1

USER MANUAL

Return the warranty certificate within

15 days together with a copy of the

invoice (without these documents the

warranty procedure cannot be

implemented).

DISC-O-MULCH

10/12m

Original Manual

AGRISEM INTERNATIONAL - 535 Rue Pierre Levasseur CS 60263 – 44158 ANCENIS CEDEX

Tel.: +33 (0)2 51 14 14 40 – Fax: +33 (0)2 40 96 32 36

NOTT-E-700 01/07/2016

2

3

FOREWORD

This manual is provided with your machine to enable you to make optimum use of your equipment, in

particular under safe working conditions.

All owners are reminded that the manual is an essential accessory which must remain with the

machine at all times, and that in the event of resale, article 1615 of the Civil Code requires that as

such it must be handed over to the new owner.

You are also reminded that as the manual is essential to the machine, all owners must undertake to

leave it physically available with the machine for all users to consult.

4

5

AGRISEM INTERNATIONAL - 535 Rue Pierre Levasseur CS 60263 – 44158 ANCENIS CEDEX

Tel.: +33 (0)2 51 14 14 40 – Fax: +33 (0)2 40 96 32 36

6

7

DECLARATION OF COMPLIANCE

WITH THE "MACHINERY" DIRECTIVE

The manufacturer referred to above certifies that the new equipment described below:

DISC-O-MULCH

Complies with the provisions of the amended "Machinery" directive (Directive 2006/42/CE) and with

the applicable national legislation.

ANCENIS,

21 May 2013

Michal Guzowski

Chief Executive Officer

8

Identification of the machine

This document should be kept inside this user manual

On receipt of the machine, please enter the corresponding information below:

Type of machine: .................................................................................

Serial number: ......................................................................................

Year of manufacture: ...........................................................................

Date of first use: ...................................................................................

Accessories: .........................................................................................

.............................................................................................................

....................................................................................................................................

Name of the Dealer: .............................................................................

Address: ...............................................................................................

.............................................................................................................

.............................................................................................................

Telephone number: ..............................................................................

AGRISEM INTERNATIONAL

535 Rue Pierre Levasseur CS 60263 – 44158 ANCENIS CEDEX

Tel.: +33 (0)2 51 14 14 40 – Fax: +33 (0)2 40 96 32 36

9

CONTENTS

1. INTRODUCTION ............................................................................................................................ 11

2. WARRANTY CONDITIONS ........................................................................................................... 12

2.1. EXCLUSIVE LIABILITY CLAUSE .......................................................................................... 15

2.2. COMPLIANT USE OF THE MACHINE ................................................................................. 16

2.3. SAFETY INSTRUCTIONS ..................................................................................................... 17

2.3.1.

Safety instructions ......................................................................................................... 17

2.3.1.1. Introduction ................................................................................................................ 17

2.3.1.2. Instructions to be followed before using the machine ............................................... 18

2.3.1.3. Instructions to be followed for hitching and unhitching .............................................. 19

2.3.1.4. Instructions to be followed before using the machine ............................................... 20

2.3.1.5. Instructions to be followed before carrying out any operations on the machine ....... 22

2.3.1.6. Instructions regarding installation .............................................................................. 23

2.3.1.7. Instructions regarding the hydraulic system .............................................................. 24

2.3.1.8. Instructions relating to the braking system ................................................................ 24

2.3.1.9. Instructions specific to AGRISEM seeders ................................................................ 25

2.3.1.10. Instructions relating to safety systems with spring assemblies ............................. 26

2.3.1.11. Instructions relating to transmission shafts with universal joints ........................... 26

2.3.1.12. Instructions relating to loading and transport ........................................................ 26

2.3.1.13. The user's workstation ........................................................................................... 26

2.3.1.14. Noise data .............................................................................................................. 26

2.3.2.

Safety symbols on the machine ..................................................................................... 27

3. TECHNICAL INSTRUCTIONS ....................................................................................................... 28

3.1. DISC-O-MULCH SETTINGS / USE ....................................................................................... 28

3.1.1.

Technical characteristics ............................................................................................... 28

3.1.2.

Hitching – Unhitching ..................................................................................................... 29

3.1.2.1. Tractor-mounted machine ......................................................................................... 29

3.1.2.2. Trailed machine ......................................................................................................... 30

3.1.3.

Folding and unfolding the extensions ............................................................................ 33

3.1.4.

Unfolding into the Work Position ................................................................................... 34

3.1.5.

Folding into the Transport Position ................................................................................ 35

4. Air Brake Coupling Procedure ........................................................................................................ 35

4.1. When Coupling ...................................................................................................................... 35

4.1.1.

When De-coupling ......................................................................................................... 35

4.1.2.

When driving on the road .............................................................................................. 36

4.2. Parking the machine .............................................................................................................. 36

4.2.1.

If the machine is to be left in the unfolded position ....................................................... 36

4.2.2.

If the machine is to be left in the folded position ........................................................... 36

4.3. Out-Rigger Wheels ................................................................................................................ 36

4.4. Work Settings ........................................................................................................................ 37

4.5. Transport wheel adjustment .................................................................................................. 37

4.5.1.

Adjusting the Transport Wheel Height ........................................................................... 37

4.5.2.

Adjusting the working depth using the roller .................................................................. 38

4.5.2.1. Adjusting the side deflectors on mounted and semi-mounted Disc-O-Mulch GOLD

machines 41

4.5.2.2. Adjusting the border spreading disk .......................................................................... 41

4.5.3.

4.6. SERVICING - MAINTENANCE ............................................................................................. 43

4.6.1.

4.6.2.

4.6.3.

4.6.4.

4.6.5.

4.6.6.

4.6.7.

4.6.8.

OPERATING RECOMMENDATIONS ........................................................................... 42

Servicing frequency ....................................................................................................... 43

Storage .......................................................................................................................... 43

Cleaning ......................................................................................................................... 44

Lubrication ..................................................................................................................... 44

Greasing ........................................................................................................................ 45

Maintenance .................................................................................................................. 45

Disks .............................................................................................................................. 47

Lighting system .............................................................................................................. 48

10

11

1. INTRODUCTION

The warranty certificate MUST be returned within 15 days of delivery of the machine to the final

user.

You have just taken ownership of your AGRISEM machine. It has been designed to give complete

satisfaction.

The equipment has been carefully designed using the latest technological solutions to reduce usage

costs.

However, for the best and most profitable use of your AGRISEM machine, please read this manual

carefully before starting it up and strictly follow the instructions. In particular, follow the instructions for

adjusting and servicing the machine, as well as the safety precautions, very carefully.

Please contact our distributor for any information or advice.

The instructions in this user manual must be read and applied by any persons who will be carrying out

work on or with the machine, in particular:

- Use of the machine (including preparation, repairs required during work and maintenance).

- Maintenance (servicing and inspection).

- Transport.

AGRISEM INTERNATIONAL cannot be held liable for personal injury or damage to equipment and

malfunctions resulting from failure to comply with the instructions given by the manufacturer in this

manual.

This user manual is an integral part of the machine and must always be kept with the machine,

especially in the event of resale.

AGRISEM INTERNATIONAL is constantly seeking to improve its products and reserves the right to

modify or improve its products with no obligation to apply these modifications or improvements to

products already on the market.

The instructions in this manual are not exhaustive and cannot cover all eventualities. The user must

comply with the applicable legislation, in particular with regard to safety, ensure that the rules of safety

and caution dictated by the situation are applied, use common sense and adapt the use of the

machine to the circumstances.

It is the Purchaser’s responsibility to check that the AGRISEM machine complies with the legislation

and regulations applicable to its final destination.

12

2. WARRANTY CONDITIONS

The warranty conditions applicable to machines fitted exclusively with genuine spare parts from

AGRISEM INTERNATIONAL are as follows:

DURATION

• If a defect is observed on a structural part within a period of 12 months as from the date of

delivery of the machine, and if this defect is due to faulty raw materials, or its manufacture at the

factory. The parts alleged to be faulty must be returned to the Company's address for an expert

inspection.

The following shall be considered to constitute proof of the date of delivery of the equipment:

- the date of the delivery slip and the purchaser’s invoice.

- the return of the warranty certificate within 15 days (with the dealer's and purchaser’s stamp

and signature) following delivery of the equipment.

