Page 1

LDH400P

400W DC Electronic Loads

INSTRUCTION MANUAL

Page 2

Contents

1. Introduction ................................................................................................... 4

2. Specification ................................................................................................. 5

3. Safety ............................................................................................................ 9

4. Installation ...................................................................................................10

4.1 Mains Operating Voltage .................................................................................................. 10

4.2 Mains Lead ....................................................................................................................... 10

4.3 Mounting ........................................................................................................................... 10

4.4 Ventilation ......................................................................................................................... 10

4.5 Fuses ............................................................................................................................... 11

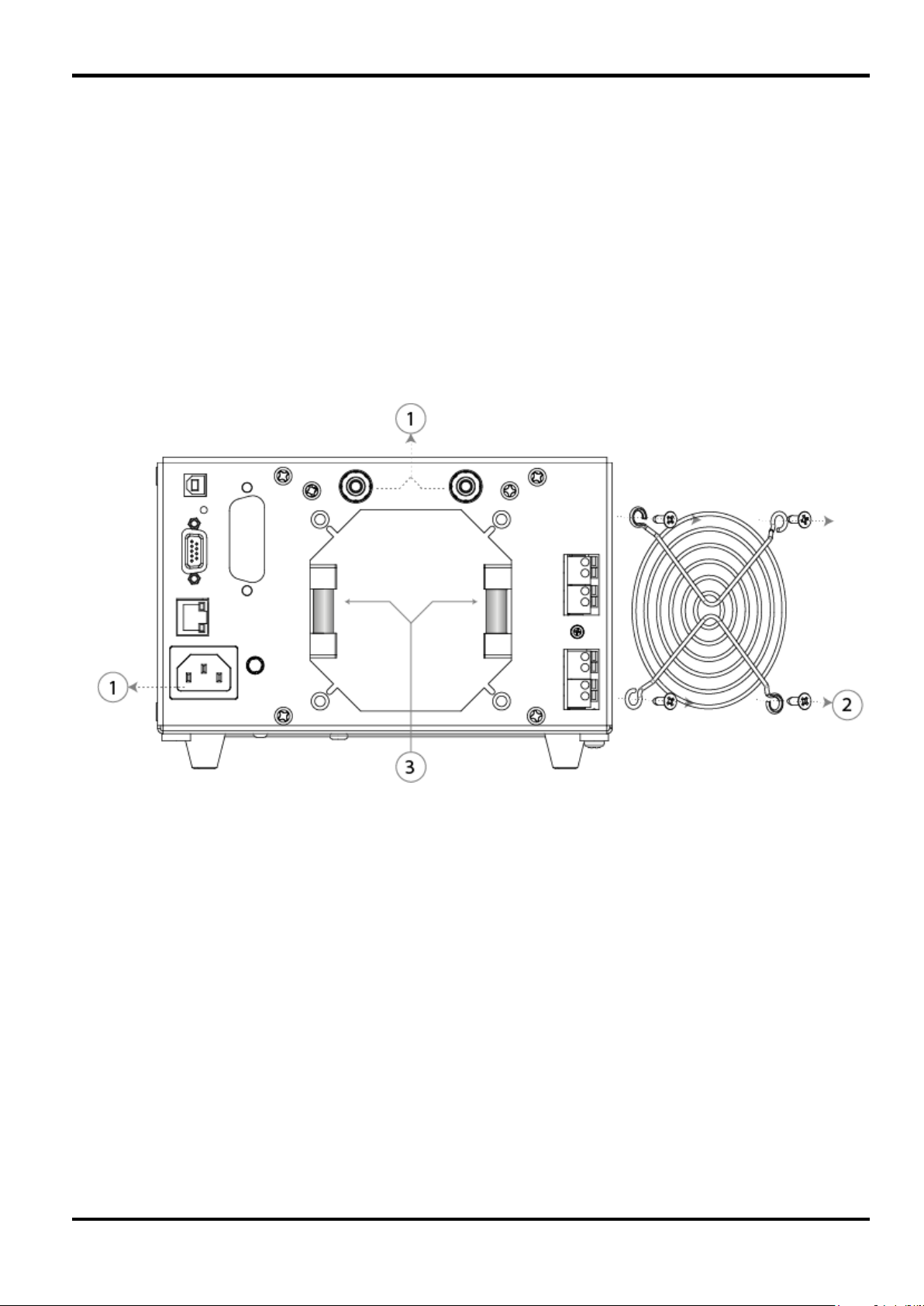

5. Connections ..................................................................................................12

5.1 Front Panel Connections .................................................................................................. 12

5.2 Rear Panel Connections ................................................................................................... 12

5.3 Prospective Fault Current Protection ................................................................................ 13

6. Initial Operation ...........................................................................................14

6.1 Organisation of this manual .............................................................................................. 14

6.2 Load modes ...................................................................................................................... 14

6.3 Constant and Transient Operation .................................................................................... 14

6.4 Dropout voltage ................................................................................................................ 14

6.5 Slow Start ......................................................................................................................... 14

6.6 Voltage and Current Limit Conditions ............................................................................... 15

6.7 Power Limit ....................................................................................................................... 15

6.8 Input Condition Lamps ...................................................................................................... 15

6.9 Fault Conditions ................................................................................................................ 15

6.10 Connecting the Load to the Source .................................................................................. 16

6.11 Switching On .................................................................................................................... 16

7. Front Panel Operation ..................................................................................17

7.1 Keys and ∆ Adjust ............................................................................................................. 17

7.2 The Display and the Home Screen ................................................................................... 18

7.3 General Numeric Entry of Parameters .............................................................................. 20

7.4 Variation of Parameter Values using ∆ Adjust ................................................................... 20

7.5 Configuring the Load ........................................................................................................ 20

7.6 Selection of Load Mode .................................................................................................... 21

7.7 Level A and Level B Setting .............................................................................................. 21

7.8 Dropout Voltage ................................................................................................................ 21

7.9 Slow Start ......................................................................................................................... 22

7.10 Introduction to Transient Operation .................................................................................. 22

7.11 Transient Menu ................................................................................................................. 22

7.12 Transient Frequency ......................................................................................................... 23

7.13 Transient Duty Cycle ........................................................................................................ 23

7.14 Slew Rate ......................................................................................................................... 23

7.15 Voltage and Current Limits ............................................................................................... 24

7.16 Store and Recall Facilities ................................................................................................ 25

1

Page 3

7.17 Utilities Menu .................................................................................................................... 26

8. Analogue Remote Control ........................................................................... 27

8.1 Remote Voltage Control ................................................................................................... 27

8.2 Remote Level Select ........................................................................................................ 27

9. Application Notes ........................................................................................ 28

9.1 Sources ............................................................................................................................ 28

9.2 Stability of Source and Load Combinations ...................................................................... 29

9.3 Dynamic Behaviour in Transient Operation ...................................................................... 29

9.4 Start-up transients ............................................................................................................ 30

9.5 Characteristics of each Operat ing Mode .......................................................................... 30

9.6 Multiple Unit Operation ..................................................................................................... 32

10. Remote Interface Configuration .................................................................. 33

10.1 GPIB Interface .................................................................................................................. 33

10.2 RS232 Interface ............................................................................................................... 33

10.3 USB Interface and Device Driver Installation .................................................................... 34

10.4 LAN Interface ................................................................................................................... 34

10.5 Interface Locking .............................................................................................................. 36

11. Status Reporting .......................................................................................... 37

11.1 Input State and Input Trip Registers (ISR & ISE and ITR & ITE). ..................................... 37

11.2 Standard Event Status Registers (ESR and ESE) ............................................................ 38

11.3 Execution Error Register (EER) ........................................................................................ 39

11.4 Status Byte Register (STB) and GPIB Service Request Enable Register (SRE) .............. 39

11.5 GPIB Parallel Poll (PRE) .................................................................................................. 40

11.6 Query Error Register - GPI B I EEE Std. 488.2 Error Handling ........................................... 40

11.7 Power on Settings ............................................................................................................ 40

11.8 LDH400P Status Model .................................................................................................... 41

11.9 Register Summary ............................................................................................................ 41

12. Remote Commands ...................................................................................... 42

12.1 Remote and Local Operation ............................................................................................ 42

12.2 Remote Command Handling ............................................................................................ 42

12.3 Remote Command Formats ............................................................................................. 42

12.4 Command Timing ............................................................................................................. 43

12.5 Response Formats ........................................................................................................... 43

12.6 Command List .................................................................................................................. 43

13. Maintenance ................................................................................................ 47

13.1 Cleaning ........................................................................................................................... 47

13.2 Fuses ............................................................................................................................... 47

13.3 Calibration ........................................................................................................................ 47

13.4 Firmware Update .............................................................................................................. 47

13.5 Troubleshooting ................................................................................................................ 47

2

Page 4

Full operating and programming instructions for this instrument can be found in the appropriate

product folder of the accompanying CD-ROM.

