Page 1

1908

5½ Digit Dual Measurement Multimeter

Page 2

CONTENTS

1 Product Description ......................................................................................................4

2 Safety .............................................................................................................................5

Symbols ...............................................................................................................................6

3 Installation .....................................................................................................................7

3.1 Mains Operating Voltage ..........................................................................................7

3.2 Mains Lead ...............................................................................................................8

3.3 Mounting ...................................................................................................................8

3.4 Handle/stand ............................................................................................................8

4 Getting Started ..............................................................................................................9

4.1 Using this Manual .....................................................................................................9

4.2 Installation and Safety ..............................................................................................9

4.3 AC Power and Battery Operation .............................................................................9

4.4 Switching On and Off ................................................................................................9

4.4.1 On/Off operation with AC Power .............................................................................9

4.4.2 On/Off operation without AC Power ......................................................................10

4.4.3 Power-up Settings.................................................................................................10

5 Measurement Connections ........................................................................................ 10

5.1 Input Sockets .......................................................................................................... 10

5.1.1 Multimet er Test Leads ..........................................................................................11

5.2 Rear Panel Connections ......................................................................................... 11

5.2.1 Trigger In/Out ........................................................................................................11

5.2.2 Digital Interfaces ...................................................................................................11

5.2.3 AC Inlet .................................................................................................................11

5.2.4 Protective Earth Terminal .....................................................................................11

6 Making Basic Measurements ..................................................................................... 12

6.1 Scale Length........................................................................................................... 12

6.2 Measurement Parameter Selection ........................................................................ 12

6.3 Measurement Range Select ion .............................................................................. 12

6.4 Making Voltage Measurements .............................................................................. 13

6.5 Making Current Measurements .............................................................................. 13

6.6 Making Resistance Measurements ......................................................................... 13

6.6.1 Two Wire Measurements ......................................................................................13

6.6.2 Four Wire Measurements .....................................................................................14

6.7 Making Continuity and Diode Checks ..................................................................... 14

6.7.1 Continuity Measurem ent .......................................................................................14

6.7.2 Diode Checks .......................................................................................................14

6.8 Making Frequency Measurements ......................................................................... 14

6.9 Making Capacitance Measurements ...................................................................... 15

6.10 Over Voltage Protection ...................................................................................... 15

6.11 Measurement Hold .............................................................................................. 15

6.12 Measurement Null ............................................................................................... 15

6.13 The Cancel Key ................................................................................................... 15

7 Additional Parameters and Functions ....................................................................... 16

7.1 Combined AC + DC Measurements ....................................................................... 16

7.2 Decibel Measurement ( dB) ..................................................................................... 16

7.3 Removing Test Lead Resistance (Ω Null) .............................................................. 16

Page 1

Page 3

7.4 Temperature Measurement (oC/oF) ........................................................................ 17

7.5 Touch and Hold (T Hold) ........................................................................................ 17

7.6 Measurement Speed and Measurement Filter........................................................ 17

7.7 Zero Re-Calibration ................................................................................................ 17

8 Dual Measurement Mode ............................................................................................ 18

8.1 Dual Measurement Combinations .......................................................................... 18

8.2 Making Voltage and Current Dual Measurements .................................................. 19

8.3 Measurement Update Ti mes .................................................................................. 19

9 Triggered Operation .................................................................................................... 20

9.1 Trigger In Signal ..................................................................................................... 20

9.2 Trigger Out Signal (Measurement Complete) ......................................................... 20

10 Advanced and Programmable Functions .............................................................. 21

10.1 Selecting or Cancelling a Function ...................................................................... 21

10.2 Limits ................................................................................................................... 21

10.3 Ax + b .................................................................................................................. 21

10.4 Min-Max .............................................................................................................. 22

10.5 Delta % ................................................................................................................ 22

10.6 Watts ................................................................................................................... 23

10.7 VA ....................................................................................................................... 23

11 Data Logging ............................................................................................................ 23

11.1 Setting-up the Logger .......................................................................................... 23

11.2 Running the Logger ............................................................................................. 24

11.3 Starting and Stopping the Logger ........................................................................ 24

11.4 Recalling Logger Readings ................................................................................. 24

11.5 Clearing Logger Readings ................................................................................... 24

12 The Utilities Menu .................................................................................................... 25

12.1 Beep Sound {BEEp} ............................................................................................ 25

12.2 Measurement Speed {SPEEd} ............................................................................ 25

12.3 Measurement Filter {FiLt} .................................................................................... 25

12.4 External Trigger {E-tr} .......................................................................................... 25

12.5 Battery Condition {bAtt} ....................................................................................... 25

12.6 dB Reference Impedance {db-rEF} ..................................................................... 25

12.7 Temperature Probe Setup {rtd} ........................................................................... 26

12.8 Set Factory Defaults {rESEt} ............................................................................... 26

12.9 Switch Off on AC Power disconnection {AC OFF}............................................... 26

12.10 Measurement Update S ym bo l {StAr} ................................................................... 26

12.11 GPIB Address {Addr} ........................................................................................... 26

13 Maintenance ............................................................................................................. 27

13.1 Calibration ........................................................................................................... 27

13.1.1 Zero Calibration ....................................................................................................27

13.1.2 Routine Calibration ...............................................................................................27

13.2 Hard Reset .......................................................................................................... 27

13.3 Fuse Replacement .............................................................................................. 27

13.3.1 Current Range Fuses ............................................................................................27

13.3.2 Internal AC power fuse .........................................................................................28

13.4 Cleaning .............................................................................................................. 28

13.5 Firmware Updates ............................................................................................... 28

Page 2

Page 4

14 Remote Operation .................................................................................................... 29

14.1 GPIB Interface ..................................................................................................... 29

14.2 RS232 Interface .................................................................................................. 29

14.3 USB Interface and Device Driver Installation ...................................................... 30

14.4 LAN Interface ...................................................................................................... 30

14.4.1 LAN IP Address and Hostname ............................................................................31

14.4.2 mDNS and DNS-SD Support ................................................................................31

14.4.3 ICMP Ping Server .................................................................................................31

14.4.4 Web Server and Configuration P as sword Protection ............................................31

14.4.5 LAN Identify ..........................................................................................................31

14.4.6 LXI Discovery Tool ................................................................................................32

14.4.7 VXI-11 Discovery Protocol ....................................................................................32

14.4.8 VISA Resource Name ...........................................................................................32

14.4.9 XML Identification Docu ment URL ........................................................................32

14.4.10 TCP Sockets .....................................................................................................32

15 Status Reporting ...................................................................................................... 32

15.1 Input Trip Registers (ITR & ITE). ......................................................................... 33

15.1.1 Input Trip Register (ITR) .......................................................................................33

15.2 Standard Event Status Registers (ESR and ESE) .............................................. 33

15.3 Execution Error Register (EER)........................................................................... 34

15.4 Status Byte Register (STB) and GPIB Service Request Enable Register (SRE) 34

15.5 GPIB Parallel Poll (PRE) ..................................................................................... 35

15.6 Query Error Register - GPIB IEEE Std. 488.2 Error Handling ............................. 35

15.7 Power on Settings ............................................................................................... 35

15.8 1908 Status Model .............................................................................................. 36

15.9 Register Summary ............................................................................................... 36

16 Remote Commands ................................................................................................. 37

16.1 General ............................................................................................................... 37

16.1.1 Remote and Local Operation ................................................................................37

16.1.2 Remote Command Handling .................................................................................37

16.1.3 Remote Command Formats ..................................................................................37

16.1.4 Command Timing..................................................................................................38

16.1.5 Response Formats................................................................................................38

16.2 Command List ..................................................................................................... 39

16.2.1 General Commands ..............................................................................................39

16.2.2 Main Display Commands ......................................................................................40

16.2.3 Dual Measurement Mode Commands...................................................................42

16.2.4 First Level Modifier Commands ............................................................................42

16.2.5 Second Level Modifier Commands .......................................................................43

16.2.6 Data Logging Commands .....................................................................................44

16.2.7 Common Commands ............................................................................................45

16.2.8 Status Commands ................................................................................................45

16.2.9 Interface Management Commands .......................................................................46

17 Default Settings........................................................................................................ 47

18 Graphical Interface PC software ............................................................................. 48

19 Specifications .......................................................................................................... 49

Note: This manual is 48581-1470 Issue 3

Page 3

Page 5

1 Product Description

This precision bench-top/portable multimeter has dual measurement capability and a dual

display which can show either two independent measur ements, a measurement together with

its range value, or a measurement with one of the many programmable functions available.

The key features are:

• Operation from AC line or built-in rechargeable batteries.

• 0.02% basic accuracy, 120,000 counts.

• Manual or Auto-ranging.

• DC and AC Volts, DC and AC current, Resistance, Capacitance, Frequency, and

Temperature measurement; Continuity and Diode checks.

• True RMS AC and AC+DC measurement.

• Two or Four wire selectable ohms measurement.

• Display nulling and Ohms null.

• Selectable measurement speed.

• Touch hold mode - holds onto a stable reading until updated.

• 500 point data logger with timer.

• Temperature measurement for PT100 or PT1000 sensors.

