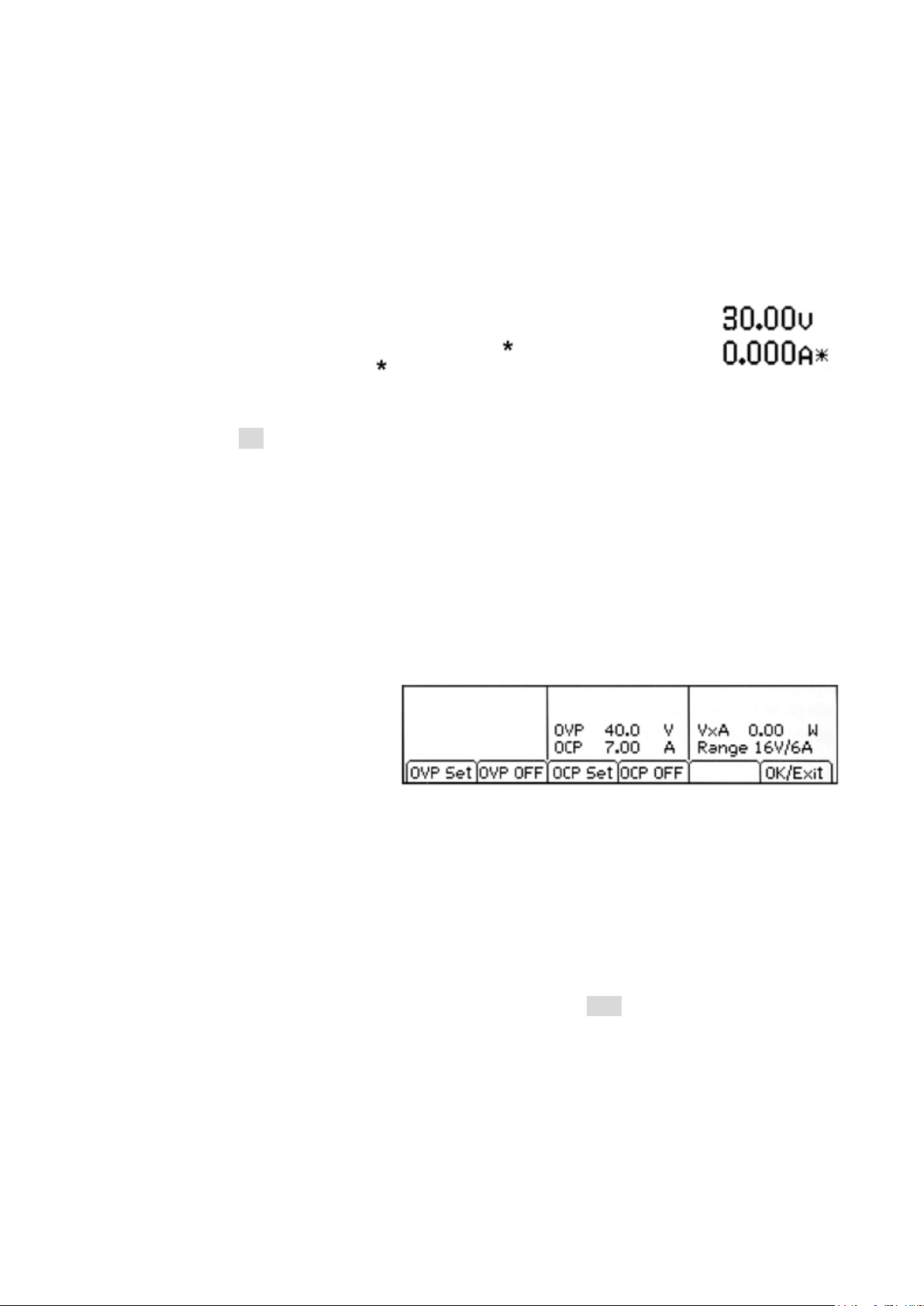

8.5 Setting Over-Voltage and Over-Current protection

OVP/OCP

The power supply offer s user adjustable over-voltage protec tion (OVP) and over-current

protection (OCP). If a voltage is detected that exceeds the O V P level, or a current is detected

that exceeds the OCP level, the output is switched off and the message OVP or OCP is

displayed.

OVP is adjustable between 1V and 40V for outputs 1 and 2, and between 1V and 80V for

output 3. OCP is adjustable bet ween 0.01A and 7A for outputs 1 and 2, and between 0.01A

and 3.5A for output 3.

Pressing the OVP/OCP soft key

creates a new set of soft keys from

which OVP & OCP values can be set

or turned on or off.

Pressing OVP Set causes the key to

illuminate and makes the OVP value settable. A new value can be entered us ing the numeric

keypad or by the spin-wheel if enabled. OVP can be turned off by pressing OVP OFF, and

turned back on by pressing OVP On. The previous OVP value is retained when OVP is off and

is displayed in brackets.

Similar capabilities ar e pr ov i ded for controlling OCP.

Note that, when set to OFF, the f unc tion is not completely disabled but is set to the maximum

value for the output. Thus if OVP was set to OFF on output 1 and an external voltage greater

than 40V was applied to the terminals, an OVP trip would occur.

More information on using OV P and OCP is provided in section 11.7.

Page 12

Page 14

8.6 Setting the Voltage /Current Range

Range

Each output has more than one range. For output 1 the choice is 35V/3A or 16V /6A. For

output 2 the choice is 35V/3A , 16V/6A or 35V/6A. For output 3 t he c hoice is 35V/3A, 70V/1.5A

or 70V/3A.

Note that selecting 35V/6A on output 2 will disable output 3, and selecting 70V/3A on output 3

will disable output 2.

Pressing the Range soft k ey brings

up a menu screen which shows t he

currently selected range by

illumination of the soft key. Pressing

another key selects a ne w range

which is actioned when OK/Exit is

pressed.

Note that a change of range can only be made when the output is off. If the output is on, a

message will prompt the user to turn it off.

8.7 Store and Recall of Settings

Stores

Each output has 50 memor y stores

capable of storing range, volt age,

current, OVP and OCP. Pressing t he

Stores soft key brings up a m enu

screen which shows the present

contents of the memor ies f r om which

settings can be stored or recalled.

The memories are numbered from 00

to 49 with the currently selected line

highlighted. The locati on can be

scrolled using the spin wheel or stepped through using the arrow keys. It is al s o pos sible to

jump directly to a location by entering a two digit number ( e.g. 07 or 45). Unused memory

locations are shown by the word Empty.

Pressing the Store key writes the present settings of the out put into the selected memory

location. If the position alr eady has settings stored within it a confirmation is required.

