Page 1

Contents

HP E1463A Form C Switch Module Use r’s Manual

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reader Comment Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1. Getting Started with the HP E14 63A F orm C Switc h . . . . . . . . . . . . . . 11

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Instrument Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Form C Switch Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Basic Operati on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Typical Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Configuring the Form C Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

General Purp os e R elay Configuration . . . . . . . . . . . . . . . . . . . . . . . . 14

Digital Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting the Logical Address Switch . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setting the Interrupt Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installing the Form C Switch in a Mainfram e . . . . . . . . . . . . . . . . . . . . . . . 17

Terminal Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Scre w Type Terminal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Terminal Module Option A3 G . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting User Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Attaching a T erminal Module to t he Form C Switch . . . . . . . . . . . . . . . . . . . 21

Wiring a Terminal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Protecting Relays and Circuit s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Relay Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Adding Rela y and Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . 25

Maximum Allowable M odule Switch Curren t . . . . . . . . . . . . . . . . . . . . 26

Programming the Form C Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Specifying SCPI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Channel List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Card Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Channel Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Initial Opera ti on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 2. Using the HP E1463 A Form C Swi tc h . . . . . . . . . . . . . . . . . . . . . . 31

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Form C Switch Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Power-on and Reset Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Module Iden tification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Switching Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Scannin g Cha nne ls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Querying the Form C S witch Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

HP E1463A Form C Switch Module User’s Manual Contents 1

Page 2

Using the Scan Complete Bi t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Recalling and Saving States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Detecting Error Conditi ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Synchronizing the Form C Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 3. HP E1463A Form C Switch C ommand Reference . . . . . . . . . . . . . . . . 49

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Command Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Common Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

SCPI Command F ormat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Linking Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

SCPI Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

ABORt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

:COUNt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

:COUNt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

DISPlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

:MONitor:CARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

:MONitor[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

INITiate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

:CONTinuous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

:CONTinuous? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

OUTPut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

:EXTernal[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

:EXTernal[:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

[:STATe] ? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

:TTLTrgn[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

:TTLTrgn[:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

[ROUTe:] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

CLOSe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

CLOSe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

OPEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

OPEN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

SCAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

STATus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

:OPERati on :CONDi tion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

:OPERati on:E N ABle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

:OPERati on:E N ABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

:OPERati on[:E VENt]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

:PRESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

SYSTem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

:CDEScript i on? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

:CPON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

:CTYPe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

:ERRor? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

TRIGger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

2 HP E1463A Form C Switch Module User’s Manual Contents

Page 3

[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

:SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

IEEE 488.2 Common Command Reference . . . . . . . . . . . . . . . . . . . . . . . . 75

SCPI Command Qui ck Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Appendix A. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Relay Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Appendix B. Register-Based Programming . . . . . . . . . . . . . . . . . . . . . . . . . . 79

About This Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Register Addressi ng . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

The Base Addres s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Register Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Reading and Writing to the Register s . . . . . . . . . . . . . . . . . . . . . . . . 82

The Manufa cturer Identifica ti on Register . . . . . . . . . . . . . . . . . . . . . . 82

The Device Type Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

The Status/ Control Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

The Relay C ontrol Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Reading the Re gisters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Making Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Scannin g Cha nne ls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Appendix C. Form C Switch Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . 93

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

HP E1463A Form C Switch Module User’s Manual Contents 3

Page 4

Notes

4 HP E1463A Form C Switch Module User’s Manual Contents

Page 5

Certification

Hewlett-Packard Company certifies that this product met its publi shed s peci fica t ions at the time of ship me nt from th e fact ory. Hewlet tPackard further certifi es that its calibrat ion mea sureme nt s are tracea ble to the Unit ed Sta tes Na tion al Institut e of Standards and Technology (formerly National Bureau of Standards), to the extent allowed by that organization’s calibration facility, and to the calibration

facilities of other International Standards Organization members.

Warranty

This Hewlet t-Pa ck ar d product is warr ante d agai nst de fect s in mate rials and w orkmansh ip for a period of three years from date of shipment. Duration and conditi ons of warranty for this product may be superse ded when the pr oduct i s i nt egrated into (becomes a part of)

other HP product s. Du ring the warranty period, Hewlett-Pa ck ar d Company will, at its opt ion, either repair or repl ace pr oducts which

prove to be defective.

For warranty se r vice or repair, this product mu st be r etur ned to a service facility designated by Hewlett-Packard (HP). Buyer shal l pr epay shipping cha rges to HP and HP shall pay shipping charges to re tu rn t he product to Bu yer. Howe ver, Buyer shall pa y all shi p ping

charges, duties, and taxe s for products returned to HP from anot her count r y.

HP warrants that its softwar e and firmwar e designa ted b y HP for use with a product will execute its programmin g instru cti ons wh en

properly installe d on that product. HP does not warrant that the operat ion of the product, or software , or firmware will be uninterrupted

or er ro r f r ee.

Limitation Of Warrant y

The foreg oin g warra nt y sh al l not apply t o defects resulting from improper or inadequa te maintenan ce by Buyer, Buyer-suppl ied products or interfacing, unauthori ze d m odificati on or misus e, operation outside of the environmenta l specificat i ons for the product, or improper site prep arat i on or maint ena nce.

The design and imp le mentation of any circuit on this product is the sole responsibility of the Buyer. HP does not warrant the Buyer’s

circuitr y or malfunctions of HP products that result from the Bu yer’s circuitry. In addition, HP does not warrant an y damage that occurs as a result of the B uyer’s circuit or an y defects that resul t from Buyer-supplied product s.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP SPECIFICALLY DISCLAIMS THE IMPLIED WARR ANT IES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedie s

THE REMED IES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES. HP SHALL NOT BE LIABLE

FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Notice

The information contained in this document is subject to change without notice. HEWLETT-PACKARD (HP) MAKES NO WARRANTY OF ANY KIND W ITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. HP shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance or use of this material. This document c ontains proprietary information which is prote ct ed by copyright. A ll rights are reserved. No part of thi s d ocument may be photocopied, reproduced, or translate d to another lan guage wit h out the prior written consent of Hewlett -Packar d C ompany. HP assumes no

responsibility for the use or reliability of its software on equipment that is not furnished by HP.

Restricted Rights Legen d

Use, dupli ca tion or discl osu re by the U. S. Go vernme nt is subje ct to rest rict i ons as set fort h in subparagraph (c)(1) (ii ) of the Rights in

Technical Data and Comp uter Softwa re clause in D F ARS 252.227-701 3.

Hewlett-Packar d Company

3000 Hanover Street

Palo Alto, Cal if ornia 943 04 U.S. A.

Rights for non-DOD U.S. Government Departments and Agen ci es are as set f orth in F AR 52.227 -19 (c) (1,2).

HP E1463A 32-Ch ann el, 5 Amp, Form C Switch M odule User’s Manua l

Copyright © 1996 He wle tt-Pa cka rd Company. All Right s Reser ve d.

Edition 3

HP E1463A 32-Channel, 5 Amp, Form C Switch Module User’s Manual 5

Page 6

Documentatio n History

All Editions and Updates of this manual and their creation date are listed below. The first Edition of the manual is Edition 1. The Edition number increment s by 1 whenever the manua l is revised . Updates , which are issued betw een Edi ti ons, c ontain repla ce ment pa ges

to correct or add additional information to the current Edition of the manual. Whenever a new Edition is created, it wil l contain all of

the Update inf ormat ion for the pre viou s Editi on. Each new Ed iti on or Update also incl ude s a revis ed c op y of this documentation history page.

Edition 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . July 1991

Edition 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . January 1994

Edition 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . January 1996

Safety Symbols

Instruction manual symbol affixed to product. Indicat es that the us er must refer to t he

manual for specific WARNING or CAUTION information to avoid personal injury

or damage to the product.

Indicates the field wiring terminal that must

be connected to earth ground before operating the equipment—protects against electrical shock in case of fault.

Frame or chassis ground termi nal — t ypi-

or

cally connects to the equipment’s metal

frame.

WARNING

CAUTION

Alternating current (AC).

Direct curren t (DC).

Indicate s ha za rdous voltages.

Calls at te nt i on t o a pr ocedure, practi ce, or

condition that could cause bodily injury or

death.

Calls at te nt i on t o a pr ocedure, practi ce, or condition that could possibly cause damage to

equipme nt or perma nen t los s of data.

WARNINGS

The following ge ner al safet y prec aut ions mus t be observed du ring al l phas es of oper ation , ser vice , and repai r of this pr oduct.

Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and inten ded use of the product. Hewlett-Packar d Company assumes no liability for the cust o mer’s failu re to

comply with these requirements.

