Page 1

the fastest way to purchase parts

www.speedepart.com

™

OWNERS MANUAL

MANUEL DU PROPRIÉTAIRE

Model No.

Modèle nº

45-0418

ATV SNOW THROWER

SOUFFLEUSE À NEIGE POUR VTT

CAUTION:

Read Rules for

Safe Operation and

Instructions Carefully

AVERTISSEMENT :

Lire et suivre attentivement

les instructions et

consignes de sécurité

PRINTED IN U.S.A. FORM NO. 40367 (10/22/07)

Safety•

Assembly•

Operation•

Maintenance•

Parts•

Sécurité•

Assemblage•

Utilisation•

Entretien•

Pièces•

Page 2

SAFETY

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate the

equipment. Exercise caution at all times, when using power equipment.

Read this owner's manual carefully and know how to •

operate your snow thrower and how to stop the unit

and disengage the controls quickly.

Never allow children to operate the equipment.•

Never allow adults to operate the equipment without •

proper instruction.

Keep the area of operation clear of all persons, •

especially small children, and pets.

Never operate the snow thrower without good visibility •

or light.

Thoroughly inspect the area where the equipment is •

to be used and remove all door mats, sleds, boards,

wires and other foreign objects.

Disengage all clutches and shift into neutral before •

starting engine.

Do not operate equipment without wearing adequate •

winter outer garments.

Wear substantial footwear which will protect feet and •

improve footing on slippery surfaces.

Never operate the ATV snow thrower without attaching •

the clip of the tethered safety switch to your clothing. A

riderless ATV with a running snow thrower could cause

serious injury to a fallen operator or to others.

Check fuel before starting the engine. Do not remove •

the fuel cap or ll the fuel tank while the engine is

running or hot. Do not ll the fuel tank indoors. Gasoline

is an extremely ammable fuel.

Make sure the snow thrower height is adjusted to clear •

the type of surface it will be used on.

Never make any adjustments while the engine is •

running.

Always wear safety glasses or eye shield during •

operation or while performing adjustment or repair.

Do not place hands or feet near rotating parts. Keep •

clear of the discharge opening at all times.

Use extreme caution when operating on or crossing •

gravel surfaces.

Do not carry passengers.•

After striking a foreign object, stop the snow thrower •

and ATV, set the brake on the ATV, remove the wire

from the spark plug on the snow thrower and then

thoroughly inspect the snow thrower for damage.

Repair any damage before restarting and operating

the snow thrower.

If the snow thrower starts to vibrate abnormally, •

stop the snow thrower and ATV immediately, set the

brake on the ATV, remove the spark plug on the snow

thrower and check for the cause. Vibration is generally

a warning of trouble.

Stop the snow thrower engine and remove the spark •

plug wire whenever you leave the operating position,

before unclogging the snow thrower or making any

adjustments or inspections.

Take all possible precautions when leaving the unit •

unattended. Disengage the clutch lever, lower the

snow thrower, set the parking brake, turn off the ATV

and snow thrower engines and remove the keys.

When cleaning, repairing or inspecting, make certain •

all moving parts have stopped. Disconnect the spark

plug wire and keep it away from the plug to prevent

accidental starting.

Do not run engine indoors except when transporting •

the snow thrower in or out of the building. Open the

outside doors. Exhaust fumes are dangerous.

Do not clear snow across the face of slopes. Exercise •

extreme caution when changing direction on slopes.

Do not attempt to clear steep slopes. Refer to the slope

guide on page 34 of this manual.

Never operate the snow thrower without guards, plates •

or other safety protection devices in place.

Never operate the snow thrower near glass enclosures, •

automobiles, window wells, drop offs etc. without proper

adjustment of the snow thrower discharge angle.

Never direct discharge at bystanders or allow anyone •

in front of the snow thrower.

Never run the snow thrower into material at high •

speeds.

Do not overload the machine capacity by attempting to •

clear snow at too fast a rate.

Never operate the machine at high transport speed •

on slippery surfaces. Look behind and use care when

backing up.

Watch for trafc and stay alert when crossing or •

operating near roadways.

Disengage power to the snow thrower when •

transporting or when not in use.

Refer to ATV owners manual before using other •

attachments or accessories.

Never operate the snow thrower without good visibility •

or light.

This document (or manual) is protected under the U.S. Copyright Laws and the copyright laws of foreign countries, pursuant to the

Universal Copyright Convention and the Berne convention. No part of this document may be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying or recording, or by any information storage or retrieval system, without the

express written permission of Agri-Fab, Inc. Unauthorized uses and/or reproductions of this manual will subject such unauthorized user

to civil and criminal penalties as provided by the United States Copyright Laws.

© 2007 Agri-Fab, Inc.

2

Page 3

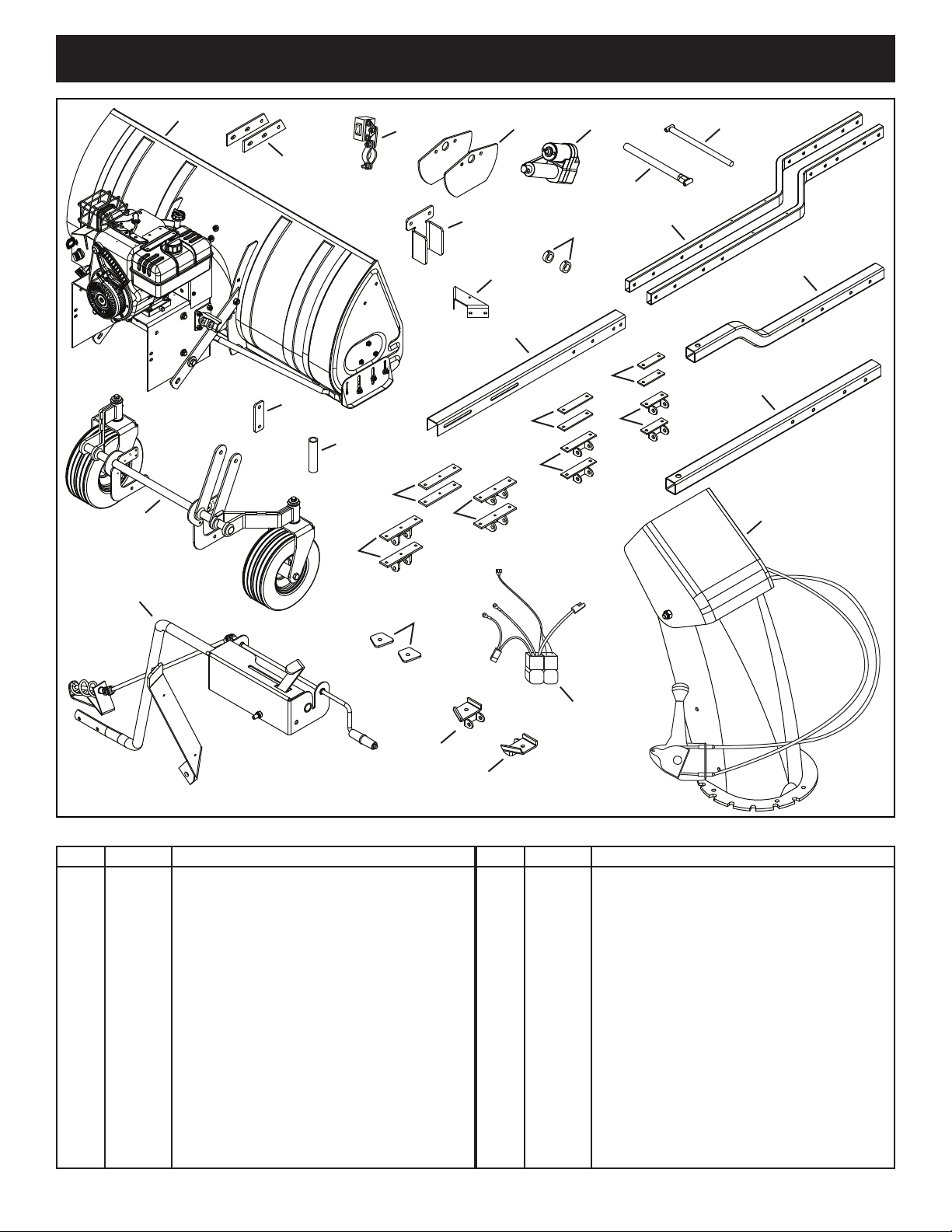

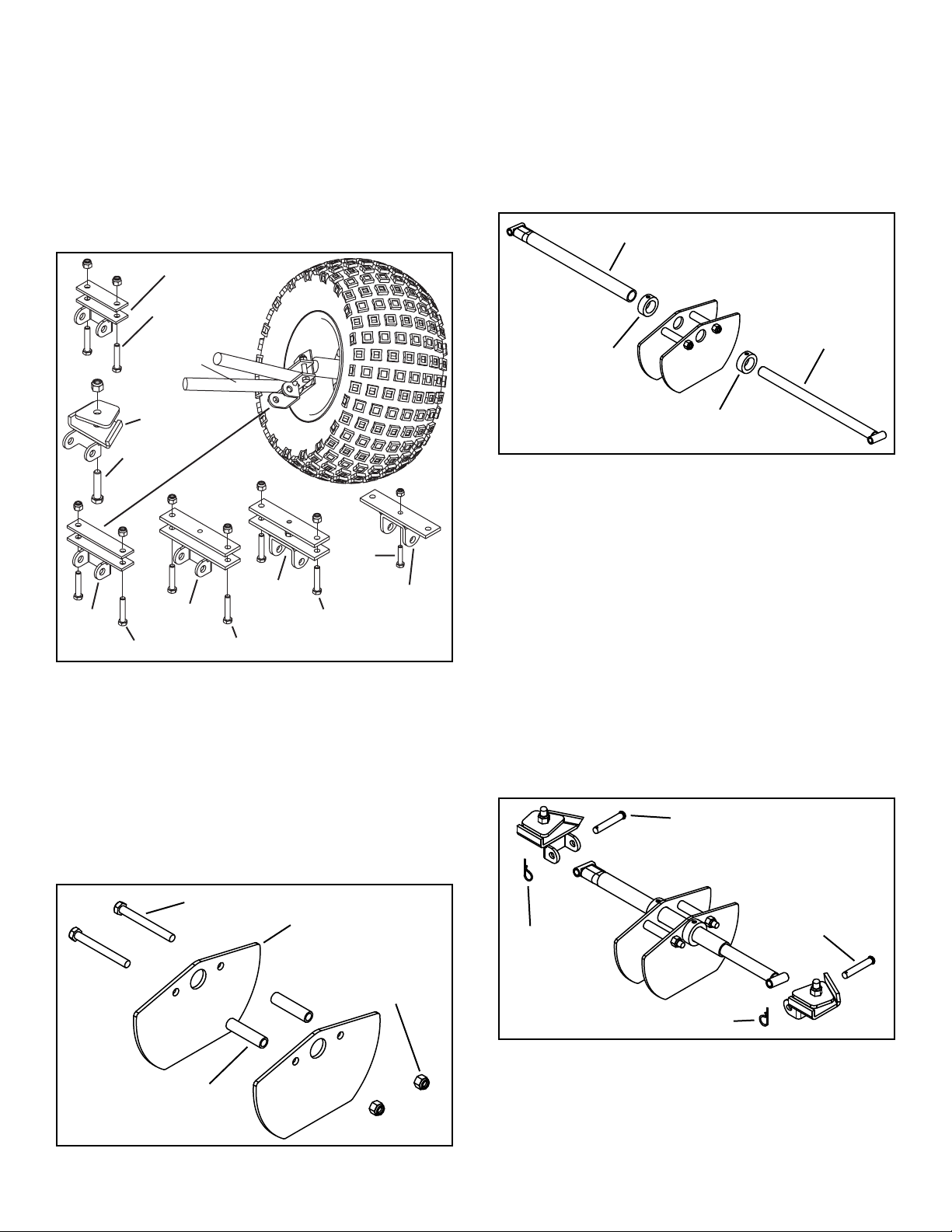

CARTON CONTENTS

1

2

5

4

6

7

10

11

15

23

30

24

9

12

25

29

26

17

18

20

22

16

19

21

28

27

3

8

13

14

REF QTY DESCRIPTION

1 1 Snow thrower Housing

2 2 Housing Anchor Strap

3 1 Handlebar Switch

4 2 Stabilizer Bracket

5 1 Actuator

6 1 Outer Mount Strut

7 1 Inner Mount Strut

8 1 Guide Bracket

9 1 Support Bracket

10 2 Collar

11 2 Mounting Tube

12 1 Wheel Assembly

13 1 Guide Plate

14 1 Spacer, 3" Long

15 1 Push Channel

3

REF QTY DESCRIPTION

16 2 6-5/8" Clamp Bracket

17 2 6-5/8" Strut Mount

18 2 6-5/8" Strut Mount

19 2 5-1/2" Clamp Bracket

20 2 5-1/2" Strut Mount

21 2 4" Clamp Bracket

22 2 4" Strut Mount

23 1 Rear Frame Tube (Bent)

24 1 Rear Frame Tube (Straight)

25 1 Control Assembly

26 2 Polaris Clamp Bracket

27 1 Polaris Strut Mount (LH)

28 1 Polaris Strut Mount (RH)

