Page 1

<<<<Caution

Caution>>>> The following conditions shall apply for the Visual Basic

CautionCaution

(hereafter “VBA”) equipped in the E4991A RF Impedance/Material Analyzer (hereafter “E4991A”). The

customer shall agree to these conditions before using E4991A.

User

User License Agreement

License Agreement of VBA for

User User

License AgreementLicense Agreement

1. The customer can use VBA only on E4991A and one specified computer.

2. The customer shall use VBA according to the method of use specified by the VBA manual,

accompanying documents, package, display screens, and so on.

3. The company shall not be under any obligation to guarantee that VBA errors will not occur and shall

not be under any obligation to correct VBA errors, even when errors exist. [T.S1]

4. The company, during the E4991A warranty period, shall cover any defect of the software recording

media [T.S2] inside E4991A if it results in the failure to execute VBA programming instructions, even

if VBA is properly installed in E4991A. The company shall not guarantee any other items except for

this item, regardless of indications or revelations, and shall not guarantee conformability towards

VBA products or special objectives. Some countries adopt legislation that does not recognize warranty

of VBA for E4991

of VBA for of VBA for

E4991AAAA

E4991E4991

â

for Applications software

exclusions of indications or revelations. In countries adopting such legislation, the above restriction

shall not apply to the customer. In such cases, the company shall allow the return of E4991A and shall

refund the purchase amount, limited to 30 days from the day VBA is transferred. The customer may

have other rights depending on the country.

5. The company shall not bear any responsibility even if it is announced that there is a possibility of

circumstantial or extraordinary damage (including direct, indirect, or carry-over profits) caused by

VBA. Some countries may adopt legislation that does not recognize the validity of limitations or

exclusions of compensative responsibility for circumstantial damage or consequential damage. In

countries adopting such legislation, the above limitations or exclusions shall not apply. In any case,

however, the company shall not be burdened with compensative responsibility of an amount that

exceeds the amount of money received for E4991A.

Visual Basic

[T.S1] If no customer support service shall be offered, we shall not guarantee that there will be no bugs

or that we will implement corrections, since proposals may be made including training.

[T.S2] We rewrote the term as recording media (i.e., HDD) since it is hard to discriminate between the

Ò

for Applications is a registered trademark of Microsoft Corp. of the U.S.

hard disk and firmware.

[T.S3] We wrote this to show that VBA is a product of Microsoft Corp.

Page 2

Page 3

Caution

Do not exceed the operating input power, voltage, and current

level and signal type appropriate for the instrument being used, refer to

your instrument's Function Reference.

Electrostatic discharge(ESD) can damage the highly sensitive

microcircuits in your instrument. ESD damage is most likely to occur as

the test fixtures are being connected or disconnected. Protect them from

ESD damage by wearing a grounding strap that provides a high

resistance path to ground. Alternatively, ground yourself to discharge any

static charge built-up by touching the outer shell of any grounded

instrument chassis before touching the test port connectors.

E4991A

Page 4

Page 5

Safety Summary

When you notice any of the unusual conditions listed below, immediately

terminate operation and disconnect the power cable.

Contact your local Agilent Technologies sales representative or

authorized service company for repair of the instrument. If you continue

to operate without repairing the instrument, there is a potential fire or

shock hazard for the operator.

n Instrument operates abnormally.

n Instrument emits abnormal noise, smell, smoke or a spark-like light

during the operation.

n Instrument generates high temperature or electrical shock during

operation.

n Power cable, plug, or receptacle on instrument is damaged.

n Foreign substance or liquid has fallen into the instrument.

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Agilent E4991A RF Impedance/Material Analyzer

Operation Manual

Fifth Edition

SERIAL NUMBERS

This manual applies directly to instruments that don’t have serial number prefix JP1KH.

For additional information about serial numbers, see Appendix A.

Agilent Part No. E4991-90050

March 2003

Printed in Japan

Page 12

Notices

The information contained in this document is subject to change without notice.

This document contains proprietary information that is protected by copyright. All rights

are reserved. No part of this document may be photocopied, reproduced, or translated to

another language without the prior written consent of Agilent Technologies.

