Page 1

MitoXpress Xtra

Quick Start Guide

Five Step Workflow

Page 2

Table of Contents

1. Plate Reader Setup 3

Find your plate reader download packet 3

Import protocol/template 3

Define the detection mode 3

2. Signal Optimization 4

Plate reader signal optimization 4

Plate preparation 4

Calculations 5

Adjustments for improved signal detection (S:B and signallevel) 6

Confirmation 6

3. Sample Optimization 7

Adherent cell titration plate 7

Suspension cell titration plate 8

Calculations 9

Adjustments for improved O2 consumption (OCR) 10

4. Running the Assay 11

Example control compound treatment (and FCCP optimization) 11

Day before measurement cell plate preparation 12

Control compound preparation 12

Assay plate preparation 12

5. Data Analysis 13

Guideline for applying data analysis tools to raw data 13

Data analysis tool options 13

This Quick Start provides all you need to know from plate

reader setup and signal optimization, to sample and compound

optimizations, as well as routine assay runs and data analysis.

For detailed instructions on product use, please see the

MitoXpress Xtra user manual.

1

Plate reader

setup

2

Signal

optimization

3

Sample

optimization

4

Running

the assay

5

Data

analytics

2

Page 3

1. Plate Reader Setup

Key steps

1.1 Find your plate reader

download packet

1.2 Import protocol/template

1.3 Define the detectionmode

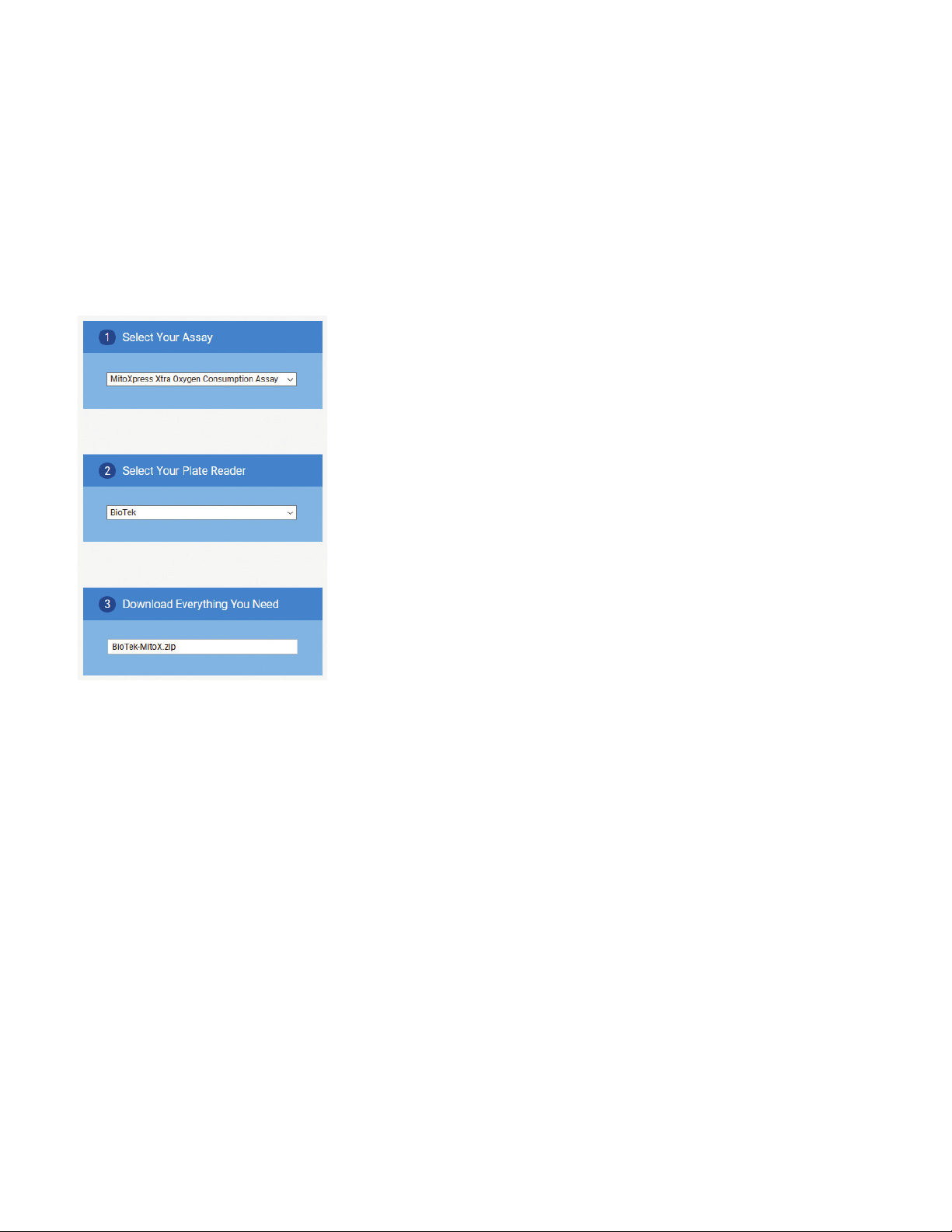

Step 1.1

Find your plate reader download packet

Find your Plate Reader online.

The download packet found in the link above contains the required collateral

and software templates you will need, including the recommended protocol

template files. These files contain default settings for your fluorescence plate

reader model, where available, or an instrument setup guide where not available.

Separately, it will contain a data analysis template specific to your plate reader

control software or, where that is not feasible, provide the data visualization tool

(Excel Macro). In addition, the MitoXpress Xtra user guide is provided, containing

detailed assay instructions.

