Page 1

EMI Measurement Receiver Guide

PSA Series Spectrum Analyzers

Option 239

This manual provides documentation for the following instruments:

Spectrum Analyzers:

E4440A (3 Hz – 26.5 GHz)

E4443A (3 Hz – 6.7 GHz)

E4445A (3 Hz – 13.2 GHz)

E4446A (3 Hz – 44.0 GHz)

E4447A (3 Hz – 42.98GHz)

E4448A (3 Hz – 50.0 GHz)

Systems:

EMI Receiver System

Manufacturing Part Number: E4440-90625

Supersedes E4440-90330

Printed in USA

June 2008

© Copyright 2007, 2008 Agilent Technologies, Inc.

Page 2

The information contained in this document is subject to change

without notice.

Agilent Technologies makes no warranty of any kind with regard to this

material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Agilent

Technologies shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing,

performance, or use of this material.

2

Page 3

Contents

1. Introduction

What Does the EMI Receiver Do? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installing Optional Measurement Personalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Do You Have Enough Memory to Load All Your Personality Options? . . . . . . . . . . . . . . . . 11

How to Predict Your Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Loading an Optional Measurement Personality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Obtaining and Installing a License Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Viewing a License Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Using the Delete License Key on PSA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ordering Optional Measurement Personalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2. Making Measurements

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Instrument Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Test Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Configuring the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Aligning the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Using Instrument Presets Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Making Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Emissions Measurements With an RF Preselector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

File Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Saving a Setup file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Loading a Setup file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Loading a Limit file from the floppy disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Loading a Corrections file from the floppy disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Interpreting Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table of Contents

3. Front-Panel Key and SCPI Command Reference

Instrument Front Panel Highlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Selected and PSA Front-Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Front-Panel Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Center Frequency, Span for lower window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Input/ Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Marker Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Meas Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Mode Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

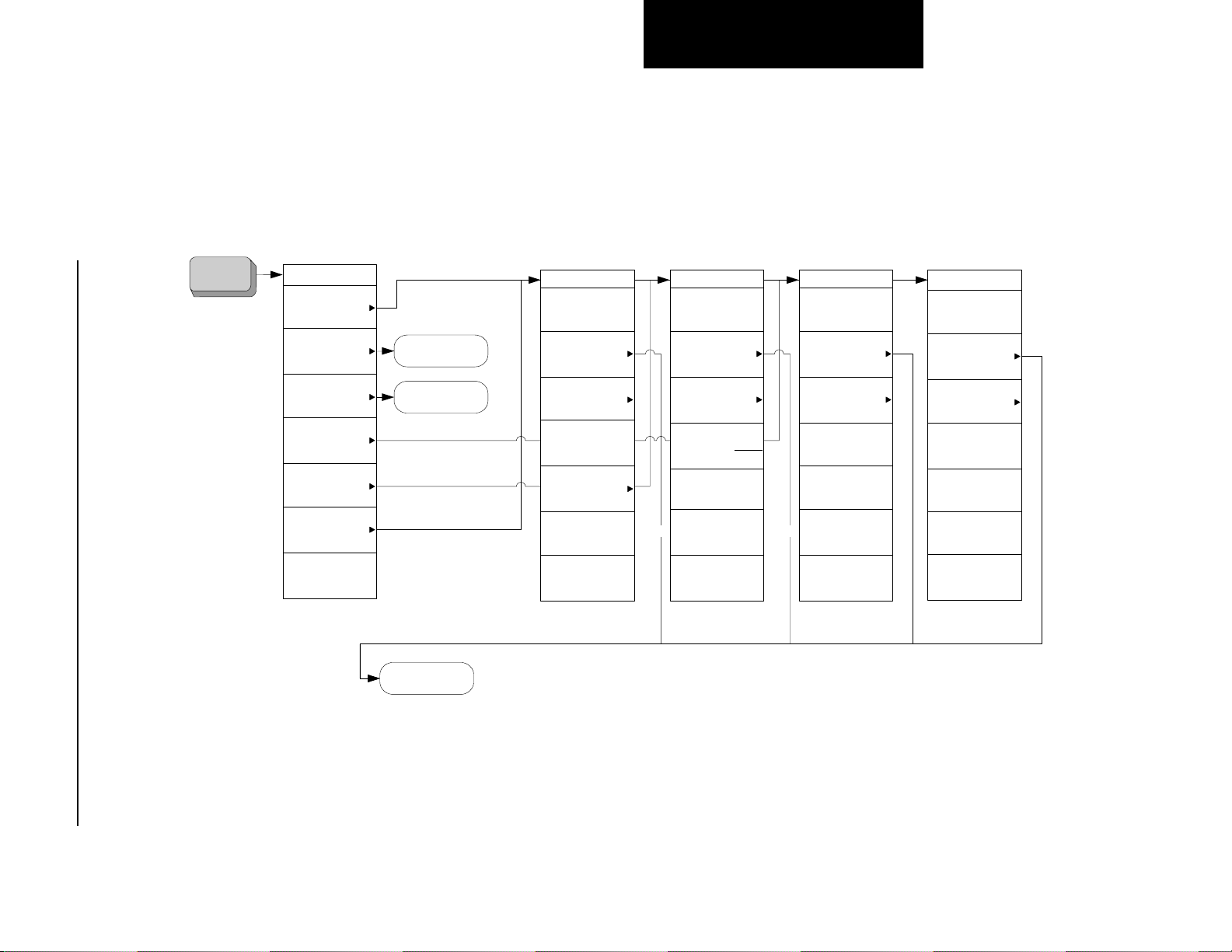

Command Interactions: MEASure, CONFigure, FETCh, INITiate and READ . . . . . . . . . 71

Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Measurement Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Emissions Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4. Menu Maps

EMI Measurement Key Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3

Page 4

Contents

Table of Contents

A. Disk Contents: Limit Lines and Transducer Factors

Directions for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Limit Line Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Transducer Factors Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

4

Page 5

List of Commands

:CALibration:PRESelector:EXTernal:AB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

:CALibration:PRESelector:EXTernal:AB[:STATe]?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

:CALibration:PRESelector:EXTernal:ALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

:CALibration:PRESelector:EXTernal:ALL[:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

:CALibration:PRESelector:EXTernal:CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

:CALibration:PRESelector:EXTernal:CD[:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

:CALibration:PRESelector:EXTernal:DEFault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

:CONFigure:EMI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

:FETCh:EMI[n]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

:INITiate:CONTinuous OFF|ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

List of Commands

:INITiate:EMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

:INITiate:PAUSe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

:INITiate:RESTart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

:INITiate:RESume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

:INPut:PRESelector[:EXTernal] RF|SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

:INPut:PRESelector[:EXTernal]:PATH FILTer|BYPass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

:INPut:PRESelector[:EXTernal]:PATH? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

:INPut:PRESelector[:EXTernal]?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

:INSTrument:NSELect 239 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

:INSTrument:NSELect? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

:INSTrument[:SELect] SA|EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

:INSTrument[:SELect]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

:MEASure:EMI:MARKer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

:MEASure:EMI:MARKer[1]|2|3|4? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

:MEASure:EMI[n]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

:MMEMory:LOAD:SETup <‘file_name’> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

:MMEMory:STORe:SETup <‘file_name’> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

:READ:EMI[n]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

:SYSTem:COMMunicate:ESOurce:CONNection LAN|LG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

:SYSTem:COMMunicate:ESOurce:CONNection? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

:SYSTem:COMMunicate:ESOurce:TCONnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5

Page 6

List of Commands

:SYSTem:COMMunicate:ESOurce:TCONnect:TOUT <time> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

:SYSTem:COMMunicate:ESOurce:TCONnect:TOUT? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

:SYSTem:COMMunicate:ESOurce:TCONnect? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

:SYSTem:COMMunicate:ESOurce:TYPE

B8648|MXG|N5181A|N5182A|ESG|E4438C|PSG|E8257D . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

:SYSTem:COMMunicate:ESOurce:TYPE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

:SYSTem:COMMunicate:ESOure:IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

:SYSTem:COMMunicate:GPIB:ESOurce[:EXTernal]:ADDRess <integer> . . . . . . . . . . . . . . . . . . . .66

:SYSTem:COMMunicate:GPIB:ESOurce[:EXTernal]:ADDRess? . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

:SYSTem:COMMunicate:GPIB:ESOurce[:EXTernal]:LUNit <integer> . . . . . . . . . . . . . . . . . . . . . . .67

List of Commands

:SYSTem:COMMunicate:GPIB:ESOurce[:EXTernal]:LUNit? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

:SYSTem:COMMunicate:LAN:ESOurce[:EXTernal]:IP <string> . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

:SYSTem:COMMunicate:LAN:ESOurce[:EXTernal]:IP? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

:SYSTem:COMMunicate:LAN:PRESelector[:EXTernal]:IP <string> . . . . . . . . . . . . . . . . . . . . . . . . .63

:SYSTem:COMMunicate:LAN:PRESelector[:EXTernal]:IP? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

:SYSTem:COMMunicate:PRESelector:IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

:SYSTem:COMMunicate:PRESelector:TCONnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

:SYSTem:COMMunicate:PRESelector:TCONnect:TOUT <time>. . . . . . . . . . . . . . . . . . . . . . . . . . . .64

