Page 1

Agilent XF Substrate Oxidation Stress Test Kits

User Manual

XF Long Chain Fatty Acid Oxidation Stress Test Kit (103672-100)

XF Glucose/Pyruvate Oxidation Stress Test Kit (103673-100)

XF Glutamine Oxidation Stress Test Kit (103674-100)

XF Palmitate Oxidation Stress Test Kit (103693-100)

Page 2

Notices

CAUTION

WARNING

© Agilent Technologies 2020

No part of this manual may be reproduced in

any form or by any means (including electronic

storage and retrieval or translation into a

foreign language) without prior agreement and

written consent from Agilent Technologies,

Inc. as governed by United States and

international copyright laws.

Manual Part Number

5994-1164EN

Rev B0

Edition

First edition, May 2020

Printed in USA

Agilent Technologies

1834 Hwy 71 West

Cedar Creek, TX 78612

Product is made in UK.

Warranty

The material contained in this document is

provided “as is,” and is subject to being

changed, without notice, in future editions.

Further, to the maximum extent permitted by

applicable law, Agilent disclaims all

warranties, either express or implied, with

regard to this manual and any information

contained herein, including but not limited to

the implied warranties of merchantability and

fitness for a particular purpose. Agilent shall

not be liable for errors or for incidental or

consequential damages in connection with

the furnishing, use, or performance of this

document or of any information contained

herein. Should Agilent and the user have a

separate written agreement with warranty

terms covering the material in this document

that conflict with these terms, the warranty

terms in the separate agreement shall

control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

U.S. Government Restricted Rights. Software

and technical data rights granted to the

federal government include only those rights

customarily provided to end user customers.

Agilent provides this customary commercial

license in Software and technical data

pursuant to FAR 12.211 (Technical Data) and

12.212 (Computer Software) and, for the

Department of Defense, DFARS

252.227-7015 (Technical Data -Commercial

Items) and DFARS 227.7202-3 (Rights in

Commercial Computer Software or Computer

Software Documentation).

Safety Notices

A CAUTION notice denotes a

hazard. It calls attention to an

operating procedure, practice, or the

like that, if not correctly performed

or adhered to, could result in

damage to the product or loss of

important data. Do not proceed

beyond a CAUTION notice until the

indicated conditions are fully

understood and met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or the

like that, if not correctly performed

or adhered to, could result in

personal injury or death. Do not

proceed beyond a WARNING notice

until the indicated conditions are

fully understood and met.

Page 3

Contents

1Introduction

Assay Background 6

XF Substrate Oxidation Stress Test - Standard Assay 8

XF Palmitate Oxidation Stress Test - Advanced Assay 12

Glossary 16

References 18

2 Kit Information

Kit Contents 20

Kit Shipping and Storage 21

Additional Agilent Products Required 21

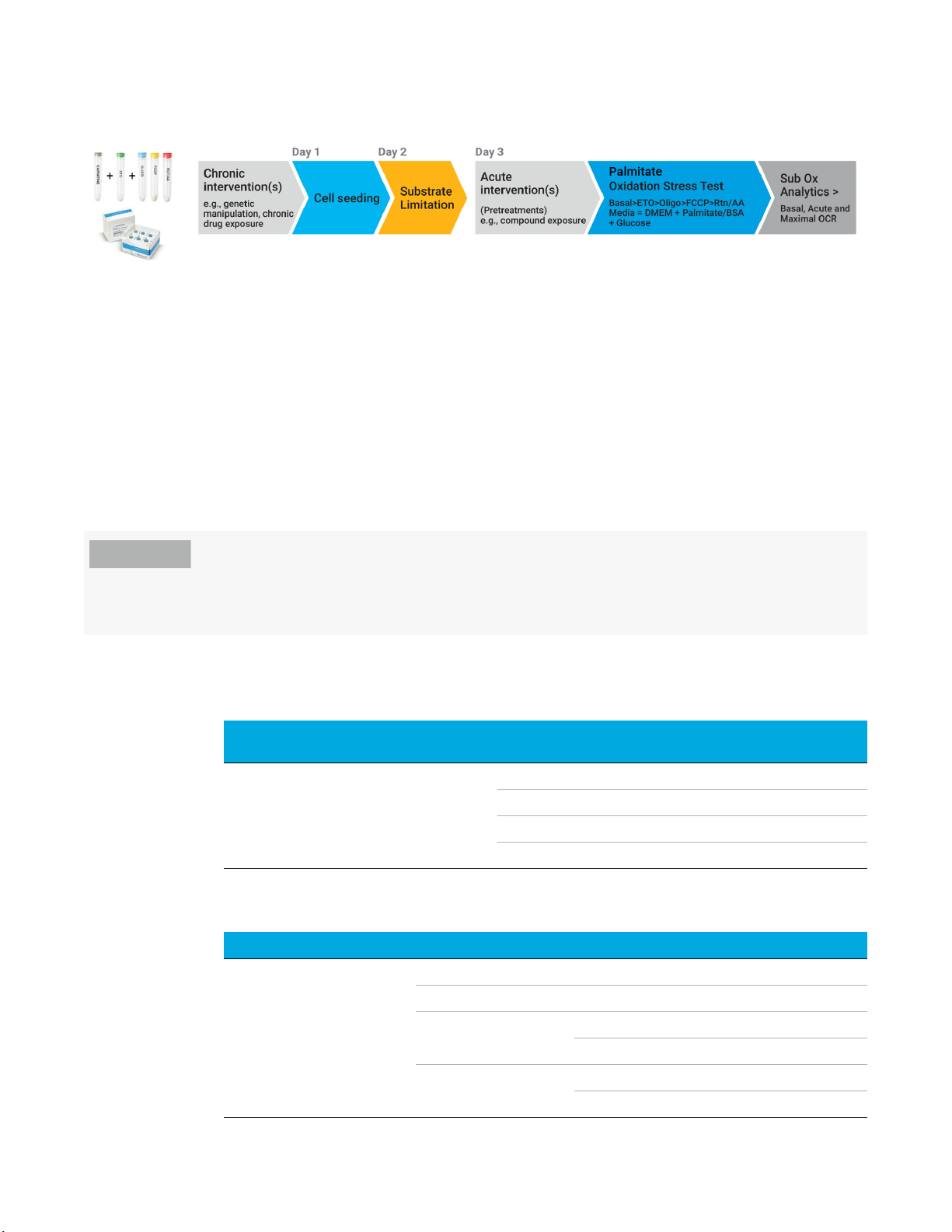

3 Assay Workflow for Standard Substrate Oxidation Stress Test

One Day Prior to Assay 24

Day of Assay 24

Data Analysis Using Agilent Seahorse Analytics 30

Examples of Data 32

4 Assay Workflow for Palmitate Oxidation Stress Test - Advanced Assay

Two Days Prior to Assay 36

One Day Prior to Assay 36

Day of Assay 37

Data Analysis Using Agilent Seahorse Analytics 42

Examples of Data 44

5 Frequently Asked Questions

6 Context of Substrate Oxidation Tests Among Other XF Kits and Applications

Agilent XF Substrate Oxidation Stress Test Kits 3

Page 4

4 Agilent XF Substrate Oxidation Stress Test Kits

Page 5

1 Introduction

Assay Background 6

XF Substrate Oxidation Stress Test - Standard Assay 8

XF Palmitate Oxidation Stress Test - Advanced Assay 12

Glossary 16

References 18

Agilent XF Substrate Oxidation Stress Test Kits 5

Page 6

Assay Background

MPC

Glucose

ATP

ATP

O

2

e

-

Glucose

Glycolysis

Glutamate

Malate

Acetyl-CoA

Ⱥ-KG

ADP + Pi

ADP + Pi

ETC

Acyl-

CoA

TCA

cycle

Amino

acids

UK5099

Pyruvate

Pyruvate

Glutamine

LCFAs

BPTES

Eto

Gluconeogenesis

LCFAs

Glutamine

CPT1a

CPT2

Ȼ-Oxidation

GLS1

Gln transporter

Lactate

Assay Background

Agilent Seahorse XF technology measures energy metabolism in live cells in real time, providing

critical functional information that relates directly to cellular health and fitness. The Seahorse XF

Substrate Oxidation Stress Test Assay provides key metrics to facilitate the assessment of

specific mitochondrial substrates that are relevant or required for cellular phenotype and function.

Agilent provides a suite of optimized, rapid solutions for measuring cellular substrate oxidation by

assessing changes in oxygen consumption (OCR) using live cells. XF Substrate Oxidation Stress

Test Kits allow for both a sensitive measure of mitochondrial function, and the interrogation of

three primary substrates that fuel mitochondria: long-chain fatty acids (LCFAs), glucose/pyruvate

(G/P), and/or glutamine (Q) (Figure 1). These kits facilitate the convenient investigation of specific

substrate oxidation processes and the central role they play in the fundamental cellular functions

of activation, proliferation, and differentiation; as well as in better characterizing cellular responses

to genetic manipulation, pharmaceutical interventions, or specific disease-relevant

microenvironments.

6 Agilent XF Substrate Oxidation Stress Test Kits

Figure 1. Primary metabolic pathways, including glycolysis, the TCA cycle, electron transport (ETC),

and oxidative phosphorylation (OXPHOS). Glucose/pyruvate, glutamine and long chain fatty

The XF Substrate Oxidation Stress Tests combine the substrate pathway specific inhibitors

(Figure 1): etomoxir for LCFAs through inhibition of carnitine palmitoyl transferase 1a (CPT1a)

UK5099 for glucose and/or pyruvate through inhibition of the mitochondrial pyruvate carrier

(MPC)

Mito Stress Test (MST). The MST, a powerful and well-accepted tool for the interrogation of

mitochondrial function, in conjunction with these inhibitors, can be used to reveal dependence on

a specific metabolic substrate. Basal and maximal respiration rates are key metrics of

acid oxidation are highlighted. Red lines denote relevant inhibitors of glucose/pyruvate, LCFA,

and glutamine transport, which in turn, specifically limits oxidation of that respective

substrate.

2

; and BPTES for inhibition of glutamine through glutaminase 1 (GLS-1)3, with the XF Cell

1

;

Page 7

Assay Background

mitochondrial function reported by the MST. In the context of substrate oxidation, the basal, and in

particular, the maximal respiration rates are largely impacted by cells capacity to transport and

oxidize available substrates.

