Page 1

Agilent AN 372-2

Battery Testing

Application Note

An electronic load can be used to discharge batteries of various

chemistries to determine actual capacity, capacity retention,

and internal impedance.

Page 2

2

Increasing demand for portable DC

power has risen from improvements

in battery and motor design technology. More than ever before, portable

DC powered products have become

available in many diverse applications.

Rechargeable batteries appear in all

types of products from analytical

electronic equipment to power tools

and toys. In some instances, these

diverse applications pose different

requirements on the source of DC

Power. Fortunately, availability of

many types of battery chemistries

yield unique characteristics. Table 1

contains just some of the different

battery types and their advantages.

Whether testing batteries in R&D or

production environments, the test

requirements for each of the different

battery types are basically the same.

Figure 1 shows a common test configuration. In general, the testing of a

battery involves discharging it over

a period of time to determine several

specifications. This application note

will concentrate on the test of secondary batteries because they require

additional tests involving recharging.

Nickel-cadmium batteries, in particular, are discussed because they are

the most universally used type of

secondary battery in today’s demanding applications.

Introduction

Table 1. Characteristics and Applications of Different Battery Types

Nickel- Gelled Lead Lithium Carbon Alkaline Silver Mercuric

Cadmium Acid Zinc Oxide Oxide

Volts/Cell 1.2 2.0 1.5 to 1 1.5 1.5 1.5 1.4

Applications portable standby service, memory backup, average use good general button-sized button-sized cells

equipment, rechargeable pacemakers, purpose battery cells for watches for watches and

rechargeable electronic and hearing aids hearing aids

door locks,

emergency

locator

transmitters

Charge CC CV, float charge N/A N/A N/A N/A N/A

Method

Cycle Life 500+ cycles 200 cycles N/A N/A N/A N/A N/A

Life 3 mos. 1 year 5 to 10+ years 1 to 5 years 5% loss/yr. 6% loss/yr. 4% loss/yr.

(Charged) (–2%/day)

Operating 20°C to 70°C –20°C to 65°C –55°C to 75°C –5°C to 55°C –30°C to 55°C –20°C to 55°C –10°C to 55°C

Temp.

Performance high discharge high capacity flat discharge, low cost, good energy flat discharge, flat discharge

Comments rate, quick long life, wide sloping density, more energy

charge rate temperature discharge, sloping per unit

range, good low energy discharge volume than

energy density density mercuric oxide

Figure 1. Common Test Configuration

Page 3

3

Seven standard test procedures1are

used to verify certain electrical characteristics of secondary batteries:

1. Rated capacity

2. Capacity retention

3. Effective internal resistance

4. Discharge rate effect on capacity

at –20°C

5. Discharge rate effect on capacity

at 23°C

6. Life cycle performance

7. Extended overcharge

Other miscellaneous tests and procedures also involve discharging a

battery such as: start-up voltage test,

forced-discharge test, timed fast charge

and dump-timed charge. Most battery

tests typically require only about 1%

accuracy unless otherwise specified.

While battery tests do not require

high accuracy, the tests must be very

repeatable. Battery characteristics

change with temperature so it is

important to be able to control and

monitor the temperature, usually to

within ±2 degrees C. Other equipment

requirements to consider are: a current source for charging secondary

batteries, a voltage monitor, a current

monitor, a load for discharge current,

and a time keeping device. More

information about test equipment

is given in the “Test Equipment

Requirements” section later in

this application note.

Note that a battery temperature rise

of more than 5 degrees C above ambient may require supplemental cooling

to prevent battery performance degradation due to elevated temperatures.

1. As specified in ANSI® C18.2-1984,

American National Standards

Rated Capacity

The principal measurement of a

battery’s performance is its rated

capacity. Capacity ratings are attained

in an accelerated test approximating

the battery’s capacity in typical use.

The capacity of a fully charged battery,

at a fixed temperature, is defined as

the product of the rated discharge

current (in amperes) and the discharge

time (in hours) to a specified minimum termination voltage (volts).

