AGROWPLOW JPC 2000, Agrowdrill Operator's Manual

i

I

r

-

'

SOIL

CARE

AG

ROW

SYSTEMS INTERNATIONAL

DJUWITJJ

PTY.

LTD. AB.N. 29 075 828 947

. I

r

Operator's Manual

Revision 0

JPC

Agrowdrill®

2000 Series

th

04

December 2003

I

JPC 2000 Series Agrowdrill

Agrowplow

Soil Care Systems International Pty Ltd

ABN

29 075 828 947

Contact Details

134 Thornton Street

WELLINGTON

PO Box 270

WELLINGTON

Phone: 02

FAX: 02 6845 1603

Email: agrowplow@agrowplow.com

Website: www.agrowplow.com

NSW

NSW

6845

2820

2820

1566

II

i Quality

' Endorsed

i

Company

i 150il001

UCIIWT

;

-do,do

Aurttllllt

'Prosperity Through Soil Care'

Page i

JPC 2000 Series Agrowdrill

Table

1.0 Safety

1.1

1.2 Safe Operation Needs a Qualified Operator ...................................... 1

1.2.1 Understand the Instructions, Rules and Regulations ................ 1

1.2.2 Have Training with Actual Operation ......................................... 1

1.2.3 Know the Work Conditions ........................................................ 2

1.3 Safety Instructions ............................................................................. 2

of

Safety

Contents

.......................................................................................................

is

the Operators responsibility ................................................ 1

1

2.0 J PC 2000 Series Specifications .............................. 4

3.0 Principles

3.1

Weed Control. .................................................................................... 6

3.2 Timing ................................................................................................ 6

3.3 Seed .................................................................................................. 6

3.4 Seed Placement ................................................................................ 7

3.5 Ensure Adequate Plant Nutrition ....................................................... 7

3.6 The Job's Not Finished at Seeding .................................................... 8

3.6.1 Weed Control ............................................................................ 8

3.6.2 Insect Pest Control .................................................................... 8

3.6.3 Use

3.6.4 Grazing Management.. .............................................................. 9

of

Direct Drilling ..................................... 6

of

Fertiliser ......................................................................... 8

4.0 Hectaremeter Installation ...................................... 1 O

4.1

Installation Procedure ......................................................................

4.2 Hectaremeter Shaft Sensor Installation ...........................................

10

11

5.0 Operating lnstructions ........................................... 13

5.1

Hitching and Levelling ...................................................................... 13

5.1.1 Hitching ...................................................................................

5.1.2 Hydraulic Lift Circuit ................................................................

5.1.3 Levelling .................................................................................. 15

5.2 Tyre Pressures ................................................................................ 15

5.3 Seeding Depth ................................................................................. 15

5.4 Row Spacing ................................................................................... 16

5.5 Operating Speed .............................................................................. 16

5.6 Hopper Selection ............................................................................. 16

13

13

Page

ii

JPC 2000 Series Agrowdrill

6.0 Calibration Instructions ......................................... 17

6.1

Farmscan 1100 Hectaremeter .........................................................

6.2 Operation of the Hectaremeter ........................................................

6.3 Calibrating the Hectaremeter ...........................................................

6.4 Metering Rates ................................................................................

6.5 Method for Checking Metering Rates ..............................................

6.5.1

6.6 Field Calibration ...............................................................................

6.

7 Plotting Calibration Charts ...............................................................

6.8 Adjusting the Seed and Fertiliser Rates ...........................................

6.8.1 Gearbox Adjustments ..............................................................

6.8.2 Restrictors ...............................................................................

6.8.3 Gate Settings ..........................................................................

6.9 Calibration Charts ............................................................................

6.10 Agrowdrill Calibration Settings .........................................................

7

.0

Operating Tips ........................................................

7.1

7.2 Gradual Slowing

7.3 Seizing of the Metering System .......................................................

7.4 Checking the Rotation

7

.5

Calibration Procedure ..............................................................

