Page 1

Model 979 Helium

NOTICE: This document contains references to Varian.

Please note that Varian, Inc. is now part of Agilent

Technologies. For more information, go to

www.agilent.com/chem.

vacuum technologies

3

FIELD SERVICE

COMPONENT REPLACEMENT

Mass Spectrometer

Leak Detector

MANUAL

DRAFT 1/27/0

Manual No. 699909976

Revision B

January 2003

Page 2

Model 979 Helium Mass Spectrometer Leak Detector

Model 979 Helium Mass Spectrometer

Leak Detector

DRAFT 1/27/03

Alconox is a registered trademark of Alconox, Inc.

Apiezon is a registered trademark of M&I Materials Ltd.

Scotch-Brite is a trademark of 3M.

Loctite and PST are registered trademarks of Loctite Corporation

Teflon is a registered trademarks of E. I. du Pont de Nemours and Company.

Copyright 2003

Varian Vacuum Technologies

Page 3

D

eclaration o

fC

ity

Declaration of Conformity

Konformitätserklärung

Déclaration de Conformité

Declaración de Conformidad

Verklaring de Overeenstemming

Dichiarazione di Conformità

We/Wir/Nous/Nosotros/Wij/Noi: Varian, Inc.

Varian Vacu um Technologies

121 Hartwell Avenue

Lexington, MA, 02421-3133 USA

declare under our sole responsibility that the product,

erklären, in alleniniger Verantwortung, daß dieses Produkt,

déclarons sous notre seule responsabilité que le produit,

declaramos, bajo nuestra sola responsabilidad, que el producto,

verklaren onder onze verantwoordelijkheid, dat het product,

dichiariamo sotto nostra unica responsabilità, che il prodotto,

Model 979 Helium Mass Spectrometer Leak Detector

onform

to which this declaration relates is in conformity with the following standard(s) or other normative documents.

auf das sich diese Erklärung bezieht, mit der/den flogenden Norm(en) oder Richtlinie(n) übereinstimmt.

auquel se réfère cette déclaration est conforme à la (auz) norme(s) ou au(x) document(s) normatif(s).

al que se refiere esta declaración es conforme a la(s) norma(s) u otro(s) documento(s) normativo(s).

waamaar deze verklaring verwijst, aan de volende norm(en) of richtlijn(en) beantwoodt.

a cui se rifersce questa dichiarazione è conforme alla/e sequente/I norma/o documento/I normativo/i.

89/336/EEC. . . . . . . . . . . . . . . . . . . . . . Electromagnetic Compatibility Directive

EN61326:1997. . . . . . . . . . . . . . . . . . . Measurement Control and Laboratory Equipment EMC Requirements

Frederick C. Campbell

Operations Manager

Varian Vacuum Technologies

Lexington, Massachusetts, USA

June 2002

Page 4

Model 979 Helium Mass Spectrometer Leak Detector

Warranty

Products manufactured by Seller are warrant ed against defects in materials and workmanship for

twelve (12) months from date of shipment thereof to Customer, and Seller’s liability under valid warranty claims is limited, at the option of Seller, to repair, to replace, or refund of an equitable portion of

the purchase price of the Product. I tems expe ndable in normal us e are not cover ed by this warr anty. All

warranty replacement or repair of parts shall be limited to equipment malfunctions which, in the sole

opinion of Seller, are due or traceable to defects in original materials or workmanship. All obligations

of Seller under this warranty shall cease in th e event of abuse, acc ident, altera tion, misuse , or neglect of

the equipment. In-warranty repaired or replaced parts are warranted only for the remaining unexpired

portion of the original warranty period applicable to the repaired or replaced parts. After expiration of

the applicable warranty peri od, Customer shall be charged at the then current prices for part s, labor,

and transportation.

Reasonable care must be used to avoid hazards. Seller expressly disclaims responsibility for loss or

damage caused by use of its Products other than in accordance with proper operating procedures.

Except as stated herein, Seller makes no warranty, express or implied (either in fact or by operation of

law), statut o r y o r otherwise; an d , e xc e p t as stated here in , Seller shall have no liab ili ty under any warranty, express or implied (eith er in f act or by oper ation of l aw), st atuto ry or other wis e. Sta tements made

by any person, including repr esentatives of Seller, which are inconsistent or i n conflict with th e terms of

this warranty shall not be binding upon Sel ler unless reduced to writing and approved by an officer of

Seller.

Warranty Replacement and Adjustment

All claims under warranty must be made promptly afte r occurrence of cir cumstances giving rise the reto,

and must be received within the applica ble warranty period by Seller or its authorized representative.

Such claims should include the Product serial number, the date of shipment, and a full description of

the circumstances giving rise to the claim. Before any Products are returned for repair and/or adjustment, written author ization f rom Sell er or it s auth orized repr esenta tive fo r the re turn and instru ctions as

DRAFT 1/27/03

to how and where these Products should be returned must be obtained. Any Product returned to Seller

for examination shall be prepaid via the means of transportation indicated as acceptable by Seller.

Seller reserves the right to reject any warranty claim not promptly reported and any warranty claim on

any item that has been altered or has been returned by non-acceptable means of transportation. When

any Product is returned for examination and inspection, or for any other reason, Customer shall be

responsible for all damage resulting from improper packing or handling, and for loss in transit, not withstanding any defect or non-conformity in the Product. In all cases, Seller has the sole responsibili ty for

determining the cause and nature of failure, and Seller’s determina tio n w ith regard the reto shall be

final.

If it is found that Seller’s Product has been returned without caus e and i s still s ervice able, Customer will

be notified and the Product returned at Customer expense; in addition, a charge for testing and examination may be made on Products so returned.

ii

Page 5

Model 979 Helium Mass Spectrometer Leak Detector

l

Items Not Covered Under Warranty

Examples of items not normally covered under warranty include ion sources, TC gauges, O-rings,

spectrometer tube cleaning and overhaul, mechanical pump oils, vacuum system overhauls, and

obvious abuse or customer error. These items are considered normal maintenance for this type of

equipment.

3/1/00

Hazard and Safety Information

Some common international symbols used in this manual and the equipment itself are

shown below.

OFF Power Switch Position Earth Ground

ON Power Switch Position Hot Surface

AC – Alternating Current Dangerous Voltage, Risk of

Electrical Shock

This manual uses the following standard safety protocols:

NOTE The notes contain important information taken from the text.

CAUTION The caution messages are displayed before procedures, which

if not followed, could cause damage to the equipment.

WARNING The warning messages are for attracting the attention of the

operator to a particular procedure or practice which, if not

followed correctly, could lead to serious injury.

DRAFT 1/27/03

iii

Page 6

Solvents

Model 979 Helium Mass Spectrometer Leak Detector

Operators and service personnel must be aware of all hazards associated with this

equipment. They must know how to recognize hazardous and potentially hazardous

conditions, and know how to avoid them. The consequences of unskilled, improper, or

careless operation of the equipment can be serious. This product must only be operat ed and

maintained by trained personnel. Every operator or service person must read and

thoroughly understand operation/maintenance manuals and any additional information

provided by Varian Vacuum Technologies. All warning and cautions should be read

carefully and strictly ob served. Consult lo cal, state, and national agencies r egarding specif ic

requirements and regulati ons. Address any safety, operation, and/or maintenance questions

to your nearest Varian Vacuum Technologies office.

CAUTION The mechanical components of leak detectors are typically

cleaned with alcohol, methanol, or other solvents. When

heated, sprayed, or exposed to high-temperature equipment,

these solvents become flammable and explosive, causing

serious injury or death. Do not use th ese solvents near a

high-temperature source. Ventilate the working area with a

blower and work in a large, well-ventilated room.

DRAFT 1/27/03

Alcohol, methanol, or other solvents are irritants, narcotics,

depressants and/or carcinogens. Their inhalation and/or

ingestion may produce serious side effects. Prolonged or

continued contact with the skin will result in absorption

through the skin and moderate toxicity. Always ensure that

cleaning operations are carried out in large, well-ventilated

rooms, and wear eyeshields, gloves, and protective clothing.

CAUTION Do not clean any aluminum parts with Alconox

not compatible with aluminum and will cause damage.

NOTE During reassembly, always use Loctite

(teflon-impregnated pipe thread compound) on pipe threads.

