Agilent 75000 SERIES C

Agilent E1463A

32-Channel, 5-Amp, Form C Switch

Service Manual

Copyright© Agilent Technologies, Inc., 1997 - 20 06

*E1463-90011*

E1463-90011

E0606

Manual Part Number: E1463- 90011 Printed: June 2006 Edition 2 Rev 2

Printed in Malaysia E0606

Agilent E1463A Form C Switch Service Manual

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

User Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 1. General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Relay Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

End-of-Life Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Replacement Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

WARNINGS and CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Inspection/Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Shipping Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switch Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Agilent E1463A Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switch Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Switch Module Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Switch Module Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Schematic s and Com ponent Locators . . . . . . . . . . . . . . . . . . . . . . . . . 17

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Contents

Chapter 2. Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Test Conditions and Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Verification Test Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Switch Module Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Operation Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring the Test Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Test 2-1: Closed Channel Resistance Test . . . . . . . . . . . . . . . . . . . . . . . 21

Test 2-2: DC Isolation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Test Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Measurement Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Test Accuracy Ratio (TAR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table of Contents 1

Chapter 3. Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 4. Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Repair Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Service Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Troubleshoot in g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Identifying the Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Testing the Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Self-Test Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Repair/Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Soldering Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Post-Repair Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Component Locators and Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . 52

2 Table of Contents

Certification

Agilent Technologies certifies that this product met its pub lished specificat ions at the time of shipment from the factory. Agilent

Technologie s further certifies tha t its calibr ation measure ments are trac eable to the Unit ed States Nati onal Ins titute of Stan dards and

Technology (formerly Nati onal Bureau of S tandards), to the ex tent allowed by that organizat ion’s calibrat ion facility , and to the calibration

facilities of other International Standards Organization members.

Warranty

This Agilent Technologies product is warranted against defects in materials and workmanship for a period of one (1) year from date of

shipment. Duration and conditions of warranty for this product may be superseded when the product is integrated into (becomes a part

of) other Agilent products. During the warranty period, Agilent Technologies will, at its option , e ith er repair or r ep la ce p ro d ucts which

prove to be def ec tive.

For warrant y service or repair, t hi s product m us t be returne d t o a servic e facility designated by Agilent Technologies. Buyer shall prepay

shipping charges to A gi le nt and Agil ent shall pa y s hi ppi ng charge s to return the product to Buyer. H ow ever, Buyer shall pay all shipping

charges, duties, and taxes for products re t urned to Agilent fr om another count ry.

Agilent warrants that its software and firmware designated by Agilent for use with a product will execute its programming instructions

when properly installed on that product. Agilent does not warrant that the operation of the product, or software, or firmware will be

uninterrupt ed or error free.

Limitation Of Warranty

The foregoi ng warranty s hall not apply to defec ts r es ul ti ng from improper or inade quate maint enance by Buye r, Buyer-supplied products

or interfacing, unauthori zed modific ation or mis use, operat ion outs ide of the envi ronmenta l specific ations for the prod uct, or improper site

preparation or maintena nce.

The design and implementation of any circuit on this product is the sole responsibility of the Buyer. Agilent does not warrant the Buyer’s

circuitry or malfunctions of Agilent products that result from the Buyer’s circuitry. In addition, Agilent does not warrant any damage th at

occurs as a r es ul t of th e B uyer’s circuit or any defects tha t res ul t fro m Bu yer -s upplied produc ts .

NO OTHER WARRANTY IS EXPRESSED OR I MPLIED. Agilen t SPECIFICALLY DISCLAIM S THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE RE MEDIES. Agilent SHALL NOT BE LIABLE

FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Notice

The information contained in this document is subject to change without notice. Agilent Technologies MAKES NO WARRANTY OF

ANY KIND WITH REGARD TO THIS MATERIAL, INCL UDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Agilent shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing, performance or use of this material. This document contains

proprietar y information whi ch is protected by copy right. All rights are reserved. No part of this docume nt may be phot ocopied, rep roduced,

or translat ed t o anot her l anguag e wi thout the prior w ritten consent of Agilent Technologies, Inc. Agilent assumes no responsibility for the

use or reliability of its software on equipment that is not furnished by Agilent.

U.S. Government Restricted Rights

The Software and Documentation have been developed entirely at private expense. They are delivered and licensed as "commercial

computer software" as defined in DFARS 252.227- 7013 (Oct 1988), DFARS 252.211-7015 (May 1991) or DFARS 252.227-7014 (Jun

1995), as a "com mercial ite m" as defined in FAR 2.101(a), or as "Restri cted comput er software" as defi ned in FAR 52.227-19 (Jun 1987)(or

any equival ent agen cy reg ulati on or contra ct cla use ), which ever i s appli cabl e. You hav e only t hose r ight s provide d for suc h Software and

Documen ta t io n by t h e a pplicable FAR or DFARS clau se or the Agilen t s ta ndard software agreement fo r the product involved.