4

This method is ideally suited to the assessment for cellular

substrate demand both under basal conditions, and in response to elevated substrate demand

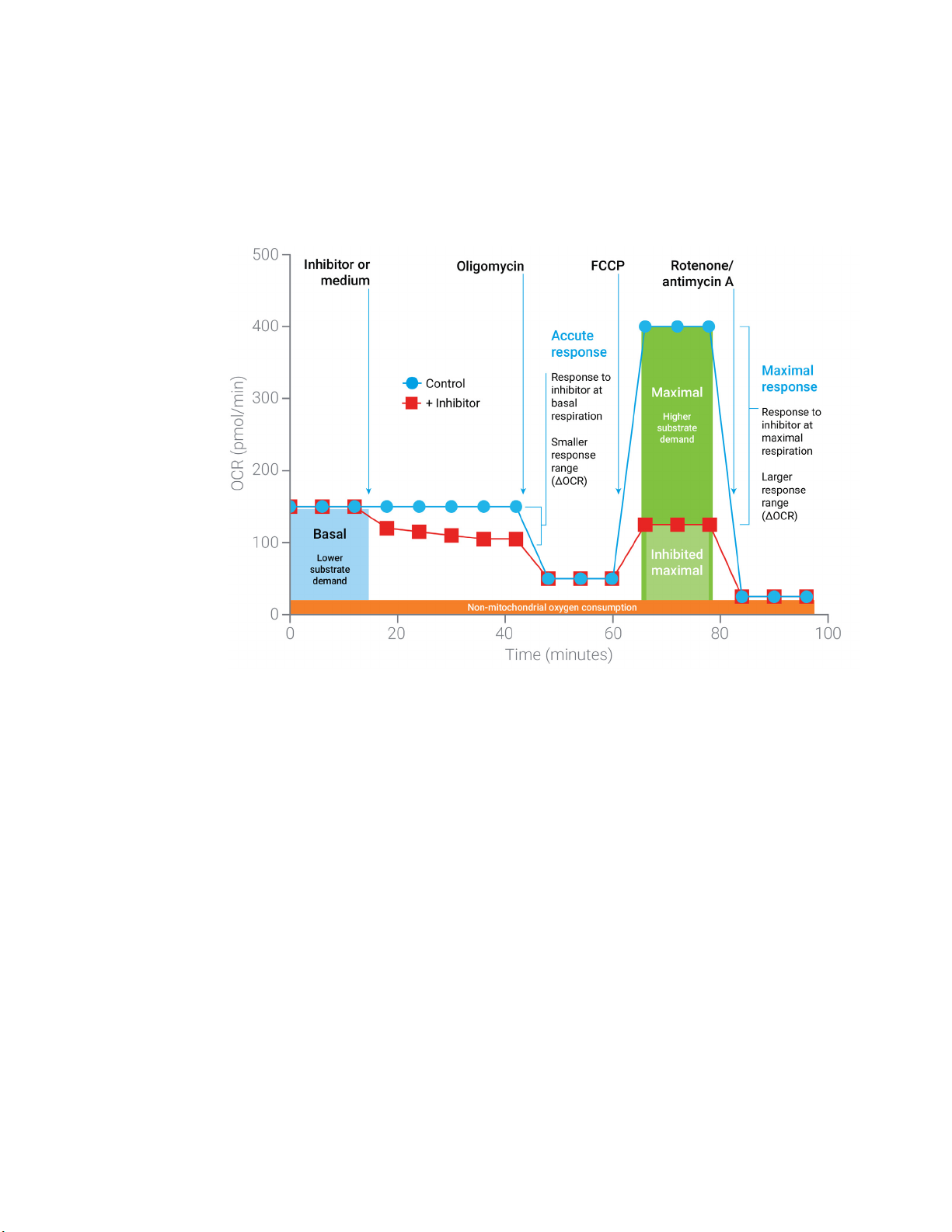

(maximal respiration). Figure 2 outlines the kinetic profile of a standard substrate oxidation assay

and relevant assay parameters.

Figure 2. Agilent Seahorse XF Substrate Oxidation Stress Test profile of the respiration parameters

critical for substrate demand. Sequential compound injections measure basal respiration,

acute response to an inhibitor (etomoxir or UK5099 or BPTES), and maximal respiration in the

absence and presence of inhibitor. Note that while minimal changes may be measured under

basal conditions, such as the acute response; much larger responses are often revealed

under conditions of high substrate demand (for example, FCCP), thus revealing differences in

the ability of the cells to oxidize the substrate in question.

Measurements are highly informative, as the design described provides information on basal

respiration and the impact of pathway inhibition under conditions of basal substrate demand,

while also characterizing the impact of pathway inhibitions on maximal respiration, reflecting the

cell's sensitivity to impairment of a specific metabolic pathway under conditions of high substrate

demand. Due to the metabolic plasticity of many cell types, it is often more informative to assess

substrate dependence when demand is high as this reveals the cell's capacity to use substrates.

When mitochondria are uncoupled (such as FCCP exposure), substrate oxidation is increased to

generate the reducing equivalents needed for the increased respiration rate. By comparing the

maximum respiration rates of control versus inhibited cells, insights can be gained into how much

a cell will rely on a specific substrate to meet this high energy demand.

This manual details how to perform all assays in the XF Substrate Oxidation Stress Test suite. In

general, there are two distinct assay types: Standard and Advanced. The XF LCFA Oxidation

Stress Test, XF Glutamine Oxidation Stress Test and Glucose/Pyruvate Oxidation Stress Test kits

are to be carried out using the Standard Assay workflow, using a single inhibitor in the presence of

multiple substrates). Conversely, the XF Palmitate Oxidation Stress Test Kit requires users to use

the Advanced Assay protocol as additional steps are required (Figures 5, 6, and 10), and is carried

out using palmitate as the long chain fatty acid substrate and etomoxir as the inhibitor. The

following are the principles and designs of these assays.

Agilent XF Substrate Oxidation Stress Test Kits 7

Page 8

XF Substrate Oxidation Stress Test - Standard Assay

NOTE

XF Substrate Oxidation Stress Test - Standard Assay

Relevant kits include:

XF Long Chain Fatty Acid Oxidation Stress Test Kit (p/n 103672-100)

XF Glucose/Pyruvate Oxidation Stress Test Kit (p/n 103673-100)

XF Glutamine Oxidation Stress Test Kit (p/n 103674-100)

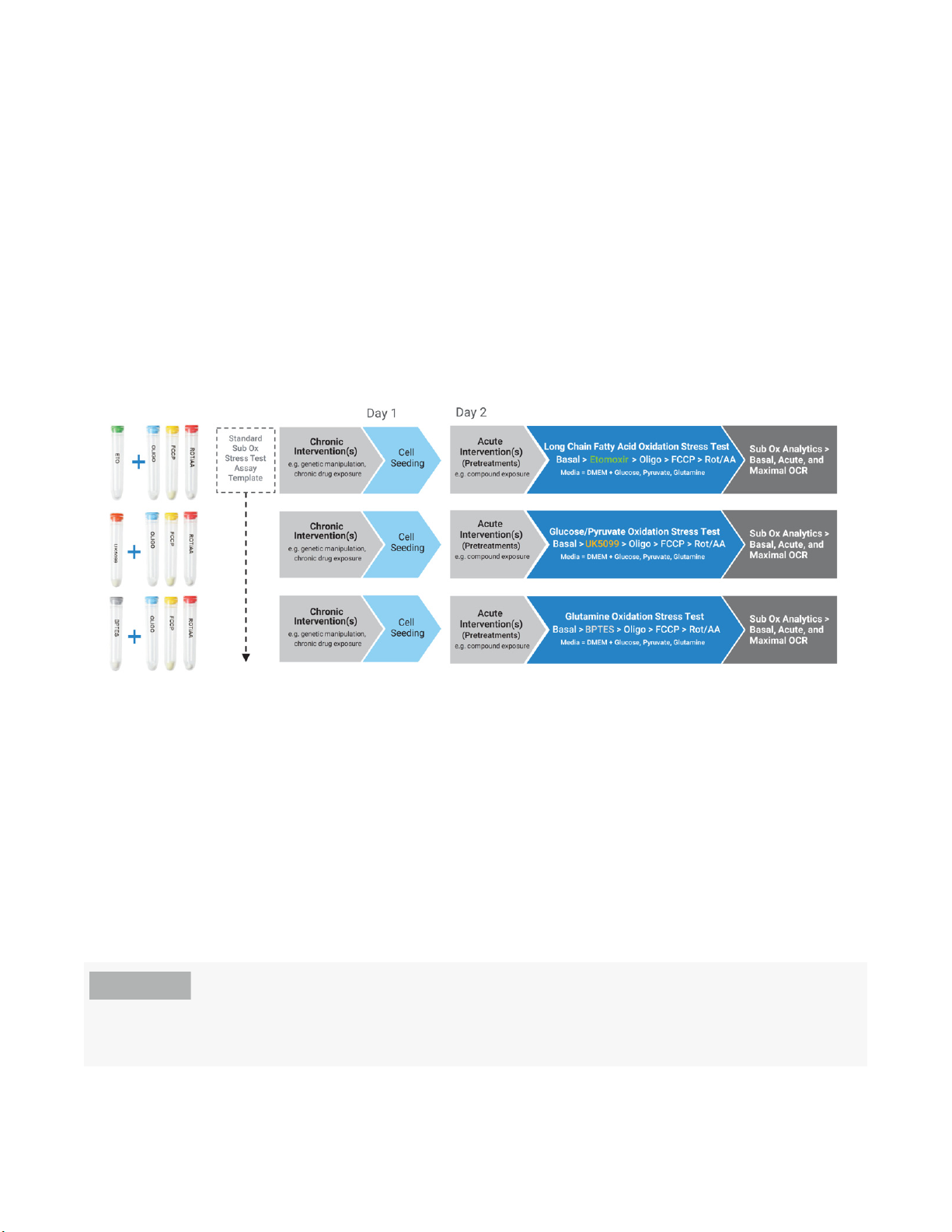

To perform a Standard Substrate Oxidation Stress Test, basal respiration is first established,

followed by injection of the relevant pathway inhibitor. The acute response to the inhibitor is

monitored over several measurement cycles (typically six). Then, the standard XF Cell Mito Stress

Test reagents, such as oligomycin, FCCP, and rotenone/antimycin A are injected sequentially,

similar to the assay scheme used for the XF Cell Mito Stress Test. Figure 3 outlines an overview of

the experimental workflow for each kit.

Figure 3. Agilent XF Substrate Oxidation Stress Test - Standard Assay Design. Each kit is focused on testing a single substrate

using the relevant inhibitor. Chronic or acute interventions (genetic manipulations/drug exposure) may be performed

upstream of the assay to understand the effects of these modulations on the oxidation of specific mitochondrial

substrates.

Each kit is focused on testing a single substrate using the optimized concentration of relevant

inhibitor: etomoxir (4 µM) to inhibit oxidation of LCFAs, UK5099 (2 µM) to inhibit the oxidation of

glucose and/or pyruvate, and BPTES (3 µM) to inhibit oxidation of glutamine (final

concentrations). These three assays are designed to be performed under conditions of saturating

substrates with respect to glucose (10 mM), pyruvate (1 mM) and glutamine (2 mM) in the assay

media. The source of long chain fatty acids is any endogenous stores of lipid/LCFAs in the cell

used, and is cell-type dependent. Figure 3 shows that the standard methods and assay conditions

for each of the XF Substrate Oxidation Stress Tests are identical with the exception of the identity

of the inhibitor used.

Users must first establish both the optimal cell seeding density and optimal FCCP

concentration for ideal assay performance and resulting data. Typically, these are the same

conditions established for a cell type in an XF Cell Mito Stress Test. For information on how to

optimize cell seeding density and FCCP concentrations, please visit the Agilent Cell Analysis

Learning Center website.

8 Agilent XF Substrate Oxidation Stress Test Kits

Page 9

XF Substrate Oxidation Stress Test - Standard Assay

In these Standard Assays, decreased respiration rates in response to an inhibitor suggest that the

cells have a demand or preference for that particular substrate under the experimental conditions

established. In general, these assays can be used to facilitate investigation to address the

following types of questions:

• Does the cell have a demand for a particular substrate or substrates?

• Is the cell highly reliant on a specific substrate, or can other substrates satisfy cellular

demands?

• How is mitochondrial substrate demand and/or reliance affected if an intervention, such as

genetic manipulation or drug exposure, is applied to the cell?

Like many XF assays, the Substrate Oxidation Stress Tests are typically performed subsequent to

a pretreatment, or intervention, as designed by the researcher. This is shown as either a chronic

intervention to the cells (for example, a genetic manipulation or long-term drug exposure), hours

to days upstream of XF assay, or as an acute intervention (for example, drug exposure) just prior

to the XF assay (Figure 3). In some cases, both chronic and acute interventions may be used (for

example, rescue of genetic dysfunction through compound exposure). The kits may be used

individually (such as focusing on one specific substrate) for investigating how a series of

interventions or compounds may affect oxidation of that particular substrate; or in combination

(such as focusing on two or more substrates) to elucidate overall effects of a given intervention

with respect to substrate oxidation and mitochondrial function.

