Version:20160722

2

Material Applications:

* Automotive renish

* Architectural

* Marine

* Industrial

* Aerospace

* Wood

* Plastic

On-off switch

Speed control knob

Carry HandlePattern adjuster

Vent tube

Air cap

Needle & Nozzle

Trigger

Cup Latch

Paint cup

Quick-release hose

coupling-Gun

Filter compartment

Fluid flow control knob

Quick-release hose

coupling-Turbine

Hose

Voltage See machine nameplate

Power Input 1400W

Turbine 3 stage

Airow 2800 l/min

Max Working Pressure 0.41 bar (6 psi)

Turbine Dimensions (LxWxH) 325mm x 250mm x 325mm

Net Weight 8.5 kg ( 18.7 Lbs)

3

GENERAL SAFETY RULES

WARNING! Read and understand all

instructions. Failure to follow all instructions

listed below may result in electric shock, re

and / or serious personal injury. The term “power

tool” in all of the warnings listed below refers to

your mains-operated (corded) power tool.

SAVE THESE INSTRUCTIONS.

WORK AREA

1. Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

2. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquid, gases, or dust. Power

tools create sparks which may ignite the dust

or fumes.

3. Keep bystanders, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

1. Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce the risk of

electric shock.

2. Grounded tools must be plugged into an

outlet properly installed and grounded in

accordance with all codes and ordinances.

Never remove the grounding prong or

modify the plug in any way. Do not use

any adaptor plugs. Check with a qualified

electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools

should electrically malfunction or break down,

grounding provides a low resistance path to

carry electricity away from the user.

3. Avoid body contact with grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

4. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

5. Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep the cord away from heat,

oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged or

entangled cords increase the risk of electric

shock.

6. When operating a power tool outdoors,

use an outdoor extension cord suitable

for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

PERSONAL SAFETY

1. Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use tool while you are tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

2. Use safety equipment. Always wear eye

protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

3. Avoid accidental starting. Ensure the switch

is in the off position before plugging in.

Carrying tools with your nger on the switch

or plugging in tools that have the switch on

invites accidents.

4. Remove adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the tool may

result in personal injury.

5. Do not overreach. Keep a proper footing

and balance at all times. This enables better

control of the power tool in unexpected

4

situations.

6. Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in

moving parts.

7. If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of these devices can reduce dust-

related hazards.

POWER TOOL USE AND CARE

1. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

2. Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

3. Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

4. Store idle tools out of reach of children and

do not allow persons unfamiliar with the

power tool or these instructions to operate

the power tool. Power tools are dangerous in

the hands of untrained users.

5. Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may aect the power tool’s operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

6. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

7. Use the power tool, accessories and

tool bits etc., in accordance with these

instructions and in the manner intended

for the particular type of power tool, taking

into account the working conditions and

the work to be performed. Use of the power

tool for operations different from intended

could result in a hazardous situation.

SERVICE

Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

If the supply cord of this power tool is damaged

it must be replaced by a specially prepared cord

available through the service organization.

Symbols used in this manual

V…….......volts

A…….......amperes

Hz……......hertz

W……......watt

~………....alternating current

n

0

………..no load speed

min

-1

….....revolutions or reciprocation

per minute

......warning of general danger

.….class II tool

.…with electrical earth

.......read these instructions

......always wear eye protection

......always wear a dust mask.

.....always wear hearing protection

.....wear safety-approved hard hat

do not dispose of electric tools,

accessories and packaging together

with household waste material

5

SPECIFIC SAFETY RULES FOR HVLP

SPRAYERS

OBSERVE ALL WARNINGS!

WARNING: Do not use guns for spraying

ammable materials.

WARNING: Be aware of any hazards presented

by the material being sprayed, and consult

the markings on the material container or the

information supplied by the manufacturer of

the material to be sprayed.

WARNING: Do not spray any material where the

hazard is not known.

WARNING: Do not clean guns with flammable

solvents with a ash-point below 55°C.

NOTE: A non-ammable solvent is here dened

as one which has a ash-point above 55°C.

WARNING: This appliance cannot be used by

children under 18 years old or persons with

reduced physical, sensory or mental capabilities

or lack of experience or knowledge of the safe

operation of the appliance.

