Page 1

Installation and User Guide

N4419B, N4420B, N4421B

Multiport Test Sets

This manual provides information for installing Multiport Test Sets for use with

PNA Option 550.

Note: If this Test Set is to be used with PLTS software, please

DO NOT USE THIS MANUAL.

Use the PLTS Installation Guide (N1930-90005) that was shipped with PLTS,

and is also available at www.Agilent.com/find/plts

Manufacturing Part Number: N4421-90002

Printed in USA

Print Date: September 2011

Supersedes: April 2010

© Agilent Technologies, Inc. 2006–2011

Page 2

WARRANTY STATEMENT

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED “AS IS,” AND IS SUBJECT

TO BEING CHANGED, WITHOUT NOTICE, IN FUTURE EDITIONS. FURTHER, TO THE

MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, AGILENT DISCLAIMS ALL

WARRANTIES, EITHER EXPRESS OR IMPLIED WITH REGARD TO THIS MANUAL AND

ANY INFORMATION CONTAINED HEREIN, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. AGILENT SHALL NOT BE LIABLE FOR ERRORS OR FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH THE FURNISHING, USE, OR

PERFORMANCE OF THIS DOCUMENT OR ANY INFORMATION CONTAINED HEREIN.

SHOULD AGILENT AND THE USER HAVE A SEPARATE WRITTEN AGREEMENT WITH

WARRANTY TERMS COVERING THE MATERIAL IN THIS DOCUMENT THAT CONFLICT

WITH THESE TERMS, THE WARRANTY TERMS IN THE SEPARATE AGREEMENT WILL

CONTROL.

DFARS/Restricted Rights Notice

If software is for use in the performance of a U.S. Government prime contract or

subcontract, Software is delivered and licensed as “Commercial computer software” as

defined in DFAR 252.227-7014 (June 1995), or as a “commercial item” as defined in FAR

2.101(a) or as “Restricted computer software” as defined in FAR 52.227-19 (June 1987) or

any equivalent agency regulation or contract clause. Use, duplication or disclosure of

Software is subject to Agilent Technologies’ standard commercial license terms, and

non-DOD Departments and Agencies of the U.S. Government will receive no greater

than Restricted Rights as defined in FAR 52.227-19(c)(1-2) (June 1987). U.S.

Government users will receive no greater than Limited Rights as defined in FAR

52.227-14 (June 1987) or DFAR 252.227-7015 (b)(2) (November 1995), as applicable in

any technical data.

ii

Page 3

Contacting Agilent Sales and Service Offices

Assistance with test and measurement needs, and information on finding a local Agilent

office, are available on the Internet at: http://www.Agilent.com/find/assist

You can also purchase accessories or documentation items on the Internet at:

http://www.Agilent.com/find/

If you do not have access to the Internet, contact your field engineer.

NOTE In any correspondence or telephone conversation, refer to the product by its

model number and full serial number. with this information, the Agilent

representative can determine whether your unit is still within its warranty

period.

Safety and Regulatory Information

The safety and regulatory information pertaining to this product is located in Chapter 3,

“Safety and Regulatory Information.”

Safety Notes

The following safety notes are used throughout this manual. Familiarize yourself with

each of the notes and its meaning before operating this instrument. All pertinent safety

notes for using this product are located in Chapter 3, “Safety and Regulatory

Information.”

WARNING Warning denotes a hazard. It calls attention to a procedure which,

if not correctly performed or adhered to, could result in injury or

loss of life. Do not proceed beyond a warning note until the

indicated conditions are fully understood and met.

CAUTION Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to, could result in damage to or destruction

of the instrument. Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

iii

Page 4

Documentation Map

PNA Help, embedded in the PNA, offers quick reference to user

documentation, including the capabilities and limitations of Option

550. Click Help on the PNA menu bar or press the Help key on the

PNA front panel.

This Installation Guide helps you to connect the Test Set to the

PNA.

The N4419B, N4420B, N4421B Service Guide, which includes an

Operators Check, is available ONLY at

www.na.tm.agilent.com/multiport

iv

Page 5

Contents

1Installing the Test Set

Step 1. Verify your Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Step 2. Set Up the PNA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Step 3. Attach the PNA to the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Step 4. Install the System on a Bench Top or in an Equipment Rack. . . . . . . . . . . . . . . . . .1-10

Step 5. Make the Interconnections between the Test Set and the PNA . . . . . . . . . . . . . . . .1-16

Step 6. Set Up the General Purpose Interface Bus (GPIB) . . . . . . . . . . . . . . . . . . . . . . . . . .1-22

Step 7. Power up the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-23

Step 8. Perform Quick Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-25

2 Specifications and Characteristics

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

General Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

3 Safety and Regulatory Information

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Service Guide N5242-90001 Contents-v

Page 6

Contents

Contents-vi Service Guide N5242-90001

Page 7

1 Installing the Test Set

1-1

Page 8

Installing the Test Set

This installation includes the following steps:

1. Verify your Shipment

2. Set Up the PNA

3. Attach the Test Set to the Network Analyzer (N4420B or N4421B Test Set Only)

4. Install the Test Set on a Bench Top or in an Equipment Rack

5. Make the Interconnections between the Test Set and the PNA

6. Set Up the General Purpose Interface Bus (GPIB)

7. Power up the System

8. Perform Quick Check

1-2

Page 9

Step 1. Verify your Shipment

Step 1. Verify your Shipment

1. Unpack your system from the containers in which it was shipped.

Installing the Test Set

WARNING The test set hardware may be heavy. Use proper lifting techniques.

2. Carefully inspect the test set hardware to make sure that it was not damaged during

shipment.

NOTE If your test set was damaged during shipment, contact Agilent

Tech nol og i es .

