Page 1

PageWriter 100, 200 and 300 Series Cardiographs

M1770A, M1771A, and M1772A

Mobile Cart M1705B

Service Manual

+

$JLOHQW3DUW1R0

3ULQWHGLQ86$'HFHPEHU

(GLWLRQ

December 10, 1999 2:55 pm DRAFT

&RS\ULJKW

$JLOHQW7HFKQRORJLHV,QFRUSRUDWHG

Page 2

Notice

WARNING

0Notice

The information in this document is subject to change without notice.

Agilent Technologies makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability and fitness for a

particular purpose. Agilent Technologies shall not be liable for errors contained herein or

for incidental or consequential damages in connection with the furnishing, performance,

or use of this material.

This document contains or refers to proprietary information which is protected by

copyright. All rights are reserved. No part of this document may be photocopied,

reproduced, or translated to another language without the prior written consent of Agilent

Technologies Company.

Responsibility of the Manufacturer

Agilent Technologies only considers itself responsible for any effects on safety, reliability

and performance of the equipment if all the following are true:

• Assembly operations, extensions, re-adjustments, modifications or repairs are done by

persons authorized by Agilent Technologies.

• The electrical installation of the relevant room complies with the IEC or national requ irements.

• The instrument is used according to the instructions for use presented in this manual.

As with all electronic equipment, radio frequency interference between this

cardiograph and any existing RF transmitting or receiving equipment at the

installation site, including electrosurgical equipment, should be evaluated

carefully and any limitations noted before the equipment is placed in service.

Monitoring during electrosurgery should not be attempted and monitoring

electrodes should be removed from the patient to preclude the possibility of

burns. Radio frequency generation from electrosurgical equipment and close

proximity transmitters may seriously degrade cardiograph performance. Agilent

Technologies assumes no liability for failures resulting from RF interference

between Agilent medical electronics and any radio frequency generating

equipment at levels exceeding those established by applicable standards.

ii

Page 3

Notice

CAUTION

CAUTION

Like all electronic devices, this cardiograph is susceptible to electrostatic discharge

(ESD). Electrostatic discharge typically occurs when electrostatic energy is transferred to

the patient, the electrodes, or the cardiograph. ESD may result in ECG artifact that may

appear as narrow spikes on the cardiograph display or on the printed report. When ESD

occurs, the cardiograph’s ECG interpretation may be inconsistent with the physician’s

interpretation.

ESD discharges to expose d m etal on th e rear of the cardiograph can o ccasion ally cau se an

error message to appear on the cardiograph display. The cardiograph returns to normal

operation after turning the power off, then on again.

The data transmission cable must have a suppression device attached to assure the

cardiograph’s compliance with the European Radiated Emissions Standard found in

CISPR 11. If your data transmission cable does not include a suppression device,

compliance can be achieved by attaching one of the following suppression devices to the

cable, near the cardiograph:

part number 0443164251 Fair-Rite Products Corporation

P. O. Box J

One Commercial Row

Wallkill, New York 12589

telephone: (914) 895-2055

FAX: (914)895-2629

or

Euro-Schaffner, S. A.

1 B Avenue de Suisse - BP 16

68311 Illzach Cedex, France

telephone: 33-8-931-0400

FAX: 33-8-931-0401

part number 28B2025-0A0 Steward

East 36th Street

P. O. Box 510

Chattanooga, TN 37401

telephone: (615) 867-4100

FAX: (615) 867-4102

or

Steward EMC, S.A.

Rue Fritz-Couvoisier 40

Ch-2300 La Chaux-de-Fonds

Switzerland

telephone: 41-39-282-387

Fax: 41-39-280-277

This is to certify that this equipment is in accordance with the Radio Interference

Requirements of the EMC Directive.

iii

Page 4

Notice

Medical Device Directive

The PageWriter M1770 series of cardiographs comply with the requirements of the Medical Device Directive 93/42/EEC and carries the

Authorized EU-representative:

Agilent Technologies GmbH

Herrenbergerstrasse 130

D-71034 Boeblingen,

Germany

Fax: +49-7031-14-2346

mark accordingly.

0123

Warranty

Agilent Technologies warrants this medical product against defects in materials and

workmanship for a period of three years in certain geographics, or one year with onsite

support.

If Agilent Technologies receives notice of such defects during the warranty period,

Agilent T echn olog ies shall, at its option, either repair or replace hardware pr odu cts which

prove to be defective.

Agilent Technologies software and firmware products that are designated by Agilent

Technologies for use with a hardware product, when properly installed on that hardware

product, are warranted not to fail to execute their programming instructions due to defects

during the warranty period. Agilent Technologies shall repair or replace software media

and firmware that do not execute their programming instructions due to such defects.

Agilent Technologies does not warrant that the operation of the software, firmware, or

hardware shall be uninterrupted or error free.

If Agilent Technologies is unable, within a reasonable time, to repair or replace any

product to a condition as warranted, Buyer shall be entitled to a refund of the purchase

upon return of the product to Agilent Technologies.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulti ng from any of the following:

1. Improper or inadequate maintenance by Buyer.

2. Buyer-supplied software or interfacing.

3. Unauthorized modification or misuse.

4. Operation outside of the environmental specifications for the product.

5. Improper site preparation and maintenance.

iv

Page 5

Notice

THE WARRANTY SET FORTH ABOVE IS EXCLUSIVE AND NO OTHER

WARRANTY, WHETHER WRITTEN OR ORAL, IS EXPRESSED OR IMPLIED.

AGILENT TECHNOLOGIES SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

Printing History

October 1994 Edition 1

May 1996 Edition 2

October 1998 Edition 3

December 1999 Edition 4

v

Page 6

Safety Summary

0Safety Summary

Safety Symbols Marked on the Cardiograph

The following symbols are used on the cardiograph or the cart:

Caution - See operating instructions

Alternating current.

Meets IEC type CF leakage current requirements and is defibrillator

protected. (Isolated ECG input.)

Equipotential (identifies independent protective earth conductor to the

cardiograph).

Fuse.

Indicates power control for cardiograph.

Hz Indicates operating frequency in cycles per second.

The maximum weight that the cart can hold

Displays the configuration menu on the PageWriter

200/200i/300pi.

Please see Chapter 2, “Performance Verificati on and Maintenance,” for safety

requirements that apply to the cardiograph.

vi

Page 7

Conventions Used in This Manual

WARNING

CAUTION

NOTE

0Conventions Used in This Manual

Warning statements describe conditions or actions that can result in personal

injury or loss of life.

Caution statements describe conditions or actions th at can result in damage to the

equipment or software.

Notes contain additional information on cardiog raph usage.

TEXT

.H\

Softkey

represents the labels that appear on the display.

represents keys on the key panel.

represents the temporary key labels that appear on the display.

vii

Page 8

Preface

0Preface

This manual contains service information for the Agilent M1770A pageWriter 300pi,

PageWriter 200i, M1771A PageWriter 200, and M1772A PageWriter 100 cardiographs.

The information and procedures in this manual apply to all models unless otherwise

specified.

This manual is organized as follows:

• Chapter 1 — Introduction. Contains a gener al description of the cardiogr aphs, lists of

technical specifications, and lists of accessories and options.

• Chapter 2 — Performance V erification and Maintenance. Explains how to check the

cardiograph’ s perf ormance using buil t-in self-tes ts, and lists main tenance procedures and

safety requirements that apply to the cardiograph.

• Chapter 3 — Theory of Operation. Provides an overview of how the cardiograph

works and describes the operation of the m a jor subassemblies.

• Chapter 4 — Troubleshooting. Contains procedures and error codes to aid the service

person in localizing faults to a replaceable subassembly.

• Chapter 5 — Removal and Replacement. Contains procedures for removing and

replacing each of the cardiograph’s major subassemblies.

• Chapter 6 — Parts List. Lists part numbers for the cardiograph’s replaceable p arts, and

provides assembly drawings.

• Appendix A — Connector Pin Assign ment s. Identifies and defines the signals

assigned to the subassembly interconnections.

• Index

viii

Page 9

Contents

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Responsibility of the Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Limitation of Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Safety Symbols Marked on the Cardiograph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

1. Introduction

PageWriter 100, 200, 200i, and 300pi Series Cardiographs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

M1705B Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Transmission and Storage, Option #A05 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Specification Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Sampling Characteristics of Cardiograph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

PageWriter 100, 200, 200i, and 300pi Cardiographs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Country/Region Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Standard Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

2. Performance Verification and Maintenance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -1

Visual Inspection and Power On Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Extended Self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Internal Circuitry Testing of PageWriter 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Internal Circuitry Testing of PageWriter 200/200i/300pi . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

How to Read the Extended Self-Test Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Display Test (PageWriter 200/200i/300pi only) 2-12

Indicator Light Test (PageWriter 100 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Printer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Keyboard Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

PageWriter 200/200i/300pi Keyboard Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

PageWriter 100 Keyboard Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

ECG Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Changing the Default Operating Language (200/200i/300pi Only) . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Resetting the Cardiograph to the Factory Default State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Resetting the PageWriter 200/200i/300pi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Resetting the PageWriter 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -18

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Cleaning the Cardiograph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Cleaning the Keyboard Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Cleaning the Digital Array Printhead and Paper Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

ix

Page 10

Cleaning the Electrodes and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Caring for the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Storing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

PageWriter 100, 200/200i, and 300pi Series Performance Verification Matrix . . . . . . . . . . . . . . . . 2-24

3. Theory of Operation

Operational Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

ECG Data Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Power-on and Power-off Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Power-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Power-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Circuit Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

The Patient Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

CPU Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

CPU/System Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

System Gate Array/Real-Time Crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

ECG Front End Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Interrupt Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

DMA for ECG Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

DMA for LCD Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

System Reset Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Watch-dog Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Real-Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

DRAM RAS and CAS Generation and Refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

NVRAM Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Keyboard Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Display Control for PageWriter 20 and 300 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

NVRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

ECG Front End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

DRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

ROM-1 and ROM-2 Address Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Printer Gate Array/SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Motor Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Analog/Digital Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Thermal Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

System Expansion Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Voltage Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Primary Line Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Power Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Rectifier/Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Switch-Mode Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

VPRINT Boost Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Switched +6V Boost Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

5V Linear Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

ECG Front End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Isolation Power Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Front End Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Opto-Isolators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

x

Page 11

Integrated Front End Circuits/Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Defibrillator Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Storage and Transmission (Option #A05 0nly) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

M177XA Expansion Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Gate Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

ROM-X1, ROM-X2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Flash1, Flash2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

VPROG Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Dual UART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

18.432 MHz Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

RS232 Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Serial Port Connectors 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

4. Troubleshoo ting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Maintenance Philosophy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Test Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Patient Cable Test Tool (M1770-87908). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Front End and RS-232 Port Test Tool (M1770-87909, Rev. B) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Testing the Instrument Signal Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Testing the Cardiograph’s RS-232 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

The Error and Event Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Using Extended Self-test in Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

How the PageWriter 100 Communicates Error Codes and Messages . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

PageWriter 100 Error Code Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

PageWriter 100 Error Message Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -4

Troubleshooting Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Testing the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

5. Removal and Replacement

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Tool Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

The Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Removing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

The Keyboard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Removing the Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Removing the Keyboard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -4

Removing the Keyboard Flexible Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Removing the Keyboard Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Replacing the Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

The Top Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Opening and Removing the Top Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Replacing the Top Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

The Printer Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Removing the Printer Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Replacing the Printer Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

The Printer Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Removing the Printer Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Replacing the Printer Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

xi

Page 12

The Printhead Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Removing the Printhead Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Removing the Optical Paper Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Replacing the Printhead Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

The Control Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Removing the Control Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Replacing the Control Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

The Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Removing the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Replacing the Power Supply Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

The Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

The Internal Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Replacing the Power Supply Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Replacing the Capacitor Board Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Replacing the Printer Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

The Storage and Transmission Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Removing the Storage and Transmission Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

6. Parts Lists

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Calling for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

United States of America: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Canada: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Marketing Center Europe: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Latin America: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Medical Distribution: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Asia Pacific Headquarters: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Parts List 6-4

A. Connector Pin Assignments

CPU Assembly Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

xii

Page 13

Introduction

WARNING

NOTE

This chapter introduces you to the M1770A PageWriter 200i/300pi, M1771A PageWriter

200, and M1772A PageWriter 100 cardiographs and lists their technical specifications.