Step 1.2

Import protocol/template

Import protocol templates into your plate reader software for easy setup. Open

the protocol and define the filter locations specific to your instrument filter

wheel/slide/cube and get started.

If a template is not provided, create a protocol in the instrument software,

inputting the instrument parameters described in the specific instrument

setupguide.

Ensure that software versions are up to date and compatible before starting.

Step 1.3

Define the detection mode

Decide/define which detection mode you intend to employ depending on the plate

reader specification used (basic, standard TR-F, and dual-read TR-F). See the user

guide contained in the download packet to inform your choice.

Use the recommended detection mode for your chosen plate reader

specifications, while ensuring that the correct excitation and emission filters are

installed correctly.

In cases where dual-read TR-F detection is recommended but the filters are not

available, it is possible to employ the standard TR-F detection as an alternative.

This is done using the monochromator rather than filters for excitation and

emission wavelength selection.

3

Page 4

2. Signal Optimization

MX pr

Blank:

Key steps

2.1 Read; 20 minutes at 37°C

2.2 Calculations

i. S:B ratio (>3:1)

ii. Signal level (10 to

20% max. instrument

intensity (RFU))

iii. Lifetime signal level

(22to 26 µs)

2.3 Adjustments

2.4 Confirmation (repeatread)

Step 2.1

Plate reader signal optimization

Measure a cell-free signal optimization plate for verification of the protocol

template/instrument settings implemented in Step 1. This can be done with a

quick assessment of the signal-to-blank (S:B) and signal level (RFU).

• The recommended S:B is >3:1

• The signal level must be ~10 to 20% maximum intensity (RFU) on the plate

reader (~15% of saturation). Otherwise, the signal will overflow/saturate the

instrument.

Usually the default protocol parameters will provide a suitable S:B and RFU;

however, in the unlikely event it is outside these recommendations, simple

adjustments can be made, found in Step 2.3.

