Page 1

Agilent Technologies 8920A

RF Communications Test Set

Programmer’s Guide

Firmware Version A.18.00 an d above

POWE

OF O

ANT INDUPLEX OUTRF IN/OUT

!

MAX POWER

!

MAX POWER 200

Agilent Part No. 08920-90220

Printed in U. S. A.

April 2000

Rev. B

USER

ASSIG

RELEA

SHIFT

k1’

k1

k2’

k2

k3’

k3

k4

k5

SCREEN CONTROL

CANCE

MIC/

REF

INCR

CONFIHELPMSSG HOLD PRINT

DUPLETXRX PREV TESTS

DATA FUNCTIONS

METER

AVG

INCR

INCR

LO HI

CURSOR CON-

PUSH TO

YES

ON/OFF

INSTRUMENT STATE

ADRS

SAVE

LOCAL

RECAL

DATA

789

456

123

_

+

0

NO

AUDIO SQUELCVOL-

MAX

!

MEAS

ENTER

dB

GHz

%

MHz

s

kHz

Hzms% Ωppm

AUDIO IN

!

PRESE

MEMO

LOHI

MAX

1

Page 2

© Copyright Agilent Technologies 1997, 2000

Notice No part of this manual may be reproduc ed in any form or by any means (i ncluding

electronic sto rage and retrie val or translat ion into a for eign language) wit hout prior

agreement and written consent from Agilent Technologies Inc. as governed by

United States and international copyright laws.

The material contained in this document is subject to change without notice.

Agilent Technologies makes no warranty of any kind with regard to th is material,

including, but not limit ed to, the implied war ranties of merc hantabil ity and fi tness

for a particular purpo se. Agilent Technologies Inc. shall not be liable fo r errors

contained herein or for inciden tal or conseque ntial damages in connection wi th the

furnishing, performance, or use of this material.

U.S. Government users will receive no greater than Limited Rights as defined in

FAR 52.227-14 (June 1987) or DFAR 252.227-7015 (b)(2) (November 1995), as

applicable in any technical data.

Agilent Technologies

Learning Products Department

24001 E. Mission

Liberty Lake, WA 99019-9599

U.S.A.

Edition/Print Date All Editions and Updates of this manual and their creation dates are listed below.

Rev. A . . . . . December 1997

Rev. B . . . . . April 2000

2

Page 3

Safety Summary The following general safety precautions must be observed during all phases of

operation of this instrument. Failure to comply with these precautions or with

specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. Agilent Technologies Inc.

assumes no liability for the customer’s failure to comply with these requirements.

GENERAL

This product is a Safety Class 1 instrument (provided with a protective earth

terminal). The protectiv e featur es of this pro duct may be impaire d if it is used in a

manner not specified in the operation instructions.

All Light Emitting Diodes (L EDs) used in this product are Clas s 1 LEDs as per IEC

60825-1.

This product has been designed and tested in accordance with IEC Publication

1010, "Safety Requirements for Electronic Measuring Apparatus," and has been

supplied in a safe condition. This ins tr uct io n documentation contains information

and warnings which must be followed by the user to ensure safe operation and to

maintain the product in a safe condition.

ENVIRONMENTAL CONDITIONS

This instrument is intended for indoor use in an installation category II, pollution

degree 2 environment. It is desi gned to operate at a maximum relative humi dity of

95% and at altitudes of up t o 2000 meters. Re fer to the s pecifications tables for the

ac mains voltage requirements and ambient operating temperature range.

V entilation Requirements: When installing the product in a cabinet, the convection

into and out of the product must not be restricted. The ambient temperature

(outside the cabinet ) must be l ess th an the maxi mum operat ing te mperatu re of t he

product by 4° C for every 100 watts dissipated in the cabinet. If the total power

dissipated in th e cabi net is gr eater than 8 00 watts , t hen for ced con vec tion mus t be

used.

BEFORE APPLYING POWER

Verify that the product is set to match the available line voltage, the correct fuse is

installed, and all safety precautions are taken. Note the instrument's external

markings described under Safety Symbols.

3

Page 4

GROUND THE INSTRUMENT

T o mi nimize s hock hazard , the inst rument chas sis and c over must be connec ted to

an electrical protective earth ground. The instrument must be connected to the ac

power mains through a grounded power cable, with the ground wire firmly

connected to an electrical ground (safety ground) at the power outlet. Any

interruption of the protective (grounding) conductor or disconnection of the

protective earth terminal will cause a potential shock hazard that could result in

personal injury.

FUSES

Only fuses with the requ ired rated current, voltage, and spe cified type (normal

blow , time de lay, etc.) should be used. Do not use repai red fuses or short-cir cuited

fuse holders. To do so could cause a shock or fire hazard.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

DO NOT REMOVE THE INSTRUMENT COVER

Operating personnel mus t not remove in strument cover s. Component repl acement

and internal adjustments must be made only by qualified service personnel.

Instruments that appear damaged or defective should be made inoperative and

secured against unintended operation until they can be repaired by qualified

service personnel.

WARNING: The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or

the like, which, if not correctly performed or adhered to, could result in personal

injury. Do not proceed beyond a WARNING sign until the in dicated conditions are

fully understood and met.

CAUTION: The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the

like, which, if not correctly performed or adhered to, could result in damage to or

destruction of part or all of the product. Do not proceed beyond a CAUTION sign until the

indicated conditions are fully understood and met.

4

Page 5

Safety Symbols

Caution, refer to accompanying documents

Warning, risk of electric shock

Earth (ground) terminal

Alternating current

Frame or chassis terminal

Standby (supply). Units with this s ymbol are not compl etely disco nnected from a c

mains when th is switch is off.

T o completely disconnec t the unit from ac mains, either disco nnect the power cord,

or have a qualified electrician install an external switch.

Product Markings CE - the CE mark is a registered trademark of the European Community. A CE

mark accompanied by a year indicated the year the design was proven.

CSA - the CSA mark is a registered trademark of the Canadian Standards

Association.

CERTIFICATION Agilent Technologies certifies that this product met its published sp ec if ications at

the time of shipment fr om the fac tory . Agilent T echnol ogies further cer tifies tha t its

calibration measurements are traceable to the United States National Institute of

Standards and Technology, to the extent allowed by the Institute’s calibration

facility, and to the calibration facilities of other International Standards

Organization members

5

Page 6

Agilent Technologies Warranty Statement for Commercial Products

Agilent Technologies 8920A RF Communications Test Set

Duration of

Warranty: 1 year

1. Agilent Technologies warrants Agilent Technologies hardware, accessories and

supplies against defects in materials and workmanship for the period specified above.

If Agilent Technologies receives notice of such defects during the warranty period,

Agilent Technologies will, at its option, either repair or replace products which prove

to be defective. Replacement products may be either new or like-new.

2 Agilent Technologies warrants that Agilent Technologies software will not fail to

execute its programming instructions, for the period specified above, due to defects in

material and workmanship when properly inst all ed and us ed. If Agil ent Technologies

receives notice of such defects during the warranty period, Agilent Technologies will

replace software media which does not execute its programming instructions due to

such defects.

3. Agilent Technologies does not warrant that the operation of Agilent Technologies

products will be uninterrupted or error free. If Agilent Technologies is unable, within

a reasonable time, to repair or replace any product to a condition as warranted,

customer will be entitled to a refund of the purchase price upon prompt return of the

product.

4 Agilent Technologies products may contain remanuf actured parts equ ivalent to new in

performance or may have been subject to incidental use.

5. The warranty period begins on the date of delivery or on the date of installation if

installed by Agilent Technologies. If customer schedules or delays Agilent

Technologies installation more than 30 days after delivery, warranty begins on the 31st

day from delivery.

6 Warranty does not apply to defects resu lting from (a) improper or inadequate

maintenance or calibration, (b) software, interfacing, parts or supplies not supplied by

Agilent Technologies, (c) unauthorized modification or misuse, (d) operation outside

of the published environmental specifications for the product, or (e) improper site

preparation or maintenance.

7 TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE WARRANTIES

ARE EXCLUSIVE AND NO OTHER WARRANTYOR CONDITION, WHETHER

WRITTEN OR ORAL IS EXPRESSED OR IMPLIED AND AGILENT

TECHNOLOGIES SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTIES

OR CONDITIONS OR MERCHANTABILITY, SATISFACTORY QUALITY, AND

FITNESS FOR A PARTICULAR PURPOSE.

6

Page 7

8. Agilent Technologies will be liable for damage to tangible property per incident up to

the greater of $300,000 or the actual amou nt pai d for the prod uct that i s the subject of

the claim, and for damages for bodily injury or death, to the extent that all such damages are determined by a court of competent jurisdiction to have been directly caused

by a defective Agilent Technologies product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS

WARRANTY STATEMENT ARE CUSTOMER’S SOLE AND EXCLUSIVE

REMEDIES. EXCEPT AS INDICATED ABOVE, IN NO EVENT WI LL AGIL ENT

TECHNOLOGIES OR ITS SUPPLIERS BE LIABLE FOR LOSS OF DATA OR FOR

DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDING LOST

PROFIT OR DATA), OR OTHER DAMAGE, WHETHER BASED IN CONTRACT,

TORT, OR OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW ZEALAND:

THE WARRANTY TERMS CONTAINED IN THIS STATEMENT, EXCEPT TO

THE EXTENT LAWFULLY PERMITTED, DO NOT EXCLUDE RESTRICT OR

MODIFY AND ARE IN ADDITION TO THE MANDATORY STATUTORY

RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

ASSISTANCE Product maintenance agreements and other customer assistance agreements are

available for Agilent Technologies products. For any assistance, contact your

nearest Agilent Technologies Sales and Service Office.