1-3

Page 10

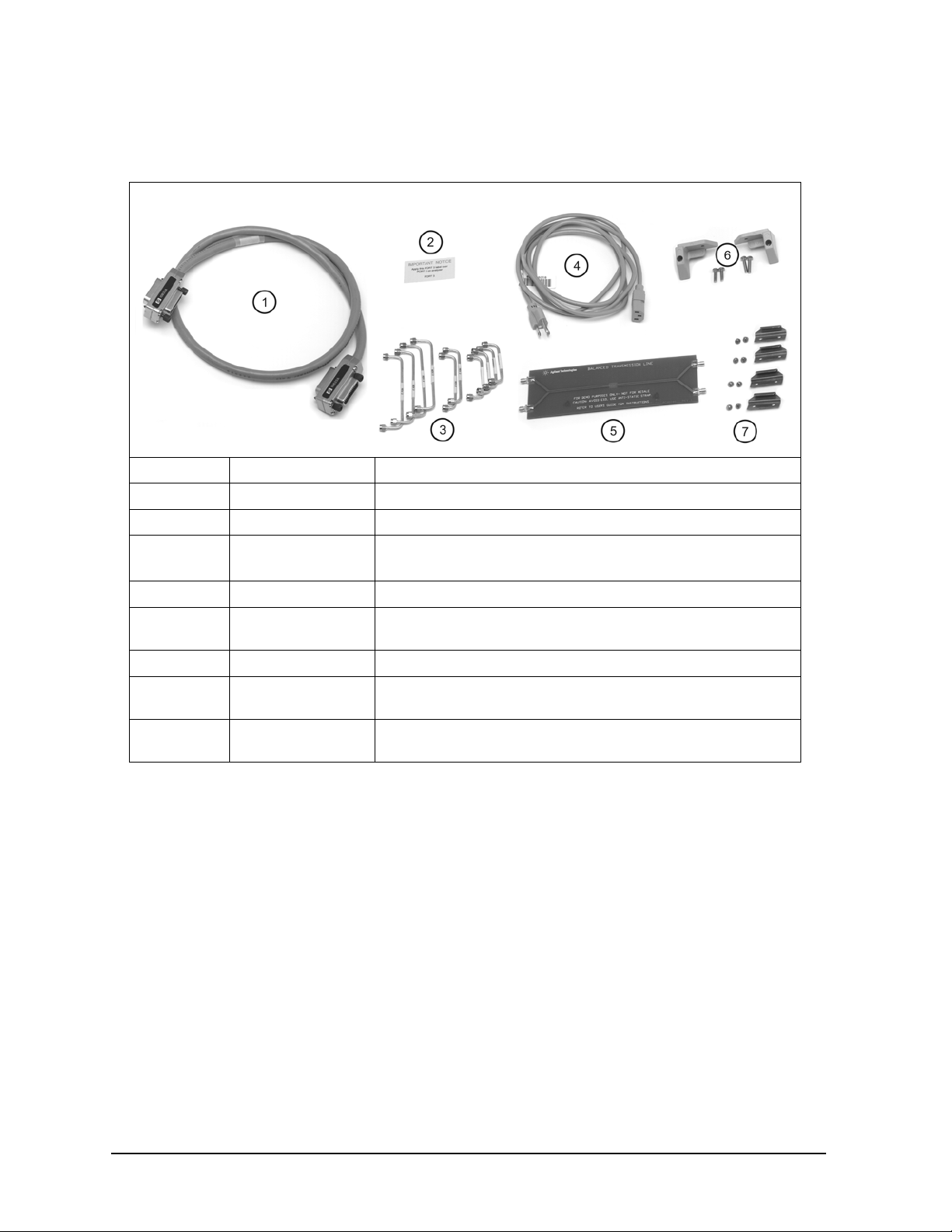

Installing the Test Set

Step 1. Verify your Shipment

3. Check the accessories that were shipped with your system. Your network analyzer

accessories will be checked during the network analyzer setup.

Item Nr Part Number Part Description

1 8120-3445 GPIB Cable (3 feet)

2 N/A “Port 3” Label

3 Varies by Test Set

Model and Option

Semirigid interconnect cables (refer to Step 5. Make the

Interconnections between the Test Set and the PNA

).

4 Unique to country AC Power Cord (for the test set)

5 AD00658 Balanced Transmission Line PC Board Device (Sample DUT).

Included ONLY when purchased with PLTS system.

6 5023-0132 Rear Locking Feet (for the PNA)

--

(not shown)

7 1600-1423 4 Lock Links (N4420B, N4421B only) with 8 screws

5063-9253 Kit Including Rear Locking Feet (for the Test Set)

(0515-1499)