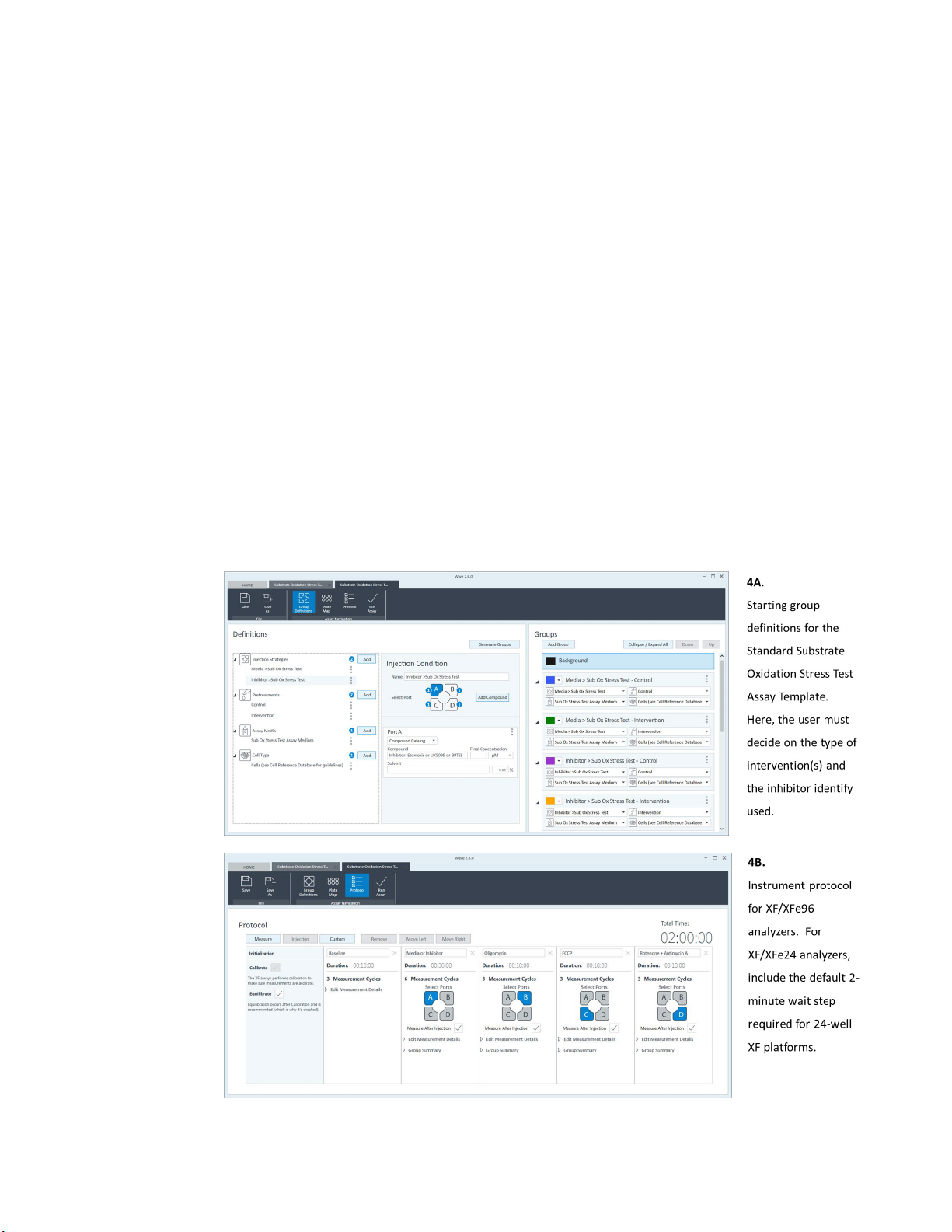

For examples of the design of assay templates for XF Substrate Oxidation Stress Tests - Standard

Assays, refer to Figure 4.

Agilent XF Substrate Oxidation Stress Test Kits 9

Page 10

XF Substrate Oxidation Stress Test - Standard Assay

10 Agilent XF Substrate Oxidation Stress Test Kits

Page 11

XF Substrate Oxidation Stress Test - Standard Assay

Figure 4. Agilent Seahorse XF Substrate Oxidation Stress Test - Assay Design Examples. These

examples are suggested designs, and the user is encouraged to modify the generic Standard

Substrate Oxidation Stress Test Assay Template file to accommodate the specific

requirements of the experimental design.

Agilent XF Substrate Oxidation Stress Test Kits 11

Page 12

XF Palmitate Oxidation Stress Test - Advanced Assay

XF Palmitate Oxidation Stress Test - Advanced Assay

Relevant kit includes:

XF Palmitate Oxidation Stress Test Kit (p/n 103693-100)

The XF Palmitate Oxidation Stress Test Advanced Assay details the workflow to specifically

analyze the long chain fatty acid oxidation pathway in live cells. The kit includes the XF

Palmitate-BSA FAO Substrate, L-carnitine, etomoxir, as well as oligomycin, FCCP, and

rotenone/antimycin A, and is designed to determine the intrinsic rate and capacity of a cell to

oxidize palmitate in the absence or limitation of other exogenous substrates. This workflow is

best applied when investigating how interventions (genetic manipulations and drug exposure)

specifically affect the LCFA oxidation process and can be a complementary and/or follow-up

assay to the Standard Assay workflow for XF Long Chain Fatty Acid Oxidation Stress Test

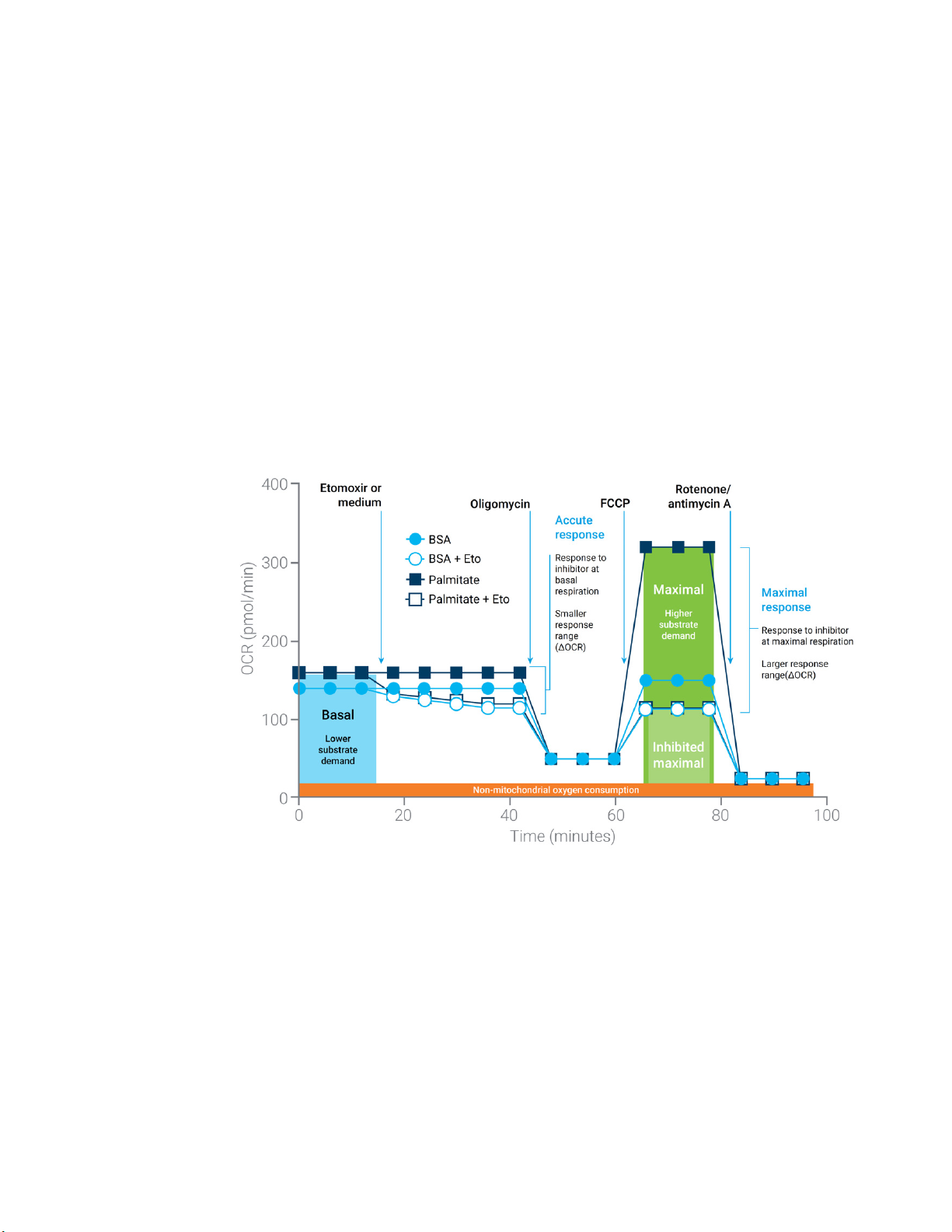

discussed in the previous section. The kinetic profile of the Advanced Palmitate oxidation assay

and relevant assay parameters is outlined in Figure 5, and an overview of the experimental

workflow for the Advance Assay is outlined in Figure 6.

Figure 5. Agilent Seahorse XF Palmitate Oxidation Stress Test profile of the respiration parameters

critical for palmitate demand. Sequential compound injections measure basal respiration,

acute response to etomoxir, and maximal respiration in the absence and presence of

etomoxir. Note that while minimal changes may be measured under basal conditions, such

as the acute response, much larger responses are often revealed under conditions of high

substrate demand (for example, FCCP), revealing differences in the ability of the cells to

oxidize palmitate.

12 Agilent XF Substrate Oxidation Stress Test Kits

Page 13

XF Palmitate Oxidation Stress Test - Advanced Assay

NOTE

Figure 6. Agilent XF Palmitate Oxidation Stress Test - Advanced Assay. This assay is specifically focused on determining the

intrinsic rate and capacity of a cell to oxidize palmitate in the absence or limitation of other exogenous substrates,

using inhibitor etomoxir to inhibit oxidation of palmitate.

The Palmitate Oxidation Stress Test is designed to be performed under conditions of saturating

palmitate (as palmitate-BSA) and L-carnitine, limited to no substrates provided with respect to

glucose, pyruvate, and glutamine in the assay media. It is best applied when the experimental

design calls for the cells to exclusively oxidize a long chain fatty acid, such as palmitate, to

investigate effects of interventions specifically on the long chain fatty acid oxidation process.

As shown in Figure 6, this workflow often requires substrate limitation before and/or during the

assay to condition the cells to obtain robust responses to the palmitate substrate added to the

assay media. The suggested initial substrate-limited growth media conditions can be found in

Table 1.

Users must first establish the optimal cell density and optimal FCCP concentration for best

assay performance and resulting data. Typically, these are the same conditions established for

a cell type in an XF Cell Mito Stress Test, except the FCCP concentration may need to be

re-optimized in the presence of BSA. For information on how to optimize cell density and FCCP

concentrations, please visit the Agilent Cell Analysis Learning Center website.

