Agilent MGA-83563

Description

Agilent’s MGA-83563 is an easyto-use GaAs RFIC amplifier that

offers excellent power output and

efficiency. This part is targeted

for 3V applications where constant-envelope modulation is

used. The output of the amplifier

is matched internally to 50Ω.

However, an external match can

be added for maximum efficiency

and power out (PAE = 37%, Po =

22 dBm). The input is easily

matched to 50 Ω.

Due to the high power output of

this device, it is recommended for

use under a specific set of

operating conditions. The thermal

sections of the Applications

Information explain this in detail.

The circuit uses state-of-the-art

PHEMT technology with proven

reliability. On-chip bias circuitry

allows operation from single

supply voltage.

+22 dBm P

3V Power Amplifier

SAT

for 0.5 – 6 GHz Applications

Data Sheet

Features

• Lead-free Option Available

at 2.4 GHz,

SAT

at 2.4 GHz,

SAT

Attention:

Observe precautions for

handling electrostatic

sensitive devices.

Surface Mount Package

SOT-363 (SC-70)

Pin Connections and

Package Marking

V

16

d1

GND

INPUT

Note:

Package marking provides orientation

and identification; “x” is date code.

83x

25

34

OUTPUT

and V

GND

GND

Equivalent Circuit

(Simplified)

• +22 dBm P

3.0 V

+23 dBm P

3.6 V

• 22 dB Small Signal Gain at

2.4 GHz

• Wide Frequency Range 0.5

to 6 GHz

• Single 3 V Supply

• 37% Power Added

Efficiency

• Ultra Miniature Package

d2

Applications

• Amplifier for Driver and

Output Applications

ESD Machine Model (Class A)

ESD Human Body Model (Class 0)

Refer to Agilent Application Note A004R:

Electrostatic Discharge Damage and Control.

V

INPUT

OUTPUT

and V

d1

BIAS

BIAS

d2

GROUND

MGA-83563 Absolute Maximum Ratings

Absolute

Symbol Parameter Units Maximum

V Maximum DC Supply Voltage V 4

P

in

T

ch

T

STG

800

700

(mW)

600

500

400

300

200

100

POWER DISSIPATED AS HEAT

Pd = (VOLTAGE) x (CURRENT) – (Pout)

0

10 30 50 70 90 150110

Temperature/ Power Derating Curve.

CW RF Input Power dBm +13

Channel Temperature °C 165

Storage Temperature °C -65 to 150

1 x 10

6

Hrs MTTF

130

CASE TEMPERATURE (°C)

[1]

2

Thermal Resistance

θ

Notes:

1. Operation of this device above any one

of these limits may cause permanent

damage.

= 25°C (TC is defined to be the

2. T

C

temperature at the package pins where

contact is made to the circuit board).

ch to c

= 175°C/W

[2]

:

3.0V

2.2 nH 18 nH20 pF

83

RF

1.2 nH

INPUT

Figure 1. MGA-83563 Final Production Test Circuit.

V

d

L120 pF

83

Tuner

RF

INPUT

Circuit A: L1 = 2.2 nH for 0.1 to 3 GHz

Circuit B: L1 = 0 nH (capacitor as close as possible) for 3 to 6 GHz

Figure 2. MGA-83563 Test Circuit for Characterization.

Tuner

1 pF

50 pF

Bias

Tee

RF

OUTPUT

RF

OUTPUT

3

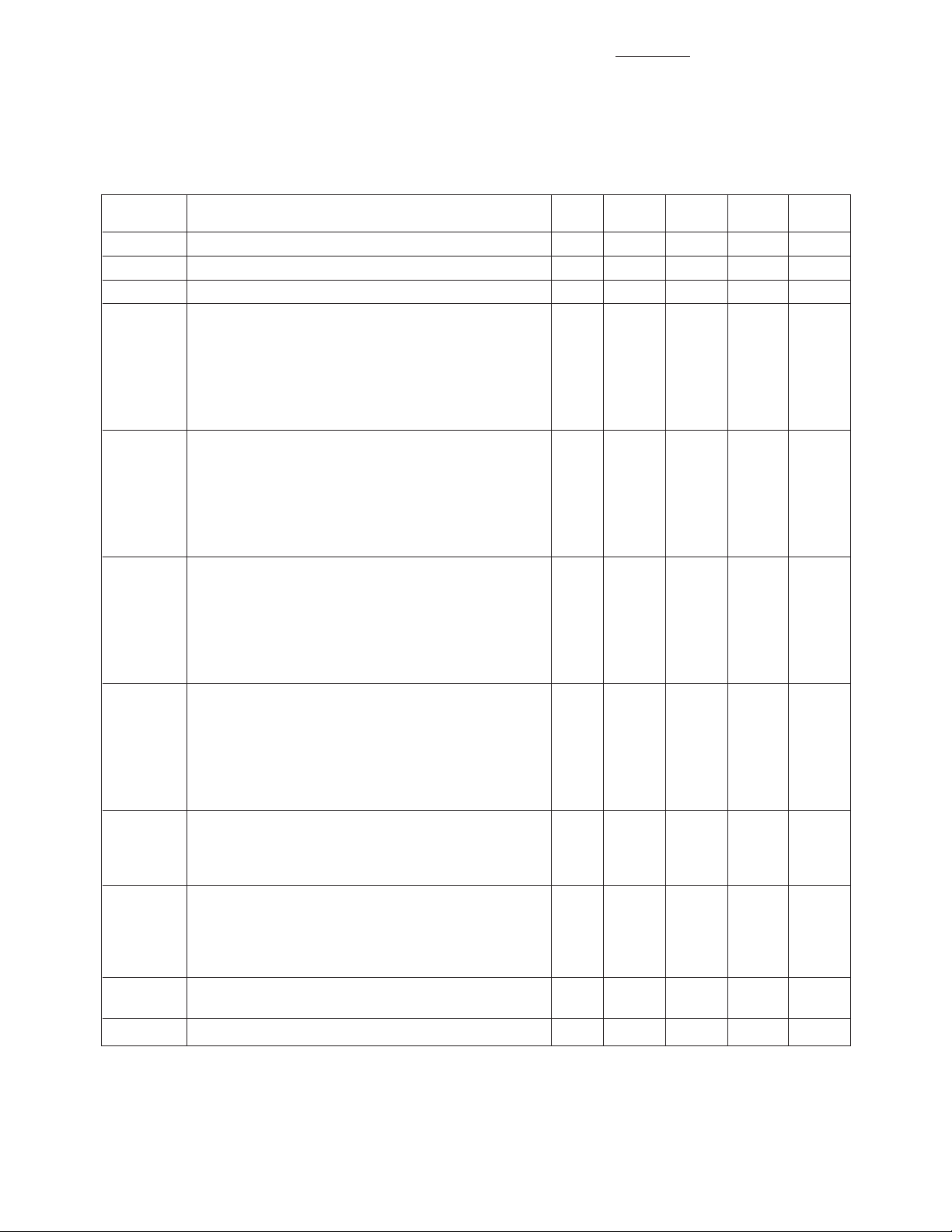

MGA-83563 Electrical Specifications,

Vd = 3 V, TC = 25°C, using test circuit of Figure 2, unless noted.

Std.

Symbol Parameters and Test Conditions Units Min. Typ. Max. Dev.

P

SAT

Saturated Output Power

PAE Power Added Efficiency

I

d

Device Current

[3,5]

[3]

[3]

f = 2.4 GHz dBm 20.5 22.4 0.75

f = 2.4 GHz % 25 37 2.5

mA 152 200 12.4

[4]

Gain Small Signal Gain f = 0.9 GHz dB 20

f = 1.5 GHz 22

f = 2.0 GHz 23

f = 2.4 GHz 22

f = 4.0 GHz 22

f = 5.0 GHz 19

f = 6.0 GHz 17

P

SAT

Saturated Output Power f = 0.9 GHz dBm 20.9

f = 1.5 GHz 21.7

f = 2.0 GHz 21.8

f = 2.4 GHz 22

f = 4.0 GHz 21.9

f = 5.0 GHz 19.7

f = 6.0 GHz 18.2

PAE Power Added Efficiency f = 0.9 GHz % 41

f = 1.5 GHz 41

f = 2.0 GHz 40

f = 2.4 GHz 37

f = 4.0 GHz 32

f = 5.0 GHz 18

f = 6.0 GHz 14

P

1 dB

Output Power at 1 dB Gain Compression

[5]

f = 0.9 GHz dBm 19.1

f = 1.5 GHz 19.7

f = 2.0 GHz 19.7

f = 2.4 GHz 19.2

f = 4.0 GHz 18.1

f = 5.0 GHz 16

f = 6.0 GHz 15

VSWR

Input VSWR into 50 Ω

in

Circuit A f = 0.9 to 1.7 GHz 3.5

= 1.8 to 3.0 GHz 2.6

f

Circuit B f = 3.0 to 6.0 GHz 2.3

VSWR

Output VSWR into 50 Ω

out

Circuit A f = 0.9 to 2.0 GHz 1.4

= 2.0 to 3.0 GHz 2.5

f

Circuit B f = 3.0 to 4.0 GHz 3.5

f = 4.0 to 6.0 GHz 4.5

ISOL Isolation f = 0.9 to 3.0 GHz dB -38

f = 3.0 to 6.0 GHz -30

IP

3

Third Order Intercept Point f = 0.9 GHz to 6.0 GHz dBm 29

Notes:

3. Measured using the final test circuit of Figure 1 with an input power of +4 dBm.

4. Standard Deviation number is based on measurement of at least 500 parts from three non-consecutive wafer lots during

the initial characterization of this product, and is intended to be used as an estimate for distribution of the typical

specification.

