Page 1

Vialsamplers

Agilent InfinityLab LC Series

User Manual

Agilent InfinityLab LC Series Vialsamplers User Manual

Page 2

Notices

CAUTION

WARNING

Document Information

Document No: SD-29000242 Rev. E

Part No: G7129-90010 Rev. E

EDITION 04/2020

Copyright

© Agilent Technologies, Inc. 2015-2020

No part of this manual may be reproduced in any form or by any means

(including electronic storage and retrieval

or translation into a foreign language)

without prior agreement and written consent from Agilent Technologies, Inc. as

governed by United States and international copyright laws.

Agilent Technologies

Hewlett-Packard-Strasse 8

76337 Waldbronn

Warranty

The material contained in this document

is provided “as is,” and is subject to being

changed, without notice, in future editions. Further, to the maximum extent

permitted by applicable law, Agilent disclaims all warranties, either express or

implied, with regard to this manual and

any information contained herein, including but not limited to the implied warranties of merchantability and fitness for a

particular purpose. Agilent shall not be liable for errors or for incidental or consequential damages in connection with the

furnishing, use, or performance of this

document or of any information contained herein. Should Agilent and the user

have a separate written agreement with

warranty terms covering the material in

this document that conflict with these

terms, the warranty terms in the separate

agreement shall control.

Technology Licenses

The hardware and/or software described

in this document are furnished under a

license and may be used or copied only in

accordance with the terms of such

license.

Safety Notices

A

CAUTION

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in damage to the product or loss

of important data. Do not proceed

beyond a

the indicated conditions are fully

understood and met.

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could

result in personal injury or death.

Do not proceed beyond a WARNING notice until the indicated

conditions are fully understood

and met.

notice denotes a

CAUTION

notice until

Restricted Rights Legend

U.S. Government Restricted Rights. Software and technical data rights granted to

the federal government include only

those rights customarily provided to end

user customers. Agilent provides this

customary commercial license in Software and technical data pursuant to FAR

12.211 (Technical Data) and 12.212

(Computer Software) and, for the Department of Defense, DFARS 252.227-7015

(Technical Data - Commercial Items) and

DFARS 227.7202-3 (Rights in Commercial Computer Software or Computer

Software Documentation).

Agilent InfinityLab LC Series Vialsamplers User Manual

Page 3

In This Book:

This manual covers the following modules:

• Agilent 1260 Infinity II Vialsampler (G7129A)

• Agilent 1290 Infinity II Vialsampler (G7129B)

• Agilent 1260 Infinity II Vialsampler (G7129C)

1Introduction

This chapter gives an introduction to the module and instrument overview.

2 Site Requirements and Specifications

This chapter provides information on environmental requirements, physical and

performance specifications.

3 Using the Module

This chapter provides information on how to use the module.

4 Preparing the Module

This chapter explains the operational parameters of the module.

5 Optimizing Performance

This chapter provides information on how to optimize the module.

6Troubleshooting and Diagnostics

This chapter gives an overview of the maintenance, troubleshooting, and

diagnostic features available for the Agilent InfinityLab Series Vialsampler.

7Error Information

This chapter describes the meaning of error messages, and provides information

on probable causes and suggested actions how to recover from error conditions.

Agilent InfinityLab LC Series Vialsamplers User Manual 3

Page 4

8 Maintenance

This chapter describes the maintenance of the module.

9 Parts and Materials for Maintenance

This chapter provides information on parts for maintenance.

10 Identifying Cables

This chapter provides information on cables used with the Agilent 1200 Infinity

Series modules.

11 Hardware Information

This chapter describes the detector in more detail on hardware and electronics.

12 LAN Configuration

This chapter provides information on connecting the module to the Agilent

ChemStation PC.

13 Appendix

This chapter provides additional information on safety, legal and web.

Agilent InfinityLab LC Series Vialsamplers User Manual 4

Page 5

Contents

1Introduction 9

Product Description (G7129A) 10

Features (G7129A) 11

Product Description (G7129B) 12

Features (G7129B) 13

Product Description (G7129C) 14

Features (G7129C) 15

Overview of the Module 16

Operating Principle 18

Leak and Waste Handling 27

2 Site Requirements and Specifications 33

Site Requirements 34

Physical Specifications 38

Performance Specifications 39

Specifications of the Sample Cooler 47

Specifications of the Sample Thermostat 49

Specifications of the Integrated Column Compartment 51

3 Using the Module 53

Magnets 55

Turn on/off 56

Status Indicators 58

Vial Drawers and Trays 59

Choice of Vials and Caps 70

Install the Optional Integrated Column Compartment 74

Using the Optional Integrated Column Compartment 96

Install the Optional Sample Cooler/Sample Thermostat 116

Using the Optional Sample Cooler/Sample Thermostat 123

Transporting the Sampler 132

Agilent Local Control Modules 137

Agilent InfinityLab LC Series Vialsamplers User Manual 5

Page 6

4 Preparing the Module 139

Leak and Waste Handling 140

Preparing the Module 141

Solvent Information 142

Capillary Color Coding Guide 149

Installing Capillaries 150

Flow Connections to the Vialsampler 152

Setting up the Vialsampler 154

5 Optimizing Performance 166

Optimization for Lowest Carryover 167

Fast Injection Cycle and Low Delay Volume 171

Precise Injection Volume 173

Choice of Rotor Seal 175

6 Troubleshooting and Diagnostics 176

Status Indicators 177

Overview of Tests and Tools 178

Maintenance and Troubleshooting Tools 179

Diagnostic Tests 187

Agilent Lab Advisor Software 189

7Error Information 190

What are Error Messages 192

General Error Messages 193

Vialsampler Error Messages 201

Sample Cooler/Sample Thermostat Error Messages 213

Integrated Column Compartment (ICC) Heater Error Messages 219

Agilent InfinityLab LC Series Vialsamplers User Manual 6

Page 7

8 Maintenance 222

Introduction to Maintenance 223

Warnings and Cautions 224

Overview of Maintenance 226

Cleaning the Module 227

Remove and Install Doors 228

Exchange the Needle Assembly 229

Exchange the Needle Seat Assembly 235

Exchange the Sample Loop Assembly 241

Exchange the Rotor Seal 245

Exchange the Metering Seal and Piston 250

Replace the Analytical Heads 255

Exchange the Gripper Arm 258

Replace the Peristaltic Pump Cartridge 261

Exchange the Wash Port Assembly 263

Replace the Module Firmware 269

Replace the Sample Cooler/Sample Thermostat 270

9 Parts and Materials for Maintenance 275

Standard Parts For Maintenance 276

Accessory Kits 279

Vial Drawers and Trays 283

Multidraw Kits 286

Sample Thermostat Upgrade 287

Integrated Column Compartment 288

Column ID Upgrade Kit 289

Parts for 900 µL Injection Upgrade 290

Cabinet and Door Kits 291

Analytical Head Assembly (100 µL) 295

Analytical-Head Assembly (900 µL) 296

Analytical Head Assembly (40 μL) 297

2 Position/6 Port Injection Valve, 600 bar 298

2 Position/6 Port Injection Valve, 800 bar 299

2 Position/6 Port Injection Valve, 1300 bar 300

Agilent InfinityLab LC Series Vialsamplers User Manual 7

Page 8

10 Identifying Cables 301

Cable Overview 302

Analog Cables 304

Remote Cables 306

CAN/LAN Cables 310

RS-232 Cables 311

USB 312

11 Hardware Information 313

Firmware Description 314

Electrical Connections 317

Interfaces 319

Setting the 6-bit Configuration Switch 326

Instrument Layout 330

Early Maintenance Feedback (EMF) 331

12 LAN Configuration 332

What You Have to Do First 333

TCP/IP parameter configuration 334

Configuration Switches 335

Initialization Mode Selection 336

Dynamic Host Configuration Protocol (DHCP) 338

Manual Configuration 341

PC and Agilent ChemStation Setup 345

13 Appendix 354

General Safety Information 355

Waste Electrical and Electronic Equipment (WEEE) Directive 361

Refrigerant 362

Radio Interference 365

Sound Emission 366

Solvent Information 367

Agilent Technologies on Internet 368

Agilent InfinityLab LC Series Vialsamplers User Manual 8

Page 9

1Introduction

Product Description (G7129A) 10

Features (G7129A) 11

Product Description (G7129B) 12

Features (G7129B) 13

Product Description (G7129C) 14

Features (G7129C) 15

Overview of the Module 16

Operating Principle 18

Sampling Sequence 18

Needle Parkstation 23

Hydraulic Box 24

Transport Assembly 26

Leak and Waste Handling 27

Leak Sensor 31

Waste Guidance 31

Waste Concept 32

This chapter gives an introduction to the module and instrument overview.

Agilent InfinityLab LC Series Vialsamplers User Manual 9

Page 10

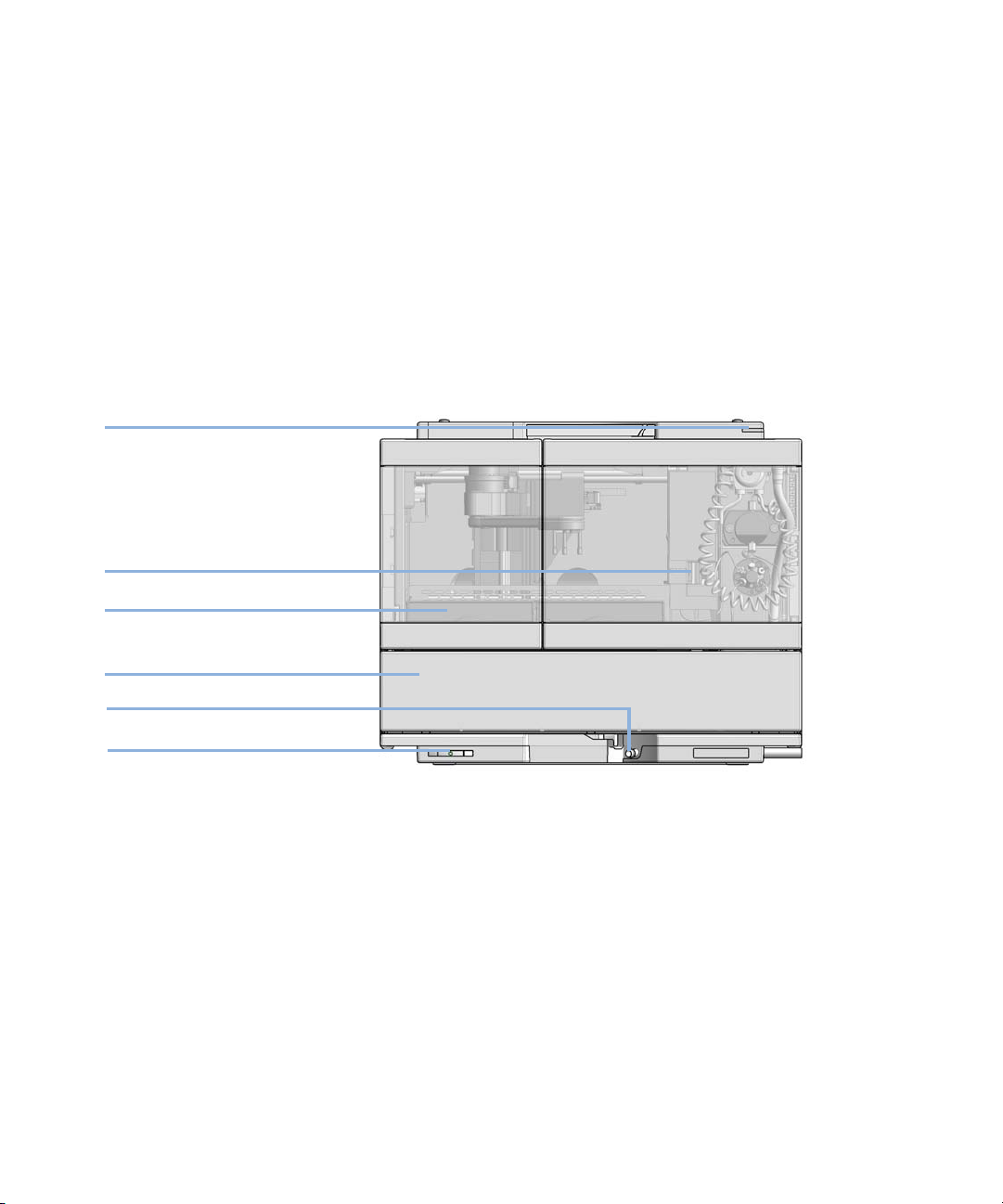

1Introduction

Status indicator

Needle assembly

Drawer

Column shelf

Leak drain

Power switch

Product Description (G7129A)

Product Description (G7129A)

The Agilent 1260 Infinity II Vialsampler is an autosampler designed for the

reliability and ease-of-use needed for routine pharmaceutical tasks and quality

control, as well as for environmental and food analyses. It can house optionally

the integrated column compartment for two LC columns with temperature

control up to 80

4

°C to 40 °C, all within one module.

°C as well as a sample thermostat for stable temperatures from

Agilent InfinityLab LC Series Vialsamplers User Manual 10

Figure 1 Overview of the Vialsampler

Page 11

1Introduction

Features (G7129A)

Features (G7129A)

• High capacity – up to 132 vials (2 mL) or up to 36 vials (6 mL).

• Reliable injections – 0.1 to 100 µL injections for up to 600 bar (G7129A) and

up to 800

• Easy volume extensions – for injection volumes up to 1800 µL for applications

ranging from microbore to semipreparative chromatography.

•Lowest carryover – with an in needle flush port included, for rinsing the outside

of the needle.

• Efficient temperature control – with an integrated column compartment as

option or upgrade available. Which holds two columns up to 30

and provides heating capacity from 5

reproducible chromatography data at optimized resolution.

• Integrated sample thermostat – available as option or upgrade, providing

cooling and heating in the range from 4

• Low internal volume – for minimum contribution to a system's total internal

volume, which can be even further reduced using "bypass" mode.

•Increased productivity – with overlapped injections.

• Customizable injection program – available for customizing advanced

injections as well as for sample preparation steps upfront injection.

bar (G7129C).

cm length,

°C above ambient up to 80 °C for

°C - 40 °C.