Table 1 Suggested substrate limitation conditions for performing the XF Palmitate Oxidation

Stress Test Advanced Assay with base growth media. Initial suggested time of

incubation under substrate limitation is overnight (16 to 24 hours).

Base growth media

DMEM or RPMI

without glucose, pyruvate,

glutamine, or GlutaMAX

Growth media supplement

Glucose 0.5 mM

Glutamine or GlutaMAX 1.0 mM

Serum (for example, FBS) 1%

Seahorse L-Carnitine 0.5 mM

Suggested initial concentration in

substrate-limited growth media

Table 2 Suggested substrate limitation conditions for performing the XF Palmitate Oxidation

Stress Test Advanced Assay with XF Assay Media.

XF Assay Media Assay Media supplement Suggested initial concentration in assay media

XF DMEM medium, pH 7.4 or

XF RPMI medium, pH 7.4

XF Glucose 2.0 mM

XF L-Carnitine 0.5 mM

XF Palmitate-BSA

*

96 well 30 µL/well

24 well 85 µL/well

XF BSA Control

* Note that XF Palmitate-BSA and XF BSA control are added directly to the XF cell culture plate wells just prior to starting the

assay. See pages 37 - 38 for further information.

*

96 well 30 µL/well

24 well 85 µL/well

Agilent XF Substrate Oxidation Stress Test Kits 13

Page 14

XF Palmitate Oxidation Stress Test - Advanced Assay

NOTE

Optimal limited substrate concentrations and optimal time of incubation are cell-dependent

and should be empirically determined for the cell type of interest.

Instead of examination of substrate demand and reliance, this Advanced Assay is designed to be

used when asking the following type of question:

• How an intervention, such as genetic manipulation or drug exposure, specifically affects the

oxidation of long chain fatty acids when applied to the cell?

This assay is most often performed under some pretreatment condition, or intervention, as

designed by the researcher. This is shown as either a chronic intervention to the cells (for

example, a genetic manipulation or long-term drug exposure), hours to days upstream of XF

assay, or as an acute intervention (for example, drug exposure) just prior to the XF assay

(Figure 6). In some cases, both chronic and acute interventions may be used (for example, rescue

of genetic dysfunction through compound treatment). For examples of the assay template design

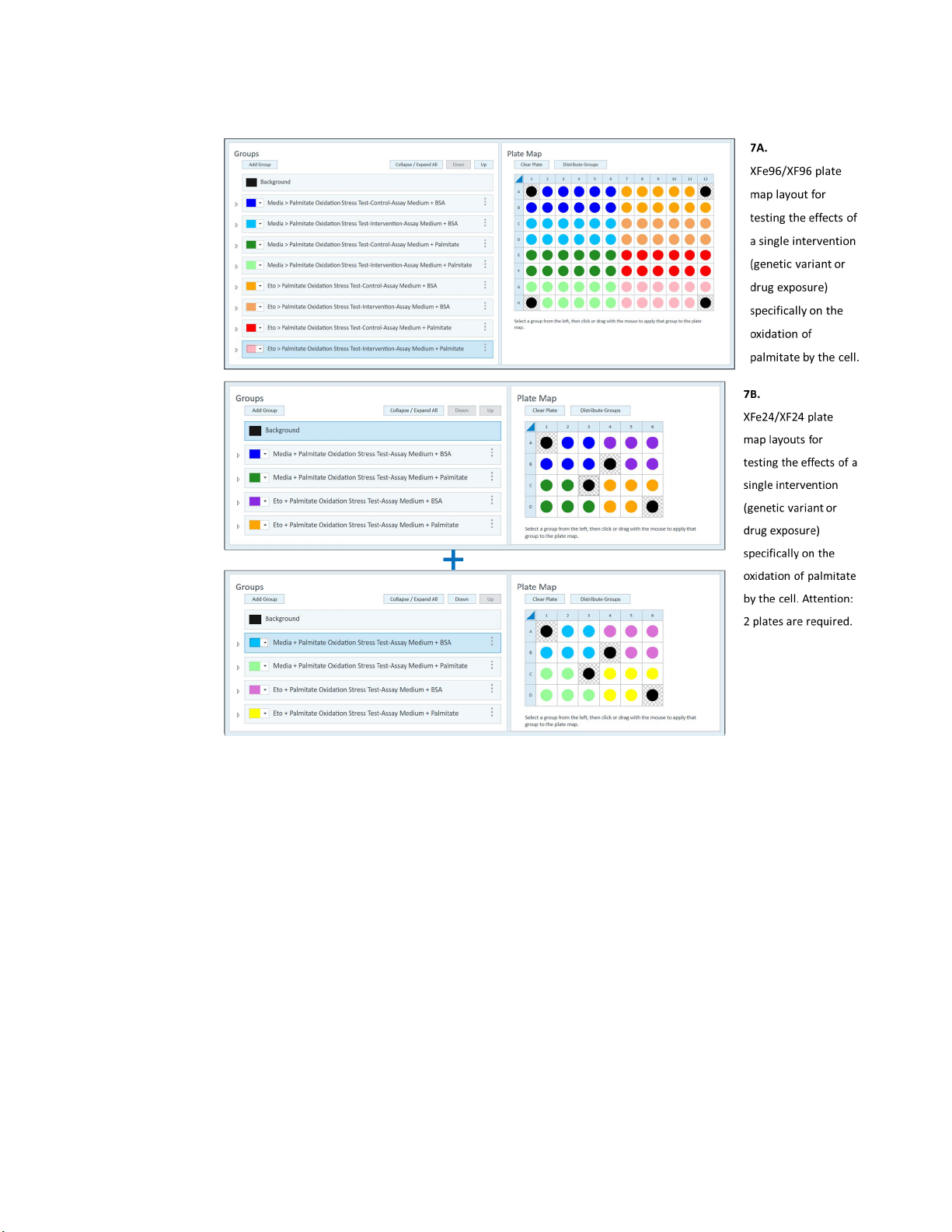

for XF Palmitate Oxidation Stress Test - Advanced Assay, refer to Figure 7.

There are critical and distinct difference between this Advanced Assay workflow and the

Standard Assay workflow described in the previous section, including:

• Cells usually require a period of substrate limitation to measure oxidation of palmitate

substrate provided, especially established cell lines. The specific conditions will be cell type

dependent, and should be determined empirically for each cell type tested, particularly for

primary type cells.

• An analogous BSA control group must be included for each condition tested to ensure that the

observed responses are associated with Palmitate-BSA in the assay media. Therefore, the

number of groups used doubles compared to a Standard Substrate Oxidation Stress Test. For

examples of Palmitate Oxidation Stress Test assay templates, refer to Figure 6.

• L-carnitine is included in substrate-limited medium and assay medium to ensure that it is not a

rate limiting factor in the assay.

• The conditions for substrate limitation and performance of the Advanced Assay are only

validated for use with the XF Palmitate-BSA substrate and BSA control.

14 Agilent XF Substrate Oxidation Stress Test Kits

Page 15

XF Palmitate Oxidation Stress Test - Advanced Assay

Figure 7. Agilent XF Palmitate Oxidation Stress Test - Plate Layout Map Examples.

Agilent XF Substrate Oxidation Stress Test Kits 15

Page 16

Glossary

Glossary

• Basal Respiration: Oxygen consumption used to meet cellular ATP demand and resulting from

mitochondrial proton leak. Shows substrate demand of the cell under baseline conditions.

• Acute Response: Change in oxygen consumption rate due to an injection of substrate

oxidation inhibitor (etomoxir, UK5099, BPTES). Reported as a change in OCR

(i.e., ∆OCR pmol/min).

• Maximal Respiration: The maximal oxygen consumption rate attained by adding the

uncoupler FCCP. FCCP increases a substrate demand by stimulating the respiratory chain to

operate at maximum capacity, which causes rapid oxidation of substrates (sugars, fats, and

amino acids) to meet this metabolic challenge. Shows substrate demand of the cell under

maximal respiration conditions.

• Non-mitochondrial Respiration: Oxygen consumption that persists due to a subset of cellular

enzymes that continue to consume oxygen after rotenone/antimycin A addition. This is

important for getting an accurate measure of mitochondrial respiration.

• Standard Substrate Oxidation Stress Test Workflow: Three complementary assays, each

focused on testing cellular demand of a single substrate (LCFAs or G/P or Q) using the

optimized concentration of relevant inhibitor: etomoxir or UK5099 or BPTES. Designed to be

performed under conditions of saturating substrates with respect to glucose, pyruvate, and

glutamine in the assay media (Figures 2, 3, 4, and 8).

• Advanced XF Palmitate Oxidation Stress Test: A single assay designed to determine the

intrinsic rate and capacity of a cell to oxidize palmitate in the absence or limitation of other

exogenous substrates. Performed under conditions of saturating palmitate (as

palmitate-BSA) and L-carnitine, in the assay media. It is best applied when the experimental

design calls for the cells to exclusively oxidize a long-chain fatty acid, such as palmitate, in

order to investigate effects of interventions specifically on the long chain fatty acid oxidation

process (Figures 5, 6, 7, 12, and Tab l e 1).

•MST: XF Cell Mito Stress Test, a well-recognized assay that provides a comprehensive view of

mitochondrial function by reporting multiple parameters for mitochondrial respiration. For

more information, visit the Agilent Seahorse XF Cell Mito Stress Test product website.

•FAO: Fatty acid oxidation.

•Etomoxir: An inhibitor of long chain fatty acid oxidation. Etomoxir inhibits carnitine

palmitoyl-transferase 1a (CPT1a), which is critical for translocating long chain fatty acids from

the cytosol into the mitochondria for beta oxidation. Note that concentrations in excess of

4 µM (final in assay) result in substantial off-target effects on mitochondrial respiration

• UK5099: An inhibitor of the glucose oxidation pathway. UK5099 inhibits the mitochondrial

pyruvate carrier (MPC), which transports pyruvate into the mitochondria. Cells convert glucose

to pyruvate through glycolysis. Pyruvate can be transported into the mitochondria and

oxidized by the TCA cycle.

•BPTES: An inhibitor of the glutamine oxidation pathway. BPTES is an allosteric inhibitor of

glutaminase (GLS1). Glutaminase converts glutamine to glutamate, glutamate is then

converted to alpha-ketoglutarate, and oxidized by the TCA cycle. Note that BPTES does not

inhibit GLS2.

•LCFAs: Long chain fatty acids.

•G/P: Glucose/pyruvate.

•Q: Glutamine.

16 Agilent XF Substrate Oxidation Stress Test Kits

Page 17

Glossary

• L-Carnitine: A supplement provided in the Palmitate Oxidation Stress Kit for use in substrate

limited growth media and substrate limited assay media. Ensures concentrations of

L-carnitine are saturating and not limiting rates of palmitate oxidation.

•Growth Media: Fully supplemented cell culture media appropriate for the specific cell type.

• Substrate Limitation: A condition used in the Palmitate Oxidation Stress Test - Advanced

Assay. It usually refers to a period of time (e.g., overnight) in which key substrates (typically

glucose, pyruvate, GlutaMAX, and serum) are reduced in concentration in the cell culture

media.

• Substrate-limited growth media: Cell culture media with key substrates (typically glucose,

pyruvate, GlutaMAX, and serum) reduced in concentration (see Table 1).

• Substrate-limited assay media: Assay media with key substrates (typically glucose, pyruvate,

and glutamine) reduced in concentration and/or omitted (see Table 2).

