Page 1

Agri-Fab

OWNERS

MANUAL

Model No.

45-03072

45-03611

¨

42" ROUGH CUT

CAUTION:

Read Rules for

Safe Operation

and Instructions

• Safety

Carefully

• Assembly

• Operation

• Maintenance

• Parts

the fastest way to purchase parts

PRINTED IN U.S.A. FORM NO. 49464 (5/04)

TRAILMOWER

www.speedepart.com

Page 2

TABLE OF CONTENTS

SAFETY RULES ...................................................... 3,4

SAFETY AND OPERATIONAL DECALS ................ 5,6

HARDWARE CHART .................................................. 7

ASSEMBLY ............................................................ 8-11

OPERATION ......................................................... 12-16

CUSTOMER RESPONSIBILITIES...................... 17-20

STORAGE ................................................................. 21

REPAIR PARTS ................................................... 22-26

WIRING DIAGRAM ................................................... 27

2

Page 3

34567

Page 4

Page 5

Page 6

Page 7

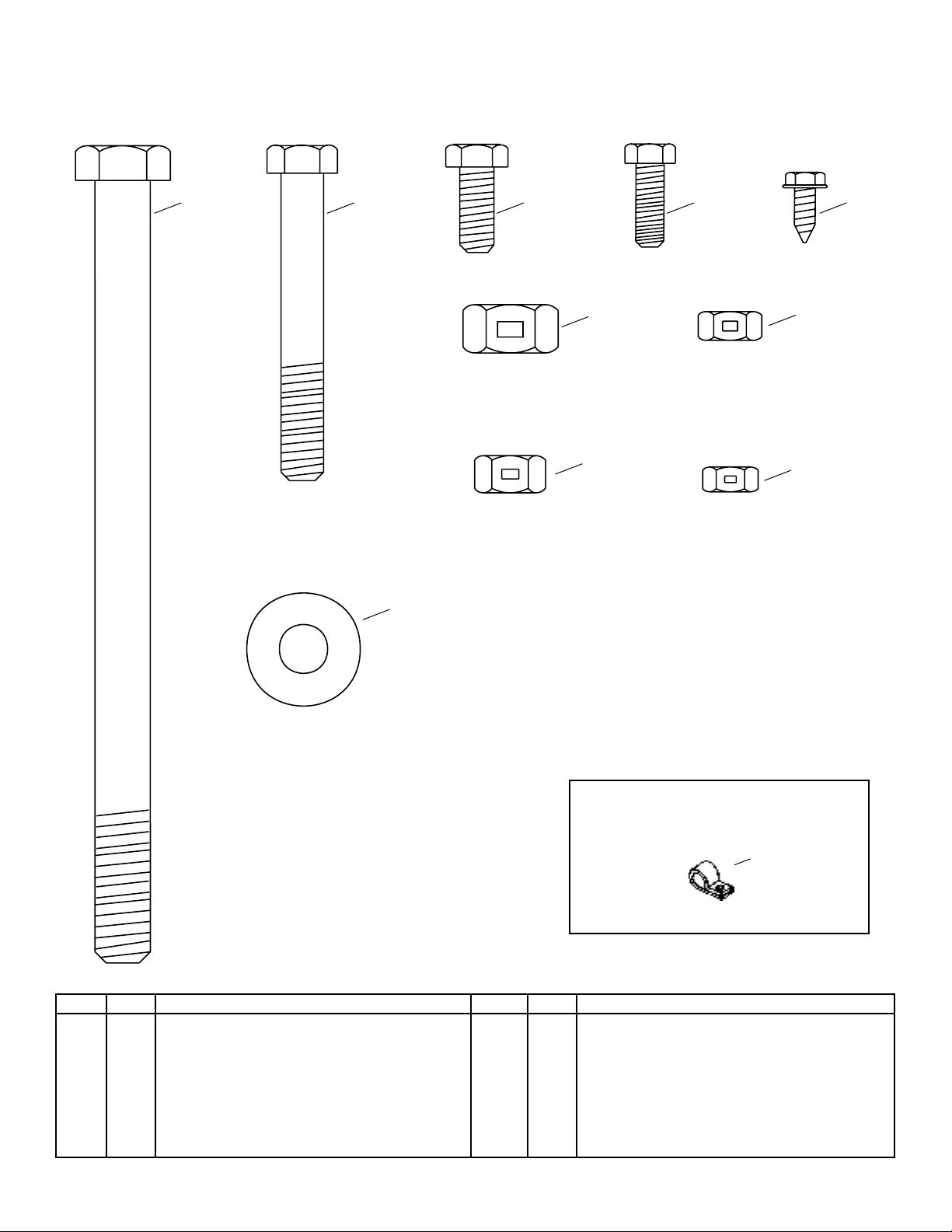

CONTENTS OF PARTS BAG

SHOWN FULL SIZE

A B C D E

F

G

J

H

I

REF. QTY. DESCRIPTION

A 1 Hex Bolt, 1/2" x 7"

