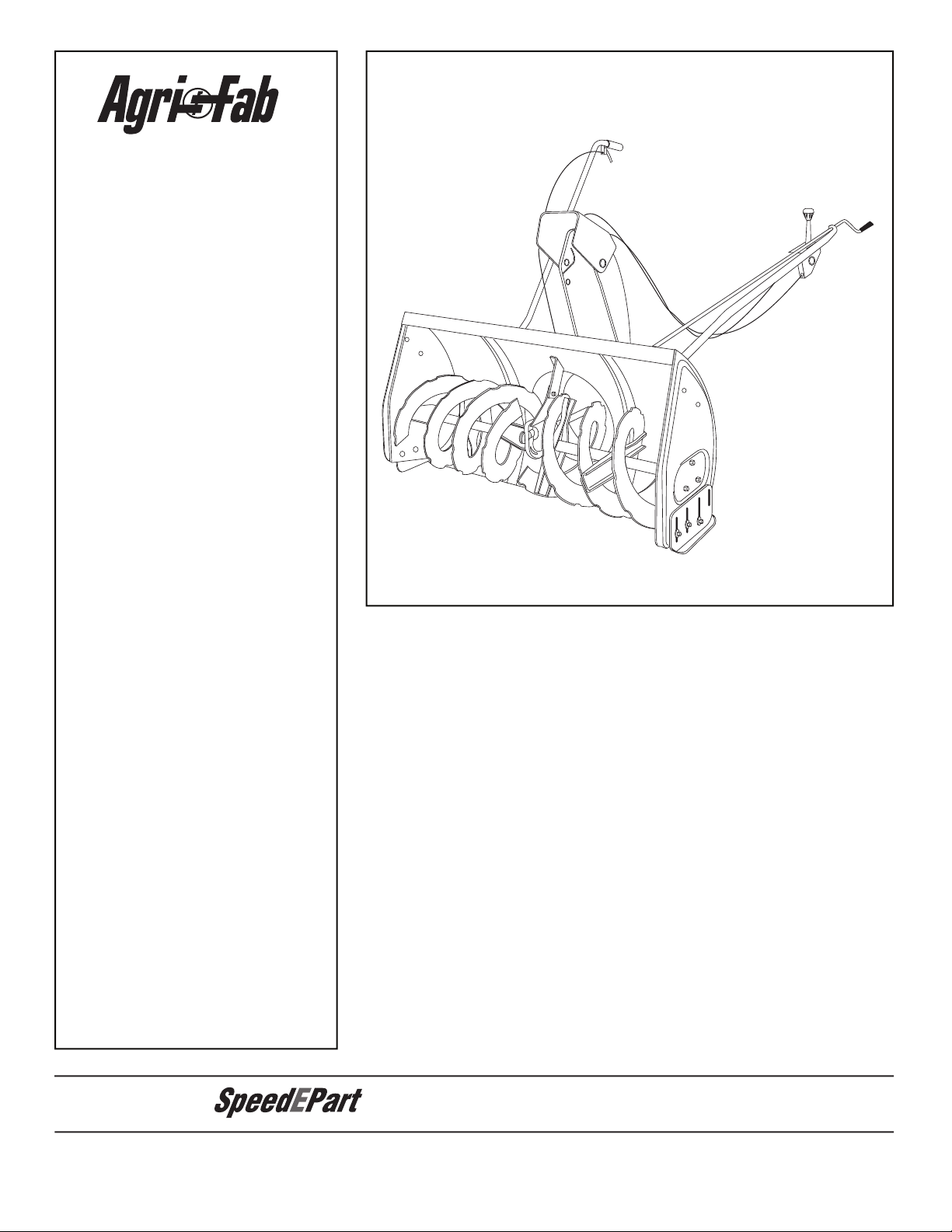

Page 1

the fastest way to purchase parts

www.speedepart.com

™

Page 2

TABLE OF CONTENTS

ACCESSORIES

....................................................................................................................................................................

...................................................................................................................................................................

..........................................................................................................................................................

ASSEMBLY

.......................................................................................................................................................................

........................................................................................................................................

TROUBLESHOOTING

........................................................................................................................................................

.............................................................................................................................

...................................................................................................................................................................

where you purchased your tractor.

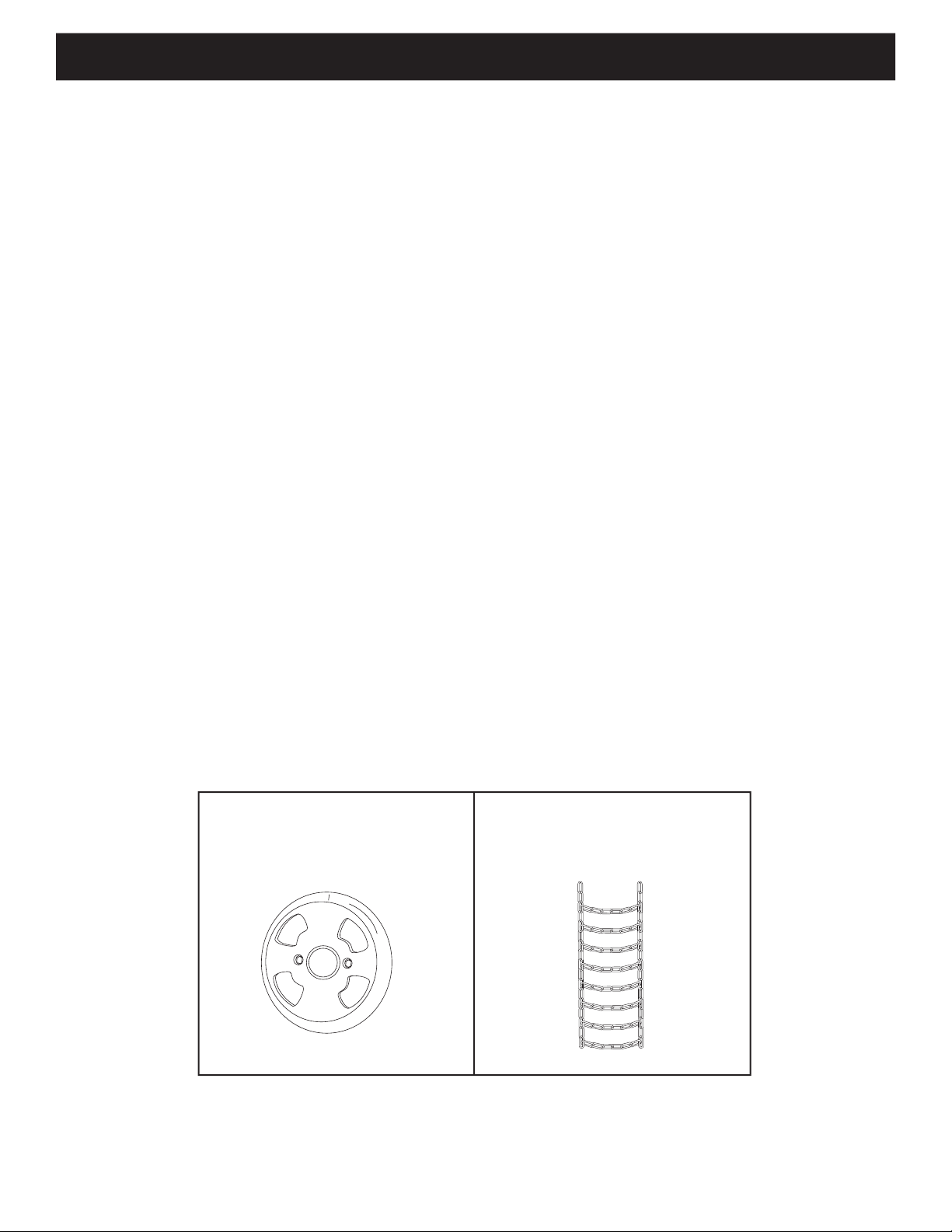

WHEEL WEIGHTS TIRE CHAINS

Page 3

SAFETY

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate the equipment.

Read this owner's manual carefully and know how to

Never allow children to operate the equipment.

Never allow adults to operate the equipment without

Keep the area of operation clear of all persons,

Thoroughly inspect the area where the equipment is

to be used and remove all door mats, sleds, boards,

wires and other foreign objects.

Disengage all clutches and shift into neutral before

Do not operate equipment without wearing adequate

winter outer garments.

Wear substantial footwear which will protect feet and

Check fuel before starting the engine. Do not remove

the fuel cap or fi ll the fuel tank while the engine

Make sure the snow thrower height is adjusted to

Do not use the snow thrower without the rear weight

Never make any adjustments while the engine is

Always wear safety glasses or eye shield during

Do not place hands or feet near rotating parts. Keep

Use extreme caution when operating on or crossing

Do not carry passengers.

After striking a foreign object, stop the engine, remove

the wire from the spark plug and then thoroughly

thrower.

If the snow thrower starts to vibrate abnormally, stop

the engine immediately and check for the cause.