Pressing the Recall key tr ansfers the stored settings of the sel ec ted memory location to the

output. This happens immediately that the Recall key is pres s ed. Note that, if the recalled

range is different fr om the present r ange, the output will be automatically turned off.

The contents of a particular loc ation can be deleted by pressing the Delete soft key. A

confirmation is required.

From the Delete confirmation screen it is also possible to delet e the contents of all 50 locations

by pressing Del All. A conf irmation is required.

Store and Recall for Multiple Outputs

It is also possible to store and r ecall settings for all three out puts simultaneously. This is

described in Advanced Func tions section 9.3.

Page 13

Page 15

8.8 The System Menu Screen

The operation of the System Menu sc r een i s selected with the key marked Menu

which illuminates when pr essed.

System menu functions are described within section 9 - A dvanced Functions.

8.9 Voltage Tracking

The power supply can be set -up such that the voltage of output 2 tracks that of

output 1, or that output 3 trac k s output 2, or that outputs 2 and 3 both track output

1. The tracking status is shown on the top line of the display. Voltage tracking is

selected from the Syst em Menu, see section 9.1.

8.10 Locking the Front Panel

Lock

The front panel can be “locked” such that the power supply will not respond to any

key presses. This is in order to pr ev ent an accidental changes to settings.

Pressing the Lock key disables the front panel. This is indic ated by the key being

illuminated in green. Onc e locked any key press creates a warning mes s age on the display.

To unlock the front panel, pres s and hold the Lock key for more than one second.

For additional security it is also possible to lock the fr ont panel using a pass-code. This is

explained in Advanced Functions section 9.5.

Page 14

Page 16

9 Display Symbols

Some functions are indi c ated by symbols or abbreviation on the display as follows:

Function Home Screen Individual Output S c r e e n

Output on, constant voltage

mode

Output on, constant current

mode

Output off SET shown on the top line

Current meter averaging on symbol after current meter symbol after current meter

Voltage tracking TRK > shown on top line

Multi-On/Multi-Off not set to

defaults (set to Delayed or

Never)

Power supply under rem ote

control (MX100TP only)

LAN connection status

(MX100TP only)

Note that the LAN symbol changes to reflect the connection status. This is detailed within the

Remote Control pages - see section 12.2.4.

CV shown on the top line next

to the output number

CC shown plus flashing ar r ow

next to the output number

next to the output number

between the Master and Slave

Clock symbol on top line next

to the mode indication

for the affected output

REM shown at top right hand

side

LAN symbol shown at top

right hand side. (see not e)

CV shown on the top line

CC shown plus flashing ar r ow

on the top line

SET shown on the top line

(and Iavg ON in small font)

V Track ON or OFF shown on

top line plus Master or Slave

Clock symbol on top line

REM shown at top right hand

side

LAN symbol shown at top

right hand side (see note)

The example screen opposite shows

output 1 in constant current (CC)

mode, output 2 in constant voltage

(CV) mode and output 3 sho wing

settings (output off).

Output 3 is set to track output 2, and

outputs 2 and 3 have Multi-On/MultiOff not set to defaults.

Output 3 current meter has aver aging

turned on.

Page 15

Page 17

10 Menu - Advanced Functions

Menu

Pressing the key marked Menu selec ts the System Menu screen.

This provides access to advanced options and functions. When the system menu is

displayed, setting of output parameters is not possible but operation of the output

On/Off keys is unaffect ed.

Each item of the system menu is selected by using the two arrow keys, or by turning

the spin wheel until the desir ed line is highlighted, and then pressing the Select soft

key. This selects a menu scr een r elating to the function selec ted.

Help Text

Alternatively, pressing the Help soft

key provides some on-screen

explanation of the highlighted function.