MACHINES AND PARTS CONCERNED

• For the purposes of this warranty, the term “Machine” is exclusively used to designate machines

and parts manufactured by AGRISEM INTERNATIONAL. (It does not include external

components, in particular tyres, hydraulic hoses, etc. even though these parts are also supplied by

the Company)

• The warranty is void if any modifications have been made to the machine without

the formal agreement of AGRISEM INTERNATIONAL or if parts other than those

manufactured by the Company have been fitted (e.g. counterfeit wear parts).

EXTENT OF THE WARRANTY

• The warranty is limited to the reimbursement or repair of parts recognised as faulty with regard to

their raw materials or machining, in our factories by our Technical Departments.

• Any costs linked to the dismantling and replacement of the faulty part are not covered by the

warranty. The cost of transporting machines or machine parts to the place of repair and their

return to their owner is not covered either.

• Wear parts are not covered by the warranty.

PRECONDITIONS

The machine must be maintained and used in accordance with the instructions in this User Manual.

All of the safety measures described in the User Manual and in the manuals of any additional

equipment must be complied with.

All of the protection and safety devices and hazardous parts (e.g. shock absorbers) must be regularly

inspected and replaced if necessary.

The warranty is only valid if the customer has met the contract's general obligations, in particular the

payment conditions.

13

WARRANTY EXCLUSIONS

The warranty does not of course apply to:

- Faults due to normal wear, incorrect use, lack of maintenance, inadequate monitoring or

negligence.

- If the machine is damaged by an accident or develops a fault due to being used for purposes

other than those specified by AGRISEM.

- In the event of non-compliant use of the machine. Please consult chapter 3 with regard to this

point: Compliant use of the machine.

- If the manufacturer's instructions and requirements given in this manual are not complied with,

particularly those regarding safety, assembly, use, operation and servicing.

- In the event of improper handling on the part of the user.

- Causes due to the presence of foreign bodies.

- In the event of damage due to the machine being combined with other machines or

instruments without the prior written agreement of AGRISEM, and/or without complying with

the instructions given by the manufacturers of the tractor and other instruments or machines.

- If the machine is used with protection and safety devices that are incorrectly fitted or not

working.

- If the machine has been modified without prior written permission from AGRISEM, or if spare

parts, accessories or equipment have been fitted to the machine which were not

recommended by AGRISEM.

- In the event of non-compliant repair.

- If faults are due to the machine being immobilised.

- In the event of damage during transport or handling by a carrier. It is the recipient’s

responsibility to lodge the necessary complaints with the carrier.

- The adverse consequences of the machine being immobilised due to a fault or incident on the

machine are not covered by the warranty.

- Personal injury to the owner or a third party and the indirect consequences resulting from this

are not covered by the warranty.

Moreover, AGRISEM INTERNATIONAL shall not be liable for the payment of compensation for

any reason whatsoever in the event of the loss of crops or any damage whatsoever due to a fault,

hidden defect or machine breakdown.

The purchaser is always responsible for the choice of product and the suitability of the machine for

the result that he hopes to obtain. He is responsible for its correct use in line with professional

practice and the regulations.

Under no circumstances will AGRISEM INTERNATIONAL have any obligation with regard to the

final result.

LIMITATIONS AND LIABILITY

- The warranty cannot be assigned or transferred to any other person without the prior written

permission of AGRISEM INTERNATIONAL.

- Under no circumstances do those selling our machines have the right or power to make any

decision whatsoever, either express or tacit, in the Company's name.

- The technical assistance given by the Company or its representatives with the repairing or

operation of equipment does not make it liable for any costs and in no way alters or leads to

the waiving of the conditions of this warranty.

WARRANTY ENFORCEMENT PROCEDURE: TO BE STRICTLY ADHERED

TO BY THE DISTRIBUTOR AND BY THE PURCHASER

14

The warranty's enforcement is subject to strict compliance by the dealer and the user with the

following requirements:

A) RETURNING BY THE DEALER OF THE WARRANTY CERTIFICATE DULY COMPLETED AND

SIGNED BY THE DEALER AND THE PURCHASER.

B) Claims must be made without fail using an AGRISEM INTERNATIONAL"WARRANTY CLAIM

FORM" (see appendix) and sent by registered letter with acknowledgement of receipt by the

dealer to the company’s technical department within 10 days of the incident. This form must be

completed legibly by the dealer and must include the following information:

- Name and address of the dealer, code No.,

- Name and address of the purchaser,

- Type of machine,

- Working width,

- Machine serial number,

- Date of delivery to the purchaser,

- Date of breakdown,

- Precise references of the parts replaced, No. and date of invoice,

- Make and model of the tractor used,

- Detailed description and alleged cause of the incident.

- Surface worked with the Disc-O-Mulch,

- Utilised agricultural land belonging to the farm,

- Type of soil in terms of % clay,

- Proof of wear part invoice

- Stones yes no

- Parts replaced yes no (send the photocopy of the invoice)

C) Allegedly faulty parts are to be returned by the dealer to the Company's address for an

expert inspection, together with the copy of the warranty claim form provided for this purpose.

The dealer must order the faulty part from the spare parts department. Any transport costs

incurred by the returning of said parts are payable by the sender.

D) The final decision regarding payment under the terms of the warranty shall be made by the

company’s technical or general management. Whatever the reason for the warranty claim, this

decision is final and irrevocable and the purchaser undertakes to accept this decision both with

regard to the fault and the replacement of the part or parts.

Under no circumstances are the company's salesmen authorised to make such a decision, which

would be void.

NOTE: In the event of refusal, the part remains at the customer’s disposal for eight days. After this time it will be scrapped

with no appeal possible.

Under no circumstances do those selling our machines have the right or power to make any

decision whatsoever, either express or tacit, in the Company's name.

5-YEAR WARRANTY AGREEMENT

If the customer subscribes to the 5-year warranty, please see this agreement for the terms and

conditions of the warranty's enforcement.

15

2.1. EXCLUSIVE LIABILITY CLAUSE

AGRISEM INTERNATIONAL denies any liability for damage (and any indirect consequences linked to

it) resulting from one or more of the following causes:

- Non-compliant use of the machine.

- Failure to follow the manufacturer's instructions or those given in this manual,

particularly those regarding safety, assembly, start-up, use, operation and servicing.

- Unsuitable assembly, start-up, use and maintenance of the machine.

- Use of the machine with faulty protection and safety devices or safety and protection

devices that are incorrectly installed or not working.

- Combining of the machine with other instruments or machines without the written

agreement of AGRISEM and/or without complying with the instructions given by the

manufacturers of the tractor and other instruments or machines.

- Modifications made to the machine without the written permission of AGRISEM.

- Fitting of spare parts, accessories or equipment on the machine which are not

genuine or which have not been recommended by AGRISEM.

- Failure to monitor the wear parts on the machine.

- Use of the machine other than for the purposes specified by the manufacturer.

- Non-compliant repair and maintenance.

- Catastrophes resulting from the presence of foreign bodies, unforeseeable

circumstances and cases of force majeure.

Moreover, AGRISEM INTERNATIONAL cannot be held liable for injury to the owner or a third party or

for the indirect consequences of such an injury, whether or not it results from a fault. You are reminded

that a safe distance of 50 metres must be maintained around the machine.

Any claim for compensation for damage that did not occur directly on the machine is excluded.

AGRISEM INTERNATIONAL cannot be held liable for damage caused by driving or use errors.

AGRISEM INTERNATIONAL cannot be held liable for compensation for the consequences of the

instrument's immobilisation due to a fault or an incident on the machine.

16

2.2. COMPLIANT USE OF THE MACHINE

AGRISEM INTERNATIONAL products must only be used for the work for which they were designed:

Work on arable land under normal conditions

In the event of damage linked to the use of the machine other than for the purposes specified by the

manufacturer, the manufacturer shall be entirely released from liability.

Only use the machine in good technical condition, in accordance with the purpose for which it was

designed and in full knowledge of the risks.

Compliant use of the machine also involves:

- Compliance with the instructions for use, servicing and maintenance issued by the

manufacturer

- Compliance with all of the instructions in this manual, particularly including the safety

instructions

- The exclusive use of genuine spare parts, accessories and equipment or those recommended

by the manufacturer.

AGRISEM machines must not be combined with other machines or instruments without prior written

permission from AGRISEM INTERNATIONAL.