These cardiographs are only to be serviced by Agilent qualified personnel.

Safe and effective use of medical instrumentation requires periodic inspection and

preventive maintenance. Perform the preventive maintenance procedures in Chapter 2 of

this manual at required intervals to ensure satisfactory instrument performance.

The cardiographs use a thermal printhead to record waveforms and label the ECG report.

The paper supplied with the cardiographs is a thermal paper designed to work with this

printhead and with the photo detector used to advancing the paper.

Agilent Technologies guarantees the performance of the cardiographs only when used

with Agilent Technologies supplies, accessories, and paper that meet or exceed Agilent

Technologies specifications.

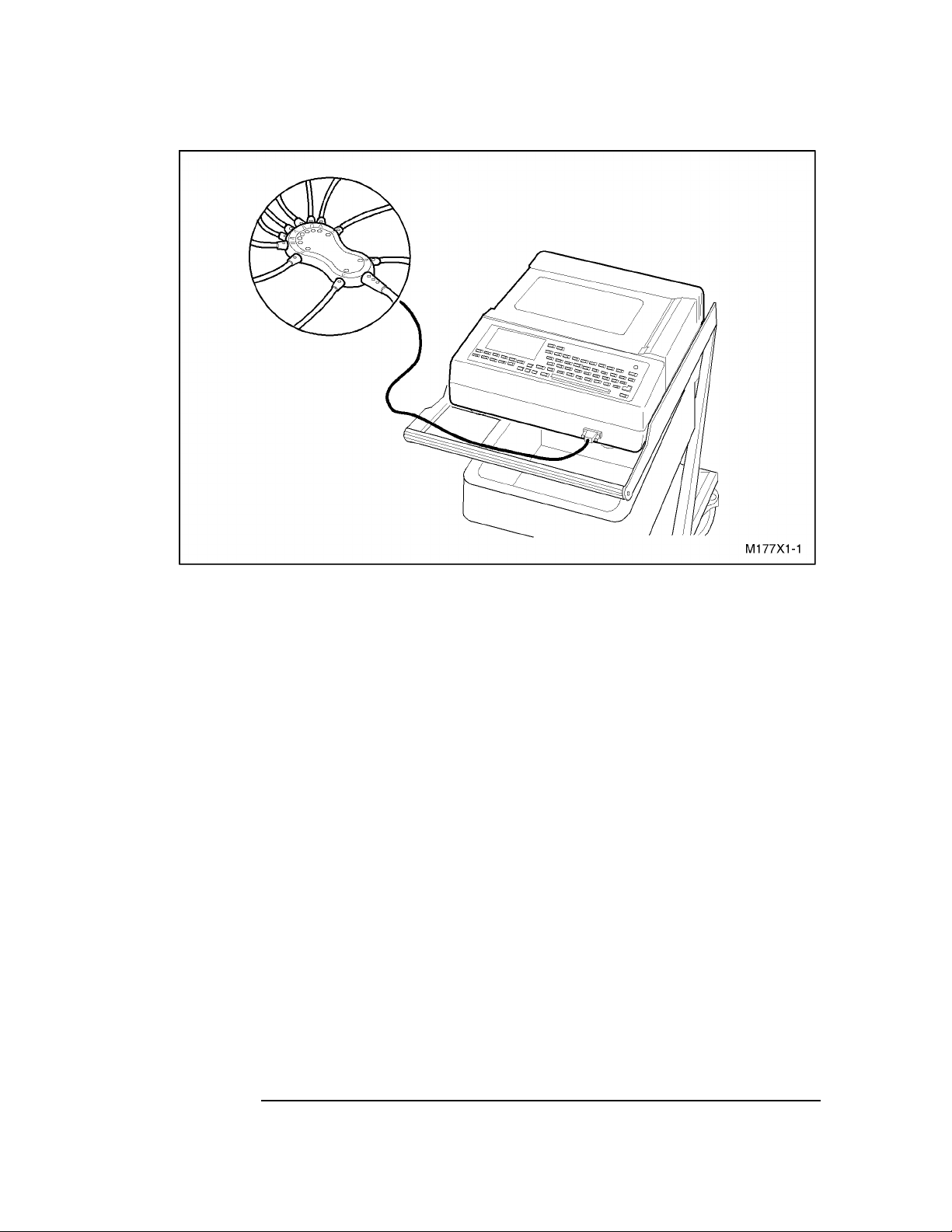

0PageWriter 100, 200, 200i, and 300pi Series Cardiographs

The M1770A PageWriter 200i/300pi is Agilent Technologies’ economical, interpretive

cardiograph. The M1771A PageWriter 200 is the economical, non-interpretive

cardiograph. The M1772A PageWriter 100 is the most economical, non-interpretive

cardiograph. The cardiograph contains the user controls, the printer, and all the processing

circuitry. All models use the same enclosure. The M1705B cart is designed for these

cardiographs. Figure 1-1 shows the M1770A mounted on the cart. Option #A05 provides

transmission and storage capability for the M1770A and M1771A. The StressWriter

option provides capability for communication between a PageWriter 100/200/200i/300pi

cardiograph and a StressW riter system.

1-1

Page 14

PageWriter 100, 200, 200i, and 300pi Series Cardiographs

Figure 1-1 M1770A/M1771A PageWriter 300pi/200i/200 Cardiograph.

The PageWriter 100, 200, and 300 family of cardiographs print ECGs in Auto and

Manual formats. All PageWriter cardiographs use a continuous feed, high-resolution,

thermal array printer. This produces electrocardiograms on standard- size paper that can

be included in patient records without cutting or mountin g. ECG reports clearly show the

ECG waveforms. The PageWriter 200 and 300 series cardiographs also annotate records

with patient information and ECG measurements. The PageWriter 200i and 300pi also

includes ECG interpretation for both adult and pediatric patients.

From a service standpoint, the PageWriter 100, 200, and 300 family of cardiographs are

similar except for two major hardware differences:

• The M1770A has additional firmware for ECG measurements and interpretation.

• The M1771A has additional firmware for ECG measurements.

• The M1772A keypanel do es no t hav e an L CD preview dis play and uses operation al k eys

instead of alphanumeric keys for user input.

All other model differences are found in the cardiograph’s software.

The PageWriter 100, 200, and 300 family of cardiographs is designed for low-cost, longterm reliability. The modular design makes extensive use of VLSI and gate array

technology, resulting in a minimum number of subassemblies. The modular approach

means less down-time for the user, since replacing subassemblies allows faster field

repairs. The internal self-test efficiently identifies faulty subassemblies, further speedin g

the repair process.

1-2

Page 15

Inquiries

M1705B Cart

The optional M1705B Cart provides mobility for the PageWriter 100, 200, and 300 family

of cardiographs. The large wheels make the cart easy to move, yet steady. Slots in the

cardiograph’s feet and a thumbscrew secure the cardiograph to the cart rails. The tray

directly below the cardiograph provides storage for the user’ s guide. Storage for the power

cable is built in. Other built-in cable retainers hold the patient data cable ou t of the way.

Two compartmented trays provide storage for spare patient electrodes and patient cables,

additional thermal paper, and consumable supplies.

Transmission and Storage, Option #A05

Transmission and storage features are available for the M1770A and M1771A with

purchase of Option #A05. Up to th irty Auto ECGs can be stored in the car diograph’s

internal flash memory. Stored ECGs can be recalled later for editing, re-analyzing,

printing, or transmi ssi on to another PageWri te r 200 /2 00i/300pi equipped with Opt i on

#A05, a PageWriter XLi cardiograph, a TraceMaster ECG Management System, or

facsimile machine. Manual ECGs cannot be transmitted or st ored.

1Inquiries

Refer any questions or comments regarding these instruments to the nearest Agilent

Technologies Sales/Service Office or to one of Agilent Technologies’ Service Dispatch

Centers. Always identify the instrument by model number and serial number in all

correspondence. Telephone numbers for Service Dispatch Centers and Sales/Service

Offices are listed in Chapter 6, “Parts List.”

1Specification Data

The following tables list the technical specifications for the cardiographs and the mobile

cart. Specifications are the same for all models except as noted

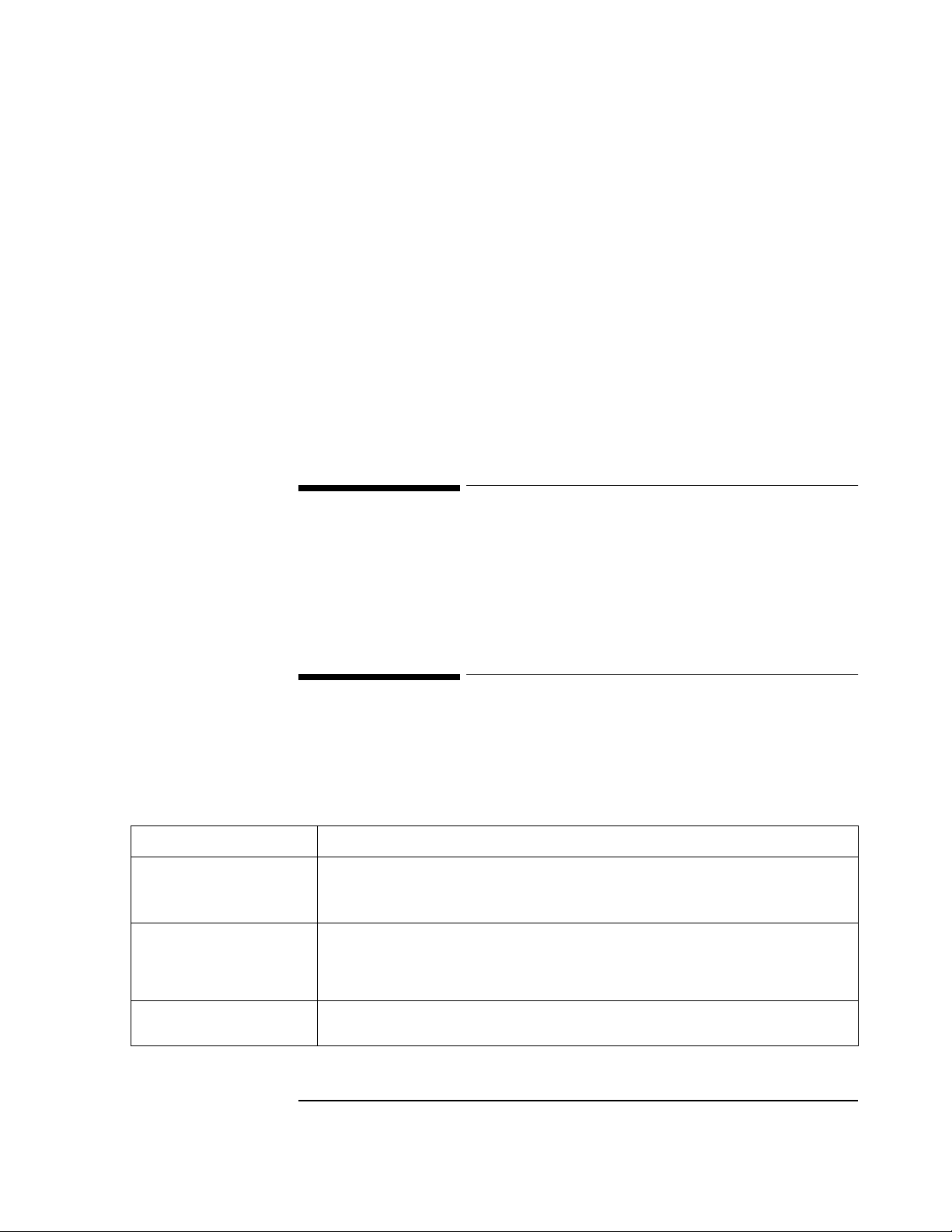

Table 1-1 Physical Specifications

Parameter Specification

Dimensions (h × w × l)

× 15 in × 17 in (11.5 cm × 39.2 cm × 43.7 cm)

cardiograph

cart

Weight

cardiograph

cart

4 in

× 17 in × 33 in (91.4 cm × 43.5 cm × 84.8 cm)

36 in

18.7 lbs. (8.5 kg) or less (includes batt ery, 200 sheets of paper, patient cable, and po w er co r d)

38 lbs. (17.24 kg)

Chemical resistance,

cleaners

Withstands the following: isopropyl alcohol (except patient cable), mild soap and water, chlorine

bleach and water (30 ml/l of water).

