Agilent E5070B/E5071B ENA Series RF Network Analyzers

Installation and Quick Start Guide

Seventh Edition

Manufacturing No. E5070-90081

November 2007

Notices

The information contained in this document is subject to change without notice.

This document contains proprietary information that is protected by copyright. All rights

are reserved. No part of this document may be photocopied, reproduced, or translated to

another language without the prior written consent of Agilent Technologies.

Microsoft®,MS-DOS®,Windows®,Visual C++®,Visual Basic®,VBA® and Excel® are

registered

UNIX is a registered trademark in U.S. and other countries, licensed

exclusively through X/Open Company Limited.

Portions ©Copyright 1996, Microsoft Corporation. All rights reserved.

© Copyright 2002, 2003, 2004, 2005, 2007 Agilent Technologies

Manual Printing History

The manual’s printing date and part number indicate its current edition. The printing date

changes when a new edition is printed (minor corrections and updates that are incorporated

at reprint do not cause the date to change). The manual part number changes when

extensive technical changes are incorporated.

August 2002 First Edition (part number: E5070-90031)

March 2003 Second Edition (part number: E5070-90041, revising minor errata)

July 2003 Third Edition (part number: E5070-90051, add Standard accessories)

January 2004 Fourth Edition (part number: E5070-90051, add power cable

information, notes, and cautions)

May 2005 Fifth Edition (part number: E5070-90061, add Standard accessories)

Feburary 2007 Sixth Edition (part number: E5070-90071)

November 2007 Seventh Edition (part number: E5070-90081)

2

Safety Summary

The following general safety precautions must be observed during all phases of operation,

service, and repair of this instrument. Failure to comply with these precautions or with

specific WARNINGS elsewhere in this manual may impair the protection provided by the

equipment. Such noncompliance would also violate safety standards of design,

manufacture, and intended use of the instrument. Agilent Technologies assumes no liability

for the customer’s failure to comply with these precautions.

NOTE The E5070B/E5071B complies with INSTALLATION CATEGORY II as well as

POLLUTION DEGREE 2 in IEC61010-1. The E5070B/E5071B is an INDOOR USE

product.

NOTE The LEDs in the E5070B/E5071B are Class 1 in accordance with IEC60825-1,

CLASS 1 LED PRODUCT

• Ground the Instrument

To avoid electric shock, the instrument chassis and cabinet must be grounded with the

supplied power cable’s grounding prong.

• DO NOT Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of inflammable gasses or fumes.

Operation of any electrical instrument in such an environment clearly constitutes a

safety hazard.

• Keep Away from Live Circuits

Operators must not remove instrument covers. Component replacement and internal

adjustments must be made by qualified maintenance personnel. Do not replace

components with the power cable connected. Under certain conditions, dangerous

voltage levels may remain even after the power cable has been disconnected. To avoid

injuries, always disconnect the power and discharge circuits before touching them.

• DO NOT Service or Adjust the Instrument Alone

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation, is present.

• DO NOT Substitute Parts or Modify the Instrument

To avoid the danger of introducing additional hazards, do not install substitute parts or

perform unauthorized modifications to the instrument. Return the instrument to an

Agilent Technologies Sales and Service Office for service and repair to ensure that

safety features are maintained in operational condition.

• Dangerous Procedure Warnings

Warnings, such as the example below, precede potentially dangerous procedures

3

throughout this manual. Instructions contained in the warnings must be followed.

WARNING Dangerous voltage levels, capable of causing death, are present in this instrument.

Use extreme caution when handling, testing, and adjusting this instrument.

Safety Symbols

General definitions of safety symbols used on the instrument or in manuals are listed

below.

Instruction Manual symbol: the product is marked with this symbol when it is necessary for

the user to refer to the instrument manual.

Alternating current.

Direct current.

On (Supply).

Off (Supply).

In-position of push-button switch.

Out-position of push-button switch.

A chassis terminal; a connection to the instrument’s chassis, which includes all exposed

metal structure.

Stand-by.

WARNING This warning sign denotes a hazard. It calls attention to a procedure, practice, or

condition that, if not correctly performed or adhered to, could result in injury or

death to personnel.

CAUTION This Caution sign denotes a hazard. It calls attention to a procedure, practice, or condition

that, if not correctly performed or adhered to, could result in damage to or destruction of

part or all of the instrument.

NOTE This Note sign denotes important information. It calls attention to a procedure, practice, or

condition that is essential for the user to understand.

4

Certification

Agilent Technologies certifies that this product met its published specifications at the time

of shipment from the factory. Agilent Technologies further certifies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institution’s calibration facility or by the

calibration facilities of other International Standards Organization members.

Documentation Warranty

The material contained in this document is provided "as is," and is subject to being

changed, without notice, in future editions. Further, to the maximum extent permitted by

applicable law, Agilent disclaims all warranties, either express or implied with regard to

this manual and any information contained herein, including but not limited to the implied

warranties of merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or consequential damages in connection with the

furnishing, use, or performance of this document or any information contained herei n.

Should Agilent and the user have a separate written agreement with warranty terms

covering the material in this document that conflict with these terms, the warranty terms in

the separate agreement will control.

Exclusive Remedies

The remedies provided herein are Buyer’s sole and exclusive remedies. Agilent

T echnologies shall not be liable for any direct, indirect, special, incidental, or

consequential damages, whether based on contract, tort, or any other legal theory.

Assistance

Product maintenance agreements and other customer assistance agreements are available

for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales and Service Office.

Addresses are provided at the back of this manual.

5

Typeface Conventions

Sample (bold) Boldface type is used when a term is defined or

emphasized.

Sample (Italic) Italic type is used for emphasis and for titles of

manuals and other publications.

Sample menu/button/box/tab Indicates a menu/button/box/tab on the screen

labeled “Sample” which can be selected/executed

by clicking. “menu”, “button”, “box”, or “tab“

may be omitted.

key Indicates a hardkey (key on the front panel or

external keyboard) labeled “Sample.” “key” may

be omitted.

[Sample] Indicates the hardkey whose key label is

“Sample“.

[Sample] - Item Indicates a series of key operations in which you

press the

“Item” on the displayed menu blink by using the

[ ↓] or in other ways, and then press the [Enter]

key.

[Sample] key, make the item called

6

E5070B/E5071B Documentation Map

The following manuals are available for the E5070B/E5071B.

• User’s Guide (Part Number: E5070-900x0, attached to optional ABA)

This manual describes most of the basic information necessary to use the

E5070B/E5071B. It provides a function overview, detailed operation procedure for

each function (from preparation for measurement to analysis of measurement results),

measurement examples, specifications, and supplemental information. For

programming guidance on performing automatic measurement with the

E5070B/E5071B, please see the Programming Manual.

• Installation and Quick Start Guide (Part Number: E5070-900x1, attached to

optional ABA)

This manual describes installation after it is delivered and the basic operation

procedures for applications and analysis. Refer to this manual when you use the

E5070B/E5071B for the first time.

• Programmer’s Guide (Part Number: E5070-900x2, attached to optional ABA)

This manual provides programming information for performing automatic

measurement with the E5070B/E5071B. It includes an outline of remote control,

procedures for detecting measurement start (trigger) and end (sweep end), application

programming examples, command reference, and related information.

• VBA Programmer’s Guide (Part Number: E5070-900x3, attached to optional ABA)

This manual describes programming information for performing automatic

measurement with internal controller. It includes an outline of VBA programming,

some sample programming examples, a COM object reference, and related

information.

NOTE The number position shown by “x” in the part numbers above indicates the edition number.

This convention is applied to each manual, CD-ROM (for manuals), and sample programs

disk issued. Here, “3” indicates the initial edition, and each time a revision is made this

number is incremented by 1. The latest edition allows the customer to specify Option ABJ

(Japanese) or Option ABA (English) of the product.

