Errata

This manual may contain references to HP or Hewlett-Packard. Please note that Hewlett-Packard's former test and

measurement, semiconductor products and chemical analysis businesses are now part of Agilent Technologies. To

reduce potential confusion, the only change to product numbers and names has been in the company name prefix: where

a product number/name was HP XXXX the current name/number is now Agilent XXXX. For example, model number

HP8648 is now model number Agilent 8648.

Ce manuel peut contenir des références à <<HP>> ou <<Hewlett-Packard.>> Veuillez noter que les produits de test et

mesure, de semi-conducteur et d'analyse chimique qui avaient fait partie de la société Hewlett-Packard sont maintenent

une partie de la société Agilent Technologies. Pour reduire la confusion potentielle, le seul changement aux noms de

reference a été dans le préfixe de nom de société : là où un nom de référence était HP XXXX, le nouveau nom de

référence est maintenant Agilent XXXX. Par example, le HP 8648 s'appelle maintenent Agilent 8648.

Diese Gebrauchsanweiseung kann Bezug nehmen auf die Namen HP oder Hewlett-Packard. Bitte beachten Sie, dass

ehemalige Betriebsbereiche von Hewlett-Packard wie HP-Halbleiterprodukte, HP-chemische Analysen oder HP-Testund Messwesen nun zu der Firma Agilent Technology gehören. Um Verwirrung zu vermeiden wurde lediglich bei

Produktname und - Nummer der vo laufende Firmenname geändert: Produkte mit dem Namen/Nummer HP XXXX

lauten nun mehr Agilent XXXX. Z.B, das Modell HP 8648 heißt nun Agilent 8648.

Questo manuale potrebbe contenere riferimenti ad HP o Hewlett-Packard. Si noti che le attività precedentemente gestite

da Hewlett-Packard nel campo di Test & Misura, Semiconduttori, ed Analisi Chimica sono ora diventate parte di

Agilent Technologies. Al fine di ridurre il rischio di confusione, l'unica modifica effettuata sui numeri di prodotto e sui

nomi ha riguardato il prefisso con il nome dell'azienda : dove precedentemente compariva "HP XXXX" compare ora

"Agilent XXXX". Ad esempio: il modello HP8648 è ora indicato come Agilent 8648.

Este manual puede hacer referencias a HP o Hewlett Packard. Las organizaciones de Prueba y Medición (Test and

Measurement), Semiconductores (Semiconductor Products) y Análisis Químico (Chemical Analysis) que pertenecían a

Hewlett Packard, ahora forman parte de Agilent Technologies. Para reducir una potencial confusión, el único cambio en

el número de producto y nombre, es el prefijo de la compañía: Si el producto solía ser HP XXXX, ahora pasa a ser

Agilent XXXX. Por ejemplo, el modelo HP8648 es ahora Agilent 8648.

Document Part Number 5971-2669

Printed in the UK September 2004

A

マニュアル・チェンジ

変更

本文中の「HP(YHP)」、または「(横河)ヒューレット・パッカード株式会社」という語句を、「Agilent」、

または「アジレント・テクノロジー株式会社」と変更してください。

ヒューレット・パッカード社の電子計測、半導体製品、化学分析ビジネス部門は分離独立し、アジ

レント・テクノロジー社となりました。

社名変更に伴うお客様の混乱を避けるため、製品番号の接頭部のみ変更しております。

(例: 旧製品名 HP 4294A は、現在 Agilent 4294A として販売いたしております。)

Service Guide

HP EPM E4418A/E4419A

(EPM-441A/442A)

Power Meters

HP Part no. E4418-90006

January 24 1997

© Copyright Hewlett-Packard Company

All rights reserved. Reproduction, adaptation, or translation without prior

written permission is prohibited, except as allowed under the copyright

laws.

Printed in the UK.

ii HP EPM-441A/442A Service Guide

Legal Information

Legal Information

Notice

Information contained in this document is subject to change without

notice. Hewlett-Packard makes no warranty of any kind with regard to

this material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishings, performance,

or use of this material. No part of this document may be photocopied,

reproduced, or translated to another language without the prior written

consent of HP.

Certification

Hewlett-Packard Company certifies that this product met its published

specifications at the time of shipment from the factory. Hewlett-Packard

further certifies that its calibration measurements are traceable to the

United States National Institute of Standards and Technology, to the

extent allowed by the Institute’s calibration facility, and to the calibration

facilities of other International Standards Organization members.

Warranty

This Hewlett-Packard instrument product is warranted against defects in

material and workmanship for a period of one year from date of shipment.

During the warranty period, Hewlett-Packard Company will at its option,

either repair or replace products which prove to be defective. For warranty

service or repair, this product must be returned to a service facility

designated by HP. Buyer shall prepay shipping charges to HP and HP

shall pay shipping charges, duties, and taxes for products returned to HP

from another country. HP warrants that its software and firmware

designated by HP for use with an instrument will execute its

programming instructions when properly installed on that instrument.

HP does not warrant that the operation of the instrument, or firmware

will be uninterrupted or error free.

HP EPM-441A/442A Service Guide iii

Legal Information

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper

or inadequate maintenance by Buyer, Buyer-supplied software or

interfacing, unauthorized modification or misuse, operation outside of the

environmental specifications for the product, or improper site preparation

or maintenance. NO OTHER WARRANTY IS EXPRESSED OR IMPLIED.

HP SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES. HP SHALL NOT BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY

OTHER LEGAL THEORY.

iv HP EPM-441A/442A Service Guide

Equipment Operation

Equipment Operation

Warnings and Cautions

This guide uses warnings and cautions to denote hazards.

WARNING A warning calls attention to a procedure, practice or the

like, which, if not correctly performed or adhered to, could

result in injury or the loss of life. Do not proceed beyond a

warning until the indicated conditions are fully

understood and met.

Caution A caution calls attention to a procedure, practice or the like which,

if not correctly performed or adhered to, could result in damage to

or the destruction of part or all of the equipment. Do not proceed

beyond a caution until the indicated conditions are fully

understood and met.

Personal Safety Considerations

WARNING This is a Safety Class I product (provided with a protective

earthing ground incorporated in the power cord). The

mains plug shall only be inserted in a socket outlet

provided with a protective earth contact. Any interruption

of the protective conductor, inside or outside the

instrument, is likely to make the instrument dangerous.

Intentional interruption is prohibited.

If this instrument is not used as specified, the protection

provided by the equipment could be impaired. This

instrument must be used in a normal condition (in which

all means of protection are intact) only.

No operator serviceable parts inside. Refer servicing to

qualified personnel. To prevent electrical shock, do not

remove covers.

For continued protection against fire hazard, replace the

line fuse(s) only with fuses of the same type and rating (for

example, normal blow, time delay, etc.). The use of other

fuses or material is prohibited.

HP EPM-441A/442A Service Guide v

Equipment Operation

ISM

Group 1

Class A

General Safety Considerations

WARNING Before this instrument is switched on, make sure it has

been properly grounded through the protective conductor

of the ac power cable to a socket outlet provided with

protective earth contact.

Any interruption of the protective (grounding) conductor,

inside or outside the instrument, or disconnection of the

protective earth terminal can result in personal injury.

Caution Any adjustments or service procedures that require operation of

the instrument with protective covers removed should be

performed only by trained service personnel.

Markings

The CE mark shows that the product complies with

all the relevant European legal Directives (if

accompanied by a year, it signifies when the design

was proven.

This is the symbol of an Industrial Scientific and

Medical Group 1 Class A product.

The CSA mark is a registered trademark of the

Canadian Standards Association.

External Protective Earth Terminal.

While this is a Class I product, provided with a

protective earthing conductor in a power cord, an

external protective earthing terminal has also been

provided. This terminal is for use where the earthing

cannot be assured. At least an 18AWG earthing

conductor should be used in such an instance, to

ground the instrument to an assured earth terminal.

vi HP EPM-441A/442A Service Guide

Equipment Operation

IEC 1010-1 Compliance

This instrument has been designed and tested in accordance with IEC

Publication 1010-1 +A1:1992 Safety Requirements for Electrical

Equipment for Measurement, Control and Laboratory Use and has been

supplied in a safe condition. The instruction documentation contains

information and warnings which must be followed by the user to ensure

safe operation and to maintain the instrument in a safe condition.