B 2 Hex Bolt, 3/8" x 2-3/4"

C 2 Hex Bolt, 5/16" x 3/4"

D 1 Hex Bolt, 1/4" x 3/4"

E 3 Screw, Self Tapping #10 x 1/2"

F 1 Hex Lock Nut, 1/2"

NOT SHOWN FULL SIZE

K

REF. QTY. DESCRIPTION

G 2 Hex Lock Nut, 3/8"

H 2 Hex Lock Nut, 5/16"

I 1 Hex Lock Nut, 1/4"

J 2 Flat Washer, 3/8"

K 3 Clip, 3/8"

Page 8

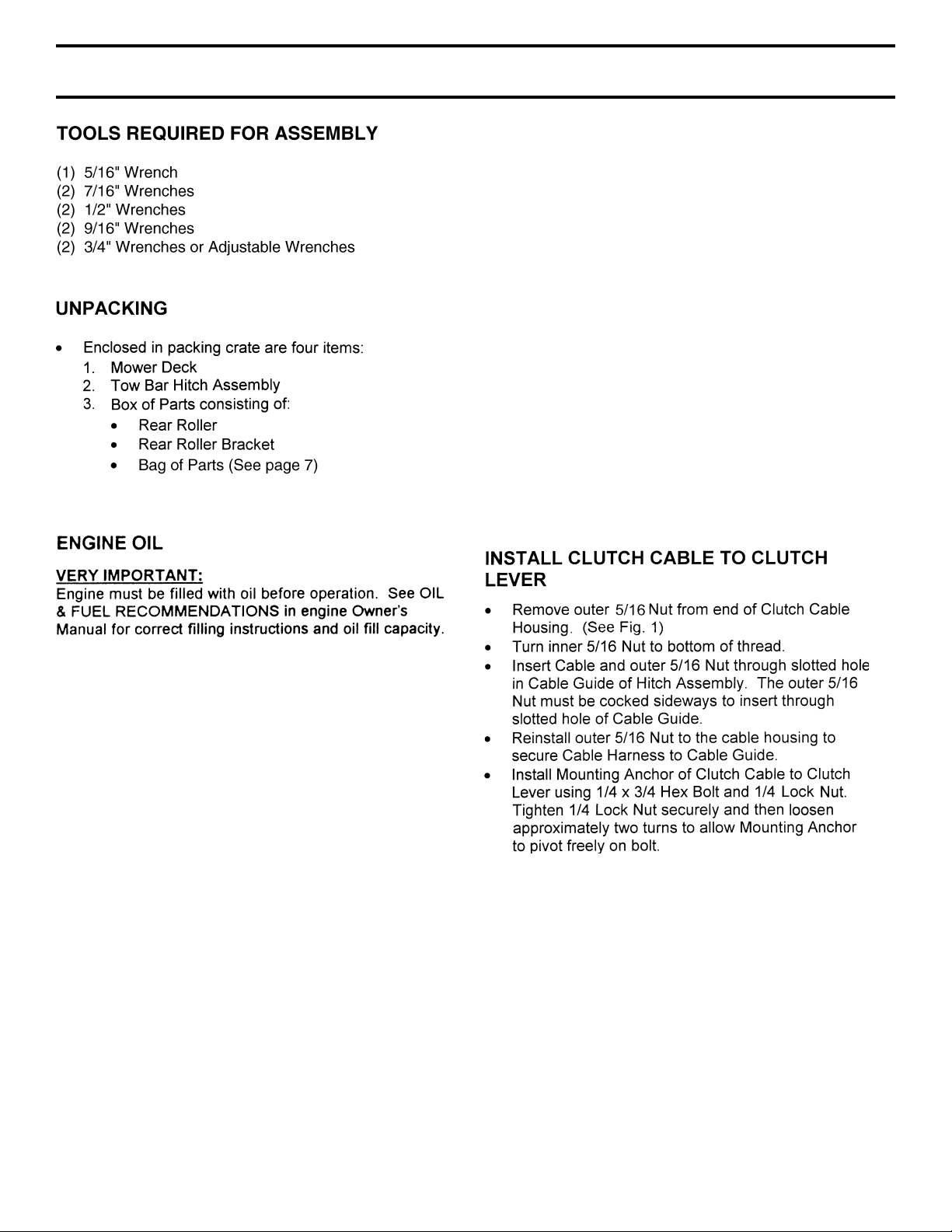

ASSEMBLY

INSTALL WIRE HARNESS TO ENGINE

• Feed Wire Harness up through hole in middle of Front

Drive Cover.

