Page 1

8510XF Network Analyzer Systems

E7340A & E7342A (2 to 85 GHz)

E7350A & E7352A (2 to 110 GHz)

Operating and Service

Manual

Agilent Part Number: E7350-90001

Printed in USA

Print Date: April 2002

Supersedes: June 2001

Page 2

Notice

The information contained in this document is subject to change without

notice.

Agilent Technologies makes no warranty of any kind with regard to this

material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Agilent Technologies

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or

use of this material.

Agilent Technologies assumes no responsibility for the use or reliability of

its software on equipment that is not furnished by Agilent Technologies.

This document contains proprietary information which is protected by

copyright. All rights are reserved. No part of this document may be

photocopied, reproduced, or translated to another language without prior

written consent of Agilent Technologies.

Restricted Rights Legend

Use, duplication, or disclosure by the U.S. Government is subject to

restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical

Data and Computer Software clause at DFARS 252.227-7013 for DOD

agencies, and subparagraphs (c)(1) and (c)(2) of the Commercial Computer

Software Restricted Rights clause at FAR 52.227-19 for other agencies.

Hewlett-Packard to Agilent Technologies Transition

This documentation supports a product that previously shipped under the

Hewlett-Packard company brand name. The brand name has now been

changed to Agilent Technologies. The two products are functionally

identical, only our name has changed. This document still includes

references to Hewlett-Packard products, some of which have been

transitioned to Agilent Technologies.

Windows ® is a registered copyright of Microsoft corporation.

© Copyright 1998, 2001, 2002 Agilent Technologies, Inc.

ii 8510XF Network Analyzer Systems

Page 3

What You’ll Find in This Manual…

Chapter 1 • Introduction to the 8510XF

Chapter 2 • How to install the system

Chapter 3 • How to use the system to make measurements

Chapter 4 • How to verify the performance of the system

Chapter 5 • How to maintain the system

Chapter 6 • How to order replacement parts

Chapter 7 • How to find information about menus, softkeys, and commands

8510XF Network Analyzer Systems iii

Page 4

Warranty

Certification Agilent Technologies certifies that this product met its published

specifications at the time of shipment from the factory. Agilent Technologies

further certifies that its calibration measurements are traceable to the

United States National Institute of Standards and Technology (NIST,

formerly NBS), to the extent allowed by the Institute’s calibration facility,

and to the calibration facilities of other International Standards

Organization members.

DOCUMENTATION WARRANTY

THE MATERIAL CONTAINED IN THIS DOCUMENT IS

PROVIDED "AS IS," AND IS SUBJECT TO BEING CHANGED,

WITHOUT NOTICE, IN FUTURE EDITIONS. FURTHER, TO

THEMAXIMUMEXTENTPERMITTEDBYAPPLICABLELAW,

AGILENTDISCLAIMSALLWARRANTIES,EITHEREXPRESS

OR IMPLIED WITH REGARD TO THIS MANUAL AND ANY

INFORMATIONCONTAINEDHEREIN,INCLUDINGBUTNOT

LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. AGILENT SHALL NOT BE LIABLE FOR ERRORS

OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH THE FURNISHING, USE, OR

PERFORMANCE OF THIS DOCUMENT OR ANY

INFORMATION CONTAINED HEREIN. SHOULD AGILENT

ANDTHEUSERHAVEASEPARATEWRITTENAGREEMENT

WITH WARRANTY TERMS COVERING THE MATERIAL IN

THIS DOCUMENT THAT CONFLICT WITH THESE TERMS,

THE WARRANTY TERMS IN THE SEPARATE AGREEMENT

WILL CONTROL.

Assistance Product maintenance agreements and other customer assistance agreements

are available for Agilent Technologies products.

For assistance, call your local Agilent Technologies office (see“Contacting

Agilent”)

iv8510XF Network Analyzer Systems

Page 5

Contacting Agilent

Online assistance: www.agilent.com/find/assist

United States

(tel) 1 800 452 4844

New Zealand

(tel) 0 800 738 378

(fax) (+64) 4 495 8950

Malaysia

(tel) 1 800 828 848

(fax) 1 800 801 664

Taiwan

(tel) 0800-047-866

(fax) (886) 2 25456723

Latin America

(tel) (305) 269 7500

(fax) (305) 269 7599

Japan

(tel) (+81) 426 56 7832

(fax) (+81) 426 56 7840

Philippines

(tel) (632) 8426802

(tel) (

PLDT subscriber only):

1 800 16510170

(fax) (632) 8426809

(fax) (

PLDT subscriber only):

1 800 16510288

People’s Republic of

China

(tel) (preferred):

800-810-0189

(tel) (alternate):

10800-650-0021

(fax) 10800-650-0121

Canada

(tel) 1 877 894 4414

(fax) (905) 282-6495

Australia

(tel) 1 800 629 485

(fax) (+61) 3 9210 5947

Thailand

(tel) outside Bangkok:

(088) 226 008

(tel) within Bangkok:

(662) 661 3999

(fax) (66) 1 661 3714

India

(tel) 1-600-11-2929

(fax) 000-800-650-1101

Europe

(tel) (+31) 20 547 2323

(fax) (+31) 20 547 2390

Singapore

(tel) 1 800 375 8100

(fax) (65) 836 0252

Hong Kong

(tel) 800 930 871

(fax) (852) 2506 9233

8510XF Network Analyzer Systems v

Page 6

Safety and Regulatory Information

Safety and Regulatory Information

Review this product and related documentation to familiarize yourself with

safety markings and instructions before you operate the instrument. This

product has been designed and tested in accordance with international

standards.

WARNING The WARNING notice denotes a hazard. It calls attention to a procedure,

practice, or the like, that, if not correctly performed or adhered to, could result

in personal injury. Do not proceed beyond a WARNING notice until the

indicated conditions are fully understood and met.

CAUTION The CAUTION notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like, which, if not correctly performed or adhered

to, could result in damage to the product or loss of important data. Do not

proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

vi 8510XF Network Analyzer Systems

Page 7

Instrument Markings

Safety and Regulatory Information

When you see this symbol on your instrument, you should refer to the instrument’s

!

instruction manual for important information.

This symbol indicates hazardous voltages.

The laser radiation symbol is marked on products that have a laser output.

This symbol indicates that the instrument requires alternating current (ac) input.

The C-Tick mark is a registered trademark of the Australian Spectrum Agency.

The CE mark is a registered trademark of the European Community. If it is

accompanied by a year, it indicates the year the design was proven.

The CSA mark is a registered trademark of the Canadian Standards Association.

Safety Requirements

Safety Earth Ground

1SM1-A This textindicates that the instrument is an Industrial Scientific and Medical Group 1

Class A product (CISPER 11, Clause 4).

This ISM device complies with Canadian ICES-001.

Cet apppareil ISM est conforme a la norme NMB du Canada.

This symbol indicates that the power line switch is ON.

This symbol indicates that the power line switch is OFF or in STANDBY position.

This product has been designed and tested in accordance with the IEC

Publication 1010, Safety Requirements for Electronic Measuring Apparatus,

and has been supplied in a safe condition. The instruction documentation

contains information and warnings which must be followed by the user to

ensure safe operation and maintain the product in a safe condition.

This is a Safety Class I product (provided with a protective earthing

terminal). An uninterruptible safety earth ground must be provided from the

main power source to the product input wiring terminals, power cord, or

supplied power cord set. Whenever it is likely that the protection has been

impaired, the product must be made inoperative and secured against any

unintended operation.

8510XF Network Analyzer Systems vii

Page 8

Safety and Regulatory Information

BeforeApplying Power Verify that the product is configured to match the available main power

source as described in the input power configuration instructions in this

manual. If this product is to be powered by autotransformer, make sure the

common terminal is connected to the neutral (grounded) side of the ac power

supply.

WARNING Danger of explosion if battery is incorrectly replaced. Replace only with the

same or equivalent type recommended. Discard used batteries according to

manufacturers’s instructions.

NOTE Please refer to the 8510C On-Ssite Service Manual for additional

information (part number 08510-90282).

viii 8510XF Network Analyzer Systems

Page 9

Typeface Conventions

Typeface Conventions

Italics • Used to emphasize important information:

Use this software only with the xxxxxX system.

• Used for the title of a publication:

Refer to the xxxxxX System-Level User’s Guide.

• Used to indicate a variable:

Type

LOAD BIN filename.

Instrument Display • Used to show on-screen prompts and messages that you will see on the

display of an instrument:

The xxxxxX will display the message

[Keycap] • Used for labeled keys on the front panel of an instrument or on a

computer keyboard:

Press

[Return].

CAL1 SAVED.

{Softkey} • Used for simulated keys that appear on an instrument display:

Press

{Prior Menu}.

User Entry • Used to indicate text that you will enter using the computer keyboard;

text shown in this typeface must be typed exactly as printed:

Type

LOAD PARMFILE

• Used for examples of programming code:

#endif // ifndef NO_CLASS

Path Name

Computer Display • Used to show messages, prompts, and window labels that appear on a

• Used for a subdirectory name or file path:

Edit the file

usr/local/bin/sample.txt

computer monitor:

The

Edit Parameterswindow will appear on the screen.

• Used for menus, lists, dialog boxes, and button boxes on a computer

monitor from which you make selections using the mouse or keyboard:

Double-click

EXIT to quit the program.

8510XF Network Analyzer Systems ix

Page 10

Compliance with Standards

Compliance with Standards

Compliance with German Noise Requirements

This is to declare that this instrument is in conformance with the German

Regulation on Noise Declaration for Machines (Laermangabe nach der

Maschinenlaermrerordnung

−3.GSGV Deutschand).