Agilent InfinityLab LC Series Vialsamplers User Manual 11

Page 12

1Introduction

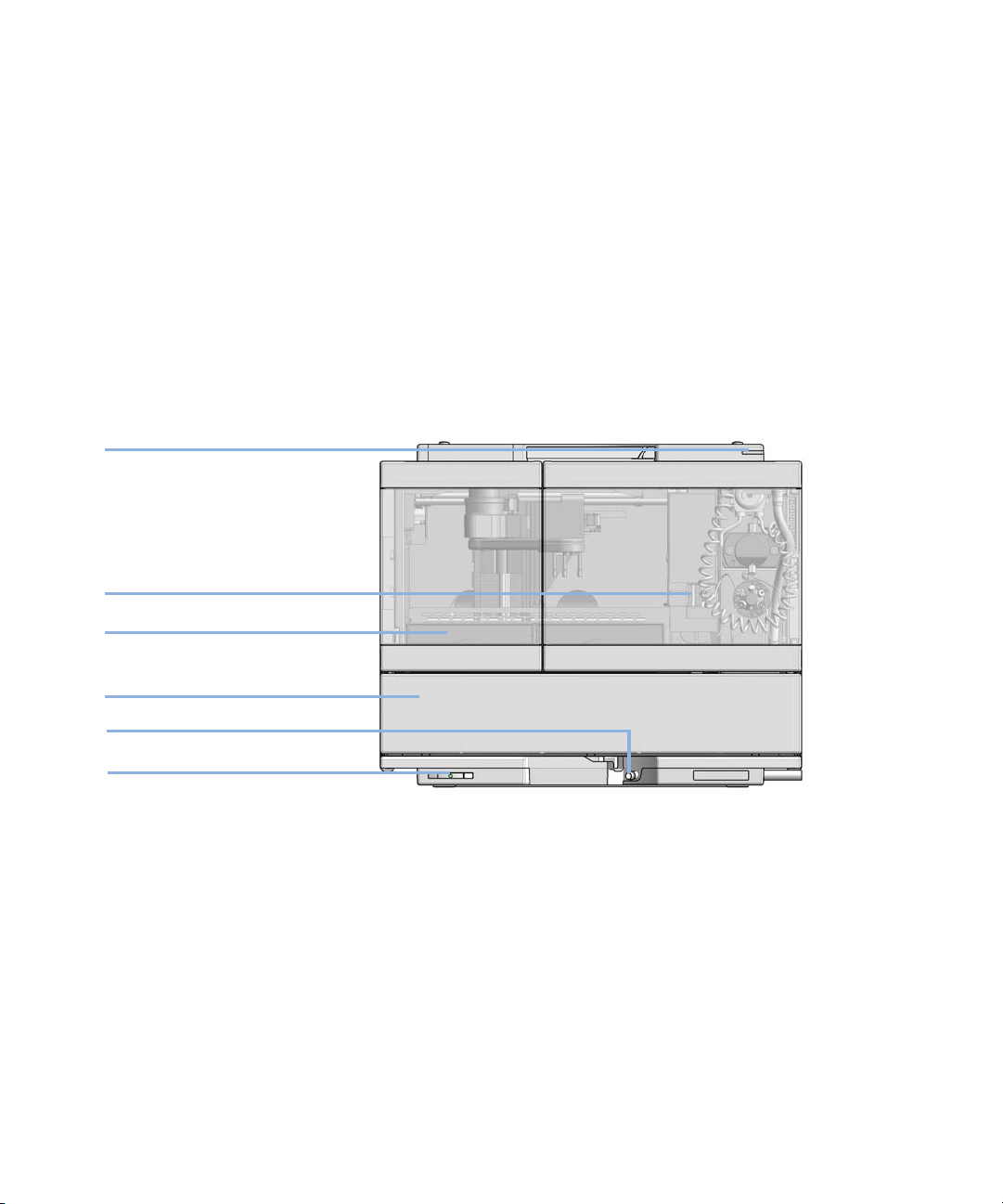

Status indicator

Needle assembly

Drawer

Column shelf

Leak drain

Power switch

Product Description (G7129B)

Product Description (G7129B)

The Agilent 1290 Infinity II Vialsampler (G7129B) is an autosampler designed for

UHPLC applications up to 1300

ease-of-use needed for routine pharmaceutical tasks and quality control, as well

as for environmental and food analyses. It can house optionally the integrated

column compartment for two LC columns with temperature control up to 80

as well as a sample thermostat for stable temperatures from 4

within one module.

bar. It provides the reliability, safety, and

°C

°C to 40 °C, all

Agilent InfinityLab LC Series Vialsamplers User Manual 12

Figure 2 Overview of the Vialsampler

Page 13

1Introduction

Features (G7129B)

Features (G7129B)

• Accurate and precise injections - within a wide and flexible range of volumes

• High capacity - up to 132 vials (2 mL) or up to 36 vials (6 mL).

• Easy volume extensions - for injection volumes up to 1500 µL for applications

ranging from microbore to semipreparative chromatography.

•Lowest carryover - with an in needle flush port included, for rinsing the outside

of the needle.

• Efficient temperature control - with an integrated column compartment as

option or upgrade available. Which holds two columns up to 30

and provides heating capacity from 5

reproducible chromatography data at optimized resolution.

• Integrated sample thermostat - available as option or upgrade, providing

cooling and heating in the range from 4

• Low internal volume - for minimum contribution to a system's total internal

volume, which can be even further reduced using bypass mode.

•Increased productivity - with overlapped injections.

• Customizable Injection program - available for customizing advanced

injections as well as for sample preparation steps upfront injection.

°C above ambient up to 80 °C for

– 40 °C.

cm length,

Agilent InfinityLab LC Series Vialsamplers User Manual 13

Page 14

1Introduction

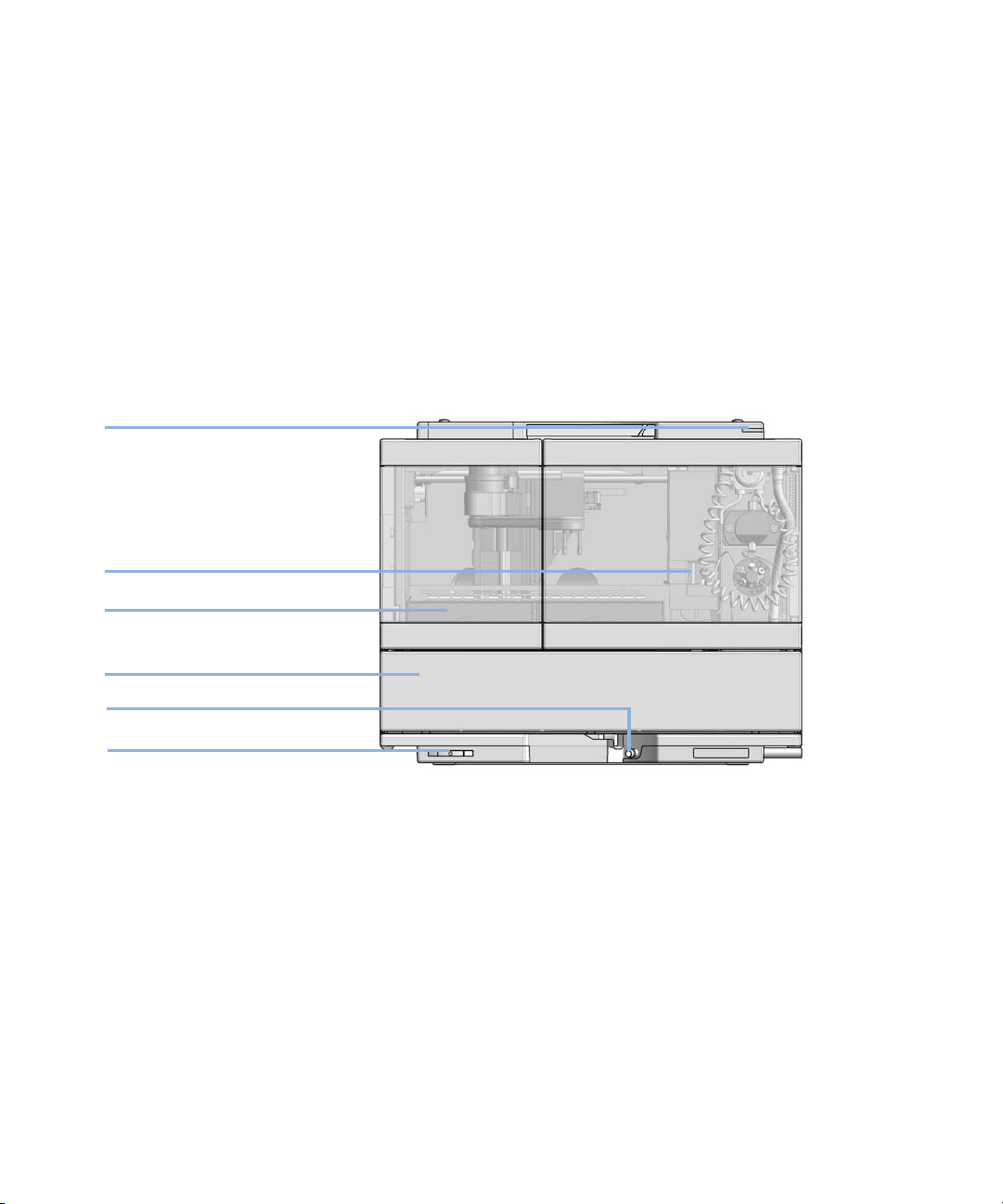

Status indicator

Needle assembly

Drawer

Column shelf

Leak drain

Power switch

Product Description (G7129C)

Product Description (G7129C)

The Agilent 1260 Infinity II Vialsampler is an autosampler designed for the

reliability and ease-of-use needed for routine pharmaceutical tasks and quality

control, as well as for environmental and food analyses. It can house optionally

the integrated column compartment for two LC columns with temperature

control up to 80

4

°C to 40 °C, all within one module.

°C as well as a sample thermostat for stable temperatures from

Agilent InfinityLab LC Series Vialsamplers User Manual 14

Figure 3 Overview of the Vialsampler

Page 15

1Introduction

Features (G7129C)

Features (G7129C)

• High capacity – up to 132 vials (2 mL) or up to 36 vials (6 mL).

• Reliable injections – 0.1 to 100 µL injections for up to 600 bar (G7129A) and

up to 800

• Easy volume extensions – for injection volumes up to 1800 µL for applications

ranging from microbore to semipreparative chromatography.

•Lowest carryover – with an in needle flush port included, for rinsing the outside

of the needle.

• Efficient temperature control – with an integrated column compartment as

option or upgrade available. Which holds two columns up to 30

and provides heating capacity from 5

reproducible chromatography data at optimized resolution.

• Integrated sample thermostat – available as option or upgrade, providing

cooling and heating in the range from 4

• Low internal volume – for minimum contribution to a system's total internal

volume, which can be even further reduced using "bypass" mode.

•Increased productivity – with overlapped injections.

• Customizable injection program – available for customizing advanced

injections as well as for sample preparation steps upfront injection.

bar (G7129C).

cm length,

°C above ambient up to 80 °C for

°C - 40 °C.

Agilent InfinityLab LC Series Vialsamplers User Manual 15

Page 16

1Introduction

Overview of the Module

Overview of the Module

The Agilent InfinityLab LC Series Vialsampler is designed for use with other

modules of the Agilent InfinityLab LC Series, 1200 Series, and 1100 Series LC, as

well as with other LC systems with adequate remote-control capabilities. The

Vialsampler can be controlled from any computer with a suitable

chromatography data system (for example, Agilent OpenLab CDS, MassHunter,

etc.) or via an Agilent local control module (InfinityLab Companion or 1200

Infinity Series Instant Pilot).

The 1290 Infinity II Vialsampler (G7129B) can be operated at up to 1300 bar. The

two 1260 Infinity II Vialsampler variants (G7129A and G7129C) are limited to a

maximum system pressure of 600 and 800

The Vialsampler can accommodate two vial drawers, providing space for up to

132 samples. The two cartesian vial drawers allow for the use of either 66 × 2

or 18 × 6

system is also available, each capable of hosting 50 × 2

drawers are designed to ease method transfer from older Agilent samplers. The

Vialsampler can also be equipped with an external tray, which can be beneficial

for automation. The Agilent WalkUp solution fully supports the external tray.

mL vials. A pair of classic vial drawers with a numerical vial assignment

bar, respectively.

mL vials. The classic vial

mL

The Vialsampler features a robotic gripper arm for the transport of vials, driven by

four stepper motors to ensure the highest precision and flexibility for the

transport movement.

The default configuration of the analytical head and sample loop allows an

injection range from 0.1

0.1

– 100 μL for the 1260 Infinity II Vialsamplers. An analytical head with

extended volume is also available for injection volumes from 0.1

can be operated at up to 400

volume can even reach 1800

The 2-position/6-port injection valve is driven by a high-speed, hybrid stepper

motor, ensuring smooth switching between the mainpass and bypass positions.

Thanks to the flow-through design of the Vialsampler, the eluent continuously

rinses the component parts of the sample introduction system. This, together

with the automated needle wash function for rinsing the outer surface of the

needle, ensures the lowest level of carryover for each analysis. For advanced

delay volume reduction, the injection valve can be programmed to automatically

switch back to the bypass position when the injection is completed.

Agilent InfinityLab LC Series Vialsamplers User Manual 16

– 20 μL for the 1290 Infinity II Vialsampler and

– 900 μL, and

bar. With the Multidraw Kit, the maximum injection

μL.

Page 17

1Introduction

Overview of the Module

The Agilent InfinityLab Integrated Column Compartment, an optional upgrade for

the Vialsampler, eliminates the need for having a standalone column thermostat

in the LC stack. It has the heating capability of reaching temperatures up to 80

and can hold a total of two columns with maximum lengths of 30

For applications requiring control over the vial temperature, the Vialsampler can

be equipped with the Agilent InfinityLab Sample Thermostat (G7167-60101). It

features a vapor-compression refrigeration system and an electric heater,

allowing the Vialsampler to reach vial temperatures down to 4

cm.

°C and up to 40 °C.

°C

Agilent InfinityLab LC Series Vialsamplers User Manual 17

Page 18

1Introduction

Operating Principle

Operating Principle

Sampling Sequence

The Vialsampler processor continuously monitors the movements of the

vialsampler components during the sampling sequence. The processor defines

specific time windows and mechanical ranges for each movement. If a specific

step of the sampling sequence can’t be completed successfully, an error

message is generated.

During the sampling sequence, the solvent bypasses the vialsampler via the

injection valve. The gripper arm selects the sample vial, either from a static

sample rack, or from external vial positions. The gripper arm places the sample

vial below the injection needle. The required volume of sample is drawn into the

sample loop by the metering device. Sample is applied to the column when the

injection valve returns to the mainpass (main path) position at the end of the

sampling sequence.

The sampling sequence occurs in the following order:

1 The injection valve switches to the bypass position.

2 The piston of the metering device moves to the initialization position.

3 The gripper arm moves from the home position, and selects the vial. At the

same time, the needle lifts out of the seat.