Agilent Technologies Japan, Ltd.

Component Test PGU-Kobe

1-3-2, Murotani, Nishi-ku, Kobe, Hyogo, 651-2241 Japan

© Copyright 2001, 2002, 3003 Agilent Technologies Japan, Ltd.

Manual Printing History

The manual’s printing date and part number indicate its current edition. The printing date

changes when a new edition is printed (minor corrections and updates that are incorporated

at reprint do not cause the date to change). The manual part number changes when

extensive technical changes are incorporated.

March 2001 Preliminary (part number: E4991-90000)

April 2001 First Edition (part number: E4991-90010)

July 2001 Second Edition (part number: E4991-90020)

September 2001 Third Edition (part number: E4991-90030)

February 2002 Fourth Edition (part number: E4991-90040)

March 2003 Fifth Edition (part number: E4991-90050)

2

Page 13

Safety Summary

The following general safety precautions must be observed during all phases of operation,

service, and repair of this instrument. Failure to comply with these precautions or with

specific WARNINGS elsewhere in this manual may impair the protection provided by the

equipment. Such noncompliance would also violate safety standards of design,

manufacture, and intended use of the instrument. Agilent Technologies assumes no liability

for the customer’s failure to comply with these precautions.

NOTE The E4991A complies with INSTALLATION CATEGORY II as well as POLLUTION

DEGREE 2 in IEC61010-1. The E4991A is an INDOOR USE product.

NOTE The LEDs in the E4991A are Class 1 in accordance with IEC60825-1,

CLASS 1 LED PRODUCT

• Ground the Instrument

To avoid electric shock, the instrument chassis and cabinet must be grounded with the

supplied power cable’s grounding prong.

• DO NOT Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of inflammable gasses or fumes.

Operation of any electrical instrument in such an environment clearly constitutes a

safety hazard.

• Keep Away from Live Circuits

Operators must not remove instrument covers. Component replacement and internal

adjustments must be made by qualified maintenance personnel. Do not replace

components with the power cable connected. Under certain conditions, dangerous

voltage levels may remain even after the power cable has been disconnected. To avoid

injuries, always disconnect the power and discharge circuits before touching them.

• DO NOT Service or Adjust the Instrument Alone

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation, is present.

• DO NOT Substitute Parts or Modify the Instrument

To avoid the danger of introducing additional hazards, do not install substitute parts or

perform unauthorized modifications to the instrument. Return the instrument to an

Agilent Technologies Sales and Service Office for service and repair to ensure that

safety features are maintained in operational condition.

• Dangerous Procedure Warnings

Warnings, such as the example below, precede potentially dangerous procedures

throughout this manual. Instructions contained in the warnings must be followed.

WARNING Dangerous voltage levels, capable of causing death, are present in this instrument.

Use extreme caution when handling, testing, and adjusting this instrument.

3

Page 14

Safety Symbols

General definitions of safety symbols used on the instrument or in manuals are listed below.

Instruction Manual symbol: the product is marked with this symbol when it is necessary for

the user to refer to the instrument manual.

Alternating current.

Direct current.

On (Supply).

Off (Supply).

In-position of push-button switch.

Out-position of push-button switch.

A chassis terminal; a connection to the instrument’s chassis, which includes all exposed

metal structure.

Stand-by.

WARNING This warning sign denotes a hazard. It calls attention to a procedure, practice, or

condition that, if not correctly performed or adhered to, could result in injury or

death to personnel.

CAUTION This Caution sign denotes a hazard. It calls attention to a procedure, practice, or condition

that, if not correctly performed or adhered to, could result in damage to or destruction of

part or all of the instrument.

NOTE This Note sign denotes important information. It calls attention to a procedure, practice, or

condition that is essential for the user to understand.

Certification

Agilent Technologies certifies that this product met its published specifications at the time

of shipment from the factory. Agilent Technologies further certifies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institution’s calibration facility or by the

calibration facilities of other International Standards Organization members.

4

Page 15

Warranty

This Agilent Technologies instrument product is warranted against defects in material and

workmanship for a period of one year from the date of shipment, except that in the case of

certain components listed in this manual, the warranty shall be for the specified period.

