Page 1

Caution

Do not exceed the operating input power, voltage, and current

level and signal type appropriate for the instrument being used, refer to

your instrument's Function Reference.

Electrostatic discharge(ESD) can damage the highly sensitive

microcircuits in your instrument. ESD damage is most likely to occur as

the test fixtures are being connected or disconnected. Protect them from

ESD damage by wearing a grounding strap that provides a high

resistance path to ground. Alternatively, ground yourself to discharge any

static charge built-up by touching the outer shell of any grounded

instrument chassis before touching the test port connectors.

Page 2

Safety Summary

When you notice any of the unusual conditions listed below, immediately

terminate operation and disconnect the power cable.

Contact your local Agilent Technologies sales representative or

authorized service company for repair of the instrument. If you continue

to operate without repairing the instrument, there is a potential fire or

shock hazard for the operator.

- Instrument operates abnormally.

- Instrument emits abnormal noise, smell, smoke or a spark-like

light during operation.

- Instrument generates high temperature or electrical shock

during operation.

- Power cable, plug, or receptacle on instrument is damaged.

- Foreign substance or liquid has fallen into the instrument.

Page 3

Herstellerbescheinigung

GERAUSCHEMISSION

LpA<70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 T.19

Manufacturer's Declaration

ACOUSTIC NOISE EMISSION

LpA<70 dB

operator position

normal operation

per ISO 7779

Page 4

Regulatory compliance information

This product complies with the essential requirements of the following applicable European Directives, and

carries the CE marking accordingly:

The Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

The EMC Directive 89/336/EEC, amended by 93/68/EEC

To obtain Declaration of Conformity, please contact your local Agilent Technologies sales office, agent or

distributor.

Page 5

Safety notice supplement

・ This equipment complies with EN/IEC61010-1:2001.

・ This equipment is MEASUREMENT CATEGORY I (CAT I). Do not use for CAT II, III, or IV.

・ Do not connect the measuring terminals to mains.

・ This equipment is POLLUTION DEGREE 2, INDOOR USE product.

・ This equipment is tested with stand-alone condition or with the combination with the accessories supplied

by Agilent Technologies against the requirement of the standards described in the Declaration of

Conformity. If it is used as a system component, compliance of related regulations and safety requirements

are to be confirmed by the builder of the system.

Page 6

Page 7

Agilent E5052A Signal Source Analyzer

User’s Guide

Seventh Edition

FIRMWARE REVISIONS

This manual applies directly to instruments that have the firmware revision A.02.5x.

For additional information about firmware revisions, see Appendix A.

Manufacturing No. E5052-90060

November 2007

Page 8

Notices

The information contained in this document is subject to change without notice.

This document contains proprietary information that is protected by copyright. All rights

are reserved. No part of this document may be photocopied, reproduced, or translated to

another language without the prior written consent of Agilent Technologies.

Microsoft®,MS-DOS®,Windows®,Visual C++®,Visual Basic®,VBA® and Excel® are

registered

UNIX is a registered trademark in U.S. and other countries, licensed

exclusively through X/Open Company Limited.

Portions ©Copyright 1996, Microsoft Corporation. All rights reserved.

© Copyright 2004, 2005, 2006, 2007 Agilent Technologies

Manual Printing History

The manual’s printing date and part number indicate its current edition. The printing date

changes when a new edition is printed (minor corrections and updates that are incorporated

at reprint do not cause the date to change). The manual part number changes when

extensive technical changes are incorporated.

August 2004 First Edition (part number: E5052-90000)

October 2004 Second Edition (part number: E5052-90010, changes for firmeware

version A.01.10)

February 2005 Third Edition (part number: E5052-90020, changes for firmeware

version A.01.50)

August 2005 Fourth Edition (part number: E5052-90030, changes for firmeware

version A.02.00)

June 2006 Fifth Edition (part number: E5052-90040, changes for firmeware

version A.02.50)

June 2007 Sixth Edition (part number: E5052-90050)

November 2007 Seventh Edition (part number: E5052-90060)

2

Page 9

Safety Summary

The following general safety precautions must be observed during all phases of operation,

service, and repair of this instrument. Failure to comply with these precautions or with

specific WARNINGS elsewhere in this manual may impair the protection provided by the

equipment. Such noncompliance would also violate safety standards of design,

manufacture, and intended use of the instrument. Agilent Technologies assumes no liability

for the customer’s failure to comply with these precautions.

NOTE The E5052A complies with INSTALLATION CATEGORY II as well as POLLUTION

DEGREE 2 in IEC61010-1. The E5052A is an INDOOR USE product.

NOTE The LEDs in the E5052A are Class 1 in accordance with IEC60825-1,

CLASS 1 LED PRODUCT

NOTE This equipment is MEASUREMENT CATEGORY I (CAT I). Do not use for CA T II, III, or

IV.

NOTE This equipment is tested with stand-alone condition or with the combination with the

accessories supplied by Agilent Technologies against the requirement of the standards

described in the Declaration of Conformity. If it is used as a system component,

compliance of related regulations and safety requirements are to be confirmed by the

builder of the system.

• Ground the Instrument

To avoid electric shock, the instrument chassis and cabinet must be grounded with the

supplied power cable’s grounding prong.