7

Page 8

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name:

Agilent Technologies

Manufacturer’s Address:

24001 E. Mission Avenue

Liberty Lake, Washington 99019-9599

USA

declares that the product

Product Name:

Model Number:

Product Options:

RF Communications T est Set / Cell Site Test Set

A g i l e nt Te c h n o l o gi e s 8 9 20 A , 8 92 0 B , a nd 8 92 1 A

This declaration covers all options of th e above

product.

conforms to the following Product specifications:

Safety: IEC 1010-1:1990+A1+A2/EN 61010-1:1993

EMC: CISPR 11:1990 / EN 55011:1991 Group 1, Class A

EN 50082 -1 : 1 9 9 2

IEC 801-2:1991 - 4 kV CD, 8 kV AD

IEC 801-3:1984 - 3V/m

IEC 801-4:1988 - 0.5 kV Sig. Lines, 1 kV Power Lines

Supplementary Information:

This is a class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

This product herewith complies with the requirements of the Low Voltage Directive

73/23/EEC and the EMC Directive 89/336/EEC and carries the CD-marking accordingly

Spokane, Washington USA November 20, 1998 Vince Roland/Quality Manager

8

.

Page 9

Table 1 Regional Sales Offices

United States of America:

Agilent Technologies

Test and Measurement Call Center

P.O. Box 4026

Englewood, CO 80155-4026

(tel) 1 800 452 4844

Japan:

Agilent Technologies Japan Ltd.

Measurement Assist ance Center

9-1 Takakura-Cho, Hachioji-Shi,

Tokyo 192-8510, Japan

(tel) (81) 456-56-7832

(fax) (81) 426-56-7840

Asia Pacific:

Agilent Technologies

24/F, Cityplaza One,

111 Kings Road,

Taikoo Shing, Hong Kong

Canada:

Agilent Technologies Canada Inc.

5150 Spectrum Way

Mississauga, Ontario

L4W 5G1

(tel) 1 877 894 4414

Latin America:

Agilent Technologies

Latin America Region

Headquarters

5200 Blue Lagoon Drive,

Suite #950

Miami, Florida 33126

U.S. A.

(tel) (305) 267 4245

(fax) (305) 267 4286

Europe:

Agilent Technologies

European Marketing Organization

P.O. Box 999

1180 AZ Amstelveen

The Netherlands

(tel) (3120) 547 9999

Australia/New Zealand:

Agilent Technologies

Australia Pty Ltd.

347 Burwood Highway

Forest Hill, Victoria 3131

Australia

(tel) 1 800 629 485

(fax) (61 3) 9272 0749

New Zealand

(tel) 0 800 738 378

(fax) (64 4) 802 6881

(tel) (852) 3197 7777

(fax) (852) 2506 9233

9

Page 10

Service and

Support

Table 2

Any adjustment, maintenance, or repair of this product must be performed by

qualified personnel. Contact your customer engineer through your local Agilent

T echnologies Ser vice Center . You can find a list of local service representat ives on

the Web at:

http://www.agilent-tech.com/services/English/index.html

If you do not have ac cess to the I nternet, one of these centers c an direct you t o your

nearest representative:

United States Test and Measu rement Call Center

(Toll free in US)

Europe

Canada

Japan Measurement Assistance Center

Latin America

Australia/New Zealand

Asia-Pacific

(800) 452-4844

(31 20) 547 9 900

(905) 206-4725

(81) 426 56 7832

|(81) 426 56 7840 (FAX)

(305) 267 4288 (FAX)

1 800 629 485 (Australia)

0800 738 378 (New Zealand)

(852) 2599 7777

(852) 2506 9285 (FAX)

10

Page 11

Manufacturer’s

Declaration

This statement is provi ded to co mply with the req uiremen ts of t he German Sou nd

Emission Directive, from 18 January 1991.

This product has a sound pressure emission (at the operator position) < 70 dB(A).

• Sound Pressure Lp < 70 dB(A).

• At Operator Position.

• Normal Operation.

• According to ISO 7779:1988/EN 27779:1991 (Type Test).

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

• Schalldruckpegel Lp < 70 dB(A).

• Am Arbeitsplatz.

• Normaler Betrieb.

• Nach ISO 7779:1988/EN 27779:1991 (Typprüfung).

In this Book Chapter 1, Using HP-IB, describes the general guidelines for using HP-IB and how to

prepare the Test Set for HP-IB usage. This chapter includes example programs for

controlling the basic functions of the Test Set.

Chapter 2, Methods For Reading Measurement Results, contains guidelines for

programming the test set for return ing measuremen t results. Topics discussed include how

to recover from a "hung" state when a measurement fails to complete. Sample code is

included.

Chapter 3, HP-IB Command Guidelines, contains information about sequential and

overlapped commands, command syntax, units of measure, and measurement states. A

short example program is also presented to familiarize the user wi th remote operation of

the Test Set.

Chapter 4, HP-IB Commands,

contains command syntax diagrams, equivalent

front-panel key commands, IEEE 488.2 Common Commands and triggering

commands.

Chapter 5, Advanced Operations, includes information about increasing measurement

throughput, status reporting, error reporting, service requests, instrume nt initialization,

and passing control.

Chapter 6, Memory Cards/Mass Storage, describes the types of mass storage (RAM

disk, ROM disk, external disk drives, SRAM cards, and ROM cards) and the file system

formats (DOS, LIF) available in the Te st Set.

11

Page 12

Chapter 7, IBASIC Controller, describes how to develop Instrument BASIC (IBASIC)

programs for use on the Test Set’s built-in IBASIC Controller. Topics discussed are:

interfacing to the IBASIC Controller using the serial ports, overview of the three program

development methods, ent ering and editing IBASIC programs , pro gram co nt rol us ing t he

PROGram Subsystem, and an i ntroduction to writin g programs for the TESTS subs ys t em.

Chapter 8, Programming the Call Processing Subsystem, describes how to control the

Test Set’s Call Processing Subsystem using the Call Processing Subsystem’s remote user

interface. Topics discussed are: accessing the Call Processing Subsystem screens,

handling error messages, controlling program flow using the Call Processing Status

Register Group, and how to query data messages received from the mobile station.

Example programs are provided showing how to control the Call Processing Subsystem

using service requests and register polling.

Error Message s describes the Text Only HP-IB Errors and the Numbered HP-IB Errors.

This section also describes other types of error messages that the Test Set displays and

where to find more information about those types of error messages.

12

Page 13

Contents

1 Using GPIB

Overview of the Test Set 26

Getting Started 34

Remote Operation 47

Addressing 49

IEEE 488.1 Remote Interface Message Capabilities 50

Remote/Local Modes 53

13

Page 14

Contents

2 Methods For Reading Measurement Results

Background 58

®

BASIC ‘ON TIMEOUT’ Example Program 60

HP

®

BASIC ‘MAV’ Example Program 64

HP

14

Page 15

Contents

3 GPIB Command Guidelines

Sequential and Overlapped Commands 70

Guidelines for Operation 71

15

Page 16

Contents

4 GPIB Commands

GPIB Syntax Diagrams 92

Adjacent Channel Power (ACP) 95

AF Analyzer 97

AF Generator 1 100

AF Generator 2 Pre-Modulation Filters 101

AF Generator 2/Encoder 102

Configure, I/O Configure 117

Call Processing 122

Decoder 141

Display 145

Measure 147

Oscilloscope 154

Program 159

Save/Recall Registers 160

RF Analyzer 161

RF Generator 163

Radio Interface 164

Spectrum A nalyzer 165

GPIB Only Commands 167

16

Page 17

Contents

Status 168

System 169

Tests 170

Trigger 173

Integer Number Setting Syntax 174

Real Number Setting Syntax 175

Multiple Real Number Setting Syntax 176

Number Measurement Syntax 177

Multiple Number Measurement Syntax 179

Equivalent Front-Panel Key Commands 180

IEEE 488.2 Common Commands 208

Triggering Measurements 224

17

Page 18

Contents

5 Advanced Operations

Increasing Measurement Throughput 234

Status Reporting 239

GPIB Service Requests 293

Instrument Initialization 303

Passing Control 313

18

Page 19

Contents

6 Memory Cards/Mass Storage

Default File System 324

Mass Storage Device Overview 325

Default Mass Storage Locations 331

Mass Storage Access 333

DOS and LIF File System Considerations 334

Using the ROM Disk 340

Using Memory Cards 341

Backing Up Procedure and Library Files 346

Copying Files Using IBASIC Commands 347

Using RAM Disk 349

Using External Disk Drives 351

19

Page 20

Contents

7 IBASIC Controller

Introduction 354

The IBASIC Controller Screen 355

Important Notes for Program Development 357

Program Development 358

Interfacing to the IBASIC Controller using Serial Ports 360

Choosing Your Development Method 373

Method #1. Program Development on an External BASIC Language

Computer 375

Method #2. Developing Progra ms on the Test Set Using the IBASIC

EDIT Mode 381

Method #3. Developing Programs Using Word Processor on a PC

(Least Preferred) 385

Uploading Programs from the Test Set to a PC 392

Serial I/O from IBASIC Programs 393

PROGram Subsystem 396

The TESTS Subsystem 419

20

Page 21

Contents

8 Programming the Call Processing Subsystem

Description of the Call Processing Subsystem’s Remote User

Interface 426

Using the Call Processing Subsystem’s Remote User Interface 429

Programming the CALL CONTROL Screen 439

Programming the CALL DATA Screen 464

CALL DATA Screen Message Field Descriptions 468

Programming the CALL BIT Screen 478

CALL BIT Screen Message Field Descriptions 487

Programming the ANALOG MEAS Screen 510

Programming the CALL CONFIGURE Screen 517

Example Programs 520

21

Page 22

Contents

9 Error Messages

22

Page 23

Contents

Index 569

23

Page 24

Contents

24

Page 25

1

Using GPIB

1. GPIB was formerly called HP-IB for Hewlett-Packard instruments. Some labels on

the instrument may still reflect the former HP

1

®

name.

25

Page 26

Chapter 1, Using GPIB

Overview of the Test Set

Overview of the Test Set

The Test Set combines up to 22 separate test instruments and an Instrument

BASIC (IBAS IC) Controller into one pack age. All of the Test Set’s functions can

be automatically controlled through application programs running on the built-in

IBASIC Controller or on an external controller connected through GPIB.

Developing programs for the Test Set is simplified if the programmer has a basic

understanding of how the Test Set operates. An overview of the Test Set’s

operation is best presented in terms of how information flows through the unit.

