Agilent Technologies 8935 Series E6380A

CDMA Cellular/PCS Base Station Test Set

AMPS Base Station Tests

Application Guide

Firmware Version: B.03.10 and above

Agilent Part Number E6380-90017

Revision E

Printed in UK

January 2001

Notice

Information contained in this document is subject to change without

notice.

All Rights Reserved. Reproduct i on, adaptation, or translation without

prior written permission is prohibited, except as allowed under the

copyright laws.

This material may be reproduced by or for the U.S. Government

pursuant to the Copyright License under the clause a t DFARS

52.227-7013 (APR 1988).

© Copyright 2001 Agilent Technologies

2

Contents

Manufacturer’s Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lifting and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Product Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Agilent Technologies Warranty Statement for

Commercial Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Getting Started with AMPS T est

About the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

What’s Included with this Test Set . . . . . . . . . . . . . . . . . . . . . 21

Manual and Automatic Operation Modes . . . . . . . . . . . . . . . . . 22

IBASIC programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Maximizing the Accuracy of Your Measurements . . . . . . . . . . . 23

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

TX Power Temperature Compensation . . . . . . . . . . . . . . . . . . 23

Display an FM Carrier Signal (Loopback Test) . . . . . . . . . . . . . 24

Connections for FM Carrier Loopback Test . . . . . . . . . . . . . . 24

Get Started with the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . 25

Preparing the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Generate an FM Carrier Signal . . . . . . . . . . . . . . . . . . . . . . . 25

Analyzing an FM Carrier Signal . . . . . . . . . . . . . . . . . . . . . . . 26

What to Do Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Testing AMPS Base Stations

AMPS Tests You Can Perform . . . . . . . . . . . . . . . . . . . . . . . . . . 30

What You Need to Know to Begin . . . . . . . . . . . . . . . . . . . . . . . 31

Connecting the Test Set to Your Base Station . . . . . . . . . . . . . 32

Compensating for Signal Losses and Gains in the Test Setup . 33

Transmitter Frequency Error/Offset and Power Test . . . . . . . . 34

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Begin Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Transmitter SAT Frequency and Deviation . . . . . . . . . . . . . . . 36

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Transmitter Data Deviation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Transmitter Maximum Voice Deviation . . . . . . . . . . . . . . . . . . 40

Table of Contents

3

Contents

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Receiver Sensitivity (SINAD) . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Receiver Squelch Threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Utility Procedures

Beeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Beeper Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Measuring Insertion Losses . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Memory Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Memory Cards and Initialization . . . . . . . . . . . . . . . . . . . . . . .52

Oscilloscope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Selecting the Oscilloscope’s Input . . . . . . . . . . . . . . . . . . . . . .53

Selecting the Oscilloscope’s Filters . . . . . . . . . . . . . . . . . . . . .54

Triggering the Oscilloscope . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Using the Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 5

Online Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Help Screen Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Ports: GPIB, Serial and Parallel . . . . . . . . . . . . . . . . . . . . . . . . . 57

GPIB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Parallel Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Configuring the Test Set for Printing . . . . . . . . . . . . . . . . . . .60

Printing a Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Measuring Swept Return Loss . . . . . . . . . . . . . . . . . . . . . . . . . .61

Tracking Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Using the Tracking Generator . . . . . . . . . . . . . . . . . . . . . . . . . 65

User Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 7

Displaying the Pre-assigned Local User Keys . . . . . . . . . . . . . 67

Assigning a Local User Key . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Assigning a Global User Key . . . . . . . . . . . . . . . . . . . . . . . . . .68

To Release a User Key Assignment . . . . . . . . . . . . . . . . . . . . .68

Using Channel Numbers to Set Analyzer and

Generator Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

RF Chan and Tune Freq Fields . . . . . . . . . . . . . . . . . . . . . . . .70

Voltmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Measuring AC Level and DC Level . . . . . . . . . . . . . . . . . . . . .71

4

In This Manual and Regulatory Information

What is Discussed This Manual

This manual explains how to use the Agilent Technologies 8935 Series

E6380A Test Set to manually test an AMPS base station.

This document presents a step-by-step approach to AMPS base station

testing using the Test Set, including what you need to know before you

can start testing.

What is Not Discussed in this Manual

• General operation of the Test Set.

Changing display screens and their associated controls is discussed

in the Reference Guide (Agilent part number E6380-90019).

• Detailed operation of the Test Set’s spectrum analyzer and

oscilloscope.

Although there are basic explanations in this manual, more de tail is

provided in the Reference Guide concerning the various control

menus and fields available.

• How to control your base station, switch system, or any other

software or hardware associated with your cell site equipment.

Each manufacturer and cellular service provider has their own cell

site control and base station c onfiguration procedures that go beyond

the scope of this documentation.

In This Manual and Regulatory

Information

• How to perform IBASIC programming operations, such as writing,

editing, copying, or cataloguing programs.

Programming the Test Set is explained in the Progra mmin g Ma nual

(Agilent part number E6380-90018), and the IBASIC language is

explained in the Agilent Technologies Instrument BASIC User’s

Handbook (Agilent part number E2083-90005).

Conventions Used in This Manual

The following conventions are used throughout this manual to help

clarify inst ructions and reduce unnecessary text:

•

Test Set

CDMA Cellular/PCS Base Station Test Set.

• Test Set keys are indicated like this:

• Test Set screen information, such as a measurement result or an

error message, is shown like this: TX Power 7.21 W

5

refers to the Agilent Technologies 8935 Series E6380A

Preset

Which Document

is Required?

The following documents are part of the Test Set’s document set. Use

the table to help you decide which document you need.

Table 1 Document Navig a ti on

Document Part Number Usage

CDMA Application

Guide

AMPS Application

Guide

Reference Guide E6380-90019 Use this manual for screen a nd field descriptions

GPIB Syntax Reference

Guide

Programmer ’s Guide E6380-90018 Use this manual to learn how to write programs

Assembly Level Repair

Guide

CD-ROM E6380-90027 All user documentation

E6380-90016 Use this manual for basic CDMA measurements

and for getti ng started with the Test Set.

E6380-90017 Use this manual for making AM PS base station

measurements.

and general operation in f ormation about the Test

Set.

E6380-90073 Use this manual to learn GPIB syntax for the Test

Set.

for the Test Set.

E6380-90015 Use this manual to perform calibration on the T est

Set and for general service information.

6

C:\Spk\AmpsGuide\legal.fm

Manufacturer’s Declaration

This statement is provided to comply with the requirements of the

German Sound Emission Directive, from 18 January 1991.

This product has the following sound pressure emission specification:

• sound pressure Lp <70 dB(A)

• at the operator position

• under normal operation

• according to ISO 7779:1988/EN 27779:1991 (Type Test).

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anf orderungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

• Schalldruckpegel Lp < 70 dB(A).

•Am Arbeitsplatz.

• Normale r B e trieb.

• Nach ISO 7779:1988/EN 27779:1991 (Typprüfung).

In This Manual and Regulatory

Information

7

Safety Considerations

GENERAL

This product and related documentation must be reviewed for

familiarization with safety markings and instructions before operation.

This product has been designed and tested in accordance with IEC

Publication 61010-1+A1+A2:1992 Safety Requirements for Electrical

Equipment for Measurement, Control and Laboratory Use and has

been supplied in a safe condition. This instruction documentation

contains information and warnings which must be followed by the user

to ensure safe operation and to maintain t he product i n a safe cond ition.

SAFETY EARTH GROUND

A uninterruptible safety earth ground must be provided from the main

power source to the product input wiring terminals, power cord, or

supplied power cord set.

CHASSIS GROUND TERMINAL

To prevent a potential shock hazard, always connect the rear-panel

chassis ground terminal to earth ground whe n operating this

instrument from a dc power source.

SAFETY SYMBOLS

Indicates instrument damage can occur if indicated oper ating limits are

!

exceeded. Refer to the instructions in this guide.

Indicates hazardous volt ages.

Indicates earth (ground) term inal

WARNING

CAUTION

A WARNING note denotes a hazard. It calls attention to a

procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in personal injury. Do not

proceed beyond a W ARNING s ign until the indicated conditi ons

are fully understood and met.

A CAUTION note denotes a hazard. It calls attention to an operation

procedure, practice, or the like, which, if not correctly performed or

adhered to, could result in damage to or destruction of part or all of the

product. Do not proceed beyond an CAUTION note until the indicated

conditions are fully understood and met.

8

C:\Spk\AmpsGuide\legal.fm

Safety Considerations for this Instrument

WARNING

Whenever it is likely that t he pr otect ion has be en impaire d, the

instrument must be made inoperative and be secured against

any unintended operation.

If this instrument is to be energized via an autotransformer (for

voltage reduction), make sure the common terminal is

connected to the earth terminal of the power source.

If this product is not used as specified, the protection provided

by the equipment could be impaired. This product must be used

in a normal condition (in which all means for protection are

intact) only.