Ground the equipment: For Safety Cl as s 1 equipmen t (equ ipment ha vin g a protective ea rth ter mi nal) , an unint erru ptib le sa fety earth

ground must be provide d from the ma in s power sour ce to the produ ct input wi rin g termi nals or suppli ed power cable .

DO NOT operate the produc t in an explosive at mospher e or in the presen ce of flammable gases or fume s.

For continued protect ion a gainst fire, repl ace the line fuse (s) only with fuse(s) of the same voltage and current rating and type .

DO NOT use repaired fuses or short-circui ted fuse holders.

Keep away from live circuits: Operatin g personnel must not remove equipment covers or shields. Procedures involving the removal

of covers or shields are for use by service-trained personnel only. Under certain conditions , dangerous voltages m ay exist even with the

equipment switched off. To avoid dangerous ele ctrical shock , DO NOT perf orm procedures involving cover or shield removal unless

you are qualified to do so.

DO NOT operate damaged equipment: Whene ver it i s p ossibl e tha t the sa fe ty protection features bui l t into t hi s product have been impaired, eithe r t hr ough physical dam age, excessive moist ure , or any other reason, REMOVE POWER and do not use the product until

safe operation can be verified by service-trained personnel. If necessary, return the product to a Hewlett-P ackar d Sale s and Ser vice Office for service and repair to ensure that safety features are maintaine d.

DO NOT service or adjust alon e: Do not attempt internal service or adjustment unless another person, capable of rendering first aid

and resuscitation, is present.

DO NOT substitute parts or modify equipment: Because of the dan ger of introducing addition al hazards , do not install substitute

parts or perform any unauthorized modifica tion to the product. Retur n the product to a Hewlet t-P ackar d Sales and Ser vice O ffice for

service and repair to ensure that sa fe ty features are ma i nt ai ned.

6 HP E1463A 32-Channel, 5 Amp, Form C Switch Module User’s Manual

Page 7

Declaration of Conformity

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: Hewlett-Pa ckar d C ompany

Loveland Manufacturing Center

Manufact urer’s Addre s s: 815 14th Street S.W.

Loveland, Colorado 80537

declares, that the product:

Product Name: 32-Channel F orm C Switch

Model Number : E1463A

Produc t Opt ion s: All

conforms to the following Pr od uct Spe cifi cati ons :

Safety: IEC 1010-1 (1990) Incl . Amend 1 (1992) /E N610 10-1 (1993)

CSA C22.2 #1010.1 (1 992)

UL 3111

EMC: CISPR 11:1990/EN55011 (1991): Group1 Class A

IEC 801-2:1991/ E N5008 2-1 (1 992) : 4kVCD, 8k VA D

IEC 801-3:1984/ E N5008 2-1 (1 992) : 3 V/m

IEC 801-4:1988/ E N5008 2-1 (1 992) : 1kV P ower Lin e

Supplementary Information: The product her ewi th c omplies w ith the requirements of t he Low Voltage Dire ctive

73/23/EEC and the EMC Directive 8 9/336/ EEC (inclu si ve 93/68/EEC ) and carr ies the "CE" mark acc ordingly.

Tested in a typical configuration in an HP C-Size VXI m ai nfr am e.

August 20, 199 5 Jim White , QA Manager

European conta ct: Your loca l He wlett-Pa cka rd Sales a nd Servi ce O ffic e or Hewlett- Packa rd GmbH, Departm ent

HQ-TRE, Herr en ber ger Straße 130, D-71034 Böblingen, Germ a ny (FAX +49-7031-14- 3143).

HP E1463A 32-Channel, 5 Amp, Form C Switch Module User’s Manual 7

Page 8

Notes

8 HP E1463A 32-Channel, 5 Amp, Form C Switch Module User’s Manual

Page 9

Please fold and tape for mailing

Reader Comment Sheet

HP E1463A 32-Channel, 5 Amp, Form C Switch User’s Manual

Editio n 3

You can help us improve our manual s b y sharing your commen ts and sug gesti ons. In apprec iat ion of your time, we will

enter yo u in a quarterly drawing for a Hewlett -Pac kar d Palmt op Personal Computer (U.S. government employees

cannot participate in the drawing).

Your Name

C ompany Nam e

Job Title

Address

Please list the s ystem controller, operati ng s ystem, progr am ming lan guage, and plug-in modules you are using.

City, State/Province

Country

Zip/Postal Code

Telephone Number with Area Code

fold here

BUSINESS REPLY MAIL

FIRST CLASS PERMIT NO.37 LOVELAND, CO

HEWLETT-PACKARD COMPANY

cut along this line

Measurement Systems Division

Learning Products Department

P.O. Box 301

Loveland, CO 80539-9984

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

fold here

Please pencil- in on e circle for each statement below: Disagree Agree

• The documentation is well organized. OOOOO

•Instructions are easy to understand. OOOOO

•The documentation is clearly written. OOOOO

•Examples are clea r a nd useful. OOOOO

•Illustrati ons are clear and help ful. OOOOO

•The documentation meets my overall expectations. OOOOO

Please write any comments or suggestions below--be specific.

Page 10

10 HP E1463A 32-Channel, 5 Amp, Form C Switch User’s Manual

Page 11

Getting Started with the HP E1463A

Using This Chapter

This chapter includes a Form C switch description, addressing guidelines,

configuration information, and an example program to check initial

operation. Chapter contents are as follows:

Chapter 1

Form C Switch

• Inst rumen t Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 11

• Form C Switch Description . . . . . . . . . . . . . . . . . . . . . . . . . . Page 11

• Warnings and C aut ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pag e 13

• Configuring the Form C Switch. . . . . . . . . . . . . . . . . . . . . . . Page 14

• Installing the Form C Switch in a Mainframe. . . . . . . . . . . . Page 17

• Terminal Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 18

• Connecting User Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 20

• Attaching a Terminal Module to the Form C Switch. . . . . . . . Page 21

• Wiri ng a Terminal M odu le . . . . . . . . . . . . . . . . . . . . . . . . . . Pag e 22

• Protecting Relays and Circuits. . . . . . . . . . . . . . . . . . . . . . . . Page 24

• Prog ramming the F orm C Switch . . . . . . . . . . . . . . . . . . . . . Page 2 7

• Initial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 29

Instrument Definition

HP plug-in modules installed in an HP mainframe or used with an

HP command module are treated as independent instruments each having

a unique secondary HP-IB address. Each instrument is also assigned a

dedicated error queue, input and output buffers, status registers and, if

applicable, dedicated mainframe/command module memory space for

readings or data. An instrument may be composed of a single plug-in

module (such as a counter) or multiple plug-in modules (for a switchbox

or scanning multimeter instrument).

Form C Switch Description

The HP E1463A 32-Channel, 5 Amp, Form C Switch Module is a C-Size

VXIbus and VMEbus r egister-based produ ct which can be used for

switching, scanning, and control. The switch can operate in a C-Size

VXIbus or VMEbus mainframe. The switch has 32 channels of Form C

relays. Each channel includes a relay with common (C), normally open

(NO), and normally closed (NC) contacts.

For th e Form C switch, switching consists of opening or closing a channel

relay to provid e alternat e co nnect ions to us er devices. Scanning consists o f

closing a set of relays, one at a time .

Chapter 1 Getting Started with the HP E1463A Form C Switch 11

Page 12

Basic Operation As shown in Figure 1-1, the Form C switch module consists of 32 channels

(channels 00 through 31). Each channel uses a nonlatching relay. Varistors

(MOVs) can be added for relay protection, and resistors or fuses can be

added for circuit protection. See “Adding Relay and Circuit Protection” on

page 25 f or more i nf ormat ion. External pull-up res istors can a lso b e adde d

for digital output applications. See pages 14 and 37 for additional

inform atio n abou t these ap p li c ations.

Figure 1-1. Form C Simplified Schemati c

Each channel is switched by opening or c losing the appropriate channel

relay. Since the relays are nonlatching, the relays are all open dur i ng

power-up or power-down. W hen a reset occurs, all channel commons (C )

are connect ed to the corresponding nor mally closed (NC) contacts. When a

channel is closed, the common contact (C) is connected to the normally

open contact (NO). Us er inputs an d outputs to each channel are via the NO,

NC, and C terminal connectors on the terminal module.

12 Getting Started with the HP E1463A Form C Switch Chapter 1

Page 13

Typical

Configuration

The Form C switch accepts us er inputs up to 125 Vdc or 250 Vac

Maximum rated power capacity (external load) is 150 Wdc or 1250 VA per

channel. Per modul e, you can switch 1500 Wdc or 12500 VA.