29 1 Wiring Harness

30 1 Discharge Chute

Page 4

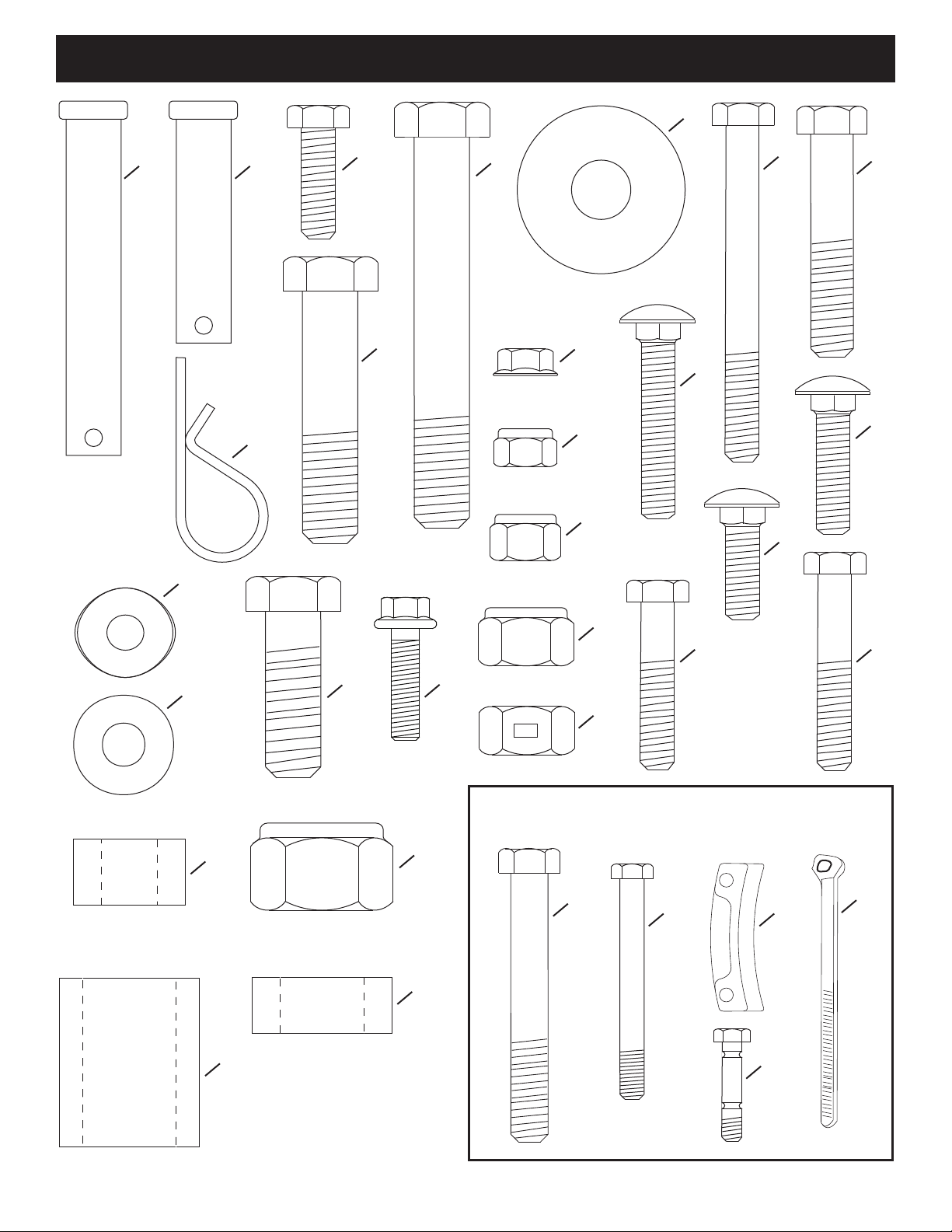

HARDWARE PACKAGE

PARTS NOT SHOWN

FULL SIZE

1 2

3

5

6

7

24

25

13

17

18

12

20

19

4

21

22 23

14

15

16

11

29

28

31

8

9

10

26

27

30

32

4

Page 5

REF QTY DESCRIPTION

OFF

LO

HI

SMALL NYLOCK

NUT

LONG,

SMALL

SCREW

HANDLEBAR

STRAP

HANDLEBAR

BRACKET

SMALL

WHIZLOCK

NUT

SWITCH

BRACKET

OFF

LO

HI

SHORT,

SMALL

SCREW

SMALL NYLOCK

NUT

1 3 Clevis Pin, 1/2" x 3"

2 1 Clevis Pin, 1/2" x 2"

3 4 Hex Bolt, 5/16-18 x 1"

4 4 Hex Bolt, 1/2-13 x 3-1/2"

5 25 Washer, 1/2" x 1-1/2"

6 2 Hex Bolt, 5/16" x 3"

7 4 Hex Bolt, 3/8-16 x 2"

8 4 Hair Pin

9 2 Bowed Washer, 1" x .32"

10 10 Washer, 5/16"

11 12 Hex Bolt, 1/2-13 x 2-1/4"

12 1 Hex Bolt, 1/2-13 x 1-1/2"

13 6 Hex Flange Bolt, 1/4-20 x 1"

14 6 Flanged Lock Nut, 1/4-20

15 18 Nylock Nut, 5/16-18

16 4 Nylock Nut, 3/8-16

REF QTY DESCRIPTION

17 19 Nylock Nut, 1/2-13

18 2 Lock Nut, 1/2-13

19 2 Carriage Bolt, 5/16-18 x 1-3/4"

20 2 Carriage Bolt, 5/16-18 x 1"

21 2 Carriage Bolt, 5/16-18 x 1-1/4"

22 2 Hex Bolt, 5/16-18 x 1-1/2"

23 4 Hex Bolt, 5/16-18 x 1-3/4"

24 2 Spacer, .5" x 1.0" x .59"

25 1 Spacer, .81" x 1.25" x 1.5"

26 1 Nylock Nut, 3/4-10

27 4 Spacer .75" x 1.25" x .5"

28 1 Hex Bolt, 3/4-10 x 7-1/2"

29 2 Hex Bolt, 1/2" x 4-1/2"

30 3 Chute Keeper

31 8 Nylon Tie

32 2 Replacement Shear Bolt

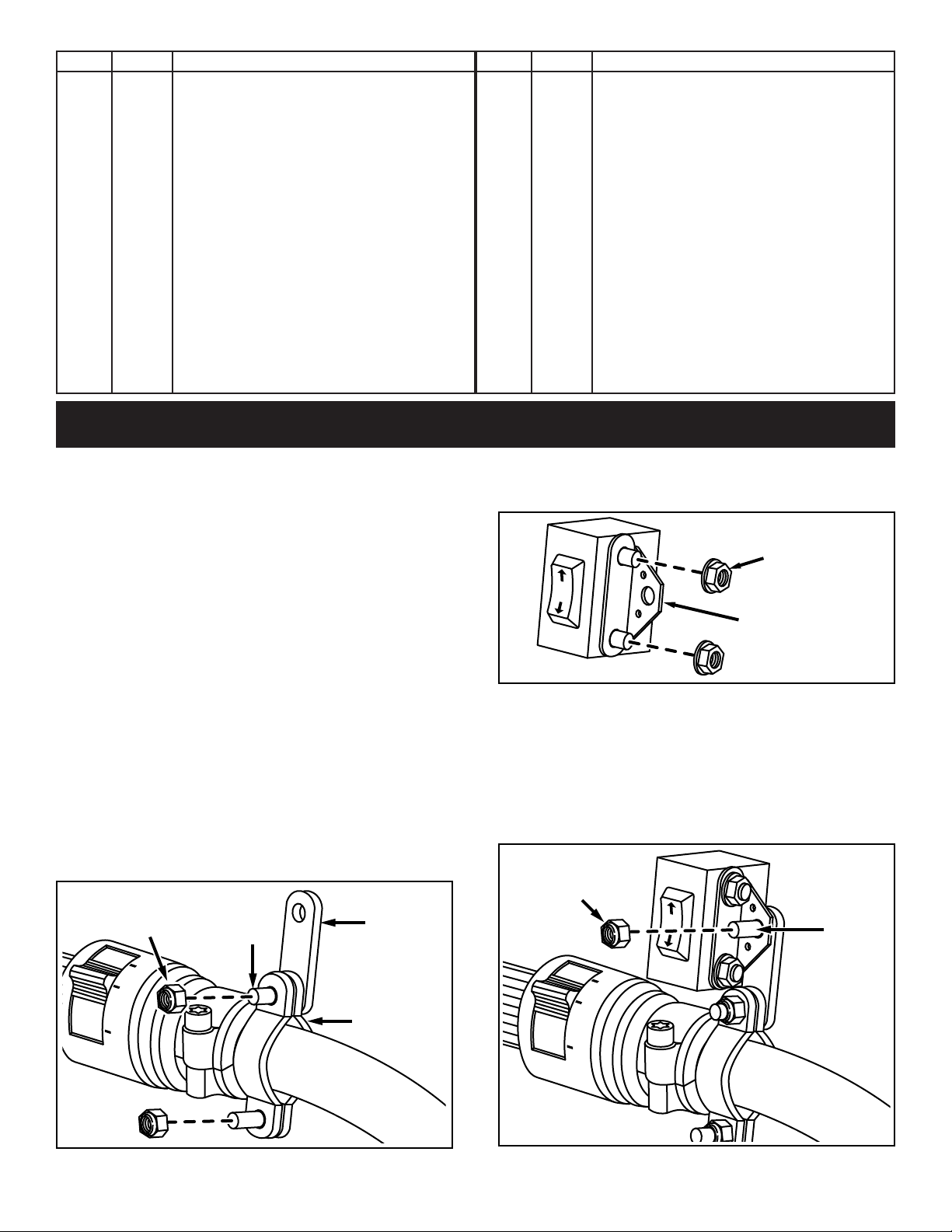

ASSEMBLY

TOOLS NEEDED

(1) 5/16" Wrench

(1) 3/8" Wrench

(1) 7/16" Wrench

(2) 1/2" Wrenches

(2) 9/16" Wrenches

(2) 3/4" Wrenches

(1) 1-1/6" Wrench or Adjustable Wrench

(1) 1-1/8" Wrench or Adjustable Wrench

(1) 3/16" Allen Wrench

(1) Phillips Screwdriver

(1) Scissors or Knife

(1) Grease Gun w/ general purpose grease

(1) 15" Concrete Block

WIRING ASSEMBLY

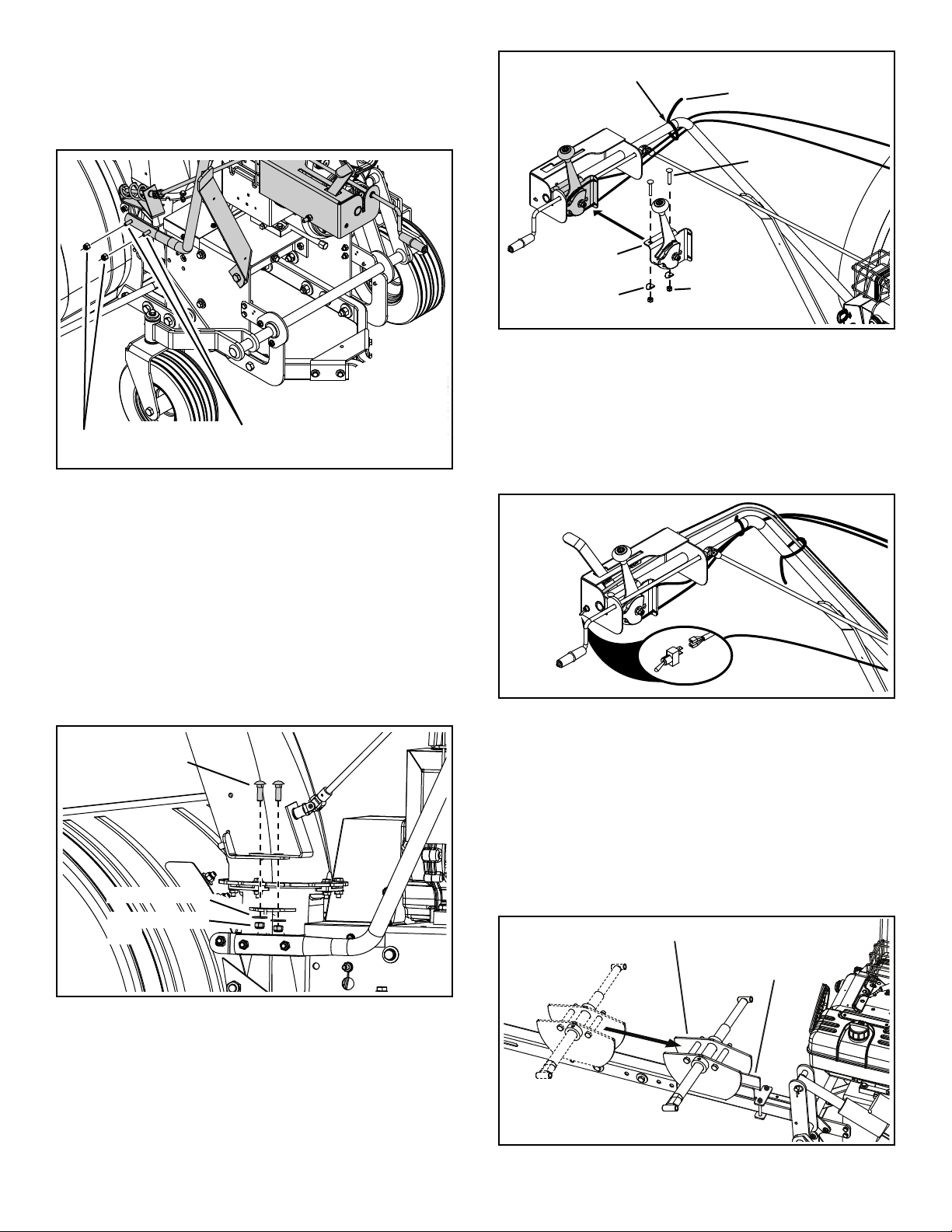

Assemble (2) handlebar brackets and (1) handlebar 1.

strap onto the handlebars using (2) long, small screws

and (2) small nylock nuts. Do not tighten yet.

Assemble the switch bracket to the handlebar switch 2.

using (2) small whizlock nuts. Tighten.

FIGURE 2

Assemble the switch bracket to the handlebar strap 3.

using (1) short, small screw and (1) small nylock nut.

See gure 3. Do not tighten yet.

Rotate handlebar switch until it is at desired angle and 4.

then tighten the screws and nuts assembled in steps

1 and 3.

FIGURE 1

FIGURE 3

5

Page 6

Secure the relay pack near the battery of the ATV or 5.