• Measurement post-processing to give:

dB and power measurement with settable reference impedances

percentage deviation from a user-entered reference

linear scaling with offset

limits comparison for go/no go testing

automatic storage of minimum and maximum readings.

• Remote control via USB interface (1908)

• Remote control via USB, RS232, GPIB and LAN (LXI) interfaces (1908P)

• External input/output remote triggering.

• 1908-PC Link software providing:

Remote control of main functions

Logging function with graphical & tabular displays

Logged data can be exported to a CSV file

• Closed case calibration.

• Fully compliant with EN61010-1, EN61010-2-030 & EN61010-2-033 Safety, and

EN61326-1 EMC standards.

Page 4

Page 6

2 Safety

This multimeter has been designed to meet the requirements of EN61010-1, EN61010-2-030 &

EN61010-2-033 (relevant parts of the ‘Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use’ standards). It can be operated from its built-in

rechargeable battery or from a standard AC mains supply (Overvoltage Category II). When

connected to AC mains, it is a Safety Class I instrument.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When operated from the internal battery, without an AC mains connection, the multimeter should be

earthed by connecting the rear panel Chassis Earth terminal to an external protective earth system.

Without this connection, ‘leakage’ current from any accessible part may exceed the Normal (s afe)

limit of 0.5mArms under some extreme measurement conditions, e.g. high voltage, high frequency,

AC volts measurement. Measurements to 300VACrms, 50/60Hz, for example, would not require this

protective earth connection.

The test leads supplied with this instrument meet the requirements of EN61010-031 and are rated to

1000V Cat III; use only these test leads with the meter or a set of equivalent performance.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment (only dry

non-conductive pollution occurs except that occasionally a temporary conductivity caused by

condensation is expected) in the temperature range 5°C to 40°C, 20% - 80% RH (non-condensing).

It may occasionally be subjected to temperatures between +5° and −10°C without degradation of its

safety.

It has been designed for measurement use to 1000VDC/750VACrms in circuits isolated from AC

mains power (derived secondary circuits within an equipment) with occasional transient overvoltages up to 1500Vpeak. It can also be used for CAT II (Measurement Category II) use to

600VDC/ACrms, and CAT III use to 300V DC/ACrms. CAT II is local domestic supply level, e.g.

portable equipment and appliances; CAT III is mains distribution parts of a building.

For this equipment 4000V is the maximum peak transient overvoltage that can be tolerated by any

terminal with respect to earth ground without impairing safety.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range. In particular excessive moisture may impair safety.

When the instrument is connected to its supply or its inputs are connected to live voltages, terminals

may be live and opening the covers or removal of parts (except those to which access can be

gained by hand) is likely to expose live parts. The apparatus shall be disconnected from all voltage

sources before it is opened for any adjustment, replacement, maintenance or repair, including the

replacement of the current range protection fuses. Any adjustment, maintenance and repair of the

opened instrument under voltage shall be avoided as far as possible and, if inevitable, shall be

carried out only by a skilled person who is aware of the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture or

chemical corrosion the safety protection may be impaired and the apparatus should be withdrawn

from use and returned for checking and repair. Make sure that only fuses with the required rated

current and of the specified type are used for replacement. The use of makeshift fuses and the

short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it and in particular use only a sof t dry cloth to clean the

display window.

Page 5

Page 7

Symbols

CAUTION - refer to accompanyi ng

Measurement Category I I. Inputs may be

alternating current

Measurement Category I II. Inputs may be

The following symbols are used on the instrument and in this manual:

WARNING - risk of electric shock.

documentation; incorrect operation may

damage the meter.

CAT II

connected to AC mains power under

Category II overvoltage conditions

CAT III

connected to AC mains power under

Category III overvoltag e conditions

mains earth (ground)

Protective Earth terminal

direct current

Standby supply. Instrument is

not disconnected fr om AC

mains power when switch is off.

Page 6

Page 8

3 Installation

3.1 Mains Operating Voltage

Check that the instrument operating voltage marked on the r ear panel is suitable for the loc al

supply. Should it be necessary to change the operating voltage, proceed as follows:

1. Warning! Disconnect the instrument from all voltage sources before beginning this

procedure.

2. Pull out both sides of the handle at the case pivot points, to fr ee the position locking

pegs, and rotate the handle from the stowed position to the position shown below. Then

pull the sides of the handle outwards fully, one at a time, to remove the handle

completely.

3. Remove the two screws on the rear panel that retain the top cover and slide the top

cover towards the rear, with the soft bezel still in place, until it can be lif ted clear.

Note: To avoid contaminating or damaging the PCB assembly, take care not to touch

any components other than the two shorting connectors described in the next step.

4. Remove the shorting connector in position PJ4 on the PCB beside the mains

transformer (TX1) and replace it with the alternative shorting connector from the

‘parking’ position PJ8; align pin1 of the connector with the pin 1 corner marker of the

header. ‘Park’ the unused connector on PJ8, see the diagrams below.

For 230V operation PJ4 should be fitted with the connector which has a single red wire

between its centre pins (pins 2 & 3).

For 115V operation PJ4 should be fitted with the connector which has a blue wire

between pins 1 & 3, and a brown wire between pins 2 & 4.

Note that the value of fuse FS3 (500mA) is the same for both AC voltage settings, see

Maintenance, section 13.

5. Reassemble in the reverse order.

6. To comply with safety standard requirements the operating voltage marked on t he rear

panel must be changed to clearly show the new voltage setting.

Page 7

Page 9

3.2 Mains Lead

For AC mains operation, connect the instrument to the AC supply using the mains lead provided.

Should a power plug be required for a different power outlet socket, a suitably rated and approved

mains lead set should be used which is fitted with the required wall plug and an IEC60320 C13

connector for the instrument end. To determine the minimum current rating of the lead-set for the

intended AC supply, refer to the power rating information on the equipment or in the Specification.

WARNING! THIS INSTRUMENT MUST BE EARTHED.

Any interruption of the power earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited.

3.3 Mounting

This instrument is suitable both for bench use and rack mounting. It is delivered with soft protective

front and rear bezels which have integral moulded feet; this is the most suitable configuration for

bench use.

For rack mounting the protective bezels and handle/stand can be removed such that the instrument

can be fitted beside any other standard 2U half-rack instrument in a 19” rack. A suitable 2U 19”

rack kit is available from the Manufacturers or their overseas agents; full details of how to remove

the handle and bezels are included with the kit.

3.4 Handle/stand

The instrument is fitted with a 4-position handle/stand. Pull out both sides of the handle at the case

pivot points, to free the position locking pegs, and rotate the handle from the stowed pos it ion to the

required stand or handle position. Release the sides of the handle to lock it in the new position.

Page 8

Page 10

4 Getting Started

4.1 Using this Manual

In this manual front panel k eys are shown in bold square brackets , e.g. [Vdc], [Function].

Sockets are shown in bold capitals, e.g. INPUT HI. LCD display dat a is show in bold curly

brackets, e.g. {SPEEd}, {AUTO}.

The manual is available in pr i nted form and as an electronic document in PDF format. The

manual includes cross r eferences which are underlined within the text. These are hyperlinks

within the PDF document . The Table of Contents is also fully h yperlinked.

Hyperlinks enable the u s er to jump rapidly to the section referred to and then jump back to

continue reading the original section. (N.B. f or hyper l ink navigation within Acrobat Reader,

enable “show all page navigat ion tools” or use the keyboard shortcuts Alt+Left_Arrow and

Alt+Right_Arrow).

4.2 Installation and Safety

Before first use, all user s should read the Safety Information in section 2 .

Before connecting AC power, c hec k that the instrument operating voltage marked on the rear

panel is suitable for t he local supply. Should a change be required, read section 3.1

Connect the instrum ent to the AC supply using the mains lead provided. Should a power plug

be required for a different power outlet socket, refer to section 3.2

.

4.3 AC Power and Battery Operation

The instrument can be operat ed from AC power or from internal rechargeable batteries which

are recharged as required when AC power is connected. A red LED is illuminated whenever

AC power is connected and a yellow LED is illuminated whilst c harging is taking place.

Battery Life from fully charged is approximately 20 hours with the backlight on, and up to 35

hours with the backlight off. Under battery operation a battery symbol will appear on the display

if the charge level falls belo w about 10%. The approximat e charge level can be checked from

the Utilities menu – see section 12.5.

For the 1908P, operation of the remote interfaces (excludi ng USB) is only possible with AC

power connected.

4.4 Switching On and Off

The instrument behaves differently depending upon whether or not AC power is connected.

4.4.1 On/Off operation with AC Power

If required, AC power can be switched on or off using the POWER switch mounted on the rear

panel. When the AC power is switched off the default setting is for the instrument to turn off. Th i s

ensures appropriate behaviour when used as part of a group of equipment for which AC power is

turned on or off simultaneously.

Note: To fully disconnect from the AC supply unplug the mains cord from the back of the

instrument or switch off at the AC supply outlet; make sure that the means of disconnection is

readily accessible. Disconnect from the AC supply when not in use.

The green front panel button marked [OPERATE] can be used to place the instrument into

Standby if required. Successive presses will alternate between On and Standby.