As noted, the switch may be configured for general purpose switching/

scanning or digital output app lications. For general purpose switching or

scannin g, no additi onal c onfigurat i on is required. To confi gure the swit ch

for digital output applications, install external pull-up resistors as required.

Multiple Form C swit ch mo dules ca n b e confi gure d as a switch b ox

instrument. When using a switchbox instrument, multiple Form C switch

modules within the switchbox instrument can be address ed using a s ing le

interface address. This configurati on, however, requires the us e of SCPI

(Standard C omm a nds for Programmable Instruments) commands. SCPI

commands are discussed throughout this manual and information on the

switchbox instrument configuration can be found in the C-Size VXIbus

System Installation an d Getting Start ed Guide.

Warnings and Cautions

rms

.

WARNING SHOCK HAZARD. Only qualified, service-trained personnel

who are aware of the hazards involved should install, configure,

or remove the Form C switch module. Use only wire rated for

the highest input voltage and remove all power sources from

the mainframe and installed modules before installing or

removing a module.

CAUTION MAXIMUM VOLTAGE/CURRENT. Maximum allowable voltage per

channel for the Form C switch is 125 Vdc or 250 Vac

per channel is 5 Adc or ac

load is 150 Wdc or 1250 VA per channel or 1500 Wdc or 12500 VA per

module. Exceeding any limit may damage th e Form C switc h.

STATIC ELECTRICITY. Stat ic electric ity is a major cause of component

failure. To prevent damage to the electrical components in the Form C

switch, observe a nt i-stat ic t echniques whenever r emoving a module from

the mainfra me or whenever working on a module. The F orm C switch is

susceptible to static discharges. Do not install the Form C switch module

without its metal shield attached.

(non-inductive). Maximum power of an external

rms

. Max imum c u rrent

rms

Chapter 1 Getting Started with the HP E1463A Form C Switch 13

Page 14

Configuring the Form C Switch

Typical Form C switch configurations are as a general purpose relay or

digital out put.

General Purpose

Relay Configuration

As factory-configured, the Form C switch module is set for general purpose

relay configuration. For th is conf igurat i on, you can switc h channels by

opening or closing channel relays or you can scan a set of channels.

Figure 1-2 shows a typical general purpose relay configuration for channel 00.

When the relay is open (NC terminal is connected to the C terminal),

load 1 is connected. When the relay is cl osed (NO terminal is c onnected

to the C terminal), load 2 is connected.

Figure 1-2. General Purpose Relay Configurat ion

Digital Ou tp u t

Configuration

By installing external pull-up resistors, the Form C switch can be

configured as a digital output device.

Figure 1-3 shows channel 00 con figured for digital output operation. W hen

the channel 00 relay is op en (NC connected to C), point 1 is at + V. When

the channel 00 relay is closed (NO connected to C), point 1 is at 0 V.

Figure 1-3. Digital Outp ut Con figu rati on

14 Getting Started with the HP E1463A Form C Switch Chapter 1

Page 15

Setting th e Logical

Address Switch

The logical address switch (LADDR) factory setting is 120. Valid

addresses are from 1 to 255. The Form C switch module can be configured

as a single instrument or as a switchbox. Refer to the C-Size VXIbus System

Installation an d Getting Start ed Guide for addressing information. Refer to

Figure 1-4 for switch position information.

Figure 1-4. Setting the Logical Address Switch

Note The addr ess switc h selec t ed valu e must b e a multiple of 8 if the modu le is

the first module in a swit chbox used with a VXIbus c ommand module, and

being instructed by SCPI commands.

Chapter 1 Getting Started with the HP E1463A Form C Switch 15

Page 16

Setting th e

Interrup t P riorit y

The Form C switch module generates an interrupt after a channel has been

closed. These interrupts are sent to, and a cknowledgments a r e received

from, the command module (HP E1406A, for example) via the VXIbus

backplane int err upt lines.

For most applications where the Form C switch module is installed in an

HP 75000 Series C mainfr a me, th e interrupt prior it y ju mper does not have

to be moved. This is because the VXIbus interrupt lines have the sa me

priority, and interrupt priority is establis hed b y installi ng mo dules in slots

numerically closest to the command module. Thus, sl ot 1 has a higher

priority than slot 2, slot 2 has a higher priority than slot 3, and so on.

Refer to Figure 1-5 to change the interrupt priority. You can select eight

different interrupt priority levels. Level 1 is the lowest priority and Level 7 is

the highest priority. Level X disables the interrupt. The module’s factory

setting is Level 1. To change, remove the 4-pin jumper (HP P/N 1258-0247)

from th e old priority loca tion a nd r einstall in the new priority loca tion. If th e

4-pin jumper is not used, the two jumper locations must have the same interrupt

priority level selected.

Figure 1-5. Setting the Interrupt Line

Note The interrupt priority jumper MUST be installed in position 1 when using the

HP E1405/06A command module. Level X interrupt priority should not be

used under normal operating conditions. Changing the priority level jumper is

not recommended. Do not change unless specifically instructed to do so.

16 Getting Started with the HP E1463A Form C Switch Chapter 1

Page 17

Installing the Form C Switch in a Mainframe

The HP E1463A may be installed in any slot (except slot 0) in a C-size VXIbus

mainframe. Refer to Figure 1-6 to install the Form C swit ch in a mai n f ra me.

Set the extraction levers out .

Slide the HP E1463A into any slot

(except slot 0) until the backplane

connectors touch.

Tighten the top and bottom screws to

secure the Form C switch module to the

mainframe.

NOTE: The extract ion levers will not

seat the backplane connectors on older

VXIbus mainframes. You must manually

seat the connectors by pushing in the

module until the module’s front panel is

flush with the front of the mainframe. The

extraction levers may be used to guide or

remove the Form C switch.

Seat the HP E1463A int o t he

mainf rame by pu shi ng in th e

extraction levers.

To remove the module from the mainf rame,

reverse the procedure.

Figure 1-6. Install ing the Form C Swi tch in a VXIbus Mai nframe

Chapter 1 Getting Started with the HP E1463A Form C Switch 17

Page 18

Terminal Modules

The HP E1463A 32-Channel, 5 Amp, Form C Switch Module is comprised

of a relay switch card and a screw type standard terminal module. User

inputs to the Form C sw it c h ar e to the normally open (NO), normally c lo sed

(NC), and commo n (C) termina l connectors on the screw type termina l

module. If the screw type terminal module is not desired, a solder eye

terminal module (Option A3G) is availa ble. If the solder eye terminal

module without the HP E1463A Form C switch card is desired, order

HP part numb er E1463-80 012. See Figure 1-9 on page 20 for the Form C

swi tch connector pin-out wh ich mates to t he terminal mod ule.

Screw Type

Terminal Module

Figure 1-7 shows the HP E1463A’s standard screw type terminal module

connectors and associated channel numbers. Use the guidelines below for

wire connections.

Figure 1-7. HP E1463A Standard Screw Type Terminal Module

Wiring Guidelines • Be sure the wires make good connections on scre w term ina ls.

• Maximum terminal w ire size is No. 16 AWG. When wiring all

channels, a smalle r gau ge wire (N o. 20 - 22 AWG ) is recomme nde d.

Wire ends s hould be stripped 6 mm (

prevent single strands from shorting to adjacent terminals.

≈ 0.25 in ch ) and t inned to

Note Refer to pages 22 and 23 before attempting to wire the terminal module.

18 Getting Started with the HP E1463A Form C Switch Chapter 1

Page 19

Terminal Module

Option A3G

A terminal module with screw type terminals is provided standard with the

HP E1463A. Option A3G can be ordered if a solder eye terminal module is

desired. Option A3G provides a plastic terminal module housing with solder

eye connectors (see Figure 1-8). This allows you to solder wires onto

connectors which are then inserted directly into the mating connector of the

Form C switch. Use the pin-out diagram on page 20 to make the connections.

Figure 1-8. Solder Eye Connecto r

Chapter 1 Getting Started with the HP E1463A Form C Switch 19

Page 20

Connecting User Inputs

Figure 1-9 shows the front panel of the HP E1463A and the Form C

swi tch’s con nect or pi n-out which mates to t he terminal mod ule.

Figure 1-9. HP E1463A Form C Switch Pin-out

20 Getting Started with the HP E1463A Form C Switch Chapter 1

Page 21

Attaching a Terminal Module to the Form C Switch

Extend the extrac tion levers on the

terminal module.

Align the terminal module connectors to the

Form C switch module connectors.