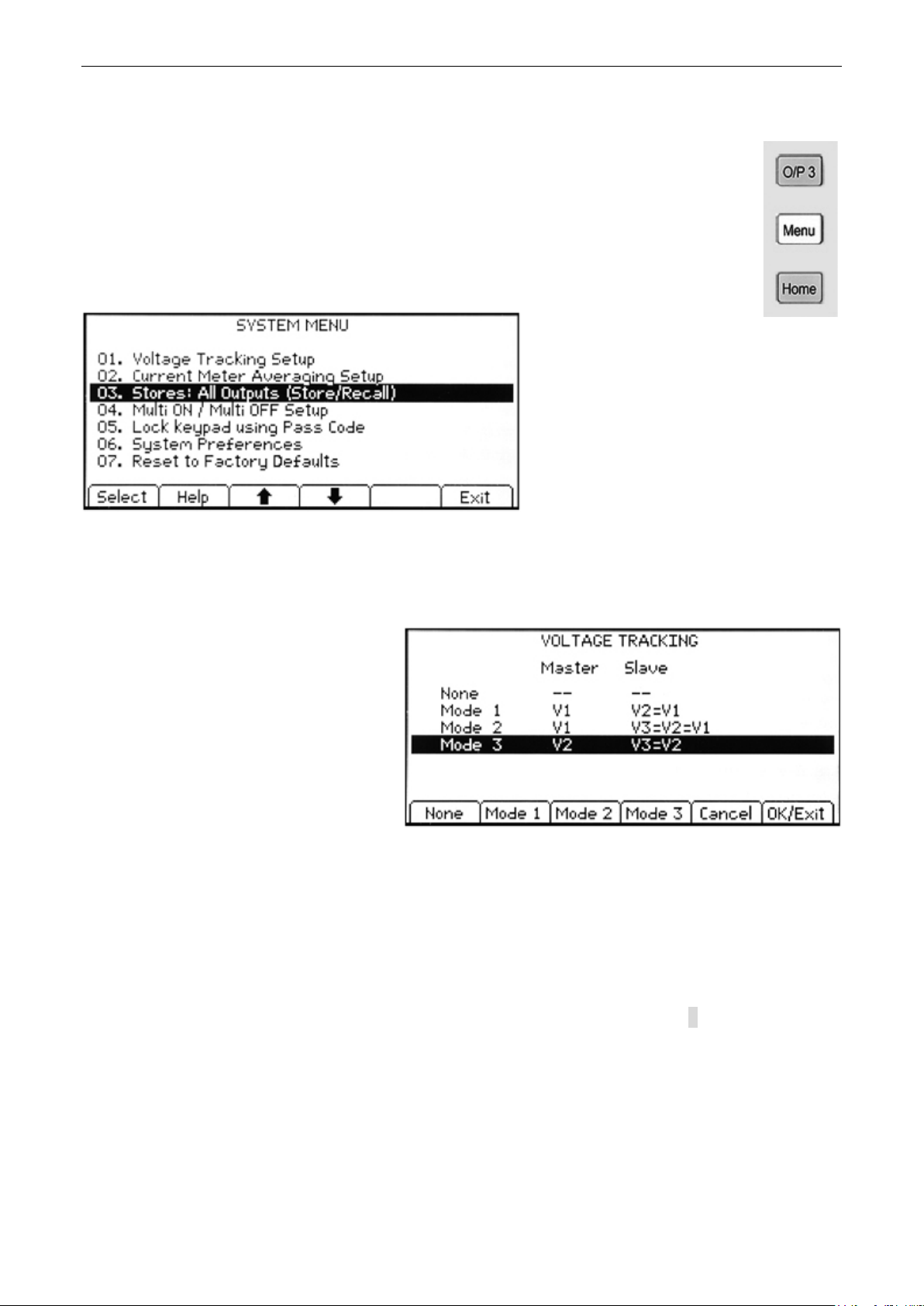

10.1 Setting Voltage Tracking

Menu > Voltage Tracking Setup

By default all three output s are

completely independent . However, it

is possible to make the volt age of an

output always equal to the volt age set

on another output. This is c al led

voltage tracking.

Tracking voltages can be useful in

setting up adjustable vol tages of equal

or opposite polarity, or when outputs

are wired in parallel or in series.

Three alternative volta ge tracking arrangements ar e possible:

Mode 1 Output 2 tracks Output 1.

Mode 2 Output 2 and Output 3 both track Output 1.

Mode 3 Output 3 tracks Output 2.

The controlling output is described as Master, whilst a controlled output is described as Slave.

Voltage tracking can only be selected when the voltage range for the Slave output is equal to or

higher than that of the Master output.

The tracking condition is displayed on the top line of the dis play, see section 8.

When tracking is set, changing the range of either the Master or Sla ve o utput will cancel

tracking regardless of the direction of the change.

Page 16

Page 18

10.2 Current Meter Averaging Setup

Menu > Current Meter Averaging Setup

The degree of averaging of the current meter reading when Iavg is turned on (see section 7.4)

can be set individually for eac h output.

The System Menu function “Curr ent Meter Averaging Setup” provides an individual choice of

low, medium or high (Low, Medium , High) for each of the three outputs set via t he s oft keys.

The default value is medium.

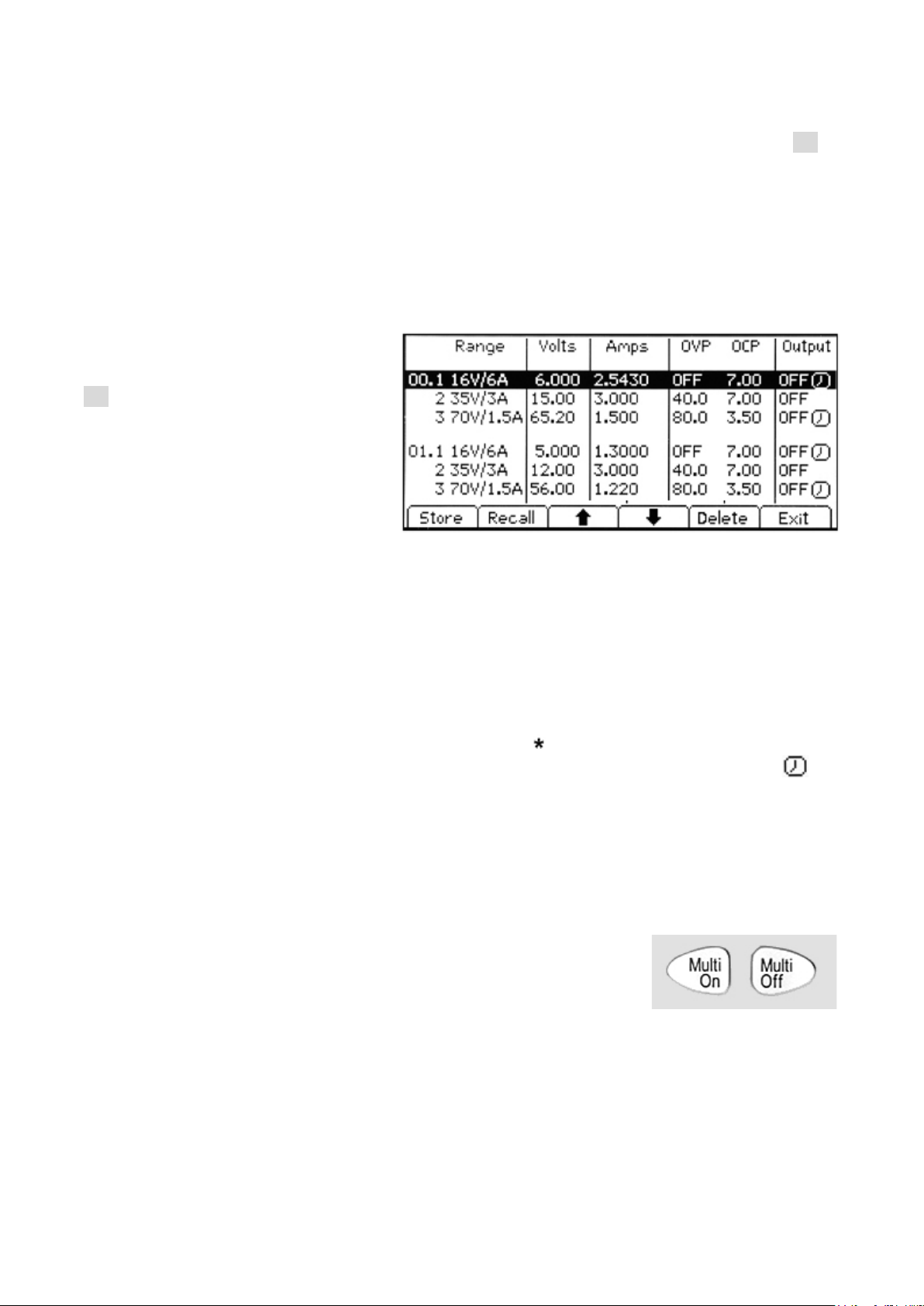

10.3 Store and Recall of Settings for All Outputs

Menu > Stores: All Outputs (Store/Recall)

Each output has its own set of 50

memories in which settings c an be

stored for that output ( see section

7.7). A further set of 50 m em ories is

provided that allow the user to store

and recall the settings status for all

three outputs simultaneous ly.

Unlike the individual memories, which

store only Range, Volts, Amps, and

OVP/OCP, these memories also store

the output ON/OFF state, current meter averaging state, and the Multi-On/Multi-Off settings.

