Page 1

Agilent E5061A/E5062A ENA Series RF Network Analyzers

Service Guide

Fifth Edition

Manufacturing No. E5061-90140

October 2008

Page 2

Notices

The information contained in this document is subject to change without notice.

This document contains proprietary information that is protected by copyright. All rights

are reserved. No part of this document may be photocopied, reproduced, or translated to

another language without the prior written consent of Agilent Technologies.

Microsoft®,MS-DOS®,Windows®,Visual C++®,Visual Basic®,VBA® and Excel® are

registered

UNIX is a registered trademark in U.S. and other countries, licensed

exclusively through X/Open Company Limited.

Portions ©Copyright 1996, Microsoft Corporation. All rights reserved.

© Copyright 2004, 2005, 2007, 2008 Agilent Technologies

Manual Printing History

The manual’s printing date and part number indicate its current edition. The printing date

changes when a new edition is printed. (Minor corrections and updates that are

incorporated at reprint do not cause the date to change.) The manual part number changes

when extensive technical changes are incorporated.

February 2004 First Edition

September 2005 Second Edition (part number: E5061-90110, changes for firmeware

version A.02.00)

February 2007 Third Edition (part number: E5061-90120, changes for firmeware

version A.03.00)

May 2007 Fourth Edition (part number: E5061-90130)

October 2008 Fifth Edition (part number: E5061-90140)

2

Page 3

Safety Summary

The following general safety precautions must be observed during all phases of operation,

service, and repair of this instrument. Failure to comply with these precautions or with

specific WARNINGS elsewhere in this manual may impair the protection provided by the

equipment. Such noncompliance would also violate safety standards of design,

manufacture, and intended use of the instrument. Agilent Technologies assumes no

liability for the customer’s failure to comply with these precautions.

NOTE The E5061A/E5062A complies with INSTALLATION CATEGORY II as well as

POLLUTION DEGREE 2 in IEC61010-1. The E5061A/E5062A is an INDOOR USE

product.

NOTE The LEDs in the E5061A/E5062A are Class 1 in accordance with IEC60825-1,

CLASS 1 LED PRODUCT

NOTE This equipment is MEASUREMENT CATEGORY I (CAT I). Do not use for CAT II, III,

or IV.

NOTE This equipment is tested with stand-alone condition or with the combination with the

accessories supplied by Agilent Technologies against the requirement of the standards

described in the Declaration of Conformity. If it is used as a system component,

compliance of related regulations and safety requirements are to be confirmed by the

builder of the system.

• Ground the Instrument

To avoid electric shock, the instrument chassis and cabinet must be grounded with the

supplied power cable’s grounding prong.

• DO NOT Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of inflammable gasses or fumes.

Operation of any electrical instrument in such an environment clearly constitutes a

safety hazard.

• Keep Away from Live Circuits

Operators must not remove instrument covers. Component replacement and internal

adjustments must be made by qualified maintenance personnel. Do not replace

components with the power cable connected. Under certain conditions, dangerous

voltage levels may remain even after the power cable has been disconnected. To avoid

injuries, always disconnect the power and discharge circuits before touching them.

• DO NOT Service or Adjust the In strument Alone

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation, is present.

• DO NO T Substitute Parts or Modify the Instrument

To avoid the danger of introducing additional hazards, do not install substitute parts or

perform unauthorized modifications to the instrument. Return the instrument to an

3

Page 4

Agilent Technologies Sales and Service Office for service and repair to ensure that

safety features are maintained in operational condition.

• Dangerous Procedure Warnings

Warnings, such as the example below, precede potentially dangerous procedures

throughout this manual. Instructions contained in the warnings must be followed.

WARNING Dangerous voltage levels, capable of causing death, are present in this instrument.

Use extreme caution when handling, testing, and adjusting this instrument.

• Do no t connect the measuring terminals to m ains.

Safety Symbol

General definitions of safety symbols used on the instrument or in manuals are listed

below.

Instruction Manual symbol: the product is marked with this symbol when it is necessary for

the user to refer to the instrument manual.

Alternating current.

Direct current.

On (Supply).

Off (Supply).

In position of push-button switch.

Out position of push-button switch.

Frame (or chassis) terminal. A connection to the frame (chassis) of the equipment which

normally include all exposed metal structure.

Stand-by.

WARNING This warning sign denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to, could result in

injury or death to personnel.

CAUTION This Caution sign denotes a hazard. It calls attention to a procedure, practice, condition or

the like, which, if not correctly performed or adhered to, could result in damage to or

destruction of part or all of the product.

NOTE Note denotes important information. It calls attention to a procedure, practice, condition or

the like, which is essential to highlight.

4

Page 5

Certification

Agilent Technologies certifies that this product met its published specifications at the time

of shipment from the factory. Agilent Technologies further certifies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institution’s calibration facility, or to the

calibration facilities of other International Standards Organization members.

Documentation Warranty

The material contained in this document is provided "as is," and is subject to being

changed, without notice, in future editions. Further, to the maximum extent permitted by

applicable law, Agilent disclaims all warranties, either express or implied with regard to

this manual and any information contained herein, including but not limited to the implied

warranties of merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or consequential damages in connection with the

furnishing, use, or performance of this document or any information contained herei n.

Should Agilent and the user have a separate written agreement with warranty terms

covering the material in this document that conflict with these terms, the warranty terms in

the separate agreement will control.

Exclusive Remedies

The remedies provided herein are buyer’s sole and exclusive remedies. Agilent

T echnologies shall not be liable for any direct, indirect, special, incidental, or

consequential damages, whether based on contract, tort, or any other legal theory.

Assistance

Product maintenance agreements and other customer assistance agreements are available

for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales and Service Office.

Addresses are provided at the back of this manual.

5

Page 6

Typeface Conventions

Sample (bold) Boldface type is used when a term is defined or

emphasised.

Sample (Italic) Italic type is used for emphasis.

key Indicates a hardkey (key on the front panel or

external keyboard) labeled “Sample.” “key” may

be omitted.

Sample menu/button/box Indicates a menu/button/box on the screen labeled

“Sample” which can be selected/executed by

clicking. “menu,” “button,” or “box” may be

omitted.

Sample block/toolbar Indicates a block (group of hardkeys) or a toolbar

(setup toolbar) labeled “Sample.”

Sample 1 - Sample 2 - Sample 3 Indicates a sequential operation of Sample 1,

Sample 2, and Sample 3 (menu, button, or box).

“-” may be omitted.

6

Page 7

1. General Information

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Software Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Organization of Service Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Instrument Covered by This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power Meter Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2. Performance Tests

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Test Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Instruction for Using the Performance Test Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Setting system controller (USB/GPIB interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Setting the GPIB address of the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setting up the E4419B Power Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Running the Performance Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Program Overall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Individual Test Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1. Frequency Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2. RF Output Level Accuracy and Flatness Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3. RF Output Level Linearity Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4. Trace Noise Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5. Crosstalk & System Dynamic Range Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6. Dynamic Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7. Uncorrected System Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

E5061A Performance Test Record (for Option 150/250). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Frequency Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

RF Output Level Accuracy and Flatness Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

RF Output Level Linearity Test (@ Port1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

RF Output Level Linearity Test (@ Port2)(Option 250 only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Trace Noise Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Crosstalk Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

System Dynamic Range Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Dynamic Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Uncorrected System Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

E5061A Performance Test Record (for Option 175/275). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Frequency Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

RF Output Level Accuracy and Flatness Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

RF Output Level Linearity Test (@ Port1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

RF Output Level Linearity Test (@ Port2)(Option 275 only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Trace Noise Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Crosstalk Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

System Dynamic Range Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Dynamic Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Uncorrected System Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

E5062A Performance Test Record (for Option 150/250). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Frequency Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

RF Output Level Accuracy and Flatness Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

RF Output Level Linearity Test (@ Port1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Contents

7

Page 8

Contents

RF Output Level Linearity Test (@ Port2)(Option 250 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Trace Noise Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Crosstalk Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

System Dynamic Range Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Dynamic Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Uncorrected System Performance Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

E5062A Performance Test Record (for Option 175/275). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Frequency Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

RF Output Level Accuracy and Flatness Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

RF Output Level Linearity Test (@ Port1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

RF Output Level Linearity Test (@ Port2)(Option 275 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Trace Noise Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Crosstalk Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

System Dynamic Range Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Dynamic Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Uncorrected System Performance Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3. Adjustment