No operator serviceable parts in this product. Refer servicing

to qualified personnel. To prevent electrical shock, do not

remove covers.

Servicing instructions are for use by qualified personnel only.

To avoid electrica l shock, do not perform any servicing unless

you are qualified to do so.

The opening of covers or removal of parts is likely to expose

dangerous voltages. Disconnect the product from all voltage

sources while it is being opened.

Adjustments described in the manual are performed with

power supplied to the instrument while protective covers are

removed. Energy available at many points may, if contacted,

result in personal injury.

In This Manual and Regulatory

Information

For Continued protection against fire hazard, replace the line

fuse(s) with T 250 V 5.0 A fuse(s) or the same current rating and

type. Do not use repaired fuses or short circuited fuseholders.

9

WARNING

This product is a Safety Class I instrument (provided with a

!

protective earthing ground incorporated in the power cord).

The mains plug shall only be inserted in a socket outlet

provided with a protective earth contact. Any interruption of

the protective conductor inside or outside of the product is

likely to make the product dangerous. Intentional interruption

is prohibited.

10

C:\Spk\AmpsGuide\legal.fm

WARNING

Always use the three-prong ac power cord supplied with this

product. Failure to ensure adequate earth grounding by not

using this cord may cause personal injury and/or product

damage.

This product is designed for use in Installation Category II and

Pollution Degree 3 per IEC 61010 and IEC 60664 respectively.

This product has autoranging line voltage input, be sure the

supply voltage is within the specified range.

To prevent electrical shock, disconnect instrument from mains

(line) before cleaning. Use a dry cloth or one slightly dampen ed

with water to clean the external case parts. Do not attempt to

clean internally.

Ventilation Requirements: When installing the product in a

cabinet, the convection into and out of the product must not be

restricted. The ambient temperature (outside the cabinet) must

be less than the maximum operating temperature of the

product by 4° C for every 100 watts dissipated in the cabinet. If

the total power dissipated in the cabinet is greater than 800

watts, then forced convection must be used.

In This Manual and Regulatory

Information

Lifting and Handling

When lifting and handling the Agilent 8935 CDMA Cellular/PCS Base

Station Test Set use ergonomically correct procedu res. Lift and c arry by

the strap on the side panel.

When moving the Test Set more than a few feet, be sure to replace the

front screen cover.

Consumables

Two AA alkalyne batteries are supplied with the Test Set and must be

replaced periodically. When replacing batteries always dispose of old

batteries in a conscientious manner, following manufacturer’s

instructions.

11

Product Markings

The CE mark shows that the product complies with all relevant

European legal Directives (if accompanied by a year, it signifies when

the design was proven).

The CSA mark is a registered trademark of the Canadian Standards

Association.

12

C:\Spk\AmpsGuide\legal.fm

Certification

Agilent Technologies certifies that this product met its published

specifications at the time of shipment from the factory. Agilent further

certifies that its calibration measurements are traceable to the United

States National Institute of Standards and Technology, to the extent

allowed by the Institute’s calibration facility, and to the calibration

facilities of other International Standards Organization members.

.

In This Manual and Regulatory

Information

13

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN45014

Manufacturer’s Name: Agilent Technologies UK Limited

Manufacturer’s Address:

Electronic Products Solutions Group - Queensferry

South Queensferry

West Lothian, EH30 9TG

Scotland, United Kingdom

Declares that the product

Product Name

:

Model Number:

Product Options:

CDMA Base Station Test Set

E6380A

This declaration covers all options of the above product as

detailed in TCF A-5951-9852-02.

EMC:

Conforms with the protection requirements of European Council Directive 89/336/EEC on the

approximation of the laws of the member states relating to electromagnetic compatibility,

against EMC test specifications EN 55011:1991 (Group 1, Class A) and EN 50082-1:1992.

As Detailed in: Electromagnetic C ompatibility (EMC)

Technical Construction File (TCF) No. A-5951-9852-02.

Assessed by: DTI Appointed Competent Body

Technical Report Number:6893/2201/CBR, dated 23 September 1997

EMC Test Centre,

GEC-Marconi Avionics Ltd.,

Maxwell Building,

Donibristle Industrial Park,

Hillend,

Dunfermline

KY11 9LB

Scotland, United Kingdom

Safety:

The product conforms to the following safety standards:

IEC 61010-1(1990) +A1(1992) +A2(1995) / EN 61010-1:1993

IEC 60825-1(1993) / EN 60825-1:1994

Canada / CSA-C22.2 No. 1010.1-93

The product herewi th complies with the requirements of the Low Voltage Directive 73/23/EEC,

and carries the CE mark accordingly

South Queensferry, Scotland. 1st November 2000

R.M. Evans / Manufacturing

Engineering Manager

For further information, please contact your local Agilent Technologies sales office, agent, or distributor.

14

C:\Spk\AmpsGuide\legal.fm

Agilent Technologies Warranty Statement for Commercial Products

E6380A

CDMA/Cellular

PCS Base

Station Test Set

Duration of

Warranty: 1 Year

1. Agilent warrants Agilent hardware, accessor ies and supplies against

defects in materials and work manship fo r the period spec ified above .

If Agilent receives notice of such defects during the warran ty period,

Agilent will, at its option, either repair or replace products which

prove to be defective. Replacement products may be either new or

like-new.

2. Agilent warrants that Agilent software will not fail to execute its

programming instructions, for the period specified above, due to

defects in material and workmanship when properly installed and

used. If Agilent receives notice of such defects during the warranty

period, Agilent will replace software media which does not execute

its programming instructions due to such defects.

3. Agilent does not warrant that the operation of Agilent products will

be uninterrupted or error free. If Agilent is unable, wit hin a

reasonable time, to repair or replace any product to a condition as

warranted, customer will be entitled to a refund of the purchase

price upon prompt return of the product.

In This Manual and Regulatory

Information

4. Agilent products may contain remanufactured part s equivalent to

new in performance or may have been subject to incidental use.

5. The warranty period begins on the date of delivery or on the date of

installation if installed by Agilent. If customer schedules or delays

Agilent installation more than 30 days after delivery, warranty

begins on the 31st day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or

inadequate maintenance or calibration, (b) software, interfacing,

parts or supplies not supplied by Agilent, (c) unauthor ized

modification or misuse, (d) operation outside of the published

environmental specifications for the product, or (e) improper site

preparation or maintenance.

15

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE

WARRANTIES ARE EXCLUSIVE AND NO OTHER

WARRANTYOR CONDITION, WHETHER WRITTEN OR ORAL IS

EXPRESSED OR IMPLIED AND Agilent SPECIFICALLY

DISCLAIMS ANY IMPLIED WARRANTIES OR CONDITIONS OR

MERCHANTABILITY, SATISFACTORY QUALITY, AND FITNESS

FOR A PARTICULAR PURPOSE.

8. Agilent will be liable for damage to tangibl e property per incident up

to the greater of $300,000 or the actual amount paid for the product

that is the subject of the claim, and for damages for bodily injury or

death, to the extent that all su ch damages are d etermined by a cour t

of competent jurisdiction to have been directly caused by a defective

Agilent product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES

IN THIS WARRANTY STATEMENT ARE CUSTOMER’S SOLE

AND EXCLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE,

IN NO EVENT WILL Agilent OR ITS SUPPLIERS BE LIABLE

FOR LOSS OF DATA OR FOR DIRECT, SPECIAL, INCIDENTAL,

CONSEQUENTIAL (INCLUDING LOST PROFIT OR DATA), OR

OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR

OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW

ZEALAND: THE WARRANTY TERMS CONTAINED IN THIS

STATEMENT, EXCEPT TO THE EXTENT LAWFULLY

PERMITTED, DO NOT EXCLUDE RESTRICT OR MODIFY AND

ARE IN ADDITION TO THE MANDATORY STATUTOR Y RIGHTS

APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

16

C:\Spk\AmpsGuide\legal.fm

Assistance

Product maintenance agreements and other customer assistance

agreements are available for Agilent Technologies products. For any

assistance, contact your nearest Agilent Technologies Sales and Service

Office.

Table 2 Regional Sales and Service Office s

United States of Amer ica:

Agilent Technologies

Test and Measurement Call

Center

P.O. Box 4026

Englewood, CO 80155-4026

(tel) 1 800 452 4844

Canada:

Agilent Technologies Canada

Inc.

5150 Spectrum Way

Mississauga, Ont ar io

L4W 5G1

(tel) 1 877 894 4414

In This Manual and Regulatory

Information

Europe:

Agilent Technologies

European Marketing

Organization

P.O. Box 999

1180 AZ Amstelveen

The Netherlands

(tel) (3120) 547 9999

Japan:

Agilent Technologies Japan

Ltd.