This information can also be downloaded from t he suppor t page of the Aim-TTi website,

http://www.aimtti.com/support

.

This manual is 48511-1830 Issue 1

Français

14. Sécurité ........................................................................................................48

Les instructions complètes de fonct ionnement et de programmation de cet instrument se

trouvent dans le dossier approprié du CD-ROM d’accompagnement.

Ces informations sont également t éléchar geables depuis la page de support du site Internet de

Aim-TTi, http://www.aimtti.com/support

.

Numéro du manuel 48511-1830, 1 édition.

Deutsch

15. Sicherheit .....................................................................................................49

Vollständige Betriebs- und Programmieranweisungen für dieses G er ät finden Sie im

entsprechenden Produktordner der beigefügten CD-ROM.

Diese Informationen können auch von der Support-Seite auf der Aim-TTi-Website

heruntergeladen werden, http://www.aimtti.com/support

Italiano

16. Sicurezza ......................................................................................................50

Le istruzioni complete per il funzionamento e la programm azione dello strum ent o sono

incluse nella relativa cartella del prodotto del CD-ROM fornito.

È anche possibile scaricare queste informazioni dalla pagina dell’assistenza del sito Web

Aim-TTi, http://www.aimtti.com/support

Questomanuale è la versione 48511-1830 revisione 1.

Español

17. Seguridad .....................................................................................................51

Las instrucciones completas de funcionamiento y prog r am ación de este instrumento

pueden encontrarse en la carpeta del producto correspondiente en el CD-ROM adjunto.

También es posible descargar esta información desde la página de asistencia de la web

de Aim-TTi, http://www.aimtti.com/support

.

Este manual es el 48511-1830 versión 1.

3

Page 5

1. Introduction

This DC electronic load is for use in investig at ing the behaviour of many different types of high

voltage DC power sources such as PFCs, batteries, solar cells, fuel cells or wind generators, as

well as electronic power supply units.

The load inputs are rated to CAT II (300V). This allows for PFCs and mains connected power

supplies to be directly tested using the electronic load without t he need for an isolation

transformer.

The unit provides four different operating modes: constant current, constant power, constant

resistance and constant conductance.

It operates over the voltage range 10 to 500 Volts and the current range 0 to 16 Amps with a

continuous power dissipation capability of up to 400 Watts.

A low voltage dropout facility is provided to protect sources such as bat t eries from damaging

levels of discharge by reducing the load current when the source voltage falls below the dropout

threshold setting.

An internal transient generator can r epeat edly switch the load between two different oper at ing

levels, level A and level B. The frequency and duty cycle of the transients can be set over a wide

range. The transients can also be initiated by an external logic signal. The transitions between

the levels have a true linear slewing characteristic in all modes, with the slew-rate being

adjustable over a wide range.

The unit meters and displays measured values of Volts & Amps and equivalent Watts & Ohms. A

monitor output providing a voltage proportional to the cur r ent flowing allows the behaviour of a

source to be viewed on an oscilloscope or external meter.

All adjustable system parameters can be set via numeric keyboard entry or via the dig ital rem ot e

interfaces for quick and convenient instrument control.

Up to 30 non-volatile storage locations can be used to store and recall instrument parameter set

ups, ideal for test and calibration procedures.

4

An external control voltage can also be used to set the level of the load. Any desired waveform

can be applied, with the internal slew rate control circuit remaining active to provide additional

control.

The unit is fully protected against excessive current , power dissipation or internal t em per ature,

and minimises audible noise by automatically controlling the fan speed according t o t he power

dissipation.

Page 6

Current:

16 Amps max. through the front and rear panel terminals.

Voltage:

500 Volts max. while conducting current.

Power:

400 Watts max. up to 28ºC, derating t o 360 watts at 40º C.

Minimum Operating Voltage:

10V.

resistance:

1180kΩ to load negative).

Reverse Polarity:

Body diode will conduct; 16 Amps max.

Isolation Voltage:

CAT II (300V) either load input to chassis ground.

Rear Panel Input:

Safety terminals accepting 4mm plugs at 16 Amps max.

Front Panel Input:

Safety terminals accepting 4mm plugs at 16 Amps max.

Current Range:

0 to 16 A (1 mA resolution).

Setting Accuracy:

± 0·2% ± 30 mA.

Regulation:

< 30 mA for 90% load power change (V > 25 Volts).

Temperature Coefficient:

< (±0·02% ± 5 mA) per ºC.

Slew Rate Range:

5 Amp per s to 500 Amp per ms.

Minimum transition time:

50 µs.

Power Range:

0 to 400 Watts (100 mW resolution).

Setting Accuracy:

± 0·5% ± 2 W ± 30 mA (V > 25 Volts).

Regulation:

< 2% over 25 V to 550 V source voltage change.

Temperature Coefficient:

< (± 0·1% ± 5 mA) per ºC.

Slew Rate Range:

60 W per s t o 6000 W per ms.

Minimum transition time:

150 µs.

Resistance Range:

50 Ω to 10 kΩ (1 Ω resolution).

Setting Accuracy:

±0·5% ± 2 digits ± 30 mA (V > 25 Volts).

Regulation:

< 2% for 90% load power change (V > 25 Volts).

Temperature Coefficient:

< (±0·04% ± 5 mA) per ºC.

Slew Rate Range:

1 Ω per ms to 100 Ω per µs.

Minimum transition time:

150 µs.

2. Specification

Accuracy specifications apply for 18°C – 28ºC, using the rear panel terminals, after 30 minutes

operation at the set conditions. Setting ac cur ac ies apply with slew rate at the ‘Default ’ setting.

INPUT

Maximum Input Ratings

Minimum effective

Off State Leakage:

Input Terminals

OPERATING MODES

Constant Current Mode (CC)

(1)

(2)

1Ω .

<5 mA (including voltage sense circuit input resistance - typically

Constant Power Mode (CP)

(1)

(2)

Constant Resistance Mode (CR)

(1)

(2)

5

Page 7

Conductance Range:

0·001 to 1 A/V (1 mA/V resolution)

Setting Accuracy:

± 0·5% ± 2 digits ± 30 mA (V > 25 Volts).

Regulation:

< 2% for 90% load power change (V > 25 Volts).

Temperature Coefficient:

< (±0·04% ± 5 mA) per ºC.

Slew Rate Range:

0·1 A/V per s to 10 A/V per ms.

Minimum transition time:

150 µs.

Pulse Repetition Rate:

Adjustable from 0·01Hz (100 seconds) to 10k Hz.

Pulse Duty Cycle:

1% to 99% (percentage of period at Level A).

Setting Accuracy:

±1 %

Setting Accuracy:

± 10% (on linear part of slope, excluding high frequency aberrations).

Variation in Level Settings:

± 5 digits of specified setting resolution for present mode and range.

internal transient generator.

Isolation:

CATII (300V) to load negative.

Setting Accuracy:

± 2% ± 200mV.

Volts & Amps:

Measured values of current through and voltage across t he load.

Watt & Ohms:

Power and equivalent load resistance, calculated from Volts and Amps.

Volt age Accuracy:

± 0·1% ± 0.02%FS.

Current Accuracy:

± 0·2% ± 0.04%FS.

Constant Conductance Mode (CG)

(1)

(2)

TRANSIENT CONTROL

Transient Generator

Slew Rate Control

The slew rate control applies to all changes of level whether caused by manual selection, remote

control or the transient gener at or.

The level change is a linear slew between the two level settings. The range available in each

mode is shown above.