Step 2.1.1

Plate preparation

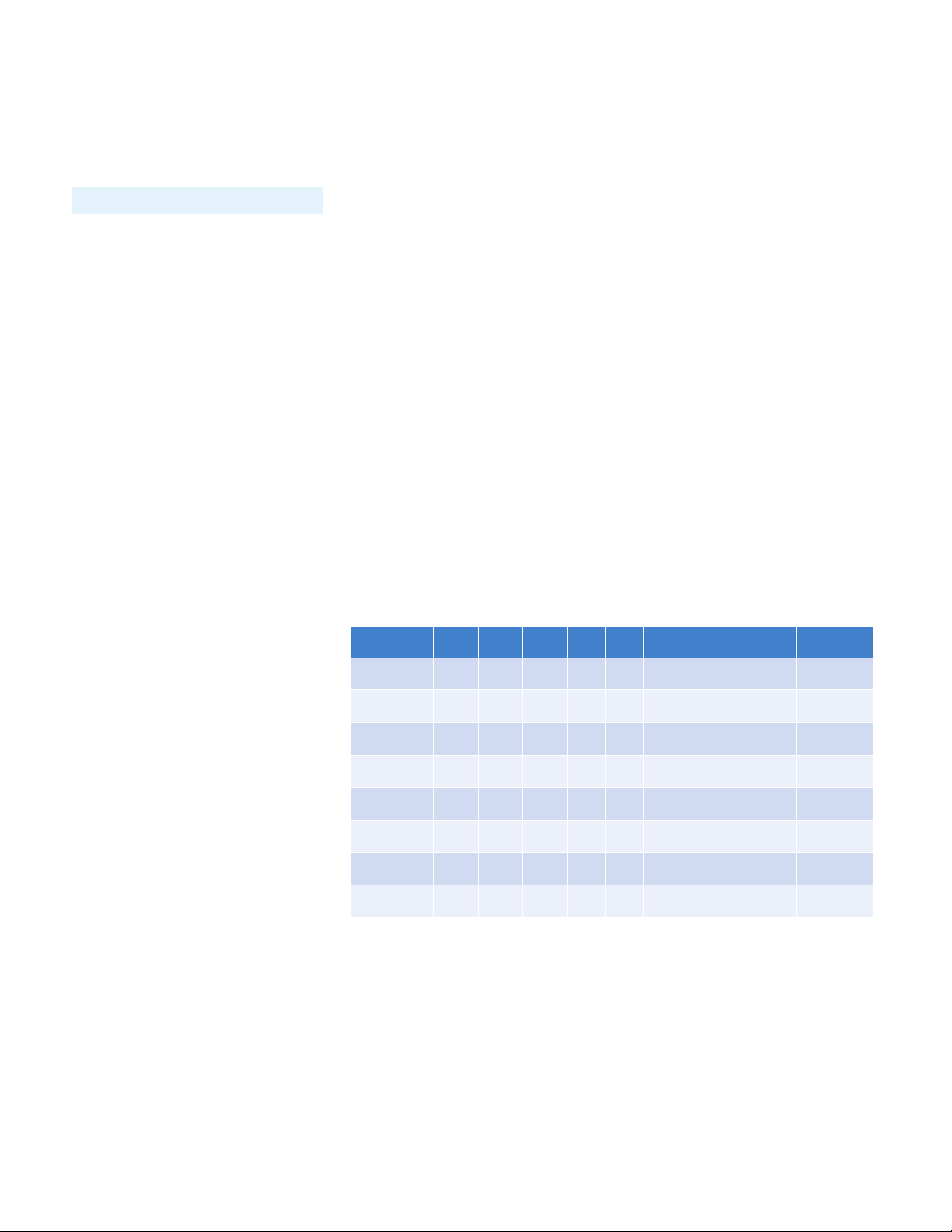

Prepare and read a signal optimization plate using the plate layout in Figure 1.

MitoXpress probe, media, and HS mineral oil preparation are described in the

MitoXpress Xtra user guide.

12345678910 11 12

MX

MX

MX

A

probe

probe

probe

BlankBlank BlankBlank

B

C

D

E

F

G

H

obe: 10 µL MitoXpress probe + 90 µL Media + 100 µL HS mineral oil

100 µL Media + 100 µL HS mineral oil

Figure 1. Signal optimization plate layout.

MX

probe

Note: It is important that the media/sample, HS mineral oil, microplate, and plate

reader are prepared and maintained at the desired assay temperature, 37 °C. The

HS mineral oil should be warmed to 37 °C before the assay for easier use.

4

Page 5

Tip: For consistent, reliable, and quick HS mineral oil dispensing, a repeater

Signal (RFU)

Signal

Blank

type pipette is recommended (using a 1.25 mL syringe tip or 2 mL combitip).

Prepare the repeater syringe tip by trimming ~3 to 4 mm off the tip at a 45°

angle. Remove the internal nozzle from the oil dropper bottle and slowly pick up

the prewarmed HS mineral oil (avoid pipetting up and down, as this can cause

bubbles) and dispense 100 μL into each well at an angle of ~45°, allowing the oil

to flow down the side of each well.

Pipetting tips are found on page 36 of the MitoXpress Xtra user guide.