1-3

Page 16

Specification Data

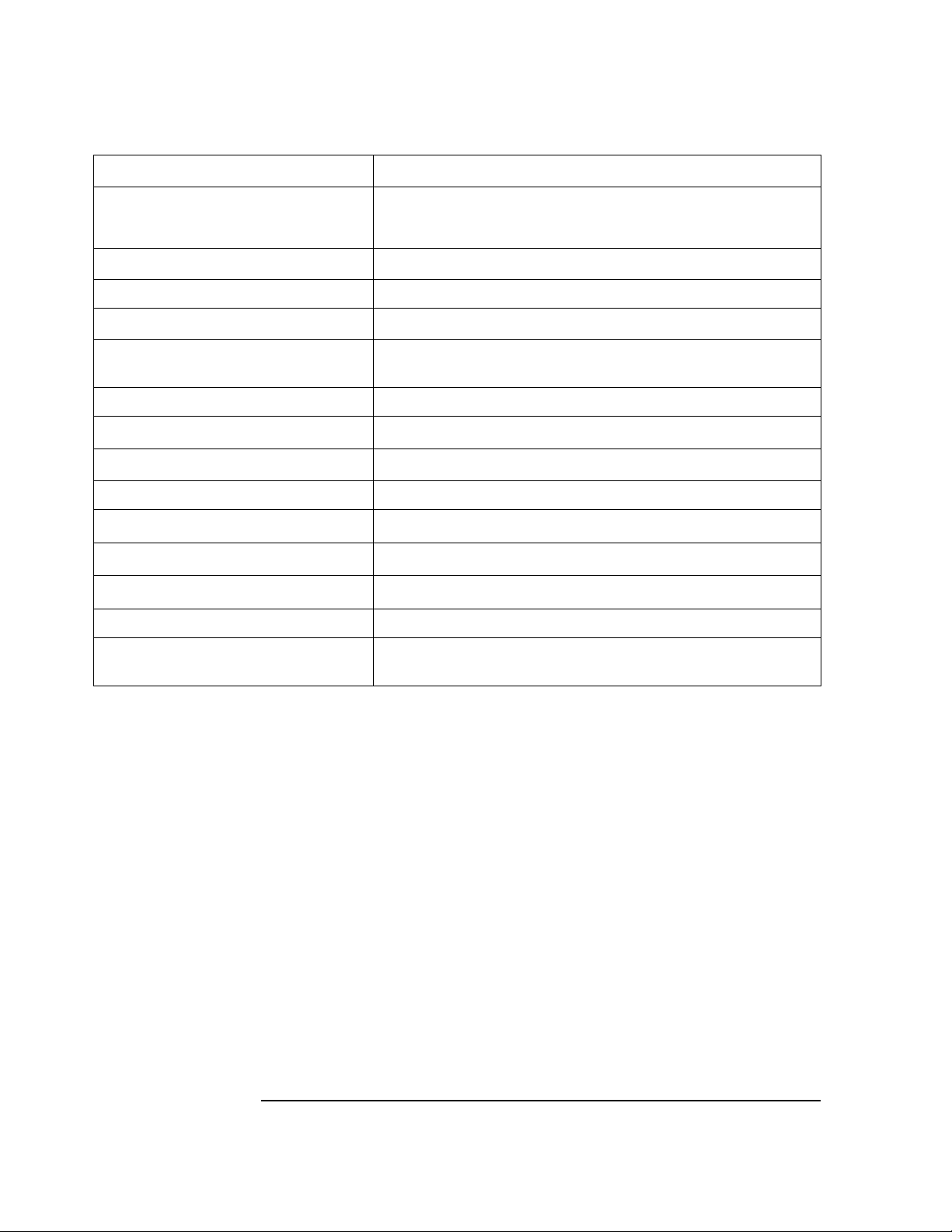

Table 1-2 Electrical Specifications

Parameter Specification

Resolution

ECG (internal)

display

5 µV

128 row pixels by 24 0 column pixels

display sweep sp eed

Input impedance greater than 2.5 MΩ@ 10 Hz, typical ly gr eat er than 100MΩ @ DC

Gain accuracy

Input bias less than 40 nA for in put leadwire, less th an 500 nA for Right Leg output lead-

Common mode rejec t io n 110 dB or greater with AAMI test ci r cui t

Defibrillator recovery

Crosstalk rejection

Sample rate 4.096M samples per second per input leadwire (unfiltered)

DC offset tole rance

Noise

Standardizing vo lt age

50/60 Hz notch filter 50/60 Hz AC line rejection filters are always active.

Pacemaker pulse display > 0.2 mV indica tion for pace puls es be tween 0.5 an d 2 ms dur ati on at amplit ude

23.1 mm/sec

±5% of input signal or ±40 µV, whichever is greater

wire

System recovery 8 seconds after 360 j o ule discharge, no dam age

Less than 2% channel crosstalk

≥ ±300 mVdc with less than 5% gain change

≤ 30 µV peak-to-peak RTI

1 mV

2 to 250 mV

± 1%

± 5% for 100 mSec ± 5 mSec

Sampling Characteristics of Cardiograph

Physiological factors such as breathing can cause variation in amplitudes of heart beats,

independent of the heart rate. In addition, sampled systems (as op posed to continuous

systems) may show changes in the apparent height of the R-wave when sampling of the Rwave occurs slightly off-peak. Because the sampling rate and the heart rate are

asynchronous, the time between the peak and an adjacent sample can vary from one QRS

complex to the next. This results in a slight variation of displayed QRS amplitu de. This

effect is more pronounced wit h narrower signals, more commonly foun d in some pediatric

electrocardiograms and in pacemaker pulses. The M177XA family of cardiographs

minimizes this effect by:

• using an integrating-type A/D converter

• sampling all leadwires simultaneously

• oversampling the signals

• processing the oversampled signals with appropriate digital signal processing techniques

1-4

Page 17

Specification Data

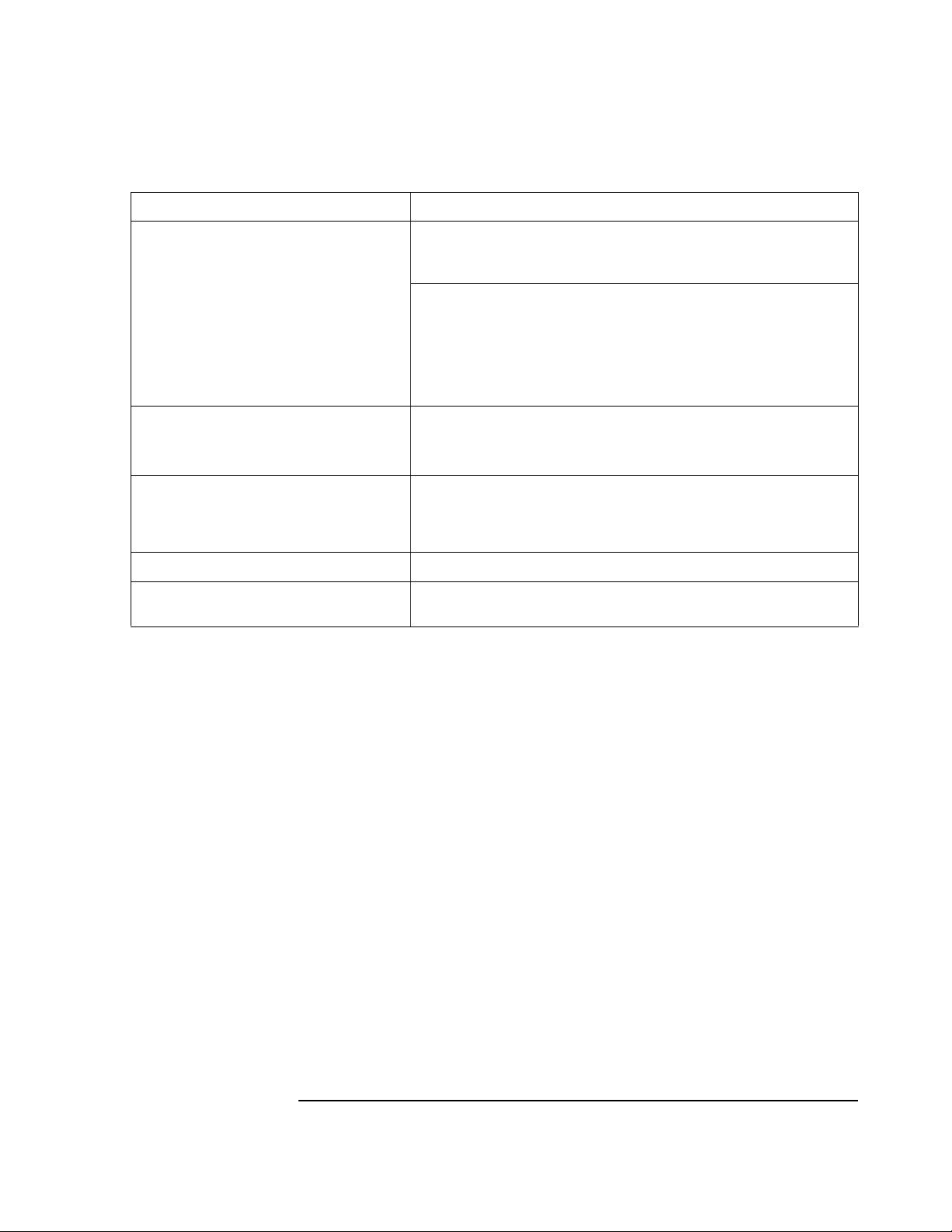

Table 1-3 ECG to Paper Specifications

Parameter Specification

Frequency respons e of PageWriter

200/200i/300pi

(-3dB bandwidth)

Auto ECG

Manual ECG

Frequency response of PageWriter 100

Auto ECG

Manual ECG

ECG resolution on paper

voltage axis

time axis

Recorder speed 5, 10, 25, and 50 mm/sec + 1.5%

ECG visibility with pace pulse Meets AMMI EC11-1991 standard for Diagnostic Electrocardiographic

<3 dB down at (user selectable):

<3 dB down at (user selectable):

Approximately 8 dots/mm (200 dots/in)

Approximately 20 dots/mm (500 dots/in) at 25mm/sec and slower

Approximately 10 dots/mm (250 dots/in) at 50mm/sec

Devices

High Pass Low Pass

0.05 Hz

0.15 Hz

0.5 Hz

0.05 Hz

0.15 Hz

0.5 Hz

0.15-150 Hz or 0.15-40 Hz

0.05-150 Hz or 0.05-40 Hz

150 Hz

100 Hz

40 Hz

150 Hz

100 Hz

40 Hz

1-5

Page 18

Specification Data

Table 1-4 Power Supply and Battery Specifications

Parameter Specification

AC line frequenc y

115 V setting

230 V setting

AC input power rating

Battery voltage 6 V DC, 6.5 Ah

Battery recharge time with unit off

(battery fully discharged)

to 90% capacity

to full capacity

Battery capacity

Auto

continuous rhythm (Manual mode)

Battery life

AC and battery operation

battery only operation

Low battery warning At least 2 Auto ECGs or at least 2 minutes of Man-

Table 1-5 Safety Specifications

Parameter Specification

50 and 60 Hz (nomina l)

90–132 Vac

198–264 Vac

50 VA

7 hours typical

16 hours typical

40 ECGs

40 minutes

Typically 24 months

Typically 14–16 months

ual ECG is allowed after the Low Battery indication is given.