4 The gripper moves into the needle station and stops in the draw position.

5 The needle lowers into the vial.

6 The metering device draws the defined sample volume.

7 The needle lifts out of the vial.

1

8 The gripper arm moves out slightly and stops in the wash position1.

9 The needle moves downwards and dips into the wash well of the wash port.

Simultaneously the peristaltic pump delivers the flush solvent.

10 The needle moves back.

11 The gripper arm moves out of the needle station and the wash port snaps

back in position.

1

only if automated needle wash is selected. If this feature is disabled, the gripper arm

positions the sample vial directly below the needle (Step 4) and lowers the needle into

the vial.

Agilent InfinityLab LC Series Vialsamplers User Manual 18

1

1

Page 19

1Introduction

Vial

Wash

port

Needle

seat

Sampling loop

Solvent

Wash

pump

Metering

device

Operating Principle

12 The gripper arm replaces the vial, and returns to the home position.

Simultaneously, the needle lowers into the seat.

13 The injection valve switches to the mainpass (main path) position.

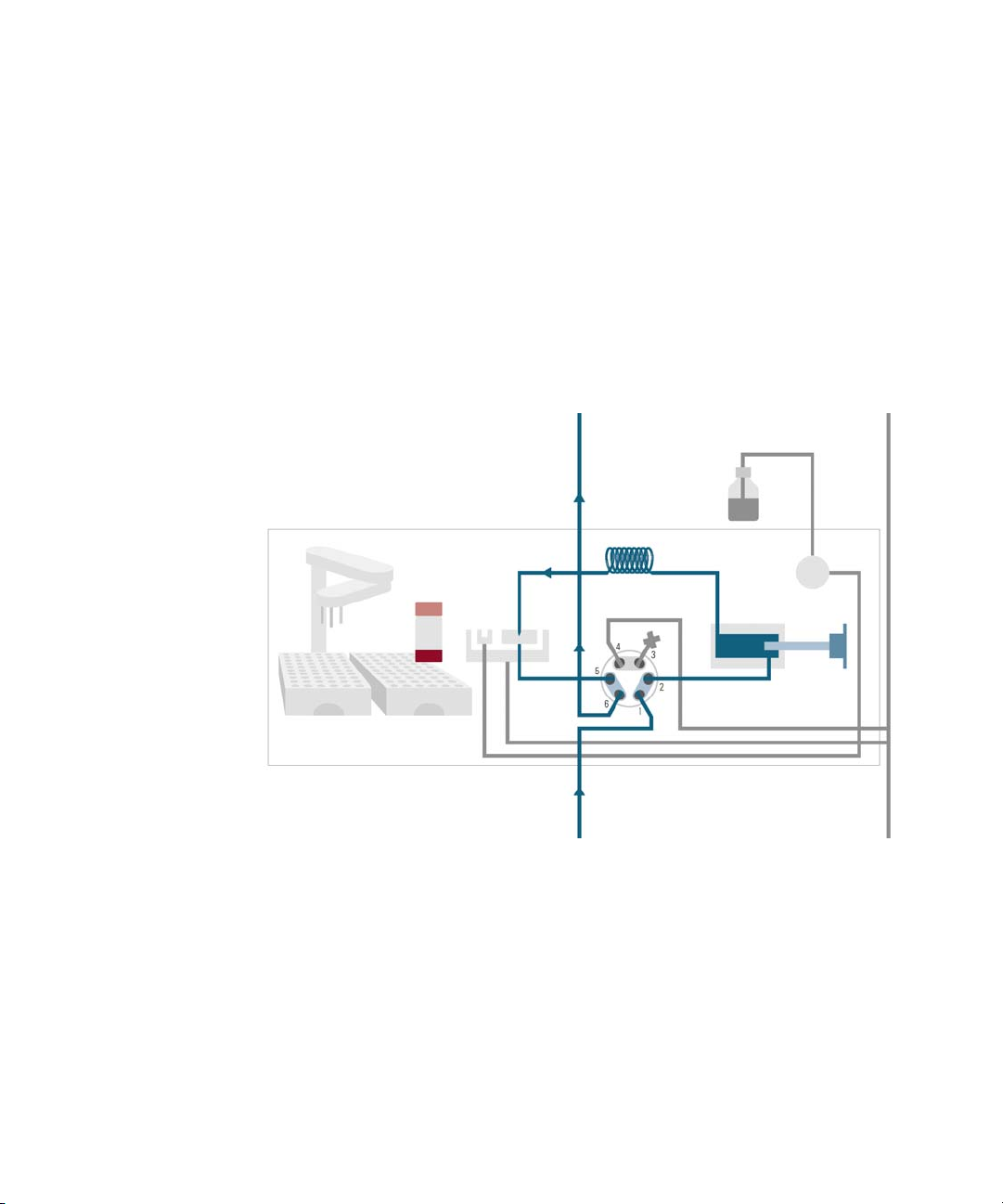

Injection Sequence

Before the start of the injection sequence, and during an analysis, the injection

valve is in the mainpass (main path) position (see

position, the mobile phase flows through the autosamplers metering device,

sample loop, and needle. This ensures that all parts in contact with sample are

flushed during the run, thus minimizing carryover.

Figure 4 on page 19). In this

Figure 4 Mainpass (main path) Position - standard position during runs and when the sampler

idle

is

Agilent InfinityLab LC Series Vialsamplers User Manual 19

Page 20

1Introduction

Vial

Wash

port

Needle

seat

Sampling loop

Solvent

Wash

pump

Metering

device

Operating Principle

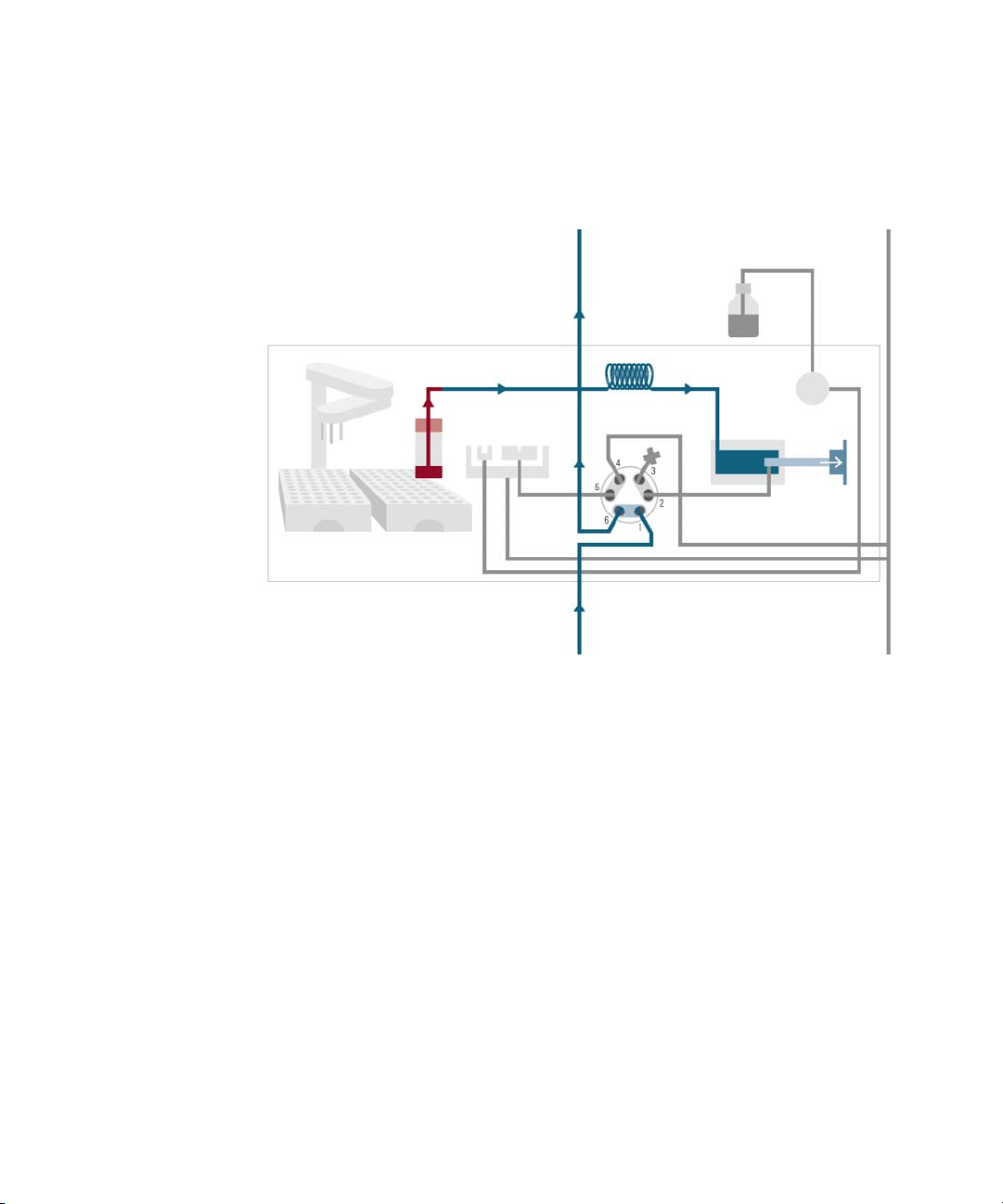

When the sample sequence begins, the valve unit switches to the bypass

position (see

Figure 5 on page 20). Solvent from the pump enters the valve unit at

port 1, and flows directly to the column through port 6.

Figure 5Valve in bypass - needle in vial, metering device aspirates sample volume

Agilent InfinityLab LC Series Vialsamplers User Manual 20

Page 21

1Introduction

Vial

Wash

port

Needle

seat

Sampling loop

Solvent

Wash

pump

Metering

device

Operating Principle

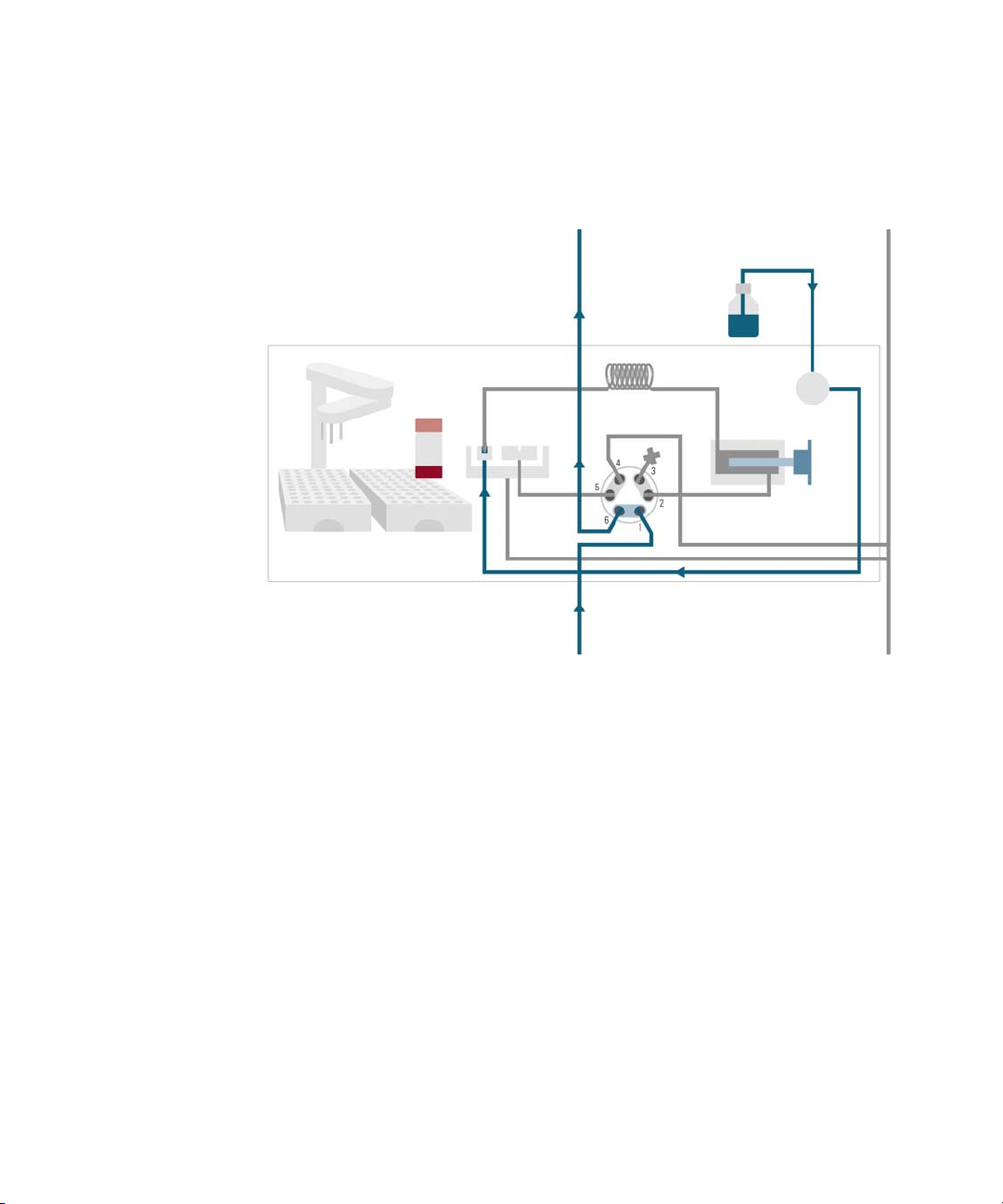

Then the vial is positioned below the needle. The needle moves down into the

vial, the metering unit draws the required sample volume into the loop, and the

needle is raised. In the next step, the needle is washed (see

Figure 6 on page 21).