1-4

Page 11

Installing the Test Set

Step 1. Verify your Shipment

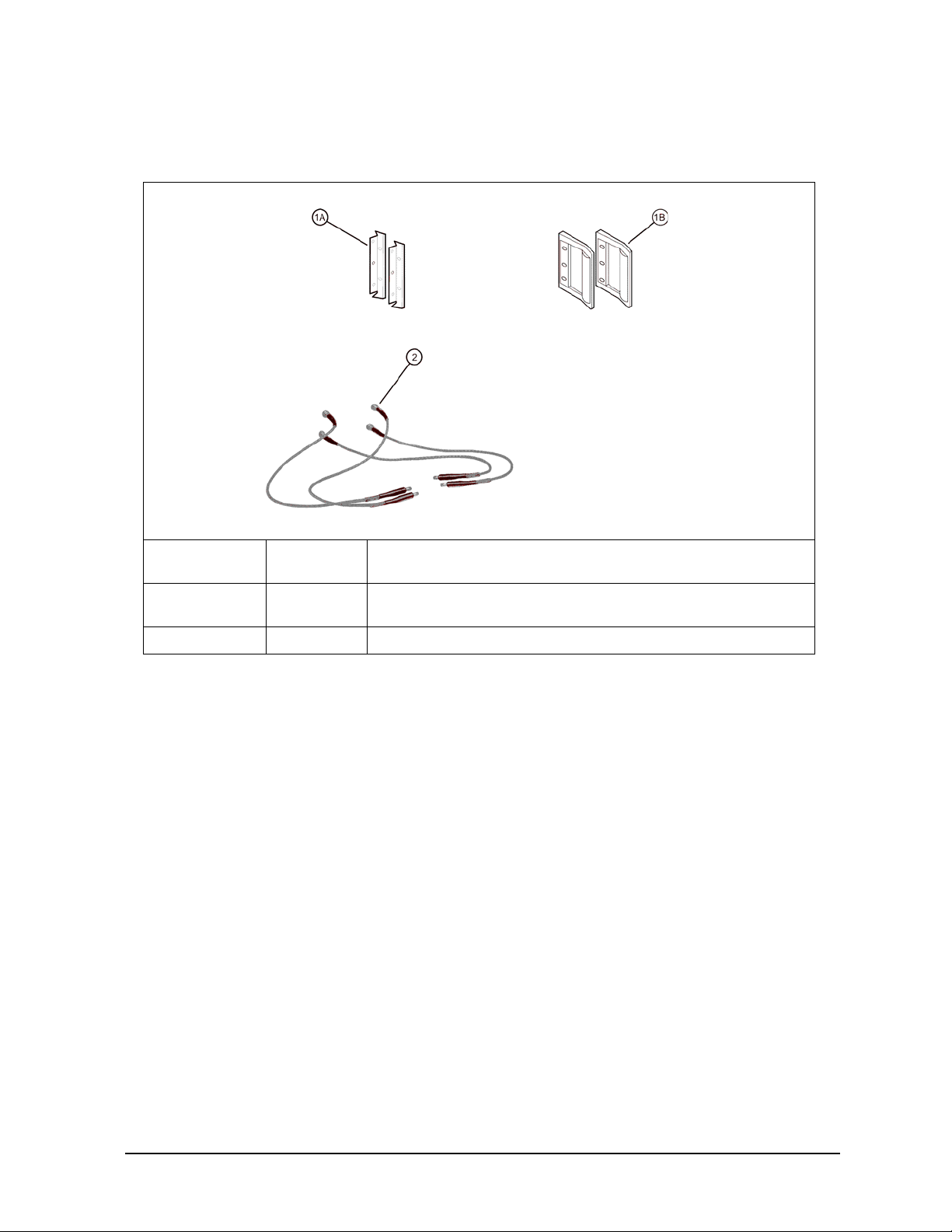

4. If you ordered any of the following options, check the parts. Option 1CP is shipped in

a separate container.

Option

Number

1CP 1A

B20 2 Precision 50-ohm cables (4)

Item

Number

1B

Part Description

Rack mount flange kit (For use with handles)

Handles (set of 2)

1-5

Page 12

Installing the Test Set

Step 2. Set Up the PNA

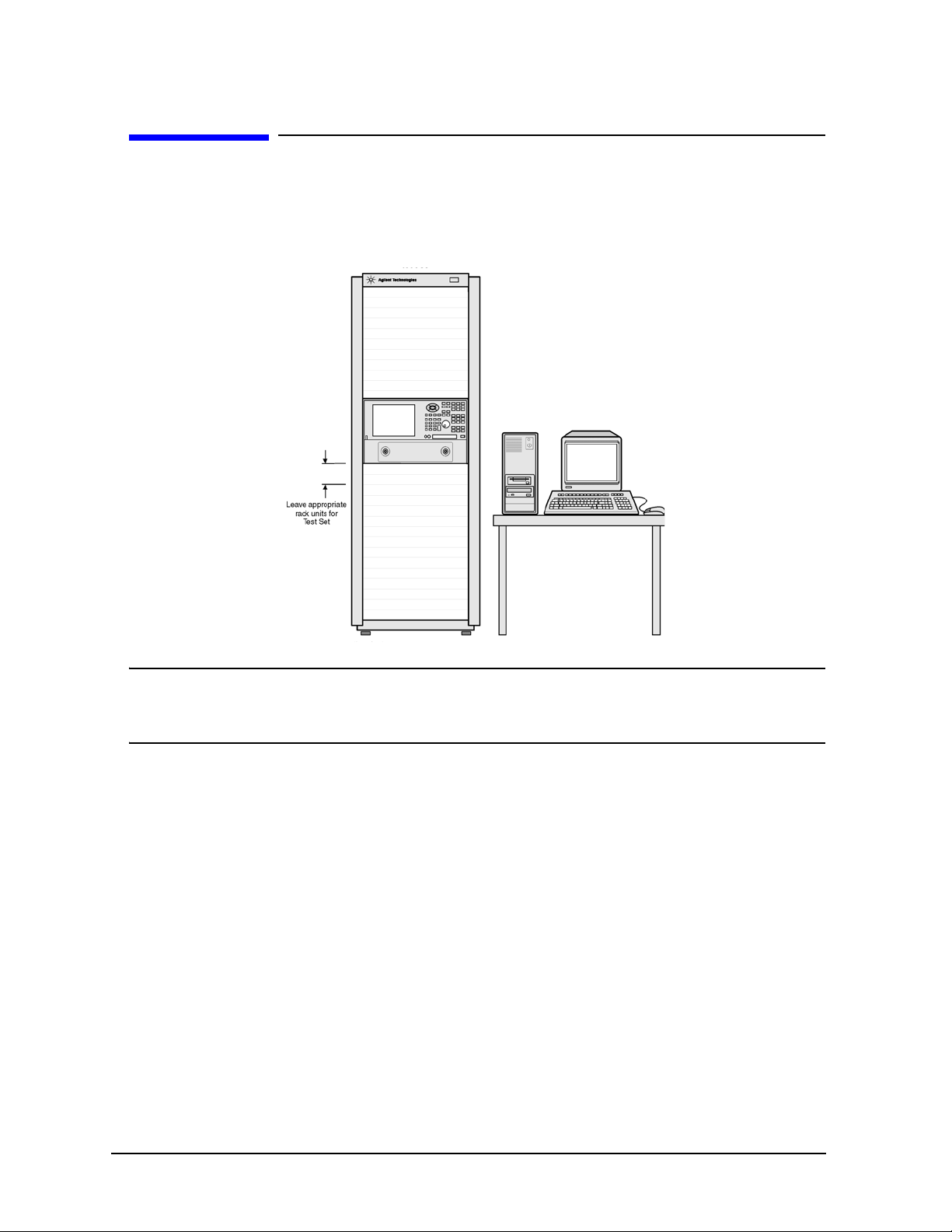

Step 2. Set Up the PNA

1. Using the PNA Installation and Quick Start Guide, set up the network analyzer.

2. If you are installing your PNA in an equipment rack, be sure to leave at least 2 rack

units of space below the analyzer to install the test set.

NOTE For the N4420B or N4421A/B test set, connect the PNA to the test set

before placing in the rack as a single unit on one set of rails. Refer to“Step

3. Attach the PNA to the Test Set” on page 1-7 for instructions.

1-6

Page 13

Installing the Test Set

Step 3. Attach the PNA to the Test Set

Step 3. Attach the PNA to the Test Set

(N4420B or N4421B Test Set Only)

If your test set is an N4419B, continue with “Step 4. Install the System on a Bench Top

or in an Equipment Rack” on page 1-11.

The PNA is attached to the N4420B and N4421B test sets using lock links at the front

and locking feet at the rear.