Oscillator Sync Output

Connection: Terminal block on rear panel. Lo terminal output grounded to chassis

DROPOUT VOLTAGE

The load will cease to conduct if the applied voltage falls below the Dropout Voltage setting;

active in all modes. The Dropout Voltage setting is also the t hr es hold for the Slow Start facility

and acts as an offset voltage in Constant Resistance mode.

Slow Start

If Slow Start is enabled, the load will not conduct any current until the source voltage reaches the

Dropout Voltage setting; it will then ramp the controlled variable up (in CC, CP and CG modes) or

down (in CR mode) to the Level setting at a rate determined by the Slew Rate setting .

METER SPECIFICATIONS

Display Ty pe: 256 x112 pixel graphic LCD with white LED backlight.

internally. TTL/CMOS (5V) output. High during Level B phase of

Measured Values

6

Page 8

Output Terminals:

BNC (chassis ground) on front panel or ter minal block on rear panel.

Output Impedance:

600Ω nominal, for >1MΩ load (e.g. oscilloscope).

Scaling:

250mV per Amp (4 Volts full scale).

Accuracy:

± 0·5% ± 5mV.

Isolation:

CATII (300V) to load negative.

Bandwidth limit (-3dB):

40kHz.

1.4 LXI Core 2011 compliant.

USB:

Standard USB 2.0 connection. Operates as virtual COM port.

Capabilities: SH1, AH1, T6, L4, SR1, RL2, PP1, DC1, DT0, C0, E2.

RS232:

Standard 9-pin D connection. Baud rate: 9600.

internally.

Input Impedance:

10kΩ. Input prot ect ed against excess input voltages up to 50V.

Isolation:

CATII (300V) to load negative.

Operating Mode:

The applied voltage sets the operating level within the range.

Scaling:

4 Volts full scale (250mV per Amp).

Accuracy:

± 2% ± accuracy of range.

Common mode rejection:

Typically better than –76dB.

Operating Mode:

The applied signal selects between Level A and Level B settings.

Threshold:

+ 1·5V nominal. A logic high selects Level B.

Input to the LED of an opto-isolator t hr ough 1kΩ resistor.

Threshold:

Apply >+3V to disable the load input. Max. Voltage 12V.

CURRENT MONITOR OUTPUT

REMOTE CONTROL

Digital Remote Interfaces

The unit provides LAN, USB, GPIB and RS232 interfaces for full remote control.

LAN:

GPIB: Conforming to IEEE488.1 and IEEE488.2.

Ethernet 100/10base-T connection with auto cross-over detection.

External Control Input Characteristics

Connection: Terminal block on rear panel. Lo terminal input grounded to chassis

External Analogue Voltage Control

External Logic Level (TTL) Control

Remote Disable Input

Connection: Terminal block on rear panel.

7

Page 9

will trip into the fault state at 460 Watts.

Protection Current:

The input is disabled if the measured current exceeds a user set limit.

a protection against high power sources

reverse polarity.

Protection Voltage:

The input is disabled if the measured voltage exceeds a user set limit.

suppressors will start to conduct at typically 800V ± 20%.

safe levels.

currents that exceed 20A.

AC Input:

110V–120V or 220V–240V AC ±10%, 50/60Hz. Installation Categor y II.

Power Consumption:

40VA max. Mains lead rating: 6A minimum.

Operating Range:

+ 5ºC to + 40ºC, 20% to 80% RH.

Storage Range:

– 40ºC to + 70ºC.

Environmental:

Indoor use at altitudes up to 2000m, Pollution Degr ee 2.

Cooling:

Variable speed fan. Air exit at rear.

Safety:

Complies with EN61010-1.

EMC:

Complies with EN61326.

Size:

130mm H (3U) x 212mm W (½ rack) x 435mm D.

Weight:

5.7 kg.

Option:

19-inch rack mount kit.

PROTECTION

Excess Power: The unit will attempt to limit the power to 430 Watts; if this fails the unit

Excess Current: The unit will trip into the fault state at nominally 20 Amps.

Excess Voltage: The unit will conduct a current pulse (to absor b induct ively generated

Temperature: The unit will trip into the fault state if t he Mosfet temperature exceeds

Reverse Polarity: The unit will trip into the f ault stat e if a reverse current is drawn that

The unit is protected by fuses that pr ot ect the unit against currents that

exceed 20A. This is primarily as

with a current capability of >20A being connected to the load with

spikes) for 1ms at about 510V.

The unit will trip into the fault state at nominally 530V. Surge

exceeds 200mA. The unit is protected fuses that protect the unit against

GENERAL

Specification Notes

(1)

Slew Rate Ranges refer to the theoretical slope of the transition between two levels,

regardless of whether that t r ansit ion can be achieved when taking into account the level

difference, the set transition dur at ion, t he minimum transition time, and the characteristics of the

source.

(2)

Minimum Transition Time specification is an indication of the f ast es t available transition using

a benign source and low inductance connections, with a minimum terminal voltage of 25V and a

minimum current of 200m A. The actual performance attainable with electronically regulated

power supplies depends on the combination of source and load loop bandwidths and

interconnection inductance.

8

Page 10

instrument.

l

3. Safety

This instrument is Safety Class I accor ding to IEC classification and has been designed to meet

the requirements of EN61010−1 (Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use). It is an Ins tallation Category II instrument intended

for operation from a nor m al single phase supply.

This instrument has been tested in accordanc e with EN61010−1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to r etain the inst r ument in a safe condition.

This instrument has been designed f or indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% −80% RH (non−condensing). It may occasionally be

subjected to temperatures bet ween +5° and −10°C without degradation of its safety. Do not

operate while condensation is present.

It has been designed for CAT II (Measurement and Overvoltage Category II) use to 300Vrms.

CAT II is local domestic supply level, e.g. portable equipment and appliances.

For this equipment 2500V is the maximum peak t r ans ient overvoltage that can be tolerated by

any load input terminal with respect to earth gr ound without impairing s afety.

Use of this instrument in a manner not spec ified by these instructions may impair the safety

protection provided.

Do not operate the instrument outside its rated supply voltages or environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conduct or inside or outside t he inst r um ent will make the

instrument dangerous. Int ent ional inter ruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, m aint enance or r epair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be

avoided as far as possible and, if inevitable, shall be carried out only by a skilled person who is

aware of the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive

moisture or chemical corrosion the safety protection may be impaired and the apparatus should

be withdrawn from use and returned for checking and repair.

The instrument contains both encapsulated fuses and non-resetting thermal fuses; t hese ar e not

replaceable by the user. The short-circuiting of these protective devices is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this m anual:−

Caution Refer to t he accompanying

Alternating Current.

Mains supply OFF.

9

documentation, incorrect

operation may damage the

CAT II

Measurement and Overvoltage

Category II (300V)

Chassis ground.

Mains supply ON.

Page 11

4. Installation

4.1 Mains Operating Voltage

The operating voltage of the instrument is shown on the rear panel. Should it be necessary to

change the operating voltage from 230V to 115V or vice-versa, proceed as f ollows:

1. Disconnect the instrument fr om all voltage sources , including the mains and all inputs.

2. Remove the screws which hold the case upper to the chassis and lift off.

3. Unplug all cable connectors from t he power supply PCB (don’t pull on the wires).

4. Remove the five nuts which hold the power supply PCB in place, and lift it off the studs.

5. Fit the soldered links (alongside the transformers) for t he required operating voltage:-

For 230V fit only LK2 and LK5

For 115V fit only LK1, LK3, LK4 and LK6.

These links may be either tinned copper wire or zero-ohm resist or s.

6. Refit the power supply PCB, ensuring that no wires are t rapped. Check that all cables are

correctly connected and that all five nuts are suff icient ly tightened.

7. Refit the case upper.

8. To comply with safety standard requirements the operating voltage marked on t he r ear

panel must be changed to clearly show the new voltage setting.

4.2 Mains Lead

Connect the instrument to the AC supply using the mains lead provided. Should a mains plug be

required for a differ ent t ype of mains outlet socket, use a suitably rated and approved 3-core

mains lead set which is fitted with the required wall plug and an IEC60320 C13 connector f or the

instrument end. This instrument req uires a lead rated at 6A for all mains supply voltages.