2x4

AWD

PRE-ASSEMBLED

SCREW

PRE-ASSEMBLED

NUT

BATTERY

+

POSITIVE

"HOT" POST

BLACK

RED

FUSE

HANDLEBAR

SWITCH

BULLET

CONNECTOR

RELAY PACK

ACTUATOR

3-WIRE

LEAD

other location on the ATV out of harms way.

Thread the 3 wire lead from the relay pack forward 6.

through the ATV frame on the same side as the handle

bar switch. Avoid threading wire close to moving parts,

hot parts or pinch points. Use 1 or 2 nylon ties to hold

wire in place.

Connect the three leads from the handlebar switch into 7.

the three leads from the relay pack matching up the

red, green and black wires. See Figure 4.

Thread the bullet connector from the relay pack forward 8.

through the frame and out through the front of the ATV.

Avoid threading wire close to moving parts, hot parts

or pinch points. Use 1 or 2 nylon ties to hold wire in

place.

Plug the bullet connector from the relay pack into the 9.

bullet connector on the actuator.

Attach the red wire from the fuse to the positive terminal 10.

on the ATV battery. Attach the negative lead (black

wire) from the relay pack to the negative terminal on

the ATV battery.

Use the handlebar switch to fully extend the actuator, 11.

then disconnect the actuator.

Attach the tethered safety switch to the handlebar using 12.

(4) pre-assembled screws and (4) pre-assembled nuts.

See gure 5.

Thread the wiring through the ATV and out the front of 13.

the ATV. Avoid threading wire close to moving parts,

hot parts or pinch points. Nylon ties can be used to

hold wire in place.

FIGURE 5

FIGURE 4

6

Page 7

4" Strut Mount

Polaris

Strut Mount

5-1/2"

Strut

Mount

6-5/8" Strut

Mount

6-5/8" Strut

Mount

Bombardier

Outlander Strut

Mount

5/16" x

1-1/2"

1/2" x 2-1/4"

3/8" x 2"

3/8" x 2"

3/8" x 2"

3/8" x 2"

ATV Lower

A Arm

1/2" x 4-1/2"

HEX BOLT

STABILIZER

BRACKET

1/2" NYLOCK NUT

3" LONG

SPACER

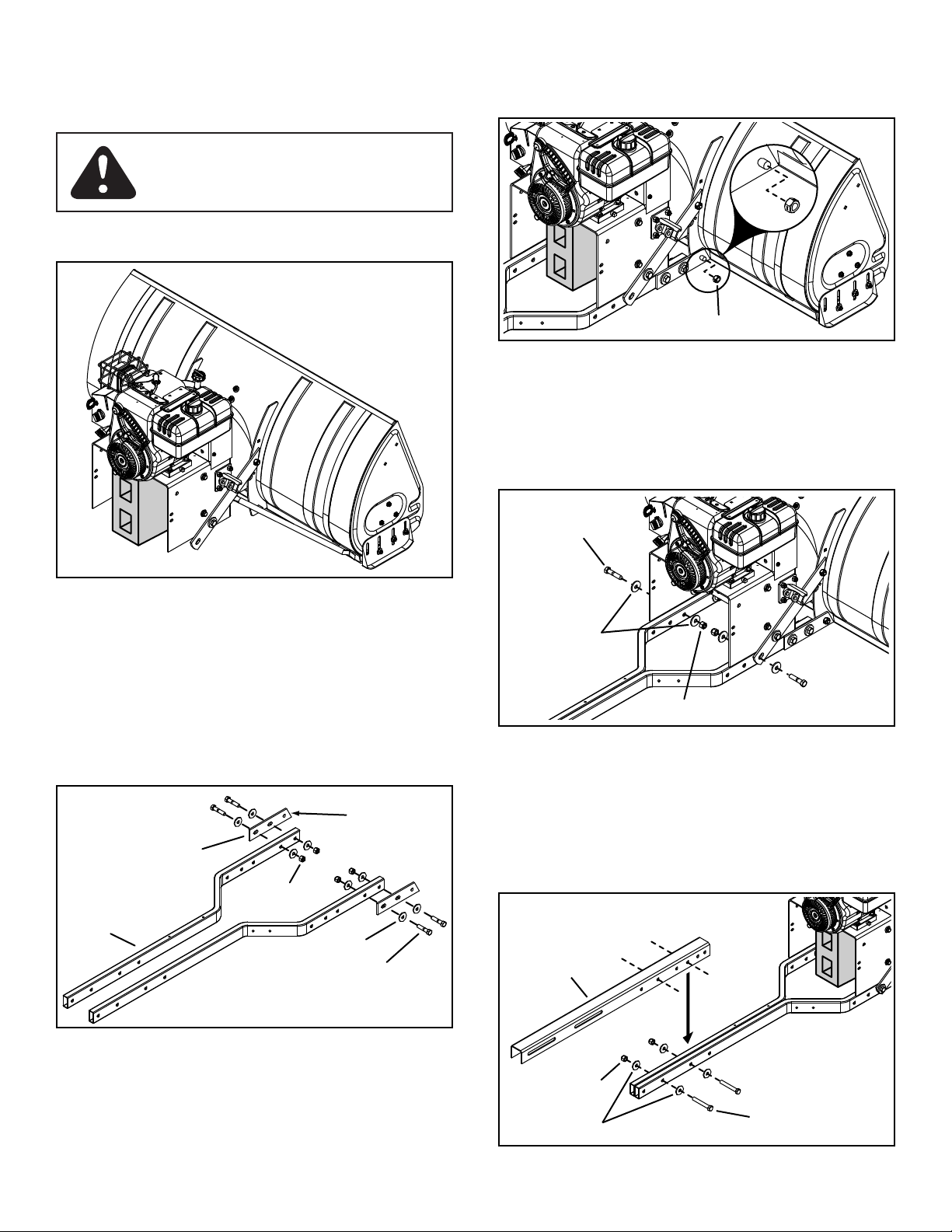

SNOW THROWER ASSEMBLY

OUTER MOUNT STRUT

COLLAR

COLLAR

INNER

MOUNT

STRUT

1/2" x 3"

CLEVIS PIN

HAIRPIN

COTTER

HAIRPIN COTTER

1/2" x 3"

CLEVIS PIN

Remove any CV boot guard or stick guard from the 1.

front lower A arms of the ATV. Select the correct strut

mount assembly shown in gure 6 for your ATV. If your

ATV is not listed in gure 6, start with the 5-1/2" strut

mount assembly. If you use the 4", 5-1/2" or 6-5/8" strut

mount assemblies, attach with the strut mount on the

bottom of the A arm and the bolts on the outside of the

A arm. Do not tighten bolts at this time.

Slide a collar over the end of the outer mount strut.3.

Slide the outer mount strut through the brackets 4.

assembled in step 2.

Slide a second collar over the end of the outer mount 5.

strut.

Apply a light coat of grease to the inner mount strut 6.

and then insert it into the outer mount strut.

Tighten7. the bolts assembled in step 2.

FIGURE 8

Assemble the stabilizer brackets together using (2) 2.

1/2" x 4-1/2" hex bolts, (2) 3" long spacers and 1/2"

nylock nuts as shown in gure 7. Do not tighten yet.

Fasten the ends of the inner and outer mount struts 8.

to the strut mount assemblies that you attached to the

ATV's A-arms. Use two (2) 1/2" x 3" clevis pins and two

(2) hairpin cotters.

Tighten9. the bolts and nuts assembled in step 1 that

FIGURE 6

fasten the strut mount assemblies to the A-arms.

Center the stabilizer brackets under the ATV. Slide the 10.

collars up against the stabilizer brackets and tighten

the set screws in the collars. The stabilizer brackets

must rotate freely after the collars are tightened.

NOTE: The ATV is not shown below for clarity.

FIGURE 9

FIGURE 7

7

Page 8

ANGLE

SLOPES

BACKWARD

1/2" WASHER

1/2" NYLOCK

NUT

1/2" X 2-1/4"

HEX BOLT

HOUSING

ANCHOR

STRAP

MOUNTING

TUBE

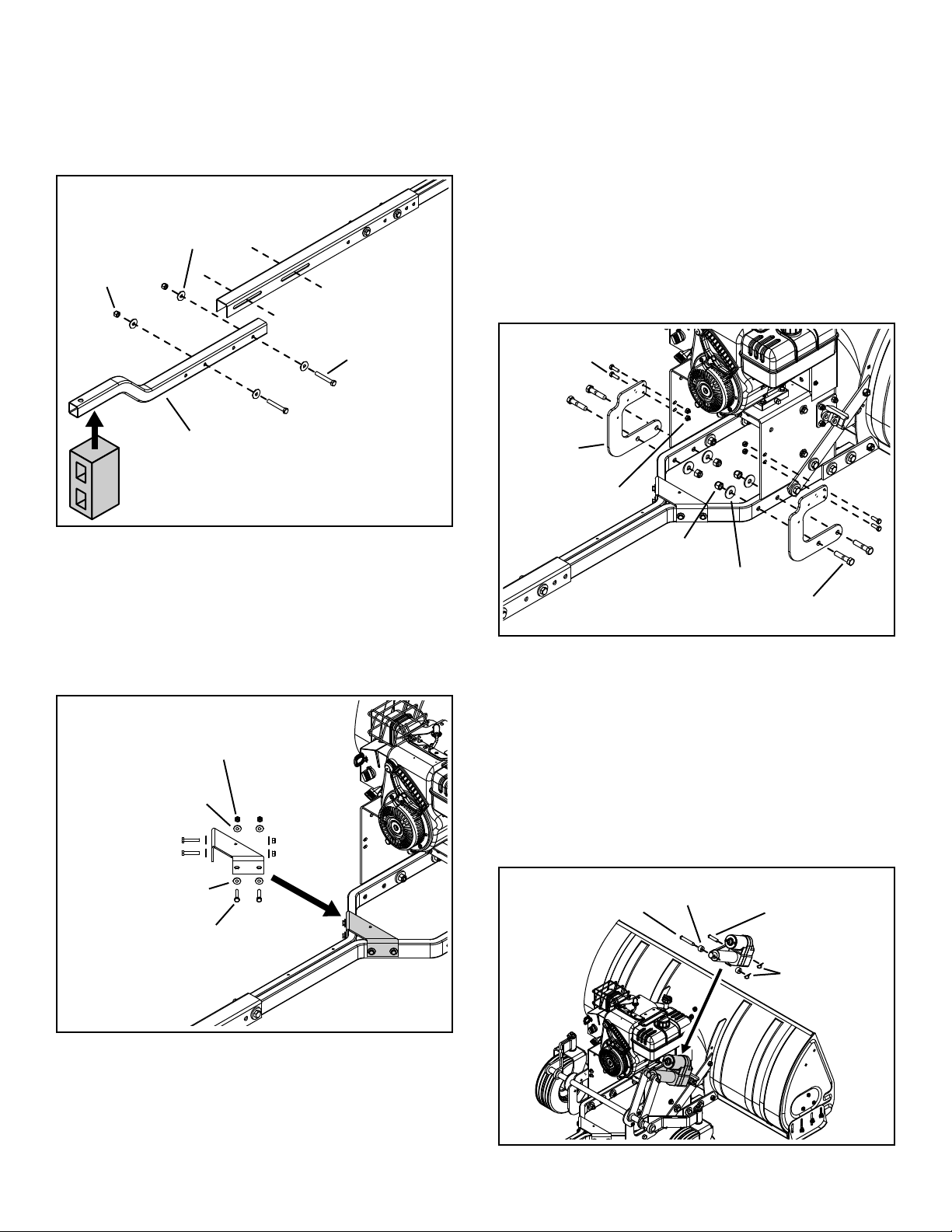

Place a 15" concrete block underneath the snow 11.

1/2" NYLOCK

NUT

PUSH

CHANNEL

1/2" WASHER

1/2" x 3-1/2"

HEX BOLT

1/2" LOCK NUT

1/2" WASHER

1/2" NYLOCK NUT

1/2" X 2-1/4"

HEX BOLT

thrower, beneath the engine. See gure 10.

CAUTION: Use caution while working

on snow thrower when it is propped up on

concrete block.

Attach the front holes of the housing anchor straps to 13.

the weld bolts on the housing using (2) 1/2" lock nuts.

Do not tighten yet.

FIGURE 12

Secure the mounting tubes to the side support straps 14.

using (2) 1/2" x 2-1/4" hex bolts, (4) 1/2" washers (inside

and outside) and (2) 1/2" nylock nuts. Do not tighten yet.

NOTE: Concrete block not shown for clarity.

Attach the housing anchor straps to the 12. outside of the

mounting tubes using (4) 1/2" x 2-1/4" hex bolts, (8)

1/2" washers and (4) 1/2" nylock nuts. Do not tighten

yet.

FIGURE 10

FIGURE 13

Place the push channel over the ends of the mounting 15.

tubes. Line up the holes as shown in the gure below

and secure the push channel using (2) 1/2" x 3-1/2"

hex bolts, (4) 1/2" washers (one on each side) and (2)

1/2" nylock nuts. Do not tighten yet.

FIGURE 11

FIGURE 14

8

Page 9

5/16" NYLOCK NUT

5/16" WASHER

5/16" x 1-3/4"

HEX BOLT

5/16" WASHER

Attach the bent rear frame tube to the push channel 16.

1/2" NYLOCK

NUT

1/2" WASHER

1/2" x 3-1/2"

HEX BOLT

REAR FRAME TUBE

1/2" x 3"

CLEVIS PIN

.5" x 1" x .59"

SPACERS (2)

1/2" x 2"

CLEVIS PIN

HAIRPINS (2)

5/16" x 1"

HEX BOLT

1/2" NYLOCK

NUT

1/2" WASHER

1/2" x 2-1/4"

HEX BOLT

5/16" NYLOCK

NUT

ANCHOR

BRACKET

using (2) 1/2" x 3-1/2" hex bolts, (4) 1/2" washers and

(2) 1/2" nylock nuts. Do not tighten yet.

