Page 1

OWNERS

the fastest way to purchase parts

www.speedepart.com

™

MANUAL

Model No.

45-02103

CAUTION:

Read Rules for

Safe Operation

and Instructions

Carefully

125 LB. PUSH

BROADCAST SPREADER

Assembly

Operation

Maintenance

Repair Parts

PRINTED IN U.S.A. FORM NO. 49030 (REV. 4/7/08)

Page 2

RULES FOR SAFE OPERATION

2

6

5

1

7

9

3 4

8

The following safety precautions are suggested. This

broadcast spreader is designed, engineered and tested to

offer reasonably safe and effective service, provided it is

operated in strict accordance with these instructions. Failure

to do so may result in personal injury. Always observe the

rules of safe operation.

1. Do not allow anyone to operate the broadcast spreader

without proper instructions.

2. Do not permit children to operate the broadcast

spreader.

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS. IT

MEANS — ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED.

3. Wear eye and hand protection when handling and

when applying lawn or garden chemicals.

4. Read the chemical label instructions and cautions for

handling and applying the chemicals purchased for

spreading.

5. Keep all nuts, bolts and screws tight to be sure

equipment is in safe working condition.

6. Follow maintenance and lubrication instructions as

outlined in this manual.

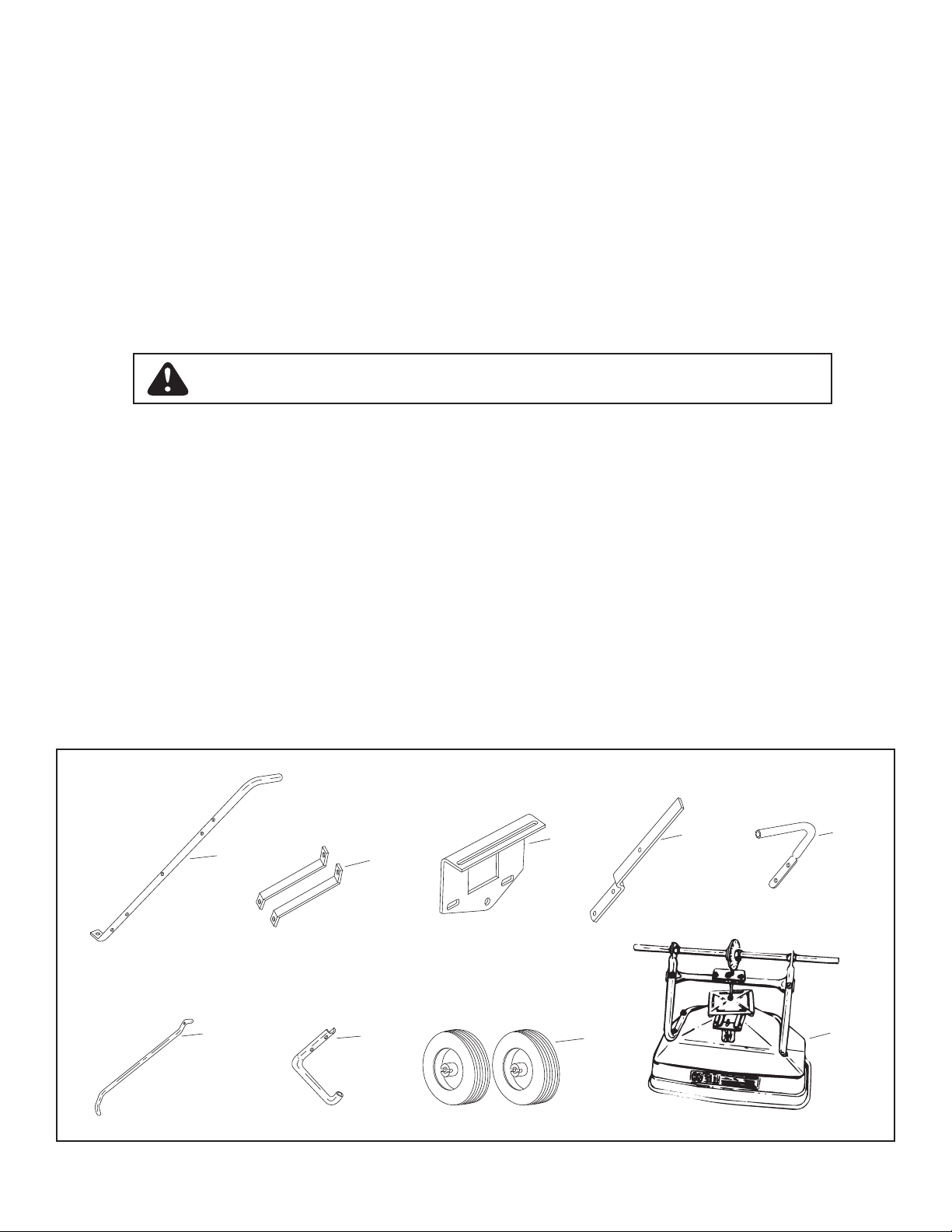

CARTON CONTENTS

LOOSE PARTS IN CARTON

1. Handle Tube (long)

2. Braces (2)

3. Flow Control Mount Bracket

4. Flow Control Arm

5. Handle Tube (short)

6. Flow Control Rod

7. Leg Stand Tube

8. Wheels (2)

9. Hopper Assembly

Hardware Package (not shown)