Measurement Assistance

Center

9-1 Takakura-Cho,

Hachioji-Shi,

Tokyo 192-8510 , Ja pa n

(tel) (81) 456-56-7832

(fax) (81) 426-56-7840

Asia Pacific:

Agilent Technologies

24/F, Cityplaza One,

111 Kings Road,

Taikoo Shing, Hong Kong

(tel) (852) 3197 7777

(fax) (852) 2506 923 3

Latin America:

Agilent Technologies

Latin America Region

Headquarters

5200 Blue Lagoon Drive,

Suite #950

Miami, Florida 33126

U.S. A.

(tel) (305) 267 4245

(fax) (305) 267 4286

Australia/New Zealand:

Agilent Technologies

Australia Pty Ltd.

347 Burwood Highway

Forest Hill, Victoria 3131

(tel) 1 800 629 485

(Australia)

(fax) (61 3) 9272 0749

(tel) 0 800 738 378

(New Zealand)

(fax) (64 4) 802 6881

17

Getting Started with AMPS

Test

1

Getting Started with AMPS Test

This chapter introduces you to the Agilent Technologies 8935 Series

E6380A CDMA Cellular/PCS Base Station Test Set and its AMPS

functions. For information on other functions in the Test Set, see

“Which Document is Required?” on page 6. To proceed immediately to

the test procedures, see “AMPS Tests You Can Perform” on page 30

19

Getting Started with AMPS Test

About the Test Set

About the Test Set

Product Description

This Test Set helps you install, commission, and maintain AMPS base

stations. It also allows you to test CDMA base stations. (This guide

discusses AMPS testing. For more information about CDMA testing,

refer to th e CDMA Base Station Tests Applications Guide.)

The Test Set contains an RF signal generator, RF analyzer, AF

analyzer, and AF generator to test AMPS base stations. The following

tools are also included:

• Code Domain Analyzer

•CDMA Analyzer

• CDMA Generator

CAUTION

• Spectrum Analyzer

• Power Meter

• Oscilloscope

• AC/DC Voltmeter

• IBASIC controller

Batteries

There are two methods the Test Set uses to back up its RAM. One is a

set of two AA batteries mounted inside the rear panel of the Test Set.

You must periodically change these batteries. The second method of

RAM backup is an internal battery. It is not user serviceable.

Failure to take prompt action may result in loss of RAM data including

IBASIC programs and SAVE/RECALL states stored in the RAM.

To change the AA batteries, use the following procedure:

1. Turn off power and unplug the Test Set.

2. Remove the six screws in the rear panel using a TX-15 TORX(R)

screwdriver.

3. Remove the rear cover.

4. Replace the AA batteries. Do not use rechargeable batteries.

5. Replace the rear panel.

20 Chapter 1

C:\Spk\AmpsGuide\Getstart.fm

Getting Started with AMPS Test

About the Test Set

Getting Help

If you have problems using this Test Set, and cannot find the solution in

these documents or the help screens, please use one of the following

contacts:

• Your local or regional sales office (“Regional Sales and Service

Offices” on page 16.)

• U.S. Call Center: 800 542-4844

• Korea Agilent Technologies Direct: (82/2) 769-0800

• Canada Agilent Technologies Direct: (800) 387-3154

• European Call center: +31 20 547-9990

• Test and Measurement Organization on the Web.

What’s Included with this Test Set

The equipment commonly shipped with the base Test Set is listed

below. Option s that you order with your Test Set may change th is list.

•Test Set

• Documentation:

— CDMA Applications Guide

— CD-ROM with the above listed manual, AMPS Base Station Tests

Applications Guide, Assembly Level Repair Manual,

Programmer’s Guide, and Agilent Technologies 8935 Series

E6380A Reference Guide in Adobe™ Acrobat Reade r format (.pdf ).

Power cord

Cover for the front panel of the Test Set

Getting Started with AMPS

Test

Chapter 1 21

Getting Started with AMPS Test

Manual and Automatic Operation Modes

Manual and Automatic Operation Modes

You can operate the Test Set in either of two modes: manual or

automatic. Controlling the Test Set with the keypad is manual

operation. Controlling the Test Set with a program is automatic

Operation.

Use manual mode when you want to control the Test Set with the front

panel. Manual operation is described in this document.

Use autom a ti c mode when you want to con trol the Test Set with its

internal IBA SIC controlle r. To use the Test Set in automa tic mode, you

must load an IBASIC program into the Test Set’s memory.

IBASIC programs

You can obtain an IBASIC program in two ways: either write it yourself,

or purchase a software package from Agilent Technologies. To write

programs yourself, refer to the Programmer’s Guide, included with the

Test Set’s documentation.

Many of Agilent Technologies software packages are

manufacturer-specific packages. Manufacturer-specific software

packages provide automated testing of the manufacturer’s base station

to greatly reduce test times and provide test setup repeatability. Once

configured, the software ty pically controls both th e base station and the

Test Set and prompts the user to make the requi red connec tio ns during

testing. Test results can be printed and/or saved to a file for later use.

Contact your local Agilent Technologies Sales Office to find out which

software packages are currently available.

22 Chapter 1

C:\Spk\AmpsGuide\Getstart.fm

Getting Started with AMPS Test

Maximizing the Accuracy of Your Measurements

Maximizing the Accuracy of Your

Measurements

This Test Set is designed to make highly accurate measurements.

However, to ensure that you have the most accurate measurements

available, you can perform the following tasks:

Calibration

You should calibrate the Test Set whenever you change or add an

internal a ssembly. You may w ant to calibrate when you upgrade

firmware. See the Assembly Level Repair Manual for calibration

procedures.

TX Power Temperature Compensation

The Test Set is internally compensated. However, power measurement

calibration can be optimized for tempera t ure changes using the

TX P wr Zero field on the RF ANALYZER screen. The new calibration

factors are stored in RAM until the next time the routine is used.

To have the Test Set zero the TX Power measurement automatically

when needed, set the Auto Zero field on the RF ANALYZER screen to

Auto. During operation, the T est Se t will temporarily halt the TX Power

measurement as it is calibrated. This can happen during a

measurement. If interrupting the measurement is a problem for your

test setup, set t he Auto Zero field to Manual, and select

TX P wr Zero whenever you want to manually calibrate the

measurement.

Getting Started with AMPS

Test

Chapter 1 23

Getting Started with AMPS Test

Display an FM Carrier Signal (Loopback Test)

Display an FM Carrier Signal (Loopback Test)

Since an AMPS base station is basically a continuous wave (CW) FM

signal, this section will g uide you through the pr ocess of gen erating and

displaying an FM signal at a cellular band frequency. It is intended to

make you feel more comfortable with using the Test Set. If you are

ready to begin testing, proceed to Chapter 2.

NOTE

In the following operating example, you enter a common frequency for

the RF generator and RF analyzer to create and view the Test Set’s own

signal. However, typical AMPS base station testing uses channel

assignments with different transmit and receive frequencies. Th is is

explained further in “Using Channel Numbers to Set Analyzer and

Generator Frequencies” on page 69.