Remove the concrete block from under the engine 17.

and place it underneath the the end of the rear frame

tube.

Place the wheel assembly behind the engine mounting 19.

base.

Fasten the bottom of the anchor brackets (part of 20.

wheel assembly) to the outside of the mounting tubes

using (4) 1/2" x 2-1/4" hex bolts, (4) 1/2" washers (on

inside of mounting tube) and (4) 1/2" nylock nuts. Do

not tighten yet.

Fasten the tops of the anchor brackets to the engine 21.

mounting base using (4) 5/16" x 1" hex bolts and (4)

5/16" nylock nuts. Do not tighten yet.

Tighten22. all nuts and bolts assembled in steps 12-

14 and 18-21. Do not tighten the nuts and bolts

assembled in steps 15-16 at this time.

NOTE: Complete wheel assembly not shown for clarity.

Attach the support bracket to the mounting tubes using 18.

(4) 5/16" x 1-3/4" hex bolts, (8) 5/16" washers and (4)

5/16" nylock nuts. Tighten.

FIGURE 15

FIGURE 17

NOTE: Before proceeding with next assembly step, make

sure the actuator is fully extended. Refer to step 11 on

page 6 in the Wiring Assembly Section.

Fasten top of actuator to wheel assembly using (1) 23.

1/2" x 3" clevis pin, (2) .5" x 1" x .59" spacers and (1)

hairpin.

Fasten bottom of actuator to actuator bracket using (1) 24.

1/2" x 2" clevis pin and (1) hair pin.

FIGURE 16

FIGURE 18

9

Page 10

GREASE

5/16" x 3"

HEX BOLT

5/16" NYLOCK NUT

GUIDE PLATE

GUIDE

BRACKET

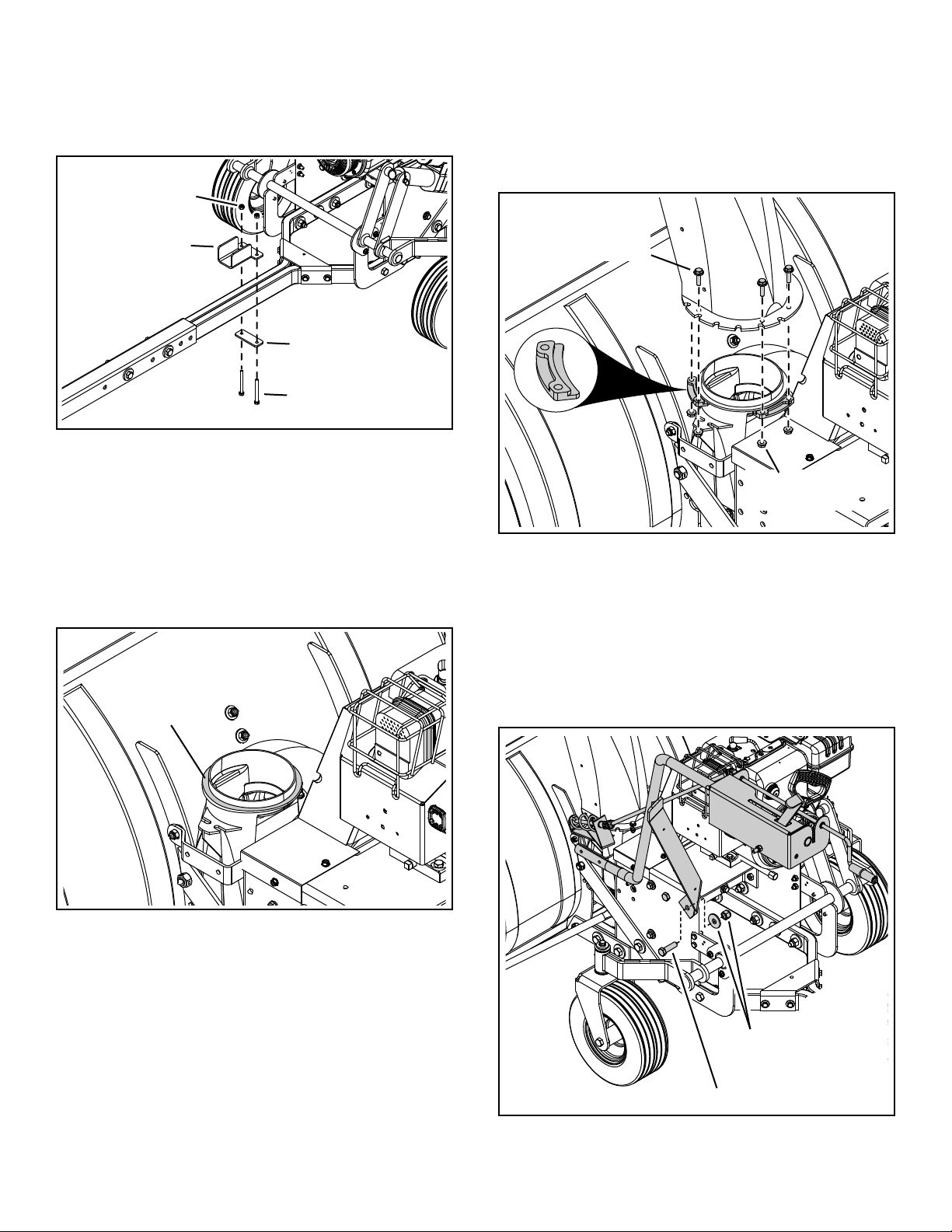

Assemble the guide bracket and guide plate to the 25.

1/2" x 1-1/2" HEX BOLT

1/2" WASHER &

1/2" NYLOCK NUT

1/4" FLANGED

LOCK NUT

1/4" x 1" HEX

FLANGE BOLT

mounting tubes using (2) 5/16" x 3" hex bolts and 5/16"

nylock nuts. Do not tighten yet.

Remove the concrete block from under the rear frame 26.

tube.

FIGURE 19

Place the discharge chute (facing forward) onto the 28.

ring. Attach (3) chute keepers (right side up as shown)

to the bottom of the ange using (6) 1/4" x 1" hex ange

bolts and (6) 1/4" anged lock nuts. Tighten carefully

so that the nuts are snug but do not dig into plastic

chute keepers. Grasp the bottom ange and make

sure the chute turns freely.

Lightly coat the top of the ring around the discharge 27.

opening with general purpose grease.

FIGURE 21

Attach the control assembly's support strap to the 29.

engine mounting base using (1) 1/2" x 1-1/2" hex bolt,

1/2" washer (on inside of mounting base) and 1/2"

nylock nut. Do not tighten yet.

FIGURE 20

FIGURE 22

10

Page 11

SECURE CABLES HERE

NYLON TIE

BOWED

WASHER

CHUTE TILT

CONTROL

5/16" NYLOCK

NUT

5/16" x 1-3/4"

CARRIAGE BOLT

5/16" x 1"

CARRIAGE BOLT

5/16" WASHER

5/16" NYLOCK

NUT

STABILIZER BRACKETS

GUIDE BRACKET

5/16" x 1-1/4"

CARRIAGE BOLTS

5/16" NYLOCK NUTS

Attach the control assembly's support tube to the 30.

welded bracket below the discharge chute using (2)

5/16" x 1-1/4" carriage bolts and (2) 5/16" nylock nuts.

Do not tighten yet.

Tighten31. bolts assembled in steps 29 and 30.

FIGURE 23

FIGURE 25

Insert the wire harness into the large hole at the front 38.

of the control box.

Connect the wire harness to the switch.39.

Using nylon ties, secure the wire harness and clutch 40.

cable to the handle assembly to keep them from

interfering with moving parts.

Cut the nylon tie that holds the two chute crank brackets 32.

together.

Attach the chute crank brackets to the discharge 33.

housing using (2) 5/16" x 1" carriage bolts, 5/16"

washers and 5/16" nylock nuts. Do not tighten yet.

Adjust position of chute crank brackets so that spiral 34.

does not rub bottom of discharge chute notches.

Tighten35. bolts and nuts assembled in step 33.

NOTE: Spiral not shown for clarity.

FIGURE 26

Roll the ATV up behind the snow thrower, keeping the 41.

push channel centered between the stabilizer brackets.

Make sure the guide bracket will slide in between

the stabilizer brackets as shown in gure 27. Keep a

minimum clearance of 3"-4" between the front of the

ATV and the snow thrower.

NOTE: ATV not shown below for clarity.

FIGURE 24

Attach the chute tilt control to the control assembly 36.

using (2) 5/16" x 1-3/4" carriage bolts, (2) bowed

washers and (2) 5/16" nylock nuts.

Using a nylon tie, secure the cables from the chute tilt 37.

control to the support tube as shown in gure 25.

Note: Do not secure the chute tilt control cables in locations

other than the one shown.

FIGURE 27

11

Page 12

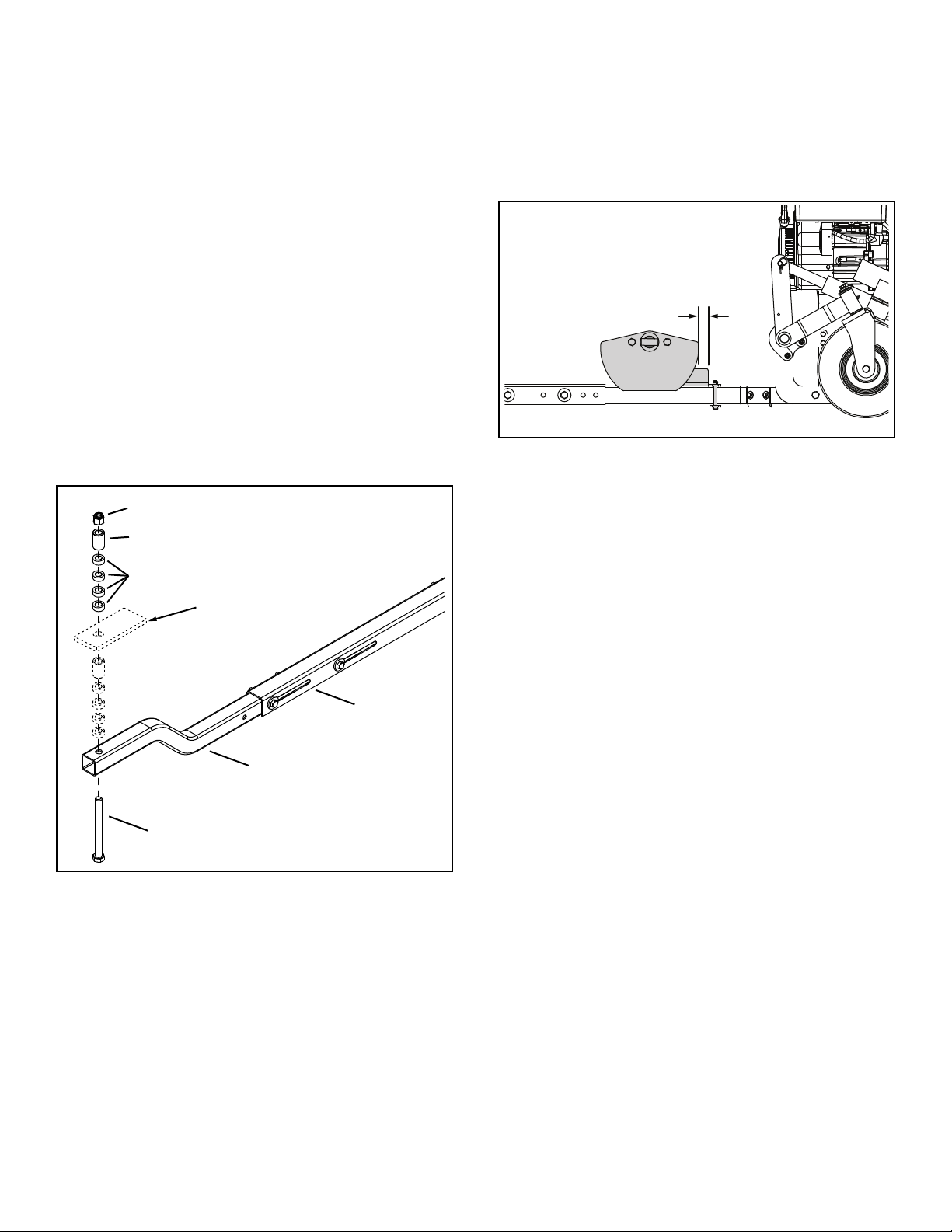

Slide the rear frame tube in or out of the push channel 42.

ATV HITCH

3/4" x 7-1/2"

HEX BOLT

3/4" NYLOCK NUT

LONG SPACER (.81" x 1.25" x 1.5")

REAR FRAME TUBE

PUSH

CHANNEL

SHORT SPACER (.75" x 1.25" x .5")

1/4"

to align it with the ATV hitch. Make sure the minimum

3"-4" clearance between the ATV and the snow thrower

is maintained.

If the rear frame tube does not slide in or out enough 43.

to align with the ATV hitch, move the bolts that fasten

the rear frame tube to the push channel to a different

set of holes. (Refer to gure 15). If alignment is still not

possible, move the bolts that fasten the push channel

to the mounting tubes to a different set of holes. (Refer

to gure 14).

Attach the rear frame tube to the ATV hitch using a 3/4" 44.

x 7-1/2" hex bolt, four (4) short spacers, a long spacer

and a 3/4" nylock nut. Place spacers above or below

the hitch as needed to maintain at least 1" clearance

with the bottom of the ATV and adequate clearance

with the ground. Tighten.

NOTE: Replace the bent rear frame tube with the straight

rear frame tube if the bent rear frame tube does not provide

adequate ground clearance and there is extra clearance

with the bottom of the ATV.

Tighten45. the nuts and bolts that fasten the push channel

to the mounting tubes, and the rear frame tube. Refer

to gures 14 and 15. Make sure the mounting tubes

stay centered with the ATV while tightening.

Slide the guide bracket along the mounting tubes until 46.

the front edge is a 1/4" in front of the front edge of the

stabilizer brackets as shown in gure 29. Tighten.