WARNING: Children may not play with this

appliance.

WARNING: Cleaning and user maintenance shall

not be made by children.

WARNING: This appliance shall be disconnected

from its power source during service and when

replacing parts. The plug must remain removed,

and must be removed in such a way that an

operator can check from any of the points to

which he has access that the plug remains

removed.

This equipment is for professional use only.

WARNING: FIRE AND EXPLOSION HAZARD.

Take all precautions to avoid sources of sparks

and ignition when spraying. Keep the machine

at least 8 meters away from the spraying

operation.

Wear Protective Equipment At All Times.

Always use a respirator, eye protection and

protective clothing and gloves.

CAUTION:

• Do not use the sprayer with flammable

paint.

• Do not use guns for spraying flammable

materials.

• Do not clean guns with flammable

solvents.

• Beware of any hazards presented by

the material being sprayed and consult

the markings on the container or the

information supplied by the manufacturer

of the material to be sprayed, including

requirements for the use of personal

protective equipment.

• Do not spray any material where the

hazard is not known

The appliance is not to be used by children or

persons with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge,

unless they have been given supervision or

instruction and children being supervised not to

play with the appliance.

EXPLOSION RISK FROM

HALOGENATED HYDROCARBON

SOLVENTS

Never use halogenated hydrocarbon solvents in

this machine. Contact with aluminum parts may

cause an explosion. Some of the most common

of these solvents are: Carbontetrachloride,

Chlorobenzene, Dichloroethane, Dichloroethyl

Ether, Ethylbromide, Ethylchloride, &

6

Tethrachloethane.

PREVENT STATIC SPARKING FIRE/

EXPLOSIONS

Vapors created when spraying can be ignited by

sparks. To reduce the risk of re, always locate the

turbine at least 20 feet (6 m.) away from spray area.

Do not plug in or unplug any electrical cords in the

spray area. Doing so can cause sparks which can

ignite any vapors still in the air. Follow the coating

& solvent manufacturers safety warnings and

precautions.

WARNING: Keep the turbine away from areas

with hazardous concentrations of flammable

vapors. NEVER operate with the turbine inside a

spray booth.

• NEVER point the spray gun at anyone or any

part of the body.

• NEVER put your hand or ngers over the uid

nozzle.

• NEVER try to stop or deect leaks with your

hand, body, or rag.

• NEVER alter equipment in any manner.

• NEVER smoke while in spraying area.

• NEVER spray highly ammable materials.

• NEVER use around children.

• NEVER allow another person to use sprayer

unless he is thoroughly instructed on its safe

use and given this operator’s manual to read.

• ALWAYS wear a spray mask/respirator, gloves

and protective eye wear while spraying.

• ALWAYS ensure re extinguishing equipment

is readily available and properly maintained.

ALWAYS INSPECT SPRAYING AREA

• Keep the spraying area free from obstructions.

• Make sure the spraying area has good

ventilation to safely remove vapors and mists.

• NEVER keep ammable material in spraying

area.

• NEVER spray in vicinity of open flame or

other sources of ignition.

• The spraying area must be at least 20 ft. away

from spray unit.

TOXIC FLUID HAZARD

• Hazardous fluid or toxic fumes can cause

serious injury or death if splashed in eyes

or on skin, inhaled or swallowed. Know the

hazards of the fluid you are using. Store

& dispose of hazardous fluid according

to manufacturer, local, state & national

guidelines.

• ALWAYS wear protective eyewear, gloves,

clothing and respirator as recommended by

uid manufacturer.

HOSES

Do not allow kinking or crushing of hoses or

allow it to vibrate against rough, sharp or hot

surfaces.

• NEVER use a damaged hose. Before each use,

check entire hose for cuts, leaks, abrasions,

or bulging. If any of these conditions exist,

replace the hose immediately.

GROUNDING

• Ground the sprayer & other components

in the system to reduce the risk of static

sparking, re or explosion which can result in

serious bodily injury and property damage.

For detailed instructions on how to ground,

check your local electrical code.

• ALWAYS ensure switch is in OFF position

before plugging unit in.