PST

®

. Alconox is

iv

Page 7

Model 979 Helium Mass Spectrometer Leak Detector

Equipment, General

WARNING Equipmen t ti gh tness is guaranteed for n o rm a l operating

CAUTION The performance and operating safety of this equipment can

CAUTION Always allow at least 4 inches of clearance adjacent to the

Power and Static

conditions when the equipment le aves the factory. It is the

user’s responsibility to maintain the level of tightness

particularly when pumping dangerous products.

only be guaranteed if it is operated acc ording to normal

conditi o ns of use.

ventilation holes at the front, back and bottom of the equipment

enclosure.

WARNING Disconnect power from the 979 before performing any

maintenance procedure that requires physically disconnecting

any part of the system.

CAUTION Varian strongly recommends the use of surge protect ion to

improve the immunity of the 979 Series leak detectors against

unidirectional transients caused by the following phenomena:

❑ Switching phenomena in the power network ( e.g., switchi ng

of capacitor banks)

❑ Faults in the power network

❑ Indirect lightning strokes

CAUTION Many components of the 979 are static sensitive devices.

Varian Vacuum Technologies recommends that you wear a

grounding device when performing any maintenance on the

979 and especially when performing maintenance of static

sensitive parts.

DRAFT 1/27/03

v

Page 8

Model 979 Helium Mass Spectrometer Leak Detector

WARNING This equipment is designed to meet current EEC regulations:

LVD (Low Voltage Directive, 73/23/EEC) and EMC

(Electromagnetic Compatibility, 89/336/EEC Directive) for

Installation Category II , Pollution Degree II environment for

Industrial, Scientific, Measuring and Process Control electrical

equipment.

❑ Any modifications on the part of the user are liable to cause

non-compliance with regulations or affect the EMC

performance and the safety of the product. Varian Vacuum

Technologies cannot be held responsibl e for consequences

resulting from such intervention.

❑ The equipment can be damaged by incorrect mains AC

supply voltages, the Radio Frequency (RF) and Electrostatic

Discharge (ESD) energy inputs that can exceed the

maximum ratings, operating in very hig h temperatures or

without adequate ventilation, immersion in liquids, and

physical abuse.

❑ All electrical connections must be perf ormed by a qualified

electrician and must comply with national and local codes.

DRAFT 1/27/03

❑ Ensure that the electrical installation conforms with your

local safety requirements.

❑ Electrical installati on must include the appropriate branch

circuit (at least 2 0 A) w i th a lo n g ti me de lay and a relia b le

earth ground. Do not use an extension cord.

❑ Use only the power cord that was provided with your leak

detector. The use of extension cords is not recommended

and could result in damage to the equipment and los s of

warranty.

❑ To avoid electric shock, connect the product power cord to

a grounded power receptacle. A protective ground

connection by way of the grounding condu ctor in the power

cord is essential for safe operation.

❑ Before powering the unit the first time, verify that the unit is

configured to operate for the local mains supply voltage.

❑ Opening the enclosure may expose hazardous voltages.

Always disconnect the power cord and inter face cables

before opening the enclosure. Do not touch the power

inlet’s contacts for at least 10 seconds after disconnecting

the power cord.

vi

Page 9

Model 979 Helium Mass Spectrometer Leak Detector

CAUTION This equipment generates , uses, and can radiate RF energy and

if not installed and used in accordance with the instructional

manual, may cause harmful interference to radio

communications.

When this equipment is operated in a commerci al environment

operation is subject to the foll owin g two conditions:

❑ This equipment may not cause harmful interference, and

❑ This equipment must accept any interference received,

including interference (RF and ESD) that may cause

undesired operation.

This equipment may need to be res et after RF and/or ES D events

by cycling the Power Switch/Circuit Breaker on the back panel

of the unit.

Operation of this equipment i n a residential ar ea is also likely t o

cause harmful radio communications interference in which

case the user will be required to correct the interference at his

own expense.

Vacuum Equipment and Cleanliness

Cleanliness is vital when servicing the leak detector or any vacuum equipment. There are

some techniques that are more important in leak detector servicing than in general vacuum

work:

CAUTION Do not use sili c o ne oil or silicon e grease.

Use powder-free butyl or polycarbonate gloves to prevent skin

oils from getting on vacuum surfaces.

Do not clean any aluminum parts with Alconox

not compatible with aluminum and will cause damage.

NOTE Normally, it is unnecessary to use vacuum grease. However, if

it must be used, avoid silicone types, and use it sparingly .

Apiezon

Technologies Part No. 695400004).

®

L grease is recommended (Varian Vacuum

®

. Alconox is

DRAFT 1/27/03

vii

Page 10

O-ring Care

When removing, checking or replacing O-rings:

Model 979 Helium Mass Spectrometer Leak Detector

NOTE Varian Vacuum Technologies recommends replacing all

O-rings during routine maintenan ce or during any maintenance

procedure requiring that O-rin gs be removed.

CAUTION Remove O-rings carefully with your fin gers. Do not use metal

tools for this task. This prevents scratching of any sealing

surfaces.

❑ Wipe all O-rings clean with a lint-free cloth before

installatio n to en s u re th at no foreign ma t te r is present to

impair the se al .

❑ Do not use grease or other substance on O-rings that will

come in contact with the spectrometer tube.

❑ Do not use alcohol, methanol or other solvents on O-rings.

To do so causes deterioration and reduces their ability to

hold a vacuum.

❑ If applicable, apply a small amount of Apiezon

and wipe the O-rings “shiny” dry.

®

L grease

DRAFT 1/27/03

NOTE Due to the effective cleaning nature of VacuSolv solvent and

its residue-free properties, Varian Vacuum T echnologies’

Component and Spectrometer Tube Cleaning Kit

(Part Number 670029096), used in accordance with the kit

instructions, is recommended for cleaning the spectrometer

tube components. The kit can also be used for fine cleaning

other parts in the leak de tector’s vacuum system such as valves

and fittings. No rinsing steps or high-t emperature d ry in g is

required following cleaning wit h VacuSolv. Although

appropriate precaution s are advised, VacuSolv is co mpa tible

with most materials and does not contain toxic chemicals or

CFCs (chlorofluorocarbons).

viii

Page 11

Model 979 Helium Mass Spectrometer Leak Detector

Spectrometer Tube

CAUTION The spectrometer tube operates at a very high vacuum

produced by the high vacuum pump. Service of the

spectrometer tube requires that this vacuum be vented to the

atmosphere.

CAUTION Do not use grease or ot her subs ta nce on O-ri ngs that will c ome

in contact with the spectrometer tube.

CAUTION If the spectro m e te r tu b e magnet com e s in co n ta c t w i th a

magnetic surface, the magnet may lose its gauss, causing the

spectrometer tube to lose sensitivity.

WARNING Store the Ion Source in a cool, dry area in a ti ghtly sealed

container. Wash hands thoroughly after handling the Ion

Source and especially befo re smoking or eating.

Gross Leak Option

If the Gross Le ak o pt ion is installe d :

CAUTION The Gross Leak is calibrated at the fact ory and if any alteration

is made, the Gross Leak must be returned to the factory for

recalibration. F or ret urns , cont act Varian Vacuum Technologies

Customer Service at 1-800-8VARIAN.

DRAFT 1/27/03

ix

Page 12

Pumps

Model 979 Helium Mass Spectrometer Leak Detector

WARNING To avoid injury, use proper lifting techniques when moving

pumps. Your system may have pumps that require two people

to move them safely.

WARNING The vacuum pumps are also compressors; incorrect operation

may be dangerous. Study the “Mechanical Pump Operation

Manual” enclosed with your pump before starting the pumps.

The pumps are designed to prevent any thermal risk for user

safety. However, specific operating conditions may generate

temperatures >70 °C.

Hot oil will burn the skin. Service of the pumps in this area

must be performed by authorized personnel onl y. Stand back

from mechanical pump before starting.

CAUTION Check the oil level often. Do not allow oil-based mechanical

pumps to run when oil level is below LOW mark. Damage to

pumps can occur if operated with no oil.

DRAFT 1/27/03

WARNING To avoid injury, wait until the turbo pump is completely

stopped before disconnecting it from the vacuum system.

x

Page 13

Model 979 Helium Mass Spectrometer Leak Detector

Varian Services

The following are just a f ew of the many se rvi ces that Varian offers i ts cust omers . Pleas e see

our catalog, or contact us to learn of the se rvi ces tha t a re avai labl e. Conta ct Varian Vacuum

Technologies Customer Service at 1-8 00-8VARIAN for details.

❑ Rebuilt spectrometer tubes are available on an exchange basis.

❑ NIST-traceable calibrated leak testi ng and verification services.