During the warranty period, Agilent Technologies will, at its option, either repair or replace

products that prove to be defective.

For warranty service or repair, this product must be returned to a service facility designated

by Agilent Technologies. Buyer shall prepay shipping charges to Agilent Technologies,

and Agilent Technologies shall pay shipping charges to return the product to Buyer.

However, Buyer shall pay all shipping charges, duties, and taxes for products returned to

Agilent Technologies from another country.

Agilent Technologies warrants that its software and firmware designated by Agilent

Technologies for use with an instrument will execute its programming instruction when

properly installed on that instrument. Agilent Technologies does not warrant that the

operation of the instrument, or software, or firmware will be uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate

maintenance by Buyer, Buyer-supplied software or interfacing, unauthorized modification

or misuse, operation outside the environmental specifications for the product, or improper

site preparation or maintenance.

IMPORTANT No other warranty is expressed or implied. Agilent Technologies specifically disclaims the

implied warranties of merchantability and fitness for a particular purpose.

Exclusive Remedies

The remedies provided herein are Buyer’s sole and exclusive remedies. Agilent

Technologies shall not be liable for any direct, indirect, special, incidental, or

consequential damages, whether based on contract, tort, or any other legal theory.

5

Page 16

Assistance

Product maintenance agreements and other customer assistance agreements are available

for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales and Service Office.

Addresses are provided at the back of this manual.

Typeface Conventions

Sample (bold) Boldface type is used when a term is defined or

emphasis.

Sample (Italic) Italic type is used for emphasis.

key Indicates a hardkey (key on the front panel or

external keyboard) labeled “Sample.” “key” may

be omitted.

Sample menu/button/box Indicates a menu/button/box on the screen labeled

“Sample” which can be selected/executed by

clicking. “menu,” “button,” or “box” may be

omitted.

Sample block/toolbar Indicates a block (group of hardkeys) or a toolbar

(setup toolbar) labeled “Sample.”

Sample 1 - Sample 2 - Sample 3 Indicates a sequential operation of Sample 1,

Sample 2, and Sample 3 (menu, button, or box).

“-” may be omitted.

6

Page 17

Documentation Map

The following manuals are available for the Agilent E4991A.

• Operational Manual (Part Number E4991-900x0, attached to Option ABA)

This manual describes most of the basic information needed to use the E4991A. It

provides a function overview, detailed operation procedure for each function (from

preparation for measurement to analysis of measurement results), measurement

examples, specifications, and supplemental information. For programming guidance on

performing automatic measurement with the E4991A, please see the Programming

Manual.

• Installation and Quick Start Guide (Part Number E4991-900x1, attached to Option

ABA)

This manual describes installation of the instrument after it is delivered and the basic

procedures for applications and analysis. Refer to this manual when you use the

E4991A for the first time.

• Programming Manual (Part Number E4991-900x2, attached to Option ABA)

This manual provides programming information for performing automatic

measurement with the E4991A. It includes an outline of remote control, procedures for

detecting measurement start (trigger) and end (sweep end), application programming

examples, a command reference, and related information.

NOTE The number position shown by “x” in the part numbers above indicates the edition number.

This convention is applied to each manual, CD-ROM (for manuals), and sample programs

disk issued. Here, “0” indicates the initial edition, and each time a revision is made this

number is incremented by 1. The latest edition allows the customer to specify Option ABJ

(Japanese) or Option ABA (English) of the product.

MicrosoftÒ, MS-DOSÒ, WindowsÒ, and Visual BasicÒ for Applications are registered

trademarks of Microsoft Corporation in U.S. and other countries.