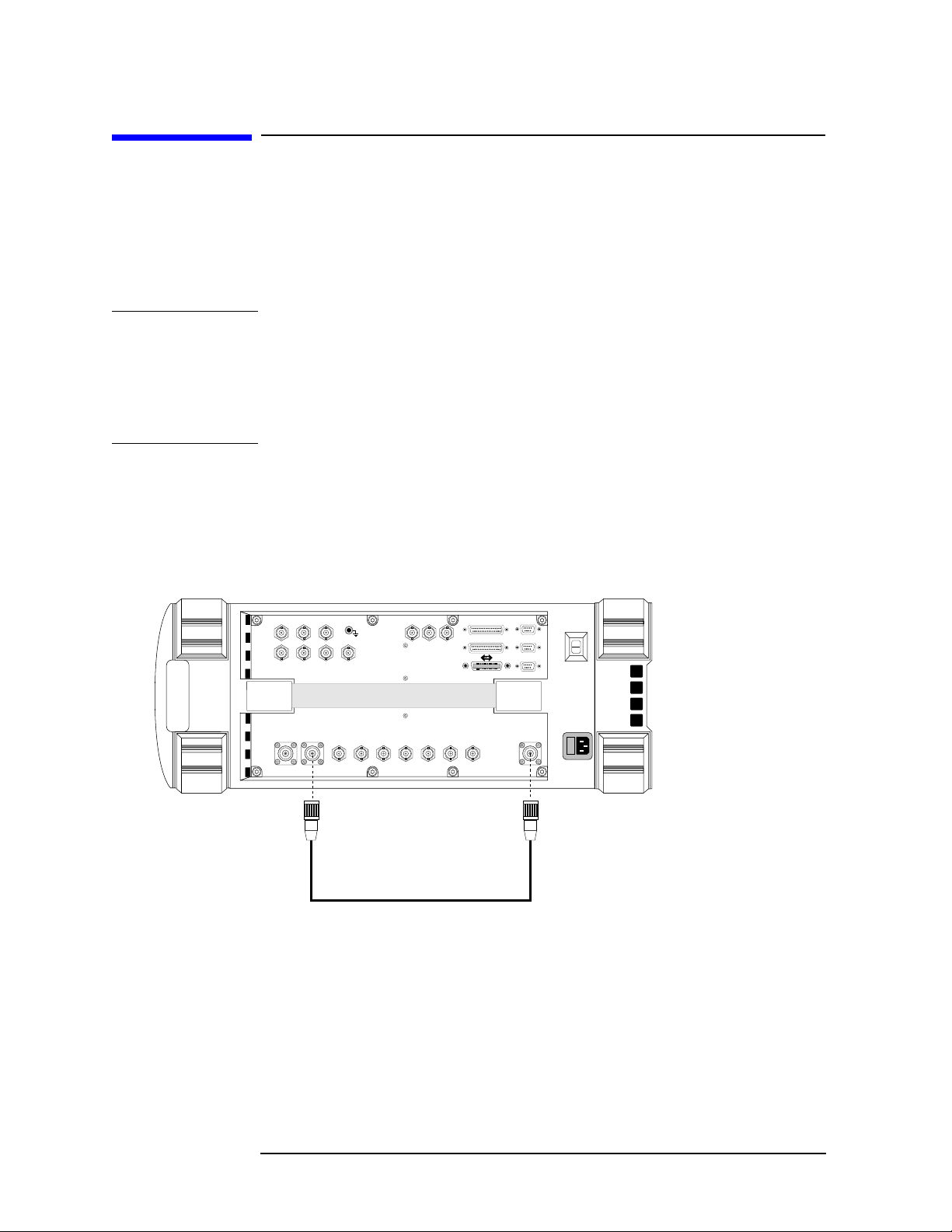

Connections for FM Carrier Loopback Test

Connect the Test Set as show n below.

Figure 1-1 FM Carrier Loopback Test Connections

AUDIO OUT

MODULATION

INPUT

ANT IN DUPLEX

HI LO

AUDIO

MONITOR

OUTPUT

AUDIO IN

EXT SCOPE

TRIG IN

16X

CHIP CLOCK

19.6608

MHz OUT

VIDEO

OUT

CHIP CLOCK

1.2288

MHz OUT

BASEBAND OUT

QI

SYNC IN

EVEN

FRAME

TRIG/QUALIN10 MHz

SECOND

CLOCK

IN

REF OUT

REF IN

PARALLEL PORT

PARALLEL PORT

SERIA PORT

SERIA PORT

SERIA PORT

RF IN/OUT

DUPLEX OUT

24 Chapter 1

RF IN/OUT

C:\Spk\AmpsGuide\Getstart.fm

Get Started with the Test Set

Getting Started with AMPS Test

Display an FM Carrier Signal (Loopback Test)

NOTE

Here are some guides for selecting screens and fields:

• Use the knob to move the cursor around the screen. Reverse video

boxes indicate fields that can be selected.

• To select a field on the screen, push the knob, or press the

•Use the

RF Gen, RF Anl

, and

Spec Anl

keys to access the RF

Enter

key.

GENERATOR, RF ANALYZER, and SPEC ANL screens.

• Selecting the title bar at the top of the screen displays a list of

screens that can be immediately accessed when selected .

Preparing the Test Set

1. Plug in the Test Set.

2. Turn on the Test Set (or press

Preset

ANALYZER screen will be displayed.

3. Press the

Inst

Config

key.

4. Select RF Display, and set the field to Freq.

5. Verify your connections. See “Connections for FM Carrier Loopback

Test” on page 24

if it is already on). The CDMA

Getting Started with AMPS

Test

NOTE

Generate an FM Carrier Signal

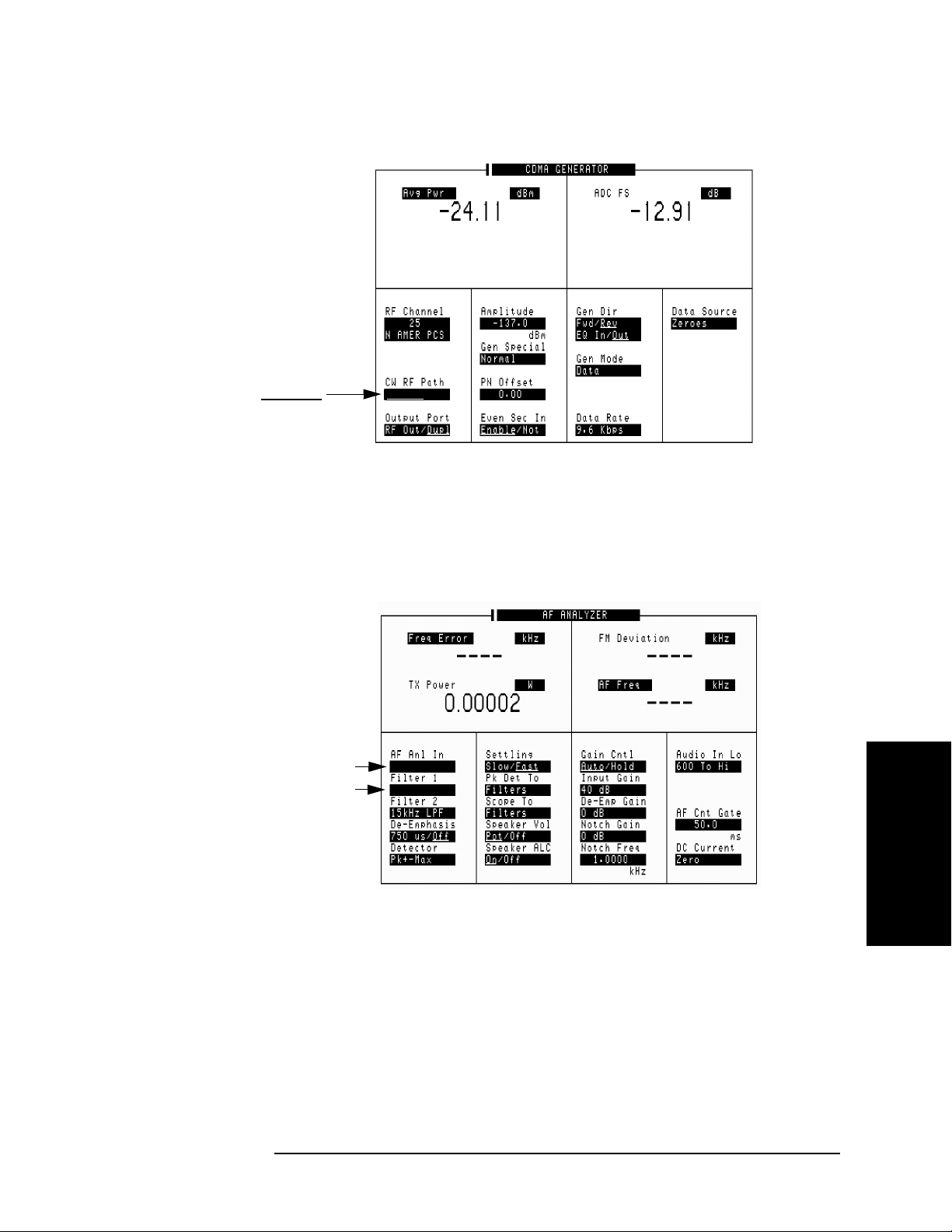

Refer to Figure 1-2.

1. Press

CDMA Gen

2. Select CW RF Path and set it to Bypass. This shuts off the IQ

modulation normally used for CDMA testing.

3. Press the

RF Gen

4. Select RF Gen Freq and use the keypad to set the frequency to

850.000 MHz.

5. Select Amplitude and set the amplitude to 0 dBm.

6. Select Output Port and verify that the port is set to Dupl.

7. T urn on FM modulati on by pos itioning the cur sor in the lower h alf of

the AFGen1 To field and pressing the

The default FM deviation is 2.9 kHz. The default FM rate is

1.0 kHz.

AF generators 1 and 2 are automatically turned off anytime you access

any of the CDMA screens (CDMA GENERATOR, CDMA ANALYZER,

to go to the CDMA GENERATOR screen.

key to go to the RF GENERATOR screen.

On/Off

key.

Chapter 1 25

Getting Started with AMPS Test

Display an FM Carrier Signal (Loopback Test)

CODE DOM). This prevents accidental addition of AM or FM when

generating a CDMA signal. If you accidentally access any of the CDMA

screens when testing an AMPS base station, any AM or FM you

specified on the RF GENERATOR screen will be turned off while on

that CDMA screen. Previously set AM and/or FM are automatically

turned back on when returning to the RF GENERATOR screen.

Figure 1-2 Setting Up the RF Generator

Enter 850 MHz

Enter 0 dBm

Tu rn on FM

Select DUPLEX

Analyzing an FM Carrier Signal

1. Press the

RF Anl

2. Select Tune Freq and use the keypad to set t he frequen cy to 850.000

MHz. Notice that the Frequency Error, TX Power, FM Deviation, and

AF Frequency for the signal are automatically displayed.