Acoustic Noise Emission/Geraeuschemission

LpA <70 dB

Operator position

Normal position

per ISO 7779

LpA <70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 t.19

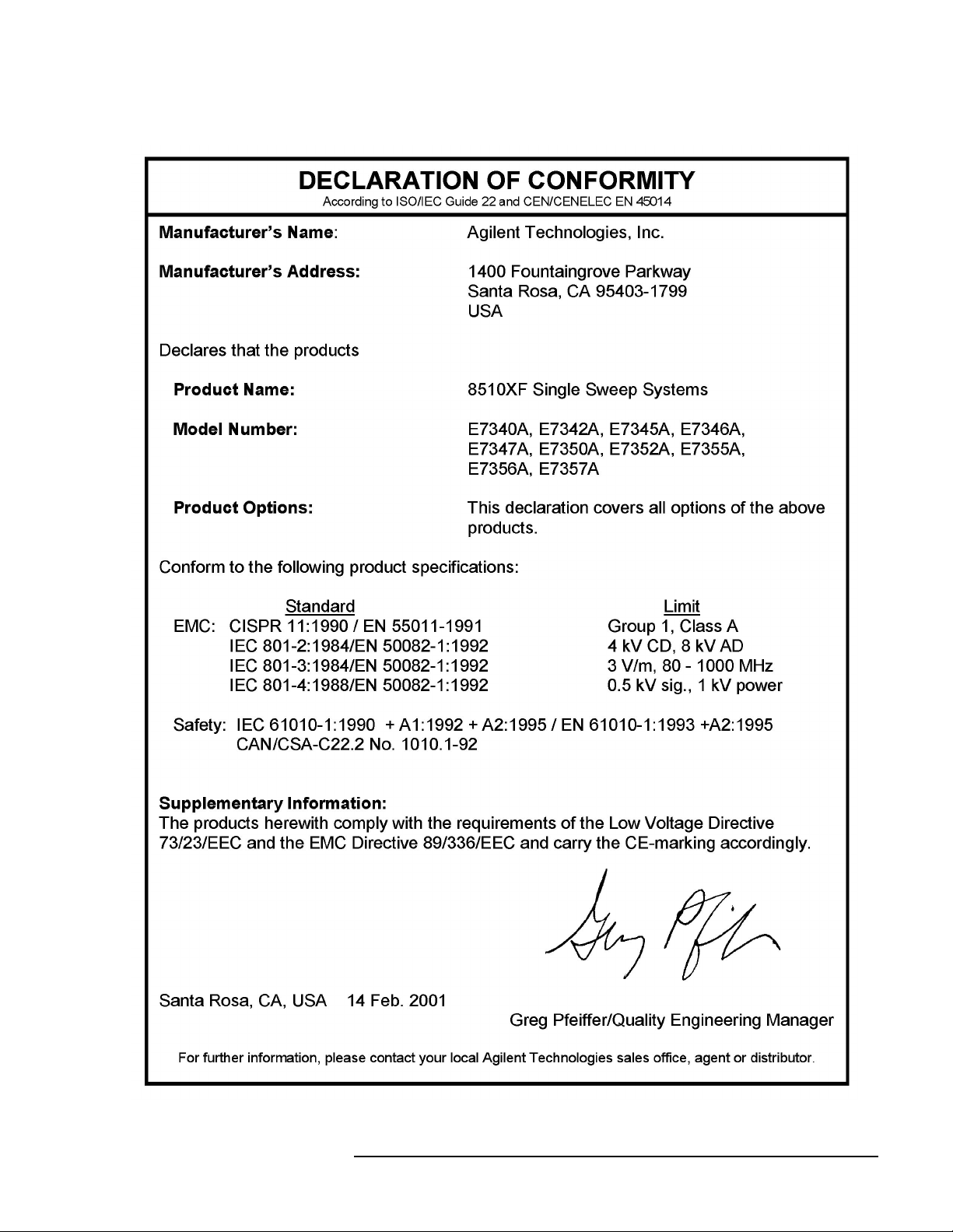

Compliance with EEC Directives

See the declaration of conformity on the following page.

x 8510XF Network Analyzer Systems

Page 11

Compliance with Standards

8510XF Network Analyzer Systems xi

Page 12

Compliance with Standards

xii 8510XF Network Analyzer Systems

Page 13

Contents

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

What You’ll Find in This Manual… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

DOCUMENTATION WARRENTY . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Contacting Agilent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Before Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Typeface Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Compliance with Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

1. Introduction

Finding System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Sources of Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

8510XF Network Analyzer Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Two Versions of the 8510XF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

What’s Included . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Frequency Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Partial Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Option 005 (45 MHz to 2 GHz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Option 006 (RF Passthrough) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Option 010 (Time Domain) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Option 230 (Line Voltage) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Upgrade Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

2. Installation

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Receiving the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

The System as Shipped . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Agilent Technologies Customer Engineering . . . . . . . . . . . . . . . . . . 2-5

In Case of Problems with the Shipment . . . . . . . . . . . . . . . . . . . . . . 2-5

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Safe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

System Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

8510XF Network Analyzer Systems Operating and Service Manual Contents xiii

Page 14

Test Port Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Unpacking the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Basic System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Installing the Work Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Millimeter-Wave Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Connectors (Port 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Connectors (Port 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

GPIB Address Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Test Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Connector Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Power Supply Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Test Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Controller / Test Head Interconnections . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Systems With Option 005 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Instruments Without Option 005 . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Cable List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Duplicate Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Turning On the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

System Operational Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Operating Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

3. Operation

8510XF Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Checking the Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Measurement Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Why Calibration Is Essential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

When to Repeat the Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Calibration Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Types of Calibration Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Load Calibration Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Set Up the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connect and Measure the Calibration Standards . . . . . . . . . . . . . . 3-10

Choosing Calibration Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Connector Sex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Offset Shorts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Banded Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Non-Banded Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Calibration Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

S22 1-Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Standard Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Contents xiv 8510XF Network Analyzer Systems Operating and Service Manual

Page 15

Standards Already Described . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Other Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Port Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

RF Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

RF Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

LO Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

LO Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

LO Power Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

85102 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Leveling Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

IF Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Alternative 1.0 mm Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Broadband Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Operation Using a Wafer Probe Station . . . . . . . . . . . . . . . . . . . . . . . . 3-46

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Available Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

Device Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

Types of Probe Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

4. Performance Verification

When to Verify . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Materials Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Calibration and Frequency Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Verification Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

General Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Verification Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Low Band Verification (< 50 GHz) . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

CW Frequency Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Materials Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

5. System Maintenance

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.0 mm Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Detector Gain Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Purpose of the Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

The Calibration Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

When to Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Conversion Loss Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Purpose of the Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

The Calibration Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

When to Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Agilent Technologies Customer Engineering . . . . . . . . . . . . . . . . . . 5-8

8510XF Network Analyzer Systems Operating and Service Manual Contents xv

Page 16

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Signal Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Frequency Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

The Leveling Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Level Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

LO Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

System Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

110 GHz Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Cycle Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Hardware Configuration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Firmware Configuration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

6. Replaceable Parts

Parts Listed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

How to Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Frequency Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Categorization of Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

110 GHz Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Complete System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

85 GHz Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Complete System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Millimeter-Wave Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

7. Menus & Commands

Menu Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

New GPIB Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

Unsupported GPIB Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-47

New Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

Contents xvi 8510XF Network Analyzer Systems Operating and Service Manual

Page 17

1 Introduction

In This Chapter...

Finding System Information, page 1-2

•

• 8510XF Network Analyzer Systems, page 1-4

• System Description, page 1-5

• Options, page 1-8

• Upgrade Paths, page 1-10

8510XF Network Analyzer Systems 1-1

Page 18

Introduction

Finding System Information

Finding System Information

Sources of Information Documents provided with the 8510XF include the following:

Table 1-1 Documents Supplied with the System

Document Part Number Description

8510XF Operation and Service Manual E7350-90001 8510XF system manual

8510C Network Analyzer Manuals set 08510-90275 includes:

8510C Operating and Programming Manual 08510-90281 A detailed operator’s guide to the

8510C network analyzer

8510C Introductory User’s Guide 08510-90290 A brief introduction to functions,

menus, and measurement setups

for the 8510C network analyzer

8510C Quick Reference Guide 08510-90292 An abbreviated, pocket-sized guide

to codes, commands, and menu

maps for the 8510C network

analyzer

8510C Keyword Dictionary 08510-90280 A thorough presentation of codes,

commands, and menu maps for the

8510C network analyzer

8510C On-Site Service Manual 08510-90282 A detailed guide to maintenance

and troubleshooting for the 8510C

network analyzer

8360 Series Dedicated Source Manual set 08360-90138 includes:

83651B & 83621B Manuals 08360-90136

08360-90137

Troubleshooting and service

manuals for the RF source and LO

source

Another important document is the Operating and Service Manual for the

85059A 1.0 mm Precision Calibration and Verification Kit (the Agilent part

number of the manual is 85059-90003).

1-2 8510XF Network Analyzer Systems

Page 19

Introduction

Finding System Information

Where to look The following table shows where to look first (and second) for particular

kinds of information.