Alternative AC Power Swi tching Options

The response of the instrument to AC power being connected or disc onnected can be altered if

required. The actions described above are the default conditions, and can be changed fr om the

Utilities menu – see section 12.9

.

Page 9

Page 11

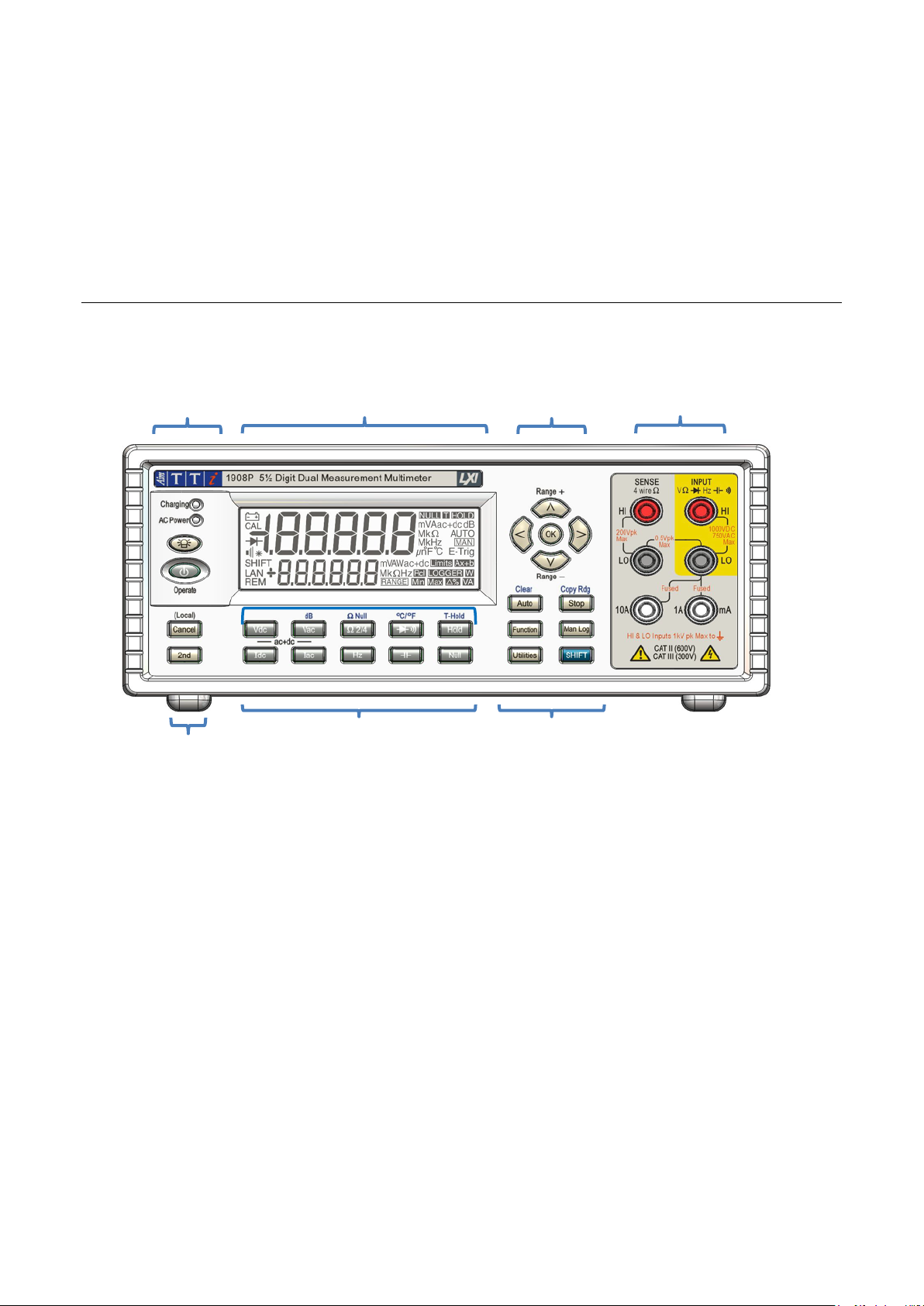

4.4.2 On/Off operation without AC Power

Display

Measurement

Measurement keys

Navigation

Function keys

Power

Function keys

With no AC power connected, operation is from the internal r ec hargeable batteries and the

instrument is turned on or off by successive presses of t he green [OPERATE] button. The rear

panel POWER switch has no funct i on.

4.4.3 Power-up Settings

At power up the display briefly shows the installed software revision; the instrument is then restored

to the same measurement conditions as at power down, including any advanced functions that were

running. However, if the instrument was showing a menu at power down, the menu will be

cancelled when powered up.

5 Measurement Connections

5.1 Input Sockets

keys

The input sockets are 4mm safety sockets on a 19mm pitch designed t o accept 4mm safety

plugs with fixed or retra ctable shrouds. All sockets are rated to 1000Vpeak with res pec t to earth

ground. Safety will be maintained if voltages up to 1000Vpe ak are accidentally applied between

inappropriate terminals in excess of their marked ratings, but restoration of normal operation

may require replacement of protection devices (e.g. cur rent range fuses).

terminals

The input impedance between INPUT HI and INPUT LO is nominally 10MΩ on dc r anges and

1MΩ on ac ranges. The black LO soc k et is considered less positive than the red socket. The

maximum voltage that can be app lied between HI & LO is 1000Vdc, 750Vrms (1000Vpeak).

The sockets are rated to 600V CAT II, 300V CAT III.

The mA/10A current sockets are low impedance; the voltage burden between mA/10A and LO

at full scale is <100mV for the 10mA range and <600mV for the 100mA, 1A and 10A ranges.

The black LO socket is considered less pos itive than the white mA/10A sockets. The mA/1A

socket is protected with a 1.6A 1kV HRC fuse, and the 10A socket with a 10A 1kV fuse; see

Maintenance, section 1 4, for replacement details.

The SENSE HI & LO sockets are only used in 4-wire Ohms and RTD temperature

measurements; refer to those sections for details. When used, the maximum differential

between SENSE LO and INPUT LO should be < 0.5V peak . The SENSE terminals are

protected against accidental connection of up to 200Vpeak between HI & LO.

Page 10

Page 12

5.1.1 Multimeter Test Leads

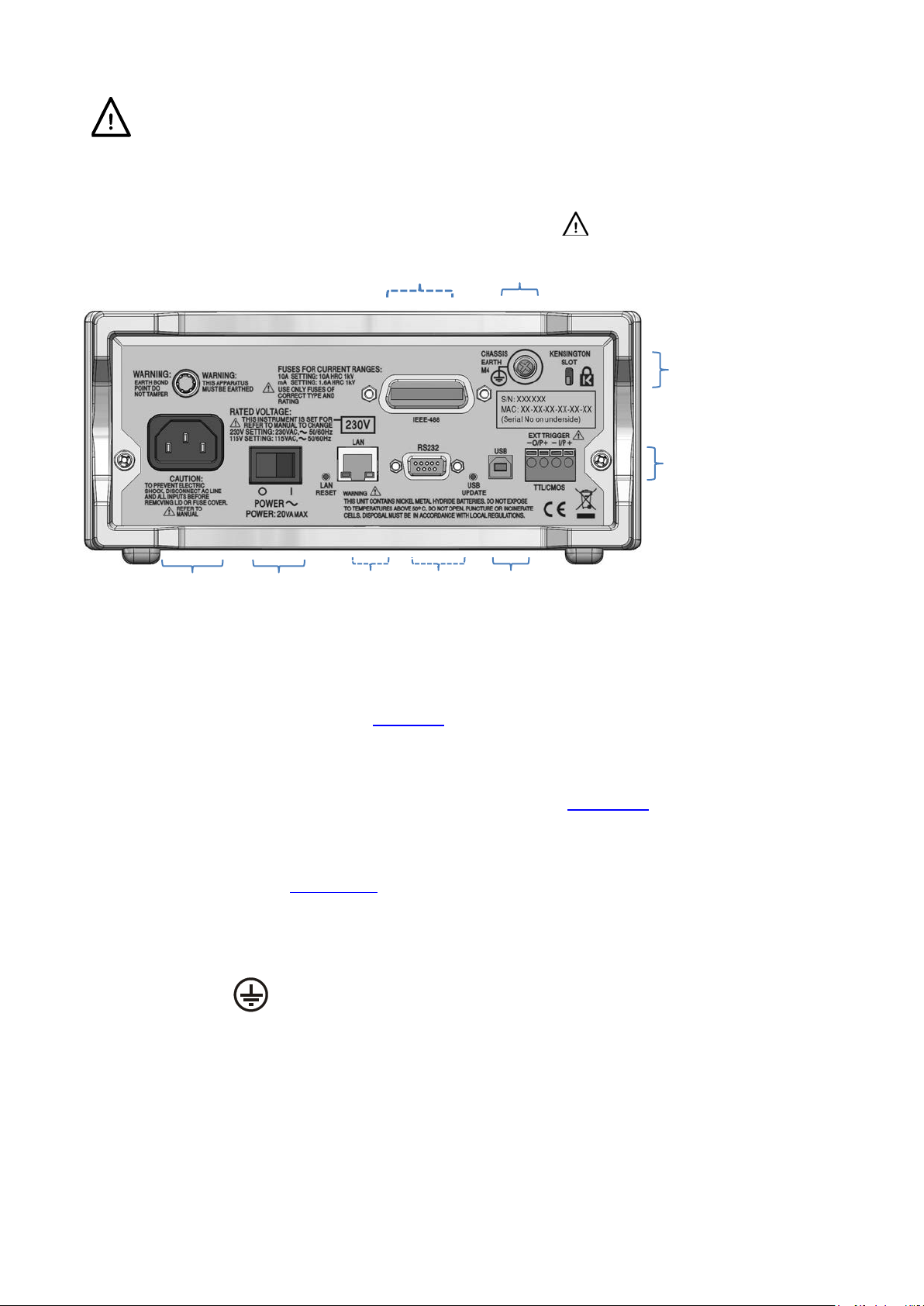

The test leads supplied meet the requirements of IEC1010-031 and are rated to 1000V Cat