The System Menu function “Stores: All Outputs (Store/Rec all)” creates a screen similar t o the

Stores screen for the individual outputs, but with an extra col umn for ON/OFF. The thr ee

outputs are listed on successive rows.

The output On/Off state is i nc luded in order to allow memor ies to be recalled in sequence

including the turning of outputs on or off. Note that recalling a memory will override the existi ng

On/Off state and this should be considered when setting up the power supply prior to storing

each status entry.

Current meter averaging being set on is indicated by the symbol after the set curr ent value.

Multi-On/Multi-Off settings other than bot h set to Quick are indicated by a clock s ymbol

after the On/Off stat e.

Note that output delay sett ings are only applied when the Multi-On/Multi-Off function is used

and not when a memory is recalled.

10.4 Multi-On / Multi-Off Operation and Sequencing

Menu > Multi-On/Multi-Off Setup

The two keys on the bottom r ight hand side marked Multi-On and

Multi-Off control the On and Off behaviour for al l three outputs.

By default these keys provide a synchronous On/Off capability

whereby all three outputs are turned on or turned off simult aneous ly

by pressing a single key.

The System Menu function “Multi-On/Multi-Off Setup ” enables the operation of these keys to be

changed to suit the user’s requi r ements. Delays between the s witchi ng of the outputs can be

introduced to create an On or Off sequence, and any individual output can be excluded from

Multi-On or Multi -Off control.

Page 17

Page 19

At ex-factory default s, the On and Off

delays are all set to Quick c ausing

them to respond immediately to the

key press. The Tab arrow keys move

through the On and Off states for the

outputs which can be changed using

the soft keys.

Delay sets a time value in millisec onds between 10ms and 20,000m s (20 seconds)

using the spin wheel.

Never removes an output complet ely from control by the Multi-On or Multi-Off key.

Quick returns to immediate response.

Note that any previously set delay value is retained when set to Quick or Never and is restored

when Delay is selected agai n.

When any of the settings is other than Quick, a clock symbol is displayed on the t op l ine of

the main (Home) display, and of the individual output screen(s) to which it appli es .

Note that the set delays appl y only to the initiation of an output bei ng turned on or turned off.

The actual delay will depend up on the slew-rate limited tur n-on or turn-off times applying to a

particular output and its l oad. See section 11.6 for more information.

For short delay sequences, the key will flash briefly when pressed. For longer delays it will

continue to flash until t he s equence is completed. Where t he longes t delay is below

approximately 250ms, the key may not flash at all.

10.4.1 Emergency Off

When an Off sequence that includes long delays is in progress, a s ec ond pr ess of the Multi-Off

key will turn all three output s off immediately, including any outputs omitted from the sequence

(i.e. set to Never). Thus a double pres s (or press and hold) of the Multi-Off key will immediately

turn off all the outputs regardless of the sequence settings.

The individual output On/Off keys also remain active during a s equence and can be used to

override a delay.

10.5 Pass Code Locking of the Front Pane l

Menu > Lock Keypad using Pass Code

In addition to the norm al locking of

the front panel (see sect i on 7.10) it is

also possible to lock the front panel

securely by setting a pass code. This

might be appropriate when t he power

supply is installed withi n a system

where, once set up, changes must

only be made by the installer.

The pass code is a “once only” code.

After the system has been unlocked,

the pass code is discarded and a n ew code (or the same one) must be entered in or der to lock

it again.

In the event that the user forgets the pass code, the power supply can be unlocked using the

master pass code of 7835 which is always active.

Page 18

Page 20

10.6 System Preferences

Menu > System Preferences

Various aspects of the power supply operation can be chan ged from the System Preferences

function. These are detailed in section 10.

10.7 Setting to Factory Defaults

Menu > Facto ry Defaults

This function can be used to return most of the instrument settings including Voltage, Current,

Range, OVP, OCP, Output On/Off, Current Meter Averaging, Multi-On/Off Action and System

Preferences back to t he fac tory default values as listed in section 18.

The Store memories f or both i ndividual outputs and All Outputs are unaffected. To clear each

bank of Stores it is necessar y t o us e the function Stores > Delete > Del All.

LCD contrast setting and remote interface settings (MX100TP only) are also unaffect ed.

10.8 Adjusting LCD Contrast

Menu > Adjust LCD Contrast

The LCD contrast can be adjusted over a wide range. The setting is displayed numerically as a

percentage. The displa y can also be inverted from black on white to white on black.

10.9 Calibration

Menu > Calibration

The Calibration function enables the instrument to be r e-calibrated when required.

Calibration will overwrite the exist i ng settings and should only be carr ied out by qualified

personnel in conjunction with the instrument Service Guide and the necessary precision

equipment.

A 4-digit pass code can be set to prevent unauthorised calibration if required.

10.10 Remote Control Int erfaces (MX100TP only)

Menu > Remote Control Interfaces

Settings for the GPIB and LAN interfaces can be observed usi ng this function.

Details for the GPIB interface are within the Remote Interfaces Configuration section 12.2.1.

Details for the LAN interface are within the Remote Interfaces Configuration section 12.2.4.

Page 19

Page 21

11 Changing System Preferences

Menu > System Preferences

Access to System Preferences is

selected from the main system menu.

A listing of system preferences is

shown.

The current system preferenc es are

indicated by ticks against the relevant

setting. Changes are made b y

moving the highlight with either the

arrow keys or the spin wheel and

pressing the Select soft key.

Alternatively a line can be selected directly by entering the two digit number from the keypad.

11.1 Status at Power-up

Outputs at power up / Settings at power up

At power-up the default beha viour is for all the outputs to be s et to Off. However, the user can

change this default sett i ng s uc h that the outputs are restored to their condition when the

instrument was powered down.

The default behaviour als o r eturns the settings (set volts, s et current, range etc.) to those t hat

existed at power-down. This can be changed so that the settings are al ways at factory defaults

(see section 18). This includes all outputs being set to Of f.

11.2 Alert Sound (Beep)

Set beep / Disable beep

An alert sounder is incor por ated that produces a “beep” un der s pecific conditions.

By default a beep will be sounded when an illegal key entry is m ade, or when a trip condition

occurs. This can be disabled if pref erred.

It is also possible for a beep to be sounded whenever an output chang es i nto constant current

(CC) mode. This is disabled by default.

11.3 Spin Wheel Action

Spin wheel action

The action of the spin wheel can be c hanged to reduce the speed-related inc rement rate.

Three choices are available: normal (default), reduced acceleration, or single d igit increment).

Page 20

Page 22

12 Notes on Operation

12.1 Accuracy and Resolution

All three outputs provide good ac c ur acy and resolution and offer remote sensing to ensure

precise regulation at the load. See section 17 for accuracy specifications.