:SYSTem:COMMunicate:PRESelector:TCONnect:TOUT? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

:SYSTem:COMMunicate:PRESelector:TCONnect? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

[:SENSe]:EMI:FREQuency:SPAN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

[:SENSe]:EMI:FREQuency:SPAN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

[:SENSe]:EMI:FREQuency[:CENTer]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

[:SENSe]:EMI:FREQuency[:CENTer]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

[:SENSe]:EMI:MEASure:DETector:AVERage[:STATe] OFF|ON|0|1 . . . . . . . . . . . . . . . . . . . . . . . .75

[:SENSe]:EMI:MEASure:DETector:DWELl <time> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

[:SENSe]:EMI:MEASure:DETector:DWELl? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

[:SENSe]:EMI:MEASure:DETector:QPEak[:STATe] OFF|ON|0|1|. . . . . . . . . . . . . . . . . . . . . . . . .75

[:SENSe]:FREQuency:PRESelector[:EXTernal]:PBANd A|B|C|D|CD|E|UPPer . . . . . . . . . . . . .61

[:SENSe]:FREQuency:PRESelector[:EXTernal]:PBANd? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

[:SENSe]:POWer[:RF]:PRESelector[:EXTernal]:ATTenuation <numeric value> . . . . . . . . . . . . . . . .62

6

Page 7

List of Commands

[:SENSe]:POWer[:RF]:PRESelector[:EXTernal]:ATTenuation? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

[:SENSe]:POWer[:RF]:PRESelector[:EXTernal]:GAIN[:STATe] ON|OFF|0|1 . . . . . . . . . . . . . . . . 63

[:SENSe]:POWer[:RF]:PRESelector[:EXTernal]:GAIN[:STATe]?. . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

[:SENSe]:POWer[:RF]:PRESelector[:EXTernal]:USE YES|NO . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

[:SENSe]:POWer[:RF]:PRESelector[:EXTernal]:USE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

List of Commands

7

Page 8

List of Commands

List of Commands

8

Page 9

1 Introduction

This chapter provides overall information on the Agilent PSA Series

EMI Receiver Option 239, and describes the EMI compliance

measurements made by the analyzer plus an RF Preselector.

Installation instructions for adding this option to your analyzer are

provided in this section, if you purchased this option separately.

Introduction

9

Page 10

Introduction

What Does the EMI Receiver Do?

What Does the EMI Receiver Do?

The EMI Receiver system consists of an Agilent PSA Series Spectrum

Analyzer, an Agilent RF Preselector, an Agilent Signal Generator for

user alignment, and optional accessories needed to prepare the system

for use. Option 239 is an embedded application in the PSA.

The PSA is used as an EMI receiver, controlling the external RF

Preselector, to perform CISPR compliance EMI measurements to test

conducted and radiated emissions.

Conducted emissions testing focuses on signals, present on the AC

mains, that are generated by the equipment under test (EUT). The test

range for these measurements is typically from 9 kHz to 30 MHz.

Radiated emissions testing looks for signals broadcasted from the EUT

through space. The test range for these measurements is typically from

30 MHz to 1 GHz, depending on the regulation.

You can also perform EMI pre-compliance measurements if you do not

have an RF Preselector. PSA EMI measurement keys are not fully

functional without the RF Preselector.

Figure 1-1 EMI Receiver System

Introduction

10 Chapter 1

Page 11

Introduction

Installing Optional Measurement Personalities

Installing Optional Measurement

Personalities

When you install a measurement personality, you need to follow a three

step process:

1. Determine whether your memory capacity is sufficient to contain all

the options you want to load. If not, decide which options you want to

install now, and consider upgrading your memory. Details follow in

“Do You Have Enough Memory to Load All Your Personality

Options?” on page 11.

2. Install the measurement personality firmware into the instrument

memory. Details follow in “Loading an Optional Measurement

Personality” on page 15.

3. Enter a license key that activates the measurement personality.

Details follow in “Obtaining and Installing a License Key” on page

15.

Adding measurement personalities requires the purchase of an upgrade

kit for the desired option. The upgrade kit contains the measurement

personality firmware and an entitlement certificate that is used to

generate a license key from the internet website. A separate license key

is required for each option on a specific instrument serial number and

host ID.

For the latest information on Agilent Spectrum Analyzer options and

upgrade kits, visit the following web location:

http://www.agilent.com/find/sa_upgrades

Do You Have Enough Memory to Load All Your Personality Options?

If you do not have memory limitations then you can skip ahead to the

next section “Loading an Optional Measurement Personality” on

page 15. If after installing your options you get error messages relating

to memory issues, you can return to this section to learn more about

how to optimize your configuration.

If you have 64 MBytes of memory installed in your instrument, you

should have enough memory to install at least four optional

personalities, with plenty of memory for data and states.

Introduction

The optional measurement personalities require different amounts of

memory. So the number of personalities that you can load varies. This is

also impacted by how much data you need to save. If you are having

memory errors you must swap the applications in or out of memory as

needed. If you only have 48 MBytes of memory, you can upgrade your

Chapter 1 11

Page 12

Introduction

Installing Optional Measurement Personalities

hardware to 64 MBytes.

Additional memory can be added to any PSA Series analyzer by

installing Option 115. With this option installed, you can install all

currently available measurement personalities in your analyzer and

still have memory space to store more state and trace files than would

otherwise be possible.

To see the size of your installed memory for PSA Series Spectrum

Analyzers:

1. Ensure that the spectrum analyzer is in spectrum analyzer mode

because this can affect the screen size.

2. Press

3. Press

System, Show System. Under Options look for 115.

System, More, Show Hdwr.

4. Read Flash Memory size in the table.

PSA Flash

Memory Size

64 Mbytes 32.5 MBytes 30.0 MBytes

48 Mbytes 16.9 MBytes 14.3 MBytes

PSA Compact Flash

Memory Size

512 Mbytes (Opt. 115) 512 MBytes

Available Memory

Without Option

B7J and Option

122 or 140

Available Additional Memory for

Measurement Personalities

Available Memory With

Option B7J and Option 122 or

140

If you have 48 MBytes of memory, and you want to install more than 3

Introduction

optional personalities, you may need to manage your memory

resources. The following section, “How to Predict Your Memory

Requirements” on page 13, will help you decide how to configure your

installed options to provide optimal operation.

12 Chapter 1

Page 13

Introduction

Installing Optional Measurement Personalities

How to Predict Your Memory Requirements

If you plan to install many optional personalities, you should review

your memory requirements, so you can determine whether you have

enough memory (unless you have a PSA Series with Option 115). There

is an Agilent “Memory Calculator” available online that can help you do

this, or you can make a calculated approximation using the information

that follows. You will need to know your instrument’s installed memory

size as determined in the previous section and then select your desired

applications.

NOTE If you have a PSA Series analyzer with Option 115, there is adequate

memory to install all of the available optional personalities in your

instrument.

To calculate the available memory on your PSA, see:

http://sa.tm.agilent.com/PSA/memory/

Select the “Memory Calculator” link. You can try any combination of

available personalities to see if your desired configuration is compatible

with your installed memory.

NOTE For PSA: After loading all your optional measurement personalities,

you should have a reserve of ~2 MBytes memory to facilitate mode

switching. Less available memory will increase mode switching time.

For example, if you employ excessive free memory by saving files of

states and/or data, your mode switching time can increase to more than

a minute.

You can manually estimate your total memory requirements by adding

up the memory allocations described in the following steps. Compare

the desired total with the available memory that you identified in the

previous section.

1. Program memory - Select option requirements from the table

“Measurement Personality Options and Memory Required” on

page 14.

2. The PSA shared libraries require 7.72 MBytes.

3. The PSA recommended mode swap space is 2 MBytes.

4. Screens - .gif files need 20-25 kBytes each.

5. State memory - State file sizes range from 21 kB for SA mode to

40 kB for W-CDMA. The state of every mode accessed since power-on

will be saved in the state file. File sizes can exceed 150 kB each when

several modes are accessed, for each state file saved.

Introduction

TIP State memory retains settings for all states accessed before the Save

State

command. To reduce this usage to a minimum, reduce the modes

Chapter 1 13

Page 14

Introduction

Installing Optional Measurement Personalities

accessed before the Save State is executed. You can set the PSA to boot

into a selected mode by accessing the desired mode, then pressing the

System, Power On/Preset, Power On keys and toggle the setting to Last.