7

Page 18

8

Page 19

1. How to Use This Operation Manual

Relationship of Operation Manual Contents to Using the E4991A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2. Function Overview

Names and Functions of Front Panel Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1. Standby switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2. 3.5-inch built-in floppy disk drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3. Color LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4. Measurement block (MEASUREMENT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5. Stimulus block (STIMULUS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6. Entry/navigation block (ENTRY/NAVIGATION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7. System block (SYSTEM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8. Utility key ( key) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9. Test head interface (TEST HEAD INTERFACE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Names and Functions of Rear Panel Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1. Power cable receptacle (-LINE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2. Unused ports (Reserved). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3. External trigger input connector (Ext Trig). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4. External monitor output terminal (VIDEO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5. LAN port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6. GPIB connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7. High stability frequency reference output connector (Ref Oven, Option 1D5 only) . . . . . . . . . . . . . . 29

8. External reference signal input terminal (Ext Ref In, 10 MHz 0 dBm) . . . . . . . . . . . . . . . . . . . . . . . . 30

9. Internal reference signal output connector (Int Ref Out) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10. Printer parallel port (PRINTER, Parallel). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

11. Mini-DIN mouse port (MOUSE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

12. Mini-Din keyboard port (KYBD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

13. Serial number plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

14. Unused ports (Reserved). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Names and Functions of LCD Display Areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1. Title bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2. Menu bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3. Marker values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4. Setup toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5. Trace 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6. Trace 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7. Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8. Scale reference line value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9. Trace 1 axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10. Sweep start value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11. Sweep stop value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

12. Trace 2 axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

13. Status bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Contents

3. Setting Measurement Conditions

Initialization of E4991A (presetting) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Setting Material Measurement Parameter (Option 002 only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9

Page 20

Contents

Selection and Confirmation of Target Trace (Active Trace) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Selecting Active Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Identifying Active Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Selecting Sweep Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Using Time as Sweep Parameter (Zero Span Sweep) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Selecting Sweep Type (Linear/Log/Segment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Selecting Sweep Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Measurement Waiting Time/Sweep Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Setting Sweep Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Setting Sweep Area with Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Setting Number of Points (NOP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Oscillator Level Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Definition of Oscillator Level Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Setting and Applying dc Bias. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Setting the Trigger Source To Start Sweep. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Selecting Trigger Target (Trigger Event) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Single Sweep, Continuous Sweep and Sweep Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Selecting Polarity of External Trigger Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

CW Frequency Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Sweeping a Plural Number of Sweep Areas under Different Conditions at One Time (Segment Sweep) . 66

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Averaging Measurement Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Averaging Plural Sweeps (Sweep-to-Sweep Averaging) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Averaging by Each Measurement Point (Point Averaging) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4. Calibration and Compensation

Outline of Calibration and Compensation Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Types of Calibration and Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Calibration Reference Plane and Calibration Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Calibration/Compensation measurement point mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Calibration and Compensation Using 7-mm Test Port as a Calibration Reference Plane . . . . . . . . . . . . . . 81

Calibration using DUT Connecting Terminal as a Calibration Reference Plane . . . . . . . . . . . . . . . . . . . . . 83

Calibration of Open/Short/Load/Low-loss Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Port Extension Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10

Page 21

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Electrical Length Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Fixture Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Measuring Fixture Compensation Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Switching Fixture Compensation On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Definition of Calibration/Compensation Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Definition of Calibration Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Definition of Calibration Kit in Permittivity Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Definition of Compensation Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Restoring Calibration/Compensation Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5. Display Setting

Setting the Types and Numbers of Display Traces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Maximize a Display Window on the Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Selecting Measurement Parameter (Impedance Measurement) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Setting Measurement Parameter (Material Measurement). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Selecting Graph Coordinate Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Autoscale Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Autoscale Adjustment for each Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Autoscale Adjustment for all Traces at Once . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Manual Scale Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Scale Setting in Rectangular Coordinates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Scale Setting on Complex Plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Scale Setting in Polar Coordinate Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Setting of Reference Line Value by Using Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Zooming a Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Overlay Display and Split Display of Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Displaying Measurement Values in List Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Trace Comparison Using Memory Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Comparison with a stored reference trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Subtraction of Offset Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Offset Value Setting by Using the Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Selecting Sweep Area Display (Start/Stop or Center/Span) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Setting Frequency Display Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Confirm the Setting Status on the Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Continuous Phase Display Without Returning at ±180°. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Contents

11

Page 22

Contents

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Selecting Phase Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Displaying Trace Title on Measurement Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Changing Display Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