FIGURE 29

Use a grease gun to apply general purpose grease 47.

to the grease ttings in the wheel hubs and wheel

spindles. Apply until grease is forced out the ends of

the hubs and spindles.

Connect the wiring from the tethered safety switch to 48.

the bullet connector on the wire harness for the switch

on the control box.

Reconnect the actuator to the handle bar switch that 49.

was unplugged in step 11 on page 6.

CHECKLIST

Before you operate your snow thrower, please review

the following checklist to help ensure that you will

obtain the best performance from your snow thrower.

All assembly instructions have been completed with all 1.

bolts and nuts properly tightened.

Check the discharge chute for proper rotation.2.

Check operation of tilt control for upper chute.3.

FIGURE 28

Verify that the wiring is correct for the actuator and that 4.

the actuator will raise and lower the snow thrower.

Check skid shoe adjustment. (Refer to the Service and 5.

Adjustments section.

Check that the tethered safety switch will shut off the 6.

engine.

Check that the wheel hubs and wheel spindles are full 7.

of grease.

12

Page 13

OPERATION

CRANK

ROD

ON/OFF

SWITCH

HANDLE BAR

SWITCH

TETHERED SAFETY

SWITCH

CHUTE TILT

HANDLE

CLUTCH

LEVER

UPPER CHUTE

LOWER CHUTE

SPIRAL AUGERS

R.H. & L.H.

SKID SHOE

SCRAPER PLATE

KNOW YOUR SNOW THROWER

Read this owner's manual and safety rules before operating your snow thrower.

Compare the illustration below with your snow thrower to familiarize yourself with the various controls and their locations.

CHUTE TILT HANDLE — Pivots the Upper Chute up or

down to control the angle and distance of discharge.

CRANK ROD — Rotates the Lower and Upper Chutes to

control the direction of discharge.

UPPER AND LOWER DISCHARGE CHUTE — Controls

direction and height of snow discharge.

SCRAPER PLATE — Replaceable plate that absorbs

wear and impact from contact with ground.

SKID SHOE — Controls amount of clearance between the

scraper plate and the ground.

HOW TO USE YOUR SNOW THROWER

BEFORE STARTING

Use the end of assembly checklist to verify that all •

instructions have been properly completed.

Make sure the skid shoes are adjusted to maintain •

adequate ground clearance between the snow thrower

and the type of surface to be cleared. (Refer to the

Service and Adjustments section.)

Make sure the ATV engine has the correct oil for winter •

operation. Refer to ATV owner's manual.

CAUTION: Never direct discharge

towards bystanders or windows. Do not

allow anyone in front of unit.

SPIRAL AUGER, R.H. & L.H. — Feeds snow to the

impeller fan at the center of the housing.

ON/OFF SWITCH — Allows snow thrower engine to be

turned off when sitting on ATV.

HANDLE BAR SWITCH — Raises and lowers the snow

thrower.

TETHERED SAFETY SWITCH — Turns snow thrower off

when pulled out.

CLUTCH LEVER — Engages and disengages the spiral

augers.

HOW TO START YOUR SNOW THROWER

Set clutch lever to "DISENGAGED"•

Attach the pull out plug to the tethered safety switch. The •

snow thrower will not run if the plug is not attached.

Set on/off switch on control mount to "ON"•

Follow instructions in your Engine Operator's Manual •

to start the snow thrower engine, then continue below.

Board your ATV and move clutch lever on control •

mount to "ENGAGED" position

HOW TO STOP YOUR SNOW THROWER

Set clutch lever on control mount to "DISENGAGED"•

Set on/off switch on control mount to "OFF"•

Follow instructions in your Engine Operator's Manual •

to nish Stop Engine procedures.

13

Page 14

CONTROLLING SNOW DISCHARGE

To control the direction snow is thrown, the discharge •

chute has 180 degrees of rotation. Turn the crank rod

clockwise to rotate the chute to the right. Turn the crank

rod counterclockwise to rotate the chute to the left.

To control the distance snow is thrown, the upper •

section of the discharge chute pivots up and down.

Push forward on the chute tilt handle to pivot the chute

down, decreasing the distance snow is thrown. Pull

back on the handle to pivot the chute up, increasing

the distance snow is thrown.

RAISING AND LOWERING

To raise, use the handle bar switch to shorten the •

actuator.

To lower, use the handle bar switch to lengthen the •

actuator.

REMOVING SNOW

Snow removal conditions vary greatly from light uffy

snowfall to wet heavy snow. Operating instructions must

be exible to t the conditions encountered. The operator

must adapt the ATV and snow thrower to depth of snow,

wind direction, temperature and surface conditions.

Before beginning operation, thoroughly inspect the •

area of operation and remove all door mats, sleds,

boards, wires and other foreign objects.

CAUTION: Never operate the ATV snow

thrower without attaching the clip of the

tethered safety switch to your clothing.

A riderless ATV with a running snow

thrower could cause serious injury to a

fallen operator or to others.

It is advisable to operate the ATV at a slow ground •

speed for safe and efcient snow removal.

In deep, drifted or banked snow it will be necessary to •

use slow ground speed. Drive forward into the snow

and allow the spiral auger to clear the snow. Repeat

this method until a path is cleared. On the second

pass, overlap the rst enough to allow the snow

thrower to handle the snow without repeated stopping

and starting of forward motion.

In extremely deep snow, raise the snow thrower from •

the ground to remove the top layer and drive forward

only until the ATVs front tires reach the uncleared

bottom layer of snow. Depress the ATV's clutch-brake

pedal and allow the spiral auger to clear the snow.

Reverse the ATV and lower the snow thrower to the

ground. Drive the ATV forward until the snow again

becomes too deep. Repeating this process into and

out of drifts will eventually clear even the deepest of

snow piles.

If the snow thrower becomes clogged with snow or •

jammed with a foreign object, disengage the snow

thrower immediately and shut off the ATV and snow

thrower engines. Set the parking break on the ATV and

unclog the snow thrower with a wooden stick before

resuming operation.

DANGER: Shut off engine and disengage

snow thrower before unclogging discharge

chute. Unclog using a wooden stick, not

your hands.

OPERATING TIPS

Discharge snow down wind whenever possible.•

To help prevent snow from sticking to the snow thrower, •

allow the snow thrower to reach outdoor temperature

before using it. A light coat of wax may also be applied

to the inside surface of the snow thrower housing and

discharge chute.

Use tire chains to improve traction if recommended by •

your ATV owners manual.

Before the rst snowfall, remove all stones, sticks and •

other objects which could become hidden by the snow.

Permanent obstacles should be marked for visibility.

Overlap each pass slightly to assure complete snow •

removal.

14

Page 15

MAINTENANCE

CUSTOMER RESPONSIBILITIES

Read and follow the maintenance schedule and the maintenance procedures listed in this section.•

MAINTENANCE SCHEDULE

Fill in dates as you

complete regular service.

Check for loose fasteners X

Check scraper and shoes for wear X X

Cleaning X

Lubrication Section X

Check engine oil level X

Maintain engine per instructions below and in engine manual.

Before each use

Every season

After each use

Before storage

Service Dates

LUBRICATION

Oil all pivot points on the snow thrower.•

Oil pivot points of two idler arms on the clutch/idler •

assembly.

Apply penetrating oil to the control cables of the •

discharge chute.

Fill grease zerks on front wheels and spindles with •

grease.

SERVICE AND ADJUSTMENTS

CAUTION: Before servicing or adjusting

the snow thrower, shut off snow thrower and

ATV engines, remove the spark plug wire(s),

set the parking brake and remove the key

from the ignition.

SPIRAL AUGERS

The spiral augers are secured to the auger shaft with •

two shear bolts and nylock nuts. If you hit a foreign

object or if ice jams the augers, the snow thrower is

designed so that the bolts will shear.

If the augers will not turn, check to see if the shear •

bolts have sheared. See gure 30. Two replacement

shear bolts and nylock nuts have been provided with

the snow thrower. For future use order part number

710-0890A shear bolt and number 47810 nylock nut.

CHECK SCRAPER AND SHOES FOR WEAR

The scraper plate and skid shoes on the bottom of the •

snow thrower are subject to wear. To prevent damage

to the spiral auger housing, replace plate and shoes

before wear is excessive.

ENGINE MAINTENANCE

Check oil level before each use. Maintain engine oil as •

instructed in the separate engine manual.

Perform spark plug or other maintenance as instructed •

in the separate engine manual.

SKID SHOE ADJUSTMENT

The skid shoes are mounted on each side of the spiral •

auger housing. They regulate the distance the scraper

plate is raised above the plowing surface. When

removing snow from a gravel driveway or and uneven

surface, it is advisable to keep the scraper plate as

high above the surface as possible to prevent possible

damage to the spiral auger. On blacktop or concrete

surface, keep the scraper plate as close to the surface

as possible.

Raise snow thrower off the ground and place a block •

under each end of the scraper plate. Loosen the six hex

nuts securing the skid shoes to the housing. Adjust the

skid shoes up or down and retighten the nuts securely.

Adjust both skid shoes to the same height to keep the

housing and the scraper plate level. See gure 31.

SHEAR BOLT AND

NYLOCK NUT

FIGURE 30 FIGURE 31

15

Page 16

REMOVING THE BELT (Figures 32-35)

SKID PLATE

PULLEY COVER

DRIVE COVER

BRAKE ASSEMBLY

Remove the key and disconnect the spark plug wire •

from the snow thrower.

Remove the engine pulley cover, the drive cover and •

the skid plate from the snow thrower.

Disengage the snow thrower clutch.•

Remove the belt from the top pulley.•

Engage the clutch.•

Remove the belt from the bottom pulley.•

Disengage the clutch.•

Lift up on the brake assembly and slip the belt between •

the brake assembly and bottom pulley to remove the

belt from the snow thrower.

INSTALLING THE BELT

Lift up on the brake assembly and slip the belt between •

the bottom pulley and the brake assembly.

Engage the clutch.•

Install the belt around the bottom pulley.•

Disengage the clutch.•

Install the belt around the top pulley. •

Make sure the belt runs inside all of the belt keepers.•

Replace the covers.•

Replace the key and reconnect the spark plug wire.•

FIGURE 33

FIGURE 34

FIGURE 32

FIGURE 35

16

Page 17

STORAGE

STORAGE RECOMMENDATIONS

Clean the snow thrower thoroughly. Wash off any salt •

deposit which may have dried on the thrower and

housing.

Any bare metal that has become exposed should be •

painted or coated with a light oil to prevent rust.

Lubricate all pivot and wear areas.•

Store in a dry area protected from weather.•

REMOVAL INSTRUCTIONS

Lower the snow thrower to the ground.•

Unplug the actuator.•

Unplug the tethered safety switch from the wire harness •

of the control box switch.

Remove the clevis pins from the strut mount assemblies •

attached to the bottom of the ATV's front A arms and

remove the stabilizer assembly from the ATV. (Refer to

gure 9 on page 7.)

Remove the 3/4" x 7-1/2" hex bolt from the rear hitch of •

the ATV to complete removal of the snow thrower.

PARTS TO REMOVE AT END OF SEASON

Remove the A-arm brackets from the suspension •

of the ATV, especially before using your ATV for offroading, trail riding or other activities hard on the

suspension. See the owners manual of your ATV for

more information.

TROUBLESHOOTING

PROBLEM CAUSE CORRECTION

Spiral augers don't turn 1. Drive belt too loose 1. Increase tension on drive belt

2. Drive belt broken 2. Replace drive belt

3. Shear bolts are sheared. 3. Replace shear bolts

Clogged discharge chute 1. ATV ground speed too fast 1. Decrease ground speed

2. ATV throttle set too low 2. Increase to full throttle

3. Snow too deep 3. Raise snow thrower

4. Snow melts during contact with snow

thrower

Snow thrower stalls 1. Object jammed in spiral auger 1. Stop ATV and snow thrower engine,

2. Hard or heavy snow 2. Decrease ground speed

Front wheels slide instead of steering 1. Not enough traction at front wheels 1. Increase scraper plate clearance by

2. Snow thrower wheels do not have

enough lubrication

Snow thrower rides up over snow 1. ATV ground speed too fast 1. Decrease ground speed

2. Bottom snow is icy or hard packed 2. Lower the skid shoes so that front of

4. Allow snow thrower to cool to outdoor

temperature before using

disengage the snow thrower clutch

and clear the auger

lowering the skid shoes

2. Fill front grease zerks with grease

until a small amount comes out the

bottom

skid shoe is lower than the rear

17

Page 18

SÉCURITÉ

Tout appareil mécanique ou motorisé risque de provoquer des blessures si ce dernier n'est pas utilisé correctement ou si l'utilisateur ne

sait pas comment l'utiliser. Faites preuve de prudence à tout moment lorsque vous utilisez un appareil mécanique ou motorisé.

Lire ce manuel attentivement et bien connaître le •

fonctionnement de la soufeuse à neige avant de l'utiliser,

savoir comment l’arrêter et mettre rapidement les commandes

au point mort.

Ne jamais laisser d'enfants utiliser l'équipement.•

Ne jamais laisser d’adultes utiliser l’équipement sans avoir •

auparavant reçu une formation adéquate.

Interdire à quiconque de se trouver dans la zone de travail, •

particulièrement aux jeunes enfants et aux animaux de

compagnie.

Vérier particulièrement la zone où l’équipement sera utilisé •

an de retirer les paillassons, luges, planches, câbles et

autres objets étrangers.

Débrayer et mettre les commandes au point mort avant de •

démarrer le moteur.

Ne pas utiliser cet équipement sans porter des vêtements •

adéquats correspondants à la température extérieure.

Porter des chaussures qui protègent les pieds et améliorent la •

prise sur les surfaces glissantes.

Vérier le niveau de carburant avant de démarrer le moteur. Ne •

pas dévisser le bouchon du réservoir de carburant ni remplir le

réservoir pendant que le moteur fonctionne ou s’il est encore

chaud. Ne pas remplir le réservoir à l'intérieur d'un bâtiment

car l'essence est un carburant extrêmement inammable.