After the First Round ........................................................................

of

Fertiliser Flow ...................................................

of

the Drives ................................................

Cleaning Seed

and

Fertiliser Hoppers .............................................

17

17

18

19

19

20

21

22

22

22

23

24

24

32

33

33

33

33

34

34

8.0 Lubrication and Maintenance ............................... 35

8.1

Pre-Operation Check .......................................................................

8.2 Daily Service ....................................................................................

8.3 Lubrication .......................................................................................

8.4 Replacing Soil Openers ...................................................................

8.5 Downtube Assembly ........................................................................

8.6 Replacing Adjustable Gates ............................................................

8.7 Servicing Fluted Rollers ...................................................................

8. 7 .1

8.7.2 Fluted Rollers ..........................................................................

8.7.3 Drive Shaft Mounting Bushes ..................................................

8.8 Major Servicing of the Metering Mechanism ....................................

8.9 Servicing the Gearboxes .................................................................

8.10 Drive Chain Adjustments .................................................................

8.11

8.12 Hectaremeter Sensor and Cable .....................................................

8.13 Hectaremeter Multimeter Test ......................................................... 40

8.13.1 Reed Type Sensor ..................................................................

8.13.2 Sensor Cable ...........................................................................

8.14

Drive Sprocket Bearings ..........................................................

Drive Chain Maintenance ................................................................ 40

End

of Season Storage ....................................................................

35

35

35

36

36

37

37

37

37

38

38

39

39

40

40

41

41

9.0 Trouble Shooting ................................................... 42

9.1

Underframe ...................................................................................... 42

9.2 Metering System ..............................................................................

9.3 Hydraulics ........................................................................................ 46

9.4 Hectaremeter ...................................................................................

44

47

Page iii

JPC 2000 Series Agrowdrill

1.0 Safety

1.1

Safety

is

the Operators Responsibility

The Agrowdrill

a wide variety of conditions. It can be used for direct drilling applications

well as traditional cultivation and seeding to maximise seed germination and

plant establishment for pastures, summer crops, cereals, oil seeds and

legumes.

The Agrowdrill presents

on

and off road transport, tillage and seeding applications, as well

service and maintenance. The operator must be aware of these hazards.

The dealer will explain the capabilities, safe application, service requirements

.and restrictions of the Agrowdrill and demonstrate the safe operation

Agrowdrill according to Soil Care Systems International instructions. The

dealer can also identify unsafe modifications or use of unapproved

attachments.

The following publications provide information on the safe use

maintenance

• The operator's manual delivered with the Agrowdrill gives operating

information as well as routine maintenance and service procedures. It

is

a part of the Agrowdrill and must stay with the machine

Replacement operator's manuals can be ordered from your Agrowplow

Dealer.

• The Agrowdrill has machine decals that instruct on safe operation

care.

is

a robust and versatile direct drill capable of operating under

an

operator with hazards associated with setting

as

of

the Agrowdrill and attachments:

if

it

as

up,

machine

of

the

and

is

sold.

and

1.2 Safe Operation Needs a Qualified Operator

1.2.1 Understand the Instructions, Rules and Regulations

• The written instructions for the operation of the Agrowdrill are included

in

the Agrowdrill operator's manual and

• Check the rules and regulations for your location. These rules may

include any Federal and State safety requirements.

1.2.2 Have Training with Actual Operation

• Operator training must consist of a demonstration and verbal

instruction. This training

delivered.

Page 1

is

given by your dealer when the Agrowdrill

on

the machine decals.

is

JPC 2000 Series Agrowdrill

• New operators must start

controls until they

of the work area.

can

in

an

area without bystanders and use all the

operate the Agrowdrill safely under all conditions

1.2.3 Know the Work Conditions

• Operators must know any prohibited uses or work areas. They need to

know about excessive slopes

• Operators must know the local road transport regulations, and

understand the dangers and requirements of transporting wide and

heavy equipment.

• Always wear protective clothing when maintaining or servicing the

Agrowdrill.