Table 1-2 Primary and Secondary Information Sources

Subject First Source Other Sources

Installing the system Chapter 2 of this manual Chapter 9, 8510C On-Site Service Manual

Using menus Chapter 3 of this manual

(also see Chapter 7 for menu maps)

Using system functions Chapter 3 of this manual Chapter 5, 8510C Operating and Programming

Measurement calibration Chapter 3 of this manual Chapter 8, 8510C Operating and Programming

Verifying performance Chapter 4 of this manual Chapter 8, 8510C On-Site Service Manual

Maintenance Chapter 5 of this manual Chapters 7 & 10, 8510C On-Site Service Manual

Ordering replacement parts Chapter 6 of this manual Chapter 5, 8510C On-Site Service Manual

GPIB programming Chapter 7 of this manual Chapter 13, 8510C Operating and Programming

Basics of network analysis 8510C Introductory User’s Guide Chapter 3, 8510C Operating and Programming

Types of measurement 8510C Operating and Programming Manual:

• Chapter 9 (Transmission)

• Chapter 10 (Reflection)

• Chapter 11 (Time Domain)

• Chapter 12 (Power Domain)

Chapter 4, 8510C Operating and Programming

Manual

Manual

Manual

Also: Supplement to 8510C Operating and

Programming Manual (“Operator’s Check and

Routine Maintenance”)

Manual

Also: 8510C Quick Reference Guide

Also: 8510C Keyword Dictionary

Manual

Chapter 3 of this manual

Printing & plotting Chapter 6, 8510C Operating and Programming

Manual

Using the disk drive Chapter 7, 8510C Operating and Programming

Manual

8510XF Network Analyzer Systems 1-3

Page 20

Introduction

8510XF Network Analyzer Systems

8510XF Network Analyzer Systems

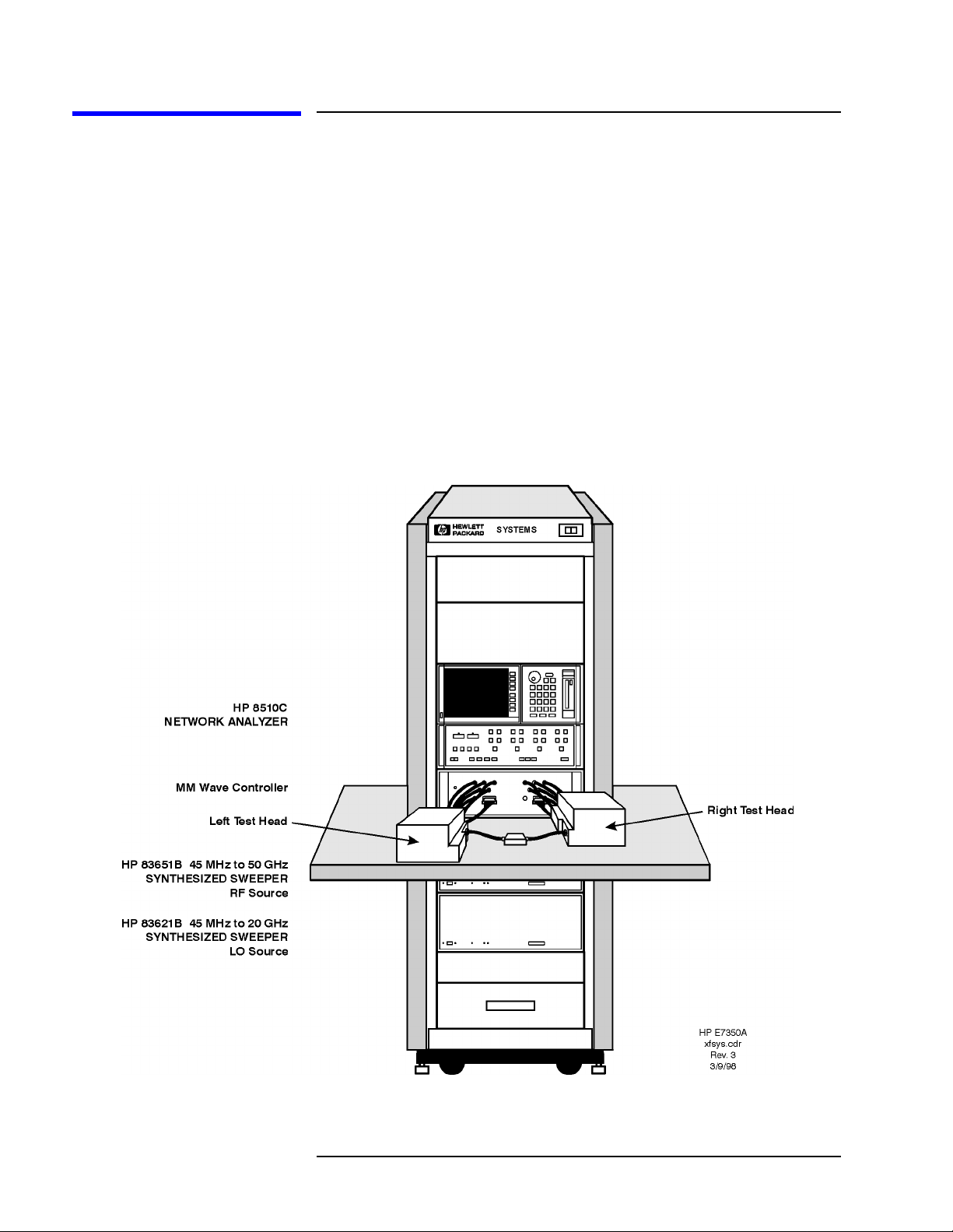

The 8510XF is a vector network analyzer with an extremely wide frequency

range. It is available in two basic versions, with frequency ranges of

2 to 85 GHz and 2 to 110 GHz. Both ranges can be optionally extended

downward to 45 MHz.

The 8510XF uses the same test port connections throughout its entire range

of test frequencies. It is never necessary to make and break connections in

order to complete a test.

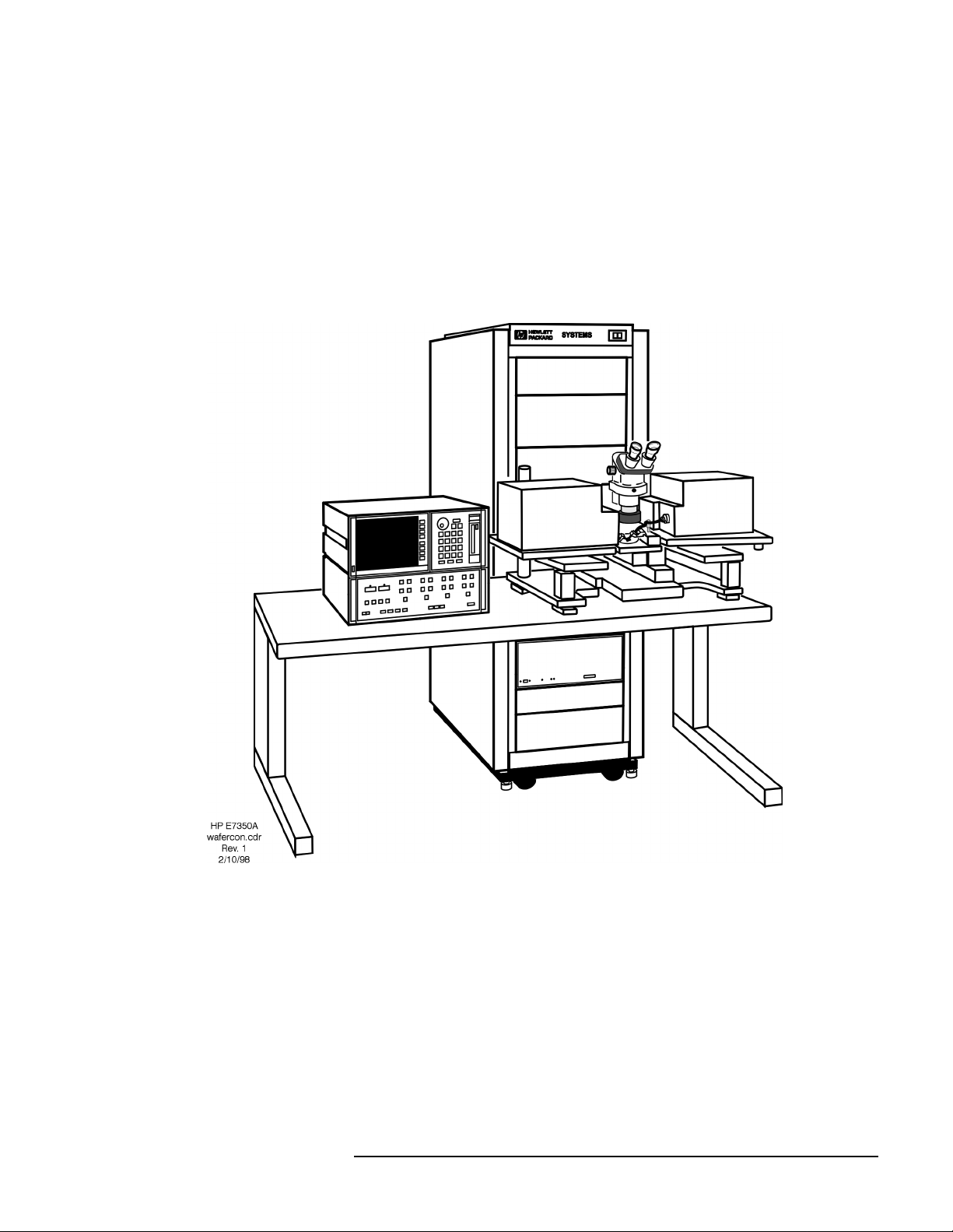

The illustration below shows the 8510XF configured for coaxial

measurement; the system can also be configured for on-wafer measurement

using a wafer probe test station.

Figure 1-1 8510XF Network Analyzer System

1-4 8510XF Network Analyzer Systems

Page 21

System Description

Introduction

System Description

Two Versions of the 8510XF

The system is available in two basic versions, distinguished by their upper

frequency limits. The 85 GHz version is ordered as E7340A; the 110 GHz

version is ordered as E7350A.

What’s Included The major components of the 8510XF system are:

• Network analyzer, 8510C

• Synthesized RF source, 83651B

• Synthesized LO source, 83621B

• Millimeter-wave controller, E7341A

• Left test head, E7342L (85 GHz) or E7352L (110 GHz)

• Right test head, E7342R (85 GHz) or E7352R (110 GHz)

• 1.6 meter instrument rack (E3661A)

Frequency Limits As the list above indicates, the upper frequency limit of the system is

determined by the type of test head that is included in it.

The lower frequency limit of an 8510XF system is normally 2 GHz. With

Option 005 installed, the lower frequency limit is 45 MHz. (See “Options”

on page 1-8.)

Partial Systems Customers who already have the network analyzer and the sources can order

partial systems which omit those items. The partial systems are known as

millimeter-wave subsystems; the 85 GHz version is ordered as E7342A, and

the 110 GHz version is ordered as E7352A.