Ne jamais utiliser le VTT et sa soufeuse à neige sans xer •

auparavant la pince du bouton de sécurité en laisse à votre

vêtement. Un VTT sans conducteur avec une soufeuse à

neige en train de fonctionner risque de gravement blesser

tout utilisateur tombé à terre ou toute personne à proximité.

S’assurer que la hauteur de la soufeuse à neige est réglée

pour déblayer le type de surface sur laquelle elle sera

utilisée.

Ne jamais effectuer de réglage pendant que le moteur est en •

train de fonctionner.

Toujours porter des lunettes de protection ou une protection •

oculaire avant d’utiliser, de régler ou de réparer la soufeuse

à neige.

Ne pas placer les mains ni les pieds à proximité des pièces en •

mouvement. Toujours s'éloigner de l'ouverture d’éjection.

Faire preuve d’extrêmes précautions en travaillant sur des •

surfaces en gravier ou en les traversant.

Ne pas transporter de passager.•

Après avoir heurté un corps étranger, arrêter la soufeuse •

et le VTT, engager le frein sur le VTT, retirer le câble de la

bougie sur la soufeuse, et inspecter ensuite rigoureusement

la soufeuse an de s’assurer qu’elle n’est pas endommagée.

Réparer tout dégât avant de redémarrer et d'utiliser la

soufeuse à neige.

Si la soufeuse à neige commence à vibrer anormalement, •

arrêter immédiatement et rechercher la cause du problème.

Les vibrations sont généralement un avertissement préliminaire

avant l’apparition de problèmes. Arrêter le moteur de la

soufeuse et retirer le câble de la bougie à chaque fois que

l'on quitte la position de fonctionnement, avant de déboucher

la soufeuse ou de faire un réglage ou une inspection.

Prendre toutes les précautions possibles avant de laisser •

l'unité sans surveillance. Débrayer le levier d'embrayage,

abaisser la soufeuse à neige, engager le frein à main, arrêter

les moteurs de la soufeuse et du VTT et retirer les clés de

contact.

Avant de nettoyer, réparer ou inspecter la soufeuse, •

s’assurer que toutes les pièces en mouvement sont à l’arrêt.

Déconnecter le câble de la bougie et l’éloigner de cette

dernière an d’éviter tout démarrage accidentel.

Ne pas faire fonctionner le moteur de la soufeuse à neige •

à l’intérieur d’un bâtiment sauf pour l’y ranger et l’en sortir.

Ouvrir les portes vers l’extérieur. Les gaz d’échappement sont

dangereux.

Ne pas dégager la neige sur des pentes abruptes. Faire •

preuve d'une extrême prudence en changeant de direction

sur une pente. Ne pas tenter de déneiger de fortes pentes. Se

reporter au guide des pentes en page 35 de ce manuel.

Ne jamais utiliser la soufeuse à neige sans ses protections, •

plaques ou dispositifs de sécurité en place.

Ne jamais utiliser la soufeuse à neige à proximité de vitres, •

d’automobiles, de fenêtres, de dénivellation importante,

etc., sans avoir correctement réglé l’angle d’éjection de la

soufeuse.

Ne jamais orienter le conduit d'éjection vers des personnes •

alentours et ne jamais laisser quiconque se tenir devant la

soufeuse.

Ne jamais utiliser la soufeuse dans de la neige à grande •

vitesse.

Ne pas retirer la neige à trop grande vitesse pour ne pas •

risquer une surcharge de la machine.

Ne jamais utiliser la machine à de grandes vitesses sur des •

surfaces glissantes. Être extrêmement prudent et regarder

derrière soi lors d'une marche arrière.

Prendre garde à la circulation routière et demeurer vigilant •

lors d’un croisement ou à proximité d’une route.

Couper le moteur de la soufeuse an de pouvoir la transporter •

ou lorsqu'elle n'est pas utilisée.

Se référer au manuel du VTT avant d'utiliser d'autres •

équipements ou accessoires

Ne jamais utiliser la soufeuse à neige sans une bonne •

visibilité ou un bon éclairage.

18

Page 19

CONTENU DU CARTON

1

2

5

4

6

7

10

11

15

23

30

24

9

12

25

29

26

17

18

20

22

16

19

21

28

27

3

8

13

14

RÉF. QTÉ DESCRIPTION

1 1 Carter de la soufeuse

2 2 Fixation d'ancrage du carter

3 1 Bouton du guidon

4 2 Support stabilisateur

5 1 Actionneur

6 1 Jambe de force extérieure

7 1 Jambe de force intérieure

8 1 Support de guidage

9 1 Étrier de support

10 2 Bague

11 2 Barre de montage

12 1 Montage des roues

13 1 Plaque de guidage

14 1 Bague d'espacement de 3 po.

15 1 Barre de poussée

19

RÉF. QTÉ DESCRIPTION

16 4 Support de xation de 6-5/8 po.

17 2 Support de jambe de force de 6-5/8 po.

18 2 Support de jambe de force de 6-58 po.

19 2 Support de xation de 5-1/2 po.

20 2 Support de jambe de force de 5-1/2 po.

21 2 Support de xation de 4 po.

22 2 Support de jambe de force de 4 po.

23 1 Tube de cadre arrière (courbé)

24 1 Tube de cadre arrière (droit)

25 1 Commandes

26 2 Support de xation Polaris

27 1 Support de jambe de force de Polaris (G)

28 1 Support de jambe de force de Polaris (D)

29 1 Faisceau de câblage

30 1 Goulotte d'éjection

Page 20

SACS DE QUINCAILLERIE

ILLUSTRATION DES PIÈCES

NON À L’ÉCHELLE

1 2

3

5

6

7

24

25

13

17

18

12

20

19

4

21

22 23

14

15

16

11

29

28

31

8

9

10

26

27

30

32

20

Page 21

REF QTY DESCRIPTION

OFF

LO

HI

PETITS ÉCROUS À

FREIN ÉLASTIQUE

PETITES VIS

LONGUES

BRIDE

PLATE

SUPPORTS

DE GUIDON

PETITS ÉCROUS À

COLLERETTE

SUPPORT DE

L'INTERRUPTEUR

OFF

LO

HI

PETITE VIS

COURTE

PETIT ÉCROU À

FREIN ÉLASTIQUE

1 3 Axe à épaulement de 1/2 x 3 po.

2 1 Axe à épaulement de 1/2 x 2 po.

3 4 Boulon hexagonal de 5/16-18 x 1 po.

4 4 Boulon hexagonal de 1/2-13 x 3-1/2 po.

5 25 Rondelle de 1/2 x 1-1/2 po.

6 2 Boulon hexagonal de 5/16-18 x 3 po.

7 4 Boulon hexagonal de 3/8-16 x 2 po.

8 4 Goupille fendue

9 2 Rondelle frein de 1 x 0,32 po.

10 10 Rondelle de 5/16 po.

11 10 Boulon hexagonal de 1/2-13 x 2-1/4 po.

12 1 Boulon hexagonal de 1/2-13 x 1-1/2 po.

13 6 Boulon hexagonal à embase de 1/4-20 x 1 po.

14 6 Écrou à collerette de 1/4-20

15 18 Écrou à frein élastique de 5/16-18

16 4 Écrou à frein élastique de 3/8-16

ASSEMBLAGE

REF QTY DESCRIPTION

17 19 Écrou à frein élastique de 1/2-13

18 2 Écrou de blocage de 1/2-13

19 2 Boulon de carrosserie de 5/16-18 x 1-3/4 po.

20 2 Boulon de carrosserie de 5/16-18 x 1 po.

21 2 Boulon de carrosserie de 5/16-18 x 1-1/4 po.

22 2 Boulon hexagonal de 5/16-18 x 1-1/2 po.

23 2 Boulon hexagonal de 5/16-18 x 1-3/4 po.

24 2 Bague d'espacement de 0,5 x 1 x 0,59 po.

25 1 Bague d'espacement de 0,81 x 1,25 x 1,5 po.

26 1 Écrou à frein élastique de 3/4-10

27 4 Bague d'espacement de 0,75 x 1,25 x 0,5 po.

28 1 Boulon hexagonal de 3/4-10 x 7-1/2 po.

29 2 Boulon hexagonal de 1/2-13 x 4-1/2 po.

30 3 Gâche de la goulotte d'éjection

31 8 Attache en nylon

32 2 Boulons de Cisaillement

OUTILS NÉCESSAIRES

Clé de 5/16 po. (1)

Clé de 3/8 po. (1)

Clé de 7/16 po. (1)

Clé de 1/2 po (2)

Clé de 9/16 po (2)

Clé de 3/4 po (2)

Clé de 1-1/6 po. (1) ou clé réglable

Clé de 1-1/8 po. (1) ou clé réglable

Tournevis cruciforme Phillips (1)

Ciseaux ou couteau (1)

Pistolet graisseur avec graisse tout usage (1)

Clé hexagonale Allen de 3/16 po (1)

Bloc en béton de 15 po. (38 cm) (1)

FAISCEAU DE CÂBLAGE

Monter deux (2) supports de guidon et une (1) bride plate de 1.

guidon sur les poignées du guidon à l'aide de deux (2) petites

vis longues et de deux (2) petits écrous à frein élastique. Ne

pas serrer pour l’instant.

Monter le support de l'interrupteur sur l'interrupteur de guidon 2.

à l'aide de deux (2) petits écrous à collerette. Serrer.

ILLUSTRATION 2

Monter le support de l'interrupteur sur la bride plate à l'aide 3.

d'une (1) petite vis courte et d'un (1) petit écrou à frein

élastique. Voir l’illustration 3. Ne pas serrer pour l’instant.

Faire pivoter l'interrupteur jusqu'à ce qu'il soit à l'angle 4.

approprié, puis serrer les vis et les écrous assemblés aux

étapes 1 et 3.

ILLUSTRATION 1

ILLUSTRATION 3

21

Page 22

Fixer la boîte-relais en sécurité près de la batterie du VTT ou 5.

BATTERIE

+

BORNE

POSITIVE

NOIR

ROUGE

FUSIBLE

BUTON DU

GUIDON

CONDUCTEURS

BOÎTE-RELAIS

L'ACTIONNEUR

3 FILS

CONDUCTEURS

2x4

AWD

PRÉMONTÉS

VIS

PRÉMONTÉS

ÉCROUS

à un autre endroit sécuritaire sur le VTT.

Passer les 3 ls conducteurs de la boîte-relais à travers le 6.

châssis du véhicule sur le même côté que l'interrupteur sur

la poignée. Éviter de faire passer les ls près de pièces en

mouvement, des pièces chaudes et des points de pincement.

Utiliser 1 ou 2 attaches en plastique pour maintenir les ls

en place.

Connecter les trois ls conducteurs de l'interrupteur aux trois 7.

ls conducteurs de la boîte-relais, en faisant correspondre

entre eux les ls rouges, verts et noirs. Voir l’illustration 4.

Passer les deux ls conducteurs de la boîte-relais à travers 8.

le châssis du véhicule. Éviter de faire passer les ls près

de pièces en mouvement, qui chauffent ou d'endroits qui

coincent. Utiliser 1 ou 2 attaches pour maintenir les ls en

place.

Brancher le connecteur de la boîte-relais dans le connecteur 9.

de l'actionneur.

Raccorder le l rouge du fusible à la borne positive de la 10.

batterie du VTT. Raccorder le l négatif (l noir) à la borne

négative sur la batterie.

Utiliser l’interrupteur du guidon an d'allonger complètement 11.

l’actionneur puis débranchez l’actionneur.

Fixer le bouton de sécurité en laisse au guidon en utilisant les 12.

quatre (4) vis et écrous prémontés. Se référer à l’illustration

5.

Faire passer le câblage à travers le VTT et le faire ressortir 13.

à l’avant. Éviter de faire passer le l à proximité des pièces

en mouvement, des pièces chaudes ou des points de

pincement. Il est possible d'utiliser des attaches en nylon

an de maintenir le l en place.

ILLUSTRATION 5

ILLUSTRATION 4

22

Page 23

4 po.

Polaris

5-1/2 po.

6-5/8 po.

6-5/8 po.

Bombardier

Outlander

5/16 po. x

1-1/2" po.

1/2 po. x

2-1/4 po.

3/8 po. x 2 po.

3/8 po. x 2 po.

3/8 po. x 2 po.

3/8 po. x 2 po.

bras inférieurs

A du VTT

ASSEMBLAGE DE LA SOUFFLEUSE

BOULONS

HEXAGONAUX

DE 1/2 PO.

X 4-1/2 PO.

SUPPORTS

STABILISATEURS

ÉCROUS À FREIN

ÉLASTIQUE DE 1/2 PO.

LONGUES BAGUES

D’ESPACEMENT DE 3 PO.

JAMBE DE FORCE EXTÉRIEURE

BAGUE

BAGUE

JAMBE DE

FORCE INTÉRIEURE

AXES À ÉPAULEMENT

DE 1/2 PO. X 3 PO.

AXES À ÉPAULEMENT

DE 1/2 PO. X 3 PO.

GOUPILLE

FENDUE

GOUPILLE FENDUE

Enlever tout dispositif de protection du joint homocinétique de 1.

l'avant des bras inférieurs A du VTT. Sélectionner le support

de jambe de force indiqué à l’illustration 6 et correspondant

à la marque du VTT. Si le VTT n'est pas mentionné à

l’illustration 6, commencer avec le montage de jambe de

force de 5-1/2 po. Si les montages de supports de jambe de

force de 4 po., 5-1/2 po. ou de 6-5/8 po. sont utilisés, xer en

mettant le support de jambe de force bras A et les boulons à

l'extérieur du bras A. Ne pas serrer pour l’instant.

Glisser une bague sur l’extrémité de la jambe de force 3.

extérieure.

Glisser la jambe de force extérieure à travers les supports 4.

qui ont été installés lors de l’étape 2.

Glisser une seconde bague sur l’extrémité de la jambe de 5.

force extérieure.

Appliquer une ne couche d'huile sur la jambe de force 6.

intérieure puis l’insérer dans la jambe de force extérieure.