ECG leads source current to ground Less than 10 µA RMS

ECG leads sink current

120 Vac, 60 Hz

240 Vac, 50 Hz

Ground wire integrity

Shunting of defibrillator energy

Operator safety during defibrillation

Less than 20 µA RMS with patient cable

Less than 50 µA RMS with patient cable

Less than 100 mΩ @ 25 A AC

< 10%

< 100 µC

1-6

Page 19

Specification Data

Table 1-6 Environmental Specifications

Parameter Specification

Temperature

operating

storage

Humidity

operating

storage

Pressure (altitude)

operating

storage

Table 1-7 Miscellaneous Specifications

Parameter Specification

Real time clock accuracy

10 to 40

° C

50

° to 104° F (10° to 40° C)

° to 122° F (0° to 50° C)

32

15 to 80% RH, non-c ondensing

15 to 90% RH, non-c ondensing

15,000 ft. (4600 m) for 2 hours

15,000 ft. (4600 m)

Less than 3 minutes deviation per month.

Printhead life Typically 100,000 pages

Table 1-8 Storage and Transmission Specifications (Option #A05 only)

Parameter Specification

Auto ECG storage ca pacity 30 ECGs

Transmission Protocols

DT

SCP

Modem command interfaces

Data modem

FAX modem

Modem protocols

Modulation

Error corre c tion

Compression

FAX modulation

Data transmission standard use d betwe en Agile nt Pag eWriter

cardiographs and A gi le nt TraceMa st er ECG Management Systems

Standard Communications Protocol

Standard AT command set

EIA/TIA-578 Service Class 1

V.34

V.42

V.42 bis

V.17

1-7

Page 20

Options and Accessories

1Options and Accessories

PageWriter 100, 200, 200i, and 300pi Cardiographs

These tables list the options and accessories available for the PageWriter 100, 200, and

300 family of cardiographs.

Country/Region Options

Each country/region option includes the appropriate power cord, voltage, printer, patient

cable, and language. See T ab le 1-9, which shows the configuration of each country/region

option.

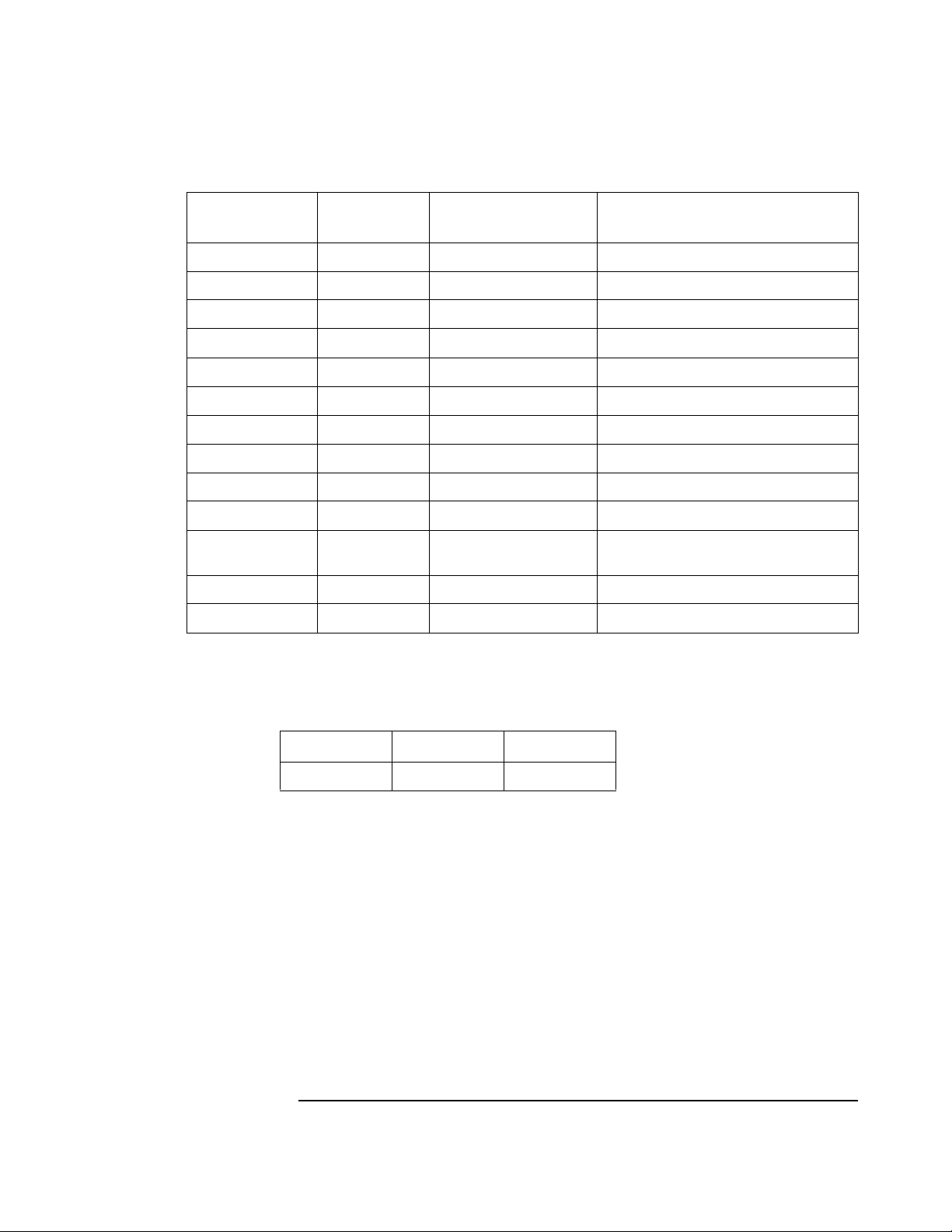

Table 1-9 Country/Region Option Configurations

Country/

Option

ABA North America English English A AHA 120 903–US Disposable

ABB Europe

ABC French Ca na da French French A AH A 120 903–US Disposable

ABD Germany German German A4 IEC 220 902–Europe None

ABE Spain Spanish Spanish A4 IEC 220 902–Europe None

ABF France French French A4 IEC 220 902–Europ e None

ABG Australia English English A4 AHA 240 901–Australia Welsh

ABH Netherlands D utch Dutch A4 IEC 220 902–Europe None

ABK Intercon

ABM Latin America Spanish Spanish A AHA 120 903–US Welsh

ABN Norwegian Norwegian Norwegian A4 IEC 230 902-Europe None

ABS Sweden Swedish Swedish A4 IEC 220 902-Europe None

ABU United

Region Labels

English English A4 IEC 220 902–Europe None

English

English English A AHA 120 903–US Welsh

English,

Taiwan

English English A4 IEC 240 900–UK None

Kingdom

User

Manuals Printer

AHA/

1

IEC Volts Power Cord

2

Electrodes

ABX Finland Finnish Finnish A4 IEC 220 902-Europe None

ABZ Italy Italian Italian A4 IEC 220 902–Europe None

AB2 China Chinese Chinese A4 IEC 220 922–China Welsh

AB4 Singapore English English A4 AHA 240 900–UK Welsh

AC6 S. Korea English English A AHA 220 902-Europe Welsh

1-8

Page 21

Options and Accessories

NOTE

Table 1-9 Country/Region Option Configurations

Country/

Option

ACJ India English English A4 IEC 240 917-SA Welsh

AKM China Chinese English A4 IEC 220 922-China Welsh

ACQ South Africa English English A4 IEC 220 917–SA None

AKV South America Spanish Spanish A AHA 220 902–Europe Welsh

AC4 Portugal Portuguese Portuguese A4 IEC 230 902-Europe None

AB9 Brazil Portuguese Portuguese A AHA 220 903-US Welsh

ACB Russia Russian Russian A4 IE C 220 902-Europe Welsh

AKD Poland Pol i sh Polish A4 IEC 220 902-Europe Welsh

AR2 Greece English Greek A4 IEC 230 902-Europe None

Region Labels

1

In Table 1-9 an “A” in the Printer column refers to 8.5 x 11-in. paper; “A4” refers to 210 x 297-mm paper

2

See Table 1-11 for Agilent part numbers

User

Manuals Printer

AHA/

1

IEC Volts Power Cord

2

Electrodes

Switzerland should order the desired language (German, French, Italian, or English) and

the Swiss power cord (Agilent 8120-2296).

Table 1-10 PageWriter 300pi, 200/200i and 100 Series Documentation Part Numbers

Document Title Language Part Number

PageWriter 100 Cardiograph U ser’s Guide

(M1772A)

English M1772-91900

French M1772-91901

German M1772-91902

Dutch M1772-91903

Spanish M1772-91904

Italian M1772-91905

Finnish M17 72-91910

Chinese M1772-91908

Portuguese M1772-91913

Russian M1772-91914

Polish M1772-91919

Greek M1772-91917

1-9

Page 22

Options and Accessories

Table 1-10 PageWriter 300pi, 200/200i and 100 Series Documentation Part Numbers

PageWriter 200/300pi Cardiograph Users’s

Guide

English M1772-91900

French M1770-91901

German M1770-91902

Dutch M1770-91903

Spanish M1770-91904

Italian M1770-91905

Swedish M1770-91906

Finnish M1770-91910

Chinese M1770-91941

Portuguese M1770-91943

Russian M1770-91944

Polish M1770-91949

Greek M1770-91947

PageWriter 300pi Pre dictive I nstruments Quick

Reference Guide (M1770A with Serial # Prefix

CND)

English M1770-92800

French M1770-92801

German M1770-92802

Dutch M1770-92803

Spanish M1770-92804

Italian M1770-92805

Swedish M1770-92806

Norwegian M1770-92808

Finnish M1770-92809

Chinese M1770-92811

Portuguese M1770-92813

Russian M1770-92814

Polish M1770-92819

Greek M1 77 0-92817

1-10

Page 23

Options and Accessories

Table 1-10 PageWriter 300pi, 200/200i and 100 Series Documentation Part Numbers

Interpretive Physic i an’s Guide (M1770A) English M17 00-92908

French M1700-92918

German M1700-92928

Dutch M1700-92938

Spanish M1700-92948

Italian M1700-92958

Interpretive Physic i an’s Guide - Addendum

(M1770A)

Predictive Instruments Physician’s Guide

(M1770A with Serial # Prefix CND)

English M1700-90700

French M1700-90701

German M1700-90702

Dutch M1700-90703

Spanish M1700-90704

Italian M1700-90705

English M1792-93900

French M1792-93901

German M1792-93902

Dutch M1792-93903

Spanish M1792-93904

Italian M1792-93905

Table 1-11 Power Cord Part Numbers

Power Cord Key Agilent Part Number

900 8120-1703

901 8120-4464

902 8120-1692

903 8120-5213

917 8120-4600

922 8120-8377

1-11

Page 24

Options and Accessories

Table 1-12 Options

Option Description

A05 Adds storage and transmission capability

M2488A-#A70, A71, A72 StressWriter system includes PageWriter cardiograph

M2488A-#C70 StressWriter system includes interface card for PageW riter

Standard Accessories

Accessories included are based on model number and localization.