2

Page 3

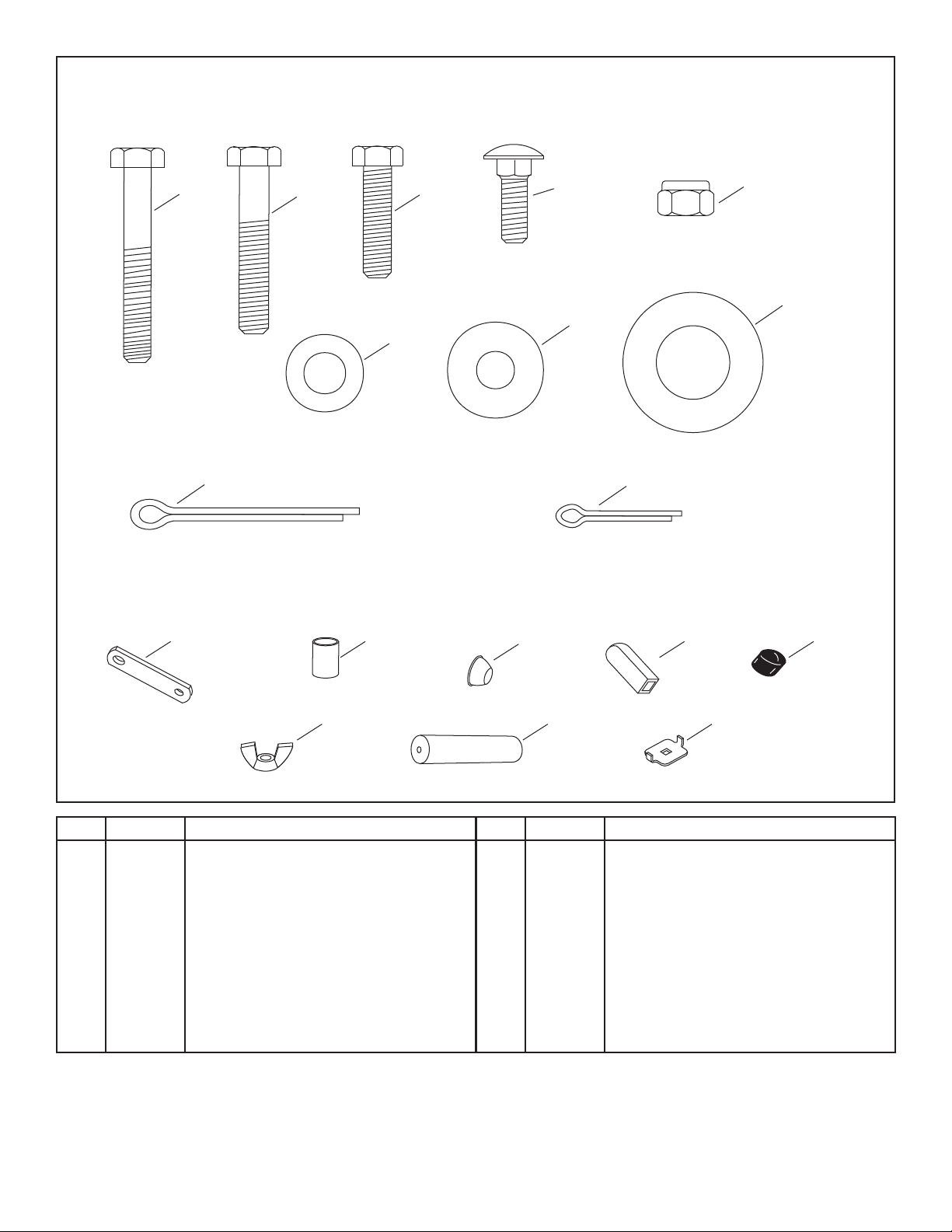

NOT SHOWN FULL SIZE

F

H

I

J

A

B

C D

E

K

L

M

N

O

Q

P

R

SHOWN FULL SIZE

G

KEY QTY. DESCRIPTION

A 2 Hex Bolt, 1/4-20 x 1-3/4" Long

B 5 Hex Bolt, 1/4-20 x 1-1/2" Long

C 2 Hex Bolt, 1/4-20 x 1" Long

D 1 Carriage Bolt, 1/4-20 x 3/4" Long

E 9 Nyock Nut, 1/4-20 Thd.

F 6 Flat Washer, 5/16" SAE

G 4 Nylon Washer

H 4 Flat Washer, 5/8"

I 1 Cotter Pin, 5/32" x 2"