Any interruption of the mains earth conduct or inside or outside t he inst r um ent will make the

instrument dangerous. Int ent ional inter ruption is prohibited.

4.3 Mounting

This instrument is suitable both for bench us e and r ack mounting. It is delivered with feet for

bench mounting. The front feet include a tilt mechanism for optimal panel angle.

A rack kit for mounting one or two of these half-width 3U high units is available from the

Manufacturers or their overseas agents; a blanking piece is also available for unused positions in

the rack.

4.4 Ventilation

The unit is cooled by a variable speed fan which vents at the rear. Take car e not t o restrict the air

inlets at the top, side and bottom panels or the exit at the rear. In rack-mounted s it uat ions allow

adequate space around the instrument and/or use a fan tray for forced cooling. If ducting is

applied to the air outlet, additional extraction is required.

WARNING! THIS INSTRUMENT MUST BE EARTHED

10

Page 12

4.5 Fuses

4.5.1 Current Range Fuses

The unit is protected by two 10A fuses that protect the unit against currents t hat exceed 20A.

This is primarily as a protection against high power sources with a current capability of >20A

being connected to the load with reverse polarity.

The replacement fuse must be a 10x38mm 10A 1kVdc rated HRC fuse. To replace a fuse:

1. Disconnect the instrument from all voltage sources.

2. Remove the screws retaining the fan guard.

3. Replace the fuse with one of identical specification and size.

4. Refit the fan guard securely.

4.5.2 Inte r nal AC Power Fuse

The AC supply transformers on the PSU PCB is protected against an internal fault by a nonresettable thermal fuse. To avoid the thermal fuse being accidentally tripped by connecting to a

230V supply when the instrument set for 115V operation, a standard 500mA (T) 250V fuse is

fitted in position FS6 on the PSU PCB. Should this fus e need r eplacing , following such an event,

remove the case upper and replace the fuse following the instructions of ‘Mains Operating

Voltage’ section 4.1.

11

Page 13

5. Connections

5.1 Front Panel Connec tions

5.1.1 Load Input

The INPUT terminals for t he load cir cuit on t he front panel accept 4mm plugs. Their maximum

current rating is 16 Amps.

Do not use both the front panel and rear panel terminals simultaneously.

The wiring and connection arrangement mus t be capable of s uppor t ing the current required.

The load circuit is isolated from g r ound, with a rat ing of CATII (300V), but it is essential to

observe safe insulation practice.

Ensure that the source is connected with the correct polarity.

The maximum current throug h t hes e t er m inals is 16 Amps.

The maximum voltage allowed across the load is 500 Volts.

The unit contains a fuse in the load circuit, see section 4.5.

5.1.2 Current Monitor Output

The Current Monitor terminals provide a voltage proportional to the load current flowing with a

scaling factor of 250 mV per Amp (4 Volts for 16 Amps full scale). The output impedance is

nominally 600Ω and the calibration assumes a high impedance load such as an oscilloscope.

The current monitor circuit is referenced to chassis ground, as such is isolated from

the load circuit with a rating of CATII (300V).

5.2 Rear Panel Connections

5.2.1 Load Input

The INPUT terminals for the load circuit on the r ear panel accept 4mm plugs. Their maximum

current rating is 16 Amps.

Do not use both the front panel and rear panel terminals simultaneously.

The wiring and connection arrangement mus t be capable of s uppor t ing the current required.

The load circuit is isolated from g r ound, with a rat ing of CATII (300V), but it is essent ial t o

observe safe insulation practice.

Ensure that the source is connected with the correct polarity.

The maximum current throug h t hes e t er m inals is 16 Amps.

The maximum voltage allowed across the load is 500 Volts.

The unit contains a fuse in the load circuit, see section 4.5.

5.2.2 Terminal Blocks

All other rear panel connections are made via the screw-less terminal blocks. To make

connections to the terminal blocks, use a flat screwdriver to press the spring-loaded orang e

actuator inwards to open the wire clamp; insert the wire end f ully into the hole and release t he

actuator. Ensure the wire is properly gripped. Take care to observe the marked polarity.

5.2.2.1 Remote Disable Input

Apply greater than +3V (preferably +5V) to the DISABLE INPUT terminals to disable t he load

input; these are the input to an opto-coupler, through 1kΩ, and are galvanically isolated from all

other terminals. The input current is less than 2· 5m A at 5V.

The maximum input voltage is +12Vdc. Avoid reverse polarity.

12

Page 14

protected against excess input voltages up to 50V.

5.2.2.2 Oscillator Sync Output

The SYNC OUTPUT is a TTL/CMOS (5V) output driven by the signal from the internal oscillator ;

this output is chassis ground ref er enc ed. There is a 1kΩ series protection resistor.

5.2.2.3 Remote Control Voltage Input

The CONTROL VOLTAGE terminals are used in two operating modes of the instrument:

In EXTERNAL VOLTAGE mode an analogue signal applied here sets the level of the load; the

scaling is 4 Volts full scale.

In EXTERNAL TTL mode, a logic signal applied here selects either the LEVEL A setting (logic

low) or the LEVEL B setting (logic high). The switching threshold is nominally +1·5V.

These terminals are refer enced to chassis ground. Input impedance 10kΩ. Inputs are

5.2.2.4 Current Monitor Output

The top pair of terminals, mar ked CURRENT MONITOR, provide the current monitor output.

They are wired in parallel with the front panel Current Monitor BNC and the same requirements

apply.

5.2.3 Digital Remote Control Connections

The LDH400P model provides full remote control capabilities through standard LAN, USB, GPIB

and RS232 interfaces. All of these are isolated from the load input term inals of the unit. The USB,

GPIB and RS232 interfaces are connect ed t o c hassis ground, and care must be taken to avoid

introducing ground loops. The LAN interface is isolated by standard network t r ans formers.

Full details are given in the ‘Remote Interface Configuration’ section 10.

5.3 Prospective Fault C urrent Protection

This unit is not intended to act as an overcurrent fault protection device for the source being

tested. However the instrument does contain two 10A, 1000V, HRC fuses that prot ect the unit

against currents that exceed 20A. This is primarily as a protection against high power sources

with a current capability of >20A being connected to the load with reverse polarity, but will also

provide protection against any other prospective fault c ur r ent >20A.

13

Page 15

6. Initial Operation

This instrument provides a controllable DC load (a power sink) intended for testing all forms of

DC power supply including PFCs, batteries, photo-voltaic cells , fuel cells, turbines and generators

as well as electronic power supply units.

6.1 Organisation of this manual

The paragraphs below are intended to briefly introduce the particular features of this instrument

and the terminology used in this manual. More technical details are given in later chapter s of the

manual.

The next chapter describes the gener al oper at ion of the front panel and its display, followed by

full instructions for setting each parameter. A short chapter then describes the Analogue Remote

Control facilities, including level selection by a logic level signal.

Following that there is a chapter giving som e application not es and implementation details, which

gives more information on some practical difficulties which may occasionally be encountered in

each operating mode, together with some advice on mitigating strategies.

Finally the digital remote control interfaces and comm and s et of the LDH400P.

6.2 Load modes

The power dissipating stage in this load is fundam entally an adjustable current s ink, which

conducts a current that does not depend on the voltage presently applied from the source being

investigated. This is known as Constant Current operation.

An analogue multiplier is used to offer other oper at ing modes in which the current does depend

on the applied voltage in a known way, providing a choice of Constant Power, Constant

Resistance, or Constant Conductance characteristics.

6.3 Constant and Transient Operation

The load offers two independent level settings, referred to as Level A and Level B. Two keys

marked A and B in the

active.

Transient changes in the magnitude of the load are generated by switching between the two

levels. The transition between the two is a straight line at a slew rate that is specified by the user.

The switching between the two levels can be controlled either by an internal transient oscillator,

which has adjustable frequency and duty cycle, or an external logic (TTL level) signal.

There is no restriction on which of the two levels is the larger.

LEVEL SELECT area of the front panel allow the choice of which level is

6.4 Dropout voltage

The primary purpose of the dropout facility is to protect batteries from being excessively

discharged. When the source voltage falls below the Dropout threshold voltage setting, the load

will reduce the current it draws, eventually to zero. This is a dynamic limit, not a latched state, so

if the source voltage recovers above the threshold (as batt eries often do) then the load will

conduct current again.