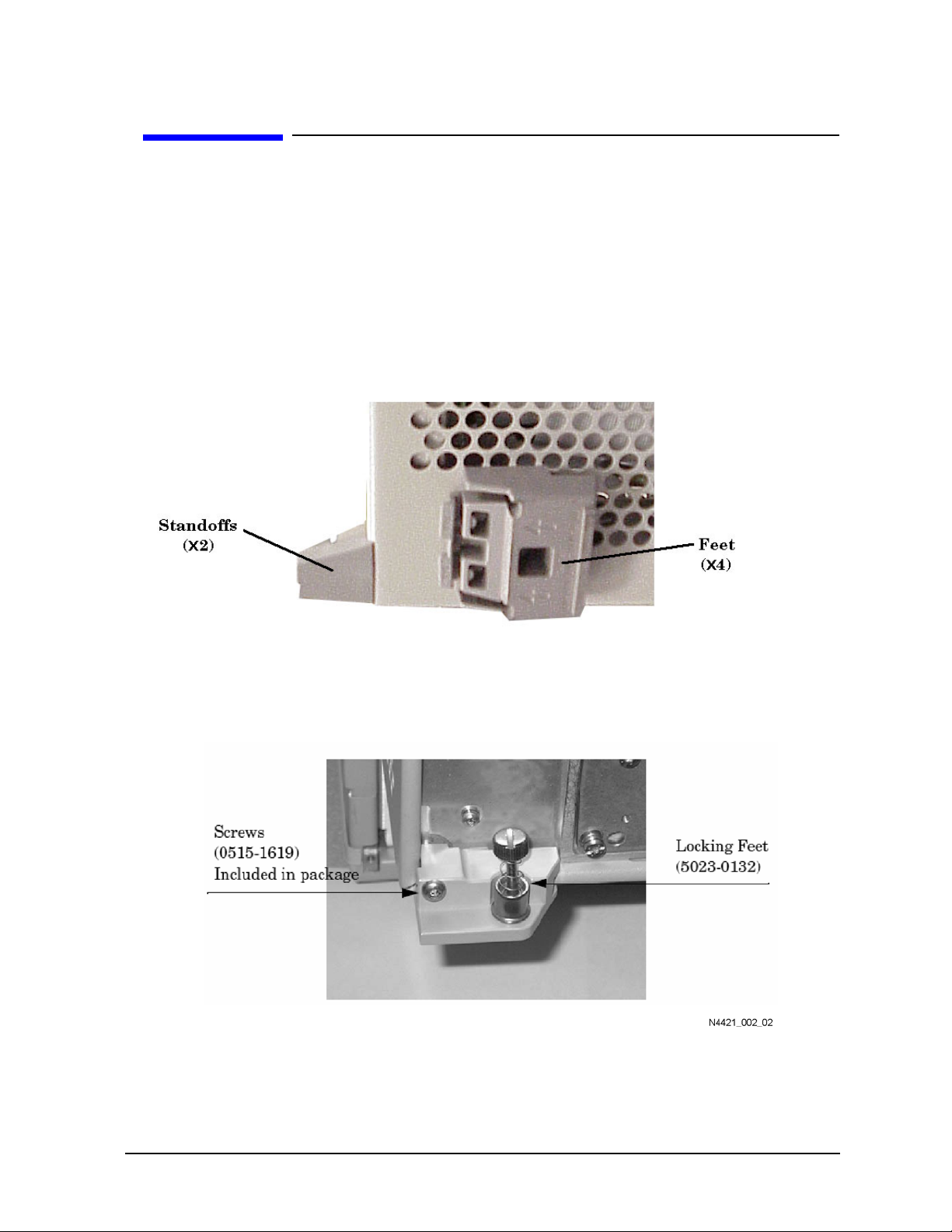

Preparing the PNA

1. Remove the four feet from the bottom of the PNA.

2. Remove the screws from the two lower rear panel standoffs.

3. Install the two rear locking feet (5023-0132) where the standoffs were removed. The

locking feet may require GENTLE tapping with a hammer to seat properly. Use the

screws (part number 0515-1619) that are included to secure the feet to the PNA.

1-7

Page 14

Installing the Test Set

Step 3. Attach the PNA to the Test Set

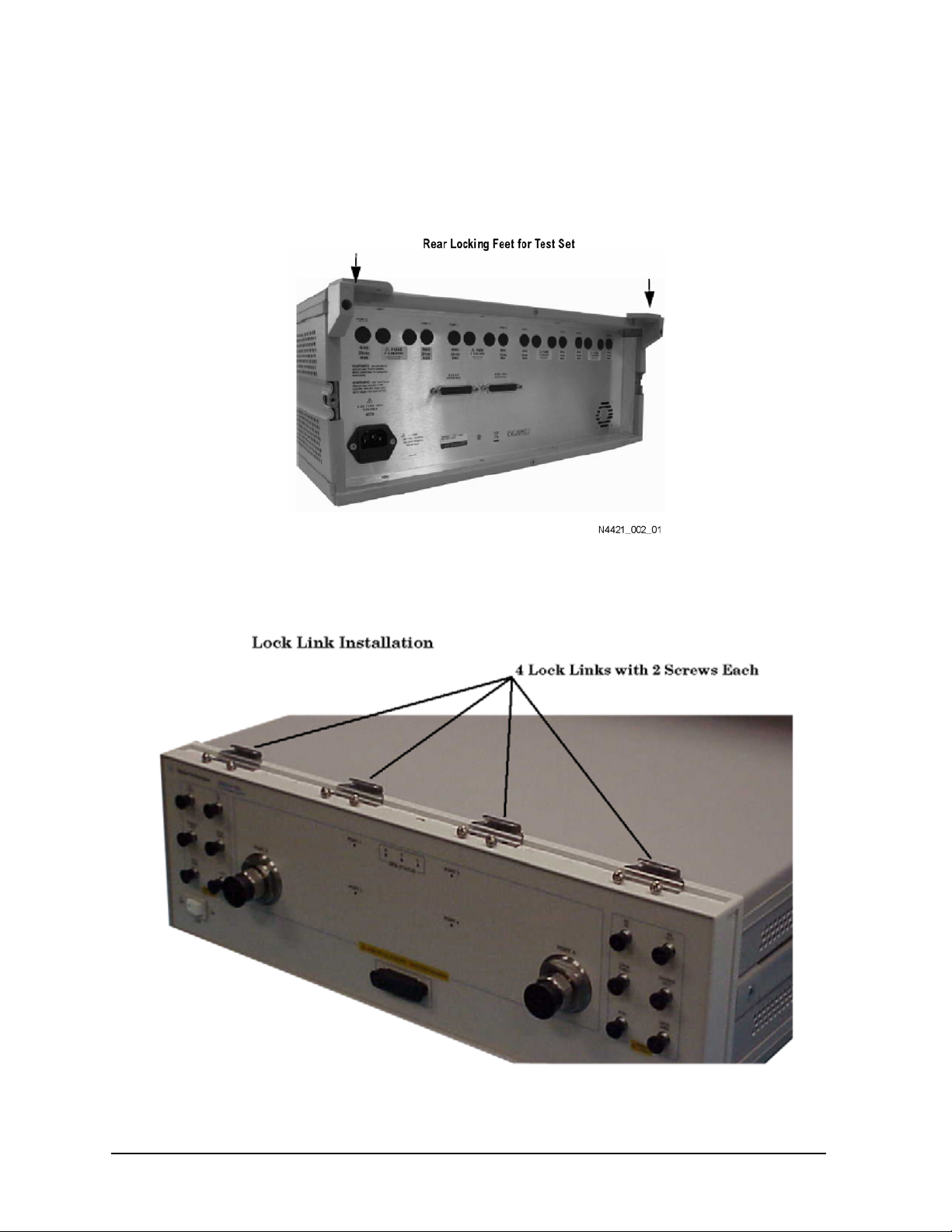

Preparing the Test Set

4. Remove the two standoffs and screws (0515-1619) from the rear panel on the test set.

5. Install the top left and right rear locking feet from the kit (5063-9253) using screws

(0515-1244).