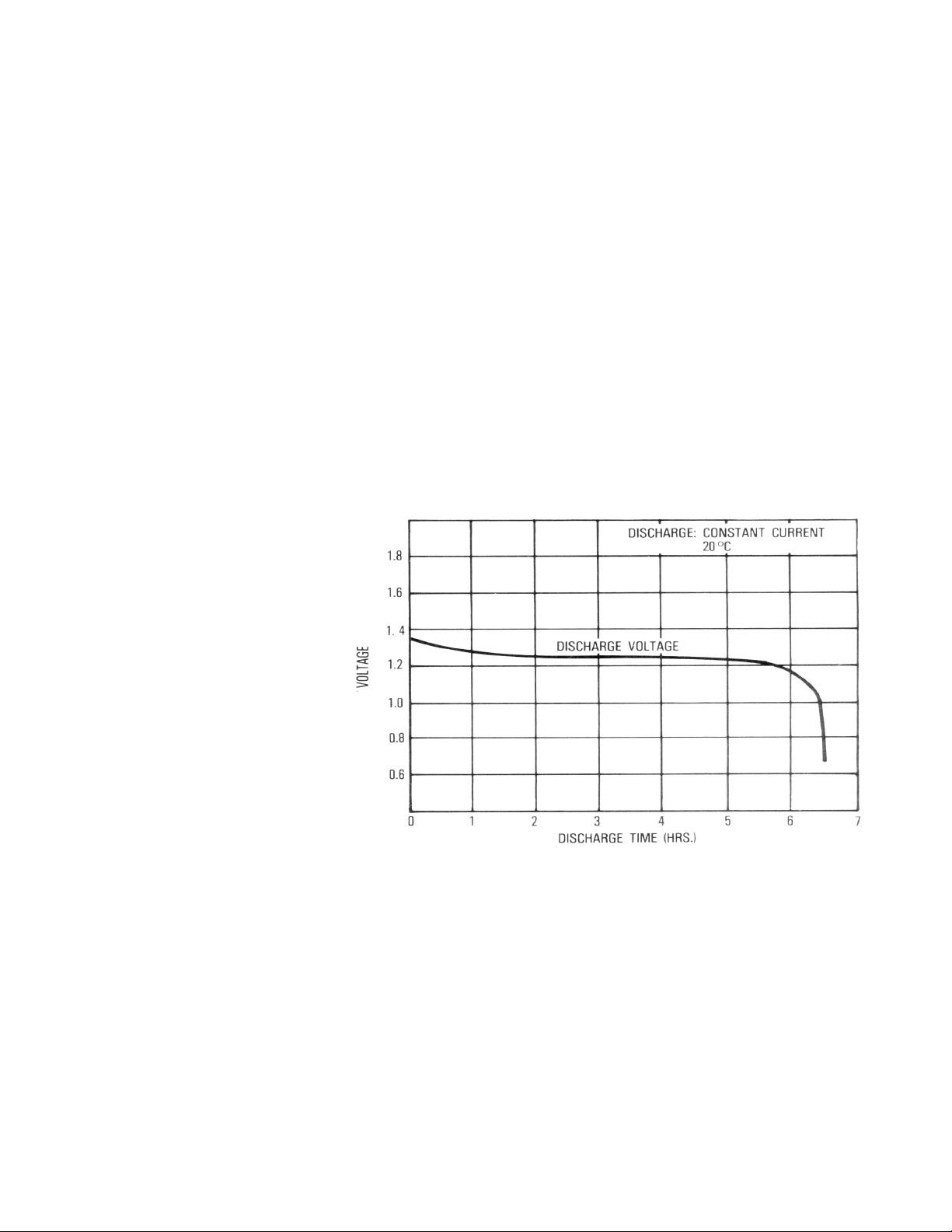

See Figure 2. A battery is considered

completely discharged when it attains

the specified minimum voltage called

the “end of discharge voltage” (EODV).

The EODV for nickel-cadmium batteries

is typically 1.1 to 0.9 Volts.

The term C, or C-rate, is used to

define the discharge current rate (in

amperes), and is numerically equal

to rated capacity, which is expressed

in ampere-hours. The term 1C is

defined as the rate of discharge that

allows a battery to provide its rated

current over a period of one hour.

Application Overview and Test Implementation

Figure 2. Typical Discharge Curve

Page 4

4

Capacity varies with the rate of discharge as shown in Figure 3. Testing

for how discharge rate affects capacity

is discussed later in more detail.

Generally, lower discharge rates over

longer periods of time yield higher

values of total capacity. It is important to realize that since discharge

rate affects how the value of C is

determined, battery manufacturers

must decide on a standard time of

discharge. Since different values for

capacity can be obtained for the same

battery, capacity is generally determined over a “standard” period of

time— from 5 to 20 hours at discharge

rates from C/5 to C/20. A complete

specification for capacity should

therefore have a C rate and the period

of time that was used to determine

the capacity. For example, Capacity:

450 mAh @ 5 hour rate.