• 200 sheets of z-fold paper

-English paper p/n M2481A

-Metric paper p/n M2483A

• PageWriter 200/300pi Agilent M1770A Cardiograph User’s Guide

cardiograph

• Interpretive Cardiograph Physician’s Guide (PageWriter 200i/300pi only)

• PageWriter 100 Agilent M1772A Cardiograph User’s Guide (PageWriter 100 only)

• Using the PageWriter 200/200i Cardiograph Operator Training Video (PageWriter

200/200i, also for use with PageWriter 300pi)

• Using the PageWriter 100 Cardiograph Operator Training Video (PageWriter 100 only)

1-12

Page 25

Performance Verification and Maintenance

NOTE

1Introduction

This chapter describes how to verify the cardiograph’s performance, explains preventive

maintenance, presents patient safety information, and prov ides a p erfo rmance verification

checklist.

1Performance Verification

Several procedures make up performance verification: visual inspection of the

cardiograph exterior, execution of Extended Self-test, visual examination of an ECG

recorded from an ECG patient simulator, and system safety tests using a safety analyzer.

A Performance Verification matrix which appears at the end of this section specifies the

tests and inspections which must be performed following servicing of th e PageWriter

cardiographs. The Performance Verification test results must be recorded on

Customer Service order records

Make copies of the matrix. Fill out a copy each time the cardiograph is tested. Attach the

printer test output, and simulator ECG trace to the completed matrix and file with the

cardiograph’s permanent maintenance record.

If any of the performance verification tests fail, refer to Chapter 4, Troubleshooting.

2-1

Page 26

Performance Verification

Visual Inspection and Power On Self Test

Before beginning the inspection, p res s the key to put the cardiograph in

2Q6WDQGE\

Standby mode, and unplug the power cord from the wall outlet. Inspect the cardiograph

for the following:

• Worn or damaged power cord

• Loose or missing hardware

• Mechanical damage

• Evidence of liquid spill

• W orn printer drive gear

• Worn printer roller

• Corroded or damaged reusable electrodes, if present

• Damaged patient cable

• Dirt/paper residue on the thermal printhead

• Frayed or damaged wiring

Replace any damaged or missing items, and clean the printhead and patient electrodes as

necessary. Cleaning instructions are listed under “Preventive Maintenance” later in this

chapter. Connect the cardiograph to AC power. Be sure that the AC indicator comes on.

Turn the cardiograph On and observe that the display turns on (PageWriter

200/200i/300pi) or that the LED’s flash on (PageWriter 100).

Extended Self-test

The cardiograph’s extended self-test checks each major subassembly. The extended selftest consists of two sections: the testing of internal circuitry and the testing of printer,

display, keyboard, and modem capabilities.

To begin the extended self-test, press and hold both the and key s while

turning on the cardiograph with the key.

2Q6WDQGE\

T o st op or exit extended self-test, yo u must press to p lace the cardiogr aph in

$XWR 0DQXDO

2Q6WDQGE\

Standby.

Internal Circuitry Testing of PageWriter 100

These tests are performed on the internal circuitry:

•Memory

• Gate Array

• Front-End Interface

• Serial Interface

Each of these tests is described in detail later in this chap ter.

When the internal circuitry test of the PageWriter 100 is performed, the LEDs show which

test is being performed. The following table shows which LED is associated with each

test.

2-2

Page 27

Performance Verification

Table 2-1 PageWriter 100 Test LED’s

Test Number Test Name LED(s) lit on Page-

Writer 100

1 ROM-1 5 mm/mV OK

2 ROM-2 10 mm/mV Normally fails for 100.

3 ROM-X1 20 mm/mV OK for A#10.

4 ROM-X2 V Leads OK for A#10.

5 RAM Filter OK

6 NVRAM Auto OK

7 GA I II III Lead Group Will also flash all LEDs. OK

8 ECG FE aVR aVL aVF Lead Group OK

9 SIO II aVF V2 Lead Group OK for A#10.

A REMOTE V Leads For future use - normally fails.

B MODEM 5 mm/sec OK for A#10, with modem or test tool

C FLASH1 10 mm/sec OK for A#10.

D FLASH2 25 mm/sec OK for A#10.

When the tests are completed, the results are also printed out in a pass/fail format

on the left-hand side of the first page of the test report.

Comments/ Ex pected Result s

attached

Table 2-2 Test Results Format

Test Passes Test Fails

Printed Result OK * *

In some cases, a test failure halts the test/test printout and an error code ind icatin g the

failure is flashed on the LED’s. See Chapter 4, “Troubleshooting,” for a list of self-test

failure codes and failure symptoms. The section “How the PageWriter 100 Communicates

Error Codes and Messages” in Chapter 4 describes how to read the LED’s.

2-3

Page 28

Performance Verification

Internal Circuitry Testing of PageWriter 200/200i/300pi

These tests are performed on the internal circuitry:

•Memory

• Gate Array

• Front-End Interface

• Serial Interface

Each test is described detail later in this chapter.

When testing the internal circuitry of the PageWriter 200/200i/300pi, the numbers 1

through 9 and the characters A through D are displayed one at a time beginning with

number 1. Each number represents a particular test. If the test fails, the character X is

placed after the test number, f or example, 3X. The test descriptions below are listed in the

order the tests are performed.

Table 2-3 PageWriter 200/200i/300pi Test Numbers

Test Number Test Name Character Displayed on Page-

Writer 200/200i/300pi

1ROM-1 1 OK

2 ROM-2 2 Passes for 300p i, 200i, and 200 with

3 ROM-X1 3 Passes for Options #A05 and #A10

4 ROM-X2 4 Passes for Options #A05 and #A10

5RAM 5 OK

6 NVRAM 6 OK

7GA 7 OK

8ECG FE 8 OK

9 SIO 9 Passes for Options #A05 and #A10

A REMOTE A For future use - normally fails

B MODEM B Passes for Options #A05 and #A10

Comments

software revision A.05.06 or later.

only.

only.

only.

only, with modem or test tool

attached

C FLASH1 C Passes for Options #A05 and #A 10

only

D FLASH2 D For future use - normally fails

2-4

Page 29

Performance Verification

CAUTION

If your cardiograph is equi p ped wi th Opt i on s # A05 or #A10, do not turn it off during Test

C or D. If you turn off the cardiograph while Test C or D are in process, you could lose

stored ECGs, the Log of ECGs Stored, or the Log of ECGs Taken.

When the tests are completed, the results are printed out in a pass /fai l format on the lefthand side of the first page of the test report.

Table 2-4 Test Results Format

Test Passes Test Fails

Printed Result OK * *

In some cases, a test failure halts the test/test printout and an error code ind icatin g the

failure appears on the display. See Chapter 4, “Troubleshooting,” for a list of self-test

failure codes and failure symptoms.

Memory Test

This test looks for failures in the following memory subsys tems:

• Read-Only Memory (ROM)

• Random Access Memory (RAM)

• Non-Volatile Random Access Memory (NVRAM)

Read-Only Memory (tests 1-4) . The cardiograph is designed to have up to four ROMs

installed, two on the main control board and two on an option board. The Read-Only

Memory test reads the contents and performs a 32-bit cyclic redundancy check (CRC) of

each of the four ROM address spaces. The test of a ROM address space will fail if the

ROM module is faulty or is not present. The four ROM address spaces are identified on

the report as

•ROM-1

•ROM-2

•ROM-X1

•ROM-X2

Depending on the serial number and model of the unit you are servicing, the

corresponding ROM part numbers vary. Refer to tables 2-5, 2-6, 2-7, and 2-8 for the

correct ROM replacement part numbers.