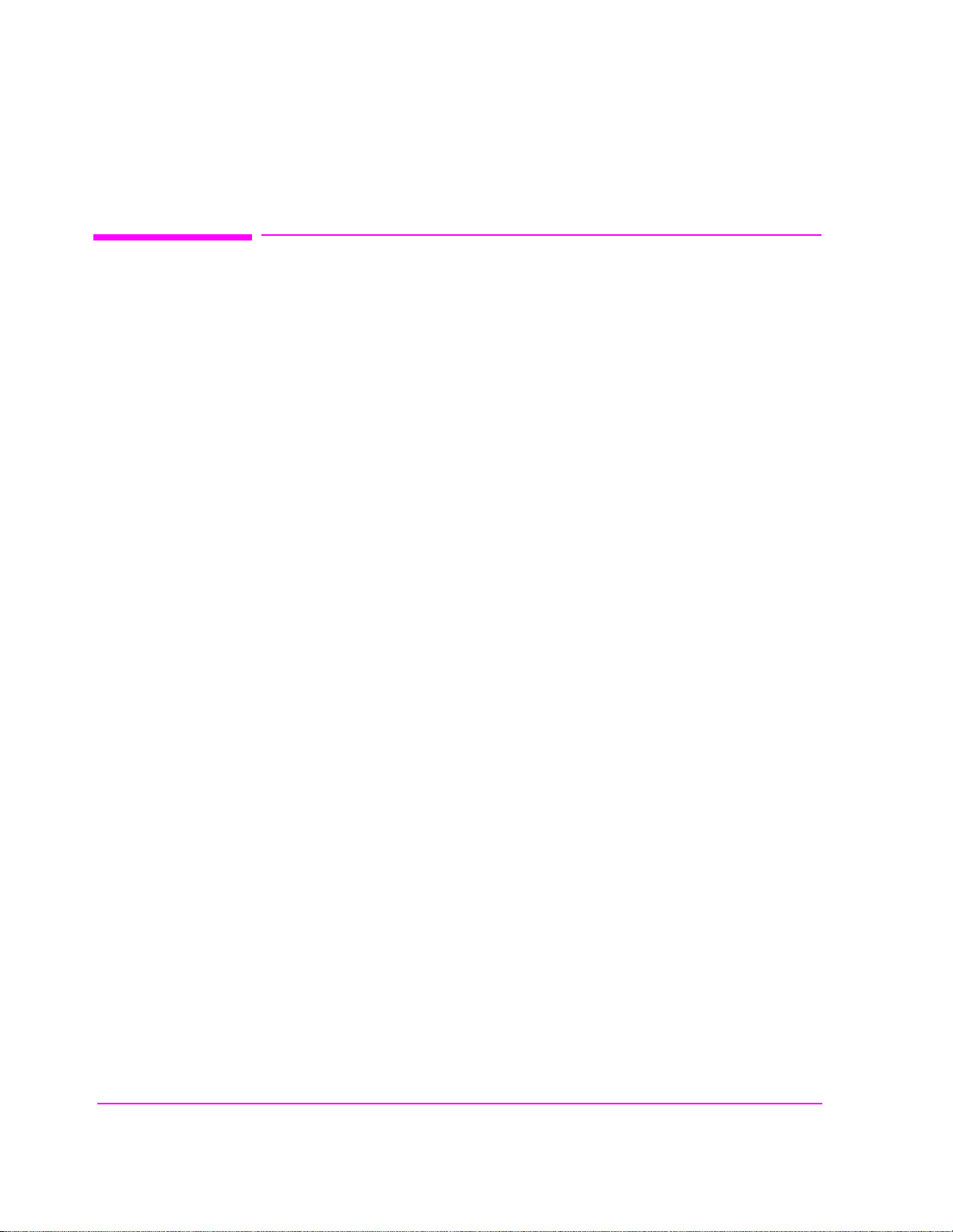

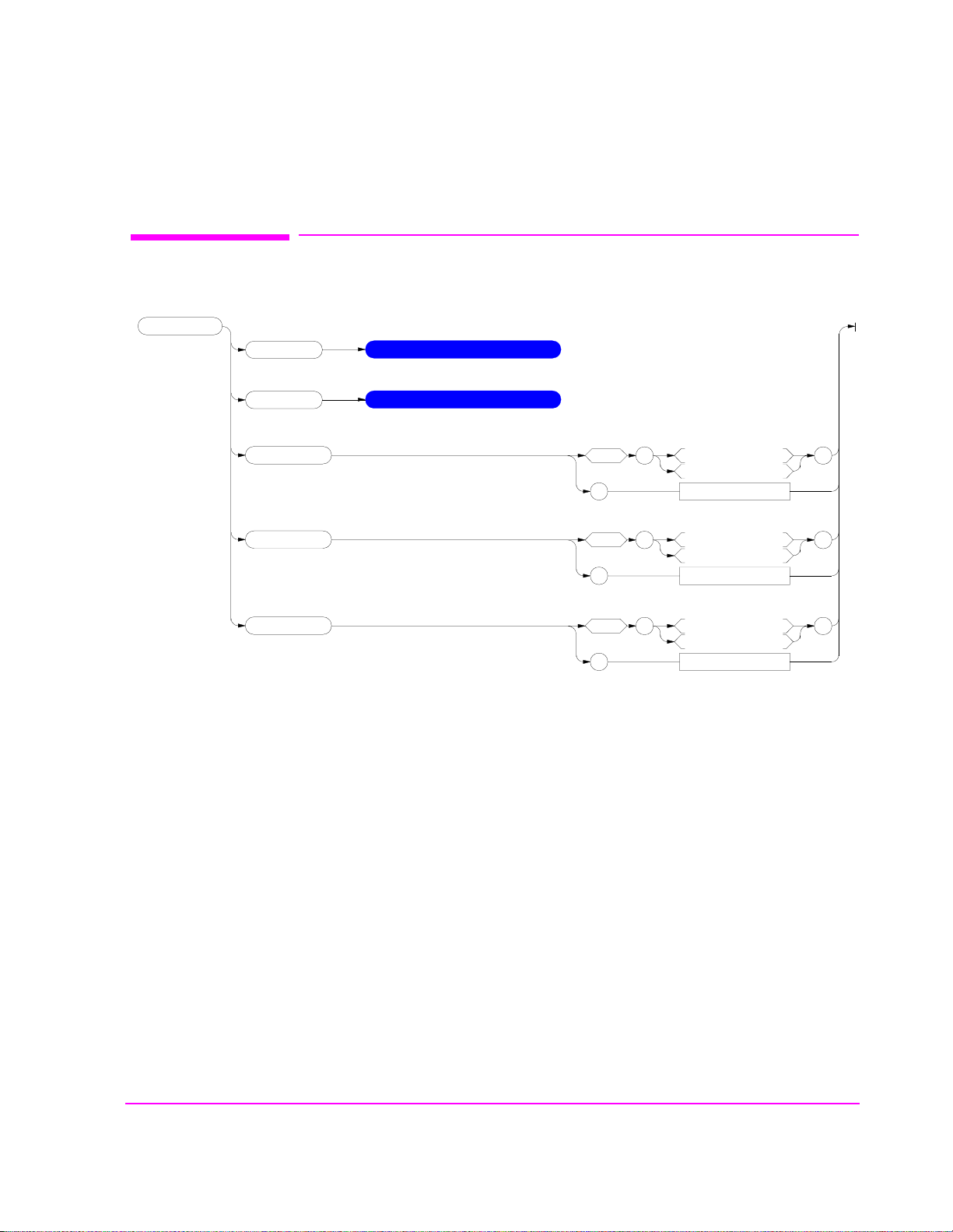

The simplified block diagrams shown in

depict how instrument control information and measurement result information

33

are routed among the Test Set’ s inst rumen ts, in stru ment c ontrol ha rdware, built -in

IBASIC controller, and other components.

Figure 1 on page 32 and Figure 2 on page

The Test Set has two operating modes: Manual Control mode and Automatic

Control mode. In Manual Control mode the Test Set’s operation is con trolled

through the front panel keypad/rotary knob. There are two Automatic Control

modes: Internal and External. In Internal Automatic Control mode the Test Set’s

operation is controll ed by an ap pli ca ti on program running on the built-in IBASIC

Controlle r. In Extern al Automatic Control mode the Test Set’s operation is

controlled by an external controller connected to the Test Set through the GPIB

interface.

26

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 27

Manual Control Mode

The Test Set’s primary instruments are shown on the left side of Figure 1. There

are two classes of instruments in the Test Set: signal analyzers (RF Analyzer, AF

Analyzer, Oscilloscope, Spectrum Analyzer, Signaling Decoder) and signal

sources (RF Generator, AF Generator #1, AF Generator #2/Signaling Encoder).

The Test Set’s measurement capability can be extended by adding application

specific “top boxes” such as the Agilent 83201A Dual Mode Cellular Adapter.

Since so many instruments are integrated into the Test Set, it is not feasible to

have an actual “front panel” for each instrument. Therefore, each instrument’s

front panel is maintained in firmware and i s displayed on the CRT whenever the

instrument is selected. Only one instrument front panel can be displayed on the

CRT at any given time (up to four measurement results can be displayed

simultaneously if desired). Just as with stand alone instruments, instrument front

panels in the Test Set can contain instrument setting information, measurement

result(s), or data input from the DUT.

Chapter 1, Using GPIB

Overview of the Test Set

Using the Test Set in Manual Control mode is very analogous to using a set of

bench or rack-mounted test equipment. To obtain a measurement result with a

bench or racked system, the desired measurement must be “active.” For example,

if an RF power meter is in the bench or racked system and the user wishes to

measure the power of an RF carrier they must turn the power meter on, and look at

the front panel to see the m easurement re sult. Other instruments in the system

may be turned off but this would not prevent the operator from measuring the RF

power.

Conceptually, the same is true for the Test Set. In order to make a measurement or

input data from a DUT, the desired measurement field or data field must be

“active.” This is done by using the front panel keypad/rotary knob to select the

instrument whose front panel contains the desired measurement or data field and

making sure that the desired measurement or data field is turned ON.