• For operators to

drinks that impair their alertness or coordination while working.

Operators who are taking prescription drugs must get medical advice to

determine if they can safely operate a machine.

be

qualified, they must not use drugs or alcoholic

and

rough terrain.

1.3 Safety Instructions

READ THESE SAFETY INSTRUCTIONS CAREFULLY BEFORE

ALLOWING ANY PERSON TO OPERATE THE AGROWDRILL

1.

Review this manual before each season of use.

2.

Never allow anyone unfamiliar or untrained to operate the implement

3.

Operators must know and abide by any road transport regulations

pertinent to the transit of your Agrowdrill.

4.

Never leave the Agrowdrill

control levers or hydraulic hose failure will result

dropping. This can cause serious injury to someone near or under the

implement.

5.

Do

not transport the Agrowdrill without the tractor drawbar being

locked position. Transporting without the drawbar locked will result

loss

of

implement control and serious damage or injury.

6.

Do not transport

greater speeds will result

serious damage or injury.

7.

Do

not transport

that of the Agrowdrill being towed. Transporting with a smaller lead

vehicle will result

damage or injury.

8.

Do not pull the Agrowdrill from any point other than from the tractor

drawbar. Pulling from a point other than the designated tractor drawbar

can result

9.

Extreme caution should be

openers. These may

10.

Do

not ride

in

on

an

Agrowdrill

an

Agrowdrill with a vehicle of less gross mass than

in

tractor instability

be

an

Agrowdrill at any time.

in

a raised position. Accidental release of

in

the machine

in

excess

in

loss of implement control and cause

loss of implement control and cause serious

and

cause serious damage or injury.

used

when clearing coulters, tynes or soil

very sharp and cause serious injury.

of

20 kph. Transporting at

in

a

in

Page 2

JPC 2000 Series Agrowdrill

11. Use due care when adjusting or maintaining any aspect of the

Agrowdrill. Failure to do so may result

12. When undertaking maintenance

ensure that the tractor

is

turned off and the hydraulics are fully lowered.

in

serious injury.

on

the Agrowdrill the operator must

Accidental release of control levers or hydraulic hose failure will cause

the implement to drop down. This can cause serious injury to someone

near or under the machine.

13. If the Agrowdrill must be

maintenance, ensure the unit

in

a raised position for service or

is

securely supported with proper support

stands or the cylinder stoppers supplied with your Agrowdrill. After the

implement

is

secured release the hydraulics

on

to the supports

stop the tractor engine before starting work. If supports are not used

accidental release of control levers or hydraulic hose failure will cause

the implement to drop down. This can cause serious injury to someone

near or under the machine.

14.

Do

not remove any safety instruction decals.

15. Ensure that any safety decals are clear and visible. Clean and replace

as necessary.