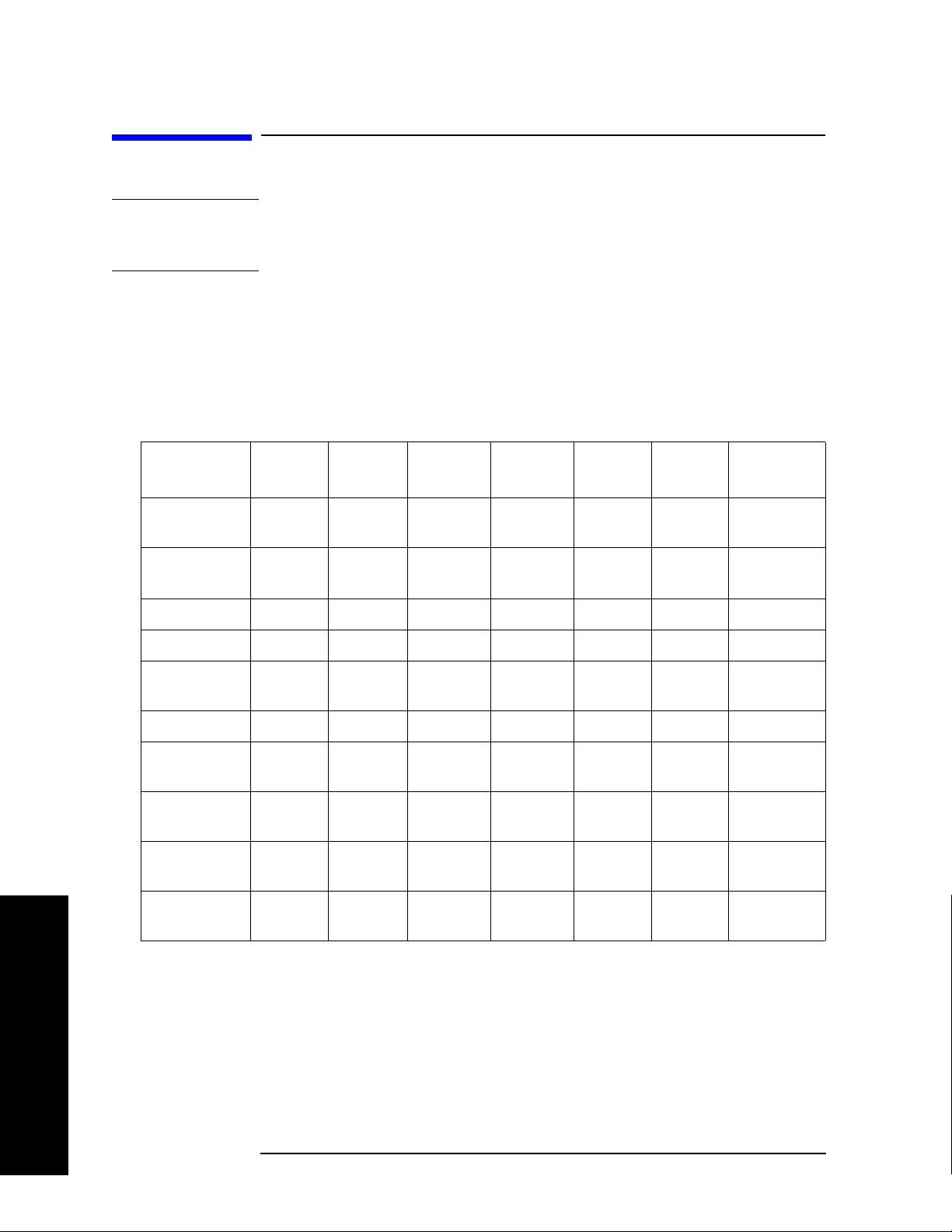

Measurement Personality Options and Memory Required

Personality Options

for PSA Series Spectrum Analyzers

a

Option File Size

(PSA Rev: A.10)

cdmaOne measurement personality BAC 1.91 Mbytes

NADC and PDC measurement personalities (not

BAE 2.43 Mbytes

available separately)

W-CDMA or W-CDMA, HSDPA, HSUPA

BAF, 210

5.38 Mbytes

measurement personality

cdma2000 or cdma2000 w/ 1xEV-DV measurement

personality

1xEV-DO measurement personality 204

GSM (with EDGE) measurement personality 202

Shared measurement library

b

Phase Noise measurement personality 226

Noise Figure measurement personality 219

Basic measurement personality with digital demod

hardware

Programming Code Compatibility Suited (8560

B78, 214

4.00 Mbytes

5.61 Mbytes

3.56 Mbytes

n/a 7.72 Mbytes

2.82 Mbytes

4.68 Mbytes

B7J Cannot be deleted

(2.64 Mbytes)

266

1.18 Mbytes

Series, 8590 Series, and 8566/8568)

b

b

b

b

c

c

c

TD-SCDMA Power measurement personality 211

Introduction

TD-SCDMA Modulation Analysis or TD-SCDMA

212, 213 1.82 Mbytes

5.47 Mbytes

c

Modulation Analysis w/ HSPA measurement

personality

Flexible Digital Modulation Analysis 241

WLAN measurement personality 217

External Source Control 215

Measuring Receiver Personality

233

2.11 Mbytes

3.24 Mbytes

0.72 Mbytes

2.91 Mbytes

b

b

c

b

(available with Option 23A - Trigger support for

AM/FM/PM and Option 23B - CCITT filter)

EMC Analyzer

239

4.06 Mbytes

b

a. Available as of the print date of this guide.

14 Chapter 1

Page 15

Introduction

Installing Optional Measurement Personalities

b. Many PSA Series personality options use a 7.72 Mbyte shared measurement library. If

you are loading multiple personalities that use this library, you only need to add this

memory allocation once.

c. Shared measurement library allocation not required.

d. This is a no charge option that does not require a license key.

Memory Upgrade Kits

The PSA 64 MByte Memory Upgrade kit part number is

E4440AU-ANE. The PSA Compact Flash Upgrade kit part number is

E4440AU-115.

For more information about memory upgrade kits contact your local

sales office, service office, or see:

http://www.agilent.com/find/sa_upgrades

Loading an Optional Measurement Personality

You must use a PC to load the desired personality option into the

instrument memory. Loading can be done from a firmware CD-ROM or

by downloading the update program from the internet. An automatic

loading program comes with the files and runs from your PC.

You can check the Agilent internet website for the latest PSA firmware

versions available for downloading:

http://www.agilent.com/find/psa_firmware

NOTE When you add a new option, or update an existing option, you will get

the updated versions of all your current options as they are all reloaded

simultaneously. This process may also require you to update the

instrument core firmware so that it is compatible with the new option.

Depending on your installed hardware memory, you may not be able to

fit all of the available measurement personalities in instrument

memory at the same time. You may need to delete an existing option file

from memory and load the one you want. Use the automatic update

program that is provided with the files. Refer to the table showing

“Measurement Personality Options and Memory Required” on page 14.

The approximate memory requirements for the options are listed in this

table. These numbers are worst case examples. Some options share

components and libraries, therefore the total memory usage of multiple

options may not be exactly equal to the combined total.

Obtaining and Installing a License Key

Introduction

If you purchase an optional personality that requires installation, you

will receive an “Entitlement Certificate” which may be redeemed for a

license key specific to one instrument. Follow the instructions that

accompany the certificate to obtain your license key.

Chapter 1 15

Page 16

Introduction

Installing Optional Measurement Personalities

To install a license key for the selected personality option, use the

following procedure:

NOTE You can also use this procedure to reinstall a license key that has been

deleted during an uninstall process, or lost due to a memory failure.

1. Press

System, More, More, Licensing, Option to accesses the alpha

editor. Use this alpha editor to enter letters (upper-case), and the

front-panel numeric keys to enter numbers for the option

designation. You will validate your option entry in the active

function area of the display. Then, press the

2. Press

License Key to enter the letters and digits of your license key.

Enter key.

You will validate your license key entry in the active function area of

the display. Then, press the

3. Press the

Activate License key.

Enter key.

Viewing a License Key

Measurement personalities purchased with your instrument have been

installed and activated at the factory before shipment. The instrument

requires a License Key unique to every measurement personality

purchased. The license key is a hexadecimal number specific to your

measurement personality, instrument serial number and host ID. It

enables you to install, or reactivate that particular personality.

Use the following procedure to display the license key unique to your

personality option that is already installed in your PSA:

Press

Personality key displays the personalities loaded, version

information, and whether the personality is licensed.

System, More, More, Licensing, Show License. The System,

Introduction

NOTE You will want to keep a copy of your license key in a secure location.

Press

System, More, then Licensing, Show License and print out a copy of

the display that shows the license numbers. If you should lose your

license key, call your nearest Agilent Technologies service or sales office

for assistance.

Using the Delete License Key on PSA

This key will make the option unavailable for use, but will not delete it

from memory. Write down the 12-digit license key for the option before

you delete it. If you want to use that measurement personality later,

you will need the license key to reactivate the personality firmware.

NOTE Using the Delete License key does not remove the personality from the

instrument memory, and does not free memory to be available to install

another option. If you need to free memory to install another option,

16 Chapter 1

Page 17

Introduction

Installing Optional Measurement Personalities

refer to the instructions for loading firmware updates located at the

URL : http://www.agilent.com/find/psa/

1. Press

System, More, More, Licensing, Option. Pressing the Option key

will activate the alpha editor menu. Use the alpha editor to enter the

letters (upper-case) and the front-panel numeric keyboard to enter

the digits (if required) for the option, then press the

Enter key. As you

enter the option, you will see your entry in the active function area of

the display.

2. Press

Delete License to remove the license key from memory.

Ordering Optional Measurement Personalities

When you order a personality option, you will receive an entitlement

certificate. You will need to go to the Web site to redeem your

entitlement certificate for a license key. You will need to provide your

instrument serial number and host ID, and the entitlement certificate

number.