Key steps

2.1 Read; 20 minutes at 37°C

2.2 Calculations

i. S:B ratio (>3:1)

ii. Signal level (10 to

20% max. instrument

intensity (RFU))

iii. Lifetime signal level

(22to 26 µs)

2.3 Adjustments

2.4 Confirmation (repeatread)

MitoXpress signal

RFU

Step 2.2

Calculations

Perform calculations i. to iii. using one of the following data analysis options:

(a) Plate reader software analysis/templates

(b) Agilent Data Visualization Tool

Review the raw results and calculate the following:

i. Signal:blank ratio: Using average RFU values measured at the 20-minute

time point, calculate signal RFU (row A)/blank RFU (row B). Ensure

that the S:B ratio is >3. If using a TRF detection mode: S:B >5 to 10 is

achievable.

ii. RFU signal level: Using RFU signal at the 20-minute time point, the

measured RFU signal level for the MX probe samples should be in the

range of ~10 to 20% of the maximum instrument intensity (RFU). See

the plate reader user manual or software help section to identify the

arbitrary maximum/saturated RFU signal level for the given plate reader

model.

iii. Lifetime signal (µs) level: MitoXpress assay signal (21% O2) ~22 to

26µs.

Blank

Note: This calculation is only applicable when using the advanced dual-read TRF

detection mode on a filter-based plate reader.

Time

3000

Decision point:

• If the recommended S:B ratio, signal level, and lifetime values (where

applicable) are successfully achieved, we recommended proceeding to Step 3.

2500

1000

1500

S:B = 11

1000

500

0

• If, however, the recommended S:B ratio, signal level, or lifetime values are not

achieved, we suggest proceeding to Step 2.3 Adjustments.

5

Page 6

Key steps

Step 2.3

2.1 Read; 20 minutes at 37°C

2.2 Calculations

i. S:B ratio (>3:1)

ii. Signal level (10 to

20% max. instrument

intensity (RFU))

iii. Lifetime signal level

(22to 26 µs)

2.3 Adjustments

2.4 Confirmation (repeatread)

Adjustments for improved signal detection (S:B and

signallevel)

If necessary, based on the calculation in Step 2.2, the following adjustments are

recommended:

i. Parameter review and confirmation

First, review and confirm that all instrument parameters were inputted

correctly and not changed or omitted. See the instrument setup guide,

MitoXpress Xtra user guide, and original template protocol.

ii. Focal (Z-) height optimization

To improve RFU signal level and S:B for a given microplate format

and volume, check and adjust the focal height setting manually or

automatically depending on reader capability. See the plate reader user

manual. Only applicable where focal height adjustment is available.

iii. Gain or photomultiplier tube (PMT) setting adjustments

The protocol templates employ fixed gain or PMT settings throughout

the kinetic measurement. Auto Gain, Dynamic, or Variable Gain should

not be used.

• If signal level is too high (>20% max. intensity), decreasing the gain or

PMT setting is recommended.

• If signal level is too low (<10% max. intensity), increasing the gain or

PMT setting is recommended.

Note: If using advanced dual-read TRF detection mode, attention should be on

the RFU signal measured from Window 1 (W1), (30 µs delay read/window), when

targeting 10 to 20% max. intensity. Also, both W1 and W2 TRF settings must

use identical gain settings; this is critically important to a successful lifetime

signal-based assay.

iv. Flash number, or number of pulses

Increase the flash number (no.) value to yield improved signal stability.

Highest flash no. will yield longer cycle time.

Note: Default TRF (time-resolved fluorescence) settings (delay time and

integration/window times) should not be adjusted.

Additional adjustments: Details on these can be found in the Troubleshooting

section of the MitoXpress Xtra user guide. These include switching to bottom

read detection, removal of phenol red and serum from media, or increasing

MitoXpress probe concentration by 5 µL/well, or a combination of all options.

Step 2.4

Confirmation

Repeat Step 2.1 and 2.2 using the same signal optimization plate to verify the

success of any adjustments made in Step 2.3. Once confirmed, move to Step 3.

6

Page 7

3. Sample Optimization

40

Cell titration

120

Slope(µs/h)

Key steps

3.1 Adherent cell titration

Determine the relative oxygen consumption rate (OCR) from a range of cell

densities. Thisis essential for identifying the suitable seeding density required

for detectable metabolism (relative OCR) for a given cell type/model under fixed

3.2 Suspension cell titration

3.3 Calculations

conditions. The cell density required is cell type-specific; these concentrations are

general guidanceonly.

3.4 Adjustments

Step 3.1

80K

60K

36

40K

30K

No cells

32

28

Mitoexpress signal (µs)

24

20

0306090

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0.0

Time (min)

80K

60K

40K

30K

No cells

Adherent cell titration plate

3.1.1 Day before measurement

Plate cells with the following seeding densities: 30,000, 40,000, 60,000, and

80,000/200 µL media overnight (n = 4) using a suitable TC+ 96-well microplate.