Contacting Varian Vacuum Technologies

In the United States, you can contact Varian Vacuum Technologies Customer Service at

1-800-8VARIAN.

Internet users:

❑ Send email to Customer Service & Technical Support at

vpl.customer.support@varianinc.com

❑ Visit our web site at www.varianinc. com/vacuum

❑ Order on line at www.evarian.com

See the back cover of this manual for a listing of our sales and service offices.

Tools Required for Component Replacement

The following tools are required for component replacement

❑ Phillips screwdriver ❑ 9-16Wrench

❑ Slotted screwdriver ❑ 13-16 Wrench

❑ Long slotted screwdriver ❑ 11-32 Nut driver

❑ Crescent wrench ❑ 5-64 Allenwrench

❑ PLCC chip extracting device,

such as an AMP 821903-5

❑ A non-metal device for removing O-rings

Materials (not Parts) Required for Component Replacement

❑

Powder-free butyl or

polycarbonate gloves

❑ VacuSolv or similar solvent

DRAFT 1/27/03

❑ Clean, non-magnet ic surface ❑ Cotton swabs

❑ Lint-free wipes ❑ Loctite PST 565 Thread Sealant

xi

Page 14

Preface

This manual contains information for field replacement of components of the Model 979

Mass Spectrometer Heli um Leak Detect or. It is organ ized so that simila r items or procedures

are included in a section. The manual moves from a brief overview of the leak detector to

specific replac ement procedur es to c ali brati on and tuning pr ocedu res t hat mus t be run a ft er

the replacement of certain componen ts. Photographs are liberally used to help document

procedures. An appendix provides Assembly Drawings and Bills of Materials for reference.

The specific sections included in the manual are:

Model 979 Helium Mass Spectrometer Leak Detector

Preface

Section 1 “System Overview”

Section 2 “Cleaning the Test Port”

Section 3 “Removing the Covers

from the 979”

Section 4 “The Internal Calibrated Leak”

Section 5 “Spectrometer Tube Assembly”

Section 6 “Test Port Thermocouple Gauge”

DRAFT 1/27/03

Section 7 “TheVarianPlatform”

Section 8 “Internal High Speed Turbo and

Mechanical Pumps”

Contains information relevant to the remainder

of the manual.

A brief overview of the 979.

How to clean the test port.

How to open individual sections or all of the

979 covers.

Detailed steps for removing and replacing the

calibrated leak.

Spectrometer tube assembly procedures from

replacement as an assembly to replacement of

individual components. This section also

includes a full overhaul procedure.

How to access and replace the test port

thermocouple gauge.

Procedures to access and replace the printed

circuit boards that make up the Varian Platform.

Replacement of the turbo pump and the

mechanical pumps.

xii

Section 9 “Calibration and Manual Tuning”

Section 10 “Leak Checking for Reliability”

Section A “Assembly Drawings and

Bills of Materials”

Section B “979 COM Cable” 979 COM Cable sketch and pinout assignments .

Section C “979 Spare Parts List” A table of the 979 Spare Parts List with ordering

Procedures that must be completed after

replacement of certain components.

General information regarding testing for leaks

after component replacement.

Assembly drawings and Bills of Materials for

reference.

numbers.

Page 15

Model 979 Helium Mass Spectrometer Leak Detector

DRAFT 1/27/03

xiii

Page 16

Model 979 Helium Mass Spectrometer Leak Detector

DRAFT 1/27/03

This page intentionally left blank.

Page 17

Model 979 Helium Mass Spectrometer Leak Detector

Table of Contents

Warranty .............................................................................................................................................ii

Preface ..............................................................................................................................................xii

Section 1. System Overview ...........................................................................................................1-1

1.1 Front Panel Displays and Controls ......................................................................................1-1

1.1.1 Key Switch ..................................................................................................................1-2

1.2 Rear Panel...........................................................................................................................1-3

1.2.2 System Control and Communication Panel ................................................................1-3

1.3 Inside the Model 979............................................................................................................1-4

1.3.1 Inside Front View ........................................................................................................1-4

1.3.2 Side View — Card Cage Side.....................................................................................1-5

1.3.3 Side View — Calibrated Leak, Valve Block Side ........................................................1-6

1.3.4 Rear View....................................................................................................................1-6

Section 2. Cleaning the Test Port ...................................................................................................2-1

Section 3. Removing the Covers from the 979 ...............................................................................3-1

3.1 Opening the Front Panel .....................................................................................................3-1

3.2 R emoving the Front Panel...................................................................................................3-3

3.3 Removing the Rear Panel....................................................................................................3-5

3.4 R emoving the Side Panel ....................................................................................................3-6

3.5 R eplacing All Covers and Panels.........................................................................................3-7

3.5.1 Replacing the Side Panel............................................................................................3-7

3.5.2 Replacing the Rear Panel...........................................................................................3-7

3.5.3 Replacing the Front Panel...........................................................................................3-7

Section 4. The Internal Calibrated Leak ..........................................................................................4-1

4.1 Recalibrating the Internal Calibrated Leak ..........................................................................4-1

4.2 Replacing the Internal Calibrated Leak................................................................................4-1

4.2.1 Removing the Valve Block Coil and Plunger Assembly..............................................4-2

4.2.2 Removing the Internal Calibrate Leak.........................................................................4-6

4.2.3 Replacing the Internal Calibrated Leak.......................................................................4-9

4.2.4 Examining and Cleaning the Valve Block Coil and Plunger Assembly.....................4-11

4.2.4.1 Examining and Cleaning the Cal Leak Valve Block .....................................4-11

4.2.4.2 Examining and Cleaning the Coil and Plunger Assembly ............................4-12

4.2.4.3 Examining and Cleaning the Valve Stem and End Cap ...............................4-13

4.2.5 Replacing the Coil and Plunger Assembly................................................................4-14

DRAFT 1/27/03

Section 5. Spectrometer Tube Assembly ........................................................................................5-1

5.1 Spectrometer Tube Exchange ............................................................................................5-1

5.1.1 Removing the Spectrometer Tube Assembly for Complete Exchange.......................5-1

5.1.2 Examining and Cleaning the Centering Ring and O-Ring...........................................5-5

5.2 Reinstalling the Spectrometer Tube.....................................................................................5-6

5.3 R emoving the Button Thermocouple from the Spectrometer Tube .....................................5-7

xv

Page 18

Model 979 Helium Mass Spectrometer Leak Detector

5.4 Replacing the Button Thermocouple..................................................................................5-10

5.5 Removing the Ion Source ..................................................................................................5-12

5.6 Replacing the Ion Source...................................................................................................5-15

5.7 Removing the Preamplifier.................................................................................................5-17

5.8 Replacing the Preamplifier.................................................................................................5-19

5.9 S pectrometer Tube Overhaul .............................................................................................5-20

5.9.1 Removing the Spectrometer Tube Assembly as Part of Overhaul............................5-21

5.9.2 Removing the Magnet Assembly from Spectrometer Tube as Part of Overhaul ......5-25

5.9.3 Removing the Button Thermocouple as part of Spectrometer Tube Overhaul.........5-26

5.9.4 Removing the Ion Source as part of Spectrometer Tube Overhaul..........................5-27

5.9.5 Removing the Preamplifier as Part of Spectrometer Tube Overhaul........................5-30

5.9.6 Removing the Deflecting Magnetic Pole Pieces as Part of

Spectrometer Tube Overhaul.............................................................................................5-31

5.9.7 Examining and Cleaning the Spectrometer Parts.....................................................5-32

5.10 Reassembling the Spectrometer Tube ............................................................................5-35

5.10.1 Replacing the Deflecting Magnetic Pole Pieces......................................................5-35

5.10.2 Replacing the Preamplifier as Part of Spectrometer Tube Overhaul......................5-35

5.10.3 Replacing the Ion Source as Part of Spectrometer Tube Overhaul........................5-36

5.10.4 Replacing the Button Thermocouple as Part of Spectrometer Tube Overhaul.......5-39

5.10.5 Replacing the Magnet Assembly.............................................................................5-40

5.10.6 Re-Installing the Spectrometer Tube ......................................................................5-43

Section 6. Test Port Thermocouple Gauge .....................................................................................6-1

6.1 R emoving the Test Port Thermocouple Gauge ..................................................................6-1

6.2 Replacing the Test Port Thermocouple Gauge....................................................................6-3

Section 7. The Varian Platform .......................................................................................................7-1

7.1 Location of Circuit Boards ...................................................................................................7-1