• Install one Wire to Engine Magneto Ground Terminal.

(The same Terminal as red Wire from inside Mower.)

• Install other Wire of Wire Harness to Engine Ground

Base. (The same Terminal as black Wire from inside

Mower.)

• Refasten Front Drive Cover to mower housing.

INSTALL CLUTCH TO TOWBAR TUBE

• Place Clutch Cable forward along Towbar Tube.

• Spread ends of three Cable Clips and place around

Clutch Cable.

• Place Clutch Cable on top of Towbar Tube and align

Cable Clips with bolt holes in Towbar Tube.

• Secure with three #10 Screws.

INSTALL TOWBAR TUBE TO REAR

QUADRANT

• Remove Hex Bolts and lift Front Drive Cover from

mower housing.

• Rest end of Tow Bar Tube on front edge of mower.

• Feed Wire Harness in end of Tow Bar Tube through

large hole in back wall of Rear Quadrant.

• Place Towbar Tube into Rear Quadrant, align holes

and insert 3/8 x 2-3/4 Hex Bolt through quadrant

and rear hole of Tube.

• Secure tightly with 3/8 Hex Lock Nut and then

loosen 1/4 turn to allow Tube to pivot freely inside

Rear Quadrant.

• Assemble a 3/8 Flat Washer onto a 3/8 x 2-3/4 Hex

Bolt.

• Insert Bolt and Washer into slot in Rear Quadrant

and into hole in Towbar Tube.

• Secure Tightly with 3/8 Flat Washer and 3/8 Hex

Lock Nut, then loosen 1/4 turn to allow Tube to

pivot freely inside Rear Quadrant.

NOTE: Towbar Tube must pivot freely inside Rear

Quadrant when Latch is pulled from notch.

8

Page 9

ASSEMBLY

ENGINE MAGNETO GROUND (RED WIRE)

ENGINE GROUND BASE

FEED WIRE HARNESS

THROUGH THIS HOLE

FRONT DRIVE COVER

REAR QUADRANT

3/8 X 2-3/4 HEX BOLT

3/8 FLAT WASHER

CLUTCH CABLE

#10 SCREW (3)

CABLE CLIPS (3)

CLUTCH LEVER

FIG. 1

3/8 HEX LOCK NUT

3/8 FLAT WASHER

HITCH ASSEMBLY

TOW BAR TUBE

1/4 X 3/4 HEX BOLT

CLUTCH CABLE

5/16 HEX NUT (2)

MOUNTING ANCHOR

CABLE GUIDE

1/4" HEX LOCK NUT

9

Page 10

ASSEMBLY

SWITCH

BODY

INNER NUT

OUTER NUT

CLUTCH CABLE ADJUSTMENT

• Remove four screws from Rear Drive Cover. Lay aside

cover and screws.

• Place Clutch Lever in "DISENGAGED" position

• The Cable should be under slight tension but should

not pull the Clutch Lever more than 1/8" away from

the Switch Body.

NOTE: If the Plunger extends more than 1/8" out from

the switch body, the cable tension is too tight and the

Engine will not start.

TO INCREASE CABLE TENSION

• Place Blade Clutch Lever in the "DISENGAGED"

position.

• Loosen the inner nut on the Clutch Cable.

• Tighten the outer nut on the Clutch Cable.

TO DECREASE CABLE TENSION

• Place Blade Clutch Lever in the "DISENGAGED"

position.

• Loosen the outer nut on the Clutch Cable.

• Tighten the inner nut on the Clutch Cable.

• Repeat the above procedure until you have the

correct tension.

1/8"

PLUNGER

CLUTCH LEVER

REAR DRIVE

COVER

FIG. 2

FOUR

SCREWS

ENGINE

PULLEY

BLADE

PULLEY

10

IDLER

PULLEY

CLUTCH LEVER

Page 11

ASSEMBLY

INSTALL REAR ROLLER TO DECK

• Install Rear Roller Mounting Bracket to rear of deck

using two 5/16 x 3/4 Hex Bolts and two 5/16 Hex

Lock Nuts. (See Fig. 3.)