In addition, 8510XF upgrade kits are available for other Agilent test systems

(see “Upgrade Paths” on page 1-10).

8510XF Network Analyzer Systems 1-5

Page 22

Introduction

System Description

Coaxial Configuration When the 8510XF is configured for measurement through coaxial

connections, the network analyzer, the millimeter-wave controller, and the

RF and LO sources are all installed in the rack. The test heads are placed on

a work surface which is mounted below the millimeter-wave controller.

The test ports feature 1.0 mm coaxial connectors. The device under test is

typically connected to one test port directly, and to the other test port by way

of a coaxial cable (or it is connected to the ports through two coaxial cables).

Figure 1-2 8510XF, Configured for Coaxial Measurement

1-6 8510XF Network Analyzer Systems

Page 23

Introduction

System Description

Wafer Probe

Configuration

For on-wafer measurements, it is usually best to remove the network

analyzer from the instrument rack, and place it on a table adjacent to the

probe station. This makes it easy to see and operate the analyzer.

No wafer probe station is supplied with the system; the illustration below

simply shows how the 8510XF combines with a typical probe station to

create an on-wafer measurement system.

Figure 1-3 8510XF, Configured for Wafer-Probe Measurement

8510XF Network Analyzer Systems 1-7

Page 24

Introduction

Options

Options

Option 005

(45 MHz to 2 GHz)

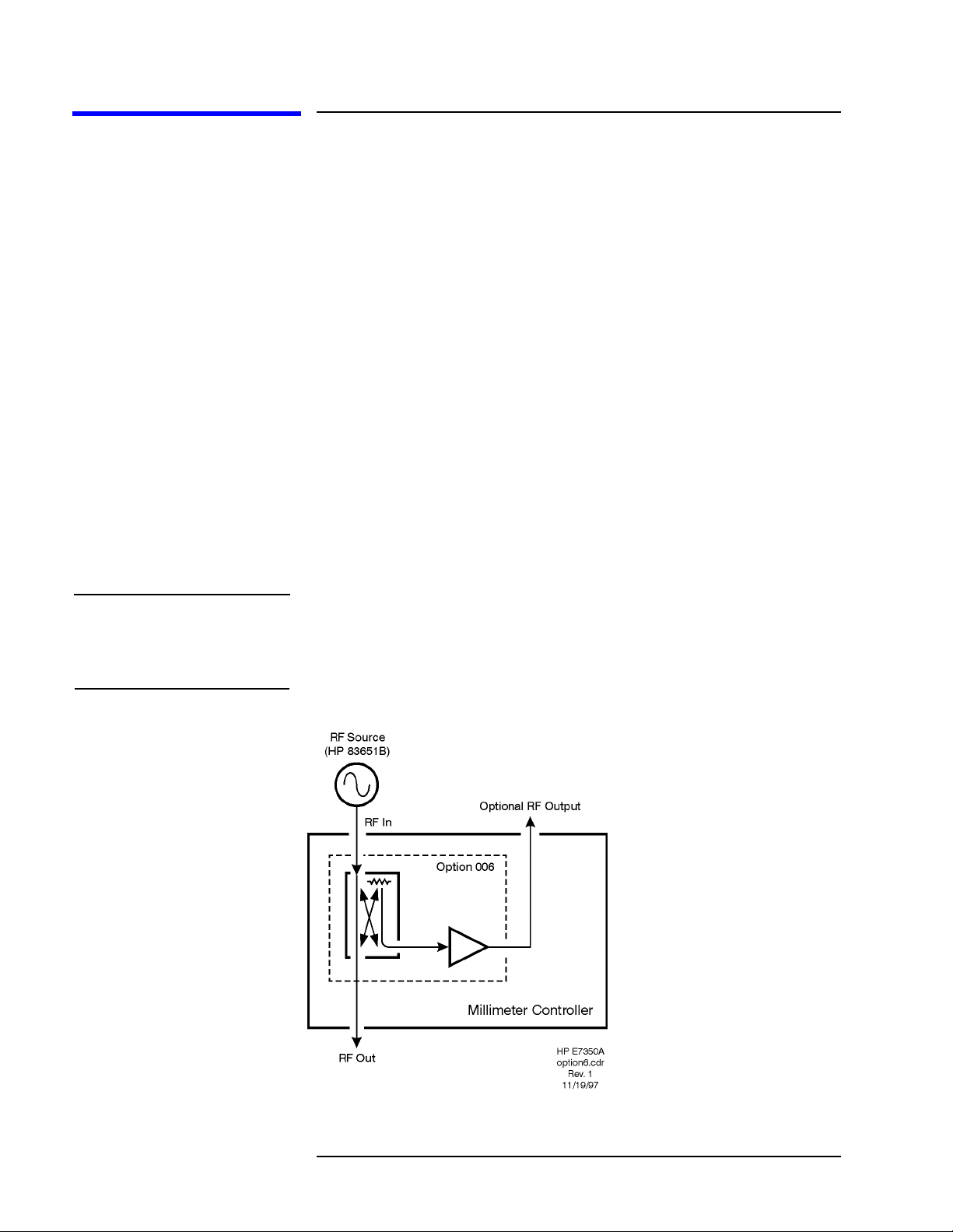

Option 006

(RF Passthrough)

NOTE The 8510XF firmware does not support multiple test sets. In order to use the

This option extends the lower limit of the 8510XF frequency range

downward to 45 MHz. The option is implemented by adding four

low-frequency mixers, which are dedicated to the .045 to 2 GHz frequency

range. These mixers are installed in the millimeter-wave controller.

This option adds a coupler, amplifier, and RF output connector to the

millimeter-wave controller. The purpose is to make the RF input to the

controller (which is supplied by the 83651B RF source) available as an

output, so that it can be routed to other devices or test sets.

The RF output on the rear panel of the millimeter-wave controller is a

2.4 mm coaxial connector. To supply this RF output to another test set, you

will need a 2.4 mm coaxial cable of adequate length (this cable is not

supplied with the 8510XF).

The system is shipped with a 50 Ω load attached to the RF output connector.

Option 006 RF output as the RF source for another test set, you must load

the standard 8510C firmware (from a diskette which is supplied with the

8510XF).

Figure 1-4 Option 006

1-8 8510XF Network Analyzer Systems

Page 25

Introduction

Options

Option 010

(Time Domain)

NOTE Option 010 is available only for complete systems (E7340A and E7350A).

Option 230

This option makes it possible to use the 8510XF in time domain mode. The

option is implemented through modification of the network analyzer

operating system.

This option configures the 8510XF for 220/240 line voltage operation.

(Line Voltage)

8510XF Network Analyzer Systems 1-9

Page 26

Introduction

Upgrade Paths

Upgrade Paths

Kits are available for upgrading another type of 8510C test system to an

8510XF system, as described below.

Upgrade Kits for the

85107A/B

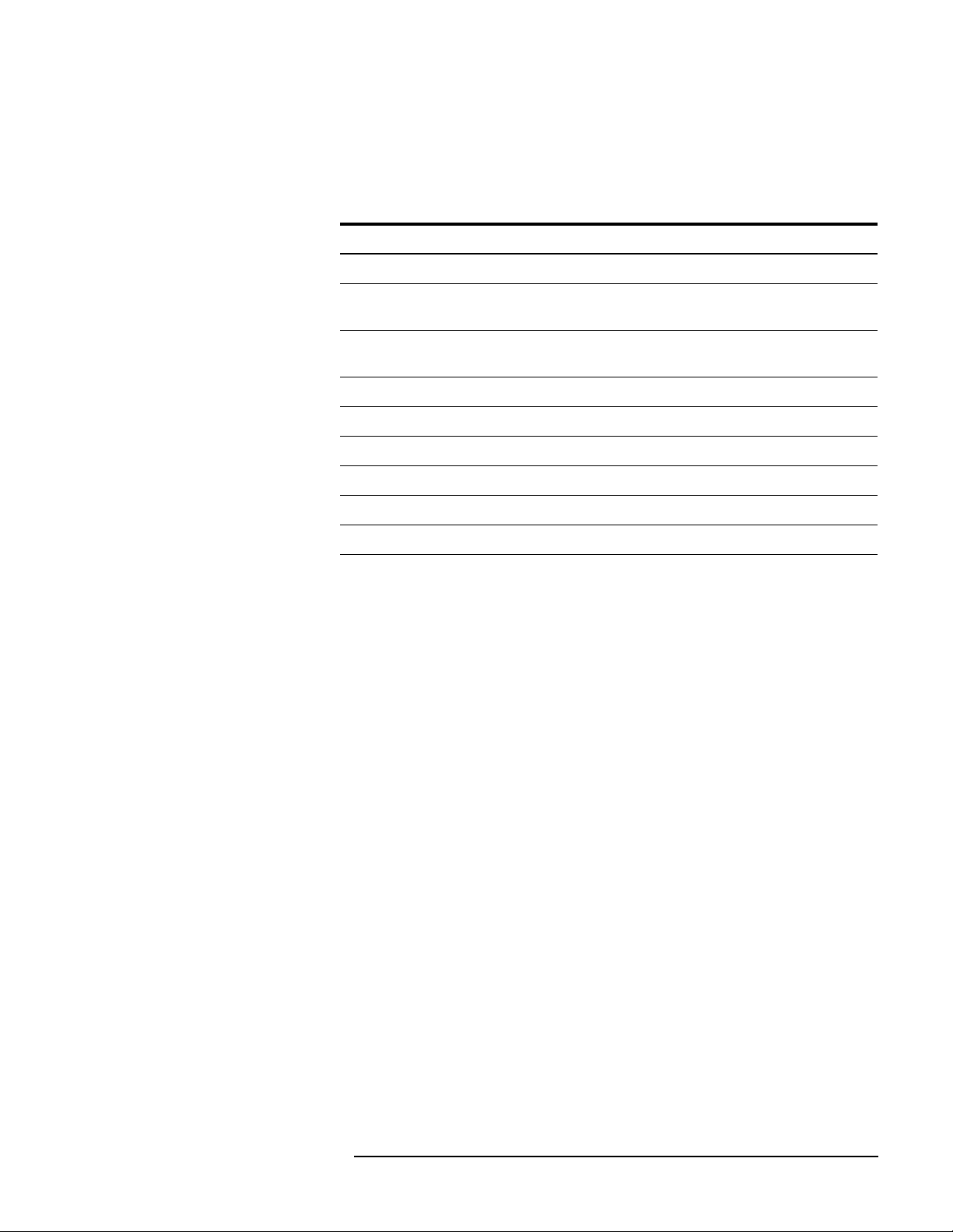

Table 1-3 Contents of Upgrade Kits for the 85107A/B

An 85107A/B can be upgraded to an 8510XF, in either the 110 GHz version

(upgrade kit E7355A) or the 85 GHz version (upgrade kit E7345A).