Figure 1-3 Default RF Analyzer Measurements

key to go to the RF ANALYZER screen.

26 Chapter 1

C:\Spk\AmpsGuide\Getstart.fm

Getting Started with AMPS Test

Display an FM Carrier Signal (Loopback Test)

3. Press the

Spec Anl

4. The signal is displayed.

5. Select Span and set it to 30.000 kHz to get a good view of the

modulated signal. See Figure 1-4.

Figure 1-4 FM Carrier Signal

key to go to the SPECTRUM ANALYZER screen.

Getting Started with AMPS

What to Do Next

Congratulations! You are now ready to begin testing your AMPS Base

Station. Proceed to Chapter 2 , “Testing AMPS Base Stations ,” on page

29.

Test

Chapter 1 27

Testing AMPS Base Stations

2

Testing AMPS Base Stations

Advanced Mobile Phone System (AMPS) base stations for cellular telephone

systems are basically contin u ous w av e (CW) FM v o ice transceivers with some

control and data signals for system operation. This chapter explains how to use

the Te st Set to manually test the RF and AF performance of the transmitter

and receiver portions of th e base station.

29

Testing AMPS Base Stations

AMPS Tests You Can Perform

AMPS Tests You Can Perform

The following tests are explained in this manual:

• “Transmitter Frequency Error/Offset and Power Test” on page 34.

• “Transmitter SAT Frequency and Deviation” on page 36.

• “Transmitter Data Deviation” on page 38.

• “Transmitter Maximum Voice Deviation” on page 40.

• “Receiver Sensitivity (SINAD)” on page 42.

• “Receiver Squelch Threshold” on page 45.

CAUTION

Transmitter power (TX Power) can only be measured through the Test

Set’s RF IN/OU T por t. Verify that the signal connected to this por t d oes

not exceed the limits print ed by the port.

If you hear a loud “warbling” sound from the Test Set, turn off your

transmitter immediately! This is the over-power alarm, warning that

instrument damage may occur. Caution: Turning the Test Set off at thi s

point does no t protect the internal circu i try. Also, re m o v i ng the cable

from the RF IN/OUT port without turning the transmitter off may

damage your transmitter or power amplifier (due to an impedance

mismatch).

The ANT IN port is only used for analyzing very low level signals

(≤60 mW). Never attempt to measure a transmitter’s power directly

using the ANT IN port, as instrument damage may occur.

The DUPLEX OUT port is only used to provide RF signals to the base

station’s receive port(s). It must not be connected to the base stations

transmit port or damage may oc cur to the Test Set.

30 Chapter 2

C:\Spk\AmpsGuide\Measure.fm

Testing AMPS Base Stations

What You Need to Know to Begin

What You Need to Know to Begin

You need to know how to control the base station and the basic

operation of the Test Set before you can test your base station.

Test Set operation includes how to change control settings, how to

navigate between control screens, and how to change the units used for

any measurement or setting. Test Set operation and feature

descriptions are included i n t h e Reference Guide.

Base station operation includes turning the transmitter on and off,

turning the SA T tone and data signals on and off, and knowing where to

connect test cables from th e Test Set to your base st at ion.

You also need to properly configure the Test Set for your test situation.

The following sections describe operations needed to simplify Test Set

operation and minimize measurement errors.

• Entering the known losses and/or gains in your test setup is

explained in “Compensating for Signal Losses and Gains in the Test

Setup” on page 33.

• Measuring the signal loss through cables and other devices is

explained in “Measuring Insertion Losses” on page 51.

• Choosing to enter your base station’s transmit and receive

frequencies by channel number or by discrete frequencies is

explained in “Using Channel Numbers to Set Analyzer and

Generator Frequencies” on page 69.

Testing AMPS Base Stations

Chapter 2 31

Testing AMPS Base Stations

Connecting the Test Set to Your Base Station

Connecting the Test Set to Your Base Station

The connections shown in Figure 2-1 indicate a “generic” base station

using a test interface for audio test signals and a laptop computer

running a control program to control the base station. A power splitter

is used for testing the receiver ports. Although this is a common setup

for performing tests, audio and RF connections to base st atio ns and the

ways base stations are controlled vary among manufacturers .

Figure 2-1 Connections Between the Test Set and the Base Station

Audio

Out

ANT IN

(≤60mW)

TX Mod RX Audio

Audio

In

DUPLEX OUT

(RF Gen Out)

AMPS BASE STATION

1

S

2

Power

Splitter

PARALLEL PORT

RF IN/OUT Port

(High Power RF Input)

side1_75.eps

Receive A

Receive B

Audio Test Signal

breakout port.

Local Control

Port

TX

32 Chapter 2

C:\Spk\AmpsGuide\Measure.fm

Testing AMPS Base Stations

Compensating for Signal Losses and Gains in the Test Setup

Compensating for Signal Losses and Gains in

the Test Setup

Signal losses or gains through cables, splitters, combiners, connectors,

amplifiers, or coaxial switches must be accounted for to ensure

measurement accuracy. These values are entered in the INST RUMENT

CONFIGURE screen (press the

Inst Config

Refer to “Measuring Insertion Losses” on page 51 for information about

measuring cable/system losses.

• Total losses/gains between the transmitter’s output and the Test

Set’s RF IN /OUT port are entered in the RF In/Out field. A negative

number (indicating a loss) causes the displayed TX power

measurement to be increased by the entered amount. A positive

number (indicating a gain) causes the RF analyzer to decrease the

displayed TX power measurement by the entered amount.

• Total losses between the Test Set’s DUPLEX OUT port and the base

station’s receive port(s) are entered in the Duplex Out field as a

negative number (such as −1.2). The RF Generator will

automatically increase its level out of the DUPLEX OUT port by the

value entered to compensate for the loss.

key).

Figure 2-2 Entering Test System Losses and Gains

Set the RF Level Offset

field to On

.

On/Off

LS AMPS

Enter the loss or gain

between each port and the

base station.

Testing AMPS Base Stations

Chapter 2 33

Testing AMPS Base Stations

Transmitter Frequency Error/Offset and Power Test

Transmitter Frequency Error/Offset and

Power Test

This test compares the measured c enter frequency of t he base station to

the AMPS channel standard. The resulting difference is the frequency

error (also called the frequency offset). The measurement can be

displayed in frequency units (Hz, kHz, MHz) or in parts per million

(ppm). Measurements are made with all modulation turned off.

The transmitter’s power can be measured any time the transmitter is

keyed, but may not be accurate unless all modulation is turned off.

Transmitter power may be specified by the manufacturer in units of

watts (W), milliwatts (mW), dBm, Volts (V), or millivolts (mV).

Prerequisites

The following conditions must be met before testing:

• The Test Set is turned on and Preset was pressed to establish a

known instrument state.

• You have configured the Test Set for channel or frequency tuning as

necessary (see “Using Channel Numbers to Set Analyzer and

Generator Frequencies” on page 69).

• You have specified any gains or losses in your test system (see

“Compensating for Signal Losses and Gains in the Test Setup” on

page 33).

Begin Testing

1. Turn off the base station’s RF transmitter. A transmitter can be

damaged if it is not transmitting into a specified load, such as an

antenna, power amplifier, duplexer, or power meter with a 50Ω input

impedance.

2. Verify that the transmitter’s rated RF power (or the level out of the

power amplifier if applicable) does not exceed the level printed next

to the Test Set’s RF IN/OUT connector.

3. Connect the transmitter’s RF output to the Test Set’s RF IN/OUT

port.

4. Turn off any modulation signals to the base station.

• Turn off the SAT tone.

• Turn off any data (digital) modulation signals.

• Turn off any audio (voice) modulation signals.

5. Press the

34 Chapter 2

RF Anl

key to access the RF ANALYZER screen.

C:\Spk\AmpsGuide\Measure.fm

Testing AMPS Base Stations

Transmitter Frequency Error/Offset and Power Test

6. Enter the transmitter’s RF Channel number.

7. Turn on the transmitter. The TX Freq Error and TX Power

measurements are displayed.

Note: Disregard any values shown for FM Deviation an d AF F req at

this time.

Figure 2-3 Transmitter Frequency Error and Power Test Results

Chapter 2 35

Testing AMPS Base Stations

Testing AMPS Base Stations

Transmitter SAT Frequency and Deviation

Transmitter SAT Frequency and Deviation

This test measures the transmitter’s Supervisory Audio Tone (SAT)

frequency and deviation in the absence of any other modulating signal.

Prerequisites

The following conditions must be met before testing:

❏ The Test Set is turned on and Preset was pressed to establish a

known instrument state.

• You have configured the Test Set for channel tuning (see “Using

Channel Numbers to Set Analyzer and Generator Frequencies” on

page 69).

• You have specified any gains or losses in your test system (see

“Compensating for Signal Losses and Gains in the Test Setup” on

page 33).