The suggested plate layout is provided in Figure 2.

12345678910 11 12

80K 80K 80K 80K

A

60K 60K 60K 60K

B

40K 40K 40K 40K

C

30K 30K 30K 30K

D

0K

E

Signal

F

control

BBllaannkkBBllaannkkBBllaannkkBBllaannkk

G

H

Cell plating densities (X *1000 cells/well): 60K is 60,000 cells/well

Signal control: Media + MitoXpress probe + HS mineral oil

Blank: Media + HS mineral oil

0K 0K 0K

Signal

control

Signal

control

Signal

control

Figure 2. Adherent cell plate layout.

* Optional: Positive signal control (GOx) can be added to row H (n = 4). For example, GOx plus

MitoXpress in media, plus HS mineral oil (positive signal control). *Add 10 µL of 1.5 mg/mL Gox

stock /well. (GOx well concentration: 0.15mg/mL).

Tip: Allow the plate to rest on the bench for 30 minutes at room temperature

after the cells have been pipetted onto the plate. This will help ensure an evenly

dispersed monolayer to help minimize plate edge effects.

7

Page 8

3.1.2 Day of measurement

28

090

Cell titration

Slope(µs/h)

Prepare the cell assay plate as per user manual guidelines, including the

appropriate control and blank samples.

• See the previous recommendation (page 4) to use a repeater type pipette for

optimum HS mineral oil addition.

• Measure the cell titration plate kinetically at 37 °C for two hours using

minimum cycle or interval time (one minute), immediately after the HS mineral

oil layer is applied.

Note: Blank and signal control samples are always required (minimum n = 2) and

should be included in all routine MitoXpress Xtra assays.

Key steps

3.1 Adherent cell titration

3.2 Suspension cell titration

3.3 Calculations

Step 3.2

Suspension cell titration plate

3.2.1 Day of measurement

Plate cells with the following density; 200,000, 300,000, 400,000, and

600,000/90µL media (n = 4) using a suitable 96-well microplate. See Figure 3.

3.4 Adjustments

12345678910 11 12

600K

400K

26

24

22

Mitoexpress signal (µs)

20

7.0

6.0

5.0

4.0

3.0

2.0

1.0

300K

200K

No cells

0306

Time (min)

600K

400K

300K

200K

No Cells

Cell plating densities (X *1000 cells/well): 400K is 400,000 cells/100 µL

Signal control: Media + MitoXpress probe + HS mineral oil

Blank: Media + HS mineral oil

Figure 3. Suspension cell plate layout.

*Optional: Positive signal control (GOx) can be added to row C (n = 4). For example, GOx plus

MitoXpress in media, plus HS mineral oil. Add 10 µL of 1.5 mg/mL GOx stock/well. (GOx well

concentration: 0.15 mg/mL).

600K 600K 600K 600K

A

400K 400K 400K 400K

B

300K 300K 300K 300K

C

200K 200K 200K 200K

D

0K

E

Signal

F

control

BBllaannkkBBllaannkkBBllaannkkBBllaannkk

G

H

0K 0K 0K

Signal

control

Signal

control

Signal

control

0.0

Tip: Temperature control and temperature equilibration of the microplate and

cell suspension during plate preparation is important in minimizing inconsistent

temperature across the plate. Use a plate heat block set to 37 °C where possible.

3.2.2

Prepare the cell assay plate as per the MitoXpress Xtra user guide instructions,

by adding 10 µL MitoXpress/well, including the appropriate control and

blanksamples.

8

Page 9

18,000

Time (min)

09

Mitoexpress signal (RFU)

Key steps

Step 3.3

3.1 Adherent cell titration

3.2 Suspension cell titration

3.3 Calculations

3.4 Adjustments

80K

60K

16,000

14,000

12,000

10,000

8,000

40K

30K

No cells

0306

0

Calculations

Perform these calculations to identify a suitable cell density for use in routine

assays. A suitable cell density is one that yields either of the criteria in i and ii.

Cell density criteria:

i. A signal fold increase (RFU increase) of ~1.3 to 2-fold over a 60-minute

period

ii. A MitoXpress Xtra lifetime signal slope of >4 µs/h if using advanced

dual-read TRF detection mode

If a higher minimum level of signal change (O2 consumption) was preferred, an

even greater cell density could be chosen.