6.5 Slow Start

The slow start facility causes the current taken by the load to r ise gently, at the rate

determined by the slew rate setting, when the load is enabled or when the source

voltage rises above the Dropout Voltage threshold setting. It also causes the current to

fall at the same rate when the load input is disabled. This facility is particularly useful in

Constant Power mode, to avoid a latch-up condition when the source is started; see the

‘Application Notes’ section 9.

14

Page 16

6.6 Voltage and Current Limit Conditions

The unit has provision for the user to specify limits on the permitted measured value of voltage or

current. If either of these limits is exceeded then the input will be disabled.

6.7 Power Lim it

The unit continuously monitors the internal power dissipation and varies the speed of the fan

accordingly. If the dissipation rises above about 430 Watts, a hardware power limit circuit will

come into operation and attempt to constrain the load current to control the dissipation. The unit

is then operating in a non-linear mode, which will change the stability conditions. If the power limit

circuit fails to prevent the power rising above a slightly higher fault threshold ( per haps because of

instability) then the fault detector will be tripped and the load will cease to conduct.

6.8 Input Condition Lamps

Two lamps above the Input Enable switch indicate the operating stat e of the unit. They are both

off when the input is disabled. The green lamp lights when the input is enabled, and if t he load is

operating normally then the yellow lamp will not be lit.

The yellow lamps lights if the load cannot conduct the required current, with a message on the

status line at the top right of the display distinguishing between the three possible reasons:

• Power Limit: the power limit circuit is operating as described above.

• Dropout: the voltage applied from t he sour c e is below the sett ing of the Dropout voltage.

• Low Voltage: the power stage is in the minimum resistance condition, because the

voltage available from the source is insufficient to maintain the curr ent level req uir ed.

The minimum resistance condition will occur either if t he sour c e is switched off and is not

providing any voltage at all, or if the voltage drop across the connection leads is causing the

actual input voltage at the load to be below its minimum operating level. Note that if the source

voltage is suddenly applied while the load circuit is in this state, then a current t ransient will

probably occur.

If only the yellow lamp is lit, with the green lamp off, then a persistent fault condition exists.

6.9 Fault Conditions

The unit detects (in hardware) the following fault conditions:

• Current above about 20 Amps.

• Power in excess of about 450 Watts (that the power limit circuit has not succeeded in

controlling to the lower threshold as described above).

• Voltage above about 530 Volts.

• Reverse Polarity (current exceeding 200mA) .

• Excessive heatsink temperat ur e.

• Fan failure.

The fault detectors for excess current, power and voltage have filter networks with a

time-constant of a few milliseconds to allow brief transients to be handled.

When any of thes e fault conditions occurs, the input is disabled, so the unit will cease to conduct

current and a fault messag e will be displayed. An excessive current or power condition will

disappear as soon as the input is disabled, but any of the other c onditions will cause t he yellow

lamp only to remain lit, and the message Fault to show on the status line, until it is cleared.

15

Page 17

6.10 Connecting the Loa d to the Source

The INPUT terminals of the load must be connect ed t o t he s our ce to be tested using sufficiently

low resistance and low inductance connections. Inductance in the interconnection can have a

significant adverse impact on the stability of the source and load com binat ion. The wiring should

be as short and as thick as possible. It is es sent ial t hat t he voltage dr op acr os s t he c onnec ting

leads is sufficiently less than the source voltage to leave enough working voltage across the load.

The load input terminals of t he inst rument are floating from ground, and are rated to CATII 300V.

Connection to an AC mains circuit, primary side DC or non isolated bridge rectifier is permitted on

the negative input terminal with a voltage limit o f 500Vdc between the positive input terminal and

the negative input terminal.

Reverse polarity of the inputs is not permitted.

The maximum permissible voltage between the negative input terminal and earth ground

425V (peak of CAT II 300V).

Ensure that all wiring is safely insulated for the working voltage involved.

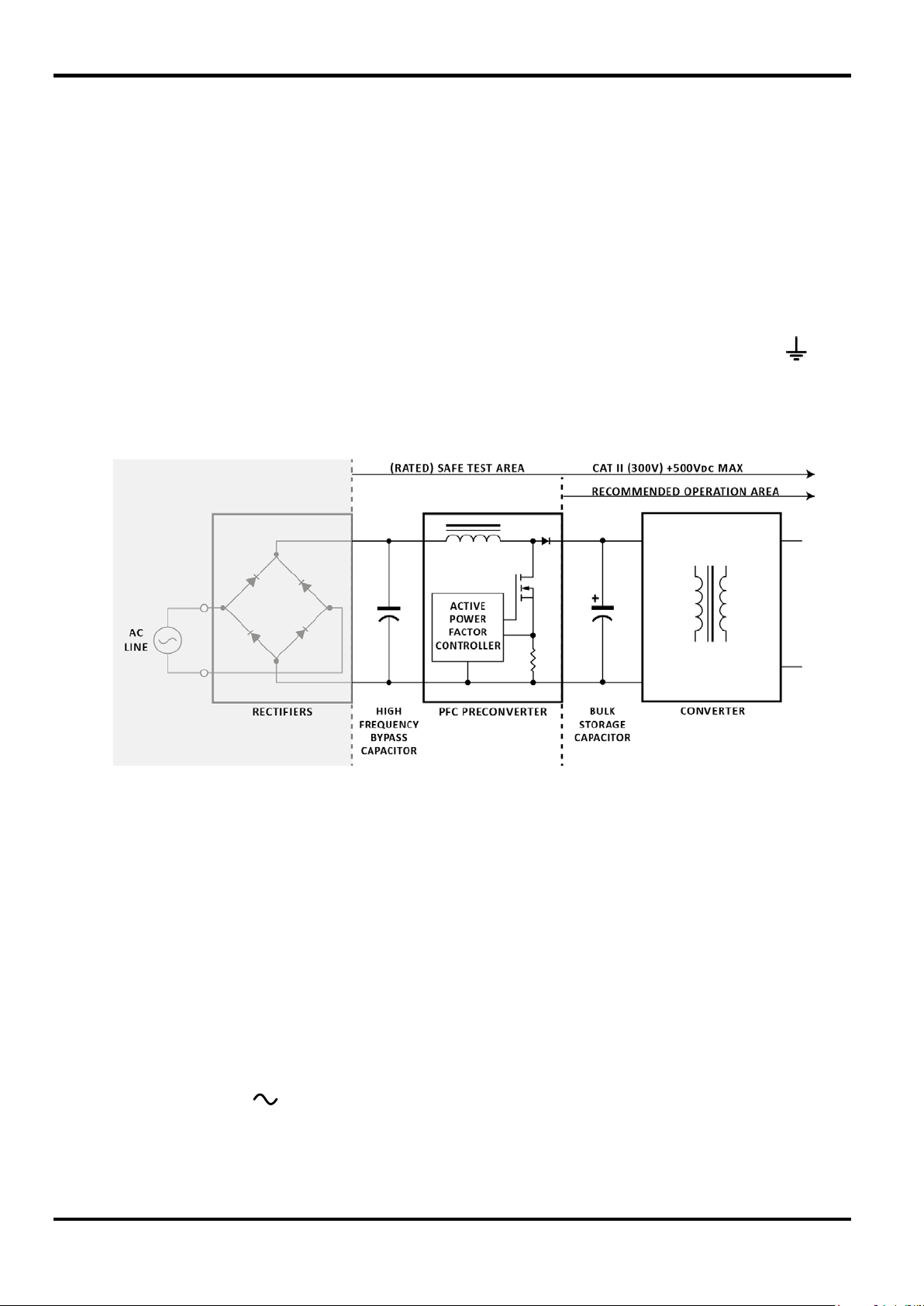

PFC safe test and operation area diagram

is

6.10.1 Prospective Fault Current

The instrument detects any fault condit ion and r esponds by disabling t he load by turning off the

power devices. As a last resort there ar e internal fuses in the load circuit, so that if the external

source applies a condition so far beyond the current rating of the unit, the f us es will protect the

instrument against dangerously high currents.