2-5

Page 30

Performance Verification

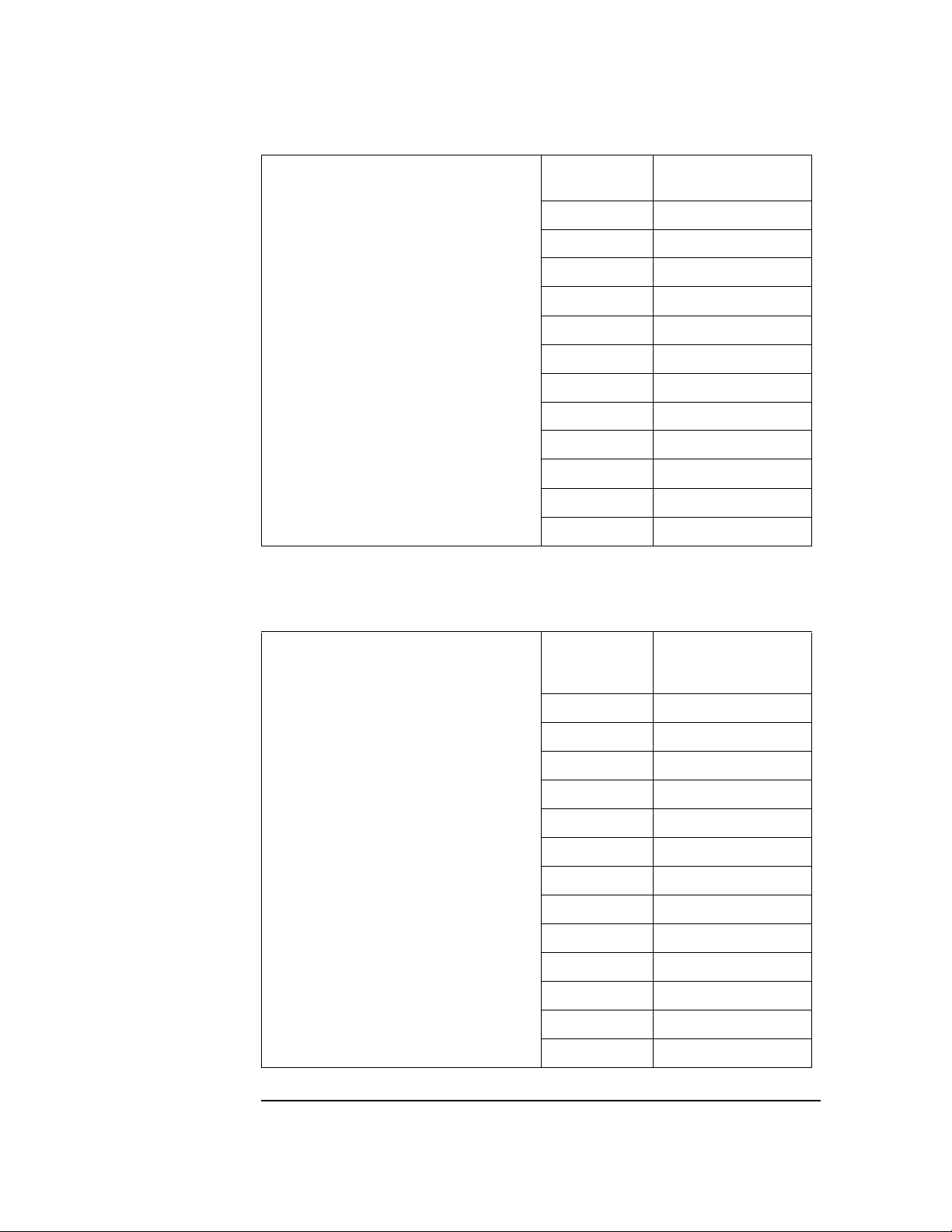

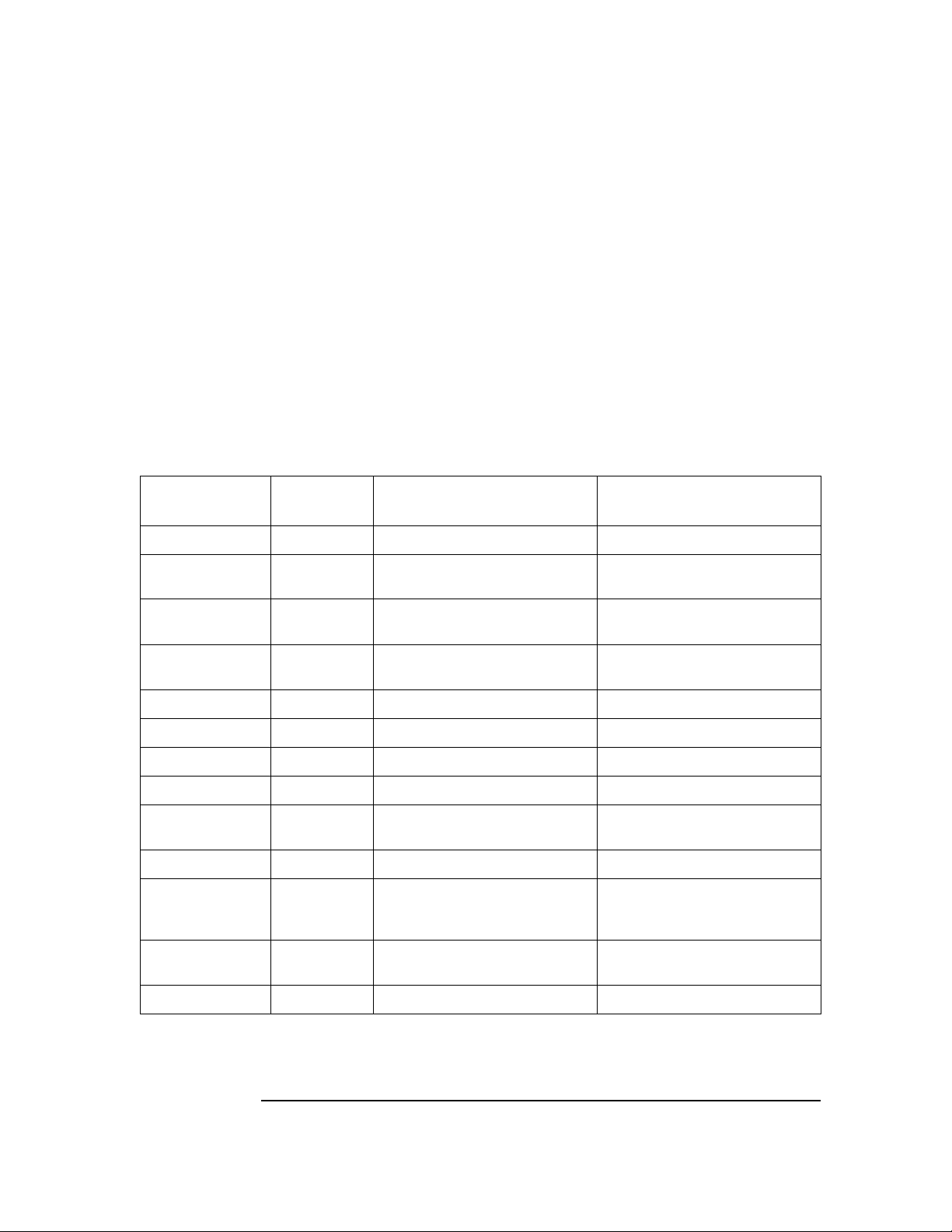

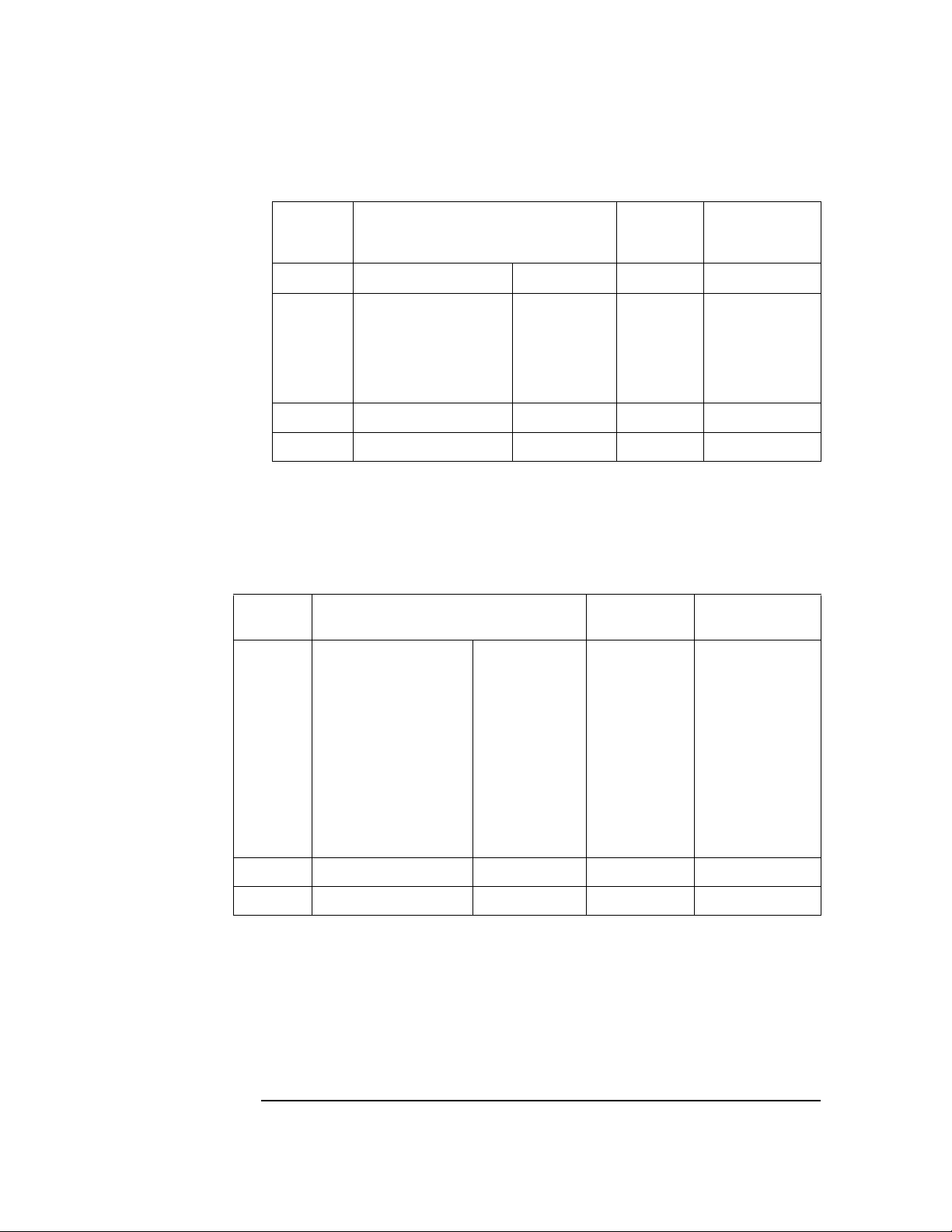

Table 2-5 ROM Replacement Part Numbers for PageWriter Cardiographs M1770, M1771A Serial Number

Prefix CNA, CNB, or CNC, XXXA or , US001

Test Part Number Language Part Number

Labeled on

ROM

ROM 1

ROM 2 U206 - Main CPU Board M1770-89521

ROM X1 U9 - Interface Board M2488-17901

ROM X2 U10 - Interface Board M2488-17902

U205 - Main CPU Board M1770-89505

M1770-89521

M1770-89522

M1770-89523

M1770-89524

M1770-89525

English

French

German

Dutch

Spanish

Italian

M1770-17905

M1770-17921

M1770-17922

M1770-17923

M1770-17924

M1770-17925

Table 2-6 ROM Replacement Part Numbers for PageWriter Cardiographs M1770, M1771A Serial Number

Prefix CND or US002

Test ROM Part Number Language P art Number

Labeled on ROM

ROM 1

ROM 2

U205 - Main CPU Board M177 0- 89550

M1770-89551

M1770-89552

M1770-89553

M1770-89554

M1770-89555

M1770-89556

M1770-89558

M1770-89559

M1770-89563

M1770-89564

M1770-89569

English

French

German

Dutch

Spanish

Italian

Swedish

Norwegian

Finnish

Portuguese

Russian

Polish

M1770-84000

M1770-84001

M1770-84002

M1770-84003

M1770-84004

M1770-84005

M1770-84006

M1770-84008

M1770-84009

M1770-84013

M1770-84014

M1770-84019

ROM X1 U9 - Interf ace Board M2488-17 901

ROM X2 U10 - Inter fa ce Board M248 8-17902

2-6

Page 31

Performance Verification

NOTE

Table 2-7 ROM Replacement Part Numbers for PageWriter Cardiographs M1772A Serial Number

Prefix CNA, CNB, or CNC, XXXA or US001

Test ROM Part Number

ROM 1

ROM 2 Not Required

ROM X1 U9 - Interface Boa rd M2488-17901

ROM X2 U10 - Interface Board M2488-17902

U205 - Main CPU Boar d M 1770-89505

Table 2-8 ROM Replacement Part Numbers for PageWriter Cardiographs M1772A Serial Number

Prefix CND, or US002

Test ROM Part Number

ROM 1

ROM 2

ROM X1 U9 - Interface Boa rd M2488-17901

ROM X2 U10 - Interface Board M2488-17902

U205 - Main CPU Boar d M 1770-89550

If ROM-1 is defective, it is unlikely this test or any other cardiograph function will

operate.