• DO NOT Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of inflammable gasses or fumes.

Operation of any electrical instrument in such an environment clearly constitutes a

safety hazard.

• Keep Away from Live Circuits

Operators must not remove instrument covers. Component replacement and internal

adjustments must be made by qualified maintenance personnel. Do not replace

components with the power cable connected. Under certain conditions, dangerous

voltage levels may remain even after the power cable has been disconnected. To avoid

injuries, always disconnect the power and discharge circuits before touching them.

• DO NOT Service or Adjust the Instrument Alone

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation, is present.

• DO NOT Substitute Parts or Modify the Instrument

To avoid the danger of introducing additional hazards, do not install substitute parts or

perform unauthorized modifications to the instrument. Return the instrument to an

Agilent Technologies Sales and Service Office for service and repair to ensure that

3

Page 10

safety features are maintained in operational condition.

• Dangerous Procedure Warnings

Warnings, such as the example below, precede potentially dangerous procedures

throughout this manual. Instructions contained in the warnings must be followed.

WARNING Dangerous voltage levels, capable of causing death, are present in this instrument.

Use extreme caution when handling, testing, and adjusting this instrument.

• Do not connect the measuring terminals to mains.

Safety Symbols

General definitions of safety symbols used on the instrument or in manuals are listed

below.

Instruction Manual symbol: the product is marked with this symbol when it is necessary for

the user to refer to the instrument manual.

Alternating current.

Direct current.

On (Supply).

Off (Supply).

In-position of push-button switch.

Out-position of push-button switch.

A chassis terminal; a connection to the instrument’s chassis, which includes all exposed

metal structure.

Stand-by.

WARNING This warning sign denotes a hazard. It calls attention to a procedure, practice, or

condition that, if not correctly performed or adhered to, could result in injury or

death to personnel.

CAUTION This Caution sign denotes a hazard. It calls attention to a procedure, practice, or condition

that, if not correctly performed or adhered to, could result in damage to or destruction of

part or all of the instrument.

NOTE This Note sign denotes important information. It calls attention to a procedure, practice, or

condition that is essential for the user to understand.

4

Page 11

Certification

Agilent Technologies certifies that this product met its published specifications at the time

of shipment from the factory. Agilent Technologies further certifies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institution’s calibration facility or by the

calibration facilities of other International Standards Organization members.

Documentation Warranty

The material contained in this document is provided "as is," and is subject to being

changed, without notice, in future editions. Further, to the maximum extent permitted by

applicable law, Agilent disclaims all warranties, either express or implied with regard to

this manual and any information contained herein, including but not limited to the implied

warranties of merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or consequential damages in connection with the

furnishing, use, or performance of this document or any information contained herei n.

Should Agilent and the user have a separate written agreement with warranty terms

covering the material in this document that conflict with these terms, the warranty terms in

the separate agreement will control.

Exclusive Remedies

The remedies provided herein are Buyer’s sole and exclusive remedies. Agilent

T echnologies shall not be liable for any direct, indirect, special, incidental, or

consequential damages, whether based on contract, tort, or any other legal theory.

Assistance

Product maintenance agreements and other customer assistance agreements are available

for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales and Service Office.

Addresses are provided at the back of this manual.

5

Page 12

Typeface Conventions

Sample (bold) Boldface type is used when a term is defined or

emphasis.

Sample (Italic) Italic type is used for emphasis.

key Indicates a hardkey (key on the front panel or

external keyboard) labeled “Sample.” “key” may

be omitted.

Sample menu/button/box Indicates a menu/button/box on the screen labeled

“Sample” which can be selected/executed by

clicking. “menu,” “button,” or “box” may be

omitted.

Sample block/toolbar Indicates a block (group of hardkeys) or a toolbar

(setup toolbar) labeled “Sample.”

Sample 1 - Sample 2 - Sample 3 Indicates a sequential operation of Sample 1,

Sample 2, and Sample 3 (menu, button, or box).

“-” may be omitted.

6

Page 13

Documentation Map

The following manuals are available for the Agilent E5052A.

• User’s Guide (Part Number E5052-900x0, attached to Option ABA)

This manual describes most of the basic information needed to use the E5052A. It

provides a function overview, detailed operation procedure for each function (from

preparation for measurement to analysis of measurement results), measurement

examples, specifications, and supplemental information. For programming guidance on

performing automatic measurement with the E5052A, please see the Programming

Manual.

• Programmer’s Guide (Part Number E5052-900x1, attached to Option ABA)

This manual provides programming information for performing automatic

measurement with the E5052A. It includes an outline of remote control, procedures for

detecting measurement start (trigger) and end (sweep end), application programming

examples, a command reference, and related information.

• VBA Programmer’s Guide (Part Number E5052-900x2, attached to Option ABA)

This manual describes programming information for performing automatic

measurement with internal controller. It includes an outline of VBA programming,

some sample programming examples, a COM object reference, and related

information.

NOTE The number position shown by “x” in the part numbers above indicates the edition number.

VBA Macro

The Agilent folder (D:\Agilent) on the hard disk of the E5052A contains the VBA macros

(VBA Projects) used in this manual.

The customer shall have the personal, non-transferable rights to use, copy, or modify the

VBA macros for the customer’s internal operations.