7.2 Removing the Card Stack from the Card Cage ................................................................... 7-3

7.2.1 Removing the Connections from the Front of the Boards...........................................7-4

7.2.2 Removing the Connections from the Back of the Boards ...........................................7-5

7.2.3 Removing the CPU Board Power Connection ............................................................7-6

7.2.4 Removing the Card Stack...........................................................................................7-7

7.3 Replacing a Board ...............................................................................................................7-8

7.4 Replacing the Card Stack into the Card Cage.....................................................................7-9

7.5 Replacing the Turbo Controller Board ...............................................................................7-10

7.5.1 Removing the Turbo Controller Board ......................................................................7-11

7.5.2 Installing the Turbo Controller Board ........................................................................7-12

7.6 The Touch Screen and Control Panel Assemblies ............................................................7-12

7.6.1 Removing the Touch Screen Assembly....................................................................7-13

7.6.2 Replacing the Touch Screen Assembly....................................................................7-15

7.6.3 Removing the Control Panel Assembly.....................................................................7-16

7.6.4 Replacing the Control Panel Assembly.....................................................................7-17

DRAFT 1/27/03

xvi

Page 19

Model 979 Helium Mass Spectrometer Leak Detector

Section 8. ...................................................... Internal High Speed Turbo and Mechanical Pumps 8-1

8.1 Removing the Turbo Pump .................................................................................................8-1

8.1.1 Moving the Spectrometer Tube Assembly ..................................................................8-2

8.1.2 Removing the Turbo-to-Spec Tube Manifold ..............................................................8-4

8.1.3 Removing the Power and Valve Block Connections...................................................8-5

8.2 Replacing the Turbo Pump ..................................................................................................8-6

8.2.1 Examining and Cleaning Centering Rings, O-rings and the Manifold.........................8-6

8.2.2 Replacing the Turbo Pump .........................................................................................8-7

8.2.3 Replace the Turbo-to-Spec Tube Manifold.................................................................8-8

8.2.4 Replacing the Spectrometer Tube ..............................................................................8-9

8.3 Replacing the Mechanical Pumps......................................................................................8-10

8.3.1 Examining and Cleaning the Centering Ring and O-Ring.........................................8-13

8.3.2 Replacing the Mechanical Pumps.............................................................................8-14

8.4 Changing the Mechanical Pump Fluid ...............................................................................8-14

8.5 Replacing Tip Seals in Dry Mechanical Pumps .................................................................8-14

Section 9. Calibration and Manual Tuning ......................................................................................9-1

9.1 Calibrate the 979 .................................................................................................................9-1

9.2 M anual Tuning.....................................................................................................................9-2

9.2.1 Manual Tuning using the Front Panel Touch Screen..................................................9-2

9.2.2 Manual Tuning using the Serial Port...........................................................................9-4

9.3 Gauge Calibration Procedures.............................................................................................9-6

9.3.1 System Pressure Gauge Calibration Procedure.........................................................9-7

9.3.1.1 Vacuum (Low Pressure) Calibration ...............................................................9-7

9.3.1.2 Atmospheric Calibration ................................................................................. 9-8

9.3.2 Test Port Pressure Thermocouple Gauge C alibration Procedure...............................9-8

9.3.2.1 Vacuum (Low Pressure) Calibration ...............................................................9-9

9.3.2.2 Atmospheric Calibration ................................................................................. 9-9

Section 10. Leak Checking for Reliability ....................................................................................... 10-i

10.1 General Suggestions for Leak Checking .........................................................................10-i

Appendix A. Assembly Drawings and Bills of Materials ..................................................................A-1

Appendix B. 979 COM Cable ..........................................................................................................B-1

Appendix C. 979 Spare Parts List .................................................................................................. C-1

Index .................................................................................................................................................. 1

xvii

DRAFT 1/27/03

Page 20

Model 979 Helium Mass Spectrometer Leak Detector

DRAFT 1/27/03

This page intentionally left blank.

Page 21

Model 979 Helium Mass Spectrometer Leak Detector

List of Figures

Figure Description Page

1-1 979 Front Panel Displays and Controls ..............................................................................1-1

1-2 979 Rear Panel...................................................................................................................1-3

1-3 979 System Control and Communication Panel .................................................................1-3

1-4 979 Interior: Front View.......................................................................................................1-4

1-5 979 Interior: Side View Card Cage .....................................................................................1-5

1-6 979 Interior: Side View Valve Block and Internal Calibrated Leak......................................1-6

2-1 Test Port with Blank-Off Flange Cap ..................................................................................2-1

2-2 Centering Ring with O-ring..................................................................................................2-2

2-3 O-ring and Centering Ring on Test Port .............................................................................2-3

2-4 Test Port with Connected Device........................................................................................2-3

3-1 979 Front Panel ..................................................................................................................3-1

3-2 Molex Connector on Touch Panel Assembly......................................................................3-2

3-3 Front Panel Ground Strap...................................................................................................3-3

3-4 Ground Strap Removal from Front Panel ...........................................................................3-3

3-5 Rear Panel Removal...........................................................................................................3-5

3-6 Side Panel Removal ...........................................................................................................3-6

3-7 Front Panel PCB Harness Connector. ................................................................................3-8

4-1 979 Side View: Removal of Valve Block Coil and Plunger Assembly.................................4-1

4-2 979 Side View.....................................................................................................................4-2

4-3 End Cap and Valve Stem....................................................................................................4-3

4-4 Valve Stem with End Cap Removed...................................................................................4-3

4-5 Valve Stem Removal ..........................................................................................................4-4

4-6 V7 Valve Block Power Connector Removal........................................................................4-4

4-7 Slotted Post on Coil and Plunger Assembly .......................................................................4-5

4-8 Securing the Coil to Loosen Plunger Assembly..................................................................4-5

4-9 979 Side View: End Cap, Valve Stem, and Coil and Plunger Assembly Removed............4-6

4-10 Elbow Flat Secured with Crescent Wrench.........................................................................4-7

4-11 Loosening Leak with Open W rench....................................................................................4-7

4-12 Removal of Calibrated Leak................................................................................................4-8

4-13 Elbow after Removal of Calibrated Leak.............................................................................4-9

4-14 Connecting Leak with Open Wrench ................................................................................4-10

4-15 Calibrated Leak Strap Replacement.................................................................................4-10

4-16 Top of Plunger..................................................................................................................4-12

4-17 Bottom of Plunger.............................................................................................................4-13

4-18 Placement of Plunger Assembly into Coil.........................................................................4-14

4-19 Coil and Plunger Assembly Replacement.........................................................................4-15

4-20 Positioning Valve Stem onto Coil and Plunger Assembly.................................................4-15

4-21 End Cap Replacement......................................................................................................4-16

5-1 Spectrometer Tube and Turbo Pump .................................................................................5-2

5-2 Ground Cable and Screw for Removing Connectors..........................................................5-3

DRAFT 1/27/03

xix

Page 22

Model 979 Helium Mass Spectrometer Leak Detector

5-3 Wing Nut Under Shelf.........................................................................................................5-3

5-4 NW-25 Quick Clamp on Turbo-to-Spec Tube Manifold......................................................5-4

5-5 O-ring Inspection ................................................................................................................5-5

5-6 Button TC, Spectrometer Tube, and Turbo Pump..............................................................5-7

5-7 Connector Removal............................................................................................................5-8

5-8 Phillips Screws on Button TC Assembly.............................................................................5-8

5-9 Flange Cap and Center Post on Button TC Assembly .......................................................5-9

5-10 Sensing Wire ....................................................................................................................5-10

5-11 Flange Cap Grooves.........................................................................................................5-11

5-12 Ion Source, Spectrometer Tube, and Turbo Pump...........................................................5-12

5-13 Ion Source Removal ......................................................................................................... 5-13

5-14 Alignment Pin.................................................................................................................... 5-14

5-15 Alignment Hold and Ground Slit Plate in Ion Source Cavity.............................................5-14

5-16 Ion Source Insertion..........................................................................................................5-15

5-17 Alignment of Flange Cap Grooves with Ion Source Center Legs .....................................5-16

5-18 Spectrometer Tube and Turbo Pump ...............................................................................5-17

5-19 Preamplifier Removal ....................................................................................................... 5-18

5-20 Preamplifier Slot and Alignment Pin ................................................................................. 5-19

5-21 Alignment of Flange Cap Grooves with Preamplifier Legs...............................................5-19

5-22 Spectrometer Tube and Turbo Pump ...............................................................................5-21

5-23 Ground Cable and Screw ................................................................................................. 5-22

5-24 Wing Nut under Shelf........................................................................................................5-22