Test Procedure

1. Turn off the base station’s RF transmitter. A transmitter can be

damaged if it is not transmitting into a specified load, such as an

antenna, power amplifier, duplexer, or power meter with a 50Ω input

impedance.

2. Verify that the transmitter’s rated RF power (or the level out of the

power amplifier if applicable) does not exceed the level printed next

to the Test Set’s RF IN/OUT connector.

3. Connect the transmitter’s RF output to the Test Set’s RF IN/OUT

port.

4. Turn off the voice modulation to the transmitter.

5. Turn off data modulation to the transmitter.

6. Enable SAT transmission.

7. Press

8. Set the Filter 2 field to 6 kHz BPF. This helps remove unwanted

noise.

Shift, RF Anl

(AF Anl) to access the AF ANALYZER screen.

36 Chapter 2

C:\Spk\AmpsGuide\Measure.fm

Figure 2-4

Testing AMPS Base Stations

Transmitter SAT Frequency and Deviation

9. Press the

RF Anl

key to access the RF ANALYZER screen.

10.Enter the transmitter’s channel number in the RF Channel field.

11.Turn on the transmitter. The FM Deviation and AF Freq for the

SAT are displayed (as well as Frequency Error and TX Power).

Figure 2-5 SAT Fre quency and Deviation Test Results

Testing AMPS Base Stations

Chapter 2 37

Testing AMPS Base Stations

Transmitter Data Deviation

Transmitter Data Deviation

This test measures the transmitter’s digital data deviation in the

absence of any other modulating signal.

Prerequisites

The following conditions must be met before testing:

• The Test Set is turned on and Preset was pressed to establish a

known instrument state.

• You have configured the Test Set for channel tuning (see “Using

Channel Numbers to Set Analyzer and Generator Frequencies” on

page 69).

• You have specified any gains or losses in your test system (see

“Compensating for Signal Losses and Gains in the Test Setup” on

page 33).

Test Procedure

1. Turn off the base station’s RF transmitter. A transmitter can be

damaged if it is not transmitting into a specified load, such as an

antenna, power amplifier, duplexer, or power meter with a 50Ω input

impedance.

2. Verify that the transmitter’s rated RF power (or the level out of the

power amplifier if applicable) does not exceed the level indicated

next to the Test Set’s RF IN/OUT connec to r.

3. Connect the transmitter’s RF output to the Test Set’s RF IN/OUT

connector.

4. Turn off voice modulation to the transmitter.

5. Turn off the SAT to the transmitter.

6. Turn on the data modulation to the transmitter.

7. Press

8. Set Filter 1 to <20Hz HPF.

9. Set Filter 2 to >99kHz LP.

Shift, RF Anl

(AF Anl) to access the AF ANALYZER screen.

38 Chapter 2

C:\Spk\AmpsGuide\Measure.fm

Figure 2-6

<20Hz HPF

>99kHz LPF

Testing AMPS Base Stations

Transmitter Data Deviation

10.Press the

RF Anl

key to access the RF ANALYZER screen.

11.Enter the transmitter’s channel number in the RF Channel field.

12. Turn on the transmitter. The FM Deviation from the data is

displayed.

Figure 2-7 Data Deviation Test Results

Data Deviation

Testing AMPS Base Stations

Chapter 2 39

Testing AMPS Base Stations

Transmitter Maximum Voice Deviation

Transmitter Maximum Voice Deviation

This test measures the transmitter’s maximum FM Deviation by a

voice signal in the absence of any other modulation signal.

Prerequisites

The following conditions must be met before testing:

• The Test Set is turned on and Preset was pressed to establish a

known instrument state.

• You have configured the Test Set for channel tuning (see “Using

Channel Numbers to Set Analyzer and Generator Frequencies” on

page 69).

• You have specified any gains or losses in your test system (see

“Compensating for Signal Losses and Gains in the Test Setup” on

page 33).

Test Procedure

1. Turn off the base station’s RF transmitter. A transmitter can be

damaged if it is not transmitting into a specified load, such as an

antenna, power amplifier, duplexer, or power meter with a 50Ω input

impedance.

2. Verify that the transmitter’s rated RF power (or the level out of the

power amplifier if applicable) does not exceed the level indicated

next to the Test Set’s RF IN/OUT connec to r.

3. Connect the transmitter’s RF output to the Test Set’s RF IN/OUT

port.

4. Connect the transmitter’s audio modulation (voice) input to the Test

Set’s AUDIO OUT port.

5. Enable the transmitter’s audio (speech) modulation.

6. Turn off any modulation signals to the base station oth er tha n audio .

7. Press the

RF Anl

8. Enter the transmitter’s channel number in the RF Channel field.

9. Press the

RF Gen

key to access the RF ANALYZER screen.

key to access the RF GENERATOR screen.

10. Set the AFGen1 To field to Audio Out, and a level of 50 mV.

40 Chapter 2

C:\Spk\AmpsGuide\Measure.fm

Figure 2-8

Audio Out

Initially 50 mV

Testing AMPS Base Stations

Transmitter Maximum Voice Deviation

11. With the cursor still positioned in front of the level setting

(50 mV), press the

Incr Set

key and enter 20 dB using the keypad.

Figure 2-9

Increment

AFGen1

level by

20 dB.

12. Turn on the transmitter.

13. With the cursor still positioned in front of the level setting (50 mV)

press the up-arrow key once to increment the level by 20 dB.

14.Read the FM deviation.

15.Vary the AFGen1 Freq from 300 Hz to 3 kHz and observe the FM

deviation at each frequency. Deviation must not exceed the rated

system specification of ±12 kHz at any time.

Testing AMPS Base Stations

Watch

the FM

Deviation

while...

...chang

ing the

AFGen

1 Freq

from

300 Hz

16.Disconnect the cable to the transmitter’s audio modulation input

(connected in step 4) to reduce the chance of errors in your next

transmitte r te st .

Chapter 2 41

Testing AMPS Base Stations

Receiver Sensitivity (SINAD)

Receiver Sensitivity (SINAD)

This test measures the receiver’s ability to demodulate voice signals

from very low RF carrier levels.

Prerequisites

The following conditions must be met before testing:

• The Test Set is turned on and Preset was pressed to establish a

known instrument state.

• You have configured the Test Set for channel tuning (see “Using

Channel Numbers to Set Analyzer and Generator Frequencies” on

page 69).

• You have specified any gains or losses in your test system (see

“Compensating for Signal Losses and Gains in the Test Setup” on

page 33).

Test Procedure

1. Turn off the base station’s transmitter.

2. Turn the base station’s radio squelch, data, and SAT off.

3. Connect the base station receiver’s inputs to the Test Set’s DUPLEX

OUT port.

4. Connect the receive r’s audio output to the Test Set’s AUDIO IN

port(s). Unless the receiver’s audio out amplifier is not referenced to

chassis ground, you should only connect to the AUDIO IN - HI port.

For floating o u tput amplifiers, see the Agilent Technologies 8935

Series E6380A Reference Manual for information on using the

AUDIO IN - LO connection.

5. Press

6. Set the CW RF Path field to Bypass. This turns off the IQ modulation

used for CDMA tests.

CDMA Gen

to access the CDMA GENERATOR screen.

42 Chapter 2

C:\Spk\AmpsGuide\Measure.fm

Figure 2-10

Testing AMPS Base Stations

Receiver Sensitivity (SINAD)

Set to Bypass.

Figure 2-11

Set to

Set to

Bypass/IQ

7. Press

SHIFT, RF Anl

(AF Anl) to access the AF ANALYZER screen.

8. Set the AF Anl In field to Audio In.

9. Set the Filter 1 field to C Message.

Audio In.

C Message.

Audio In

C Message

Testing AMPS Base Stations

10. Press the

RF Gen

key to access the RF GENERATOR screen.

11. Change the lower audio measurement to SINAD. This is done by

selecting the existing measurement and choosing SINAD from a list

of choices.

12. Set the AFGen1 To field to FM and turn it on (2.9 kHz) using the

On/Off

key.

13. Enter the transmitter’s channel number in the RF Channel field.

Chapter 2 43

Figure 2-12

Enter the

RF Channel number.

Set an initial

level of

−90 dBm.

Testing AMPS Base Stations

Receiver Sensitivity (SINAD)

14. Set an initial RF generator level in the Amplitude field. This value

depends on the sensitivity of the receiver; but −90 dBm should be a

good starting point. At this point you should be able to turn the Test

Set’s Volume knob clockwise and hear a 1 kHz tone from the Test

Set’s speaker.

Set to

SINA

Turn

on FM

modulation

15. Set the Amplitude field to increment in 1 dB units. To do this,

position the cursor in front of the Amplitude field, press the

Incr Set

key, and enter 1 dB using the keypad.

16. With the cursor front of the field, turn the knob to decrease the

Amplitude setting until the desired SINAD measurement is

displayed (commonly 12 dB). You should hear the 1 kHz tone get

noisy as you approach the 12 dB SINAD reading.