Apply data analysis using one of the options provided:

(a) Plate reader software analysis/templates

(b) Agilent Data Visualization Tool

For more detail, see Step 5 for data analysis recommendations.

3.3.1

To accurately measure slope (signal increase), choose a suitable time range

over which the RFU signal is analyzed. When using the data visualization tool,

visualize the kinetic signal profiles in the chart and choose an appropriate start

time and end time for slope calculation that best captures the linear portion of

the signal profiles from all samples. Typically, this would be after any initial RFU

signal decrease (temperature equilibration of the sample) during the initial 10 to

20minutes.

3.3.2

Review the results and determine the measured rates (slope of signal increase)

of all the titrated samples. Calculate average and standard deviation, and plot

average slope values versus cell density, including the probe-only signal control.

3.3.3

Determine the cell density that achieves the signal fold increase or lifetime

signal slope criteria above.

Decision point:

• If the recommended cell density criteria are successfully achieved, we

recommended proceeding to Step 4.

• If the criteria are not achieved, we recommend performing the adjustments

described in Step 3.4

9

Page 10

Key steps

Step 3.4

3.1 Adherent cell titration

3.2 Suspension cell titration

3.3 Calculations

3.4 Adjustments

Adjustments for improved O2 consumption (OCR)

This is essential for identifying the suitable cell density required for detectable

metabolism (relative OCR) in each cell type/model under fixed conditions. The

cell density required is cell type-specific.

If the cell density criteria are not achieved, we recommend performing some or a

combination of the following adjustments:

i. Re-evaluate the results, ensuring that the correct time range is being

used for analysis (avoid temperature equilibration) and that there

are no outliers, incorrect calculations, or data corrections being

appliedincorrectly.

ii. Repeat the titration experiment, ensuring the following:

• Better temperature control at 37 °C of the media, assay test

plate, plate reader microplate chamber, and HS mineral oil during

platepreparation.

• Accurate control of media and sample volume.

iii. Repeat the titration experiment with an increased cell density (amount

of sample), repeating Step 3 again.

iv. Repeat the titration experiment with a decreased well volume, 75 or

50µL. (for example: 50 µL/well, 10 µL MitoXpress plus 40 µL media). Do

not decrease well volume below 50 µL/well (96-well microplate). The

volume of HS mineral oil added does not change.

After any adjustments/repeat titration experiments, perform Step 3 calculations

again to ensure that cell density criteria are achieved. Only once this is done

should you proceed to Step 4.

10

Page 11

4. Running the Assay

Key steps

4.1 Control compound acute

treatment

4.1.1 Cell plate preparation

4.1.2 Control compound

preparation

4.1.3 Assay plate preparation

and compound addition

Step 4.1

Example control compound treatment (and FCCP optimization)

Prepare a control compound plate as follows:

i. Seed the plate with the optimum cell density (X) identified in Step 3.

ii. Prepare and add control compound treatments described in Step 4.1.2

and in Figure 4.

12345678910 11 12

FCCP

FCCP

FCCP

FCCP

FCCP

FCCP

1 µM

mycin

DMSO

Signal

FCCP

2.5 µM

FCCP

1.25 µM

FCCP

0.625 µM

FCCP

0.313 µM

1 µM

Rot/Anti

mycin

DMSO

control

Signal

control

A

2.5 µM

2.5 µM

FCCP

B

C

D

E

F

G

H

1.25 µM

0.625 µM

0.313 µM

Rot/Anti

control

control

FCCP

1.25 µM

FCCP

FCCP

0.625 µM

FCCP

FCCP

0.313 µM

1 µM

1 µM

Rot/Anti

mycin

mycin

DMSO

DMSO

control

Signal

Signal

control

Blank Blank Blank Blank

2.5 µM

1.25 µM

0.625 µM

0.313 µM

Rot/Anti

control

control

Cell Plating Density: Rows A to F, columns 1 to 4 (for example, adherent cell type: 50,000/well)

FCCP: A range of concentrations from 0.3 µM to 2.5 µM

Rot/Antimycin: 1 µM final concentration

Signal Control: Media + MitoXpress probe + HS mineral oil

Blank: Media + HS mineral oil

Figure 4. Cell compound treatment plate layout. For suspension cell type, plate the cells on the day

of measurement, for example 400,000/100 µL.

*Optional: Positive signal control (GOx) can be added to G3 and G4 wells (n = 2). For example, GOx

plus MitoXpress in media, plus HS mineral oil. Add 10 µL of 1.5 mg/mL GOx stock/well. (GOx well

concentration: 0.15 mg/mL).