Figure 6 Outer face of needle getting washed in wash port

Agilent InfinityLab LC Series Vialsamplers User Manual 21

Page 22

1Introduction

Vial

Wash

port

Needle

seat

Sampling loop

Solvent

Wash

pump

Metering

device

Operating Principle

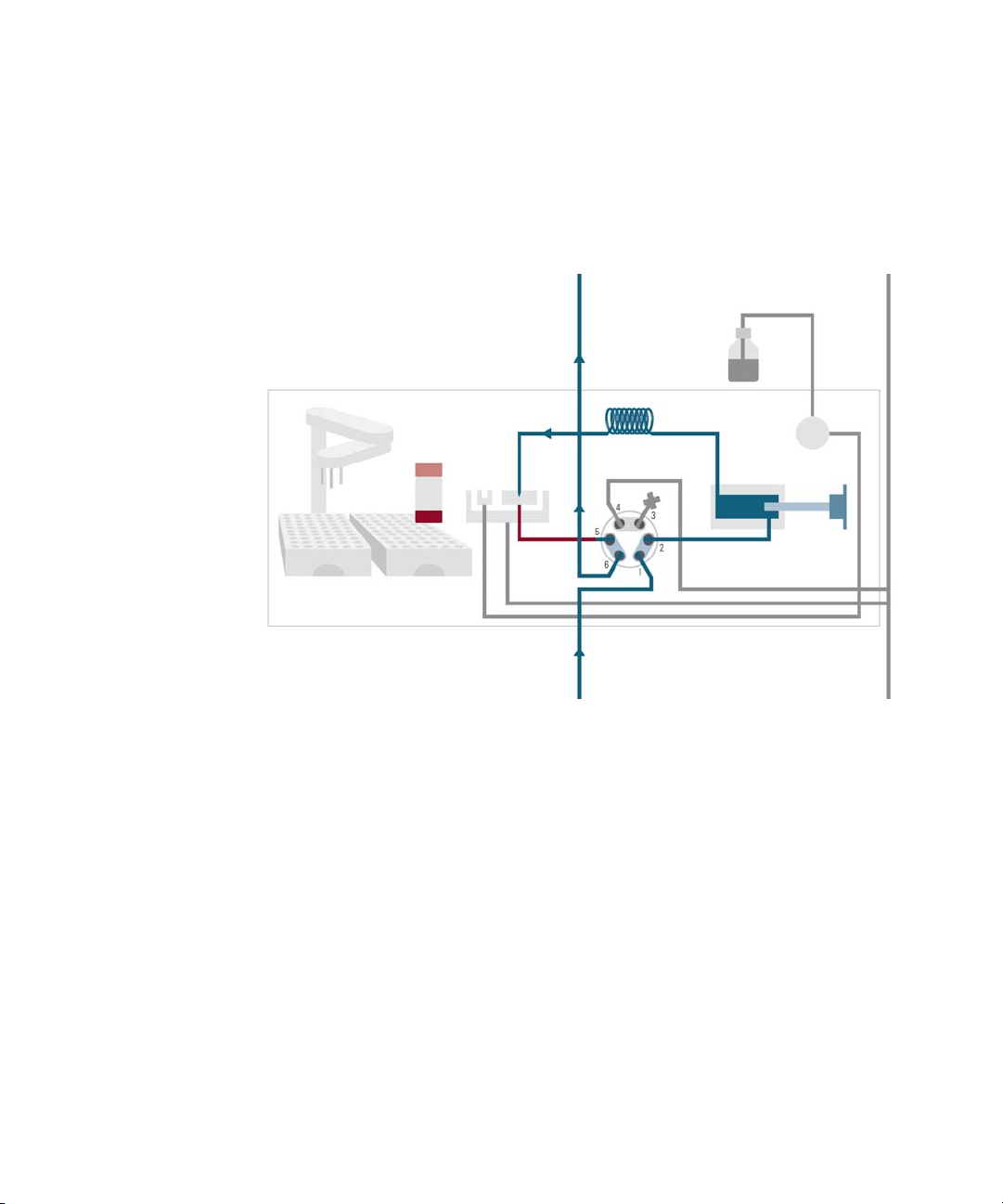

When the metering unit has drawn the required volume of sample into the

sample loop, the vial is replaced in the sample tray. The wash port flips into the

origin position, the needle is lowered into the needle seat, and the injection valve

switches back to mainpass (main path) position, flushing the sample onto the

column (see

Figure 7 on page 22).

Figure 7 Valve switches to mainpass (main path) - sample is transferred towards the LC column

Agilent InfinityLab LC Series Vialsamplers User Manual 22

Page 23

1Introduction

Operating Principle

Needle Parkstation

The needle parkstation comprises two main assemblies: needle drive and wash

port.

Figure 8Needle Station

Needle-Drive

The needle movement is driven by a stepper motor connected to the spindle

assembly by a toothed belt. The circular motion of the motor is converted to

linear motion by the drive nut on the spindle assembly. The upper and lower

needle positions are detected by reflection sensors on the needle station board,

while the needle-in-vial position is determined by counting the motor steps from

the upper needle-sensor position.

Agilent InfinityLab LC Series Vialsamplers User Manual 23

Page 24

1Introduction

NOTE

Operating Principle

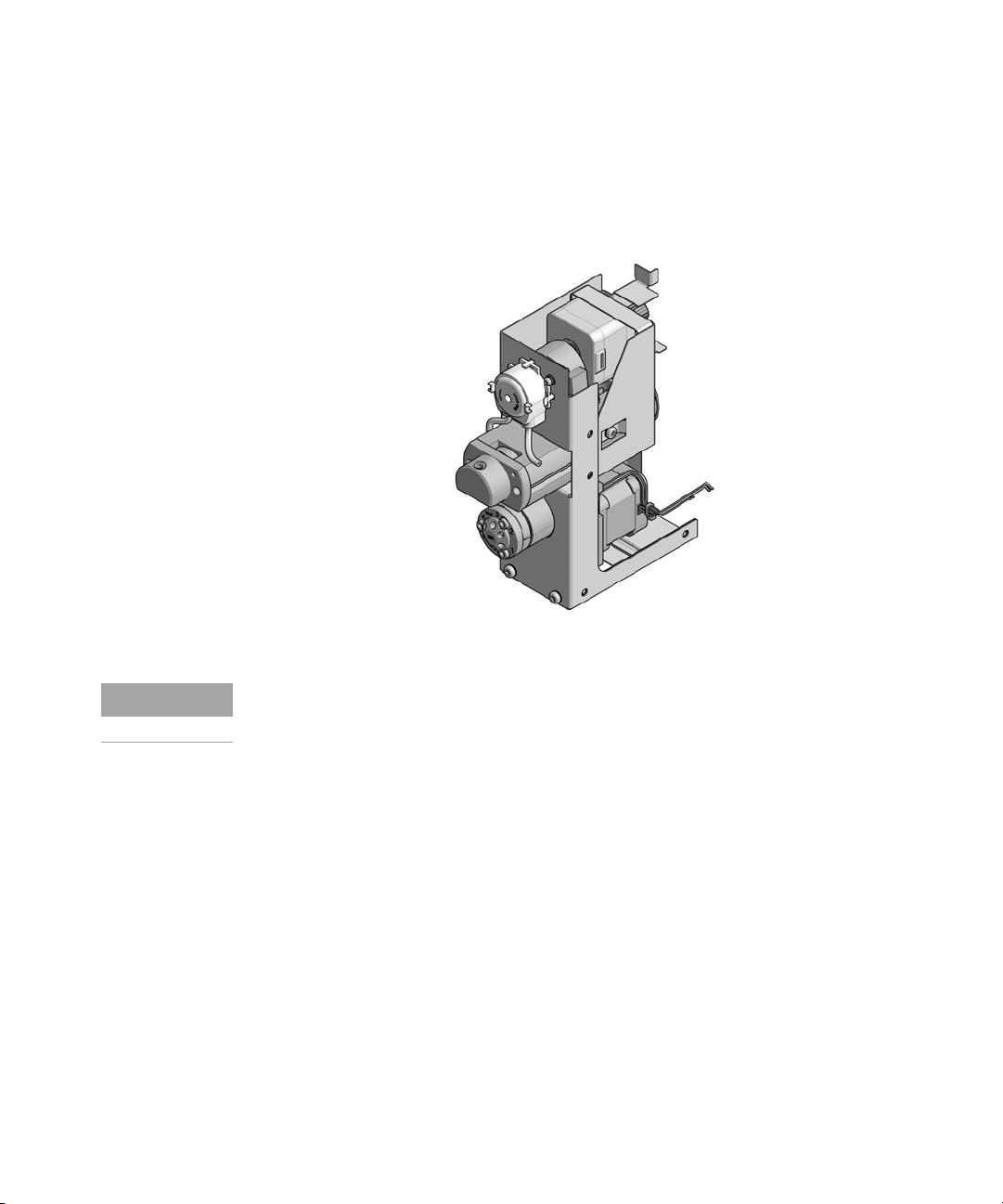

Hydraulic Box

The hydraulic box comprises two main assemblies: metering device, and

injection valve.

Figure 9 Hydraulic Unit

The replacement hydraulic box excludes the injection valve and metering head

assemblies.

Agilent InfinityLab LC Series Vialsamplers User Manual 24

Page 25

1Introduction

Operating Principle

Analytical Head

The analytical head is driven by the stepper motor that is connected to the drive

shaft by a toothed belt. The drive nut on the spindle converts the circular

movement of the spindle to linear motion. The drive nut pushes the sapphire

piston against the tension of the spring into the analytical head. The base of the

piston sits on the large bearing of the drive nut, which ensures the piston is

always centered. A ceramic ring guides the movement of the piston in the

analytical head. The home position of the piston is sensed by an optical sensor

on the hydraulic unit board while the sample volume is determined by counting

the number of steps from the home position. The backward movement of the

piston (driven by the spring) draws sample from the vial.

Injection Valve

The two-position 6-port injection valve is driven by a stepper motor. Only five of

the six ports are used (port 3 is not used). A lever/slider mechanism transfers the

movement of the stepper motor to the injection valve. Two microswitches

monitor switching of the valve (bypass and mainpass (main path) end positions).

No valve adjustments are required after replacing internal components.

Agilent InfinityLab LC Series Vialsamplers User Manual 25

Page 26

1Introduction

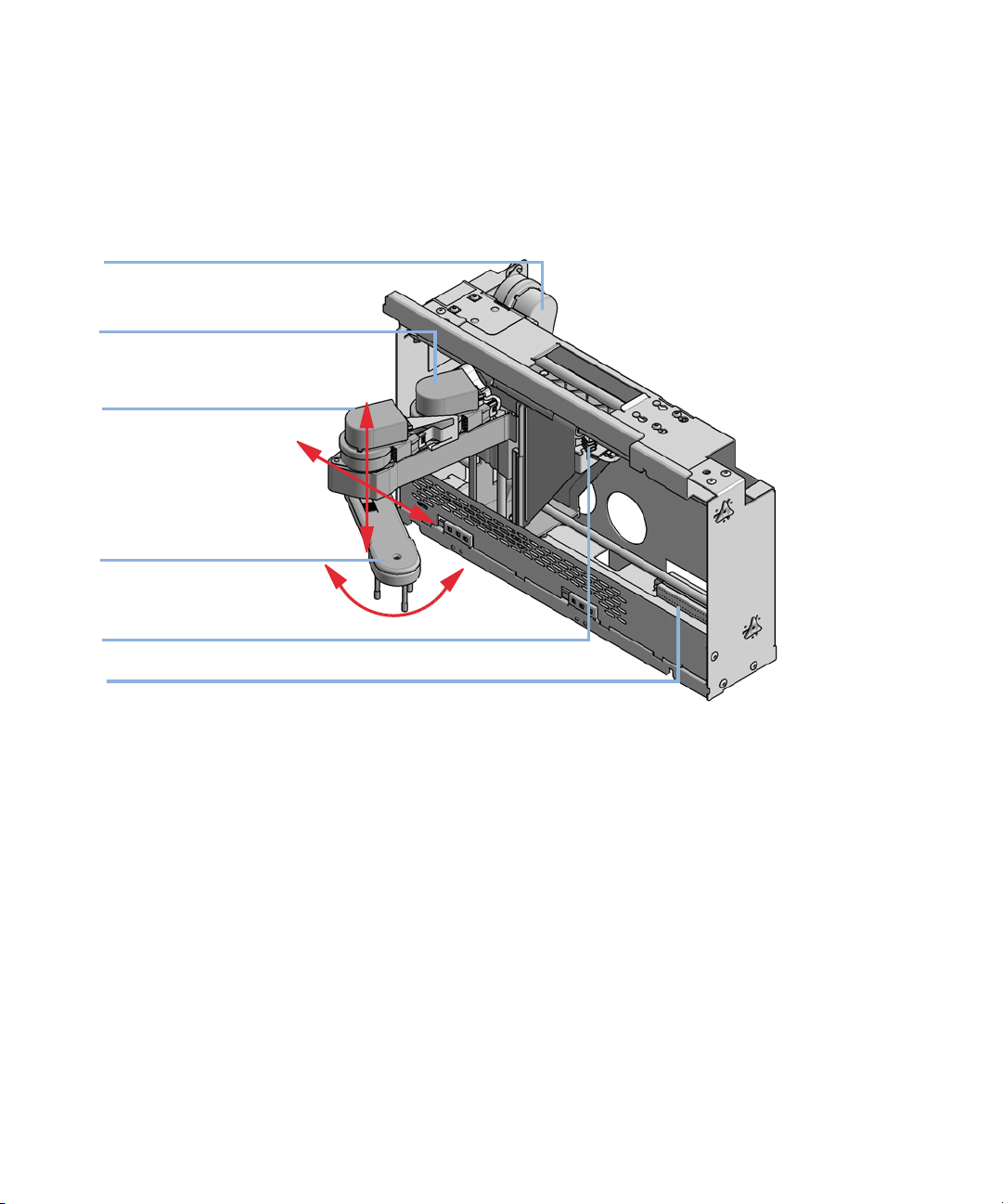

X motor

Theta motor

Gripper motor

Gripper arm

Z motor

Flex board

Theta axis

X axis

Z axis

Operating Principle

Transport Assembly

The transport unit comprises an X-axis slide (left-right motion), a Z-axis arm

(up-down motion), and a gripper assembly (rotation and vial-gripping).

Figure 10 Transport Assembly

The transport assembly uses four stepper motors driven in closed-loop mode for

accurate positioning of the gripper assembly. The rotational movement of the

motors is converted to linear motion (X- and Z-axes) by toothed belts connected

to the drive spindles. The rotation (theta axes) of the gripper assembly is

transferred from the motor by a toothed belt and series of gears. The opening

and closing of the gripper fingers are driven by a stepper motor linked by a

toothed belt to the planetary gearing inside the gripper assembly.

The stepper motor positions are determined by the optical encoders mounted

onto the stepper-motor housing. The encoders monitor the position of the

motors continually, and correct for position errors automatically (e.g. if the

gripper is accidentally moved out of position when loading vials into the vial tray).

The initialization positions of the moving components are sensed by reflection

sensors mounted on the flex board. These positions are used by the processor to

calculate the actual motor position. An additional six reflection sensors for tray

recognition are mounted on the flex board at the front of the assembly.