6. Remove the trim strip from the top of the front frame.

7. Install the four lock links from the kit (5063-9253) to the top of the front frame using

eight screws. Refer to the graphic below.

1-8

Page 15

Installing the Test Set

Step 3. Attach the PNA to the Test Set

Attaching the PNA to the Test Set

8. Place the PNA on top of the test set ensuring that the front frame of the PNA is

positioned slightly forward of the lock links that are attached to the the test set. Then

slide the PNA back so the lock links engage the front frame of the analyzer.

1-9

Page 16

Installing the Test Set

Step 3. Attach the PNA to the Test Set

9. Secure the PNA lower locking feet to the test set’s upper locking feet, using the

spring-loaded screws.

NOTE If the screw holes are not aligned, loosen the screws that secure the feet to

both the PNA and the test set to align the screw holes.

10.Tighten all screws.

1-10

Page 17

Installing the Test Set

Step 4. Install the System on a Bench Top or in an Equipment Rack

Step 4. Install the System on a Bench Top or in an

Equipment Rack

The test system can be installed on a bench top or in an equipment rack.

In all installations, consider the following ventilation requirements when deciding

where to set up your test system.

CAUTION Ventilation Requirements:

When installing the product in a cabinet, the convection into and out of the

product must not be restricted. The ambient temperature (outside the

cabinet) must be less than the maximum operating temperature of the

instrument by 4 °C for every 100 watts dissipated in the cabinet. If the total

power dissipated in the cabinet is greater than 800 watts, then forced

convection must be used.

Refer to the section that applies to your installation.

• For bench top installation, continue on page 12.

• For equipment rack installation, continue on page 13.

1-11

Page 18

Installing the Test Set

Step 4. Install the System on a Bench Top or in an Equipment Rack

To Install on a Bench Top

1. Place the test set and PNA on a bench top. In the example illustration shown below,

the system is placed on a riser as an alternative to the bench top. Make sure that

there is at least four inches of clearance on the sides and back of the system for

adequate ventilation.

The front panel test cables are shown only as a reminder to make sure they can easily

reach the test surface of the bench.

CAUTION Consider the ventilation requirement described on page 11 when selecting

the location of your system.

2. Continue with “Step 5. Make the Interconnections between the Test Set and the PNA”

on page 1-17.

1-12

Page 19

Installing the Test Set

Step 4. Install the System on a Bench Top or in an Equipment Rack

To Install in an Equipment Rack

You may install the system in an equipment rack in one of following two ways:

Removing Feet from PNA Leaving Feet attached to PNA

1. Install one set of rails into the

equipment rack

2. Remove feet from Test Set and PNA

3. Attach mount flanges and the handles to

Tes t S et

4. Attach mount flanges and the handles to

PNA

5. Insert test set on rails in equipment rack

and screw to rack

6. Place PNA on top of test set and screw

PNA into rack

7. Bend Semi-rigid interconnect cables to

fit between the test set connector and the

PNA connector

8. Connect semirigid between test set and

PNA

1. Install one set of rails into the

equipment rack

2. Remove feet from Test Set only

3. Attach mount flanges and the handles to

Tes t S e t

4. Attach mount flanges and the handles to

PNA

5. Insert test set on rails in equipment rack

and screw to rack

6. Place PNA on top of test set

7. Connect semirigid between test set and

PNA

When you install the test set in an equipment rack, you will install rails in the rack to

support the weight of the test set, attach the handles and the rack mount flanges to the

test set, and secure the test set to the equipment rack.

1. Ensure that the front handle kit, the rack mount flange kit, and the rack mount rail

set are complete.

Handle Kit Contents Flange Kit Contents

• 4 Screws

• 2 Side Trim Strip

•2 Handles

• Installation Instructions

• 4 Screws (Long)

• 4 Screws with Washers

• 4 Nuts with Metal Clips

•2 Flanges

• Installation Instructions

NOTE If any items are damaged or missing from a kit, contact us to order a

replacement kit. Items within these kits are not individually available.

2. Install the rails into the equipment rack using the instructions provided. Consider

that the test set is two rack units high (3.5 inches). Mount the test set immediately

below the PNA.

NOTE For the N4420B or N4421B test set, connect the network analyzer to the

test set before placing in the rack as a single unit on one set of rails.

3. Attach the cabinet mount flanges and the handles to the sides of the front panel,

1-13

Page 20

Installing the Test Set

Step 4. Install the System on a Bench Top or in an Equipment Rack

using two long screws per side. (Attach the flanges to the outside of the handles.)

WARNING If an instrument handle is damaged, you should replace it

immediately. Damaged handles can break while you are moving or

lifting the instrument and cause personal injury or damage to the

instrument.

1-14

Page 21

Installing the Test Set

Step 4. Install the System on a Bench Top or in an Equipment Rack

4. Remove the feet before cabinet mounting the analyzer using the directions imprinted

on the feet.

5. Ensure there is adequate clearance between the system cabinet and the sides and

back of the test system for adequate ventilation.

CAUTION Consider the ventilation requirements described in “Step 4. Install the

System on a Bench Top or in an Equipment Rack” on page 11 when

selecting the location of your system.

1-15

Page 22

Installing the Test Set

Step 4. Install the System on a Bench Top or in an Equipment Rack

6. Lift the test set and slide it onto the rails that you installed earlier from the front of

the equipment rack. Secure the test set to the equipment rack using the screws with

washers and metal-clipped nuts provided in the flange kit.

7. Continue with “Step 5. Make the Interconnections between the Test Set and the PNA”

on page 17.

1-16

Page 23

Installing the Test Set

Step 5. Make the Interconnections between the Test Set and the PNA

Step 5. Make the Interconnections between the Test Set

and the PNA

1. Locate your test set and PNA model on the following pages for information describing

the interconnections between the test set and the network analyzer.