Item Part#

Millimeter-wave controller E7341A

Left test head E7342L (85 GHz)

or E7352L (110 GHz)

Right test head E7342R (85 GHz)

or E7352R (110 GHz)

LO source 83621B

Rack flange kit for LO source 83621B #913

8510XF operating & service manual E7350-90001

E7345A/E7355A upgrade kit installation manual E7350-90003

8510XF system software on diskette E7340-10001

8 chips for expanding non-volatile memory in the 8510C 1818-4075

NOTE The upgrade kits for the 85107A/B can also be used for an 85109C system

which lacks Option 002. To upgrade an 85109C with Option 002, see the

upgrade kit described on page 1-12).

1-10 8510XF Network Analyzer Systems

Page 27

Introduction

Upgrade Paths

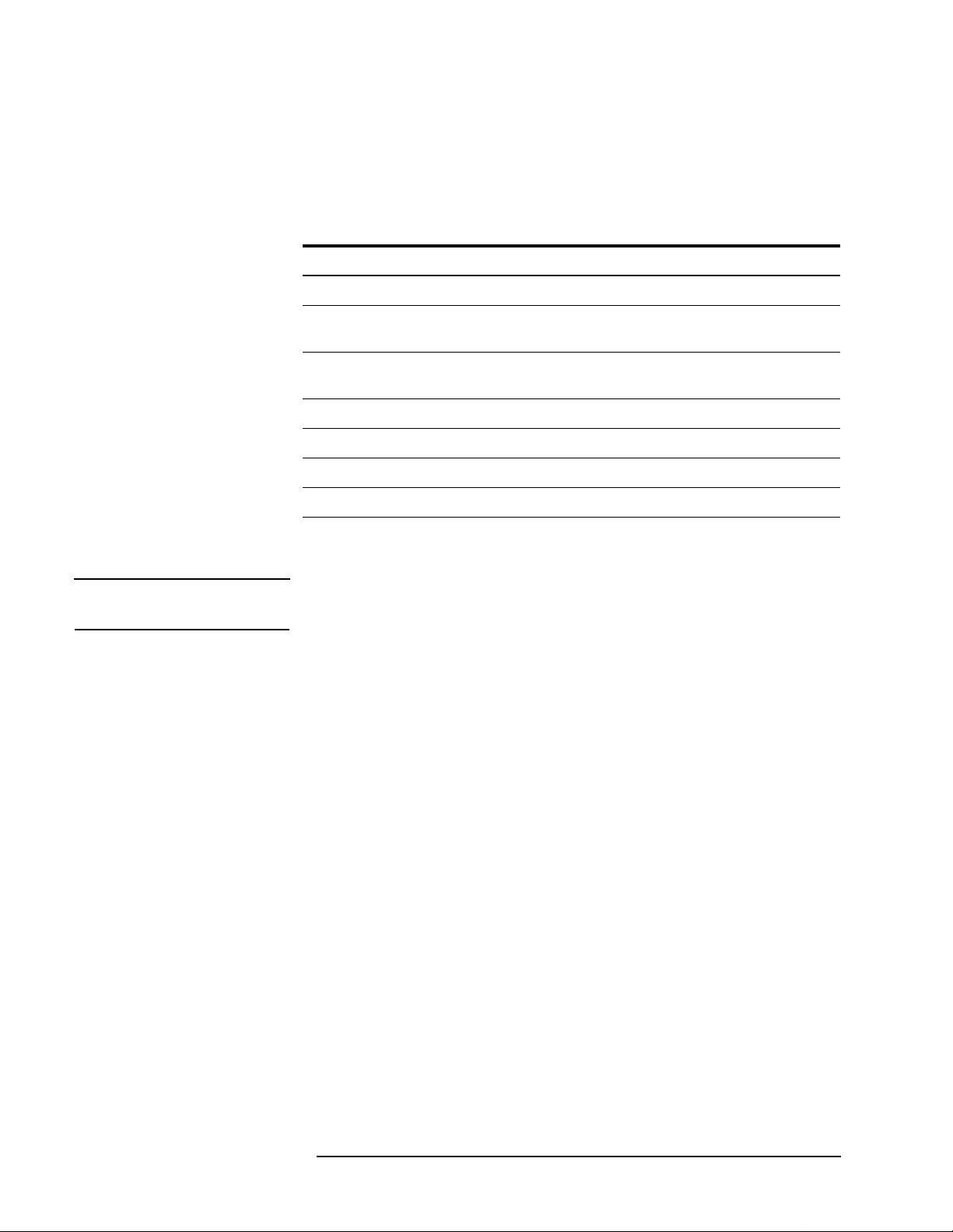

Upgrade Kits for the

85106C/D

Table 1-4 Contents of Upgrade Kits for the 85106C/D

An 85106C/D can be upgraded to an 8510XF, in either the 110 GHz version

(upgrade kit E7356A) or the 85 GHz version (upgrade kit E7346A).

Item Part#

Millimeter-wave controller E7341A

Left test head E7342L (85 GHz)

or E7352L (110 GHz)

Right test head E7342R (85 GHz)

or E7352R (110 GHz)

RF source 83651B

Rack flange kit for RF source 83651B #913

8510XF operating & service manual E7350-90001

E7346A/E7356A upgrade kit installation manual E7350-90004

8510XF system software on diskette E7340-10001

8 chips for expanding non-volatile memory in the 8510C 1818-4075

8510XF Network Analyzer Systems 1-11

Page 28

Introduction

Upgrade Paths

Upgrade Kits for the

85109C

(With Option 002)

Table 1-5 Contents of Upgrade Kits for the 85109C

An 85109C with Option 002 can be upgraded to an 8510XF, in either the

110 GHz version (upgrade kit E7357A) or the 85 GHz version (upgrade kit

E7347A).

Item Part#

Millimeter-wave controller E7341A

Left test head E7342L (85 GHz)

or E7352L (110 GHz)

Right test head E7342R (85 GHz)

or E7352R (110 GHz)

8510XF operating & service manual E7350-90001

E7347A/E7357A upgrade kit installation manual E7350-90005

8510XF system software on diskette E7340-10001

8 chips for expanding non-volatile memory in the 8510C 1818-4075

NOTE To upgrade an 85109C which lacks Option 002, see the upgrade kit

described on page 1-10.

1-12 8510XF Network Analyzer Systems

Page 29

2 Installation

In This Chapter...

Site Preparation, page 2-2

Power Requirements, page 2-2

Environmental Requirements, page 2-3

Receiving the System, page 2-5

Precautions, page 2-9

Unpacking the System, page 2-11

Basic System Configurations, page 2-17

Millimeter-Wave Controller, page 2-23

Test Heads, page 2-26

Controller / Test Head Interconnections, page 2-28

Cable List, page 2-32

Other Connections and Settings, page 2-37

Turning On the System, page 2-38

System Operational Test, page 2-39

Operating Notes, page 2-42

8510XF Network Analyzer Systems 2-1

Page 30

Installation

Site Preparation

Site Preparation

Power Requirements Before installing the system, be sure that the required ac power is available

at all necessary locations.

• Three-wire power cables (which provide a safety ground) must be used

with all instruments.

• Air-conditioningequipment (or other motor-operated equipment) should

not be placed on the same ac line that powers the system.

• The table below lists the maximum VA ratings and BTU/hour ratings for

all instruments in the system. This table can be used to determine both

the electrical requirements and the air conditioning requirements of the

system.

Table 2-1 Power requirements of the system

Standard Equipment

Instrument Maximum VA Rating Maximum BTU/hour

85101C display processor 250 850

85102B IF detector 210 714

83621B synthesized source (LO) 400 1360

83651B synthesized source (RF) 400 1360

E7341A millimeter-wave controller 500 1700

E7342L left test head (85 GHz)

or E7352L left test head (110 GHz)

E7342R right test head (85 GHz)

or E7352R right test head (110 GHz)

Total 1760 5984

NOTES:

(1) Values are based on 120 Vac supplied to each instrument at 60 Hz.

(2) The millimeter-wave controller supplies power to the test heads.

(powered from controller) (powered from controller)

(powered from controller) (powered from controller)

2-2 8510XF Network Analyzer Systems

Page 31

Installation

Site Preparation

Environmental Requirements

The environmental requirements of the system are listed in the table below.

Note that these requirements are the same as those of the 8510C Network

Analyzer.

Table 2-2 Environmental Requirements

Temperature (Operation) 5 °C to 40 °C (41 °F to 104 °F)

Temperature (Storage) −40

Temperature (Measurement Calibration) 20

Temperature (Performance Verification) Temperature must be within 1

Relative Humidity (Operation) 5% to 95% at 40

Relative Humidity (Storage) 5% to 95% at 65

Pressure Altitude (Operation or Storage) Less than 4600 meters (~15,000 feet)

System heating and cooling

°C to +65 °C (-40 °F to +158 °F)

°C to 26 °C (68 °F to 79 °F)

°C (1.8 °F) of the

temperature at which the measurement

calibration was performed.