Stop the engine whenever you leave the operating

Take all possible precautions when leaving the unit

the parking brake, stop the engine and remove the

When cleaning, repairing or inspecting, make certain

Do not run engine indoors except when transporting

the snow thrower in or out of the building. Open the

Do not clear snow across the face of slopes. Exercise

Never operate the snow thrower without guards,

Never operate the snow thrower near glass

Never direct discharge at bystanders or allow anyone

Never run the snow thrower into material at high

Do not overload the machine capacity by attempting

to clear snow at too fast a rate.

Never operate the machine at high transport speed

Watch for traffi c and stay alert when crossing or

Disengage power to the snow thrower when

transporting or when not in use.

Use only attachments and accessories approved by

the manufacturer of the snow thrower (such as wheel

weights, counter weights, cabs etc.)

Never operate the snow thrower without good visibility

Page 4

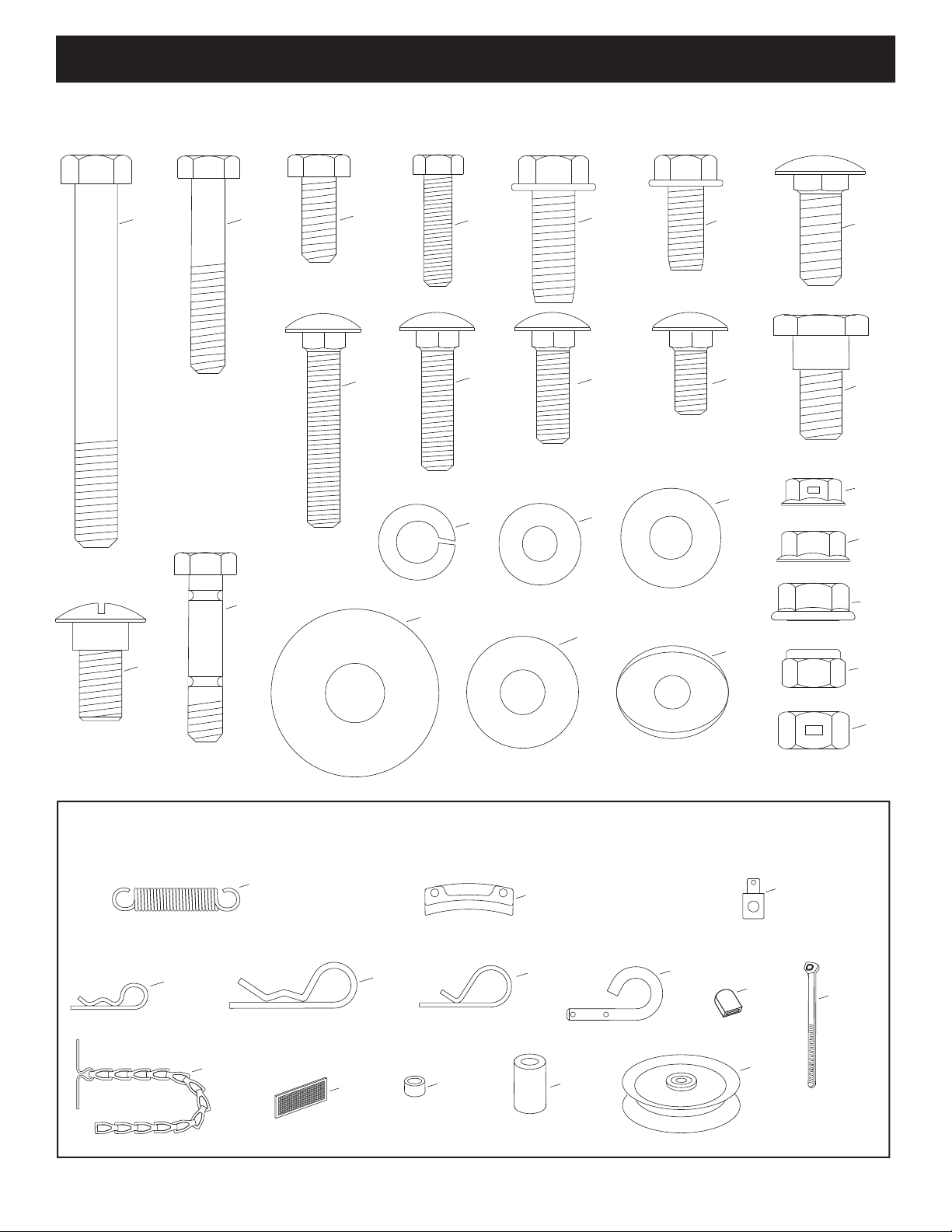

E

B

D

G

H

I

K

O

F

X

U

Y

C

W

L

Q

S,T

R

Z

KK

EE

N

CC

BB

AA

NOT SHOWN ACTUAL SIZE

SHOWN ACTUAL SIZE

DD

M

J

JJ

FF

GG

II

V

P

HH

A

LL

NN

MM

HARDWARE PACKAGE CONTENTS

Page 5

REF. QTY. DESCRIPTION

U 2 Bowed Washer

V 6 Flanged Nut, 1/4"

W 1 Flanged Nut, 5/16"

X 10 Flanged Nut, 3/8"

Y 17 Nylock Nut, 5/16" (2 spare parts)

Z 2 Hex Lock Nut, 3/8"

AA 1 Spring

BB 3 Chute Keeper

CC 1 Trunnion

DD 2 Hairpin Cotter, 5/64"

EE 3 Hairpin Cotter, 1/8"

FF 1 Hairpin Cotter, 3/32"

GG 2 Lock Pin

HH 1 Plastic Cap

II 2 Nylon Tie

JJ 1 Chain, Tensioning

KK 2 Tail Refl ector

LL 1 Small Spacer

MM 1 Large Spacer

NN 1 Pulley

A 1 Hex Bolt, 3/8" x 3-1/4"

B 2 Hex Bolt, 5/16" x 1-3/4"

C 4 Hex Bolt, 5/16" x 3/4"

D 6 Hex Bolt, 1/4" x 1"

E 6 Hex Bolt, 3/8" x 1" (Thread Forming)

F 2 Hex Bolt, 5/16" x 3/4" (Thread Forming)

G 6 Carriage Bolt, 3/8" x 1"

H 2 Carriage Bolt, 5/16" x 1-3/4"

I 2 Carriage Bolt , 5/16" x 1-1/4"

J 4 Carriage Bolt, 5/16" x 1"

K 2 Carriage Bolt, 5/16" x 3/4"

L 4 Shoulder Bolt

M 2 Shoulder Bolt

N 2 Shear Bolt (spare parts)

O 7 Lock Washer, 3/8"

P 7 Washer, 1/4"

Q 6 Washer, 5/16"

R 8 Washer, 1/2"

S 1 Washer, 3/8" (Thin)

T 3 Washer, 3/8"

Page 6

Hardware Package (Stored inside Plastic Keg)

14

1

2

4

5

6

12

9

8

10

20

19

11

17

16

15

18

13

7

3

Page 7

Remove all parts and hardware packages from the

the illustrations on pages 4 and 6.

Not all of the supplied parts and hardware will be

the two

the Service and Adjustments section on page 27.

TOOLS REQUIRED FOR ASSEMBLY

TRACTOR PREPARATION

for specifi c safety instructions.

Allow engine, muffl er and exhaust defl ector to cool

Remove any front or rear attachment which is

Remove the tractor hood. Refer to your tractor owner's

to

from the tractor ignition.

Right hand (R.H.) and left hand (L.H.) side

while seated on the tractor.