Figure 1 shows that instrument selection is handled by the To Screen control

hardware which routes the selected instrument’s front panel to the CRT for

display. Once an instrument’s front panel is displayed on the CRT, the user can

manipulate the i nstrume nt sett ings, such as turni ng a s pecific measurement or data

field on or off, using the keypad/rotary knob.

Figure 1 also shows that instrument

setup is handled by the Instrument Control hardware which routes setup

information from the front panel to the individual instruments.

A GPIB/RS-232/Parallel Printer interface capability is available in the Test Set. In

Manual Control mode this provides the capability of connecting an external

GPIB, serial, or parallel printer to the Test Set so that display screens can be

printed.

27

Page 28

Chapter 1, Using GPIB

Overview of the Test Set

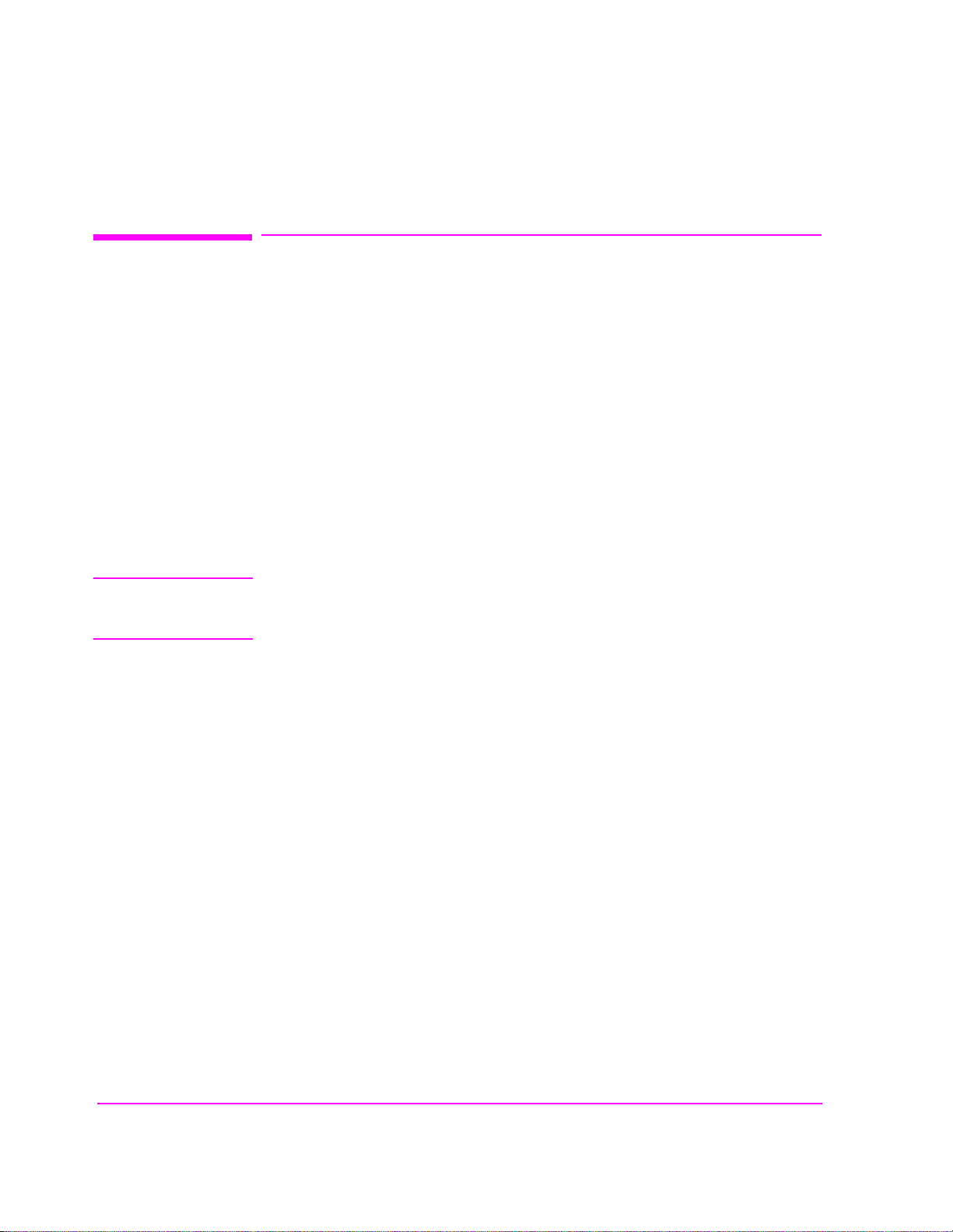

Internal Automatic Control Mode

In Internal Automatic Control mode the Test Set’s operation is controlled by an

application program running on the built-in Instrument BASIC (IBASIC)

Controller. The built-in controller runs programs written in IBASIC, a subset of

the HP

System Controllers. IBASIC is the only programming language supported on the

built-in IBASIC Controller.

Similarities Between the Test Set’s IBASIC Controller and Other Single-Tasking

Controllers

The architecture of the IBASI C Controll er is similar t o that of other si ngle-tas king

instrumentation controllers. Only one program can be run on the IBASIC

Controller at any given time. The program is loaded into RAM memory from

some type of mass storage device. Five types of mass storage devices are

available to the Test Set: SRAM memory cards, ROM memory cards, external

disk drives connected to the GPIB in terface, inte rnal RAM disc, and internal

ROM disc. Three types of interfaces are available for connecting to external

instruments and equipment: GPIB, RS-232, and 16-bit parallel (available as Opt

020 Radio Interface Card).

®

BASIC programming language used on the HP® 9000 Series 200/300

Figure 2 shows how information is routed inside the Test Set when it is in Internal

Automatic Control mode. In Manual Control mode certain Test Set resources are

dedicated to manual operation. These resources are switched to the IBASIC

Controller when an IBASIC prog ram is runni ng. These inc lude the se rial int erface

at select code 9, the GPIB int erface at sele ct code 7, the paral lel printer interface at

select code 15, and the CRT. In Manual Control mode, front panel information

(instrument settings, measurement results, data input from the DUT) is routed to

the CRT through the To Screen control hardware. In Internal Automatic Control

mode the measurement results and data input from the DUT are routed to the

IBASIC Controller through a dedicated GPIB interface. Also, in Internal

Automatic Control mode, the CRT is dedicated to the IBASIC Controller for

program and graphics display. This means instrument front panels cannot be

displayed on the CRT when an IBASIC program is running.

28

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 29

Chapter 1, Using GPIB

Overview of the Test Set

Differences Between the Test Set’s IBASIC Controller and Other Single-Tasking

Controllers

The IBASIC Controller is unlike other single tasking instrumentation controllers

in several ways. First , i t d oes not have a keyboard. Thi s i mposes some limitations

on creating and editing IBASIC programs directly on the Test Set. In Internal

Automatic Control mode a “virtual” keyboard is available in firmware which

allows the operator to enter alphanumeric data into a dedicated input field using

the rotary knob. This i s not t he re commended pr ogramming mode for the I BASIC

Controller. This feature is provided to allow user access to IBASIC programs for

short edits or troubleshooting. Several programming modes for developing

IBASIC pro grams to run on the interna l IBASIC Controller are discussed in this

manual.

Secondly, the IBASIC Controller has a dedicated GPIB interface, select code 8 in

Figure 2, for communi cating with the internal instruments of the Test Set. This

GPIB interface is only available to the IB ASIC Controll er. There is no external

connector for this GPIB interface. No external instruments may be added to this

GPIB interface. The GPIB interfa ce, se le ct code 7 in

Figure 2, is used to interface

the Test Set to external instruments or to an external controller. The dedicated

GPIB interface at select code 8 conforms to the IEEE 488.2 Standard in all

respects but one. The difference being that each instrument on the bus does not

have a unique address. The Instrument Control Hardware determines which

instrument is being addressed through the command syntax. Refer to

“GPIB Commands,”

for a listing of the GPIB c ommand syntax for the Test Set.

Chapter 4,

29

Page 30

Chapter 1, Using GPIB

Overview of the Test Set

External Automatic Control Mode

In External Automatic Cont rol mode the Test Set’s operation is controlled by an

external controlle r co nnec te d to t he Test Set through the GPIB interface. When in

External Automatic Control mode the Test Set’s int ernal confi guratio n is the same

as in Manual Control Mode with two exceptions:

1. Configuration and setup commands are received through the external GPIB interface,

select code 7, rather than from the front-panel keypad/rotary knob.

2. The MEASure command is used to obtain measurement results and DUT data through

the external GPIB interface.

Figure 1 on page 32

Control mode.

shows how informat ion i s rout ed i nside the Test Set in Manual

Figure 1 on page 32 also shows that certain Test Set resources are

dedicated to the IBASIC Con troller (Memory Card, ROM disk, Serial Interface

#10) and are not directly accessible to the user in Manual Control Mode. In

addition,

Figure 1 on page 32 shows that Serial Interface #9 and Parallel Printer

Interface #15 are accessible as write-only interfaces for printing in Manual

Control mode. These same conditions are true when in External Automatic

Control mode. If the user wished to access these resources from an external

controller, an IBASIC program would have to be run on the Test Set from the

external controller.

30

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 31

Writing programs for the Test Set

One of the desi gn goals for aut omatic control of the Test Set was that it o perate t he

same way programmatically as it does manually. This is a key point to remember

when developing programs f or the Test Set. The benefit o f t hi s ap pro ach i s t hat to

automate a particular task, one need only figure out how to do the task manually

and then duplicate the same process in software. This has several implications

when designing and writing programs for the Te st Set:

1. In Manual Control mode a measurement must be “active” in order to obtain a

measurement result or input data fro m the DUT. From a programming perspective this

means that before attempting to read a measurement result or to input data from the

DUT , the desired screen for the measurement result or d ata field must be selected using

the DISPlay command and the field must be in the ON state.

2. In Manual Control mode inst rument configuration i nformation is not rout ed through the

To Screen control hardware block. From a programming perspective this means that

configuration info rmation can be s ent to any des ired inst rument wi thou t havi ng to first

select the instrument’s front panel with the DISPlay command.

Chapter 1, Using GPIB

Overview of the Test Set

Keeping these points in mind during program development will minimize

program development time and reduce problems encountered when running the

program.