5-25 NW-25 Quick Clamp on Turbo-to-Spec Tube M anifold ....................................................5-23

5-26 Magnet Body Bracket Screws . ..........................................................................................5-24

5-27 Spectrometer Tube Magnet Assembly Slotted Screws ....................................................5-25

5-28 Sliding the Magnet Assembly off the Spectrometer Tube.................................................5-25

5-29 Phillips Screws on Button TC Assembly...........................................................................5-26

5-30 Flange Cap, Center Post, and Button TC.........................................................................5-26

5-31 Button TC w ith Flange Cap and Sensing Wire .................................................................5-27

5-32 Removal of Ion Source from Spectrometer Tube.............................................................5-28

DRAFT 1/27/03

5-33 Ion Source and Alignment Pin .......................................................................................... 5-28

5-34 Ion Source Cavity .............................................................................................................5-29

5-35 Ground Slit Plate...............................................................................................................5-29

5-36 Removal of Preamplifier ...................................................................................................5-30

5-37 Deflecting Magnetic Pole Piece Slotted Screws...............................................................5-31

5-38 O-ring Removal from Deflecting Magnetic Pole Piece......................................................5-31

5-39 Removal of Second Deflecting Magnetic Pole Piece........................................................5-32

5-40 Discolored Ground Slit Plate.............................................................................................5-32

5-41 Discolored Deflecting Magnetic Pole Piece......................................................................5-33

5-42 VacuSolv Cleaning Wipes ................................................................................................5-33

5-43 O-ring Inspection ..............................................................................................................5-34

5-44 Replace the Preamplifier ..................................................................................................5-35

5-45 Flange Cap Grooves Aligned with Preamplifier Legs.......................................................5-36

5-46 Insertion of Ground Slit Plate in Ion Source Cavity...........................................................5-36

5-47 Properly Inserted Ground Slit Plate ..................................................................................5-37

5-48 Ion Source Alignment Pin ................................................................................................. 5-38

xx

Page 23

Model 979 Helium Mass Spectrometer Leak Detector

5-49 Flange Cap Grooves Aligned with Ion Source Legs .........................................................5-38

5-50 Button TC..........................................................................................................................5-39

5-51 Flange Cap Grooves Aligned with Button TC Center Post Key........................................5-40

5-52 Magnet Assembly Bracket Screws ...................................................................................5-40

5-53 Set Screw and GA Pole Piece ..........................................................................................5-41

5-54 Screws for Mounting Magnet Assembly to Spectrometer Tube........................................5-42

6-1 Test Port Thermocouple Gauge, P lug, and Valve Block....................................................6-2

6-2 Test Port Thermocouple Gauge O-ring and Backing Ring ................................................6-2

6-3 Test Port Thermocouple Gauge O-Ring amd Backing Ring...............................................6-3

7-1 979 Interior: Side View of Card Cage .................................................................................7-1

7-2 979 Circuit Boards in Card Cage........................................................................................7-2

7-3 Card Cage Bracket and Connectors on Front of Boards....................................................7-3

7-4 Shared Power Cable...........................................................................................................7-4

7-5 Connectors on Rear of Boards ...........................................................................................7-5

7-6 Wire to CPU Power Connection..........................................................................................7-5

7-7 Boards Partially out of Card Cage ......................................................................................7-6

7-8 CPU Power Connector........................................................................................................7-6

7-9 Card Stack Removed from Card Cage............................................................................... 7-7

7-10 Boards in Card Cage .......................................................................................................... 7-8

7-11 Card Cage Interior ..............................................................................................................7-9

7-12 Turbo Controller Board .....................................................................................................7-11

7-13 Touch Screen Assembly...................................................................................................7-13

7-14 Control Panel Assembly (Right)........................................................................................7-14

7-15 Control Panel Assembly (Right)........................................................................................7-17

8-1 Turbo Pump ........................................................................................................................8-1

8-2 Spectrometer Tube and Turbo Pump .................................................................................8-2

8-3 Wing Nut .............................................................................................................................8-3

8-4 NW-25 Quick Clamp on Turbo-to-Spec Tube Manifold ......................................................8-4

8-5 NW-25 and NW-40 Quick Clamp on Turbo-to-Spec Tube Manifold...................................8-4

8-6 Remove the Turbo Power Connection................................................................................8-5

8-7 Inspecting an O-ring............................................................................................................8-6

8-8 Remove the Turbo Power Connection................................................................................8-7

8-9 Turbo-to-Spec Tube Manifold Connections........................................................................8-8

8-10 Connections at the Top of the Mechanical Pump .............................................................8-11

8-11 Connection at the Bottom of the Pump to Exhaust...........................................................8-11

8-12 One Mechanical Pump on a Cart......................................................................................8-12

8-13 Inspecting an O-ring..........................................................................................................8-13

9-1 Manual Spectube Tuning Screen........................................................................................9-2

9-2 Gauge Calibration Screen...................................................................................................9-6

9-3 979 Touch Panel Home Screen..........................................................................................9-7

B-1 979 COM Cable Wiring Diagram ........................................................................................B-1

DRAFT 1/27/03

xxi

Page 24

Model 979 Helium Mass Spectrometer Leak Detector

DRAFT 1/27/03

This page intentionally left blank.

Page 25

Model 979 Helium Mass Spectrometer Leak Detector

List of Tables

Table Description Page

9-1 Example: Setting the REPELLER Parameter using the Manual Spectube Tuning Screen 9-3

9-2 Example: Setting the REPELLER Parameter Value using J12 Diagnostic Port ................ 9-5

A-1 Assembly Drawings Included .............................................................................................A-1

A-2 Bills of Materials Included ..................................................................................................A-1

B-1 Summary Table of Non-Isolated I/O ..................................................................................B-1

C-1 979 Spare Parts ................................................................................................................C-1

xxiii

DRAFT 1/27/03

Page 26

Model 979 Helium Mass Spectrometer Leak Detector

DRAFT 1/27/03

This page intentionally left blank.

Page 27

Model 979 Helium Mass Spectrometer Leak Detector

Section 1. System Overview

The V arian Model 979 is a portable wide-rang e Helium Mass Spectrometer Leak Detector. It

is comprised of a turbomolecular high vacuum pump, spectrometer tube, valve block,

Varian Vacuum Technologies’ Platform leak detecto r el e ctronics, a n d a n op e rator interface

in a rugged housing. The 979 is available as a stand-alone, bench-mount unit or as a single

or dual, dry or oil sealed mechanically pumped leak testing station on a cart.

The 979 uses Varian Vacuum Technologies’ Platform leak detector electronics architecture

to operate the spectrometer assembl y, control the mechanical and high vacuum pumps,

control the valve block, and provide leak rate and syst em status information to the operator

interface. The Platf orm is a collectio n of printed c ircuit boards th at operate usi ng the PC/1 04

Bus Structure to perform the various functions of a helium mass spectrometer leak detector.

1.1 Front Panel Displays and Controls

The 979 front panel leak rate display and control buttons are locat ed on the front right-hand

side of the leak detector (Figure 1-1). The panel features large, color coded and clearly

labeled buttons, and a large, easy to read bar graph display.

A touch panel display for the initial setup and configuration of the leak detector is located

on the left of the front panel. The touch panel menus also include some service operations.

If you need additional information abo ut operations of the 979, see the Model 979

Instruction Manual.

Audio Volume

Control

Sniffer

On/Off

Pressure

Displays

Zero

Leak Rate

Display

DRAFT 1/27/03

Touch

Panel

Figure 1-1 979 Front Panel Displays and Controls

Key

Switch

Standard

Read

Leak

Calibrate

Vent

Test/Hold

1-1

Page 28

1.1.1 Key Switch

The 979 Key Switch allows three different levels of access to the touch panel system

controls—RUN, SET-UP or SER VICE. Two di fferent keys are provi ded with the le ak detector :

❑ Key T009 operates the switch in RUN, SET-UP or SERVICE positions.

The T009 key is intended for service personnel and those who are very familiar with

the operation of the unit. Operations such as manually chang ing th e valv es can only

be performed when the key switch is in the SERVICE position. No changes to the

operating parameters are allowed when the key switch is in the RUN position.

❑ Key T008 operates the switch in either the RUN or SET-UP positions.

The T008 key is intended for use by a line supervisor or engineer and allows most

parameters to be changed, but does not allow any operation that could damage the

unit. No changes to the operating parame ters are allowed when the key switch is in

the RUN position.