TTL/CMOS

External Trigger

Kensington

USB

RS232

LAN

Power

switch

AC power

Protective

(1908P)

GPIB

III. Use only the test leads pr ovided, or a set of similar performance, to ensure safe

operation. Alternativ e test leads should be rated to at least 1000V, 600V (Cat II) and 10A

current capability.

5.2 Rear Panel Connections

connection

(1908P

only)

Conductor

Terminal

Warning! This instrument must be

earthed. Connect terminal to an external

protective earth system when instrument

is used without an AC mains connection.

Lock

5.2.1 Trigger In/Out

Screw-less connectors are provide d on the rear panel for the connec tion of an external trigger

signal, and a trigger out s ignal . See section 9

for full details.

5.2.2 Digital Interfaces

Depending upon model, r ear panel connectors are provided for USB only (1908) or USB,

RS232, LAN and GPIB (1908P). Refer to Remote Operation, section 14

, for full details.

5.2.3 AC Inlet

The instrument can be connected to AC mains using the power lead supplied or a suitable

alternative, see Installation section 3.2.

When the power lead is connected this lead provides the

necessary protective earth connection to an external protective earth system.

5.2.4 Protective Earth Terminal

For battery only operation, without an AC power lead connected, the M4 threaded chassis

connection marked must be connected to an external protective earth system via a

green/yellow insulated cable, with a cross-section of at least 0.75mm

Without this connection, ‘leakage’ current from any accessible part may exceed 0.5mArms, t he

Normal (safe) limit specified by EN61010-1, under some extreme measurement conditions, e.g. high

voltage, high frequency, AC volts measurement.

. WARNING! THIS INSTRUMENT MUST BE EARTHED.

2

, fitted with a M4 terminal.

Page 11

Page 13

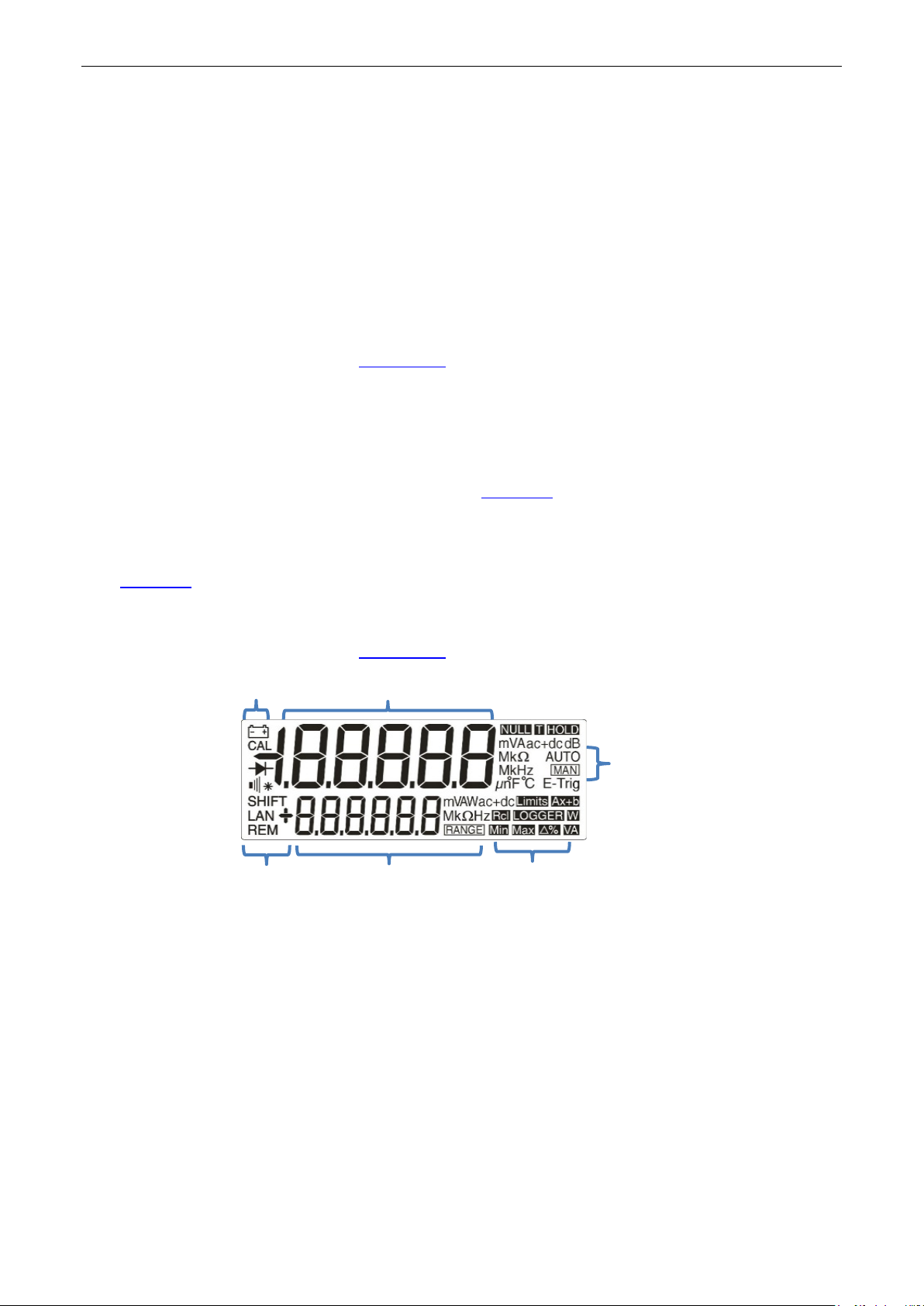

6 Making Basic Measurements

Primary measurement

Range or

Functions

Remote

Status

Range

This section describes how basic measurements are made, i.e. single measurement mode

without post-processing of the results.

6.1 Scale Length

The scale length is ±120,000 f or all measurements except frequency (full scale 12,000) and

capacitance (full scale 1200). {OFL} is displayed when the range maximum is exceeded.

Note, however, that safety considerations limit the maximum voltage and current that can be

measured to below the scale length maximum.

6.2 Measurement Parameter Selection

Refer to the f r ont panel diagram in section 5.1

The two rows of darker grey keys below the display directly select t he measurement

parameters for either the primary or secondary display. When pressed alone the param eter

keys select the measurement parameter for the primary display, cancel any secondar y

functions, and set the range to auto-range.

Pressing [2nd] followed by a parameter key selects the parameter for the secondary display;

this is explained fully in Dual Measurement Mode, section 8

combinations of parameters that can be used.

Additional paramet ers marked in blue above certain keys are selected by first pressing [SHIFT].

Whilst shift is operational a {SHIFT} symbol appears on the left side of the display.

See section 7

for full details.

, which also details the

6.3 Measurement Range Selection

Refer to the front panel diagram in section 5.1, and to the display diagram below.

communications

2nd measurement

When a parameter is first selected, auto-ranging is enabled and a n {AUTO} s ymbol is

displayed. Pressing either of the [ᴧ] / [v] arrow keys (Range+/Range-) cancels auto-ranging

whilst leaving the range set to its existing value. The {MAN} symbol is displayed and further

presses then change the range up wards or downwards. Pressing [OK] returns the ins trument

to auto-ranging operation.

The units appropriate to the function and range (e.g. {mV ac}) ar e s hown to the right of the

display. When the secondary display is not being used to sho w m easurement values, the

selected range is shown there.

Note that the 10A range, which uses a different input socket from mA measurements, can only

be selected manually. Once 10A has been selected, however, this setting will be retained for

current measurem ent unt il i t is returned to mA.

Note that the {AUTO} and {MAN} symbols apply only to the pr imary display.

Mode

Page 12

Page 14

6.4 Making Voltage Measu rements

The maximum voltage that can be applied between INPUT HI and LO is 1000V DC or 750V

The input test leads and AC power lead must be disconnected before opening the fuse

Having selected Vdc or Vac, volt age measurements are made us ing the red INPUT HI socket

and the black INPUT LO socket within the yello w area of the panel. Five measurement ranges

(auto or manual) are available from 100mV to 1000V (dc) or 750V (ac).