HP EPM-441A/442A Service Guide vii

List of Related Publications

List of Related Publications

The HP EPM-441A and HP EPM-442A User’s Guides are also available in

the following languages:

• English Language User’s Guide - Standard

• German Language User’s Guide - Option ABD

• Spanish Language User’s Guide - Option ABE

• French Language User’s Guide - Option ABF

• Italian Language User’s Guide - Option ABZ

• Japanese Language User’s Guide - Option ABJ

HP EPM-441A/442A Service Guide is available by ordering Option 915.

HP EPM-441A/442A CLIPs (Component Location and Information Pack)

is available by ordering E4418-90007.

viii HP EPM-441A/442A Service Guide

Sales and Service Offices

Sales and Service Offices

If you need technical assistance with a Hewlett-Packard test and

measurement product or application please contact the Hewlett-Packard

office or distributor in your country.

Asia Pacific:

Hong Kong: (852) 2599 7889

India: (91-11) 647 2311

Japan:

Hewlett-Packard Japan Ltd.

Measurement Assistance Center

9-1, Takakura-Cho, Hachioji-Shi,

Tokyo 192, Japan

Tel: (81-426) 56-7832

Fax: (81-426) 56-7840

Korea: (82-2) 769 0800

Malaysia: (60-3) 291 0213

Philippines: (63-2) 894 1451

PRC: (86-10) 6505 0149

Singapore: (1800) 292 8100

Taiwan: (886-3) 492 9666

Thailand: (66-2) 661 3900

For countries in Asia Pacific not listed contact:

Hewlett-Packard Asia Pacific Ltd.

17-21/F Shell Tower, Times Square,

1 Matheson Street, Causeway Bay,

Hong Kong

tel: (852) 2599 7070

fax: (852) 2506 9285

HP EPM-441A/442A Service Guide ix

Sales and Service Offices

Australia/New Zealand:

Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

Australia

1 800 629 485

Canada:

Hewlett-Packard Canada Ltd.

5150 Spectrum Way

Mississauga, Ontario

L4W 5G1

(905) 206 4725

In Europe, Africa and Middle East please call your local HP sales office or

representative:

Austria: (1) 25000-0

Belgium and Luxembourg: (02) 778 3417

Baltic Countries: (358) 08872 2100

Czech Republic: (0042) 2-4743111

Denmark: 45 99 10 00

Finland: (90) 88 721

France: (0) 1 69.29.41.14

Germany: (0180) 532 62-33

Greece: (1) 7264045

Hungary: (1) 252 4705

Ireland: (01) 284 4633

Israel: (03) 5380 333

Italy: 02 - 92 122 241

Netherlands: (020) 547 6669

Norway: (22) 73 56 50

Poland: (22) 608 7700

x HP EPM-441A/442A Service Guide

Sales and Service Offices

Portugal: (11) 482 85 00

Russia: tel (7/095) 928 6885, fax (7/095) 916 9844

South Africa: (011) 806 1000

Spain: (34) 1 631 1323

Sweden: (08) 444 22 77

Switzerland: (01) 735 7111

Turkey: (212) 224 59 25

United Kingdom: (01344) 366 666

For countries in Europe/Middle East and Africa not listed, contact:

Hewlett-Packard

International Sales Europe

Geneva, Switzerland

Tel: +41-22-780-4111

Fax: +41-22-780-4770

Latin America:

Hewlett-Packard

Latin American Region Headquarters

5200 Blue Lagoon Drive

9th Floor

Miami, Florida 33126

USA

(305) 267 4245/4220

United States:

Hewlett-Packard Company

Test and Measurement Organization

5301 Stevens Creek Blvd.

Bldg. 51L-SC

Santa Clara, CA 95052-8059

1 800 452 4844

In any correspondence or telephone conversations, refer to the power

meter by its model number (which is on the front panel) and full serial

number (which is on the rear panel). With this information, the HP

representative can quickly determine whether your unit is still within its

warranty period.

HP EPM-441A/442A Service Guide xi

Sales and Service Offices

Returning Your Power Meter for Service

Use the information in this section if you need to return your power meter

to Hewlett-Packard.

Package the Power Meter for Shipment

Use the following steps to package the power meter for shipment to

Hewlett-Packard for service:

1. Fill in a blue service tag (available at the end of this guide) and

attach it to the power meter. Please be as specific as possible about

the nature of the problem. Send a copy of any or all of the

following information:

■ Any error messages that appeared on the power meter display.

■ Any information on the performance of the power meter.

Caution Power meter damage can result from using packaging materials

other than those specified. Never use styrene pellets in any shape

as packaging materials. They do not adequately cushion the power

meter or prevent it from shifting in the carton. Styrene pellets

cause power meter damage by generating static electricity and by

lodging in the rear panel.

2. Use the original packaging materials or a strong shipping

container that is made of double-walled, corrugated cardboard

with 159 kg (350 lb) bursting strength. The carton must be both

large enough and strong enough to accommodate the power meter

and allow at least 3 to 4 inches on all sides of the power meter for

packing material.

3. Surround the power meter with at least 3 to 4 inches of packing

material, or enough to prevent the power meter from moving in

the carton. If packing foam is not available, the best alternative is

TM

SD-240 Air Cap

from Sealed Air Corporation (Commerce, CA

90001). Air Cap looks like a plastic sheet covered with 1-1/4 inch

air filled bubbles. Use the pink Air Cap to reduce static electricity.

Wrap the power meter several times in the material to both

protect the power meter and prevent it from moving in the carton.

4. Seal the shipping container securely with strong nylon adhesive

tape.

5. Mark the shipping container “FRAGILE, HANDLE WITH CARE”

to ensure careful handling.

6. Retain copies of all shipping papers.

xii HP EPM-441A/442A Service Guide

About this Guide

About this Guide

Chapter 1: Specifications

This chapter lists the power meter’s specifications and describes how to

interpret these specifications.

Chapter 2: Performance Tests

This chapter contains procedures which allow you to test the power

meter’s electrical performance to it’s specifications.

Chapter 3: Adjustments

This chapter contains checks and adjustments that ensure proper

performance of the power meter.

Chapter 4: Theory of Operation

This chapter describes how each of the power meter’s individual

assemblies operate.

Chapter 5: Replaceable Parts

This chapter details the power meter’s replaceable parts. It also explains

how to assemble and disassemble the power meter.

HP EPM-441A/442A Service Guide xiii

About this Guide

xiv HP EPM-441A/44 2A Service Guide

Table of Contents

Page

Legal Information ........................................................................ iii

Equipment Operation ................................................................... v

Personal Safety Considerations............................................. v

General Safety Considerations ............................................. vi

Markings ................................................................................ vi

IEC 1010-1 Compliance........................................................ vii

List of Related Publications ...................................................... viii

Sales and Service Offices ............................................................. ix

Returning Your Power Meter for Service ............................ xii

About this Guide ........................................................................ xiii

Specifications....................................................................................... 1-1

Introduction................................................................................... 1-2

Power Meter Specifications .......................................................... 1-3

Meter ....................................................................................... 1-3

Accuracy.................................................................................. 1-4

Power Reference ..................................................................... 1-5

Power Meter Supplemental Characteristics ............................... 1-6

Power Reference ..................................................................... 1-6

Measurement Speed ............................................................... 1-6

Zero Drift of Sensors .............................................................. 1-7

Measurement Noise................................................................ 1-7

Settling Time .......................................................................... 1-9

Power Sensor Specifications .................................................. 1-12

General Characteristics ................................................................ 1-13

Rear Panel Connectors ........................................................... 1-13

Environmental Characteristics .................................................... 1-14

General Conditions................................................................. 1-14

Operating Environment ......................................................... 1-14

Storage Conditions ................................................................. 1-14

General .......................................................................................... 1-15

Dimensions ............................................................................. 1-15

Weight ..................................................................................... 1-15

Safety ...................................................................................... 1-15

Remote Programming ............................................................ 1-15

Non-Volatile Memory ............................................................. 1-16

HP EPM-441A/442A Service Guide Contents-1

Performance Tests .............................................................................. 2-1

Introduction................................................................................... 2-2

Equipment Required .............................................................. 2-3

Performance Test Record ....................................................... 2-4

Performance Tests .................................................................. 2-4

Calibration Cycle .................................................................... 2-4