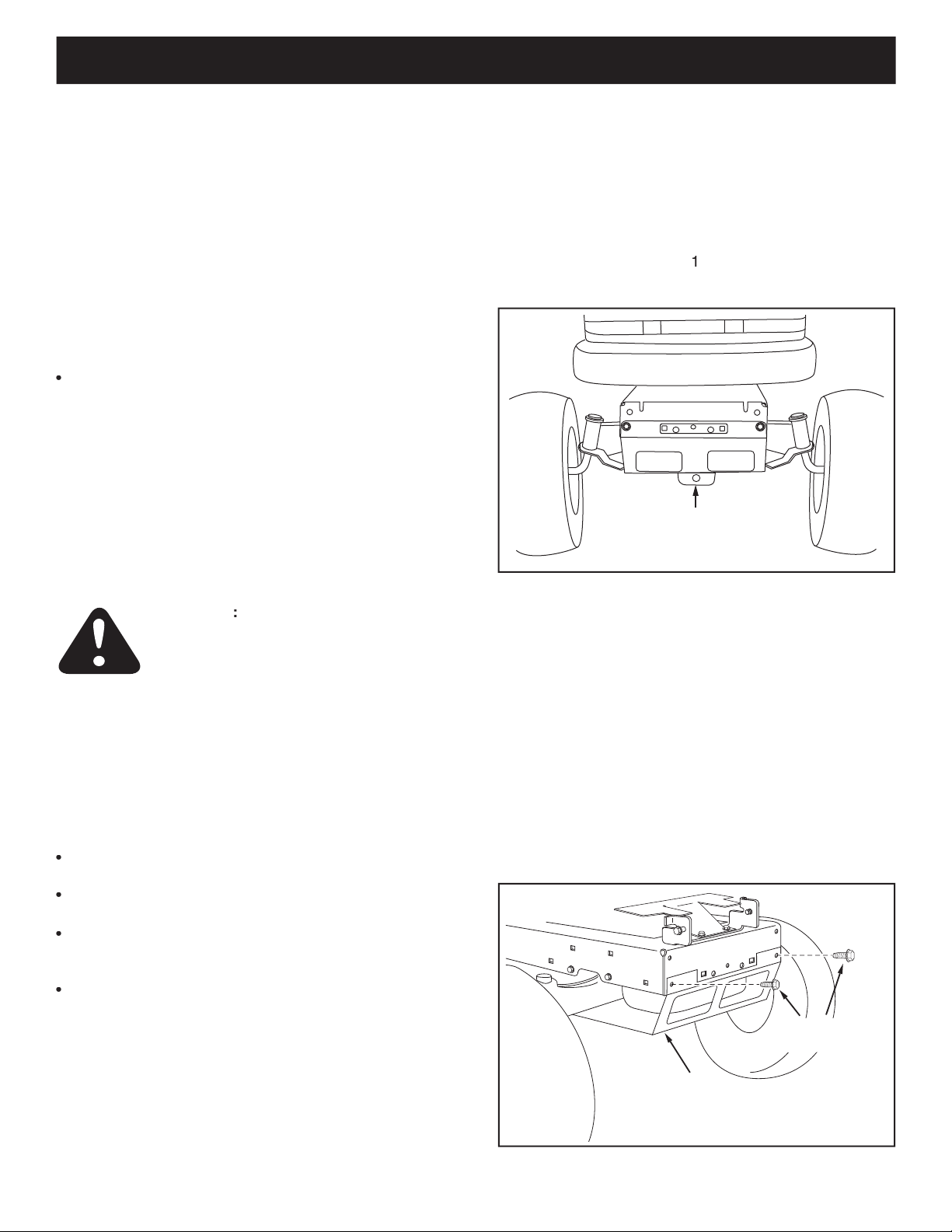

REMOVE

FRONT SCREWS

REMOVE

BROWNING SHIELD

MOWER DECK

SUSPENSION

BRACKET

• Remove the browning shield from the front of the

tractor as shown. Hold onto the shield as you remove

the second screw to prevent it from falling.

•

•

under the front of your tractor

f there is a single

the mi

yo

for tractors with dual

ASSEMBLY

Page 8

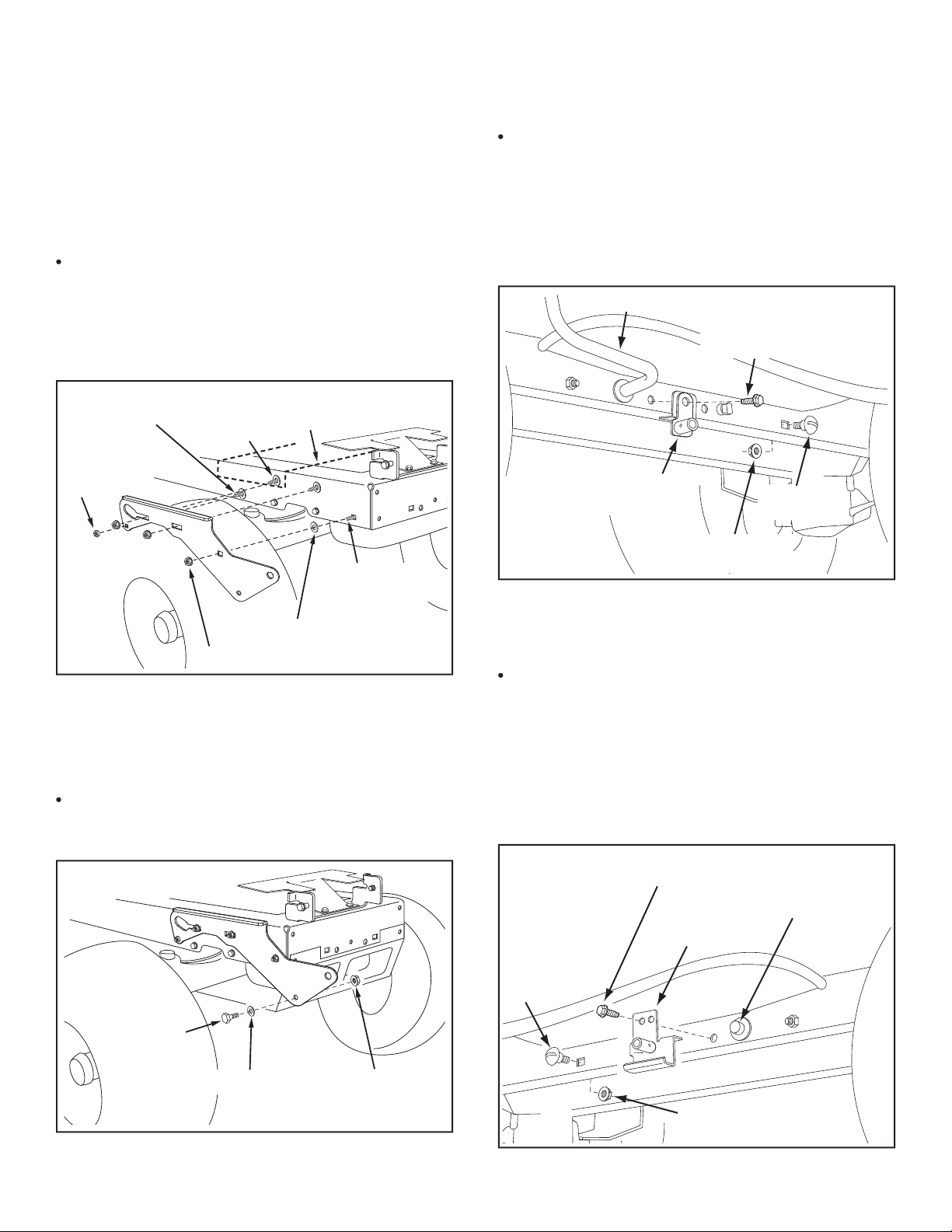

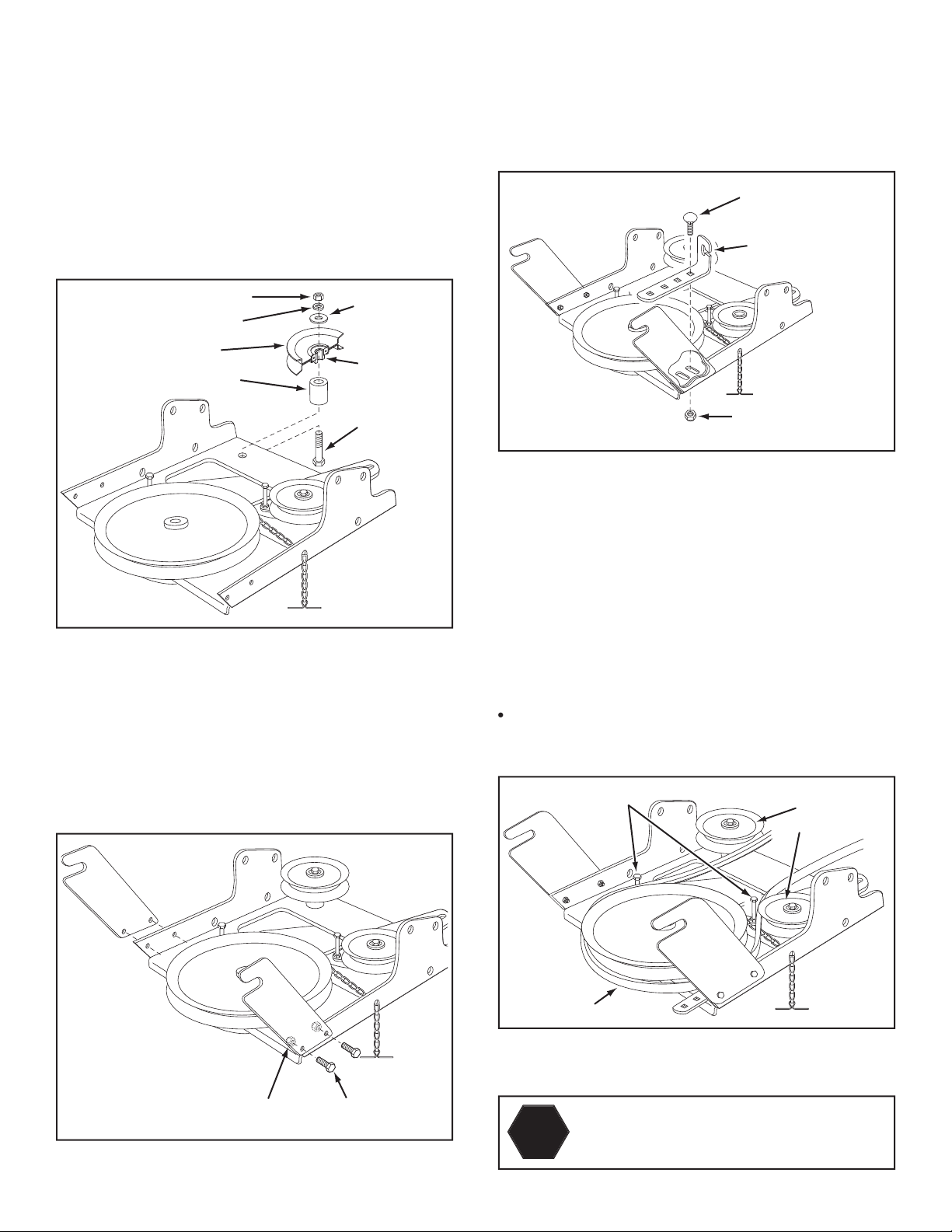

Assemble a shoulder bolt (L) and a 3/8" washer (T) to

the outside of R.H. side plate, securing it with a 3/8"

fl anged nut (X). Repeat for L.H. side plate.