Model 979 Helium Mass Spectrometer Leak Detector

DRAFT 1/27/03

1-2

Page 29

Model 979 Helium Mass Spectrometer Leak Detector

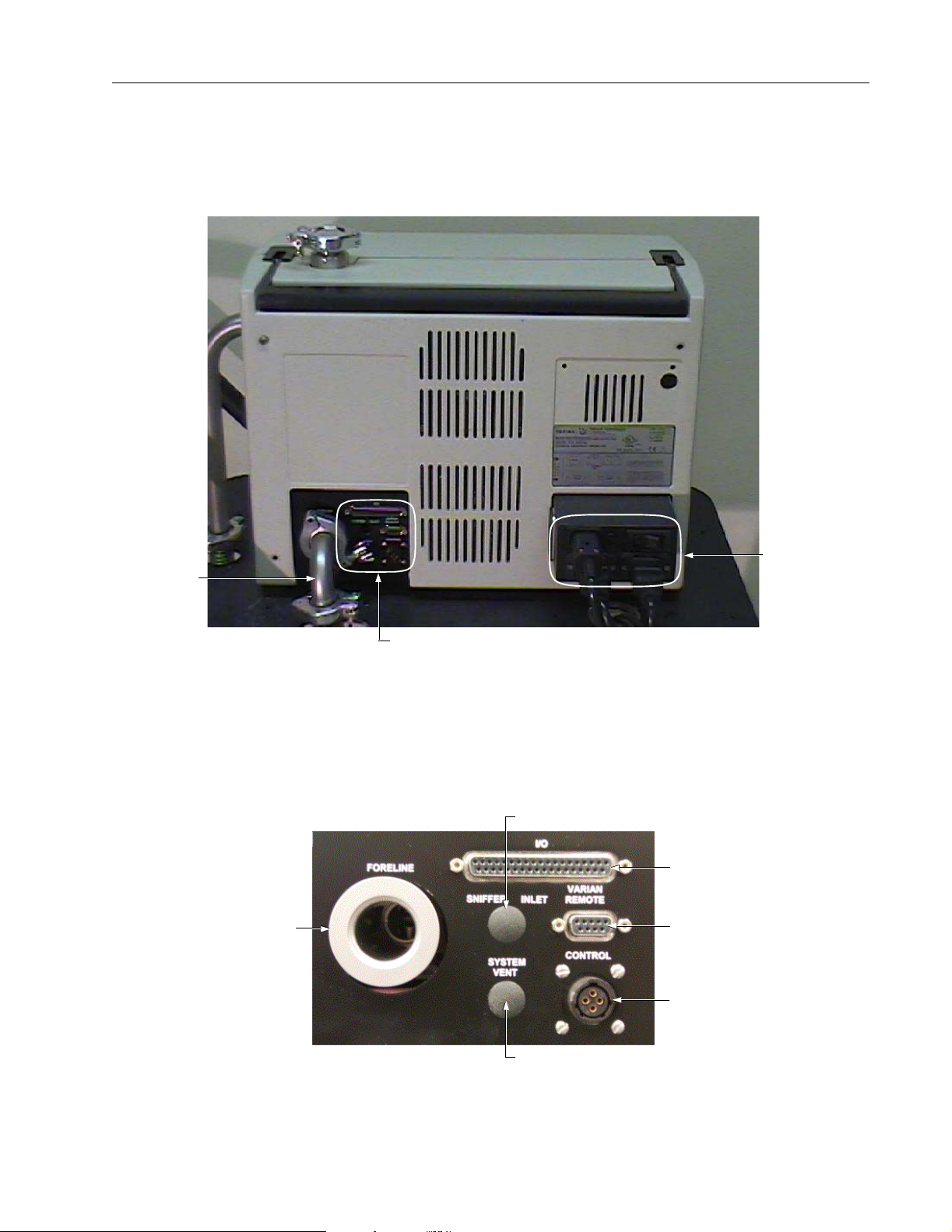

1.2 Rear Panel

The rear panel of the 979 (Figure 1-2) includes power and communications connections as

well as a manifold for connection to a mechanical pump.

Foreline

Pump

Connection

Communication Connections

Figure 1-2 979 Rear Panel

1.2.2 System Control and Communication Panel

The system control and communication panel (Figure 1-3) is located on the lower left

section of the rear panel.

Sniffer Inlet

Foreline Pump

Connection

Power

Connections

DRAFT 1/27/03

I/O Connector

Remote Control Input

Roughing Valve /

Compression Box

Control

System VentPort

Figure 1-3 979 System Control and Communication Panel

1-3

Page 30

Model 979 Helium Mass Spectrometer Leak Detector

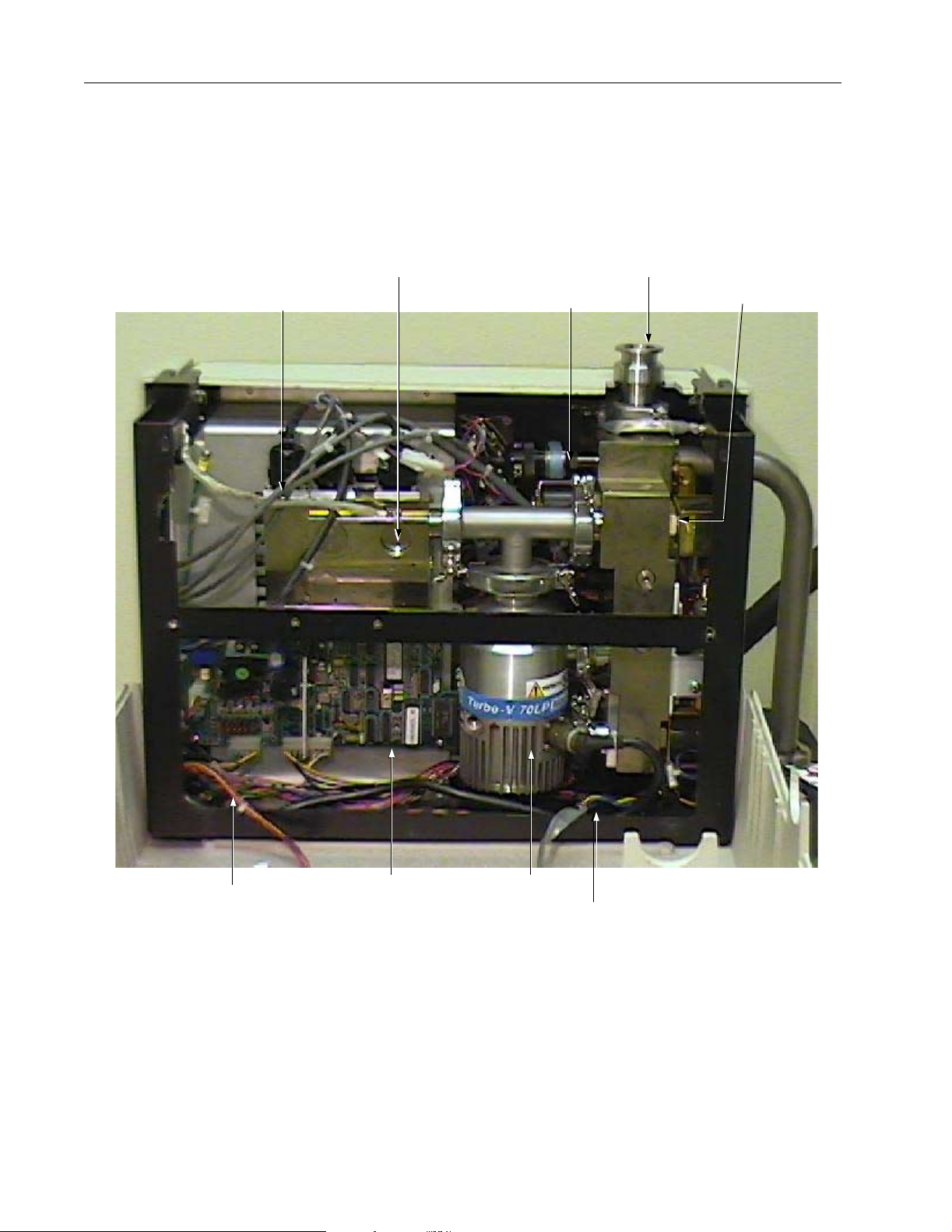

1.3 Inside the Model 979

1.3.1 Inside Front View

Most serviceable parts are accessed from the front of the leak detector (Figure 1-4).