The meter will show a minus sign {-} (on dc measurements) when the volt age applied to the

INPUT HI socket is more negative than that applied to the INPUT LO socket.

AC; damage to the instrument may result if this limit is exceeded.

WARNING! The maximum input volt age to ground must not exceed 1000V peak. Safety will be

impaired if thes e ratings are exceeded, see Safety section at the beginning of the manual.

6.5 Making Current Measu rements

Having selected Idc or Iac , current measurements up to 1. 2A (1200.00mA) are made using the

white mA socket and the black INPUT LO socket; cur rent measurements up to 10A are made

using the 10A and LO sockets. The meter will show a minus sign {-} (on dc measurements)

when the polarity of the cur r ent is such that it flows out of the mA or 10A sockets rather than

into it.

Using the mA socket three measurement ranges ( auto or manual) are available f r om 10mA to

1000mA. Measurements up to 10A c an be made using the 10A socket having manually ranged

to 10A with [ᴧ].

The 10mA, 100mA and 1000mA ranges, using the mA socket, are protect ed by a 1.6A (F) HRC

fuse. The 10A range, using the 10A socket, is protected by a 10A (F) HRC fuse. Both fuses are

accessed via a panel on the bas e of the instrument.

access panel.

Note: After measuring high currents (i.e. above half sc ale) using the 1A or 10A ranges, thermal

voltages are generated t hat may create errors when making measurements on the most

sensitive dc voltage, current or Ohms ranges immediat el y afterwards. To ensure that t he

specified accuracy is maintained, allow 10 minutes for the thermal effects to reduce before

making sensitive meas ur ements.

6.6 Making Resistance Measurements

Pressing [Ω 2/4] selects resistance measurement in either 2 wire or 4 wire mode. Successive

presses alternate between the modes as indicated by {2W

secondary display. Six measurement ranges (auto or manual) ar e available from 100Ω to

10MΩ.

6.6.1 Two Wire Measurements

Normal (2 wire) resistanc e measurements are made using the INPUT HI and LO sockets within

the yellow area of the panel. This measurement mode is appropriate for higher r es istance

measurements, and for lower res istance measurement s where high precision is not required.

Ω} or {4WΩ} appearing briefly in the

The effects of test lead resis tance can be removed using Ω Null if required – see section 7.3

Page 13

.

Page 15

6.6.2 Four Wire Measurements

4 wire measurements are appropr iate for precision measur ement of low resistances where the

effects of the connectin g l eads and contact resistances are significant. 4 wire measurement

uses the HI and LO SENSE sockets in addition to the HI and LO INPUT sockets.

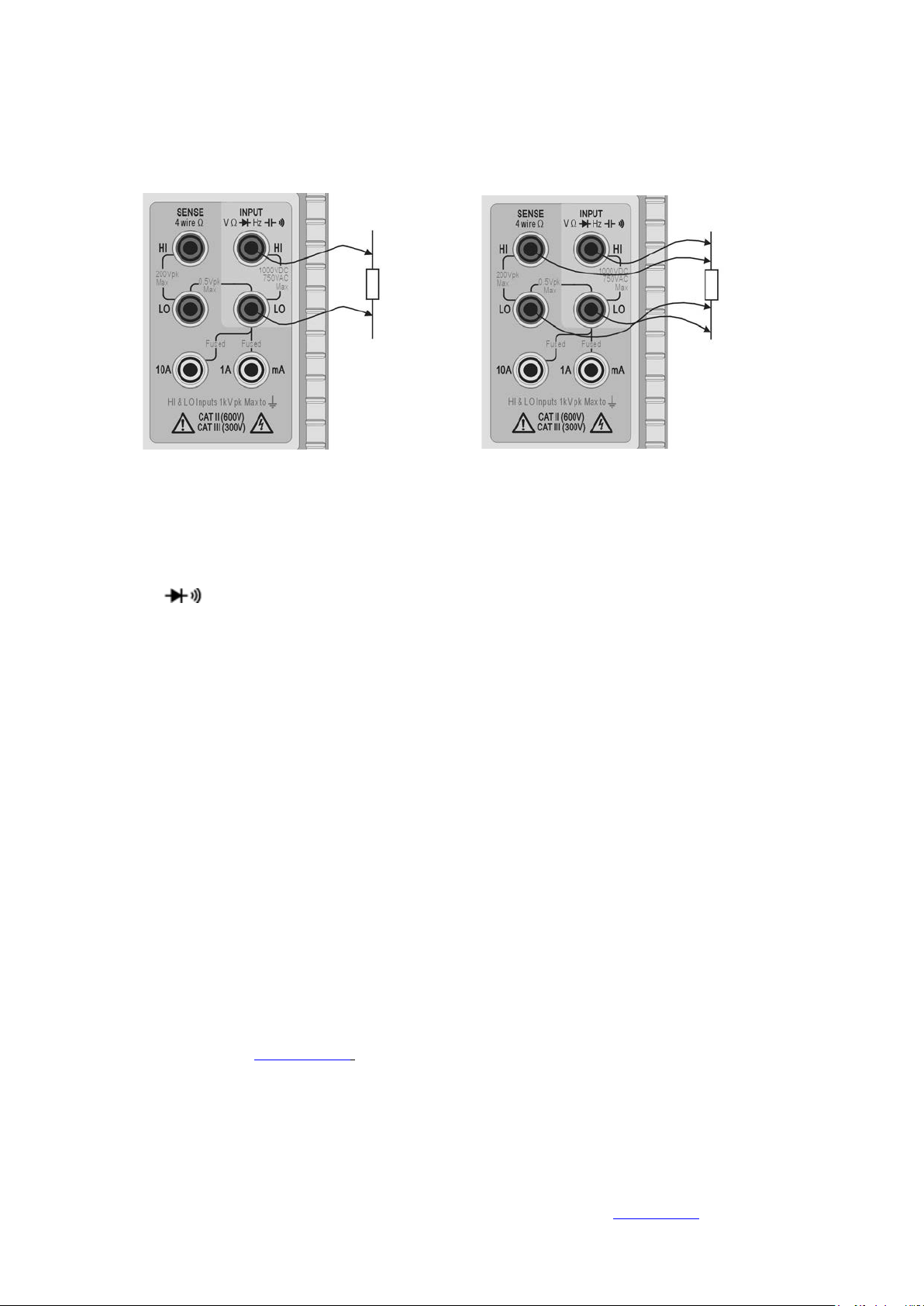

Connections are made as shown below.

Two Wire Measurement Four Wire Measurement

Because no significant current is flowing through the SE NS E connections when utilising 4 wire

measurement, contact resistance does not affect the measurement result.

6.7 Making Continuity and Diode Checks

Pressing [ ] selects either cont inuity measurement or diode test. Successive presses

alternate between the two as indicated by symbols on the left side of the displ ay. Continuity

and diode checks are made using the INPUT HI and LO sockets within the yellow area of the

panel.

6.7.1 Continuity Measurement

Setting continuity causes the 1000Ω range to be selected such that readings be low

approximately 10Ω will sound the continuity buzzer. Readings above the range maximum will

show {OPEn}.

6.7.2 Diode Checks

Setting diode check caus es the 1000mV range to be selected and a current of approximately

1mA to flow out of the INPUT HI socket. W ith the anode of the diode connected to this t erminal

the diode forward voltage will be shown. Reverse diode connecti on will show {OFL}.

6.8 Making Frequency Measurements

Pressing [Hz] selects frequency m eas urement. Measurements are m ade using the INPUT HI

and LO sockets within the yellow area of the panel. Four ranges (100Hz to 100k Hz) are

available, giving resol utions of 10mHz to 10Hz respectively over an operating fr equenc y range

of <10Hz to 120kHz. Reciprocal counting techniques ensure fast reading updates

(4 readings/second) even on the lowest range. This can be increased to 8 readings/second in

fast speed mode see section 12.2

measuring low frequencies in the 100Hz range to ensure accurat e r eadings.

; however the slow speed mode should always be used when

Measurements are m ade using the ac Volts input circuitry which is auto-ranged to provide

suitable sensitivity. At low signal levels use a screened lead an d an adaptor (BNC to 4mm

plugs, 19mm pitch) to preserv e signal quality and avoid spurious r eadings from stray pick-up.

The minimum measurable signal is <30mV rms across the frequency range (100mV range) or

<10% of range maximum for other ac voltage and current ranges.

Frequency can also be meas ur ed in dual measurement mode, see section 8.1

Page 14

.

Page 16

6.9 Making Capacitance Measurements

Pressing [ ] selects capacitance measurement. Measurements are made using the INPUT

HI and LO sockets within the yello w area of the panel. Five ranges ( 10nF to 100µF) are

available with 1200 count full scale giving resolutions of 10pF to 100nF respectively.

Zero calibration at the factory is carried out with no test leads c onnected; ideally, capacitor s to

be measured should be connected directly to the sockets. Test leads, if used, should be kept as

short as possible to minimise stray capacitance but never theless a non-zero reading will

generally be present when the lowest ranges are selected. To eliminate this offset it is

recommended that the meter reading is nulled, once the required range has been selected, with

the test leads in their measurement positions but no capacit or connected.