5/16"

NYLOCK

NUT (Y)

5/16" x 1"

CARRIAGE BOLT (J)

ENGINE MOUNTING

PLATE

(4) 1/2" WASHERS (R)

(3) 3/8" FLANGE NUTS (X)

(3) 3/8" x 1"

CARRIAGE

BOLTS (G)

SEE NOTE

3/8" WASHER (T)

SHOULDER

BOLT (L)

3/8" FLANGED

NUT (X)

•

front three holes in the tractor frame using three 3/8"

x 1" carriage bolts (G), three 1/2" washers (R) (see

for L.H. side plate.

Reinstall the browning shield onto the tractor frame

through the plate.

the brake rod on the left side of the tractor frame.

•

Attach the L.H. Hanger Bracket (tube facing out) to the

• Install a round head shoulder bolt (M) into the hole

that is 9-1/2" to the rear of the bolt you just installed.

frame.

5/16" x 3/4" SELF

THREADING BOLT (F)

L.H. HANGER

BRACKET

BRAKE ROD

3/8" FLANGED

NUT (X)

SHOULDER

BOLT (M)

5/16" x 3/4" SELF

THREADING BOLT (F)

R.H. HANGER

BRACKET

RIGHT END OF

BRAKE ROD

3/8" FLANGED

NUT (X)

SHOULDER

BOLT (M)

the tractor frame. Store the bracket and bolt.

Attach the R.H. Hanger Bracket to the hole using a

• Install a round head shoulder bolt (M) into the hole

that is 9-1/2" to the rear of the bolt you just installed.

frame.

Page 9

3/8" X 3-1/4"

HEX BOLT

(A)

LARGE SPACER (MM)

PULLEY (NN)

3/8" LOCKWASHER (O)

3/8" HEX LOCK NUT (Z)

3/8"

WASHER (T)

LONG END

OF HUB

•

Attach the pulley (long end of hub facing down) and

the large spacer (MM) to the hole shown in the clutch/

washer (T), a 3/8" lock washer (O) and a 3/8" hex lock

Attach the cable bracket to the slot shown in the

the front hole of the bracket and in the end of the slot

CABLE

BRACKET

5/16" x 3/4"

CARRIAGE BOLT (K)

5/16" NYLOCK

NUT (Y)

THIS SECTION IS FOR TRACTORS WITH A

HEX BOLTS

(#48138)

DRIVE BELT

FLAT IDLER

PULLEYS

tractor? Using the wrong length belt may

• Two different length drive belts are included with

your snow thrower. Tractors with manual attachment

the 56" drive belt with

#48138

printed on the outside of

the belt.

the other belt.

fl at idler pulley with the fl at side of the belt against the

Loop the belt around the large v-pulley, placing it

5/16" NYLOCK

NUT (Y)

5/16" x 3/4"

HEX BOLT (C)

Attach the two suspension arms to the rear of the

the rear.

STOP

Page 10

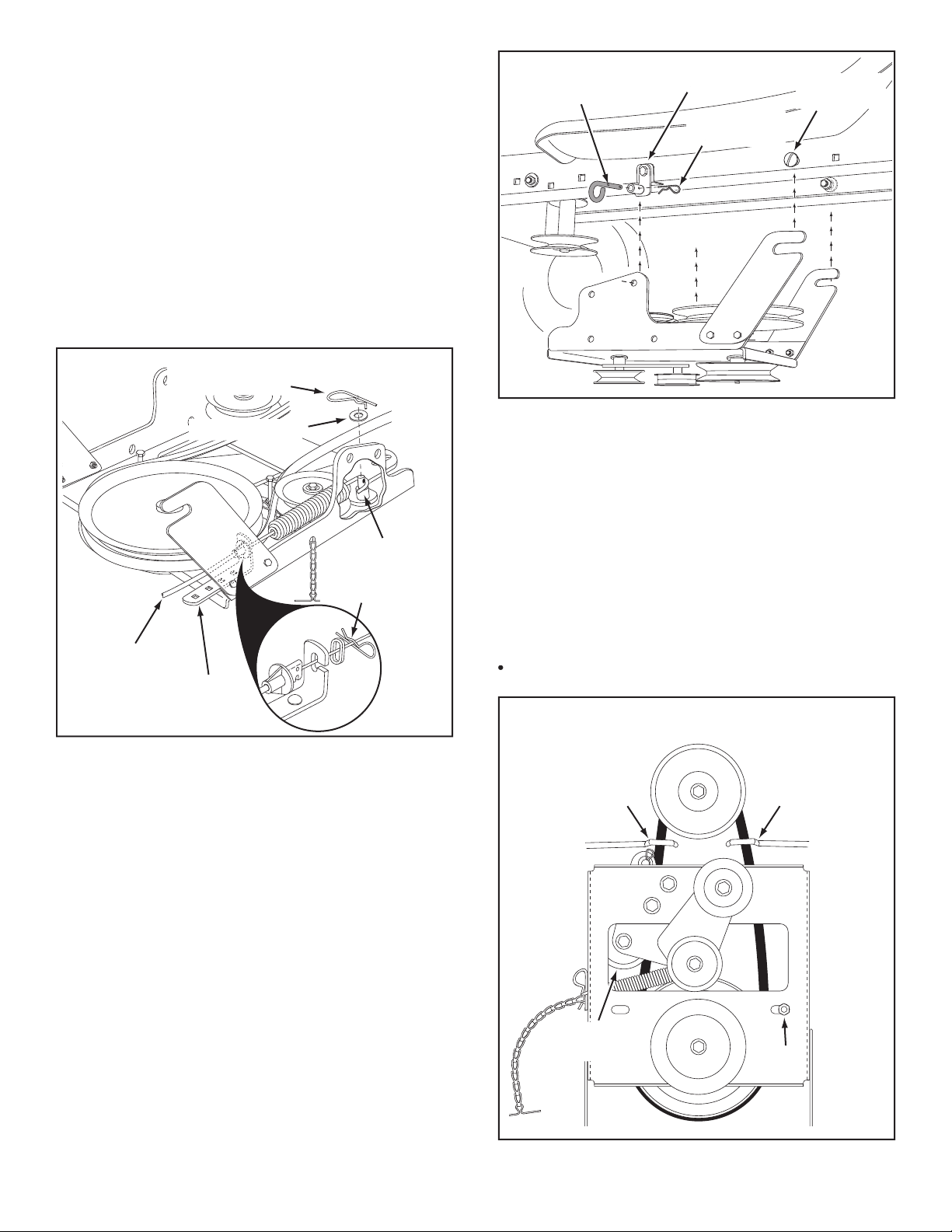

Attach the clutch/idler assembly to the tractor frame.

tractor frame. Lift the front of the assembly and attach

PIVOT LOCK PIN (GG)

(use this hole)

SHOULDER

BOLT (M)

1/8" HAIRPIN

COTTER (EE)

L.H. HANGER

BRACKET

•

Assemble the drive belt onto the engine pulley fi rst

assemble the "V" belt outside of

the engine pulley keepers or outside of the keeper bolt

ENGINE

PULLEY

ENGINE

PULLEY

Left Side

of Tractor

ENGINE

PULLEY

KEEPER

ENGINE

PULLEY

KEEPER

KEEPER BOLT

IDLER

PULLEY

5/64" HAIR

COTTER PIN (DD)

1/4" WASHER (P)

SPACER (LL)

TRACTOR'S

CLUTCH CABLE

CABLE

BRACKET

5/64" HAIR

COTTER PIN (DD)

the disengaged (down) position.

•

Attach the tractor's clutch cable to the cable bracket.

•

• Align cable bracket with welded pin and tighten the

Page 11

THIS SECTION IS FOR TRACTORS WITH AN

•

Attach the two suspension arms to the rear of the

the rear.

through the end link of the tensioning chain.

•

With the clutch/idler assembly turned upside down,

the spring to pivot freely.