31

Page 32

Chapter 1, Using GPIB

Overview of the Test Set

FRONT PANEL

#9

SETUP

#10

SERIAL I/F

INFORMATION

PARALLEL

SERIAL I/F

CRT

KEYPAD/

ROTARY KNOB

CONTROL

TO SCREEN

HARDWARE

FRONT

PANEL

INFORMATION

MEMORY CARD

ROM DISK

IBASIC

CONTROLLER

#8

GPIB

TROL HARDWARE

INSTRUMENT CON-

INSTRUMENT

#7

#15

GPIB

PRINTER

RF GEN

AF GEN #1

MEASUREMENT RESULTS AND DUT DATA

AF GEN #2

GEN

SIGNALING

ENCODER

AF ANALYZER

SPECTRUM

ANALYZER

OSCILLOSCOPE

RF ANALYZER

FUNCTION

Figure 1 Manual Control Mode

32

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

SIGNALING

TOP

BOXES

DECODER

Page 33

Chapter 1, Using GPIB

Overview of the Test Set

FRONT PANEL

TO SCREEN

#9

SETUP

#10

SERIAL I/F

INFORMATION

PARALLEL

SERIAL I/F

CRT

KEYPAD/

ROTARY KNOB

CONTROL

HARDWARE

FRONT

PANEL

INFORMATION

ROM DISK

MEMORY CARD

IBASIC

CONTROLLER

#8

GPIB

TROL HARDWARE

INSTRUMENT CON-

INSTRUMENT

#7

#15

GPIB

PRINTER

RF GEN

AF GEN #1

MEASUREMENT RESULTS AND DUT DATA

GEN

AF GEN #2

FUNCTION

SIGNALING

ENCODER

AF ANALYZER

Figure 2 Internal Automatic Control Mode

TOP

BOXES

SPECTRUM

ANALYZER

OSCILLOSCOPE

DECODER

SIGNALING

RF ANALYZER

33

Page 34

Chapter 1, Using GPIB

Getting Started

Getting Started

What is GPIB?

The General Purpose Interface Bus (GPIB) is an implementation of the IEEE

488.1-1987 Standard Digital Interface for Programmable Instrumentation.

Incorporation of the GPIB into the T est Set provides several valuable capabilities:

• Programs running in the Test Set’s IBASIC Controller can control all the Test Set’s

functions using its internal GPIB. This capability provides a single-instrumen t

automated test system. (The Agilent 11807 Radio Test Software utilizes this

capability.)

• Programs running in the Test Set’s IBASIC Controller can control other instruments

connected to the external GPIB. (The Test Set requires Option 103, RS-232/HP-IB/

Centronics/Current Measurement.)

• An external controller, connected to the external GPIB, can remotely control the Test

Set. (The Test Set requires Option 103 — RS-232/HP-IB/Centronics/Current

Measurement.)

• A GPIB printer, connected to the external GPIB, can be used to print test results and

full screen images. (The Test Set requires Option 103 — RS-232/HP-IB/Centronics/

Current Measurement.)

34

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 35

GPIB Information Provided in This Manual

What Is Explained

• How to configure the Test Set for GPIB operation

• How to make an instrument setting over GPIB

• How to read-back instrument settings over GPIB

• How to make measurements over GPIB

• How to connect external PCs, terminals or controllers to the Test Set

• GPIB command syntax for the Test Set

• IBASIC program development

• IBASIC program transfer over GPIB

• Various advanced functions such as, increasing measurement throughput, status

reporting, error reporting, pass control, and so forth

Chapter 1, Using GPIB

Getting Started

What Is Not Explained

• GPIB (IEEE 488.1, 488.2) theory of operation

• GPIB electrica l specifications

• GPIB connector pin functions

1

1

1

• IBASIC programming (other than general guidelines related to GPIB)

1. Refer to the Tutorial Description of the Hewlett-Packard Interface Bus

(Agilent P/N 5952-0156) for detailed information on GPIB theory and operation.

35

Page 36

Chapter 1, Using GPIB

Getting Started

General GPIB Programming Guidelines

The following guidelines shoul d be co nsi dered when developing programs which

control the Test Set through GPIB:

• Guideline #1. Avoid using the TX TEST and RX TEST screens.

The RX TEST and TX TEST screens are specifically designed for manual testing of

land mobile FM radios and, when displayed, automa tically configure six “priority”

fields in the Test Set for this purpose. The priority fields and their preset values are

listed in Table 3 on page 37. When the TX TEST screen or the RX TEST screen is

displayed, certain priority fields are hidden and are not settable. The priority fields

which are hidden are listed in Table 3 on page 37.

NOTE: When the TX TEST screen or the RX TEST screen is displayed, any GPIB commands sent to

the Test Set to change the value of a hidden priority field are ignored. Hidden priority fields

on the TX TEST or RX TEST screens are not settable manually or programmatically.

Displaying either of these screens automatically re-configures the 6 “priority” f ields as

follows:

1. When entering the RX TEST screen,

a. the RF Generator’s Amplitude field, the AFGen1 To field and the AF

Analyzer’s measurement field (measurement displayed in upper, right portion

of CRT display) are

• set to their preset values upon entering the screen for the first time since

power-up, OR

• set to their preset values if the PRESET key is selected, OR

• set to the last setting made while in the screen

b. the RF Generator Amplitude field and the AFGen1 To field are

• set to their preset values whenever entering the screen, OR

• set to their preset values if the PRESET key is selected

36

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 37

Chapter 1, Using GPIB

Getting Started

2. When entering the TX TEST screen,

a. The AF Anl In field, the De-Emphasis field, the Detector field and the

AF Analyzer Measurement field (measurement displayed in upper, right portion

of CRT display) are,

• set to their preset values upon entering the screen for the first time since

power-up, OR

• set to their preset values if the PRESET key is selected, OR

• set to the last setting made while in the screen

b. The AF Analyzer AF Anl In, De-Emphasis and Detector fields are,

• set to their preset values whenever entering the screen, OR

• set to their preset values if the PRESET key is selected

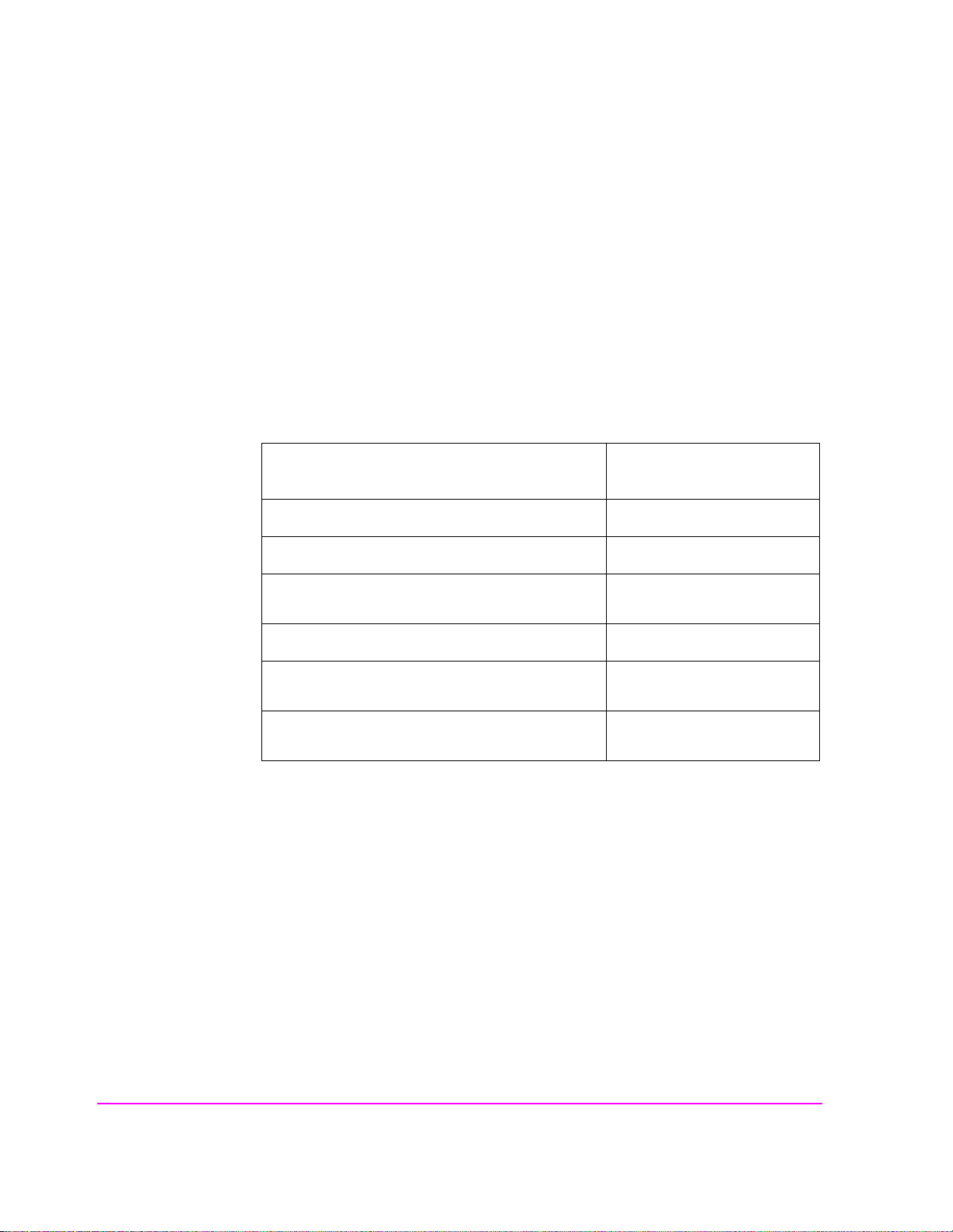

Table 3 RX TEST Screen and TX TEST Screen Priority Field Preset Values

Priority

Field

RF Gen

Amplitude

AFGen1 To FM No Audio Out Yes

AF Anl In Audio In Yes FM Demod No

Detector RMS Yes Pk ± Max No

De-emphasis Off Yes 750 µsNo

AF Analyzer

Measurement

RX TEST

Screen Preset

Value

80 dBm No Off Ye s

−

SINAD No Audio Freq No

Field Hidden

On RX TEST

Screen

TX TEST

Screen Preset

Value

Field

Hidden On

TX TEST

Screen

37

Page 38

Chapter 1, Using GPIB

Getting Started

• Guideline #2. When developing programs to make measurements always follow this

recommended sequence:

1. Bring the Test Set to its preset state using the front-panel PRESET key. This initial

step allows you to start developing the measurement sequence with most fields in a

known state.