For any combinations, the user must also comply with the instructions given by the tractor

manufacturer.

AGRISEM machines must only be used, serviced and repaired by competent persons who are familiar

with the machine's features and operating procedures. These persons must be informed of the

dangers to which they may be exposed.

The user is required to strictly comply with the current legislation with regard to:

Accident prevention

Safety at work (labour code)

Driving on the public highway (Highway code)

He is required to observe the warnings affixed to the machine. Any modifications made to the machine

by the user or any other person without the prior written permission of the manufacturer releases the

latter from any liability for the damage which may result.

Damage resulting from non-compliant use of the machine:

Is entirely the user's responsibility,

May under no circumstances be assumed by AGRISEM INTERNATIONAL

17

2.3. SAFETY INSTRUCTIONS

2.3.1. Safety instructions

2.3.1.1. Introduction

Most accidents which occur during work, maintenance or travel from one place to another are due to a

failure to observe the most basic safety rules. It is therefore essential for anyone likely to be working

with this machine to adhere to the basic rules listed below and to the safety instructions displayed on

the stickers affixed to the machine.

This machine has been designed for a specific task. It must always be in good working order and must

only be repaired using genuine AGRISEM INTERNATIONAL spare parts.

This machine must only be used, maintained and repaired by competent persons who are familiar with

its features and its operating procedures and who are aware of the safety rules for accident prevention

and the dangers to which they may be exposed.

This machine must only be used in accordance with its purpose and in a condition that does not

present any safety risks. Any malfunctions likely to be detrimental to safety must be corrected

immediately.

The user is required to strictly adhere to the safety instructions in this manual and the stickers affixed

to the machine.

The user is also required to strictly comply with the current legislation with regard to accident

prevention, safety at work (labour code), occupational medicine and highway legislation.

Before using the machine for the first time, read all of the safety instructions in this user manual

carefully and familiarise yourself with the controls.

The machine must never be entrusted to a person who is not trained to use it.

Liability and warranty:

In addition to the other cases mentioned in this manual, the manufacturer denies any liability for any

injury or damage to equipment resulting from one or more of the following causes:

- Failure to follow the manufacturer's instructions or those given in this manual,

particularly those regarding safety, assembly, start-up, use, operation and servicing.

- Non-compliant use of the machine.

- Unsuitable assembly, start-up, use and maintenance of the machine.

- Use of the machine with faulty protection and safety devices or safety and protection

devices that are incorrectly installed or not working.

- Combining of the machine with other instruments or machines without the written

agreement of AGRISEM and/or without complying with the instructions given by the

manufacturers of the tractor and other instruments or machines.

- Modifications made to the machine without the written permission of AGRISEM.

- Fitting of spare parts, accessories or equipment on the machine which are not

genuine or which have not been recommended by AGRISEM.

- Failure to monitor the wear parts on the machine.

- Use of the machine other than for the purposes specified by the manufacturer.

- Non-compliant repair and maintenance.

- Catastrophes resulting from the presence of foreign bodies, unforeseeable

circumstances and cases of force majeure.

18

Similarly, in addition to the other cases mentioned in this manual, any claim under the warranty linked

to damage resulting from one or more of the above-mentioned causes is excluded.

2.3.1.2. Instructions to be followed before using the machine

Wear close-fitting clothes. Loose clothing may become caught in moving parts.

Wear individual protective equipment corresponding to the work you are planning to do

(gloves, shoes, goggles, helmet, ear protection, etc.).

Be aware that tillage equipment, even if not very wide, has very sharp parts (blades, shares,

disks, etc.) which can cause serious injury in the event of an accident.

Whenever the machine is used, check the area around the machine beforehand (presence of

children). Ensure you have sufficient visibility.

Before any work, ensure that the tractor is sufficiently weighted at the front to avoid any risk of the

front lifting. If not, add weights to the front of the tractor.

Check that screws, nuts and bolts are correctly tightened whenever you use the machine. Tighten if

necessary. Also check the condition of the tools and their fastening elements in accordance with the

instructions in this manual.

No-one must be within 50 metres of the machine when it is being folded and unfolded.

Check that the machine is correctly hitched.

Always install the pins and locking systems.

Check that the machine meets personal safety requirements.

Whenever you use the machine, check that the safety and protection devices are in place and

working. Replace any worn or damaged protectors immediately.

Move any people or animals likely to be in the area where the machine is being manoeuvred or

used. A 50-metre safety zone must be kept clear around the machine.

Go around the machine looking for any external damage and checking the condition of the protection

devices.

Only persons authorised by the owner of the machine and who have been trained and instructed are

allowed to work on and with this machine. The operator is responsible towards third parties when he is

working on and with the machine.

The owner of the machine must:

- Provide the operator with the user manual.

- Ensure that the operator has read it and understands it.

- Ensure that the operator knows the basic instructions regarding safety at work and accident

prevention.

19

2.3.1.3. Instructions to be followed for hitching and unhitching

Pay attention to the various possibilities permitted for the connecting of the tractor’s coupling

equipment to that of the machine.

Only combine equipment that is compatible (machine and tractor).

Check that the tractor has the characteristics necessary to hitch the machine.

WARNING:

Non-compliant implementation may result in a risk of the tractor breaking during operation,

being insufficiently stable when loaded and having insufficient manoeuvrability and braking

power.

Check that the tractor meets the necessary requirements before installing or hitching the machine.

The machine must only be mounted on or hitched to a tractor if it meets the necessary requirements.

Perform a braking test to check that the tractor can provide the regulatory deceleration power even

with the machine mounted or hitched.

The requirements relating to the tractor include:

- The total authorised weight

- The authorised axle loads

- The authorised vertical load on the tractor coupling point

- The permissible load capacities of the tyres mounted on the tractor

- Sufficient authorised load on the coupling point

You will find this information on the data plate or in the vehicle's registration papers and in the tractor

user manual.

The front axle must support at least 20% of the tractor's empty weight at all times.

Calculation of the real values of the total tractor weight, tractor axle load and the load capacity

of the tyres, and of the minimum ballast required:

The total authorised weight of the tractor indicated in the vehicle’s registration papers must be greater

than the sum of:

- The tractor's empty weight,

- The ballast,

- The total weight of the mounted machine or the vertical load of the hitched machine.

This instruction only applies in Germany:

If the axle loads and/or the total authorised weight are not complied with after all the possibilities have

been exhausted, the competent authority according to the law of the Land may issue a waiver based

on the report of an approved expert in the field of motor vehicle circulation and with the agreement of

the manufacturer, in accordance with article 70 of the German law governing the authorisation of

vehicles to use the public highway, and the obligatory authorisation under the German highway code.

Combining of machines: do not combine machines that are incompatible or are incompatible with the

tractor when combined.

20

AGRISEM denies any liability in the event of damage resulting from a combination of machines

No one must be standing between the tractor wheels and the tool when

that has not received written authorisation from AGRISEM.

Accidents linked to the breaking of components during operation may result from

unauthorised combinations of hitching equipment.

Hitching and ballasting are operations which involve a risk of injury.

Before hitching or unhitching:

- Place the machine on stable ground.

- Chock the machine and take all of the necessary measures to avoid the accidental

movement of the tractor.

The machine must only be coupled using the coupling points provided for this purpose and in

accordance with the applicable rules.

When hitching, do not exceed:

- The tractor's total authorised weight

- The tractor's authorised axle loads

- The permissible load capacities of the tyres mounted on the tractor.

hitching or unhitching.

2.3.1.4. Instructions to be followed before using the machine

WARNING

A failure to take movement or operating safety measures may result in accidents involving

crushing, cuts, entanglement, pinching or impacts.

Before start-up, check that the machine and the tractor are able to move and operate in complete

safety.

Never climb onto the machine or stand on it when it is moving.

Never work in reverse.

Never allow children to climb on the tractor or the machine, or to play near the equipment, even

if the machine is stopped.

When using or manoeuvring the machine ensure that no-one is within the manoeuvring or

working area.

The elements of the machine that are controlled by an external force have crushing and

shearing zones. Keep away from these hazardous areas.

Be aware of hidden obstacles (stones, roots, pipes, cables, etc.) in the event of a collision with an

obstacle.

In such an event you must stop the drive, stop the tractor engine, remove the ignition

key and wait for the machine to stop completely.

