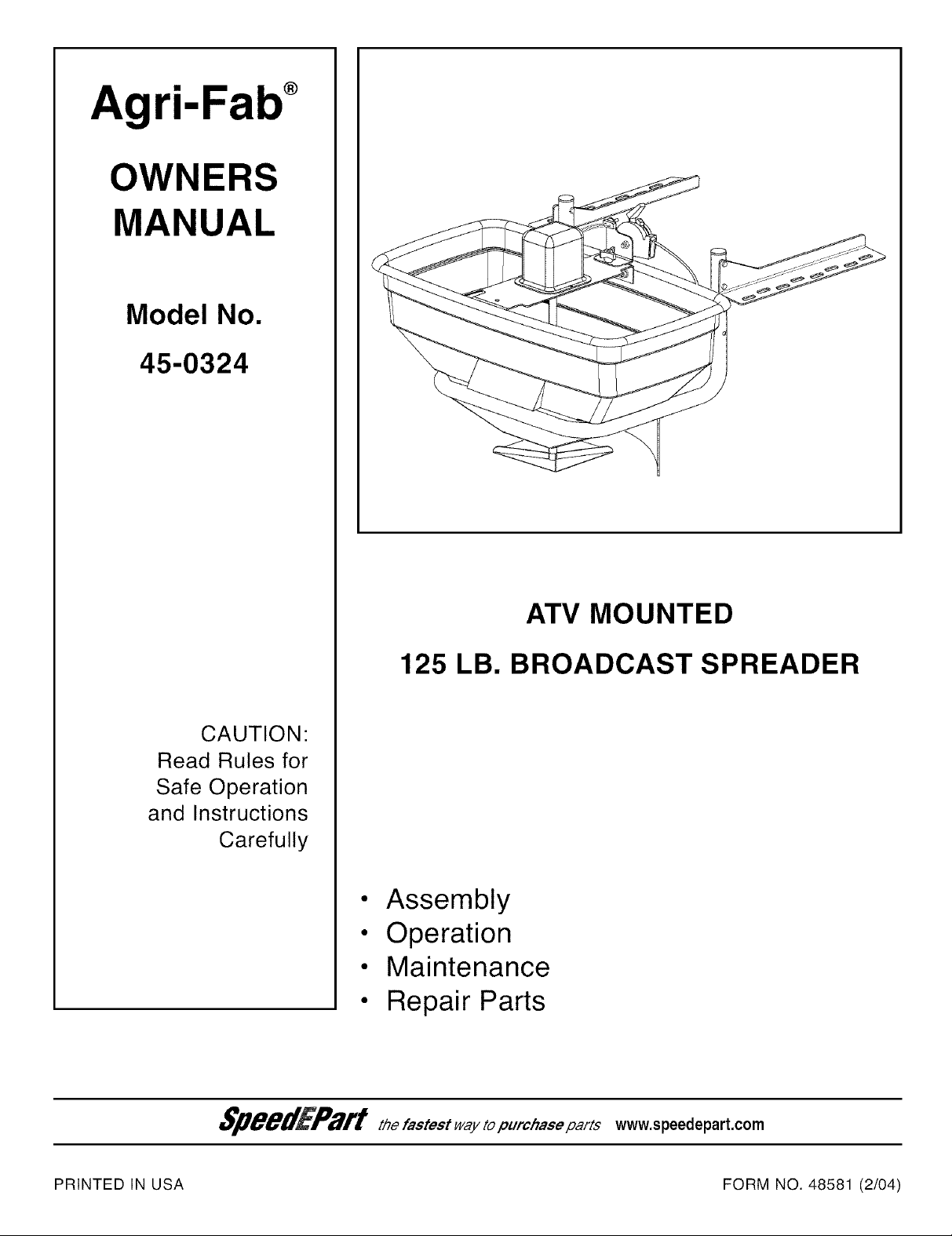

Agri-Fab 45-0324 Owner’s Manual

Agri-Fab ®

OWNERS

MANUAL

Model No.