2. Make the measurement manually using the front-panel controls of the Test Set.

Record, in sequential order, the screens selected and the settings mad e within each

screen. The record of the screens selected and settings made in each screen becomes

the measurement procedure.

3. Record the measurement result(s).

In addition to the DISPlay command, the signaling ENCoder and DECoder require

further commands to display the correct fields for each signaling mode. For

example, DISP ENC;:ENC:MODE 'DTMF'.

4. Develop the program using the measurement procedure generated in step 2. Be sure

to start the programmatic measurement sequence by bringing the Test Set to its preset

state using the *RST Common Command. As the measurement procedure requires

changing screens, use the DISPlay command to select the desired screen f ollowed by

the correct commands to set the desired field(s).

NOTE: When IBASIC programs are running the CRT is dedicated to the IBASIC Controller for

program and graphics display. This means instrument front panels are not displayed on the

CRT when an IBASIC program is running. However, the DISPlay <screen > command ca uses

all setting and measurement fields in the <screen> to be accessible programmatically.

Attempting to read from a screen that has not been made accessible by the DISPlay command

will cause

HP-IB Error:-420 Query UNTERMINATED, or

HP-IB Error: -113 Undefined header

5. Make sure the desired measurement is in the ON state. This is the preset state for

most measurements. However, if a previous program has set the state to OFF, the

measurement will not be available. Attempting to read from a measu remen t field

that is not in the ON state will cause HP-IB Error:-420 Query

UNTERMINATED.

6. If the trigger mode has been changed, trigger a reading.

NOTE: Triggering is set to FULL SETTling and REPetitive RETRiggering after receipt of the *RST

Common Command. These settings caus e the Test Set t o trigger its elf and a sep arate trigger

command is not necessary.

38

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 39

Chapter 1, Using GPIB

Getting Started

7. Send the MEASure query command to initiate a reading. This will place the

measured value into the Test Set’s Output Queue.

NOTE: When making AF Analyzer SINAD, Distortion, Signal to Noise Ratio, AF Frequency, DC

Level, or Current measurements, the measurement type must first be selected using the SELect

command. For example, MEAS:AFR:SEL'SINAD' followed by MEAS:AFR:SINAD?

8. Use the ENTER statement to transfer the measured value to a variable within the

context of the program.

The following example program illustrates how to make settings and then take a

reading from the Test Set. This setup takes a reading from the spectrum analyzer

marker after tuning it to the RF generator’s output frequency.

Example

10 Addr=714

20 OUTPUT Addr;"*RST" !Preset to known state

30 OUTPUT Addr;"TRIG:MODE:RETR SING" !Sets single trigger

40 OUTPUT Addr;"DISP RFG" !Selects the RF Gen screen

50 OUTPUT Addr;"AFG1:FM:STAT OFF" !Turns FM OFF

60 OUTPUT Addr;"RFG:AMPL -66 DBM" !Sets RF Gen ampl to -66 dBm

70 OUTPUT Addr;"RFG:FREQ 500 MHZ" !Sets RF Gen freq to 500 MHz

80 OUTPUT Addr;"RFG:AMPL:STAT ON" !Turns RF Gen output ON

90 OUTPUT Addr;"DISP SAN"!Selects Spectrum Analyzer’s screen

100 OUTPUT Addr;"SAN:CRF 500 MHZ" !Center Frequency 500 MHz

110 ! -------------------MEASUREMENT SEQUENCE------------------120 OUTPUT Addr;"TRIG" !Triggers reading

130 OUTPUT Addr;"MEAS:SAN:MARK:LEV?" !Query of Spectrum

140 !Analyzer’s marker level

150 ENTER Addr;Lvl !Places measured value in variable Lvl

160 DISP Lvl!Displays value of Lvl

170 END

The RF Generator’s o utp ut port and th e Spect rum Analyz er’ s input port a re pre set

to the RF IN/OUT port. This allows the Spectrum Analyzer to measure the RF

Generator with no extern al connect ions. The Spec trum Analyze r marker is alwa ys

tuned to the center frequency of the Spectrum Analyzer after preset. With the RF

Generator’s ou tput port and Spectr um Anal yz er input port both d ir ect ed t o t he RF

IN/OUT port, the two will inter nally couple with 46 dB of gain, giving a measur ed

value of approximate ly -20 dBm. While not a no rmal mode of ope ration th is setup

is convenient for demonstration since no external cables are required. This also

illustrates the value of starting from the preset state since fewer programming

commands are required.

39

Page 40

Chapter 1, Using GPIB

Getting Started

• Guideline #3. Avoid program hangs.

If the program stops or “han gs up” when tryi ng to ENTER a measured valu e, it is most

likely that the desired measurement field is not available. There are several reasons

that can happen:

1. The screen where the measurement field is located has not been DISPlayed before

querying the measurement field.

2. The measurement is not turned ON.

3. The squelch control is set too high. If a measur ement is turned ON but is not

available due to the Squelch setting, the measurement field contains four dashes

(- - - -). This is a valid state. The Test Set is waiting for a signal of sufficient strength

to unsquelch the receiver before making a measurement. If a measurement field

which is squelched is queried the Test Set will wait indefinitely for the receiver to

unsquelch and return a measured value.

4. The RF Analyzer’s Input Port is set to ANT (antenn a) while trying to read TX

power. TX power is not measurable with the Input Port set to ANT. The TX power

measurement field will display four dashes (- - - -) indicating the measurement is

unavailable.

5. The input signal to the Test Set is very unstable causing the Test Set to continuously

autorange. This condition will be apparent if an attempt is made to make the

measurement manually.

6. Trigger mode has been set to single trigger (TRIG:MODE:RETRig SINGle) and a

new measurement cycle has not been triggered before attempting to read the

measured value.

7. The program is attempting to make an FM deviation or AM depth measurement

while in the RX TEST screen. FM or AM measurements are not available in the RX

TEST screen. FM or AM measurements are made from the AF Analyzer screen b y

setting the AF Anl In field to FM or AM Demod.

40

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 41

Chapter 1, Using GPIB

Getting Started

• Guideline #4. Use si ngle quotes and spaces properly.

The syntax diagrams in Chapter 4, “GPIB Commands,” show where single quotes

are needed and where spaces are needed.

Example

OUTPUT 714;"DISP<space>AFAN"

OUTPUT 714;"AFAN:DEMP<space>’Off’"

Improper use of single quotes and spaces will cause,

HP-IB Error:-103 Invalid Separator

• Guideline #5. Ensure that settable fields are active by using the STATe ON command.

When making settings to fields that can be turned OFF with the STATe ON/OFF

command (refer to the Chapter 4, “GPIB Commands ,”), make sure the STA Te is ON

if the program uses that field. Note that if the STATe is OFF, just setting a numeric

value in the field will not change the STATe to ON. This is different than front-panel

operation whereby the process of selecting the field and entering a value automatically

sets the ST ATe to ON. Programmatically, fields must be explicitly set to the ON state if

they are in the OFF state.

For example, the following command li ne woul d set a new AMPS ENCod er SAT tone

deviation and then turn on the SAT tone (note the use of the ; to back up one level in

the command hierarchy so that more than one command can be executed in a single

line):

Example

OUTPUT 714;"ENC:AMPS:SAT:FM 2.1 KHZ;FM:STAT ON"

To just turn on the SAT tone without changing the current se tting the following

commands would be used:

OUTPUT 714;"ENC:AMPS:SAT:FM:STAT ON"

41

Page 42

Chapter 1, Using GPIB

Getting Started

• Guideline #6. Numeric values are returned in GPIB Units or Attribute Units only.

When querying measurements or settings through GPIB, the Test Set always returns

numeric values in GPIB Units or Attribute Units, regardl ess of the current Display

Units setting. GPIB Units, Attribute Units and Display Units determine the units-ofmeasure used for a measurement or setting, for example, Hz, Volts, Watts, Amperes,

Ohms. Refer to “Specifying Units-of-Measure for Settings and Measurement

Results” on page 75 for further information.

For example, if the Test Set’s front panel is displaying TX Frequency as 835.02 MHz,

and the field is queried through GPIB, the value returned will be 835020000 since the

GPIB Units for frequency are Hz. Note that changing Display Units will not change

GPIB Units or Attribute Units. Note also that setting the value of a numeric field

through GPIB can be done using a variety of units-of-measure. The GPIB Units or

Attribute Units for a queried value can always be determined us ing the :UNITs?

command or :AUNits? command respectively (refer to “Number Measurement

Syntax” on page 177 or “Multiple Number Measurement Syntax” on page 179,

for command syntax).

Control Annunciators

The letters and symbols at the top right corner of the display indicate these

conditions:

• R indicates the Test Set is in remote mode. The Test Set can be put into the remote mode

by an external controller or by an IBASIC program running on the built-in IBASIC

controller.

• L indicates that the Test Set has been addressed to Listen.

• T indicates that the Test Set has been addressed to Talk.

• S indicates that the Test Set has sent the Require Service message by setting the Service

Request (SRQ) bus line true. (See “Status Reporting” on page 239.)

• C indicates that the Test Set is currently the Active Controller on the bus.

• * indicates that an IBASIC program is running.

• ? indicates that an IBASIC program is waiting for a user response.

• - indicates that an IBASIC program is paused.

42

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 43

Preparing the Test Set For GPIB Use

1. If other GPIB devices are in the system, attach a GPIB cable from the Test Set’s rear-

panel GPIB connector to any one of the other devices in the test system.