and

Page 3

JPC 2000 Series Agrowdrill

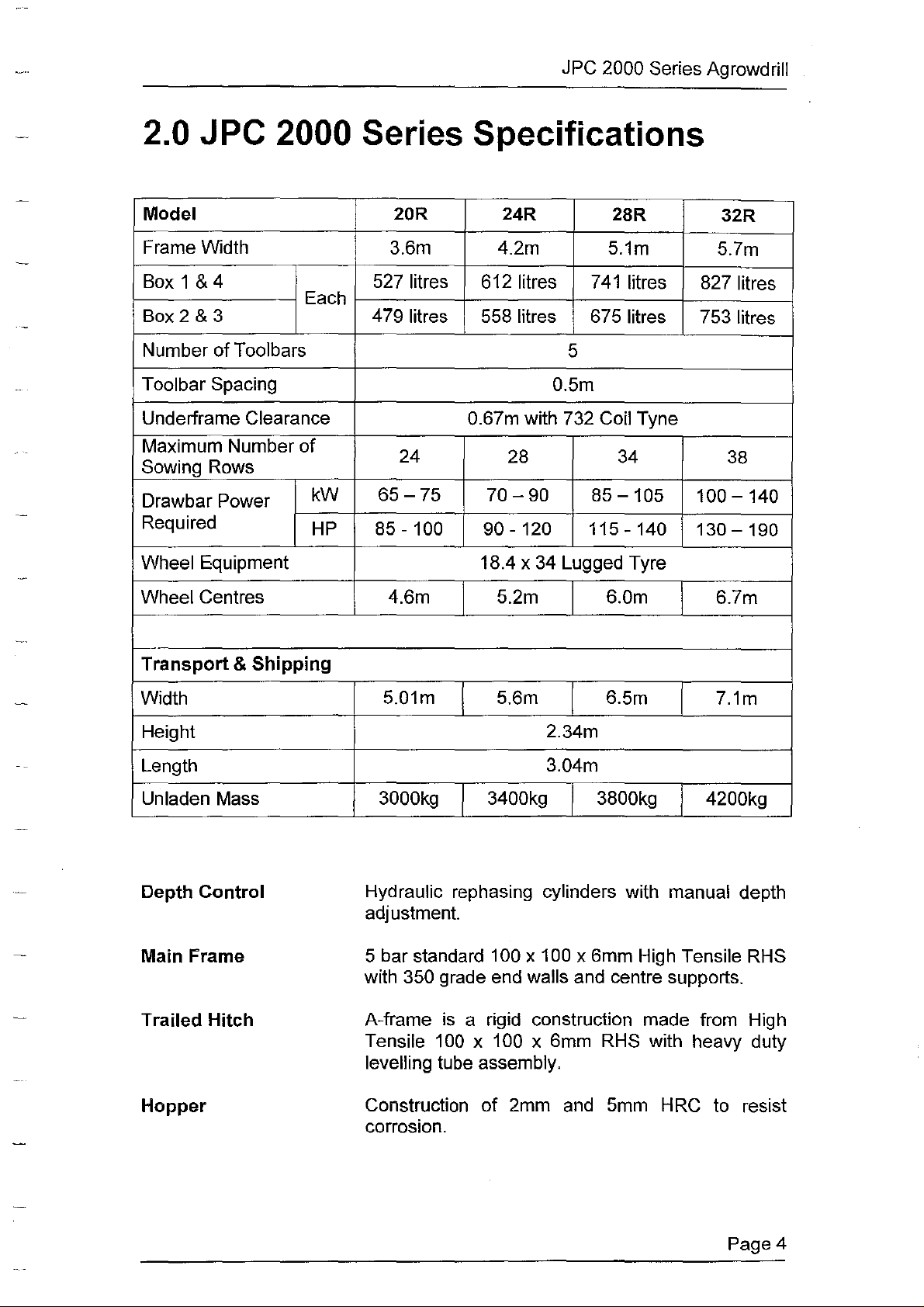

2.0 JPC 2000 Series Specifications

Model

Frame Width

Box 1 & 4

Each

Box 2 & 3

Number of Toolbars

Toolbar Spacing

Underframe Clearance

Maximum Number of

Sowing Rows

Drawbar Power

Required

Wheel Equipment

Wheel Centres

-

Transport & Shipping

kW

HP

20R 24R

3.6m 4.2m 5.1m

527 litres 612 litres

479 litres

558 litres 675 litres

741

5

0.5m

0.67m with 732 Coil Tyne

24

65-75

85

- 100 90 - 120

28

70-90

18.4 x

85-105

115-140

34

Lugged Tyre

4.6m 5.2m 6.0m

28R

litres

34

32R

5.7m

827 litres

753 litres

38

100-140

130-190

6.7m

Width

Height

Length

Unladen Mass

Depth Control

Main Frame

Trailed Hitch

Hopper

5.01m 5.6m 6.5m

7.1m

2.34m

3.04m

3000kg 3400kg 3800kg

4200kg

Hydraulic rephasing cylinders with manual depth

adjustment.

5 bar standard 100 x 100 x 6mm High Tensile RHS

with 350 grade end walls and centre supports.