5. For linear operation, refer to thermal sections in the Applications section of this data sheet.

4

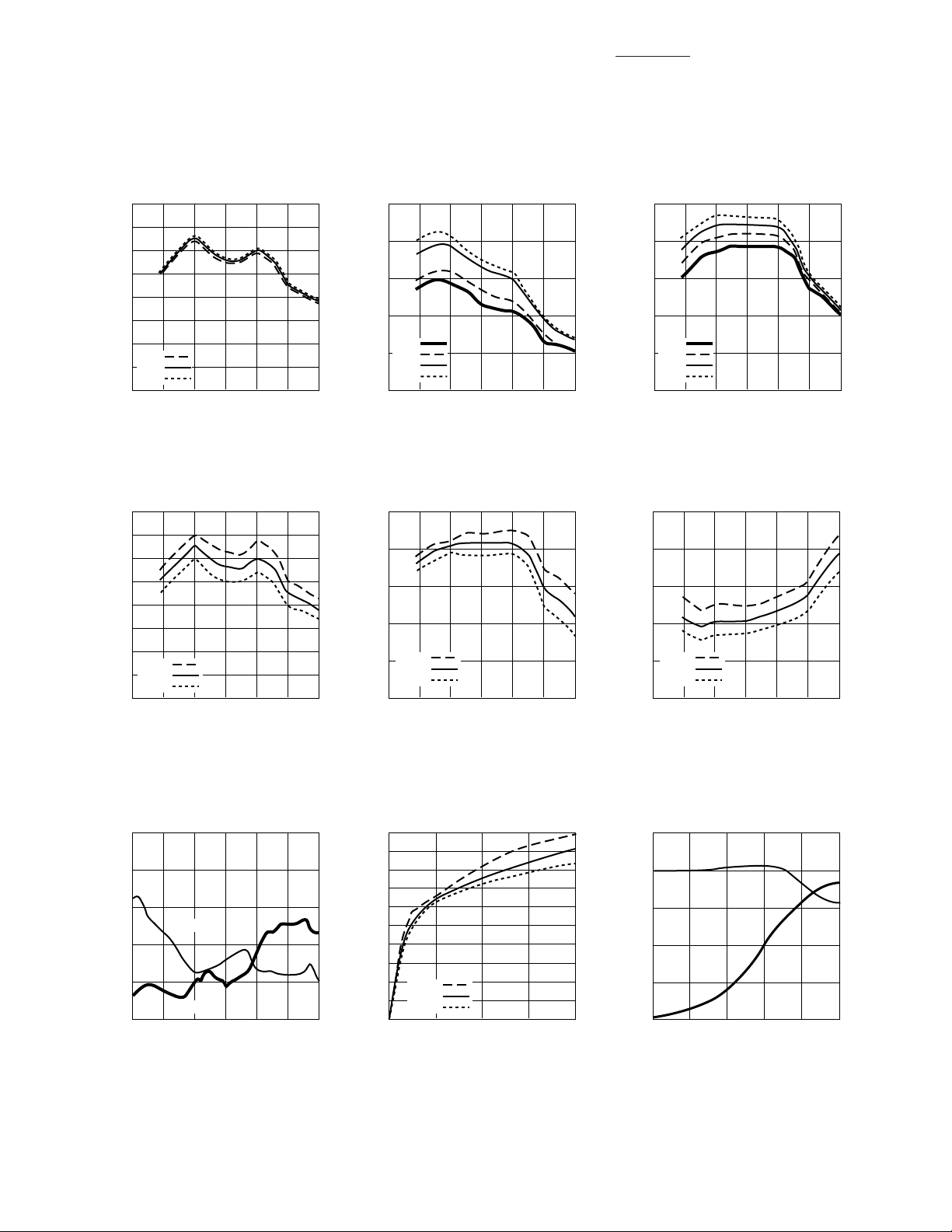

MGA-83563 Typical Performance,

26

24

22

20

(dB)

18

GAIN

16

14

3.3V

12

3.0V

2.7V

10

012 3 4 65

FREQUENCY (GHz)

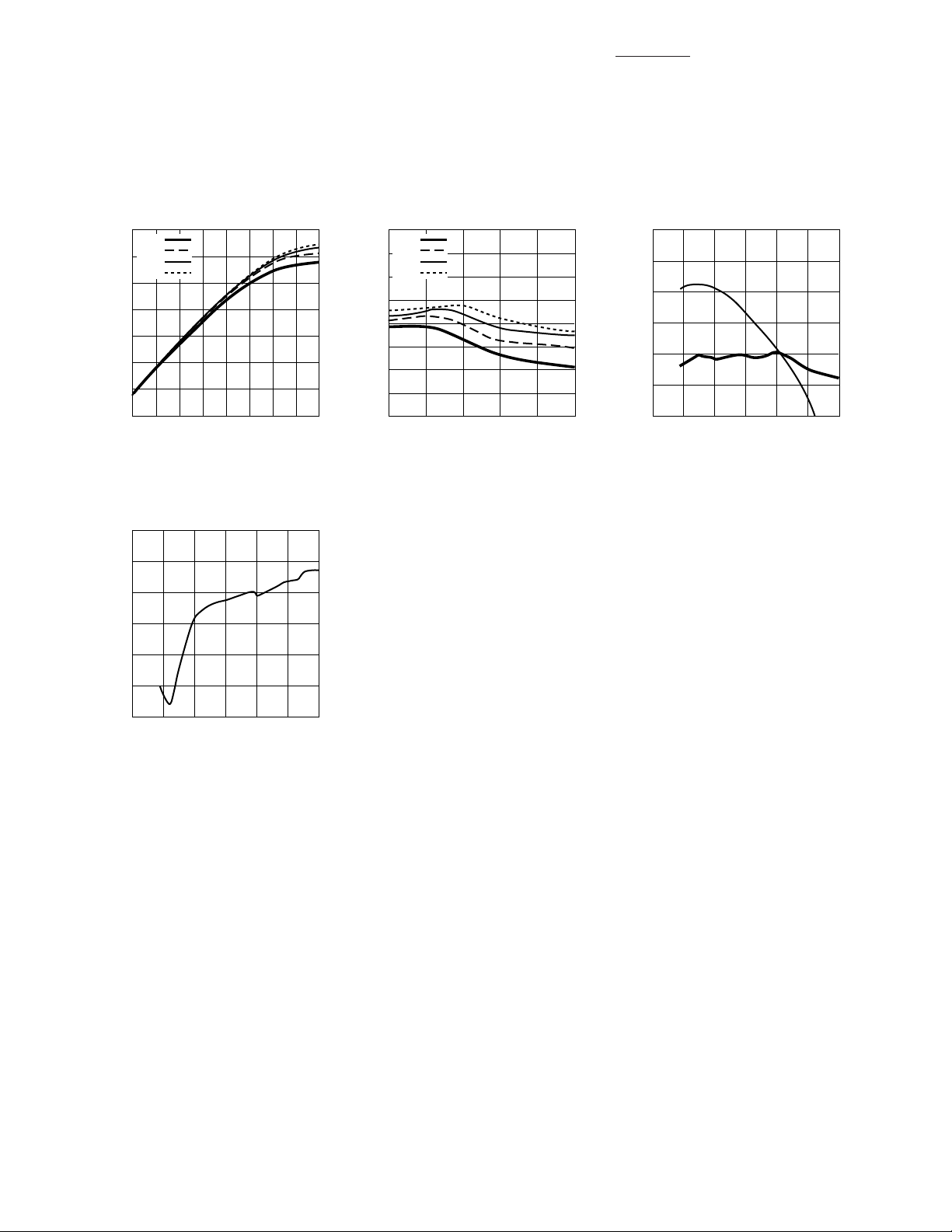

Figure 3. Tuned Gain vs. Frequency

and Voltage.

26

24

22

20

(dB)

18

GAIN

16

14

-40°C

12

+25°C

+85°C

10

012 3 4 65

FREQUENCY (GHz)

Figure 6. Gain vs. Frequency and

Temperature.

24

22

20

(dBm)

1dB

18

P

2.7V

16

3.0V

3.3V

3.6V

14

012 3 4 65

Figure 4. Output Power at 1 dB

Compression vs. Frequency and Voltage.

24

22

(dBm)

20

18

OUTPUT POWER

16

14

012 3 4 65

Figure 7. Saturated Output Power

(+4 dBm in) vs. Frequency and

Temperature.

Vd = 3 V, TC = 25°C, using test circuit of Figure 2, unless noted.

24

22

20

(dBm)

SAT

18

P

2.7V

16

3.0V

3.3V

3.6V

14

012 3 4 65

FREQUENCY (GHz)

-40°C

+25°C

+85°C

FREQUENCY (GHz)

Figure 5. Saturated Output Power

(+4 dBm in) vs. Frequency and Voltage

12

10

(dB)

8

6

NOISE FIGURE

4

2

012 3 4 65

Figure 8. Noise Figure vs. Frequency

and Temperature.

FREQUENCY (GHz)

-40°C

+25°C

+85°C

FREQUENCY (GHz)

.

10

8

6

VSWR

INPUT

4

2

OUTPUT

0

012 3 4 65

FREQUENCY (GHz)

Figure 9. Input and Output VSWR

vs. Frequency.

200

180

160

(mA)

d

140

120

100

80

60

40

DEVICE CURRENT, I

-40°C

+25°C

20

+85°C

0

012 43

FREQUENCY (GHz)

Figure 10. Supply Current vs. Voltage

and Temperature. Pin = -27 dBm.

190

I

d

170

(mA)

d

150

130

110

DEVICE CURRENT, I

90

-14 -10 -6 -2 2 6

INPUT POWER (dBm) @ 2.4 GHz

PAE

50

40

30

20

10

0

Figure 11. Device Current and Power

Added Efficiency vs. Input Power.

Note: Figure 1 test circuit.

PAE (%)

5

MGA-83563 Typical Performance,

continued

Vd = 3 V, TC = 25°C, using test circuit of Figure 2, unless noted.

24

2.7V

3.0V

22

3.3V

3.6V

20

(dBm)

18

16

14

OUTPUT POWER

12

10

-10 -8 -6 -2

INPUT POWER (dBm) @ 2.4 GHz

-4 2064

Figure 12. Output Power vs. Input

Power and Voltage.

Note: Figure 1 test circuit.