7

8

1. Introduction of This Manual

Contents of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Overview of the E5070B/E5071B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2. Installation

Checking the Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Operating Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Protection Against Electrostatic Discharge (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ensuring Adequate Free Space around Analyzer for Immediate Disconnection of Power Cable in Case of Emergency

22

Installing Front Handles/Rack Mounting Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

How to Install the Handle Kit (Option 1CN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

How to Install the Rack-mount Kit (Option 1CM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

How to Install the Rack-mount and Handle Kit (Option 1CP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting the Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting the Mouse and Keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting the BNC Adaptor (Option 1E5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connecting a LAN Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connecting a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting the Ecal Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power Supply and Blown Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Verification of the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Verification and Connection of Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Blown Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Starting the E5070B/E5071B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Turning the Power ON and OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Disconnection from Supply Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Setting the Internal Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Setting the Date/Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Turning the Date/Time Display ON and OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Initial Registration of E5070B/E5071B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cleaning Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Maintaining an N-type Connector on Each Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Self-test When Turning on the Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Considerations When Shipping to a Service Center Due to Breakdown or Other Problem. . . . . . . . . . . 42

Contents

3. Quick Start Guide

Names and Descriptions of E5070B/E5071B parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Display Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Three Methods of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Operating Method Using Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Operation Method Using a Mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Operation Method Using the Touch Screen (Option 016) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Basic Measurement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9

Contents

Basic Measurement Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Measurement Example of a Bandpass Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

STEP 1. Determining Measurement Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

STEP 2. Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

STEP 3. Connecting the Device Under Test(DUT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

STEP 4. Analyzing Measurement Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

STEP 5. Outputting Measurement Results (Save) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

A. Manual Changes

Manual Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Change 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Change 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10

1. Introduction of This Manual

1 Introduction of This Manual

This chapter provides an overview of this manual to use this manual efficiently and

describes the features of the Agilent E5070B/E5071B briefly. See this manual first when

you use the E5070B/E5071B for the first time.

11

Introduction of This Manual

Contents of This Manual

Contents of This Manual

This Quick Start Guide has been prepared to quickly familiarize users with the

E5070B/E5071B basic oeration and measurement. The following shows the contents of

this manual.

R Chapter 1, “Introduction of This Manual”

This chapter provides an overview of this manual to use this manual efficiently

and describes the features of the Agilent E5070B/E5071B briefly. See this

manual first when you use the E5070B/E5071B for the first time.

R Chapter 2, “Installation”

This chapter provides information about how to set up the Agilent

E5070B/E5071B RF network analyzer, and about daily maintenance.

R Chapter 3, “Quick Start Guide”

This chapter describes the functions of parts on the front panel and display area

of the Agilent E5070B/E5071B RF Network Analyzer. Using the example of

measuring a bandpass filter, you will quickly learn how to easily operate the

E5070B/E5071B by understanding the basic measurement procedures and

operation of the E5070B/E5071B.

R Appendix A, “Manual Changes,”

This appendix contains the information required to adapt this manual to versions

or configurations of the E5070B/E5071B manufactured earlier than the current

printing date of this manual.

NOTE The Chapter 3, “Quick Start Guide,” on page 43 describes only a measurement example of

the bandpass filter. For other measurement examples, see Chapter “Measurement

Examples” in the E5070B/E5071B User’s Guide.

12 Chapter 1

Introduction of This Manual

Overview of the E5070B/E5071B

Overview of the E5070B/E5071B

The E5070B/E5071B RF Network Analyzer is an instrument that can quickly and

accurately evaluate multi-port device measurements. The major features of the

E5070B/E5071B are described as follows.

1. You can equip the instrument with a measurement frequency range at high frequencies

required when you measure RF multi-port devices such as mobile communication

components (E5070B:300 kHz to 3 GHz; E5071B:300 kHz to 8.5 GHz) and with up to

four test ports.

2. Simultaneously measuring all the built-in test ports realizes high-speed measurement,

while executing full-port calibration removes error factors thoroughly to achieve high

accuracy measurement.

3. The built-in balanced measurement function, matching circuit simulation function, and

port impedance transformation function enables you to correctly evaluate RF balanced

devices such as balanced SAW filters.

1. Introduction of This Manual

4. The ease of operation based on the use of a GUI (Graphic User Interface), excellent

connection compatibility with peripherals, and graphical programming environment

created by the built-in VBA enables the user to efficiently process measurement data.

5. The instrument is capable of simultaneously displaying up to 16 measurement channels

as well as up to 16 measurement parameters per channel.

Chapter 1 13

Introduction of This Manual

Overview of the E5070B/E5071B

14 Chapter 1

2. Installation

2 Installation

This chapter provides information about how to set up the Agilent E5070 B/E5071B RF

network analyzer, and about daily maintenance.

15

Contents of this

Chapter

Installation

R Checking the Shipment on page 17

After you receive the analyzer, check all the items in the packing container.

R Environmental Requirements on page 20

Describes the system requirements needed to install the E5070B/E5071B and

how to secure space for heat radiation.

R Installing Front Handles/Rack Mounting Flanges on page 23

Shows how to mount the front handles used to transport the E5070B/E5071B

and how to install the flanges needed to install it in a rack.

R Connect ing the Accessories on page 26

Provides information for connecting the mouse, keyboard, BNC adaptor, and

Ecal module to the E5070B/E5071B.

R Power Supply and Blown Fuses on page 31

Shows how to check the power supply as well as check and connect the power

cable. This section also describes what to do for a blown fuse.

R Starting the E5070B/E5071B on page 34

Describes turning on/off of the Power switch and cutting off the power supply.

In this section you can also find how to set the internal clock.

R Daily Maintenance on page 41

Describes the daily maintenance for the E5070B/E5071B.

16 Chapter 2

Installation

Checking the Shipment

Checking the Shipment

After you receive the analyzer, carry out checks during unpacking according to the

following procedure.

WARNING When unpacking the analyzer, if the external face of the analyzer (such as the cover,

front/rear panel, LCD screen, power switch, and port connectors) appear to be

damaged during transport, do not turn on the power switch. Otherwise, you may get

an electric shock.

Step 1. Check that the packing box or shock-absorbing material used to package the analyzer has

not been damaged.

NOTE If the packing box or shock-absorbing material has been damaged, leave the packing box

and shock-absorbing material as is until other inspection items are checked as follows:

Step 2. Check the packaged items supplied with the analyzer for any damage or defects.

Step 3. By referring to Table 2-1 and Figure 2-1, check that all packaged items supplied with the

analyzer have been provided as per the specified options.

2. Installation

Step 4. After checking, if one of the following applies, contact your nearest Agilent Technologies

sales and service office.

1. The packing box or shock-absorbing material used to package the analyzer has been

damaged or the shock-absorbing material has traces where extreme force has been

applied.

2. A packaged item supplied with the analyzer has mechanical damage or defects.

3. A packaged item supplied with the analyzer is missing.

4. A fault has been detected in the subsequent operation check of the analyzer.

If an abnormality is detected in step 1, contact the company that transported the analyzer as

well as your nearest Agilent Technologies sales and service office. For inspection by the

transport company, save the packing box, shock-absorbing material, and packaged items as

you received them.

Chapter 2 17

Installation

Checking the Shipment

Table 2-1 Items Packaged with the E5070B/E5071B

Name Agilent Product/

Part Number

Standard Accessories

R E5070B/E5071B

R Power cable

*1

*2

R CD-ROM (of the manual)

*3

E5070B/E5071B 1

-1

E5070-905xx 1

R CD-ROM (of the Agilent IO Libraries Suite) E2094-60003 1

R System recovery disk E5070-16000 1

R GPIB adapter

*4

E2078-62101 1

Options

R Keyboard (Option 810) - 1

R Mouse (Option 820) - 1

R Manual (Option ABA)

*5

• User’s Guide E5070-900x0 1

• Installation and Quick Start Guide E5070-900x1 1

• Programmer’s Guide E5070-900x2 1

• Sample program disk E5070-180x0 1

R BNC adaptor (Option 1E5) 1250-1859 1

R Handle Kit (Option 1CN)

*6

R Rack Mount Kit Without Handles

(Option 1CM)

*6

5063-9229 1

5063-9216 1

Qty

R Rack Mount Kit With Handles

(Option 1CP)

*6

5188-4430 1

*1.Figure 2-1 shows the E5070B/E5071B main unit when Option 413 (4-port S-parameter

test set) is specified.

*2.This accessory varies from country to country. For the power cable option, see Figure

2-10.

*3.The CD-ROM contains the same information as in the User’s Guide, Installation and

Quick Start Guide, Programmer’s Guide, VBA Programmer’s Guide and two Sample

Program Disks. The ‘xx’ in the part number is a number that is incremented each time a

revision is made, with ‘00’ regarded as the first edition. The network analyzer will

always be supplied with the latest versions of these items.

*4.Use this adapter when a GPIB cable is connected to the rear panel GPIB connector.

*5.The ‘x’ in the part number of the Manual, or sample program disk is a number that is

incremented each time a revision is made, with ‘0’ re garded as the first edit ion. The net -

work analyzer will always be supplied with the latest versions of these items.

*6.This accessory is not shown in Figure 2-1. For the detail contents, see Table 2-3 on

page 23.