Agilent XF Substrate Oxidation Stress Test Kits 17

Page 18

References

References

1 Divakaruni, A. S.; et al. 2018. 'Etomoxir Inhibits Macrophage Polarization by Disrupting CoA

2 Divakaruni, A. S.; et al. 2014. 'Analysis and interpretation of microplate-based oxygen

3 Hildyard, J. C.; et al. 2005. 'Identification and characterisation of a new class of highly specific

4 Robinson, Mary M.; et al. 2007. 'Novel mechanism of inhibition of rat kidney-type glutaminase

Homeostasis', Cell Metab, 28: 490-503.e7.

consumption and pH data', Methods Enzymol, 547: 309-54.

and potent inhibitors of the mitochondrial pyruvate carrier', Biochim Biophys Acta, 1707:

221-30.

by bis-2-(5-phenylacetamido-1,2,4-thiadiazol-2-yl)ethyl sulfide (BPTES)', Biochemical Journal,

406: 407-14.

18 Agilent XF Substrate Oxidation Stress Test Kits

Page 19

2 Kit Information

Kit Contents 20

Kit Shipping and Storage 21

Additional Agilent Products Required 21

Agilent XF Substrate Oxidation Stress Test Kits 19

Page 20

Kit Contents

Kit Contents

Products relevant to the Seahorse XF Substrate Oxidation Stress Tests include four Kits. Each kit

contains reagents sufficient for three complete XF Substrate Oxidation Stress Tests in either a

96- or 24-well Agilent Seahorse XF Cell Culture Microplate. The contents or components for each

kit are different, depending on the substrate being examined, and are listed in Table 3.

Table 3 Agilent Seahorse XF Substrate Oxidation Stress Test Kits contents are shown per pouch,

Compound Cap color Qty per vial

Agilent Seahorse XF Long Chain Fatty Acid Oxidation Stress Test kit contents (p/n 103672-100)

Etomoxir Green 112 nmol

Oligomycin Blue 63 nmol

FCCP Yellow 72 nmol

Rotenone/Antimycin A Red 27 nmol each

Agilent Seahorse XF Glucose/Pyruvate Oxidation Stress Test kit contents (p/n 103673-100)

UK5009 Orange 56 nmol

Oligomycin Blue 63 nmol

three (3) pouches or vials (Palmitate and BSA control) per kit.

FCCP Yellow 72 nmol

Rotenone/Antimycin A Red 27 nmol each

Agilent Seahorse XF Glutamine Oxidation Stress Test kit contents (p/n 103674-100)

BPTES Grey 84 nmol

Oligomycin Blue 63 nmol

FCCP Yellow 72 nmol

Rotenone/Antimycin A Red 27 nmol each

Agilent Seahorse XF Palmitate Oxidation Stress Test kit contents (p/n 103693-100)

Etomoxir Green 112 nmol

Oligomycin Blue 63 nmol

FCCP Yellow 72 nmol

Rotenone/Antimycin A Red 27 nmol each

XF Palmitate-BSA - 2 mL

XF BSA control - 2 mL

Seahorse L-carnitine Brown 10 mg

20 Agilent XF Substrate Oxidation Stress Test Kits

Page 21

Kit Shipping and Storage

Kit Shipping and Storage

Products are shipped at ambient temperature, and can be stored at room temperature, except for

XF Palmitate BSA FAO substrate. The XF Palmitate BSA FAO substrate is shipped with ice packs,

and should be stored at -20 °C upon arrival. All kits are stable for one year from the date of

manufacture, while XF L-carnitine is stable for two years from the date of manufacture. The kit

expiration date is printed on the label of the kit box. Depending on the shipping date, the actual

shelf life of the kit in the user's hand can vary between 3 and 12 months.

Additional Agilent Products Required

The following products are also required for performing the Seahorse XF Substrate Oxidation

Stress Tests but not supplied with the kits. For a complete list of materials required to perform an

XF assay, please visit the Agilent Cell Analysis Assay Learning Center website.

Table 4 Additional required items.

Item Vendor Part number

Seahorse XF96, XF24, XFe96 or XFe24 Analyzer Agilent Technologies

Seahorse XF DMEM Medium, pH 7.4

Seahorse XF RPMI Medium, pH 7.4

Seahorse XF FluxPak for the Analyzer being used Agilent Technologies Various

Seahorse XF 1.0 M Glucose solution Agilent Technologies 103577-100

Seahorse XF 100 mM Pyruvate solution

Seahorse XF 200 mM Glutamine solution

* XF DMEM or RPMI media can also be purchased together with the supplements listed in this table as bundled products

(p/n 103680-100 and 103681-100). For a full list of all medium types and our recommendation for each assay kit, please refer

to the Seahorse XF Media Selection Guide.

† Not required when performing the Seahorse XF Palmitate Oxidation Stress Test kit (p/n 103693-100).

*

or

*

†

†

Agilent Technologies 103575-100

Agilent Technologies 103576-100

Agilent Technologies 103578-100

Agilent Technologies 103579-100

Agilent XF Substrate Oxidation Stress Test Kits 21

Page 22

Additional Agilent Products Required

22 Agilent XF Substrate Oxidation Stress Test Kits

Page 23

3 Assay Workflow for Standard Substrate

Standard XF Substrate Oxidation Stress Test

XF Long Chain Fatt y Acid Oxidation Stress Test Kit (p/n 103672-10 0)

XF Glucose/Pyru vate Oxidation S tress T est Kit (p/n 103673-10 0)

XF Glutamine Oxidation Str ess Test Kit. (p/n 103674-100)

and/or

and/or

NOTE

Oxidation Stress Test

One Day Prior to Assay 24

Day of Assay 24

Data Analysis Using Agilent Seahorse Analytics 30

Examples of Data 32

Figure 8. Agilent Seahorse XF Substrate Oxidation Stress Test-Standard Assay Workflow.

Optimal cell seeding density and FCCP concentration should be empirically determined for

your cell type prior to the assay. For more details, please refer to the Basic Procedures on

Agilent Cell Analysis Learning Center website.

The Cell Line Reference Database is an excellent resource for finding information regarding the

cell type of interest.

Agilent XF Substrate Oxidation Stress Test Kits 23

Page 24

One Day Prior to Assay

NOTE

One Day Prior to Assay

1 Turn on the Seahorse XFe/XF96 or XFe/XF24 Analyzer, and let it warm up overnight to allow

the temperature to stabilize (minimum five hours).

2 Hydrate a sensor cartridge in sterile or distilled water at 37 °C in a non-CO

overnight. For more information, refer to the Basic Procedure, “Hydrating the sensor cartridge”,

on the Agilent Cell Analysis Learning Center website.

3 For adherent cells, plate cells at a pre-determined density in the Seahorse XF Microplate using

the appropriate cell culture growth medium. Refer to the Agilent Cell Analysis Learning

Center website for details.

For suspension cells, see section: Day of Assay/Prepare Seahorse XF Cell Culture

Microplate for Assay.

4 Create an Assay Template file with Wave Desktop software using the Standard Substrate

Oxidation Stress Test Assay Template. Make any necessary group modifications to the

template for your specific assay design.

Day of Assay

Complete hydration of sensor cartridge by removing water, adding the appropriate volume of

XF calibrant to each well, and placing in a 37 °C non-CO

Prepare assay media

1 Prepare Standard Substrate Oxidation Stress Test assay media by supplementing 97 mL of

Seahorse XF DMEM Medium, pH 7.4 with 1.0 mL each of XF glucose, XF pyruvate, and

XF glutamine (10 mM, 1 mM, and 2 mM final in assay media, respectively). These are the

recommended initial conditions. However, the desired assay medium composition can be

modified if needed.

2

incubator for 60 minutes.

2

incubator

Table 5 Standard Substrate Oxidation Stress Test Assay Media.

Component Volume Final concentration

Agilent Seahorse XF DMEM or RPMI Medium, pH 7.4 97 mL -

XF 1.0 M Glucose Solution 1.0 mL 10 mM

XF 100 mM Pyruvate Solution 1.0 mL 1 mM

XF 200 mM Glutamine Solution 1.0 mL 2 mM

2 Warm media to 37 °C until it is ready to use.

No pH adjustment to the assay media is necessary when recommended supplement

concentrations are used.

24 Agilent XF Substrate Oxidation Stress Test Kits

Page 25

Prepare Seahorse XF Cell Culture Microplate for assay

CAUTION

Prepare Seahorse XF Cell Culture Microplate for assay

For adherent cells

1 Remove cell culture microplate from 37 °C cell culture incubator and examine cells under

microscope to confirm consistent plating and proper cell morphology.

2 Remove the growth medium from the cell culture microplate. Wash once with warmed assay

medium. Add assay medium to a final volume of 180 µL/well for 96-well plates and

500 µL/well for 24-well plates. Refer to the Agilent Cell Analysis Learning Center for more

details.

3 Incubate cell plates with assay medium at 37 °C in a non-CO

prior to the assay.

4 Before starting the XF assay, remove the assay medium AGAIN and add fresh, warm assay

medium to each well. Total volume should be 180 µL/well for 96-well plates and 500 µL/well

for 24-well plates.

incubator for 45 to 60 minutes

2

For suspension cells

1 Pellet cells out of their growth medium and resuspend in warm assay medium.

2 Count cells and suspend at a concentration such that seeding 50 µL (XF96/XFe96) or

100 µL (XFe24) of cells contains the desired cell number per well, leaving four wells without

cells as background correction wells.

3 Add desired cells/well, then centrifuge gently to adhere.

4 Gently add assay medium to each well. Total well volume should be 180 µL/well for 96-well

plates and 500 µL/well for 24-well plates.

5 Incubate the plate at 37 °C in a non-CO

Refer to the Agilent Cell Analysis Learning Center for more information on preparation of

suspension cells for XF assays.

incubator for 45 to 60 minutes prior to the assay.

2

Prepare compound stock solutions and working solutions

Agilent XF Substrate Oxidation Stress Test Kits 25

Use compounds on the same day they are reconstituted. Do not freeze and reuse. Discard any

remaining compound solutions.

1 Remove one foil pouch and the decapper from the kit box.

2 Open pouch and remove all four vials: Oligomycin (blue cap), FCCP (yellow cap),

Rotenone/Antimycin A (red cap), and the inhibitor vial (specific to each kit; either etomoxir

(green cap), UK5099 (orange cap), or BPTES (grey cap)).

3 Tap down the vials to ensure powder is on the bottom of the vial before removing the vial cap

using the decapper provided with the kits.

Page 26

Prepare compound stock solutions and working solutions

4 Resuspend the content in each vial with the appropriate volume of prepared assay medium as

described in Table 6. Vortex ~1 minute to ensure full resuspension of compounds. These are

compound stock solutions.

Table 6 Stock solutions.

Compound

Volume of assay

medium

Stock concentration

Etomoxir from XF Long Chain Fatty Acid Oxidation Stress Test kit or

UK5099 from XF Glucose/Pyruvate Oxidation Stress Test kit or

BPTES from XF Glutamine Oxidation Stress Test kit

Oligomycin 420 µL 150 µM

FCCP 720 µL 100 µM

Rotenone/Antimycin A 540 µL 50 µM

700 µL 160 µM

700 µL 80 µM

700 µL 120 µM

5 Using the compound stock solutions to prepare working solutions for loading into the injection

ports on sensor cartridges.

6 Prepare 2 or 3 mL working solutions for each compound in assay medium as indicated in

Table 7 for XF/XFe96 sensor cartridges and Table 8 for XF/XFe24 sensor cartridges. It is

recommended to use 1.5 µM of oligomycin and 0.5 µM rotenone/antimycin A (final

concentration) for most cells. Optimal FCCP concentration should be determined prior to the

assay.

Table 7 Compound preparation for loading to XFe/XF96 sensor cartridges. Starting assay

medium volume for cell plate is 180 µL per well.