A-frame

Tensile

is

a rigid construction made from High

100

x 100 x 6mm RHS with heavy duty

levelling tube assembly.

Construction

of

2mm and 5mm HRC to resist

corrosion.

Page4

JPC 2000 Series Agrowdrill

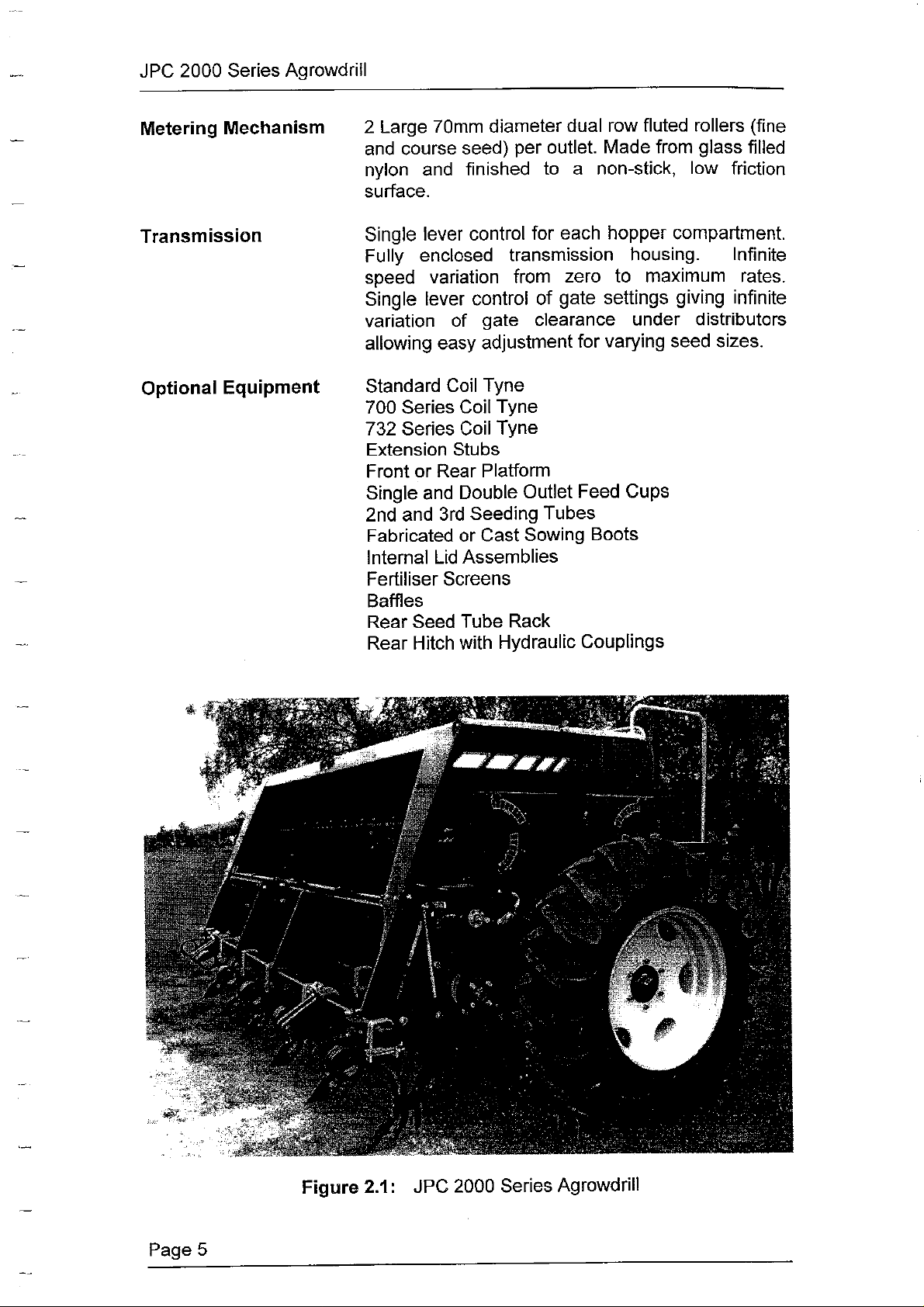

Metering Mechanism

Transmission

Optional Equipment

2 Large 70mm diameter dual row fluted rollers (fine

and

course seed) per outlet. Made from glass filled

nylon and finished to a non-stick, low friction

surface.