21

Before starting work again, check the machine for any damage.

If the obstacle is an electric cable or gas pipe, inform the appropriate authorities.

When using the machine, stones or other foreign bodies are likely to be thrown a considerable

distance.

Move any people or animals likely to be in the danger area around the machine.

Do not stand in the machine's working area or in the area where the machine rotates and pivots.

Each time the machine is used, carry out a careful visual inspection of the machine to detect any

external damage and ensure that the safety and protection devices are operating correctly. Also carry

out regular inspections of the various adjustments.

Do not approach the machine until all of the moving parts are completely immobile.

Enforce a 50-metre safety area around the machine.

With regard to driving:

Adapt your driving to ensure that you are in control of the tractor with the machine mounted or hitched

under all circumstances.

Take into account your personal faculties, the conditions of the land or road, the traffic, the visibility

and the weather, the tractor’s driving characteristics and the conditions of use when the machine is

mounted or hitched.

Ensure that the rules of safety and caution dictated by each situation are applied.

The speed and driving style must always be appropriate to the land, roads and tracks.

Reduce your speed on uneven ground or tight corners.

On bends, take into account the overhang and the inertia of the mounted tool.

Avoid sudden changes of direction at all times.

Do not leave the driver's seat until the equipment has completely stopped, the engine is off and the

parking brake is on.

Do not transport any people or animals on the machine and the additional tools during work or

transport.

When driving on the public highway:

Comply with the highway code applicable in your country.

Before going out onto the public highway, check the width of the machine and unbolt or

remove elements that exceed the regulatory width.

Take into account the widths authorised for transport and the transported height depending on the

hitched machine, in line with current legislation.

Before setting off on the road, ensure that the hitched machine is fitted with the lighting and signalling

devices required by the highway code and any other devices required by the current regulations.

AGRISEM rear signalling lights and panels may be removed when working. Check that this signalling

equipment has been correctly refitted.

Check that the equipment is clean and operating correctly. Replace all missing or damaged

equipment.

22

Before travelling on the road, secure all of the machine's pivoting parts in their transport position to

avoid dangerous changes of position. Also check that the screws, nuts and bolts are tightened and

that all of the machine parts are correctly attached and cannot move or become detached.

If your machine is a folding machine, the locking system must be engaged.

Follow the instructions in this manual on how to prepare the machine for transport.

If necessary, also check:

- The connection of the supply pipes;

- The braking system and the hydraulic circuit.

If the equipment does not already have them, fit signalling devices: lighting board, reflectors, reflective

plates or adhesive strips.

Ensure that the machine or additional equipment does not hide the tractor’s lights.

Ensure that the tractor tyres are inflated to the correct pressure.

Ensure that the tractor and additional equipment is correctly balanced.

Install ballast at the front and back to ensure that the brakes and steering are effective.

The tractor's front axle must systematically support at least 20% of the tractor's empty weight to

guarantee sufficient manoeuvrability.

Never drive at more than 25km/hour when under load.

Clean off any soil stuck to the machine before going out onto the road.

After using the public highway, ensure that the road is cleaned of any mud left by the tractor and tools.

The driver/owner has sole responsibility when transporting the machine on the public highway.

2.3.1.5. Instructions to be followed before carrying out any

operations on the machine

In particular during cleaning, servicing and repairs.

Comply with the instructions in this manual regarding the servicing of the machine.

Before carrying out any operations on the machine:

- Ensure that the machine is on stable ground.

- Stop the tractor engine, remove the ignition key, wait for all of the moving parts

to stop and engage the hand brake.

- Set the machine on the ground, depressurise the hydraulic circuit and allow the

machine to cool down.

- Secure the machine or elements that are in a raised position to avoid any accidental

lowering.

- Chock the machine.

If using a high-pressure washer or steam cleaner, it is essential to comply with the following points:

23

Do not clean the electrical and hydraulic components.

Never direct the high-pressure washer or steam cleaner nozzle directly at the

lubrication points or bearings.

Systematically keep the nozzle a reasonable distance from the machine.

Comply with the rules for using high-pressure washers.

Wear appropriate personal protective equipment for the work to be performed. In particular,

wear safety shoes and gloves to handle sharp parts.

Take all of the necessary precautions when fitting working parts that are both heavy and sharp.

The machine must only be serviced and repaired by competent persons who are familiar with the

machine's features and operating procedures.

The machine must only be repaired with genuine AGRISEM International spare parts.

For bare metal parts, use either an anti-rust product that leaves a greasy film or thick grease.

According to the type of machine: before carrying out any work on the electrical circuit or before any

welding operations, disconnect the wiring harnesses coming from the tractor. Disconnect the battery

and alternator cables.

Do not weld or use blow torches near pressurised fluids or inflammable products.

2.3.1.6. Instructions regarding installation

The machine may be fitted with electronic components and elements which may be affected by

electromagnetic emissions from other devices. This type of interference may be a source of danger for

people if the following safety instructions are not followed:

If devices and/or electrical components are installed on the machine and

connected to the on-board electrical circuit at a later date, the user must first

check that installing these components will not interfere with the vehicle's

electronics or other components.

Ensure that electrical and electronic components subsequently installed

comply with the current version of electromagnetic compatibility directive

2004/108/CEE and that they have a CE marking.

Before carrying out any operations on the electrical system, disconnect the battery's negative terminal.

Only use the recommended fuses. Using fuses which have too high an amperage may damage the

electrical system and create a risk of fire.

Ensure that the battery terminals are correctly connected, starting with the positive terminal and then

the negative terminal. When disconnecting the terminals, start with the negative terminal and then

disconnect the positive terminal.

Systematically fit the cover provided for this purpose on the battery's positive terminal. Be aware of the

risk of explosion when earthing.

24

Risk of explosion: avoid sparks and naked flames near the battery.

2.3.1.7. Instructions regarding the hydraulic system

If your machine is fitted with a hydraulic circuit, you must comply with the following instructions:

Warning! The hydraulic circuit is pressurised.

When mounting cylinders and hydraulic devices, take particular care to ensure that the circuits are

correctly connected, in accordance with the manufacturer's instructions.

Mark the sockets and connectors of the hydraulic connections between the tractor and the machine to

avoid handling errors.

Before connecting a hose to the tractor's hydraulic circuit, ensure that the circuits on both the tractor

side and the machine side are perfectly clean and not under pressure.

Before connecting, check that the hydraulic quick connectors on the machine and the tractor are free

from impurities.

Before performing any operations on the hydraulic circuit, lower the machine, depressurise the circuit,

switch off the tractor engine, engage the parking brake and remove the ignition key.

Before carrying out any operations, allow the machine to cool down and discharge the hydraulic

circuits' accumulators.

Check the hydraulic hoses regularly. Damaged or worn hoses must be replaced immediately. Check

the appearance of the hydraulic hoses to detect any signs of tears or abnormal wear.

When replacing hydraulic hoses, ensure that you only use hoses of the characteristics and quality

recommended by the machine's manufacturer.

Each time the machine is used, the hydraulic quick connectors' end fittings must be cleaned and the

protective caps must be fitted afterwards. Replace connectors which do not lock correctly or which

leak.

Hydraulic hoses must never trail on the ground.

If you find a leak, take all of the necessary precautions to avoid accidents. Never try to plug the leak

with your hand or fingers.

Any pressurised liquid, in particular oil in the hydraulic circuit, can penetrate the skin and

cause serious injury and infections.

In the event of injury, consult a doctor immediately.

To avoid accidents caused by unexpected hydraulic movements or by third parties, the distributors on

the tractor must be locked or immobilised when they are not being used or in their transport position.

2.3.1.8. Instructions relating to the braking system

The braking system must be checked and serviced regularly. Servicing and repair work and

adjustments must only be carried out by brake system specialists.

Stop the tractor immediately in the event of a brake system malfunction and have it repaired.

25

Before performing any operations on the braking system, place the machine on stable ground and

chock it.

After any adjustment or repair work on the braking system, perform a braking test.

2.3.1.9. Instructions specific to AGRISEM seeders

In addition to the instructions applicable to all of machines, AGRISEM seeder users must comply with

the following instructions:

Never climb onto the machine elsewhere than on the AGRISEM walkway provided for this

purpose.

Only climb onto the machine when it is stopped.