Final well

µM

Stock

solution

volume (µL)

Medium

volume (µL)

10× (Port)

µM

Volume

added to port

(µL)

Port A: Etomoxir or

UK5009 or

BPTES

Port B: Oligomycin 1.5 300 2,700 15 22

Port C: FCCP 0.25 75 2,925 2.5 25

Port D: Rotenone/Antimycin A 0.5 300 2,700 5 27

4 500 1,500 40 20

2 500 1,500 20 20

3 500 1,500 30 20

0.5 150 2,850 5 25

1.0 300 2,700 10 25

2.0 600 2,400 20 25

26 Agilent XF Substrate Oxidation Stress Test Kits

Page 27

Load the injection ports on sensor cartridge

Table 8 Compound preparation for loading to XFe/XF24 sensor cartridges. Starting assay

medium volume for cell plate is 500 µL per well.

Stock

Final well

µM

Port A: Etomoxir or

UK5009 or

BPTES

Port B: Oligomycin 1.5 300 2,700 15 62

Port C: FCCP 0.25 75 2,925 2.5 69

Port D: Rotenone/Antimycin A 0.5 300 2,700 5 75

4 500 1,500 40 56

2 500 1,500 20 56

3 500 1,500 30 56

0.5 150 2,850 5 69

1.0 300 2,700 10 69

2.0 600 2,400 20 69

solution

volume (µL)

Medium

volume (µL)

10× (Port)

µM

Volume

added to port

(µL)

Load the injection ports on sensor cartridge

Proper port loading techniques can be found in Basic Procedure “Loading the Sensor Cartridge

with Compounds”, on the Agilent Cell Analysis Learning Center website.

Please read the information prior to loading compounds. Ensure that the sensor cartridge is

properly hydrated prior to use.

For the location of the ports, please refer to Figure 9.

Figure 9. Layout of injection ports on sensor cartridges for XFe96, XF96, and XFe24 sensor cartridges.

Note the XF24 sensor cartridges have a different layout. Please consult the XF Assay

Learning Center for XF24 injection port layout.

Agilent XF Substrate Oxidation Stress Test Kits 27

Page 28

Load template onto the Seahorse XFe Analyzer

NOTE

Refer to Tab l e 9 for loading volume and port designation for compounds in different types of

assays.

Table 9 Recommended injection volumes for Substrate Oxidation Stress Test injection schemes.

Starting assay medium volume is 180 µL per well for 96-well cell plates and 500 µL per

well for 24-well cell plates.

Port Compound Port concentration 96 well 24 well

A Inhibitor (etomoxir, UK5099, or BPTES)

B Oligomycin 10× 22 µL 62 µL

C FCCP 10× 25 µL 69 µL

D Rotenone/Antimycin A 10× 27 µL 75 µL

* For controls, assay medium should be used in port A instead of inhibitors.

Load template onto the Seahorse XFe Analyzer

Add to port volume

*

10× 20 µL 56 µL

If templates(s) are already present on the XFe analyzer, skip this step.

Personal computer (internet access required)

1 Use the hyperlink below to download the Seahorse XF Substrate Oxidation Stress Test -

Standard Template (for Long Chain Fatty Acid, and/or Glucose/Pyruvate, and/or Glutamine

Oxidation Stress Tests).

www.agilent.com/cs/library/software/public/software-agilent-seahorse-xf-subox-assay-te

mplate-files-cell-analysis-agilent.zip

2 Unzip the folder, then copy and paste the assay template files to a USB drive or network drive

(if Seahorse XFe Analyzer is networked).

Seahorse XFe96/XFe24 Analyzer

1 Insert USB drive in front USB port and wait ~10 seconds.

2 Click Import (bottom of the New Assay view).

3 Locate the Assay Template file to import on the USB or network drive.

4 Click Open in the Windows dialogue box. The imported Assay template will be available for

selection from the Templates view on the XFe Analyzer.

5 Repeat for next template, if applicable.

6 The imported Assay template(s) will now be available for selection in the list of available

templates.

Running the XF substrate oxidation stress test assay

1 Select the Seahorse XF Substrate Oxidation Stress Test-Standard template from the list of

available templates and click Open File (or double-click the template).

2 Group Definitions: confirm or modify the default groups and conditions for your assay.

3 Plate Map: confirm or modify the plate layout map for your assay.

28 Agilent XF Substrate Oxidation Stress Test Kits

Page 29

Running the XF substrate oxidation stress test assay

4 Protocol: No action required - confirm or modify the Instrument Protocol for additional

measurements cycles during the assay.

5 Run Assay: Click Start Run when ready.

6 When prompted, remove the cartridge lid and place the loaded sensor cartridge with the utility

plate on the thermal tray of the Seahorse XFe Analyzer. Ensure correct plate orientation and

the cartridge lid has been removed. Then, click I'm Ready. Calibration takes approximately

15 to 30 minutes.

7 After completing Calibration, Wave Controller will display the Load Cell Plate dialog. Click

Open Tray to eject Utility Plate and load the Cell Plate. Ensure the lid is removed from Cell Plate

before Loading.

8 Click Load Cell Plate to run the assay.

Agilent XF Substrate Oxidation Stress Test Kits 29

Page 30

Data Analysis Using Agilent Seahorse Analytics

Data Analysis Using Agilent Seahorse Analytics

Agilent Seahorse Analytics is a new, web-based software platform that provides a simple,

streamlined data analysis workflow for the XF Substrate Oxidation Stress Test assay. Seahorse

Analytics automatically calculates the Substrate Oxidation Stress Test Parameters: basal

respiration, acute response to inhibitor, and maximal respiration. Visit

https://seahorseanalytics.agilent.com to register or log in to your Seahorse Analytics account.

1 After the assay is completed, transfer your assay result file to your personal computer using a

USB drive or network drive.

2 Go to https://seahorseanalytics.agilent.com to register or log in to your Seahorse Analytics

account.

30 Agilent XF Substrate Oxidation Stress Test Kits

Page 31

Data Analysis Using Agilent Seahorse Analytics

3 Import the assay result file to your account.

4 Open the assay result file, and select the XF Substrate Oxidation Stress Test analysis view

found under the Assay Kit Companion views menu.

5 Select groups to add to the analysis view, then click Add View.

Agilent XF Substrate Oxidation Stress Test Kits 31

Page 32

Examples of Data

Examples of Data

Figure 10 shows example Standard Substrate Oxidation Assay data from Seahorse Analytics for

A549 cells.

Figure 10. Standard Substrate Oxidation Assay data derived from Agilent Seahorse Analytics for

A549 cells.

32 Agilent XF Substrate Oxidation Stress Test Kits

Page 33

Examples of Data

Figure 11 shows example data from experiments with A549 (Panel A), C2C12 (Panel B), and

HepG2 cells (Panel C).

Control

Etomoxir (LCFAs)

UK5099 (Glucose/Pyruvate)

AB C

A549 Mitochondrial respiration

10

Inhibitor Oligo FCCP Rot/AA

9

8

7

6

5

4

3

2

1

OCR (pmol/min/1,000 cells)

0

0 24487296120

Time (min)

C2C12 Mitochondrial respiration

18

Inhibitor Oligo FCCP Rot/AA

15

12

9

6

3

OCR (pmol/min/1,000 cells)

0

0 24 48 72 96 120

Time (min)

30

25

20

15

10

5

OCR (pmol/min/1,000 cells)

0

0 24 48 72 96 120

BPTES (Glutamine)

HepG2 Mitochondrial respiration

Inhibitor Oligo FCCP Rot/AA

Time (min)

A549 Basal (rate 3)

8

7

6

5

4

3

2

1

OCR (pmol/min/1,000 cells)

0

A549 Acute response (rate 9)

1

0

-1

-2

-3

-4

-5

-6

∆OCR (pmol/min/1,000 cells)

-7

0.5

0

-0.5

-1.0

-1.5

A549 Maximal respiration (rate 14)

8

7

6

5

4

3

2

1

OCR (pmol/min/1,000 cells)

0

C2C12 Basal (rate 3)

16

14

12

10

8

6

4

2

OCR (pmol/min/1,000 cells)

0

C2C12 Acute response (rate 9)

1

-3

0.2

-7

0

-0.2

-0.4

-11

∆OCR (pmol/min/1,000 cells)

-15

-0.6

-0.8

-1.0

C2C12 Maximal respiration (rate 14)

16

14

12

10

8

6

4

2

OCR (pmol/min/1,000 cells)

0

HepG2 Basal (rate 3)

24

20

16

12

8

4

OCR (pmol/min/1,000 cells)

0

HepG2 Acute response (rate 9)

2

-2

-6

-10

-14

-18

∆OCR (pmol/min/1,000 cells)

-22

1

0

-1

-2

-3

-4

HepG2 Maximal respiration (rate 15)

24

20

16

12

8

4

OCR (pmol/min/1,000 cells)

0

Figure 11. Comparing substrate oxidation in A549, C2C12 and HepG2 cells using XF Glucose Pyruvate,

Long Chain Fatty Acid, and Glutamine Oxidation Stress Tests. A549 (A), C2C12 (B), and

HepG2 (C) cells were seeded in XF96 Cell Culture Plates and grown overnight. Cells were

subject to XF Substrates Oxidation Stress Tests using injections of assay media (control),

etomoxir (LCFA oxidation), UK5099 (glucose/pyruvate oxidation) or BPTES (Glutamine

oxidation), followed by common sequential injections of oligomycin, FCCP, and Rtn/AA. XF

Assay Media = XF DMEM, pH 7.4 supplemented with 10 mM glucose, 1 mM pyruvate and

2 mM glutamine. Each cell type was assayed on three individual days, with result data being

compiled and processed through Seahorse Analytics. Error is reported as ± SEM. Similar

results for all cell types tested were obtained using an XFe24 Analyzer (data not shown).

Agilent XF Substrate Oxidation Stress Test Kits 33

Page 34

Examples of Data

Inspection of the Basal Respiration parameter for each cell type reveals the expected results with

all conditions showing identical basal OCRs before inhibitors are added. Upon injection of inhibitor,

each cell type displays a detectable, but relatively small, acute response with respect to respiration

under basal assay conditions. However, under conditions of maximal respiration (such as under

conditions of higher substrate demand by the mitochondria), responses to inhibitors are

significantly increased, and different responses to different inhibitors become apparent across the

different cell types tested. Please see the Agilent application note: Revealing Cellular Metabolic

Phenotype and Function Using Agilent XF Substrate Oxidation Stress Tests for further discussion

regarding interpretation of substrate demand for each cell type, as well as suggestions for

Standard Substrate Oxidation Stress Test experimental design in the context of cancer cell and

immune cell biology and drug discovery.

34 Agilent XF Substrate Oxidation Stress Test Kits

Page 35

4 Assay Workflow for Palmitate

Advanced XF Palmitate Oxidation Stress Test Method

XF Palmitate Oxidation Stress Test Kit (p/n 103693-100)

Change to

Substrate Limited

CultureMedia

Seed cells in

Culture Media

Design assay

Hydrate

cartridge

Change cells to

assay medium

Run assay,

analyze results

Prepare assay

components

y

s

One day prior to assay

Two days prior to assay

Day of assay

Oxidation Stress Test - Advanced

Assay

Two Days Prior to Assay 36

One Day Prior to Assay 36

Day of Assay 37

Data Analysis Using Agilent Seahorse Analytics 42

Examples of Data 44

Figure 12. Agilent Seahorse XF Palmitate Oxidation Stress Test Workflow - Advanced Assay workflow.

onent

com

Prepare assa

Agilent XF Substrate Oxidation Stress Test Kits 35

Page 36

Two Days Prior to Assay

Two Days Prior to Assay

For adherent cells, plate cells at a predetermined density in the Seahorse XF Tissue Culture plate

using the appropriate cell culture growth medium. Refer to the Agilent Cell Analysis Learning

Center website for details.