Spectrometer Tube

Ground Strap

Spectrometer

Tube

Thermocouple

Gauge

Test

Port

Valve Block

DRAFT 1/27/03

(to Touch Screen Panel Assembly) (to Inside Front Panel)

1-4

Front Panel

Display Harness

Turbo

Controller Board

Turbo Pump

Ground Strap

Figure 1-4 979 Interior: Front View

Page 31

Model 979 Helium Mass Spectrometer Leak Detector

1.3.2 Side View — Card Cage Side

The left side of the 979 provides access to the card cage (Figure 1-5).

Card Cage

Front Side

of Unit

Card Cage

Bracket

Figure 1-5 979 Interior: Side View Card Cage

DRAFT 1/27/03

1-5

Page 32

Model 979 Helium Mass Spectrometer Leak Detector

1.3.3 Side View — Calibrated Leak, Valve Block Side

The right side of the 979 allows access to the Internal Calibrated Leak (option) (Figure 1-6).

Internal

Calibrated

Leak

Figure 1-6 979 Interior: Side View Valve Block and Internal Calibrated Leak

1.3.4 Rear View

DRAFT 1/27/03

There are no field serviceable part s on the back of the 979 under the rear panel.

Cal Leak

Valve Block

Assembly

Swagelok Fitting

1-6

Page 33

Model 979 Helium Mass Spectrometer Leak Detector

Section 2. Cleaning the Test Port

The test port is located on the outside of the Model 979 leak detector. Therefore, it is not

necessary to turn the leak det ector off or dis con n ect it from main s po w e r if this is the only

procedure being performed. If you are cleaning the test port in conjunction with other

procedures that require opening the leak detector, be sure to turn the leak detector off and

disconnect it from mains power.

The NW25 uses the blank-of f flange ca p on top of the cen tering ring when t he sys tem is not

in use or when in use but not connected to a device.

To clean the test port:

1. Turn the test port wing nut counterclockwise to loosen it (Figure 2-1), remove the quick

clamp (Varian p/n KQ25AWP) from the test port, and remove any connected devices.

CAUTION Be careful not to drop the test port blank-off flange cap when

you remove the test port tightening nut. It is deceptively heavy

for its size.

Test Port

Blank-off Flange Cap

Test Port

Tightening

Nut

Figure 2-1 Test Port with Blank-Off Flange Cap

DRAFT 1/27/03

2-1

Page 34

Model 979 Helium Mass Spectrometer Leak Detector

2. Remov e the test port blank-off flange cap and/or centering ring from the top of the test

port (Figure 2-2).

Figure 2-2 Centering Ring with O-ring

3. Remov e the O-ring from the centering ring.

4. Ex amine the O-ring for wear.

If necessary, use a new O-ring, otherwise clean the O-ring.

NOTE Varian Vacuum Technologies recommends replacing all

O-rings during routine maintenan ce or during any maintenance

procedure requiring that O-rin gs be removed.

DRAFT 1/27/03

5. Examine all parts of the test port, including inside the test port.

6. Pl ace the O-ring into the groove of the centering ring.

CAUTION Remove O-rings carefully with your fin gers. Do not use metal

tools for this task. This prevents scratching of any sealing

surfaces.

Do not use alcohol, methanol or other solvents on O-rings. To

do so causes deterioration and reduces their ability to hold a

vacuum.

Wipe all O-rings clean with a lint-free cloth before installation

to ensure tha t n o fo r ei gn matter is pr es e n t to im p air the seal.

If applicable, apply a small amount of Apiezon L grease and

wipe the O-ri n g s “shiny” dry.

In necessary, use a V acuSolv wipe to remove any dirt or foreign matter and allow parts

to air dry.

2-2

Page 35

Model 979 Helium Mass Spectrometer Leak Detector

7. Pl ace the centering ring onto the top of the test port (Figure 2-3).

Figure 2-3 O-ring and Centering Ring on Test Port

8. Replace the blank-off flange cap or connected device.

9. Rep lace the quic k clamp onto the test port and ti ghten the wing nut clockwise unt il it is

just tight enough to stay in place.

Figure 2-4 shows the system with a connected device.

Figure 2-4 Test Port with Connected Device

DRAFT 1/27/03

2-3

Page 36

Model 979 Helium Mass Spectrometer Leak Detector

DRAFT 1/27/03

This page intentionally left blank.

Page 37

Model 979 Helium Mass Spectrometer Leak Detector

Section 3. Removing the Covers from the 979

There are three main covers that encl ose the Model 979 leak detector:

❑ Front Panel

❑ Rear Panel

❑ Left Side Panel

The front and rear panels can be removed independently of each other. If you have to

remove the side panel to get to the card cage, you mus t remove the front panel, the rear

panel and the side panel in that order.

3.1 Opening the Front Panel

To open the Model 979 front panel:

Front Panel

Screw

1. Di sconnect the mains power supply and make sure all pumps are off.

WARNING Disconnect power from the 979 before performing any

maintenance procedure that requires physically disconnecting

any part of the system.

2. Remov e the 2 Phillips screws from the 979 front panel (Figure 3-1).

DRAFT 1/27/03

Front Panel

Screw

Figure 3-1 979 Front Panel

3-1

Page 38

Model 979 Helium Mass Spectrometer Leak Detector

3. Lean the top of the front panel forward.

CAUTION Be careful not to place tension on the front panel display PCB

harness.

4. I f it is not already supported on a bench, support the front panel with one hand and

press the release tab on the white molex connector (Figure 3-2) located on the touch

panel assembly and pull it to disconnect the PCB harness.

DRAFT 1/27/03

Molex

Connector

Figure 3-2 Molex Connector on Touch Panel Assembly

3-2

Page 39

Model 979 Helium Mass Spectrometer Leak Detector

3.2 Removing the Front Panel

To remove th e front panel:

1. Open the front panel as described in Section 3.1 “Opening the Front Panel”.

The ground strap, which must be removed, is located in the right bottom corner of the

front panel (Figure 3-3).

Front Panel

Ground Strap

Figure 3-3 Front Panel Ground Strap

2. Usi ng a 11-32 nut driver, remove the 8-32 nut that holds the ground strap (Figure 3-4).

Figure 3-4 Ground Strap Removal from Front Panel

DRAFT 1/27/03

3-3

Page 40

Model 979 Helium Mass Spectrometer Leak Detector

3. I f it is not already supported on a bench, support the front panel with one hand and lift

the ground strap up and away from the screw post it is on.

4. Remove the front panel and place it in a safe place where damage cannot occur to the

front panel displays, buttons, or to the touch panel assembly PCB located inside the

front panel.

CAUTION Although the Touch Screen Panel is made of i ndustrial-strength

glass and is high ly durable, it ca n be br oken if it is hit sharply.

DRAFT 1/27/03

3-4

Page 41

Model 979 Helium Mass Spectrometer Leak Detector

3.3 Removing the Rear Panel

To perform this procedure:

1. Di sconnect the mains power supply and make sure all pumps are off.

WARNING Disconnect power from the 979 before performing any

maintenance procedure that requires physically disconnecting

any part of the system.

2. Remov e the 4 l ar g e P hilli ps screws l ocat ed on ea ch corn er of t he rear panel (Fi gur e 3-5).

Handle

Screws

Figure 3-5 Rear Panel Removal

3. Li ft the handle up.

4. Remove the panel and put it in a safe place.

Screws

DRAFT 1/27/03

3-5

Page 42

Model 979 Helium Mass Spectrometer Leak Detector

3.4 Removing the Side Panel

To remove the side panel:

1. Open and remove the fron t panel as descr ibed in Secti on 3.1 “Opening the Front Panel”

on page 3-1 and Section 3.2 “Removing the Front Panel” on page 3-3.

2. Remov e the rear panel as described in Section 3.3 “Removing the Rear Panel” on

page 3-5.

3. Bac k out one of the silver Phillips screws on the black vented side panel (Figure 3-6).

Silver Screw

4. Slide the screw toward th e ce n te r of the panel.

5. Support the panel with one hand and back out the other screw on the side panel.

DRAFT 1/27/03

6. Slide the screw toward the center, moving the latch from under the chassis.

7. Place the panel where it will not get damaged.

Silver Screw

Figure 3-6 Side Panel Removal

This moves the latch from under the chassis and dis engages this side of the panel.

The panel disengages, completel y exposing the card cage.

3-6

Page 43

Model 979 Helium Mass Spectrometer Leak Detector

3.5 Replacing All Covers and Panels

Each of the pro c edures in thi s se ction is comp l e te for its state d p u rp o se. If all pane l s an d

covers have been removed, however, they must be replaced in the order given in this

procedure.