2. Connect the provided interconnect cables between the test set and the PNA. Torque

the semirigid cable connectors to 8 inch-pounds.

NOTE The Reference channel path through the test set is used to compensate for

electrically long DUTs. This also results in added loss in the Reference

channel and higher trace noise.

Therefore, do NOT use the Reference channel interconnect cables unless

making high speed measurements of electrically long devices.

For more information, see ‘Electrically long devices’ in the PNA Help

system.

CAUTION Be careful to install the interconnect cables correctly. The longer end of the

interconnect cable connects to the PNA front panel connector as shown

in the following image.

Figure 1-1 Interconnect Cable Orientation

1-17

Page 24

Installing the Test Set

Step 5. Make the Interconnections between the Test Set and the PNA

Damage to the interconnect cable can result from improper connection of

the cable.

TIP If the test set and the PNA are rack mounted, the screws securing the rack

mount flanges to the instrument rack may be loosened slightly to allow for

minor repositioning of the instruments. Don't forget to retighten the screws

when you are done.

3. Continue with “Step 6. Set Up the General Purpose Interface Bus (GPIB)” on

page 1-23.

1-18

Page 25

Step 5. Make the Interconnections between the Test Set and the PNA

N4420B Test Set with E8363B and N4421B Test Set with E8364B

Installing the Test Set

CAUTION Damage to the interconnect cable can result from improper orientation of

the cable. Refer to page 1-16 for detailed information regarding the correct

cable orientation.

1-19

Page 26

Installing the Test Set

Step 5. Make the Interconnections between the Test Set and the PNA

Call Out

Sequence

1* Z5623-20215 REF 1 SOURCE OUT REF 1 R1 OUT

2* Z5623-20215 REF 1 RCVR R1 IN REF 1 RCVR R1 IN

3* Z5623-20215 REF 2 RCVR R2 IN REF 2 RCVR R2 IN

4* Z5623-20215 REF 2 SOURCE OUT REF 2 R2 OUT

5 Z5623-20216 PORT 1 SOURCE OUT PORT 1 SOURCE OUT

6 Z5623-20216 PORT 1 CPLR THRU PORT 1 CPLR THRU

7 Z5623-20216 PORT 2 CPLR THRU PORT 2 CPLR THRU

8 Z5623-20216 PORT 2 SOURCE OUT PORT 2 SOURCE OUT

9 Z5623-20217 PORT 1 CPLR ARM PORT 1 CPLR ARM

10 Z5623-20217 PORT 1 RCVR A IN PORT 1 RCVR A IN

11 Z5623-20217 PORT 2 RCVR B IN PORT 2 RCVR B IN

12 Z5623-20217 PORT 2 CPLR ARM PORT 2 CPLR ARM

13* E8364-20059 REF 1 on rear panel of the test set

14* E8364-20059 REF 2 on rear panel of the test set

Cable Part

Number

From

Network Analyzer

To

Test S e t

NOTE * The Reference channel path through the test set is used to compensate for

electrically long DUTs. This also results in added loss in the Reference

channel and higher trace noise.

Therefore, unless making high speed measurements of electrically long

devices, do NOT remove the PNA REFERENCE 1 and REFERENCE 2

front-panel loops, and do NOT use the Reference channel interconnect

cables (items 1, 2, 3, 4, 13, and 14).

For more information, see ‘Electrically long devices’ in the PNA Help

system.

1-20

Page 27

Step 5. Make the Interconnections between the Test Set and the PNA

N4419B Test Set with E8362B or N5230A Option 225

Installing the Test Set

CAUTION Damage to the interconnect cable can result from improper orientation of

the cable. Refer to page 1-16 for detailed information regarding the correct

cable orientation.

1-21

Page 28

Installing the Test Set

Step 5. Make the Interconnections between the Test Set and the PNA

NOTE: Cables are orderable only as cable set AD00756.

Call Out

Sequence

1* AD00756-1 REF 1 SOURCE OUT REF 1 SOURCE OUT

2* AD00756-1 REF 1 RCVR R1 IN REF 1 RCVR R1 IN

3* AD00756-1 REF 2 RCVR R2 IN REF 2 RCVR R2 IN

4* AD00756-1 REF 2 SOURCE OUT REF 2 SOURCE OUT

5 AD00756-2 PORT 1 SOURCE OUT PORT 1 SOURCE OUT

6 AD00756-2 PORT 1 CPLR THRU PORT 1 CPLR THRU

7 AD00756-2 PORT 2 CPLR THRU PORT 2 CPLR THRU

8 AD00756-2 PORT 2 SOURCE OUT PORT 2 SOURCE OUT

9 AD00756-3 PORT 1 CPLR ARM PORT 1 CPLR ARM

10 AD00756-3 PORT 1 RCVR A IN PORT 1 RCVR A IN

11 AD00756-3 PORT 2 RCVR B IN PORT 2 RCVR B IN

12 AD00756-3 PORT 2 CPLR ARM PORT 2 CPLR ARM

13* AD00756-4 REF 1 on rear panel of the test set

14* AD00756-4 REF 2 on rear panel of the test set

Cable Part

Number

From

Network Analyzer

To

Test S e t

NOTE * The Reference channel path through the test set is used to compensate for

electrically long DUTs. This also results in added loss in the Reference

channel and higher trace noise.

Therefore, unless making high speed measurements of electrically long

devices, do NOT remove the PNA REFERENCE 1 and REFERENCE 2

front-panel loops, and do NOT use the Reference channel interconnect

cables (items 1, 2, 3, 4, 13, and 14).

For more information, see ‘Electrically long devices’ in the PNA Help

system.

1-22

Page 29

Installing the Test Set

Step 6. Set Up the General Purpose Interface Bus (GPIB)

Step 6. Set Up the General Purpose Interface Bus (GPIB)

The PNA uses the General Purpose Interface Bus (GPIB) to communicate with the test

set.

NOTE There are 31 GPIB addresses, numbered 0 to 30. However, there may be

the occasion that you need to change the GPIB address for test equipment.

GPIB addresses are set either using rear panel switches or using the

equipment firmware. Refer to the PNA or PLTS online help for more

information.

1. Connect a GPIB cable from the rear panel GPIB connector on the PNA to the rear

panel GPIB connector on the test set.

If the PNA has two GPIB ports, connect the test set to the CONTROLLER GPIB port.

1-23

Page 30

Installing the Test Set

Step 7. Power up the System

Step 7. Power up the System

1. Ensure the available ac power supply meets the Power Source Requirements and the

operating environment meets the Operating Environment Requirements listed below.