When operations are performed on the AGRISEM seeder or during flow tests, the seeder must be

stationary and a 50-metre safety area must be enforced around it. The hydraulic system must be

depressurised (e.g. turbine stopped) and the rear window of the tractor must be shut, the tractor

switched off and the ignition keys removed.

Ensure that no one is on or near the seeder when the grain is being loaded. The AGRISEM walkway

must only be used when the seeder is stationary.

Always ensure that the entire area within the seeder's dimensions is completely clear.

Never stand under the sun wheel when it is in its transport position.

When testing the distribution flow, the user must turn the sun wheel with care to avoid any injury.

When the wheel is rotating, no-one must be within 50 metres of the machine. This means that no-one

must put their fingers into the distribution grooves unless the transmission system is completely

stopped.

When changing the transmission gear ratios, ensure that the gearing and chain are handled with the

greatest care to avoid any injury. No-one must be within 50 metres of the machine. Avoid putting

yourself in danger when changing the gearing by avoiding climbing on the machine's beams or disks,

as this could be dangerous.

Ensure that the sun wheel is protected during transport to avoid it hitting anything or injuring anyone.

Similarly, when the turbine is started up, a safety area must be enforced around the machine due to

the risk of objects or liquids being ejected (e.g. soil, oil, stones, metal, etc.).

When travelling on the public highway, always be very careful and alert. As the rear visibility is

reduced during transport, ensure that the way is clear before reversing the machine (50-metre safety

area).

The user must comply with the highway regulations applicable in his country with regard to the front

hopper.

If the tractor’s signalling equipment is not sufficient (or not sufficiently visible) ensure that you fit your

front hopper with lighting and signalling plates.

When working, a 50-metre safety area must be enforced due to the risk of

objects being ejected.

26

2.3.1.10. Instructions relating to safety systems with spring

assemblies

Safety devices with pre-compressed spring assemblies are fitted on many AGRISEM tools. These can

be very dangerous when performing technical operations on the machine if all of the necessary

precautions are not taken.

WARNING: Written authorisation must be obtained from AGRISEM International before

carrying out any operations on the "Spring Assembly".

2.3.1.11. Instructions relating to transmission shafts with universal

joints

Consult the tractor manufacturer’s instructions when performing any operations on transmission shafts

with universal joints.

2.3.1.12. Instructions relating to loading and transport

Unless there is a specific transport agreement:

- For deliveries of less than three tonnes: the carrier is responsible for the loading, chocking,

securing and unloading of the equipment from when he takes charge of it until its delivery.

- For deliveries of more than three tonnes: loading, chocking and securing on the one hand, and

unloading on the other hand, are the responsibility of the contracting party or the recipient

respectively. The responsibility for any equipment damage that occurs during these operations

lies with the person carrying them out.

Unless there is a specific transport agreement, and for deliveries of more than 3 tonnes, the Purchaser

will therefore unload the machine under his own responsibility.

Similarly, if the Purchaser sells the machine and has it delivered, as the sender, he will be responsible

for the loading, chocking and securing of the equipment when it is sent.

In case of doubt regarding the unloading or loading, chocking and securing of the machine,

please contact AGRISEM International.

2.3.1.13. The user's workstation

The machine must be operated by one person only, from the tractor driver's seat.

2.3.1.14. Noise data

The sound pressure level is 77 dB(A), as measured at the level of the user's ear during operation with

the cab closed.

The sound pressure level mainly depends on the tractor used.

Measuring device: NICETY SL801A.

27

WARNING

ETIQ-501

ETIQ-502

ETIQ-503

ETIQ-504

2.3.2. Safety symbols on the machine

Keep a safe distance from the machine during work. Risk of serious injury.

Ensure that no-one is in the danger zone around the machine when the tractor engine is

running.

Keep a safe distance from the machine when lowering it. Risk of serious injury.

Ensure that no-one is under the machine when lowering it.

Beware of pinching. Risk of serious injury.

Do not touch the hazardous areas under any circumstances while the tractor engine is

running and the universal joint shaft, hydraulic circuit or electronic system is operating.

Keep a safe distance from the rear of the tractor during manoeuvres. Risk of serious

injury.

1- Connect turbine motor’s red hose to tractor

pressure distributor.

2- Connect turbine motor’s blue hose to tractor’s oil

tank inlet.

3- To avoid damaging the turbine, never let the air

pressure exceed 60 mbar.

Warning: never exceed a maximum air pressure of 60 mbar as this may damage the turbine.

ETIQ-908

Read the maintenance book and safety instructions before starting up the machine

and abide by them during operation.

28

3. TECHNICAL INSTRUCTIONS

depending on the

3.1. DISC-O-MULCH SETTINGS / USE

FOREWORD:

As far as possible, read this chapter while standing in front of the machine.

The DISC-O-MULCH's frame may be fitted with a variable number of elements. Each element is fitted

with a replaceable wear disk. The working depth of the disks is controlled by a depth control device in

the form of a roller (e.g. cage roller or Flexi-Pack roller).

When you receive the DISC-O-MULCH, check that its characteristics are appropriate. Then carry out

all of the preliminary operations prior to start-up as described in this manual.

3.1.1. Technical characteristics

=> Disc-O-Mulch GOLD TRAINE

Working width

(in metres)

Tractor power

minimum

Tractor power

maximum

Weight (variable

equipment)

Hitch type

Folding versions

10.00 12.00

257 KW 257 KW

350 ch 350 ch

331 KW 368 KW

450 ch 500 ch

13 330 Kg 15 240 Kg

Category 4 hitch

29

3.1.2. Hitching – Unhitching

No-one must be within 50 metres of the machine while it is being hitched or

It is ESSENTIAL to read the safety ins

tructions before reading the practical

Check that the tractor meets the necessary requirements before

instructions for hitching and unhitching the machines

Before hitching or unhitching the Disc-O-Mulch, it is important to ensure that:

- The top-links of the tractor's three point hitch are adjusted to the same dimensions

- The tractor tyres are inflated to the same pressure

- The tractor is suitable for the tool to be hitched and is weighted appropriately

- The tractor connections are suited to the tool to be hitched.

- When hitching, do not exceed:

Required tractor characteristics

- Total authorised weight

- Permissible load capacities of the tyres

unhitched

- The tool is or will be on stable ground and no-one is within 50 metres of the machine.

- The tractor's total authorised weight

- The permissible load capacities of the tyres mounted on the tractor.

- The tractor's authorised axle loads

hitching the machine:

The authorised values for the total weight, the axle loads and the tyre load

capacities can be found in the tractor's registration papers.

3.1.2.1. Tractor-mounted machine

Hitching a tractor-mounted machine:

1/ Ensure that the machine is on stable ground

2/ Bring the tractor up to the coupling on the machine.

3/ Place the lower link arms in line with the drawbar couplings.

4/ Hitch the lower link arms using the appropriate equipment.

5/ Adjust the length of the top link and attach it using the pin and clip provided.

6/ Lock all of the hitch pins with lock handles using the clip pins.

7/ Connect the hydraulic hoses if the machine is fitted them.

8/ Connect the plug for the lighting equipment and check that it is operating.

9/ Lift the machine.

10/ Fold the side extensions for transport.

11/ Lock the machine for transport if it folds using the hydraulic controlled hook or mechanical

locks.

30

12/ Ensure that everything is correctly connected and locked and that no there are no foreign

Take into account the c

learance, in particular to ensure that there is

bodies on the machine.

Point of convergence:

The point of convergence can be adjusted to improve the tractor's traction, stability and grip.

This also affects the tractor's lifting capacity.

On a tractor with 2 drive wheels, the point of convergence

must be near to the centre of the tractor.

On a tractor with 4 drive wheels, the point of convergence

must be towards the front drive axle.

To follow the land better, it is recommended to use the slotted hole.

If the slotted hole is used, make sure that the coupling pin is in the middle of the slot at all

times.

Parking:

1/ Ensure that the machine is unhitched on stable ground.

2/ Unlock the machine before unfolding it.

3/ Unfold the machine if it folds.

4/ Disconnect the hydraulic hoses if the machine is fitted with them.

5/ Disconnect the plug for the lighting equipment.

6/ Unhitch the machine.

room to pass under bridges and low power lines

Depending on the working conditions, the tractor's push bar can be positioned in a fixed hole

or in the slotted hole.