-20

-25

-30

(dB)

-35

33

2.7V

3.0V

32

3.3V

(dBm)

3.6V

31

30

29

28

27

26

THIRD ORDER INTERCEPT

25

-14 -10 -6

INPUT POWER (dBm) @ 2.4 GHz

-2 62

Figure 13. Third Order Intercept

vs. Input Power and Voltage.

Note: Figure 1 test circuit.

50

45

40

(dBm)

3

35

30

PAE (%) and IP

25

20

012 3 4 65

FREQUENCY (GHz)

Figure 14. Power Added Efficiency

and Third Order Intercept vs.

Frequency (V

= 3.6 V).

d

-40

ISOLATION

-45

-50

012 3 4 65

FREQUENCY (GHz)

Figure 15. Isolation vs. Frequency.

6

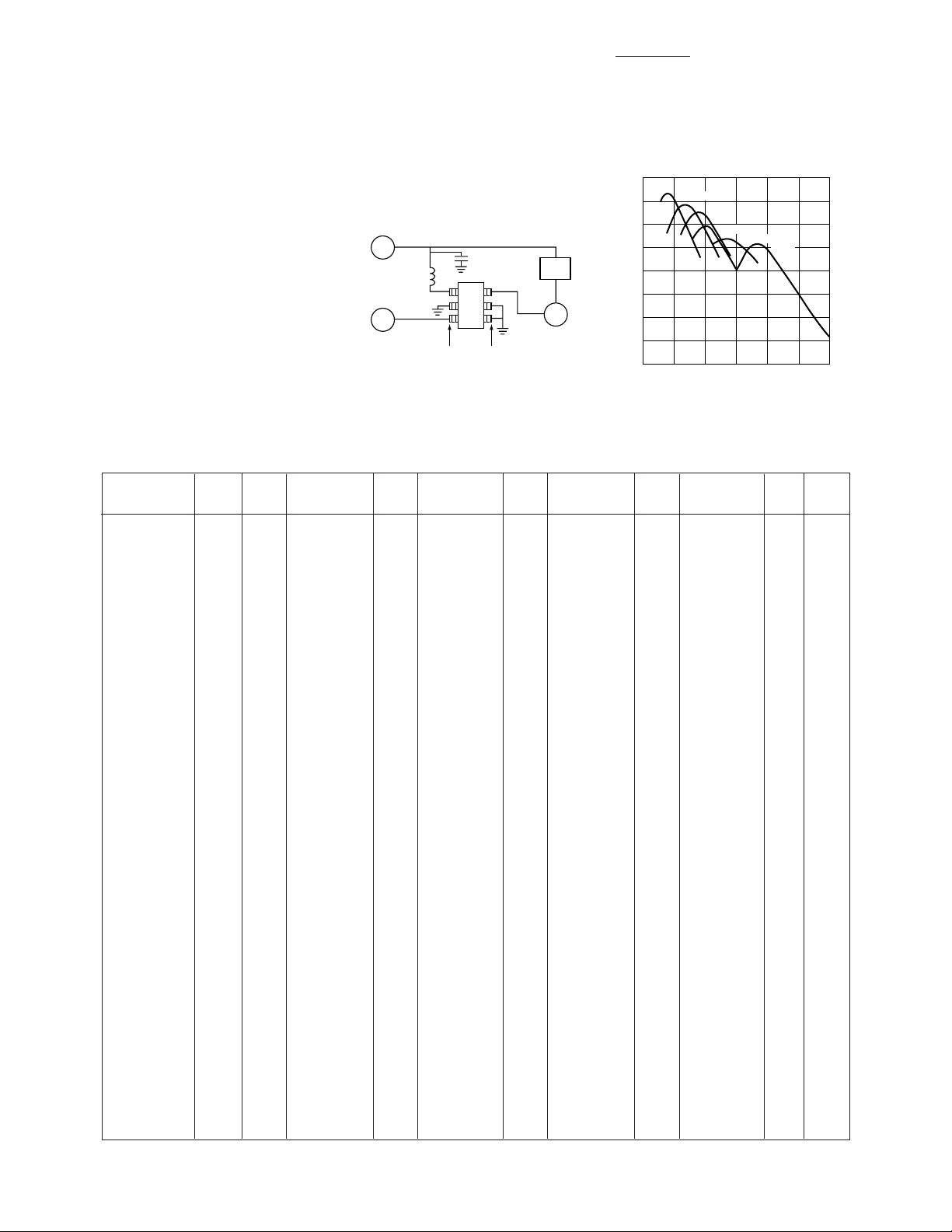

MGA-83563 Test Circuit

Typical s-parameters are shown

below for various inductor values

(L). Those marked “Sim” are

simulated and those marked

“Meas” are measured using an

frequency before designing an

input, output, or power matching

structure.

V

d

L

50 pF

ICM (Intercontinental Microwave) fixture. Figure 17 shows

IN

the available gain for each L

value. The user should first select

the L value for the application

Figure 16. S-parameter Test Circuit.

s-parameter reference plane

Table 1.

MGA-83563 Typical Scattering Parameters

83

[1]

Bias

Tee

OUT

26

18 nH

24

22

20

(dB)

18

GAIN

16

14

12

10

Figure 17. Available Gain (G

Frequency for the MGA-83563 Amplifier

over Various Inductance Values.

8.2 nH

4.7 nH

2.2 nH

1.2 nH

0 nH

012 3 4 65

FREQUENCY (GHz)

max

TC = 25°C, Vd = 3.0 V, Id = 165 mA, CW Operation, Pin = -27 dBm

Freq. RLin S

11

|S21|2 S

21

Gain S

12

RL

out

S

22

Gmax

L GHz dB Mag Ang Gain Mag Ang dB Mag Ang dB Mag Ang K dB

Sim 18.0 nH 0.6 -4.6 0.59 -48 23.9 15.61 43 -46.7 0.005 105 -21.1 0.09 150 4.47 25.8

Sim 18.0 nH 0.8 -9.6 0.33 -57 24.6 16.96 6 -39.0 0.011 102 -16.8 0.15 -130 2.37 25.2

Sim 18.0 nH 1.0 -16.0 0.16 -27 24.1 16.02 -25 -35.5 0.017 87 -10.1 0.31 -146 1.80 24.6

Sim 18.0 nH 1.4 -10.1 0.31 22 21.7 12.22 -68 -32.8 0.023 66 -5.8 0.51 177 1.48 23.5

Sim 18.0 nH 1.8 -7.3 0.43 17 19.1 9.03 -97 -31.7 0.026 54 -4.4 0.61 150 1.45 22.0

Sim 8.2 nH 0.8 -4.1 0.63 -36 21.2 11.52 48 -47.4 0.004 95 -17.2 0.14 121 6.01 23.5

Sim 8.2 nH 1.0 -5.8 0.51 -45 22.7 13.65 22 -41.1 0.009 111 -35.2 0.02 130 3.13 24.0

Sim 8.2 nH 1.4 -13.0 0.22 -45 23.7 15.30 -27 -33.7 0.021 94 -10.4 0.30 -139 1.54 24.3

Sim 8.2 nH 1.8 -13.0 0.22 13 22.4 13.15 -68 -30.9 0.029 74 -5.5 0.53 -179 1.21 24.1

Sim 8.2 nH 2.0 -10.7 0.29 18 21.3 11.65 -84 -30.3 0.031 67 -4.4 0.60 166 1.16 23.7

Sim 8.2 nH 2.4 -8.2 0.39 15 19.1 8.98 -111 -29.5 0.034 57 -3.4 0.68 141 1.14 22.5

Sim 4.7 nH 1.4 -6.7 0.46 -44 22.1 12.72 4 -37.6 0.013 109 -26.7 0.05 -78 2.44 23.1

Sim 4.7 nH 1.8 -12.0 0.25 -43 22.9 13.99 -37 -32.3 0.024 94 -9.9 0.32 -143 1.44 23.7

Sim 4.7 nH 2.0 -14.3 0.19 -23 22.6 13.53 -57 -30.8 0.029 85 -7.1 0.44 -164 1.26 23.7

Sim 4.7 nH 2.4 -11.9 0.26 10 21.1 11.36 -90 -29.2 0.035 70 -4.3 0.61 163 1.09 23.4

Sim 4.7 nH 2.8 -9.4 0.34 12 19.1 9.03 -115 -28.3 0.038 61 -3.2 0.69 138 1.05 22.5

Meas 2.2 nH 1.8 -6.3 0.49 -53 21.5 11.92 -23 -37.2 0.014 90 -15.1 0.18 -100 2.40 22.8

Meas 2.2 nH 2.0 -7.4 0.43 -51 21.9 12.48 -45 -34.8 0.018 85 -9.7 0.33 -130 1.82 23.3

Meas 2.2 nH 2.4 -7.9 0.40 -36 20.9 11.07 -82 -32.4 0.024 68 -6.2 0.49 -175 1.52 22.8

Meas 2.2 nH 2.8 -7.1 0.44 -27 19.0 8.93 -113 -31.2 0.027 56 -4.1 0.63 150 1.40 22.1

Meas 2.2 nH 3.0 -6.6 0.47 -25 18.0 7.90 -123 -31.0 0.028 52 -4.1 0.62 138 1.48 21.1

Sim 1.2 nH 2.4 -7.9 0.40 -41 20.5 10.61 -36 -33.4 0.021 97 -18.0 0.13 -120 1.98 21.3

Sim 1.2 nH 2.8 -10.8 0.29 -37 20.7 10.90 -67 -30.4 0.030 88 -9.6 0.33 -168 1.47 21.6

Sim 1.2 nH 3.0 -11.9 0.25 -29 20.5 10.56 -82 -29.4 0.034 82 -7.4 0.43 176 1.34 21.6

Sim 1.2 nH 3.2 -12.3 0.24 -20 20.0 9.97 -95 -28.6 0.037 76 -5.9 0.51 161 1.24 21.5

Sim 1.2 nH 3.6 -11.7 0.26 -7 18.6 8.49 -120 -27.5 0.042 67 -4.1 0.62 137 1.14 21.0