One Day Prior to Assay

Prepare substrate-limited growth media

1 Remove one foil pouch from Agilent Seahorse L-Carnitine box. Open pouch and remove the

L-carnitine vial. Bring to a cell culture hood.

2 Add 100 µL sterile, tissue culture-grade water to the L-carnitine vial. The resulting stock

concentration is 0.5 M.

3 Aliquot 18.5 mL unsupplemented growth media (without glucose, pyruvate, glutamine, or

GlutaMAX) to a sterile 50 mL conical tube in a cell culture hood.

4 Supplement with 0.5 mM glucose, 1 mM glutamine or GlutaMAX, and 1% fetal bovine serum

(final concentrations). Also add 20 µL of carnitine prepared in Step 2. This is the

substrate-limited growth media with a final carnitine concentration of 0.5 mM.

5 Place the remainder of carnitine stock solution at 4 °C after use. This carnitine solution will

also be used to supplement the assay media the next day.

Prepare cell plates

1 For both adherent cells or suspension cells, replace the cell growth media with

substrate-limited growth media. It is recommended to wash the cell plate one time with either

PBS or substrate-limited growth media to ensure the complete removal of residual growth

media.

2 Add 100 µL of substrate-limited growth media in each well for 96-well plates and 250 µL in

each well for 24-well plates.

3 Place the cell plates back to 37 °C cell culture incubator.

Other preparation

1 Turn on the Seahorse XFe/XF96 or XFe/XF24 Analyzer and let it warm up overnight to allow

the temperature to stabilize (minimum five hours).

2 Hydrate a sensor cartridge in sterile or distilled water at 37 °C in a non-CO

overnight. For more information, refer to the Basic Procedure, “Hydrating the sensor cartridge”,

on the Agilent Cell Analysis Learning Center website.

incubator

2

3 Create an Assay Template file with Wave Desktop software using the Palmitate Oxidation

Stress Test Advanced Assay Template. Make any necessary group modifications to the

template for your specific assay design.

36 Agilent XF Substrate Oxidation Stress Test Kits

Page 37

Day of Assay

NOTE

Day of Assay

Complete Hydration of sensor cartridge: remove water and add the appropriate volume of XF

calibrant to each well and replace in a 37 °C non-CO

Prepare assay media

1 Prepare Advanced Palmitate Oxidation Stress Test assay media by supplementing 75 mL of

Seahorse XF DMEM or RPMI Medium, pH 7.4 with 2 mM of XF glucose and 0.5 mM L-carnitine

(no pyruvate or glutamine). This is the recommended initial condition for glucose

concentration and can be modified if needed.

Table 10 Advanced Palmitate Oxidation Stress Test Assay Media.

Component Volume Final concentration

Agilent Seahorse XF DMEM or RPMI Medium, pH 7.4 75 mL -

XF Glucose 150 µL 2.0 mM

Seahorse L-Carnitine 75 µL 0.5 mM

incubator for 60 minutes.

2

2 Warm up at 37 °C until ready to use. (Palmitate-BSA substrate will be added immediately

before the assay.)

No pH-adjustment to the assay medium is necessary when recommended supplement

concentrations are used. Also, remove Palmitate-BSA and BSA control from the freezer. Warm

to 37 °C before use.

Prepare Seahorse XF Cell Culture Microplate for assay

For Adherent Cells

1 Remove cell culture microplate from 37 °C CO2 incubator and examine cells under

microscope to confirm consistent plating and proper cell morphology.

2 Remove the substrate-limited growth medium from the cell culture microplate. Wash once

with warmed assay medium using. Add assay medium to a final volume of 180 µL/well for

96-well plates and 500 µL/well for 24-well plates. Refer to the Agilent Cell Analysis Learning

Center for more details.

3 Incubate cell plates with substrate limited assay medium at 37 °C in a non-CO

45 to 60 minutes prior to the assay.

4 Before starting the XF assay, remove the assay medium from cell plates again and add fresh,

warm assay medium to each well to a volume of 150 µL for 96-well plates and 415 µL for

24-well plates.

incubator for

2

5 Finally, just prior to starting the assay, add 30 µL of 1X Palmitate-BSA or 30 µL of 1X BSA

control to the appropriate wells in 96-well plates. Or add 85 µL of 1X Palmitate-BSA or 85 µL of

1X BSA control to the appropriate wells in 24-well plates. The total volumes before the assay

are 180 µL/well for 96-well plates and 500 µL/well for 24-well plates.

Agilent XF Substrate Oxidation Stress Test Kits 37

Page 38

Prepare compound stock solutions and working solutions

CAUTION

For Suspension Cells

1 Pellet cells out of their growth medium and resuspend in warm assay medium.

2 Count cells and suspend at a concentration such that seeding 50 µL (XF96/XFe96) or

100 µL (XFe24) of cells contains the desired cell number per well, leaving four wells without

cells as background correction wells.

3 Add desired cells/well then centrifuge gently to adhere.

4 Gently add assay medium to each well: 100 uL for XF96 well plates and 315 µL for XF24 well

plate. Total well volume should now be 150 µL for XF96 well plates and 415 µL for XF24 well

plates.

5 Incubate the plate at 37 °C in a non-CO

incubator for 45 to 60 minutes prior to the assay.

2

6 Finally, just prior to starting the assay, add 30 µL of 1X Palmitate-BSA or 30 µL of 1X BSA

control to the appropriate wells in 96-well plates. Alternatively, add 85 µL of 1X Palmitate-BSA

or 85 µL of 1X BSA control to the appropriate wells in 24-well plates. The total volumes before

the assay are 180 µL/well for 96-well plates and 500 µL/well for 24-well plates.

Refer to the Agilent Cell Analysis Learning Center for details on preparation of suspension cells for

XF assays.

Prepare compound stock solutions and working solutions

Use compounds on the same day they are reconstituted. Do not freeze and reuse. Discard any

remaining compound solutions.

1 Remove one foil pouch and decapper from the XF Oxidation Stress Test kit box.

2 Open the pouch and remove all four vials: Oligomycin (blue cap), FCCP (yellow cap),

Rotenone/Antimycin A (red cap) and Etomoxir (green cap).

3 Tap down the vials to ensure powder is on the bottom of the vial before removing the vial cap

using the decapper provided with the kits.

4 Resuspend the content in each vial with the appropriate volume of prepared assay medium as

described in Table 11. Vortex ~one minute to ensure full resuspension of compounds. These

are compound stock solutions.

38 Agilent XF Substrate Oxidation Stress Test Kits

Table 11 Stock solutions.

Compounds from XF Long Chain Fatty Acid Oxidation

Stress Test kit box

Etomoxir 700 µL 160 µM

Oligomycin 420 µL 150 µM

FCCP 720 µL 100 µM

Rotenone/Antimycin A 540 µL 50 µM

Volume of assay

medium

Stock concentration

5 Use the compound stock solutions to prepare working solutions for loading into the injection

ports on sensor cartridges.

Page 39

Load the injection ports on sensor cartridge

6 Prepare 2 or 3 mL working solutions for each compound in Palmitate Oxidation Stress Test

assay medium, using the volumes indicated in Tabl e 12 for XF/XFe96 sensor cartridges and

Table 13 for XF/XFe24 sensor cartridges. It is recommended to use 1.5 µM of oligomycin and

0.5 µM Rotenone/Antimycin A (final concentration) for most cells. Optimal FCCP

concentration should be determined prior to the assay.

Table 12 Compound preparation for loading to XFe/XF96 sensor cartridges. Starting assay

medium volume for cell plate is 180 L per well.

Stock

Final well

µM

Port A: Etomoxir 4 500 1,500 40 20

Port B: Oligomycin 1.5 300 2,700 15 22

Port C: FCCP 0.25 75 2,925 2.5 25

0.5 150 2,850 5 25

1.0 300 2,700 10 25

2.0 600 2,400 20 25

Port D: Rotenone/Antimycin A 0.5 300 2,700 5 27

solution

volume (µL)

Medium

volume (µL)

10× (Port)

µM

Volume

added to

port (µL)

Table 13 Compound preparation for loading to XFe/XF24 sensor cartridges. Starting assay

medium volume for cell plate is 500 L per well.

Stock

Final well

µM

Port A: Etomoxir 4 500 1,500 40 56

Port B: Oligomycin 1.5 300 2,700 15 62

Port C: FCCP 0.25 75 2,925 2.5 69

solution

volume (µL)

Medium

volume (µL)

10× (Port)

µM

Volume

added to

port (µL)

0.5 150 2,850 5 69

1.0 300 2,700 10 69

2.0 600 2,400 20 69

Port D: Rotenone/Antimycin A 0.5 300 2,700 5 75

Load the injection ports on sensor cartridge

Proper port-loading techniques can be found on the Agilent Cell Analysis Learning Center

website.

Please read the information prior to loading compounds. Ensure that the sensor cartridge is

properly hydrated prior to use.

For the location of the ports, please refer to Figure 9 on page 27.

Refer to Tab l e 14 for loading volume and port designation for compounds in different types of

assays.

Agilent XF Substrate Oxidation Stress Test Kits 39

Page 40

Load template onto the Seahorse XFe Analyzer

NOTE

Table 14 Recommended injection volumes for Substrate Oxidation Stress Test injection schemes.

Starting assay medium volume is 180 µL per well for 96-well cell plates and 500 µL per

well for 24-well cell plates.

Port Compound Port concentration 96 well 24 well

AEtomoxir

B Oligomycin 10× 22 µL 62 µL

C FCCP 10× 25 µL 69 µL

D Rotenone/Antimycin A 10× 27 µL 75 µL

* For controls, assay medium should be used in port A instead of inhibitors.

*

Load template onto the Seahorse XFe Analyzer

If templates(s) are already present on the XFe analyzer, skip this step.

Add to port volume

10× 20 µL 56 µL

Personal Computer (internet access required)

1 Use the hyperlink below to download the Seahorse XF Substrate Oxidation Stress Test -

Advanced Template (for Palmitate Oxidation Stress Tests).

www.agilent.com/cs/library/software/public/software-agilent-seahorse-xf-subox-assay-te

mplate-files-cell-analysis-agilent.zip

2 Unzip the folder, then copy and paste the assay template files to a USB drive or network drive

(if Seahorse XFe Analyzer is networked).

Seahorse XFe96/XFe24 Analyzer

1 Insert a USB drive in the front USB port, and wait ~10 seconds.

2 Click Import (bottom of the New Assay view).

3 Locate the Assay Template file to import on the USB or network drive.

4 Click Open in the Windows dialogue box. The imported Assay Template will be available for

selection from the Templates view on the XFe Analyzer.

5 Repeat for next template, if applicable.

6 The imported Assay Template(s) will now be available for selection in the list of available

templates.

Running the XF Palmitate Oxidation Stress Test assay

1 Select the Seahorse XF Palmitate Oxidation Stress Test-Advanced template from the list of

available templates, and click Open File (or double-click the template).

2 Group Definitions: confirm or modify the default groups and conditions for your assay.

3 Plate Map: confirm or modify the plate layout map for your assay.

4 Protocol: No action required - confirm or modify the Instrument Protocol for additional

measurements cycles during the assay.