3.1.2.2. Trailed machine

Hitching a trailed machine:

1/ Ensure that the machine is on stable ground.

2/ Bring the tractor up to the coupling on the machine.

3/ Hitch the machine to the coupling ring or the tractor's links depending on the type of

drawbar fastening.

31

4/ Connect the hydraulic hoses if the machine is fitted with them according to the colour

Take into account the clearance during transport, in particular to ensure that there is

On tractor

-

mounted machines, the drawbar must be hitched to the top holes on the

marking. If you are using a towing hook, connect the hydraulic hoses first to be able to

adjust the height of the drawbar.

5/ Connect the plug for the lighting equipment and check that it is operating.

6/ Remove the parking stands (if the machine is fitted with them).

7/ Lift the machine with the drawbar and the trailed or semi-mounted kit.

8/ Fold the side extensions for transport (follow the instructions).

9/ Lock the machine for transport if it folds using the hydraulic controlled hook or mechanical

locks.

10/ Ensure that everything is correctly connected and locked and that no there are no foreign

bodies on the machine.

room to pass under bridges and low power lines (e.g. Disc-O-Mulch 9.00m)

lower arms. This improves the stability of the machine when working.

Parking:

1/ Ensure that the machine is unhitched on stable ground.

2/ Unlock the machine before unfolding it.

3/ Unfold the machine if it folds.

4/ Put the parking stands in place (if the machine is fitted with them).

5/ Lower the machine with the drawbar and the trailed or semi-mounted kit.

6/ Disconnect the hydraulic hoses if the machine is fitted with them. If you are using a towing

hook, disconnect the hydraulic hoses last to be able to adjust the height of the drawbar.

7/ Disconnect the plug for the lighting equipment.

8/ Unhitch the machine.

Connecting the hydraulic couplings:

The hydraulic couplings have coloured caps. This enables each of the functions to be identified using

the colour code.

Please refer to the table below:

Colours Functions

Blue Folding the extensions

Green Trailed kit

Red

Yellow

Black Other options

Locking hook

Drawbar

32

RBS2012 = Stop Valve

V60100200-001 = Cylinder of Lifting to set the first row of disc.

VS901601550-001 = Cylinder of folding/unfolding the DOM between the transport and work position

VS70120600-001 = Cylinder of folding/unfolding the side of DOM (6m).

VS60100070 = Cylinder to set the deep wheel control of DOM.

AAV-001 = Accumulator

MANO-0-250B = Manometer

33

It is ESSENTIAL to read the safety instructions before reading the

No-one must be within 50 metres of the machine while it is being folded or

Before folding or unfolding check that there are no foreign bodies that

Position

A

→

stop position

Position

B

MULTISTOP

3.1.3. Folding and unfolding the extensions

If you have a folding Disc-O-Mulch, take care when folding or unfolding. Please refer to the

chapter:

Follow the procedure below to fold your Disc-O-Mulch:

- Place the folding extensions' roller arms in the highest

MULTISTOP position (e.g. 15). This allows the rollers to be retracted

within the machine as much as possible in their transport position (see

section on adjusting the roller's height). The rollers must therefore

remain within the regulatory width (width of less than 2.98m during

transport).

- - Move the valves from position A to position B

valves are located at the level of the hydraulic hoses or the hydraulic couplers).

- The hydraulic locking kits will be engaged otherwise put the mechanical locking kit in

place (depending on the Disc-O-Mulch model)

practical instructions for hitching and unhitching the machines

could hinder movement

unfolded

(the stop

• Stop valve in position A:

→

→ standard position

→ →

• Stop valve in position B:

34

D

3.1.4. Unfolding into the Work Position

C

E G

F

1. Open the machine if possible on level ground, if this is not possible try and orientate the machine so

the drawbar and tractor is pointing up any slope.

2. Fold down the light units and open the inline hydraulic tap on the wing catcher circuit (A).

3. Operate the wing circuit (blue) spool. Then open the wings out (C and D). Continue to pressure the

wings out keep pumping until the wing cylinders have reached full stroke. When the wings are fully

open they will appear not to be parallel. This is to enable the machine to ‘float’ over uneven ground in

work and is normal.

4. With the wings fully open (E) operate the tilt (green) spool to lower the machine rearwards (F).

Continue to operate the tilt spool once the working elements have touched the ground. (G).

NOTE: when tilting rearwards from folded there will be a delay (5-15 seconds depending on flow)

before the machine begins to tilt. This is normal; continue to pump oil as normal.

5. With the machine now tilted onto the rear roll fully turn off the inline hydraulic tap on the wing (blue)

circuit. This will isolate the catcher arm circuit.

6. The machine is now ready to be set for work.

35

3.1.5. Folding into the Transport Position

Before folding the machine move the tines into their shallowest setting in order to achieve a transport

width of less than 3 metres when folded.

1. Remove any excess soil and debris from the machine.

2. If it has not already been done, turn off the inline hydraulic tap on the catcher line (blue).

3. Raise the transport wheels fully by extending the wheel cylinders (blue) to full stroke! This must be

done to avoid any damage to the machine.

4. Turn off the power source to the solenoid valve (the machine comes with this wired into the side

light function on the light cable). This must be done to allow oil flow out of the tilt cylinders.

5. With the wheel unit fully raised operate the tilt cylinder (green) circuit to fold the machine forward.

Continue to pump until the spine touches the stops on the drawbar.

6. With the wings now vertical, checking the taps on the catcher line is closed, operate the wing (blue)

circuit to close the wings around the drawbar.

7. With the wings closed around the drawbar open the tap on the catcher line.

8. With the catcher inline tap open continue to operate the wing (yellow) circuit to lift the catchers and

take the load of the machine.

9. Turn off the inline tap to lock the catchers up, fold the light units up and make one final check

around the machine.

10. The press is now ready for road transport.

4. Air Brake Coupling Procedure

Please refer to the following procedure when coupling or decoupling any item of

Simba Great Plains machinery fitted with an AIR brake or AIR and HYDRAULIC brake system. Please

note that this procedure does not apply to any machines fitted with a HYDRAULIC system ONLY.

4.1. When Coupling

1. Reverse up to the machine and connect the machine to the tractor as instructed.

2. With the machine connected couple the air lines. When coupling ensure the yellow line is attached

first followed by the red line.

3. Your brake hoses are now attached and are ready for operation.

4. Continue with the coupling process as instructed.

4.1.1. When De-coupling

1. Bring the machine to the parking position as instructed.

2. With the machine still connected to the tractor remove the red brake line followed by the yellow line.

3. Your brakes will now be ON and will hold, ensuring they have been adjusted and maintained

correctly, the machine in position. (note: if the machine‘s tank is drained of air once all lines have been

detached the brakes will come off (same situation as pushing the shunt valve).

4. Continue de-coupling the machine until it is fully disconnected.

36

By following the above instructions you will see that at NO point in the coupling or decoupling process

has the red line been left in the tractor on its own.

This is intentional and should be considered the ‘rule’ to coupling the hoses.

4.1.2. When driving on the road

When driving on the road the machine must be converted to the transportation position. When driving

on the road, raise the machine completely to prevent the working elements dragging on the ground.

Road transport speed should not exceed 16mph (25kph).

4.2. Parking the machine

In order to avoid damage as a result of moisture, the machine should be parked, if possible, indoors or

under cover. When maneuvering the machine, pay attention to your surroundings. Ensure that nobody

is in the maneuvering area (watch for children!). Park with the machine on level solid ground, if leaving

parked for a long period of time it is advised the machine is left in the unfolded or work position.

4.2.1. If the machine is to be left in the unfolded position

1. Follow the steps to unfold the machine but stop at the point where all working elements are touching

the ground.

2. At this point it will be possible to raise the drawbar and relieve the weight on the tractor hitch.

3. Turn off the tractor and remove the hitch pin.

4. Checking that the tilt cylinders are supporting the weight of the drawbar draw the tractor forward

enough so as to clear the hitch.

5. Lower the drawbar onto the ground. Fit the wheel chocks.

6. Turn off the tractor, depressurize all hydraulic lines and remove all hoses and cables from the rear

of the tractor, slowly draw the tractor forward.