Agilent InfinityLab LC Series Vialsamplers User Manual 26

Page 27

1Introduction

Leak and Waste Handling

Leak and Waste Handling

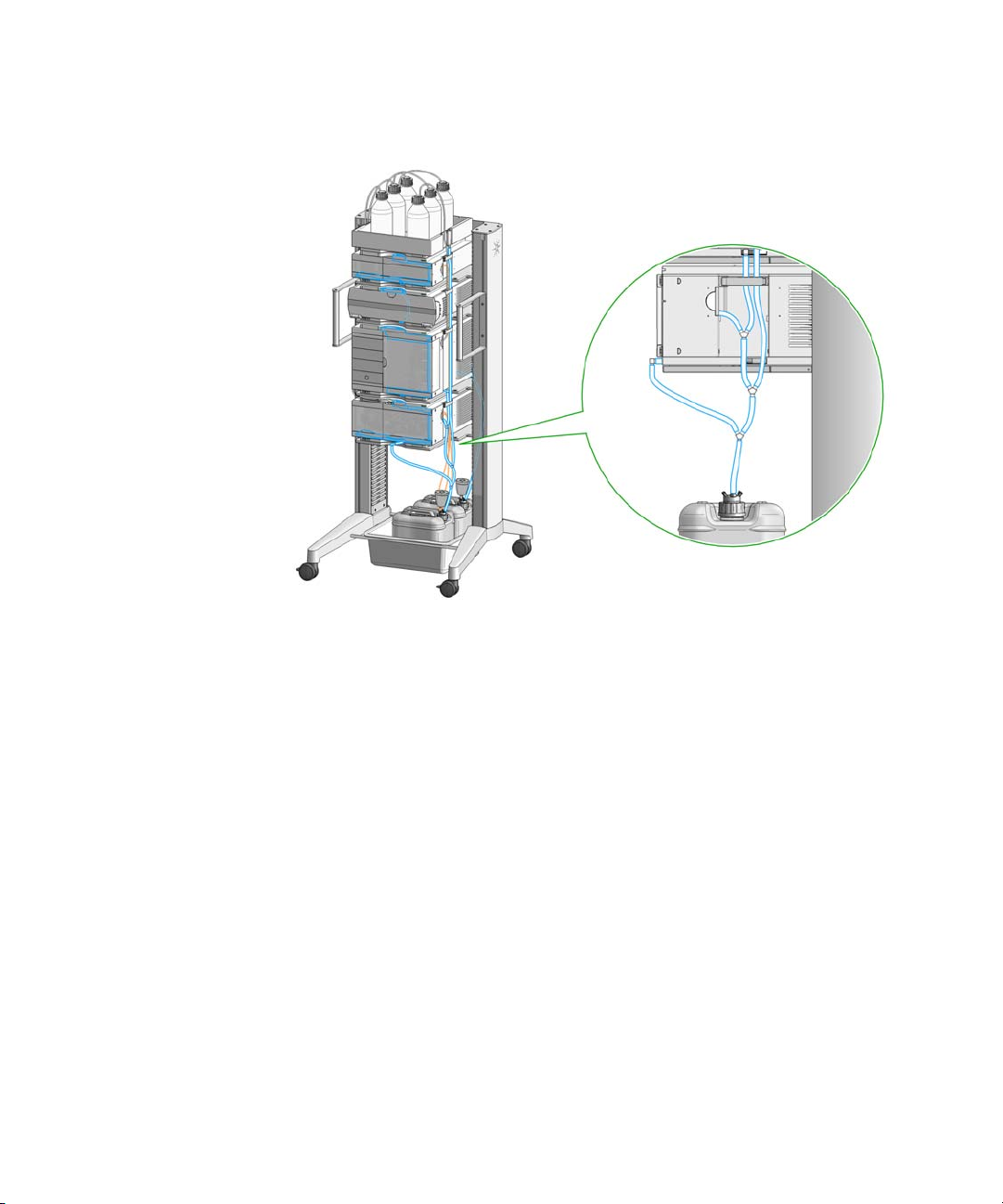

The Agilent InfinityLab LC Series has been designed for safe leak and waste

handling. It is important that all security concepts are understood and

instructions are carefully followed.

The solvent cabinet is designed to store a maximum volume of 8 L solvent. The

maximum volume for an individual bottle stored in the solvent cabinet should not

exceed 2

Cabinets (a printed copy of the guideline has been shipped with the solvent

cabinet, electronic copies are available on the Internet).

All leak plane outlets are situated in a consistent position so that all Infinity and

Infinity II modules can be stacked on top of each other. Waste tubes are guided

through a channel on the right hand side of the instrument, keeping the front

access clear from tubes.

The leak plane provides leak management by catching all internal liquid leaks,

guiding them to the leak sensor for leak detection, and passing them on to the

next module below, if the leak sensor fails. The leak sensor in the leak plane

stops the running system as soon as the leak detection level is reached.

Solvent and condensate is guided through the waste channel into the waste

container:

• from the detector's flow cell outlet

• from the Multisampler needle wash port

• from the Sample Cooler or Sample Thermostat (condensate)

• from the pump's Seal Wash Sensor (if applicable)

• from the pump's Purge Valve or Multipurpose Valve

L. For details, see the usage guideline for the Agilent Infinity II Solvent

Agilent InfinityLab LC Series Vialsamplers User Manual 27

Page 28

1Introduction

Leak and Waste Handling

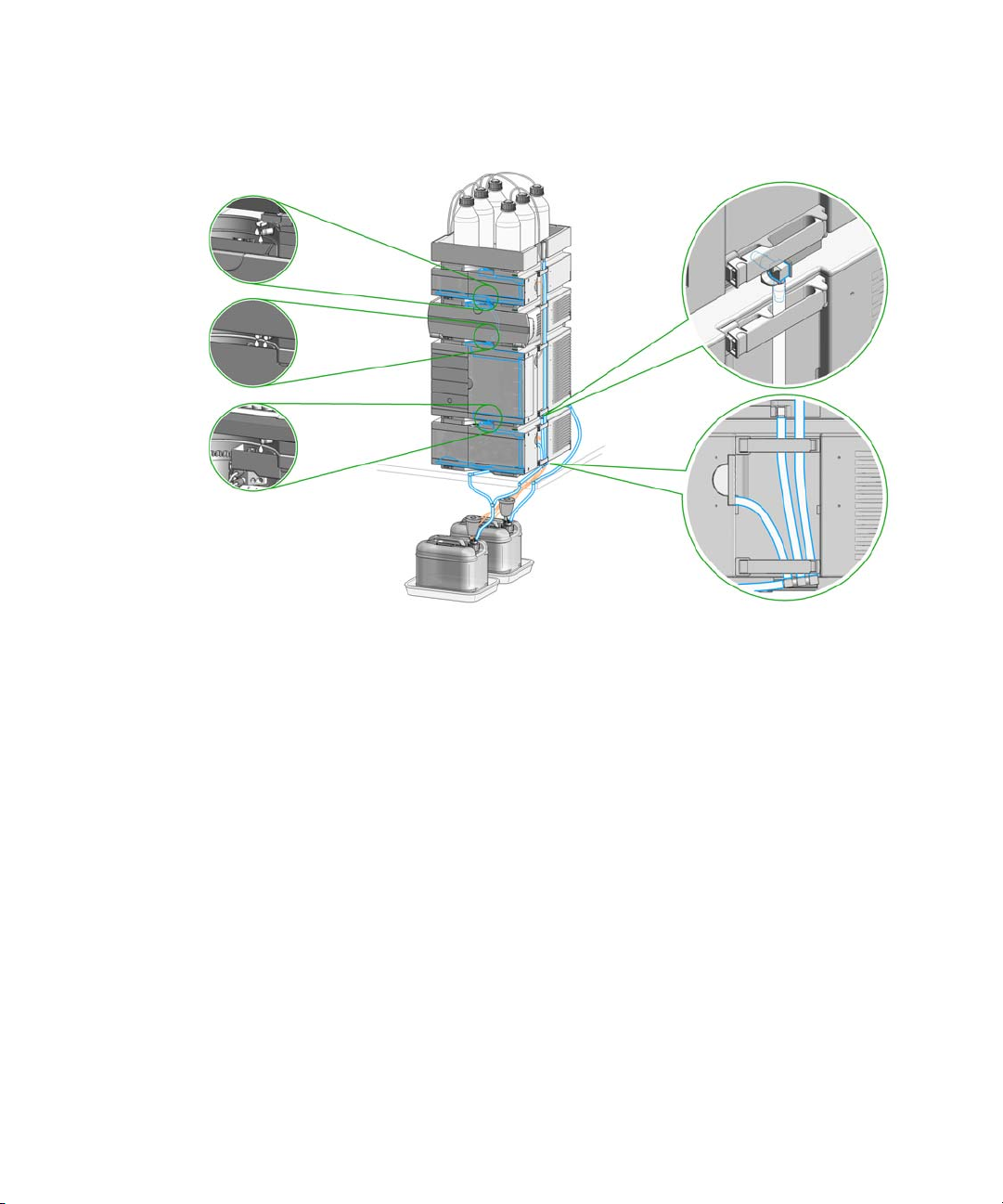

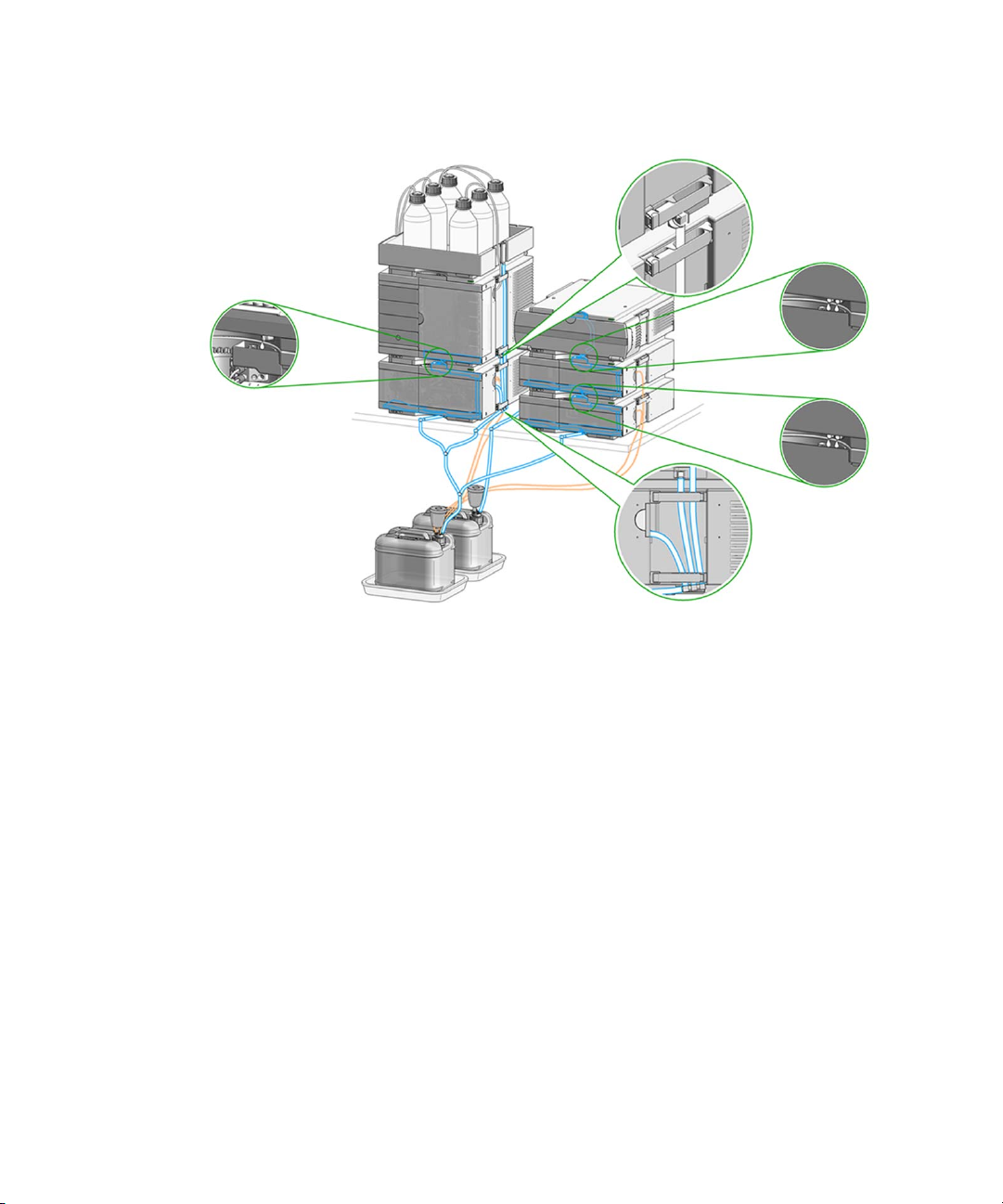

Figure 11 Infinity II Leak Waste Concept (Flex Bench installation)

Agilent InfinityLab LC Series Vialsamplers User Manual 28

Page 29

1Introduction

Leak and Waste Handling

Figure 12 Infinity II Single Stack Leak Waste Concept (bench installation)

Agilent InfinityLab LC Series Vialsamplers User Manual 29

Page 30

1Introduction

Leak and Waste Handling

Figure 13 Infinity II Two Stack Leak Waste Concept (bench installation)

The waste tube connected to the leak plane outlet on each of the bottom

instruments guides the solvent to a suitable waste container.

Agilent InfinityLab LC Series Vialsamplers User Manual 30

Page 31

1Introduction

CAUTION

NOTE

NOTE

Leak and Waste Handling

Leak Sensor

Solvent incompatibility

The solvent DMF (dimethyl formamide) leads to corrosion of the leak sensor.

The material of the leak sensor, PVDF (polyvinylidene fluoride), is incompatible

with DMF.

Do not use DMF as mobile phase.

Check the leak sensor regularly for corrosion.

The leak sensor in the sampler is hidden under the ICC Column Heater or Column

Shelf respectively.

Waste Guidance

Agilent InfinityLab LC Series Vialsamplers User Manual 31

The waste drainage must go straight into the waste containers. The waste flow

must not be restricted at bends or joints.

Page 32

1Introduction

Leak and Waste Handling

Waste Concept

1 Agilent recommends using the 6 L waste can with 1 Stay Safe cap GL45 with

4 ports (5043-1221) for optimal and safe waste disposal. If you decide to use

your own waste solution, make sure that the tubes don't immerse in the liquid.

Agilent InfinityLab LC Series Vialsamplers User Manual 32

Page 33

2 Site Requirements and Specifications

Site Requirements 34

Physical Specifications 38

Performance Specifications 39

Performance Specifications (G7129A) 39

Performance Specifications (G7129B) 42

Performance Specifications (G7129C) 45

Specifications of the Sample Cooler 47

Specifications of the Sample Thermostat 49

Specifications of the Integrated Column Compartment 51

This chapter provides information on environmental requirements, physical and

performance specifications.

Agilent InfinityLab LC Series Vialsamplers User Manual 33

Page 34

2 Site Requirements and Specifications

WARNING

WARNING

WARNING

Site Requirements

Site Requirements

Site Requirements

A suitable environment is important to ensure optimum performance of the

instrument.