KEY QTY. DESCRIPTION

J 1 Cotter Pin, 3/32" x 3/4" Long

K 1 Flow Control Link

L 2 Spacer Tube

M 2 Hub Cap

N 1 Grip

O 1 Vinyl Cap

P 1 Nylon Wing Nut

Q 2 Handle Grip

R 1 Adjustable Stop

3

Page 4

ASSEMBLY INSTRUCTIONS

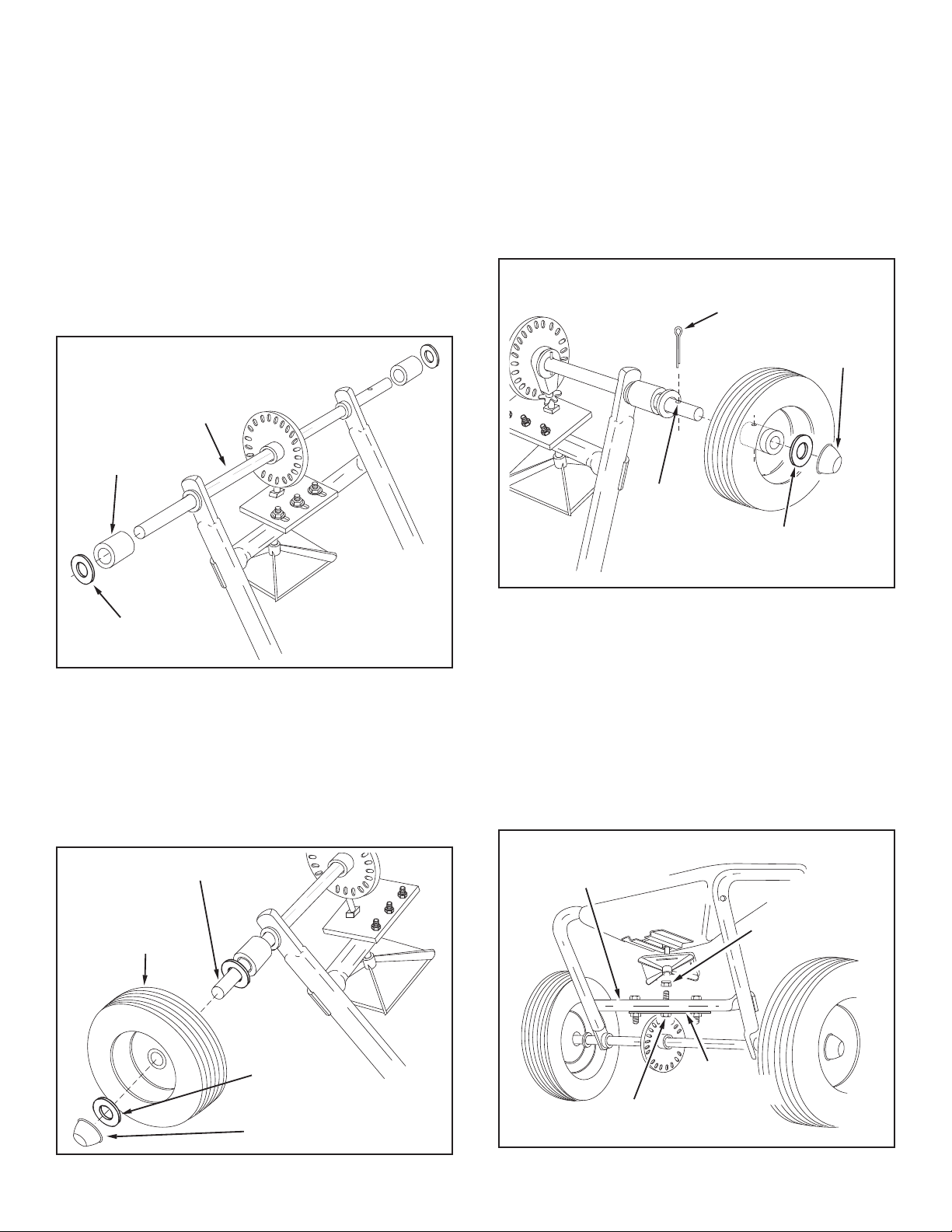

AXLE

SPACER

5/8" FLAT

WASHER

5/8" FLAT

WASHER

HUB CAP

WHEEL

NO CROSS HOLE

HUB CAP

5/32" x 2"

COTTER PIN

CROSS

HOLE

5/8" FLAT

WASHER

CROSSOVER

TUBE

MIDDLE NUT

SHAFT

SUPPORT

PLATE

MIDDLE BOLT

TOOLS REQUIRED FOR ASSEMBLY

5. Place a wheel onto the end of the axle that has a cross

hole. The long end of the hub goes to the inside. See

gure 3.

(1) Pliers

(1) Hammer

(2) 7/16" Open or Boxed End Wrenches

1. Remove the spreader, the loose parts and the hardware

package from the carton. Lay out parts and hardware

and identify using the illustrations on pages 2 and 3.

2. With the spreader resting upside down on the top of

the hopper, assemble a spacer and then a 5/8" at

washer onto each end of the axle. See gure 1.

6. Assemble a 5/32" x 2" cotter pin through the hole in

the wheel hub and the axle. See gure 3.

7. Place a 5/8" at washer onto the axle and then lightly

tap a hub cap onto the axle until it is snug against the

washer and wheel hub. See gure 3.

FIGURE 1

3. Place a wheel onto the end of the axle that has no

cross hole. The long end of the hub goes to the inside.

See gure 2.

4. Place a 5/8" at washer onto the axle and then lightly