4.2.2. If the machine is to be left in the folded position

1. Turn off the tractor. Swing the hydraulic jack from the transport position into the work position.

2. Fit the wheel chocks under the wheels.

3. Open the inline hydraulic tap and operate the hydraulic jack to take the weight of the machine. Turn

off the tractor and remove the drawbar pin.

4. Draw the tractor forward to clear the hitch. Lower the jack down so the ram rod is completely hidden

e.g.; there is now no oil pressure in the hydraulic hose. At this point turn off the tractor and place all

spools into float. Remove all hoses and slowly draw the tractor forward.

4.3. Out-Rigger Wheels

The Out-Rigger units support the wing tips in work

ensuring a level soil finish. The out-Rigger units

also support and lock the wings during road

transport.

37

4.4. Work Settings

In work the wing cylinders should be fully extended. A simple pressurized hydraulic circuit

automatically sets itself as the wings are unfolded. Optimum performance has been found to be when

the press roller has worn away the painted finish leaving a smooth shiny surface. When the press

roller is new or rusty, soil may tend to pick up on the surface and a blockage may occur. This will

reduce when the rings are shiny again. The press should be run with the chassis level by extending

the tilt cylinders to the necessary position then adjusting the trip switch.

NOTE: to ensure the correct machine pitch is achieved it is necessary to extend the tilt rams enough

to reset the switch then lower it back into work again. If this is not done it may appear that continual

switch movement has not effect. In practice it is possible to operate the press on ground conditions

that are unsuitable to achieve the desired effect, and it is usually possible to operate without regular

blockage. As such, especially under wet conditions, it is advisable to check on the cultivation effect of

the press. Generally a forward speed of 5-9 mph (8-12kph) will achieve optimum results, maximizing

inversion and burial. Speeds in excess of those stated above will tend to give deterioration in the

quality of the work. This may be seen as ridges or troughs across the work surface due to soil being

thrown too far by the disc/tine elements. In normal operation the machine should be drawn on forward

on the tilt cylinders until the limit switch is activated. For this to happen the power to the solenoid valve

must be on (switch on the side lights). With this system it is possible to run the tilt cylinder circuit in the

float position. This will allow the implement to contour follow as the tractor drawbar drops (e.g.: over

the brow of a hill).

4.5. Transport wheel adjustment

If when in work the center of the machine begins to dip or the machine enters a wet spot it is possible

to support weight on the middle transport wheels.

4.5.1. Adjusting the Transport Wheel Height

Operate the main tilt circuit (red) to extend the cylinders and support the weight of the machine on the

rear roll, continue to extend the cylinders until all tines/discs are out of work. Now, operate the wheel

cylinder circuit (blue). This will push the wheel cylinders open (the rear roll cylinders will also extend at

the same time). Add/remove the required number of shims from the wheel cylinders then operate the

circuit in the opposite direction to close the wheel cylinders. NOTE: ensure the shims on the wheel

cylinders and the rear roll are clamped up tight. Making sure no one is near the machine lower the

machine back into the work position. As long as the power to the limit switch is still on then the

pressure will return to the previously set pitch.

38

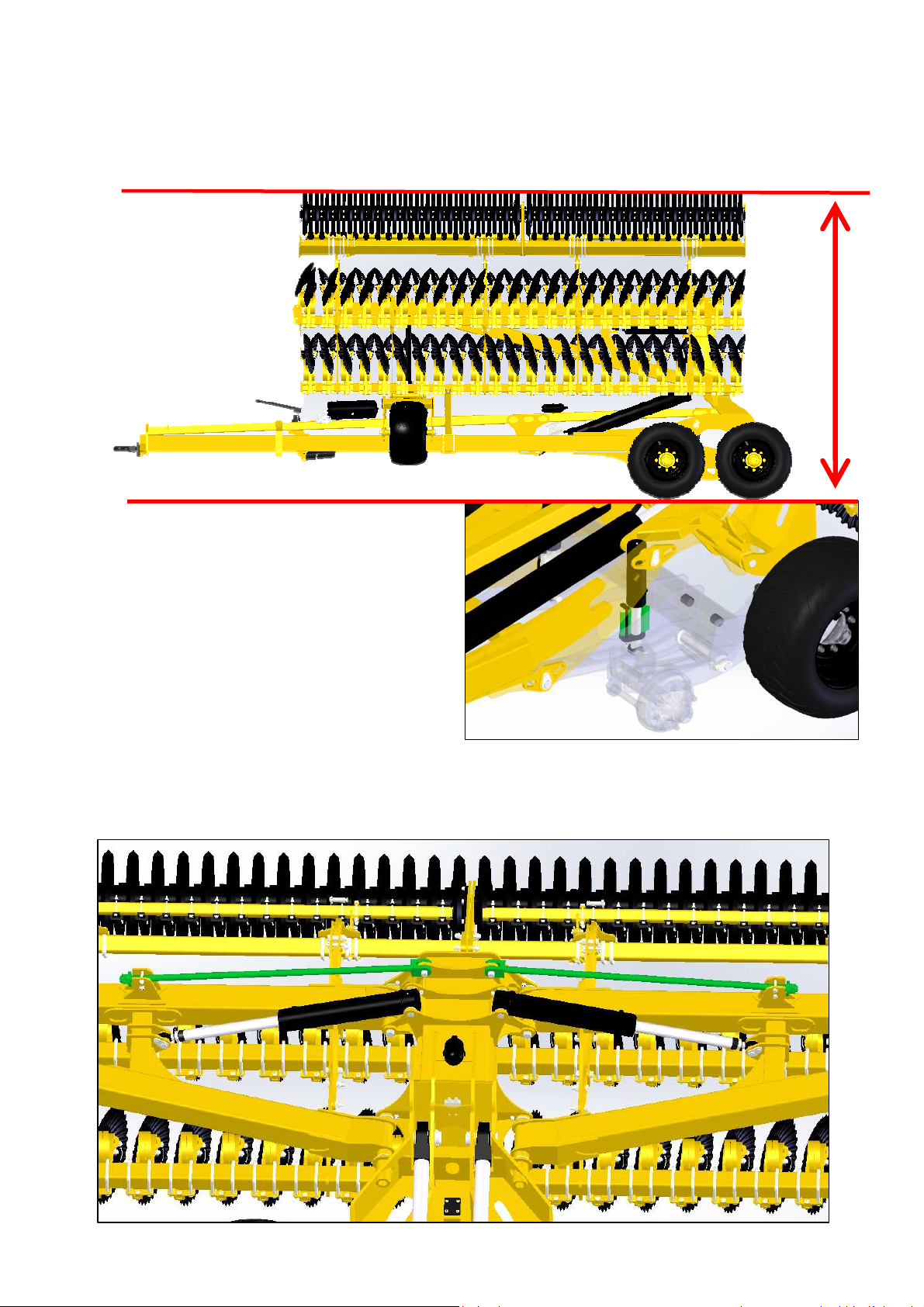

4.5.2. Adjusting the working depth using the roller

The working depth of the disks is controlled using the roller.

The roller also levels and compresses the soil after the seeds have been sown.

Example:

Several working depth settings are possible thanks to the Agrisem "MULTISTOP".

The lowest position produces the minimum working depth, here position 1

The highest position produces the maximum working depth, here position 15

Position A is the position of the roller in relation to the Disc-O-Mulch. This is the position in

which the roller kit and the rear row of disks are the closest. This is the standard mounting of a

roller kit on a Disc-O-Mulch.

Position B is the position in which the roller is the furthest away for a greater distance between

the roller kit and the rear row of disks.

Positions C and D correspond to the bottom roller stop. This allows you to limit the travel of

the roller arm between the lower and upper stops.

RECOMMENDATION:

• If this is permitted by the working position, immobilise the roller arms using the lower stop pins.

This prevents friction between the roller arms and the multistops that might otherwise cause

premature wear.

• It is the setting of the multistops and therefore the height of the roller that dictates the working

depth. A Disc-O-Mulch works on the surface (between 2 and 6 cm) at a high forward speed

(around 12 km/h).

At the end of the field, the DISCO-O-MULCH must be lifted to avoid

subjecting the tool to crossways movements before turning around.

The tractor should therefore be aligned with the direction of work before the

DISCO-O-MULCH is lowered.