• Install Roller to Rear Roller Bracket using 1/2 x 7

Hex Bolt and 1/2 Hex Lock Nut.

• Make sure Roller turns freely on Bolt.

5/16 X 3/4 HEX BOLTS

AND 5/16 HEX LOCK NUTS

ROLLER

1/2 X 7 HEX BOLT

REAR ROLLER

MOUNTING BRACKET

1/2 HEX LOCK NUT

FIG. 3

11

Page 12

OPERATION

HEIGHT ADJUSTMENT STRAP

HEIGHT ADJUSTMENT

LIFT LEVER

RECOIL START HANDLE

MOWER BLADE

CLUTCH LEVER

SHUT OFF

CONTROL

TOW HITCH OFFSET

ADJUSTMENT

TOW BAR HEIGHT

ADJUSTMENT

FIG. 4

12

Page 13

OPERATION

13

Page 14

OPERATION

HAIR COTTER PIN

TOW BAR

ADJUSTMENT

HAIR COTTER PIN

LOCATING PIN

CLEVIS PIN

TOW BAR

GROUND LEVEL

HEIGHT ADJUSTMENT STRAP

HEIGHT ADJUSTMENT

LIFT LEVER

CUTTING

HEIGHTS

1-1/2"

2"

2-1/2"

3"

3-1/2"

4"

4-1/2"

5"

CUTTING HEIGHT

FIG. 6

14

Page 15

OPERATION

This mower has been designed to run offset from the

center of the tow vehicle. This allows the operator to

drive along side high brush with the tow vehicle while

cutting down the brush beside him. The adjustable

hitch gives you three offset cutting positions plus

straight behind for narrow paths.

MODEL 45-03071

The adjustable hitch of this mower can be set in seven

positions including straight and offsets of 15", 29" and

39" on both sides.

MODEL 45-0361

The adjustable hitch of this mower can be set in seven

positions including straight and offsets of 9", 17" and

23" on both sides.

15

Page 16

OPERATION

16

Page 17

CUSTOMER RESPONSIBILITIES

WHEEL 2

SWIVEL 2

17

WHEEL PIVOT 3

QUADRANT 3

WHEEL PIVOT 3

SPINDLE 2

WHEEL 2

Page 18

CUSTOMER RESPONSIBILITIES

BLADE CARE AND SERVICE

CAUTION:

DO NOT HANDLE MOWER BLADES WITH

BARE HANDS. CARELESS OR IMPROPER

HANDLING MAY RESULT IN SERIOUS

INJURY.

BLADE CARE

For best results mower blades must be kept sharp. The

blades can be sharpened with a file or on a grinding

wheel. Do not attempt to sharpen blades while they are

still on the mower.

BLADE SERVICE (Refer to fig. 9)

TO REMOVE BLADE ASSEMBLY FROM DECK

• Remove cotter pin from the spindle shaft.

• Remove nut and washer from the spindle shaft.

• Pull blade assembly off the spindle shaft. (Watch for

a key in the spindle shaft.)

TO REMOVE BLADES FROM BLADE ASSEMBLY.

• Remove cotter pin from the blade bolt.

• Remove nut from the blade bolt.

• Remove blade from the blade assembly.

BLADE SHARPENING

• Blades can be sharpened with a file or grinding wheel.

NOTE: When sharpening blades take care to maintain

blade balance. Sharpen both blades equally even if one

blade does not need to be sharpened. Check balance by

weighing each blade to make sure they are equal in weight.

BLADE ASSEMBLY

FIG. 9

WARNING:

SHUT OFF MOWER ENGINE AND REMOVE

SPARK PLUG WIRE FROM SPARK PLUG

BEFORE MAKING ANY ADJUSTMENTS OR

REPAIRS TO THE MOWER.

CLEANING THE MOWER

Water pressure from a garden hose will remove fresh

clippings from the underside of the mower. Clean mower

after each mowing.

CAUTION:

IF YOUR BLADE BOLTS SHOW WEAR,

REPLACE THEM WITH FACTORY

REPLACEMENTS ONLY.

TO REINSTALL BLADES

• Assemble a blade bolt through a flat washer, a blade

and then another flat washer.

• Assemble the bolt through the hole in the stump

plate and the blade hub assembly.

• Assemble a flat washer and nut onto the blade bolt.

• Tighten nut, then loosen just until blade can pivot.

• Install a cotter pin to secure the nut.

TO REINSTALL BLADE ASSEMBLY TO MOWER

• Reinstall key in spindle shaft, if necessary.

• Install the blade assembly onto the spindle shaft.

• Secure with flat washer and nut.