Safety Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Warm-up for Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Required Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Required Adjustment after Replacing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Writing ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Frequency Reference Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Synthesizer Gain Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Local Output Power Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Source Output Power Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Receiver IF Range Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Receiver Ports Characteristics Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4. Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

How to exit from the E5061A/E5062A Measurement View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

To Troubleshoot the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Primary Trouble Isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

No Display troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Booting Process Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Troubleshooting Using Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Power On Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

PLL unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Contents of the diagnostic test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Test equipment required for diagnostic test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

To Execute the Diagnostic Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Program Overall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Diagnostic Test Failure Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Function Specific Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

To Check the Device Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

To Check the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8

Page 9

Contents

To Check the Touch Panel (Option 016 only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

To Check the LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

To Check the External Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

To Check the Mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

To Check the FDD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

To Check the Video output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

To Check the External Trigger Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

To Check the LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

To Check the Printer Parallel Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

To Check the GPIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Performance test failure troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Recommended adjustment for performance test failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Performance test failure troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

To configure the A20 Digital Motherboard and BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

To Identify the Motherboard Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Configure the Motherboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Testing DRAM on the Motherboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

To Confirm or Set the BIOS Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

5. Replaceable Parts

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Direct Mail Order System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Exchange Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Replaceable Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Power Cables and Plug Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Top View (Major Assemblies) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Top View (Cables). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Top View (Under Power Supply) for E5061A : JP1KLxxxxx, MY44101900 and below, E5062A :

JP1KLxxxxx, MY44102842 and below.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

T op View (Under Power Supply) for E5061A : MY44101901 and above, E5062A : MY44102843 and above

136

Top View (Miscellaneous Parts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Front View (Analog Boards) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Front View (Semirigid Cables) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A28 FDD Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A27 HDD Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A21 PCI DSP CARD / A24 GPIB CARD Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Analog Mother Board Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Power Supply Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Front Assembly (Front Keyboard / USB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Front Assembly (Inverter). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Front Assembly (LCD) for E5061A : JP1KLxxxxx, MY44101900 and below, E5062A : JP1KLxxxxx,

MY44102842 and below. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Front Assembly (LCD) for E5061A : MY44101901 and above, E5062A : MY44102843 and above . 155

Front Assembly (Standby Switch / LCD Cable) for E5061A : JP1KLxxxxx, MY44101900 and below,

9

Page 10

Contents

E5062A : JP1KLxxxxx, MY44102842 and below. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Front Assembly (Standby Switch / LCD Cable) for E5061A : MY44101901 and above, E5062A :

MY44102843 and above. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Front Assembly (Cover 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Front Assembly (Cover 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Front Assembly (Cover 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Label on Rear Face. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Other Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

6. Replacement Procedure

Replacing an Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Outer Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Front Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

A27 HDD (Hard Disk Drive) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Restore Backup Files onto the New HDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Calibration of the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

A28 FDD (Floppy Disk Drive) Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Removal procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

A50 ATX Power Supply Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

A25 Handler I/O Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

A20 Digital Motherboard Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

A1 Source Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

A2 Receiver Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

10

Page 11

Contents

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

A10 Analog Motherboard Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

A21 PCI DSP Card / A24 GPIB Card Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

A22 Front Panel Keyboard Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

A52 Inverter Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

A51 LCD Display Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

LCD Backlight Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

7. Post-Repair Procedures

Post-Repair Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

A. Manual Changes

Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Change 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

B. System Recovery

System Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Types of system recoveries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Notes on executing the factory recovery function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Procedure to execute the factory recovery function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Procedure to create the user backup image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Procedure to execute the user recovery function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Initial Registration of E5061A/E5062A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Calibration of the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

C. Firmware Update

Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

11

Page 12

Contents

How to make E5061A/E5062A Firmware Installation Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

How to update the E5061A/E5062A firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

D. Computer Virus Check

Computer Virus Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Required equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

How to check the drive C and D of E5061A/E5062A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

E. Power Requirement

Preparation for Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Turning the Power ON and OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Turning the power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Turning the power OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

F. Messages

Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

M. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

12

Page 13

1. General Information

1 General Information

The Service Guide is a guide to servicing the E5061A/E5062A RF Network Analyzer. The

guide contains information requisite to do performance tests, adjustments, troubleshooting,

and repairs.

13

Page 14

General Information

Precautions

Precautions

This section describes cautions that must be observed in operating the E5061A/E5062A.

Software Installed

The Windows operating system installed in this machine is customized for more effective

operation, and has different functions that are not part of the Windows operating system for

ordinary PCs (personal computers).

Therefore, do not attempt to use the system in ways other than those described in this

manual or to install Windows-based software (including anti-virus software) for ordinary

PCs as doing so may cause malfunctions.

Also note the followings.

• Do not update the Windows operating system installed in this machine to the Windows

operating system for ordinary PCs. Doing so will cause malfunctions.

• Do not attempt to update VBA (Visual Basic for Applications) software installed in this

machine to its equivalent developed for ordinary PCs. Doing so will cause

malfunctions.

• Do not allow any computer virus to infect the system. This machine has no virus check

function nor anti-virus software installed.

Agilent Technologies will not be held liable for any failure or damage arising from

negligence regarding these prohibitions and warnings.

NOTE If the pre-installed software is damaged somehow, resulting in errant behavior by the

machine, perform a system recovery. For further details of system recovery, refer to

Appendix B.

14 Chapter 1

Page 15

General Information

Organization of Service Guide

Organization of Service Guide

Tabs are used to divide the major chapter and appendix of this manual. The contents of

each chapter and appendix in this manual is as follows;

Chapter 1 , “General Information,”

The Service Guide is a guide to servicing the E5061A/E5062A RF Network

Analyzer. The guide contains information requisite to do performance tests,

adjustments, troubleshooting, and repairs.

Chapter 2 , “Performance Tests,”

This chapter provides information on how to verify the E5061A/E5062A

performance.

Chapter 3 , “Adjustment,”

This chapter provides the adjustment information for the E5061A/E5062A to ensure

that it is within its specifications. The adjustment must be performed Agilent’s

qualified service personnel. If you need the adjustment for your E5061A/E5062A, it

should be sent to the nearest Agilent Technologies service office.

1. General Information

Chapter 4 , “Troubleshooting,”

This chapter provides the procedure to isolate a faulty assembly in the

E5061A/E5062A.

Chapter 5 , “Replaceable Parts,”

This chapter contains information for ordering replacement parts for the

E5061A/E5062A.

Chapter 6 , “Replacement Procedure,”

This chapter provides procedure for removing and replacing the major assemblies in

the E5061A/E5062A.

Chapter 7 , “Post-Repair Procedures,”

This chapter lists the procedures required to verify the E5061A/E5062A operation

after an assembly is replaced with a new one.

Appendix A , “Manual Changes,”

This appendix contains the information required to adapt this manual to versions or

configurations of the E5061A/E5062A manufactured earlier than the current printing

date of this manual. The information in this manual applies directly to

E5061A/E5062A units with the serial number that is printed on the title page of this

manual.

Appendix B , “System Recovery,”

This appendix describes how to recover the operating system (Windows 2000) when

the operating system has been damaged.

Appendix C , “Firmware Update,”

Chapter 1 15

Page 16

General Information

Organization of Service Guide

This appendix describes how to update the E5061A/E5062A firmware. When you

want to update the E5061A/E5062A firmware, refer to this appendix.

Appendix D , “Computer Virus Check,”

This appendix describes an example of how to check the system of E5061A/E5062A

for computer viruses using computer viruses check software.

Appendix E , “Power Requirement,”

Appendix F, “Messages,”

The E5061A/5062A can display error messages as well as messages that indicate the

internal operating status of the equipment. This appendix explains what these

messages mean. They are listed in alphabetical order.

16 Chapter 1

Page 17

Instrument Covered by This Manual

Agilent Technologies uses a two-part, ten-character serial number label (See Figure 1-1)

attached to the instrument's rear panel. The first five characters are the serial prefix and the

last five digits are the suffix.

Figure 1-1 Serial Number Label Example

An instrument manufactured after the printing date of this manual may have serial number

prefix that is not listed on the title page. This unlisted serial number prefix indicates the

instrument is different from those described in this manual. The manual for this new

instrument may be accompanied by a yellow Manual Changes supplement or have a

different manual part number. This sheet contains “change information” that explains how

to adapt the manual to the newer instrument.