Power Considerations

The module power supply has wide ranging capability. It accepts any line voltage

in the range described in

selector in the rear of the module. There are also no externally accessible fuses,

because automatic electronic fuses are implemented in the power supply.

Hazard of electrical shock or damage of your instrumentation

can result, if the devices are connected to a line voltage higher than

specified.

Connect your instrument to the specified line voltage only.

Table 1 on page 38. Consequently there is no voltage

Agilent InfinityLab LC Series Vialsamplers User Manual 34

Electrical shock hazard

The module is partially energized when switched off, as long as the power

cord is plugged in.

The cover protects users from personal injuries, for example electrical

shock.

Do not open the cover.

Do not operate the instrument and disconnect the power cable in case

the cover has any signs of damage.

Contact Agilent for support and request an instrument repair service.

Inaccessible power plug.

In case of emergency it must be possible to disconnect the instrument

from the power line at any time.

Make sure the power connector of the instrument can be easily reached

and unplugged.

Provide sufficient space behind the power socket of the instrument to

unplug the cable.

Page 35

2 Site Requirements and Specifications

WARNING

WARNING

WARNING

Site Requirements

Power Cords

Country-specific power cords are available for the module. The female end of all

power cords is identical. It plugs into the power-input socket at the rear. The male

end of each power cord is different and designed to match the wall socket of a

particular country or region.

Agilent makes sure that your instrument is shipped with the power cord that is

suitable for your particular country or region.

Unintended use of power cords

Using power cords for unintended purposes can lead to personal injury or

damage of electronic equipment.

Never use a power cord other than the one that Agilent shipped with this

instrument.

Never use the power cords that Agilent Technologies supplies with this

instrument for any other equipment.

Never use cables other than the ones supplied by Agilent Technologies

to ensure proper functionality and compliance with safety or EMC

regulations.

Agilent InfinityLab LC Series Vialsamplers User Manual 35

Absence of ground connection

The absence of ground connection can lead to electric shock or short

circuit.

Never operate your instrumentation from a power outlet that has no

ground connection.

Electrical shock hazard

Solvents may damage electrical cables.

Prevent electrical cables from getting in contact with solvents.

Exchange electrical cables after contact with solvents.

Page 36

2 Site Requirements and Specifications

WARNING

NOTE

Site Requirements

Room Size and Ventilation

Flammable refrigerant

Formation of flammable gas-air mixtures inside the Sample Thermostat

and laboratory.

Keep open fire or sources of ignition away from the device.

Ensure a room size of 4 m3 (1 m3 for every 8 g of R600a refrigerant

inside of the Sample Thermostat).

Ensure adequate ventilation: typical air exchange of 25 m3/h per m2 of

laboratory floor area.

Keep all ventilation openings in the enclosure clear of obstructions. Do

not block the openings on the circumference of the Sample Thermostat.

Bench Space

Agilent InfinityLab LC Series Vialsamplers User Manual 36

The module dimensions and weight (see Table 1 on page 38) allow you to place

the module on almost any desk or laboratory bench. It needs an additional

2.5

cm (1.0 inches) of space on either side and approximately 8 cm (3.1 inches)

in the rear for air circulation and electric connections.

If the bench shall carry a complete HPLC system, make sure that the bench is

designed to bear the weight of all modules.

The module should be operated in a horizontal position, especially if a Sample

Cooler or Sample Thermostat is installed. Use a bubble level to check the leveling

of the sampler.

Agilent recommends that you install the HPLC instrument in the InfinityLab Flex

Bench rack. This option helps to save bench space as all modules can be placed

into one single stack. It also allows to easily relocate the instrument to another

laboratory.

Page 37

2 Site Requirements and Specifications

WARNING

CAUTION

Site Requirements

Heavy weight

The module is heavy.

Carry the module at least with 2 people.

Avoid back strain or injury by following all precautions for lifting heavy

objects.

Ensure that the load is as close to your body as possible.

Ensure that you can cope with the weight of your load.

Condensation

Condensation within the module

Condensation can damage the system electronics.

Do not store, ship or use your module under conditions where temperature

fluctuations could cause condensation within the module.

Agilent InfinityLab LC Series Vialsamplers User Manual 37

If your module was shipped in cold weather, leave it in its box and allow it to

warm slowly to room temperature to avoid condensation.

Page 38

2 Site Requirements and Specifications

Physical Specifications

Physical Specifications

Tab le 1 Physical Specifications G7129A, G7129B, G7129C

Type Specification Comments

Weight 19 kg (41.9 lbs) w/o sample thermostat

Dimensions

(height × width × depth)

Line voltage 100 – 240 V~, ± 10 % Wide-ranging capability

Line frequency 50 or 60 Hz, ± 5 %

Power consumption 350 VA, 350 W, 1195 BTU/h

Ambient operating temperature

320 x 396 x 468 mm

(12.8 x 15.6 x 18.4 inches)

4 - 40 °C (39 - 104 °F); without sample thermostat up to 55 °C (131 °F)

Ambient non-operating temperature

Humidity

Operating altitude Up to 3000 m (9842 ft)

Safety standards:

IEC, EN, CSA, UL

ISM Classification ISM Group 1 Class B According to CISPR 11

Permitted solvents Boiling point ≥56 °C (133 °F).

1

If a sample thermostat is included the upper value for humidity can be reduced. Please check your lab

conditions to stay beyond dew point values for non–condensing operation.

-40 – 70 °C (-40 – 158 °F)

< 95 % r.h. at 40 °C (104 °F)

Installation category II, Pollution degree 2 For indoor use only.

Auto-ignition temperature ≥200 °C

(394

°F).

1

Non-condensing

Agilent InfinityLab LC Series Vialsamplers User Manual 38

Page 39

2 Site Requirements and Specifications

Performance Specifications

Performance Specifications

Performance Specifications (G7129A)

Tab le 2 Performance Specifications G7129A

Type Specification Comments Method/Conditions

Injection range 0.1 – 100 µL in 0.1 µL incre-

ments with 100 µL up to

60

MPa

0.1 – 900 µL in 0.1 µL increments with 900 µL up to

40

MPa

Injection precision <0.25 % RSD of peak areas from

5

µL to 100 µL

Pressure range 0 – 60 MPa (0 – 600 bar,

– 8702 psi)

0

0 – 40 MPa (0 – 400 bar,

0

– 5801 psi)

Sample viscosity

range

Sample capacity 132 x 2 mL vial (two trays

0.2 – 5.0 cP

default)

100 x 2 mL vial (two classic

trays optional)

36 x 6 mL vials (two trays

optional)

Up to 1800 µL with multiple

draw (hardware modification

required)

Requires 900 µL analytical head

Measured caffeine

for 900 µL Analytical Head

Agilent InfinityLab LC Series Vialsamplers User Manual 39

Page 40

2 Site Requirements and Specifications

Performance Specifications

Table 2 Performance Specifications G7129A

Type Specification Comments Method/Conditions

Carryover <0.004 % (40 ppm) with needle

wash

Injection cycle time 18 s for draw speed 200 µL/min

Ejection speed: 200 µL/min

Injection volume: 1 µL

Minimum sample volume

1 µL from 5 µL sample in 100 µL

microvial, or 1

sample in 300

µL from 10 µL

µL microvial.

Needle height offset has to be

adapted to ensure that needle

doesn’t touch vial bottom.

Default needle height = 0

equates to 2

bottom.

mm above the vial

Using the following conditions:

• Column: Agilent Pursuit XRs

3 C18, 2.0 x 50

• Mobile Phase:

• A: 0.1 % TFA in water

• B: 0.1 % TFA in acetoni-

trile

• Isocratic : %B = 40 %

• Flow rate: 0.5 mL/min

• Temperature: Ambient

• Wavelength: 257/4 nm

• Injection volume: 1 µL

• Sample: 1200 ng/µL Chlor-

hexidine for UV (dissolved

with mobile phase A), 1

injected and measured with

Agilent UV detector

• Wash solution: H2O with

0.1

% TFA (3 s)

mm

µL

Instrument Control LC & CE Drivers A.02.12 or

above

Instrument Control Framework

(ICF) A.02.03 or above

Instant Pilot (G4208A) with firmware B.02.19 or above

Lab Advisor B.02.07 or above

Communication Controller Area Network

(CAN),Local Area Network

(LAN)

ERI: ready, start, stop and

shut-down signals

For details about supported

software versions refer to the

compatibility matrix of your ver

sion of the LC & CE Drivers

-

Agilent InfinityLab LC Series Vialsamplers User Manual 40

Page 41

2 Site Requirements and Specifications

Performance Specifications

Table 2 Performance Specifications G7129A

Type Specification Comments Method/Conditions

Maintenance and

safety-related features

GLP features Early maintenance feedback

Housing All materials recyclable.

Extensive diagnostics, error

detection and display with Agi

lent Lab Advisor software

Leak detection, safe leak handling, leak output signal for

shutdown of pumping system,

and low voltages in major main

tenance areas

(EMF) for continuous tracking

of instrument usage with

user-settable limits and feed

back messages. Electronic

records of maintenance and

errors.

-

-

-

Agilent InfinityLab LC Series Vialsamplers User Manual 41

Page 42

2 Site Requirements and Specifications

Performance Specifications

Performance Specifications (G7129B)

Tab le 3 Performance Specifications G7129B

Type Specification Comments Method/Conditions

Injection range 0.1 – 20 µL in 0.1 µL increments

(default)

0.1 – 40 µL in 0.1 µL increments

µL loop is installed)

(if 40

0.1 – 120 µL in 0.1 µL incre-

ments with 1290 Infinity large

volume injection kit (hardware

modification required)

0.1 – 100 µL in 0.1 µL (if 100 µL

loop and 100

installed)

Injection precision <0.25 % RSD of peak areas from

µL to 100 µL

5

Pressure range Up to 130 MPa (1300 bar,

18854

Sample viscosity

range

Sample capacity 132 x 2 mL vial (two trays

0.2 – 5.0 cP

default)

100 x 2 mL vial (two classic

trays optional)

36 x 6 mL vials (two trays

optional)

µL head is

psi)

Up to 1500 µL (with 1400 µL

multi-draw kit and 100

lytical head)

up to 130 MPa (1300 bar,

18854

psi)

up to 60 MPa (600 bar,

psi)

8702

Measured caffeine

µL ana-

Agilent InfinityLab LC Series Vialsamplers User Manual 42

Page 43

2 Site Requirements and Specifications

Performance Specifications

Table 3 Performance Specifications G7129B

Type Specification Comments Method/Conditions

Carryover <0.004 % (40 ppm) with needle

wash

Injection cycle time 18 s for draw speed 200 µL/min

Ejection speed: 200 µL/min

Injection volume: 1 µL

Minimum sample volume

1 µL from 5 µL sample in 100 µL

microvial, or 1

sample in 300

µL from 10 µL

µL microvial.

Needle height offset has to be

adapted to ensure that needle

doesn’t touch vial bottom.

Default needle height = 0

equates to 2

bottom.

mm above the vial

Using the following conditions:

• Column: Agilent Pursuit XRs

3 C18, 2.0 x 50

• Mobile Phase:

• A: 0.1 % TFA in water

• B: 0.1 % TFA in acetoni-

trile

• Isocratic : %B = 40 %

• Flow rate: 0.5 mL/min

• Temperature: Ambient

• Wavelength: 257/4 nm

• Injection volume: 1 µL

• Sample: 1200 ng/µL Chlor-

hexidine for UV (dissolved

with mobile phase A), 1

injected and measured with

Agilent UV detector

• Wash solution: H2O with

0.1

% TFA (3 s)

mm

µL

Instrument control LC & CE Drivers A.02.12 or

above

Instrument Control Framework

(ICF) A.02.03 or above

Instant Pilot (G4208A) with firmware B.02.19 or above

Lab Advisor B.02.07 or above

Communication Controller Area Network (CAN),

Local Area Network (LAN),

ERI: ready, start, stop and

shut-down signals

For details about supported

software versions refer to the

compatibility matrix of your ver

sion of the LC & CE Drivers

-

Agilent InfinityLab LC Series Vialsamplers User Manual 43

Page 44

2 Site Requirements and Specifications

Performance Specifications

Table 3 Performance Specifications G7129B

Type Specification Comments Method/Conditions

Maintenance and

safety-related features

GLP features Early maintenance feedback

Housing All materials recyclable.

Extensive diagnostics, error

detection and display with Agi

lent Lab Advisor software

Leak detection, safe leak handling, leak output signal for

shutdown of pumping system,

and low voltages in major main

tenance areas

(EMF) for continuous tracking

of instrument usage with

user-settable limits and feed

back messages. Electronic

records of maintenance and

errors.

-

-

-

Agilent InfinityLab LC Series Vialsamplers User Manual 44

Page 45

2 Site Requirements and Specifications

Performance Specifications

Performance Specifications (G7129C)

Tab le 4 Performance Specifications G7129C

Type Specification Comments Method/Conditions

Injection range 0.1 – 100 µL in 0.1 µL incre-

ments with 100 µL up to

80

MPa

Injection precision <0.25 % RSD of peak areas from

5

µL to 100 µL

Pressure range 0 – 80 MPa (0 – 800 bar,

– 11603 psi)

0

Sample viscosity

range

Sample capacity 132 x 2 mL vial (two trays

Carryover <0.004 % (40 ppm) with needle

0.2 – 5.0 cP

default)

100 x 2 mL vial (two classic

trays optional)

36 x 6 mL vials (two trays

optional)

wash

Up to 1800 µL with multiple

draw (hardware modification

required)

Measured caffeine

Using the following conditions:

• Column: Agilent Pursuit XRs

3 C18, 2.0 x 50

• Mobile Phase:

• A: 0.1 % TFA in water

• B: 0.1 % TFA in acetoni-

trile

• Isocratic : %B = 40 %

• Flow rate: 0.5 mL/min

• Temperature: Ambient

• Wavelength: 257/4 nm

• Injection volume: 1 µL

• Sample: 1200 ng/µL Chlor-

hexidine for UV (dissolved

with mobile phase A), 1

injected and measured with

Agilent UV detector

• Wash solution: H2O with

0.1

% TFA (3 s)

mm

µL

Injection cycle time 18 s for draw speed 200 µL/min

Ejection speed: 200 µL/min

Injection volume: 1 µL

Agilent InfinityLab LC Series Vialsamplers User Manual 45

Page 46

2 Site Requirements and Specifications

Performance Specifications

Table 4 Performance Specifications G7129C

Type Specification Comments Method/Conditions

Minimum sample volume

Instrument Control LC & CE Drivers A.02.17 or

Communication Controller Area Network (CAN),

Maintenance and

safety-related features

1 µL from 5 µL sample in 100 µL

microvial, or 1

sample in 300

above

Instrument Control Framework

(ICF) A.02.05 or above

Instant Pilot (G4208A) with firmware B.02.22 or above

InfinityLab LC Companion

(G7108A)

Lab Advisor B.02.10 or above

Local Area Network (LAN),

ERI: ready, start, stop and

shut-down signals

Extensive diagnostics, error

detection and display with Agi

lent Lab Advisor software

Leak detection, safe leak handling, leak output signal for

shutdown of pumping system,

and low voltages in major main

tenance areas

µL from 10 µL

µL microvial.