18 Chapter 2

Figure 2-1 E5070B/E5071B Accessories

Installation

Checking the Shipment

2. Installation

Chapter 2 19

Installation

Environmental Requirements

Environmental Requirements

Set up the E5070B/E5071B where the following environmental requirements are met.

Operating Environments

Ensure that the operating environment meets the following requirements.

Temperature 5 °C to 40 °C

Temperature range at the

error-correction

Humidity

Altitude 0 to 2,000 m (0 to 6,561 feet)

Vi bration 0.5 G maximum, 5 Hz to 500 Hz

NOTE Above environmental requirements are NOT for the specifications and measurement

accuracy of the analyzer, but for the operating environment of the analyzer .

23 °C ± 5 °C (< 1 °C deviation from the temperature

when performing the error-correction)

20% to 80% at wet bulb temperature < +29 °C

(non-condensation)

20 Chapter 2

Installation

Environmental Requirements

Ventilation Requirements

To ensure safety requirements, the specifications and measurement accuracy of the

analyzer, you must keep environmental temperature within the specified range by

providing appropriate cooling clearance around the analyzer or, for the rackmount type, by

forcefully air-cooling inside the rack housing. For more information on environmental

temperature to satisfy the specifications and measurement accuracy of the analyzer, see

“Specifications And Supplemental Information” in the E5070B/E5071B User’s Guide.

When the environmental temperature around the analyzer is kept within the temperature

range of the operating environment specification (See Section “Operating Environments”

on page 20), the analyzer conforms to the requirements of the safety standard.

Furthermore, under that temperature requirement, the analyzer still conforms to the

requirements of the safety standard even when placing the analyzer with cooling clearance

as follows:

Requirements

Back ≥ 180 mm

Sides ≥ 60 mm (both right and left)

2. Installation

Figure 2-2 Ventilation space at the installation

Chapter 2 21

Installation

Environmental Requirements

Protection Against Electrostatic Discharge (ESD)

Set up a static-safe work-station to protect the electronic components from the damage by

the electrostatic discharge (ESD) as shown in Figure 2-3. Table 2-2 shows the accessories

available that provide ESD protection.

Figure 2-3 Example of the static-safe work-station

Ensuring Adequate Free Space around Analyzer for Immediate

Disconnection of Power Cable in Case of Emergency

As described in “Disconnection from Supply Source” on page 35, the power supply is

disconnected by removing the power cable’s connector plug from either the AC outlet or

the E5070B/E5071B unit. When installing the E5070B/E5071B, ensure that there is

sufficient free space around the unit to permit quick disconnection of the plug (from AC

outlet or E5070B/E5071B unit) in case of emergency.

22 Chapter 2

Installing Front Handles/Rack Mounting Flanges

Installing Front Handles/Rack Mounting Flanges

The E5070B/E5071B can be installed on a workbench or in a rack. This section describes

how to install the front handles (Option 1CN) used for moving or transporting the

instrument, and how to install the analyzer in an equipment rack as part of a measurement

system (Option 1CM: without the handles, Option 1CP: with the handles).

Table 2-2 Agilent E5070B/E5071B handles/rack mounting options

Installation

Option Name Agilent Part Number

1CN Handle Kit 5063-9229

1CM Rack-mount Kit 5063-9216

1CP Rack-mount and Handle Kit 5188-4430

Table 2-3 Contents of each option

Option Contents Quantity

Front Handles 2

1CN

1CM

1CP

Screws 6

Trim Strips 2

Rack-mounting flanges (locking side plate) 2

Screws 6

Rack-mounting flanges (locking side plate) 2

Front Handles 2

Screws 8

2. Installation

Chapter 2 23

Installation

Installing Front Handles/Rack Mounting Flanges

Figure 2-4 Installing front handle/rack-mount kits

How to Install the Handle Kit (Option 1CN)

The handle kit is used for transport and relocation of the E5070B/E5071B. While referring

to Figure 2-4, install the handle kit by following these steps.

Step 1. Remove the adhesive-backed trim strip (1) from each side of the outer frame of the

E5070B/E5071B front panel.

Step 2. Use the provided screws to mount the front handles (2) on each side of the

E5070B/E5071B front panel frame.

Step 3. Attach the provided modified trim strip (3) to each front handle in order to cover the front

panel locking screws.

WARNING If the installed front handle becomes damaged, replace it with a new one immediately.

A damaged handle can break while moving or lifting the instrum e nt and cause

personal injury or damage to the instrument.

24 Chapter 2

Installation

Installing Front Handles/Rack Mounting Flanges

How to Install the Rack-mount Kit (Option 1CM)

The rack-mount kit includes two flanges (locking side plates) for mounting the

E5070B/E5071B on a rack (482.6 mm/19 inches) conforming to the EIA Standard. While

referring to Figure 2-4, install the rack-mount kit by following these steps.

Step 1. Remove the adhesive-backed trim strip (1) from each side of the outer frame of the

E5070B/E5071B front panel.

Step 2. Use the provided screws to mount a rack-mounting flange (4) on each side of the

E5070B/E5071B front panel frame.

Step 3. Remove the four bottom feet of the E5070B/E5071B (lift the bar marked T AB on the inner

side of the foot and slide the foot toward the bar).

Step 4. Mount the E5070B/E5071B on the rack.

How to Install the Rack-mount and Handle Kit (Option 1CP)

The rack-mount and handle kit includes both the rack-mounting flanges (locking side

plates) and front handles. While referring to Figure 2-4, install the rack-mount kit by

following these steps.

2. Installation

Step 1. Remove the adhesive-backed trim strip (1) from each side of the outer frame of the

E5070B/E5071B front panel.

Step 2. Use the provided screws to mount a front handle (2) and rack-mounting flange (4) on each

side of the E5070B/E5071B front panel frame.

CAUTION Use both a front handle and a rack-mounting flange in the same time certainly. Do

not attempt to install flanges or handles separately with hardware provided. Serious

electrical damage will occur to the instrument.

Step 3. Remove the four bottom feet of the E5070B/E5071B (lift the bar marked T AB on the inner

side of the foot and slide the foot toward the bar).

Step 4. Mount the E5070B/E5071B on the rack.

Chapter 2 25

Installation

Connecting the Accessories

Connecting the Accessories

The E5070B/E5071B allows you to connect a variety of accessories using the USB ports

on the front panel or each of the ports on the rear panel.

Connecting the Mouse and Keyboard

As shown in Figure 2-5, connect the mouse and keyboard to the mini-DIN mouse port and

mini-DIN keyboard port, respectively, before turning ON the power.

Figure 2-5 Connecting the mouse and keyboard

26 Chapter 2

Connecting the BNC Adaptor (Option 1E5)

When the E5070B/E5071B is equipped with Option 1E5 (high-stability frequency

standard), connect the BNC adaptor from the Ref Oven terminal to the Ref In terminal on

the rear panel as shown in Figure 2-6. The BNC adaptor is included in Option 1E5. When

Option 1E5 is installed, the frequency accuracy and stability of the E5070B/E5071B will

further improve.

Figure 2-6 Connecting the BNC adaptor

Installation

Connecting the Accessories

2. Installation

Chapter 2 27

Installation

Connecting the Accessories

Connecting a LAN Cable

When using a LAN (local area network), follow the procedure below to connect the

E5070B/E5071B to the LAN.

Step 1. By referring to Section “Configuring the Network” in the E5070B/E5071B User’s Guide,

set the E5070B/E5071B LAN.

Step 2. As shown in Figure 2-7, connect a LAN cable to the LAN port on the rear panel of the

E5070B/E5071B.

Figure 2-7 Connecting the LAN cable

NOTE When connecting the E5070B/E5071B to a LAN for use, consult the network administrator

about proper LAN settings.

Do not connect a LAN cable until the proper LAN settings have been completed.

Connecting the E5070B/E5071B to a LAN with improper settings may cause a problem in

the network.

28 Chapter 2

Connecting a Printer

When using a printer, connect an available printer to the printer parallel port or USB

(Universal Serial Bus) port on the rear panel of the E5070B/E5071B as shown in Figure

2-8.

For the available printers of the E5070B/E5071B in its factory-shipped condition, see

Section “Compatible Printers” in the E5070B/E5071B User’s Guide.

Figure 2-8 Connecting the printer

Installation

Connecting the Accessories

2. Installation

Chapter 2 29

Installation

Connecting the Accessories

Connecting the Ecal Module

When using the Ecal module, connect one end of the USB cable to the Ecal module and the

other end to the USB port on the front panel as shown in Figure 2-9.

Figure 2-9 Connecting the ECal module

30 Chapter 2

Installation

Power Supply and Blown Fuses

Power Supply and Blown Fuses

Before turning on the E5070B/E5071B power, check the following.