2. Access the I/O CONFIGURE screen and perform the following steps:

a. Set the Test Set’s GPIB address using the HP-IB Adrs field.

b. Set the Test Set’s GPIB Controller capability using the Mode field.

• Talk&Listen configures the Test Set to not be the System Controller. The Test Set

has Active Controller capability (take control/pass control) in this mode. Use this

setting if the Test Set will be controlled through GPIB from an external controller.

• Control configures the Test Set to be the System Controller. Use this setting if the

Test Set will be the only controller on the GPIB. Selecting the Control mode

automatically makes the Test Set the Active Controller.

Chapter 1, Using GPIB

Getting Started

NOTE: Only one System Controller can be configu red in a GPIB system. R efer to “Passin g Contr ol”

on page 313 for further information.

3. If a GPIB printer is or will be connected to the Test Set’s rear panel GPIB connector

then,

a. access the PRINT CONFIGURE screen.

b. select one of the supported GPIB printer models using the Model field.

c. set the Printer Port field to HP-IB.

d. set the printer address using the Printer Address field.

43

Page 44

Chapter 1, Using GPIB

Getting Started

Using the GPIB with the Test Set’s built-in IBASIC Controller

The Test Set has two GPIB interfaces, an internal-only GPIB at select code 8 and

1

an external GPIB at select code 7

. The GPIB at select code 8 is only available to

the built-in IBASIC Controller and is used exclusively for communication

1

between the IBASIC Controller and the Test Set. The GPIB at select code 7

serves three purposes:

1. It allows the Test Set to be controlled by an external controller

2. It allows the Test Set to print to an external GPIB printer

3. It allows the built-in IBASIC Controller to control external GP IB dev ices

IBASIC programs running on the Test Set’s IBASIC Controller must use the

internal-only GPIB at select code 8 to control the Test Set. IBASIC prog rams

1

would use the external GPIB at select code 7

to control GPIB devices connected

to the rear panel GPIB connector.

NOTE: Refer to “Overview of the Test Set” on page 26 for a detailed explanation of the Test Set’s

architecture.

When using a BASIC language Workstation with an GPIB int erfac e at s elect code

7 to control the Test Set, GPIB commands would look like this:

Example

! This command is sent to the Test Set at address 14.

OUTPUT 714;"*RST"

! This command is sent to another instrument whose address is 19.

OUTPUT 719;"*RST"

When executing the same commands on the Test Set’s IBASIC Controller, the

commands would look like this:

Example

OUTPUT 814;"*RST"

! Command sent to internal-only GPIB at select code 8,

! Test Set’s address does not change

OUTPUT 719;"*RST"

! Command sent to external GPIB at select code 7,

! other instrument’s address does not change.

1. Optio nal Connector on the Test Set.

44

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 45

Basic Programming Examples

The following simple examples illustrate the basic approach to controlling the

Test Set through the GPIB. The punctuation and command syntax used for these

examples is given in

The bus address 714 used in the following BASIC language examples assumes a

GPIB interface at select code 7, and a Test Set GPIB address of 14. All examples

assume an external controller is being used.

To Change a Field’s Setting over GPIB

1. Use the DISPlay command to access the screen containing the field whose setting is to

be changed.

2. Make the desired setting using the proper command syntax (refer to Chapter 4, “GPIB

Commands,” for p roper syntax).

The following example makes several instrument setting changes:

Chapter 1, Using GPIB

Getting Started

Chapter 4, “GPIB Commands.”.

Example

OUTPUT 714;"DISP RFG" !Display the RF Generator screen.

OUTPUT 714;"RFG:FREQ 850 MHZ" !Set the RF Gen Freq to 850 MHz.

OUTPUT 714;"RFG:OUTP ’DUPL’"!Set the Output Port to Duplex.

OUTPUT 714;"DISP AFAN"!Display the AF Analyzer screen.

OUTPUT 714;"AFAN:INP ’FM DEMOD’"!Set the AF Anl In to FM Demod.

To Read a Field’s Setting over GPIB37

1. Use the DISPlay command to access the screen containing the field whose setting is to

be read.

2. Use the Query form of the syntax for that field to place the setting value into the Test

Set’s output buffer.

3. Enter the value into the correct variable type within the program context (refer to

Chapter 4, “GPIB Commands,”, for proper variable type).

45

Page 46

Chapter 1, Using GPIB

Getting Started

The following example reads several fields.

Example

OUTPUT 714;"DISP AFAN"!Display the AF Analyzer screen.

OUTPUT 714;"AFAN:INP?"!Query the AF Anl In field

ENTER 714;Af_input$ !Enter returned value into a string ariable.

OUTPUT 714;"DISP RFG"!Display the RF Generator screen

OUTPUT 714;"RFG:FREQ?"!Query the RF Gen Frequency field.

ENTER 714;Freq !Enter the returned value into a numeric variable

NOTE: When querying measurements or s ettings through GPIB, the Test Set always returns numeric

values in GPIB Units or Attribute Units, regardless of the current Display Units setting. Refer

to “GPIB Units (UNITs)” on page 78 and “Attribute Units (AUNits)” on page 81 for

further information.

To Make a Simple Measurement

The basic method for making a measurement is very similar to the method used to

read a field setting.

1. Use the DISPlay command to access the screen containing the desired measurement.

2. Use the MEASure form of the syntax for that measurement to p lace the measured value

into the Test Set’s output buffer.

3. Enter the value into the correct variable type within the program context (refer to

Chapter 4, “GPIB Commands,” for proper variable type).

The following example measures the power of an RF signal.

Example

!Display the RF Analyzer screen.

OUTPUT 714;"DISP RFAN"

!Measure the RF power and place result in output buffer.

OUTPUT 714;"MEAS:RFR:POW?"

!Enter the measured value into a numeric variable.

ENTER 714;Tx_power

The above example is very simple and is desi gned to demonstrate the fundamental

procedure for obtaining a measurement result. Many other factors must be

considered when designing a measurement procedur e, such as instrume nt settings,

signal routing, settling time, filtering, triggering and measurement speed.

46

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 47

Remote Operation

Chapter 1, Using GPIB

Remote Operation

The Test Set can be operated remotely thr ough the General Purpose Interface Bus

(GPIB). Except as otherwise noted, the Test Set complies with the IEEE

488.1-1987 and IEEE 48 8.2-1987 Standards . Bus compati bility, programming and

data formats are described in the following sections.

All front-panel functions, except those listed in

Table 4, are programmable

through GPIB.

Table 4 Non-Programmable Front Panel Functions

Function Comment

ON/OFF Power Switch

Volume Cont ro l Knob

Squelch Control Knob The position of the Squ e lch Control knob cannot be programmed. How-

ever squelch can be programmed to either the Open or Fixed position.

Refer to the Test Set’s User’s Guide for more information.

Cursor Control Knob

SHIFT Key

CANCEL Key

YES Key

NO Key

ENTER Key

Backspace (left-arrow) Key

PREV Key

HOLD ( SHIFT, PREV Keys)

PRINT ( SHIFT, TESTS Keys)

ADRS ( SHIFT, LOCAL Keys)

ASSIGN ( SHIFT, k4 Keys)

RELEASE ( SHIFT, k5 Keys)

47

Page 48

Chapter 1, Using GPIB

Remote Operation

Remote Capabilities

Conformance to the IEEE 488.1-1987 Standard

For all IEEE 488.1 functions implemented, the Test Set adheres to the rules and

procedures as outlined in that Standard.

Conformance to the IEEE 488.2-1987 Standard

For all IEEE 488.2 functions implemented, the Test Set adheres to the rules and

procedures as outlined in that Standard with the exception of the *OPC Common

Command. Refer to the *OPC Common Command description.

IEEE 488.1 Interface Functions

The interface functions that the Test Set implements are listed in Table 5.

Table 5 Test Set IEEE 488.1 Interface Function Capabilities

Function Capability

Talker T6: No Talk Only Mode

Extended Talker T0: No Extended Talker Capability

Listener L4: No Listen Only Mode

Extended Listener LE0: No Extended Listener Capability

Source Handshake SH1: Complete Capability

Acceptor Handshake AH1: Complete Capability

Remote/Local RL1: Complete Capability

Service Request SR1: Complete Capability

Parallel Poll PP0: No Parallel Poll Capability

Device Clear DC1: Complete Capability

Device Trigger DT1: Complete Capability

Controller C1: System Controller

C3: Send REN

C4: Respond to SRQ

C11:No Pass Control to Self, No Parallel Poll

Drivers E2: Tri-State Drivers

48

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 49

Addressing

Factory Set Address

Extended Addressing

Chapter 1, Using GPIB

Addressing

The Test Set’s GPIB address is set to decimal 14 at the factory. The address can be

changed by following t he instructions in

.

49

Extended addressing ( secondary command) capa bility i s not implemen ted in the Test

Set.

“Setting the Test Set’s Bus Address” on page

Multiple Addressing

Multiple addressing capability is not im plemented in the Test Set.

Setting the Test Set’s Bus Address

The Test Set’s GPIB bus addr es s i s set using the HP-IB Adrs field which is located

on the I/O CONFIGURE screen. To set the GPIB bus address; select the I/O

CONFIGURE screen and position the cursor next to the

address can be set fr om decimal 0 t o 30 using the numeric DATA ke ys, or by pus hing

and then rotating the Cursor Contr ol knob. Ther e ar e no DIP swi tc hes f or se tt ing the

GPIB bus address in the Te st Set. The new setting is retained when the Test Set is

turned off.

Displaying the Bus Address

The Test Set’s GPIB bus address can be displayed by pressing and releasing the

SHIFT key, then the LOCAL key. The address is displayed in the upper left-hand

corner of the display sc reen.

HP-IB Adrs field. The

49

Page 50

Chapter 1, Using GPIB

IEEE 488.1 Remote Interface Message Capabilities

IEEE 488.1 Remote Interface Message Capabilities

The remote interface message capabilities of the Test Set and the associated IEEE

488.1 messages and control lines are listed in

Table 6 Test Set IEEE 488.1 Interface Message Capability

Message Type Implemented Response

Table 6.

IEEE

488.1

Message

Data Yes All front-panel functions, except those listed in Table 4

on page 47, are programmable. The Test Set can send sta-

tus byte, message and setting inform ation. All measure-

ment results (except dashed “- - - -” displays) and error

messages are available through the bus.