Needle height offset has to be

adapted to ensure that needle

doesn’t touch vial bottom.

Default needle height = 0

equates to 2

bottom.

For details about supported

software versions refer to the

compatibility matrix of your ver

sion of the LC & CE Drivers

-

-

mm above the vial

-

GLP features Early maintenance feedback

(EMF) for continuous tracking

of instrument usage with

user-settable limits and feed

back messages. Electronic

records of maintenance and

errors.

Housing All materials recyclable.

-

Agilent InfinityLab LC Series Vialsamplers User Manual 46

Page 47

2 Site Requirements and Specifications

Specifications of the Sample Cooler

Specifications of the Sample Cooler

The Agilent Infinity II Sample Cooler is a vapor-compression refrigeration system

that uses a fluorinated greenhouse gas (HCF-134a) as the refrigerant. For

information on carbon dioxide equivalency (CDE) and global warming potential

(GWP), see the instrument label.

Tab le 5 Physical Specification of the Sample Cooler

Type Specification Comment

Weight < 6 kg (< 13.2 lbs)

Dimensions (height × width × depth) 205 x 340 x 370 mm

(8.1 x 13.4 x 14.6 inches)

Refrigerant gas HFC-134a (0.042 kg) Ozone depletion poten-

tial (ODP) = 0

Supply voltage 24 VDC

Current 10 A max.

Ambient operating temperature 4 – 40 ° C (39 – 104 ° F)

Ambient non-operating temperature -40 – 70 ° C (-40 – 158 ° F)

Humidity < 95 % r.h. at 40 °C (104 °F) Non-condensing

Operating altitude Up to 3000 m (9842 ft)

Safety standards:

IEC, EN, CSA, UL

ISM Classification ISM Group 1 Class B According to CISPR 11

Installation category II, Pollution

degree 2

For indoor use only

Agilent InfinityLab LC Series Vialsamplers User Manual 47

Page 48

2 Site Requirements and Specifications

CAUTION

NOTE

Specifications of the Sample Cooler

General hazards and improper disposal

Improper disposal of the media and components used pollutes the

environment.

The disposal or scrapping of the Sample Cooler or the Sample Thermostat

must be carried out by a qualified disposal company.

All media must be disposed of in accordance with national and local

regulations.

Please contact your local Agilent Service Center in regard to safe

environmental disposal of the appliance or check www.agilent.com for

more info.

Tab le 6 Performance Specifications of the Sample Cooler

Type Specifications

Operating principle High performance, low-energy consumption

micro-compressor based cooler with

ozone-friendly HFC-134a coolant (42 g),

user-upgradable.

Agilent InfinityLab LC Series Vialsamplers User Manual 48

Temperature range from 4 °C to 5 °C below ambient

Temperature settable from 4 – 40 °C in 1 ° increments

Temperature accuracy (<25 °C, <50 % r.H.) 2 °C to 6 °C at a setpoint of 4 °C

The Agilent Infinity II Sample Cooler is not available for trade sales anymore and

has been replaced by the Agilent InfinityLab Sample Thermostat.

Page 49

2 Site Requirements and Specifications

Specifications of the Sample Thermostat

Specifications of the Sample Thermostat

The Agilent InfinityLab Sample Thermostat is the combination of an electric

heater and a vapor-compression refrigeration system. It uses isobutane as a

non-Freon refrigerant, which is harmless to the environment and does not affect

the ozone layer and global warming but is combustible. Please adhere to the

warnings listed in the manual.

Tab le 7 Physical Specifications of the Sample Thermostat

Type Specification Comments

Weight <6 kg (< 13.2 lbs)

Dimensions

(height x width x depth)

Refrigerant gas R600a (0.030 kg) Ozone depletion potential (ODP) =0

Supply voltage 24VDC

205 x 340 x 370 mm

(8.1 x 13.4 x 14.6 inches)

Global warming potential (GWP) =3

Current 10 A max.

Ambient operating

temperature

Ambient non-operating temperature

Humidity < 95 % r.h. at 40 °C (104 °F) Non-condensing

Operating altitude Up to 3000 m (9842 ft)

Safety standards:

IEC, EN, CSA, UL

ISM Classification ISM Group 1 Class B According to CISPR 11

4 – 40 °C (39 – 104 °F)

-40 – 70 °C (-40 – 158 °F)

Installation category II,

Pollution degree 2

For indoor use only

Agilent InfinityLab LC Series Vialsamplers User Manual 49

Page 50

2 Site Requirements and Specifications

CAUTION

NOTE

Specifications of the Sample Thermostat

General hazards and improper disposal

Improper disposal of the media and components used pollutes the

environment.

The disposal or scrapping of the Sample Cooler or the Sample Thermostat

must be carried out by a qualified disposal company.

All media must be disposed of in accordance with national and local

regulations.

Please contact your local Agilent Service Center in regard to safe

environmental disposal of the appliance or check www.agilent.com for

more info.

Tab le 8 Performance Specifications for the Sample Thermostat

Type Specifications

Operating principle High performance, low-energy consumption micro-compressor based

cooler with natural R600a coolant (Butane 30

Temperature range from 4 – 40 °C

Temperature settable from 4 – 40 °C in 1 ° increments

g), user-upgradable

Agilent InfinityLab LC Series Vialsamplers User Manual 50

Temperature accuracy

(<25 °C, <50 % r.H.)

2 °C to 6 °C at a setpoint of 4 °C

Minimum firmware revision for the Sample Thermostat is D.07.22.

Minimum LC driver revision for the Sample Thermostat is A.02.14.

Page 51

2 Site Requirements and Specifications

Specifications of the Integrated Column Compartment

Specifications of the Integrated Column

Compartment

Physical Specifications Agilent InfinityLab LC Series Integrated Column Compartment (G7130A)

Tab le 9 Physical Specifications (G7130A)

Type Specification Comment

Weight 1.8 kg (4.0 lbs)

Dimensions

(height x width x depth)

Supply Voltage 24 V DC

Power consumption 110 W

Ambient operating temperature 4 – 55 °C (39 – 131 °F)

Ambient non-operating temperature

Humidity

Operating altitude Up to 3000 m (9842 ft)

Safety standards

IEC, EN, CSA, UL

ISM Classification ISM Group 1 Class B According to CISPR 11

1

If a sample cooler is included the upper value for humidity can be reduced. Please check your lab conditions to stay beyond dew point values for non–condensing operation.

86.5 x 396.0 x 106.5 mm

(3.4 x 15.6 x 4.2 inches)

-40 – 70 °C (-40 – 158 °F)

< 95 % r.h. at 40 °C (104 °F)

Installation category II, Pollution

degree 2

1

Maximum outside

Non-condensing

For indoor use only

Agilent InfinityLab LC Series Vialsamplers User Manual 51

Page 52

2 Site Requirements and Specifications

Specifications of the Integrated Column Compartment

Performance Specifications Agilent InfinityLab LC Series Integrated Column Compartment (G7130A)

Tab le 10 Performance Specifications G7130A

Type Specification Comments

Temperature range 5 °C above ambient to 80 °C

Column capacity 2 columns up to 30 cm and

mm ID

4.6

Temperature stability ±0.10 °C at sensor

Temperature accuracy ±0.8 K (±0.5 K with calibration)

Warm up time 20 – 40 °C in 5 min at sensor

Agilent InfinityLab LC Series Vialsamplers User Manual 52

Page 53

3Using the Module

Magnets 55

Turn on/off 56

Status Indicators 58

Vial Drawers and Trays 59

List of Drawers and Trays 59

Exchange Drawers 62

Insert a Vial Into the Sampler 65

Install the External Tray 67

Choice of Vials and Caps 70

Compatible Vials and Caps for the 2 mL Vial Drawers 70

Compatible Vials and Caps for the 6 mL Vial Drawer 73

Install the Optional Integrated Column Compartment 74

Unpacking the Unit 74

Install the Integrated Column Compartment 76

Install a Column in the ICC 82

Remove a Column from the ICC 86

Install the Column Shelf 88

Install the Column ID Upgrade Kit 92

Connect a Column Identification Tag to the Tag Reader 94

Using the Optional Integrated Column Compartment 96

Dashboard 96

Control Interface 97

Control 98

Method Parameters 99

Online Signals 101

Column Assignment 102

Column Tag Information Table 103

Using Column Identification Tags 104

Install the Optional Sample Cooler/Sample Thermostat 116

Unpacking the Unit 116

Install the Sample Cooler/Sample Thermostat 117

Using the Optional Sample Cooler/Sample Thermostat 123

Dashboard 123

Control Interface 124

Control 125

Temperature Mode 127

Online Signals 128

Agilent InfinityLab LC Series Vialsamplers User Manual 53

Page 54

3Using the Module

Specifications of the Integrated Column Compartment

Reporting Sample Temperature 129

Operation Information 130

Transporting the Sampler 132

Prepare a Sampler Without Cooler/Thermostat for Transportation 132

Prepare a Sampler with Cooler/Thermostat for Transportation 133

Install the Transport Protection Foam 135

Agilent Local Control Modules 137

This chapter provides information on how to use the module.

Agilent InfinityLab LC Series Vialsamplers User Manual 54

Page 55

3Using the Module

Magnets

Magnets

1 Magnets in doors of pumps, autosamplers, detectors, and fraction collectors.

Agilent InfinityLab LC Series Vialsamplers User Manual 55

Page 56

3Using the Module

Turn on/off

Turn on/off

This procedure exemplarily shows an arbitrary LC stack configuration.

1 2

Power switch: On

Agilent InfinityLab LC Series Vialsamplers User Manual 56

Page 57

3Using the Module

Turn on/off

3 Turn instrument On/Off with the control software. 4

Power switch: Off

5

Agilent InfinityLab LC Series Vialsamplers User Manual 57

Page 58

3Using the Module

Status Indicators

Status Indicators

This procedure exemplarily shows an arbitrary LC stack configuration.

1 The module status indicator indicates one of six possible module conditions:

Status indicators

1. Idle

2. Run mode

3. Not-ready. Waiting for a specific pre-run condition to be reached or

completed.

4. Error mode - interrupts the analysis and requires attention (for example a

leak or defective internal components).

5. Resident mode (blinking) - for example during update of main firmware.

6. Bootloader mode (fast blinking). Try to re-boot the module or try a

cold-start. Then try a firmware update.

Agilent InfinityLab LC Series Vialsamplers User Manual 58

Page 59

3Using the Module

NOTE

Vial Drawers and Trays

Vial Drawers and Trays

List of Drawers and Trays

Supported drawers for the module:

p/n Description

G7129-60010 Drawer for 66 x 2 mL Vials

G7129-60110 Drawer for 18 x 6 mL Vials

G7129-68210 Classic Vial Drawer Kit

G7129-60210 Classic Drawer for 50 x 2 mL Vials, Left

G7129-60220 Classic Drawer for 50 x 2 mL Vials, Right

G7129-60000 External Tray for 5 x 2 mL Vials

Install all drawers for best cooling performance.

Drawer Combinations

Drawers can be installed in any combination enabling both 2 mL- and 6 mL-vials

to be used simultaneously. The only exception is the usage of the classical

drawer option (100 x 2

mL). This option can't combine with the other drawers.

Numbering of Vial Positions

The standard 2*66 vial drawers have 132 vial positions from P1-A1-P2-F11.

However, when using two drawers, the numbering convention is slightly different.

The vial positions of the right-hand drawer begin at position P2-A1 as follows:

Left-hand Drawer for 66 x 2 mL Vials: P1-A1 to P1-F11

Left-hand Drawer for 18 x 6 mL Vials: P1-A1 to P1-C6

Right-hand Drawer for 66 x 2 mL Vials: P2-A1 to P2-F11

Right-hand Drawer for 18 x 6 mL Vials: P2-A1 to P2-C6

Drawer for 50 x 2 mL Vials Classic Left: Vial 1-50

Agilent InfinityLab LC Series Vialsamplers User Manual 59

Page 60

3Using the Module

P1-A1

P1-F11

P2-A1

P2-F11

P1-A1

P1-C6

P2-A1

P2-C6

Vial Drawers and Trays

Drawer for 50 x 2 mL Vials Classic Right: Vial 51-100

External Tray 5-position: 201 – 205 Position

(The disposal tube is installed into the external tray by turning and pushing it into

the backside of the hole position, No. 206)

Figure 14 Numbering of drawer position (left-hand Drawer for 66 x 2 mL Vials)

Figure 15 Numbering of drawer position (right-hand Drawer for 66 x 2 mL Vials)

Figure 16 Numbering of drawer position (left-hand Drawer for 18 x 6 mL Vials)

Figure 17 Numbering of drawer position (right-hand Drawer for 18 x 6 mL Vials)

Agilent InfinityLab LC Series Vialsamplers User Manual 60

Page 61

3Using the Module

1

50

51

100

201

202

203

204

205

206

(Waste Disposal)

Vial Drawers and Trays

Figure 18 Numbering of drawer position (Drawer for 50 x 2 mL Vials Classic)

Agilent InfinityLab LC Series Vialsamplers User Manual 61

Figure 19 Numbering of tray position (External tray)

Page 62

3Using the Module

NOTE

NOTE

NOTE

Vial Drawers and Trays

Exchange Drawers

Do not operate the sampler without drawers installed.

Install all drawers for best cooling performance.

Do not mix standard and classic drawers.

Install classic drawer 1-50 to the left, classic drawer 51-100 to the right side.

Agilent InfinityLab LC Series Vialsamplers User Manual 62

Page 63

3Using the Module

Vial Drawers and Trays

1 Open the doors of the module. 2 Remove the drawer.

a Pull the drawer out.

b Lift the front of the drawer.

c Lift the drawer out.

d Remove the drawer.