Required Information: Front Panel Key Path:

Model #: (Ex. E4440A)

Host ID:

__________________

System, Show System

Instrument

Serial Number:

__________________

System, Show System

Introduction

Chapter 1 17

Page 18

Introduction

Installing Optional Measurement Personalities

Introduction

18 Chapter 1

Page 19

2 Making Measurements

This chapter describes instructions to help you set up the system,

procedures to perform the measurements of signals, and examples of

measurement results for EMC analysis.

Making Measurements

19

Page 20

Making Measurements

Introduction

Introduction

All the keys and SCPI commands have the same function as those

under

following sections. Refer to PSA User's and Programmer's Reference for

more details.

The following subjects are presented in this chapter:

• “Instrument Requirements” on page 21

• “Test Equipment Setup” on page 22

• “Making Measurements” on page 34

• “File Operation” on page 44

• “Interpreting Error Codes” on page 46

Meas Off in the Spectrum Analysis mode unless stated in the

Making Measurements

20 Chapter 2

Page 21

Making Measurements

Instrument Requirements

Instrument Requirements

The following are required:

• PSA Series Spectrum Analyzer

— PSA Serial Prefix of US4430, MY4430, SG4430, or above

— PSA Firmware A.10.xx or later

— PSA Option 239 EMI Measurement Receiver

• One of the following signal generators

— N5181A MXG

— N5182A MXG

— E4438C ESG

— E8257D PSG

— 8648B (a LAN/GPIB gateway is required, or you can order Option

011)

• N9039A RF Preselector

• One of following options to connect the RF Preselector to the PSA

— N9039A-019 — Type-N to Type-N

— N9039A-027 — APC 3.5 mm to APC 3.5 mm (for PSA Option

BAB)

— N9039A-030 — APC 3.5 mm to APC 2.4 mm (for PSA Model

Number E4446A/E4447A/E4448A)

• One of following LAN connectivity options (optional, if your

instrument have access to an existing network)

— N9039A-010 — Ethernet hub and 3 shielded LAN cables

— N9039A-011 — LAN/GPIB Gateway and GPIB cable, Ethernet

hub and 3 shielded LAN cables

Making Measurements

Chapter 2 21

Page 22

Making Measurements

Test Equipment Setup

Test Equipment Setup

CAUTION Before connecting a signal to the instrument, make sure the instrument

can safely accept the signal level provided. The signal level limits are

marked next to the connectors on the front panel.

NOTE Before you can begin making measurements, make sure you have

Option 239 application firmware installed.

If you have purchase a new PSA, Option 239 was installed at the

factory. If you purchased Option 239 as an upgrade to be installed in a

pre-existing PSA, refer to “Installing Optional Measurement

Personalities” on page 11.

Connecting the System

Stack the instruments and attached the support brackets as shown in

the EMI Measurement Receiver Quick Start Guide. Use appropriate

cables to connect the system hardware as shown in Figure 2-1,

“Hardware Connections - Emissions Measurement System”. Use the

provided LAN cables to connect the PSA, source, and RF Preselector to

the Hub.

If you are using a source that does not have a LAN port (8648B), use a

GPIB cable to connect your source to a LAN/GPIB gateway (N5810A),

and use the provided LAN cables to connect the gateway, PSA, and RF

Preselector to the Hub. See Figure 2-2, “Hardware Connections - Using

LAN/GPIB Gateway”.

If you are using only a PSA to perform pre-compliance measurements,

connect the system as shown in Figure 2-3, “Hardware Connections -

Using PSA only”.

NOTE If you are using the RF Preselector, make sure you have connected the

EXT TRIGGER INPUT (front panel) and the TRIGGER 2 IN (rear

panel) of the PSA to the RF Preselector. See Figure 2-1, “Hardware

Connections - Emissions Measurement System” and Figure 2-2,

“Hardware Connections - Using LAN/GPIB Gateway”.

Making Measurements

22 Chapter 2

Page 23

Making Measurements

Test Equipment Setup

Figure 2-1 Hardware Connections - Emissions Measurement System

Chapter 2 23

Making Measurements

Page 24

Making Measurements

Test Equipment Setup

Figure 2-2 Hardware Connections - Using LAN/GPIB Gateway

Making Measurements

24 Chapter 2

Page 25

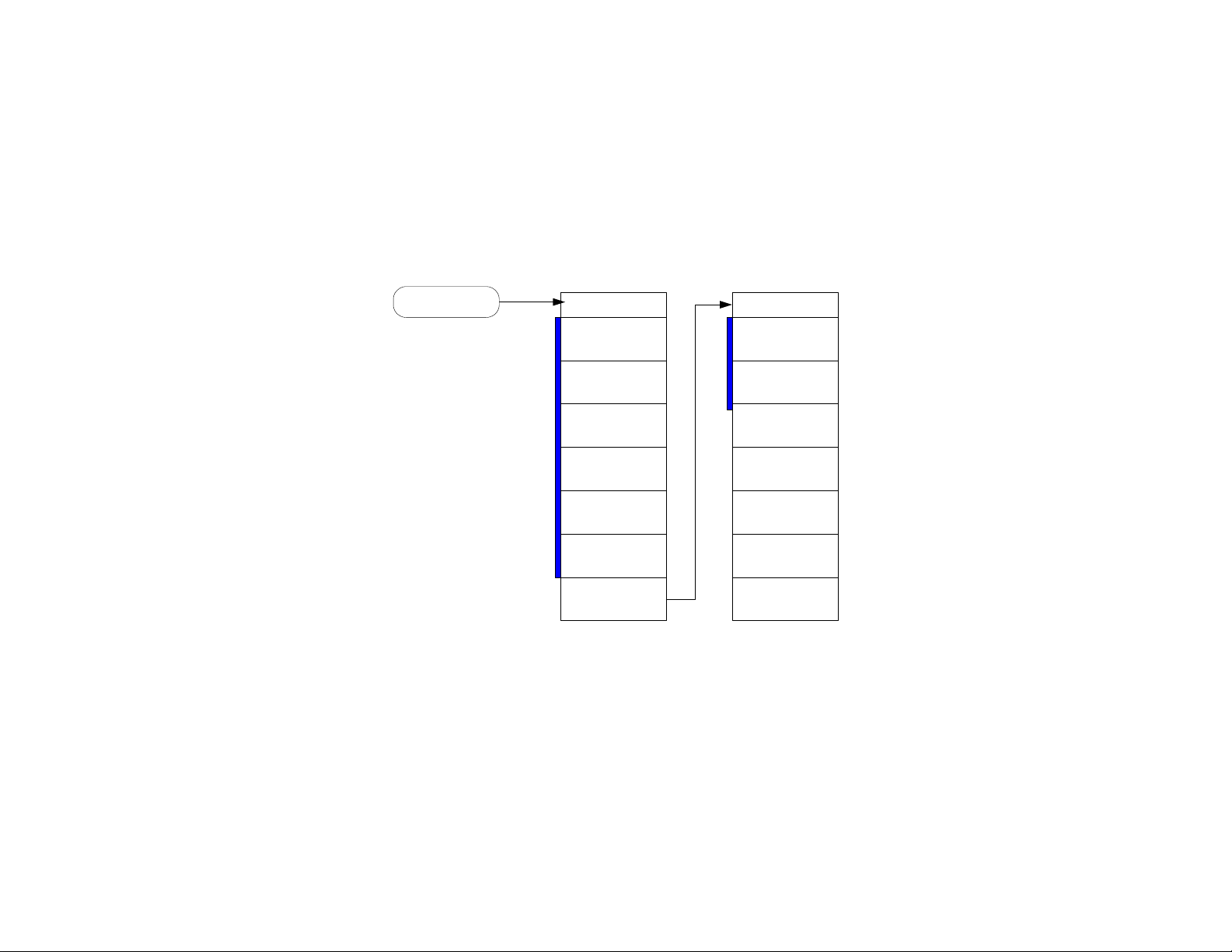

Figure 2-3 Hardware Connections - Using PSA only

Configuring the System

The following steps describe how to configure the PSA to recognize the

RF Preselector and source. The source is used only for system

alignment. Once the system alignment is done, you can disconnect the

source.

Step 1. Connect the instruments and apply power to them. See “Connecting the

System” on page 22. Ensure the instruments have an adequate

warm-up time.

Making Measurements

Test Equipment Setup

Configure the IP address of the RF Preselector and source, respectively.

Refer to the RF Preselector User’s and Programmer’s Guide.

You may need to press the

Local key on the source to activate front

panel access if it was controlled remotely.

Step 2. On the PSA, press

System, Config I/O to access the I/O configuration

menu for the PSA:

•Press

•Press

•Press

press

NOTE Consult your IT support if you have questions about the IP address,

IP Address, enter the PSA IP address, and press Enter.

Subnet Mask, enter the subnet mask, and press Enter.

Gateway Address, enter the network gateway address, and

Enter.

subnet mask, or gateway address.

Step 3. Press

Step 4. Press

MODE, EMC Analyzer to select the desired mode.

Mode Setup, Config EMI Receiver, RF Presel Config to access the

configuration menu for the RF Preselector.

Making Measurements

•Press

press

•Press

IP Address, enter the IP address for the RF Preselector, and

Enter.