Single lever control for each hopper compartment.

Fully enclosed transmission housing. Infinite

speed variation from zero to maximum rates.

Single lever control of gate settings giving infinite

variation of gate clearance under distributors

allowing easy adjustment for varying seed sizes.

Standard Coil Tyne

700 Series Coil Tyne

732 Series Coil Tyne

Extension Stubs

Front or Rear Platform

Single and Double Outlet Feed Cups

2nd and

3rd

Seeding Tubes

Fabricated or Cast Sowing Boots

Internal

Lid

Assemblies

Fertiliser Screens

Baffles

Rear Seed Tube Rack

Rear Hitch with Hydraulic Couplings

Page 5

Figure 2.1: JPC 2000 Series Agrowdrill

JPC 2000 Series Agrowdrill

3.0 Principles

3.1

Weed

Good weed control

pasture.

Weed control

the ground-engaging tool physically cuts and tears the roots of unwanted

plants from the soil.

Direct drilling calls for a different approach. Some of the alternatives available

for weed control include:

• Heavy grazing

• Spraying with herbicides

• Slashing

• A combination of the above

Control

is

essential for successful establishment of a new crop or

is

one of the main reasons for traditional cultivation practices -

of

Direct Drilling

3.2 Timing

Timeliness

and best yield results.

There are two main aspects of timeliness you must consider:

• Always check the optimum seeding date for your district and seed

• Ensure the best use

of

time.

the soil

the seeding operation

of

available moisture after rain by seeding while

is

moist.

is

critical for good germination, growth

on

3.3 Seed

Use only good quality certified seed. Certified seed

minimum standard germination percentage and to be free of weed seeds

impurities. Use the recommended seeding rate.

Your seed supplier or your local advisory officer can tell you how many

kilograms per hectare (kg/Ha) you should sow. Adequate plant population will

also help your establishing crop or pasture compete with weeds.

is

guaranteed to meet a

and

Be

sure to inoculate legume seed with the correct strain of Rhizobia bacteria.

Failure to inoculate could lead to a poor pasture stand. Talk to your seed

supplier about inoculation and ask them to supply the inoculant.

Page 6

JPC 2000 Series Agrowdrill

Your seed supplier will also

your seed for insect attack and various soil borne diseases.