Power Source Requirements

Input Voltage Range 100 − 120 Vac - or - 220 − 250 Vac

Frequency Range 47 − 62 Hz / 400 Hz

Power 40 VA maximum.

Operating Environment Requirements

Operating Environment Indoor use

Altitude Operating:

Storage:

Tempe r atu r e 0 °C to 40 °C

Maximum Relative Humidity 80% for temperatures up to 31 °C; decreasing

linearly to 50% for a temperature of 40 °C

0 to 2.0 km (6,560 ft.)

0 to 15.24 km (50,000 ft.)

2. Verify that the ac power cable is not damaged, and that the power-source outlet

provides a protective earth contact.

CAUTION Always use the three-prong ac power cord supplied with this product.

Failure to ensure adequate earth grounding by not using this cord may

cause product damage.

3. Turn off the PNA.

4. Connect the ac power cable from the power-source outlet to the ac input on the rear

panel of the test set.

5. Turn on the PNA and the test set by pressing the ON/OFF button on the front panel

of each instrument.

NOTE Perform Step 6 ONLY when both of the following are true. Otherwise, skip

to Step 7.

• Using the Reference channel paths through the test set. See page

1-16 for more information

• Using a PNA model E8362A/B, E8363A/B, or E8364A/B.

6. The Phase-Lock IF Gain Adjustment adjusts the R Channel receivers ALC gain to

ensure phase lock over the entire frequency range. Refer to Phase-Lock IF Gain

Adjustment in the PNA Help system for details.

a. Ensure the PNA is NOT already in 4-port mode (Step 7).

b. On the PNA, from the System menu, click Service, then Adjustments, then IF

1-24

Page 31

Installing the Test Set

Step 7. Power up the System

Gain Adjustment.

c. In Select Specials, select None.

d. No connections to the test ports are required.

e. Click Begin Adj. The adjustment takes about a minute to complete.

The advanced screen is for factory personnel only.

NOTE To start the PNA in 4-port mode (Step 7), Option 550 must already be

enabled on the PNA. See PNA Help to learn more about Option 550.

In addition, the PNA must have firmware version A.06.03.05 or later.

To check both of these on the PNA, click Help, then About Network

Analyzer.

7. When the PNA application has completely powered up, and the default trace is

present, then:

a. Click System, point to Configure, then click Multiport Capability

b. On the Multiport Restart dialog, select Testset: N44xx, then click Restart as a

Multiport PNA with this testset.

c. Click OK

The PNA should shut down and restart as a 4-port PNA. To learn more about the

Option 550 capabilities and limitations, see PNA Help. In the Help file index, type

“Option 550”.

8. If you intend to always use the default port mapping, attach the “Port 3” label

(included with accessories) over the “Port 2” label on the PNA front panel. This will

help to eliminate confusion when referring to the system “logical” ports. To learn

more about port mapping, see the PNA Help, option 550 topic.

1-25

Page 32

Installing the Test Set

Step 8. Perform Quick Check

Step 8. Perform Quick Check

This Quick Check procedure helps to ensure that the system is properly configured.

Perform this check after the PNA has rebooted as a 4-port PNA (previous step).

NOTE An Operator’s Check, used to confirm that the 4-port system is fully

functional, is contained in the N4419B, N4420B, N4421B Service Guide.

Download the Service Guide at www.na.tm.agilent.com/multiport

All four test ports should be open and in the default port mapping configuration.

1. Preset the PNA.

2. Set the stop frequency on the PNA channel to the maximum frequency of either the

test set or the PNA, which ever is lower. This is probably the default setting.

3. On the PNA, click Trace, then Delete Trace to delete the S11 trace.

4. On the PNA, click Trace, then New Trace, then check S12, S13, and S14. Click OK.

This creates three new traces in the same channel and window. All of the new traces

should appear at the bottom, or below, the window.

5. Connect a Thru cable between logical ports 1-2, then between ports 1-3, then between

ports 1-4. This assumes that you have NOT changed port mapping. Port 3 is the PNA

“physical” port 2. Port 2 and port 4 is on the test set.

Each trace should look similar to the uncorrected trace in the following figure.

1-26

Page 33

2 Specifications and

Characteristics

2-1

Page 34

Specifications and Characteristics

Definitions

Definitions

All specifications and characteristics apply over a 25 °C ±5 °C range (unless otherwise

stated) and 90 minutes after the instrument has been turned on.

Specification (spec.) Warranted performance. Specifications include guard bands to

account for the expected statistical performance distribution,

measurement uncertainties, and changes in performance due to

environmental conditions.

Characteristic (char.) A performance parameter that the product is expected to meet

before it leaves the factory, but that is not verified in the field

and is not covered by the product warranty. A characteristic

includes the same guard bands as a specification.

Typical (typ.) Expected performance of an average unit which does not

include guard bands. It is not covered by the product warranty.

Nominal (nom.) A general, descriptive term that does not imply a level of

performance. It is not covered by the product warranty.

NOTE There are NO specifications for multiport test set performance; only

Characteristics and Typicals.

The Characteristic and Typical performance information is contained in the

N4419B, N4420B, N4421B Service Guide, which is available at

www.na.tm.agilent.com/multiport

2-2

Page 35

Specifications and Characteristics

General Characteristics

General Characteristics

The frequency range, environmental operating conditions, and physical characteristics

are displayed on the following pages.

Frequency Range

Table 2-1Test Set Frequency Range and PNA Model

Test Set Model Frequency Range Recommended PNA Model

N4419B 10 MHz to 20 GHz E8362B or N5230A Opt 225

N4420B 10 MHz to 40 GHz E8363B or N5230A Opt 425

N4421B 10 MHz to 50 GHz E8364B or N5230A Opt 525

2-3

Page 36

Specifications and Characteristics

General Characteristics

Physical Characteristics

The weight and dimensions for the test sets are listed below.

Weight and Dimensions

Table 2-2Test Set Weight and Dimensions

Model Number Weight Dimensions

Height (A) Width (B) Depth (C)

N4419B 9.0 kilograms

(19.9 pounds)

N4420B and N4421B 9.0 kilograms

(19.9 pounds)

3.0 in

(7.62 cm)

5.5 in

(13.97 cm)

16.75 in

(42.55 cm)

16.75 in

(42.55 cm)

19.25 in

(48.90 cm)

16.75 in

(42.55 cm)

2-4

Page 37

3 Safety and Regulatory

Information

3-1

Page 38

Safety and Regulatory Information

Safety Information

Safety Information

Review to the safety information in this section before operating your physical layer test

system.

Safety Symbols

The following safety symbols are used throughout this manual. Familiarize yourself

with each of the symbols and its meaning before operating the physical layer test

system.