The customer shall use the VBA macros solely and exclusively for their own purposes and

shall not license, lease, market, or distribute the VBA macros or modification of any part

thereof.

Agilent Technologies shall not be liable for any infringement of any patent, trademark,

copyright, or other proprietary right by the VBA macros or their use. Agilent Technologies

does not warrant that the VBA macros are free from infringements of such rights of third

parties. However, Agilent Technologies will not knowingly infringe or deliver software

that infringes the patent, trademark, copyright, or other proprietary right of a third party.

7

Page 14

8

Page 15

1. Precautions

Software Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Before contacting us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2. Overview of Functions

Front Panel: Names and Functions of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1. Standby Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2. LCD Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3. WINDOW/TRACE Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4. MEASUREMENT Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5. CONTROL Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6. Floppy Disk Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7. NAVIGATION Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8. ENTRY Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9. INSTR STATE Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10. MKR/ANALYSIS Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

11. DUT Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

12. OPTIONAL RF Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

LCD Screen: Names and Functions of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1. Data Entry Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2. Softkey Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3. Instrument Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4. Measurement Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Rear Panel: Names and Functions of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1. 24-bit I/O Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2. LAN Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3. External Monitor Output Terminal (Video). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4. GPIB Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5. External Trigger Input Connector (Ext Trig) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6. Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7. Line Switch (Always ON). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8. Power Cable Receptacle (to LINE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9. High Stability Frequency Reference Output Connector (Ref Oven) . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10. External Reference Signal Input Connector (Ref In) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11. Internal Reference Signal Output Connector (Ref Out) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

12. Serial Number Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

13. Certificate of Authenticity Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

14. Rear USB port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

15. Reserved Port (Reserved) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

16. Printer Parallel Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

17. Mini-DIN Keyboard Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

18. Mini-DIN Mouse Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

19. USB (USBTMC) Interface Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Contents

3. Installation

Checking the Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9

Page 16

Contents

Ventilation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Protection against electrostatic discharge (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Ensuring adequate free space around analyzer for immediate disconnection of power cable in case of emergency

58

Installing Front Handles/Rack Mounting Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

How to install the handle kit (Option 1CN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

How to install the rack-mount kit (Option 1CM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

How to install the rack-mount and handle kit (Option 1CP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