It is also recommended that battery operation is used when making capacitance

measurements, to m inim i s e reading jitter. Note that, becaus e the capacitor is discharged

between each measurem ent, the reading rate on the 100µF range is slower.

6.10 Over Voltage Protection

When making measurements of Resistance, Capacitance, Temperature, Continuity or Diode

checks an internal protection circuit protects t he current source from source voltages applied to

the INPUT HI and LO sockets. If a voltage of greater than typically 10V is applied to the INPUT

HI and LO sockets the protection circ ui t will be engaged, the buzzer will sound and {trIP} will be

displayed. After completion of the trip event, the measurement mode is set to V dc to show the

over-voltage that is bein g appl ied to the input sockets. BIT 0 of the Input Trip Register (IT R) is

set to 1 (over voltage protec t) see section 15.1

.

6.11 Measurement Hold

Hold operates only on the primary display. Pressing [Hold] causes t he measurement to be

frozen on the display along with a {HOLD} symbol. Provided that the meter is not in dual

measurement mode and not measuring capacitance, t he normal, updated, reading will be

shown in the secondary display.

Hold only operates on the primary display, any measurement being shown on the secondary

display will continue to updat e normally.

Hold is cancelled by pres s i ng [Hold] again, or by changing range or function.

6.12 Measurement Null

Null operates only on the primary display. Pressing [Null] causes the measurement to be

stored and subtracted f rom all future readings. Pressing [Null] locks the meter in the selected

range and shows {NULL} (and {MAN}) symbols. Provided that the meter is not in dual

measurement mode and not measuring capacitance, t he normal, un-nulled, reading will be

shown in the secondary display.

Null is cancel by pressing [Null] again, or by changing range or function.

6.13 The Cancel Key

[Cancel] can be used to return t he meter to a basic measurement mode. It cancels dual

measurement mode, dB, N ull, Hold and T-Hold, and any programmable functions including the

Logger. It does not cancel Ω Null.

Consequently [Cancel] should not be used to cancel a single function, such as Hold, if other

functions need to be maintained.

Page 15

Page 17

7 Additional Parameters and Functions

A number of additional capabilities can be accessed using the measurement parameter keys,

as described below. Further functions also can be selected from the Functions menu key – see

section 10.1

7.1 Combined AC + DC Mea surements

Vdc+Vac or Idc+Iac measurements are made by pressing both keys t ogether. The reading

displayed is the RMS sum √(dc

Both ac and dc measurements are made on the same range: the instrument will auto-range to a

range which gives an in-range reading for both the ac and dc component of the parameter.

Clearresult to be shown as an in-range reading.

2

+ ac2) and ac+dc is shown on the displa y.

Note that this is a special case of Dual Measurement mode (see section 8.3

measurement update rate is slowed accordingly.

) and the

7.2 Decibel Measurement (dB)

dB (deciBel) can be selected only when Vac is already in the main display. Pressing [Shift]

followed by [Vac] shows the dB value of the Vac measurement (referred to the chosen

impedance setting) and dis plays the {dB} symbol. If no secondary f unc tion is selected the

normal reading in volts will be s hown in the secondary displa y.

dBs are shown in a fixed format with 0.1dB resolution, whatever r ange the Vac measurement is

being made on. The value displayed is in dBm and is calculated from the formula:

dB = 10 log10 (1000 x V2/R), where R is the selected reference impedance.

The default reference impedance is 600Ω but a different value can be selected within the

Utilities menu. Press [Utilities], use the Navigator keys to select {rEF} and confirm with [OK].

The existing reference v alue will flash. Alternativ e val ues can be selected using the Navigator

keys and confirmed with [OK].

Available values are 50, 75, 93, 110, 124, 125, 135, 150, 250, 300, 500, 600, 900, 1000, 1200,

and 8000Ω. Pressing [Shift] followed b y [Auto] (Clear is the shifted function of Auto) returns

the value to 600Ω. Press [Utilities] again to exit the Utilities menu.

dB is cancelled by pressing [Vac], or by selecting any other measur ement parameter or

function.

7.3 Removing Test Lead Resistance (Ω Null)

Residual test lead resistanc e c an be nulled out using the Ohms Null facility as follows:

Connect the test leads together and press [Shift] followed by [Ω 2/4] (Ω Null is the shifted

function of Ω). The 100Ω range is set automatically and the {NULL} symbol flashes; the meter

stores the reading that it detects after 5 seconds provided that it is less than 1.000Ω (1000

counts). A beep sounds when the null is completed and the display should show zero Ohms

and no {NULL} symbol.

If the reading cannot be nulled, because the offset is too lar ge, the reading will not change and

the buzzer will not sound.

The Ohms null is stored as a floating point value which is used on all ra nges; it is not lost when

the function is changed or when the ins trument is turned off. Ohms null can be cancelled by

selecting Ohms Null and not generating a sub 1.000Ω reading within t he next 5 seconds, or by

restoring the instrument to factory defaults – see section 12.8

Normal Null can be used together with Ohms Null.

Page 16

.

Page 18

7.4 Temperature Measurement (oC/oF)

The instrument incorporates linearised measurements for PT100 and PT1000 platinum

resistance temperat ur e detectors (RTDs).

The temperature function is selected by pressing the shifted function marked °C/°F [Shift]

[ ]. The default measurement is in degrees centigrade. To change to degrees fahrenheit

select the function again.

The default probe type is P T100. To change to PT1000 use [<] / [>].

The measurement can use either a 2 wire or 4 wire connecti on, the latter using the HI and LO

SENSE terminals in addition to the HI and LO INPUT terminals. The selection is made from the

Utilities menu – see sec tion 12.7

.

7.5 Touch and Hold (T Hold)

T-Hold causes the meter to “hold” a reading on the display until a new non-zero measurement

has been detected; this allows the user to touch-probe the measurement point, rem ove the

probes and read the meter afterwards. It is not available for Ohms, Continuity, or Diode Tes t

measurements.

T Hold is selected by the shifted key marked T-Hold [Shift] [Hold]. The {T-HOLD} symbol is

displayed, and each new readi ng is indicated by a beep sound. Measurement update is slo w,

and small changes to the signal that occur after the probes have been connected will not be

shown.

Note that care should be taken when using T-Hold with the most s ens i tive voltage ranges; when

the probes are lifted fr om the circuit being measured, their high impedance means that s tray

pick-up might generate another ‘valid’ reading and the true T-Hold reading may be lost.

T-Hold operates only on the primary display in both m anual and auto-range modes; it is

cancelled by pressing T-Hold again [Shift] [Hold] or by changing the measurement parameter

or range.

7.6 Measurement Speed and Measurement Filter

The normal measurement speed is 4 readings/sec for most single measurement parameters.

For voltage, current and resistance measurements, the speed can be increased to 20

readings/sec at the expense of resolution which reduces t o 12,000 counts. This is done fr om

the Utilities menu, see section 12.2

In order to minimise jitter for sensitive measurements, an analogue filter is incor porated that

provides high rejection of 50Hz or 60Hz noise. Where the user requires quicker response to

signal changes, the f i lter can be switched off. This is part ic ul ar r elevant when the measurement

speed is set to 20 readings/s ec. The filter is controlled from the Utilities menu, see

12.3.

.

section

7.7 Zero Re-Calibration

An automatic zero calibration of the basic DC measurement circuitry is performed every time

that the instrument is switched on. However, if the meter has been stored at a temperature

outside the specified operating range, and is switched on before it has fully acclimatised to the

working environment, accuracy may be affected as the meter’s temperature changes. To

ensure optimum accur acy, particularly on the 100mV and mA current ranges, zero calibration

can be repeated when the m eter has acclimatised by using the Null k ey as follows:

Press [Null] and continue to hold it down unt il {nULL} shows in the main display (about 3

seconds later). {nULL} continues to show whilst the auto-zero is being performed (typically 5

seconds); on completion the display returns to its previous mode.

Auto-zeroing in this way cancels N ull if this was already selected; pr es s [Null] again to re-select

if required.

Page 17

Page 19

8 Dual Measurement Mode

Main Measurement

Secondary Measurement

Vdc

Vac, Idc, Iac

Vac

Vdc, Idc, Iac, Hz

Vdc + Vac

Vdc, Vac, Hz

dB

Vdc, Idc, Iac, Hz

Idc

Vdc, Vac, Iac

Iac

Vdc, Vac, Idc, Hz

Idc + Iac

Idc, Iac, Hz

Hz

Vac, Iac

In Dual Measurement mode a completely independent but complementary measurement can be

made and displayed on the secondary display. The two independent measurements are actually

made alternately, not simultaneously, and the display update rate for each measurement is

consequently reduced.

Note that this is not the same as dual display mode, where both a measurement and a modified

version of that measurement are displayed, e.g. ac Volts and the dB equivalent. In this case only a

single measurement is being made and the measurement rate is unchanged; further information is

given later in this section.