General Information

Instrument Covered by This Manual

1. General Information

In addition to change information, the supplement may contain information for correcting

errors (Errata) in the manual. To keep this manual as current and accurate as possible,

Agilent T echnologies recommends that you periodically request the latest Manual Changes

supplement. The supplement for this manual is identified by this manual's printing data and

is available from Agilent Technologies. If the serial prefix or number of an instrument is

lower than that on the title page of this manual, see Appendix A, Manual Changes. For

information concerning, a serial number prefix that is not listed on the title page or in the

Manual change supplement, contact the nearest Agilent Technologies office.

Chapter 1 17

Page 18

General Information

Required Equipment

Required Equipment

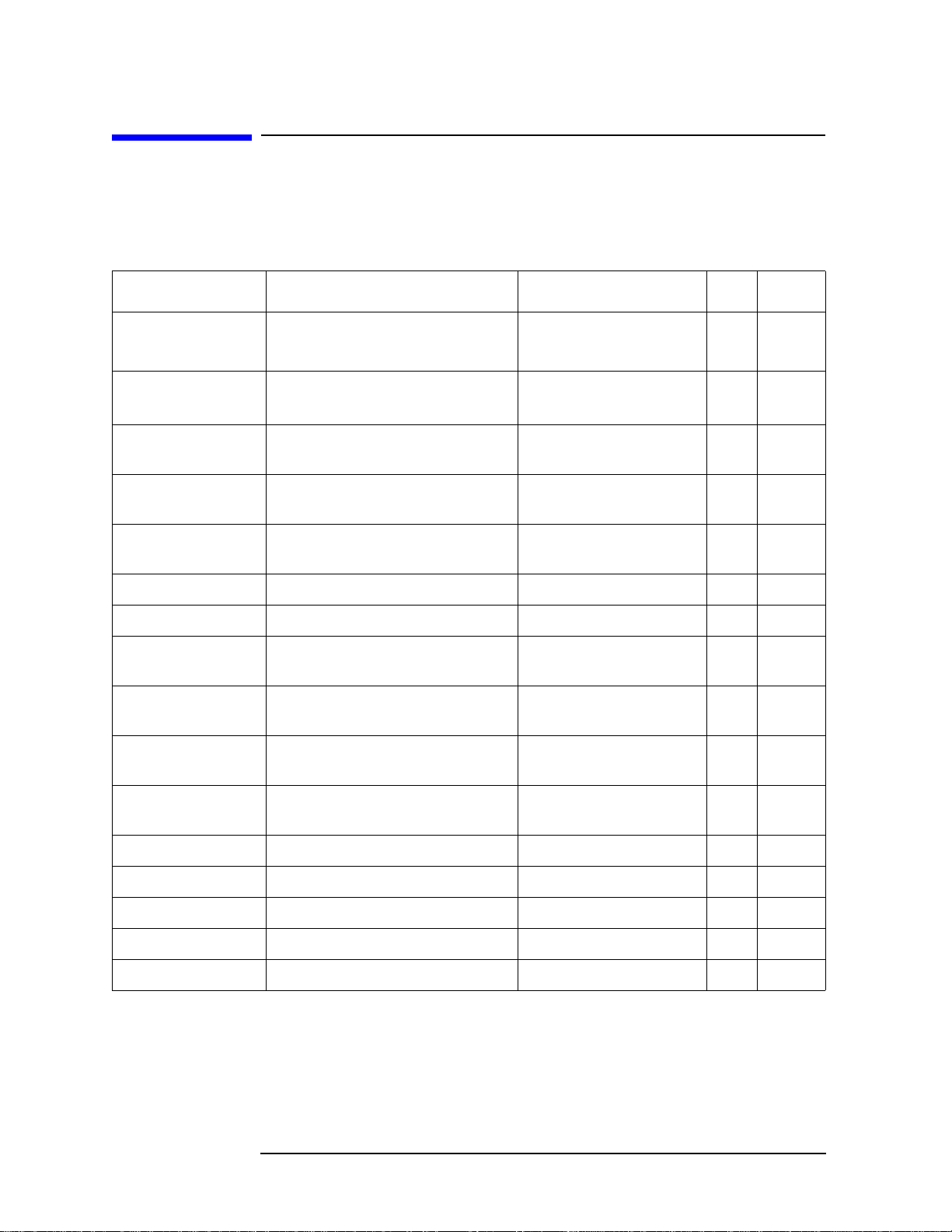

T able 1-1 lists the recommended equipment for performing maintenance on the

E5061A/E5062A.

Table 1-1 Recommended Test Equipment

Equipment Critical specifications Recommended Model Qty.

Frequency Counter Frequency: 50 MHz to 3 GHz

Accuracy: < 2.5 ppm

Power Meter No Substitute Agilent E4419B with Opt.

Agilent 53131A with

Opt.010 & 030

G12 or H12

*2

*3

1 P,A

1 P,A

Use

Power Sensor No Substitute Agilent 8482A 1 P,A

Power Sensor (75 Ω) No Substitute Agilent 8483A with Opt.

1 P

H03

Dynamic Accuracy

Test K it

No substitute Agilent Z5623A with Opt.

H01

1 P

Calibration Kit No Substitute Agilent 85032B 1 P,T

Calibration Kit No Substitute Agilent 85032F 1 A

Calibration Kit (75

No Substitute Agilent 85036B 1 P,A,T

Ω)

Short Type-N(m), N(f) part of Agilent 85032B

2 P,T

with Type-N adapter

*1

Short (75 Ω) Type-N(m), N(f) part of Agilent 85036B

2 P,T

with Type-N adapter

Fixed attenuator (6

dB)

50 Ω, N(m)-N(f), VSWR ≤ 1.015 Agilent 8491A w/Opt.006

and H60

1 P,A

Minimum Loss Pad 50 Ω N(f)-75 Ω N(m) Agilent 11852B 1 P,A

Minimum Loss Pad 50 Ω N(m)-75 Ω N(f) Agilent 11852B Opt. 004 1 P

Power Splitter N(m) 50 Ω in, N(f) 50 Ω out Agilent p/n 0955-0751 1 A,T

Power splitter (75 Ω) N(m) 75 Ω in, N(f) 75 Ω out Agilent p/n 0955-0752 1 A,T

Handler I/O Test Kit No substitute Agilent p/n E5070-65001 1 T

18 Chapter 1

Page 19

Table 1-1 Recommended Test Equipment

General Information

Required Equipment

1. General Information

Equipment Critical specifications Recommended Model Qty.

Cable BNC(m)-BNC(m) Cable, 30 cm

BNC(m)-BNC(m) Cable, 122 cm

Coaxial cable with Type-N (m)

connectors, 61 cm (24 in), 2 ea.

Coaxial cable with 75 Ω Type-N (m)

connectors, 61 cm (24 in), 2ea

Adapter N(m)-N(m) 50 Ω Adapter

N(m)-N(m) 75 Ω Adapter

N(m) 50 Ω - N(f) 75 Ω Adapter

N(m)-BNC(f) Adapter

BNC(m)-BNC(m)

BNC Tee (m) (f) (f)

Torque Wrench Size: 3/4 inch

Agilent p/n 8120-1838

Agilent p/n 8120-1840

Agilent N6314A (p/n

1

1

1

8120-8862)

Agilent p/n 8120-8898

Agilent p/n 1250-0778

Agilent p/n 1250-1528

Agilent p/n 1250-0597

Agilent p/n 1250-0780

Agilent p/n 1250-0216

Agilent p/n 1250-0781

1

1

1

1

1

1

1

Agilent p/n 8710-1766 1 P,A

Use

P

P,A

P,A,T

P,A,T

A,T

A,T

P

P,A

P

P

T orque: 136 N-cm

USB/GPIB Interface No Substitute Agilent 82357A 1 P,A

*1

Personal Computer

with GPIB board

*1.P: Performance Tests, A: Adjustment, T: Troubleshooting

*2.Opt.050 and Opt.124 can be substituted for Opt.030. In this case, a N(m)-BNC(f) adapter is necessary.

*3.The accuracy of a standard E4419B of ±0.02 dB is adequate for all tests/adjustments except “Dynamic Accuracy

Test”. This test requires a power meter with Option G12 or H12 that has been certified to a higher accuracy specification. If an Option G12 or H12 power meter is not available, a test is provide on “Power Meter Accuracy Test”

on page 20 to verify the accuracy of a standard power meter.