tap a hub cap onto the axle until it is snug against the

washer and wheel hub. See gure 2.

FIGURE 3

8. Remove the nut from the middle bolt in the crossover

tube. See gure 4.

FIGURE 2

FIGURE 4

4

Page 5

HANDLE TUBE (LONG)

1/4" x 1-1/2"

HEX BOLTS

1/4"

NYLOCK

NUTS

VINYL CAP

LEG STAND TUBE

IMPORTANT: Do Not asssemble handle tube to same

MIDDLE

BOLT

MIDDLE

NUT

HANDLE TUBE (LONG)

HEX BOLT

1/4" x 1-1/2"

HEX BOLT

1/4" x 1-1/2"

HITCH

BRACE

1/4"

NYLOCK

NUT

CROSSOVER

TUBE

SHAFT

SUPPORT

PLATE

FLOW CONTROL

LINK

FLOW

CONTROL

ARM

1/4"

NYLOCK

NUT

1/4" x 1"

HEX BOLT

SMALLEST

HOLE

NYLON

WASHER

side of crossover tube as shaft support plate.

9. Place the long handle tube onto the crossover tube

on the side opposite from the shaft support plate.

Fasten with the bolt, washer and nut removed in the

previous step. See gures 4 and 5. Do not tighten

at this time.

10. Assemble two handle braces to the inside of the hopper

frame, one on each side, using two 1/4" x 1-1/2" hex

bolts and two 1/4" nylock nuts. See gure 5. Do not

tighten at this time.

11. Assemble the other end of the two handle braces to

the long handle tube using a 1/4" x 1-1/2" hex bolt and

1/4" nylock nut. Do not tighten at this time.See gure

5.

12. Tighten all nuts and bolts in same sequence as

assembled in steps 9 through 11. See gure 5.

13. Assemble the leg stand tube to the handle tube (long)

using two 1/4" x 1-1/2" hex bolts. Secure tightly with

two 1/4" nylock nuts. See gure 6.