7

ALWAYS GROUND ALL OF THESE

COMPONENTS

1. Turbine: plug the power supply cord, or

extension cord, each equipped with an

undamaged three-prong plug, into a properly

grounded outlet. DO NOT USE AN ADAPTER.

Use only a 3 wire extension cord that has a

grounding plug, and a receptacle that will

accept the grounding plug on the product.

Make sure your extension cord is in good

condition. When using an extension cord, be

sure to use one heavy enough to carry the

current your product will draw. If in doubt,

use the next heavier gauge.

2. Hose: use only grounded hoses.

3. Spray gun: grounding is obtained through

connection to a properly grounded hose and

turbine.

• NEVER use cleaning solvents with ash points

below 140 degrees F. Some of these are:

acetone, benzene, ether, gasoline, naptha.

Consult your supplier to be sure.

FUNCTIONAL DESCRIPTION

This HVLP (High Volume, Low Pressure) turbine

uses a controlled cone of high volume, low

pressure air created by the gun which can spray

with very little waste and overspray. This high

efficiency delivery absolutely minimizes air

pollution emissions associated with paint spraying.

Media which are traditionally sprayed by high

pressure compressor driven paint sprayers can be

sprayed by this new technology. The paint drying

times are even quicker because the air from the

turbine is naturally warm.

UNPACKING AND ASSEMBLY

1. Remove all parts from the carton.

2. Check for any damage.

3. Attach the hose to the turbine.

4. Attach the hose to the gun.

PREPARATION

Prepare the paint solution

Strain the paint and all other media components

before you spray

Remember to use a slower drying reducer than you

would normally use with a conventional air sprayer.

The warm air of the turbine causes faster drying

times. Usually one step slower will do.

For Automotive finishes, reduce and catalyze

according to the paint manufacturer’s instructions,

just remember to use one step slower reducer.

For Industrial finishes, reduce and catalyze

according to the paint manufacturer’s instructions.

If there are no reduction instructions, add reducer

step by step untill the proper consistency is found.

Droplets off the stir stick should be about one

second apart.

WARNING:

Universal motors, like the one used in this

turbine, by their nature create sparks at the

commutator. Whenever spraying flammable

media, keep the turbine at least 6 meters (20

feet) away from the spraying area.

OPERATION

1. Ensure that all protective clothing and safety

devices are in place and Fill the paint cup.

2. Allow the turbine to warm up by turning it on

for a few minutes before beginning spraying.

(This will make adjusting the gun easier).

3. Adjust the gun on a test surface, then begin

spraying

8

CHOOSING FLUID SETS

The fluid set includes a Needle, a Nozzle and an

Air Cap. These parts are a matched set. Do not mix

parts from other sizes. The standard uid set which

comes with the gun is a 1.3mm, which will work

well for most applications.

Different sizes of fluid set will give different flow

rates. A more viscous uid will need a larger size. A

thinner uid will need a smaller size.