Time Out to adjust the time that the PSA needs to connect to

the RF Preselector. The default setting is 10 s.

Chapter 2 25

Page 26

Making Measurements

Test Equipment Setup

•Press Verify RF Presel Connection to verify the connection between

the PSA and RF Preselector.

NOTE If you do not see any connection error messages, the connection to the

RF Preselector has been established. Ignore the alignment required

message at this time.

Step 5. Press

configuration menu for the source.

•Press

that you are using. The

according to the selected model number.

•Press

If you select the 8648B as the model number,

—Press

—Press

—Press

•Press

the signal generator.

•Press

PSA and source.

Mode Setup, Config EMI Receiver, Source Config to access the

Model Number and select the signal generator model number

Conn Mode will be automatically set

IP Address, enter the IP address for the source, and press Enter.

IP Address and enter the IP address for the LAN/GPIB

Gateway.

GPIB Address and enter GPIB Address for the source.

Logic Unit and enter the GPIB Gateway Logic Unit for the

signal generator.

Time Out to adjust the time that the PSA needs to connect to

Verify Source Connection to verify the connection between the

Making Measurements

NOTE If you do not see any connection error messages, the connection to the

signal source has been established. Ignore the alignment required

message at this time.

Step 6. Press

Mode Setup, Config EMI Receiver, Show Config to display and

confirm the system configuration information. You will get the following

screen.

26 Chapter 2

Page 27

Making Measurements

Test Equipment Setup

Figure 2-4 Show Config Screen

Aligning the System

NOTE Before performing any Emissions measurement, a system alignment is

required.

During the alignment, the front panel keys are locked. If you want to

abort the alignment, press the ESC key.

The following steps describe how to perform the alignment for the RF

Preselector:

Step 1. If you get the following message on the PSA screen, press

Alignments, Align All Now to perform the PSA alignment.

Figure 2-5 PSA Alignment Needed

System,

Making Measurements

Chapter 2 27

Page 28

Making Measurements

Test Equipment Setup

Step 2. Press Mode Setup, Align RF Presel to display the Alignment menu for the

RF Preselector. Select the desired signal band from one of the following

options:

• Align 9 kHz to 30 MHz

• Align 30 MHz to 1 GHz

•Align 9 kHz to 1 GHz

For conducted measurements, you need to align 9 kHz to 30 MHz.

For radiated measurements, you need to align 30 MHz to 1 GHz.

Wait until the alignment is done. This can take up to 25 minutes. Once

the alignment is done, the system is ready for use.

Pressing

Restore Presel Align Default will restore the RF Preselector

factory calibration data to both the conducted and radiated bands. If

you restore the defaults, you will need to perform the alignment again.

NOTE Anytime you get one of the following warning or error messages,

perform the respective alignment.

• PreselCondAlign — press

Align 9 kHz to 30 MHz or Align 9 kHz to 1 GHz

• PreselRadAlign — press Align 30 MHz to 1 GHz or Align 9 kHz to 1 GHz

• Conducted Align failed — press Align 9 kHz to 30 MHz or Align 9 kHz to

1 GHz

• Radiated Align failed — press Align 30 MHz to 1 GHz or Align 9 kHz to 1

GHz

• Connection failed — see “Configuring the System” on page 25 and

“Aligning the System” on page 27.

The following examples show alignment failures that require you to

perform the alignment again.

Making Measurements

28 Chapter 2

Page 29

Making Measurements

Test Equipment Setup

Figure 2-6 Example of Alignment Needed (conducted and radiated)

Figure 2-7 Example of Alignment Failure (conducted)

Making Measurements

Chapter 2 29

Page 30

Making Measurements

Test Equipment Setup

Figure 2-8 Example of Alignment Failure (radiated)

For more warning messages or error information, see “Interpreting

Error Codes” on page 46.

Using Instrument Presets Functions

Factory Preset

When the Power On/Preset function

you want to set your current measurement personality to a known,

factory default state, press

Preset. This initializes the instrument by

returning the mode setup and all of the measurement setups in the

mode to the factory default parameters.

NOTE Pressing the Preset key may switch instrument modes if you have set

the Power On/Preset function Preset Type to Factory.

Table 2-1 PSA Model Numbers and Frequency Ranges

Model

E4440A (3Hz to 26.5GHz) 26.5GHz

Preset Type is set to Factory and

Factory Preset Stop Frequency

with Preselector enabled

Making Measurements

E4443A (3Hz to 6.7GHz) 6.7GHz

E4445A (3Hz to 13.2GHz) 13.2GHz

E4446A (3Hz to 44GHz) 44GHz

E4447A (3Hz to 42.98GHz) 42.98GHz

E4448A (3Hz to 50GHz) 50GHz

30 Chapter 2

Page 31

Table 2-2 Factory Preset Settings

Making Measurements

Test Equipment Setup

Parameters

Default settings

Mode Setup/EMI Presets 1 GHz — Above

Mode Setup/Use RF Presel No

Meas Setup/Meas At Marker

On

Detector/Quasi Peak

Meas Setup/Meas At Marker

On

Detector/EMI Averages

Meas Setup/Dwell Time 200.0 ms

Mode Setup/RF Presel Att 10 dB (grayed-out)

Mode Setup/RF Presel Gain Off (grayed-out)

Input/Output /Presel Input RF (grayed-out)

Input/Output /Presel Path Bypass (grayed-out)

Detector EMI Peak

Res BW 1 MHz (CISPR)

Span

depends on PSA model

a

Center Frequency

depends on PSA model

Start Freq 1 GHz

Stop Freq

depends on PSA model

AMPLITUDE Y Scale/Y Axis Unit dBuV

AMPLITUDE Y Scale/Ref Level 106.99 dBuV

Sweep Time Auto

Gate Off

Sweep Points 8192

AMPLITUDE Y Scale/

10 dB

Attenuation

a. Span = Stop Frequency – 1 GHz

b. Center Frequency = 1 GHz + Span/2

c. See Table 2-1, “PSA Model Numbers and Frequency

Ranges.”

b

c

Making Measurements

Chapter 2 31

Page 32

Making Measurements

Test Equipment Setup

Mode Preset

When the Power On/Preset function Preset Type is set to Mode and you

want to set your current measurement personality to a known, mode

default state, press

Preset. This initializes the instrument by returning

the mode setup and all of the measurement setups in the mode to the

mode default parameters.

Table 2-3 Mode Preset Settings

Parameters Default settings

Mode Setup/EMI Presets 1 GHz — Above

Mode Setup/Use RF Presel

Meas Setup/Meas At Marker

Detector/Quasi Peak

Meas Setup/Meas At Marker

Detector/EMI Averages

Meas Setup/Dwell Time 200.0 ms

Mode Setup/RF Presel Att 10 dB

Mode Setup/RF Presel Gain Off

Input/Output /Presel Input

Input/Output /Presel Path

Detector EMI Peak

Res BW 1 MHz (CISPR)

Span

Center Frequency

Start Freq 1 GHz

Stop Freq

The previous state

On

On

c

RF

d

Bypass

depends on PSA model

depends on PSA model

depends on PSA model

a,b

e

f

g

Making Measurements

AMPLITUDE Y Scale/Y Axis Unit dBuV

AMPLITUDE Y Scale/Ref Level 106.99 dBuV

Sweep Time Auto

Gate Off

Sweep Points 8192

AMPLITUDE Y Scale/ Attenuation 10 dB

a. If the PSA cannot communicate to the RF Preselector,

Use RF Presel will be set to No.

b. If you cycle the PSA power,

No.

32 Chapter 2

Use RF Presel will be set to

Page 33

Making Measurements

Test Equipment Setup

Use RF Presel is set to No, Presel Input will be unavail-

c. If

able (grayed-out).

d. If

Use RF Presel is set to No, Presel Path will be unavail-

able (grayed-out).

e. Span = Stop Frequency - 1 GHz

f. Center Frequency = 1 GHz + Span/2

g. See Table 2-1, “PSA Model Numbers and Frequency

Ranges.”

NOTE All the parameter settings in the Config EMI Receiver menu will not

change when you cycle the PSA power or press Preset.

Chapter 2 33

Making Measurements

Page 34

Making Measurements

Making Measurements

Making Measurements

CAUTION Before connecting a signal to the instrument, make sure the instrument

can safely accept the signal level provided. The signal level limits are

marked next to the connectors on the front panel.

Once the system alignment is done, you can perform Emissions

measurements.

Emissions Measurements With an RF Preselector

Table 2-4 The default values when the EMI Presets key is pressed for a

full-compliance measurement

Band

Setup

Start

Frequency

Stop

Frequency

Sweep Point 706 3318 2251 5835 8085 8192 8192

RBW 200Hz 9kHz 120kHz 120kHz 120kHz 1MHz 1MHz

Detector EMI

Y Axis Units dBµVdBµVdBµVdBµVdBµVdBµVdBµV

PSA

Attenuation

Ref Level 70

Preselector

Attenuation

Preselector

Gain

Band A Band B Band C Band D Band

C&D

9kHz 150kHz 30MHz 300MHz 30MHz 1GHz 1GHz

150kHz 30MHz 300MHz 1GHz 1GHz 18 GHz See

Band EAbove

1GHz

Table 2-1

EMI

Peak

10dB 10dB 10dB 10dB 10dB 10dB 10dB

dBµV

10dB 10dB 10dB 10dB 10dB 10dB 10dB

Off Off Off Off Off Off Off

Peak

75

dBµV

EMI

Peak

80

dBµV

EMI

Peak

80

dBµV

EMI

Peak

80

dBµV

EMI

Peak

107

dBµV

EMI

Peak

107

dBµV

Making Measurements

34 Chapter 2

Page 35

Conducted Emissions Measurements

Step 1. Complete the EMI Receiver system connections, system configuration,

and system alignment. See “Connecting the System” on page 22,

“Configuring the System” on page 25 and “Aligning the System” on

page 27.