6.10.2 Remote Input Disable

This input is provided for remote override of the INPUT ENABLE function of t he load, poss ibly for

safety reasons. It is available in all operating modes of the instrument. It is a fully floating input to

an opto-isolator: apply 3 to 12 volts (observing polarity) to disable the load. The load is only

enabled if this signal is absent and the input has been enabled with the front panel controls.

6.11 Switching On

The line POWER ( ) switch is at the bottom left of the front panel. Before switching on ( l ),

check that the line operating voltage of the unit (marked on the rear panel) is suitable for the local

supply. After switching the power on (

information. Avoid turning off the power until the instrument is fully initialised and the home

screen is displayed.

16

l ) the LCD should light and display firmware version

Page 18

7. Front Panel Operation

In this manual, front panel labels are shown as they appear, in capitals, e.g. LEVEL SELECT.

Individual key names are shown in bold, e.g.

their present function, as labelled on the bottom line of the display, shown in bold italics, e.g.

Limits. Text or messages displayed on the LCD are shown in bold, e.g

Transient, and the blue soft-keys are referred to by

. Enabled, Utilities.

7.1 Keys and ∆ Adjust

The front panel keys are divided into four areas:

① The numeric keys.

② The blue keys below the display - Used to configure the instrument t hrough the menu

structure described in section 7.2.4.

③ The

selection and returns to the home scr een. The

request from digital remote control.

④ The three

settings is active, or engage t he transient mode which switches between them. The associated

lamps indicate the presently active state; these keys are also used to retur n from external

analogue control to manual selection.

⑤ The

choose and modify the existing value of any one of t he num eric parameters of the instrument.

⑥ The

load, with alternate presses switching between the conducting and non-conducting conditions.

The green lamp shows if the input is enabled; t he yellow lamp reports if t he power stag e is

saturated, as described in the paragraph ‘Input Condition Lamps’ in the ‘Initial Operation’ section

6.8.

CE key - Cancels the last numeric keystroke while the Home key cancels an entire menu

LEVEL SELECT keys (A, B and Transient) - Determine which of the two level

∆ ADJUST k nob and its three associated keys (Levels, Off and Transient) - Used to

ENABLE key in the INPUT section (referred to as the INPUT ENABLE key) - Controls the

Home key is also used for the ‘return to local’

17

Page 19

7.2 The Display and the Home Screen

All parameter settings and meter readings are shown on the backlit liquid crystal display (LCD).

At power up the instrument initialises to the home scr een, which is the nor mal display during

operation of the unit. This screen displays all of t he load m et er readings and the most important

load parameter settings as described below, and is also the top level of the soft-key driven menu

structure. The display changes to show other sc r eens as select ions ar e m ade to enter parameter

values and then returns to the home screen when entry is complete.

7.2.1 [A] Status Line

The status line of the instrument is visible along the top of the display at all times except when

one of the store, recall or ut ilities menus is being shown. It indicates the current status of the

instrument as follows (in order, from left to rig ht across the display):

• The load mode field indicates the present load mode – CC, CP, CR, or CG.

• Slow is displayed when slow start operation has been enabled.

• Slew is displayed as a warning when the present slew rate setting is too slow with

regards to the level difference, tr ansient frequency and duty cycle, see ‘Slew Rate’ section

7.14.

• Lim is displayed when either of the user defined current or voltage limits is enabled.

• The level select field (in the centre) indicates which input level or control method is

currently selected – Level A, Level B, Transient, Ext V or Ext TTL.

• The LAN field indicates the status of the Local Area Network (if fitted) . When there is no

LAN connection the field displays

indicator will flash between

See the ‘Remote Interface Configuration’ chapter for more infor m ation.

• The input status field (at t he right hand end) indicates the instrument’s present load input

condition – Disabled, Enabled, Low Voltage, Dropout, Power Limit or Fault, as

described in the paragraph on ‘Input Condition Lamps’ section 6.8.

7.2.2 [B] Home Screen Data

Below the status line are the meter displays which show the actual measured source voltage and,

once the load is enabled, the load current.

7.2.3 [C] S ettings Data

The screen is divided into three areas. On the left , under the heading METERS, the display

shows the present power in the load and the equivalent resistance; these values are comput ed

from the measured voltage and current readings. Any of these meter displays will show

MAX for power) if the measur ed value is beyond the capabilities of the unit.

In the centre, under the heading

Level B (the units depend on the operating mode) and the Dropout Voltage setting.

On the right, under the heading

and Duty cycle of the internal oscillator, and the Slew Rate of the transit ions.

. While a connect ion is being established the

and , and then while connected the field will show .

HIGH (or

LEVELS, the display shows the present settings for Level A and

TRANSIENT, the display shows the settings for the Frequency

18

All six of these parameters can be m odified either by direct numeric entry or by using the k nob to

increment or decrement the present value.

Page 20

Mode

To select the operating mode.

Limits

To impose cut-off limits on the applied voltage or current values.

Level

To enter numeric values for Level A and Level B.

Dropout

To enter a numeric value for the Dropout Voltage.

Transient

To access a second level to set-up the transient functionality.

Store & Recall

To setup, review and use saved settings of the unit.

‘Analogue Remote Control’.

parameters of the remote int er faces.

Freq

To enter a numeric value for the Frequency of the internal oscillator.

Duty

To enter a numeric value for the Duty cycle of the internal oscillator.

Slew

To enter a numeric value for the S lew Rate of the transitions.

Slow

To enable or disable the Slow start and stop facility.

7.2.4 [D] Soft-Keys

The soft-keys are the six blue keys found dir ectly below the LCD. The function of each of these

keys changes as the instrument is operated. The available function is shown on the bottom line

of the display in a tab above each key. If any of the keys have no functionality in a particular

menu then the tab is lowered to show it is inactive.

On the home screen there are two sets of soft-key functions available; the right hand key,

alternately labelled More > or More < switches between the two. All additional menus are

accessed through the soft-keys in one of these sets.

The major parameters accessible in the first set are:

The second set includes:

Extern

Utilities

The Transient second level menu (when selected from the first set above) includes:

On most of the lower level menus, the left hand key, labelled Back or Cancel, can be used to

return to the previous menu. This allows exploration of the various menus without risk of putting

the unit into unexpected configurations. Back returns to the previous menu, keeping any

changes that have been made in the current menu, while Cancel (if offered) will undo any

change made before reverting t o t he pr evious menu. The

screen and the top level of the menu structure (also abandoning any incomplete value entry).

To enable or disable analogue remote control of the level, or logic (TTL)

level selection between the two levels, as described in the chapter on

To configure some secondary facilities of t he inst rument and to set

Home key reverts directly to the home

19

Page 21

7.3 General Numeric Entry of Parameters

All user modifiable load parameters can be set using the numeric keypad. The desired parameter

is first selected from the menu using the soft-keys. The display then changes t o show the

parameter entry screen which indicates the name of t he paramet er, its present value prior to

editing, and in most cases the entry limits and resolution. A message prompting for the entry of

the new value is shown. When any number k ey is pressed this prompt is removed and replaced

by the new value being constructed, and the soft-key labels change to show a list of units

applicable to the parameter being edited. The

the entire entry may be cancelled by pressing either the

Once the number entry is complete it must be terminated by pressing the required units soft-key

(choosing A or mA, for example). The value is then checked against the parameter lim its and, if it

falls within the allowed range, it is accepted and immediately implemented as the new value for

that parameter. If the value does not fall within the permitted range t hen an error message is

displayed and the buzzer will sound. If applicable the entry may be rounded to fit within the

specified parameter resolution.

Paragraphs below describe particular features associat ed with each parameter.

CE key deletes individual keystrokes; alternatively

Home key or the Cancel soft-key.

7.4 Variation of Parameter Values using ∆ Adjust

The level and transient parameters of t he load can be adjusted by incrementing or decrementing

the present value using either the knob or sof t-keys.

Note: this adjustment mechanism is only available whilst the instrument is on the hom e sc r een.

Two keys above the knob, labelled

and initiate the adjustment. Press ing the

selects Level B and a third press selects the Dropout Voltage setting. The cycle can be repeated

if required. Similarly, multiple presses of the

and Slew Rate. A lamp above each of these keys blinks whilst adjustment is enabled and four

cursor soft-keys are shown.