Apply gentle pressu re to atta ch the

terminal module to the Form C switch

module.

Push in the extraction levers to

lock the terminal module onto the

Form C switch module.

To remove the terminal module from the HP E1463A, use a

small screwdriver to release the two extraction levers. Push

both levers out simultaneously to free the terminal module from

the Form C switch module.

Chapter 1 Getting Started with the HP E1463A Form C Switch 21

Page 22

Wiring a Terminal Module

The following illustra tions show how to connect field wiring to the terminal

module.

Remov e Cl ear Cover

Make Connection s

Remove and Retain Wiring Panel

Install Connectors (solder eye only)

Continued on Next Pag e

Route Wiring

22 Getting Started with the HP E1463A Form C Switch Chapter 1

Page 23

Replace Wiring Panel Replace Clear Cover

Install the Terminal

Module

Push in the Extraction Levers to Lock the

Terminal M odule onto the HP E1463A

Chapter 1 Getting Started with the HP E1463A Form C Switch 23

Page 24

Protecting Relays and Circuits

Relays have a shorter life span than other electronic parts such as ICs.

Because of their mechanical nature, relays usually have about 10 million

operations (at 30 operations per second) which is not quite 100 hours.

Therefore, to get the full lif e out of a rela y in a switching module, you must

protect the relay. The following sections provide additional information

about protecting your relays and circuits.

Relay Reliability To make sure you get t he full life of your relays, keep the f ol lowing in mind:

• Be aware of non-resistive loads. When switching inductive loads,

high voltages (thousands of volts) are pr oduced a cross the relay

contacts. T his c ause s a rc ing a nd tr ansfer of material between contacts.

Oxides and carbides from components of the atmosphere coat the

contacts and cause high c ontact r esista nce. The transfer of material

creates hills and valleys which lock together to "weld" contacts. Motor

loads, for example, produce large inrush currents that can be 5 to 10

times greater than the steady state current. Table 1-1 summarizes how

many times greater the inrush current can be for different types of loads.

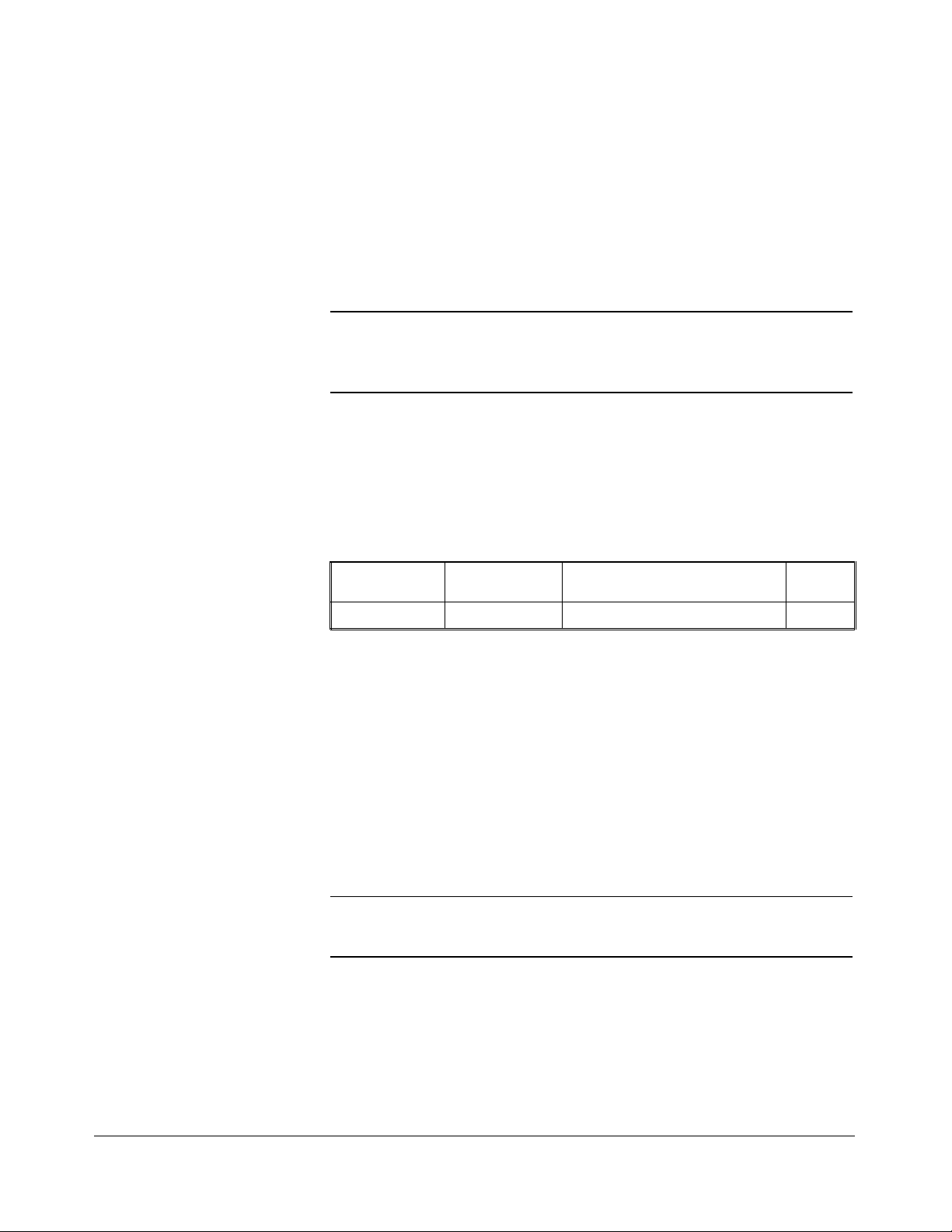

Table 1-1. Inrush Currents

Type of Load

Resistive 1

Solenoid 10 - 20

Motor 5 - 10

Incandescent Lamp 10 - 15

Mercury Lamp 3

Sodium Vapor Lam p 1 - 3

Capacitive 20 - 40

Transformer 5 - 15

Inrush Current Times

Steady State

• Be aware of heavy current applications. When a relay is used in

heavy current app lications, the thin layer of gold plating on the

contact may be destroyed. This will not affect the heavy current

application. If you go back to a low current application, however,

you may experi ence a h igh contact re s ist ance and b e u nable to use

the relay for low current applications.

24 Getting Started with the HP E1463A Form C Switch Chapter 1

Page 25

• Use protective circuits with your relay connections. The relay

manufacture r recommends some protective circuits that can b e us ed

with your relay connections. Refer to the Aromat Technical Data

Book (AGC-C0064-A-1) for additional information:

Aromat

401 River Oaks Par k way

San Jose, CA 95134

(408) 433-0466

Capacitors are n ot to b e placed across the load or rela y contacts. Capacitors

may suppr e ss a rcs, but the energy stored in the capa citors will flow throu gh

the relay contacts, welding them.

You can also add circuit protection within the HP E1463A component

module. See the sections following.

Adding Relay and

Circuit Protection

Space has been made available o n the HP E1463A Form C module for

adding relay and circuit protection. Relay protection can be added by

placing a protective device across the specified pads. This is done by

adding metal oxide varistors (MOVs) between the common (C) and

normally open (NO) or nor mally closed (NC) t ermi nals. No w as th e

voltage goes up, the varistor draws current to protect the relay. Figure 1-10

shows the locations where these protective devices can be added.

Circuit protection can be ad ded by placing a protective device in series with

the common lea d. This is done by ad ding a res istor or fuse between the

common (C) terminal and your circuit. When installing circuit protection

a jumper must b e removed first.

xx = channel number

Figure 1-10. Adding Relay and Circuit Protect ion

Chapter 1 Getting Started with the HP E1463A Form C Switch 25

Page 26

To install these protectiv e devices it is ne cessary to remove the sheet metal

covers from t he mod ule. The locatio ns f or installing the devices are labeled

as follows:

Table 1-2. Protective Devices Board L ocat ion

Relay Prote ctio n Circuit Pro tection

xxO

V

xxC

V

Cir cui t P r otec tion

xx

JM

Where xx is the channel number.

The varistor location across common (C) and normally open (NO).

The varistor location across common (C) and normally closed (NC).

The resist or or fus e locati on in s eries wi th commo n (C) .

Again, do not instal l a capacit or in any of t hese locations.

Maximum

Allowable Module

Switch Current

The HP E1463A has an i ndiv idual channel current specification of 5 A.