Average and maximum capacities are

obtained by putting the battery through

five successive charge/discharge stabilizing cycles. The batteries are given

five stabilizing cycles where they are

charged, discharged and rested at an

ambient temperature of 23 degrees C.

Batteries are charged at C/10 A for

a period of from 20 to 24 hours and

rested for a period of from 2 to 4 hours.

The batteries are then discharged at

a constant current of 1C amperes to

an EODV of 0.9 volts.

The value of the capacity used in the

following tests is the value obtained

in the fifth stabilizing cycle. Also, the

capacity obtained in the last three

cycles must not be less than that

stated by the manufacturer as rated

capacity (1C).

Capacity Retention

This test characterizes how much of a

fully charged battery’s capacity is

retained over a long period of time

under specific conditions. This time

is sometimes referred to as the “shelf

life” of the battery. This test is not to

be confused with an attempt to characterize the self-discharge effect of

the spontaneous internal chemical

actions in batteries. Self-discharge

occurs regardless of the battery’s

connection to an external circuit.

The procedure to determine the effective capacity retention of a battery is

relatively simple. Immediately following the 5 cycles of capacity measurement, the battery is fully recharged. It

is then stored open circuit for a period of days at a specific temperature.

Then it is discharged at a constant

current rate to an EODV of 0.9 V as

before. The capacity obtained should

not be less than 37% of the rated

capacity for the battery. The number

of days of shelf life are typically provided for values of temperature from

23 degrees C to 50 degrees C.

Figure 3. Effect of Discharge Rate on Capacity

Page 5

5

Effective Internal Impedance

Battery impedance is dependent

on temperature, its state of charge,

and the load frequency. The effective

internal impedance is lower for a fully

charged battery than it is for a discharged one. Having a low internal

resistance is very important when the

battery must support a high current

for a short time. Low temperature, use,

and long storage periods all increase

a battery’s internal resistance. Nickelcadmium batteries also have a high

effective capacitance. Their total effective impedance is so low that, in

applications where they are continuously being “trickel-charged” at rates

from 0.01C to 0.1C, they make excellent ripple filters. Resistance and

impedance tests are explained in the

following paragraphs.

Resistance Test

The battery must be fully charged as

outlined above. Batteries rated 5 Ah or

less are discharged at 10C for 2 minutes and then switched to 1C. The

battery voltage is recorded just prior

to switching and again upon reaching

its maximum value after switching.

All voltage measurements are made at

the terminals of the battery independently of the contacts used to carry

current. The effective internal resistance (R

e

) is then calculated as follows:

R

e

=

∆V

=

VL–V

H

∆

I =IH–IL

I

H, VH = the current and voltage,

recorded just prior

to switching

I

L, VL = the current and maximum

voltage, recorded

after switching

Impedance Test

The battery must be fully charged as

outlined above. An AC current source

(~1 kHz) is applied to the terminals of

the battery. The AC current through

the battery and the voltage across it

are measured. The impedance is simply

calculated as V/I. An interesting

alternative testing method that yields

the same result is to place a varying

(~1 kHz) load across the fully charged

battery instead of the AC power source.

Discharge Rate Effect on Capacity

The rate of discharge has an effect on

the total capacity of a battery. Heavy

discharge rates decrease the total

available capacity of a battery. The

test is done at two temperatures:

–20 degrees C and 23 degrees C.

The battery is first fully charged at

23 degrees C and then immediately

stored for 24 hours at an ambient

temperature of –20 degrees C. It is

then discharged at an ambient temperature of –20 degrees C at a constant current rate of 1C to an EODV

of 0.8 volts. Then the procedure is

repeated at discharge rates of 5C and

C/5. The whole test is then repeated

at a temperature of 23 degrees C to

an EODV of 0.9 volts.

For each of the six discharge cycles,

the manufacturer supplies the value of

capacity to be expected as a percent of

C1. Charging and discharging at temperatures below the specification sheet

recommendation should be avoided.

Life Cycle Performance

Life cycle testing is a measure of

expected battery performance in actual

service. Life cycle performance is

characterized by dynamically loading

the battery in a simulated “real-life”

situation for 50 or more charge and

discharge cycles as follows:

The battery is given five stabilizing

cycles in accordance with the previously outlined procedure.

Life Cycles 1 through 48

1. Charge 11 hours and

20 minutes at C/10

2. Discharge immediately at

1C for 40 minutes

3. No rest

Life cycles 49 and 50

1. Charge for 20 hours at C/10

2. Rest 2 to 4 hours

3. Discharge at 1C to 0.9 volts

EODV

Repetition of Life Cycles

Repeat cycles 1 to 50 as desired.