Verification of the Power Supply

Confirm that the power supplied to the E5070B/E5071B meets the following requirements:

Requirements

Vol tage

Frequency 47 to 63 Hz

Maximum power consumption 350 VA

*1. Switched automatically by the E5070B/E5071B in conformity to the voltage used.

90 to 132 VAC or 198 to 264 VAC

*1

Verification and Connection of Power Cable

The three-wire power cable attached to the E5070B/E5071B has one wire serving as a

ground. Using this power cable allows the E5070B/E5071B to be grounded, thereby

protecting you against electrical shock from the power outlet.

Step 1. Confirm that the power cable is not damaged.

WARNING NEVER use a power cable showing any sign of damage. Faulty cables can cause

electrical shock.

Step 2. Use the supplied cable to connect between the power cable receptacle (Figure 2-11 on

page 35) on the rear panel of the E5070B/E5071B and a three-wire power outlet with the

grounding prong firmly connected in the ground slot.

2. Installation

WARNING Use the supplied power cable with grounding wire to securely ground the

E5070B/E5071B.

Figure 2-10 shows the power cable options.

Chapter 2 31

Installation

Power Supply and Blown Fuses

Figure 2-10 Power cable options

32 Chapter 2

Installation

Power Supply and Blown Fuses

Blown Fuses

If the fuse appears to have blown during operation, this instrument may be subject to

failure and must be repaired. Ship the E5070B/E5071B to the nearest Agilent Technologies

Service Center by seeing Section “Considerations When Shipping to a Service Center Due

to Breakdown or Other Problem” on page 42

The E5070B/E5071B uses the following fuse type: UL/CSA Type, Slow-Blo, 6.3 A/250

Vac

WARNING Do NOT replace the fuse yourself; doing this may expose you to dangerous electrical

shock.

2. Installation

Chapter 2 33

Installation

Starting the E5070B/E5071B

Starting the E5070B/E5071B

This section describes how to turn on/off the E5070B/E5071B power, how to cut off the

power supply in an emergency, and how to set the internal cl ock.

Turning the Power ON and OFF

Perform the following steps to turn the power ON or OFF .

Turning the Power ON

Step 1. If the standby switch ( ) in the lower-left part of the front panel is in the depressed

( ) position, press it to put it in the popped up position ( ).

Step 2. Press the standby switch to put it in the depressed position ( ).

This operation turns ON the power, and the E5070B/E5071B starts the self-test.

Step 3. Confirm that the self-test indicates normal operation.

Normal operation is confirmed by the self-test if no error message appears.

Turning the Power OFF

Step 1. Use either of the following methods to turn the power OFF.

• Press the standby switch ( ) in the lower-left part of the front panel (now in the

pressed down ( ) position) to put it in the popped up ( ) position.

• Send the shutdown command from an external controller.

These operations will start the E5070B/E5071B shutdown process (required software and

hardware processes for turning the power off), and the power will turn OFF after a few

seconds.

NOTE Under normal circumstances, always press the standby switch ( ), or send the shutdown

command from an external controller, to execute the E5070B/E5071B shutdown process.

Never cut off the power supply directly by disconnecting the power cable plug from

the rear panel of the unit.

If the power supply is cut off directly by disconnecting the power cable plug from the

instrument or the AC outlet, the shutdown process is not carried out and there is a risk of

damage to the E5070B/E5071B’s software or hardware.

34 Chapter 2

Figure 2-11 Line switch (Always ON) and power cable receptacle

Installation

Starting the E5070B/E5071B

2. Installation

Disconnection from Supply Source

The power supply of the E5070B/E5071B is cut off by disconnecting the plug of the power

cable (on either AC outlet side or E5070B/E5071B side). When it is necessary to

disconnect the power supply in order to avoid shock hazards, etc., pull out the power cable

plug from either the AC outlet side or the E5070B/E5071B side.

NOTE To allow this operation to be performe d smoothly, be sure to follow the guidelines in

“Ensuring Adequate Free Space around Analyzer for Immediate Disconnection of Power

Cable in Case of Emergency” on page 22.

When turning the power OFF under normal circumstances, always follow the methods

described in “Turning the Power OFF” on page 34.

Chapter 2 35

Installation

Setting the Internal Clock

Setting the Internal Clock

You can set the date/time displayed at the lower right of the screen. When you save data in

the storage unit, for example, the internal clock data will be used. The following describes

the setting procedure that uses keys on the front panel.

NOTE When turning on the instrument power for the first time after delivery, always be sure to set

the internal clock.

Setting the Date/Time

Step 1. Press the [System] key in the INSTR STATE block. Press the [↓]or [↑] key to move the

focus to the

key to move the focus to the

Point the focus to the

Properties dialog box will appear (Figure 2-12).

Figure 2-12 Date/Time Properties Dialog Box (“Date & Time” Tab)

Misc Setup button and then press the [Enter] or [→] key. Press the [↓]or [↑]

Clock Setup button and then press the [Enter] or [→] key.

Set Date and Time button and press the [Enter] key. The Date/Time

Step 2. Turn the rotary knob ( )on the front panel to point the focus to the

press the

36 Chapter 2

[→] key to move the focus to the Time Zone tab (Figure 2-13).

Date & Time tab and

Figure 2-13 Date/Time Properties Dialog Box (“Time Zone” Tab)

Installation

Setting the Internal Clock

2. Installation

Step 3. Turn the rotary knob ( ) on the front panel to point the focus to the

press the

[←]/[→] or [↓]/[↑] key to select the time zone.

Time Zone box and

NOTE When you select the time zone for summer time, the Automatically adjust clock for

daylight saving changes

box becomes selectable. To set the function of automatically

making summertime adjustment to ON, turn the rotary knob ( ) to point the focus to the

Automatically adjust clock for daylight saving changes box and press the rotary knob

( ) to display the √ mark (Figure 2-13).

Step 4. Turn the rotary knob ( ) on the front panel to point the focus to the

press the

[←] key to move the focus to the Date & Time tab.

Time Zone tab and

Step 5. By referring to Figure 2-12, turn the rotary knob ( ) on the front panel to point the focus

to the desired item. Press the

Step 6. Turn the rotary knob ( ) on the front panel to point the focus to the

[Enter] key.

press

[←]/[→] or [↓]/[↑] key to set each item.

OK button and then

Turning the Date/Time Display ON and OFF

The Date/time is displayed within the instrument status bar at the lower right of the display

screen.

Step 1. Press the

focus to the

key, move the focus to the

focus to the

on/off.

Chapter 2 37

[System] key in the INSTR STATE block. Press the [↓]or [↑] key to move the

Misc Setup button and then press the [Enter] or [→] key . Press the [↓] or [↑]

Clock Setup button, and press the [Enter] or [→]key. Point the

Show Clock button and press the [Enter] key to set the date/time display

Installation

Initial Registration of E5070B/E5071B

Initial Registration of E5070B/E5071B

When you start up the E5070B/E5071B for the first time or after executing system

recovery, you need to perform the initial registration of the Windows 2000 operati ng

system of the E5070B/E5071B.

NOTE You cannot use the front panel keys during the initial registration of the E5 070B/E5071B

therefore connect the mouse and the keyboard before turning on the power.

NOTE If you perform the following procedure incorrectly, a message asking you whether to return

to the previous registration screen and perform the registration appears. In this case, follow

the instruction to return to the previous registration screen.

Step 1. Turns on the E5070B/E5071B.

Step 2. The Windows 2000 Professional Setup wizard appears. Click the

2-14).

Figure 2-14 Windows 2000 Professional Setup wizard

Next > button (Figure

38 Chapter 2

Step 3. In the Windows 2000 Professional Setup dialog box, select the I accept this agreement

box and click the

Next >button (Figure 2-15). Then, the Windows 2000 operating system is

restarted automatically.

Figure 2-15 Windows 2000 Professional Setup dialog box

Installation

Initial Registration of E5070B/E5071B

2. Installation

Step 4. The Network Identification wizard appears. Click the

Figure 2-16 Network Identification wizard

Next > button (Figure 2-16).

Chapter 2 39

Installation

Initial Registration of E5070B/E5071B

Step 5. In the Network Identification Wizard dialog box (1/2), select the Windows always

assumes the following user has logged on to this computer

is in the

User Name box. If not, type in agena. Finally, click the Next> button (Figure

2-17).

Figure 2-17 Network Identification Wizard dialog box (1/2)

box and check that agena

Step 6. In the Network Identification Wizard dialog box (2/2), click the

initial registration of the E5070B/E5071B (Figure 2-17). Then, the measurement display of

theE5070B/E5071B appears.