Test Procedures ...................................................................... 2-4

Zero Test........................................................................................ 2-5

Specification........................................................................... 2-5

Description.............................................................................. 2-5

Equipment .............................................................................. 2-5

Test Setup ............................................................................... 2-5

Procedure ................................................................................ 2-6

Instrument Accuracy Test ............................................................ 2-7

Specification........................................................................... 2-7

Description.............................................................................. 2-7

Equipment .............................................................................. 2-7

Test Setup ............................................................................... 2-7

Procedure ................................................................................ 2-8

Power Reference Level Test ......................................................... 2-10

Description.............................................................................. 2-10

Equipment .............................................................................. 2-11

Test Setup ............................................................................... 2-11

Procedure ................................................................................ 2-11

HP E-Series Power Sensor Interface Test................................... 2-14

Procedure ................................................................................ 2-14

HP E-Series Power Sensor Functional Test ................................ 2-15

Description.............................................................................. 2-15

Equipment .............................................................................. 2-15

Procedure ................................................................................ 2-16

Performance Test Record.............................................................. 2-18

Adjustments.......................................................................................... 3-1

Introduction................................................................................... 3-2

Safety Considerations ............................................................ 3-2

Equipment Required .............................................................. 3-3

Post-Repair Adjustments ....................................................... 3-3

Power Reference Oscillator Frequency Adjustment ................... 3-4

Description.............................................................................. 3-4

Equipment .............................................................................. 3-4

Procedure ................................................................................ 3-4

Power Reference Oscillator Level Adjustment............................ 3-6

Description.............................................................................. 3-6

Contents-2 HP EPM-441A/442A Service Guide

Equipment .............................................................................. 3-8

Procedure ................................................................................ 3-8

Measurement Uncertainty..................................................... 3-11

Display Brightness and Contrast Adjustment ............................ 3-12

Introduction ............................................................................ 3-12

Procedure ................................................................................ 3-12

Theory of Operation ........................................................................... 4-1

Introduction................................................................................... 4-2

A1 Power Supply ........................................................................... 4-3

A2 Processor Assembly ................................................................. 4-4

A3 Front Panel Assembly ............................................................. 4-7

A4 Interface Assembly.................................................................. 4-8

A5 Daughter Assembly ................................................................. 4-9

A6 Measurement Assembly .......................................................... 4-10

Replaceable Parts ............................................................................... 5-1

Introduction................................................................................... 5-2

Assembly Part Numbers............................................................... 5-3

Front Panel Connector Repair ..................................................... 5-5

Firmware Upgrades ...................................................................... 5-6

Downloading Firmware.......................................................... 5-6

Assembly and Disassembly Guidelines ....................................... 5-7

Removing the Power Meter Cover ......................................... 5-7

Removing the A1 Power Supply Assembly ........................... 5-8

Removing the A2 Processor Assembly................................... 5-9

Removing the A4 Interface Assembly ................................... 5-10

Removing the A5 Daughter or A6 Measurement

Assemblies .............................................................................. 5-11

Removing the A7 Fan Assembly ............................................ 5-12

Removing the Power Meter Battery (BT1)............................ 5-13

Removing the A3 Front Panel Assembly............................... 5-14

Replacing the Front Panel Power Reference Cable

Assembly ................................................................................. 5-17

Replacing the Rear Panel Power Sensor Cable

Assemblies (Options 002 and 003)......................................... 5-18

Replacing the Rear Panel Power Reference Cable

Assembly (Option 003) ........................................................... 5-20

HP EPM-441A/442A Service Guide Contents-3

Contents-4 HP EPM-441A/442A Service Guide

List of Figures

Page

2-1 Zero Test Setup .......................................................................... 2-5

2-2 Instrument Accuracy Test Setup .............................................. 2-7

2-3 Power Reference Level Test Setup ........................................... 2-11

2-4 Sensor Functional Test Setup................................................... 2-16

2-5 Sensor Functional Test Setup with Attenuator ....................... 2-17

3-1 Adjustment Setup ...................................................................... 3-4

3-2 A2L9 Adjustment Location ....................................................... 3-5

3-3 Adjustment Setup ...................................................................... 3-6

3-4 A2R90 Adjustment Location ..................................................... 3-10

HP EPM-441A/442A Service Guide Contents-5

Contents-6 HP EPM-441A/442A Service Guide

List of Tables

Page

1-1 Zero Set Specifications .............................................................. 1-4

1-2 Noise Multiplier ......................................................................... 1-7

1-3 Power Sensor Specifications± ................................................... 1-8

1-4 Settling Time ............................................................................. 1-9

1-5 Settling Time ............................................................................. 1-10

2-1 Required Equipment ................................................................. 2-3

2-2 Zero Test Results ....................................................................... 2-6

2-3 Instrument Accuracy Results.................................................... 2-9

2-4 Power Reference Level Result................................................... 2-13

2-5 Functional Test Result .............................................................. 2-17

2-6 Performance Test Record .......................................................... 2-18

3-1 Post Repair Adjustments, Tests, and Checks .......................... 3-3

HP EPM-441A/442A Service Guide Contents-7

Contents-8 HP EPM-441A/442A Service Guide

1

Specifications

Specifications

Introduction

Introduction

This chapter details the power meter’s specifications and supplemental

characteristics.

Specifications describe the warranted performance and apply after a 30

minute warm-up. These specifications are valid over the power meter’s

operating and environmental range unless otherwise stated and after

performing a zero and calibration.

Supplemental characteristics, which are shown in italics, are intended to

provide information useful in applying the power meter by giving typical,

but nonwarranted performance parameters. These characteristics are

shown in italics or denoted as “typical”, “nominal” or “approximate”.

For information on measurement uncertainty calculations, refer to

HP Application Note 64-1A, “Fundamentals of RF and Microwave Power

Measurements”, Literature Number 5965-6630.

1-2 HP EPM-441A/442A Service Guide

Specifications

Power Meter Specifications

Power Meter Specifications

Meter

Frequency Range

100 kHz to 50 GHz and 75 GHz to 110 GHz, power sensor dependent

Power Range

-70 dBm to +44 dBm (100 pW to 25 W), power sensor dependent

Power Sensors

Compatible with all HP 8480 series power sensors and HP ECP-series

power sensors.

Single Sensor Dynamic Range

90 dB maximum (HP ECP-series power sensors)

50 dB maximum (HP 8480 series power sensors)

Display Units

Absolute: Watts or dBm

Relative: Percent or dB

Display Resolution

Selectable resolution of:

1.0, 0.1, 0.01 and 0.001 dB in logarithmic mode, or

1, 2, 3 and 4 significant digits in linear mode

Default Resolution

0.01 dB in logarithmic mode

3 digits in linear mode

HP EPM-441A/442A Service Guide 1-3

Specifications

Power Meter Specifications

Accuracy

Instrumentation

Absolute:

sensor linearity specification in your power sensor manual to assess

overall system accuracy.)

Relative:

sensor linearity specification in your power sensor manual to assess

overall system accuracy.)

Zero Set (digital settability of zero): Power sensor dependent (refer to

Table 1-1). For HP ECP-series power sensors, this specification applies

when zeroing is performed with the sensor input disconnected from the

POWER REF.

±0.02 dB (Logarithmic) or ±0.5% (Linear). (Refer to the power

±0.04 dB (Logarithmic) or ±1.0% (Linear). (Refer to the power

Table 1-1: Zero Set Specifications

Power Sensor Zero Set

HP 8481A

HP 8481B

HP 8481D

HP 8481H

HP 8482A

HP 8482B

HP 8482H

HP 8483A

HP 8485A

HP 8485D

HP R8486A

HP R8486D

HP Q8486A

HP Q8486D

HP W8486A

HP 8487A

HP 8487D

HP ECP-E18A

HP ECP-E26A

±50 nW

±50 µW

±20 pW

±5 µW

±50 nW

±50 µW

±5 µW

±50 nW

±50 nW

±20 pW

±50 nW

±30 pW

±50 nW

±30 pW

±200 nW

±50 nW

±20 pW

±50 pW

±50 pW

1-4 HP EPM-441A/442A Service Guide

Power Reference

Power Output

Specifications

Power Meter Specifications

1.00 mW (0.0 dBm). Factory set to

Institute of Standards and Technology.

Accuracy

±1.2% worst case (±0.9% rss) for one year.