14. Place a vinyl cap over the end of the leg stand tube.

See gure 6.

FIGURE 5

FIGURE 6

15. Assemble the ow control link (end with small hole)

to the ow control arm using a 1/4" x 1" hex bolt, a

nylon washer and a 1/4" nylock nut as shown in gure

7. Tighten carefully. The ow control link should not

be loose but should pivot with no more than slight

resistance.

FIGURE 7

5

Page 6

16. Assemble the ow control arm to the ow control

1/4" x 1-3/4"

HEX BOLT

1/4"

NYLOCK

NUT

HANDLE

TUBE

(SHORT)

HANDLE

TUBE

(LONG)

HANDLE GRIP

FLOW CONTROL

MOUNTING BRACKET

5/16"

FLAT

WASHERS

HOPPER

SLIDE

GATE

BRACKET

FLOW

CONTROL

ROD

FLOW

CONTROL

ROD

FLOW

CONTROL

LINK

3/32"

COTTER

PIN

5/16" FLAT

WASHER

SLOT

1/4" x 1"

HEX BOLT

1/4"

NYLOCK

NUT

FLOW CONTROL

MOUNTING

BRACKET

FLOW

CONTROL

ARM

(2) NYLON

WASHERS

VINYL GRIP

mounting bracket using a 1/4" x 1" hex bolt, two nylon

washers and a 1/4" nylock nut as shown in gure 8.

Tighten carefully. The ow control arm should be

snug, but should pivot with no more than a slight

resistance.

17. Assemble the vinyl grip. See gure 8.

19. Hook the free end of the ow control rod through the

hole in the slide gate bracket located near the bottom

of the hopper. See gure 10.

FIGURE 10

FIGURE 8

18. Place a 5/16" at washer onto the end of the ow control

rod. Insert the end of the ow control rod through the

slot in the ow control mounting bracket and through

the hole in the ow control link. Secure with a 3/32" x

3/4" cotter pin. See gure 9.

20. Assemble both the ow control mounting bracket and

the short handle tube to the long handle tube. Use two

1/4" x 1-3/4" hex bolts, four 5/16" at washers and two

1/4" nylock nuts as shown in gure 11. Do not tighten

at this time.

21. Place a handle grip on each handle. See gure 11.

FIGURE 9

FIGURE 11

6

Page 7

22. Place the adjustable stop into the "ON" end of the slot

5/16" FLAT

WASHER

NYLON

WASHER

1/4" x 3/4"

CARRIAGE BOLT

NYLON

WING NUT

ADJUSTABLE

STOP

OFF

ON

1

2

3

4

6

7

8

9

10

5

FLOW

CONTROL

ARM

ON

OFF

AJDUSTABLE

STOP

SETTING "5"

in the top of the ow control mounting bracket. Secure

with the 1/4" x 3/4" carriage bolt, a nylon washer, a

5/16" at washer and the nylon wing nut. See gure

12.

FIGURE 12

23. Position the ow control mounting bracket (gure

13).

a. Push on ow control arm until it locks in "OFF"

position.

b. Slide ow control mounting bracket along tube until

closure plate in bottom of hopper just closes.

c. Snug the 1/4" lock nuts just enough to hold ow

control mounting bracket in place.

d. Set adjustable stop at "5". Pull ow control arm

against stop. Verify that closure plate has opened

about half way.

e. If closure plate does not open half way, it may be

closed too far at "OFF". Adjust position of ow control

mounting bracket until closure plate will open about

half way at "5" and still close when arm is locked

in "OFF". Tighten 1/4" lock nuts.

FIGURE 13

24. Before operating the spreader, pre-lubricate per the

lubrication instructions in the owner's manual.

7

Page 8

OPERATION

OVERLAP

8' to

10'

HOW TO USE YOUR SPREADER

SETTING THE FLOW CONTROL

(Refer to gure 13 on page 7.)

1. Loosen the nylon wing nut, set the adjustable stop to

the desired ow rate setting and retighten the wing nut.

The higher the setting number, the wider the opening

in the bottom of the hopper.

2. Refer to the application chart on page 8 and to the

instructions on the fertilizer bag to select the proper

ow rate setting.

3. Pull the ow control arm against the adjustable stop

for the on position and toward the hopper for the off

position.