39

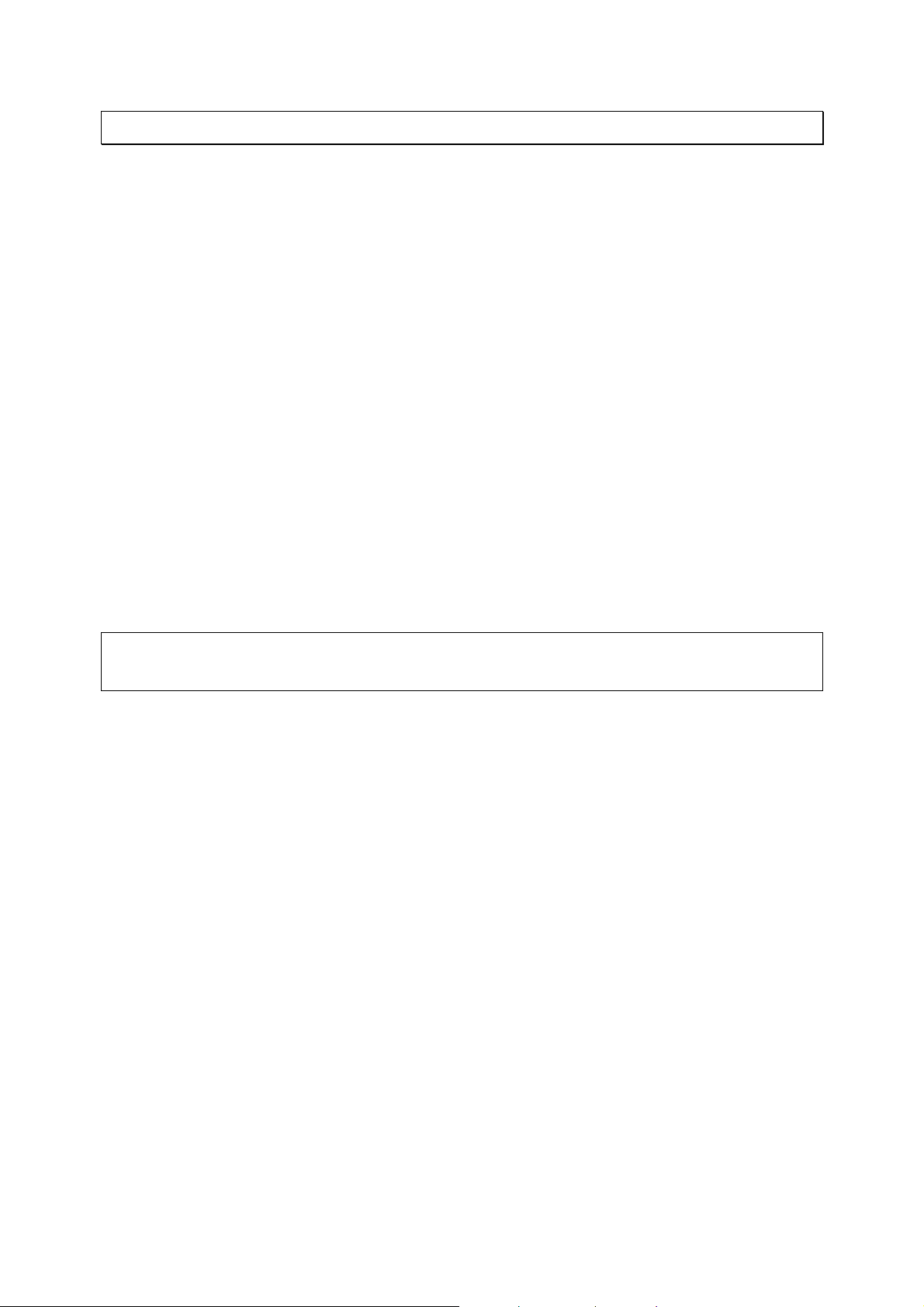

Setting of Transport position

The transport height is adjustable by clips on the

cylinder following:

The height with cage roller will be from 3.80m to

4.00m.

The height with V-sem roller will be from 3.90m

to 4.10m

You can set the inclination from left to right side of extension by the cylinders and also by the lower

stop adjustable stem

40

Setting the inclination of DOM

When you are on the end of field, you have to lift up the DOM just enough in order the disc don’t touch

the ground. The deep wheel of control will support the side of DOM in order to help the central frame

when the user turns on the field. If you don’t do that, you can have some damage on the Security

spring or other elements of DOM.

41

4.5.2.1. Adjusting the side deflectors on mounted and semimounted Disc-O-Mulch GOLD machines

The left-hand side deflector may be adjusted to limit the spraying of soil from the first row of disks

during work.

The following procedure must be followed:

- Loosen the lock nuts and screws "A"

- Adjust the deflector to the required position

- Retighten the screws and the lock nuts

4.5.2.2. Adjusting the border spreading disk

Mounting the Disc-O-Mulch SILVER:

Adjustments may be made to the border spreading disk to avoid a ridge forming during work.

The following procedure must be followed:

- Loosen the 3 screws "D" and the

lock nut

- Adjust the border spreading disk using

the oblong hole.

- Retighten the screws and the lock nut.

Mounting the Disc-O-Mulch GOLD:

- Retighten the 3 screws "E"

- Adjust the border spreading disk using

the oblong holes.

- Retighten the screws

42

Assembling the Disc-O-Mulch GOLD with a

folding roller:

- The gap of the deflector can be adjusted.

- The work intensity of the disk can also

be adjusted.

4.5.3. OPERATING RECOMMENDATIONS

Problems Point to be checked Solutions

The Disc-O-Mulch is

veering Working depth Check that the working

to one side to the other depth is the same for

both rows of disks.

The Disc-O-Mulch is not

working The tractor's top-links

at the same depth The tractor's top-links must be adjusted

on the right and the left to the same length

A ridge forms between Adjust the border

two passages of the Disc-O-Mulch spreading disk.

border spreading disk

Working depth Reduce the working depth

The disks are of the Disc-O-Mulch

jammed

Wear on the disks Replace the disks

Adjustment of the

Irregular working depth

extensions Adjust the extensions

43

4.6. SERVICING - MAINTENANCE

Comply with the safety instructions regarding servicing and maintenance. Your machine has been

designed and built for maximum yield, profitability and comfort under many different usage conditions.

Your machine has been checked at the factory and by your dealer before its delivery to ensure that

you receive a machine in perfect condition. To maintain it in good working condition, it is important that

servicing and maintenance operations are performed at the recommended frequency.

In order to ensure that your machine always operates correctly and to obtain an optimum

performance, you must clean and maintain it at regular intervals. The hydraulic components and

bearings must not be cleaned with a high-pressure washer or directly hosed down. The units, screwed

connectors and bearings are not watertight to VERY high pressure cleaning.

4.6.1. Servicing frequency

The servicing frequency is determined by various factors. Different usage conditions, the weather,

driving and working speeds, dust and the type of soil, etc. affect the frequency, and the lubrication and

maintenance products used also determine the time until the next servicing work is required.

The servicing frequency indicated is therefore only to be used as a reference. If you deviate from the

normal conditions of use, you must adapt the frequency at which this maintenance and servicing is

carried out to suit the conditions:

1/ After the first 10 hours of use:

- Check the tightness of the nuts and screws

- Check the hydraulic system (tightness and sealing)

- Check the tightness of the wheels

- Perform a complete diagnosis of the machine to ensure that there are no elements

causing problems.

- Clean the soil off the machine

2/ Every 50 hours of use

- Check the tightness of the nuts and screws

- Check the hydraulic system (tightness and sealing)

- Check the tightness of the wheels

- Perform a complete diagnosis of the machine to ensure that there are no elements

causing problems.

- Lubricate the joints with greasers

- Clean the soil off the machine

4.6.2. Storage

If the machine is not going to be used for an extended period:

• Store the machine under a roof if possible.

• Disconnect the electrical control devices and store them in a dry place.

• Protect the machine against rust. Only spray with oils that are easily biodegradable, e.g. rape

oil.

• Unload the wheels.

• Protect the hydraulic cylinder piston rods against corrosion.

44

Do not spray plastic and rubber parts with oil or an anti-corrosion agent or these parts may become

fragile and break.

4.6.3. Cleaning

Before folding the machine, the beam under the cylinder must always be cleaned.

A build-up of soil, stones or other obstacles can damage the cylinder.