The display of the selected parameter value is expanded to fill its edit box, with an adjustment

indicator (

which digit position will be adjusted, and then either the knob or the ▲and ▼ soft-keys can be

used to increment or decrement the value at that position. Digits to the left of the one being

varied are automatically incremented or decrem ent ed when the decade overflow or underflow

point is reached. Digits to the right of the one being varied always remain unchanged unless a

point of decade resolution change is reached, in which case digits to t he r ight may be lost

through truncation. If the least significant digit is being increm ented and a decade resolution

change is reached, the new least significant digit becomes the one being adjusted.

Each change made is applied immediately, so long as the value remains within the permitted

limits of that parameter. If an increment or dec r em ent of the current position would exceed a

range limit then the parameter value remains unchanged; partial adj ustments are not made.

Pressing the Off soft-key or the Off key above the k nob ( or the

retaining the new value, and returns the display to the home screen. Pressing the Cancel softkey ends the adjustment and r est ores the last parameter to the value it had when it was selected

for adjustment.

) positioned under the digit to be varied. The ◄ and ► soft-keys can be used to select

Levels and Transient, select the parameter to be modified

Levels key initially selects Level A; a second press

Transient key select between Frequency, Duty Cycle

Home key) ends the adjustment,

7.5 Configuring the Load

The normal sequence of operat ion is t o s elect t he load Mode, set t he required operating Level

and Dropout Voltage, and then Enable the input. If transient operation is required, the second

Level setting and the Slew Rate parameter s m us t be s et , as well as the f r equency and duty cycle

of the internal oscillator if it is t o be us ed.

The home screen shows all the parameter settings , which can be viewed before the input is

enabled. All parameters except load Mode can be adjusted as req uir ed while the input is enabled.

20

Page 22

CC

Constant Current

The current is the Level setting, independent of voltage.

CP

Constant Power

Implements I = W / V where W is the Level setting.

CG

Constant Conductance

Implements I = V * G where G is the Level setting.

and V

dropout

is the Dropout Voltage setting.

Changing the load mode while the input is enabled will trip a fault detector and cause the input to

be disabled before the change is implemented.

7.6 Selection of Load Mode

The first action in conf iguring the unit for a particular application is to choose the load mode,

which determines how the current drawn by the load varies with the applied voltage (V). The

Mode soft-key on the home screen opens a m enu offering the various modes listed in the table

below. More detailed descriptions of the properties of each mode are given in the ‘Application

Notes’ section 9.

Changing the mode requires the load input to be disabled, which will be done automatically if not

already done by the user. The display returns to the home screen as s oon as a m ode is s elect ed.

The available operating modes are:

Constant Resistance

CR

Implements I = (V – V

7.7 Level A and Level B Sett ing

Pressing the Level soft-key on the home screen initially opens the level setting prompt for either

Level A or Level B, depending on which was altered last. The right hand soft-keys, labelled

A SET and B SET, can be used to switch the prompt to the other level. If the level being edited is

not currently active in controlling the load, a Select soft-key will appear allowing it to be made the

active selection if required. A new numeric value can be entered as described above. Separate

settings for bot h level values are retained f or each operating mode.

The level setting menu remains on screen, allowing f ur t her c hanges to be made, until either the

Back soft-key or the

Home key is pressed to return t o the home screen.

7.8 Dropout Voltage

Pressing the Dropout soft-key on the home screen opens the Dropout Voltage setting prompt. In

the usual way this displays the present Dropout Voltage setting, the range in which the new value

can be set, and the maximum resolution of t he s et t ing. After entry of the num ber pr es s eit her t he

mV or V soft-key to implement t he set ting. Either the Back soft-key or the

display to the home screen.

The primary purpose of the dropout voltage set t ing is to protect batteries from excessive

discharge. The load will cease to conduct current when the applied voltage from the sourc e falls

below this setting. Note that this is a dynamic limit, not a lat ching condition, so if there is any

wiring resistance between the source and the voltage sensing point of the load then there will be

a soft entry into the dropout condition – the s er ies voltage drop will reduce as the cur r ent star ts t o

fall, so raising the voltage measured by the load. Batteries may also recover as the load is

reduced, raising the voltage back above the dropout t hr eshold so the load resumes conduction.

There is a possibility of hunting or instability in this operating condition. The front panel lamp will

show yellow and the status line report Dropout when the dropout circuit becomes active.

) / R where R is the Level setting

dropout

Home key returns the

The Dropout Voltage setting has a special effect in Constant Resistance (CR) mode, when it

provides a starting point for the constant r esistance char ac t er ist ic (see the description in the

‘Application Notes‘ chapter for more detail).

The Dropout Voltage setting is also used as the threshold for the Slow Start circuit (see below).

If the dropout f acility is not required, set the Dropout Voltage to 0 Volts. The status line will show

Dropout as a warning whenever this setting is above 0V and no current is being drawn.

21

Page 23

7.9 Slow Start

The purpose of the slow start circuit is to r am p t he demand of the load up slowly from zero to the

final value. The rate of rise is determined by the Slew Rate setting. The ramp starts either when

the Input is Enabled, or when the voltage from the attached sour ce passes the level of the

Dropout Voltage setting. When the Input is Disabled the demand will ramp back down to provide

a slow stop (assuming, of course, that the source voltage remains active).

The setting for t h is facility is on the Transient menu, so first press the Trans soft-key on the

home screen to enter the Transient menu, and then press the Slow soft-key on that menu to

access a soft-key to alternately enable or disable slow start. While it is enabled, Slow will appear

on the status line of the instrument. Pr ess t he Back soft-key to return to the transient m enu or

the Home key to return dir ec t ly to the hom e s cr een.

In CP (constant power) mode the slow start facility will almost always be needed, to avoid the

lock-up condition that will occur at low voltages (when attaining the desired power requires a high

current) if the sour ce does not have suff icient current capability to reach the power level

demanded. See the ‘Application Notes’ chapter later for a discussion of some of the implications

of the fact that c onstant power mode caus es the load to act as a negative resistance.

In CR (constant resistance) mode the load will start at the maximum O hm s level of t he active

range and ramp down to the final Ohms value. Becaus e t he initial r esistance is not infinite there

will be an initial current step before the ramp starts when the load becomes active. Note also that

a linear slew in Ohms is not a linear slew in Amps if the source voltage is constant.

7.10 Introduction to Transient Operation

The unit includes the capability of generating load tr ansients, which are intended t o help in

testing the transient response of a source. Transient operation is available in all operating modes.

A transient is an alternation between the Level A and Level B settings, with the transition between

the two levels being a straight line (in the controlled variable of the act ive mode) whose slope is

determined by the Slew Rate setting. Note that the transient is specified by setting the two

absolute levels, not the difference between them (as is the case with some electr onic loads) .

There is no limitation on which of the two levels is the larger.

Transients can be timed either by an internal oscillator or by an external TTL signal (see the

description of the Extern menu, section 8 ). Transient operation controlled by the internal

oscillator always starts with the Level A setting, including a transition from Level B if r equired. The

oscillator starts when the last of the three required conditions occurs: either when the input is

Enabled, or when the Transient level control key is selected, or (if the slow start circuit is active)

when the source voltage rises above the Dropout Voltage threshold.

It is also possible to use the External Analogue Voltage control mode to g ener at e transients of

any required shape by using an external generator to produce the required waveform. This is

also controlled by the Extern menu, section 8 ). Note t hat t he exter nal signal still passes through

the internal slew rate control circuits, so appropriate Slew Rate set tings need to be made.

To end Transient operation (whether internal or external) and return to a constant level press

either the A or B key (in the

LEVEL SELECT section) as required.

7.11 Transient Menu

Press the Trans soft-key on the home screen to enter the Transient menu which gives access to

the controls for the Fr equency and Duty Cycle of the internal oscillator and the Slew Rate

settings which apply to all changes in level, however caused.

These parameters can also be changed using t he

do this the unit must be on the home screen not the Transient menu.

Note that changes to the transient frequency or duty cycle do not take effect until the end of t he

present cycle, at the return to Level A. This is particularly noticeable at very low frequencies.

Disabling and then re-enabling the load input will also immediately start a new cycle.

22

∆ ADJUST facilities described previously, but to

Page 24

7.12 Transient Frequency

The repetition rate of t he internally timed transients can be set in terms of f r equency or period.