• Torque the spindle shaft and nut to 15 FT. LBS. and

secure with a hair cotter pin.

DAILY MAINTENANCE

Make sure all nuts and bolts are tight, cotter pins and

retainer springs are secure. Keep blades sharp. Observe

all Safety Precautions. Keep mower well lubricated.

REPAIR PARTS

Your rotary mower has been produced with components

designed for your unit. Although standard V-belts,

bearings, blades, pulleys, etc. may look like parts used

on your rotary mower, while similar in appearance many

are of a different construction and could in some cases

cause a malfunction in the operation of the machine.

For continued satisfactory performance use only repair

parts supplied by the manufacturer. See the dealer

where the mower was purchased for factory replacement

parts.

18

Page 19

CUSTOMER RESPONSIBILITIES

SWITCH

BODY

INNER NUT

OUTER NUT

CLUTCH CABLE ADJUSTMENT

• Remove four screws from Rear Drive Cover. Lay aside

cover and screws.

• Place Clutch Lever in "DISENGAGED" position

• The Cable should be under slight tension but should

not pull the Clutch Lever more than 1/8" away from

the Switch Body.

NOTE: If the Plunger extends more than 1/8" out from

the switch body, the cable tension is too tight and the

Engine will not start.

TO INCREASE CABLE TENSION

• Place Blade Clutch Lever in the "DISENGAGED"

position.

• Loosen the inner nut on the Clutch Cable.

• Tighten the outer nut on the Clutch Cable.

TO DECREASE CABLE TENSION

• Place Blade Clutch Lever in the "DISENGAGED"

position.

• Loosen the outer nut on the Clutch Cable.

• Tighten the inner nut on the Clutch Cable.

• Repeat the above procedure until you have the

correct tension.

CL

•

•

•

NO

the

Eng

TO

•

•

•

TO

•

•

•

•

1/8"

PLUNGER

CLUTCH LEVER

REAR DRIVE

COVER

FOUR

SCREWS

ENGINE

PULLEY

BLADE

PULLEY

19

IDLER

PULLEY

CLUTCH LEVER

Page 20

CUSTOMER RESPONSIBILITIES

V-BELT REPLACEMENT

• V-belt must be replaced if it becomes stretched to

the point that it can no longer be adjusted, or if it

becomes frayed or otherwise can not function

properly.

• Move Blade Clutch Lever to the "DISENGAGED"

position.

CAUTION:

DISCONNECT SPARK PLUG WIRE

REMOVING OLD V-BELT

• Remove Rear Drive Cover.

• Remove Front Drive Cover.

• Remove Hair Pin and Clevis Pin from Clutch Cable.

• Loosen two Rear Belt Guides and pivot them away

from Blade Pulley.

• Remove V-belt from around Blade Pulley.

• Remove one small Hair Pin from Belt Keeper Rod

and slide Belt Keeper Rod to the side.

• Pull V-belt down from around Engine Pulley and

remove V-belt from Mower.

INSTALLING NEW V-BELT

• Feed new V-belt between the two belt guides at the

Engine Pulley.

• Place V-belt up and around the Engine Pulley. Check

to make sure the V-belt is seated properly in the

groove of the Engine Pulley.

• Place V-belt along inside of Idler Pulley.

• Wrap V-belt down around Blade Pulley, placing Belt

inside of Rear Belt Guides.

• Reinstall V-belt Keeper Rod and secure with Small

Hair Pin. Check to make sure V-belt is over top of

Keeper Rod.

• Reposition and retighten two Rear Belt Guides at the

rear of the Blade Pulley. Leave approximately 1/16"

between Guides and Pulley.

• Reinstall Clevis Pin and Hair Pin into Clutch Cable.

• Reinstall Front Drive Cover and Rear Drive Cover.

ENGINE PULLEY

BELT GUIDES

HAIRPIN AND CLEVIS PIN

BLADE PULLEY

REAR BELT GUIDES

BELT KEEPER ROD V-BELT

20

Page 21

STORAGE

21

Page 22

42" ROUGH CUT TRAILMOWER - MODELS 45-03072 & 45-03611

22

Page 23

42" ROUGH CUT TRAILMOWER - MODELS 45-03072 & 45-03611

ITEM PART NO. DESCRIPTION

1. HA24255 MOWER DECK

2. HA24378 GUARD WHEEL

3. HA23193 SCREW 3/8-16 X 1-1/4 THD. FORMING

4. HA24292 BRACKET BELT GUIDE

5. HA24293 ROD BELT GUIDE

6. HA3090 PIN HAIR COTTER

7. HA24294 V-BELT (B SEC. 60" O.C.)

8. HA24295 CHANNEL CLUTCH LEVER

9. 45100 BOLT 1/2-13 X 4" HEX HEAD

10. HA120396 WASHER 1/2 FLAT

11. 43262 NUT 1/2-13 HEX LOCK

12. HA14232 WASHER FLAT

13. HA24296 ROD CLUTCH LINK

14. 44101 PIN, COTTER 3/32" X 3/4"

15. 43081 WASHER FLAT 5/16" STD. WRT.