Output 1 offers greater resolution and accuracy than outputs 2 and 3 and uses 5 digit meters to

give 1mV and 0.1mA resolution ( as against 10mV and 1mA for outputs 2 and 3). Consequently

output 1 should be chosen to power circuits where particular ly high precision is required.

12.2 Remote Sense

Each output has a very low output impedance, but this is inevit ably increased by the resistance

of the connecting leads and the contact resistance between terminals and leads. At high

currents this can result in s i gnificant differences between the indicated source voltage and the

actual load voltage (two 20 milliohm connecting leads will drop 0.2V at 5 Amps, for exam ple) .

This problem can be minim i s ed by using short, thick, connecting leads, but where necessary it

can be completely overc ome by using the remote sense capabil ity.

This requires the sense t erminals to be connected to the output at the load instead of at the

source by inserting wires into the SENSE terminals and connec ting them directly to the load.

The switch should then be set to REMOTE instead of LOCAL.

To avoid instability and transient response problems, care must be taken to ensure good

coupling between each output and sense lead; this can best be done by twisting the leads

together. An electrolyti c c apacitor directly across the l oad c onnec tion point may also be

beneficial.

The voltage drop in each output lead should not exceed 0.5 Volts. Higher voltage drops could

result in small metering errors or an inability to supply full power to the load when approaching

maximum voltage and current.

12.3 Parallel Wiring of Outputs

If currents above 6 amps are r equired, this can be achieved by wiring two or more outputs in

parallel. For example, outputs 1 and 2 could be paralleled to provide 16V/12A. In this situation

it would be appropriate to us e vo l tage tracking (Mode1 V2=V1 in this example) so that the

voltage can be adjusted directly on one output. See section 9.1 .

The drawing shows a parallel c onnec tion of two outputs using loc al or remote sensing.

Page 21

Page 23

12.4 Series Wiring of Outputs

If voltages above 70 volts are required, this can be achieved by wiring two or more outputs i n

series. For example, outputs 1, 2 and 3 could be series connected to pr ov ide up to 140V.

Voltages up to 115V could be achi eved by connecting all three outputs in series and selecting

voltage tracking so that full voltage adjustments can be made using one output control.

The drawing shows a series connect ion of two outputs using local or r emote sensing.

Warning! Voltages above 70Vdc are hazar dous live according to EN 61010-1 and

great care must be taken when using the power supply at voltages abo ve thi s level.

Ensure that the exposed end of any wires are fully inserted and inaccessible to the

touch. Always make connections to the power supply with the outputs off.

See also the information regarding t erminal voltages and safety within section 4.3.

12.5 Instantaneous Current Output

The current setting control can be set to limit the continuous out put current to levels down to the

milliamps. However, in common with all precision bench power s upplies, a capacitor is

connected across the output to maintain stability and good tr ansient response.

This capacitor charges to t he output voltage and short-circuiting of the output will produce a

current pulse as the capacitor discharges which is independent of the current limit setting.

12.6 Output On/Off and Response Speed

The output On/Off cont rol of the power supply is entirely electronic . The Off condition is

achieved by setting the voltage to zero and the current level t o low. There is no physical

disconnection of the output s.

When an output is turned on or of f there is a delay between the key being pres s ed and the

output voltage or current goi ng to zero (off) or rising to the set voltage or current (on).

The delay is a function of the loop response time of the power supply and of the stability

capacitor which is placed ac ross the output terminals. This c apac i tance has to be charged or

discharged before the out put can reach the set voltage or return t o zero respectively.

Because bench power supplies are used primarily in CV (constant voltage) mode, the following

explanation applies to CV mode. The situation for CC mode is differ ent.

When switching on, the out put will normally rise to the s et value within a fixed length of time,

typically a few milliseconds (see section 17 – Specifications). However this time c oul d be

Page 22

Page 24

increased if the current s etting is very low or is very close to the c ur r ent required by the load. A

large external capacitance at the load could also slow down the response.

When switching off with no load, the output will normally fall bac k to zero within a fixed length of

time (see section 17 – Specifications). If a load is connected t he response may be quicker

because of the additional dis c harge provided by the load. Ho wever, if the load includes a large

capacitance the respons e may be slower.

Turn-on and turn-off speeds are particularly relevant to Multi -On/Multi-Off output sequencing

(see section 9.4) where delays between the switching of different outputs can be set to a

resolution of 10ms. T hese delays apply only to the initiation of an output being turned on or

turned off, the actual delay will depend upon the actual turn-on or turn-off times applying as

described above.

In situations where the us er needs to know the actual response speeds for specific conditions it

will be necessary to observe this us ing an oscilloscope.

12.7 Using OVP and OCP

OVP (over-voltage protection) monit or s the voltage on the output terminals and switches the

output off if it exceeds the OVP setting. The response speed is typically 100us. Control of OVP

is described in section 7.5.

OVP might be used to guard agains t accidental mis-setting of the power supply, or might be

used to identify a fault conditi on when operating in constant current mode. Unlike the voltage

limit setting, exceedin g the OVP will turn the output off in a situation where damage to the

device under test might otherwise occur.

OCP (over-current protec tion) monitors the current flowing at the output and switches the output

off if it exceeds the OCP sett ing. The response speed is <0.5s. Control of OCP is described in

section 7.5.

OCP might be used to guard against accidental mis-setting of the power supply, or might be

used to identify a fault conditi on when operating in constant voltage mode. Unlike the current

limit setting, exceedin g the OCP will turn the output off in a situation where damage to the

device under test might otherwise occur.

12.7.1 OCP Trip at Output On

If the OCP level is set to a very low level whilst also bein g bel ow the set current level, it is

possible for a trip condition to be created when the output is s witc hed on. This is caused by the

current needed to charg e the output capacitance. Whether a trip occurs is a function of the

OCP trip response speed, the OCP level, the set current and the set output voltage.

12.8 Over-te mperature Trip (OTP)

The power supply has a sensor that monitors the internal ambient temperature. Should that

exceed a safe level, as might occur if the ventilation input or output was blocked, an overtemperature protect ion trip (OTP) will occur. Should O TP occur, all three outputs will be tur ned

off and an OTP message will appear on t he s creen.

Normal operation can onl y be restored by turning the AC supply (Power) off, rectifying the

ventilation problem and allowing the unit to cool bef or e switching back on.