However, if you apply the 5 A to all the channels with a relay contact

resistanc e of .25 ohms, th e power dissipat i on would b e 200 W. Since the

HP E1401A mainframe can only provide cooling for 60 W per slot (keeps

the temperature rise to 10° C), this cannot be allowed to happen.

A reasonable maximum current for the entire module is 50 A. That is,

10 channels each carrying 5 A or some combination of channels and currents

that total 50 A. This will produce a bout 67.5 W of internal dissipation, leading

to a 15° C temperature rise. Figure 1-11 shows how to derate the chann els, in

terms of current throughout the channels, to keep internal power dissipation

under 45 W and 67.5 W or 10° C and 15° C temperature rise, respectively.

HP E1401A Mainframe and

.25 Ω Relay Contact Resistance

Figure 1-11. HP E1463A Allowable Switch Current

26 Getting Started with the HP E1463A Form C Switch Chapter 1

Page 27

Programming the Form C Switch

There are several ways you can program the Form C switch module. One way

is to write directly to the registers. This method can provide better throughput

speed, however, it requires more knowledge of the Form C switch design. See

Appendix B for information on regis ter programming.

Another way to program the Form C switch module is to use an HP E1406

command module and SCPI comma nds. With SCPI commands the HP

command module pars es the commands and wr ites to the approp riate Form

C switch register. The examples in this manual use the SCPI pr ogra mm ing

language. See Appendix B for examples on writing direct ly to the registers.

You can use different controllers and different programming languages. The

examples in this manual, however, are based on the following configurations:

– HP 9000 Series 200/300 Computer ru nni ng HP B ASIC

– HP Vectra Computer (or compatible) with an HP 82335A HP-IB

Interface Card (with command library) running Borland® Turbo C

See the C-Size VXIbus System Installation and Getting Sta rted Guid e for

informati on on additiona l c onfiguratio ns .

Note Most exa mples in this m anua l us e SCPI co mman ds. See Appen dix B for

Specifying SCPI

Commands

information on writi ng direc t ly to the regis ters.

To address specific channels (relays) within a Form C switch module, you

must specify the SCPI command and switch channel list. Table 1-3 lists the

most commonl y us ed commands.

Table 1-3. Common SCPI Commands

SCPI Command Command De scr ip tion

CLOSe <

OPEN <

SCAN <

channel_list>

channel_list>

channel_list>

Connects the normally open (NO) terminal to the common (C)

terminal for the specified channels.

Connects the normally closed (NC) terminal to the common (C)

terminal f or t he channel s specified.

Closes the set of Form C r elays, one at a time.

Chapter 1 Getting Started with the HP E1463A Form C Switch 27

Page 28

Channel List The channel list is a combination of the switch card number and the channel

numbers. The channel_list ta ke s t he form of

cc = switch card number (01-99)

nn = channel number (00-31)

@ccnn where,

Card Numbers The card nu mber (cc of the channel list) identifies the module within a

switchbox. The card number assigned depends on the switch configuration

used. Leading zeroes can be ignored for the card nu mb er.

Single-module Switchbox. In a single-module switchbox configuration,

the card nu mber is always 01.

Multiple-module Switchbox. In a multiple-module switchbox configuration,

modules are set to successive logical addresses. The module with the lowest

logical address is always card number 01. The module with the next successive

logical address is card number 02, and so on. Figure 1-12 illustr ates the card

numbers an d logical addre s ses of a typical mu lt iple-m odu le swit c hbox

configuration. See the C-Size VXIbus System Insta llat ion an d G etting

Started Guide for a d diti onal switchbox instrument information.

Figure 1-12. Card Numbers in a Multiple-mo d ule Sw itch b ox

28 Getting Started with the HP E1463A Form C Switch Chapter 1

Page 29

Channel Address The channel address (nn of the channel lis t) d etermine s wh ich relay on the

selected card will be addr e s s ed. F orm C switch channel numbers are 00

through 31. The channels can be addressed using channel nu mbers or

channel ranges. You can address the following:

• single channels (@ccnn);

• multiple channels (@ccnn,ccnn,...);

• sequential chann els (@ccnn:ccnn);

• groups of sequent ial channels (@ccnn:ccnn,cc nn:ccnn);

• or any combination of the ab ove.

Use a comma (,) to form a channel list or a colon (:) to form a channel

range. Only valid channels can be accessed in a channel list or channel

range. Also, the channel range must be from a lower channel number to

a higher channel number. For example,

CLOS (@215:100) generates an e r ror.

but

CLOS (@100:215) is acceptable,

Initial Operation

Two example programs follow which use Hewlett-Packard BASIC and

TURBO C languag es to get you started using the Form C switch module.

The first example assumes an HP 9000 Ser i es 200/300 c ontrol ler and a

Hewlett-Packard Interface Bus (HP-IB). (HP-IB is the Hewlett-Packard

implementation of the IEEE 488.2-1987 standard.) The second example

assumes an HP Vectra Computer (or compatible) with an HP 82335A

HP-IB Interface Card (with command library) running Borland® Turbo C.

Thi s p rogr am clos es cha n n e l 02 o f a Fo r m C s w i t ch module at lo g ica l

address 120 (s econdary addr ess = 12 0/8 = 15) and querie s t h e channel

closure state. The result is returned to the computer and displayed

(1 = channel closed, 0 = channel open). See Chapter 3 for information

on the SCPI commands.

HP BASIC 10 !Reset th e module.

20 OUTPUT 70915;"*RST"

30 !

40 OUTPUT 70915;"CLOS (@102)"

50 !

60 OUTPUT 70915;"CLOS? (@102)"

70 !

80 ENTER 70915;Value

90 !

100 PRINT Val u e

110 END

Close channel 02.

Query channel 02 state.

Enter result into Value.

Display result (should print a "1" to indicate that the channel is closed).

Chapter 1 Getting Started with the HP E1463A Form C Switch 29

Page 30

TURBO C #include <stdi o. h>

#include <chpi b.h> /*Include f ile for HP-I B*/

#define IS C 7L

#define FORMC 70915L /*Form C default address*/

#define TASK1 "*RST " /*Command for a re set*/

#define TASK2 "CLOSE (@102)" /*Command to close channel 02*/

#define TASK3 "CLOS? (@ 102)" /*Command to query channel 02*/

main ( )

{

char into[257];

int length = 256;

error_handler (IOTIMEOUT (7L,5.0), "TIMEOUT");

error_handler (IOOUTPUTS (FORMC, TASK1, 4), "OUTPUT command");

error_handler (IOOUTPUTS (FORMC, TASK2, 12), "OUTPUT command");

error_handler (IOOUTPUTS (FORMC, TASK3, 12), "OUTPUT command");

error_handler (IOENTERS (F ORM C, into, &length), "ENT ER comm and");

printf("Now let’s see if the switch is closed: %s",into);

return;

}

int error_handler (int error, char *routin e)

{

char ch;

if (error ! = NO ERR)

{

printf ("\n Error %d % s \n", error, errstr (error ));

printf (" in call to HP-IB function %s \n\n", routine);

printf ("Press ’Enter’ to exit: ");

scanf ("%c", &ch);

exit(0);

}

return 0;

}

/*Output commands to For m C*/

/*Enter from Form C*/

30 Getting Started with the HP E1463A Form C Switch Chapter 1

Page 31

Using the HP E1463A Form C Switch

Using This Chapter

This chapter uses typical examples to show how to use the Form C switch

module for switching channels and scanning channels. See Chapter 3 for

command inf orm at ion. C hapt er contents are as follows:

All examples in this chapter use the HP-IB select code of 7, primary address

of 09, and a secondary addre ss of 15 (L ADDR=120).

Chapter 2

• Form C Switch Commands . . . . . . . . . . . . . . . . . . . . . . . . . . Page 31

• Po we r-on and Reset C onditions. . . . . . . . . . . . . . . . . . . . . . . Pag e 32

• Module Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 32

• Switching Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 34

• Scanning Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 39

• Querying the Form C Switch Module . . . . . . . . . . . . . . . . . . Page 43

• Using the Sc an Complete Bi t. . . . . . . . . . . . . . . . . . . . . . . . . Pag e 43

• Recalling and Saving States. . . . . . . . . . . . . . . . . . . . . . . . . . Page 45

• Detecting E rror Co nd itions . . . . . . . . . . . . . . . . . . . . . . . . . . Page 46

• Synchronizing the Form C Switch. . . . . . . . . . . . . . . . . . . . . Page 48

Form C Switch Commands

Table 2-1 explains some of the SCPI co mmands used in this chapt er.

Refer to Chapter 3 for more information on these commands.