Figure 2-18 Network Identification Wizard dialog box (2/2)

Finish button to finish the

40 Chapter 2

Installation

Daily Maintenance

Daily Maintenance

This section provides the maintenance information for the E5070B/E5071B and describes

the self-test function (which checks the instrument for failure). This section also provides

information required for shipping the E5070B/E5071B due to breakdown or other

problem.

Cleaning Method

T o clean the surface of the E5070B/E5071B, wipe the surface gently with a dry cloth or

soft cloth dampened with water and wrung dry. Never attempt to clean the inside of the

instrument.

WARNING To avoid an electric shock, always disconnect the power cord of the E5070B/E5071B

from the power outlet when cleaning.

NOTE To clean a touch screen type LCD (Option 016), do not wet the cloth with water.

Occasionally, a few pixels may appear on the screen as a fixed point of blue, green or red.

Please note that this is not a failure and does not affect the performance of your product.

Maintaining an N-type Connector on Each Port

Each port on the front panel of the E5070B/E5071B has an N-type connector (female). In

the RF band, soil or damage on the connector or cable will affect the measurements. The

following describes how to handle and maintain these N-type connectors.

• The connectors should always be kept clean and away from dirt.

• To prevent the electrostatic discharge (ESD), do not touch the contact face of the

connector.

2. Installation

• Never attempt to use a damaged or nicked connector.

• When cleaning, blow air on the connector. Never attempt to use abrasives such as

emery paper.

NOTE Each port on the front panel of the E5070B/E5071B is a 50 Ω-based N-type connector

(female). Note that use of an N-type connector for 75 Ω cables will result in an electrical

contact failure.

Self-test When Turning on the Power

When the power is turned on, the E5070B/E5071B automatically performs a self-test. If

any error is detected by the self-test at power-on, the error message “Power on test fail”

appears in the instrument status bar. This causes the E5070B/E5071B to enter the service

mode. When being in the service mode, ship the E5070B/E5071B to the nearest Agilent

Technologies Service Center by seeing Section “Considerations When Shipping to a

Chapter 2 41

Installation

Daily Maintenance

Service Center Due to Breakdown or Other Problem” on page 42.

Considerations When Shipping to a Service Center Due to Breakdown or Other Problem

When shipping the E5070B/E5071B to an Agilent T echnologies Service Center because of

breakdown or other problem, for shipment use the packing box and shock-absorbing

material used to package the analyzer or static-protective package that replaces them. For

your nearest Agilent Technologies Service Center, contact the Agilent Technologies

Customer Center shown at the end of the Manual.

NOTE Occasionally, a few pixels may appear on the screen as a fixed point of blue, green or

red. Please note that this is not a failure and does not affect the performance of your

product.

42 Chapter 2

3Quick Start Guide

3. Quick Start Guide

This chapter describes the functions of parts on the front panel and display area of the

Agilent E5070B/E5071B RF Network Analyzer. Using the example of measuring a

bandpass filter, you will quickly learn how to easily operate the E5070B/E5071B by

understanding the basic measurement procedures and operation of the E5070B/E5071B.

43

Chapter Contents

Quick Start Guide

R Names and Descriptions of E5070B/E5071B parts on page 45

Describes the front panel, display area, and three methods of operation (keys,

mouse, and touch panel).

R Basic Measuremen t Proc e dur e s on page 53

Describes the basic measurement procedures for using the E5070B/E5071B.

R Measurement Example of a Bandpass Filter on page 54

Illustrates the basic measurement method for the E5070B/E5071B through an

example of the transmission measurement of a bandpass filter.

44 Chapter 3

Names and Descriptions of E5070B/E5071B parts

This section describes the names and outlines of the E5070B/E5071B parts on the front

panel and display area. For more information, see Chapter 2 “Overview of Functions” in

theE5070B/E5071B User’s Guide. This section also describes three operation methods

using the keys, mouse, and touch panel (Option 016).

Front Panel

The names and short descriptions of the E5070B/E5071B parts on the front panel are as

shown as follows.

Figure 3-1 Front Panel

Quick Start Guide

Names and Descriptions of E5070B/E5071B parts

3. Quick Start Guide

Chapter 3 45

Quick Start Guide

Names and Descriptions of E5070B/E5071B parts

1. Standby Switch

Allows the switch between power-on (|) and standby mode ( ) on the E5 070B/E5071B.

2. LCD Screen

Displays measurement traces, instrument setting conditions, menu bars, the Visual Basic

Editor, etc. Consists of a 10.4-inch TFT color LCD. For details on the information

displayed on the LCD screen, see “Display Area” on page 47.

3. ACTIVE CH/TRACE Block

A group of keys used for selecting the active channel and an active trace. For more

information on the functions of the keys in the ACTIVE CH/TRACE Block, see Chapter 2

“Overview of Functions” in the E5070B/E5071B User’s Guide.

4. RESPONSE Block

A group of keys used for the selection of a measurement parameters/data formats ,

displaying, calibration, etc. For more information on the functions of the keys in the

RESPONSE Block, see Chapter 2 “Overview of Functions” in theE5070B/E5071B User’s

Guide.

5. STIMULUS Block

A group of keys used for specifying the setup for signal sources, trigger, etc. For more

information on the keys in the STIMULUS Block, see Chapter 2 “Overview of Functions”

in the E5070B/E5071B User’s Guide.

6. Floppy Disk Drive

Stores/installs from/to the E5070B/E5071B the files containing the instrument setting

conditions of the E5070B/E5071B, measurement data, the VBA (Visual Basic for

Applications) program, etc. Compatible with 3.5-inch, 1.44 MB, DOS (Disk Operating

System) formatted floppy disks.

7. NAVIGATION Block

A group of keys used for the movement/selection of the focus in menu bars/softkey m enu

bar/dialog boxes and for manipulating markers. For the functions of the keys in the

NAVIGATION Block, see Chapter 2 “Overview of Functions” in the E5070B/E5071B

User’s Guide.

8. ENTRY Block

A group of keys used for entering numeric data on the E5070B/E5071B settings. For more

information on the functions of the keys in the ENTRY Block, see Chapter 2 “Overview of

Functions” in the E5070B/E5071B User’s Guide.

9. INSTR STATE Block

A group of keys used for specifying the setup for controlling and managing the

E5070B/E5071B such as executing the limit test function, printing measurement results,

executing VBA macros, and presetting (initializing) the E5070B/E5071B. For more

information on the keys in the INSTR STATE Block, see Chapter 2 “Overview of

Functions” in the E5070B/E5071B User’s Guide.

46 Chapter 3

Quick Start Guide

Names and Descriptions of E5070B/E5071B parts

10. MKR/ANALYSIS Block

A group of keys used for analyzing measurement results throu gh markers, the fixture

simulator function, etc. For more information on the keys in the MKR/ANALYSIS Block,

see Chapter 2 “Overview of Functions” in the E5070B/E5071B User’s Guide.

11. Test Po rt

While the signal is being output from a test port, the yellow LED above the test port lights

up. The connector type adopted is the 50 Ω-based N-type (female) connector.

12. Front USB Port

Used to connect a printer, a multiport test set or an ECal module compatible with the USB

(Universal Serial Bus). Using a USB port allows the accessories to be connected after the

E5070B/E5071B has been powered on.

13. Ground Terminal

Connected to the chassis of the E5070B/E5071B. You can connect a banana type plug to

this terminal.

Display Area

The names and short description of the E5070B/E5071B parts on the display area are

shown as follows.

Figure 3-2 Display area

3. Quick Start Guide

Chapter 3 47

Quick Start Guide

Names and Descriptions of E5070B/E5071B parts

1. Menu Bar

Using a menu bar, you can perform the same operations as when using the keys in the

ACTIVE CH/TRACE Block, RESPONSE Block, STIMULUS Block, MKR/ANALYSIS

Block, and INSTR STATE Block on the front panel of the E5070B/E5071B.

2. Data Entry Bar

Using the data entry bar, you can enter numeric data or label names.

3. Channel Title Bar

Using the channel title bar, you can cause a title arbitrarily entered by the user to appear on

each channel.

4. Softkey Menu

A group of softkeys used for specifying the setup of the E5070B/E5071B.

5. Trace Bar

Displays the settings for each trace (from left: trace number, S-parameter , data format, and

scale). Using the mouse, you can also select the active trace.

6. Marker Indicator

Indicates a marker position on the horizontal axis.