°C or less (non-condensing)

°C or less (non-condensing)

Install air conditioning and heating, if necessary to maintain the ambient

temperature within the appropriate range (as given in the table above). Air

conditioning capacity must be consistent with the BTU ratings given in the

table under “Power Requirements” on page 2-2.

Required conditions for accuracy-enhanced measurement

Accuracy-enhanced (error-corrected) measurements require the ambient

temperature of the 8510XF to be maintained within ±1°C of the ambient

temperature at calibration.

8510XF Network Analyzer Systems 2-3

Page 32

Installation

Site Preparation

Weight and dimensions

The table below shows the maximum weight and dimensions of the 8510XF

system, as installed in the system rack, with the test heads on an attached

work surface.

Table 2-3 System Weight and Dimensions

Weight Height Width Depth

280.3 kg (618 lbs) 162 cm (63.8 in) Rack only: 60 cm (23.6 in)

Plus work surface: 100 cm (39.4 in)

The table below shows the weight and dimensions of a single test head (left

or right):

Table 2-4 Test Head Weight and Dimensions

Test Head Model Weight Height Width Depth

E7342 L/R 9.07 kg

(20 lb)

E7352 L/R 9.75 kg

(21.5 lb)

18.5 cm

(7.3 in)

18.5 cm

(7.3 in)

Rack Only: 90.5 cm (35.6 in)

Plus work surface: 145.4 cm (57.3 in)

24.7 cm

(9.7 in)

24.7 cm

(9.7 in)

31.4 cm

(12.4 in)

31.4 cm

(12.4 in)

Figure 2-1 Testhead Footprint Dimensions for Mounting (left or right)

2-4 8510XF Network Analyzer Systems

Page 33

Installation

Receiving the System

Receiving the System

The System as Shipped The 8510XF system will arrive with all rack components and instruments

installed and cabled in the system cabinet. The system cabinet is shipped

upright in a special crate (as illustrated in “Unpacking the System” on

page 2-11). The work surface is included in the system cabinet packaging.

The test heads are packaged separately from the system cabinet, in two

padded cartons.

When the entire shipment has arrived, contact your nearest Agilent

Technologies office to arrange for system installation, if installation is

available in your area (see “Contacting Agilent”).

Agilent Technologies Customer Engineering

In Case of Problems with the Shipment

An Agilent Technologies Customer Engineer will be assigned to help you

install the system. During installation, the Customer Engineer will do the

following:

• Uncrate the system cabinet (see “Unpacking the System” on page 2-11).

• Complete the system checklist (see “System Checklists” on page 2-7).

• Assemble the work surface and connect it to the system cabinet.

• Install the test heads.

• Verify that the GPIB addresses are set properly and power up the

system.

• Run a performance verification of the system, which includes a

measurement calibration.

• Provide user training for one engineer.

If the shipment is damaged or incomplete, notify the nearest Agilent

Technologies office. If the shipping container is damaged or the packaging

material shows signs of stress, notify the carrier as well as the Agilent

Technologies Customer Engineer. Keep the shipping materials for the

carrier’s inspection. Agilent Technologies will arrange for repair or

replacement of damaged equipment without waiting for a claim settlement

from the carrier.

8510XF Network Analyzer Systems 2-5

Page 34

Installation

Receiving the System

Shipping Containers Keep the shipping containers in one area until the system checklist has been

completed. This makes it easier to verify that everything ordered has been

shipped.

Keep the containers, and all packing materials, until the entire shipment has

been verified for completeness, and the system has been checked

mechanically and electrically. The crate may be used one more time only to

ship the 8510XF cabinet.

If you need to ship your 8510XF system, repackage it in its original shipping

crate. Make all surface shipments via padded van with an air suspension

ride.

CAUTION Regardless of the crate style, all surface shipments must be made via padded

van (air suspension ride). Surface shipments in vehicles without air

suspension may result in damage to the system components, cabinet, and

shipping crate.

2-6 8510XF Network Analyzer Systems

Page 35

Installation

Receiving the System

System Checklists Usethe tables below to verify that the shipment is complete. These are items

that are supplied (as indicated below) with E7340A or E7350A complete

systems only. For a list of items supplied with upgrade kits see “Upgrade

Paths” on page 1-10 through page 1-12.

Standard Items Items that are supplied with all 8510XF (E7340A or E7350A) systems are

listed in Table 2-5.

Table 2-5 8510XF System Checklist (Standard Items)

✔

Equipment Serial Number

8510C network analyzer

83621B synthesized source (LO source), with

83621B #913 rack flange kit

83651B synthesized source (RF source), with

83651B #913 rack flange kit

Millimeter-wave controller & test heads --

see “Optional/Variable Items” on page 2-8

E3661A system rack (1.6 meter)

Cables (for a complete list of cables supplied with the system,

see “Cable List” on page 2-32).

E7340-10001 (8510XF firmware diskette) N/A

System manual:

8510XF Operating and Service Manual, E7350-90001

Network analyzer manuals:

8510C Manual set 08510-90275

Source manuals:

83651B & 83621B Manual set 08360-90138

See page 2-8

N/A

N/A

N/A

N/A

8510XF Network Analyzer Systems 2-7

Page 36

Installation

Receiving the System

Optional/Variable Items Table 2-6 lists those items that are supplied only if the applicable frequency

range or option has been ordered with the 8510XF (E7340A or E7350A)

system.

Table 2-6 8510XF System Checklist (Optional/Variable Items)

Equipment Included In Serial Number

✔

Left test head:

E7342L

E7352L

Right test head:

E7342R

E7352R

Millimeter-wave controller:

E7341A

E7341A #005

E7341A #006

E7341A #056

Systems to 85 GHz

Systems to 110 GHz

Systems to 85 GHz

Systems to 110 GHz

Systems without options

Systems with Option 005

Systems with Option 006

Systems with Options 005 & 006

8510C #010 (time domain option for network analyzer) Systems with Option 010

85106-60038 (1 meter table top) E7340A and E7350A complete systems N/A

2-8 8510XF Network Analyzer Systems

Page 37

Installation

Precautions

Precautions

Safe Installation Install the system so that the ON/OFF switch is readily identifiable and is

easily reached by the operator. The ON/OFF switch or the detachable power

cord is the system disconnecting device. It disconnects the mains circuits

from the mains supply before other parts of the system. Alternatively, an

externally installed switch or circuit breaker (which is readily identifiable

and is easily reached by the operator) may be used as a disconnecting device.

Install the system according to the enclosure protection provided:

• The system protects against finger access to hazardous parts within the

enclosure.

• The system does not protect against the ingress of water.

CAUTION This product is designed for use in Installation Category II and Pollution

Degree 2 per IEC 1010 and 664 respectively.

CAUTION Always use the three-prong ac power cord supplied with this product.

Failure to insure adequate earth grounding by not using this cord may cause

product damage.

CAUTION Before switching on the system, make sure that the correct fuse is installed,

and that the supply voltage is in the specified range.

CAUTION Ventilation requirements:

Convection in and out of the system cabinet must not be restricted. The

ambient temperature (outside the cabinet) must be less than the maximum

operating temperature of the system by 4°C for every 100 watts dissipated in

the cabinet. If the total power dissipated in the cabinet is greater than 800

watts, then forced convection must be used.

WARNING This is a Safety Class 1 Product (provided with a protective earthing ground

incorporated in the power cord). The mains plug shall only be inserted in a

socket outlet provided with a protective earth contact. Any interruption of the

protective conductor inside or outside the product is likely to make the

product dangerous. Intentional interruption is prohibited.

8510XF Network Analyzer Systems 2-9

Page 38

Installation

Precautions

WARNING If this product is not used as specified, the protection provided by the

equipmentcould be impaired.This product must be usedin a normal condition

(in which all means for protection are intact) only.

Electrostatic Discharge

CAUTION The millimeter-wave controller and the test heads are sensitive to

electrostatic discharge (ESD). Ground your work station before unpacking

and installing the test heads. See “Electrostatic Discharge” on page 5-2 for

more information.

System Voltages All instruments in the 8510XF system must be set to the same voltage as the

system rack (either 120 Vac or 220 Vac). 120 Vac is the factory setting.

CAUTION The cabinet fans may be permanently damaged if a 120V system is plugged

into a 220V ac power outlet. The cabinet fans can be wired for either 120V

or 220V, but not both. Therefore, a system wired for 120V operation cannot

be switched to 230V operation simply by changing the voltage selection

switches on individual instruments.

Test Port Inputs

CAUTION Input power to the test ports must not exceed +27 dBm. Input power in

excess of this level will damage expensive components. Observe proper

precautions, especially when measuring amplifiers with gains of 20 dB or

greater.

Cleaning

WARNING To prevent electrical shock, disconnect the E734X/E735X mains before

cleaning. Use a dry cloth or one slightly dampened with water to clear the

external case parts. Do not attempt to clean internally.

2-10 8510XF Network Analyzer Systems

Page 39

Installation

Unpacking the System

Unpacking the System

Tools Required • 9/16 inch wrench or adjustable-end wrench

• Screwdriver (to pry off packing clamps)

CAUTION When you remove the clamps from the packing crates, be careful not to bend

them; they may be reused when the system is repacked.

Figure 2-2 The Outer Packing Crate

NOTE The figures show a double rack crate. The unpacking procedure is essentially

the same for either a single rack or a double rack crate (differences will be

noted where they occur).

8510XF Network Analyzer Systems 2-11

Page 40

Safety Glasses

Installation

Unpacking the System

Figure 2-3 Removing the Outer Packing Crate

WARNING Always wear safety glasses when removing the clamps and other packing

materials from the crates.

Remove the outer packing crate

1. Remove the clamps holding the packing crate top cover in place.

Remove the top cover and set it aside.