8.1 Dual Measurement Combinations

The full list of dual measurement functions is as follows:

The parameter for the secondar y display is selected by pressi ng [2nd] followed by the chosen

measurement parameter. The secondary display param eter must be selected after the main

parameter has been set. P r essing an illegal parameter will cause a warning double beep and

the key entry will be ignored

Capacitance, Ω, and Continuity/Diode check cannot meaningfully be combined with other

measurements and are therefore always excluded fr om the secondary display. Vac+Vdc and

Iac+Idc are also excluded bec ause they already involve dual measurements; when they are

being used no secondary displ ay can be set.

The secondary measurement, with the exception of the 10A curr ent ranges, always autoranges. The 10A current ranges are set by first selecting t he function ([2nd] followed by [Iac] or

[Idc]) then pressing [2nd] followed by [ᴧ]. To return to the mA measurement select [2nd]

followed by [v]. However, if both main and secondary displays are making current

measurements, the range of the secondary measurement is always that of the main displa y.

If Vdc and Vac are the two meas ur ement functions, auto-ranging of the secondary display is

restricted such that the dc measurement range is not lower than the ac range; this ensures that

the dc measurement is not affected by a high ac si gnal, see the table within the Specification

section 19

.

For example, if the main display is set to 10Vdc the secondar y display can auto-range between

the 100mV, 1000mV and 10Vac ranges. In this example, low levels of ripple could be measured

(on the 100mV range) on a 10Vdc supply rail, but an ac input >12V will cause the secondary

display to show Overload {OFL} warning the user to select a higher main display dc range such

that the secondary ac measurement is in range. Similar ly, if the main display is set to 100Vac

then the secondary display will not auto-range below 100Vdc, even for small dc inputs.

When frequency is sele c ted for the secondary display the measurement is made using the ac

range set in the main display. This presents no problems if the main display is in auto-range but

if a higher range has been set manually, such that the reading is less than 5% of the range

maximum, the signal level may not be adequate for frequency measurement.

Page 18

Page 20

8.2 Making Voltage and Current Dual Measurements

Measuring ac and dc Volts, or ac Volts and frequency, etc. still only require two measurement

probes because both parameters of the dual measurement are made at the same physical

point. Simultaneous measurement of voltage and current on the same circuit will however

require a third connecti on, see the diagram:

Note that the voltage measured at the multimeter terminals is that across the load plus the

voltage drop in the common lead which is now carrying the whole c i r c ui t current. Even if the

resistance of the lead is very low, errors may arise at high current s and low voltages (i.e. low

load resistance) becaus e the lead resistance becomes significant compared with the load.

8.3 Measurement Update Times

As discussed at the beginning of this section, the reading update rate is reduced in Dual

Measurement Mode because the two readings are made alternately. However, the reading rate

is not simply halved because eno ugh time must be allowed for each measurement to fully settle

to the different conditions before the display is updated; unless this is done neither display will

reliably show the true measurement value. The settling time depends on the differenc es

between the main and secondary measurement range, function, and signal level; the dela y is

longest when both displays s how an ac measurement. Note that the settling times allowed

assume a steady state signal; varying signals, or signals t hat exceed the range maxim um on

either measurement, will give unpredictable readings .

The following table summarises the measurement time (i.e. the time for the measurement to settle

and the display to be updated) for each parameter in all t he perm itted display combinations.

Page 19

Page 21

Main

Secondary

Measurement Time

(4SPS)

Measurement Time

Any Dual Function

None

.25s

.05s

Vac, dB, Iac

Hz*

.25s

.05s

Hz*

Vac, Iac

.25s

.05s

Vac, dB, Iac

Vdc, Idc

.5s

.1s

Vdc, Idc

Vac, Iac

.5s

.1s

Vac, dB

Iac

6s

3s

Iac

Vac

6s

3s

Vdc + Vac

Vdc, Vac, Hz

.5s

.1s

Idc + Iac

Idc, Iac, Hz

.5s

.1s

*Any Hz dual measurement

.25s

.125s

(20SPS)

Measurement Time

(4SPS)

Measurement Time

(20SPS)

Frequency measurem ents have a fixed measurement tim e (gate time) of 0.25s or 0.125s

depending on the sample speed. This fixed measurement time only applies to the frequency

measurement, not the other dual measurement. For example if the sample speed is set to fast

(20SPS), the main measurement is Hz and the secondary measurement is VAC, then VAC will

be updated every 0.05s but the frequency measurement will only update every .125s.

9 Triggered Operation

A screw-less connector on the rear panel provides both an input and output si gnal.

9.1 Trigger In Signal

The trigger input (- I/P+) connects to the LED of an opto-isolator through a 1kΩ resistor.

Apply >+3V to set trigger input True; maximum safe applied input is +10V.

The trigger input can be set to perform either of two actions, as set from the Utilities menu – see

section 12.4

1. Hold measurement – the measurement in progress at the point that the input is set True

2. Log measurement – with the Logging func tion operating, the measurement i n pr ogress

.

is frozen on the display.

at the point that the input is set True will be logged.

9.2 Trigger Out Signal (Measuremen t C o m p l ete)

The trigger out signal (- O/P+) goes True each time an input trigger action is c ompleted.

The trigger out signal is an opto-isolated open collector output with Low = True. The output

conducts for 250ms on completion of an input t rigger action.

The trigger output requir es an external pull-up (e.g. 4.7kΩ to 5V) and sinks typically 2mA

maximum when True; maximum safe off-state voltage is +10V.

Page 20

Page 22

10 Advanced and Programmable Functions

A number of additional funct ions are available via the Funct i ons menu, accessed by pressing

the [Function] key. These include:

Limits, Min/Max, Ax+b, D elta%, Watts and VA. An additional function of Logging is describe d in

the next section.

All functions are m utually exclus ive and use the secondary display to show the result.

Consequently they cannot be used with any measurement that requires the secondary display

such as dual measurements and dB. Selecting a function will cancel dual measurement mode.

To cancel a function, press [Function] again. Changing the measurement parameter or

selecting dual measurements will also cancel a func tion.

10.1 Selecting or Cancelling a Function

A function is selected by pressing [Function]. This causes symbols for all of the availabl e

functions to be displayed, with the most recently used one flashing. The Navigator keys are

then used to change the f unc tion (if required) and [OK] is used to select i t.

A Function is cancelled by pressing [Function] again. Selecting a new measurement

parameter will also cancel the function. Note that pressing [Cancel] will also cancel the

function, but will also canc el other things such as Hold – see section 6.13

10.2 Limits

.

High and low limits can be set, against which the reading is compared. When running, the main

display shows the actual r eading and the secondary display shows {PASS} (reading between

or equal to set points), {HI} (r eading > H I) or {LO} (reading <LO).

The units and decimal point pos ition for the limit values are set by the existing measurement

parameter and range which must be selected before the function is selected.

To select Limits, press [Function] and use the Navigator keys to choose {Limits} as the

flashing symbol. Confirm with [OK]; the secondary display will flash the word {run}.

To view or edit the Limit values, press the Navigator [<] or [>] key to s elect {Edit} and confirm

with [OK]. The existing High limit {HI} value will be displayed and can be changed using the

Navigator keys ([<] / [>] to select the digit and [ᴧ] / [v] to c hange the value). Once the value is

set, it is confirmed with [OK], after which t he Low limit value {LO} can be viewed and edited in

the same way.

Once the {LO} value has been confirmed the display will return to flashing the word {run}.

Pressing [OK] at this point will start the f unc tion running.

The limits can be set anywhere in the range ±000000 to ±999999 with the decimal point set by

the range selected during editing. Pressing the shifted key Clear [Shift] [Auto] enters the

default value of +000000; pressing the shifted key Copy Rdg [Shift] [Stop] enters the current

reading as the value.

Limit values are stored as floating point numbers which are retained for any range and any

measurement parameter until {Edit} is selected again. At that point the displayed value, which

may be truncated or under-flowed by the limitations of the display with a changed decimal point

position, becomes t he st or ed number.

10.3 Ax + b

When running, the scaled value (Ax + b) is shown in the secondary display and the normal

value (x) is shown in the m ai n dis pl ay. If the scaled reading exceeds ±999999, {-Or-} is shown

in the secondary display to indicate over-range.

The decimal point positi on for the b value is set by the existing measurement parameter and

range which mus t be selected before the function is s elected.

Page 21

Page 23

To select Ax + b, press [Function] and use the Navigator keys to choose {Ax+b} as the

flashing symbol. Confirm with [OK]; the secondary display will flash the word {run}.

To view or edit the A or b values, press [<] or [>] to select {Edit} and confirm with [OK]. The

existing A value will be displayed and can be changed using the Navigator keys ([<] / [>] to

select the digit and [ᴧ] / [v] to change the value) . Once the value is set, it is confirmed with the

[OK], after which the b value can be viewed and edited in the same way.

Once the b value has been set and confirmed with [OK], the display will retur n to flashing the

word {run}. Pressing [OK] at this point will start the function running.

A is variable from ±00.0001 to ±99.9999, with the decim al point in a fixed position after the

second digit; the default value is +01.0000, which can be restored by pressing shift ed key Clear

[Shift] [Auto]. The A value is retained for any range and an y measurement parameter until

changed using Edit.

b is a floating point number variable over the range ±000000 to ±999999 with the decimal point

and units set by the range selected during editing. Pressing the shifted key Clear [Shift] [Auto]

enters the default value of +000000; pressing the shifted key Copy Rdg [Shift] [Stop] enters

the current reading as the va lue.