6. Analysis of Measurement Results

Reading Value on the Trace by Specifying Stimulus Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Displaying the Values of Plural Points on a Trace in a Value List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Reading Difference from Reference Point on a Graph (Delta Marker) . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Delta Marker Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Reading Only the Actual Measurement Point/Reading the Distance between Measurement Points through

Interpolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Move the Marker for Each Trace Independently . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Selecting Marker Value Display for Plural Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Selecting Marker Analysis Target Trace (Data/Memory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Search for Max. and Min. Measurement Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Search for Target Point of Measurement Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Peak Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Maximal Point and Minimal Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Positive Peak and Negative Peak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Outline of Peak Search Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Define the Peaks Using Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Working Out Trace Average, Standard Deviation, and Peak to Peak. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Specify the Partial Search Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Execution of Automatic Search in Each Sweep (Search Tracking) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Changing Marker Stimulus Value Display to Time/Relaxation Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Calculation of Equivalent Circuit Parameter and Simulation of Frequency Characteristics . . . . . . . . . . . 157

Calculation of Equivalent Circuit Parameter based on Measurement Results . . . . . . . . . . . . . . . . . . . . 157

Frequency Characteristics Simulation based on Equivalent Circuit Parameters . . . . . . . . . . . . . . . . . . 158

Setting a Limit to the Trace and Making a Pass/Fail Determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

12

Page 23

7. Saving and Recalling Internal Data

Overview of Save and Recall Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Saving and Recalling Setting States (Save State) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

To save setting states: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

To recall setting states: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Saving and Recalling Measurement Data in Binary Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

To save measurement data in binary format:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

To recall measurement data: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Saving Measurement Data to Read in Spreadsheet Software (Saving in ASCII Format) . . . . . . . . . . . . . 175

To save measurement data in ASCII format: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

To import measurement data saved in ASCII format into Microsoft ExcelÔ:. . . . . . . . . . . . . . . . . . . . 177

Saving Measurement Data in CITIfile Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Overview of CITIfile Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

How to Create a CITIfile on the E4991A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

CITIfile Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

To create a CITIfile: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Saving Display Information (Save Graphics). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

To save display information:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Recalling Saved Image File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Contents

8. Printing Measurement Results and Internal Data

Printing Measurement Graphs and Internal Data Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Supported Printers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

How to print data on the screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Installing Printer Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

How to install a printer driver: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

9. Setup and Use of Control/Management Functions

Setup and Confirmation of GPIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Operation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Setting the Built-in Speaker (beep sound) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Procedure for turning the beeping sound on or off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Setting the Internal Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Procedure for setting the internal clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Setting the Mouse Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Setting procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Confirmation of Options and Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Operation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

System Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Notes on executing system recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Procedure to execute system recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

10. Using LAN

LAN Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Setup procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

File Transfer Using FTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

FTP file transfer using MS-DOSÔ prompt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

FTP file transfer using FTP application software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

13

Page 24

Contents

Stop/Abortion of process/Cut off from server by E4991A operation. . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Using Remote User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Outline of Remote User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Installation of E4991A user interface software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Procedure to uninstall E4991A user interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Starting up the E4991A user interface and connecting to the E4991A measurement server. . . . . . . . . 222

Disconnection of E4991A measurement server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Closing the E4991A user interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Copying measurement plot and internal data to other application software. . . . . . . . . . . . . . . . . . . . . . 225

11. Specifications and Supplemental Information

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Measurement Parameters and Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Measurement Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Measurement Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Source Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Oscillator Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Output Impedance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

DC Bias (Option 001). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

DC Voltage Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

DC Current Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

DC Bias Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Probe Station Connection Kit (Option 010) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Oscillator Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Sweep Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Sweep Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Segment Sweep. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Conditions for Defining Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Accuracy When Open/Short/Load Calibration is Performed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Accuracy When Open/Short/Load/Low-Loss Capacitor Calibration is Performed (point averaging factor ³

8, typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Definition of Each Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Calculated Impedance Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Measurement Support Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Error Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Trigger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Marker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Equivalent Circuit Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Limit Marker Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Mass Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Measurement Terminal (at Test Head) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Rear Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

General Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Environment Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