7. Marker Value

Displays the stimulus value and response value of each marker. Symbol > displayed to the

left of a marker number indicates that that marker is the active marker. When the reference

marker is set ON, symbol Δ is displayed instead of the marker number and indicates the

marker value of the reference marker. When the reference marker is set ON, the stimulus

value and response value of other markers indicate the differences from the values of the

reference marker.

8. Reference Line Indicator

Displays the position of the reference line.

9. Marker

Used for reading out values on a trace. Using a marker makes it easy to analyze

measurement results or change stimulus settings. The active marker is represented with an

inverted triangle.

10. Channel Status Bar

Displays channel-specific information on the E5070B/E5071B for each channel. This

information consists of the channel number, the start frequency (center frequency), the stop

frequency (span frequency), ON/OFF of the error correction function, and whether or not

the sweep is in progress. When the averaging function is ON, the channel status bar also

displays that information.

11. Instrument Status Bar

Displays the information on the status of the E5070B/E5071B that is common to all

channels.

48 Chapter 3

Three Methods of Operation

You can operate the E5070B/E5071B using one of three operating methods: using keys on

the front panel, using a mouse and keyboard, and using a touch screen (Option 016). This

section illustrates these three operating methods through the example in which the channel

window layout is set to the four-channel display as shown in Figure 3-3.

In the next section and those following it, a series of operations is expressed as follows:

•

[Display] - Allocate Channels -

Figure 3-3 Four-Channel Display

Quick Start Guide

Three Methods of Operation

3. Quick Start Guide

Chapter 3 49

Quick Start Guide

Three Methods of Operation

Operating Method Using Keys

Step 1. Press the key in the RESPONSE Block.

Figure 3-4 Step 1

Step 2. Press the or the key to move the cursor to the

press the or the key.

Figure 3-5 Step 2

• Press the or the key to move the cursor to the button, then

press the key.

Figure 3-6 Step 3

Allocate Channels button, then

50 Chapter 3

Operation Method Using a Mouse

Step 1. From the Response menu, click the Display button.

Figure 3-7 Step 1

Quick Start Guide

Three Methods of Operation

Step 2. Click the

Figure 3-8 Step 2

Step 3. Click the button.

Figure 3-9 Step 3

Allocate Channels button.

3. Quick Start Guide

Chapter 3 51

Quick Start Guide

Three Methods of Operation

Operation Method Using the Touch Screen (Option 016 )

Step 1. Press the Display button after presetting the E5070B/E5071B (Executing key).

Figure 3-10 Step 1

Step 2. Press the

Figure 3-1 1 Step 2

• Press the button.

Figure 3-12 Step 3

Allocate Channels button.

52 Chapter 3

Quick Start Guide

Basic Measurement Procedures

Basic Measurement Procedures

To better understanding how to use the E507 0B/E5071B, this section describes the basic

measurement procedure using the E5070B/E5071B and presents an example of the

transmission measurement of a bandpass filter.

Basic Measurement Flow

STEP 1. Determining measurement conditions

R Presetting the E5070B/E5071B

R Selecting the S-parameter

R Selecting the data format

R Specifying the frequency range

R Specifying the number of measurement points

R Specifying the power level

R Specifying the IF bandwidth

STEP 2. Calibration

R Specifying the calibration kit

R Selecting the calibration type

R Measuring the calibration data

R Making the error correction ON

R Saving the calibration data

STEP 3. Connecting the device under test (DUT)

R Connecting the device under test (DUT)

R Adjusting the scale

STEP 4. Analyzing measurement results

R Analysis using the markers

STEP 5. Outputting measurement results

R Storing the measurement file to a disk

3. Quick Start Guide

Chapter 3 53

Quick Start Guide

Measurement Example of a Bandpass Filter

Measurement Example of a Bandpass Filter

This section describes how to measure the transmission characteristics of a 947.5 MHz

bandpass filter. The measurement conditions for this measurement example are those

suitable for a 947.5 MHz bandpass filter. To measure another device under test (DUT),

change the measurement conditions to suit the particular DUT.

For other measurement examples of the E5070B/E5071B, see Chapter “Measurement

Examples” in the E5070B/E5071B User’s Guide.

STEP 1. Determining Measurement Conditions

Step 1. Preset the E5070B/E5071B.

•

[Preset] - OK

Step 2. Set the S-parameter to S21.

•

[Meas] - S21

NOTE When measuring the reverse transmission characteristics, set the S-parameter to S12.

Step 3. Set the data format to the log magnitude format.

[Format] - Log Mag

•

Step 4. Set the center frequency to the bandpass filter center frequency. Next, specify the span

frequency, which is set to 200 MHz in this measurement example.

•

[Center] - [9] [4] [7] [.] [5] [M/μ]

• [Span] - [2] [0] [0] [M/μ]

NOTE When entering the frequency unit using the keyboard, type "G" for GHz, "M" for MHz,

and "k" for kHz.

Step 5. Specify the number of measurement points per sweep. The number of measurement points

in this measurement example is set to 401.

•

[Sweep Setup] - Points - [4] [0] [1] [x 1]

Step 6. Specify the power level of the signal source. The power level in this measurement example

is set to -10 dBm.

•

[Sweep Setup] - Power - [+/-] [1] [0] [x 1]

Step 7. Specify the IF bandwidth of the receiver as necessary . In this measurement example, the IF

bandwidth is set to 10 kHz because of the need to lower the noise floor.

•

[Avg] - IF Bandwidth - [1] [0] [k/m]

54 Chapter 3

Quick Start Guide

Measurement Example of a Bandpass Filter

STEP 2. Calibration

To turn the error correction ON, set the calibration type to the full 2-port calibration and

measure the calibration data.

For details about calibration, see Chapter “Calibration” in the E5070B/E5071B User’s

Guide.

Step 1. Select the calibration kit suitable for the measurement cable. In this measurement example,

Calibration Kit 85032F is selected.

•

[Cal] - Cal Kit - 85032F

Step 2. Set the calibration type to the full 2-port calibration using the test port 1 and 2.

•

[Cal] - Calibrate - 2-Port Cal - Select Ports - 1-2

Step 3. Connect the OPEN standard (included in the calibration kit) to the other end of the

measurement cable that is connected to the test port 1 as shown in Figure 3-13, and

measure the open calibration data at the test port 1. After measuring the open calibration

data, symbol √ is displayed to the left of the

[Cal] - Calibrate - 2-Port Cal - Reflection - Port1 Open

•

Port 1 Open button.

In the same way , measure the calibration data for the SHORT/LOAD standards at the test

port 1.

Figure 3-13 Connecting the OPEN/SHORT/LOAD standards

Step 4. In the same way as described above, measure the calibration data for the

OPEN/SHORT/LOAD standards at the test port 2.

3. Quick Start Guide

Chapter 3 55

Quick Start Guide

Measurement Example of a Bandpass Filter

Step 5. Connect the THRU standard (included in the calibration kit) betwween the measurement

cables as shown in Figure 3-14, and measure the thru calibration data. After measuring the

thru calibration data, symbol √ is displayed to the left of the

•

[Cal] - Calibrate - 2-Port Cal - Transmission - Port 1-2 Thru

Figure 3-14 Connecting the THRU standard

Port 1-2 Thru button.

Step 6. Make the full 2-port calibration measurement DONE. The calibration factor is calculated

based on the calibration data acquired, and the error correction is turned ON.

•

[Cal] - Calibrate - 2-Port Cal - Done

Step 7. Select the type in which the data is to be saved before saving the calibration factor

(calculated based on the calibration data).

•

[Save/Recall] - Save Type - State & Cal

Step 8. Store the calibration file to the disk of the E5070B/E5071B. The symbol “X” appearing in

the operations below represent the assigned numbers to be used when the file is saved.

•

[Save/Recall] - Save State - State 0X

For more information on saving/reading internal data, see Chapter “Data Output“ in the

E5070B/E5071B User’s Guide.