16. HA24297 SPRING CLUTCH

17. HA24617 CLUTCH CABLE ASSY (Model 45-03071)

49165 CLUTCH CABLE ASSY (Model 45-0361)

18. 25292 STRAP, CLUTCH ADJUSTING

19. 43661 BOLT, 1/4-20 X 1" HEX HEAD

20. 43016 NUT 1/4-20 HEX LOCK

21. 25262 BRACKET INTERLOCK MOUNTING

22. HA23199 SWITCH INTERLOCK

23. 64904 MODULE ASSY WITH WIRES

24. 712-0121 NUT #10-24 HEX

25. 47078 SCREW #10-24 X 3/4"

26. 48840 SCREW 1/4-20 WASHER HEAD

27. 48298 CLIP, CORD

28. HA24300 WHEEL MOUNTING BRACKET L.H.

29. HA24301 WHEEL MOUNTING BRACKET R.H.

30. HA4143 WASHER FLAT

31. HA137258 PIN COTTER 3/16" X 1-3/4"

32. HA24308 TIRE

33. HA23229 CAP HUB

34. HA24309 STRAP ADJUSTING

35. HA6979 WASHER FLAT

36. 43020 BOLT 1/2-13 X 1-1/2 HEX HEAD

37. 43019 NUT 1/2-13 HEX JAM

38. HA23220 PIN LOCATING

39. 47134 PIN HAIR COTTER .08" X 1.58"