45-0324

CAUTION:

Read Rules for

Safe Operation

and Instructions

Carefully

ATV MOUNTED

125 LB. BROADCAST SPREADER

• Assembly

• Operation

• Maintenance

• Repair Parts

SpeedEPart the_._ .._top...h._p..t_www.speedepart.com

PRINTED IN USA FORM NO. 48581 (2/04)

RULES FOR SAFE OPERATION

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate

the equipment. Exercise caution at all times when operating equipment.

• Read this owners manual before attempting to

assemble or operate the spreader.

• Read the vehicle owners manual and know how to

operate your vehicle, before using the spreader at-

tachment.

• Do not allow anyone to ride on or sit on spreader

attachment frame.

• Never allow children to operate the vehicle or spreader

attachment.

• Do not allow adults to operate the vehicle or spreader

attachment without proper instructions.

• Never operate vehicle and spreader attachment

without wearing solid, substantial footwear.

• Wear eye and hand protection when handling and

using lawn chemicals.

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS. IT

MEANS -- ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED.

• Always begin with the transmission in first (low) and

gradually increase speed as conditions permit.

• When using broadcast spreader do not drive too

close to a creek or ditch and be alert for holes and

other hazards which could cause you to loose control

of the broadcast spreader and vehicle.

• Always operate vehicle and spreader up and down a

slope, never across a slope.

• Read instructions and caution notes for handling and

application of materials purchased for spreading.

• Follow maintenance and lubrication instructions as

outlined in this manual.