Figure 2-9 Conducted Measurement System Example

Making Measurements

Making Measurements

Step 2. Turn on the EUT power.

Connect the EUT to the EMI Receiver system using the appropriate

accessories, such as an 11947A Transient, limiter and LISN, as shown

in Figure 2-9, “Conducted Measurement System Example”.

Step 3. Press

Step 4. Press

NOTE The Use RF Presel key cannot be set to Yes when the PSA cannot

MODE, EMC Analyzer to select the desired mode.

Mode Setup and toggle Use RF Presel to Yes .

communicate with the RF Preselector.

Step 5. Press

NOTE The Presel Path key is unavailable (grayed-out) when Use RF Presel is

set to

Input/Output, Presel Path to ensure the Filter path is selected.

No.

If you manually set a signal frequency below 20 MHz you will get a

warning message “AC Coupled: unspecified below 20 MHz”. Press

Input/Output and toggle RF Coupling to DC. The message will disappear.

NOTE If you switch to Spectrum Analysis mode, the Presel Path will

Making Measurements

Chapter 2 35

Page 36

Making Measurements

Making Measurements

automatically be changed to Bypass.

Step 6. Press

CISPR B 150 kHz - 30 MHz.

Step 7. If you get a message of “RF Presel input is overloaded”, press

Presel Att

NOTE The RF Presel Att key is unavailable (grayed-out) when Use RF Presel is

Mode Setup, EMI Presets, and select the desired band, such as

RF

to increase the attenuation of the RF Preselector.

set to No, or Presel Path is set to Bypass.

When you change the attenuation setting on the RF Preselector, the

PSA reference level display may change accordingly.

When

Presel Path is set to Filter, the system attenuation only includes

the RF Preselector attenuator although the PSA has a 10 dB fixed

attenuation.

When

Presel Path is set to Bypass, the system attenuation is what you

set on the PSA.

Step 8. To load limit lines for the most common standards, as well as typical

correction factors for a wide variety of measurement transducers, insert

the provided floppy disk of Limit Lines and Transducer Factors into the

floppy disk drive on the PSA and load the desired files for your test. For

more information, see “File Operation” on page 44 and Appendix A ,

“Disk Contents: Limit Lines and Transducer Factors,” on page 101.

Making Measurements

• Select

• Select

Limits as the type for loading the Limit Lines files.

Corrections as the type for loading the Transducer Factors

files.

NOTE After loading correction factors for antennas, verify that the reference

level unit is set to dBµV/m

Once the limits have been loaded,

to

On and the limit line will be displayed on the screen.

Step 9. Press

information about using the

Display, Limits, Limit 1, toggle Limit Test to On. For more

Limit Display will automatically be set

Display function, see the PSA User’s and

Programmer’s reference.

CAUTION To avoid damaging the input of the EMC Receiver do not make the

connection to the RF Input of the RF Preselector until the EUT power

has been turned on, and do not change the state of the EUT power, or

the LISN output, while the input is connected, without the use of an

input limiter, such as the 11947A.

Step 10. Switch the power of the EUT off and check the display to ensure the

36 Chapter 2

Page 37

noise floor is at least 10 dB below the limit line.

Making Measurements

Making Measurements

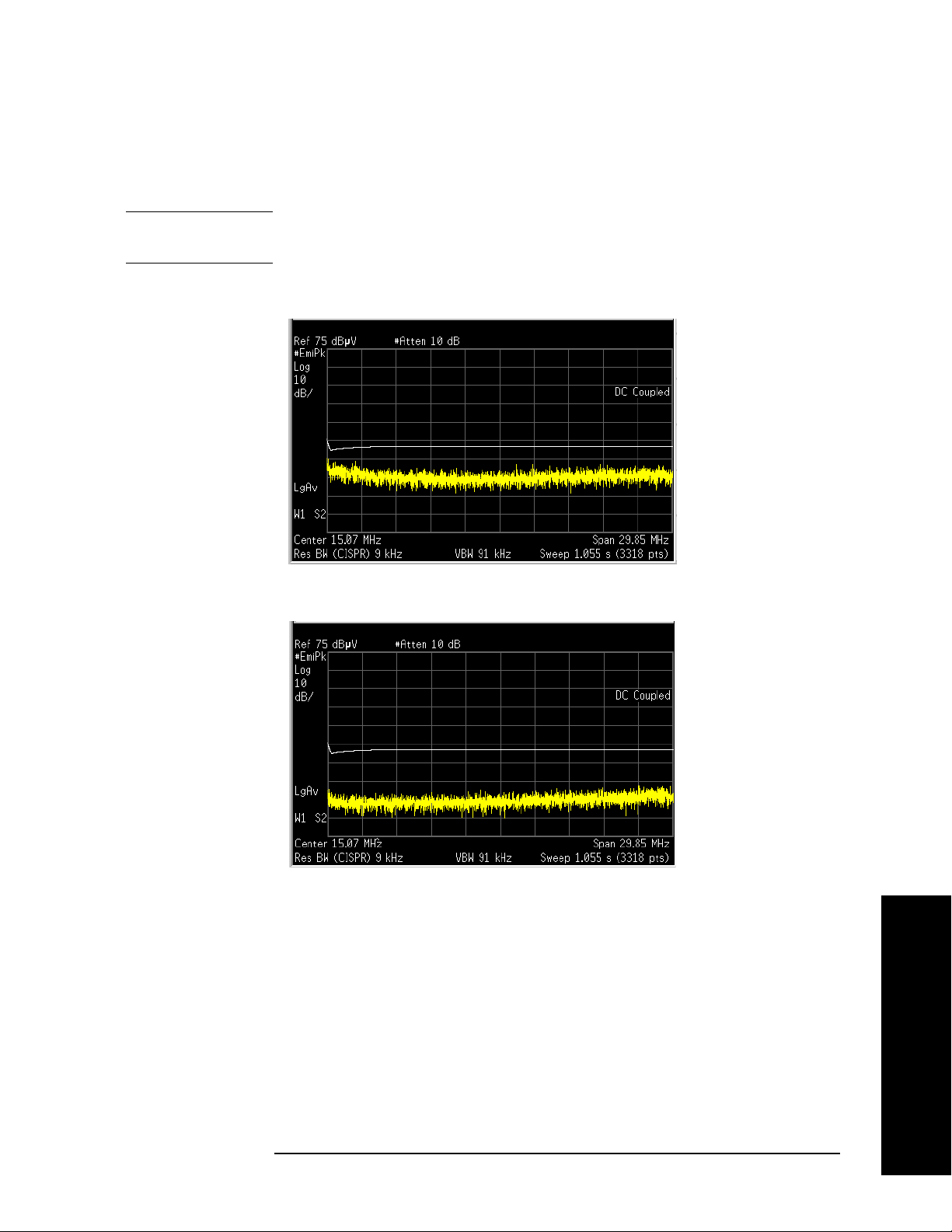

If the noise floor is less than 10 dB below the limit line, toggle

Gain

to On to improve the noise floor versus limit line.

NOTE RF Presel Gain is unavailable (grayed-out) when Use RF Presel is set to

No, or Presel Path is set to Bypass.

RF Presel

Figure 2-10 RF Presel Gain Off

Figure 2-11 RF Presel Gain On

Step 11. On the PSA screen, the PASS/FAIL indicator will show “PASS LIMIT1”

in green color when the peak value of all signals present are below the

regulatory limit, or “FAIL LIMIT1” in red color when the signal exceeds

the limit being used.

Chapter 2 37

Making Measurements

Page 38

Making Measurements

Making Measurements

Figure 2-12 PASS Indicator

Figure 2-13 FAIL Indicator

Making Measurements

Step 12. To analyze signals further, press

windows:

• The upper window is the previous full-screen window, displaying a

full-trace.

• The lower window displays a portion of the trace.

38 Chapter 2

Zoom to split the screen to show two

Page 39

Figure 2-14 Zoomed Screen

Making Measurements

Making Measurements

Step 13. Press

Next Window to toggle to the lower window. The green outlined

window is the active window.

Figure 2-15 Next Window

Step 14. Press

Center Frequency to set the desired center frequency in the lower

window. The value of the center frequency will be automatically coupled

according to the data trace captured.

When you change the center frequency in the lower window, a vertical

positioning indicator in the upper window will move accordingly.

Step 15. Press

displayed data points in the lower window will be changed accordingly.

Around the selected frequency, a minimum of 11 data points and a

maximum of 462 data points will be displayed.

Step 16. Press

detectors to be used to further analyze signals of interest.