11

Page 12

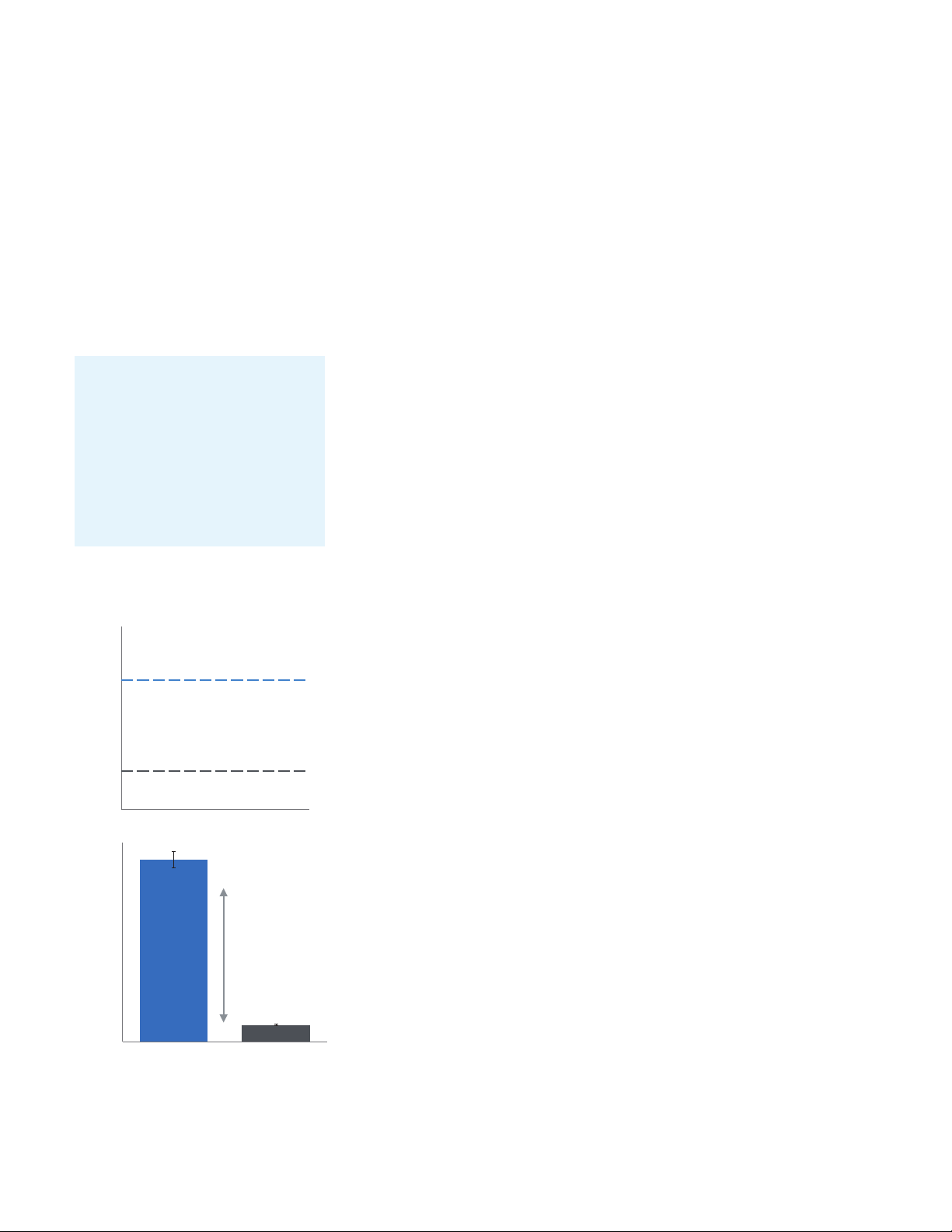

150

MitoXpress Signal (µs)

An

Key steps

Step 4.1.1

4.1 Control compound acute

treatment

4.1.1 Cell plate preparation

4.1.2 Control compound

preparation

4.1.3 Assay plate preparation

and compound addition

A

40

35

30

25

20

B

FCCP

Vehicle

Antimycin A

050 100

Time (min)

20

Day before measurement cell plate preparation

Plate cells with the optimum cell density:

Adherent cells

Plate cells at X *1000 cells/200 µL media overnight (n = 36), using a suitable

TC+96-well microplate. For example, 50,000 cells/200 µL for HepG2 cells row

AtoF, column 1 to 4 of microplate. See Figure 4.