Pressing the Freq or Period soft-key on the Transient menu opens the Frequency and Period

setting menu. A new value can be entered, in the present representation, in the usual manner.

Two soft-keys labelled Freq and Period allow the alternative representation to be chosen. Press

the Back soft-key to retur n to the transient menu or the

The soft-key label on the transient menu will show either Freq or Period to reflect the most

recent choice of representation.

7.13 Transient Duty Cycle

Pressing the Duty soft-key on the Transient menu opens the Duty cycle setting menu. This

setting specifies the percentag e of each repetition spent at the Level A setting, including the

transition from Level B to Level A; the transition back to Level B and the time stable at that

setting occupies the remainder of the cycle.

The available duty cycle range is 1% to 99%, but note that the t im e duration of each portion of

the cycle must be sufficient for t he t r ans it ion defined by the Slew Rate and Level settings to

occur; otherwise the load will never reach the steady state at the set value before t he next

transition in the opposite direction starts. This error condition is discuss ed below. Press the Back

soft-key to return to t he Transient menu or the

Home key to return to t he home screen.

Home key to return to t he home screen.

7.14 Slew Rate

Pressing the Slew soft-key on the Transient menu opens the Slew Rate setting menu. This Slew

Rate setting sets the slope of the t r ansit ions bet ween the two level settings. It applies to all

changes in level whether caused by manual setting, adjustment using the knob, the internal

transient generator or external voltage contr ol. It is also used to determine the rate of rise and fall

when the Slow Start circuit is triggered.

The slew control circuit introduces a small additional error int o t he ac cur ac y of the level settings,

which varies depending on the actual Slew Rate setting . I f the dynamic facilities of the load are

not being used, then the Default soft-key sets the circuit to the calibrated state f or best accuracy.

The circuit provides a linear transition in the control value of t he ac t ive mode, s o, for example, in

Constant Power (CP) mode the slew rate is expressed in Watts per microsecond, Watts per

millisecond or (at very slow rates) Watts per second. The shape of t he c ur r ent transition is

therefore not necessarily linear in any mode other than Constant Current (CC).

In addition to the usual numeric prompt t his m enu also shows the calculated theoretical transition

time considering the present Slew Rate setting and the differenc e bet ween Level A and Level B.

This theoretical value takes no account of any dependency of t he actual transition time on the

source and load characteristics, impedances and interconnection inductance which may occur,

particularly at f ast s lew rates. The user m ust ensure that the transition time which results from the

values entered is not shorter than the minimum at tainable trans it ion tim e in t he pr esent mode,

which is documented in the Specification. It is emphasised that severe overshoots can occur if

the slew rate is set faster than the combination of source and load is capable of supporting

(which may be slower than the value in the Specification, which applies to optimal conditions) ,

see the section on ‘Fast Slew Rate Limitations’ section 7.14.2.

To set the slew rate to the minimum attainable transition time in the pres ent m ode as

documented in the Specification, press the Optimum soft-key.

Pressing the Range soft-key produces a display of the limits of available slew rate for the present

operating mode. If a slew rate value is entered that falls outside the parameter limit range, an

error message is displayed, followed also by a display of these ra n ge limits.

23

Page 25

The bandwidth of the power stages of the load is reduced (by changing the compensation

networks) when the slew rate is set to less than 0·1% of the maximum slew rate for the given

load mode. For example, in constant current mode, the maximum slew rate sett ing is 500A/ms,

so the bandwidth is reduced when the slew rate is set < 500A/s. This change is made even if the

transient facilities are not being used, and alters the dynamic behaviour of the unit. This may

improve stability with some difficult combinations of source and load characteristics.

Upon completion of the slew rate setting update, press the Back soft-key to return t o t he

transient menu or the

Home key to return to t he hom e s cr een.

7.14.1 Slow Slew Rate Limitations

There is a lower limit to the slew rate value that can be used, wh ich is determined by the

combination of slew rate, fr equency, duty cycle, and t he difference between the two levels. If the

requested transition time ( which is the diff er ence between the level settings divided by the slew

rate) is longer than the available time (which is the oscillator period m ult iplied by the smaller duty

factor), then the transition will not complete before the oscillator initiat es a r eturn to the other

level. As a result, the intended level setting will never be reached. In this case, Slew is displayed

in the status line as a warning.

7.14.2 Fast Slew Rate Limitations

In practice there are a number of limitations on the fastest slew rate actually attainable. O ne is

the minimum transition time of t he power stages of the load (which depends on the operating

mode – see the Specification). If a combination of a fast slew rate and a small change in level

imply a transition time shorter than this, t hen the settling time of the power stage will dominate.

The dynamic behaviour of a source and load combination at high slew rates depends on many

factors, particularly interconnection inductance and the dam ping factor of feedback loops. In

addition, the response of the power stages of the load is slower when operated at very low or

high currents, or at low voltages. In many circumstances, a lower slew rate setting will be needed

to avoid aberrations.

If an attempt is made t o set a slew rate faster than is possible in the circumstances, then

significant overshoots and extended settling times can arise. When configuring fast transitions

approaching the limits of the capabilities of the unit , it is st rongly recommended that the current

monitor output be viewed on an oscilloscope to verify the results actually obtained. Particular

care should be taken to avoid a fast transition down to a low current, as t his m ay result in t he

power stage entering the cut-off stat e, which incurs a long recovery time and possibly multiple

current pulses.

In CR (constant resistance) mode, where the cur r ent is inversely related to the resistance

transition, it is particularly difficult to predict the m aximum us eful slew rate setting.

7.15 Voltage and Current Limits

These limits specify values of sour c e voltage and load curr ent which will cause the load to

automatically disable its input if the actual measured voltage or current exceeds the set limit. This

is not an independent hardware trip, but a simple comparison against t he m et er m eas ur em ents.

To access the Limits menu, press the Limits soft-key on the home screen.

The V / I soft-key toggles the menu between setting up the two limits, allowing a numeric value

for each to be entered in the usual way. Pressing the None soft-key (or entering a value of zero)

disables that particular limit. Press the Back soft-key or the

screen.

Home key to return to t he home

24

While a value is specif ied for either limit, Lim appear s on t he stat us line of the display. Then, if

either of the limits is exceeded a fault messag e is displayed and the load input is disabled.

Page 26

7.16 Store and Recall Facilities

The instrument is able to store and rec all up to 30 user defined sets of load parameters in

non-volatile memory. Each memory location holds all the parameter set tings – load Mode, active

level, Level A value, Level B value, Dropout Voltage level, transient Frequency, Duty and Slew

Rate and the state of Slow start.

Both the store and recall menus display a preview of the parameters that ar e alr eady stor ed

within each memory location. If a memory location is empty then ( ---) is displayed. A memory

location can be selected either by using the ▲ or ▼ soft-keys or the knob to step t hr ough the

locations in sequence, or by entering the location number dir ectly using the numeric keypad (with

a leading zero if required). The currently selected m em or y location number (and user-specified

name) is highlighted on t he display, and the location number is also displayed above the table of

previewed parameters (this copy of the location number also updates during num eric entry).

Note: the store and recall menus look almost ident ical, see the menu name in the top left corner

to distinguish between the two.

7.16.1 Store Menu

To access the Store menu, press the Store soft-key on the home scr een. There are three

available options that can be applied to each memory location – store the pr esent settings to the

memory location, delete the contents of the memory location and rename the memor y location.

To store the present load configuration and sett ings to a memory location, select the desired

location and then press either the Confirm soft-key (if the location is presently empty) or the

Replace soft-key to overwrite the existing contents. O nce s t or ed, the parameters will be shown in

the preview table. If the location was empty prior to the store operation, then the location will

initially be given a default name of Store_nn, where nn is the location number.

To rename a memory location, press the Rename soft-key which opens the character entry

screen. Select a character using t he knob, or alternatively the digits 0 to 9 and the decimal point

can be entered using the numeric keys. To enter the selected character, press the Enter soft-key.

To delete the previously entered character press either the CE soft-key or the CE hard-key.

Use the ◄ and ► soft-keys to select the character position. The maximum number of charac t er s

in a memory location name is limited to 10. Upon completion of t he c har act er string entry, press

the Confirm soft-key to accept the changes and return to the store menu where the memory