Attach a 3/32" hairpin cotter (FF) to the chain, placing

CHAIN

(L.H. SIDE)

3/32" HAIR

COTTER PIN (FF)

5TH LINK

LEFT

SIDE

3/8" HEX

LOCK NUT (Z)

SPRING

RIGHT

SIDE

ATTACH

SPRING

HERE

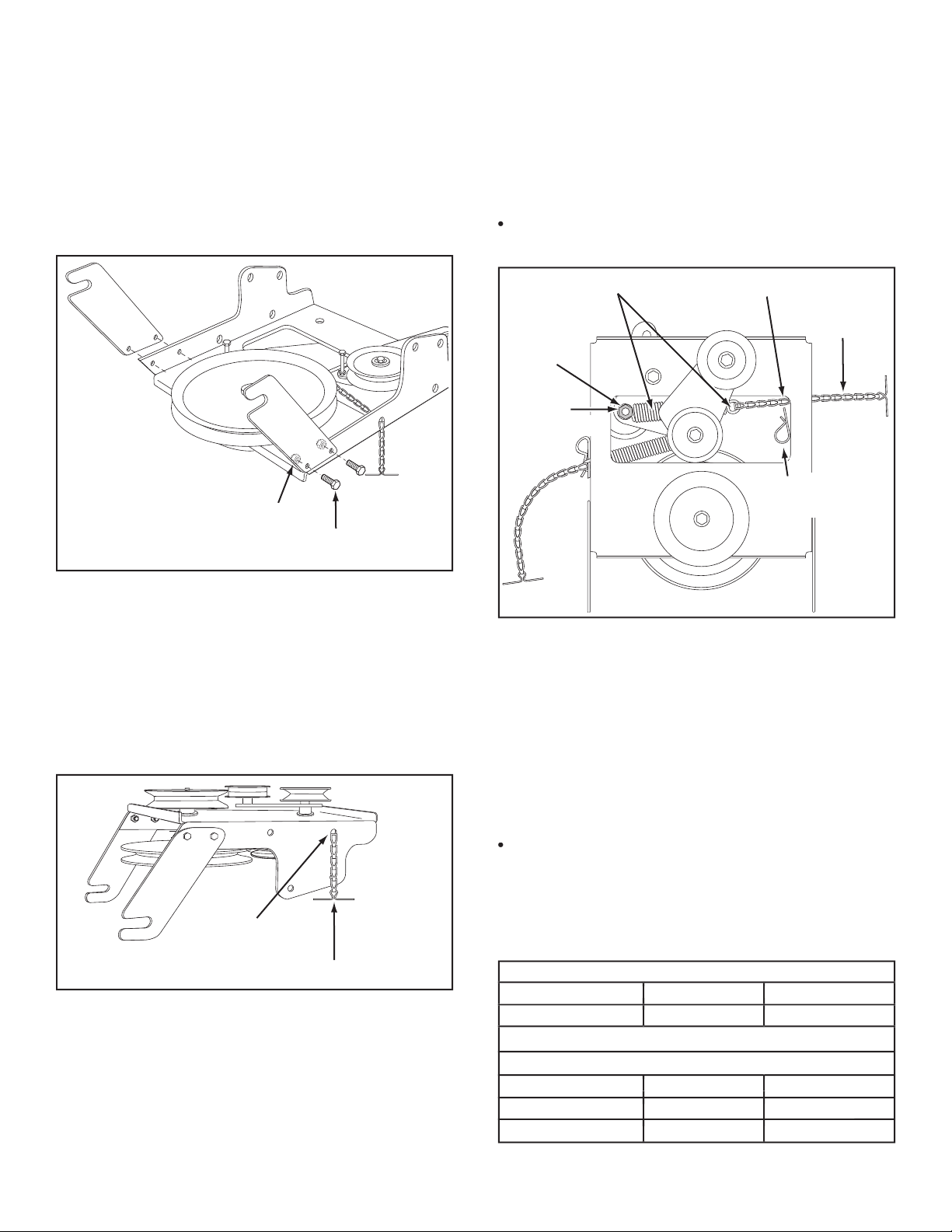

•

Turn the clutch/idler assembly upside down and place

the extra tensioning chain (JJ) through the left front

TENSIONING CHAIN (JJ)

LEFT FRONT HOLE

Two different length drive belts are included with

your snow thrower.

the correct drive belt for your type tractor. The part

• Set aside the belt that is not for your tractor to avoid

TRACTOR TYPE DECK SIZE CLUTCH TYPE

(LT) Lawn Tractor 38", 42" Electric

TRACTOR TYPE DECK SIZE CLUTCH TYPE

(LT) Lawn Tractor 48" Electric

(LT) Lawn Tractor 48" Electric

(GT) Garden Tractor 48", 54" Electric

5/16" NYLOCK

NUT (Y)

5/16" x 3/4"

HEX BOLT (C)

Page 12

•

Attach the clutch/idler assembly to the tractor frame.

tractor frame. Lift the front of the assembly and attach

PIVOT LOCK PIN (GG)

(use second hole)

SHOULDER

BOLT (M)

1/8" HAIRPIN

COTTER (EE)

L.H. HANGER

BRACKET

Assemble the drive belt onto the engine pulley fi rst

Place tension on the belt by pulling the left side

tensioning chain (JJ) out as far as the 3/32" hairpin

the chain.

assemble the drive belt around the

1/8" HAIRPIN

COTTER (EE)

ENGINE

PULLEY

ENGINE

PULLEY

KEEPER

BOLT

IDLER

PULLEY

CHAIN (JJ)

(L.H. SIDE)

• Turn the clutch/idler assembly right side up.

fl at idler pulley with the fl at side of the belt against the

Loop the belt around the large v-pulley, placing it

STOP

your tractor? Using the wrong length belt

HEX BOLTS

DRIVE BELT

FLAT IDLER

PULLEY

Page 13

•

front three holes shown in the tractor frame using

three 3/8" x 1" thread forming bolts (E), three 3/8"

the third bolt as a shim between the side plate and

the frame. Tighten all bolts. Repeat for the L.H. side.

If you installed a bolt in the fourth hole in step 21,

•

(3) 3/8" x 1"

THREAD FORMING

BOLTS (E)

5/16" FLANGED

NUT (W)

(SEE NOTE)

(3) 3/8" LOCK

WASHERS (O)

1/2" WASHER (R)

5/16" x 1"

CARRIAGE BOLT (J)

(SEE NOTE)

SUSPENSION

BRACKET

REMOVE BOLTS

IF PRESENT

three holes shown in the tractor frame. Use three 3/8"

x 1" thread forming bolts (E) and 3/8" lock washers (O).

Tighten all bolts and repeat for the L.H. side.

If the bolt inserts freely into the front hole, assemble

(3) 3/8" x 1"

THREAD FORMING

BOLTS (E)

(3) 3/8" LOCK

WASHERS (O)

3/8" FLANGED NUT (X)

(SEE NOTE)

• If a bolt is present in the fourth hole, replace it with a

fastened to inside of frame must remain in place.

FRONT

SUSPENSION

BRACKET

REPLACE BOLT

(IF PRESENT)

REMOVE BOLTS

(IF PRESENT)

f your tractor resembles fi gure 20, go to step 21.

Assemble a shoulder bolt (L) and a 3/8" washer (T) to

the outside of each side plate, securing them with a

3/8" WASHER (T)

SHOULDER

BOLT (L)

3/8" FLANGED

NUT (X)

Page 14

foot rest brackets to the frame.

Attach the L.H. Hanger Bracket (marked "L") to the

•

frame using a 3/8" x 1" carriage bolt (G) and a 3/8"

fl anged nut (X). Bolt head goes on inside of tractor

frame. Repeat for the R.H. side.

Assemble a shoulder bolt (L) and 3/8" fl anged nut (X)

to the R.H. side of the tractor frame, using the fi rst

•

BOLT REMOVED

FROM THIS HOLE

SWAY BAR

BRACKET

SHOULDER BOLT (L)

3/8"

FLANGED

NUT (X)

3/8" x 1"

CARRIAGE

BOLT (G)

3/8" FLANGED

NUT (X)

L.H. HANGER

BRACKET

SUSPENSION ARM

SHOULDER BOLT (L)

3/8"

FLANGED

NUT (X)

R.H. HANGER BRACKET

BOLT REMOVED

FROM THIS HOLE

3/8" x 1"

CARRIAGE

BOLT (G)

3/8" FLANGED

NUT (X)

L.H. HANGER

BRACKET

SUSPENSION ARM

Page 15

This section covers the installation of the Clutch/Idler

tractor.

•

the disengaged (down) position.

•

thrower engagement rod.

Locate the clutch arm (where the mower clutch rod

was connected) underneath the right hand side the

tractor, just to the inside of the suspension arm.

there is an extension

attached to the clutch lever, the

with the mower deck.

to the clutch

•

through the arm. Secure with a 5/64" hairpin cotter

ENGAGEMENT ROD

5/64" HAIRPIN

COTTER (DD)

TRACTOR'S CLUTCH ARM

SUSPENSION ARM

TRUNNION (CC)

REMOVE EXTENSION,

BOLT AND NUT

(IF PRESENT)

•

Attach the two suspension arms to the inside of the

the assembly frame.