Serrer les boulons qui ont été installés lors de l’étape 2.7.

ILLUSTRATION 8

Assembler les supports stabilisateurs en utilisant deux (2) 2.

boulons hexagonaux de 1/2 po. x 4-1/2 po., deux (2) longues

bagues d’espacement de 3 po. et deux (2) écrous à frein

élastique de 1/2 po. comme indiqué sur l’illustration 7. Ne

pas serrer pour l’instant.

Fixer les extrémités des jambes de force extérieure et 8.

intérieure aux supports des jambes de force qui ont été

ILLUSTRATION 6

installés sur les bras A du VTT. Utiliser deux (2) axes à

épaulement de 1/2 po. x 3 po. et deux (2) goupilles fendues.

Serrer les boulons et les écrous qui ont été installés lors de 9.

l’étape 1 et retiennent les supports des jambes de force aux

bras A.

Centrer les supports stabilisateurs sous le VTT. Glissez les 10.

bagues vers le haut an de les placer contre les supports

stabilisateurs et serrer les vis sans tête dans les bagues. Les

supports stabilisateurs doivent pouvoir tourner librement

après avoir serré les bagues.

REMARQUE: Pour des raisons de clarté, le VTT n'est pas indiqué

pas sur le dessin ci-dessous.

ILLUSTRATION 9

ILLUSTRATION 7

23

Page 24

Placer le bloc de béton de 15 po. (38 cm) sous la soufeuse 11.

RONDELLE DE

1/2 X 1-1/2 PO.

ÉCROU À FREIN

ÉLASTIQUE

ANGLE EN

ARRIÈRE

BOULON HEXAGONAL

DE 1/2-13 X 2-1/4 PO.

FIXATION

D'ANCRAGE

DU CARTER

BARRE DE

MONTAGE

ÉCROU À FREIN

ÉLASTIQUE DE

1/2 PO.

RONDELLE DE 1/2 PO.

BARRE DE

POUSSÉE

BOULON

HEXAGONAL

DE 1/2-13

X 3-1/2 PO.

ÉCROUS DE BLOCAGE

DE 1/2 PO.

RONDELLE DE 1/2

ÉCROU À FREIN

ÉLASTIQUE DE 1/2 PO.

BOULON HEXAGONAL

DE 1/2-13 X 2-1/4 PO.

à neige, sous le moteur. Se référer à l’illustration 10.

Fixer les trous avant des xations d'ancrage du carter aux 13.

boulons soudés sur le carter à l'aide de deux (2) écrous de

blocage de 1/2 po. Ne pas serrer pour l’instant.

ILLUSTRATION 12

Verrouiller les barres de montage aux brides plates latérales 14.

de support à l'aide de deux (2) boulons hexagonaux de 1/2

x 2-1/2 po., quatre (4) rondelles de 1/2 po. (une sur chaque

ILLUSTRATION 10

côté) et deux (2) écrous à frein élastique de 1/2 po. Ne pas

serrer pour l’instant.

Mettre une xation d'ancrage du carter à l'extérieur de chaque 12.

barre de montage à l'aide de quatre (4) boulons hexagonaux

de 1/2 x 2-1/4 po., de huit (8) rondelles de 1/2 po. (une sur

chaque côté) et quatre (4) écrous à frein élastique de 1/2 po.

Ne pas serrer pour l’instant.

ILLUSTRATION 13

Placer la barre de poussée au dessus des extrémités 15.

des barres de montage. Aligner les trous comme l'indique

l’illustration ci-dessous et verrouiller la barre de poussée à

l'aide de deux (2) boulons hexagonaux de 1/2 x 3-1/2 po.,

quatre (4) rondelles de 1/2 po. (une sur chaque côté) et

quatre (2) écrous à frein élastique de 1/2 po. Ne pas serrer

pour l’instant.

ILLUSTRATION 11

ILLUSTRATION 14

24

Page 25

Fixer le tube du cadre arrière (courbé) à la barre de poussée 16.

ÉCROU À

FREIN

ÉLASTIQUE

DE 1/2 PO.

RONDELLE

DE 1/2 PO.

BOULON HEXAGONAL

DE 1/2-13 X 3-1/2 PO.

TUBE DU CADRE

ARRIÈRE

ÉCROU À FREIN

ÉLASTIQUE DE 5/16 PO.

BOULON HEXAGONAL

DE 5/16-18 X 1-3/4 PO.

RONDELLE DE

5/16 PO.

RONDELLE DE

5/16 PO.

AXE À ÉPAULEMENT

DE 1/2 X 3 PO.

AXE À ÉPAULEMENT

DE 1/2 X 2 PO.

BAGUE D'ESPACEMENT

DE 0,5 X 1 X 0,59 PO.

GOUPILLE

FENDUE

BOULON HEXAGONAL

DE 5/16 X 1 PO.

BOULON HEXAGONAL

DE 1/2 X 2-1/4 PO.

RONDELLE

DE 1/2 PO.

ÉCROU À FREIN

ÉLASTIQUE DE

5/16 PO.

ÉCROU À FREIN

ÉLASTIQUE

DE 1/2 PO.

SUPPORT

D'ANCRAGE

à l'aide de deux (2) boulons hexagonaux de 1/2 x 3-1/2 po.,

quatre (4) rondelles de 1/2 po. (une sur chaque côté) et

quatre (2) écrous à frein élastique de 1/2 po. Ne pas serrer

pour l’instant.

Retirer le bloc de béton de sous le moteur et le placer sous 17.

l’extrémité du tube du cadre arrière.

Placer le montage des roues derrière la base de montage 19.

du moteur.

Fixer le bas des supports d'ancrage (partie intégrante du 20.

montage des roues) sur l'extérieur des barres de montage

en utilisant quatre (4) boulons hexagonaux de 1/2 po. x 2-1/4

po. et quatre (4) rondelles de 1/2 po. (à l'intérieur de la barre

de montage) et quatre (4) écrous à frein élastique de 1/2 po.

Ne pas serrer pour l’instant.

Fixer le dessus des supports d'ancrage à la base de montage 21.

du moteur en utilisant quatre (4) boulons hexagonaux de

5/16 po. x 1 po. et quatre (4) écrous à frein élastique de 5/16

po. Ne pas serrer pour l’instant

Serrer tous les écrous et tous les boulons qui ont été 22.

installés lors des étapes 12 à 14 et 18 à 21. Ne pas serrer

pour l’instant les boulons et les écrous qui ont été installés

lors des étapes 15 et 16.

REMARQUE: Pour des raisons de clarté, le montage des roues

n'est pas indiqué pas sur le dessin.

Fixer la bride plate de support aux barres de montage à 18.

l'aide de quatre (4) boulons hexagonaux de 5/16 x 1-3/4 po.,

huit (8) rondelles de 5/16 po. (l'une à l'intérieur et l'autre à

l'extérieur) et quatre (4) écrous à frein élastique de 5/16 po.

Ne pas serrer pour l’instant.

ILLUSTRATION 15

ILLUSTRATION 17

REMARQUE: Avant de passer à la prochaine étape, s’assurer

que l’actionneur est complètement sorti. Voir l’étape 11 de la

page 22 du Faisceau de câblage.

Fixer le haut de l'actionneur au montage des roues à l'aide 23.

d'un (1) axe à épaulement de 1/2 x 3 po., deux (2) bagues

d'espacement de 0,5 x 1 x 0,59 po. et d'une (1) goupille

fendue de 3/32 po.

Fixer le bas de l'actionneur au support de l'actionneur à 24.

l'aide d'un (1) axe d'épaulement de 1/2 x 2 po. et d'une (1)

goupille fendue de 3/32 po.

ILLUSTRATION 16

ILLUSTRATION 18

25

Page 26

Assembler le support de guidage et la plaque de guidage aux 25.

BOULON

HEXAGONAL

DE 5/16 X 1-1/2 PO.

ÉCROU À FREIN

ÉLASTIQUE DE 5/16 PO.

PLAQUE

DE GUIDAGE

SUPPORT

DE GUIDAGE

GRAISSE

BOULON HEXAGONAL À

EMBASE DE 1/4-20 X 1 PO.

ÉCROU À

COLLERETTE

DE 1/4-20

BOULON HEXAGONAL DE

1/2-13 X 1-1/2 PO.

RONDELLE DE 5/16 PO.,

ÉCROU À FREIN ÉLASTIQUE

DE 5/16 PO.

barres de montage en utilisant deux (2) boulons hexagonaux

de 5/16 po. x 3 po. et deux (2) écrous à frein élastique de

5/16 po. Ne pas serrer pour l’instant.

Retirer le bloc en béton du dessous du tube du cadre 26.

arrière.

Placer la goulotte d'éjection (avec l'ouvertuire vers l'avant) 28.

dans l'anneau. Fixer trois (3) gâches de la goulotte d'éjection

(le côté droit vers le haut, comme indiqué) au bas du rebord

à l'aide de six (6) boulons hexagonaux à embase de 1/4 x 1

po. et six (6) écrous de blocage à collerette de 1/4 po. Serrer

avec précaution de sorte que les écrous soient bien ajustés

sans mordre dans les gâches en plastique de la goulotte

d'éjection.

ILLUSTRATION 19

Recouvrir le haut de l'anneau entourant l'ouverture d'éjection 27.

avec une graisse tout usage.

ILLUSTRATION 21

Assembler les commandes à la base de montage du moteur 29.

à l'aide d'un (1) boulon hexagonal de 1/2 x 1-1/2 po., une

rondelle de 1/2 po. (à l'intérieur de la base de montage) et

un écrou à frein élastique de 1/2 po. Ne pas serrer pour

l’instant.

ILLUSTRATION 20

ILLUSTRATION 22

26

Page 27

BOULON DE

CARROSSERIE DE

5/16-18 X 1 PO.

RONDELLE

DE 5/16 PO.

ÉCROU À FREIN

ÉLASTIQUE DE

5/16-18

FIXER LES CÂBLES

ATTACHE EN NYLON

RONDELLES

FREINS ET DEUX

COMMANDE

D'INCLINAISON

ÉCROUS À

FREIN ÉLASTIQUE

DE 5/16 PO.

BOULONS DE

CARROSSERIE

DE 5/16 X 1-3/4 PO.

SUPPORTS STABILISATEURS

SUPPORT DE GUIDAGE

BOULONS DE CARROSSERIE

DE 5/16-18 X 1-1/4 PO.

ÉCROUS À FREIN

ÉLASTIQUE DE 5/16 PO.

Assembler les commandes au montage de la soufeuse à 30.

l'aide de deux (2) boulons de carrosserie de 5/16 x 1-1/4 po.

et de deux (2) écrous à frein élastique de 1/4 po. Ne pas

serrer pour l’instant.

Serrer les boulons qui ont été assemblés lors des étapes 29 31.

et 30.

Couper l'attache en plastique retenant ensemble les deux 32.

pièces du support de la bielle de la goulotte d'éjection.

Attacher les supports de la bielle à l'adaptateur de la goulotte 33.

d'éjection à l'aide de deux (2) boulons de carrosserie de 5/16

x 1 po., deux (2) rondelles de 5/16 po. et deux (2) écrous à

frein élastique de 5/16 po. Ne pas serrer pour l’instant.

Régler la position des supports du réglage de la goulotte 34.

d'éjection de manière à ce que la spirale ne touche pas le

bas des crans de la goulotte d'éjection

Serrer les boulons et écrous assemblés aux étapes 33. 35.

ILLUSTRATION 25

Insérer le faisceau de câblage dans le grand trou à l'avant du 38.

boîtier de commande.

Brancher les connecteurs du faisceau de câblage dans 39.

l'interrupteur.

ILLUSTRATION 23

À l'aide d'attaches en plastique, attacher fermement tous les 40.

ls et tous les câbles au montage de la poignée pour qu'ils

n'interfèrent pas avec les pièces en mouvement.

Fixer la commande d'inclinaison de la goulotte d'éjection aux 36.

commandes à l'aide de deux (2) boulons de carrosserie de

5/16 x 1-3/4 po., deux (2) rondelles freins et deux (2) écrous

à frein élastique de 5/16 po.

Utiliser une attache en nylon an de xer les câbles de 37.

commande de la goulotte d'éjection à la barre de support

comme indiqué sur l’illustration 25

REMARQUE: Ne pas xer les câbles de commande de la

goulotte d'éjection à des emplacements autres que ceux indiqués

ci-dessous.

ILLUSTRATION 26

Avancer le VTT derrière la soufeuse à neige, en veillant à 41.

ce que la barre de poussée demeure bien centrée entre les

supports stabilisateurs. S'assurer que le support de guidage

glisse entre les supports stabilisateurs comme indiqué sur

l’illustration 27. Veiller à laisser un espace minimum de 7,6 à

10 cm entre l’avant du VTT et la soufeuse à neige.

REMARQUE: Pour des raisons de clarté, le VTT n'est pas indiqué

pas sur le dessin.

ILLUSTRATION 24

ILLUSTRATION 27

27

Page 28

Glisser le tube du cadre arrière vers l'intérieur ou l’extérieur 42.

ATTELAGE DU VTT

TUBE DU CADRE ARRIÈRE

BARRE DE

POUSSÉE

ÉCROUS À FREIN ÉLASTIQUE DE 3/4 PO.

BOULON HEXAGONAL DE 3/4 PO. X 7-1/2 PO.

BAGUES D’ESPACEMENT COURTES

(.75 PO. x 1.25 PO. x .5 PO.)

LONGUE BAGUE D’ESPACEMENT

(.81 PO. x 1.25 PO. x 1.5 PO.)

6 mm

de la barre de poussée an de l’aligner avec la plaque

d’attelage du VTT. Veiller à maintenir l’espace minimum de

7,6 à 10 cm entre le VTT et la soufeuse à neige.