In addition, there is a temperature sensor on the power device of the PFC (power factor

correction) stage. If this detects an over-temperature problem, all power outputs will shut down;

the auxiliary supply f or the CP U and di splay will, however, remain active, and the ‘Hardware

Failure or Over-temperature’ message screen will be dis played. If poor ventilation is suspected,

correct the problem, al low the instrument to cool, and use the Reset soft-key to re-initialise the

instrument. However, if the ‘Hardware Failure or Over-temperature’ message screen continues

to be displayed after the ins trument has cooled and been restar ted, there may be a component

fault; if in doubt, the unit should be returned for service.

Page 23

Page 25

13 Remote Interface Operation (MX100TP only)

13.1 MX100TP Rear Panel Connections

Output Connections

The Output and Sense terminals are duplicated on the rear panel terminal block marked

Output +, Output -, Sense + and Sense -. These connections are paral leled with their front

panel equivalents.

Switch the front panel LO CAL/REMOTE switch to REMOTE when remote sensing is required.

When the rear panel output terminals are used, the use of remote sense is always

recommended to ensure that output regulation is maintained within specification; connections

can be made to either the front or the rear remote sense terminals but never to both pairs of

terminals at the same time. Switch back to LOCAL when remote s ens ing is not in use.

Interface Connecti ons

Interface connectors for USB, RS-232, LAN and GPIB are m ounted on the rear panel. These

are described in detail within the following sections.

13.2 Remote Interface Configurati on

The MX100TP model can be remotely controlled via its RS232, US B, GPIB or LAN interfaces.

The GPIB interface provides full facilities as described in I E E E Std. 488 parts 1 and 2.

The RS232 interface communicates directly with a st andar d COM port.

The USB interface enumerates as a Communications Class device and interacts with

application software through a standard virtual COM port device driver on the PC. The

instrument firmware can be updated in the f ield via t he USB port; see Maintenance, section

16.4 .

Page 24

Page 26

The LAN interface is designed to meet LXI (Lan eXtensions for Instrumentation) version 1.4 LXI

Core 2011. Remote control using the LAN interface is possible using the TCP/IP Socket s

protocol. The instrument also contains a basic W eb server which provides information on the

unit and allows it to be configured from a web browser. Simple command line control from the

browser is also possible.

13.2.1 GPIB Interface

The standard GPIB interface 24-way connector is located on the instrument rear panel. The pi n

connections are as specified in IEEE Std. 488.1-1987 and the inst r ument complies with both

IEEE Std. 488.1-1987 and IEE E Std. 488.2-1987.

It provides full talker, l is tener, service request, serial poll and parallel poll capabilit ies. There are

no device trigger or cont roller capabilities. The IEEE Std.488.1 interface subsets provided are:

S H 1, AH1, T6, L4, SR1, RL2, PP1, DC1, DT0, C0, E2.

The GPIB address of the unit is s et from the system menu:

Settings can be changed f r om the System Menu (Menu > Remote Cont r ol Interfaces). The

present GPIB address is dis played. To change the address, use the spin-wheel to set the

desired address and then press the OK/Exit soft key.

The interface will operate with any commercial GPIB interface card, using the device drivers

and support software prov ided by the manufacturer of that card.

13.2.2 RS232 Interface

The 9-way D-type serial interface connec tor is located on the instrument rear panel. It should be

connected to a standard PC port preferably using a fully wired 9 way 1:1 male-female cable

without any cross-over connections. Alternatively, a 3 way cable can be used, connect ing only

pins 2, 3 and 5 to the PC, but with links made in the connector at the PC end between pins 1, 4

and 6 and between pins 7 and 8, as s hown in the diagram:

Most commercial cables provide these connections.

In addition to the transm i t and rec eive data lines, the instrument passively asserts pins 1 (DCD)

and 6 (DSR), actively drives pin 8 (CTS) and monitors pin 4 (DTR) from the PC. This allows the

use of a fully wired 9-way cable.

The Baud Rate for this instr ument is fixed at 9600; the other parameters are 8 data bits, no

parity and one stop bit. Flow control uses the XON/XOFF prot oc ol , but because of the low

volume of data associated with this instrument it is very unlikely that flow control will actuall y be

invoked.

Page 25

Page 27

13.2.3 USB Interface and Device Driver Installation

The instrument firmware can be updated in the field through the US B port. This does not need

the driver described her e. It requires a PC software utility provided by the manufact ur er, and

uses a HID driver that will already be installed on the PC. If that is the only USB functionality

required, download the pac k age containing the firmware update together with the PC utility from

the manufacturer, and follow the instructions included.

Using the USB interface for remote control requires a Communications Device Class driver on

the PC to provide a virtual COM port instance. In Windows a suitable driver is provided by

Microsoft, but it is not installed by default. The data (.INF) file to control the installation is

provided on the Product Documentation CD delivered with t he unit; however the same driver is

also used by many other instr uments from this manufactur er and may already be known to the

PC.

To install the driver f or the first time, first switch the unit on, and then connect the USB port to

the PC. The Windows plug and play functions should automatically recognise the attachment of

new hardware to the USB interface and (possibly after searching the internet for some time)

prompt for the location of a suitable driver. Follow the Windows prompts and point to the CD,

then the sub-directory for this product, and then to the USB Driver sub-directory below that. The

file is named USB_ARM_VCP_x xx.INF, where xxx is a version number. (A readme.pdf file will

also be found in that director y if further assistance is needed.)

In some cases Windows will not complete this procedure (especial ly recent versions which

search the internet first, looking for the unique Vendor ID and Pr oduct ID), in which case the

instrument will show in Device Manager as “not working properl y”. If this happens, select this

device, right click and choos e “update driver software...” and then “browse this com puter for

driver software...” and t hen loc ate the .INF file on the CD as descr ibed above.

Once Windows has installed the d evice driver it will assign a CO M port number to this particular

unit. This number will depen d on previous COM port assignments on this PC, and it may be

necessary to use Device Manager to discover it. Each instrument has a unique USB identif i er

which is remembered by the syst em, so it will receive the same COM port number whenever it

is attached to the same PC (r egar dl es s of the physical interfac e socket used), even though the

COM port will disappear while the instrument is disconnect ed or switched off. Other instruments

will receive different COM port numbers.

Note that a different PC will not necessarily assign the same COM port number to a particular

instrument (it depends on the history of installations ) , however Device Manager can be used to

change the assignments given.

This virtual COM port can be driven by Windows applications (inc l uding a terminal emulat or ) i n

exactly the same way as any standard COM port, except that the Baud rate and other settings

are unnecessary and are ignored. Some old applications might not function with COM port

numbers 3 or 4, or above 9. In this case, use Device Manager to change the allocation given.

Once it is installed, the driver will be maintained by Windows Update in the usual way.