±0.7% traceable to the US National

HP EPM-441A/442A Service Guide 1-5

Specifications

Power Meter Supplemental Characteristics

Power Meter Supplemental Characteristics

Power Reference

Frequency

50 MHz nominal

SWR

1.05 maximum

Connector

Type N (f), 50

Ω

Measurement Speed

Over the HP-IB, three measurement speed modes are available as shown,

along with the typical maximum measurement speed for each mode:

• Normal: 20 readings/second

• x2: 40 readings/second

• Fast: 200 readings/second, for HP ECP-series power sensors only

Maximum measurement speed is obtained using binary output in free run

trigger mode.

1-6 HP EPM-441A/442A Service Guide

Specifications

Power Meter Supplemen tal Characteristics

Zero Drift of Sensors

Power sensor dependent (refer to Table 1-3).

Measurement Noise

Power sensor dependent (refer to Table 1-2 and Table 1-3).

Averaging effects on measurement noise. Averaging over 1 to 1024

readings is available for reducing noise. Table 1-3 provides the

measurement noise for a particular power sensor with the number of

averages set to 16 for normal mode and 32 for x2 mode. Use the “Noise

Multiplier” for the appropriate mode (normal or x2) and number of

averages to determine the total measurement noise value.

For example, for an HP 8481D power sensor in normal mode with the

number of averages set to 4, the measurement noise is equal to:

(<45 pW x 2.75) = <124 pW

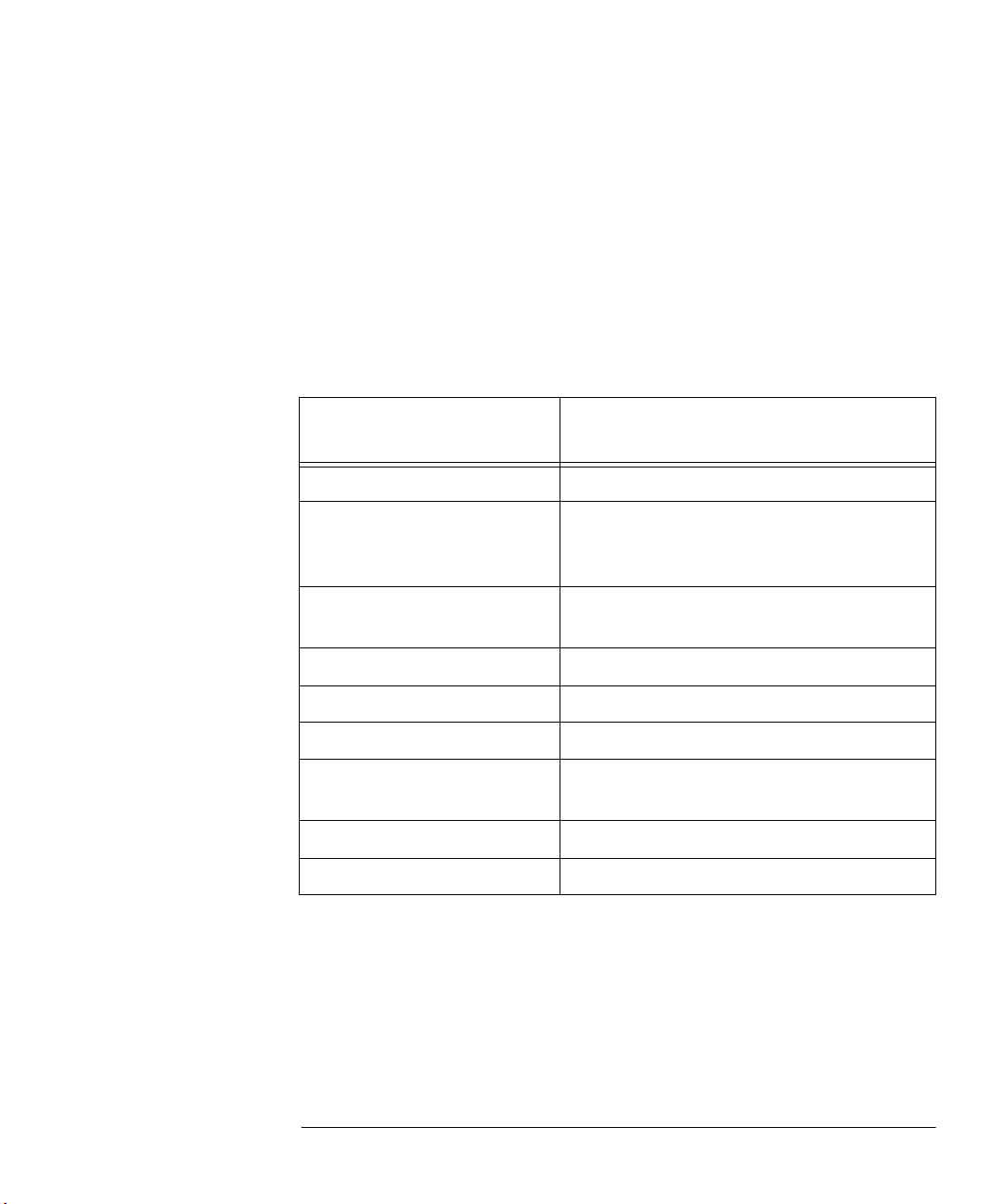

Table 1-2: Noise Multiplier

Number of

Averages

Noise Multiplier

(Normal Mode)

Noise Multiplier

(x2 mode)

1 2 4 8 16 32 64 128 256 512 1024

5.5 3.89 2.75 1.94 1.0 0.85 0.61 0.49 0.34 0.24 0.17

6.5 4.6 3.25 2.3 1.18 1.0 0.72 0.57 0.41 0.29 0.2

HP EPM-441A/442A Service Guide 1-7

Specifications

Power Meter Supplemental Characteristics

Table 1-3: Power Sensor Specifications±

1

Power Sensor Zero Drift

Measurement Noise

HP 8481A <±10 nW <110 nW

HP 8481B <

HP 8481D <

HP 8481H <

HP 8482A <

HP 8482B <

HP 8482H <

HP 8483A <

HP 8485A <

HP 8485D <

HP R8486A <

HP R8486D <

HP Q8486A <

HP Q8486D <

±10 µW <110 µW

±4pW <45 pW

±1 µW <10 µW

±10 nW <110 nW

±10 µW <110 µW

±1 µW <10 µW

±10 nW <110 nW

±10 nW <110 nW

±4pW <45 pW

±10 nW <110 nW

±6pW <65 pW

±10 nW <110 nW

±6pW <65 pW

2

HP W8486A <

HP 8487A <

HP 8487D <

HP ECP-E18A

HP ECP-E26A

1. Within 1 hour after zero set, at a constant temperature, after a 24

hour warm-up of the power meter.

2. The number of averages at 16 (for normal mode) and 32 (for x2 mode),

at a constant temperature, measured over a 1 minute interval and 2

standard deviations. For HP ECP-series power sensors the

measurement noise is measured within the low range. Refer to the

relevant power sensor manual for further information.

±40 nW <450 nW

±10 nW <110 nW

±4pW <45 pW

<± 15 pW <70 pW

<± 15 pW <70 pW

1-8 HP EPM-441A/442A Service Guide

Power Meter Supplemen tal Characteristics

Settling Time

0 to 99% settled readings over the HP-IB.