Toggle

Toggle

Chapter 2 39

SPAN X Scale, Span to change the span. The number of the

Making Measurements

Meas Setup, Meas at Mkr Detector, you can select or remove the

Quasi Peak to On or Off.

EMI Average to On or Off.

Page 40

Making Measurements

Making Measurements

Figure 2-16 Removing the Quasi Peak and EMI Average Detectors

Figure 2-17 Selecting the Detectors

Step 17. To adjust the measurement dwell time, press

and set the desired time.

Step 18. To analyze individual signals, place a marker on the signal of interest

and press

Marker Fctn, Measure at Marker to perform a measurement of

that signal.

Figure 2-18 Measure at Marker Results

For more information about using the Marker functionality, see the

PSA User's and Programmer's Reference.

Step 19. Repeat the measurement procedure until all of the signals greater than

or equal to the limit line have been measured and record the

measurement results.

Meas Setup, Dwell Time

Making Measurements

40 Chapter 2

Page 41

Radiated Emissions Measurements

Step 1. Complete the system connections, system configuration and system

alignment. See “Connecting the System” on page 22, “Configuring the

System” on page 25 and “Aligning the System” on page 27.

Figure 2-19 Radiated Measurement System Example

Making Measurements

Making Measurements

Step 2. Connect the EUT to the EMI Receiver system using the appropriate

accessories and antenna, as shown in “Radiated Measurement System

Example” on page 41.

Step 3. Press

Step 4. Press

Step 5. Press

NOTE The Presel Path key is unavailable (grayed-out) when Use RF Presel is

set to

Before you switch to

Mode, EMC Analyzer to select the desired mode.

Mode Setup and toggle Use RF Presel to Yes .

Input/Output, Presel Path to ensure the Filter path is selected.

No.

Spectrum Analysis mode, make sure Presel Path is

set to Bypass.

Step 6. Press

CISPR D 300 MHz to 1 GHz.

Mode Setup, EMI Presets, and select the desired band, such as

Step 7. Turn on the EUT power and sweep the frequency range of interest.

Step 8. If you get a message of “RF Presel input is overloaded”, press

Presel Att

NOTE This key is unavailable (grayed-out) when Use RF Presel is set to No, or

Presel Path is set to Bypass.

to increase the attenuation of the RF Preselector.

RF

Making Measurements

Chapter 2 41

Page 42

Making Measurements

Making Measurements

When you change the attenuation setting on the RF Preselector, the

PSA reference level display may change accordingly.

When

Presel Path is set to Filter, the system attenuation only includes

the RF Preselector attenuator although the PSA has a 10 dB fixed

attenuation.

When

Presel Path is set to Bypass, the system attenuation is what you

set on the PSA.

Step 9. To load limit lines for the most common standards, as well as typical

correction factors for a wide variety of measurement transducers, insert

the provided floppy disk of Limit Lines and Transducer Factors into the

floppy disk drive on the PSA and load the desired files for your test. For

more information, see “File Operation” on page 44 and Appendix A ,

“Disk Contents: Limit Lines and Transducer Factors,” on page 101.

• Select

• Select

Limits as the type for loading the Limit Lines files.

Corrections as the type for loading the Transducer Factors

files.

NOTE After loading correction factors for antennas, verify that the reference

level unit is set to dBµV/m

Once the limits have been loaded,

to

On and the limit line will be displayed on the screen.

Limit Display will automatically be set

Making Measurements

Step 10. Press

information about using the

Display, Limits, Limit 1, toggle Limit Test to On. For more

Display function, see the PSA User’s and

Programmer’s reference.

Step 11. Switch the power of the EUT off and check the display to ensure the

noise floor is at least 10 dB below the limit line.

If the noise floor is less than 10 dB below the limit line, toggle

Gain

to On to improve the noise floor versus limit line.

NOTE This key is unavailable (grayed-out) when Use RF Presel is set to No, or

Presel Path is set to Bypass.

Step 12. On the PSA screen, the

PAS S/FAIL indicator will show “PASS LIMIT1” in

RF Presel

green color when the peak value of all signals present are below the

regulatory limit, or “FAIL LIMIT1” in red color when a signal exceeds

the limit being used.

42 Chapter 2

Page 43

Making Measurements

Making Measurements

Step 13. To analyze signals further, press Zoom to split the screen to show two

windows:

• The upper window is the previous full-screen window, displaying a

full-trace.

• The lower window displays a portion of the trace.

Step 14. Press

Next Window to toggle to the lower window. The green outlined

window is the active window.

Step 15. Press

Center Frequency to set the desired center frequency in the lower

window. The value of the center frequency will be automatically coupled

according to the data trace captured.

When you change the center frequency in the lower window, a vertical

positioning indicator in the upper window will move accordingly.

Step 16. Press

SPAN X Scale, Span to change the span. The number of the

displayed data points in the lower window will be changed accordingly.

Around the selected frequency, a minimum of 11 data points and a

maximum of 462 data points will be displayed.

Step 17. Press

Meas Setup, Meas at Mkr Detector, you can select or remove the

detectors to be used to further analyze signals of interest.

Toggle

Toggle

Step 18. To adjust the measurement dwell time, press

Quasi Peak to On or Off.

EMI Average to On or Off.

Meas Setup, Dwell Time

and set the desired time.

Step 19. To analyze individual signals, place a marker on the signal of interest

and press

Marker Fctn, Measure at Marker to perform a measurement of

that signal.

For more information about using the Marker functionality, see the

PSA User's and Programmer's Reference.

Step 20. Repeat the measurement procedure until all of the signals greater than

or equal to the limit line have been measured and record the

measurement results.

Chapter 2 43

Making Measurements

Page 44

Making Measurements

File Operation

File Operation

To access the File menu, press the File front-panel key in the EMC

Analyzer

Saving a Setup file

You can save your current analyzer measurement settings to a Setup

file, and load the Setup file the next time you want to repeat the current

measurement.

Step 1. Press File, Save, Type and select Setup as the type to be saved.

mode.

Step 2. Press

Save Now to save the current measurement settings, including

the State, Trace, Limit and Corrections that you set, to a file with a

default name *.SET. The next time you turn on the PSA, you can load

this Setup file to repeat your test.

NOTE Some settings will not be saved in the Setup file, for example, RF

Preselector IP Address and Source IP Address.

To specify the file name, press

select the directory, use the

Name and enter the desired name. To

Dir Up, Dir Select, and Up and Down keys.

Loading a Setup file

Step 1. Press File, Load, Type and select Setup as the type to be loaded.

Step 2. Select the file to be loaded.

Step 3. Press

Load Now to load the setup as the current measurement.

Making Measurements

44 Chapter 2

Page 45

Making Measurements

File Operation

Loading a Limit file from the floppy disk

You can load a desired limit line file and turn on the Limit Test.

Step 1. Insert the provided floppy disk containing Limit Lines for the most

common standards and typical correction factors for a wide variety of

measurement transducers.

Step 2. Press

File, Load, Type and select Limits.

Step 3. Select the desired file on the A: drive.

Step 4. Press

Load Now to load the file into the PSA.

Loading a Corrections file from the floppy disk

You can load a desired Transducer Factor file for antennas and cables

you are using.

Step 1. Insert the provided floppy disk containing Limit Lines and Transducer

Factors.

Step 2. Press

Step 3. Select the desired file on the A: drive.

Step 4. Press

File, Load, Type and select Corrections.

Load Now to load the file into the PSA.

Chapter 2 45

Making Measurements

Page 46

Making Measurements

Interpreting Error Codes

Interpreting Error Codes

During the execution of your measurement you may encounter

problems which generate error codes. The following list of common

errors may be helpful.

If Err is shown in the annunciator bar, press

System, Show Errors to see

the detailed error information.

• Connection with Presel could not be established at the IP

The analyzer cannot communicate with the RF Preselector with the

given IP address. This error is reported when communication with

the RF Preselector times out.

Verify that the RF Preselector is turned on and the Agilent RF

Preselector application is running.

Verify that the LAN connections of the RF Preselector and PSA are

correct.

Check the RF Preselector IP address information on the PSA by

pressing

Mode Setup, Config EMI Receiver, Show Config.

Verify compliance with the instrument requirements,

see“Instrument Requirements” on page 21, then press

Config

, Verify RF Presel Connection. If no error message appears, the

RF Presel

connection has been established.

• RF Presel model is not supported

The model of the RF Preselector is not supported with the current

version of the Option 239 software.

Making Measurements

• Connection with Source could not be established at the IP

The analyzer cannot communicate with the external signal source

with the given IP address. This error is reported when

communication with the external signal source times out.

Verify that the source and PSA are turned on.

Verify that the LAN connections of the source and PSA are correct. If

your source does not have a LAN port, see Figure 2-2 on page 24 for

instructions on how to connect the source, LAN/Gateway, and PSA.

Check the source configuration information by pressing

Config EMI Receiver, Show Config.

Mode Setup,

Verify compliance with instrument requirements, see“Instrument

Requirements” on page 21, then press

Connection

. If no error message appears, the connection has been

Source Config, Verify S ource

established.