Tip: Allow the plate to rest on the bench for 30 minutes at room temperature,

asbefore.

Suspensions cells

Prepare on the day of measurement as described in Figure 4, rows A throughF,

columns 1 through 4 of the microplate. For example, 400,000 cells/100 µL for

HL60 cells rows A to F, columns 1 to 4 of microplate.

Tip: Prepare a master mix stock of suspension cells in media plus the MitoXpress

Xtra probe, for best consistency.

Step 4.1.2

Control compound preparation

Prepare 100X stock concentrations in vehicle (DMSO):

• FCCP (positive control). A serial 1:2 dilution dose response is advisable

between 2.5 and 0.3 µM, final concentration.

15

10

MitoXpress rate (µs/h)

• Rotenone/Antimycin is the recommended negative control. 1 µM final

concentration.

Note: The information in 4.1.1 and 4.1.2 is general guidance only. Response may

be cell-type dependent. Adjust compound concentrations as required.

Tip: For initial investigative experiments with compounds, measuring at 37 °C

with minimum interval time (one minute) is recommended for a minimum of

5

0

Vehicle

FCCP

timycin A

twohours.

Step 4.1.3

Assay plate preparation

Prepare the assay plate per the user manual instructions, including the

appropriate signal control and blank samples. Adding 1 µL of the control

compounds (100X) stock to the appropriate wells (see Figure 4). Then add

100µL of HS mineral oil (warmed to 37 °C) to all test wells, before starting assay

measurement.

Tip: Prepare a master mix of MitoXpress Xtra probe plus media for the consistent

and simplified addition of MitoXpress reagent. Prepare suitable volume and

excess to dispense 100 µL/well.

For consistent, reliable, and quick HS mineral oil dispensing, see pipetting tips

found in the user manual on page 36.

12

Page 13

5. Data Analysis

Key steps

5.1 Apply data analysis, and

select a suitable time

range for slope analysis

5.2 Data analysis tool options

available:

a) Plate reader software

analytics templates

b) Agilent Data

Visualization Tool

Step 5.1

Guideline for applying data analysis tools to raw data

Using either (a) plate reader software analysis/templates or (b) the Agilent Data

Visualization Tool, all of which are contained in the download packet retrieved in

Step 1, or here:

a) Find your Plate Reader

b) Agilent Data Visualization Tool

To accurately measure slope (signal increase), choose a suitable time range over

which the RFU signal is analyzed. When using the data visualization tool, visualize

the kinetic signal profile chart and choose an appropriate start and end time

for slope calculation that best captures the linear portion of the signal profiles

from all samples. Typically, this should be after any initial RFU signal decrease

(temperature equilibration of the sample) during the initial 10 to 20 minutes.

For plate reader software templates, there are specific functions/buttons for

correctly choosing start and end times for the slope calculations. Look for these

in the slope or the V max reduction/calculation step in each case, and consult the

vendor analysis software user manual if necessary.

Step 5.2

Data analysis tool options

Plate reader software analytics templates

Plate reader software analysis templates or data analysis as part of software

protocol files are available from the following plate reader vendors:

1. BioTek - Gen5 protocols (.prt)

2. BMG Labtech - MARS data analysis templates (.MTF)

3. Molecular Devices - SoftMaxPro protocols (.spr)

Agilent MitoXpress and pH Xtra data visualization tool

Carefully read to the Data Visualization Tool (DVT) user manual before use. Save

and export the results in the designated compatible format, (csv,.txt file) from the

plate reader software.

The data visualization tool is a Microsoft Excel Macro that automatically

transforms experimentally derived fluorescence data into kinetic signal curves,

applies time range slope calculation, with slope and endpoint results conveniently

tabulated and illustrated as charts.

Simple approach

• Export results into the correct DVT-compatible file format: .TXT or .CSV.

• Load the .TXT or .CSV file into DVT.

• Follow the directions for annotation, data visualization, and time range

selection (slope calculation) in the Graph tab.

• Summary data table and charts output available.

13

Page 14

For Research Use Only. Not for use in diagnostic procedures.

DE.404837963

This information is subject to change without notice.

© Agilent Technologies, Inc. 2020

Published in the USA, May 5, 2020

5994-1822EN

Loading...

Loading...