Figure 2-13 SINAD Tes t Res u lts

As you decrease the

RF generator

amplitude into your

receiver....

...the SINAD

reading goes

down and the

signal through

the Test Set’s

speaker gets

noisy.

44 Chapter 2

C:\Spk\AmpsGuide\Measure.fm

Testing AMPS Base Stations

Receiver Squelch Threshold

Receiver Squelch Threshold

This test determines the RF Signal level where the receiver squelches

(switches off) the audio output.

Prerequisites

The following conditions must be met before testing:

• The Test Set is turned on and PRESET was pressed to establish a

known instrument state.

• You have pressed the

state.

• You have configured the Test Set for channel tuning (see “Using

Channel Numbers to Set Analyzer and Generator Frequencies” on

page 69).

• You have specified any gains or losses in your test system (see

“Compensating for Signal Losses and Gains in the Test Setup” on

page 33).

Preset

key to establish a known instrument

Test Procedure

1. Turn off the base station’s transmitter.

2. Turn the base station’s data and SAT off.

3. Connect the base station receiver’s inputs to the Test Set’s DUPLEX

OUT port.

4. Connect the receive r’s audio output to the Test Set’s AUDIO IN

port(s). Unless the receiver’s audio out amplifier is not referenced to

chassis ground, you should only connect to the AUDIO IN - HI port.

For floating o u tput amplifiers, see the Agilent Technologies 8935

Series E6380A Reference Manual for information on using the

AUDIO IN - LO connection.

Testing AMPS Base Stations

5. Press

6. Set the CW RF Path field to Bypass. This turns off the IQ modulation

used for CDMA tests.

Chapter 2 45

CDMA Gen

to access the CDMA GENERATOR screen.

Figure 2-14

Testing AMPS Base Stations

Receiver Squelch Threshold

Set to Bypass.

Bypass/IQ

7. Press

SHIFT, RF Anl

(AF Anl) to access the AF ANALYZER screen.

8. Set the AF Anl In field to Audio In.

9. Press the

RF Gen

key to access the RF GENERATOR screen.

10.Set the AFGen1 To field to FM and set it to 8 kHz deviation.

11.Enter the transmitter’s channel number in the RF Channel field.

12.Set the Atten Hold field to On. The prevents the Test Set from

changing its internal attenuators during the test to prevent

erroneous squelch interruption.

13.Set an initial RF generator level in the Amplitude field. This value

depends on the sensitivity of the receiver; but −90 dBm should be a

good starting point. At this point you should be able to turn the Test

Set’s Volume knob clockwise and hear a 1 kHz tone from the Test

Set’s speaker.

46 Chapter 2

C:\Spk\AmpsGuide\Measure.fm

Figure 2-15

Enter the

RF channel

number.

Set a initial

level of

−90 dBm.

Set to On.

Testing AMPS Base Stations

Receiver Squelch Threshold

Turn

on FM

modulation

for the

8.00

On/off

RF

generator

14.Set the Amplitude field to increment in 1 dB units. To do this,

position the cursor in front of the Amplitude field, press the

Incr Set

key, and enter 1 dB using the keypad.

15.With the cursor in front of the Amplitude field, turn the knob

counterclockwise to decrease the Amplitude setting until the

received audio is no longer heard on the Test Set’s speaker (or until

the AC Level reading drops suddenly). The RF amplitude at which

the audio signal is no longer output is the squelch threshold.

Testing AMPS Base Stations

Chapter 2 47

3

Utility Procedures

This chapter contains procedures an d instructions that will help you

make the most efficient use of your Test Set.

Utility Procedures

49

Utility Procedures

Beeper

Beeper

The beeper notifies you when a message is displayed. Since a message

may be removed from the screen before you notice it, it is better to leave

the beeper on to alert you to errors during operation.

The beeper’s volume setting is retained when the instrument is turned

off.

Beeper Control

1. Press the

Inst Config

key to go to the INSTRUMENT CONFIGURE

screen.

2. Select Beeper.

3. Choose from Off, Quiet, or Loud.

50 Chapter 3

C:\Spk\AmpsGuide\Utilites.fm

Utility Procedures

Measuring Insertion Losses

Measuring Inse rtio n Losses

To make accurate power and receiver measurements, the signal loss

through the cables or other devices used in your test setup must be

known and entered into the Test Set’s INSTRUMENT CONFIGURE

screen to compensate for these losses.

Signal losses are measured using a built-in automated routine that

runs on the Test Set’s IBASIC controller. Los ses can be calibrated at a

discrete (single) frequency or over a frequency range. This is one

routine included in a set of utility procedures called the RF TOOLS.

During the test, a calibrated signal goes through two 6-dB

attentuators/pads (suc h as Mini-Circuits model NAT-6-60) and a short

type-N male-to-male cable to establish a known reference point. The

Test Set then prompts you to connect the device under test to measure

the additional loss through that device. (The pads and cable are not

part of the standard equ i pment shipped wi th th e Test Set.)

Figure 3-1 on page 51 shows how to load and run the RFTOOLS

routines and select the desired insertion loss test.

Figure 3-1 Loading and Running the Insertion Loss Test

1 Select

Select

2

3

Select

When the screen below appears.......

ROM.

RFTOOLS.

Run T e st.

...use the knob to move the cursor

and select either

Insertion L o ss

tion Loss

. When run, the test

Discrete Freq

or

Swept Inser-

prompts you to enter the nec essary

test frequency information and displays setup diagrams. Make the

indicated connections and follow

Utility Procedures

Chapter 3 51

Utility Procedures

Memory Cards

Memory Cards

The slot on the front of the Test Set is used for memory cards. The slot

is used for the following:

• Storage of save/recall registers

• Loading of software (either Agilent Technologies or self-written)

• Collecting data (only when using software)

• Upgrading firmware or software

Memory Cards and Initialization

There are several types of memory cards available, and the followin g

cards are used with the Test Set:

• SRAM: used for save/recall and data storage

• Flash ROM: used when upgrading firmware

• OTP (One-Time Programmable): used for Agilent Technologies

software

Flash ROM cannot be used for collecting data and Save/Recall.

Data cannot be loaded on Flash RAM and OTP cards with the T es t Set’ s

memory card slot.

SRAM can be initialized with the Test Set.

Initializing SRAM Cards for Save/Recall and Data Collection

1. Insert the SRAM card into the slot. If the card is uninitialized, a

message will appear at the top of the display.

2. Press

Shift

and

IO Confg

to display the I/O CONFIGURE screen.

3. Using the knob, locate the FORMAT CARD field.

4. Select the FORMAT CARD field. A prompt will appear at the top o f the

display. Pressing

will erase and initialize the card.

Yes

52 Chapter 3

C:\Spk\AmpsGuide\Utilites.fm

Oscilloscope

The built-in 50 kHz oscilloscope provides

• multiple triggering formats (internal and external)

• single-shot and pre-trigger viewing for single events

• full marker capability with automatic level and time readout

Time/division, volts/ division and vertical offset are displayed and can be

changed using the front-panel knob.

Input to the Oscilloscope (SCOPE) is provided from various sources

including direct inputs to the Audio Input and Modulation Input

connectors. Oscilloscope functio ns are accessed from the AF Anl and

SCOPE screens.

Figure 3-2 Inputs and Filters for the Oscilloscope

Utility Procedures

Oscilloscope

FM Demod

AM Demod

SSB Demod

AUDI O IN connecto r

Analog Modulati on In

connector

FM Mod

AM Mod

Audio O ut

Controlled by

AF Anl In

field

Input

Controlled by

Scope To

field

Filters

De-emp

Notch

Selecting the Oscilloscope’s Input

1. Press

2. Select the AF Anl Input field. A list of choices appears.

Shift

, then

RF Anl

(AF Anl) to select the AF ANALYZER screen.

To

Scope

To

Audio Monitor

Out connector

Chapter 3 53

Utility Procedures

Utility Procedures

Oscilloscope

3. Select the desired input to the scope:

• FM Demod for FM demodulated audio from input signals

connected to the RF IN/OUT or ANT IN connectors.

• AM Demod for AM demodulated audio from input signals

connected to the RF IN/OUT or ANT IN connectors.

• SSB Demod for SSB demodulated audio from input signa l s

connected to the RF IN/OUT or ANT IN connectors.

• Audio In for a s ignal connecte d to th e AUDIO IN connector.

• Ext Mod for a signal connected to the rear panel MODULATION

INPUT connector.

• FM Mod for the FM modulated audio from the RF generator

section.

• AM Mod for the AM modulated audio from the RF generator

section.

• Audio Out for the signal present at the AUDIO OUT connector.