Windows 2000 / XP, VEE 6.2 or

VEE 7.xx

1 P,A

Table 1-2 Alternative Test Equipment

Equipment Critical specifications Model Qty.

Frequency Counter Frequency: 50 MHz to 3 GHz

Accuracy: < 2.5 ppm

Power Meter No Substitute

Calibration Kit No Substitute Agilent 85032F 1 T

Short Type-N(m) Agilent 11512A 2 P,T

*1.P: Performance Tests, A: Adjustment, T: Troubleshooting

*2.Opt.050 and Opt.124 can be substituted for Opt.030. In this case, a N(m)-BNC(f) adapter is necessary.

*3.If an accurate measurement of the dynamic accuracy specification is not required, a standard E4419B can be used.

Agilent 53132A/181A with

Opt.010 and 030

Agilent E4419B

*2

*3

1 P,A

1 P,A

Use

*1

Chapter 1 19

Page 20

General Information

Required Equipment

Power Meter Accuracy Test

This test is intended for power meters used in testing the E5061A/E5062A. The “Dynamic

Accuracy Test” requires the use of a power meter that has been calibrated to a higher

accuracy than the standard power meter.

Power meters with options G12 and H12 specify an improved instrument accuracy over a

limited power range. (These power meters do not contain unique hardware.) A power

meter may be returned to the factory to have one of these options added to an existing

power meter or to renew the calibration for one of these options.

This test procedure is an alternative to returning the power meter to the factory. When a

power meter passes this test, it is considered to be calibrated for the G12 or H12 option

even though it has not been returned to the factory.

Power Meters That Can Be Tested Using This Procedure

This procedure assume that the E4419B power meter is being tested.

NOTE It is recommended that the revision number for the power meter “Main Firmware” be

Ax.03.00 or higher.

Equipment Used for the Power Meter Accuracy Te st

Equipment Type Recommended Model

or Part Number

Alternate

Model or Part Number

Range calibrator Agilent 11683A None

Precision digital

voltmeter

Power sensor

cable

Agilent 3458A Any with the required

accuracy and resolution

Agilent 11730A, p/n

Any equivalent

8120-8319

Cable, BNC, 50 Ω Any Any

Adapter for

Any Any

connecting BNC

cable to DVM

inputs

*1.Required accuracy and resolution at the following voltage levels:

14 mV input: 0.0100% accuracy, 10 nV resolution

0.14 V input: 0.0050% accuracy, 100 nV resolution

0.45 V input: 0.0030% accuracy, 100 nV resolution

Description of the Test

*1

The power meter accuracy is verified for various power inputs and the actual readings are

recorded in a test record. A range calibrator is used to provide the reference inputs.

NOTE It is recommended that a copy of the test record on page 24 be made, and the values be

recorded on the copy, thus preserving the original for future use.

20 Chapter 1

Page 21

General Information

Required Equipment

Test Procedure

NOTE This procedure assumes the use of the recommended equipment model numbers. The

actual step required, therefore, may differ for other model numbers of equipment used.

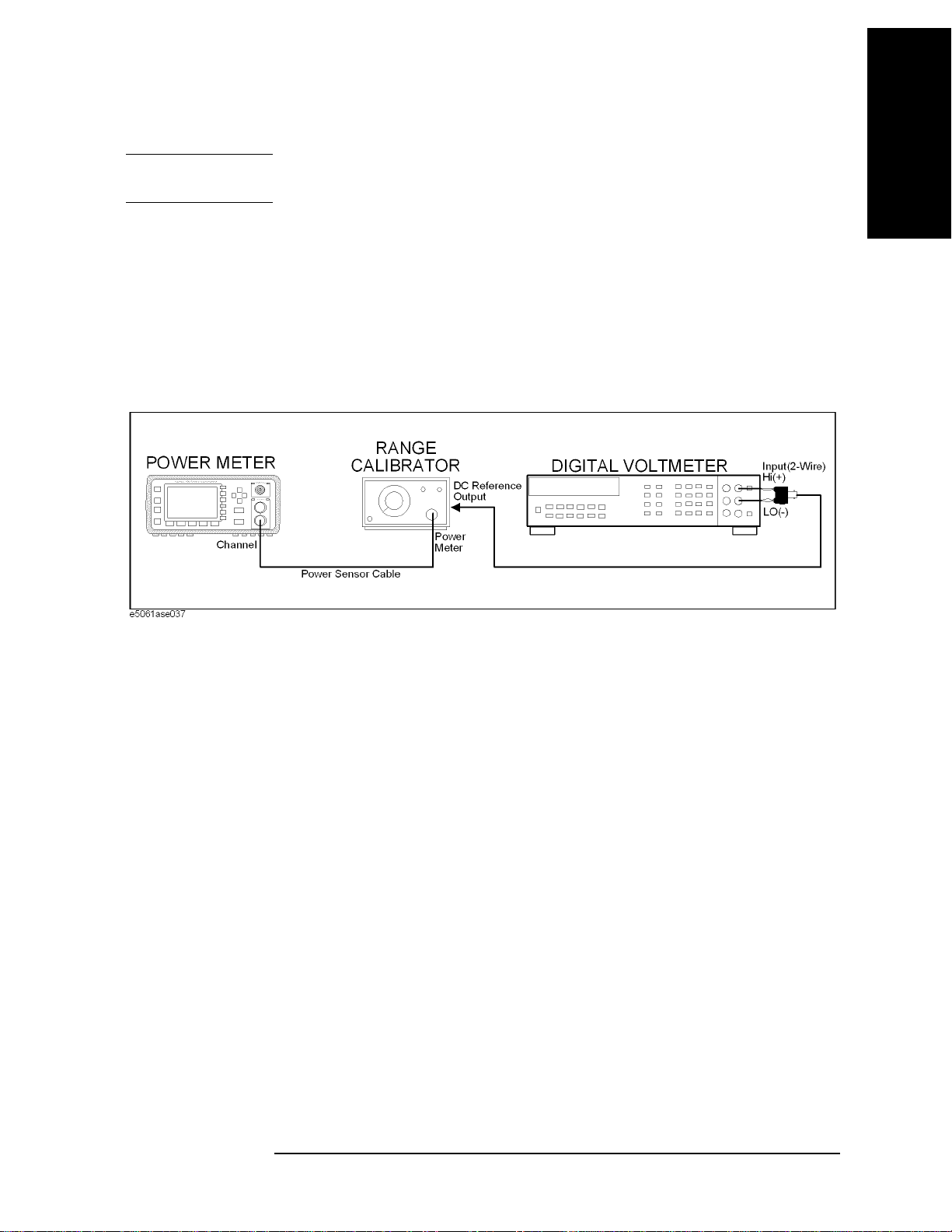

Step 1. Setup the equipment as shown in Figure 1-2.

a. Connect the DC REFERENCE OUTPUT connector on the rear panel of the range

calibrator to the DVM voltage input.

b. Connect the POWER METER output of the range calibrator to the input of the power

meter being tested.

c. Switch on the power to the power meter, the range calibrator, and the digital voltmeter.

Figure 1-2 Setup for the Power Meter Accuracy Test

1. General Information

Step 2. Press the power meter: Press [Preset/Local], then Confirm.

Step 3. Perform the following steps for each channel on the power meter:

a. Set to read in dBm: Press [dBm/W], then dBm.

b. Set the ref cal factor to 100%: Press [Zero/Cal], Cal, A/B Ref CF, then set to 100.0, if

necessary.

c. Set the cal factor to 100%: Press [Frequency/Cal Fac], A/B Cal Fac, then set to 100.0,

if necessary.

d. Set readout to 0.001 dBm: Press [Meas Setup], then Resolution 1234, to highlight 4.

e. Set filter step detect on and filter length to 512: Press [System/Inputs], channel Aor B

Input Setting

then set the filter length to

, [More], Ch A/B Filter, Step Det O n, Filter On, Mode MAN, Length,

512.

Step 4. Setup the digital voltmeter (DVM) as follows:

a. Reset the DVM: Press the blue key followed by Reset.

b. Set the sample period to a value greater than one second: Press NPLC, 5, 0, then Enter.