14

Page 25

Contents

Other Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Option 002 Material Measurement (typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Measurement Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Frequency Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Measurement Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Examples of Calculated Permittivity Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Examples of Calculated Permeability Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Option 007 Temperature Characteristic Test Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Operation Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Source Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Measurement Accuracy (at 23°C ± 5°C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Typical Effects of Temperature Change on Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Typical Material Measurement Accuracy When Using Option 002 and 007. . . . . . . . . . . . . . . . . . . . . . . 274

Measurement Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Typical Effects of Temperature Change on Permittivity Measurement Accuracy . . . . . . . . . . . . . . . . . 287

A. Manual Changes

Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Change 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

B. Probe Station Connection Kit (Option 010)

Option 010 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Recommended Probe Stations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Recommended Probe Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Mounting Test Head and Connecting Cables

(using recommended probe station) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Mounting Test Head and Connecting Cables

(using probe stations other than recommended models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

OPEN/SHORT/LOAD Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Selecting Fixture Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Definition of Calibration Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Calibration/Compensation Measurement Point Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Calibration of Open/Short/Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

C. Temperature Characteristic Test Kit (Option 007)

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Cautions for protecting cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

Calibration/compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Temperature compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Execution procedure of temperature compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Information to create program to execute temperature compensation . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Acquiring temperature compensation data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Measuring temperature characteristic using sample program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Measuring temperature characteristic using Tctest.Start macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Temperature compensation for measurement result using Compensation.Start macro . . . . . . . . . . . . . 347

Modifying attached sample program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

15

Page 26

Contents

Changing limits when setting temperature change pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Changing GPIB address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Modifying other temperature chambers than recommended . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Recovery of the sample program furnished the option 007 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

D. Menu References

Menu References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

Trace Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

Meas/Format Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Scale Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Marker Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Stimulus Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Trigger Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

Utility Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

Save/Recall Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 396

E. Theory on Material Measurement

Dielectric Material Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Definition of Permittivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Measurement Principle of Dielectric Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

Error Components of 16453A Test Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

Magnetic Material Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406

Definition of Permeability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406

Measurement Principle of Magnetic Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

Structure of 16454A Test Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 410

F. Information on Maintenance

Cleaning this Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

Cleaning an LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

Maintenance of Connectors/Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

Cleaning a Display Other than an LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

Cautions Applicable to Requesting Repair, Replacement, Regular Calibration, etc. . . . . . . . . . . . . . . . . 415

Devices to be Sent Back for Repair or Regular Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 415

Recommended Calibration Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 415

G. Initial Settings

Initial Settings, Settings that can be Saved/Recalled, Settings that can be Backed Up . . . . . . . . . . . . . . . 418

H. Comparison Information of 4291B and E4991A

Major Differences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

Channels and Traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

Calibration/Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

Marker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

Limit test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

Function Comparison List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 432

16

Page 27

I. Messages

Alphabetical Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440

A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440

C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 442

E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 442

F. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 445

N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 445

O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

P. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450

U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 451

Messages indicating the internal status of the equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

Messages indicating measurement failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

Messages indicating the results (or current status) of processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Contents

17

Page 28

Contents

18

Page 29

Operation Manual

1. How to Use This

1 How to Use This Operation Manual

This chapter explains how to most efficiently use this Operation Manual.