4. The input to the oscilloscope is displayed on the SCOPE screen.

Selecting the Oscilloscope’s Filters

1. Press

2. Select the Scope To field. A list of choices should appear.

3. Select the desired filterin g f or the signa l :

• Input if you want no filtering (dc coupled)

• Filters to route the audio to the osc illoscope after pas sing through

filters 1 and 2. (ac coupled)

• De-emp to route the audio to the oscilloscope after passing

through filters 1 and 2, and the de-emphasis circuitry.(ac coupled)

• Notch to route the audio to the oscilloscope after passing through

Filters 1 and 2, the de-emphasis circuitry, and notch filter

circuitry. (ac coupled)

Shift

, then

RF Anl

(AF Anl) to select the AF ANALYZER screen.

54 Chapter 3

C:\Spk\AmpsGuide\Utilites.fm

Utility Procedures

Oscilloscope

Triggering the Oscilloscope

You can control following triggering features of the oscilloscope:

• Trigger: external or internal

• Automated or normal triggering

• Continuous or single shot triggering

• Trigger level

• Trigger delay

The oscilloscope is triggered using the Trigger menu. Select this menu

with the following procedure:

1. Press

Shift

, then

Spec Anl

(Scope) to go to the SCOPE screen.

2. Select the Controls field, then choose Trigger from the list of

choices.

Using the Marker

The marker is used to help you make measurements with the

oscilloscope. By repositioning the marker, you can measure the level

and time.

The Marker is controlled using t he Marker menu. Select this menu with

the following procedure:

1. Press

Shift

, then

Spec Anl

2. Select the Controls field, the choose Marker from the list of choices.

(Scope) to go to the SCOPE screen.

Chapter 3 55

Utility Procedures

Utility Procedures

Online Help

Online Help

The Test Set contains help screens which briefly identify the most

commonl y u sed features of the Test Set.

Access the help screens by pressing the

the Help Topic of interest.

Pressing the

key allows you to switch between the HELP screen

Prev

and the previous screen you had accessed. This is particularly useful

when you are following a procedure described in the HELP screen.

Help Screen Display

Figure 3-3 Help Screen Display

key. Use the knob to select

Help

56 Chapter 3

C:\Spk\AmpsGuide\Utilites.fm

Utility Procedures

Ports: GPIB, Serial and Parallel

Ports: GPIB, Serial and Parallel

There are three types of data ports on the Test Set: GPIB, Serial, and

Parallel. They each have specific purposes.

NOTE

Throughout this manual the terms GPIB and HP-IB may be used

interchangeably except in the case of specified command statements.

GPIB Port

This port is provided on the Test Set for IEEE 488.2 communications. I t

is used to control the Test Set with an external IBASIC controller, or to

control oth er GPIB equipped devices.

This port can be used with an external programming device when

writing programs, although it is also common to program the Test Set

using a serial port.

The default address of the GPIB port is 14. This is commonly used in

Agilent Technologies Instrument BASIC (IBASIC) programs. An

example command providing output to the port is

OUTPUT 714;”*RST”, w hich pres et s t he Test Set.

It has two modes, which correspond to modes useful when

programming the Test Set. Talk&Listn is the normal mode. Use

Control only when you need to control GPIB instruments external to

the Test Set.

Controlling the GPIB Port

1. Press

CONFIGURE screen.

2. Set the address of the GPIB port with the HP-IB Adrs field.

3. Use the Mode field to set the mode to either Talk&Listn or Control.

Shift

, then the

Inst Config

(I/O Config) key to display the I/O

Serial Ports

Three serial ports are available on the Test Set. SERIAL 9 is used for

printing, IBASIC control and data communications. SERIAL 10 is used

only for data communications from IBASIC. SERIAL 11 is reserved for

future use with special soft ware t hat enables remo te oper atio n through

a PC.

Configuring Serial Ports

All serial ports are configured via the I/O CONFIGURE screen. Baud

Rate, Parity, Data Length, Stop Length and Flow Control are all

configured in this screen.

Chapter 3 57

Utility Procedures

Utility Procedures

Ports: GPIB, Serial and Parallel

1. Press Shift, then I/O Config to go to the I/O CONFIGURE screen.

2. Select Serial Port to choose the port you want to configure.

3. Change the settings for the port as desired.

NOTE

Do not set Flow Cntl to Hardware on the I/O CONFIGURE screen for

the serial port until you have a device attached to the port that can

respond to the flow control communications.

Example: Assume you have a printer attached to Serial Port 9. Power is

off to the printer. Before y o u start to run any IBASIC softwar e (for

example, the RFTOOLS program), you must make sure the printer is

attached and power is on to the printer.

Additionally, port 9 can be configured for IBASIC control from this

screen. See “Configuring Se rial Port 9 for IBASIC Communications” on

page 59.

Using Serial Ports for Printing

Serial Port 9 is the only serial port that can be used for printing. See

“Printing” on page 60

1. If you want to change the serial port configuration, see “Configuring

Serial Port 9 for IBASIC Communications” on page 59 It is not

necessary t o change the Serial_9 In field.

2. Press Shift, then Printer Config to display the CONFIGURE

PRINTING screen.

3. Select Printer Port. Choose Serial 9 to direct the output to Serial

Port 9.

4. Press Print to print the screen.

58 Chapter 3

C:\Spk\AmpsGuide\Utilites.fm

Utility Procedures

Ports: GPIB, Serial and Parallel

Configuring Serial Port 9 for IBASIC Communications

The internal connection to Serial Port 9 is controlled in the I/O

CONFIGURE screen. The port has two purposes with IBASIC:

• Inst: Serial Port 9 is connected to a terminal (e.g. a PC running

Microsoft Windows HyperTerminal program). IBASIC

commands are input from the terminal and are used to control the

Test Set.

• IBASIC: Serial Port 9 is connected to a device that can communicate

with an IBASIC program already running inside the Test Set.

Typically used for input/output to a PC or other device.

1. Press Shift, then I/O Config to go to the I/O CONFIGURE screen.

2. Select Serial_9 In to toggle between Inst and IBASIC.

Parallel Ports

There are two parallel ports on the Test Set.

Parallel Port 15 is the only parallel port that can be us ed for printing. It

can be selected in the PRINTER CONFIGURATION screen.

Both parallel ports (Port 15 and Port 16) may be used for controlling a

base station. The port can be put in an input or an output mode. The

data is then written or read under IBASIC control. When in either of

these modes, the printing function on Parallel Port 15 is disabled.

Chapter 3 59

Utility Procedures

Utility Procedures

Printing

Printing

You can print from t he Test Set via Parallel Port 15, Serial Port 9, or the

GPIB port.

Note that data collection is not the same as printing. Data collection

can only be done from a software program.

Configuring the Test Set for Printing

1. Press

Shift

, then

(Printer Config) to display the PRINTER

Print

CONFIGURE screen.

2. Select the Model field and choose the printer that most closely

matches your printer.

3. Select the Printer Port field and choose the port you will connect

the printer to. If necessary, use the I/O CONFIGURE screen to set

up addresses and communication modes.

a. SERIAL PORT 9: This is the uppermost serial port. Conf iguration

defaults are 9600, none, 8, 1, Xon/Xoff.

b. GPIB: The GPIB address (HP-IB Adrs ) is set to printer address

701. Enter this number as 01. Set Mode to CONTROL. (The

default address 14 is reserved for a n external controller .)

c. PARALLEL PORT: There are two ports available. Port 15 (the

printer po rt) is the uppermost port.

4. Connect the proper cable to the connector you selected.

• SERIAL PORT: standard NULL MODEM cable.

• GPIB: GPIB cable (such as Agilent Technologies 10833B)

• PARALLEL PORT: parallel cable

5. Change the FF (form feed) and Lines/Page as needed.

Printing a Screen

1. Configure the Test Set for Printing.

2. Go to the screen you want to print.

3. Press the

(Optional).

4. Press the

5. To cancel the print, go to the PRINTER CONFIGURE screen and

select Abort Print.

60 Chapter 3

key if you want to te mporarily stop the measur ement.

Hold

key. Data will be sent to the printer.

Print

C:\Spk\AmpsGuide\Utilites.fm

Utility Procedures

Measuring Swept Return Loss

Measuring Swept Return Loss

This procedure measures the return loss (VSWR) of an antenna using

an IBASIC program that is in the Test Set’s memory. An external

directional bridge must be provided (such as an Eagle RLB 150X5

Option N5A or equivalent).

Press the

key to access the SOF TWARE MENU screen, and follow

Menu

the instructions illustrated on the following pages.

Figure 3-4 Loading and Running the Return Loss Program

Select

Select

Select

ROM.

RFTOOLS.

Run Test.

Use the knob to move the cursor and

select

Swept Return Loss

Chapter 3 61

.

(Next Page)

Utility Procedures

Utility Procedures

Measuring Swept Return Loss

Figure 3-5 Entering Swept Return Loss Measurement Information

Enter the

Start

and

Stop Frequency

values for the measurement.

The

Max expec ted loss

value is used

to determine the graphics scaling

when the m easurement is displayed.

The

DUPLEX OUT level

is adjustable to reduce the RF level used when

measuring the loss of sensitive devices,