Meas 0.0 nH 3.0 -5.6 0.53 -33 17.9 7.87 -13 -39.1 0.011 109 -12.8 0.23 -7 4.07 19.6

Meas 0.0 nH 3.4 -4.7 0.58 -31 20.1 10.13 -43 -34.1 0.020 107 -7.9 0.40 -73 1.72 22.7

Meas 0.0 nH 3.8 -5.5 0.53 -50 20.0 9.95 -81 -31.7 0.026 94 -6.2 0.49 -132 1.43 22.6

Meas 0.0 nH 4.0 -7.4 0.43 -52 19.4 9.28 -94 -30.9 0.028 93 -4.5 0.60 -148 1.38 22.1

Meas 0.0 nH 4.2 -8.4 0.38 -48 18.7 8.62 -106 -30.2 0.031 91 -3.5 0.67 -163 1.27 21.9

Meas 0.0 nH 4.6 -9.0 0.36 -44 17.0 7.08 -129 -28.8 0.036 84 -3.1 0.70 173 1.25 20.5

Meas 0.0 nH 5.0 -9.2 0.35 -39 15.4 5.87 -145 -27.9 0.040 78 -3.0 0.71 155 1.29 19.0

Meas 0.0 nH 5.4 -9.7 0.33 -32 13.8 4.88 -159 -27.2 0.044 77 -3.0 0.71 140 1.38 17.3

Meas 0.0 nH 5.8 -7.8 0.41 -29 12.4 4.16 -170 -25.9 0.051 73 -3.6 0.66 127 1.47 15.7

Meas 0.0 nH 6.0 -6.6 0.47 -46 12.1 4.03 177 -24.9 0.057 64 -3.3 0.68 123 1.33 15.9

Note:

1. Reference plane per Figure 43 in Applications Information section.

) vs.

7

RF

Input

RF

Input

RFC

V

d

3

L2

1

6

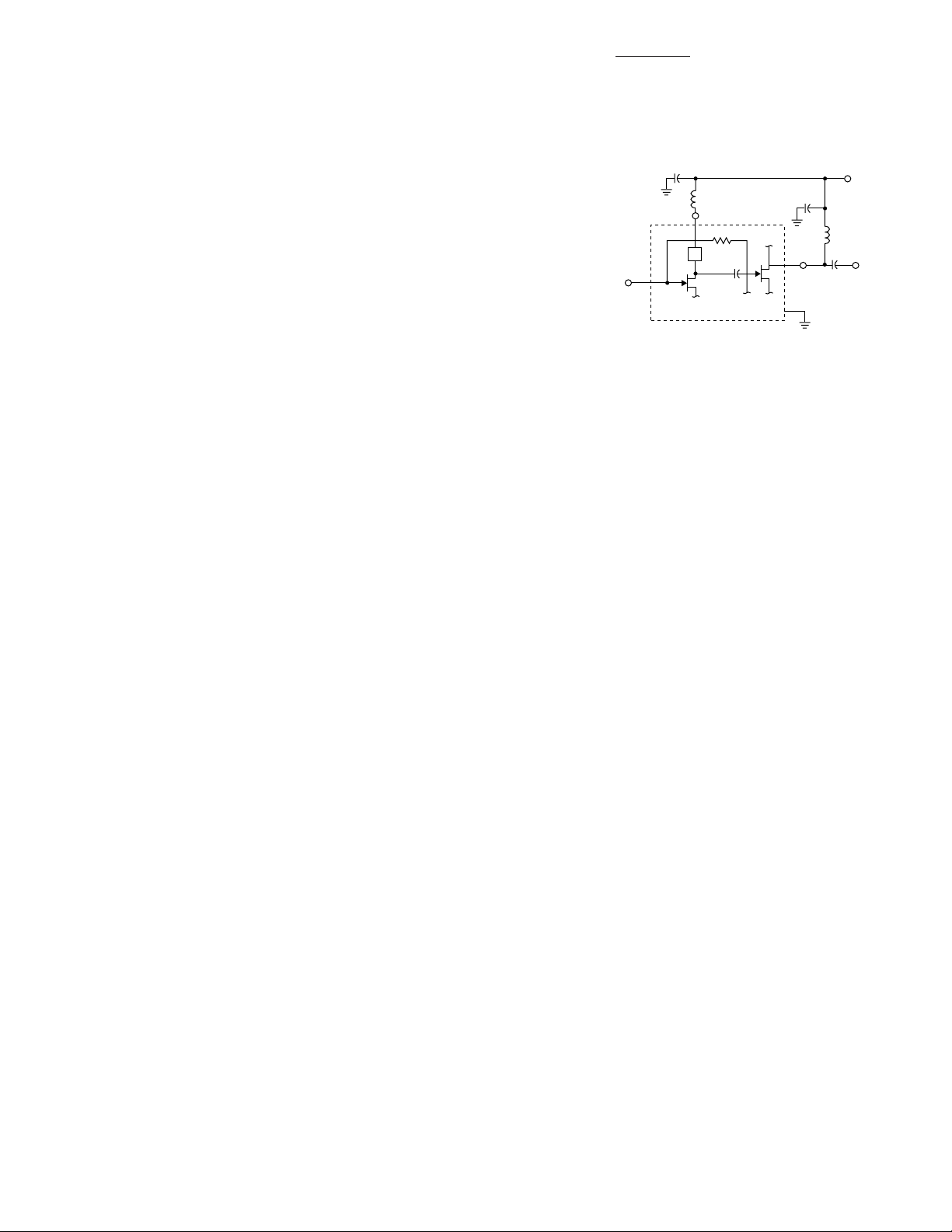

MGA-83563 Applications

Information

The MGA-83563 is two-stage,

medium power GaAs RFIC

amplifier designed to be used for

driver and output stages in

MGA-83563 for linear applications

at reduced power levels is

discussed in the “Thermal Design

for Reliability” and “Use of the

MGA-83563 for Linear Applications” in this applications note.

transmitter applications operating

within the 500 MHz to 6 GHz

frequency range.

This device is designed for

operation in the saturated mode

where it delivers a typical output

power of +22 dBm (158 mW) with

a power-added efficiency of 37%.

The MGA-83563 has a large signal

gain of 18 dB requiring an input

signal level of only +4 dBm to

drive it well into saturation. The

high output power and high

efficiency of the MGA-83563,

combined with +3-volt operation

and subminiature packaging,

make this device especially useful

for battery-powered, personal

communication applications such

as wireless data, cellular phones,

and PCS.

The upper end of the frequency

range of the MGA-83563 extends

Application Guidelines

The use of the MGA-83563 is very

straightforward. The on-chip,

partial RF impedance matching

and integrated bias control circuit

simplify the task of using this

device.

The design steps consist of (1)

selecting an interstage inductor

from the data provided, (2)

adding provision for bringing in

the DC bias, and (3) designing

and optimizing an output impedance match for the particular

frequency band of interest. The

input is already well matched to

50 ohms for most frequencies and

in many cases no additional input

matching will be necessary.

Each of the three design steps for

using the MGA-83563 will now be

discussed in greater detail.

Figure 18. Interstage Inductor L2 and

Bias Current.

The values for inductor L2 are

somewhat dependent on the

specific printed circuit board

material, thickness, and RF layout

that are used. The inductor values

shown in Figure 19 have been

created for the PCB and RF

layout that is used for the circuit

examples presented in this

application note. The methodology that was used to determine

the optimum values for L2 and for

creating Figure 19 is presented in

the Appendix. If the user’s PCB

and/or layout differ significantly

from the example circuits, refer

to the Appendix for a description

of how to determine the values of

L2 for any arbitrary frequency,

PCB material, or RF layout.

to 6 GHz making it a useful

solution for medium power

amplifiers in wireless communications products such as 5.7 GHz

spread spectrum or other ISM/

license-free band applications.

Internal capacitors on the RFIC

chip limit the low-end frequency

response to applications above

approximately 500 MHz.

The thermal limitations of the

subminiature SOT-363 (SC-70)

package generally restrict the use

of the MGA-83563 to applications

that use constant envelope types

of modulation. These types of

systems are able to take full

advantage of the MGA-83563’s

high efficiency, saturated mode of

operation. The use of the

Step 1 — Selecting the

Interstage Inductor

The drain of the first stage FET of

this two-stage RFIC amplifier is

connected to package Pin 1. The

supply voltage Vd is connected to

this drain through an inductor,

L2, as shown in Figure 18. The

supply end of the inductor is

bypassed to ground.

This interstage inductor serves

the purpose of completing the

impedance match between the

first and second stages. The value

of inductor L2 depends on the

particular frequency for which

the MGA-83563 is to be used and

is chosen from the look-up graph

in Figure 19.

Step 2 — Bias Connections

The MGA-83563 is a voltage-

biased device and operates from

a single, positive power supply.

The supply voltage, typically

+3-volts, must be applied to the

drains of both stages of the RFIC

amplifier. The connection to the

first stage drain is made through

the interstage inductor, L2, as

described in the previous step.

The supply voltage is applied to

the second stage drain through

Pin 6, which is also the RF Output

connection. Referring to

Figure 18, an inductor (RFC) is

used to separate the RF output

signal from the DC supply. The

8

)

40

30

20

10

9

8

7

6

5

4

L2 (nH)

3

2

1

0.9

0.8

0.7

0.5 1.0 1.5 2.0 2.5 3.0

FREQUENCY (GHz

Figure 19. Values for Interstage Inductor L2.

supply side of the RFC is capacitively bypassed. A DC blocking

capacitor is used at the output to

isolate the supply voltage from

feedback from the RF output to

the drain of the first stage.

Otherwise, the circuit could

become unstable.

the succeeding stage.

The RF Input (Pin 3) connection

In order to prevent loss of output

power, the value of the RFC is

chosen such that its reactance is

several hundred ohms at the

frequency band of operation. At

higher frequencies, it may be

practical to use a length of high

impedance transmission line

(preferably λ/4) in place of the

RFC.