Random-Access Memory (test 5) . The RAM test performs a read/write test of the

instrument’s memory. If this subsystem is defective, it is unlikely this test or any other

cardiograph functions will operate. The RAM is identified on the report as

•RAM

2-7

Page 32

Performance Verification

Non-Volatile Random Access Memory (test 6) . Each 2-byte location of NVRAM is

written and read with a pseudo-random pattern. This is a non-destructive test. The

contents of the NVRAM are saved in RAM prior to this test, and then restored when the

test is complete. The NVRAM test result is identified on the report as

• NVRAM

System Gate Array Test (test 7) . Various registers in the System Gate Array are read

and written. The System Gate Array test result is identified on the report as

• GA

Front-End Interface Test (test 8) . The front-end interface test verifies that the ECG

front-end circuitry is responding to commands, and that the input multiplexers are

operating between ground and internal reference voltage. The front-end interface test

result is identified on the report as

•ECG FE

Manufacturing/Serial Interface Test (test 9) . The manufacturing/serial interface test

checks for proper communication with the optional expansion card UART. For this test to

pass, an extender card must be plugged into the expansion connector. The serial interface

test result is identified on the report as

•SIO

Remote Test (test A). The remote test checks the ability to transmit and receive data

through the spare remote port on the optional expansion board. The remote test is

identified on the report as

• REMOTE

Modem Test (test B) . The modem test verifies that the cardiograph is sending the

expected signals to the modem, and that the modem is receiving and responding

appropriately to signals from the cardiograph. The optional expansion board must be

installed to connect to the modem. The front end and RS-232 port test tool described in

Chapter 4 can help differentiate modem and cardiograph problems. See the section in

Chapter 4 titled “Test Tools” for instructions about using this tool. The modem test is

identified on the report as

• MODEM

2-8

Page 33

Performance Verification

CAUTION

Flash Memory Tests (tests C and D) . The flash memory tests verify that the flash

memory on the optional expansion board can be erase, and that information can be stored

and retrieved. The flash memory tests are identified on the report as

•FLASH1

•FLASH2

If your cardiograph is equipped with Option #A05 or #A10, do not turn it off during Test

C or D. If you turn off the cardiograph while Test C or D are in process, you could lose

stored ECGs, the Log of ECGs Stored, or the Log of ECGs Taken.

2-9

Page 34

Performance Verification

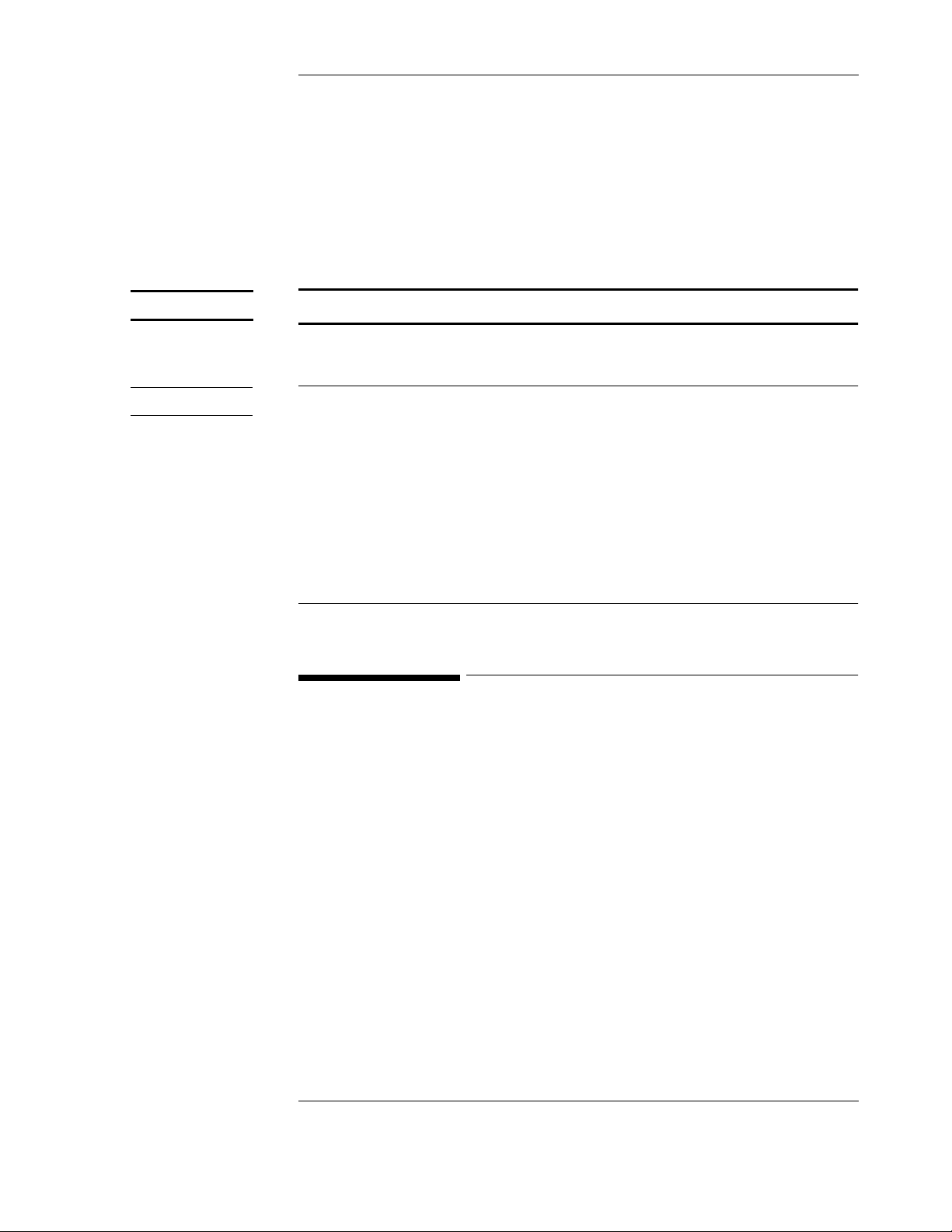

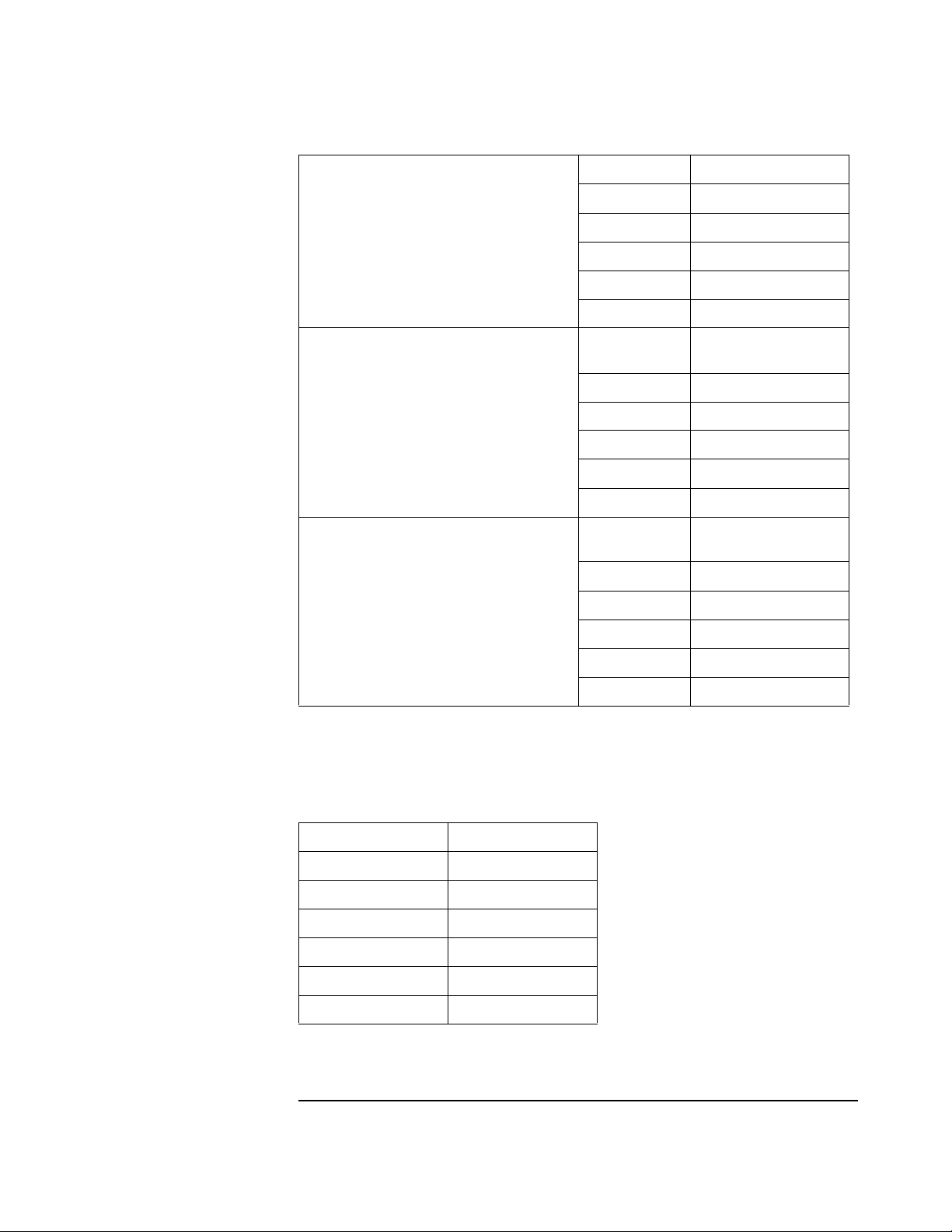

Figure 2-1 An Extended Self-Test Report Example

F

G

I

D

K

L

A. Test Results

B. Character Set

C. Timing Tics

D. Diagonal Lines

E. Stepped Bars

F. Software Revision

G. Printer Speed

H. Printhead Voltage

I. Printhead Temperature

J. Battery Voltage

K. Time Stamp

L. Last Error

M. Event Log (Option #A05 only)

B

H

J

A

M

E

C

2-10

Page 35

Performance Verification

How to Read the Extended Self-Test Report

Each printed page of the extended self-test contains the following information:

A Test Results - See the previous section.

B Character Set - Characters 0 through 255 are printed as a table 4x64 characters in

size. This checks the character tables and printhead performance.

C Timing Tics - Vertical lines are drawn from the bottom of the page. Each vertical

line is 25 mm long as measured from the horizontal line drawn ac ross the bottom o f

the page. Spacing between timing ticks is 25 mm ± 1.5%.

D Diagonal Lines - These dense diagonal lines are printed across the top 2 inches of

the report and quickly show speed variations. An 8 cm wide column of diagonal

lines is also printed down the left-hand side of the report, starting at the top-of-form

hole, to show whether the print roller is round.

E Stepped Bars - The stepped bars are 1/4-inch thick and 3/4-inch tall, stepping from

the top of the page to the bottom of the page. These bars are used to show printhead

dots that are burned out.

F Software Revision - The software revision number for the base ROM.

G Printer Speed - mm/sec

H Printhead Voltage - Voltage range is 25.6 to 26.6 V

I Printhead Temperature - degrees Celsius.

J Battery Voltage - Voltage range is 5.2 - 7.5 V.

K Time Stamp - Number of seconds that the printer test has run.

L Last Error - The last error code encountered. An error code of 65535 indicates that

no errors have occurred since the instrument left the factory. See Table 4-1 for the

table of error codes.

M Event Log - List of the last 46 events with time and date stamp. The events are listed

with the most recent first. Event sub-codes have the same time stamp as the event

code, and appear on the line above the event code. See Table 4-2 for a table of event

codes.

2-11

Page 36

Performance Verification

NOTE

Display Test (PageWriter 200/200i/300pi only)

The display test shows test patterns on the display. Each of the following patterns appear

in this order:

• all pixels lit to create a black screen

• no pixels lit to create a white screen

• a vertical bar scrolling from left to right

You must observe the display while the test pattern is running to ensure:

• no burned out pixels

• no random lines or dots in the display

• no permanent patterns visible at normal contrast. Patterns may be visible at low contrast

(darker screen); this is normal.

• no LCD flickering

It is normal for the top row of the LCD to have some pixels on during the first sweep of

the vertical bar.

This test relies on the visual inspection of the test patterns for detecting failures. There is

no failure message for the display test.

Indicator Light Test (PageWriter 100 only)

During this test, all indicator lights turn on and off at least once. At one point, the indicator

lights flash rapidly for a short time.