Table 2-1. Form C Switch Command s Used in Chapter 2

SCPI Command Command Description

[ROUTe:]CLOSe

[ROUTe:]CLOSe?

[ROUTe:]OPEN

[ROUTe:]OPEN?

[ROUTe:]SCAN

INITiate[:IMMediate] Starts the scan sequence and closes the first channel

TRIGger:SOURce BUS | EXT | HOLD | IMM | TTLT Selects the trigger source to advance the scan.

<channel_list>

<channel_list>

<channel_list>

<channel_list>

<channel_list>

Closes the chann els in the channel list.

Queries the state of the channels in the channel list.

Opens the channels in the channe l list.

Queries the state of the channels in the channel list.

Closes the chann els in the channel li st, one at a time.

in the

channel list.

Chapter 2 Using the HP E1463A Form C Switch 31

Page 32

Power-on and Reset Conditions

Since the Form C switch module has nonlatching relays, a l l relays are in the

normally closed (NC) position at power-down and power-up.

*RST command opens all channels, invalidates the current channel list

The

for scann ing, and sets the following:

Table 2-2. Reset Conditions

Parameter Default Description

ARM:COUNt 1 Number of scanning cycles is 1.

TRIGger:SOURce IMM Will advance scanning cycles a utomatically.

INITiate:CONTinuous OFF Number of scanning cycles set by ARM:COUNt.

OUTPut[:STATe] OFF Trigger o utpu t from E XT o r TT L sou rce s is disa bl ed .

Module Identification

The following short programs use the *RST, *CLS, *IDN?, SYST:CTYP?, and

SYST:CDES? commands to reset and identify the Form C switch module.

HP BASIC 10 !Dimensions three string variables to fifty characters.

20 DIM A$[50], B$[50], C$[50]

30 !

40 OUTPUT 70915; "*RST; *CLS"

50 !

60 OUTPUT 70915; "*IDN?"

70 !

80 ENTER 70915; A$

90 !

100 OUTPUT 70915; "SYST:CDES? 1"

110 !

120 ENTER 70915; B$

130 !

140 OUTPUT 70915; "SYST:CT YP? 1"

150 !

160 ENTER 70915; C$

170 !

180 PRINT A$, B$, C$

190 END

Outputs the commands to reset and clear the status register.

Queries for module identification.

Enters the results into A$ .

Output the command for a card description.

Enters the results into B$ .

Outputs the command for the card type.

Enters the results into C$.

Prints the contents of variables A$, B$, and C$.

32 Using the H P E1463A Form C Swit ch Chapter 2

Page 33

TURBO C

#include <stdio.h>

#include <chpi b.h> /*Include f ile for HP-I B*/

#define IS C 7L

#define FORMC 70915L /*Form C default address*/

#define TASK1 "*RST; *CLS;*I DN?" /*Reset, clear, and query identification*/

#define TASK2 "SY ST:CDES ? 1" /*Command for card de scription*/

#define TASK3 "SY ST:CT YP? 1" /*Command for card type*/

main ( )

{

char into1[51], into2[51] , into3[51];

int length = 50; /*Out p u t and enter commands to Form C*/

error_handler (IOTIMEOUT (7L,5.0), "TIMEOUT");

error_handler (IOOUTPUTS (FO RMC, TASK1, 15), "OUTPUT command" );

error_handler (IOENTERS (F ORM C, into1, &length), "ENT ER comm and");

error_handler (IOOUTPUTS (FO RMC, TASK2, 12), "OUTPUT command" );

error_handler (IOENTERS (F ORM C, into2, &length), "ENT ER comm and");

error_handler (IOOUTPUTS (FO RMC, TASK3, 12), "OUTPUT command" );

error_handler (IOENTERS (F ORM C, into3, &length), "ENT ER comm and");

printf("IDENTIFICAT ION: % s",into1);

printf("CARD DESCRIPTION: %s",i nto2);

printf("CARD TYPE: %s",into3);

return;

}

int error_handler (int error, char *routin e)

{

char ch;

if (error ! = NO ERR)

{

printf ("\n Error %d % s \n", error, errstr (error ));

printf (" in call to HP-IB function %s \n\n", routine);

printf ("Press ’Enter’ to exit: ");

scanf ("%c", &ch);

exit(0);

}

return 0;

}

A typical print for the HP E1463A will look like the following:

HEWLET T- PA CKAR D, SW IT CH BO X, 0, A. 04 .00

32 Channel General Purpose Relay

HEWLETT-PACKARD,E1463A,0,A.04.00

Chapter 2 Using the HP E1463A Form C Switch 33

Page 34

Switching Channels

For general purpose relay operation, you can connect or disconnect a load

by opening or closing specified channel relays. By adding external pull-up

resistors, th e switch can be configured for digital output operat ions.

Use

terminal to its common (C) terminal, or use

connect a channel’s normally closed (NC) contact to its common (C)

terminal. The channel_list has the form

To

channel numbers. For example, to close channels 101 and 103, execute

CLOS (@101,103). T o OPEN or CLOSe a continuous range of channels

place a colon (:) between the first and last channel numbers.

The fo llowing HP BASIC program shows how to clos e and open chan nel 2

on an HP E1463A Form C module (card #1):

10 DISP "TEST E1463A Module"

20 OUTPUT 70915; "ROUT:CLOS (@102)"

30 OUTPUT 70915; "ROUT:OPEN (@102)"

40 END

CLOS <channel_list> to connect a channel’s normally open (NO)

OPEN <channel_ list> to

(@ccnn) where,

cc = card number (01-99)

nn = channel number (00-31)

OPEN or CLOSe multiple channels, plac e a comma (,) b etwe en the

Note Implied commands are those which appear in square brackets ([ ]) in the

command syntax. Note that the brackets are not part of the command and

are not sent to the instrument. For example, as in the program above,

ROUTe can be eliminat ed and just the CLO Se command can be us ed.

34 Using the H P E1463A Form C Swit ch Chapter 2

Page 35

Example: Voltage

Switching

This example closes channel 00 of a Form C switch module to switch the

load voltage (E) from load 1 to load 2. When the channel relay is open, the

load voltage is applied to load 1. When the relay is closed, the voltage is

applied to load 2. See Figure 2-1 for typical user connections.

The following program sh ows how to close channel 00 of the HP E1463A

Form C Switch:

10 DISP "Testing the HP E1463A"

20 OUTPUT 70915; "CLOS (@100)" !Close channe l 00 relay (connect

NO to C). 1 is the card number

and 00 is the channel number.

30 END

To open channel 00 , us e OPEN (@100).

Figure 2-1. Voltage Switching

Chapter 2 Using the HP E1463A Form C Switch 35

Page 36

Example: Controlling

RF Switches /

Step Attenuators

Figure 2-2 shows one way to drive the HP 8761 SPDT RF Switches or

HP 33300 Series Progra mmable Step Attenuators. (This figure only shows

control for t he HP 33300 40 dB st ep. Additional drive relays are require d

for the 10 dB and 20 dB steps.) The HP 8761A and HP 33300A/C operate

from a 12 - 15 V coil voltage, while the HP 8761B and HP 33300B/D

operate from a 24 V - 30 V coil voltage. To close channel 00, execute:

10 DISP "Applying -12V"

20 OUTPUT 70915; "CLOS (@100)" !Close ch annel 00 relay (connec t

NO to C). 1 is the card number

and 00 is the channel number.

30 END

To open channel 00 , us e OPEN (@100).

Figure 2-2. Controllin g RF Switch es/St ep Atten uato r s

36 Using the H P E1463A Form C Swit ch Chapter 2

Page 37

Example: Digital

Output Configuration

Figure 2-3 shows channel 00 con figured for digital output operation. W hen

the channel 00 relay is op en (NC conn ected to C), po int 1 is at + V and

point 2 is at 0 V. When the channel 00 relay is closed (NO connected to C),

points 1 and 2 are both at 0 V. To close channel 00, execute the following:

10 DISP "Closing channel 0"

20 OUTPUT 70915; "CLOS (@100)" !Close ch annel 00 relay (connec t

NO to C). 1 is the card number

and 00 is the channel number.

30 END

To open channel 00 , us e OPEN (@100).

Figure 2-3. Digital Output Configuration

Chapter 2 Using the HP E1463A Form C Switch 37

Page 38

Example: Matrix

Switching

The Form C switc h modu le can be con figure d as a 4 x 8 single- wire mat r i x

to conn ect any c ombination of up to f our user sources (S0, S1, S2 , S 3) t o

any combinatio n of up to eight user instruments (I0, I1, I1…I7) at a time.