The b value is retained for any ra nge and any measurement parameter until {Edit} is selected

again. At that point the display ed v al ue, which may be truncated or under-flowed by the

limitations of the display with a changed decimal point position, becomes the stored num ber.

10.4 Min-Max

The Min-Max function stores the maximum (most positive) an d minimum (most negative) values

that occur when the function is r un, and displays either in the s ec ondary display simultaneously

with the normal measurement in the main display.

To select Min-Max, press [Function] and use the Navigator keys to choose {Min Max} as the

flashing symbols. Confirm with [OK]; the secondary display will flash the word {run}.

When running the maximum reading will be shown on the secondary display initially with the

{Max} symbol displaye d. Press [<] to view the Min value. Press [<] or [>] to alternate between

displaying the maximum and minimum values.

Min and Max are stored as floating point numbers and the function can be operated with the

meter changing ranges eit her manually or by auto-range.

After leaving the function, the values remain stor ed and can be viewed at any time. To do this

re-select Min-Max as the func tion and use the navigator keys to select {rECALL}. Confirm with

[OK] and use [<] and [>] to alternate between the two values which are s hown on the primary

display.

Pressing the shifted key Clear [Shift] [Auto] with either Max or Min displayed will r es et it.

10.5 Delta %

The Delta % function displays the percentage deviation of the measurement from a refer enc e

value in the secondary display. The main display shows the normal reading.

Delta % = Reading - Reference %

Reference

The Delta % maximum display is ±999.99% and the resolution is fixed at 0.01%. The display

shows {–Or–} (over-range) if the maximum is exceeded.

To select Delta %, press [Function] and use the Navigator keys to choose {Δ%} as the

flashing symbol. Confirm with [OK]; the secondary display will flash the word {run}.

To view or edit the reference value, press the Navigator [<] / [>] to select {Edit}

with [OK]. The reference value will be displayed and can be changed using the Navigator keys

([<] / [>] to select the digit and [ᴧ] / [v] to chang e the value). Once the value is set and

Page 22

and confirm

Page 24

confirmed with [OK], the display will ret urn to {run}. Pressing [OK] at this point will start the

function running.

The reference value is can be number variable over the range ±000000 to ±999999; the

decimal point position is set by the range in use during edit. The reference default value of

10000 (decimal point determined by range) can be entered by press ing the shifted key Clear

[Shift] [Auto]. The latest meter reading can be ent er ed by pressing the shifted key Copy Rdg

[Shift] [Stop].

10.6 Watts

The Watts function calculat es power using the formula

Watts = V2/R

It can only be run when Vdc or Vac ar e selected in the main display. The reference impedance

can be set anywhere between 0.1 and 99999.9 Ohms.

To select Watts, press [Function] and use the Navigator keys to choose {W} as the flashing

symbol. Confirm with [OK]; the secondary display will flash the word {run}.

To view or edit the reference value, press the Navigator Lef t or Right key to select {Edit} and

confirm with [OK]. The ref er ence value will be displayed and can be chang ed us ing the

Navigator keys ([<] / [>] to select the digit and [ᴧ] / [v] to c hange the value). Once the value is

set confirmed with [OK], the display will return to {run}. Pressing [OK] at this point will start the

function running.

10.7 VA

The VA function calculates power by multiplying voltage and c urrent readings. The meter must

be connected for both voltage and current measurement, see Making Voltage and Current Dual

Measurements, section 8.2

To select VA, press [Function] and use the Navigator keys to choose {VA} as the flashing

symbol. Confirm with [OK]; the secondary display will flash the word {run}. Pressing [OK]

again will start the function running.

, with Vdc or Vac selected f or the main display.

11 Data Logging

The logger function can store up to 500 readings from the main display in non-volatile memory.

The store is linear, with no wrap-around. Readings are triggered by either the internal t imer,

manual key press, external tr i gger input (-I/P+) True, or remote interface command. Readings

are stored as floating-point numbers with their units and reading number but without an y form of

time stamping.

11.1 Setting-up the Logger

To select the Logger, press [Function] and use the Navigator keys to c hoos e {LOGGER} as

the flashing symbol. Confirm with [OK]; the secondary disp lay will flash the word {run}.

Use the Navigator keys to select {Edit} and confirm with [OK]. The primary display will show

{PEr} (Period) with the s econdary display showing the existing setting (default value = Off)

{OFF}.

Manual or External Triggered Logging (Off)

With the period set to {Off}, t he timer is inoperative and readings are stored only in response to

the Man Log key, the Ext Trigger, or a Remote Interface command. To return to {Off} from

another setting press the shifted key Clear [Shift] [Auto]. Confirm with [OK].

To log from the external tr igger input, the External Trigger function must be set accordingly –

see section 12.4

.

Page 23

Page 25

Logging Every reading (All)

With the period set to All {ALL}, the timer is inoperative and readings are stored after every

measurement, i.e. at t he m easurement rate of 4 readings/sec or 20 r eadi ngs/sec dependant on

mode and measurement speed s etting. To select All, fir st s et t he period to Off (using the shifted

key Clear [Shift] [Auto]) and press [v]. Confirm with [OK].

Logging from the Timer

To engage the timer starting from Off or All, press the Navigator Up key once or twice

respectively. The displ ay will show 0001 representing a t imer period of 1 second. This can be

changed to any value up to 9999 sec onds using the Navigator keys ([<] / [>] to select the digit

and [ᴧ] / [v] to c hange the value). Confirm with [OK].

Multiple Trigger Sources

A reading is logged in response to any valid trigger source. Thus, for example, the timer can be

set to log at fixed intervals and additional intermediate readings logged by pressing

[Man Log], or generating an external trigger command.

11.2 Running the Logger

Once the logger has been set up as described above, confirmation of the period will return the

secondary display to flashing the word {run}. Pressing [OK] at this point will start the logger

running.

The reading number is shown in the secondary display (001 to 499). When the maximum

number of readings is reached the display shows {FULL}. If the logger has existin g readings

stored, new readings will commence at the next available store number.

Note that all logging sourc es are OR’ed so that, the timer (if active), manual logging key, trigger

input, or remote interface command can all cause a measurement to be stored.

11.3 Starting and Stopping the Logger

Logging can be paused by pressi ng [Stop]. This returns the display to show a flashing {run}

and logging can be resum ed by pres s ing [OK]. Alternatively logger Edit, Recall or Clear can be

selected at this point.

When paused, no measurements, and no change to the measurement parameter or range, can

be made. To make changes or view the measurement without logging, the function must be

exited by pressing [Function]. Logging can be restarted by pressing [Function] and then

pressing [OK] twice.

11.4 Recalling Logger Readings

Logger readings are held in non-volatile memory until cleared, and can be viewed at any time.

To recall readings to the display, select the logger function and use the Navigator keys to sel ect

{rECALL}. Confirm with [OK].

The last viewed logger position is shown in the secondary display with the associated

measurement reading in t he main display. Use the Navigator keys to s croll through the

readings.

11.5 Clearing Logger Readings

To clear the contents of the logger, select the logger f unction and use the Navigator keys to

select {CLEAr}. Conf irm with [OK]. The secondary display wil l s how {nOnE} and all logger

entries will be cleared. It is not possible to clear individual logger entries.

Once cleared, the logger will commence from position 000 when run.

Page 24

Page 26

12 The Utilities Menu

A number of options can be set via t he Utilities menu. Pressing [Utilities] will cause the main

display to show {–Util–} with the currently selected menu item f las hi ng in the secondary

display. Use the Navigator keys to select the required item and select it with [OK].

When selected the item name will appear in the main display with the current status flashing in

the secondary display. Use the Navigator keys to change the stat us or value, and confirm it

with [OK].

Press the [Utilities] key again to exit the Utilities menu.

12.1 Beep Sound {BEEp}

An internal sounder is used to provide warnings of illegal actions or confirmation of completed

actions; it also provides a short beep whenever a key is pressed when the c ondition is set to on

{On}. The default condition is set to off {Off}. Note that even when the internal sounder is s et to

off, the continuity buzzer will still sound in continuity mode.

12.2 Measurement Speed {SPEEd}

The normal measurement speed is 4 readings/sec for most single measurement parameters.

For voltage, current and resistance measurements , the speed can be increased to 20

readings/sec at the expens e of resolution which reduces t o 12,000 counts (Speed = fast)

{FASt}. The default condition is slow {SLO}.

Note that Continuity m eas ur ements are always made at the higher speed. The measurement

speed is indicated by a flashing asterisk symbol on the left of the display – see section 12.10

.

12.3 Measurement Filter {FiLt}

In order to minimise jitter for sensitive measurements of DC volts and Resistance, an analogue

filter is incorporated that provides high rejection of 50Hz or 60Hz noise. Where the user

requires quicker response to signal changes, the filter can be switched off {OFF}. This is

particularly relevant when the measurement s peed is set to Fast.

The default condition is on {On}.