be

able

to

advise about chemical protection of

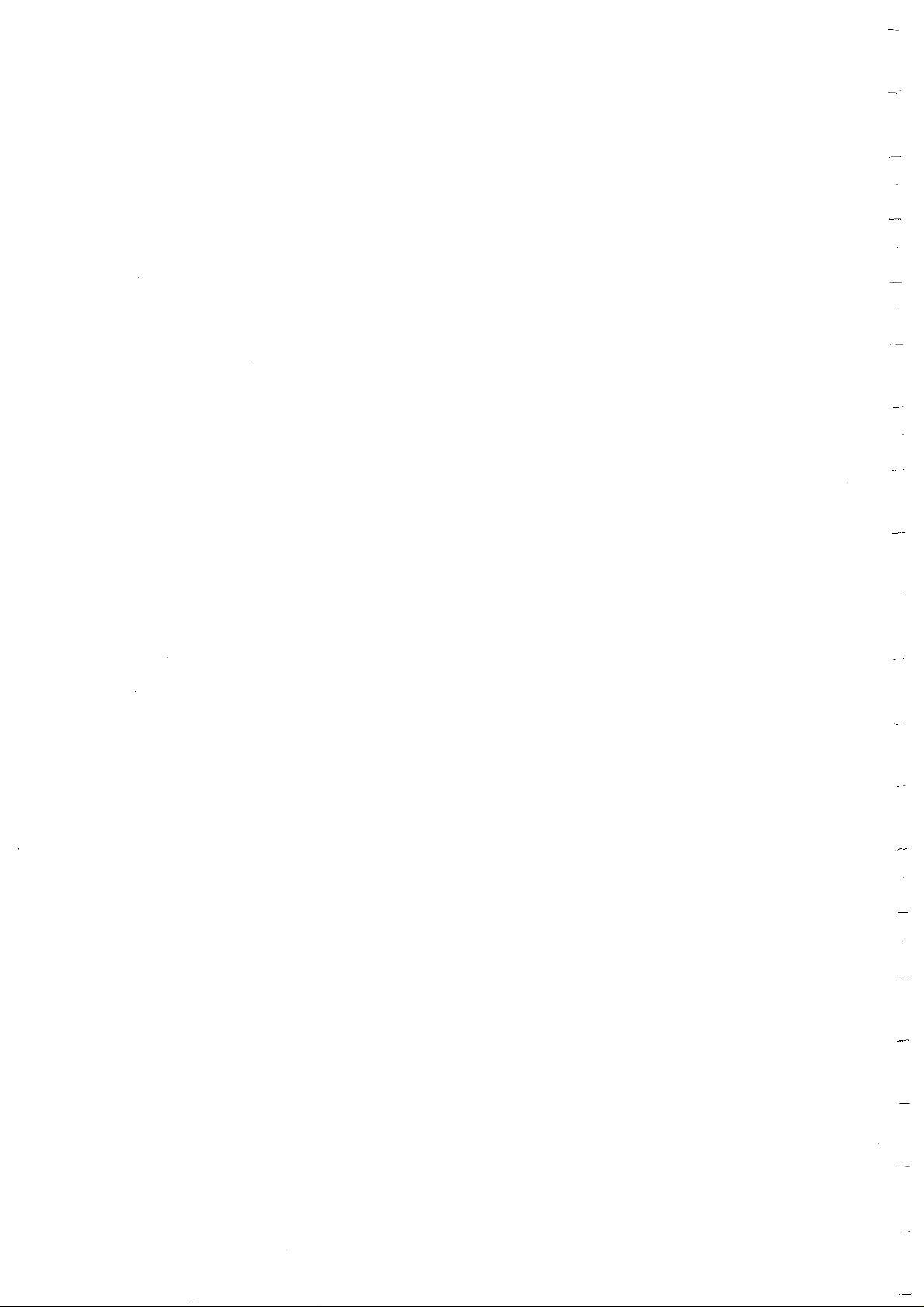

3.4 Seed Placement

Accurate seed placement

always be covered and

depth varies with species and is generally related to seed size.

Small seeds generally need to

of placing seed accurately at any depth from a few millimetres down to 75mm

(3"). Ask your seed supplier or advisory officer how deep you should be

sowing and adjust the Agrowdrill accordingly.

The Agrowdrill can be set up to seed at various row spacings. Sowing row

spacing,

if

coulters are not fitted,

is

crucial for successful germination. Seed should

in

contact with moist soil (see figure

be

placed shallow. The Agrowdrill

can

be

virtually infinite.

3.1

).

is

Seeding

capable

Figure 3.1: Seed to soil contact.

3.5 Ensure

Most Australian soils are low

boost pasture and crop growth. Young plants especially need good nutrition.

The need for fertiliser can be assessed

• Paddock history.

• The vigour of existing vegetation.

• Chemical soil tests.

• Trial plots.

Advice

officers, agricultural consultants or fertiliser companies.

Fertilisers are available

different ways. The Agrowdrill can "band" artificial fertilisers close to the seed

and provide nutrition where it

on

fertiliser requirements

Adequate

in

in

many different forms and can be applied

is

most

Plant Nutrition

fertility and need to have nutrients added to

in

a number of ways:

can

be

sought from government advisory

in

many

need.

Page 7

Loading...

Loading...