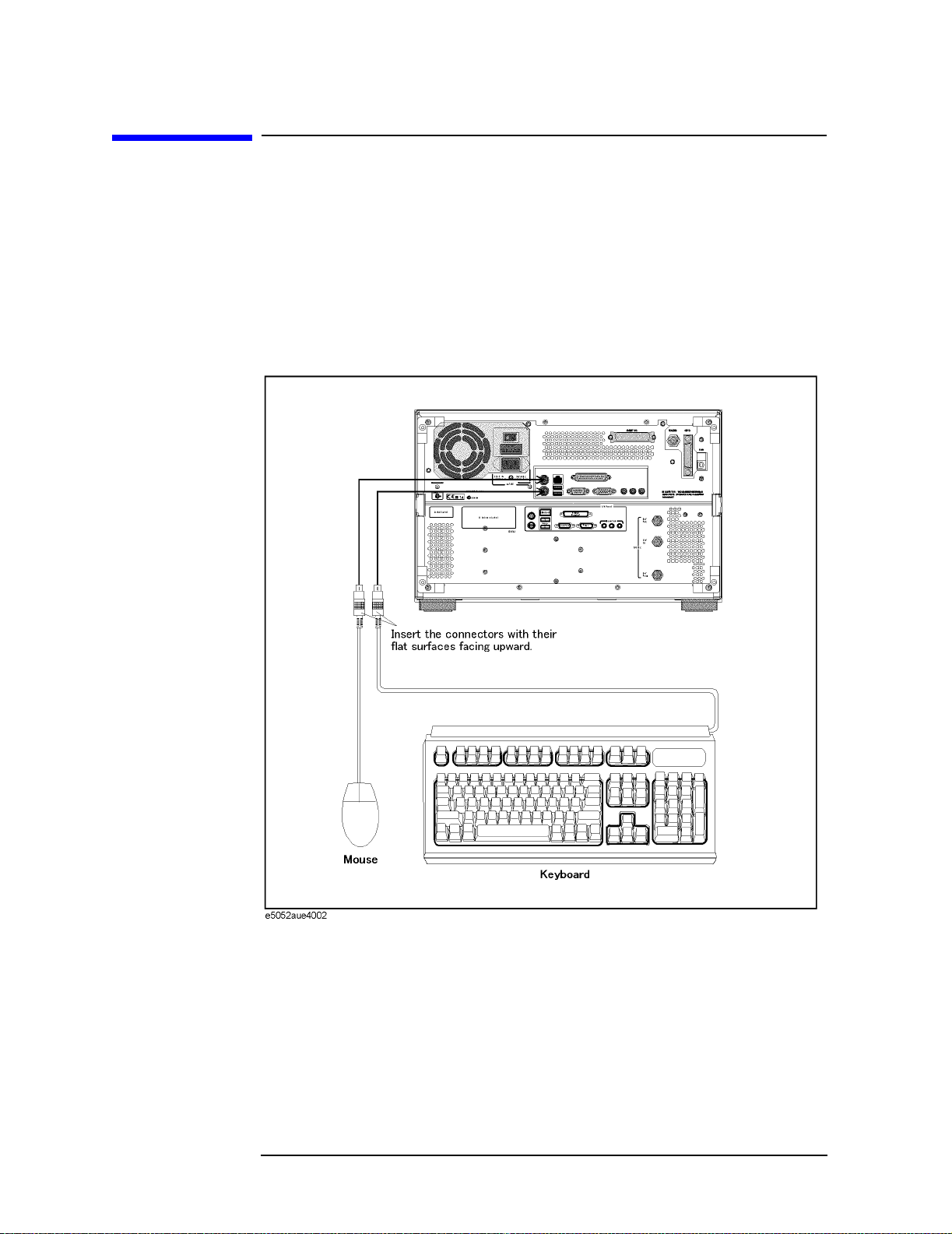

Connecting the Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Connecting the mouse and keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Connecting a LAN cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Connecting a printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Power Supply and Blown Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Veri fication of the power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Verification and connection of power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Blown fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Starting the E5052A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Turning the Power ON and OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Disconnection from supply source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Initial Registration of E5052A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Setting the Internal Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Setting the Date/Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Turning the Date/Time display ON and OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Cleaning method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Maintaining connectors/ports on test port (DUT interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Self-test When Turning on the Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Considerations When Shipping to a Service Center Due to Breakdown or Other Problems. . . . . . . . . . 76

4. Basic Measurement Using E5052A

Frequency/Power Measurement in Frequency/Power Measurement Mode. . . . . . . . . . . . . . . . . . . . . . . . . 78

Overview of frequency/power measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

About analyzer mode and tester mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Setting Trace Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Common settings in RF power, frequency and power supply DC current measurement. . . . . . . . . . . . . 81

Setting DC power/DC control and protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Auto Frequency Control Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