Step 5. Set the range calibrator controls as follows:

• POLARITY: NORMAL

• RANGE: 1 mW

Chapter 1 21

Page 22

General Information

Required Equipment

• FUNCTION: CALIBRATE

Step 6. Allow the equipment to warm up for approximately 30 minutes. Do not change any

connections or control setting during this time.

Step 7. Zero and calibrate the power meter channel to which the range calibrator is connected:

a. The range calibrator’s RANGE switch should be set to 1 mW.

b. Set the range calibrator’s FUNCTION switch to STAN DBY.

c. Press [Zero/Cal], then Zero A or Zero B (as appropriate). Wait for the operation to

complete.

d. Set the range calibrator’s FUNCTION switch to CALIBRATE.

e. Press [Zero/Cal], Cal, then Cal A or Cal B (as appropriate). Wait for the operation to

complete.

Step 8. Monitor the drift rate of the power meter reading: Five minutes following calibration, the

meter must read 0.001, 0.000, or -0.001 dBm. If the power meter reading is not one of these

values, allow additional warm up time, then check the drift rate again. The range calibrator

must remain connected to the power meter during this warm up time.

Step 9. Zero and calibrate the power meter channel to which the range calibrator is connected:

NOTE After a channel on the power meter is calibrated, do not allow more than 5 minutes to

elapse before completing the remaining measurement steps for that channel.

a. The range calibrator’s RANGE switch should be set to 1 mW.

b. Set the range calibrator’s FUNCTION switch to STAN DBY.

c. Press [Zero/Cal], then Zero A or Zero B (as appropriate). Wait for the operation to be

completed.

d. Set the range calibrator’s FUNCTION switch to CALIBRATE.

e. Press [Zero/Cal], Cal, then Cal A or Cal B (as appropriate). Wait for the operation to

complete.

Step 10. Record the DVM voltage reading as value A in the test record on page 24.

NOTE All DVM readings in this procedure should be recorded showing five significant digits.

Step 11. The reading on the power meter should be 0.000±0.001 dBm.

Step 12. Switch the range calibrator RANGE to 300 µW.

Step 13. Record the DVM voltage reading as value B in the test record.

Step 14. Wait for the power meter reading to settle (no settling drift withi n 20 seconds).

Step 15. Record the power meter reading as value C in the test record.

Step 16. Switch the range calibrator RANGE to 100 µW.

Step 17. Record the DVM voltage reading as value D in the test record.

Step 18. Wait for the power meter reading to settle (no settling drift withi n 20 seconds).

22 Chapter 1

Page 23

General Information

Required Equipment

Step 19. Record the power meter reading as value E in the test record.

Step 20. If testing a dual-channel power meter, perform Step 7 through Step 19 for the other

channel.

Step 21. Perform the pass/fail calculations indicated on the test record.

NOTE If a channel of the power meter does not pass this test, the power meter cannot be used in

applications that require Option G12 or H12. There are no adjustments that can be

performed to improve the performance of the power meter. Typically, replacing the A6

measurement assembly associated with the failed channel will correct the problem.