The value of the DC blocking and

RF bypass capacitors are chosen

to provide a small reactance

(typically < 1Ω) at the lowest

operating frequency.

to the MGA-83563 is at DC ground

potential. The use of a DC

blocking capacitor at the input of

the MGA-83563 is not required

unless a circuit that has a DC

voltage present at its output

precedes the RFIC. Although at

ground potential, the input to the

MGA-83563 should not be used as

a current sink.

Step 3 —

Output Impedance Match

The most interesting aspect of

using the MGA-83563 is arriving

at an optimum, large signal

impedance match at the output. A

Since both stages of the RFIC are

biased from the same voltage

source, particular care should be

taken to ensure that the supply

line between the two is well

bypassed to prevent inadvertent

simple but effective approach is

to begin with a circuit that

provides a small signal impedance match, then empirically

adjust the tuning for optimum

large signal performance.

The starting place is to design a

circuit that matches the small

signal Γml (the reflection coeffi-

cient of the load impedance

required to conjugately match the

output of the MGA-83563) to

50 ohms. The small signal

S-parameter data for designing

the output circuit is taken from

Table 1, using the data corre-

sponding to be nearest value of

interstage inductor that was

chosen in step one.

A RF CAD program such as

Agilent’s Touchstone can be used

to easily calculate Γml. Touch-

stone will interpolate the Table 1

S-parameter data for the particu-

lar design frequency of interest.

As the MGA-83563 is driven into

saturation, the output impedance

will generally become lower.

Choose a circuit topology that

will match Γml as well as the

range of impedances on the low

side of Γml. Beginning with this

small signal output match, tune

the circuit under large signal

conditions for maximum

saturated output power and best

efficiency.

It should be noted that both the

saturated output power (P

sat

) and

power-added efficiency (PAE) for

each MGA-83563 is 100% RF

tested at 2.4 GHz in a production

test fixture that simulates an

actual amplifier application. This

method of testing not only

guarantees minimum

performance standards, but also

ensures repeatable RF

performance in the user’s

production circuits.

9

Step 4 (Optional)—

Input Impedance Match

As previously noted, the internal

input impedance match to the

MGA-83563 is already reasonably

good (return loss is typically

8 dB) and may be adequate for

many applications as is. The

design of the MGA-83563 is such

that the second stage will enter

into compression before the first

stage. The isolation provided by

the first stage therefore results in

a minimal impact on the input

matching as the amplifier

becomes saturated.

If an improved input return loss is

needed, an input circuit is designed to match 50 Ω to Γ

ms

(the

reflection coefficient of the

source impedance for a conjugate

match at the input of the

MGA-83563). The value of Γms is

calculated from the S-parameters

in Table 1 in the same way as was

done for Γml. Since the real part

of the input impedance to the

MMIC is near 50 Ω and the

reactive part is capacitive, the

addition of a simple series

inductor is often all that is needed

if a better input match is required.

PCB Layout

Recommendations

When laying out a printed circuit

board for the MGA-83563, several

points should be taken into

account. The PCB layout will be a

balance of electrical, thermal, and

assembly considerations.

Package Footprint

A recommended printed circuit

board footprint for the miniature

SOT-363 (SC-70) package that is

used by the MGA-83563 is shown

in Figure 20.

This package footprint provides

ample allowance for package

placement by automated assembly equipment without adding

parasitics that could impair the

high frequency performance of

the MGA-83563. (The padprint in

Figure 20 is shown with the

footprint of a SOT-363 package

superimposed on the PCB pads

for reference.)

PCB Materials

FR-4 or G-10 printed circuit board

type of material is a good choice

for most low cost wireless

applications for frequencies

through 3 GHz. Typical singlelayer board thickness is 0.020 to

0.031 inches. Multi-layer boards

generally use a dielectric layer

thickness in the 0.005 to

0.010 inch range.

For higher frequency applications, e.g., 5.8 GHz, circuit boards

made with PTFE/glass dielectric

materials are suggested.

0.026

0.079

0.039

0.018

Dimensions in inches.

Figure 20. Recommended PCB Pad

Layout for Agilent’s SC70 6L/SOT-363

Products.

RF Considerations

Starting with the package padprint

of Figure 20, the nucleus of a PCB

layout is shown in Figure 21. This

layout is a good general purpose

starting point for designs using the

MGA-83563 amplifier.

V

d1

Bypass

RF

Input

83

Figure 21. Basic PCB Layout.

Capacitor

L2

RF

Output

This layout is a microstripline

design (solid groundplane on the

backside of the circuit board)

with a 50 Ω input and output and

provision for inductor L2 with its

bypass capacitor.

Adequate RF grounding is critical

to obtain maximum performance

and to maintain device stability.

All of the ground pins of the RFIC

should be connected to the RF

groundplane on the backside of

the PCB by means of plated

through holes (vias) that are

placed very near the package

terminals. As a minimum, one via

should be located next to each

ground pin to ensure good RF

grounding. It is a good practice to

use multiple vias as in Figure 21

to further minimize ground path

inductance.

While it might be considered an

effective RF practice, it is recommended that the PCB pads for the

ground pins not be connected

together underneath the body of

the package for two reasons. The

first reason is that connecting the

ground pins of multi-stage

amplifiers together can sometimes result in undesirable

feedback between stages. Each

ground pin should have its own

independent path to ground. The

second reason is that PCB traces

hidden under the package cannot

be adequately inspected for

solder quality.

10

Thermal Considerations

The DC power dissipation of the

MGA-83563, which can be on the

order of 0.5 watt, is approaching

the thermal limits of subminiature

packaging such as the SOT-363.

As a result, particular care should

be taken to adequately heatsink

the MGA-83563.

The primary heat path from the

MMIC chip to the system heatsink

is by means of conduction

through the package leads and

ground vias to the groundplane

on the backside of the PCB. As

previously mentioned in the

“PCB Layout” section, the use of

multiple vias near all of the

ground pins is desirable for low

inductance. The use of multiple

vias is also an especially important part of the heatsinking

function.

For heatsinking purposes, a

thinner PCB with more vias,

thicker clad metal, and heavier

plating in the vias all result in

lower thermal resistance and

better heat conduction. Circuit

boards thicker than 0.031 inches

are not recommended for both

thermal and electrical reasons.

The importance of good thermal

design on reliability is discussed

in the next section.

Thermal Design for

Reliability

Good thermal design is an

important consideration in the

reliable use of medium power

devices such as the MGA-83563

because the Mean Time To

Failure (MTTF) of semiconductor

devices is inversely proportional

to the operating temperature.

The following examples show the

thermal prerequisites for using

the MGA-83563 reliably in both

saturated and linear modes.

Saturated Mode Thermal

Example

Less heat is dissipated in the

MGA-83563 when operated in the

saturated mode because a

significant amount of power is

removed from the RFIC as RF

signal power. It is for this reason

that the saturated mode allows

the device to be used reliably at

higher circuit board temperatures

than for full power, linear

applications.

As an illustration of a thermal/

reliability calculation, consider

the case of an MGA-83563 biased

at 3.0 volts for use in a saturated

mode application with a MTTF

reliability goal of 10

(114 years). Reliability calculations will first be presented for

nominal conditions, followed by

the conservative approach of

using worst-case conditions.

The first step is to calculate the

power dissipated by the

MGA-86353 as heat. Power flow

for the MGA-83563 is represented

in Figure 22.

P

DC

P

in

Σ

HEAT

Figure 22. Thermal Representation

of MGA-83563.

Pn = 0

6

hours

P

diss

P

out

From Figure 22,

Pin + PDC = P

where Pin and P

+ P

out

are the RF

out

diss

input and output power, PDC is

the DC input power, and P

diss

is

the power dissipated as heat. For

the saturated mode, P

out

= P

sat

,

and,

P

= Pin + PDC – P

diss

sat

From the table of Electrical

Specifications, the device current

(typical) is 152 mA with a power

supply voltage of 3 volts. Referring to Figure 10, it can be seen

that the current will decrease

approximately 8% at elevated

temperatures. The device DC

power consumption is then:

PDC = 3.0 volts * 152 mA * 0.92

PDC = 420 mW

For a saturated amplifier, the RF

input power level is +4 dBm

(2.51 mW) and the saturated

output power is +22 dBm

(158 mW).

The power dissipated as heat is

then:

P

= 2.51 + 420 – 158 mW

diss

P

= 264 mW

diss

The channel-to-case thermal

resistance (θ

) from the table

ch-c

of Absolute Maximum Ratings is

175°C/watt. Note that the meaning of “case” for packages such as

the SOT-363 is defined as the

interface between the package

pins and the mounting surface,

i.e., at the PCB pads. The temperature rise from the mounting

surface to the MMIC channel is

then calculated as

0.264 watt * 175°C/watt, or 46°C.

[1]

Operating life tests

for the

MGA-83563 have established that

a MTTF of 10

6

hours will be met

for channel temperatures ≤ 150°C.

To achieve the 106 hour MTTF

goal, the circuit to which the

device is mounted (i.e., the case

temperature) should therefore

not exceed 150° – 46°C, or 104°C.

Repeating the reliability calculation using the worst case maximum device current of 200 mA,

the DC power dissipation is

552 mW. Summing the RF input

and output powers, P

diss

is

397 mW which results in a

channel-to-case temperature rise

of 69°C. The maximum case

temperature for the MTTF goal of

106 hours is then 150°– 69°C, or

81°C.

For other MTTF goals, power

dissipation, or operating temperatures, Agilent publishes reliability

data sheets based on operating

life tests to enable designers to

arrive at a thermal design for

their particular operating environment. For a reliability data sheet

covering the MGA-83563, request

Agilent publication number 59644128E, titled “GaAs MMIC Amplifier Reliability Data.” This reliability data sheet covers the Agilent

family of PHEMT GaAs RFICs.

Linear Amplifier Thermal

Example

If the MGA-83563 is used in a

linear application, the total power

dissipation is significantly higher

than for the saturated mode. The

dissipated power is greater due to

higher device current (not as

efficient as the saturated mode)

and also because no signal power

is being removed.