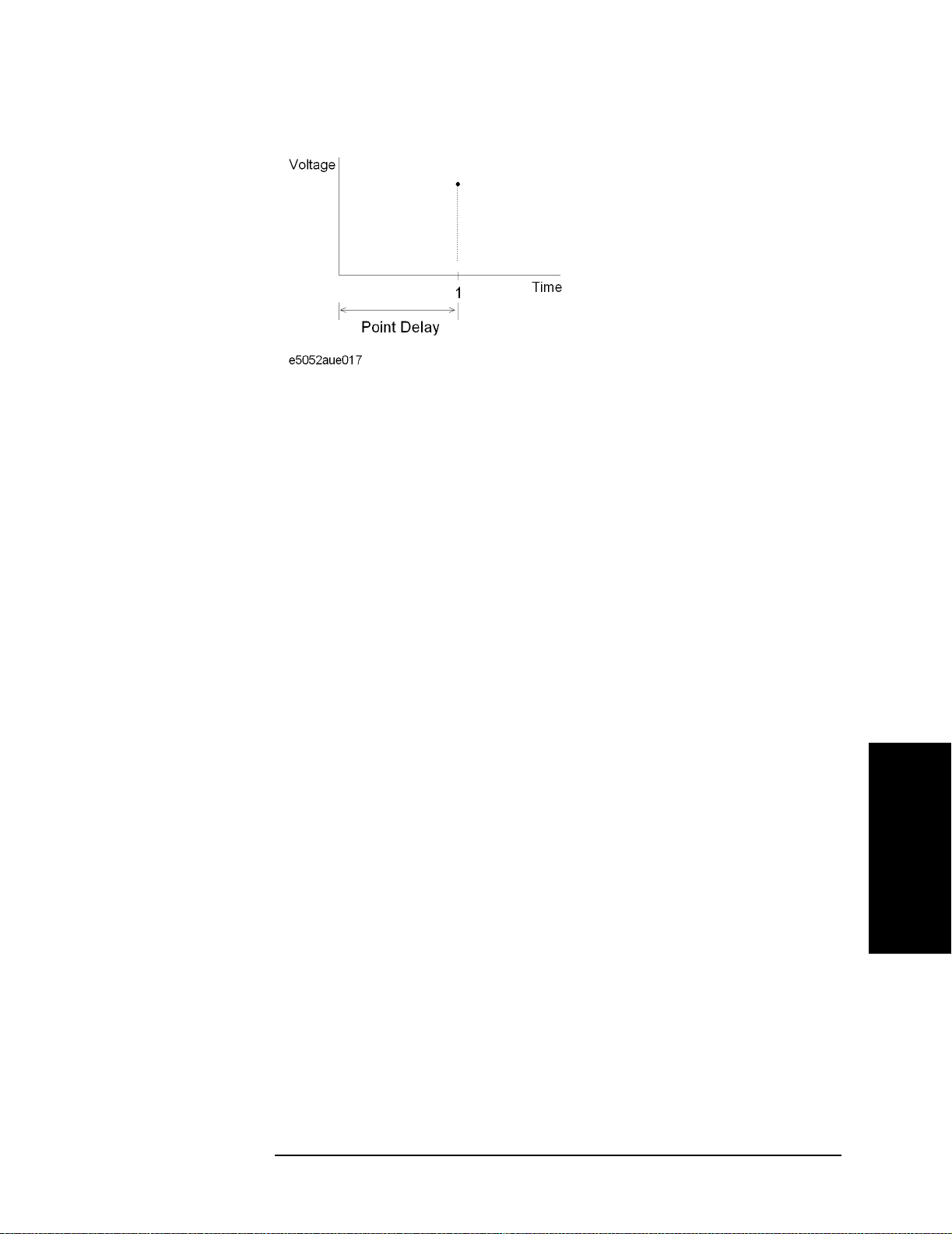

About DC control voltage delay, DC power delay and point delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Confirming Result of Frequency Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Confirming Result of RF Power Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Confirming Result of Power Supply DC Current Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Phase Noise Measurement in Phase Noise Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Overview of Phase Noise Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Setting Phase Noise Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Confirming Result of Phase Noise Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Spectrum Monitor Measurement in Spectrum Monitor Measurement Mode . . . . . . . . . . . . . . . . . . . . . . 119

Overview of Spectrum Monitor Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Spectrum Monitor Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Setting Averaging Trigger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

10

119

Page 17

Contents

Confirming Result of Spectrum Monitor Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Transient Measurement in Transient Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Overview of transient measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Common Settings for Transient Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Setting Video Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Setting External Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Confirming the result of frequency transient (Wide Band) measurement . . . . . . . . . . . . . . . . . . . . . . . 138

Confirming Result of Frequency Transient (Narrow Band) Measurement. . . . . . . . . . . . . . . . . . . . . . . 142

Confirming Result of Power Transient Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Confirming the phase transient measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

User Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Overview of User Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Setting User Calibration Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Format of the correction data file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Correction Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

5. Measurement Using E5053A and External Mixer

E5053A Microwave Downconverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Connection of E5052A and E5053A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Device Configuration Using E5052A and E5053A Microwave Downconverter . . . . . . . . . . . . . . . . . . 164

Setting E5053A Microwave Downconverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Effects of Setting of Downconverter and Input Port for RF Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

External Mixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Setup Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Frequency Offset Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Setting Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Frequency Conversion Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Consideration on Frequency Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Applicable Measurement Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Making phase-noise measurement above 26.5 GHz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Basic configuration for expanding frequency range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Setup considerations for > 26.5 GHz measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Measurement noise floor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Configuring millimeter-wave phase-noise measurement setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Advanced measurement techniques for a free-running source measurement. . . . . . . . . . . . . . . . . . . . . 189

Large frequency drift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

High phase noise that may saturate phase detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Prescaler techniques to suppress frequency drift and high phase noise . . . . . . . . . . . . . . . . . . . . . . . . . 191

Configuring millimeter-wave setup to allow prescaler techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Operation of the AgtmmWave VBA macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Start up the AgtmmWave macro. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Set up millimeter-wave measurement parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Setup for prescaler techniques (Advanced technique for measuring a free-running source) . . . . . . . . . 196

6. Data Analysis and Result Output

11

Page 18

Contents

Analyzing Data on Trace Using Marker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

About Marker Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Reading Values on Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Changing Display Position of Marker Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Specifying Sweep Range by Using Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Reading Relative Value From Reference Point on Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Reading Only Actual Measurement Point/Reading Value Interpolated Between Measurement Points. 205

Setting Up Markers for Each Trace/Setting up Markers for Coupled Operations Between Traces. . . . 206

Listing All Marker Values in All Displayed Traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Searching for Positions that Match Specified Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Setting Search Range (Bandmarkers). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Searching in Specified Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Setting up Bandmarker for Each Trace/Setting up Markers for Coupled Operations Between T race s . 210

Automatically Executing Search Each Time Sweep is Done (search tracking). . . . . . . . . . . . . . . . . . . 212

Searching for Maximum and Minimum Measured Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Searching for Target Value (target search) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Searching for Peak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Searching for Multiple Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Determining Mean, Standard Deviation, and Peak-to-Peak of the Trace. . . . . . . . . . . . . . . . . . . . . . . . . . 220

Specifying Range for Statistical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Displaying Statistical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Comparing Traces/Performing Data Math. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Operational Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Comparing Measurement Results in User Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Copy Traces to User Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Add Annotation to Each Trace in User Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Limit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Concept of Limit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Displaying Judgment Result of Limit Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Defining Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Initializing Limit Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

File Saving and Loading Instrument Status Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Saving Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Recalling Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Recall Procedure Using “Recall by File Name” Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Managing Files/Folders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Running Windows Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Copying Files/Folders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Moving Files/Folders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Removing Files/Folders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Changing the Name of File/Folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Formatting Floppy Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Saving Trace on File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Saving Trace Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Saving Trace Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Linearity Evaluation of Chirped FM Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Create Reference Regression Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Evaluate the Linearity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hiding Numeric Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

. . . . . . . . . . 242

12

Page 19

Hiding Frequency Information on Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Hiding All Numeric Information Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Saving Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Operational Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Printing Screen Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Supported Printers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Installing Printer Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Images You Can Print/save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Printing Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

7. Clock Jitter Measurement

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Overview of clock jitter measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Relation between phase deviation (spurious) and jitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Clock jitter measurement with the E5052A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Executing Clock Jitter Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Starting the VBA program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Random jitter analysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Frequency analysis for periodic jitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Decomposition analysis for periodic jitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Installing the program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Contents