For HP 8480 series power sensors

Manual filter, 10 dB decreasing power step:

Table 1-4: Settling Time

Specifications

Number of

Averages

Settling Time (s)

(Normal Mode)

Response Time (s)

(x2 mode)

Normal Mode x2 Mode

Maximum dBm

Maximum dBm

Maximum dBm

150 ms

Typica l

Settling

Settling

Settling

Times

Times

Times

200 ms

500 ms

1 2 4 8 16 32 64 128 256 512 1024

0.15 0.2 0.3 0.5 1.1 1.9 3.4 6.6 13 27 57

0.15 0.18 0.22 0.35 0.55 1.1 1.9 3.5 6.9 14.5 33

Auto filter, default resolution, 10 dB decreasing power step,

normal and x2 speed modes:

Maximum dBm

20 dB

20 dB

20 dB

10 dB

10 dB

10 dB

10 dB

10 dB

10 dB

Power

Power

Power

Sensor

Sensor

Sensor

Dynamic

Dynamic

Dynamic

Range

Range

Range

Typical

Settling

Settling

Settling

Times

Times

Times

150 ms

180 ms

350 ms

20 dB

20 dB

20 dB

10 dB

10 dB

10 dB

10 dB

10 dB

10 dB

Power

Power

Power

Sensor

Sensor

Sensor

Dynamic

Dynamic

Dynamic

Range

Range

Range

6.6 s

Minimum dBm

Minimum dBm

Minimum dBm

10 dB

10 dB

10 dB

3.5 s

Minimum dBm

10 dB

10 dB

10 dB

HP EPM-441A/442A Service Guide 1-9

Specifications

Power Meter Supplemental Characteristics

For HP ECP-series power sensors

Number of

Averages

Settling Time (s)

(Normal Mode)

Response Time (s)

(x2 mode)

In FAST mode, within the range -50 dBm to +17 dBm, for a 10 dB

decreasing power step, the settling time is 10 ms

and 20 ms

1

When a decreasing power step crosses the power sensor’s auto-range

1

for the HP EPM-442A

1

for the HP EPM-441A

switch point, add 25 ms. Refer to the relevant power sensor manual for

further information.

For HP ECP-series power sensors in normal and x2 speed modes, manual

filter, 10 dB decreasing power step:

Table 1-5: Settling Time

1 2 4 8 16 32 64 128 256 512 1024

0.07 0.12 0.21 0.4 1 1.8 3.3 6.5 13 27 57

0.04 0.07 0.12 0.21 0.4 1 1.8 3.4 6.8 14.2 32

1-10 HP EPM-441A/442A Service Guide

Power Meter Supplemen tal Characteristics

Auto filter, default resolution, 10 dB decreasing power step,

normal and x2 speed modes:

Normal Mode x2 Mode

Specifications

Typical

Settling

Times

Maximum dBm

70 ms

120 ms

400 ms

6.5 s

60 dB

10 dB

10 dB

10 dB

Minimum dBm

Power

Sensor

Dynamic

Range

Typical

Settling

Times

Maximum dBm

40 ms

70 ms

210 ms

3.4 s

60 dB

10 dB

10 dB

10 dB

Minimum dBm

Power

Sensor

Dynamic

Range

HP EPM-441A/442A Service Guide 1-11

Specifications

Power Meter Supplemental Characteristics

Power Sensor Specifications

Definitions

Zero Set

In any power measurement, the power meter must initially be set to zero

with no power applied to the power sensor. Zero setting is accomplished

within the power meter by digitally correcting for residual offsets.

Zero Drift

This parameter is also called long term stability and is the change in the

power meter indication over a long time (usually one hour) for a constant

input power at a constant temperature, after a defined warm-up interval.

Measurement Noise

This parameter is also known as short term stability and is specified as

the change in the power meter indication over a short time interval

(usually one minute) for a constant input power at a constant

temperature.

1-12 HP EPM-441A/442A Service Guide

General Characteristics

Rear Panel Connectors

Recorder Output

Specifications

General Characteristics

Analog 0-1 Volt, 1 k

HP-IB

Allows communication with an external controller.

Ground

Binding post, accepts 4 mm plug or bare-wire connection

Line Power

• Input Voltage Range: 85 to 264 Vac, automatic selection

• Input Frequency Range: 47 to 63 Hz

• Power Requirement: approximately 50 VA (14 Watts)

Ω output impedance, BNC connector

HP EPM-441A/442A Service Guide 1-13

Specifications

Environme ntal Characteristics

Environmental Characteristics

General Conditions

Complies with the requirements of the EMC Directive 89/336/EEC. This

includes Generic Immunity Standard EN 50082-1: 1992 and Radiated

Interference Standard EN 55011:1991/CISPR11:1990, Group 1 - Class A.

Operating Environment

Temperature

0ºC to 55ºC

Maximum Humidity

95% at 40ºC (non-condensing)

Minimum Humidity

15% at 40ºC (non-condensing)

Maximum Altitude

3,000 meters (9,840 feet)

Location

For use indoors.

Storage Conditions

Storage Temperature

-20ºC to +70ºC

Non-Operating Maximum Humidity

90% at 65ºC (non-condensing)

Non-Operating Maximum Altitude

15,240 meters (50,000 feet)

1-14 HP EPM-441A/442A Service Guide

Specifications

General

Dimensions

The following dimensions exclude front and rear panel protrusions:

212.6 mm W x 88.5 mm H x 348.3 mm D (8.5 in x 3.5 in x 13.7 in)

Weight

Net

HP EPM-441A, 4.0 Kg (8.8 lb)

HP EPM-442A, 4.1 Kg (9.0 lb)

Shipping

HP EPM-441A, 7.9 Kg (17.4 lb)

General

HP EPM-442A, 8.0 Kg (17.6 ib)

Safety

Conforms to the following Product Specifications:

• EN61010-1: 1993/IEC 1010-1:1990+A1/CSA C22.2 No.

1010-1:1993

• EN60825-1: 1994/IEC 825-1: 1993 Class 1

• Low Voltage Directive 72/23/EEC

Remote Programming

Interface

HP-IB interface operates to IEEE 488.2.

Command Language

SCPI standard interface commands.

HP EPM-441A is HP 437B code compatible.

HP EPM-441A/442A Service Guide 1-15

Specifications

General

HP EPM-441A HP-IB Compatibilty

SH1, AH1, T6, TE0, L4, LE0, SR1, RL1, PP1, DC1, DT1, C0

Non-Volatile Memory

Battery

Lithium Polycarbon Monoflouride, approximate lifetime 5 years at 25ºC.

1-16 HP EPM-441A/442A Service Guide

2

Performance Tests

Performance Tests

Introduction

Introduction

The procedures in this chapter test the power meter’s electrical

performance using the specifications in Chapter 1 as the performance

standards. All tests can be performed without access to the interior of the

power meter. A simpler operational test is included in “Self Test” of the

User’s Guide.

Note For valid performance tests, the following conditions must be met:

a. The power meter and test equipment must have a 30 minute

warm-up for all specifications.

b. The line voltage for the power meter must be 85 to 264 Vac and

the line frequency must be 47 to 63 Hz.

c. The ambient temperature must be 00 to 550C.

2-2 HP EPM-441A/442A Service Guide

Performance Tests

Introduction

Equipment Required

Table 2-1 lists all the equipment required for the adjustments and

performance tests. If substitutions must be made, the equipment used

must meet the critical specifications.

Table 2-1: Required Equipment

Equipment

Required

Model

Number

Critical Specification Usage

Digital Multimeter HP 3458A Range 0 to 20 V

Resolution 0.01 V

Range Calibrator HP 11683A Calibration Uncertainty

±0.25%

Frequency Counter HP 5314A Range 10 Hz to 50 MHz

Resolution 1 Hz

Power Meter HP 432A Range 1 mW

Transfer Accuracy 0.2%

Thermistor Mount HP 478A

Option H75

SWR<1.05 at 50 MHz

Accuracy

±0.5% at 50 MHz

HP 478A

Option H76

Power Sensor HP E-series

power sensor

30 dB Attenuator HP 11807A

or

HP 8491A

Option 030

1

P and A

P and A

P and A

P and A

P and A

P

P

Power Sensor Cable HP 11730A P and A

1. P = Performance Tests, A = Adjustments

HP EPM-441A/442A Service Guide 2-3

Performance Tests

Introduction

Performance Test Record

Results of the performance tests may be tabulated in Table 2-6,

“Performance Test Record,” on page 2-18. The Performance Test Record

lists all of the performance test specifications and the acceptable limits for

each specification. If performance test results are recorded during an

incoming inspection of the power meter, they can be used for comparison

during periodic maintenance. The test results may also prove useful in

verifying proper adjustments after repairs are made.

Performance Tests

The performance tests given in this chapter are suitable for incoming

inspection or preventive maintenance. During any performance test, all

shields and connecting hardware must be in place.

The tests are designed to verify published power meter specifications.

Perform the tests in the order given and record the data in Table 2-6 on

page 2-18 and/or in the data spaces provided at the end of each procedure.

Calibration Cycle

This power meter requires periodic verification of performance to ensure

that it is operating within specified tolerances. The performance tests

described in this chapter should be performed once each year. Under

conditions of heavy usage or severe operating environments, the tests

should be more frequent. Adjustments that may be required are described

in Chapter 3.