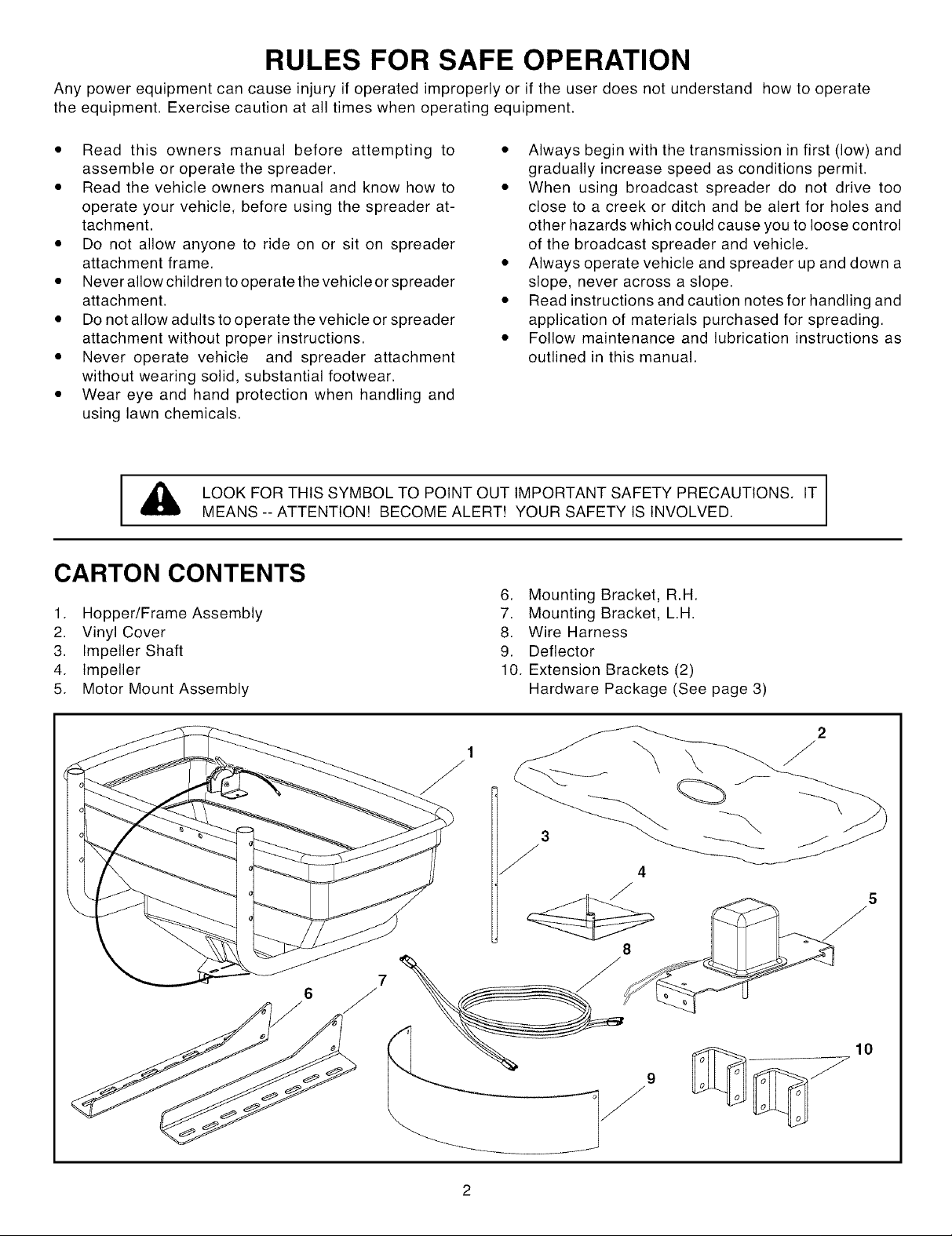

CARTON CONTENTS

6. Mounting Bracket, R.H.

1. Hopper/Frame Assembly 7. Mounting Bracket, L.H.

2. Vinyl Cover 8. Wire Harness

3. Impeller Shaft 9. Deflector

4. Impeller 10. Extension Brackets (2)

5. Motor Mount Assembly Hardware Package (See page 3)

3

8

7

10

9

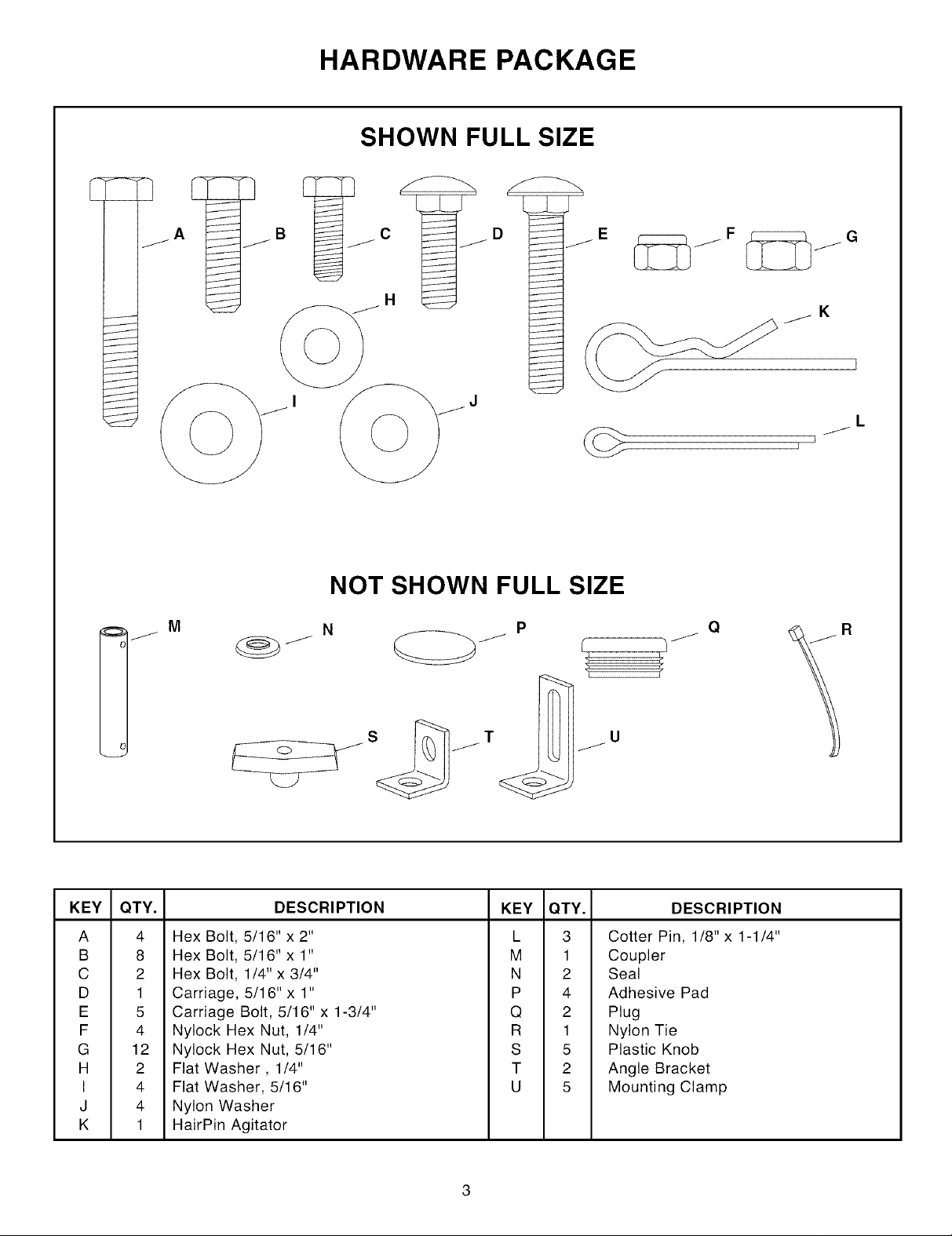

HARDWARE PACKAGE

SHOWN FULL SIZE

E zF zo

K

J

L

J

J

KEY

A

B

C

D

E

F

G

H

I

J

K

J

o

0

QTY.

4

8

2

1

5

4

12

2

4

4

1

NOT SHOWN FULL SIZE

M

_J

DESCRIPTION

Hex Bolt, 5/16" x 2"

Hex Bolt, 5/16" x 1"

Hex Bolt, 1/4" x 3/4"

Carriage, 5/16" x 1"

Carriage Bolt, 5/16" x 1-3/4"

Nylock Hex Nut, 1/4"

Nylock Hex Nut, 5/16"

Flat Washer, 1/4"

Flat Washer, 5/16"

Nylon Washer

HairPin Agitator

S_jT_jU

P

KEY QTY.

L 3

M 1

N 2

P 4

Q 2

R 1

S 5

T 2

U 5

Q

",r

Cotter Pin, 1/8" x 1-1/4"