5/16" NYLOCK

NUT (Y)

5/16" x 3/4"

HEX BOLT (C)

5/16" WASHER (Q)

your tractor? Using the wrong length belt

HEX BOLTS

DRIVE BELT

FLAT IDLER

PULLEY

• Two different length drive belts are included with

your snow thrower. Tractors with manual attachment

the 55" drive belt with

#46989

printed on the outside

the other belt.

fl at idler pulley with the fl at side of the belt against the

Loop the belt around the large v-pulley, placing it

STOP

Page 16

PIVOT LOCK PIN (GG)

(use second hole)

1/8" HAIRPIN COTTER (EE)

ENGAGEMENT

ROD

•

the idler arm slot. Attach the trunnion (CC) to the slot

•

the tractor frame by removing the washer and nut

that secure the keeper. Attach the new pulley keeper

Some tractors may already be equipped with a

IDLER ARM

5/64" HAIRPIN

COTTER (DD)

TRUNNION (CC)

STOP BOLT

3/8" THIN

WASHER (S)

NEW ENGINE PULLEY KEEPER WITH

ORIGINAL BOLT, NUT AND WASHER

Assemble the short "V" belt onto the engine pulley

assemble the "V" belt around the

ENGINE

PULLEY

KEEPER BOLT

IDLER

PULLEY

ENGINE

PULLEY

KEEPER

Left Side

of Tractor

tied to the engine pulley keeper.

Attach the clutch/idler assembly to the tractor frame

the two shoulder bolts you assembled to the inside

two pivot lock pins (GG) and 1/8" hairpin cotters (EE).

Page 17

•

Assemble the cable bracket to the clutch/idler

•

the disengaged (down) position.

•

Attach the tractor's clutch cable to the cable bracket.

CABLE

BRACKET

5/16" x 3/4"

CARRIAGE BOLT (K)

5/16" NYLOCK

NUT (Y)

42"

DECKS

46"

DECKS

TRACTOR'S

CLUTCH CABLE

5/64" HAIR

COTTER PIN (DD)

1/4" WASHER (P)

SPACER (LL)

5/64" HAIR

COTTER PIN (DD)

Attach the two suspension arms to the rear of the

with the notches to the rear.

5/16" NYLOCK

NUT (Y)

5/16" x 3/4"

HEX BOLT (C)

5/16" WASHER (Q)

HEX BOLTS

DRIVE BELT

FLAT IDLER

PULLEY

• Two different length drive belts are included with

your snow thrower. Tractors with manual attachment

the 55" drive belt with

#46989

printed on the outside

the other belt.

your tractor? Using the wrong length belt

•

fl at idler pulley with the fl at side of the belt against the

Loop the belt around the large v-pulley, placing it

STOP

Page 18

Assemble the short "V" belt onto the engine pulley

assemble the "V" belt around the

the tractor frame by removing the washer and nut

that secure the keeper. Attach the new pulley keeper

Some tractors may already be equipped with a

Attach the clutch/idler assembly to the tractor frame

the two shoulder bolts you assembled to the inside

two pivot lock pins (GG) and 1/8" hairpin cotters (EE).

NEW ENGINE PULLEY KEEPER WITH

ORIGINAL BOLT, NUT AND WASHER

PIVOT LOCK PIN (GG)

(use second hole)

1/8" HAIRPIN COTTER (EE)

ENGINE

PULLEY

KEEPER BOLT

IDLER

PULLEY

ENGINE

PULLEY

KEEPER

Left Side

of Tractor

Page 19

TENSIONING CHAIN (JJ)

LEFT FRONT HOLE

the tensioning chain.

•

the bolt and nut which secure the idler pulley to the

Attach a 3/32" hairpin cotter (FF) to the chain, placing

CHAIN

(L.H. SIDE)

3/32" HAIR

COTTER PIN (FF)

5TH LINK

LEFT

SIDE

3/8" HEX

LOCK NUT (Z)

SPRING

RIGHT

SIDE

ATTACH

SPRING

HERE

Two different length drive belts are included with

your snow thrower.

the correct drive belt for your type tractor. The part

• Set aside the belt that is not for your tractor to avoid

TRACTOR TYPE DECK SIZE CLUTCH TYPE

TRACTOR TYPE DECK SIZE CLUTCH TYPE

(LT) Lawn Tractor 48" Electric

(LT) Lawn Tractor 38", 42", 46" Electric

Attach the two suspension arms to the rear of the

with the notches to the rear.

•

front hole in the clutch/idler assembly and then turn

the assembly upside down.

5/16" NYLOCK

NUT (Y)

5/16" x 3/4"

HEX BOLT (C)

5/16" WASHER (Q)

Page 20

1/8" HAIRPIN

COTTER (EE)

ENGINE

PULLEY

ENGINE

PULLEY

Left Side

of Tractor

KEEPER

BOLT

IDLER

PULLEY

Assemble the drive belt onto the engine pulley and

then onto the large pulley on top of the clutch/idler

the idler pulley and the keeper bolt located beside the

Place tension on the belt by pulling the left side

tensioning chain out as far as the 3/32" hairpin cotter

assemble the "V" belt around the

•

Attach the clutch/idler assembly to the tractor frame

the two shoulder bolts you assembled to the inside

two pivot lock pins (GG) and 1/8" hairpin cotters (EE).

PIVOT LOCK PIN (GG)

(use second hole)

1/8" HAIRPIN COTTER (EE)

HEX BOLTS

DRIVE BELT

FLAT IDLER

PULLEY

STOP

your tractor? Using the wrong length belt

• Turn the clutch/idler assembly right side up.

fl at idler pulley with the fl at side of the belt against the

Loop the belt around the large v-pulley, placing it

Page 21

Place the lift handle into the lift bracket on the right side

LIFT RELEASE

CABLE

HEX NUT

LOCK

WASHER

HEX NUT

CABLE

WIRE

LIFT

ROD

TRIGGER

ASSEMBLY

Be sure the lift release cable's plastic covering

Push the lift handle down into the locked position.

For easier assembly of the lift release cable, tilt the

5/16" NYLOCK NUT (Y)

5/16" x 1-3/4"

HEX BOLT (B)

Tilt the snow thrower back down to the ground.

Assemble the crank rod support tube to the bracket

CHUTE CRANK ROD

CRANK SUPPORT TUBE

TILT CONTROL HANDLE

5/16" x 1-3/4"

CARRIAGE BOLT (H)

BOWED WASHER (U)

5/16" NYLOCK NUT (Y)

TILT

CONTROL

ASSEMBLY

Attach the chute tilt control assembly to the top side

5/16" NYLOCK NUT (Y)

5/16" x 1-1/4"

CARRIAGE BOLT (I)

CRANK ROD

SUPPORT TUBE

DISCHARGE

HOUSING

Page 22

5/16" NYLOCK NUT (Y)

CHUTE CRANK

BRACKET

5/16" WASHER (Q)

CHUTE

CRANK

ROD

ROD

SUPPORT

BRACKET

5/16" x 1"

CARRIAGE BOLT (J)

SPIRAL

ANTI-ROTATION

BRACKET

1/4" FLANGED

LOCK NUT (V)

1/4" FLAT

WASHER (P)

1/4" x 1"

HEX BOLT (D)

PLASTIC CAP (HH)

GREASED

SURFACE

FLANGE

with general purpose grease.

Place the discharge chute (facing forward) onto the

fl ange, aligning it with the holes on the right hand side

Tighten carefully

so

that the nuts are snug but do not dig into the plastic

Place the plastic cap (HH) onto the short end of the

Position the crank rod spiral (see fi gure 51) so that it

Tighten

the nuts.

Check if the crank rod rotates the chute freely. If not,

the chute keepers to the chute fl ange.

Secure the control cables to the crank rod support

tube using a nylon tie (II).

This step is for garden tractors only.

•

Attach the chute crank rod assembly brackets to

the plastic bracket on the left side of the discharge

washers (Q) and 5/16" Nylock nuts (Y).

tighten yet.

STOP BOLT

Page 23

An additional person's help may be required to

Place the tractor and snow thrower on a fl at, level

Remove the Attachment Pin from the snow thrower.

Extend the auger belt out behind the snow thrower,

the large drive pulley and underneath the two idler

Roll the tractor up behind the snow thrower, centering

Raise the rear of the snow thrower by lifting up on

the lift handle until the notches in the mounting plates

To ease the assembly of the auger drive belt, delay

the installation of the attachment pin until you have

The auger belt comes preassembled to the pulleys on

the snow thrower housing. Make sure the belt passes

to pass underneath each side idler pulley. The "V" side

Place the auger belt around the rear pulley and

v-pulleys.