40 Agilent XF Substrate Oxidation Stress Test Kits

Page 41

Running the XF Palmitate Oxidation Stress Test assay

5 Run Assay: Click Start Run when ready.

6 When prompted, remove the cartridge lid, and place the loaded sensor cartridge with the utility

plate on the thermal tray of the Seahorse XFe Analyzer. Ensure correct plate orientation and

the cartridge lid has been removed. Then, click I'm Ready. Calibration takes approximately

15 to 30 minutes.

7 After completing Calibration, Wave Controller will display the Load Cell Plate dialog. Click

Open Tray to eject Utility Plate and load the Cell Plate. Ensure the lid is removed from Cell Plate

before Loading.

8 Click Load Cell Plate to run the assay.

Agilent XF Substrate Oxidation Stress Test Kits 41

Page 42

Data Analysis Using Agilent Seahorse Analytics

Data Analysis Using Agilent Seahorse Analytics

Agilent Seahorse Analytics is a new, web-based software platform that provides a simple,

streamlined data analysis workflow for the XF Substrate Oxidation Stress Test assay. Seahorse

Analytics automatically calculates the XF Palmitate Oxidation Stress Test parameters: basal

respiration, acute response to inhibitor, and maximal respiration. Visit

https://seahorseanalytics.agilent.com to register or log-in to your Seahorse Analytics account.

1 After the assay is completed, transfer your assay result file to your personal computer using a

USB drive or network drive.

2 Go to https://seahorseanalytics.agilent.com to register or log in to your Seahorse Analytics

account.

42 Agilent XF Substrate Oxidation Stress Test Kits

Page 43

Data Analysis Using Agilent Seahorse Analytics

3 Import the assay result file to your account.

4 Open the assay result file and select the XF Substrate Oxidation Stress Test analysis view

found under the Assay Kit Companion views menu.

5 Select groups to add to the analysis view, then click Add View.

Agilent XF Substrate Oxidation Stress Test Kits 43

Page 44

Examples of Data

Examples of Data

Figure 13 shows example Advanced Palmitate Oxidation Assay data from Seahorse Analytics for

HepG2 cells.

Figure 13. Advanced Palmitate Oxidation Assay data derived from Seahorse Analytics for HepG2 cells.

44 Agilent XF Substrate Oxidation Stress Test Kits

Page 45

Examples of Data

0

1

2

3

4

OCR (pmol/min/1,000 cells)

0.0

0.5

1.0

1.5

2.0

2.5

OCR (pmol/min/1,000 cells)

Basal

0.0

0.5

1.0

1.5

2.0

2.5

OCR (pmol/min/1,000 cells)

Maximal respiration

-2.5

-2.0

-1.5

-1.0

-0.5

0.0

-0.2

-0.4

-0.6

-0.8

-1.0

0.0

-0.2

-0.4

-0.6

-0.8

-1.0

0.0

∆OCR (pmol/min/1,000 cells)

Acute response

A549 Mitochondrial respiration

Etomoxir Oligo FCCP Rot/AA

Time (min)

BSA control + Eto

BSA control – Eto

Palmitate + Eto

Palmitate – Eto

0 24487296120

0

1

2

3

4

5

6

7

8

OCR (pmol/min/1000 cells)

0

1

2

3

4

5

6

OCR (pmol/min/1000 cells)

Basal

OCR (pmol/min/1000 cells)

0

1

2

3

4

5

6

Maximal respiration

Etomoxir Oligo FCCP Rot/AA

HepG2 Mitochondrial respiration

Time (min)

0 24487296120

-6

-5

-4

-3

-2

-1

0

Acute response

∆OCR (pmol/min/1,000 cells)

Figure 14 shows example data from experiments with A549 (Panel A) and HepG2 cells (Panel B).

Agilent XF Substrate Oxidation Stress Test Kits 45

Figure 14. Palmitate oxidation in A549 and HepG2 cells using XF Palmitate Oxidation Stress Tests.

A549 (A) and HepG2 (B) cells were seeded in XF96 Cell Culture Plates and grown overnight in

appropriate cell growth media. The next day growth media was exchanged for substrate

limited media (Table 1) and cultured for an additional 16 to 24 hours. Cells were then subject

to XF Palmitate Oxidation Stress Tests using injections of assay media (control), or etomoxir

(LCFA oxidation), followed by common sequential injections of oligomycin, FCCP, and

Rtn/AA. XF Assay Media = XF DMEM, pH 7.4 + 2 mM glucose, + 0.5 mM L-carnitine. Each cell

type was assayed on three individual days, with result data being compiled and processed

through Seahorse Analytics. Error is reported as ± SEM. Similar results for both cell types

tested were obtained using an XFe24 Analyzer (data not shown).

Page 46

Examples of Data

Inspection of the Basal Respiration parameter for each cell type shows the expected results for

the given condition: the Palmitate groups show slightly increased OCR relative to BSA control

groups, which are sensitive to etomoxir, with inhibition decreasing rates to those observed for the

BSA control - Etomoxir groups (Rate 9, ~55 minutes). This indicates some palmitate is being

oxidized in the basal (lower substrate demand) state. However, upon addition of FCCP, substrate

demand is increased, and the Palmitate - Etomoxir groups show significant increases in maximal

respiration compared to the groups with either BSA and/or +etomoxir. This indicates that these

cell types not only have the ability to oxidize palmitate under the experimental conditions

established, but that palmitate is the bulk of the substrate oxidized when forced to respire at a

maximal rate (compare Palmitate ± Etomoxir groups). This data suggests that A549 and HepG2

cells are good candidate cell types for investigating how an intervention, such as genetic

manipulation or drug exposure, applied to the cell specifically affect the oxidation of long chain

fatty acids.

46 Agilent XF Substrate Oxidation Stress Test Kits

Page 47

5 Frequently Asked Questions

NOTE

Will these assays work for my cell type? Most likely. The basis of the Substrate Oxidation Stress

Tests is the XF Cell Mito Stress, which has been used successfully with numerous cell types,

including cell lines and primary cells. Please visit the Agilent Cell Analysis Publication Database

to search for cell types used in publications.

Will these assays work for suspension, primary and/or immune, cells? Yes. However, please

ensure proper experimental and assay procedures are followed for the cell type of interest.

Do I need to optimize cell seeding density? Yes. Please visit the XF Assay Learning Center and

the Agilent Cell Analysis Publication Database for further information on basic cell density

optimization procedures. Note that for the Advanced Palmitate Oxidation Stress Test, the cell

density seeded may need to be decreased if cells are to be subject to substrate limitation, as this

step requires an extra day of cell culture.

Do I need to optimize FCCP concentration? Yes. For the Standard Substrate Oxidation Stress

Tests, this will likely be the same FCCP concentration used if the cell type of interest has been

previously subject to a Cell Mito Stress Test.

For the Advanced Palmitate Oxidation Stress Test, the concentration of FCCP may need to be

increased due to the presence of BSA in the assay media. This should be performed before or

during your initial Advanced Palmitate Oxidation Stress Test. Please visit the XF Assay

Learning Center and the Agilent Cell Analysis Publication Database for further information on

basic FCCP optimization procedures.

How do I know the inhibitors are at the correct concentration? The optimal concentration of each

inhibitor is based on both testing at Agilent as well as information provided for etomoxir, UK5099

and BPTES in the following references, respectively: Divakaruni et al. 20181; Hildyard et al. 20052;

and Robinson et al. 20073.

What does it mean if there is no response to an inhibitor? Biologically, this suggests that the cell

has no demand or reliance on that particular substrate under the experimental conditions defined.

Note that it is common to see low to no responses to these inhibitors under basal respiration

conditions (such as conditions of lower substrate demand).

Should I increase the concentration of the inhibitor? No. Each inhibitor is optimized for the

correct final concentration: 4 µM for etomoxir, 2 µM for UK5099, and 3 µM for BPTES. Increased

concentrations of inhibitors, especially etomoxir, will result in off-target effects, including effects

on mitochondrial respiration.

What is the difference between the Long Chain Fatty Acid Oxidation Stress Test and the Palmitate

Oxidation Stress Test? The Long Chain Fatty Acid Oxidation Stress Test is one of the three

Standard Substrate Oxidation Stress Tests. This assay is focused on testing cellular demand of

endogenous LCFAs under conditions of saturating substrates with respect to glucose, pyruvate

and glutamine in the assay media, and best applied to answer questions about substrate demand

and reliance with regard to LCFAO.

Agilent XF Substrate Oxidation Stress Test Kits 47

Page 48

The Advanced Palmitate Oxidation Stress Test is designed to be performed under conditions of

saturating palmitate (as Palmitate-BSA) and L-carnitine, with limited to no substrate provision with

respect to glucose, pyruvate, and glutamine in the assay media. It is best applied when the

experimental design calls for the cells to exclusively oxidize a long chain fatty acid, such as

palmitate, to investigate effects of interventions specifically on the long chain fatty acid oxidation

process.

When should I use Standard Assay workflow? The standard substrate oxidation assay is

designed to be used when asking the following types of questions:

• Does the cell have a demand for a particular substrate or substrates?

• Is the cell highly reliant on a specific substrate, or can other substrates satisfy cellular

demands?

• How is mitochondrial substrate demand and/or reliance affected if an intervention, such as a

genetic manipulation or drug exposure, is applied to the cell?

What is the source of LCFAs for Standard LCFA assays? The source of long chain fatty acids are

any endogenous stores of lipid/LCFAs in the cells used, and thus is cell-type dependent.

Can/Should I add Palmitate-BSA (source of FAs) to Standard Substrate Oxidation Stress Test

assays? It is not recommended to add Palmitate-BSA to Standard Substrate Oxidation Stress

Tests, as previous investigation has shown that cells typically will not respond to exogenous

palmitate under conditions of fully supplemented cell culture media and subsequent saturating

concentrations of glucose, pyruvate and glutamine in the XF assay media. No enhanced response

to etomoxir has been demonstrated for cells supplemented with palmitate under these same

conditions. For specific investigation of palmitate oxidation by cells, the Advance Assay for

Palmitate Oxidation Stress Test is recommended

Can I alter the composition of the substrate oxidation stress test assay media (with regard to

substrates)? It is recommended to begin the investigation with suggested substrate

concentrations to establish cell behavior under saturating substrate concentrations. Final

concentrations of supplements of glucose, pyruvate and glutamine may be altered, but care

should be demonstrated when designing experiments and subsequent interpretation of data.

How is this different from the Seahorse XF Mito Fuel Flux Test? The XF Substrate Oxidation

Stress Tests combine substrate pathway specific with the XF Cell Mito Stress Test (MST). Basal

and maximal respiration rates are key metrics of mitochondrial function reported by the MST. In

the context of substrate oxidation, the basal, and in particular, the maximal respiration rates are

largely impacted by cells capacity to transport and oxidize available substrates

4

. This method is

therefore ideally suited, and thus different from the mFFT, in that assessment for cellular

substrate oxidation under conditions of both basal and elevated substrate demand (maximal

respiration) where critical substrate dependence/reliance is more often revealed.

Do the Seahorse XF Mito Fuel Flex Test (mFFT) parameters (dependency, flexibility, capacity) apply

here? No. The mFFT quantitative parameters do not apply to these assays. The well-recognized

and accepted MST parameters (basal respiration, acute response and maximal respiration) are

used for both Standard and Advanced Substrate Oxidation Stress Tests. Note, however, that

terms such as substrate demand and reliance are used here qualitatively to describe cellular and

mitochondrial function.

Can two (or more) inhibitors be injected at the same time? It is recommended to begin the

investigation with the use of a single inhibitor to establish cell behavior. Two or more inhibitors

can be applied at the same time to the same group of cells, but care should be taken when

designing experiments and subsequent interpretation of data.