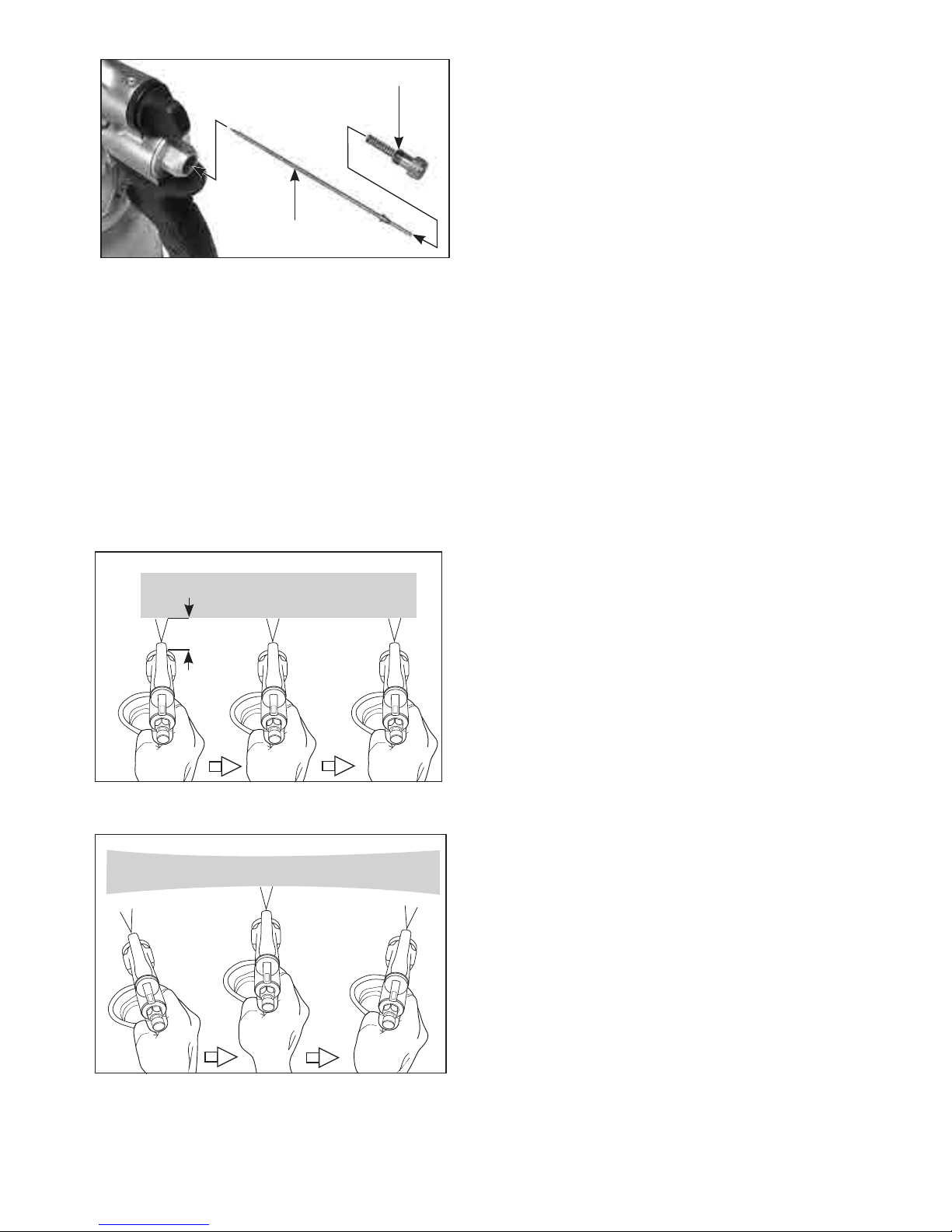

TO CHANGE TO A DIFFERENT FLUID

SET

1. Loosen and remove the Air Cap.

2. Unscrew and remove the Nozzle. Whenever

tightening or loosening the nozzle, pull the

trigger all the way and hold it to prevent

damage to the seating surfaces of the Needle

and Nozzle.

3. Unscrew the Fluid Control Knob all the way

and remove it, together with the spring.

4. Pull out the Needle through the back of the

Gun.

5. Replacement is the opposite of removal.

ADJUSTING THE GUN

The gun will normally need to be adjusted before

each use. This is similar to tuning a musical

instrument before playing it.

1. First adjust the Fluid Flow Control Knob. Turn

anti-clockwise for more fluid, clockwise for

less fluid. A good starting point would be

about 2-1/2 turns out from closed.

2. Test the spray pattern and atomization on a

test piece. Hold about 20cm (8 inches) away.

Turn the Pattern Adjustor knob for the desired

pattern.

3. Adjust the Speed Control knob on the turbine

to control the air volume. Generally, it is best

to use the minimum air volume which will

achieve satisfactory atomization. The point

is to get the droplet size as small as possible

while still having the desired coverage.Too

much air will only cause overspray mist and

waste paint. If the Speed Control knob is at

maximum and the atomization is still not

satisfactory, the atomization can also be

controlled by thinning the paint. One can also

use a different fluid set ( the needle, nozzle

and air cap).

Fluid flow control knob

Pattern adjuster

On-off switch

Speed control knob

Air cap Nozzle

Trigger

Retaining ring

9

CLEAN-UP

Always clean the gun at the end of the day or

between colors

1. Using a rag moistened with a compatible

solvent, clean the cup and the outside of the

gun.