IDLER

PULLEY

AUGER PULLEY

TWIST

1/4 TURN

TWIST

1/4 TURN

IDLER

PULLEY

ATTACHMENT PIN

(After installing auger belt)

1/8" HAIRPIN

COTTER (EE)

SHOULDER

BOLT

MOUNTING

PLATE

SIDE PLATE

IDLER

ARM

REAR

PULLEY

LEFT SIDE

OF

TRACTOR

1/8" HAIRPIN

COTTER (EE)

(Removed from

end of spring)

Page 24

Lift the front of the snow blower to align the holes in

the mounting plates and the side plates. From the left

the holes. Secure it with by reinstalling the 1/8" hairpin

Pull the tensioning chain until the end of the spring is

the end of the spring, securing it on the outside of the

For correct belt tension,

the 1/8" hairpin

To prevent the chain from dragging on the

END OF

SPRING

1/8"

HAIRPIN

COTTER (EE)

LEFT SIDE

OF

TRACTOR

FLAT

PULLEY

REAR REFLECTORS (KK)

If your tractor is not equipped with rear refl ectors,

fender. Place the refl ectors as close to the bottom of

the fender and as far apart as the shape of the fender

will allow.

following checklist to help ensure that you will obtain

the best performance from your snow thrower.

they are routed properly around pulleys and inside all

the raised transport position. (Refer to the Service and

Adjustments section.)

Adjustments section.)

Page 25

OPERATION

Pivots the Upper Chute up or

Rotates the Lower and Upper Chutes to

control the direction of discharge.

Used to lift or lower the snow thrower

to transport or operating position.

Releases the lock which

holds the snow thrower in the transport position

Controls

direction and height of snow discharge.

Replaceable plate that absorbs

wear and impact from contact with ground.

Controls amount of clearance between

the scraper plate and the ground.

Feed snow to the

impeller fan at the center of the housing.

Use the end of assembly checklist to verify that all

Make sure the skid shoes are adjusted to maintain

thrower and the type of surface to be cleared. (Refer

to the Service and Adjustments section.)

Make sure the tractor engine has the correct oil

for winter operation (SAE 5W-30). Refer to tractor

The tractor should be sitting with the engine running

the tractor clutch is engaged.

To stop the snow thrower, disengage the tractor's

towards bystanders or windows. Do not

To control the direction snow is thrown, the discharge

To control the distance snow is thrown, the upper

LIFT HANDLE

LIFT RELEASE TRIGGER

CRANK ROD

CHUTE TILT HANDLE

UPPER CHUTE

LOWER CHUTE

SPIRAL AUGERS, R.H. & L.H.

SKID SHOE

SCRAPER PLATE

Page 26

To raise, push down on the lift handle until the snow

thrower locks in the raised transport position.

To lower, push down slightly on the lift handle and pull

the trigger. With the trigger pulled, slowly lower the

•

Check scraper and shoes for wear X X

Cleaning X

Lubrication Section X

MAINTENANCE SCHEDULE

complete regular service.

After each use

Every season

Before storage

Oil the pivot points of the two idler arms on the clutch/

Apply penetrating oil to the control cables of the

Apply a good grade of spray lubricant to the trigger

thrower without the rear weight attached

to the tractor to provide extra traction and

The scraper plate and skid shoes on the bottom of the

to the spiral auger housing, replace plate and shoes

Before beginning operation, thoroughly inspect the

The spiral auger speed is directly related to engine

to operate the lawn tractor at a slow ground speed

In deep, drifted or banked snow it will be necessary to

the snow. Repeat this method until a path is cleared.

the snow thrower to handle the snow without repeated

In extremely deep snow, raise the snow thrower from

the ground to remove the top layer and drive forward

to the ground. Drive the tractor forward until the snow

If the snow thrower becomes clogged with snow or

jammed with a foreign object, disengage the snow

thrower immediately and shut off the tractor engine.

Discharge snow down wind whenever possible.

To help prevent snow from sticking to the snow thrower,

to the inside surface of the snow thrower housing and

Use tire chains to improve traction.

Use rear wheel weights to improve traction.

Before the fi rst snowfall, remove all stones, sticks and

Overlap each pass slightly to assure complete snow

MAINTENANCE

Page 27

SERVICE AND ADJUSTMENTS

the snow thrower, shut off the engine, remove

the spark plug wire(s), set the parking brake

Disengage the tractor's attachment clutch.

•

Remove the attachment pin.

Lock the snow thrower's lift handle in the down

Release the spring tension from the auger belt idler

Remove the auger drive belt from the clutch/idler

Install new belt over top of large auger drive pulley

turn to seat the "V" of the belt in the groove of each

fi gure 55 on page 23.

Assemble the belt onto the clutch/idler assembly.

The skid shoes are mounted on each side of the spiral

Raise the snow thrower off the ground and place a

Adjust the skid shoes up or down and retighten the

If the lift rod does not lock the snow thrower securely

the lift bracket a few turns and tighten the lower hex

If the lift rod fails to unlock completely to lower the

when the attachment clutch lever on the tractor is

follows. Refer back to fi gure 33 on page 16.

Place the attachment clutch lever in the disengaged

Remove the hairpin cotter from the engagement rod

trunnion and lift the trunnion out of the hole in the idler

Screw the trunnion a few turns towards the front end

Replace the trunnion into the hole in the idler arm and

Check the operation of the snow thrower. If the spiral

the augers stop when the attachment clutch lever is

The spiral augers are secured to the auger shaft with

two shear bolts and nylock nuts. If you hit a foreign

If the augers will not turn, check to see if the shear

the snow thrower. For future use order part number

Page 28

Remove the clutch/idler assembly. (The two hanger

Remove the drive belt from the engine pulley.

If you replaced the engine pulley keeper on a manual

fi gure 39 on page 18.

• If you have a rod operated attachment clutch, remove

the engagement rod from the tractor's clutch arm. See

fi gure 29 on page 15.

• If a rear mounted attachment is to be used, remove

the rear weight tray, leaving the bolts that you installed

If a front mounted attachment is to be used, remove

the side plates from the tractor. Be sure to assemble

•

Remove the snow thrower from the tractor.

Clean the snow thrower thoroughly. Wash off any salt

Any bare metal that has become exposed should be

Store in a dry place.

•

Remove the attachment pin. See fi gure 54 on page

Lock the snow thrower's lift handle in the down

Release the spring tension from the auger belt idler

Remove the auger drive belt from the clutch/idler

Pull the spiral auger housing assembly off of the

tractor.

Clogged discharge chute

Spiral augers don't turn

Snow thrower stalls tractor engine

STORAGE

the snow thrower outdoor temperature before using

Front wheels slide instead of steering

Snow thrower rides up over snow

thrower clutch and clear the auger

decrease ground speed

by lowering skid shoes

2. Pull down on lift handle to

increase weight on front wheels

of skid shoe is lower than the rear

TROUBLESHOOTING

Page 29

Page 30

PARTS

Page 31

REF. PART QTY. DESCRIPTION

NO. NO.

2 64184 1 Housing Assembly

3 618-0616 1 Gear Assembly

4 63579 1 Chute Crank Rod Assembly

5 63768 1 Impeller Assembly

6 24773 1 Scraper Plate

7 703-2734 1 Bracket, Housing Brace

8 703-2735A 1 Bracket, Chute Crank

9 24816 1 Cover, Belt

10 705-5226 1 Chute Reinforcement

11 705-5269 1 Spiral Assembly, L.H. (not shown)

12 705-5270 1 Spiral Assembly, R.H.

13 43182 3 Hex Bolt, 5/16-18 x 3/4" Lg.

14 44950 5 Carriage Bolt, 1/4-20 x 3/4"

15 44917 1 Palnut, 3/8"

16 44326 4 Carriage Bolt, 5/16-18 x 1" Lg.

17 43080 10 Carriage Bolt, 5/16-18 x 3/4" Lg.

18 46703 8 Bolt, Self-Tap 5/16" x 3/4"

19 710-0890A 2 Bolt, Shear 5/16-18 x 1-1/2"

20 43088 11 Washer, 1/4"

21 43064 27 Hex Lock Nut, 5/16-18 Thd.

22 43013 5 Hex Lock Nut, 1/4-20

23 47810 2 Hex Nut, 5/16-18 Nylock

24 715-0114 2 Spiral Pin, 1/4" x 1-1/2" Lg.

25 750-0437 2 Bushing

26 731-1379A 1 Chute Adapter

27 43086 15 Lock Washer, 5/16"

28 736-0188 6 Washer, .76" x 1.49" x .06"

29 711-0469 4 Spacer, .75 ID x 1.25 OD x .5 L

30 43081 18 Washer, 5/16" Std. Wrt.

31 47615 2 Bearing, Flange

32 741-0309 1 Bearing, Ball

33 741-0475 2 Bushing, Plastic 3/8"

34 741-0493A 4 Bearing, Split, 3/4"

35 24279 2 Skid Shoe

36 48015 5 Washer, Nylon

37 784-5618 2 Housing, Bearing

38 24393 1 Bracket, Chute Crank

39 24281 1 Bracket, Idler

40 49933 2 Shoulder Bolt, Round Head

41 65367 1 Hanger Bracket Assembly, L.H.

42 65450 1 Hanger Bracket Assembly, R.H.

43 41576 2 Hex Bolt, 3/8-16 x 1-3/4"

44 44377 1 Hex Bolt, 3/8-24 x 1"

45 784-5594 1 Bracket, Cable

46 746-0929 1 Cable, Chute Control With Clip

47 711-0242 1 Spacer

48 746-0928 1 Cable, Chute Control

49 43082 4 Nut, Hex Lock, 3/8-16

REF. PART QTY. DESCRIPTION

REF. PART QTY. DESCRIPTION

NO. NO.