1. General Information

Chapter 1 23

Page 24

General Information

Required Equipment

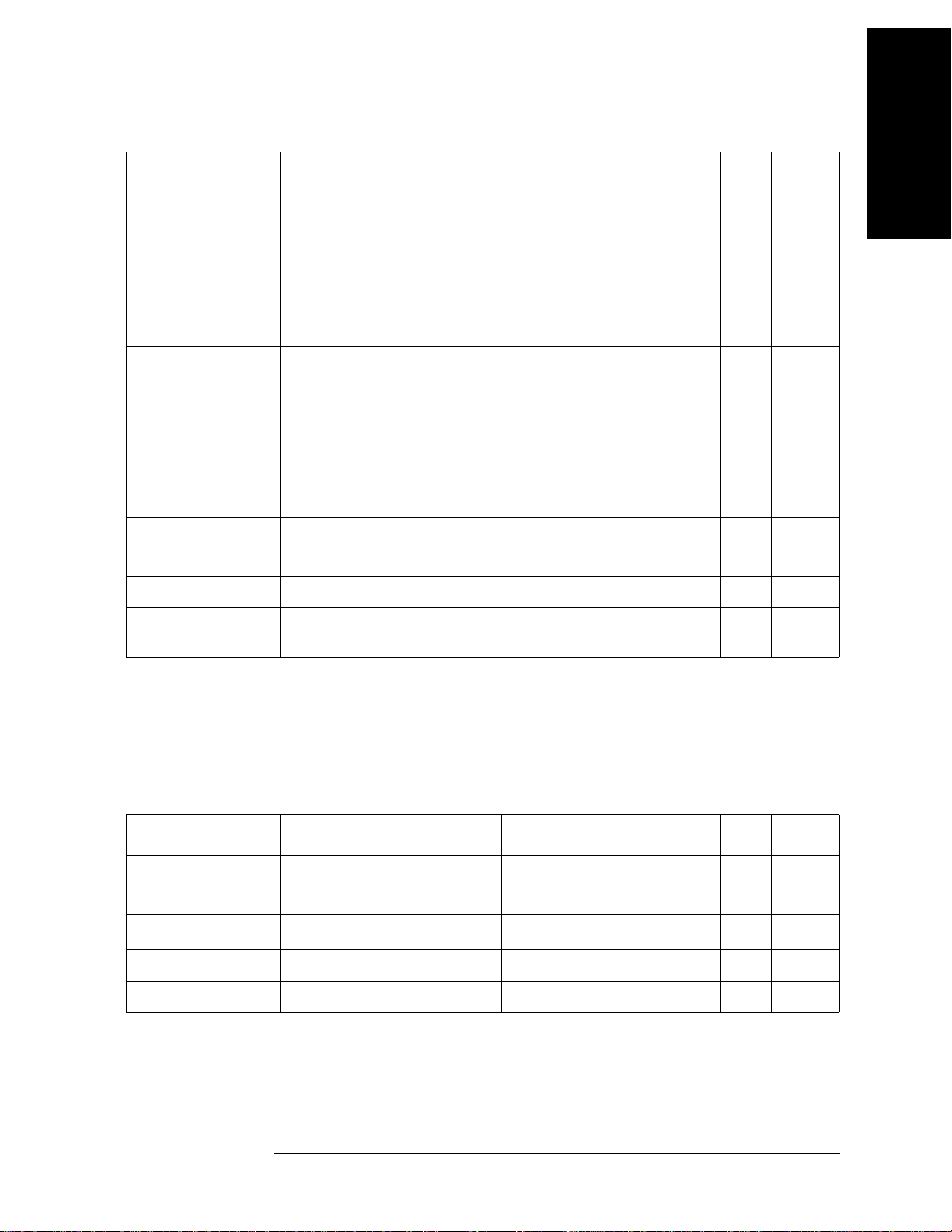

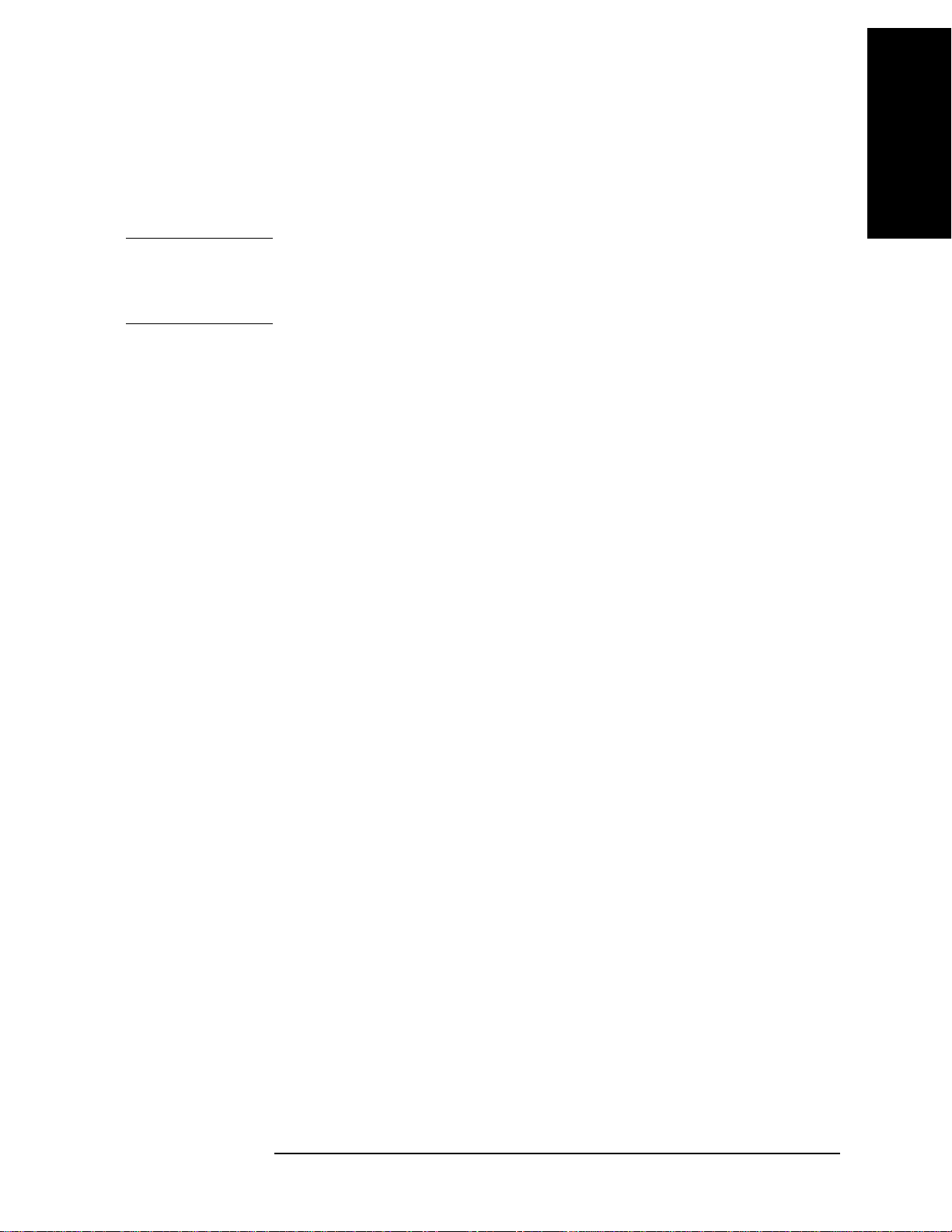

TEST RECORD FOR POWER METER ACCURACY TEST

Power Meter Tested

Model Number: Test D ate:

Serial Number: Tested by:

Test Equipment Used

Range Calibrator: Model No.: Serial No.:

Digital Voltmeter: Model No.: Serial No.:

Test Results

Range

Channel A Channel B

Calibrator:

Setting

DVM Reading

(Vdc)

Power Meter

Reading (dBm)

DVM Reading

(Vdc)

Power Meter

Reading (dBm)

1 mW A= 0.00±0.001 A= 0.00±0.001

300 µW B = C = B = C=

100 µW D = E= D = E =

Pass/Fail Calculation

300 µW R=B/A =

(C/10)

S=10

% ERROR=((R-S)/R)x100 =

Limits: ±0.13%

Pass __ Fail __

100 µW T=D/A =

(E/10)

U=10

=

=

R=B/A =

(C/10)

S=10

=

% ERROR=((R-S)/R)x100 =

Limits: ±0.13%

Pass __ Fail __

T=D/A =

(E/10)

U=10

=

% ERROR=((T-U)/T)x100 =

Limits: ±0.10%

Pass __ Fail __

% ERROR=((T-U)/T)x100 =

Limits: ±0.10%

Pass __ Fail __

24 Chapter 1

Page 25

2. Performance Test

2 Performance Tests

This chapter provides information on how to verify the E5061A/E5062A performance.

25

Page 26

Performance Tests

Introduction

Introduction

The performance tests for Agilent E5061A/E5062A make up the VBA performance test

software program. The software is included in the E5061A/E5062A Opt.0BW(add service

guide), it can not be ordered separately. This chapter shows how to run the software and

describes a brief test procedure to test the performance of the E5061A/E5062A. The

performance test names are listed in

NOTE Allow the analyzer to warm up for at least 30 minutes before you execute any of the

performance tests.

Perform all performance tests in an ambient temperature of 23 ± 5 °C

NOTE The performance tests should be performed periodically. The recommended test interval is

12 months.

The test interval depends on maintenance of use and the environmental conditions under

which the instrument is used. You may find that the interval could be shortened or

lengthened; however, such a decision should be based on substantial quantitative data.

Table 2-1.

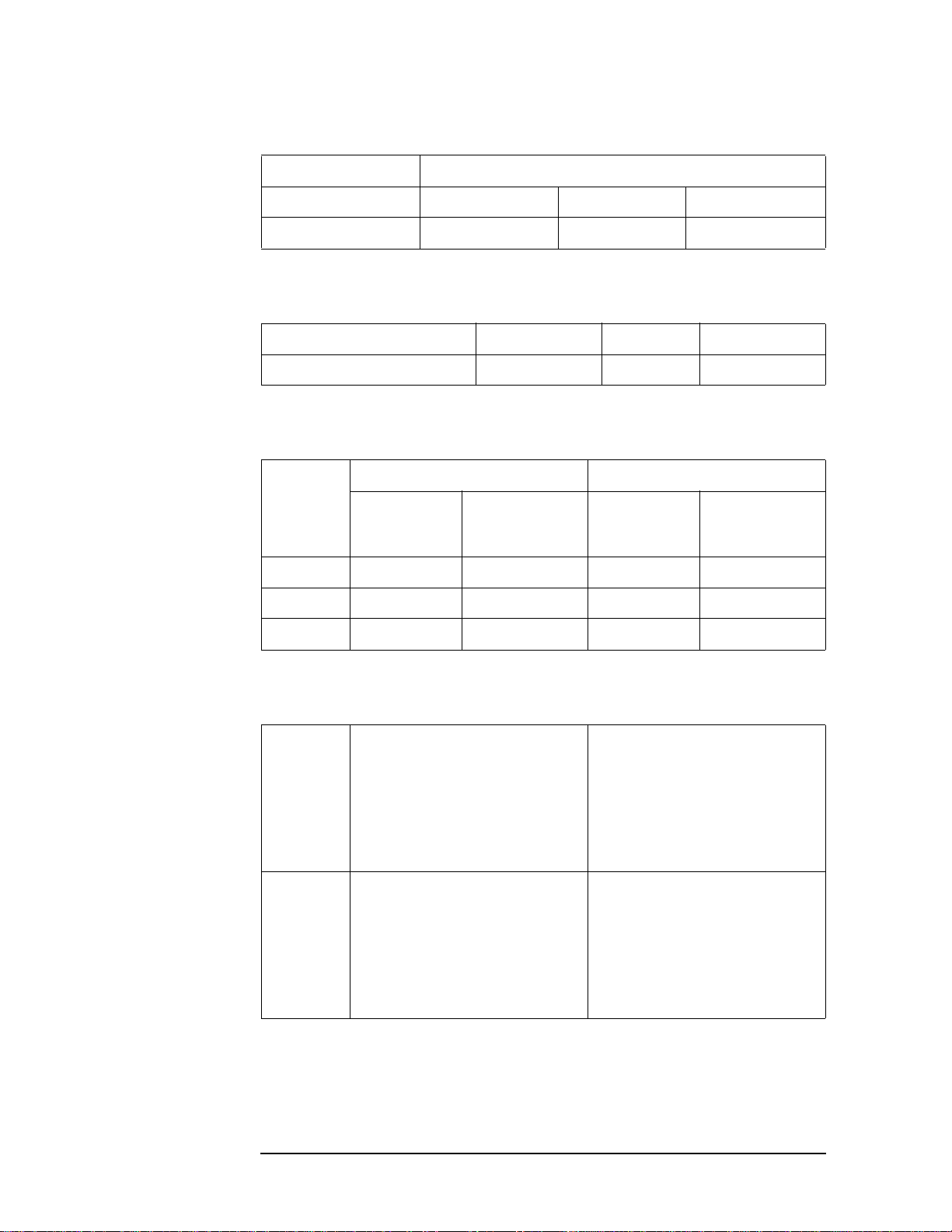

Ta ble 2-1 List of the E5061A/E5062A performance tests

Para. Title

1 Frequency accuracy test

2 RF output level accuracy and flatness test

3 RF output level linearity test

4 Trace noise test

5 Crosstalk test & System dynamic range test

6 Dynamic accuracy test

7 Uncorrected system performance test

Test Equipment Required

The required equipment for the performance test is listed on Table 1-1and Table 1-2. Use

only calibrated equipment when doing the performance test.