8. Setting and Using the Control and Management Functions

Setting the GPIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Setting talker/listener GPIB address of E5052A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Setting system controller (USB/GPIB interface) when c drive volume label in hard disk is less than CL250

268

Setting system controller (USB/GPIB interface) when c drive volume label in hard disk is more than CL251

271

Setting the Mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Setup steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Configuring the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Enabling/disabling network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Setting IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Specifying computer name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Accessing Hard Disk of E5052A from External PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Enabling access from an external PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Accessing hard disk of E5052A from external PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Disabling USB Mass Storage Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Steps for Setting Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Locking the Front Keys, Keyboard, and Mouse (Touch Screen) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Locking the front keys, keyboard, and mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Setting the Beeper (Built-in Speaker). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Setting the Operation Complete Beeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Setting the Warning Beeper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Turning off the LCD Screen Backlight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Turning off the LCD Screen Backlight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

13

Page 20

Contents

Setting display colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Selecting display mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Setting display color for each item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Resetting the display colors to factory defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Checking the Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Checking the serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Checking the firmware revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Checking the option number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

9. Information on Maintenance

Backing Up the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Making backup files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Maintenance of removable hard disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Saving system calibration data from removable hard disk to floppy disk . . . . . . . . . . . . . . . . . . . . . . . 2 93

Removing Removable Hard Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Mounting Removable Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Recalling system calibration data to removable hard disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

System Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Types of system recoveries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Notes on executing system recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Procedure to execute factory recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Procedure to create the user backup image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Procedure to execute the user recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Calibration of the Touch Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Cleaning the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Cleaning the LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Maintenance of test ports (DUT INTERFACE) and other connectors/ports . . . . . . . . . . . . . . . . . . . . . 307

Cleaning parts other than the LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Replacement of Parts with Limited Service Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Cautions Applicable to Requesting Repair, Replacement, Regular Calibration, etc. . . . . . . . . . . . . . . . . 309

Backing up data in the hard disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Devices to be sent back for repair or regular calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Recommended Calibration Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

10. Specifications and Supplemental Information

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Phase Noise Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Measurement capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Frequency, RF Power, DC current Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Specifications of the E5052A use only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Measurement capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Softkeys and SCPI commands that are not available when using “Tester” mode or option 011 is installed

322

Transient Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Measurement capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Spectrum Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Measurement capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Port Output (DC Power/Control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

14

Page 21

Test Port Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Measurement capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

DC Power/Control Voltage Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Trace functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

System capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Automation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Function differences between standard and option 011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

System performance with E5053A Microwave Downconverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

Clock jitter Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

A. Manual Changes

Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Change 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Change 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Change 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Change 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Change 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Contents

B. Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Troubleshooting during Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Troubleshooting during Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Troubleshooting for External Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

F. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

P. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

C. List of Default Values

List of Default Values, Save/Recall Settings, and Backup Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

FP Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

PN Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

SP Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

TR Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

15

Page 22

Contents

USER Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

D. Softkey Functions

Phanse Noise Menu (Top Menu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

PN Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

Spectrum Monitor Menu (Top Menu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

SP Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

Frequency Power Menu (Top Menu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 442

FP Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

Transient Menu (Top Menu). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 458

TR Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 459

User Defined Menu (Top Menu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

USER Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 476

16

Page 23

1. Precautions

1 Precautions

This chapter describes cautions that must be observed in operating the E5052A.

17

Page 24

Precautions

Software Installed

Software Installed

The Windows operating system installed in this machine is customized for more effective

operation, and has different functions that are not part of the Windows operating system for

ordinary PCs (personal computers).

Therefore, do not attempt to use the system in ways other than those described in this

manual or to install Windows-based software (including anti-virus software) for ordinary

PCs as doing so may cause malfunctions.

Also note the followings.

• Do not update the Windows operating system installed in this machine to the Windows

operating system for ordinary PCs. Doing so will cause malfunctions.

• Do not attempt to update VBA (Visual Basic for Applications) software installed in this

machine to its equivalent developed for ordinary PCs. Doing so will cause

malfunctions.

• Do not allow any computer virus to infect the system. This machine has no virus check

function nor anti-virus software installed.

Agilent Technologies will not be held liable for any failure or damage arising from

negligence regarding these prohibitions and warnings.

NOTE If the pre-installed software is damaged somehow, resulting in errant behavior by the

machine, perform a system recovery. For further details of system recovery, refer to

“System Recovery” on page 296.

18 Chapter 1

Page 25

Precautions

Before contacting us

Before contacting us

If you encounter the following problems during startup or operation of the E5052A, in

which initial registration of the Windows 2000 Operating System has been properly

performed, execute system recovery and update the firmware version. As for the system

recovery procedure, refer to “System Recovery” on page 296.

The system starts up, but the normal measurement screen does not appear

• The system automatically shuts down immediately after the startup, or the startup

process stops.

• The measurement screen appears, but "Power on test fail" or "Calibration data lost" is

displayed in the instrument message/warning area against a red background in the

lower-left part of the screen. The system enters the service mode. (The instrument

status bar in the lower-right displays SVC in red).

Unstable Operation

• The system hangs up while the instrument is controlled from VBA or external PCs.

• The blue screen appears and the system hangs up.

1. Precautions

• The response is much slower than usual.