40. HA24311 CHAIN DEFLECTOR

ITEM PART NO. DESCRIPTION

41. HA24312 ROD CHAIN

42. HA24313 BRACKET CHANNEL

43. HA9131 SCREW SELF THREADING

44. 25428 PLATE ENGINE MOUNTING

45. 49161* ENGINE, 11 HP

46. HA24457 PULLEY

47. HA3073 KEY 1/4" SQ. X 1"

48. HA115321 SCREW 5/16-18 X 5/16 SOC. SET

50. 43555 WASHER 7/16" LOCK

51. HA181668 BOLT 7/16-20 X 1-1/4 HEX HEAD

52. 25051 COVER, GAS TANK

53. 25265 COVER, FRONT DRIVE

55. 43182 BOLT 5/16-18 X 3/4 HEX HEAD

56. 43064 NUT 5/16-18 HEX LOCK

57. 25264 COVER, REAR DRIVE

58. HA23732 TANK GASOLINE

59. HA24317 PLATE FUEL TANK

60. HA163318 SCREW 1/4-14 X 7/8 TAPPING PAN HEAD

61. HA23733 CAP GASOLINE TANK

62. 48837 HOSE FUEL TANK LONG

63. HA24455 HOSE FUEL TANK SHORT

64. HA23792 CLAMP FUEL LINE

65. HA23791 FILTER FUEL LINE

66. 48095 PIPE

67. 48096 CAP

68. HA24310 BRACKET ROLLER

69. HA12138 ROLLER MOWER

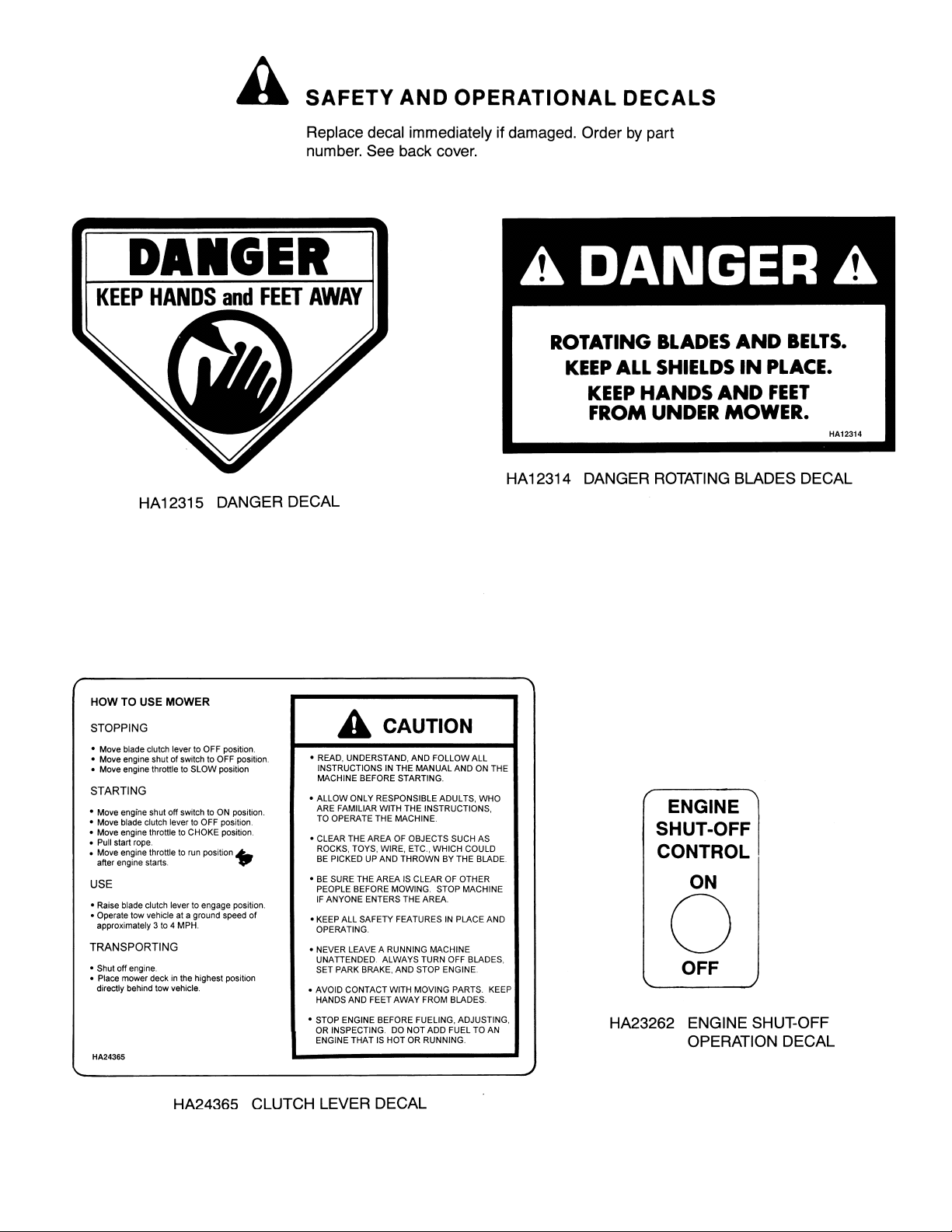

70. HA12315 DECAL DANGER (HAND)

71. HA12314 DECAL DANGER

72. HA24365 DECAL OPERATION/CAUTION

73. HA24366 DECAL HEIGHT ADJUSTMENT

74. HA126145 BOLT 1/2-13 X 7" HEX HEAD

75. 43982 PIN, CLEVIS 1/4" X 5/8"

76. HA22981 BELT GUIDE

77. HA24298 SPRING RETURN

78. 49156 ROD, CABLE GUIDE

79 43013 NUT 1/4-20 HEX

80. 44488 WHEEL BEARING

* Order engine repair parts from your nearest Briggs & Stratton

dealer.