26 Chapter 2

Page 27

Instruction for Using the Performance Test Software

Instruction for Using the Performance Test Software

Setting system controller (USB/GPIB interface)

The test program needs a USB/GPIB interface to control the test equipment from the

E5061A/E5062A.

Follow these steps to set the USB/GPIB interface:

Step 1. Connect the USB port of the E5061A/E5062A to the USB/GPIB interface. The USB/GPIB

Interface Detected dialog box (

NOTE Do not connect two or more USB/GPIB interfaces.

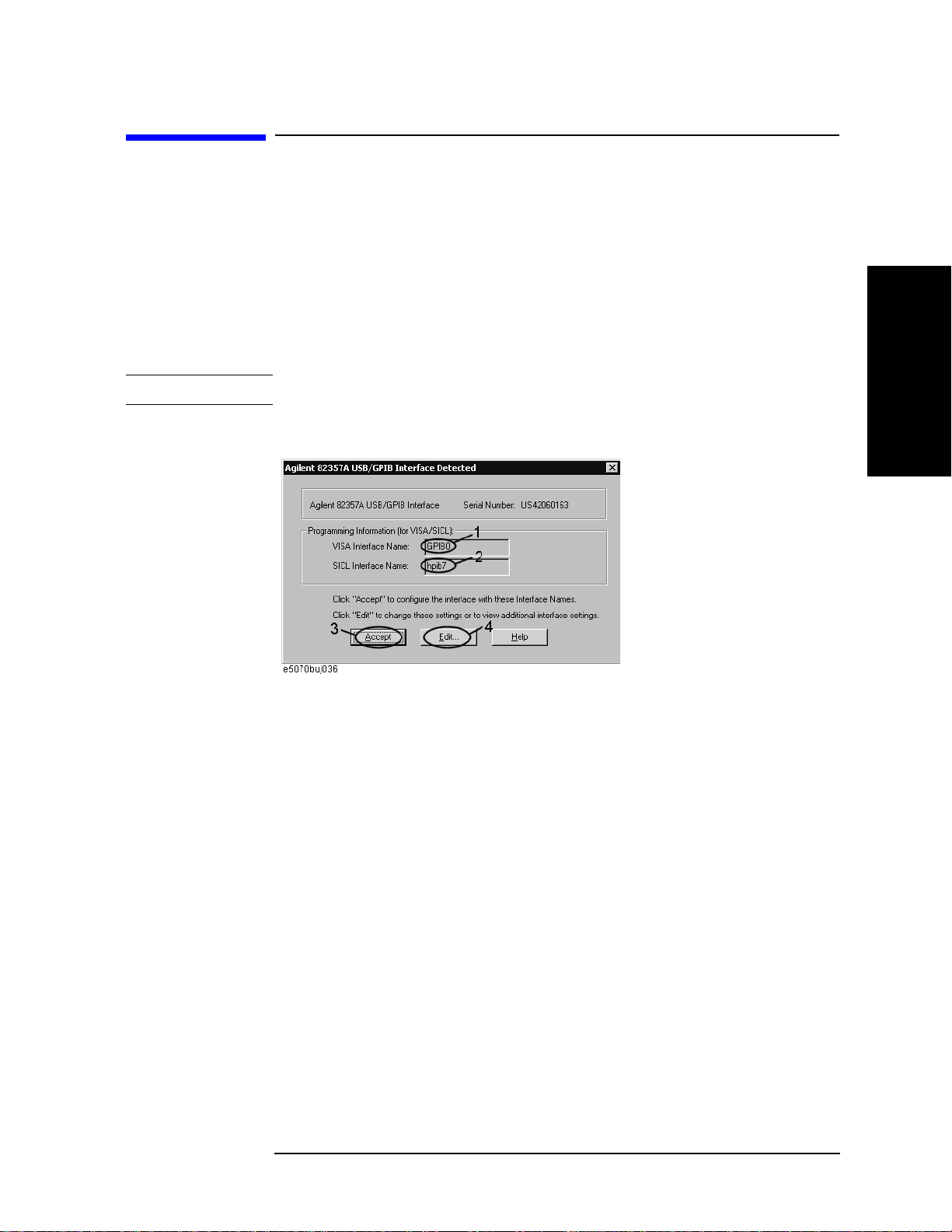

Figure 2-1 USB/GPIB Interface Detected dialog box

Figure 2-1) appears.

Performance Tests

2. Performance Test

Step 2. Confirm that VISA Interface Name is set to GPIB0 (1 in Figure 2-1) and SICL Interface

Name is set to hpib7 (2 in Figure 2-1) and then click the Accept button (3 in Figure 2-1). If

the setting is correct, the procedure is complete. If the setting is different, click the Edit

button (4 in

Step 3. The USB to GPIB Configuration dialog box (Figure 2-2) appears. Make the setting

enclosed in the thick lines in Figure 2-2 (1 in Figure 2-2) according to the figure and then

click the OK button (2 in Figure 2-2).

Chapter 2 27

Figure 2-1).

Page 28

Performance Tests

Instruction for Using the Performance Test Software

Figure 2-2 USB to GPIB Configuration dialog box

If you need to check/change the setting of the USB/GPIB interface after connecting the

USB/GPIB interface, follow these steps:

Step 1. Press .

Step 2. Press Misc Setup.

Step 3. Press GPIB Setup.

Step 4. Press System Controller Configuration.

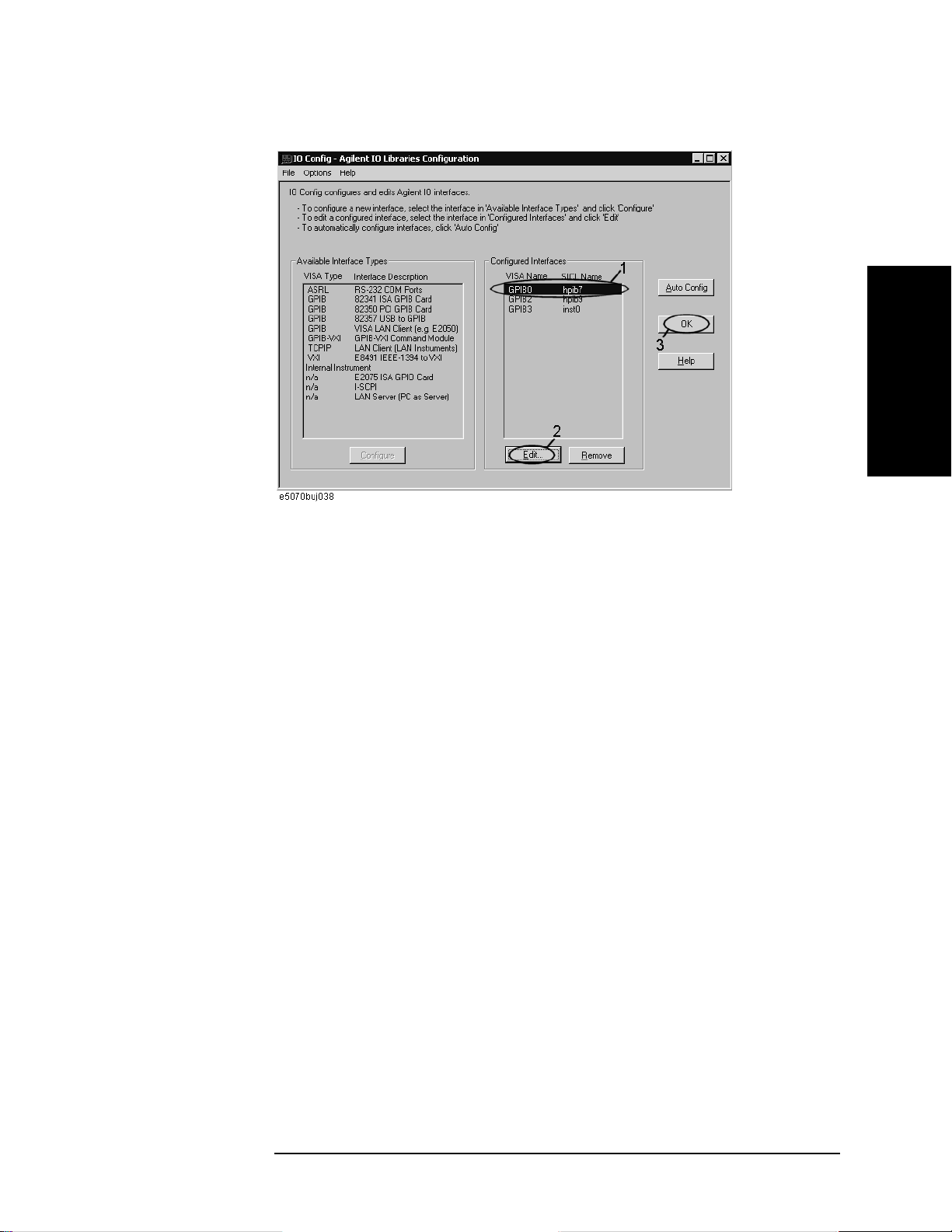

Step 5. The IO Config dialog box (Figure 2-3) appears. Select (highlight) GPIB0 hpib7 (1 in

Figure 2-3) and then click the Edit button (2 in Figure 2-3).