APPLICATION DIAGRAM

USING YOUR SPREADER

We do not recommend the use of any powdered lawn

chemicals, due to difculty in obtaining a satisfactory or

consistent broadcast pattern.

1. Determine approximate square footage of area to be

covered and estimate amount of material required.

2. Before lling the hopper make sure the ow control arm

is in the off position and the closure plate is shut.

3. Break up any lumpy fertilizer as you ll the hopper.

4. Set the adjustable stop with the ow control arm still

in the off position. Refer to the application chart on

this page and to the instructions on the fertilizer bag

to select the proper ow rate setting.

5. The application chart is calculated for light to heavy

application at a walking speed of 3 mph, or 100 ft. in 23

seconds. A variation in speed will require an adjustment

of the ow rate to maintain the same coverage. The

faster you walk, the wider the broadcast width.

6. Always start the spreader in motion before opening

the closure plate.

7. Always shut the closure plate before turning or stopping

the spreader.

8. If fertilizer is accidentally deposited too heavily in a

small area, soak the area thoroughly with a garden

hose or sprinkler to prevent burning of the lawn.

9. To insure uniform coverage, make each pass so that the

broadcast pattern slightly overlaps the pattern from the

previous pass as shown in gure 14. The approximate

broadcast widths for different materials are shown in

the application chart on this page.

10. When broadcasting weed control fertilizers, make sure

the broadcast pattern does not hit evergreen trees,

owers or shrubs.

11. Heavy moisture conditions may require a cover over the

hopper to keep contents dry. The vinyl cover (available

as an accessory) acts as a wind and moisture shield,

but should not be used as a rain cover. Refer to the

parts list on page 11.

FIGURE 14

IMPORTANT: Application rates shown in the chart are af-

fected by humidity and by the moisture content of the material

(granular and pellet). Some minor setting adjustments may

be necessary to compensate for this condition.

APPLICATION CHART

MATERIAL

TYPE

FERTILIZER

Powder 3 - 5 3' - 4'

Granular 3 - 5 8' - 10'

Pelleted 3 - 5 10' - 12'

Organic 6 - 8 6' - 8'

GRASS SEED

Fine 3 - 4 6' - 7'

Coarse 4 - 5 8' - 9'

ICE MELTER 6 - 8 10' - 12'

OPERATING SPEED - 3 MPH. (100 ft. in 23 seconds)

FLOW SETTING SPREAD

WIDTH

8

Page 9

MAINTENANCE STORAGE

GREASE

OIL

OIL

SPROCKET

SHAFT

AGITATOR

HAIRPIN

CHECK FOR LOOSE FASTENERS

1. Before each use make a thorough visual check of

the spreader for any bolts and nuts which may have

loosened. Retighten any loose bolts and nuts.

CHECK FOR WORN OF DAMAGED PARTS

2. Check for worn or damaged parts before each use.

Repair or replace parts if necessary.

CHECK TIRE INFLATION

3. Check if tires are adequately inated before each use.

Do not inate tires beyond maximum recommended

pressure.

CAUTION: DO NOT inate tires beyond the

maximum recommended pressure printed

on side of tire.

CLEANING

4. Rinse inside of hopper and exterior of spreader and

dry off before storing.

LUBRICATE (See gure 15)

5. Lightly apply automotive grease as needed to the

sprocket and gear.

6. Oil the nylon bushings on the vertical sprocket shaft

and on the axle at least once a year, or more often as

needed.

7. Oil right hand (idler) wheel at least once a year or more

often as needed.

1. Rinse inside of hopper and exterior of spreader and

dry off before storing.

2. Store in a clean, dry area.

SERVICE AND ADJUSTMENTS

1. If the axle, slotted gear and sprocket assembly is

disassembled, mark down the positions of the parts

as they are removed. The drive wheel and sprocket

positions in relation to the slotted gear determine

which direction the spreader plate will spin. Be sure

to reassemble them in their original positions. (Refer

to gure 3 on page 4.) Use shim washers (Ref. no. 21

on pages 10 and 11) as needed for minimum backlash.

Add grease to gear and sprocket.

2. If the agitator hairpin becomes damaged or worn it can

be replaced. Remove old agitator hairpin from hole in

sprocket shaft and replace with new agitator hairpin.

See gure 16.