the fastest way to purchase parts

23

www.speedepart.com

Page 24

42" ROUGH CUT TRAILMOWER - MODELS 45-03072 & 45-03611

9

11

12

6

5

4

3

1

20

18

33

32

18

21

19

23

4

8

7

2

18

13

14

15

24

23

34

21

22

25

22

25

16

17

30

31

28

24

37

6

5

4

36

35

38

6

15

27

28

29

25

26

28

27

28

24

Page 25

42" ROUGH CUT TRAILMOWER - MODELS 45-03072 & 45-03611

ITEM PART NO. DESCRIPTION

1. 64906 IDLER MOUNTING BRACKET

2. 64899 IDLER ARM

3. 24472 BUSHING

4. 43070 WASHER FLAT

5. 43003 WASHER 3/8" LOCK

6. 43062 BOLT 3/8-16 X 1-1/2" HEX HEAD

7. 49148 SPACER

8. HA21341 IDLER PULLEY (FLAT)

9. 43054 BOLT 3/8-16 X 2" HEX HEAD

10. 43082 NUT 3/8-16 HEX LOCK

11. HA22981 GUIDE BELT

12. HA22224 SCREW 3/8-16 X 3/4 SELF TAPPING

13. 43087 BOLT 3/8-16 X 1-1/4" HEX HEAD

14. HA15200 WASHER FLAT

15. HA21362 NUT 3/8-16 NYLOCK

16. HA24367 GREASE FITTING

17. HA24278 HUB (WITH STUDS)

18. HA24280 BEARING

19. 64913 HUB BLADE

20. 49148 SHAFT SPINDLE

21. HA24282 SEAL O-RING

22. HA3073 KEY 1/4" SQ X 1"

23. HA456151 WASHER 13/16 X 1-1/2 X .134 FLAT

24. HA427639 NUT 3/4-16 SLOTTED HEX

25. 43010 PIN 1/8" X 1" COTTER

26. HA24624 DISC BLADE MOUNTING

27. HA24288 BLADE

28. HA24625 WASHER - FLAT

29. HA24592 BOLT - 7/8-9 X 2-1/4 HEX BOLT

30. HA137258 PIN 3/16 X 1-3/4 COTTER

31. HA24593 NUT 7/8-9 SLOTTED HEX

32. 43353 WASHER 1/2 MED. LOCK

33. HA120371 NUT 1/2-20 HEX

34. 65102 PULLEY, SPINDLE

35. 64902 BRAKE

36. 49155 TRUNNION

37. 49160 BRAKE ROD

38. HA20186 SPRING

the fastest way to purchase parts

25

www.speedepart.com

Page 26

42" ROUGH CUT TRAILMOWER - MODELS 45-03072 & 45-03611

ITEM PART NO. DESCRIPTION

1. 25273 TUBE DRAWBAR (MODEL 45-0361)

HA24321 TUBE DRAWBAR (MODEL 45-03071)

2. HA24441 STRAP HITCH

3. HA20186 SPRING EXTENSION

4. 44180 BOLT 5/16-18 X 2" HEX HEAD

5. 43064 NUT 5/16-18 HEX LOCK

6. 64909 HITCH ASSEMBLY

7. HA180132 BOLT 3/8-16 X 2-1/4 HEX HEAD

8. 43509 BOLT 3/8-16 X 2-3/4 HEX HEAD

9. 43070 WASHER 3/8 FLAT

10. 43082 NUT 3/8-16 HEX LOCK

11. HA23636 PIN CLEVIS

12. 47134 PIN HAIR COTTER .08 X 1.58

13. 49157 LEVER CLUTCH

14. 43062 BOLT 3/8-16 X 1-1/2 HEX HEAD

15. HA19445 SPRING COMPRESSION

16. 43012 BOLT 1/4-20 X 3/4 HEX HEAD

the fastest way to purchase parts

ITEM PART NO. DESCRIPTION

17. 43013 NUT 1/4-20 LOCK

18. HA23262 DECAL ENGINE SHUT-OFF

19. HA23265 DECAL CLUTCH LEVER

20. 64910 BRACKET DRAWBAR ADJUSTMENT

21. HA24326 DRAWBAR SWIVEL

22. HA5074 FITTING GREASE

23. HA15200 WASHER

24. 43003 WASHER 3/8 LOCK

25. 43087 BOLT 3/8-16 X 1-1/4 HEX HEAD

26. HA24330 PIN CLEVIS

27. HA3341 PIN HAIR COTTER, 5/32"

28. HA22759 SWITCH ON/OFF

29. HA23761 CLIP HOSE 3/8"

30. HA9411666 SCREW #10-16 X 1/2 SELF TAPPING

31. 49164 WIRE HARNESS (MODEL 45-0361)

HA24353 WIRE HARNESS (MODEL 45-03071)

www.speedepart.com

26

Page 27

WIRING DIAGRAM

SWITCH

BLACK WIRE

FROM MODULE TO

ENGINE GROUND

BLACK WIRE

FROM ON/OF SWITCH

TO MAGNETO GROUND

ENGINE ON/OFF SWITCH

BLACK WIRE

FROM ON/OFF SWITCH

TO ENGINE GROUND

OIL

ENGINE

BLACK WIRE

FROM MODULE

TO SWITCH

RED WIRE FROM MODULE

TO MAGNETO GROUND

BLACK WIRE

FROM MODULE

TO SWITCH

A B C D E F

ELECTRONIC

CONTROL

MODULE

27

Page 28

© 2004 Agri-Fab, Inc.

the fastest way to purchase parts

REPAIR PARTS

Agri-Fab, Inc.

303 West Raymond

Sullivan, IL. 61951

217-728-8388

www.agri-fab.com

www.speedepart.com

Loading...

Loading...