The maximum power dissipation

for reliable linear operation is

calculated in the same manner as

was done for the saturated

amplifier example. For linear

circuits, the RF input and output

power are negligible and assumed

to be zero. All of the DC power is

thus dissipated as heat. For

purposes of comparison to the

saturated mode example, this

calculation will use the same

MTTF goal of 106 hours and

supply voltage of 3 volts.

Calculations are again made for

both nominal and worst case

conditions.

From the data of Figure 10, the

typical 3-volt, small signal device

current for the MGA-83563 at

elevated temperatures is 156 mA.

The total device power dissipation, P

, is then 3.0 volts

diss

*

156 mA, or 468 mW. The temperature increment from the RFIC

channel to case is 0.468 watt

*

175°C/watt, or 82°C.

Commensurate with the MTTF

goal of 106 hours, the circuit to

which the device is mounted

should therefore not exceed

150°– 82°C, or 68°C.

For the worst case calculation, a

guard band of 40% is added to the

typical current to arrive at a

maximum DC current of 218 mA.

The P

is 655 mW and the

diss

channel-to-case temperature rise

is 115°C. The maximum case

temperature for worst case

current condition is 35°C.

A case temperature of 68°C for

nominal operation, or 35°C in the

worst case, is unacceptably low

for most applications. In order to

use the MGA-83562 reliably for

linear applications, the P

diss

must

be lowered by reducing the

supply voltage.

11

The implication on RF output

power performance for amplifiers

operating with a reduced Vd is

covered later in this application

note in the section subtitled “Use

of the MGA-83563 for Linear

Applications”.

Design Example for

2.5 GHz

The design of a 2.5 GHz amplifier

will be used to illustrate the

approach for using the

MGA-83563. The basic design

procedure outlined earlier will be

used, in which the interstage

inductor (L2) is chosen first,

followed by the design of an

initial small signal, output match.

The output match will then be

empirically optimized for large

signal conditions after which an

input match will be added.

The printed circuit layout in

Figure 21 is used as the starting

place. The circuit is designed for

fabrication on 0.031-inch thick

FR-4 dielectric material.

Interstage Inductor L2

The first step is to choose a value

for the interstage inductor, L2.

Referring to Figure 19, a value of

1.5 nH corresponds to the design

frequency of 2.5 GHz. A chip

inductor is chosen for L2 in this

example. However, for small

inductance values such as this,

the interstage inductor could also

be realized with a length of high

impedance transmission line.

The interstage inductor is bypassed with a 62 pF capacitor,

which has a reactance of 1 Ω at

2.5 GHz. Connecting the supply

voltage to the bypassed side of

the inductor completes the

interstage part of the amplifier.

12

Output Match

The design of the small signal

output matching circuit begins

with the calculation of the small

signal match impedance, Γml. The

set of S-parameters in Table 1 for

an inductor value of 1.2 nH is

used since this is the closest

value to the 1.5 nH that was

chosen for L2 in the first design

step.

Agilent’s Touchstone program

was used to interpolate the sparameter data and calculate a

Γml of 0.14 ∠172° for 2.5 GHz.

This Γml point is plotted on the

Smith chart in Figure 23 as

Point C, along with an indication

of the area of lower impedance

from this point. (The output

impedance is expected to

decrease under large signal

conditions.) A two-element

matching network consisting of a

shunt capacitor and series

transmission line is chosen to

match the output to 50 ohms.

1

0.5

MLIN

C

B

A

B

-1

C (Γml)

0.2

LARGE SIGNAL

-0.2

Figure 23. Initial Output Match for

Small Signal.

-0.5

RF

Output

The shunt-C, series-line topology

is chosen based on its ability to

cover the expected range of

impedance to be matched and

because it will pass DC bias into

the output pin of the MGA-83563.

A

(50 Ω)

C

21

2

-2

(For the latter reason, impedance

matching circuits using series

capacitors are avoided.)

In some cases, it may be more

practical to implement the series

transmission line element with a

chip inductor. If the series line is

excessively long, the cost of an

additional chip component can be

traded off against circuit board

space. The substitution of an

open-circuit line for the shunt C

may also be possible, thus

eliminating the a capacitor.

Referring to the Smith chart in

Figure 23, the initial output match

for Γml was determined to be a

0.4 pF shunt capacitor followed

by a 0.32-inch length of 50 Ω

microstripline.

DC Bias

A 22 nH RFC is added to the 50 Ω

side of the output matching

circuit to apply bias voltage to the

drain of the second stage. The

RFC is bypassed with a 62 pF

capacitor. A series DC blocking

capacitor, also 62 pF, is added to

the RF output to complete the

bias circuit.

Optimizing the Output

Match

To reach the final output

matching circuit for maximum

saturated output power, an input

power of +4 dBm is applied to

saturate the amplifier circuit. The

output matching circuit is then

experimentally optimized by

adjusting the value of the shunt

capacitor and the distance the

capacitor is located along the

output line from the MGA-83563.

During the tuning process, the

saturated output power of the

amplifier is monitored with a

power meter connected to the

amplifier’s output. An ammeter is

used to observe total device DC

current drain (Id) as an indication

of amplifier efficiency. The

desired output match is then

achieved at the tuning point of

maximum P

and minimum Id.

sat

The optimum output match for

2.5 GHz was achieved with a

shunt capacitor value of 0.9 pF

located 0.08 inches along the 50 Ω

line from the output pin of the

MGA-83563. The final output

circuit is shown in Figure 24.

RF

Input

MGA83563

Figure 24. Final RF Output Match for

the 2.5 GHz Amplifier Tuned for

Maximum P

sat

50 Ω

0.08 in.

.

Output

0.9 pF

RF

When tuned for maximum

saturated output power, the small

signal output return loss for the

amplifier was measured as 5.5 dB

at 2.5 GHz.

Input Match

The input return loss without any

external matching was measured

as 7.6 dB (2.4:1 VWSR). For many

applications no further matching

is necessary. If, however, an

improved input match is required,

a simple series inductor is all that

will be needed.

Agilent’s Touchstone CAD program is again used to extrapolate

the 2.5 GHz S-parameters in Table

1 and calculate a small signal Γ

of 0.37 ∠47°. The conjugate of

Γms, 0.37 ∠-47°, is plotted on the

Smith chart as Point A in

Figure 25.

ms

13

1

0.5

C (50 Ω)

0.2

-0.2

Figure 25. Initial Small Signal Input

Match.

0.2

-0.5

RF

Input

0.5

B

L1

MLIN

1

C

B

-1

A (Γ

2

A

2

*)

ms

-2

The addition of a 0.15 inch length

(actual length on FR-4) of 50 Ω

transmission line rotates Point A

around to Point B on the R = 1

circle of the Smith chart. A series

2.5 nH inductor (L1) is then all

that is required to complete the

match to 50 Ω at Point C.

While the input impedance of the

MGA-83563 is somewhat isolated

from the nonlinear effects of the

saturated output stage, some

empirical optimization of the

input inductor may increase the

input return loss still further. The

input is easily fine-tuned under

large signal conditions by observing the input return loss while an

input power of +4 dBm is applied

to the amplifier. The input

inductor is then “swept” by

placing various values of chip

inductors across the gap provided

in the 50 Ω line at the input of the

MGA-83563. For this example

amplifier, increasing the inductor

from the initial small signal value

of 2.5 nH to 2.7 nH was found to

provide the best input match. The

final input circuit tuned as for

large signal conditions is shown

in Figure 26.

RF

2.7 nH

Input

50 Ω

0.17 in.

Figure 26. Final Large Signal RF Input

Match for the 2.5 GHz Amplifier.

MGA83563

RF

Output

The addition of the 2.7 nH series

inductor increased the large

signal input return loss from

7.6 dB (with no matching) to

14.8 dB (1.4:1 VSWR) at 2.5 GHz.

Completed 2.5 GHz

Amplifier

A schematic diagram of the final

2.5 GHz circuit is shown in

Figure 27. All unmarked capacitors are 62 pF.

V

RF

Output

RFC

Output

d

L1 = 2.7 nH

50 Ω

RF

0.17 in

Input

Figure 27. Schematic Diagram of

2.5 GHz Amplifier.

3

L2 = 1.5 nH

1

83

RFC =

6

50 Ω

0.08 in

22 nH

C2 = 0.9 pF

The completed 2.5 GHz amplifier

assembly with all components is

shown in Figure 28.

+3V

L2

C

C

Input

Figure 28. Completed 2.5 GHz

Amplifier Assembly.

L1

83

CC2

The small signal gain of the

completed amplifier was measured as 22.0 dB at 2.5 GHz. Gain

over a frequency range of 2.0 to

3.0 GHz is shown in Figure 29.

28

26

24

22

(dB)

20

GAIN

18

16

14

2 2.2 2.4 2.6 32.8

FREQUENCY (GHz)

Figure 29. Small Signal Gain of the

Completed 2.5 GHz Amplifier.

The (small signal) input and

output return losses for the

completed amplifier are 14.9 dB

and 5.5 dB respectively at

2.5 GHz. Input and output return

loss over the 2.0 to 3.0 GHz

frequency range is shown in

Figure 30.

0

-5

(dB)

-10

-15

RETURN LOSS

-20

-25

2 2.2 2.4 2.6 32.8

Figure 30. Input and Output

Return Loss of the Completed

2.5 GHz Amplifier.

OUTPUT

INPUT

FREQUENCY (GHz)

Table 2 summarizes measured

results for this particular amplifier at 2.5 GHz.

Output

Mode Gain Power I

(dB) (dBm) (mA)

Small Signal 22.0 — 148

G

-1dB

21.0 19.2 165

Saturated 17.8 21.8 139

Table 2. Performance Summary for

2.5 GHz Amplifier.

d

14

The power-added efficiency

(PAE) in the saturated mode is

36% as calculated from:

P

PAE =

PAE =

Σ

P

(P

P

RF

DC

out – Pin

DC

)

Note the current increases

slightly from small signal conditions to the 1 dB compression

point, then falls appreciably as

the amplifier goes into saturation.

(The 1-dB compressed output

power will be higher for amplifiers that are tuned for linear

performance.)