13.2.4 LAN Interface

The LAN interface is designed to comply with the LXI standar d vers ion 1.4 LXI Core 2011 and

contains the interfaces and protocols described below. For more information on LXI st andards

refer to www.lxistandard. org .

When powered up and attached t o a network, the unit will by default attempt to obtain IP

address and netmask sett i ngs via DHCP, or, if DHCP times out ( aft er 30 seconds ) , via Auto-IP.

In the very unlikely event that an Auto-IP address cannot be found a static IP address is

assigned; the default is 192.168.0.100, but this can be changed on the web page. Connecting

via a router is recommended as this is significantly quicker to assign an IP address; connecting

directly to a PC will only begin t o assign an Auto-IP address after the 30 second DHCP timeout.

Page 26

Page 28

Since it is possible to mis c onfigure the LAN interface, m ak ing i t impossible to communicate with

then the LAN status indicator is .

and

display becomes

the instrument over LAN, a LA N C onfiguration Initialise (LCI) mechanism is provided via a push

switch (marked LAN RESET) accessible thr ough a small hole in the rear panel. T hi s r estores

the default configurati on with DHCP enabled, so the unit will then follow the sequence

described in the previou s paragraph. Note that resetting t he LA N i nterface removes any

password protection.

The progress of establis hing a LAN connection can be viewed either by inspecting the Remote

Control Interfaces screen (Menu > Remote Control Interfaces) or by int er preting the symbol

shown on the status line of t he Home screen, which has four possible indications:

No LAN

Configuring The unit has det ec ted a LAN connection but is not yet c onfigured, e.g. is

LAN OK The LAN connec tion is now configured and the unit can communicate. The

LAN FAULT The unit has detected a problem with LAN conn ection, e.g. Its IP address is in

If the unit cannot detect any connec tion to a LAN, e.g. the cable is unplugged,

waiting for DHCP. The LAN status indi c ator is animated, flashing between

use by another device. Communication is not possible and the display shows

13.2.5 LAN IP Address and Hostname

To communicate with the inst rument through the LAN interface, the IP address (which was

allocated during the con nec tion procedure described abo ve) must be known. Once connected

and correctly configured, the IP address of the unit is displayed within the Remote Control

Interfaces screen (Menu > R emote Control Interfaces). Alternatively the address can be

obtained from the DHCP server, or by using the LXI Discovery Tool des c r i bed below.

mDNS and DNS-SD Support

The instrument supports these multicast name resolut ion protocols, which allow a meaningful

host name to be assigned to the unit without needing an entry in the database of a central

nameserver. The desired hos tname can be entered on the webpage (whic h will have to be

accessed by IP address t he first time); spaces are not allowed. The name then appears in the

.local domain (e.g. myMX100.local), if the accessing de vice is configured to support the

protocol (which is the case with most modern PCs). The default name is followed by the serial

number.

ICMP Ping Server

The unit contains an ICMP serv er allowing the instrument to be ‘pinged’ using its IP address as

a basic communication check , or by its host name if name resolution i s working.

Web Server and Configuration Password Protection

The unit contains a basic web server. This provides information on the instrument and allo ws it

to be configured. The Configure and Instrument Control pages c an be password protected to

deter unauthorised changes to the remote operation conf iguration; the default configuration is

‘no password’. The Configure page itself explains how to set t he password. The password can

be up to 15 characters long; not e that the User Name should be left blank. The password and

hostname will, however, be reset to the default (no password) if the rear panel LAN reset switc h

is used to reset all the LAN parameters to their factory default.

LAN Identify

The instrument's main web page has an 'Identify' function which allows the user to send a

command to the instrum ent which causes its display to flas h until the command is cancelled.

Page 27

Page 29

LXI Discovery Tool

This tool can be used to display the IP addresses and other associated information of all

connected devices that comply with the VXI-11 discovery prot ocol. It is a Windows PC

application, which is provided on the supplied CD ROM that can be installed and run on the

controlling PC, with the uni t either connected directly to the PC network connector or via a

router. Double clicking on any entry in the list of discovered de vices will open the PC's web

browser and display the Home page of that device. For a later version of the tool that supports

discovery by both VXI-11 and mDNS visit www.lxistandard.or g . There are also tools for LA N

discovery included as part of the National Instruments Measurement and Automation E xplorer

package and the Agilent V ee appli c ation.

VXI-11 Discovery Protocol

The instrument has very limited support of VXI-11 which is sufficient for the discovery protocol

and no more.

It implements a Sun RPC Port-mapper on TCP port 111 and UDP port 111 as defined in

RFC1183. The calls supported are:

NU LL, GET PORT and DUMP.

On TCP port 1024 a very simple V X I-11 protocol is implemented, suff ic i ent only for instrument

discovery. This impl em ents the following calls:

CREATE LINK, DEVICE_WRITE, DEVICE_READ and DESTROY_LINK.

Once a link has been created anyt hing written to the device is ignor ed and any attempt to read

from the device returns t he same identification string as the *IDN? query.

V ISA Resource Name

Because of the limited suppor t for VXI-11 (Discovery Protocol only), the instrument must be

referred to by its raw socket information when used with software packages which communicate

using a VISA resource name. For example, an instrument at IP address 192.168.0.100 would

normally have a VISA resourc e name of "TCPIP0::192.168.0. 100::inst0::INST R" but for this

instrument the nam e must be modified to read "TCPIP0::192.168.0.100::9221::SOCKET" where

9221 is the TCP port used by this inst r ument for control and monit or i ng, see below.

XML Identificat ion Document URL

As required by the LXI standard, the instrument provides an XML identification document that

can be queried via a GET at “htt p://IPaddress:80/lxi/identification” that conforms to the LXI XSD

Schema (available at http://www.lxistandard.org/InstrumentIdentification/1.0

XML Schema Standards ( http://www.w3.org/XML/Schema ). This document describes t he

instrument. The hostname can be used instead of the IP address if name resolution is working.

TCP S ockets

The instrument uses 2 sockets on TCP port 9221 for instrument control and monitoring. Text

commands are sent to this port as defined in ‘Remote Commands’ and any replies are returned

via the same port. Any command string must contain one or mor e c omplet e c om mands.

Multiple commands may be separ ated with either semicolons “;” or line feeds. No final

terminator is required, s i nc e the TCP frame implies a term i nator, but one may be sent if desired.

) and the W3C

13.2.6 Interface Locking

All the remote interf ac es are live at all times, to remove any need to select the active interface

and to ensure that the LAN interface is always available (as demanded by the LXI standard). To

reduce the risk of the instr ument being inadvertently under t he c ontrol of two interfaces at once

a simple lock and release mechanism is provided in the instruction s et. The lock is

automatically release d where it is possible to detect disc onnec tion, or when the Local key is

pressed. Access to the interfaces may also be restricted using t he web pages.