FIGURE 15

FIGURE 16

9

Page 10

REPAIR PARTS FOR BROADCAST SPREADER MODEL 45-02103

1

4

22

22

3

5

6

13

46

10

11

18

18

19

20

20

33

25

38

26

36

31

49

17

35

35

B

A

D

E

D

16

14

27

48

37

37

43

44

34

41

42

8

11

11

45

39

50

50

23

23

15

15

21

28

28

29

32

40

40

9

9

9

9

9

9

9

9

9

7

7

7

7

7

7

9

29

21

21

32

21

A

B

24

32

9

4

E

9

30

39

51

40

9

39

39

C

C

40

32

47

52

29

21

10

Page 11

REPAIR PARTS LIST FOR BROADCAST SPREADER MODEL 45-02103

the fastest way to purchase parts

www.speedepart.com

REF.

NO.

1 44466 1 Hopper

2

3 62482 1 Ass'y, Guide Closure

4 48842 1 Tube, Frame

5 23753 1 Slide Gate Angle Bracket

6 23758 1 Slide Gate Bracket

7 43648 9 Bolt, Hex 1/4-20 x 1-1/2" Lg.*

8 24857 1 Flow Control Link

9 47189 22 Nut, Nyock 1/4-20 Thd. *

10 48841 1 Tube, Crossover

11 43661 3 Bolt, Hex 1/4-20 x 1" Lg.*

13 44566 1 Spring, Torsion

14 44590 1 Tube, Handle (Long)

15 40880 2 Wheel

16 44589 1 Tube, Handle (Short)

17 25067 1 Shaft, Axle

18 44665 2 Pin, Spring 5/32" Dia. x 1-1/4" Lg.

19 48916 1 Bushing, Axle Shaft

20 44125 4 Washer, Shim 5/8" I.D.

21

22 741-0249 2 Bearing, Flange

23 48857 2 Tube, Spacer

24 25305 1 Shaft, Sprocket

25 04367 1 Spreader Plate

26 43850 1 Pin, Spring 1/8" Dia. x 5/8" Lg.

27 44587 1 Tube, Leg Stand

PART

NO.

C-9M5732

R19212016

QTY. DESCRIPTION

2 Pop Rivet (not shown)

Washer, Flat 5/8" I.D.

5

REF.

NO.

28 44285 2 Bushing, Delrin 3/8" I.D.

29 1509-69 9 Bolt, Hex 1/4-20 x 1-3/4" Lg.*

30 47063 1 Pin, Cotter 5/32" x 2"

31 48934 1 Hairpin, Agitator

32 43088 16 Washer, Flat 1/4" Std.

33 44468 1 Sprocket - 6 Tooth

34 44514 1 Rod, Flow Control

35 23525 2 Brace, Hitch

36 23780 1 Support, Shaft

37 44482 2 Grip, Handle

38 46055 1 Pin, Spring 1/8" Dia. x 1" Lg.

39 1543-69 10 Washer, Nylon

40

41 24858 1 Stop, Adjustable

42 24855 1 Bracket, Flow Control Mount

43 48888 1 Gear

44 24856 1 Flow Control Arm

45 44101 1 Cotter Pin 3/32" x 3/4" Lg.*

46 23533 1 Plate, Closure

47 44950 1 Bolt, Carriage 1/4-20 x 3/4" Lg.

48 43848 1 Grip, Flow Control Arm

49 44481 1 Cap, Vinyl

50 48499 2 Hub Cap

51 47141 1 Nylon Wing Nut, 1/4-20

52 40825 1 Vinyl Hopper Cover (Optional)

PART

NO.

R19111116

49030 1 Owner's Manual

QTY. DESCRIPTION

Washer, 5/16 SAE

6

*Purchase common hardware locally.

11

Page 12

REPAIR PARTS

the fastest way to purchase parts

www.speedepart.com

Agri-Fab, Inc.

303 West Raymond

Sullivan, IL. 61951

217-728-8388

www.agri-fab.com

This document (or manual) is protected under the U.S. Copyright Laws and the copyright laws of foreign countries,

pursuant to the Universal Copyright Convention and the Berne convention. No part of this document may be reproduced

or transmitted in any form or by any means, electronic or mechanical, including photocopying or recording, or by any

information storage or retrieval system, without the express written permission of Agri-Fab, Inc. Unauthorized uses and/or

reproductions of this manual will subject such unauthorized user to civil and criminal penalties as provided by the United

States Copyright Laws.

© 1990 Agri-Fab, Inc.

Loading...

Loading...