Agilent InfinityLab LC Series Vialsamplers User Manual 63

Page 64

3Using the Module

Vial Drawers and Trays

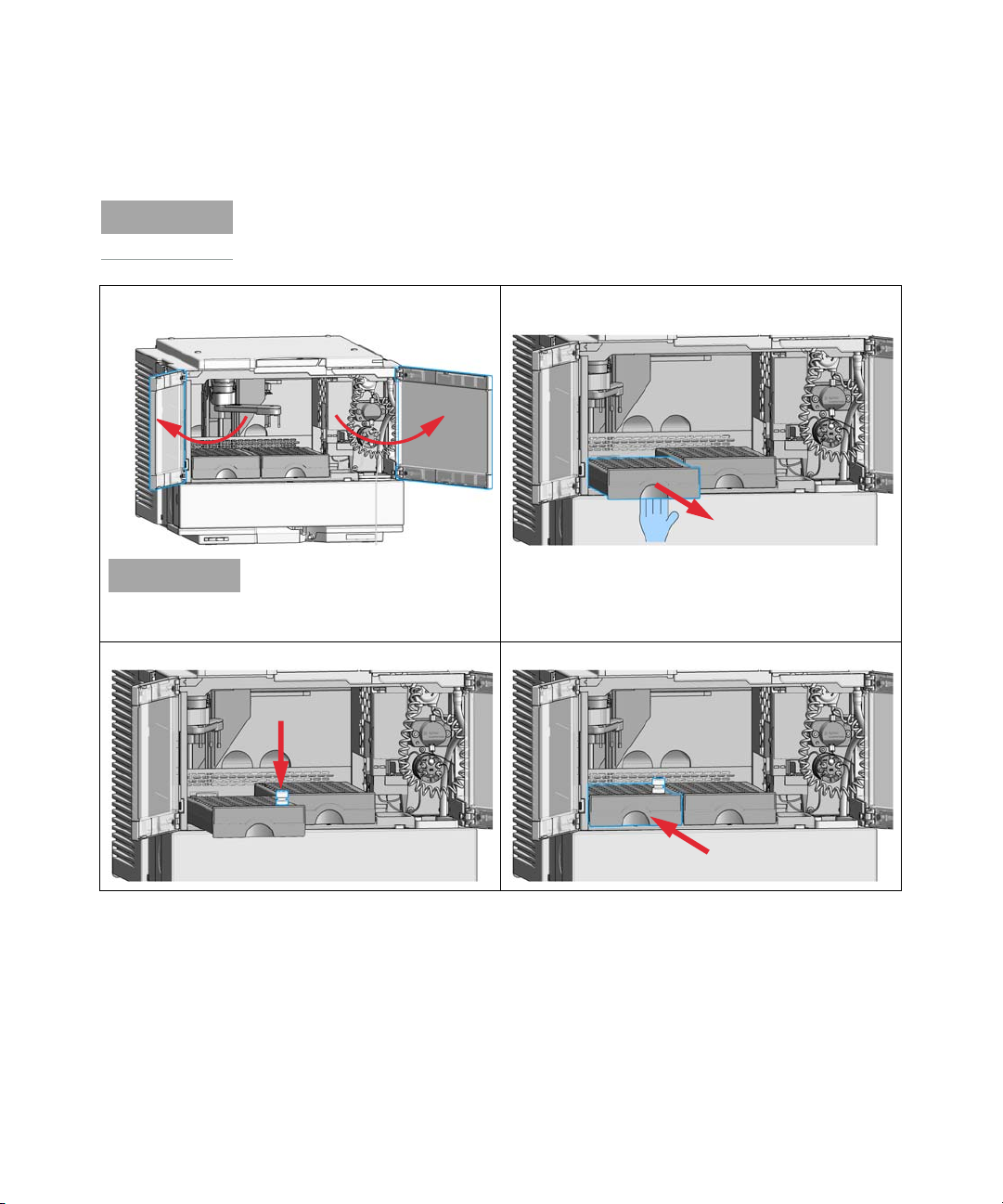

3 Install the drawer.

a Insert the back of the drawer.

b Align the drawer.

c Push in the drawer.

4 Close the doors.

Agilent InfinityLab LC Series Vialsamplers User Manual 64

Page 65

3Using the Module

NOTE

NOTE

Vial Drawers and Trays

Insert a Vial Into the Sampler

Attempting to insert a new vial into the sampler while the gripper arm is moving

might lead to aborting the ongoing analysis.

1 Open the doors of the module.

For accessing the left drawer, it is sufficient to open the left

door only.

3 Insert the vial into an appropriate position of the drawer. 4 Push the vial drawer back into place.

2 Pull out the vial drawer into which you want to insert the

vial.

Agilent InfinityLab LC Series Vialsamplers User Manual 65

Page 66

3Using the Module

Vial Drawers and Trays

5 Close the doors.

Agilent InfinityLab LC Series Vialsamplers User Manual 66

Page 67

3Using the Module

NOTE

Vial Drawers and Trays

Install the External Tray

Tools required Description

Flathead screwdriver

Parts required p/n Description

G7129-60000 External Tray for 5 x 2 mL Vials

G1313-27302 Disposal tube

Preparations

• Turn off the sampler

• Open the doors

• Remove the samples

Keep foam and plastic cover in a safe place.

For best temperature performance, and if the external tray is not in use, it is best

to cover the opening for the external tray with the original parts.

Agilent InfinityLab LC Series Vialsamplers User Manual 67

Page 68

3Using the Module

Vial Drawers and Trays

1 Remove the foam and the plastic cover.

a Lift up the front part of the foam with a flathead

screw driver.

b Remove the foam.

2 Install the external tray and the disposal tube.

a Mount the external tray in the mounting holes on

the left side of the sampler and ensure that it is

pushed in all the way.

b Install the disposal tube.

c Push out the plastic cover.

Agilent InfinityLab LC Series Vialsamplers User Manual 68

Page 69

3Using the Module

Vial Drawers and Trays

3 Close the doors. 4 Configure the External Tray in the online view of the

Chromatographic Data System: right-click on the sam

pler dashboard and select Modify> External Tray. In the

dialog, select the External Tray installed check box.

-

Agilent InfinityLab LC Series Vialsamplers User Manual 69

Page 70

3Using the Module

Choice of Vials and Caps

Choice of Vials and Caps

Compatible Vials and Caps for the 2 mL Vial Drawers

List of Compatible Vials and Caps

For reliable operation vials used with the autosampler must not have tapered

shoulders or caps that are wider than the body of the vial. The vials in

Vials” on page 70, “Snap Top Vials” on page 71 and “Screw Top Vials” on page 71

and caps in “Crimp Caps” on page 72, “Snap Caps” on page 72 and “Screw

Caps” on page 72 (shown with their Part numbers) have been successfully tested

using a minimum of 15,000 injections with the autosampler.

Crimp Top Vials

p/n Description

“Crimp Top

5181-3375 Crimp Top Vial, 2 mL, clear glass, 100/Pack

5183-4491 Crimp Top Vial, 2 mL, clear glass, 1000/Pack

5182-0543 Crimp Top Vial, 2 mL, clear glass, write-on spot, 100/Pack

5183-4492 Crimp Top Vial, 2 mL, clear glass, write-on spot, 1000/Pack

5183-4494 Crimp Top Vial, 2 mL, clear glass, write-on spot, 100/Pack (silanized)

5181-3376 Crimp Top Vial, 2 mL, amber glass, write-on spot, 100/Pack

5183-4493 Crimp Top Vial, 2 mL, amber glass, write-on spot, 1000/Pack

5183-4495 Crimp Top Vial, 2 mL, amber glass, write-on spot, 100/Pack (silanized)

5182-0567 Crimp Top Vial, 1 mL, polypropylene, wide opening, 100/Pack

5183-4496 Crimp Top Vial, 1 mL, polypropylene, wide opening, 100/Pack

(silanized)

9301-0978 Crimp top vial, 250 µL, polypropylene, wide opening, 1000/Pack

Agilent InfinityLab LC Series Vialsamplers User Manual 70

Page 71

3Using the Module

Choice of Vials and Caps

Snap Top Vials

p/n Description

5182-0544 Snap Top Vial, 2 mL, clear glass, 100/Pack

5183-4504 Snap Top Vial, 2 mL, clear glass, 1000/Pack

5183-4507 Snap Top Vial, 2 mL, clear glass, 100/Pack (silanized)

5182-0546 Snap Top Vial, 2 mL, clear glass, write-on spot, 100/Pack

5183-4505 Snap Top Vial, 2 mL, clear glass, write-on spot, 1000/Pack

5183-4508 Snap Top Vial, 2 mL, clear glass, write-on spot, 100/Pack (silanized)

5182-0545 Snap Top Vial, 2 mL, amber glass, write-on spot, 100/Pack

5183-4506 Snap Top Vial, 2 mL, amber glass, write-on spot, 1000/Pack

5183-4509 Snap Top Vial, 2 mL, amber glass, write-on spot, 100/Pack (silanized)

Screw Top Vials

p/n Description

5182-0714 Screw Cap Vials, 2 mL, clear glass, 100/Pack

5183-2067 Screw Top Vial, 2 mL, clear glass, 1000/Pack

5183-2070 Screw Top Vial, 2 mL, clear glass, 100/Pack (silanized)

5182-0715 Screw Top Vial, 2 mL, clear glass, write-on spot, 100/Pack

5183-2068 Screw Top Vial, 2 mL, clear glass, write-on spot, 1000/Pack

5183-2071 Screw Top Vial, 2 mL, clear glass, write-on spot, 100/Pack (silanized)

5182-0716 Screw Cap Vial, 2 mL, amber glass, write-on spot, 100/Pack

5183-2069 Screw Top Vial, 2 mL, amber glass, write-on spot, 1000/Pack

5183-2072 Screw Top Vial, 2 mL, amber glass, write-on spot, 100/Pack (silanized)

Agilent InfinityLab LC Series Vialsamplers User Manual 71

Page 72

3Using the Module

Choice of Vials and Caps

Crimp Caps

p/n Description

5181-1210 Crimp Cap, silver aluminum, septum (clear PTFE/red rubber), 100/Pack

5183-4498 Crimp Cap, silver aluminum, septum (clear PTFE/red rubber), 1000/Pack

5181-1215 Crimp Cap, blue aluminum, septum (clear PTFE/red rubber), 100/Pack

5181-1216 Crimp Cap, green aluminum, septum (clear PTFE/red rubber), 100/Pack

5181-1217 Crimp Cap, red aluminum, septum (clear PTFE/red rubber), 100/Pack

Snap Caps

p/n Description

5182-0550 Snap Cap, clear polypropylene, septum (clear PTFE/red rubber), 100/Pack

5182-3458 Snap Cap, blue polypropylene, septum (clear PTFE/red rubber), 100/Pack

5182-3457 Snap Cap, green polypropylene, septum (clear PTFE/red rubber), 100/Pack

5182-3459 Snap Cap, red polypropylene, septum (clear PTFE/red rubber), 100/Pack

Screw Caps

p/n Description

5182-0717 Screw Cap, blue polypropylene, septum (clear PTFE/red rubber), 100/Pack

5182-0718 Screw Cap, green polypropylene, septum (clear PTFE/red rubber), 100/Pack

5182-0719 Screw Cap, red polypropylene, septum (clear PTFE/red rubber), 100/Pack

5182-0720 Screw Cap, blue polypropylene, septum (clear PTFE/silicone), 100/Pack

5182-0721 Screw Cap, green polypropylene, septum (clear PTFE/silicone), 100/Pack

5182-0722 Screw Cap, red polypropylene, septum (clear PTFE/silicone), 100/Pack

Agilent InfinityLab LC Series Vialsamplers User Manual 72

Page 73

3Using the Module

NOTE

Choice of Vials and Caps

Compatible Vials and Caps for the 6 mL Vial Drawer

For reliable operation of the sampler, the combined height of the vial and cap

should never exceed 40 mm.

Screw Top Vials and Caps

p/n Description

9301-1377 Screw Top Vial, 6 mL, clear glass, flat bottom, 100/Pack

5188-5369 Screw Top Vial, 5 mL, clear glass, high recovery, 100/Pack

9301-1379 Screw Cap, 16 mm, w/o septum, for 6 mL vials, 100/Pack

9301-1378 Septum, PTFE/silicone, for 16 mm caps, 100/Pack

5188-2758 Septum, preslit, PTFE/silicone, for 16 mm caps, 100/Pack

Crimp Top Vials and Caps

p/n Description

9301-1419 Crimp Top Vial, 6 mL, clear glass, flat bottom, 100/Pack

9301-1425 Crimp Cap, silver aluminum, septum (PTFE/silicone), 100/Pack

Agilent InfinityLab LC Series Vialsamplers User Manual 73

Page 74

3Using the Module

CAUTION

CAUTION

Install the Optional Integrated Column Compartment

Install the Optional Integrated Column

Compartment

Unpacking the Unit

Damaged Packaging

Damaged Packaging

If the delivery packaging shows signs of external damage, please call your Agilent

Technologies sales and service office immediately. Inform your service

representative that the instrument may have been damaged during shipment.

"Defective on arrival" problems

If there are signs of damage, please do not attempt to install the module.

Inspection by Agilent is required to evaluate if the instrument is in good

condition or damaged.

Agilent InfinityLab LC Series Vialsamplers User Manual 74

Notify your Agilent sales and service office about the damage.

An Agilent service representative will inspect the instrument at your site and

initiate appropriate actions.

Condensation

Condensation within the module

Condensation can damage the system electronics.

Do not store, ship or use your module under conditions where temperature

fluctuations could cause condensation within the module.

If your module was shipped in cold weather, leave it in its box and allow it to

warm slowly to room temperature to avoid condensation.

Page 75

3Using the Module

Install the Optional Integrated Column Compartment

Delivery Checklist

Ensure all parts and materials have been delivered with your module. The delivery

checklist is shown below. For parts identification please check the illustrated

parts breakdown in

report any missing or damaged parts to your local Agilent Technologies sales

and service office.

Tab le 11 Delivery checklist for the Integrated Column Compartment (ICC)

Description Quantity

Integrated Column Compartment (G7130-60030 or G7130-60060) 1

Accessory Kit for ICC 1

“Integrated Column Compartment” on page 288. Please

Agilent InfinityLab LC Series Vialsamplers User Manual 75

Page 76

3Using the Module

WARNING

Install the Optional Integrated Column Compartment

Install the Integrated Column Compartment

Tools required p/n Description

8710-0510 Open-end wrench 1/4 — 5/16 inch

Parts required # p/n Description

1 G7130-60030 Integrated Column Compartment, 3 µL Heater

OR 1 G7130-60060 Integrated Column Compartment, 6 µL Heater

1 Accessory Kit for ICC

(includes capillaries and column holder clips)

For more information on recommended capillary types refer to “Capillary

Connections” on page 278.

Preparations

• Switch off the pump.

• Switch off the sampler.

• Remove the column.

• Open the doors of the sampler.

Fire or explosion due to missing leak drainage

Solvents may run into the module if column shelf or Integrated Column

Compartment are not installed.

Install either column shelf or Integrated Column Compartment before

starting the module.