P

and PAE Sensitivity to

sat

Inductor L2

The output match of the completed 2.5 GHz amplifier was held

fixed while various values of L2

were substituted for the purposes

of (1) verifying the optimum

value for L2, and (2) determining

the sensitivity of P

the value of L2. These results are

plotted in Figure 31.

and PAE to

sat

The length of the series line

between the output of the

MGA-83563 and C2 is also part of

the matching circuit. This line was

not considered as a variable in the

sensitivity analysis since photofabrication of micro-striplines on

circuit boards is highly repeatable.

The most important observation

of this data is that the PAE

remains high for values of C2 that

are toward the left of the maximum P

point (lower values of

sat

C2), while the PAE begins to drop

off toward for higher values of

C2. This data points out the

importance of choosing a value

P

and PAE for each value of C2

sat

are plotted in Figure 32.

Inspection of Figure 32 reveals

that a variation in C2 of ±10% is

acceptable for most applications.

25

20

15

(dBm)

sat

P

10

5

0

0 0.5 1 1.5 42 2.5 3 3.5

for C2 that is toward the lower

side of the maximum P

(lower C2) in order to maintain

high efficiency with production

tolerance components.

P

sat

PAE

L2 (nH)

sat

point

40%

35%

30%

25%

PAE (%)

20%

15%

10%

The data in Figure 31 indicates

there is some tradeoff between

tuning for maximum output

power and maximum efficiency.

The original choice of 1.5 nH for

the interstage inductor L2 appears well optimized.

The results of this tuning process

supplied the 2.5 GHz data point

referred to in the Appendix that

was used to create Plot B of

Figure 47.

Output Match Sensitivity

The sensitivity of P

the value of the shunt capacitor in

the output matching circuit was

investigated by varying the value

of C2 while noting P

current. The input power was

fixed at +4 dBm for this test.

and PAE to

sat

and device

sat

Figure 31. 2.5 GHz P

23

22.5

22

21.5

21

(dBm)

sat

P

20.5

20

19.5

19

18.5

18

0 0.5 1 1.5 2

Figure 32. 2.5 GHz P

and PAE vs. L2.

sat

P

sat

C2 (pF)

and PAE vs. C2.

sat

PAE

50%

45%

40%

35%

30%

25%

20%

15%

10%

(%)

PAE

15

Amplifier Designs for

1.9 GHz and 900 MHz

The same design process used for

the 2.5 GHz amplifier above was

repeated for the design of amplifiers for the 1.9 GHz and 900 MHz

frequency bands. Example

circuits were built using the same

PCB layout as used for the

2.5 GHz amplifier. The schematic

diagram, component values, and

assembly drawing for the 1.9 GHz

and 900 MHz designs are shown

in the “Summary of Example

Amplifiers“ section.

1.9 GHz Amplifier Measured

Results

Performance of this amplifier is

summarized in Table 3. The PAE

is 41%.

Output

Mode Gain Power I

(dB) (dBm) (mA)

Small Signal 23.8 — 155

G

-1dB

22.8 19.6 182

Saturated 17.5 21.5 114

Table 3. Performance Summary for

1.9 GHz Amplifier.

Small signal gain over the 1.5 to

2.3 GHz frequency range is shown

in Figure 33.

26

d

The small signal input and output

return loss over the 1.5 to 2.3 GHz

frequency range is shown in

Figure 34.

0

-4

(dB)

-8

-12

RETURN LOSS

-16

-20

1.5 1.7 1.9 2.1 2.3

Figure 34. Input and Output

Return Loss of the 1.9 GHz

Amplifier.

OUTPUT

INPUT

FREQUENCY (GHz)

900 MHz Amplifier Measured

Results

Measured results for this 900 MHz

amplifier is shown in Table 4. The

PAE is 40%.

Output

Mode Gain Power I

d

(dB) (dBm) (mA)

Small Signal 24.5 — 168

G

-1dB

23.5 20.9 177

Saturated 18.5 22.5 144

Table 4. Performance Summary for

900 MHz Amplifier.

Gain over the 500 to 1300 MHz

frequency range is shown in

Figure 35.

26

24

22

(dB)

20

GAIN

18

16

14

0.5 0.7 0.9 1.1 1.3

FREQUENCY (GHz)

Figure 35. Small Signal Gain of the

900 MHz Amplifier.

Input and output return loss

(small signal) from 500 to

1300 MHz is shown in Figure 36.

0

OUTPUT

-5

(dB)

-10

RETURN LOSS

-15

-20

0.5 0.7 0.9 1.1 1.3

Figure 36. Input and Output

Return Loss of the 900 MHz

Amplifier.

INPUT

FREQUENCY (GHz)

24

22

(dB)

20

GAIN

18

16

14

1.5 1.7 1.9 2.1 2.3

FREQUENCY (GHz)

Figure 33. Small Signal Gain of the

Completed 1.9 GHz Amplifier.

P

and PAE Sensitivity to

sat

Inductor L2 for the 900 MHz

Amplifier

As was done for the 2.5 GHz

amplifier example, values for L2

were “swept” for verification and

to observe sensitivity of P

sat

and

PAE. The results are plotted in

Figure 37. This process verified

the correct value of L2 and

Summary of Example

Amplifiers

A schematic diagram for the three

example amplifiers covering

2.5 GHz, 1.9 GHz, and 900 MHz is

shown in Figure 38.

Component values for the three

designs are summarized in

Table 5.

provided the 900 MHz data point

used in the Appendix to create

Plot B of Figure 47.

23.0

22.8

22.6

22.4

22.2

(dBm)

22.0

sat

P

21.8

21.6

21.4

21.2

21.0

0 5 10 15 454020 25 30 35

P

L2 (nH)

sat

PAE

55%

50%

45%

40%

35%

30%

16

(nH, pF)

900 MHz 1.9 GHz 2.5 GHz

L1 5.6 2.2 2.7

L2 12 2.7 1.5

L3 82 33 22

L4 Not used (short circuit)

C2 3.6 1.2 0.9

C1, C3, C4 150 82 62

C5 1000

Table 5. Component Values for

Example Amplifiers.

Frequency

The completed amplifier with all

components and SMA connectors

is shown in Figure 39. The circuit

is fabricated on 0.031-inch FR-4

material.

The additional 1000 pF bypass

capacitor, C5, was added to the

(%)

bias line near the Vd connection

PAE

to eliminate interstage feedback.

This layout has provision for an

inductor (L4) at the output of the

MGA-83563. This inductor is not

used in for these example amplifiers and is replaced by a short.

Figure 37. 900 MHz P

L1

RF

Input

Figure 38. Schematic Diagram for the Example Amplifiers.

0.17 in

sat

50 Ω

and PAE vs. L2.

C1

L2

3

46

83

1

50 Ω

L4

0.08 in

C4

C2

L3

(RFC)

C3

C5

V

d

RF

Output

17

+V

d

C5

L3

C2

L2

C4

C3

OUT

IN

L1

83

L4

MGA-83-A

Figure 39. Completed MGA-83563 Amplifier Assembly.

Use of the MGA-83563 for

Linear Applications

Due to the thermal limitations

covered in the “Thermal Design

for Reliability” section, the MGA83563 is best suited for use as a

saturated mode amplifier. The

MGA-83563 can however be used

with reduced output power

performance by lowering the

supply voltage.

Some saturated amplifier applications may also benefit from

operation at reduced Vd for the

purpose of reducing current drain

and extending battery life.

P

and P

1dB

2.5 GHz and 900 MHz circuit

examples are shown in Figures 40

and 41, respectively. The methods

presented in the “Thermal Design

for Reliability” section may be

used to arrive at a maximum

supply voltage that corresponds

to the desired MTTF goal.

vs. Vd for the

sat

The P

40 and 41 is taken from the

example amplifiers tuned for

maximum P

higher with linear tuning. When

designing for linear applications,

the value for the interstage

inductor L2 is taken from Plot A

of Figure 47 in the Appendix.

The data in Tables 2–4 shows

that some increase in device

current occurs as the output

power approaches P

ance should be made in the

thermal analysis for the increased

P

diss

or near P

(dBm)

OUTPUT POWER

Figure 40. Output Power vs. Supply Voltage for the 2.5 GHz Amplifier.

power plotted in Figures

1dB

if the circuit is to be used at

1dB

25.00

23.00

21.00

19.00

17.00

15.00

13.00

11.00

9.00

7.00

5.00

1.00 1.25 1.50 1.75 3.00

sat

.

. P

1dB

P

P

will be

. Allow-

1dB

sat

1dB

SUPPLY VOLTAGE, Vd (V)

Operation at Higher

Supply Voltages

While the MGA-83563 is designed

primarily for use in +3 volt

applications, the output power

can be increased by using a

higher supply voltage. Referring

to Figure 5, the P

can be

sat

increased by up to 1 dB by using a

power supply voltage of

+3.6 volts.

Note: If bias voltages greater than

3 volts are used, appropriate

caution should be given to both

the thermal limits and the Absolute Maximum Ratings.

Hints and

Troubleshooting

Oscillation

Unconditional stability of the

MGA-83563 is dependent on

having good grounding. Inadequate device grounding or poor

PCB layout techniques could

cause the device to be potentially

unstable. In a multistage RFIC

such as the MGA-83563, feedback

through bias lines supplying

voltage to both stages can lead to

oscillation. It is important to well

bypass the connections to bias

supply to ensure stable operation.

3.30 3.502.00 2.25 2.50 2.70

18

68%

95%

99%

Parameter Value

Mean (µ)

(typical)

-3σ -2σ -1σ +1σ +2σ +3σ

26.00

24.00

22.00

(dBm)

20.00

18.00

16.00

OUTPUT POWER

14.00

12.00

1.5 3.0 3.52.0 2.5

Figure 41. Output Power vs. Supply Voltage for the 900 MHz Amplifier.

Statistical Parameters

Several categories of parameters

appear within this data sheet.

Parameters may be described

with values that are either

“minimum or maximum,” “typical,” or “standard deviations.”