Printer Test

The printer test exercises the printhead and paper drive mechanism by printing test

patterns and diagnostic data on the page. The patterns consist of a rectangular area that

contains the entire character font set, timing tics, diagonal lines, and stepped bars. On the

PageWriter 200/200i/300pi cardiographs, the printer test and the display test are

conducted simultaneously. The printer test continues until the cardiograph is placed in

Standby mode.

When the printout is complete, inspect it for:

• straight diagonal lines

• even spacing between diagonal lines

• consistent print quality for all patterns

• constant width betw een timing tics (25 mm ±1%)

• consistent length of timing tics

• accurate rendition of all characters

• clean stepped bars with no dropout in black areas

• even spacing between diagonal lines at the beginning of the page

2-12

Page 37

Performance Verification

NOTE

6SHHG

NOTE

&KDUW6SHHG

Keyboard Tests

The keyboard tests are not automatically performed during the extended self-test. These

must be manually performed and the results visually inspected to verify correctness.

PageWriter 200/200i/300pi Keyboard Test

The keyboard test for 200/200i/300pi models in volves pressing each key on e at a time and

observing that the key character and/or key hex number is displayed on the display. The

keyboard test can be performed anytime after the extended self-test has started.

Pressing changes the speed of the printer test pattern and restarts the extended

self-test.

PageWriter 100 Keyboard Test

To test the keyboard press each key, cycling through the available choices. Be sure that

each LED associated with a key lights when you cycle through the cho ices. This test is no t

performed as part of the extended self-test.

Pressing the key changes the speed of the printer test pattern and restarts the

extended self-test.

2-13

Page 38

Performance Verification

NOTE

NOTE

ECG Simulation

T aking an ECG using a 12-lead ECG simulator allows you to verify areas of operation that

the extended self-test cannot check:

• integrity of the patient cable

• accuracy of the paper speed (not available on all simulators)

• accuracy of the gain settings (not available on all simulators)

The recorded ECG trace should look similar to the one shown in Figure 2-2. Trace

differences may result from differences in simulators, simulator settings, and from

differences in configuration and control settings on the cardiograph. To make a recording

similar to the one in Figure 2-2:

1. Connect the patient cable leadwires to the simulator.

2. On a PageWriter 200/200i/300pi, verify that all leadwires are connected by cycling

through each lead group and observing the display for flatline. Firmly pull each leadwire taut and look for excessive noise on the display.

3. Select the 12-lead Manual format on the front panel display.

If you are using a PageWriter 100, cycle through all lead group selections to verify the

performance of all leads.

4. Press twice to start the recording.

5. Print approximately 2-1/2 pages. Press .

6. Press twice to print an Auto ECG. Make sure the cardiograph advances the

0DQXDO

6WRS

$XWR

paper to the top of form.

When the recording is complete:

• Verify trace activity for all 12 leads. This assures integrity of all patient electrodes and

leadwires. Noise should measure less than 1 mm, and there should be no baseline wander.

• Verify no gross distortion of complexes or calibration pulses (no overshoot, etc.).

• Verify that calibration pulses are of pr oper duration. This assures the correct pap er speed.

With the cardiograph set to record at 25 mm/sec, the calibration pulse should measure 5

mm (calibration pulse duration is 200 ms).

• Verify that calibration pulse amplitude is correct.

An arrhythmia simulator is not an acceptable tool for verifying computerized ECG

analysis. The analysis software is biased to process human ECG data.

2-14

Page 39

Performance Verification

Figure 2-2 12-Lead ECG from ECG Simulator (200/200i/300pi only).

2-15

Page 40

Changing the Default Operating Language (200/200i/300pi Only)

$OW

$OW

$OW

$OW

$OW

$OW

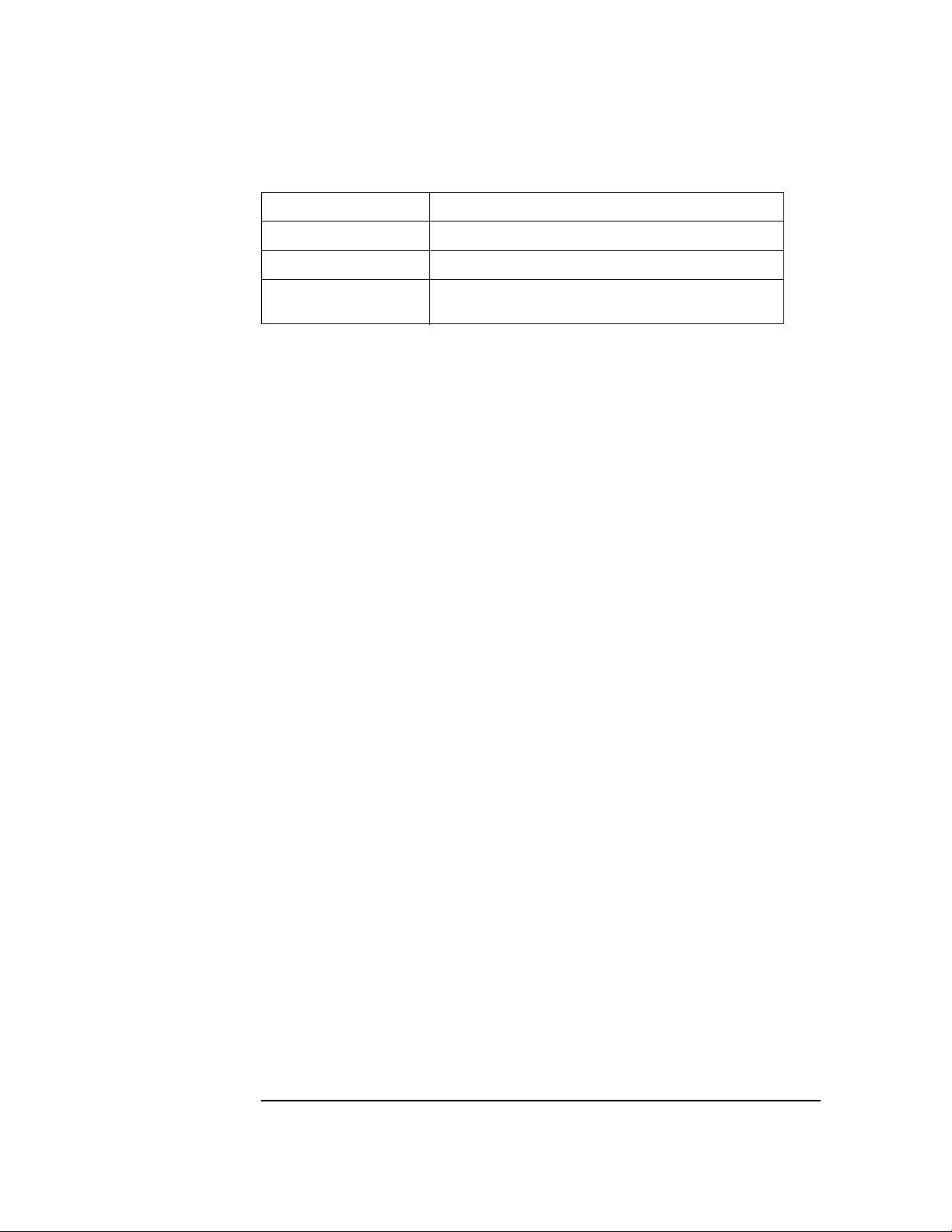

2Changing the Default Operating Language (200/200i/300pi

Only)

The default operating language is selected by holding down the desired key combination

while turning on the instrument. Table 2-9 lists the key combinations.

Table 2-9 Language Key Combinations

Language PageWriter

200/200i/300pi

English

French

German

Dutch

Spanish

Italian

Swedish

Finnish

Norwegian

Portuguese

Polish

$OW

$OW

$OW

$OW

$OW

$OW

–0

–1

–2

–3

–4

–5

–6*

–8*

–9*

–6*

–8*

Russian

–9*

*Only available on certain models.

2-16

Page 41

Resetting the Cardiograph to the Factory Default State

2Resetting the Cardiograph to the Factory Default State

Resetting the cardiograph sets the Auto ECG report counter to 0, and resets the

PageWriter 200/200i/300pi configuration to the factory default.

Resetting the PageWriter 200/200i/300pi

To reset the PageWriter 200/200i/300pi perform the following steps:

1. Using Table 2-9, turn the cardiograph On in a language different from the current lan-

guage.

2. The cardiograph is now reset to the factory default state.

3. If it is necessary to operate the cardiograph in the original language, turn the cardio-

graph to Standby, then turn the cardiograph On using the appropriate key combination from Table 2-9.

Resetting the PageWriter 100

To reset the PageWriter 100 perform the following steps:

1. Turn the cardiograph to Standby.

2. Press and hold and while turning the cardiograph on.

&RS\

3. Turn the cardiograph to Standby.

4. Press and hold and while turning the cardiograph on.

&RS\

5. The cardiograph is now reset to the factory default state.

3DJH$GYDQFH

&KDUW6SHHG

2-17

Page 42

Preventive Maintenance

CAUTION

CAUTION

2Preventive Maintenance

Routine maintenance of the cardiograph consists of cleaning and inspection. This should

be done as needed.

The cardiograph does not require lubrication. Lubricating any part of the cardiograph

could damage it or diminish its performance.

Care and Cleaning

The outside surfaces of the cardiograph and its accessories (except the patient cable) can

be cleaned by mild soap and water or isopropyl alcohol. The patient cable cannot be

cleaned with isopropyl alcohol. The patient cable can be cleaned only with mild

disinfectant or soap and water.

Cleaning the Cardiograph

1. Unplug the power cord and ensure that the cardiograph is in Standby mode (the dis-

play is off).

2. Wipe the external surfaces of the cardiograph with a soft cloth dampened with mild

soap and water or isopropyl alcohol. Avoid applying cleaning fluids to cable connectors.

Do not use any strong solvents or abrasive cleaning materials.

Do not spill any liquids on the surface of the cardiograph. Service the cardiograph

immediately if any liquids spill on the surface.

Do not use any of the following to clean the cardiograph:

• Acetone

• Chlorine bleach

• Ammonia-based cleaners

• Iodine-based cleaners

• Phenol-based cleaners

• Ethylene oxide sterilization (ETO)

• Autoclave

2-18

Page 43

Preventive Maintenance

CAUTION

CAUTION

Cleaning the Keyboard Overlay

1. Carefully insert a small flat-bladed screwdriver into the notches at the front edge of

the keyboard overlay and pry the front edge of the keyboard overlay up. Refer to Figure 2-3.

2. Repeat with the rear notches of the keyboard overlay and remove the overlay.

Figure 2-3 Removing the Keyboard Overlay

A. Notches

Do not wash the keyboard overlay in hot water. Do not attempt to clean the keyboard

overlay in a dishwasher.

3. Rinse off the keyboard overlay and thoroughly dry it.

The rubber keypad and/or keyboard assembly may be damaged if any key or LED

becomes trapped under the overlay while replacing the overlay. Make sure each and every

key and LED comes through its ho le in the overlay befor e snapping the over lay into place.

4. Align the overlay with each of the keyboard keys and LEDs. Position your thumbs

along the front edge of the overlay near each end. Apply pressure on the overlay

toward the rear of the unit and then press down on the overlay in one continuous

motion. The front of the overlay should now be snapped into place. Snap the rear of

the overlay into place.

2-19

Page 44

Preventive Maintenance

CAUTION

Cleaning the Digital Array Printhead and Paper Sensor

If you use Agilent Technologies recording paper, you should not have to clean the

printhead for the life of the product. If you need to clean the printhead, this is the