The capacity at cycle 50, and multiples

thereof, should be no lower than that

stated for this procedure by the manufacturer.

Extended Overcharge

The ability of a battery to withstand

overcharge is determined by charging

the battery at a constant current of

C/10, or at the maximum overcharge

rate recommended by the manufacturer, at an ambient temperature of

23 degrees C for 6 months. The battery should at no time show either

electrolyte leakage or visual evidence

of distortion beyond the standard

maximum dimensions for that battery. When discharged at a constant

current of 1C to an EODV of 0.9V, the

battery should have a capacity equal

to or greater than the extended overcharge capacity specification.

Page 6

6

Miscellaneous Tests

In addition to the tests already mentioned, there are also other miscellaneous tests performed on nickelcadmium batteries. These tests usually

involve high rate charge and/or

discharge.

High rate discharge and charge of

nickel-cadmium batteries is possible

with today’s new and better designed

cells having advanced plate and cell

construction. The low internal resistance of nickel-cadmium batteries

yields high discharge currents. If they

are discharged continuously under

short circuit conditions, however,

self-heating may do irreparable damage. Continuous discharge at rates

greater than 1C should be prevented

to avoid potentially hazardous conditions due to high internal gas pressure build-up.

Very high currents (>2C) can be withdrawn in low duty cycle pulses providing that internal temperatures and

pressures are maintained. Output

capacity in any type of pulse discharge

application is difficult to predict

because of the infinite number of

possible combinations of discharge

time, rest time, and EODV. Simulation

of actual events, as in the Life-Cycle

test, is the best way to quantify a

battery exposed to such conditions.

Many cells can be quick-charged at a

rate up to C/3 in as little as 3 to 5 hours

instead of the standard 12 to 15 hours

at the C/10 rate. High rate charging

should be done under controlled conditions where temperature, voltage,

pressure, or some combination of

these parameters can be monitored to

assure they are within specifications.

One fast-charge method involves

charging the battery at a rate exceeding the specified maximum charge rate

for a finite period of time, after which

the charge rate is reduced to currents

below C 10. This method, called “timed

fast charge,” can indeed give a quick

“boost” charge to a partially discharged

battery, but unfortunately has the

potential of permanently destroying

the battery. The destruction occurs

due to overcharging the battery because its unused capacity is unknown

prior to charging.

A safer variation of the timed fast

charge method is called “dump timedcharge” where the battery is first

fully discharged (“dumped”) to its

EODV before recharging via the “timed

fast charge” method. The “dump

timed-charge” method has the advantage of knowing just how much energy

must be pumped back into the battery

to bring it to full capacity; the risk of

overcharging is therefore eliminated.

One final test, called the “forced discharge test,” determines the safety of

a battery under certain abusive conditions. This test is very dangerous

because, during the test, the battery

is very likely to explode. The test

must be done under extremely well

controlled conditions in an explosion

proof safety chamber to prevent personal injury. The test involves connecting a current source in series

with the battery. The polarity is in

the same direction as normal or short

circuit current flow. See Figure 4. The

current source is set to a value such

that the resultant current flow is

greater than the short circuit current

flow. This test simulates what may

happen if a battery were improperly

installed in a circuit where it may not

be the only source in the application.

Ideally the battery should withstand

the stress, with some degree of margin,

when the test currents are similar to

actual conditions.

Figure 4. Forced Discharge

Page 7

7

From the various tests described

so far, we can see some common

requirements for test equipment. All

the tests require a discharge cycle

using a constant current. A constant

discharge current cannot be attained

with a simple resistor because the

battery voltage changes as current is

drawn from it. An active device is

required, such as an electronic load

with a constant current mode of

operation. Also note that, because

many levels of constant current are

used from test to test, you should be

able to control the electronic load

dynamically as the test demands.

The ability to control the load with a

computer is important because discharge is typically over a long period

of time and, if the test were not automated, constant attendance would be

an unproductive use of an operator’s

time. Long term tests also bring about

another requirement: reliability. The

electronic load must be very reliable

because, if it should fail, the test

would take a long time to repeat.

In battery or single cell testing the

electronic load only has to function

down to the EODV, not zero volts. See

Figure 5. If the minimum load operating voltage is above the EODV for the

battery being tested, two alternatives

are available: stack more than one

battery in series until the required

voltage is reached (Figure 6) or place

a DC power supply (of sufficient voltage and current) in series with the

battery (Figure 7). A power supply

applied in this way is sometimes

called an “offset supply.”