NO. NO.

51 43343 2 Pin, Hair Cotter #4 (1/8")

52 43350 4 Carriage Bolt, 3/8-16 x 1"

53 24394 1 Bracket, Chute Anti-rotation

54 43003 3 Lock Washer, 3/8"

55 1643-60 1 Plastic Cap

56 64452 1 Hanger Bracket Assembly, R.H.

57 64451 1 Hanger Bracket Assembly, L.H.

58 47043 1 Keeper, Engine Pulley

60 24466 2 Bracket, Down Stop

61 736-0247 1 Washer,

62 47598 6 Hex Lock Nut, 1/4" Flanged

63 731-0921 1 Chute, Upper

64 731-1313C 1 Guide, Cable

65 47044 2 Pulley, V Type 4"

66 47026 1 Pulley, V Type

67 43085 1 Hex Bolt, 5/16-18 x 1-1/2"

68 710-0896 1 Screw, 1/4-14 x 5/8"

69 731-0851A 3 Chute Keeper

70 43661 6 Hex Bolt, 1/4-20 x 1"

71 731-1300C 1 Chute, Lower

72 43070 2 Washer, 3/8"

73 47572 6 Hex Lock Nut, 3/8-16 Flanged

49957 1 Owner's Manual

Page 32

67

36

60

57

61

65

58

62

11

65

58

58

62

63

32

33

Page 33

REF. PART QTY. DESCRIPTION

NO. NO.

1 64637 1 Lift Shaft Assembly

2 710-0865 2 Hex Bolt, 1/2-13 x 1"

3 710-0367 2 Hex Bolt, 5/8-11 x 1-1/2"

4 711-0332 2 Pin, Bracket Lift

5 712-0261 2 Nut, Hex Lock 5/8-11 Thread

6 43262 6 Nut, Hex Lock 1/2-13

8 142 5 Pin, Cotter 1/8" x 3/4"

9 43093 1 Pin, Cotter 1/8" x 1-1/2"

10 R19171616 4 Washer, 17/32" x 1"

11 43350 6 Carriage Bolt, 3/8-16 x 1"

12 741-0192 2 Bearing, Flange With Flats

13 783-0380 2 Link, 15.80" Long

14 783-0381 2 Link, 11.75" Long

15 24476 2 Link, 4.88" Long

16 24311 1 Rod, Spacer

17 47599 2 Hex Bolt, 5/16-18 x 1" (Locking)

18 43086 4 Lock Washer, 5/16"

19 24820 1 Bracket, Lift

20 63773 1 Assembly, Handle Lift Bracket

21 48049 1 Rod, Index Lift

22 47369 1 Pin, Spring 3/16" x 1-3/4"

23 732-0306 1 Spring, Compression

24 R19131316 2 Washer, 13/32" x 13/16"

25 47788 2 Refl ector, Rear

26 43080 1 Carriage Bolt, 5/16-18 x 3/4"

27 43182 2 Hex Bolt, 5/16-18 x 3/4"

28 R19111116 2 Washer, 11/32 x 11/16 x 3/64

30 46954 1 Pin, Attachment

31 43343 1 Pin, Haircotter #4 (1/8")

32 25678 1 Plate, Side (R.H.)

33 25679 1 Plate, Side (L.H.)

34 49916 1 Tube, Lift Handle

35 49912 1 Trigger and Lift Cable Assembly

36 43070 2 Washer, 3/8"

37 710-1233 1 Screw, Oval #10-24 x 1"

38 46446 1 Grip, Handle

39 47027 1 Tube, Crank Rod Support

40 741-0475 2 Bushing, 3/8" Plastic

41 703-2735A 1 Bracket, Chute Crank

REF. PART QTY. DESCRIPTION

NO. NO.

42 720-0201A 1 Knob, Crank

43 44917 1 Palnut, 3/8"

45 63579 1 Assembly, Chute Crank Rod

46 784-5604 1 Handle, Chute Tilt

47 720-0232 1 Knob

48 603-0302 1 Assembly, Chute Tilt Bracket

49 731-1313C 1 Guide, Cable

50 746-0928 1 Cable, Chute Control

51 746-0929 1 Cable, Chute Control with Clip

52 43064 5 Nut, Hex Lock 5/16-18

54 24285 1 Plate, Mounting (L.H.)

55 24284 1 Plate, Mounting (R.H.)

56 43601 1 Washer, 1.59" x 1.032" x .060"

57 46584 1 Nut, Whizlock, 5/16-18

58 R19172410 8 Washer, 1/2"

59 726-0178 3 Tie, Nylon

60 47631 6 Hex Bolt, 3/8-16 x 1" Self Tap

61 43003 6 Lock Washer, 3/8"

62 47572 6 Nut, Flanged Lock 3/8-16

63 47810 8 Nut, Nylock Hex 5/16-18

64 43084 2 Hex Bolt, 5/16-18 x 1-3/4"

65 44326 2 Carriage Bolt, 5/16-18 x 1"

66 44215 2 Carriage Bolt, 5/16-18 x 1-3/4"

67 48106 2 Bolt, Shoulder

68 43682 2 Carriage Bolt, 5/16-18 x 1-1/4"

69 44695 2 Washer, Bowed

Page 34

REF. PART QTY. DESCRIPTION

NO. NO.

2 43064 3 Hex Lock Nut, 5/16-18

3 43083 2 Hex Nut, 5/16-18

4 43086 4 Lock Washer, 5/16"

5 43081 4 Washer, 5/16" Std. Wrt.

6 25727 1 Frame, Clutch and Pulley

7 63904 1 Idler Arm Assembly

8 24286 1 Spacer, Pivot

9 63762 1 Idler Bracket Assembly

10 43015 1 Hex Nut, 3/8-16

11 46981 1 Pulley, V Type 9"

12 43082 8 Nut, Hex Lock, 3/8-16

13 46982 1 Pulley, V Type 5-1/2"

14 738-0680 1 Shaft

15 750-0456 1 Spacer

16 750-0660 1 Spacer

17 43003 6 Lock Washer, 3/8"

18 714-0161 2 Key

19 741-0919 2 Bearing, Ball

20 08253B 1 Housing, Bearing

21 15296A 1 Housing, Open Bearing

22 14088B 1 Spacer, Spindle

23 44377 2 Hex Bolt, 3/8-24 x 1"

24 736-0247 2 Washer

25 43063 3 Hex Bolt, 5/16-18 x 1"

26 46989 1 Belt, V Type Drive (55")

48138 1 Belt, V Type Drive (56")

27 47846 1 Belt, V Type Auger

28 47044 1 Pulley, V Type 4"

29 47025 1 Hex Bolt, 5/16-18 x 3-1/2"

30 43432 1 Hex Bolt, 3/8-16 x 2-1/2"

31 43054 3 Hex Bolt, 3/8-16 x 2"

32 24571 1 Spacer

33 24472 1 Spacer, Pivot

34 43070 8 Washer, 3/8"

35 46959 1 Spring

36 46963 2 Chain

37 43055 1 Pin, Hair Cotter, 3/32"

38 23727 1 Spacer

39 43088 1 Washer, 1/4"

40 43343 2 Pin, Hair Cotter #4 (1/8")

41 47134 2 Pin, Hair Cotter 5/64"

42 711-0198 1 Trunnion

43 46948 1 Rod, Engagement

44 47620 1 Spring

45 47607 1 Spring, Torsion

46 23625 1 Spacer

47 43509 1 Hex Bolt, 3/8-16 x 2-3/4" Lg.

48 47605 1 Washer, Flat 3/8"

49 24558 1 Cable Bracket

50 49870 1 Hex Bolt, 1/4-20 x 2-1/2"

51 43178 2 Hex Nut, 1/4-20

52 43177 1 Lock Washer, 1/4"

53 48883 3 Pulley, Flat 3-5/8"

54 25728 2 Rear Pulley Frame Bracket

55 46938 1 Hex Bolt, 3/8-16 x 3-1/4"

56 25780 1 Spacer

57 47810 6 Hex Nut, 5/16-18 Nylock

58 43182 4 Hex Bolt, 5/16-18 x 3/4"

Page 35

thrower. Refer also to the instructions in your vehicle owners manual.

CAUTION: DO NOT OPERATE YOUR TRACTOR AND SNOW

THROWER ON A SLOPE IN EXCESS OF 10 DEGREES. BE SURE

OF YOUR TRACTOR'S TOWING AND BRAKING CAPABILITIES

BEFORE OPERATING ON A SLOPE. AVOID ANY SUDDEN TURNS OR

MANEUVERS WHILE ON A SLOPE.

A POWER POLE

A CORNER OF A BUILDING

OR A FENCE POST

FOLD ALONG DOTTED LINE, REPRESENTING A 10 DEGREE SLOPE

SIGHT AND HOLD THIS LEVEL WITH A VERTICAL TREE

Page 36

the fastest way to purchase parts

www.speedepart.com

Agri-Fab, Inc.

www.agri-fab.com

© 2003 Agri-Fab, Inc.

Loading...

Loading...