Remote Yes Remote programming mode is entered when the Remote

Enable (REN) bus control line is true and the Test Set is

addressed to listen. The R annunciator will appear in the

upper-right corner of the display screen when the Test Set

is in remote mode. All front-panel keys are disabled

(except for the LOCAL key, POWER switch, Volume control and Squelch control knobs). When the Test Set enters

remote mode the output signals and internal settings

remain unchanged, except that triggering is reset to the

state it was last set to in remote mode (Refer to “Trigger-

ing Measurements” on page 224).

Local Yes The Test Set returns to local mode (full front-panel con-

trol) when either the Go To Local (GTL) bus command is

received, the front-panel LOCAL key is pressed or the

REN line goes false. When the Test Set returns to local

mode the output signals and internal settings remain

unchanged, except that triggering is reset to

TRIG:MODE:SETT FULL;RETR REP. The LOCAL key

will not function if the Test Set is in the local lockout

mode.

DAB

END

MTA

MLA

OTA

REN

MLA

GTL

MLA

Local Lockout Yes Local Lockout disables all front-panel keys including the

LOCAL key. Only the System Controller or the POWER

switch can return the Test Set to local mode (front-panel

control).

50

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

LLO

Page 51

IEEE 488.1 Remote Interface Message Capabilities

Table 6 Test Set IEEE 488.1 Interface Message Capability (Continued)

Message Type Implemented Response

Chapter 1, Using GPIB

IEEE

488.1

Message

Clear Lockout/

Set Local

Service Request Yes The Test Set sets the Service Request (SRQ) bus line true

Status Byte Yes The Test Set responds to a Serial Poll Enable (SPE) bus

Status Bit No The Test Set does not have the capability to respond to a

Clear Yes This message clears the Input Buffer and Output Queue,

Yes The Test Set returns to local mode (front-panel control)

and local lockout is cleared when the REN bus control line

goes false. When the Test Set returns to local mode the

output signals and internal settings remain unchanged,

except that triggering is set to TRIG:MODE:SETT

FULL;RETR REP.

if any of the enabled conditions in the Status Byte Register, as defined by the Service R equest Enable Register, are

true.

command by sending an 8-bit status byte when addressed

to talk. Bit 6 will be true, logic 1, if the Test Set has sent

the SRQ message

Parallel Poll.

clears any commands in process, puts the Test Set into the

Operation Complete idle state and prepares the Test Set to

receive new commands. The Device Clear (DCL) or

Selected Device Clear (SDC) bus commands

REN

SRQ

SPE

SPD

STB

MTA

PPE

PPD

PPU

PPC

IDY

DCL

SDC

MLA

• do not change any settings or stored data (except as

noted previously)

• do not interrupt front panel I/O or any Test Set

operation in progress (except as noted previously)

• do not change the contents of the Status Byte Register

(other than clearing the MAV bit as a consequence of

clearing the Output Queue).

The Test Set responds equally to DCL or SDC bus commands.

51

Page 52

Chapter 1, Using GPIB

IEEE 488.1 Remote Interface Message Capabilities

Table 6 Test Set IEEE 488.1 Interface Message Capability (Continued)

Message Type Implemented Response

IEEE

488.1

Message

Trigger Yes If in remote programming mode and addressed to listen,

the Test Set makes a triggered measurement following the

GET

MLA

trigger conditions currently in effect in the instrument.

The Test Set responds equally to the Group Execute Trigger (GET) bus command or the *TRG Common Command.

Take Control Yes The Test Set begins to act as the Active Controller on the

bus.

TCT

MTA

Abort Yes The Test Set stops talking and listening IFC

52

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 53

Remote/Local Modes

Remote Mode

In Remote mode all front-panel keys are disabled (except for the LOCAL key,

POWER switch, Volume control and Squelch control). The LOCAL key is only

disabled by the Local Lockout bus command. When in Remote mode and

addressed to Listen the Te st Set responds to the Data, Remote, Local, Clear

(SDC), and Trigger messages. When the Test Set is in Remote mode, the

annunciator will be displayed in the upper right corner of the display screen and

triggering is set to the state it was last set to in Remote mode (if no previo us

setting, the default is FULL SETTling and REPetitive RETRiggering). When the

Test Set is being addressed to Listen or Talk the

displayed in the upper-right corner of the display screen.

Chapter 1, Using GPIB

Remote/Local Modes

R

L or T annunciators will be

Local Mode

In Local mode the Test Set’s front-panel controls are fully operational. The Test

Set uses FULL SETTling and REPetiti ve RETRiggering in Lo cal mode. When the

Test Set is being addressed to Listen or Talk the

displayed in the upper-right corner of the display screen.

Remote or Local Mode

When addressed to Talk in Remote or Local mode , t he Test Set can is sue t he Data

and Status Byte messages and respond to the Take Control message. In addition

the Test Set can issue the Service Request Messag e (S RQ). Reg ardles s of whethe r

it is addressed to talk or listen, the Test Set will respond to the Clear (DCL), Local

Lockout, Clear Lockout/Set Local, and Abort messages.

L or T annunciators will be

53

Page 54

Chapter 1, Using GPIB

Remote/Local Modes

Local To Remote Transitions

The Test Set switches from Local to Remote mode upon receipt of the Remote

message (REN bus line true and Test Set is addressed to listen). No instrument

settings are changed by the transition from Local to Remote mode, but triggering

is set to the state it was last set to in Remote mode (if no previous setting, the

default is FULL SETTling and REPetitive RETRiggering). The

the upper-right corner of the display is turned on.

When the Test Set makes a transition from local to remote mode, all currently

active measurements are flagged as invalid causing any currently available

measurement results to become unavailable. If the GPIB trigger mode is

:RETR REP then a new measurement cycle is started and measurement results

will be available for all active measurements when valid results have been

obtained. If the GPIB trigger mode is :RETR SING then a measurement cycle

must be started by issuing a trigger event. Refer to

page 224

R annunciator in

“Triggering Measurements” on

for more inform ation.

Remote To Local Transitions

The Test Set switches from Remote to Local mode upon receipt of the Local

message (Go To Local bus message is sent and Test Set is addressed to listen) or

receipt of the Clear Lockout/Set Local message (REN bus line false). No

instrument settings a re change d by the tr ansit ion fr om Remote to Loca l mode, but

triggering is reset to FULL SETTling and REPetitive RETRiggering. The

annunciator in the upper right corner of the display is turned off.

If it is not in Local Lockout mode the Test Set switches from Remote to Local

mode whenever the front-panel LOCAL key is pressed.

If the Test Set was in Local Lockout mode when the Local message was received,

front-panel cont ro l is returned, but Loca l Lo ckout mode is not clea red . Unl ess the

T est Set re ceive s the Cl ear Lock out/Se t Local message , the Test Set will still be in

Local Lockout mode the next time it goes to the Remote mode.

R

54

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 55

Chapter 1, Using GPIB

Remote/Local Modes

Local Lockout

The Local Lockout mode disables the front-panel LOCAL key and allows return

to Local mode only by commands f rom the Sys tem Contr oller (Clear Lockout /Set

Local message).

When a data transmission to the Test Set is interrupted, which can happen if the

LOCAL key is pressed, the data bei ng t ra nsmitted may be lost. This can l eav e the

Test Set in an unknown state. The Local Lockout mode prevents loss of data or

system control due to someone unintentionally pressing front-panel keys.

NOTE: Return to Local mode can also be accomplished by setting the POWER switch to OFF and

back to ON. However, returning to Local mode in this way has the following disadvantages:

1. It defeats the purpose of the Local Lockout mode in that the Active Controll er will lose

control of the test set.

2. Instrument configuration is reset to the power up condition thereby losing the

instrument configuration set by the Active Controller.

Clear Lockout/Set Local

The Test Set returns to Local mode when it receives the Clear Lockout/Set Local

message. No instrument set ting s are c hanged by the t ransi tion f rom Remote mod e

with Local Lockout to Local mode but triggering is reset to FULL SETTling and

REPetitive RETRiggering.

55

Page 56

Chapter 1, Using GPIB

Remote/Local Modes

56

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\usehpib.fb

Page 57

2

Methods For Reading Measurement Results

57

Page 58

Chapter 2, Methods For Reading Measurement Results

Background

Background

One of the most common remote user interface operations performed on an

Test Set is to query and read a measurement result. Generally, this operation is

accomplished by sending the query command to the Test Set, followed

immediately by a request to read the requested measurement result. Using

Hewlett-Packard Rocky Mou nta in BASIC (RMB) language, this op era ti on would

be written using the OUTPUT and ENTER command as follows:

OUTPUT 714;"MEAS:RFR:POW?"

ENTER 714;Power

Using this programming structure, the control program will stay on the ENTER

statement until i t is satisfied - t hat is - until t he Test Set has returned the req ues ted

measurement result. This structure works correctly as long as the Test Set returns

a valid measurement result. If, for some reason, the Test Set does not return a

measurement result, the control program becomes “hung” on the ENTER

statement and program execution effectively stops.

In order to prevent the control program from becoming “hung” programmers

usually enclose the operati on with some form of t imeout func tion. The f orm of the

timeout will of course depend upon the programming language being used. The

purpose of the timeout is to specify a fixed amount of time that the control

program will wait for the Test Set to return the reque sted re sult. Aft er this time has

expired the control program will abandon the ENTER statement and try to take

some corrective action to regain control of the Test Set.

If the control program does not send the pr oper commands in the prop er seque nce

when trying to regain co ntrol of the Test Set, unexpected operation will result.

When this condition is encountered, power must be cycled on the Test Set to

regain control.

58

S:\agilent\8920\8920b\PRGGUIDE\BOOK\CHAPTERS\measrslt.fb

Page 59

Chapter 2, Methods For Reading Measurement Results

Background

This situation can be avoided entirely by:

1. sending a Selected Device Clear (SDC) interface message to put the Test Set’s GPIB

subsystem into a known state.

2. sending a command to terminate the requested measurement cycle.

These comman ds issued in this order will al low the control program to reg ain