Any interface may request to have exclusive control of the instrument by sending an “IF LOCK

1” command. The lock may only be released by sending an “IFLO CK 0” command from the

Page 28

Page 30

interface instance that currently has the lock, and m ay be queried from any interface by sendi ng

an “IFLOCK?” command. The reply to this query will be “-1” if the lock is owned by another

interface instance, “0” if the interface is free and “1” if the lock is owned by the requesting

interface instance. Sending any command from an interface without control privileges that

attempts to change the inst rument status will set bit 4 of the Standard Event Status Register

and put 200 into the Executi on E r ror Register to indicate that there are not sufficient privileges

for the required action.

Note: it is also possible to configure the privileges f or a particular interface to either ‘read only’

or ‘no access’ from the Web page interface.

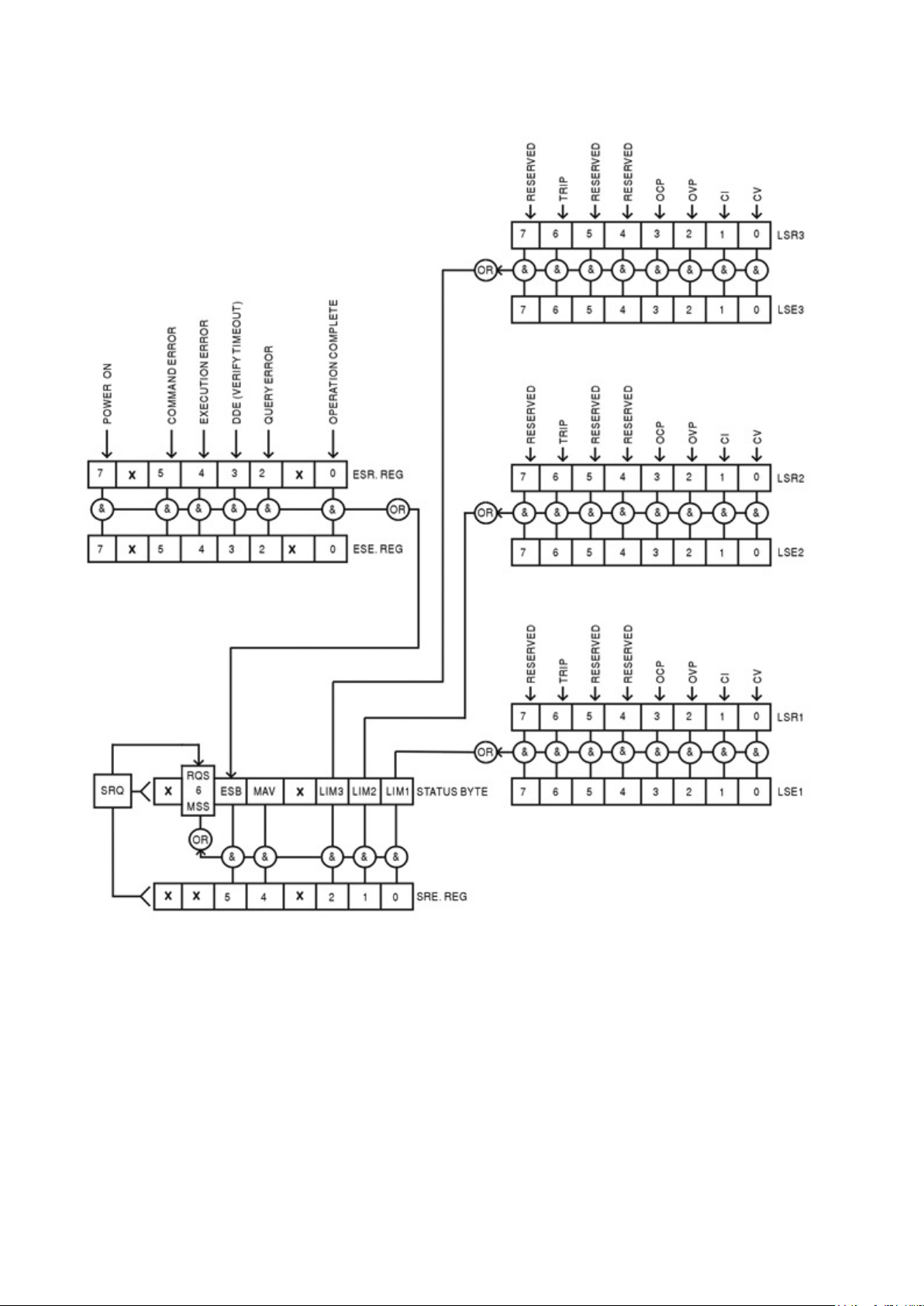

13.2.7 Status Reporting

The standard status and error reporting model described in IEE E S td. 488.2 was designed for

the GPIB interface and contains s ome features intended for use with the Service Request and

Parallel Poll hardware c apabilities of that interface, and to accommodate its semi-duplex

operation. Although tho s e facilities are of little use with other interfaces, this instrument makes

the full set of capabilities available to all of the interfaces. A separate set of many of the status

and error registers is maintai ned for each potential interface instance. The GPIB, USB and

RS232 interfaces each provide a s i ngle instance, while the LAN interface provides three: one

for the Web page and one each f or the two TCP socket interfaces. Having a separ ate status

model for each interface instance ensures that data does not get lost, as some status query

commands (e.g. ‘*ESR?’) clear the contents of a register after reading the present value.

The full set of error and status registers and the individual bit s they contain is shown in the

Status Model Diagram and descri bed in detail below, but in brief the status is maintained usin g

five primary registers, the Limit Event Status Register for each output, the Standard Event

Status Register and the E xecution Error Register. A summary is reported in the Status Byte

Register, as selected by four masking registers, the Limit Status Enable Register for each

output and the Standard Event Status Enable Register. Two further mask registers, the Service

Request Enable register and the Parallel Poll Response Enable r egister, control operation of

the GPIB hardware Service Reques t and Parallel Poll (and the associated ist message)

respectively. It is r ec ommended that, when controlling the unit through any interface ot her than

GPIB, the controller program should simply read the primary status r egisters directly.

The Standard Event Status R egis ter, supported by the Execution Error and Query Error

registers, records event s c oncerned with command parsing and ex ecution, and the flow of

commands, queries and res pons es across the interface. These are mainly of use during

software development , as a production test procedure shou ld never generate any of thes e

errors.

Limit Event Status and Limit Event Status Enable Regi sters

This pair of registers are implemented for each output as an addition to the IEEE Std.488.2.