Figure 5. Single Battery Test Configuration

The first alternative (Figure 6) requires

a method of scanning the voltage of

each battery in the stack so that when

any one battery reaches its EODV,

either the test can be halted or the

battery switched out of the circuit

and replaced by a short circuit. Even

as each battery is switched out of the

circuit, the discharge current will

remain the same if the load has a

constant current mode of operation.

Figure 6. Batteries in Series

The second alternative (Figure 7) shows

that using a power supply may be more

desirable because timed fast charge,

dump-timed charge, and forced discharge tests all require a DC power

source anyway. Additionally, a constant current power supply could then

be used to test ampere-hour efficiency

of secondary batteries. This rating is

simply the ratio of the ampere-hours

delivered during discharge to the

ampere-hours required to restore the

initial state of charge to the battery.

Figure 7. Using an Offset DC Power Supply

Voltage and current must be monitored throughout all the tests because

actual battery voltage varies with the

battery chemistry as well as the discharge rate involved. Therefore, a

voltmeter and ammeter are required.

They should be computer controlled

so that the various tests can be halted

when the EODV is reached. If an

ammeter is unavailable, a current

shunt can be used in conjunction with

either a second voltmeter or a scanner.

Test Equipment Requirements

Page 8

Agilent Technologies Electronic

Loads are ideally suited for battery

test applications. Their many features

make the test system easy to configure and provide safe, reliable, and

repeatable operation.

The Agilent 6060A Electronic Load

and 6050A Electronic Load mainframe

have the required constant-current

modes as well as constant-resistance

and constant-voltage modes. Built-in

voltmeters and ammeters eliminate

the need for external meters and provide measurement accuracy which, in

most cases, greatly exceeds the 0.5 to

1% that is typically required.

These electronic loads can be controlled from their front panel, from

a computer via GPIB, or by a 0 to

10 volt analog signal. By varying the

analog control input (up to 10 kHz),

a battery’s effective internal impedance

can be easily measured. The electronic

load’s built-in GPIB interface makes it

simple to connect any computer that

supports GPIB. Agilent’s electronic

loads are not limited to just being

controlled over the bus. Measured

current, voltage, power and complete

status can also be read back over the

bus so that time consuming discharge

tests can be attended automatically.

Agilent’s electronic loads truly provide

a “One Box” solution.

Testing cells down to an EODV of

0.9 volts is easily done with the Agilent

6060A, 6063A, 60501A, 60502A,

60503A, or 60504A Electronic Loads.

While the operating characteristics

of these loads are guaranteed to meet

all specifications above 3 volts, the

DC operating characteristics extend

below 3 volts (see Figure 8). This figure

shows that at 0.9 volts the Agilent

6060A Electronic Load is capable of

reliably drawing up to 27 amperes.

That means an 80 Ah battery could

be discharged to an EODV of 0.9 volts

at a discharge rate of C/3. For applications requiring V/I characteristics

below the operating curve of Figure 8,

Agilent offers a full family of DC power

supplies to be used as an offset supply.

Agilent’s full featured Electronic Load

Family offers quality and reliability

backed with a three year warranty.

Refer to the 1990/91 DC Power Supply

Catalog with Electronic Loads (Part

Number 5952-4203) for more information about Electronic Loads.

By internet, phone, or fax, get assistance

with all your test and measurement needs.

Online Assistance

www.agilent.com/find/assist

Phone or Fax

United States:

(tel) 1 800 452 4844

Canada:

(tel) 1 877 894 4414

(fax) (905) 206 4120

Europe:

(tel) (31 20) 547 2323

(fax) (31 20) 547 2390

Japan:

(tel) (81) 426 56 7832

(fax) (81) 426 56 7840

Latin America:

(tel) (305) 269 7500

(fax) (305) 269 7599

Australia:

(tel) 1 800 629 485

(fax) (61 3) 9210 5947

New Zealand:

(tel) 0 800 738 378

(fax) (64 4) 495 8950

Asia Pacific:

(tel) (852) 3197 7777

(fax) (852) 2506 9284

Product specifications and descriptions in this

document subject to change without notice.

Copyright © 1988, 1991, 2000 Agilent Technologies

Printed in U.S.A. 9/00

5952-4191

Battery Testing with Agilent Electronic Loads

Figure 8. Operating Characteristics of an Agilent Electronic Load

Loading...

Loading...