19

Page 30

How to Use This Operation Manual

Relationship of Operation Manual Contents to Using the E4991A

Relationship of Operation Manual Contents to Using the E4991A

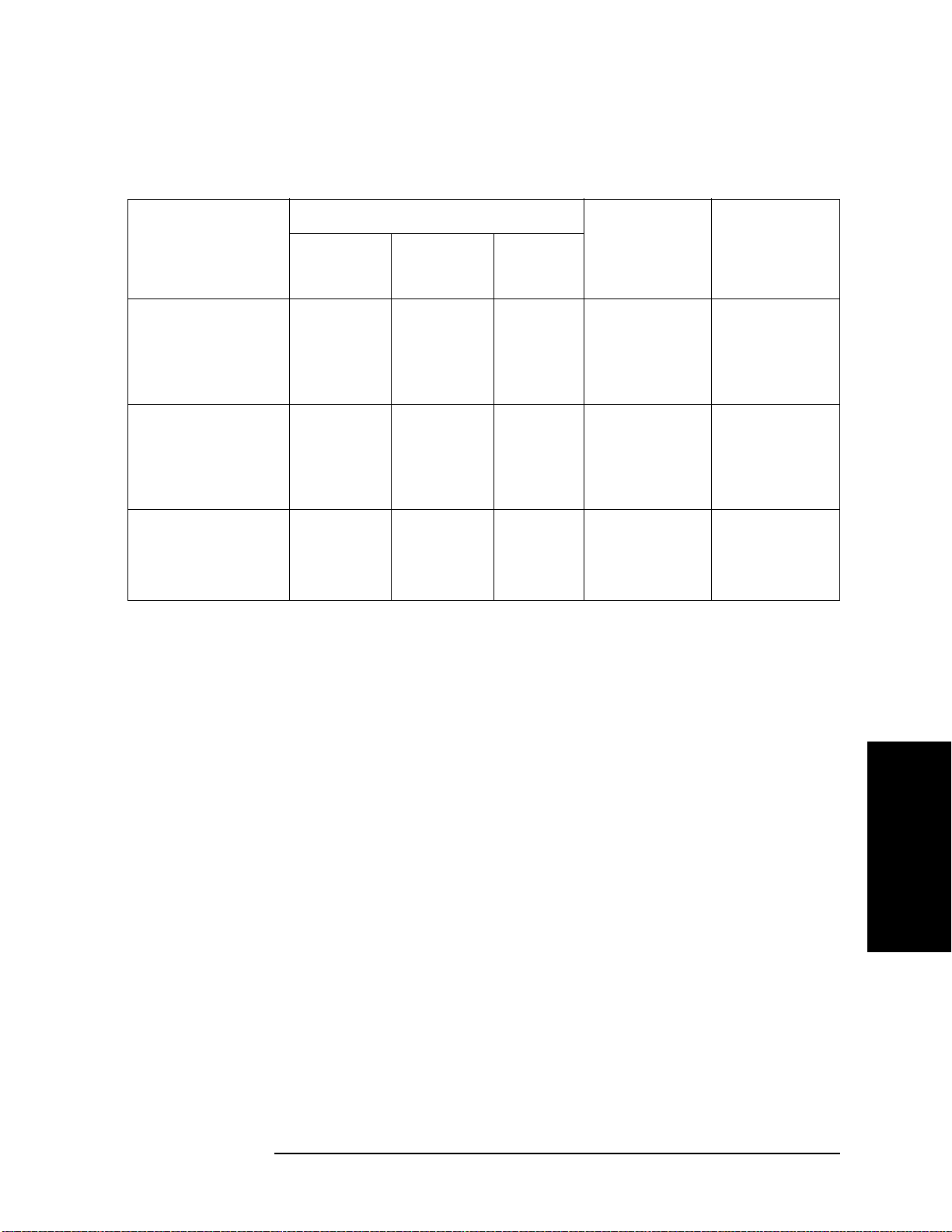

The chapters of this Operation Manual cover the usage of this product from when it is

delivered until when the user has obtained sufficient understanding of the instrument’s

functions to use it efficiently. Table 1-1 lists the product’s operations along with the

corresponding manuals and chapters.

Table 1-1 Operations of E4991A and Corresponding Manuals/Chapters

Operation Corresponding

Manual

1. Installation Installation and Quick

Start Guide

2. Understanding functions and measurement flow

3. Performing measurements (manual operation)

Installation and Quick Start Guide

Operation Manual

(this book)

Operation Manual

(this book)

Corresponding Chapter

Chapter 2, “Installation Guide”

Chapter 3, “Basic Operations for RF Devices

Measurement”

Chapter 4, “Basic Operations for Dielectric

Measurement”

Chapter 5, “Basic Operations for Magnetic

Measurement”

Chapter 2, “Function Overview,” on page 21

Chapter 3, “Setting Measurement Conditions,” on

page 41

Chapter 4, “Calibration and Compensation,” on

page 75

Chapter 5, “Display Setting,” on page 95

Appendix B, “Probe Station Connection Kit (Option

010),” on page 299

Appendix C, “Temperature Characteristic Test Kit

(Option 007),” on page 311

4. Analyzing and handling measurement data (manual operation)

5. Using control and management facilities (manual operation)

6. Development of automatic measurement system

20 Chapter 1

Operation Manual

(this book)