2. Remove the clamps holding the first packing crate wall in place. It does

not matter which wall you remove first.

3. Remove the other walls. Make sure you have people holding the last two

walls in place when you remove the last set of clamps.

4. Set the loading ramp aside for now.

NOTE In double-rack crates, the heaviest wall is the loading ramp. In single rack

crates, the loading ramp is shipped inside the package, placed on top of the

rack (it is a hinged assembly, shipped in the folded position).

2-12 8510XF Network Analyzer Systems

Page 41

Foam cover

Installation

Unpacking the System

Figure 2-4 Removing the Foam Cover and Plastic Wrapping

Remove the top cover and plastic wrapping

1. Remove the foam top cover. Save the cover for possible future use.

2. Remove the plastic wrapping from the system.

8510XF Network Analyzer Systems 2-13

Page 42

Installation

Unpacking the System

Figure 2-5 Removing the Bolts

Brace bolts (Item A)

Brace (Item B)

Figure 2-6 Removing the Anchor Bolt

Ramp anchor bolt (Item D)

Hinged slat (Item C)

Ramp Ledge

2-14 8510XF Network Analyzer Systems

Page 43

Ramp anchor bolt (Item D)

Ramp end flap

(hinged to ramp) (Item E)

Figure 2-7 Replacing the Anchor Bolt

Installation

Unpacking the System

Unload the system

1. Pull out the two bolts (item A) from the base using a screwdriver or

pliers. See Figure 2-5 on page 2-14.

2. Remove the brace assembly (item B).

3. Lift the hinged slat (item C) and remove the ramp anchor bolt (item D).

See Figure 2-6 on page 2-14.

4. Place one end of the ramp on the ramp ledge. See Figure 2-7 above.

5. Insert the ramp anchor bolt and fold down the hinged slat. To secure the

ramp, you may place long wood screws through the ramp and into the

ramp edge.

6. Fold down the ramp’s end flap (item E).

WARNING A racked system is tall and top-heavy. It is easy to tip the rack over while

movingit, which could result in personalinjury or death. Unloadingthe system

safely requires the participation of four persons, and they must exercise care

to prevent the rack from tipping over.

8510XF Network Analyzer Systems 2-15

Page 44

Installation

Unpacking the System

Figure 2-8 Moving the System Down the Ramp

7. Make sure the leveling feet are fully retracted and that the cabinet

casters are rolling freely.

WARNING Do not stand in front of the rack as it rolls down the ramp.

8. Roll the system down the ramp using extreme care.

9. In case you must move the system in the future, you can retain and reuse

these packing materials or you can purchase replacement packing

materials from Agilent Technologies.

2-16 8510XF Network Analyzer Systems

Page 45

Installation

Basic System Configurations

Basic System Configurations

The 8510XF can be used in either of two basic configurations, depending on

the means by which the test ports are connected to the device under test.

Coaxial measurement

This configuration is used when the device under test has

coaxial connectors. The 8510XF test ports have 1.0 mm

coaxial connectors, designed to cover a frequency range of

45 MHz to 110 GHz.

In this configuration, the test heads are placed on a work

surface which is attached to the instrument rack, slightly below

the millimeter-wave controller.

The device under test is normally connected to the test ports by

way of coaxial cables. It is also possible to connect the device

to one test port directly, and to the other test port by way of a

coaxial cable.

CAUTION Do not attempt to connect a test device directly between the two test ports,

without cables. The test heads will not move freely enough to allow such a

connection to be made safely.

Wafer probe measurement

This configuration is used for on-wafer testing; each test port is

connected (through a 1.0 mm coaxial cable, or through an

adapter and another type of coaxial cable) to a wafer test

probe. Contact the manufacturer of the wafer probe station and

an Agilent office for information on the cables and adapters

needed to connect the test heads to the wafer probe station

(refer to “Contacting Agilent” on page -v).

In this configuration, the test heads are placed on X-Y

positioners that are mounted to the wafer probe station.

It is usually best to remove the 8510C from the rack, and place

it on the work surface beside the probe station; this makes it

easier to see the network analyzer’s display and to reach its

front panel controls.

8510XF Network Analyzer Systems 2-17

Page 46

Installation

Basic System Configurations

Coaxial Configuration Figure 2-9 shows how the instruments are installed in the rack for the coaxial

configuration. The test heads (which are placed on the work surface) are

omitted here, in order to give an unobstructed view of the rack instruments.

Figure 2-9 Rack Diagram for Coaxial Configuration

Figure 2-10 on page 2-19 shows rack cabling for the coaxial configuration.

For cabling between the millimeter-wave controller and the test heads, see

“Controller / Test Head Interconnections” on page 2-28.

2-18 8510XF Network Analyzer Systems

Page 47

Installation

Basic System Configurations

Figure 2-10 Rear-View Cabling Diagram (Coaxial Configuration)

8510XF Network Analyzer Systems 2-19

Page 48

Installation

Basic System Configurations

Installing the Work Surface

NOTE The 1 meter table top is included in the E7340A and E7350A complete

The work surface is a 1 meter wide table top, to be attached to the system

rack just below the millimeter-wave controller.

1. Extend the lock feet (located at the bottom of the cabinet) to stabilize the

rack.

2. Attach the work surface support rails to the inside of the cabinet.

3. Slide the work surface onto the support rails.

systems. It is optional in the upgrade kits.

Figure 2-11 Installing the Work Surface

2-20 8510XF Network Analyzer Systems

Page 49

Installation

Basic System Configurations

Wafer Probe

Configuration

Figure 2-12 shows how the instruments are installed in the rack for the wafer

probe configuration. The test heads (which are placed on X-Y positioners

mounted to the wafer probe station) are omitted here, in order to give an

unobstructed view of the rack instruments.

Figure 2-12 Rack Diagram for Wafer Probe Configuration

Figure 2-13 shows rack cabling for the wafer probe configuration. For

cabling between the millimeter-wave controller and the test heads, see

“Controller / Test Head Interconnections” on page 2-28.

8510XF Network Analyzer Systems 2-21

Page 50

Installation

Basic System Configurations

Figure 2-13 Rear-view Cabling Diagram (Wafer-Probe Configuration)

2-22 8510XF Network Analyzer Systems

Page 51

Installation

Millimeter-Wave Controller

Millimeter-Wave Controller

The front panel of the millimeter-wave controller is illustrated below. (See

page 2-28 for information on controller/test head interconnections.)

Figure 2-14 Millimeter-Wave Controller

NOTE The illustration above shows the front panel of the controller as it appears in

systems with Option 005 (.045 MHz to 2 GHz range added). If the system

does not have Option 005, the four “RF Input” connectors (a1, b1, a2, and

b2) will be omitted.

LEDs Four LEDs are used as indicators on the front panel:

LINE Lights to indicate that line power to the controller is ON.

ACTIVE Lights to indicate that this is the active test set (useful in

distinguishing among multiple test sets tied to the same

analyzer).

a1 This LED, located at the upper left of the S-parameter

diagram, is lit when the RF source is switched to Port 1.

a2 This LED, located at the lower right of the S-parameter

diagram, is lit when the RF source is switched to Port 2.

8510XF Network Analyzer Systems 2-23

Page 52

Installation

Millimeter-Wave Controller

Connectors (Port 1) RF OUTPUT This 2.4 mm connector provides the left test head with

the RF signal that is used for frequencies up to 50 GHz.

MM DRIVE This 2.4 mm connector provides the left test head with

the RF signal that is used for frequencies above 50 GHz

(this signal is multiplied within the test head).

LO OUTPUT This 3.5 mm connector provides the left test head with

the LO signal that is used for all frequencies.

a1 RF INPUT This 3.5 mm connector is installed only in systems that

include Option 005; it receives (from the left test head)

the “a1” RF input for frequencies below 2 GHz.

b1 RF INPUT This 3.5 mm connector is installed only in systems that

include Option 005; it receives (from the left test head)

the “b1” RF input for frequencies below 2 GHz.

BIAS This multi-pin connector provides power supply voltages

to the left test head.

TEST HEAD

INTERFACE This multi-pin connector provides paths for various

signals between the controller and the left test head

(including 20 MHz IFs from mixers in the test head).

Connectors (Port 2) RF OUTPUT This 2.4 mm connector provides the right test head with

the RF signal that is used for frequencies up to 50 GHz.

MM DRIVE This 2.4 mm connector provides the right test head with

the RF signal that is used for frequencies above 50 GHz

(this signal is multiplied within the test head).

LO OUTPUT This 3.5 mm connector provides the right test head with

the LO signal that is used for all frequencies.

a2 RF INPUT This 3.5 mm connector is installed only in systems that

include Option 005; it receives (from the right test head)

the “a2” RF input for frequencies below 2 GHz.

b2 RF INPUT This 3.5 mm connector is installed only in systems that

include Option 005; it receives (from the right test head)

the “b2” RF input for frequencies below 2 GHz.

BIAS This multi-pin connector provides power supply voltages

to the right test head.

TEST HEAD

INTERFACE This multi-pin connector provides paths for various

signals between the controller and the right test head

(including 20 MHz IFs from mixers in the test head).

2-24 8510XF Network Analyzer Systems

Page 53

Installation

Millimeter-Wave Controller

GPIB Address Switch The millimeter-wave controller has an GPIB address switch located in the

lower right area of the rear panel. The address of the controller is normally

set to 23 (binary 10111).

The address switch is illustrated below; the individual bits are set by rocker

switches (in the illustration, the darkened side of each switch is the side that

is pressed in). Note that the switch has the MSB on the right, not the left, so

the selected address (binary 10111) reads, left to right, as “11101”.

Figure 2-15 GPIB Switch Setting

Fuse The fuse is located inside the line module on the rear panel of the

millimeter-wave controller, as shown in the illustration below. For 110 V

operation, the fuse rating should be 6 A; for 220 V operation, it should be

3 A (or 3.15 A). Review the information on the right of the drawing to

replace the line fuse or to set the voltage selector cam.