When execution of system recovery does not result in normal operation, a failure may have

occurred. Contact Agilent Technology’ s Customer Contact listed at the end of this guide or

the company from which you bought the device.

For other problems, refer to “Troubleshooting” on page 352.

Chapter 1 19

Page 26

Precautions

Before contacting us

20 Chapter 1

Page 27

2. Overview of

Functions

2 Overview of Functions

This chapter describes the functions of the E5052A that can be accessed from the front

panel, LCD screen, and rear panel.

21

Page 28

Overview of Functions

Front Panel: Names and Functions of Parts

Front Panel: Names and Functions of Parts

This section describes the names and functions of the parts on the front panel of the

E5052A. For more about the functions displayed on the LCD screen, see “LCD Screen:

Names and Functions of Parts” on page 34. For more about the functions of softkeys, see

Appendix D, “Softkey Functions,” on page 411.

Figure 2-1 Front Panel

22 Chapter 2

Page 29

Overview of Functions

Front Panel: Names and Functions of Parts

1. Standby Switch

Used for choosing between power-on ( | ) and standby ( ) states of the E5052A.

NOTE To turn off the power of the E5052A, be sure to follow the steps described below.

1. First, press the standby switch or send a shutdown command from the external

controller to activate the shutdown process (the processing of software and hardware

necessary to turn off the power supply). This will put the E5052A into the standby

state.

2. Next, if necessary, turn off the power supply to the “8. Power Cable Receptacle (to

LINE)” on page 48 on the rear panel.

Under normal use, never directly interrupt the power supply to the power cable

receptacle on the rear panel when the power supply is on. Always keep the “7. Line

Switch (Always ON)” on page 47 at (|). Never turn it off ( ).

If you directly interrupt the power supply to the power cable receptacle when the power

supply is on, or turn off the “7. Line Switch (Always ON)” on page 47, the shutdown

process will not work. This could damage the E5052A’s software and hardware and lead to

device failure.

2. Overview of

Functions

Turning on the power supply after a faulty shutdown may cause the system to start up in a

condition called “safe mode.” If this occurs, first shut down the system to put it into the

standby state and then turn on the power supply again to start up the system in normal

mode.

See also Chapter 3, “Installation,” for further information on power on/off.

2. LCD Screen

A 10.4-inch touch screen TFT color LCD used for displaying traces, scales, settings,

softkeys, etc. The touch screen LCD allows you to manipulate softkeys by touching the

LCD screen directly with a finger. For more about the LCD screen, see “LCD Screen:

Names and Functions of Parts” on page 34.

NOTE Do not press the surface of the LCD screen (both standard and touch screen types)

with a sharp object (e.g., a nail, pen, or screwdriver). Pressing the surface with a

sharp-pointed object can damage the LCD screen surface or cause the screen to fail.

NOTE Occasionally, a few pixels may appear on the screen as a fixed point of blue, green or

red. Please note that this is not a failure and does not affect the performance of your

product.

Chapter 2 23

Page 30

Overview of Functions

Front Panel: Names and Functions of Parts

3. WINDOW/TRACE Block

A group of keys for selecting active measurement windows and active traces. For more

about the concepts of measurement windows and traces, see “4. Measurement Window” on

page 41.

Table 2-1

Key

Key

Key

Key

Pressing this key causes the active measurement window to

switch over to the next higher window number of four

measurement windows. It is possible to define sweep range and

other parameters of an active measurement window. To change

the settings of a window, use this key to first activate the window.

Switches over between normal and maximum display of the active

measurement window. In normal display, all four measurement

windows (both active and non-active) are displayed in split views

on the screen. In maximum display, only the active measurement

window is displayed over the entire area, without showing

non-active measurement windows. You can also switch over

between the normal and maximum windows by double-clicking

the measurement window frame. Measurements are also carried

out on the non-active measurement windows that are not

displayed.

Switches over the active trace to the next one. (Each time the key

is pressed the active trace steps up from the trace with the

designated number to the one with a higher number.) An active

trace is one for which the measurement parameters are defined. To

change the settings for a trace, use this key to first make the trace

active.

Switches over between normal and maximum display of the active

trace within the measurement window. In normal display, all

traces are displayed in split views on the measurement window. In

maximum display, only the active trace is displayed over the

entire area, without showing non-active traces. To maximize the

active trace, you can also double-click the area inside the

measurement window (excluding the frame). Measurements are

also carried out on the non-active traces that are not displayed.

24 Chapter 2

Page 31

Overview of Functions

Front Panel: Names and Functions of Parts

4. MEASUREMENT Block

A group of keys used mainly for setting up measurements on the E5052A.

Table 2-2

Key

Key

Key

Key

Key

Key

Displays the “Measurement View Menu” in the right part of the

screen. Manipulating the “Measurement View Menu” enables you to

select any active measurement window. Active measurement

windows are also selectable in maximum display. In this case, the

measurement window in maximum display will switch over to the

one you have selected.

Displays the “Input Menu” in the right part of the screen.

Manipulating the “Input Menu” enables you to select any port for the

measurement signal input.

Displays the “Scale Menu” in the right part of the screen.

Manipulating the “Scale Menu” enables you to specify the scale for

displaying a trace (magnitude per division, value of the reference

line, etc.) for each trace.