2. Remove the Air Cap, Baffle and Nozzle and

clean with a cleaning brush. Take care to

avoid damage to the air cap holes.

3. Remove the needle and clean. Clean the paint

carrying orifices of the gun. Do not allow

solvent to enter the air carrying orifices of

the gun. Therefore point the gun down while

cleaning the paint orces.

Never soak the entire gun in solvent.

USING OPTIONAL REMOTE PRESSURE

POTS

The standard set-up of this gun is as an HVLP

turbine cup-feed gun. It is also possible to use

this gun and turbine with a remote pressure pot

(pressure feed set-up). All that is necessary is to

convert the gun. To convert:

1. Use an appropriate wrench to loosen the nut

to remove the paint cup.

2. Connect the hose from the pressure pot.

3. Use an appropriate wrench to unscrew the

nipple for the vent tube from the gun body.

4. Use a bolt with the correct thread to plug the

hole from the nipple.

PRESSURE RELIEF PROCEDURE

When using a pressure pot, the pot must always

be relieved of pressure before opening. To relieve

pressure:

1. Shut o the air supply to the pot.

2. Open the pressure relief valve on the pot.

SPRAYING TECHNIQUE

Keep the gun about 150 to 200mm away from the

surface. Do not swing the arm in an arc. Rather,

keep the gun perpendicular to the surface and

move in a parallel motion. Make sure the gun is

already in motion before triggering and release the

trigger while the gun is still in motion. Overlap 50%

with each stroke.

Fluid flow control knob

Needle

6 to 8 in

(150 to 200mm)