3.5.1 Replacing the Side Panel

To replace the side panel:

1. Pl ace the panel on the side with the card cage oriented so the screws are up and facing

you.

2. Support the panel and insert a Phillips screwdriver into one of the silver screws.

3. Sl ide the screw toward the outside of the panel to move the latch under the chassis.

4. Tighten the screw.

5. Repeat for the other side of the panel.

3.5.2 Replacing the Rear Panel

To replace the rear panel:

1. Place the rear panel onto the chassis, fitting the top under the port nut.

2. Replace and tight e n the 4 Phillips sc rews locate d in each corner of the panel.

3.5.3 Replacing the Front Panel

To replace the front panel:

1. Support the panel with one hand, if it is not already supported on a bench.

2. Align the bottom of the panel with the bottom of the leak detector, leaving it propped

open.

3. Place the grounding strap over the screw post.

4. Pl ace the 8-32 nut onto the screw post and tighten it using an 11-32 nut driver.

DRAFT 1/27/03

3-7

Page 44

Model 979 Helium Mass Spectrometer Leak Detector

5. Lift the panel towards the leak detector and insert the white PCB harness molex

connector plug into the connector located on the touch panel PCB assembly

(Figure 3-7).

NOTE Be sure the white PCB harness molex connector plug clicks int o

place securely.

DRAFT 1/27/03

6. Rai se the panel until it is closed, f itting the top unde r the port nut and maki ng sure that it

7. Replace and tighten the 2 Phillips screws on the front of the panel.

PCB Harness

Connector

Figure 3-7 Front Panel PCB Harness Connector

CAUTION Be careful not to place tension on the front panel display PCB

harness.

fits securely with the rear panel, and that it is not pinching any wires.

3-8

Page 45

Model 979 Helium Mass Spectrometer Leak Detector

Section 4. The Internal Calibrated Leak

4.1 Recalibrating the Internal Calibrated Leak

Helium calibrated leaks typically degrade at 3 percent per year. The calibrated leak

supplied with your 979 must be checked at least on ce a year to ensure it is at the value

stated on its tag. Failure to che ck the leak could res ult in unreli able testi ng. You can arrange

for testing and recalibration at a lab of your choice.

Varian Vacuum Techn ologies provides NIST-traceable calibrated leak testing and

verification services. You can contact Customer Service at 1-800-8VARIAN to arrange for

recalibration.

4.2 Replacing the Internal Calibrated Leak

The Internal Calibrated L eak is located su ch that the Valve Block Coil and Plun ger Assembly

must be removed (Figure 4-1) to have room to remove the calibrated leak.

Internal

Calibrated Leak

V alve Block

Coil & Plunger

Assembly

Figure 4-1 979 Side View: Removal of Valve Block Coil and Plunger Assembly

CAUTION If the Gross Le ak o pt io n is installed:

(1) Do not make any alterations to the Gross Leak. Do not touch

the knurled nut on the Gross Leak.

(2) The Gross Leak is calibrated at the factory and if any

alteration is made, the Gross Leak must be returned to the

factory for recalibration. For returns, contact Varian Vacuum

Technologies Customer Service at 1-800-8VARIAN.

DRAFT 1/27/03

4-1

Page 46

Model 979 Helium Mass Spectrometer Leak Detector

4.2.1 Removing the Valve Block Coil and Plunger Assembly

To remove the Valve Block Coil and Plunger Assembly:

1. Di sconnect the mains power supply and make sure all pumps are off.

WARNING Disconnect power from the 979 before performing any

procedure that requires physi cally disconnectin g any part of the

system.

2. Open the front and rear panels (Figure 4-2) as described in Section 3.1 “Opening the

Front Panel”.

DRAFT 1/27/03

Internal

Calibrated Leak

End Cap

Valve Stem

Valve Block

Coil & Plunger

Assembly

Valve Power Connections

Figure 4-2 979 Side View

CAUTION Use powder-free butyl or polycarbonate gloves to prevent skin

oils from getting on vacuum surfaces.

4-2

Page 47

Model 979 Helium Mass Spectrometer Leak Detector

3. Loosen and remove the end cap from the valve stem (Figure 4-3) using a 9-16 wrench.

NOTE Be careful not to drop or lose the black sleev e located inside

the end cap.

End Cap

Valve Stem

Figure 4-3 End Cap and Valve Stem

Figure 4-4 shows the Valve Stem with the end cap removed.

Figure 4-4 Valve Stem with End Cap Removed

DRAFT 1/27/03

4-3

Page 48

Model 979 Helium Mass Spectrometer Leak Detector

4. Use a 9-16 wrench to loosen the valve stem (Figure 4-5), then rotate the connection

counterclockwise until you hit the stop.

Reposition the wrench and repeat. When it is loose enough, you can finish removing it

by hand.

5. Di sconnect th e 2 pink v alv e block power con nectors ( Figure 4-6), labeled V7, th at have

DRAFT 1/27/03

Figure 4-5 Valve Stem Removal

black and yellow wires.

Power Connectors

Figure 4-6 V7 Valve Block Power Connector Removal

4-4

Page 49

Model 979 Helium Mass Spectrometer Leak Detector

6. Bei ng careful not to scratc h the valve block, insert a lo ng slotted screwdriver thro ugh the

top of the leak detector down to the slotted post on the top of the coil and plunger

assembly (Figure 4-7).

Figure 4-7 Slotted Post on Coil and Plunger Assembly

7. Hol ding the coil with one hand so it doesn’t spin (Figure 4-8), loosen the coil and

plunger assembly using the long slotted screwdriver.

Figure 4-8 Securing the Coil to Loosen Plunger Assembly

CAUTION The plunger is located on the bottom of the coil and plunger

assembly . I t has a spring. Be care ful not to drop th e plunger into

the leak detector.

DRAFT 1/27/03

4-5

Page 50

Model 979 Helium Mass Spectrometer Leak Detector

8. Li ft the coil and plunger assembly away from the cal leak valve block, and slip your

other hand or finger under the bottom of the assembly so the plunger that is located at

the bottom of th e coil does not fall.

9. Place the coil and plunger assembly aside.

Once the coil and plunger assembly is removed, the calibrated leak can be removed. Refer

to Section 4.2.4 “Examining and Cleaning the Valve Block Coil and Plunger Assembly” on

page 4-11 before re assembling.

4.2.2 Removing the Internal Calibrate Leak

To remove the Internal Calibrated Leak:

CAUTION Handle the calibrated leak carefully. It is a delicate piece of

equipment that contains a glass liner that can break if it is

dropped or hit sharply.

1. Remove the 2 large Phillips screws that hold the calibrated leak straps (Figure 4-9).

Leak Strap

and Screw

Leak Strap

and Screw

DRAFT 1/27/03

Swagelok

Fitting

Brass Valve Block

Figure 4-9 979 Side View: End Cap, Valve Stem, and Coil and Plunger Assembly Removed

4-6

Page 51

Model 979 Helium Mass Spectrometer Leak Detector

2. Remove the straps by sliding them up and over the top of the calibrated leak.

3. Hol d the flats of t he nut on the swagel ok fittin g (elbow) below the cal ibrated lea k with a

crescent wrench (Figure 4-10).

Compression Box

Logic Connection

Figure 4-10 Elbow Flat Secured with Crescent Wrench

NOTE Figure 4-10 (and others that follow) show the side panel of a

leak detector that is using a dry pump. It is connected to a

compression box and the wire supplies val ve lo gic . If your l eak

detector is not a dry configuration, you will not use a

compression box and will not see this connection.

4. Usi ng a 13- 16 op en wrench, pl ace it on the flat s of the cal ibrat ed leak (F igu re 4-11) and

rotate the leak counterclockwise until you hit the stop.

DRAFT 1/27/03

Figure 4-11 Loosening Leak with Open Wrench

4-7

Page 52

Model 979 Helium Mass Spectrometer Leak Detector

5. Reposition the wrench and repeat this action until the leak is loose enough to fi nish

loosening it by hand (Figure 4-12).

Figure 4-12 Removal of Calibrated Leak

CAUTION Handle the calibrated leak carefully. It is a delicate piece of

equipment that contains a glass liner that can break if it is

dropped or hit sharply.

6. Li ft the calibrated leak up and off of the elbow.

7. Det ermine which replacement plan you have, and take the appropriate action:

DRAFT 1/27/03

❑ Return the leak to Varian for recalibration

❑ Return the leak to Varian for replacement as part of the replacement program