46 Chapter 2

Page 47

Making Measurements

Interpreting Error Codes

• Connection with Source could not be established at the

IP/GPIB

The analyzer cannot communicate with the external signal source

with the given IP and GPIB addresses, when the source was

connected through a LAN/GPIB gateway. This error is reported

when communication with the external signal source times out.

Verify that the source is turned on.

Verify that the LAN/GPIB connections of the source, LAN/Gateway

and PSA are correct. See Figure 2-2 on page 24.

Check the source configuration information on the PSA by pressing

Mode Setup, Config EMI Receiver, Show Config.

Verify compliance with instrument requirements, see “Instrument

Requirements” on page 21, then press

Connection

. If no error message appears, connection has been

Source Config, Verify S ource

established.

• Source model is not supported

The model of the signal generator is not supported with the current

version of the Option 239 software.

Replace the signal generator with a supportable model. See

“Instrument Requirements” on page 21 for a list of signal generator

models.

• RF Preselector alignment required, 9 kHz to 1 GHz

Alignment for the conducted and radiated paths in the RF

Preselector needs to be performed.

See “Aligning the System” on page 27 for instructions on how to

perform the needed alignment.

• RF Preselector alignment required, 9 kHz to 30 MHz

Alignment for the conducted path in the RF Preselector needs to be

performed.

If you are making radiated measurements, you can choose to ignore

this message.

If you are making conducted measurements, see “Aligning the

System” on page 27 for instructions on how to perform the conducted

path alignment.

Making Measurements

Chapter 2 47

Page 48

Making Measurements

Interpreting Error Codes

• RF Preselector alignment required, 30 MHz to 1 GHz

Alignment for the radiated path in the RF Preselector needs to be

performed.

If you are making conducted measurements, you can choose to

ignore this message.

If you are making radiated measurements, see “Aligning the

System” on page 27 for instructions on how to perform the radiated

path alignment.

• RF Presel input is overloaded

Increase the RF Preselector attenuation. Press

Attn

and adjust the attenuation accordingly.

Mode Setup, Presel

• RF Preselector alignment terminated by user

Press the

ESC key to terminated the RF Preselector alignment.

See “Aligning the System” on page 27 for instructions on how to

perform the alignment again before making EMI Receiver

measurements.

• RF Preselector alignment failed, 9 KHz to 30 MHz

If you are making radiated measurements, you can choose to ignore

this message.

If you are making conducted measurements, see “Aligning the

System” on page 27 for instructions on how to perform the conducted

path alignment.

• RF Preselector alignment failed, 30 MHz to 1 GHz

If you are making conducted measurements, you can choose to

ignore this message.

If you are making radiated measurements, see “Aligning the

System” on page 27 for instructions on how to perform the radiated

path alignment.

Making Measurements

• Freq crossing of conducted and radiated bands is not

supported

When Preset path is set to Filter, the instrument sweep cannot cross

over both the conducted and radiated bands.

Either select a band by pressing

the preselector path to

48 Chapter 2

Bypass by pressing Input/Output, Presel Path.

Mode Setup, EMI Presets or toggle

Page 49

Making Measurements

Interpreting Error Codes

• RF Preselector changed, new alignment required

The RF Preselector in the system has been changed. A new

alignment for the RF Preselector is needed.

See “Aligning the System” on page 27 for instructions on how to

perform the needed alignment.

• Cal Source Signal missing, check all the connections

The analyzer could not detect an input signal from the calibration

source.

Verify that the source is turned on.

Verify that the cable connections are correct:

— Source RF OUT to the RF Preselector SRC IN

— RF Preselector RF OUT to the PSA RF INPUT.

• Not available when zoomed graph selected

Some key functions are not supported when the lower window of the

zoomed graph is selected.

Making Measurements

Chapter 2 49

Page 50

Making Measurements

Interpreting Error Codes

Making Measurements

50 Chapter 2

Page 51

Front-Panel Key and SCPI Command

Reference

Chapter 3

3 Front-Panel Key and SCPI

Command Reference

This chapter provides detailed descriptions of the front-panel keys and the

associated SCPI commands and screens used to set up and make EMI Receiver

measurements.

51

Page 52

Front-Panel Key and SCPI Command Reference

Instrument Front Panel Highlights

Reference

Front-Panel Key and SCPI Command

3.1 Instrument Front Panel Highlights

The most commonly used function keys on the PSA front panel are located as shown in the

illustrations below. The operation of the keys is briefly explained on the following page. Refer to

your PSA Series User’s Guide for complete details on all keys.

Figure 3-1 Selected PSA Series Front Panel Feature Locations

3.1.1 Selected and PSA Front-Panel Features

1. The On/Off switch toggles the AC Line power between On and Standby. A green LED will light

52

Chapter 3

Page 53

Front-Panel Key and SCPI Command Reference

Instrument Front Panel Highlights

when the instrument is On. When energized in the standby mode, a yellow LED is lit above

the switch.

2. FREQUENCY Channel accesses a key menu to set the analyzer center frequency in units of Hz,

kHz, MHz, or GHz, or by channel number. These parameters apply to all measurements in the

current mode.

3. MODE accesses a key menu to select one of the measurement personalities installed in the

instrument. Each mode is independent from all other modes.

4. Mode Setup accesses a key menu that sets parameters specific to the current mode and can

affect all measurements within that mode.

5. MEASURE accesses a display key menu to initiate one of the various measurements that are

specific to the current mode.

6. Meas Setup accesses the menus of test parameters that are specific to the current

measurement.

7. Restart causes a measurement to start again from the initial process according to the current

measurement setup parameters.

Front-Panel Key and SCPI Command

Reference

8. RF INPUT port: Type N connector for the E4443A, E4445A, and E4440A PSAs. It is a 2.4 mm

connector on the E4446A, E4447A and E4448A PSAs and a 3.5 mm connector on all PSAs with

Opt BAB. The maximum input power level is shown next to the port.

9. The Data Entry keypad is used to enter numeric values. Keypad entries are displayed in the

active function area of the screen and become valid for the current measurement upon

pressing the

10.The Display Menu keys allow you either to activate a feature or to access a more detailed

Enter key or selecting a unit of measurement, depending on the parameter.

sub-menu. An arrow on the right side of a softkey label indicates that the key has a further

selection menu. The active menu key is highlighted, however, grayed-out keys are currently

unavailable for use or only show information. If a menu has multiple pages, succesive pages

are accessed by pressing the

11. Return allows you to exit the current menu and display the previous menu. If you are on the

first page of a mult-page menu (a menu with

that menu.When you activate another measurement, the return list is cleared. The

More key located at the bottom of the menu.

(1 of 3) for example), the Return key will exit from

Return key

will not return you to a previously activated mode, nor will it alter any values you have

entered in previous menus.

12.BNC Audio Input (PSA Option 233 Measuring Receiver only) Provides a 100 kOhm input for

audio measurements. Frequency range is 20 Hz to 250 kHz. The safe input level is 7 Vrms or

20 V DC.

Chapter 3

53

Page 54

Front-Panel Key and SCPI Command Reference

Front-Panel Keys

Reference

Front-Panel Key and SCPI Command

3.2 Front-Panel Keys

NOTE Only front-panel keys affected by selecting the EMC Analyzer mode are described

here. For a complete description of all front-panel keys, see the PSA Series User’s

and Programmer’s Guide.

3.2.1 Center Frequency, Span for lower window

Allows you to access the center frequency setup menu.

3.2.1.1 Center Frequency

Allows you to set the desired frequency for the lower window.

Mode: EMC Analyzer

Key Path:

Remote Command: [:SENSe]:EMI:FREQuency[:CENTer]

Preset: The center frequency of the upper window

FREQUENCY/Channel

[:SENSe]:EMI:FREQuency[:CENTer]?

State Saved: Saved in instrument state.

Min:

Max:

Dependencies/Couplings: When the start frequency, stop frequency, center or span of the upper

Example: :EMI:FREQ 10000.0

a. Min = Start Freq

b. Max = Stop Freq

Dependent on the start freq of upper window

Dependent on the stop freq of upper window

window changes, it results in a new frequency boundary (start Freq, stop

Freq) in the upper window. If the frequency range of the lower window

exceeds the new boundary of the upper window, the center freq of the lower

window is reset to the center Freq of the upper window, span is also reset

to minimum of the 462 pixels and boundary limitation.

:EMI:FREQ?

upper window

upper window

+ Span

- Span

upper window

upper window

/(SweepPoint

/(SweepPoint

a

b

upper window

upper window

- 1) * 5

- 1) * 5

54

Chapter 3

Page 55

3.2.1.2 Span

Allows you to set the span.

Mode: EMC Analyzer

Front-Panel Key and SCPI Command

Front-Panel Key and SCPI Command Reference

Front-Panel Keys

Reference

Key Path:

SPAN/X Scale, Span

Remote Command: [:SENSe]:EMI:FREQuency:SPAN

[:SENSe]:EMI:FREQuency:SPAN?

Preset: VFreq: freq of vertical marker

USpan: span of upper window

USweepPoint: sweep point of upper window

RightDistance(Hz): vertical marker to right boundary in upper window.

LeftDistance(Hz): vertical marker to left boundary in upper window.

Minimal Distance(Hz) = min(RightDistance, LeftDistance)

LSpan: span of lower window