Test Procedures

It is assumed that the person performing the following tests understands

how to operate the specified test equipment. Equipment settings, other

than those for the power meter, are stated in general terms. It is assumed

that the person will select the proper cables, adapters, and probes

required for test setups illustrated in this chapter.

2-4 HP EPM-441A/442A Service Guide

Zero Test

Specification

Electrical Characteristics Performance Limits

Performance Tests

Zero Test

Accuracy: Zero set (Digital settability of zero)

1. This performance limit is determined by the zero set specification of the power

sensor used in the measurement plus the measurement noise. The range

calibrator has a zero set specification of

noise specification is 110 nW at 16 averages. At 512 averages a noise multiplier of

0.24 is required, giving a measurement noise specification of 0.0264 µW

(0.24x512).

±0.05 µW. The calibrator measurement

±0.0764 µW

1

Description

After the power meter is initially calibrated and zeroed, the change in the

digital readout is monitored. This test also takes drift and noise into

account, since drift, noise and zero readings cannot be separated.

Equipment

Range Calibrator .................................. HP 11683A

Power Sensor Cable ............................. HP 11730A

Test Setup

Power Meter

Range

Calibrator

CHANNEL A

HP 11730A

POWER

METER

Figure 2-1: Zero Test Setup

HP EPM-441A/442A Service Guide 2-5

Performance Tests

Zero Test

Procedure

The following procedure should be performed for the Zero Test.

Note The procedure details the key presses required on the

HP EPM-441A. For the HP EPM-442A the equivalent key presses

should be performed on both channels.

1. Connect the equipment as shown in Figure 2-1.

2. Switch the power meter on.

3. Press then .

4. Press , for a reading in watts.

Preset

Local

dBm/W

5. Set the range calibrator as follows:

RANGE............................................ 3

POLARITY ...................................... NORMAL

FUNCTION..................................... STANDBY

LINE................................................ ON

Confirm

W

µW

Note When switching the range calibrator to STANDBY, allow enough

time for the range calibrator to settle to its zero value before

attempting to zero the power meter. This settling would appear on

the power meter display as downward drift. When the drift has

reached minimum, (typically less than 60 seconds), the range

calibrator is settled.

6. On the power meter press ,

System

Inputs

select 512 from the pop up window then press .

7. On the power meter press , . When the wait symbol

disappears press . Wait approximately 10 seconds for the

Zero

Zero

Cal

Input Settings Filter

,

Enter

Cal

wait symbol to disappear.

8. Wait 30 seconds then verify that the power meter’s reading is

within

±0.05 µW. Record the reading.

Table 2-2: Zero Test Results

Channel B

Min

Channel A

Actual Result

Actual Result

(HP EPM-442A

Max

Only)

-76.40 nW ________________ ________________ +76.40 nW

2-6 HP EPM-441A/442A Service Guide

Instrument Accuracy T est

Instrument Accuracy Test

Specification

Electrical Characteristics Performance Limits

Performance Tests

Accuracy

1. This performance limit does not include the corresponding sensor power

linearity specification.

±0.5% or ±0.02 dB

1

Description

The power meter accuracy is verified for various power inputs. The range

calibrator is switched to provide these reference inputs.

Equipment

Range Calibrator ................................... HP 11683A

Power Sensor Cable .............................. HP 11730A

Test Setup

Power Meter

Range

Calibrator

CHANNEL A

HP 11730A

POWER

METER

Figure 2-2: Instrument Accuracy Test Setup

HP EPM-441A/442A Service Guide 2-7

Performance Tests

Instrument Accuracy Test

Procedure

The following procedure should be performed for the Instrument Accuracy

Test.

Note The procedure details the key presses required on the

HP EPM-441A. For the HP EPM-442A the equivalent key presses

should be performed on both channels.

1. Connect the equipment as shown in Figure 2-2.

2. Switch the power meter on.

3. Press then .

4. Press , for a reading in watts.

Preset

Local

dBm/W

5. Set the range calibrator as follows:

RANGE............................................ 3

POLARITY ...................................... NORMAL

FUNCTION..................................... STANDBY

LINE ............................................... ON

Confirm

W

µW

Note When switching the range calibrator to STANDBY, allow enough

time for the range calibrator to settle to its zero value before

attempting to zero the power meter. This settling would appear on

the power meter display as downward drift. When the drift has

reached minimum, (typically less than 60 seconds), the range

calibrator is settled.

6. On the power meter press ,

System

Inputs

select 512 from the pop up window then press .

7. On the power meter press , . Wait approximately 10

Zero

Cal

Input Settings Filter

,

Enter

Zero

seconds for the wait symbol to disappear. Verify that the display

reads 0

±0.05 µW.

8. Set the range calibrator’s FUNCTION switch to CALIBRATE.

9. Set the range calibrator’s RANGE switch to 1 mW.

10. Press to calibrate the power meter.

Cal

11. Set the range calibrator’s RANGE switch to the positions shown in

Table 2-3 on page 2-9. For each setting, verify that the power

meter’s reading is within the limits shown.

2-8 HP EPM-441A/442A Service Guide

Table 2-3: Instrument Accuracy Results

Performance Tests

Instrument Accuracy T est

Range

Calibrator

Setting

Min

1

Channel A

Actual Results

Channel B

Actual Results

(HP EPM-442A

only)

Max

1

3 µW3.100 µW _______________ _______________ 3.230 µW

10 µW9.900 µW _______________ _______________ 10.10 µW

30 µW31.40 µW _______________ _______________ 31.80 µW

100 µW99.50 µW _______________ _______________ 100.5 µW

300 µW0.314 µW _______________ _______________ 0.318 µW

1 mW 0.995 mW _______________ _______________ 1.005 mW

3 mW 3.141 mW _______________ _______________ 3.171 mW

10 mW 9.984 mW _______________ _______________ 10.08 mW

30 mW 31.63 mW _______________ _______________ 31.94 mW

100 mW 100.9 mW _______________ _______________ 101.8 mW

1. These performance limits are determined by the zero set specification of the power sensor

used in the measurement plus the measurement noise.

Note The nominal outputs for the 3 µW, 30 µW, 3 00 µW, 3 m W, 1 0 m W,

30 mW and, 100 mW settings are 3.16

µW, 31.6 µW, 316 µW,

3.156 mW, 10.03 mW, 31.78 mW, and 101.3 mW respectively.

Note It is not necessary to check instrument accuracy in dBm. The

power meter uses the same internal circuitry to measure power

and mathematically converts watts to dBm.

HP EPM-441A/442A Service Guide 2-9

Performance Tests

Power Reference Level Test

Power Reference Level Test

Electrical

Characteristics

Power Reference 1 mW Internal 50 MHz oscillator

Power Reference

Accuracy

Performance

Limits

factory set to ±0.7% traceable to

National Institute of Standards

and Technology (NIST).

±1.9% Worst case (power meter

accuracy plus verification

system error).

±0.9% RSS for one year.

Conditions

Description

The power reference oscillator output is factory adjusted to 1 mW ±0.7%.

This accuracy is achieved using a measurement system accurate to 0.5%

(traceable to the National Institute of Standards and Technology) and

allows for a transfer error of

If an equivalent measurement system is employed for verification, the

power reference oscillator output can be verified to 1 mW

maximum error is made up of

worst case oscillator drift for one year,

±0.2% transfer error.

±0.2% when making the adjustment.

±1.9%. The 1.9%

±0.7% factory adjustment accuracy, ±0.5%

±0.5% verification system error and

If the Power Reference Oscillator Level Adjustment is carried out before

this verification test is performed, the result obtained here will be more

accurate.

The power reference oscillator can be set to

equipment and following the adjustment procedure. To ensure maximum

accuracy in verifying the power reference oscillator output, the following

procedure provides step by step instructions for using specified

Hewlett-Packard test instruments of known capability. If equivalent test

instruments are used, signal acquisition criteria may vary and reference

should be made to the manufacturer’s guidelines for operating the

instruments.