CAUTION Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to, would result in damage to or destruction

of the instrument. Do not proceed beyond a caution note until the indicated

conditions are fully understood and met.

WARNING Warning denotes a hazard. It calls attention to a procedure which,

if not correctly performed or adhered to, could result in injury or

loss of life. Do not proceed beyond a warning note until the

indicated conditions are fully understood and met.

3-2

Page 39

Safety and Regulatory Information

Safety Information

Instrument Markings

Familiarize yourself with each of the markings and its meaning before operating the

physical layer test system.

The instruction documentation symbol. The product is marked with this symbol

when it is necessary for the user to refer to the instructions in the documentation.

This symbol indicates that the instrument requires alternating current (ac) input.

This symbol indicates separate collection for electrical and electronic equipment,

mandated under EU law as of August 13, 2005. All electric and electronic equipment

are required to be separated from normal waste for disposal (Reference WEEE

Directive, 2002/96/EC).

This symbol indicates that the power line switch is ON.

This symbol indicates that the power line switch is in the STANDBY position.

This symbol indicates that the power line switch is in the OFF position.

ICES/NMB-001

This symbol is used to identify a terminal which is internally connected to the

product frame or chassis.

The CE mark is a registered trademark of the European Community. (If

accompanied by a year, it is when the design was proven.)

The CSA mark is a registered trademark of the CSA International. This instrument

complies with Canada: CSA 22.2 No. 61010-1-04.

This is a symbol of an Industrial Scientific and Medical Group 1 Class A product.

This is a marking to indicate product compliance with the Canadian

Interference-Causing Equipment Standard (ICES-001).

Direct Current.

This is a required mark signifying compliance with an EMC requirement. The C-Tick

mark is a registered trademark of the Australian Spectrum Management Agency.

China RoHS regulations include requirements related to packaging, and require

compliance to China standard GB18455-2001.

This symbol indicates compliance with the China RoHS regulations for

paper/fiberboard packaging.

3-3

Page 40

Safety and Regulatory Information

Safety Information

Safety Considerations

Familiarize yourself with each of the safety considerations before operating the physical

layer test system.

NOTE Positioning the Test System for Use

When setting up the test set for use, position the equipment so that the

front panel power switch is easy to reach.

NOTE This instrument has been designed and tested in accordance with the

standards listed on the Manufacturer’s Declaration of Conformity and has

been supplied in a safe condition. This instruction documentation contains

information and warnings which must be followed by the user to ensure

safe operation and to maintain the instrument in a safe condition.

Safety Earth Ground

WARNING This is a Safety Class 1 product (provided with a protective

earthing ground incorporated in the power cord). The mains plug

shall only be inserted in a socket outlet provided with a protective

earth contact. Any interruption of the protective conductor, inside

or outside the instrument, is likely to make the instrument

dangerous. Intentional interruption is prohibited.

CAUTION Always use the three-prong AC power cord supplied with this product.

Failure to ensure adequate earth grounding by not using this cord may

cause product damage.

3-4

Page 41

Safety and Regulatory Information

Safety Information

Before Applying Power

CAUTION Install the instrument so that the ON/OFF switch is readily identifiable

and is easily reached by the operator. The ON/OFF switch or the detachable

power cord is the instrument disconnecting device. It disconnects the mains

circuits from the mains supply before other parts of the instrument.

Alternately, an externally installed switch or circuit breaker (which is

readily identifiable and is easily reached by the operator) may be used as a

disconnecting device.

CAUTION Before switching on this instrument, make sure that the correct fuse is

installed and the supply voltage is in the specified range.

Servicing

WARNING No operator serviceable parts inside. Refer servicing to qualified

personnel. To prevent electrical shock, do not remove covers.

WARNING These servicing instructions are for use by qualified personnel

only. To avoid electrical shock, do not perform any servicing unless

you are qualified to do so.

WARNING The opening of covers or removal of parts is likely to expose

dangerous voltages. Disconnect the instrument from all voltage

sources while it is being opened.

WARNING The power cord is connected to internal capacitors that may

remain live for 5 seconds after disconnecting the plug from its

power supply.

WARNING For continued protection against fire hazard replace line fuse only

with same type and rating (115V and 230V operation: T2.5A 250V).

The use of other fuses or material is prohibited.

3-5

Page 42

Safety and Regulatory Information

Safety Information

General

WARNING To prevent electrical shock, disconnect the Agilent Technologies

(N4419B, N4420B, and N4421B) S-parameter test set from mains

before cleaning. Use a dry cloth or one slightly dampened with

water to clean the external case parts. Do not attempt to clean

internally.

WARNING If this product is not used as specified, the protection provided by

the equipment could be impaired. This product must be used in a

normal condition (in which all means for protection are intact)

only.

CAUTION This product is designed for use in Installation Category II and Pollution

Degree 2.

CAUTION VENTILATION REQUIREMENTS: When installing the product in a

cabinet, the convection into and out of the product must not be restricted.

The ambient temperature (outside the cabinet) must be less than the

maximum operating temperature of the product by 4° C for every 100 watts

dissipated in the cabinet. If the total power dissipated in the cabinet is

greater that 800 watts, then forced convection must be used.

3-6

Page 43

Safety and Regulatory Information

Regulatory Information

Regulatory Information

The Agilent Technologies S-Parameter test set complies with the regulatory

requirements listed in this section.

EMC

Complies with European EMC Directive 2004/108/EC.

• IEC/EN 61326-2-1

• CISPR Pub 11 Group 1, class A

• AS/NZS CISPR 11

SAFETY

Complies with European Low Voltage Directive 2006/95/EC.

• IEC/EN 61010-1, 2nd edition

• Canada: CSA C22.2 No. 61010-01-04

• USA: UL std no 61010-1, 2nd edition

Compliance with Canadian EMC Requirements

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme a la norme NMB du Canada.

Compliance with German Noise Requirements

This is to declare that this instrument is in conformance with the German Regulation on

Noise Declaration for Machines (Laermangabe nach der Maschinenlaermrerordung −3.

GSGV Deutschland).

Acoustic Noise Emission/Geraeuschemission

LpA <70 dB LpA <70 dB

Operator position am Arbeitsplatz

Normal position normaler Betrieb

per ISO 7779 nach DIN 45635 t. 19

Declaration of Conformity

A copy of the Declaration of Conformity is available upon request, or a copy is available

on the Agilent Technologies web site at

http://regulations.corporate.agilent.com/DoC/search.htm.

3-7

Page 44

Safety and Regulatory Information

Regulatory Information

3-8

Loading...

Loading...