NOTE In the IO Config dialog box, do not click buttons other than specified here or do not change

other settings because doing so may cause serious damage to the functions of the

E5061A/E5062A.

28 Chapter 2

Page 29

Figure 2-3 IO Config dialog box

Performance Tests

Instruction for Using the Performance Test Software

2. Performance Test

Step 6. The USB to GPIB Configuration dialog box (Figure 2-2) appears. Check/change the

setting of the USB/GPIB interface and then click the OK button (2 in Figure 2-2).

Step 7. In the USB to GPIB Configuration dialog box, click the OK button (3 in Figure 2-3).

Setting the GPIB address of the equipment

The test program needs the following GPIB address for the equipment.

• 53131A Frequency Counter --- 03

• E4419B Power Meter --- 13

• Z5623A Dynamic Accuracy Test Set --- 12

Setting up the E4419B Power Meter

You must set up the power meter before running the performance test program.

1. Connect the power sensor you use to the power meter’s channel.

• 8482A Power Sensor --- Connect to the channel A for testing the E5061A/E5062A

option 150/250

• 8483A Power Sensor --- Connect to the channel B for testing the E5061A/E5062A

option 175/275

2. Edit a Sensor Calibrattion Table for your power sensor. If you have already edited the

table for your power sensor, you can skip this step. Refer to the E4419B User’s Guide

for further information.

3. Select the Sensor Calibration Table for your power sensor. Refer to the E4419B User’s

Guide for further information.

4. Zero and calibrate the power meter. The reference calibration factor used during the

Chapter 2 29

Page 30

Performance Tests

Instruction for Using the Performance Test Software

calibration is automatically set by the power meter from the sensor calibration table

you selected.

Running the Performance Tests

The program file name is “PerformanceTest.vba”. To perform the performance test for the

E5061A/E5062A, execute the program in accordance with the following procedure.

Step 1. Connect a mouse and an external keyboard to the E5061A/E5062A’s rear panel

connectors, then turn the E5061A/E5062A on.

Step 2. Insert the program disk.

Step 3. Press key.

Step 4. Press Load Project to select Load Project function. "Open" dialog box as shown below

appears.

Figure 2-4 Open dialog box

Step 5. Select "User [A]" from menu in the "Look in:" box.

Step 6. Click "PerformanceTest.vba" program file.

Step 7. Click "Open" button to download the test program.

Step 8. Press Select Macro to select Select Macro function.

Step 9. Press Module1 main to open the Module1 main program file. "E5061A/62A Performance

Test Program" dialog box (Main Menu) as shown below will appear.

Figure 2-5 Performance Test Program dialog box

30 Chapter 2

Page 31

Instruction for Using the Performance Test Software

Step 10. To exit the program, click "Exit" button.

Program Overall

Instrument

Information The option and serial number for the E5061A/E5062A, and test date

can be entered automatically.

Performance Tests

Test Conditions The test conditions, “Temperature”, “Humidity” and person doing the

test (“Tested by”) can be entered.

Test Items The following test can be selected. To execute the test you select, click

“Execute” button.

• Frequency Accuracy Test

• RF Output Level Accuracy Test

• RF Output Level Linearity Test

• Trace Noise Test

• Crosstalk & System Dynamic Range Test

• Dynamic Accuracy (Magnitude) Test

• Uncorrected System Performance Test

When each test is executed, the test dialog box is displayed. The

following screen is an example of the test dialog box.

Figure 2-6 Test di alog box

2. Performance Test

To execute the test, click “Execute” button. To return the

E5061A/E5062A performance test program dialog box (Main Menu),

click “Back to Main Menu”.

The test program will prompt you to connect cables and O/S/L

terminations to the equipment or E5061A/E5062A. Follow the

instructions as shown below on the E5061A/E5062A display for

performing the test.

Chapter 2 31

Page 32

Performance Tests

Instruction for Using the Performance Test Software

Figure 2-7 Setup dialog box

The test result file named “resultPT.txt” is created on the drive D

(D:\Agilent\Service\Log\) of the E5061A/E5062A after “Exit” button

of the Main Menu is pressed. The text file can be read and edited with

a PC. The test points of the test result correspond to the

Performance Test Record (for Option 150/250)” on page 37,

“E5061A Performance Test Record (for Option 175/275)” on page

47, “E5062A Performance Test Record (for Option 150/250)” on

page 57, or “E5062A Performance Test Record (for Option 175/275)”

on page 69. You can record the test results in the Performance Test

Record.

“E5061A

The test result of the tests except “Frequency Accuracy Test” can also

be displayed as a graphic result as shown below by selecting “Graph”

in the Test Result box.

32 Chapter 2

Page 33

Individual Test Description

1. Frequency Accuracy Test

Description

Performance Tests

Individual Test Description

This test checks the frequency accuracy of the E5061A/E5062A test port output signal.

The frequency accuracy is checked at 300 kHz, 50 MHz, 1.5 GHz and 3 GHz (for E5062A)

with a frequency counter. Since the E5061A/E5062A employs a PLL frequency

synthesizer for the signal source, the frequency accuracy test at these frequency points can

verify the accuracy for the entire frequency range.

Test equipment

Frequency Counter Agilent 53131A with Opt. 010 and 030

BNC Tee (m) (f) (f) Agilent p/n 1250-0781

BNC cable, 30 cm Agilent p/n 8120-1838

BNC cable, 122 cm Agilent p/n 8120-1840

N(m)-BNC(f) adapter Agilent p/n 1250-0780

BNC(m)-BNC(m) adapter Agilent p/n 1250-0216

Minimum Loss Pad (for

opt.175/275)

Agilent 11852B

2. RF Output Level Accuracy and Flatness Test

2. Performance Test

Description

This test checks the level accuracy and frequency flatness of the E5061A/E5062A test port

output signal. The level accuracy is checked for an output power level setting of 0 dBm at

50 MHz using a power meter. The frequency flatness is tested by measuring the power

level at the following frequency points and calculating the differences of the power meter

readings from the level at 50 MHz.

E5061A: 300 k, 1.5 M, 3 M, 7 M, 15 M, 275 M, 575 M, 875 M, 1.175 G, 1.5 GHz

E5062A: 300 k, 1.5 M, 3 M, 7 M, 15 M, 275 M, 575 M, 875 M, 1.175 G, 1.5 G, 1.775 G,

2 G, 2.375 G (for opt. 150/250), 2.675 G (for opt. 150/250), 3 GHz (for opt. 150/250)

Test equipment

Power meter Agilent E4419B

Power sensor (for opt. 150/250) Agilent 8482A

Power sensor (for opt. 175/275) Agilent 8483A with Opt. H03

Chapter 2 33

Page 34

Performance Tests

Individual Test Description

3. RF Output Level Linearity Test

Description

This test checks the level accuracy of the E5061A/E5062A test port output signal across

the specified level range. The RF output level is measured for power level settings of -5

dBm to 10 dBm in 2.5 dB step increments at 300kHz, 50 MHz, 1.5 GHz, and 3 GHz (for

E5062A).

Test equipment

Power meter Agilent E4419B

Power sensor (for opt. 150/250) Agilent 8482A