RIGHT

WRONG

10

MAINTENANCE

1. Keep the gun clean

2. Keep the inlet lters of the turbine clean.

Entrust repairs to a qualied service technician

11

WIRING

12

HVLP TURBINE EXPLODED VIEW

NO.01~68 G V2.0

20

54

53

52

51

50

30

31

272625

272625

29

29

28

24

31

30

33

32

34

43

44

48

20

36

23

21

20

42

18

13A

15

14

13B

15

14

13B

12

11

09

10

09

08

07

03

04

05

06

16

17

38

37

39

02

01

22

35

49

19

40

41

45

43-2

43-1

64

65

66

67

68-1

68-2

68-3

68-4

68-5

68-5

68-7

68-8

68-9

68A-6

68B-6

68

G

13

HVLP TURBINE PARTS LIST

NO. Parts Name Q'TY

1 HEX NUT-LEFT HAND THREAD M6 1

2 FAN 70 x 6 1

3 MOTOR HOUSING 1

4 BRUSH HOLDER 2

5 CARBON BRUSH 7 x 12 2

6 SCREW M4 x 12 4

7 STATOR 1

8 STATOR SCREW M5 x 60 2

9 BEARING 6200 LLU 2

10 ARMATURE 1

11 MOTOR FRONT COVER 1

12 SPACER-LARGE 1

13A TURBINE IMPELLER 1

13B TURBINE IMPELLER 2

14 EXHAUST HOUSING 2

15 SPACER 2

16 FLAT ALUMINUM WASHER 8 x 23 x 2 1

17 HEX NUT M8 1

18 INTAKE HOUSING 1

19 SOUND DEADENING-MOTOR 10 x 190 x 580 1

20 SCREW M4 x 10 12

21 MOTOR VENT 1

22 SOUND DEADENING-RH 20 x 130 x 140 1

23 CASING-RH 1

24 SCREW M6 x 200 4

25 SCREW M6 x 25 4

26 FLAT WASHER Ø6 x Ø13 x 1 4

27 FOOT 4

28 SCREW M4 x 16 2

29 SCREW M5 x 8 4

30 HANDLE BRACKET 2

31 SCREW M4 x 16 10

32 CARRY HANDLE 1

33 SCREW M6 x 20 2

34 BODY 1

35 SOUND DEADENING-LOWER 10 x 170 x 215 1

36 BOTTOM PLATE 1

NO. Parts Name Q'TY

37 POWER SUPPLY CORD 1

38 SCREW M4 x 16 2

39 CORD CLIP 1

40 SUN WASHER M5 1

41 NUT M4 x 8 2

42 CORD ARMOR 1

43 OVERLOAD UNIT 1

43-1 FLAT WASHER Ø7 x Ø12 x 0.5 1

43-2 NUT 9.9 x Ø6.3 x 2 1

43 OVERLOAD UNIT 1

43-1 FLAT WASHER Ø7 x Ø12 x 0.5 1

43-2 NUT 9.9 x Ø6.3 x 2 1

44 SWITCH 1

45 SWITCH BOOT 1

46~47 N/A -

48 SPEED CONTROL DIAL 1

49 SOUND DEADENING-LH 10 x 180 x 220 1

50 CASING-LH 1

51 PLEATED MAIN FILTER 1

52 FILTER FRAME 1

53 FOAM FILTER 20 x 160 x 260 1

54 FILTER VENT 1

55~63 N/A -

64 BLEEDER TUBE 5 x 8 x 150mm 1

65 SCREW M4 x 55 4

66 SET SCREW M4 x 4 1

67 TERMINAL 2

68B AIR HOSE ASSY. -TRANSPARENT 1

68-1 EXTERNAL CIRCLIP S-48 1

68-2 QUICK RELEASE COLLAR 1

68-3 SPRING Ø2.2 x Ø49 x 4T x 40L 1

68-4 SPRING SEAT Ø36.5 x Ø40.5 x 2 1

68-5 CHECK BALL Ø5 4

68B-6 HOSE - CLEAR 6M 1

68-7 SPRING Ø1.7 x Ø26 x 5T x 25L 1

68-8 QUICK RELEASE COLLAR 1

68-9 EXTERNAL CIRCLIP S-26 1

GUN ASSY. (w/ 1.3 NOZZLE) 1

GUN ASSY. (w/ 1.8 NOZZLE) 1

GUN ASSY. (w/ 2.0 NOZZLE) 1

GUN ASSY. (w/ 0.8 NOZZLE)(PLASTIC CUP) 1

14

HVLP GUN EXPLODED VIEW

NO.G1~G42 V1.5

B

A

B

A

G4

G3

G5

G12

G13

G21

G22

G23

G25

G26

G27

G28

G29

G30

G35G34

G33

G36

G39

G38

G37

G40

G14A

G42

G41

G6A

G19

G20

15

HVLP GUN PARTS LIST

No. Parts Name Q'TY

G1~G2 N/A -

G3 NOZZLE PLATE 1

G4 GUN BODY 1

G5 SOCKET SET SCREW 1

G6A PATTERN ADJUSTING ASSEMBLY 1

G6~G11 N/A -

G12 NEEDLE SPINDLE 1

G13 SPRING 1

G14A SEAL ASSEMBLY 1

G14~G18 N/A -

G19 NEEDLE SPRING 1

G20 FLUID CONTROL KNOB 1

G21 GRIP 1

G22 AIR PIPE 1

G23 AIR INLET NIPPLE 1

G24 N/A -

G25 PACKING 1

G26 PACKING NUT 1

G27 FLUID INLET 1

G28 TRIGGER STUD 1

G29 E-CLIP 1

G30 TRIGGER 1

G31~32 N/A -

G33 VENT TUBE ASSEMBLY 1

G34 CLEANING BRUSH 1

G35 MULTI-PURPOSE WRENCH 1

G36 NOZZLE PLATE SEAL 1

G37 WASHER 1

G38 GASKET 1

G39 GASKET 1

G40 L-FITTING 1

G41 AIR NOZZLE SET 0.5mm 1

G42 AIR NOZZLE SET 0.8mm 1

G43 AIR NOZZLE SET 1.0mm 1

G44 AIR NOZZLE SET 1.2mm 1

G45 AIR NOZZLE SET 1.3mm 1

G46 AIR NOZZLE SET 1.8mm 1

G47 AIR NOZZLE SET 2.0mm 1

G48 AIR NOZZLE SET 2.5mm 1

G49 PAINT CUP ASSEMBLY 1

Loading...

Loading...