56 Chapter 3

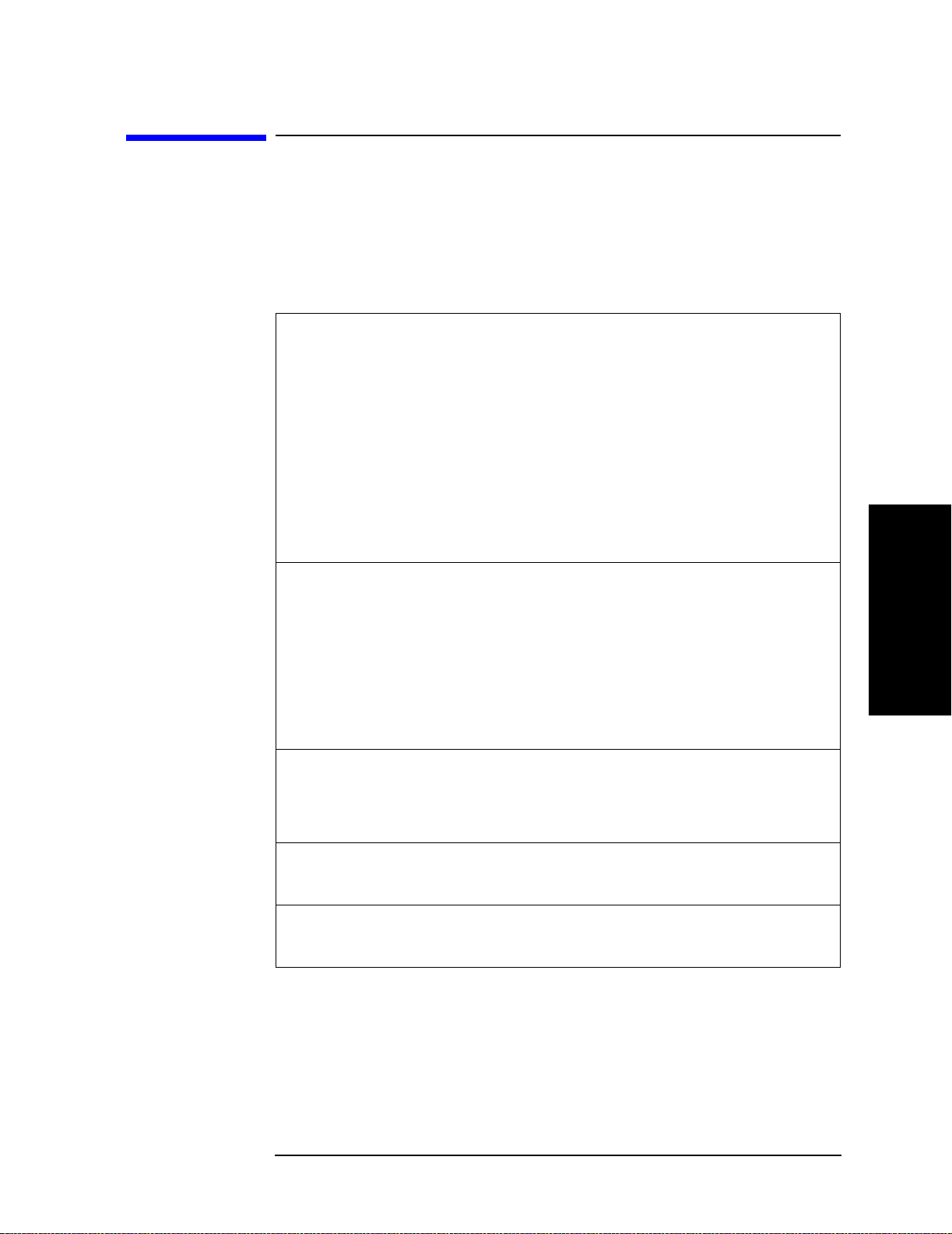

STEP 3. Connecting the Device Under Test(DUT)

Step 1. Connect t the DUT to the E5070B/E5071B. (See Figure 3-15.)

Figure 3-15 Connecting the DUT

Quick Start Guide

Measurement Example of a Bandpass Filter

NOTE Applying the setting value for the power level (-10 dBm) may destroy some DUTs. Should

this occur, first select the proper power level and then connect the DUT to the

E5070B/E5071B.

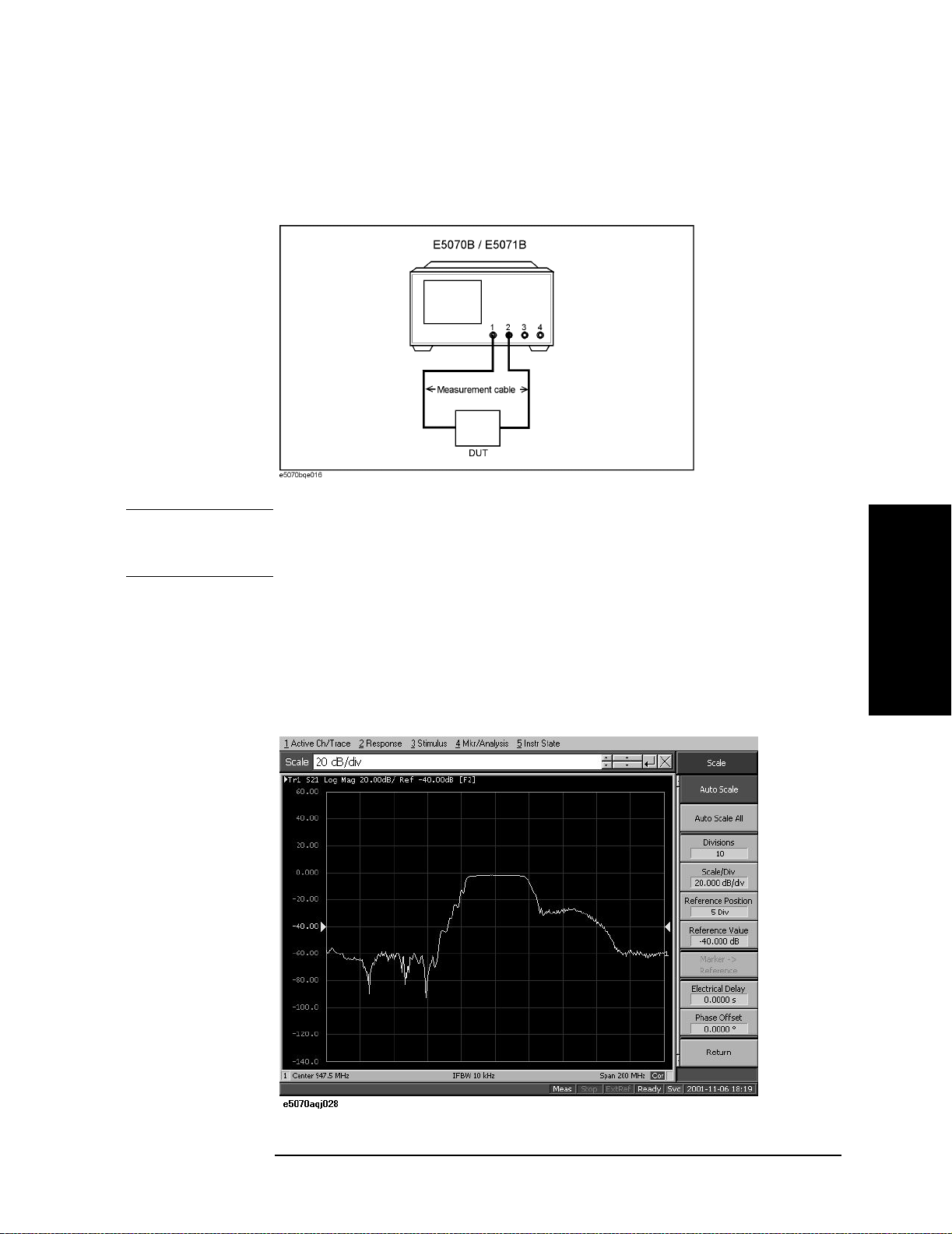

Step 2. Set the appropriate scale by executing the auto scale. (See Figure 3-16.)

[Scale] - Auto Scale

•

You can also adjust the scale by entering arbitrary values in the Scale/Div button,

Reference Position button, and Reference Value.

Figure 3-16 S21 trace after executing the auto scale

3. Quick Start Guide

Chapter 3 57

Quick Start Guide

Measurement Example of a Bandpass Filter

STEP 4. Analyzing Measurement Results

This section describes how to use the marker function to read out important parameters for

the transmission measurement of the bandpassfilter (insertion loss, -3 dB bandwidth).

Measuring the Insertion Loss

Step 1. Display a marker.

•

[Marker] - Marker 1

Step 2. Using one of the following methods, move the marker to the center frequency of the

bandpass filter.

• On the entry bar, press

• Turn the rotary knob ( ) on the front panel to set it to the center frequency (947.5

MHz).

Step 3. Read the marker value displayed as shown in Figure 3-17. In this example, the response

value denotes the insertion loss.

Figure 3-17 Measuring an Insertion Loss

[9] [4] [7] [.] [5] [M/μ].