2-10 HP EPM-441A/442A Service Guide

±0.7% using the same

Performance Tests

Power Reference Level Test

Equipment

Test power meter ................................... HP 432A

Thermistor Mount ................................ HP 478A Option H75 or H76

Digital Voltmeter (DVM)....................... HP 3458A

Test Setup

Power Meter

POWER

REF

HP 432A

Power Meter

RF

V

Digital

Multimeter

+

INPUT

INPUT

HP 478A

Option H75

Vcomp

Figure 2-3: Power Reference Level Test Setup

Procedure

The following equation allows the Power Reference Oscillator power to be

calculated by measuring the voltages V

2

0

P

meas

2V

compV1V0

-----------------------------------------------------------------------------------=

()

4R CalibrationFactor

–()V

, V1, V

0

2

V

–+

1

The definitions of the terms in this equation are:

•V

is the voltage measured between V

0

applied and after the HP 432A has been zeroed.

is the voltage measured between V

•V

1

applied. This power is approximately 1 mW.

•V

is the voltage between the HP 432A V

comp

chassis ground with power applied.

• R is the resistance of the mount resistor in the HP 432A power

meter.

• Calibration Factor is the value of the thermistor mount at

50 MHz.

, and the resistance R.

comp

comp

comp

and V

and V

comp

with no power

RF

with power

RF

connector and

HP EPM-441A/442A Service Guide 2-11

Performance Tests

Power Reference Level Test

The following procedure should be performed to allow you to calculate

.

P

meas

Note The procedure details the key presses required on the

HP EPM-441A. For the HP EPM-442A the equivalent key presses

should be performed on both channels.

1. Set the DVM to measure resistance. Connect the DVM between

the V

connector on the rear panel of the HP 432A and pin 1 on

RF

the thermistor mount end of the sensor cable. Verify that no power

is applied to the HP 478A.

2. Round off the DVM reading to two decimal places and record this

value as the internal bridge resistance (R) of the HP 432A

(approximately 200

■ R ____________Ω

Ω).

3. Connect the equipment as shown in Figure 2-3, ensuring that the

DVM input leads are isolated from chassis ground.

Note Ensure that the HP 432A and the power meter under test have

been powered on for at least 30 minutes before performing the

following steps.

4. Press on the power meter.

Preset

Local

5. Set the HP 432A RANGE switch to Coarse Zero. Adjust the front

panel Course Zero control to obtain a zero meter indication.

6. Fine zero the HP 432A on the most sensitive range, then set the

RANGE switch to 1 mW.

7. Set the DVM to measure microvolts. Connect the positive and

negative input leads, respectively, to the V

and VRF connectors

comp

on the rear panel of the test power meter.

8. Observe the reading on the DVM. If less than 400

the next step. If 400

µV or greater, press and hold the test power

µV, proceed to

meter Fine Zero switch and adjust the Coarse Zero control so that

the DVM indicates 200

µV or less. Release the Fine Zero switch

and proceed to the next step.

9. Round the DVM reading to two decimal places. Record this

reading as V

■ V

___________

0

.

0

2-12 HP EPM-441A/442A Service Guide

Performance Tests

Power Reference Level Test

10. Turn the power reference on by pressing

Zero

■ , on the HP EPM-441A.

■ , , , on the

Power Ref Off On

Cal

Zero

Cal

Cal

More

Power Ref Off On

HP EPM-442A.

11. Round the DVM reading to two decimal places. Record this

reading as V

■ V

___________

1

12. Disconnect the DVM negative input lead from the V

.

1

connector

RF

on the HP 432A. Reconnect it to the HP 432A chassis ground.

13. Observe the DVM reading. Record the reading as V

■ V

__________

comp

comp

.

14. Calculate the Power Reference Oscillator power using the

following equation:

2

P

meas

-----------------------------------------------------------------------------------=

15. Verify that P

2V

compV1V0

()

4R CalibrationFactor

meas

–()V

0

is within the limits shown in Table 2-4. Record

2

V

–+

1

the reading.

Table 2-4: Power Reference Level Result

Channel B

Min

Channel A

Actual Result

Actual Result

(HP EPM-442A

Max

Only)

0.981 mW ________________ ________________ 1.019 mW

HP EPM-441A/442A Service Guide 2-13

Performance Tests

HP E-Series Power Sensor Interface Test

HP E-Series Po wer Sensor Interface Test

The HP E-series power sensors have their sensor calibration tables stored

in EEPROM which enables the frequency and calibration factor data to be

downloaded automatically by the power meter. The frequency and

calibration factor data have checksums which are compared with the data

downloaded by the power meter. For the HP EPM-442A dual channel

power meter, this test should be performed on both channels.

Procedure

1. When there is no power sensor connected to the Channel A input

the message “No Sensor” (“No Sensor ChA” on the

HP EPM-442A) appears on the measurement window.

2. Connect the HP E-series power sensor to the power meter’s

Channel A input. The message “Reading Sensor ChA” appears.

When all the data is downloaded this message disappears and a

reading is displayed on the measurement window. If the download

fails, a warning message and error flag are displayed on the front

panel. Also, SCPI error message “-310, System Error” is

generated.

3. For the HP EPM-442A repeat these steps for Channel B.

2-14 HP EPM-441A/442A Service Guide

Performance Tests

HP E-Series Power Sensor Functional Test

HP E-Series Power Sensor Functional Test

Description

This test verifies that the meter/sensor combination can make RF

measurements.

The HP E-series power sensors operate over a 90 dB dynamic range

(-70 to +20 dBm). However, since there is an amplifier in these power

sensors, the voltages presented to the power sensor connector are always

within the range of voltages available from the HP 11683A range

calibrator.

Equipment

Power Sensor Cable .............................. HP 11730A

Reference Attenuator ............................ HP 11708A

HP E-series power sensor

HP EPM-441A/442A Service Guide 2-15

Performance Tests

HP E-Series Power Sensor Functional Test

Procedure

To complete the Functional Test the following procedure should be

performed.

Note The procedure details the key presses required on the

HP EPM-441A. For the HP EPM-442A the equivalent key presses

should be performed on both channels.

1. Connect the equipment as shown in Figure 2-4.

Power Meter

HP E-Series

Power Sensor

POWER

REF

CHANNEL A

HP 11730A

Figure 2-4: Sensor Functional Test Setup

2. Press .

3. On the power meter press , . Wait approximately

Preset

Local

Zero

Cal

Zero

10 seconds for the wait symbol to disappear. Verify that the

display reads 0

4. Press to calibrate the power meter.

Cal

±50 pW.

5. Turn the power reference on by pressing

Zero

■ , on the HP EPM-441A.

■ , , , on the

Power Ref Off On

Cal

Zero

Cal

Cal

More

Power Ref Off On

HP EPM-442A.

2-16 HP EPM-441A/442A Service Guide

Performance Tests

HP E-Series Power Sensor Functional Test

6. Connect the 30 dB attenuator as shown in Figure 2-5.

Power Meter

HP E-Series

Power Sensor

HP 11708A

30 dB ATTENUATOR

CHANNEL A

HP 11730A

Figure 2-5: Sensor Functional Test Setup with Attenuator

7. Press , , , and select to

System

Inputs

Input Settings

More

Range

“LOWER”. This switches to the power sensor’s low range.

8. Verify that the display reads -30 dBm

9. Press and set to “UPPER”. This switches to the power

Range

±1 dB. Record the reading.

sensor’s upper range.

10. Verify that the display reads -30 dBm

11. Press and set to “LOWER”.

Range

±1 dB. Record the reading.

12. Disconnect the 30 dB attenuator and reconnect as shown in

Figure 2-4.

13. Verify that an overload error is displayed on the status line at the

top of the power meter’s display.

14. Press and set to “UPPER”.

15. Verify that the display reads 0 dBm

Range

±1 dB. Record the reading.