WARNING Forcontinued protection against fire hazard, replace the linefuse only with the

same type and rating. The use of other fuses or materials is prohibited.

Figure 2-16 Fuse and Voltage Cam Location

8510XF Network Analyzer Systems 2-25

Page 54

Installation

Test Heads

Test Heads

Port 1 and Port 2 are in the left and right test heads, respectively. The test

heads are placed on the work surface in front of the system rack, or (for

on-wafer measurement), on a wafer probe station.

Connector Positions The test heads are asymmetrical with regard to the positions of the test port

connectors. When the test heads are placed side by side, facing each other,

the Port 1 connector is set further back than the Port 2 connector.

It is usually best to position the left test head slightly forward of the right test

head, so that the test ports are in line. This reduces strain on test cables.

Power Supply Inputs The test heads do not have their own power supplies; each head receives dc

power supply inputs from the millimeter-wave controller, by way of a

multi-pin interface cable.

Illustrations The left test head is illustrated below; it is shown from the rear (that is, from

the point of view of the controller). The multiple-connector panel provides

connections between the test head and the controller (see page 2-28 for

controller/test head interconnections). The single-connector panel contains

test port 1.

Figure 2-17 Left Test Head

2-26 8510XF Network Analyzer Systems

Page 55

Installation

Test Heads

The right test head is illustrated below; it is shown from the rear (that is,

from the point of view of the controller). The multiple-connector panel

provides connections between the test head and the controller. The

single-connector panel contains test port 2.

Figure 2-18 Right Test Head

Test Ports Theillustration below shows a test port. The “ON” LED to the left of the test

port lights to indicate that the test head is receiving the required DC supply

voltages from the controller.

Figure 2-19 Test Port

NOTE The model number which appears below the test port refers to the

millimeter-wave subsystem, which consists of a millimeter-wave controller

and two test heads (85 GHz or 110 GHz).

8510XF Network Analyzer Systems 2-27

Page 56

Installation

Controller / Test Head Interconnections

Controller / Test Head Interconnections

Systems With

Option 005

NOTE The order in which cables are connected to a test head is significant; see

The interconnections between the controller and the test heads are shown

below, for a system with Option 005 (for systems without this option, see

page 2-30).

“Sequence of test head connections” on page 2-29.

Figure 2-20 Controller / Test Head Cabling Diagram (With Option 005)

2-28 8510XF Network Analyzer Systems

Page 57

Installation

Controller / Test Head Interconnections

Sequence of test head connections

NOTE Use a 57 N-cm (5 in-lb) torque wrench to tighten the SMA connectors, and a

90 N-cm (8 in-lb) torque wrench to tighten the 2.4 mm and 3.5 mm

connectors.

The connectors on the backs of the test heads are very closely spaced.

Attaching cables to these connectors is easiest if they are attached in the

following sequence (as illustrated in Figure 2-21 below):

1. b RF OUTPUT; SMA connector

(NOTE: In systems without Option 005, this connector is not used, and

should be fitted with a male SMA termination.)

2. a RF OUTPUT; SMA connector

(NOTE: In systems without Option 005, this connector is not used, and

should be fitted with a male SMA termination.)

3. LO INPUT; 3.5 mm connector

4. MM DRIVE; 2.4 mm connector

5. RF INPUT; 2.4 mm connector

6. BIAS; LEMO multi-pin connector

7. BIAS TEE; SMB connector (if not in use, should be fitted with an SMB

termination)

8. CONTROLLER INTERFACE (multi-pin connector)

Figure 2-21 Test Head Cabling Sequence

NOTE To remove cables from the test head, use the reverse of the sequence

described above.

8510XF Network Analyzer Systems 2-29

Page 58

Installation

Controller / Test Head Interconnections

Instruments Without Option 005

NOTE The order in which cables are connected to a test head is significant; see

The interconnections between the controller and the test heads are shown

below, for a system without Option 005.

“Sequence of test head connections” on page 2-31.

Figure 2-22 Controller / Test Head Cabling Diagram (Without Option 005)

2-30 8510XF Network Analyzer Systems

Page 59

Installation

Controller / Test Head Interconnections

Sequence of test head connections

NOTE Use a 57 N-cm (5 in-lb) torque wrench to tighten the SMA connectors, and a

90 N-cm (8 in-lb) torque wrench to tighten the 2.4 mm and 3.5 mm

connectors.

The connectors on the backs of the test heads are very closely spaced.

Attaching cables to these connectors is easiest if they are attached in the

following sequence (as illustrated in Figure 2-23 below):

1. b RF OUPTUT: In systems without Option 005, this connector is not

used. Check to see that it is fitted with a male SMA termination.

2. a RF OUTPUT: In systems without Option 005, this connector is not

used. Check to see that it is fitted with a male SMA termination.

3. LO INPUT; 3.5 mm connector

4. MM DRIVE; 2.4 mm connector

5. RF INPUT; 2.4 mm connector

6. BIAS; LEMO multi-pin connector

7. BIAS TEE; SMB connector (if not in use, should be fitted with an SMB

termination)

8. CONTROLLER INTERFACE (multi-pin connector)

Figure 2-23 Test Head Cabling Sequence

NOTE To remove cables from the test head, use the reverse of the sequence

described above.

8510XF Network Analyzer Systems 2-31

Page 60

Installation

Cable List

Cable List

System cabling for the 8510XF is outlined in the tables below.

Duplicate Listings In these tables, a complete from/to connection list is given for the network

analyzer, the RF source, the LO source, the controller, the left test head, and

the right test head. In other words, each cable is listed twice, and can be

found by looking up the connection from either end. The duplicate listings

make it easier to check the cabling after installation, if a cabling error is

suspected.

In the Notes column, the phrase “duplicate listing” means that the cable has

already been listed once before. The phrase “factory installed” means that

the cable was installed prior to shipment (generally, cables between rack

instruments are factory installed; cables between the millimeter-wave

controller and the test heads are not).

Table 2-7 Cable List (Connections from the 8510C)

From 85101C... To: Notes Cable Type Part No.

IF/display interconnect 85102B -- IF/display interconnect factory installed Multi-pin 08510- 60101

8510 interconnect Millimeter-wave controller --

8510 system bus

From 85102B...

IF/display interconnect 85101C -- IF/display interconnect factory installed;

Test set interconnect Millimeter-wave controller -- test set

Interconnect

10 MHz in 83651B -- 10 MHz RF output factory installed BNC 8120-5370

Trigger in 83651B -- trigger output factory installed BNC 8120-5370

factory installed GPIB 8120-3447

(Model 10833C)

Multi-pin 08510-60101

duplicate listing

factory installed Multi-pin 08510-60107

2-32 8510XF Network Analyzer Systems

Page 61

Table 2-8 Cable List (Connections from the 83621B)

From 83621B... To: Notes Cable Type Part No.

10 MHz ref output 83651B -- 10 MHz ref input factory installed BNC 8120-1838

Installation

Cable List

RF output Millimeter-wave controller -- LO input factory installed 3.5mm semi-rigid

coax

GPIB 83651B -- GPIB factory installed GPIB 8120-3444

E7340-20076

(Model 10833D)

Table 2-9 Cable List (Connections from the 83651B)

From 83651B... To: Notes Cable Type Part No.

10 MHZ ref input 83621B -- 10 MHz ref output factory installed

duplicate listing

10 MHz ref output 85102B -- 10 MHz in factory installed

duplicate listing

Trigger output 85102B -- trigger in factory installed

duplicate listing

GPIB 83621B -- GPIB factory installed

duplicate listing

GPIB Millimeter-wave controller --

8510 system bus

factory installed GPIB 8120-3445

BNC 8120-1838

BNC 8120-5370

BNC 8120-5370

GPIB 8120-3444

(Model 10833D)

(Model 10833A)

Ext ALC in Millimeter-wave controller -- ALC output factory installed BNC 8120-1839

RF output Millimeter-wave controller -- RF Input factory installed 2.4 mm semi-rigid

coax

E7340-20075

8510XF Network Analyzer Systems 2-33

Page 62

Installation

Cable List

Table 2-10 Cable List (Connections from the Millimeter-Wave Controller)

From Millimeter-Wave Controller,

Front Panel:

Port 1 RF output Left test head -- RF input 2.4 mm RF flex E7342-60005

Port 1 mm drive Left test head -- mm drive 2.4 mm RF flex E7342-60005

Port 1 LO output Left test head -- LO input 3.5 mm RF flex E7342-60004

Port 1 RF input (a1) [Option 005 only] Left test head -- “a” RF output SMA RF flex E7342-60003

Port 1 RF input (b1) [Option 005 only] Left test head -- “b” RF output SMA RF flex E7342-60003

Port 1 bias Left test head -- bias DC E7342-60009

Port 1 test head interface Left test head -- controller interface Multi-pin 08510-60126

Port 2 RF output Right test head -- RF input 2.4 mm RF flex E7342-60005

Port 2 mm drive Right test head -- mm drive 2.4 mm RF flex E7342-60005

Port 2 LO output Right test head -- LO input 3.5 mm RF flex E7342-60004

Port 2 RF input (a2) [Option 005 only] Right test head -- “a” RF output SMA RF flex E7342-60003

Port 2 RF input (b2) [Option 005 only] Right test head -- “b” RF output SMA RF flex E7342-60003

Port 2 bias Right test head -- bias DC E7342-60009

Port 2 test head interface Right test head -- controller interface Multi-pin 08510-60126

To: Notes Cable Type Part No.

From Millimeter-Wave Controller,

Rear Panel:

LO input 83621B -- RF out factory installed;

duplicate listing

RF input 83651B -- RF out factory installed;

duplicate listing

RF output [Option 006 only] (Optional RF passthrough output)

ALC output 83651B -- ext ALC in factory installed;

duplicate listing