Displays the “Format Menu” in the right part of the screen.

Manipulating the “Format Menu” enables you to specify the data

format (data transformation and graph formats) for each trace.

Displays the “Trace View Menu” in the right part of the screen.

Manipulating the “Trace View Menu” enables you to specify the data

smoothing, data saving on memory, title of trace, etc. for each trace.

Displays the “Display Menu” in the right part of the screen.

Manipulating the “Display Menu” enables you to specify the screen

title display, digit of the y-axis value, marker position, etc. for each

active measurement window .

2. Overview of

Functions

Key

Key

Chapter 2 25

Displays the “Average Menu” in the right part of the screen.

Manipulating the “Average Menu” enables you to specify

enabling/disabling and number of times for averaging, etc. For

spectrum measurements only, you can specify the bandwidth of

resolution.

Displays the “Attenuator Menu” in the right part of the screen.

Manipulating the “Attenuator Menu” enables you to change the

setting of the input signal attenuator.

Page 32

Overview of Functions

Front Panel: Names and Functions of Parts

5. CONTROL Block

A group of keys for defining the values of the DC output port and sweeps as well as trigger

settings.

Table 2-3

Key

Key

Displays the data input bar in the upper part of the screen by

which you can specify the start value of the sweep range for the

active measurement trace or the time offset value for the transient

measurement. Also displays the menu in the right part of the

screen that allows you to specify the sweep range. You can use the

following menus:

• Phase noise measurement “Start Menu”

• Spectrum measurement “Start/Center Menu”

• Frequency power measurement “Start/Center Menu”

• Transient measurement “Time Offset Menu”

Displays the data input bar in the upper part of the screen by

which you can specify the stop value of the sweep range for the

active measurement trace or the span value for the transient

measurement. Also displays the menu in the right part of the

screen that allows you to specify the sweep range. You can use the

following menus:

• Phase noise measurement “Stop Menu”

• Spectrum measurement “Stop/Span Menu”

• Frequency power measurement “Stop/Span Menu”

• Transient measurement “Span Menu”

In these menus, the titles are different from those at the start, but

the function of the softkey is the same.

Key

Key

Key

Key

26 Chapter 2

Displays the “DC Control Voltage Menu” by which you can

specify the values of control voltage output for the DC

CONTROL port.

Displays the “DC Power Voltage Menu” by which you can specify

the values of power voltage output for the DC power port.

Displays the “Setup Menu” in the right part of the screen.

Manipulating the “Setup Menu” enables you to specify the

frequency range, IF Gain, input level, etc. required for individual

measurements.

Displays the “Trigger Menu” in the right part of the screen.

Manipulating the “Trigger Menu” enables you to specify the

trigger mode and trigger source and obtain triggers. Specify the

trigger mode for each measurement window.

Page 33

Overview of Functions

Front Panel: Names and Functions of Parts

6. Floppy Disk Drive

A device to use for storing to and reading from a floppy disk the setup state of the E5052A,

measurement data, calibration data, data on images displayed on the LCD screen, VBA

(Visual Basic for Applications) programs, etc. The floppy disk drive is compatible with a

3.5-inch, 1.44-MB DOS (Disk Operating System) formatted floppy disk.

A floppy disk access lamp is provided at the lower left of the floppy disk drive opening.

When the floppy disk drive is accessing a disk (for reading or writing), this lamp is lit

green.

A disk eject button is provided at the lower right of the floppy disk drive opening. Pressing

this button ejects the inserted floppy disk.

NOTE Insert a floppy disk into the floppy disk drive opening rightside up in the direction of the

arrow marked on the disk.

Do not press the disk eject button while the floppy disk access lamp is on. Trying to

forcefully pull the floppy disk out while the lamp is on may damage the floppy disk or disk

drive.

2. Overview of

Functions

Chapter 2 27

Page 34

Table 2-4

Overview of Functions

Front Panel: Names and Functions of Parts

7. NAVIGATION Block

The keys and knob in the NAVIGATION block are used to navigate between softkey

menus or selected (highlighted) areas in a dialog box and to change numeric values in the

data entry area by stepping up or down. When selecting one of two or more objects

(softkey menus, data entry areas, etc.) to manipulate with the NAVIGATION block keys

displayed on the screen, first press the key in the “8. ENTRY Block” on page 30

to select the object to be manipulated (focus on the object) and then manipulate the

NAVIGATION block keys (knob) to move your selection (highlighted object) or change

numeric values.

In the following, you will see how the NAVIGATION block keys work in both the softkey

menu and the data entry area. For more on manipulating tables and dialog boxes, refer to

the manipulation procedure for each of those functions.

Operation in softkey menu (softkey menu is selected)

When the focus is on the softkey menu (the menu title area in the uppermost part is

displayed in blue), the NAVIGATION block keys work as described below.

Table 2-5

Knob

(turned clockwise or

counterclockwise)

Key

Key

Key

Knob (pressed) or

key

After pressing the data entry softkey, the focus automatically moves to the data entry area.

Operation in data entry area (data entry area is selected)

When the focus is on the data entry area (the data entry bar is displayed in blue), the

NAVIGATION block keys work as described below.

Knob