Operation Manual

(this book)

Programming Manual All chapters

Chapter 6, “Analysis of Measurement Results,” on

page 127

Chapter 7, “Saving and Recalling Internal Data,” on

page 165

Chapter 8, “Printing Measurement Results and

Internal Data,” on page 185

Chapter 9, “Setup and Use of Control/Management

Functions,” on page 193

Chapter 10, “Using LAN,” on page 207

Page 31

2. Function Overview

2 Function Overview

This chapter describes the functions of the Agilent E4991A Impedance/Material Analyzer

available to the user from the front panel, rear panel, and LCD display blocks.

21

Page 32

Function Overview

Names and Functions of Front Panel Blocks

Names and Functions of Front Panel Blocks

The names and functions of the E4991A front panel blocks are shown below.

Figure 2-1 E4991A front panel

2. 3.5" built-in floppy disk drive

3. Color LCD display

4. Measurement block

5. Stimulus block

6. Entry/navigation block

1. Standby switch

22 Chapter 2

7. System block

8. Utility

9. Test head interface

Page 33

Function Overview

Names and Functions of Front Panel Blocks

1. Standby switch

Used to turn on/off the power to the E4991A.

NOTE To turn off the power to the E4991A, be sure to press this power supply switch.

Alternatively, activate the E4991A shutdown process (i.e., software and hardware process

required to turn off the power) by sending a shutdown command from the external

controller. You must never directly shut off the power supply by removing the power

cable from the receptacle on the rear panel.

If the power supply is directly shut off by removing the power cable, the shutdown process

is not activated, and this may damage the E4991A software and hardware, resulting in

operational failures.

If the E4991A shutdown process is not properly executed, the E4991A may restart in

safe mode. If this happens, activate the shutdown process to turn off the power to the

E4991A and then press the standby switch to turn the power on again.

For turning on/off the power, also refer to Chapter 1, “Installation Guide” in the

Installation and Quick Start Guide.

2. Function Overview

2. 3.5-inch built-in floppy disk drive

This device is used to save the E4991A settings, measured data, calibration/compensation

data, image data displayed on the LCD display, VBA (Visual Basic for Applications)

programs, and other data to a floppy disk or to recall them. It works with 3.5-inch 1.44 MB

DOS formatted floppy disks.

The floppy disk access lamp is located to the left of the disk slot. It lights up in green when

the floppy disk drive accesses the disk by either read or write operation.

The disk eject button is located to the right of the disk slot. By pressing it, the currently

inserted disk can be ejected.

NOTE Insert the floppy disk into the slot in the direction of the arrow denoted on the disk, with

the labeled side facing the LCD display.

Do not press the disk eject button while the floppy disk access lamp is lit. If you

attempt to forcibly eject the disk, the disk or drive may be destroyed.

3. Color LCD display

This displays all of the information required to operate the E4991A (e.g., measurement

trace, settings, menu and setup bars). It is an 8.4-inch TFT type display.

For details on the information displayed on the LCD display, see “Names and Functions of

LCD Display Areas” on page 32.

4. Measurement block (MEASUREMENT)

This contains a set of keys that are used to set the basic measurement conditions, except for

the test signal settings. Pressing one of these keys brings up the associated toolbar to the

right of the display.

Chapter 2 23

Page 34

Function Overview

Names and Functions of Front Panel Blocks

key

key

key

key

key

Used to select the desired trace to set (i.e., active trace).

Each time you press this key, one of the active traces on the

display is selected in order. When setting the measurement

conditions, you must first use this key to select the active

trace.

Used to show the Meas/Format toolbar at the right of the

display. By working with this toolbar, you can select

measurement parameters, set the vertical-axis form (linear

or log) of a measurement graph, and perform other related

tasks.

Used to show the Scale toolbar at the right of the display.

By working with this toolbar, you can set the scale of a