P

sat

P

1dB

SUPPLY VOLTAGE, Vd (V)

Values for most of the parameters

in the table of Electrical Specifications that are described by

typical data are the mathematical

mean (µ), of the normal distribution taken from the characterization data. For parameters where

measurements or mathematical

The values for parameters are

based on comprehensive product

characterization data, in which

automated measurements are

made on of a minimum of 500

parts taken from three nonconsecutive process lots of

semiconductor wafers. The data

derived from product character-

averaging may not be practical,

such as S-parameters or Noise

Parameters and the performance

curves, the data represents a

nominal part taken from the

center of the characterization

distribution. Typical values are

intended to be used as a basis for

electrical design.

ization tends to be normally

distributed, e.g., fits the standard

bell curve.

To assist designers in optimizing

not only the immediate amplifier

circuit using the MGA-83563, but

Parameters considered to be the

most important to system performance are bounded by minimum

or maximum values. For the

MGA-83563, these parameters

are: Saturated Output Power

(P

), Power Added Efficiency

sat

(PAE), and Device Current (Id).

Each of the guaranteed parameters is 100% tested as part of the

manufacturing process.

to also evaluate and optimize

trade-offs that affect a complete

wireless system, the standard

deviation (σ) is provided for

many of the Electrical Specifica-

tions parameters (at 25°C) in

addition to the mean. The stan-

dard deviation is a measure of the

variability about the mean. It will

be recalled that a normal distribu-

tion is completely described by

the mean and standard deviation.

Standard statistics tables or

calculations provide the probability of a parameter falling between

any two values, usually symmetrically located about the mean.

Referring to Figure 42 for example, the probability of a

parameter being between ±1σ is

68.3%; between ±2σ is 95.4%; and

between ±3σ is 99.7%.

Figure 42. Normal Distribution.

Phase Reference Planes

The positions of the reference

planes used to specify S-parameters and Noise Parameters for

the MGA-83563 are shown in

Figure 43. As seen in the illustration, the reference planes are

located at the point where the

package leads contact the test

circuit.

REFERENCE

PLANES

TEST CIRCUIT

Figure 43. Phase Reference Planes.

19

Appendix —

Determination of

Interstage Inductor

Value.

A methodology is presented here

for determining the value of the

interstage inductor, L2 that

produces optimum large signal

performance at any frequency.

This is the method used to create

the plot of Optimum L2 vs.

Frequency in Figure 19. This

procedure is included as a

reference for PCB designs that

may differ considerably from the

example circuit of Figure 40.

While the method described here

covers a wide range of frequencies for generic applications, the

same approach can be used for a

single frequency of interest.

Although the printed circuit

board layout of Figure 40 is used

here for demonstration purposes,

the same procedure is equally

applicable to the any other circuit

board material, thickness, or

topology.

This is a 2-step process in which

the value for L2 for best small

signal performance is first

ascertained followed by an

empirical adjustment of L2 to

allow for large signal effects.

The first step in this process is to

assemble a test circuit for the

MGA-83563 with 50-ohm input

and output lines. This test circuit

should use the same printed

circuit board material, thickness,

and ground via arrangement for

the MGA-83563 that will be used

to the final amplifier circuit. The

connection to Pin 1 should have

provision for a chip inductor that

is bypassed to ground. The

bypassed side of the inductor is

connected to the supply voltage.

The supply voltage is also con-

nected to the RF Output/V

d2

(Pin 6) by means of an external,

wideband bias tee. The test

circuit is shown in Figure 44.

BIAS

TEE

+V

OUT

Test Circuit

L2

IN

Figure 44. L2 Test Circuit.

MGA83563

50 Ω50 Ω

Next, the wideband gain response

of the test circuit is observed

while substituting various values

of chip inductors for L2. For each

value of L2, the gain should be

plotted and/or the frequency at

which the maximum gain occurs

recorded. Note that the small

signal input and output match

provided by the internal matching

of the MGA-83563 is sufficiently

close to 50 ohms for most combi-

nations of L2 and frequencies that

further matching would not

significantly skew the data. This

is a small signal test and the input

power level should be less than

-15 dBm.

25

20

15

(dB)

10

GAIN

5

0

0.5 1.0 2.0

FREQUENCY (GHz)

Figure 45. Small Signal Gain vs.

Frequency for Various Values of L2.

6.8

15

33

4.0

Various values of Toko, Inc.

4.7

0 nH

1.5

2.7

5.03.0 6.0

©

type LL1608 inductors were used

for this particular example. An

inductance value of 0.5 nH was

used for the case of a short

circuit placed across the gap

provided for L2. For use at

5.8 GHz, Pin 1 should be bypassed

through the most direct path

(minimum inductance) to ground.

d

Referring to Figure 21, L2 is not

used and a bypass capacitor is

placed from Pin 1 directly to the

ground pad for Pin 2.

The result of this step is the

multiple plot shown in Figure 45

of gain vs. frequency with L2 as a

parameter. This plot is similar to

the plot in Table 1, but differs in

that the data in Figure 45 is

specific to the designer’s particular PCB layout. The Table 1 data

is a combination of test data

taken in a relatively parasiticsterile characterization fixture

and computer simulations. The

test data in Figure 45 includes the

effects of all circuit parasitics,

ground vias, parasitics of the

actual chip inductor that will be

used, and also takes into account

the length of line and bypass

capacitor used to make the

connection to L2 that will be used

in the final circuit.

The value of L2 is then plotted vs.

the frequency at which the gain

peak occurred for each value of

inductance. This plot is done as a

log plot with a straight-line curve

fit added to smooth the data. This

data, shown as Plot A in Figure

46, then gives the optimum value

of L2 for maximum small signal

gain, i.e., linear performance.

The results of the 2.5 GHz and

900 MHz example amplifiers

presented in this Application

Note were used to modify Plot A

for large signal use. The optimum,

large signal value for L2 at

2.5 GHz was determined to be

20

1.5 nH, and 12 nH for 900 MHz.

These two L2-frequency points

are added to the data plot of

Figure 46. A straight line is drawn

through these two points to

create Plot B.

Plot B provides a look-up for

values of L2 for saturated amplifier designs. Plot A is used for

linear amplifiers. Note: Plot B is

replicated as Figure 19 in the

“Application Guidelines” section

of this note.

[1]

Operating life test conducted for a case

temperature of 60°C and with a Vd of

3.6 volts. After 1000 hours, there were 0

failures.

40

30

20

10

9

8

7

6

5

4

L2 (nH)

3

2

1

0.9

0.8

0.7

0.5 1.0 1.5 2.0 2.5 3.0

PLOT A

PLOT B

FREQUENCY (GHz)

Figure 46. Optimum L2 for Small Signal Gain vs. Frequency.

Package Dimensions

Outline 63 (SOT-363/SC-70)

21

HE

A1

SYMBOL

E

D

HE

A

A2

A1

Q1

e

b

c

L

e

b

DIMENSIONS (mm)

MIN.

1.15

1.80

1.80

0.80

0.80

0.00

0.10

0.650 BCS

0.15

0.10

0.10

D

MAX.

1.35

2.25

2.40

1.10

1.00

0.10

0.40

0.30

0.20

0.30

E

Q1

A2

A

L

NOTES:

1. All dimensions are in mm.

2. Dimensions are inclusive of plating.

3. Dimensions are exclusive of mold flash & metal burr.

4. All specifications comply to EIAJ SC70.

5. Die is facing up for mold and facing down for trim/form,

ie: reverse trim/form.

6. Package surface to be mirror finish.

c

Part Number Ordering Information

No. of

Part Number Devices Container

MGA-83563-TR1 3000 7" Reel

MGA-83563-TR2 10000 13" Reel

MGA-83563-BLK 100 antistatic bag

MGA-83563-TR1G 3000 7" Reel

MGA-83563-TR2G 10000 13" Reel

MGA-83563-BLKG 100 antistatic bag

Note: For lead-free option, the part number will have the

character “G” at the end.

Device Orientation

REEL

TOP VIEW

4 mm

END VIEW

CARRIER

8 mm

TAPE

USER

FEED

DIRECTION

COVER TAPE

Tape Dimensions and Product Orientation

For Outline 63

P

P

0

C

t

(CARRIER TAPE THICKNESS) Tt (COVER TAPE THICKNESS)

1

10° MAX.

D

D

1

K

0

83x 83x 83x 83x

P

2

10° MAX.

E

F

W

A

0

CAVITY

PERFORATION

CARRIER TAPE

COVER TAPE

DISTANCE

For product information and a complete list of Agilent

contacts and distributors, please go to our web site.

DESCRIPTION SYMBOL SIZE (mm) SIZE (INCHES)

LENGTH

WIDTH

DEPTH

PITCH

BOTTOM HOLE DIAMETER

DIAMETER

PITCH

POSITION

WIDTH

THICKNESS

WIDTH

TAPE THICKNESS

CAVITY TO PERFORATION

(WIDTH DIRECTION)

CAVITY TO PERFORATION

(LENGTH DIRECTION)

A

0

B

0

K

0

P

D

1

D

P

0

E

W

t

1

C

T

t

F

P

2

www.agilent.com/semiconductors

E-mail: SemiconductorSupport@agilent.com

Data subject to change.

Copyright © 2004-2005 Agilent Technologies, Inc.

Obsoletes 5989-1800EN

November 3, 2005

5989-4188EN

2.40 ± 0.10

2.40 ± 0.10

1.20 ± 0.10

4.00 ± 0.10

1.00 + 0.25

1.55 ± 0.10

4.00 ± 0.10

1.75 ± 0.10

8.00 + 0.30 - 0.10

0.254 ± 0.02

5.40 ± 0.10

0.062 ± 0.001

3.50 ± 0.05

2.00 ± 0.05

0.094 ± 0.004

0.094 ± 0.004

0.047 ± 0.004

0.157 ± 0.004

0.039 + 0.010

0.061 + 0.002

0.157 ± 0.004

0.069 ± 0.004

0.315 + 0.012

0.0100 ± 0.0008

0.205 + 0.004

0.0025 ± 0.0004

0.138 ± 0.002

0.079 ± 0.002

B

0

Loading...

Loading...