To do this you must make the following co nnections:

Connect Common (C) Channel

Numb e rs T o gether

0, 8, 16, and 24 0 - 7

1, 9, 17, and 25 8 - 15

2, 10, 18, an d 26 16 - 23

3, 11, 19, an d 27 24 - 31

4, 12, 20, an d 28

5, 13, 21, an d 29

6, 14, 22, an d 30

7, 15, 23, an d 31

Connect Normall y Open (NO)

Channel Numbers To gether

Close this channel to connect S to I.

Figure 2-4. Matrix Switch in g

When the c onnec t ions are completed you will have the following matrix:

Close the channel number enclosed in the circle to connect the

correspondi ng row and column. The following examp le c loses channel 25

to connect S3 to I1 and closes channel 20 to connect S2 to I4. To close

channels 20 and 25, execute the following:

10 DISP "Testing Switch Matrix"

20 OUTPUT 70915; "CLOS (@120,125)"!Clo se ch an ne ls 20 a n d 25.

1 is the card number; 20 and 25

are channel numbers.

30 END

To open th e channels, use OPEN (@120,125).

38 Using the H P E1463A Form C Swit ch Chapter 2

Page 39

Scanning Channels

For the Form C switch module, sca nning c hannels consists of c losing a

specified set of channels, one channel at a time. You can scan any combination

of channels for a single-module or a multiple-module switchbox. Single,

multiple, or continuous scanning modes are available. See Chapter 3 for

additional information on scanning Form C switch chan n els.

Channel lists can extend across boundaries. For multiple-module switchbox

instruments, the channels to be scanned can extend across switch modules.

For example, f or a two-module switc hbox instrume nt,

will scan all channels of both Form C switch modules.

Use

32,767 scans). Use

See Chapter 3 for information about these SCPI commands.

SCAN (@100:231)

ARM:COUNt <number> t o set multiple/continuous scans (from 1 to

INITiate:CO NT i nuous ON to set continuous scanning.

Figure 2-5. Scannin g Usin g "Tri g Out" Po rt

Chapter 2 Using the HP E1463A Form C Switch 39

Page 40

Example: Scanning

Channels with an

External Instrument

Using “Trig In” and

“Trig Out” Ports

HP BASIC 10 !Reset and clear the module.

This example shows one way to synchronize instrument measurements of a

device under test (DUT) with Form C switch channel closures. For

measurement synchronizati on, the HP E1406A "Trig In" and "Trig Out"

ports are connected to the instrument "Voltmeter Complete" and "External

Trigger" ports. See Figure 2-5 for typical user connections.

For this exa mp le, the normally closed (NC) c ont ac ts ( channels 00-02) are

connected to ground, and the m easure ments are made on the co mmon (C)

contacts. The command module and instrument are connected via HP-IB. The

Form C switch module has a logical address 120 ( secondar y a ddress 15) , an d

the external instrument has an address o f 722.

20 OUTPUT 70915; "*RST;*CLS"

!External trigger, dc volts.

30

40 OUTPUT 722;"TRIG EXT;DCV"

!Memory first in, first out.

50

60 OUTPUT 722;"MEM FIFO"

!Enable "Trig Out".

70

80 OUTPUT 70915;"OUTP ON"

!External triggering.

90

100 OUTPUT 70915;"TRIG:SOUR EXT"

!Scan channels 00-02.

110

120 OUTPUT 70915;"SCAN (@100:102)"

!Enable scan.

130

140 OUTPUT 70915;"INIT"

!Wait for switch closures.

150

160 WAIT 2

!Start loop.

170

180 FOR Channel=1 TO 3

!Enter result.

190

200 ENTER 722;Result

!Display result.

210

220 PRINT Re sult

!Increment count.

230

240 NEXT Channel

250 END

40 Using the H P E1463A Form C Swit ch Chapter 2

Page 41

Example: Scanning

Channels with Sy stem

Multimeter Using

TTL Trigger

This examp le us es the HP E140 6A c ommand module’s TTL trigger bus

lines to synchronize Form C channel closures to a system multimeter

(HP E1412A). For measur ement synchron izat ion:

– HP E1406A TTL trigger bus line 0 is used by the Form C

module to trigger the multimeter to perform a measurement.

– HP E1406A TTL trigger bus line 1 is used by the multimeter to

advance the Form C scan.

These trigger bus lines are not actual ha r dw a r e connections. Th e trig ger i ng

is accomplished by the HP E1406A’s f irmware. The measure ment is ta ken

from the common (C) terminal. The co mmon terminals for channels 0

through 2 are connected together for this example. When one of these

switches is closed (C connected to NO), different DUTS are switched in for

a measurement. Figu re 2-6 shows how to connect the Form C modul e to the

HP E1412A multimeter module. The connections shown wit h dott ed lines

are not actual har dwa r e connections. These connections indicate how the

firmwa re operates to accomplish the triggering.

Figure 2-6. Scanni ng Usin g TTL Trig g er Bus Li nes

Chapter 2 Using the HP E1463A Form C Switch 41

Page 42

The following HP BASIC pro gra m sets up t he mu lt ime t er (HP-IB address

70903) to scan ma king 2-wire res ista n ce mea sur e men t s.

HP BASIC 10 ALLOCATE REAL Rdgs(1:3)

20 !

30 OUTPUT 70915; "*RST;*CLS"

40 OUTPUT 70903; "*RST;*CLS"

50 !

60 !

70 !range, NPLC.

80 OUTPUT 70903;"ABORT;:TRIG:SOUR TTLTRG0"

90 OUTPUT 70903; "OUTP:TTLT1:STAT ON"

100 OUTPUT 70903; "CONF:RES AUTO,DEF"

110 OUTPUT 70903; "TRIG:DEL 0; COUN 3;:CAL:ZE RO:AUT O ON"

120 !

130 OUTPUT 70903; "*OPC?"

140 ENTER 70903; Check

150 OUTPUT 70903; "INIT"

160 !

170 OUTPUT 70915; "OUTPUT:TTLT0:STATE ON"

180 !

190 OUTPUT 70915;"TRIG:SOUR TTLT1"

200 OUTPUT 70915; "SCAN (@100:102)"

210 OUTPUT 70915; "INIT"

220 !

230 OUTPUT 70903; "FETCH?"

240 ENTER 70903; Rdgs(*)

250 PRINT Rdgs(*)

260 END

Reset and clear the modules.

Multimeter triggers on TTL trigger line 0, multimeter pulse s TTL trigger

line 1 on measurement complete. Set multimeter function to resistance,

Check to see if multimeter re ady; when ready, initialize trigger 1.

Set up the Form C: Form C pulses TTL Trigger line 0 on channel closed.

Set Form C to be triggered by TTL Trigger line 1.

Enter and print readings.

42 Using the H P E1463A Form C Swit ch Chapter 2

Page 43

Querying the Form C Switch Module

All query commands end with a "?". These commands are used to

determine a specific state of the module. The data is sent to the output

buffer where you can retrieve it int o your computer. See C hapter 3 for more

information on these commands.

CLOSe? <channel_list> or OPEN? <channel_list > to query the channel

Use

state (open/closed).

channel(s) op en.

channel(s) open. (Commands are so ftware queries and do not acc ou nt for

relay hardware failures.)

The following example closes a range of channels and queries for the results.

HP BASIC 10 !Dimensions a string variable to 32 characters.

20 DIM Channels$[32]

30 !

40 OUTPUT 70915;"CLOS (@100:131)"

50 !

60 OUTPUT 70915;"CLOS? (@100:131)"

70 !

80 ENTER 70915; Channels$

90 !

100 PRINT "Channels Closed:";Channels$

110 END

Closes channels 00 through 31.

Queries to see if the channels are closed.

Enters the results from the switch card into the variable Channels$.

Prints the channels clo se d (should pr int 1’s).

CLOS? returns a "1" for channel(s) closed and a "0" for

OPEN? returns a "0" for channel(s) closed and a "1" for

Using the Scan Complete Bit

You can use the Scan Complete bit (bit 8) in the Operation Status Register (in

the command module) of a switchbox to determine when a scanning cycle

completes (no other bits in the register apply to the switchbox). Bit 8 has a

decimal value of 256 and you can read it directly with th e

command. Refer to the STATus:OPERation[:EVENt]? command in Chapter 3

for an example.

When enabled by the

STAT:OPER:ENAB 256 command, the Scan Complete

bit will be re ported a s bit 7 of the Status Register. Use the HP- I B Serial Poll or

the IEEE 488.2 Common Co mmand

*STB? to read the Status Register.