Si le tube du cadre arrière ne glisse pas sufsamment an de 43.

pouvoir l’aligner avec la plaque d’attelage du VTT, déplacer

les boulons qui retiennent le tube du cadre arrière à la barre

de poussée et utiliser d’autres trous (voir illustration 15). Si

l’alignement ne peut toujours pas être effectué, déplacer les

boulons qui retiennent la barre de poussée aux barres de

montage et utiliser d’autres trous (voir illustration 14).

Fixer le tube du cadre arrière à la plaque d’attelage du VTT 44.

en utilisant un (1) boulon hexagonal de 3/4 po. x 7-1/2 po.,

quatre (4) bagues d’espacement courtes, une (1) longue

bague d’espacement et un (1) écrous à frein élastique de

3/4 po. Placer les bagues d’espacement au-dessus et en-

dessous de la plaque d’attelage an de conserver un espace

de 2,5 cm sous le VTT et un dégagement sufsamment entre

le sol et le dispositif. Serrer les boulons et les écrous.

REMARQUE: Remplacer le tube courbé du cadre arrière par le

tube droit du cadre arrière si le tube courbé du cadre arrière

n’offre pas un dégagement sufsamment entre le sol et le

dispositif et s’il y a sufsamment d'espace sous le VTT.

Serrer les écrous et les boulons qui retiennent la barre 45.

de poussée aux barres de montage et le tube du cadre

arrière. Voir illustrations 14 et 15. S’assurer que les barres

de montage demeurent centrées sur le VTT lorsque les

xations sont serrées.

Glisser le support de guidage le long des barres de montage 46.

jusqu’à ce que la bord avant se trouve à 6 mm devant le

bord avant des supports stabilisateurs comme indiqué sur

l’illustration 29 puis serrer.

ILLUSTRATION 29

Utiliser un pistolet à graisse an d’appliquer une graisse tout 47.

usage sur les pièces des moyeux des roues et des axes.

Appliquer sufsamment de graisse jusqu’à ce qu’elle sorte

par les extrémités des moyeux et des axes.

Raccorder les ls du bouton de sécurité en laisse au 48.

connecteur du faisceau de câblage du bouton du boîtier de

commande.

Rebrancher l’actionneur à l’interrupteur du guidon qui avait 49.

été débranché lors de l’étape 11 de la page 22.

LISTE DE VÉRIFICATION

Avant d’utiliser la soufeuse à neige, revoir la liste de

véricationsuivanteandes’assurerquelasoufeusesera

la plus performante possible.

Toutes les instructions de montage doivent avoir été suivies 1.

et les boulons et écrous doivent être serrés correctement.

Vérier la bonne rotation de la goulotte d’éjection.2.

Vérier le fonctionnement de la commande d’inclinaison 3.

pour la goulotte d’éjection supérieure.

Vérier si le câblage de l'actionneur est correct et si ce 4.

ILLUSTRATION 28

dernier lève ou abaisse la soufeuse.

Vérier le réglage des patins. (Se référer à la section 5.

Entretien et réglage.)

S’assurer que le bouton de sécurité en laisse fonctionne 6.

correctement et permet de couper le moteur.

S’assurer que les moyeux et les axes des roues sont remplis 7.

de graisse.

28

Page 29

CRANK

ROD

ON/OFF

SWITCH

HANDLE BAR

SWITCH

TETHERED SAFETY

SWITCH

CHUTE TILT

HANDLE

CLUTCH

LEVER

UPPER CHUTE

LOWER CHUTE

SPIRAL AUGERS

R.H. & L.H.

SKID SHOE

SCRAPER PLATE

UTILISATION

BIEN CONNAÎTRE LA SOUFFLEUSE

Lirecemanueldupropriétaireetlesrèglesdesécuritéavantd’utiliserlasoufeuse.

Comparer l’illustration ci-dessous avec la soufeuse an de se familiariser avec les diverses commandes et leurs emplacements.

GOULOTTE

D’ÉJECTION

GOULOTTE

D’ÉJECTION

INFÉRIEURE

TARIÈRES GAUCHE

ET DROITE

SUPÉRIEURE

PLAQUE D’USURE

POIGNÉE D’INCLINAISON

DE LA GOULOTTE

D’ÉJECTION

BOUTON DE SÉCURITÉ

PATIN

BOUTON

ON/OFF

EN LAISSE

LEVIER

D'EMBRAYAGE

BIELLE

D’INCLINAISON DES

GOULOTTES

BOUTON DE

GUIDON

POIGNÉE D’INCLINAISON DE LA GOULOTTE D’ÉJECTION

Pivote la goulotte d’éjection vers le haut ou vers le bas pour

contrôler l’angle et la distance de l’éjection.

BIELLE D’INCLINAISON DES GOULOTTES Fait tourner les

goulottes d’éjection supérieure et inférieure an de contrôler la

direction de l’éjection.

GOULOTTE D’ÉJECTION SUPÉRIEURE ET INFÉRIEURE

Contrôle la direction et la hauteur de l’éjection de neige.

PLAQUE D’USURE Plaque remplaçable qui s’use et absorbe

les impacts à la suite du contact avec le sol.

COMMENT UTILISER LA SOUFFLEUSE

AVANT DE COMMENCER

Se reporter à la n de la liste de vérication de l'assemblage •

pour vérier si les instructions ont été correctement suivies.

S’assurer que les patins sont réglés de manière à maintenir •

un espace libre adéquat avec le sol entre la soufeuse et le

type de surface à déblayer. (Se référer à la section Entretien

et réglage).

S’assurer que l’huile de moteur du VTT est bien celle qu’on •

utilise en hiver. Se référer au manuel du propriétaire du VTT.

AVERTISSEMENT: Ne jamais diriger

l’éjection en direction de passants ou de

fenêtres. Interdire à toute personne de se

mettre devant l’unité.

29

PATIN Contrôle l’espace libre entre la plaque d’usure et le sol.

TARIÈRES GAUCHE ET DROITE Alimentent en neige le venti-

lateur de la turbine au centre du carter.

BOUTON ON/OFF (marche/arrêt) Permet d'arrêter le moteur

de la soufeuse tout en restant assis sur le VTT.

BOUTON DE GUIDON Soulève et baisse la soufeuse.

BOUTON DE SÉCURITÉ EN LAISSE Arrête la soufeuse

quand il est retiré du coupe-circuit.

LEVIER D’EMBRAYAGE Permet d’embrayer et de débrayer les

tarières en spirale.

COMMENT FAIRE DÉMARRER LA SOUFFLEUSE

COMMENT ARRÊTER LA SOUFFLEUSE

Mettre le levier d’embrayage sur le boîtier de commande en •

position de débrayage.

Fixez la che amovible sur bouton de sécurité en laisse. La •

soufeuse à neige ne fonctionnera pas si la che n'est pas

xée.

Mettre le bouton marche/arrêt en position ON (marche). •

Suivre les instructions du manuel de l'utilisateur du moteur pour •

mettre la soufeuse en marche, puis continuer comme suit.

Monter sur le VTT et mettre le levier en position •

d'embrayage.

Désengager le levier d’embrayage sur le boîtier de commande.•

Mettre le bouton marche/arrêt sur le boîtier de commande •

en position OFF (arrêt).

Suivre les instructions du manuel de l'utilisateur concernant •

le moteur pour nir la procédure d'arrêt du moteur.

Page 30

CONTRÔLER L’ÉJECTION DE LA NEIGE

Pour contrôler la direction dans laquelle la neige est projetée, •

la goulotte d’éjection de la décharge a une rotation de 180

degrés. Tourner la bielle d’inclinaison des goulottes dans le

sens des aiguilles d’une montre pour faire tourner la goulotte

vers la droite. Tourner la bielle d’inclinaison des goulottes

dans le sens contraire pour faire tourner la goulotte vers la

gauche.

Pour contrôler la distance à laquelle la neige est projetée, la •

section supérieure de la goulotte d’éjection de la décharge

pivote vers le haut et vers le bas. Pousser la poignée

d’inclinaison des goulottes an de pivoter la goulotte

d’éjection vers le bas, diminuant ainsi la distance à laquelle

la neige est projetée. Tirer la poignée pour faire pivoter la

goulotte vers le haut, augmentant ainsi la distance à laquelle

la neige est projetée.

LEVER ET BAISSER

Pour lever, utiliser le bouton du guidon pour ramener •

l’actionneur.

Pour abaisser, utiliser le bouton du guidon pour allonger •

l’actionneur.

ENLEVER LA NEIGE

Les conditions de déblayage varient beaucoup, la neige pouvant

être légère, ou lourde et mouillée. Les instructions d’utilisation

doivent être assouplies pour s’adapter aux circonstances. Le

conducteur doit adapter le VTT et la soufeuse à la profondeur

de la neige, la direction du vent, la température et les conditions

de surface.

Avant d’utiliser la soufeuse, bien inspecter la zone à •

déblayer et enlever les paillassons, les luges, les planches,

les câbles et tout autre corps étranger.

Il est conseillé de faire fonctionner le VTT à une vitesse au •

sol plus lente (première vitesse) pour enlever la neige en

toute sécurité et avec efcacité.

Quand la neige est profonde, forme des congères ou •

s’amoncelle, il peut être nécessaire d'utiliser une faible

vitesse au sol. Avancer dans la neige et laisser la tarière

déblayer la neige. Répéter cette méthode jusqu’à ce qu’un

chemin soit ouvert. Lors du second passage, chevaucher

sufsamment sur le premier pour permettre à la soufeuse

de traiter la neige en évitant de s’arrêter et de redémarrer

trop souvent.

Quand la neige est extrêmement profonde, soulever la •

soufeuse du sol pour enlever la couche supérieure et

n’avancer que jusqu’à ce que les pneus avant du VTT

atteignent la couche inférieure de la neige qui n’a pas encore

été nettoyée. Appuyer sur la pédale de frein de l’embrayage

du VTT et laisser la tarière déblayer la neige. Reculer le

VTT et abaisser la soufeuse au sol. Faire avancer le VTT

jusqu’à ce que la neige devienne à nouveau trop profonde.

En répétant ce processus d’aller et venue, même les amas

de neige les plus profonds niront par être déblayés.

Si la soufeuse à neige s’avère bouchée avec de la neige ou •

si un objet se loge à l’intérieur et bloque le fonctionnement

de la soufeuse, débrayer immédiatement la soufeuse et

couper le moteur du VTT ainsi que celui de la soufeuse.

Mettre le frein à main du VTT et retirer la neige qui bouche

la soufeuse en utilisant un bâton avant de remettre la

soufeuse en marche.

DANGER: Éteindre le moteur et débrayer la

soufeuse avant de déboucher la goulotte

d’éjection de la décharge. Déboucher avec un

bout de bois, jamais avec les mains.

ATTENTION: Ne jamais utiliser le VTT et sa

soufeuse à neige sans xer auparavant la

pince du bouton de sécurité en laisse à votre

vêtement. Un VTT sans conducteur avec une

soufeuse à neige en train de fonctionner

risque de gravement blesser tout utilisateur

tombé à terre ou toute personne à proximité.

CONSEILS PRATIQUES D’UTILISATION

Éjecter la neige dans le sens du vent, si possible.•

Attendre que la soufeuse soit à la température extérieure •

avant de s’en servir, de manière à éviter que la neige colle à

la soufeuse. Une légère couche de cire peut également être

appliqué à l’intérieur de la surface du carter de la soufeuse

et de la goulotte d’éjection de la décharge.

Mettre des chaînes antidérapantes pour améliorer la traction •

si le manuel du propriétaire du VTT le recommande.

Avant la première chute de neige, enlever toutes les pierres, •

les bouts de bois et les autres objets que la neige pourrait

cacher. Les obstacles permanents devraient être marqués

pour assurer leur visibilité.

Chevaucher légèrement sur le passage précédent pour •

enlever complètement la neige.

30

Page 31

ENTRETIEN

RESPONSABILITÉS DE L'UTILISATEUR

Lire et suivre le planning et les procédures d’entretien énumérées dans cette section•

PLANNING D’ENTRETIEN

Remplir les cases suivantes en indiquant la date à fois que

vous procédez à l'entretien

Avant chaque utilisation

Vérier si tout est bien attaché X

Vérier l’usure de la plaque et des patins X X

Nettoyage X

Section lubrication X

Chaque saison

Après chaque utilisation

Avant rangement

Dates des opérations d'entretien

LUBRIFICATION

Huiler tous les points de pivot sur la soufeuse.•

Huiler tous les points de pivot sur les deux bras de renvoi de •

l’ensemble embrayage et galet tendeur.

Mettre de l’huile pénétrante sur les câbles de commande de •

la goulotte d’éjection de la décharge.

Remplir de graisse les embouts de graissage sur les roues •

avant.

ENTRETIEN ET RÉGLAGES

AVERTISSEMENT: Avant de procéder à l'entretien

ou au réglage de la soufeuse, arrêter le moteur,

enlever le ou les ls de bougies d’allumage, serrer le

frein à main et retirer la clé de contact du tracteur.

TARIÈRES

Les tarières sont xées fermement à l’arbre de tarière à •

l’aide de deux boulons de cisaillement et d'écrous à frein

élastique. La soufeuse est conçue de manière à ce que les

boulons se cassent si la soufeuse touche un corps étranger

ou si de la glace coince les tarières.

Si les tarières ne tournent pas, vérier si les boulons de •

cisaillement se sont cassés. Voir l’illustration 30. Deux

boulons de cisaillement et deux écrous à frein élastique sont

fournis avec la soufeuse. En prévision, commander les

pièces no. 710-0890A pour les boulons de cisaillement et

les pièces no. 47810 pour les écrous à frein élastique.

VÉRIFIER L’USURE DE LA PLAQUE ET DES PATINS

La plaque d’usure et les patins au bas de la soufeuse •

peuvent s’user. Pour éviter d’endommager le carter de la

tarière, remplacer la plaque d’usure et les patins avant qu’ils

soient trop usés.

RÉGLER LES PATINS

Les patins sont montés de chaque côté du carter de la •

tarière. Ils règlent la distance d’élévation de la plaque d’usure

au dessus de la surface de déblaiement. Il est conseillé de

maintenir la plaque d’usure le haut possible de la surface