Coupler

Seal

Adhesive Pad

Plug

Nylon Tie

Plastic Knob

Angle Bracket

Mounting Clamp

_J

¢

DESCRIPTION

R

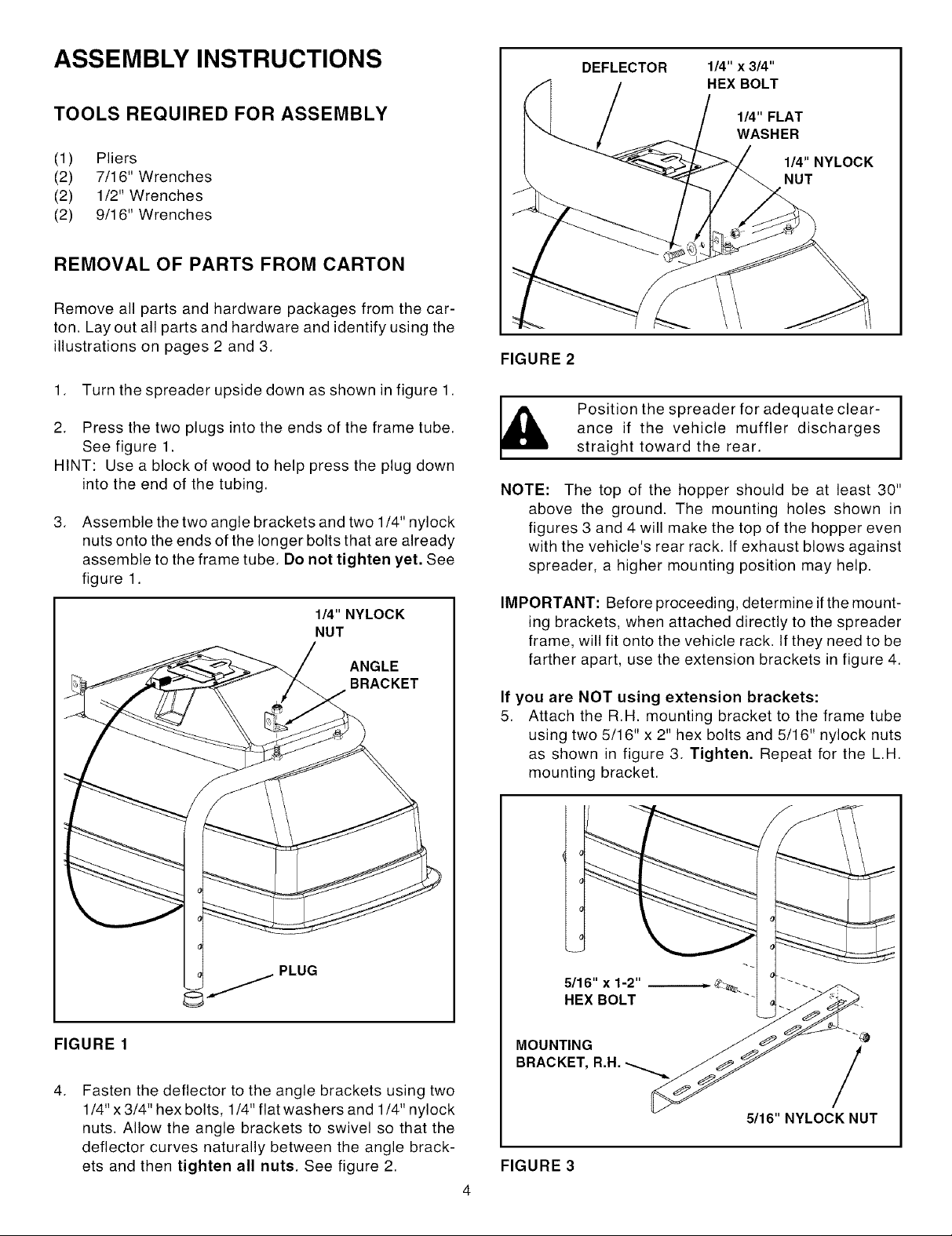

ASSEMBLY INSTRUCTIONS

DEFLECTOR 1/4" x 3/4"

HEX BOLT

TOOLS REQUIRED FOR ASSEMBLY

(1) Pliers

(2) 7/16" Wrenches

(2) 1/2" Wrenches

(2) 9/16" Wrenches

REMOVAL OF PARTS FROM CARTON

Remove all parts and hardware packages from the car-

ton. Lay out all parts and hardware and identify using the

illustrations on pages 2 and 3.

1. Turn the spreader upside down as shown in figure 1.

2. Press the two plugs into the ends of the frame tube.

See figure 1.

HINT: Use a block of wood to help press the plug down

into the end of the tubing.

.

Assemble the two angle brackets and two 1/4" nylock

nuts onto the ends of the longer bolts that are already

assemble to the frame tube. Do not tighten yet. See

figure 1.

1/4"NYLOCK

NUT

ANGLE

BRACKET

1/4" FLAT

WASHER

I/4"NYLOCK

NUT

FIGURE 2

ance if the vehicle muffler discharges

Position the spreader for adequate clear- I

straight toward the rear.

NOTE: The top of the hopper should be at least 30"

above the ground. The mounting holes shown in

figures 3 and 4 will make the top of the hopper even

with the vehicle's rear rack. If exhaust blows against

spreader, a higher mounting position may help.

IMPORTANT: Before proceeding, determine ifthe mount-

ing brackets, when attached directly to the spreader

frame, will fit onto the vehicle rack. If they need to be

farther apart, use the extension brackets in figure 4.

If you are NOT using extension brackets:

5. Attach the R.H. mounting bracket to the frame tube

using two 5/16" x 2" hex bolts and 5/16" nylock nuts

as shown in figure 3. Tighten. Repeat for the L.H.

mounting bracket.

PLUG

FIGURE 1

4.

Fasten the deflector to the angle brackets using two

1/4" x 3/4" hex bolts, 1/4" flat washers and 1/4" nylock

nuts. Allow the angle brackets to swivel so that the

deflector curves naturally between the angle brack-

ets and then tighten all nuts. See figure 2.

MOUNTING

BRACKET,

5/16" NYLOCK NUT

FIGURE 3

4

Loading...

Loading...