When b it 7 of the Status Register is e n a bled by the

Comman d to ass ert an HP- IB S ervice Request (SRQ), you can interrupt the

computer when the Scan Complete bit is set, after a scanning cycle

completes. This allows the computer to do other operations while the

scannin g cycle is in progress.

Chapter 2 Using the HP E1463A Form C Switch 43

STAT:OPER?

*SRE 128 Common

Page 44

The following exampl e monitors bit 7 in the Status Register to determi ne

when the scanning cycle is complete. The computer used in this example is

an HP 9000 Series 200/ 300 ru nn ing HP BASIC as th e programming

languag e. The computer int erfa ces wit h an HP E1406A command module

over HP-IB. The HP-IB select code is 7, the HP-IB primary address is 09,

and the HP-IB secondary address is 15.

HP BASIC 10 !Resets and Clears the module.

20 OUTPUT 70915;"*RST; *CLS"

30 !

40 OUTPUT 70915;"STAT:OPER:ENAB 256"

50 !

60 OUTPUT 70915; "TRIG:SOUR IMM"

70 !

80 OUTPUT 70915; "SCAN (@100:115)"

90 !

100 OUTPUT 70915; "*OPC?"

110 ENTER 70915; A$

120 PRINT "*O PC? = ";A$

130 !

140 OUTPUT 70915;"STAT:OPER:ENAB?"

150 ENTER 70915; A$

160 !

170 PRINT "STAT:O PE R:ENA B?=";A$

180 !

190 OUTPUT 70915; "*STB?"

200 ENTER 70915; A$

210 !

220 PRINT "S wit ch Status = ";A$

230 !

240 OUTPUT 70915; "INIT"

250 !

Enable Scan Complete Bit.

Set the Form C switch up for continuous triggering.

Select channels to scan.

Wait for operation complete.

Query the c ontents in the operation status register.

Print the contents of the operation status register.

Query the contents of the status byte register.

Print the contents of the status byte register.

Start scan cycle.

Initialize the value of the counter.

260 I = 0

!Stay in loop until some value is returned from the SPOLL (70915) command.

270

280 WHILE (I=0)

290

300 PRINT "Waiting for scan to complete: SPOLL = ";

310 END WHILE

320

330 PRINT "Scan com pl ete: spoll = ";

340 END

I = SPOLL(70915)

I

I = SPOLL(70915)

I

44 Using the H P E1463A Form C Swit ch Chapter 2

Page 45

Recalling and Saving States

The *SAV <numeric_state> command saves the current instrument state.

The state number (0-9) is specified by the numeric_state paramete r.

The settings saved by this command a r e as follows:

• Channel relay states (open or clos ed)

• ARM:COUNt

• TRIGger:SOURce

• OUTPut:STATe

• INITiate:CO NTinuous

The *RCL <numeric_state> comma nd recalls the state when the last *SAV

was executed for the specif ie d numeri c_ stat e parame ter (0-9). If no *SAV

was executed for the numeric_stat e, *RST default settings are used. Refer

*SAV settings list for the settings recalled by *RCL.

to the

The following program s h ows how to sa ve and recall Form C switch states.

HP BASIC 10 !Dimension a string variable for 150 characters.

20 DIM A$[150]

30 !

40 OUTPUT 70915; "CLOS (@100:131)"

50 !

60 OUTPUT 70915; "*SAV 5"

70 !

80 OUTPUT 70915 "*RST;*CLS"

90 !

100 OUTPUT 70915;"CLOS? (@100:131)"

110 ENTER 70915;A$

120 !

130 PRINT "Channels Closed:";A$

140 !

150 OUTPUT 70915; "*RCL 5"

160 !

170 OUTPUT 70915 "CLOS? (100:131)"

180 ENTER 70915;A$

190 !

200 PRINT "Channels Closed:";A$

210 END

Close channels 00 - 31 on the Form C.

Save as numeric state 5.

Reset and clear the module.

Query the channels closed.

Prints closed channels (should print 0’s).

Recall numeric state 5.

Query to see what channels are closed.

Print the closed channels (should print 1’s).

Chapter 2 Using the HP E1463A Form C Switch 45

Page 46

Detecting Error Conditions

The SYSTem:ERRor? query requests a value from instrument’s error

register. This register contains an integer in the range [-32,768 to 32,767].

The response takes the following form:

<err_number>,<err_message>

where, <err_number> is the value of the instrument’s e rror , and

<err_message> is a s hort descrip tion of the error.

The following programs attempt an illegal channel closure and polls for an

error message:

HP BASIC 10 !Dimension a string variable for 256 characters.

20 DIM Err_num$[256]

30 !

40 OUTPUT 70915; "CLOS (@135)"

50 !

60 OUTPUT 70915; "SYST:ERR?"

70 ENTER 70915; Err_num$

80 !

90 PRINT Err_num$

100 END

Try to close an illegal channe l.

Query for a system error.

Prints error +2001, "Invalid channel number".

46 Using the H P E1463A Form C Swit ch Chapter 2

Page 47

TURBO C

#include <stdio.h>

#include <chpi b.h> /*Include fi le for HP-I B*/

#define IS C 7L

#define FORMC 70915L /*Form C default address*/

#define TASK1 "CLOSE (@135)" /*Command for illegal switch closure*/

#define TASK2 "SY ST:ERR?" /*Command for system error*/

main ( )

{

char into[257];

int length = 256;

/*Output commands to For m C*/

error_handler (IOTIMEOUT (7L,5.0), "TIMEOUT");

error_handler (IO O UTPUTS (FORMC, TASK1, 12 ), "OUTPU T comm and ");

error_handler (IO O UTPUTS (FORMC, TASK2, 9), "O UTPUT com mand");

/*Enter from Form C*/

error_handler (IO E NTER S ( FORM C , into , & length), "ENTER command");

printf("Now let’s print the errors: %s",into);

return;

}

int error_handler (int error, char *routin e)

{

char ch;

if (error ! = NO ERR)

{

printf ("\n Error %d % s \n", error, errstr (error ));

printf (" in call to HP-IB function %s \n\n", routine);

printf ("Press ’Enter’ to exit: ");

scanf ("%c", &ch);

exit(0);

}

return 0;

}

If no error occurs, the switchbox responds with 0, "No error". If there

has been more than one error, the instrument will respond with the first one in

its error queue. Subsequent queries continue to read the error queue until it is

empty. The maximum

<err_message> string length is 255 characters.

Chapter 2 Using the HP E1463A Form C Switch 47

Page 48

Synchronizing the Form C Switch

The following example shows how to synchronize a Form C switch module

with a measurement instrument. In this example, the Form C switch

module s witches a signal to a multimeter. The program then verifies that

the channel is closed before the multimeter begins its measurement.

HP BASIC 10 !Closes channel 5.

20 OUTPUT 70915; "CLOS (@105)"

30 !

40 OUTPUT 70915; "*OPC?"

50 ENTER 70915; Opc_value

60 !

70 OUTPUT 70915; "CLOS? (@105)"

80 ENTER 70915;A

90 !

100 If A=1 THEN

110 OUTPUT 70903;"MEAS:VOLT:DC?"

120 ENTER 70903; Meas_value

130 !

140 PRINT Meas_value

150 ELSE

160 PRINT "CHANNEL DID NOT CLOSE"

170 END IF

180 END

Wait for operation complete.

Check to see if channel is closed.

When channel is close d, measur e the voltage.

Print the measured voltage.

48 Using the H P E1463A Form C Swit ch Chapter 2

Page 49

HP E1463A Form C Switch Command

Using This Chapter

This chapter describes Standard Commands for Programmable Instruments

(SCPI) commands and summarizes IEEE 488.2 Common (*) Commands

used in this manual.

See t he HP E1406A Command Module User’s Manual for additional

information on SCPI a nd common commands. Chapter contents are as follows:

Chapter 3

Reference

• Command Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 49

• SCPI Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . Page 52

• IEEE 488.2 Common C ommand Reference . . . . . . . . . . . . . Page 75

• SCPI Command Quick Reference . . . . . . . . . . . . . . . . . . . . . Page 76

Command Types

Common

Command Format

SCPI Command

Format

Comman ds are s eparat ed i nto two types: IEEE 488.2 Common C ommands

and SCPI Co mmands.

The IEEE 488.2 standar d de fines the common c ommands that perform

functions like reset, self-test, status b yte qu ery, and so on. Common

commands are four or five characters in length, always begin with the

asterisk character (*), and may include one or more parameters. Th e

command keyword is separated from the first parameter by a space

character. So me examples of common c ommands are shown belo w:

*RST *ESE <unmask> *STB?