Table 2-5: Functional Test Result

Channel B

Test

Channel A

Overload Error

Overload Error

(HP EPM-442A

Only)

Low Range, 30 dB pad

Upper Range, 30 dB pad

Low Range, no pad

High Range, no pad

HP EPM-441A/442A Service Guide 2-17

Performance Tests

Performance Test Record

Performance Test Record

Model HP EPM-441A/442A Power Meter

Tested by ___________________________________________

Serial Number _______________________________________

Date _______________

Table 2-6: Performance Test Record

Channel A

Test Min Result

Zero Test

Instrument Accuracy

3

µW

10

µW

µW

30

µW

100

300

µW

1 mW

3 mW

10 mW

30 mW

100 mW

Power Reference

P

meas

Interface Test Pass/Fail ___________ ___________ Pass/Fail

Functional Test

Low Range, 30 dBm pad

Low Range, 30 dBm pad

Low Range, no pad

Upper Range, no pad

−76.40 nW +76.40 nW

µW

3.100

9.900

µW

µW

31.40

µW

99.50

0.314 mW

0.995 mW

3.141 mW

9.984 mW

31.63 mW

100.9 mW

0.981 mW ___________ ___________ 1.019 mW

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Actual

Result

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

Channel B

Actual

Result

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

___________

Max

Result

µW

3.230

10.10

µW

µW

31.80

µW

100.5

0.318 mW

1.005 mW

3.171 mW

10.08 mW

31.94 mW

101.8 mW

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

2-18 HP EPM-441A/442A Service Guide

3

Adjustments

Adjustments

Introduction

Introduction

This chapter describes adjustments and checks which ensure proper

performance of the power meter. Adjustments are not normally required

on any fixed periodic basis, and normally are performed only after a

performance test has indicated that some parameters are out of

specification. Performance tests should be completed after any repairs

that may have altered the characteristics of the power meter. The test

results will make it possible to determine if adjustments are required.

Allow 30 minutes for the power meter to warm up, and then remove the

cover, for access to the test and adjustment points.

To determine which performance tests and adjustments to perform after a

repair, see “Post-Repair Adjustments”, on page 3-3.

Safety Considerations

This warning must be followed for your protection and to avoid damage to

the equipment being used.

WARNING Adjustments described in this chapter are performed with

power applied to the instrument and with protective

covers removed. Maintenance should be performed only by

trained personnel who are aware of the hazards involved.

When the maintenance procedure can be performed

without power, the power should be removed.

3-2 HP EPM-441A/442A Service Guide

Adjustments

Introduction

Equipment Required

The adjustment procedures include a list of recommended test equipment.

The test equipment is also identified on the test setup diagrams.

Post-Repair Adjustments

Table 3-1 lists the adjustments related to repairs or replacement of any of

the assemblies.

Table 3-1: Post Repair Adjustments, Tests, and Checks

Assembly Replaced

A1 Power Supply Self Test

A2 Processor Assembly Frequency and Level Adjustments,

A3 Front Panel Assembly Instrument Accuracy Test, Display

A4 Interface Assembly All automated Tests

A5 Daughter Assembly Instrument Accuracy Test

A6 Measurement Assembly Zero Test, Instrument Accuracy Test

W1 or W2 Power Sensor

Cable

BT1 Battery Battery Self Test

Power Reference Cable Kits Power Reference Level Test

Related Adjustments, Performance

Tests or Sel f Tes t s

Power Reference Level Test, Display

Brightness and Contrast Adjustment.

Brightness and Contrast Adjustment.

Instrument Accuracy Test, Zero Test

HP EPM-441A/442A Service Guide 3-3

Adjustments

Power Reference Oscillator Frequency Adjustment

Power Reference Oscillator Frequency Adjustment

Note Adjustment of the power reference oscillator frequency may also

affect the output level of the oscillator. Therefore, after the

frequency is adjusted to 50.0

checked as described in “Power Reference Oscillator Level

Adjustment”, on page 3-6.

The power reference oscillator frequency is a nominal

specification.

Description

Variable inductor A2L9 is adjusted to set the power reference oscillator

output frequency to 50.0

characteristic.

Power Meter

±0.5 MHz. This frequency is a supplemental

±0.5 MHz, the output level should be

Frequency Counter

POWER

REF

Figure 3-1: Adjustment Setup

Equipment

Frequency Counter................................ HP 5314A

Procedure

1. Ensure that the power meter has been powered on for at least

30 minutes before making any measurements.

2. Connect the equipment as shown in Figure 3-1. Set up the counter

to measure frequency.

3-4 HP EPM-441A/442A Service Guide

Power Reference Oscillator Frequency Adjustment

3. Turn the power reference on by pressing

Zero

■ , on the HP EPM-441A.

■ , , , on the

Power Ref Off On

Cal

Zero

Cal

Cal

More

Power Ref Off On

HP EPM-442A.

4. Observe the reading on the frequency counter. If it is

±0.5 MHz, no adjustment of the power reference oscillator

50.0

frequency is necessary. If it is not within these limits, adjust the

power reference oscillator frequency as described in step 5 and

step 6.

5. Remove the power meter cover.

6. Adjust A2L9 to obtain a 50.0

±0.5 MHz indication on the

frequency counter. Refer to Figure 3-2 for the position of A2L9.

A2R90

BT1

Adjustments

A2 Assembly

A2J13

J12

A2L9

Front Panel

Figure 3-2: A2L9 Adjustment Location

HP EPM-441A/442A Service Guide 3-5

Adjustments

Power Reference Oscillator Leve l Adjustme nt

Power Reference Oscillator Level Adjustment

Description

The power reference oscillator is factory adjusted to 1.0 mW ±0.7%. This is

done using a special measurement system accurate to 0.5% traceable to

the National Institute of Standards and Technology (NIST) and allowing

for a 0.2% transfer error. To ensure maximum accuracy in re-adjusting the

power reference oscillator, the following procedure provides step-by-step

instructions for using specified Hewlett-Packard instruments of known

capability. If equivalent instruments are used, signal acquisition criteria

may vary and reference should be made to the manufacturer’s guidelines

for operating the equipment.

Note The power meter may be returned to the nearest HP office to have

the power reference oscillator checked and/or adjusted.

Power Meter

POWER

REF

HP 478A

Option H75

HP 432A

Power Meter

Digital

Multimeter

RF

V

Vcomp

Figure 3-3: Adjustment Setup

+

INPUT

INPUT

3-6 HP EPM-441A/442A Service Guide

Adjustments

Power Reference Oscillator Level Adjustment

For this adjustment the following mathematical assumptions are made:

Equation 1:

2

2

V

–+

1

P

meas

2V

compV1V0

-----------------------------------------------------------------------------------=

()

4R CalibrationFactor

–()V

0

can be manipulated to give equation 2:

V

V

1

compV0

V

comp

2

– 4R

10()

3–

()CalibrationFactor()–+=

by using the following assumptions:

2

V

V

– V

0

2

=

1

1V0

2

–()–

The error in doing this is:

2

V

1

So if , that is, then the error can

2

V

–+()– V

0

2V0V1V

–()2V

2V1V

0

0

compV1V0

be ignored. In practice and . The error is less

2

2

V

–()– 2V

0

1

–()«V

V

4Volts~V

comp

2

– 2V

+2V

0

«

0Vcomp

400µV<

0

1V0

–()==

0V1V0

than 0.01%.

By substituting equation 3 into equation 1 and manipulating the result

you get:

0V1V

–()

2

2– V

0

compV1V0

–()=410

3–

()R CalibrationFactor()+

This quadratic can be solved to give equation 2.

The definitions of the terms in equation 2 are:

•V

is the voltage measured between V

0

comp

and V

with no power

RF

applied and after the HP 432A has been zeroed.

is the voltage measured between V

•V

1

comp

and V

with power

RF

applied. This power is approximately 1 mW.

•V

comp

is the voltage between the HP 432A V

connector and

comp

chassis ground with power applied.

• R is the resistance of the mount resistor in the HP 432A power

meter.

• Calibration Factor is the value of the thermistor mount at

50 MHz.

HP EPM-441A/442A Service Guide 3-7

Adjustments

Power Reference Oscillator Leve l Adjustme nt

Equipment

Test power meter ................................... HP 432A

Thermistor Mount ................................ HP 478A Option H75

Digital Voltmeter (DVM)....................... HP 3456A

Procedure

Note The procedure details the key presses required on the

HP EPM-441A. For the HP EPM-442A the equivalent key presses

should be performed on both channels.

1. Set up the DVM to measure resistance. Connect the DVM between

the V

the thermistor mount end of the sensor cable. Verify that no power

is applied to the HP 478A

2. Round off the DVM reading to two decimal places and record this

value as the internal bridge resistance (R) of the test power meter

(approximately 200

■ R (Internal Bridge Resistance)_______________Ω

3. Connect the equipment as shown in Figure 3-3. The leads should

be isolated from ground. Ensure that the power reference

oscillator is off. Ensure that both the power meter under test and