58 Chapter 3

Quick Start Guide

Measurement Example of a Bandpass Filter

Measuring the -3 dB Bandwidth

Using the marker bandwidth search function, the bandwidth, center frequency between two

cutoff frequency points, Q value, and insertion loss are all read out. These parameters are

described in Table 3-1.

NOTE If the two cutoff frequency points are not found, all data items except the insertion loss

revert to zero.

Table 3-1 Parameters for the Bandwidth Search Function

Parameter Description

BW (Bandwidth) Stimulus width between two cutoff frequency points

(low and high)

cent (Center Frequency) Center point between cutoff frequency points (low and

high)

low (Left-side Cutoff

The lower frequency of the two cutoff frequency points

Frequency)

high (Right-side Cutoff

Frequency)

Q (Q Value)

The higher frequency of the two cutoff frequency

points

cent

Q

---------- -=

BW

loss (Insertion Loss) The amplitude difference between at the center

frequency and at 0 dBm

Step 1. Display the marker.

•

[Marker] - Marker 1

Step 2. Using one of the following methods, move the marker to the center frequency of the

bandpass filter.

• On the entry bar, press

[9] [4] [7] [.] [5] [M/μ].

• Turn the rotary knob ( ) on the front panel to set it to the center frequency (9 47.5

MHz).

Step 3. Specify the bandwidth definition value that defines the pass band of the filter. In this

measurement example, it is set to -3 dB.

3. Quick Start Guide

•

[Marker Search] - Bandwidth Value - [+/-] [3] [x 1]

Step 4. Set the bandwidth search function ON.

•

[Marker Search] - Bandwidth

Step 5. The bandwidth data items (BW, cent, low, high, Q, loss) will be displayed. (See Figure

3-18.)

Chapter 3 59

Quick Start Guide

Measurement Example of a Bandpass Filter

Figure 3-18 Measuring the -3 dB Bandwidth

60 Chapter 3

Measurement Example of a Bandpass Filter

STEP 5. Outputting Measurement Results (Save)

You can save not only the internal data but also the measurement results such as trace data

and display screens to the disk .

Saving the Trace Data(in CSV format)

You can save the trace data to the disk of the E5070B/E5071B in CSV file format

(extension: .csv). Since the CVS-formatted data to be saved is a text file, you can analyze

the data using Microsoft Excel.

Step 1. Follow the operation method described below to save the trace data.

•

[Save/Recall] - Save Trace Data

Saving the Display Screen

You can save the screen displayed on the E5070B/E5071B to the disk of the

E5070B/E5071B in Windows bitmap file format (extension: .bmp) or Portable Network

Graphics format (extension: .png).

Quick Start Guide

Step 1. Follow the operation method described below to save the display screen.

•

[System] - Dump Screen Image

NOTE The image on the LCD display memorized in the volatile memory (clipboard) (the imag e

on the LCD display when the [Capture] ([System]) key is pressed) is saved.

3. Quick Start Guide

Chapter 3 61

Quick Start Guide

Measurement Example of a Bandpass Filter

62 Chapter 3

A Manual Changes

This appendix contains the information required to adapt this manual to versions or

configurations of the E5070B/E5071B manufactured earlier than the current printing date

of this manual.

A. Manual Changes

63

Manual Changes

Manual Changes

Manual Changes

To adapt this manual to your E5070B/E50 71B, refer to Table A-1 and Table A-2.

Table A-1 Manual Changes by Serial Number

Serial Prefix or Number Make Manual Changes

MY424 Change 2

MY42100211 (E5070B)

MY42100407 (E5071B)

Table A-2 Manual Changes by Firmware Version

Version Make Manual Changes

Agilent Technologies uses a two-part, ten-character serial number that is stamped on the

serial number plate (Figure A-1). The first five characters are the serial prefix and the last

five digits are the suffix.

Figure A-1 Example of Serial Number Plate

Change 1

Change 2

• CD-ROM (of the Agilent IO Libraries Suite) is added as standard accessories.

• Sample program disk and VBA sample program disk are deleted as options.

Change 1

• GPIB adapter is added as standard accessories.

64 Appendix A

Index

A

accessories

connecting accessories, 26

items packaged with the E5070B/E5071B, 18

ACTIVE CH/TRACE block, 46

Agilent Technologies sales and service office

shipping considerations due to breakdown, etc., 42

analysis

analyzing measurement results, 58

assistance, 5

auto scale

executing auto scale, 57

B

bandpass filter

basic measurement example, 54

bandwidth search function

measuring -3dB bandwidth, 59

BNC cable

connecting the BNC cable, 27

BW

bandwidth search function, 59

C

cable

power cable options, 31

calibration

performing full 2-port calibration, 55

calibration kit

selecting the calibration kit, 55

cent

bandwidth search function, 59

certification, 5

channel status bar, 48

channel title bar, 48

cleaning

how to clean the instrument, 41

maintaining an N-type connector, 41

clock

setting the internal clock, 36

connection

connecting accessories, 26

connecting the DUT, 57

connecting the standards, 55

connector

maintaining an N-type connector, 41

D

data entry bar, 48

date

setting the date/time, 36

display

names and descriptions of the LCD screen, 47

saving the display screen, 61

turning the date/time display ON and OFF, 37

Documentation Warranty, 5

DUT

connecting the DUT, 57

E

E5070B/E5071B

basic measurement procedures, 53

items packaged with the E5070B/E5071B, 18

overview of the E5070B/E5071B, 13

starting the E5070B/E5071B, 34

three methods of operation, 49

Ecal module

connecting the Ecal module, 30

ENTRY block, 46

environmental requirements

operation environment, 20

ventilation space, 21

error correction

performing full 2-port calibration, 55

exclusive remedies, 5

F

features

overview of the E5070B/E5071B, 13

floppy disk drive, 46

front handles

how to install the handle kit, 24

front panel

names and description of E5070B/E5071B parts, 45

fuse

fuse type of the E4991A, 33

G

GPIB adapter, 64

H

handle and rack-mount kit

how to install the rack-mount and handle kit, 25

handle kit

how to install the handle kit, 24

high

bandwidth search function, 59

history,

manual printing, 2

I

IF bandwidth

specifying the IF bandwidth, 54

Initial registration, 38

insertion loss

measuing the insertion loss, 58

inspection

checking the shipment, 17

Installation and Quick Start Guide, 7

INSTR STATE block, 46

instrument status bar, 48

Index

65

Index

K

keyboard

connecting the keyboard, 26

L

LAN cable

connecting the LAN cable, 28

LCD screen, 46

names and descriptions of the LCD screen, 47

LOAD standard

Connecting LOAD standard, 55

loss

bandwidth search function, 59

low

bandwidth search function, 59

M

maintenance, 41

manual

contents, 12

manual changes, 63

manual printing history, 2

marker, 48

analyzing measurement results, 58

marker indicator, 48

marker value, 48

measurement

basic measurement procedures, 53

measurement conditions

determining measurement conditions, 54

menu bar, 48

MKR/ANALYSIS block, 47

mouse

connecting the mouse, 26

N

NAVIGATION block, 46

Network Identification Wizard, 38

O

OPEN standard

Connecting OPEN standard, 55

operations

three methods of operation, 49

outputting

outputting measurement results(save), 61

P

power

check the power supply, 31

disconnecting device, 35

disconnection from supply source, 35

power cable options, 31

power-on test, 41

shutdown, 34

turning the power ON and OFF, 34

verification and connection of power cable, 31

power supply

blown fuse, 33

presetting the E5070B/E5071B, 54

printer

connecting the printer, 29

product

overview of the E5070B/E5071B, 13

Professional Setup wizard, 38

Programmer's Guide, 7

Q

Q

bandwidth search function, 59

Quick Start Guide, 7

contents, 12

R

rack-mount and handle kit

how to install the rack-mount and handle kit, 25

rack-mount kit

how to install the rack-mount kit, 25

reference line indicator, 48

Registration, 38

RESPONSE block, 46

S

safety

symbols, 4

safety summary, 3

save

outputting measurement results, 61

saving the calibration factor, 56

self-test, 41

Serial number plate, 64

service center

shipping considerations due to breakdown, etc., 42

shipment

shipment considerations due to breakdown, etc., 42

SHORT standard

Connecting SHORT standard, 55

shutdown

turning the power OFF, 34

softkey menu, 48

standby switch, 46

status bar

channel status bar, 48

instrument status bar, 48

STIMULUS block, 46

system

installing rack mount flanges, 23

T

test port, 47

THRU

66

connecting THRU standard, 56

time

setting the date/time, 36

title

channel title bar, 48

trace bar, 48

trace data

saving trace data, 61

transmission

measurement example of a bandpass filter, 54