Agilent E1463A 32-Channel, 5-Amp, Form C Switch Module Service Manual

Copyright © 1997-2006 Agilent Technologies, Inc. Al l Rights Reserved.

Edition 2 Rev 2

Agilent E1463A 32-Channel, 5-Amp, Form C Switch Module Service Manual 3

Printing H is tory

The Printing History shown below lists all Editions and Updates of this manual and the printing date(s). The first printing of the manual

is Edition 1. The Edition number increme n ts b y 1 whenev e r th e ma nua l is r ev is ed. Up date s, wh ich are issued between Ed itio n s, contain

replacement pages to correct the current Edition of the manual. Updates are numbered sequentially starting with Update 1. When a new

Edition is crea ted, it cont ains all the Upda te i nfor mat ion for the p revious Ed ition. E ach ne w E dition or U pdat e a lso incl udes a re vised copy

of this prin ti ng history p age. Many pr oduct updates or revisions do not r equire manu al changes and, converse l y, manual corr ections may

be done without accompanying product changes. Therefore, do not expect a one-to-one correspondence between product updates and

manual updates.

Edition 1 (Part Number E1463-90010). . . . . . . . . . . . . . . . . . . . . . October 1992

Edition 2 (P ar t Number E1463 -90 011). . . . . . . . . . . . . . . . . . . . . . January 1997

Edition 2 Rev 2 (Part Number E14 63- 90011) . . . . . . . . . . . . . . . . . . . June 2006

Safety Symbols

Instructi on manual sy mbol affixed to product.

Indic ates th at the user must refer to the manual for specific WARNING or CAUTION

informatio n to avoi d personal injury or damage to the pr oduct.

Alternating current (AC).

Direct current (DC).

Indicates t he field wir ing termina l that must

be connec ted to earth gr ound before op erating

the equipment—protects against electrical

shock in cas e of fa ul t.

or

Frame or chassis ground terminal—typically

connects to the equipment’s metal frame.

WARNING

CAUTION

Indicate s ha zardous volta ges.

Calls a tt ention to a procedure, practice, or condition that could cause bodi l y injury or death.

Calls attention to a procedur e, practice, or con dition that could possibly cause damage to

equipme nt or pe rm anent loss of dat a.

WARNINGS

The following general safety precautions must be observed during all phases of operation, service, and repair of this product.

Failure to comply w ith these precautions o r with spe cific warni ngs elsewher e in this ma nu a l violates safety s ta n d ar d s of desig n,

manufacture, and intended use of the product. Agilent Technologies assumes no liability for the customer’s failure to comply with

these re qu i rements .

Ground the equipment: For Safety Class 1 equipment (equipment having a protective earth terminal), an uninterruptible safety earth

ground must be provided from t he m ains power sour ce to the product i nput wiring term i nal s or supplied pow er cable.

DO NOT operate the pr od uct in an expl osive atmosp here or in th e presence of flammabl e gases or fum es.

For continued protection against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current rating and type.

DO NOT use re pai red fuses or sho rt-c ircuited fuse holders.

Keep away fr om live circuits: Ope ra t in g personnel must not rem ove equipme nt cove rs or s hi el ds. Procedures i nvol vi ng the removal of

covers or shields are for use by service-trained personnel only. Under certain conditions, dangerous voltages may exist even with the

equipmen t switch ed off. To avoid da ngerou s elec trica l shoc k, DO NO T perform proced ures i nvolv ing cove r or shield re mova l unle ss you

are qualified to do so.

DO NOT operate damaged equipment: Whenever it is possible that th e safety protectio n features built into this product have been

impaired, either through physical damage, excessive moisture, or any other reason, REMOVE POWER and do not use the product until

safe oper at i on can be ve ri fied by serv i ce -t ra i ned personn el . If necess ar y, return th e product to an Agilent Technologies Sales a nd Service

Office for service and repair to ensure that safety features are maintained.

DO NOT serv ice or adjust al one: Do not at tempt inte rnal ser vice or adjus tment unles s anot her per son, ca pabl e of renderi ng first aid and

resuscitation, is present.

DO NOT substitute parts or modify equipm ent: Because of the danger of introducing additional hazards, do not install substitute parts

or perform any unauthorized modification to the product. Return the product to an Agilent Technologies Sales and Service Office for

service and repair to ensure that safety features are maintained.

4 Agilent E1463A 32-Channel, 5-Amp, Form C Switch Module Service Manual

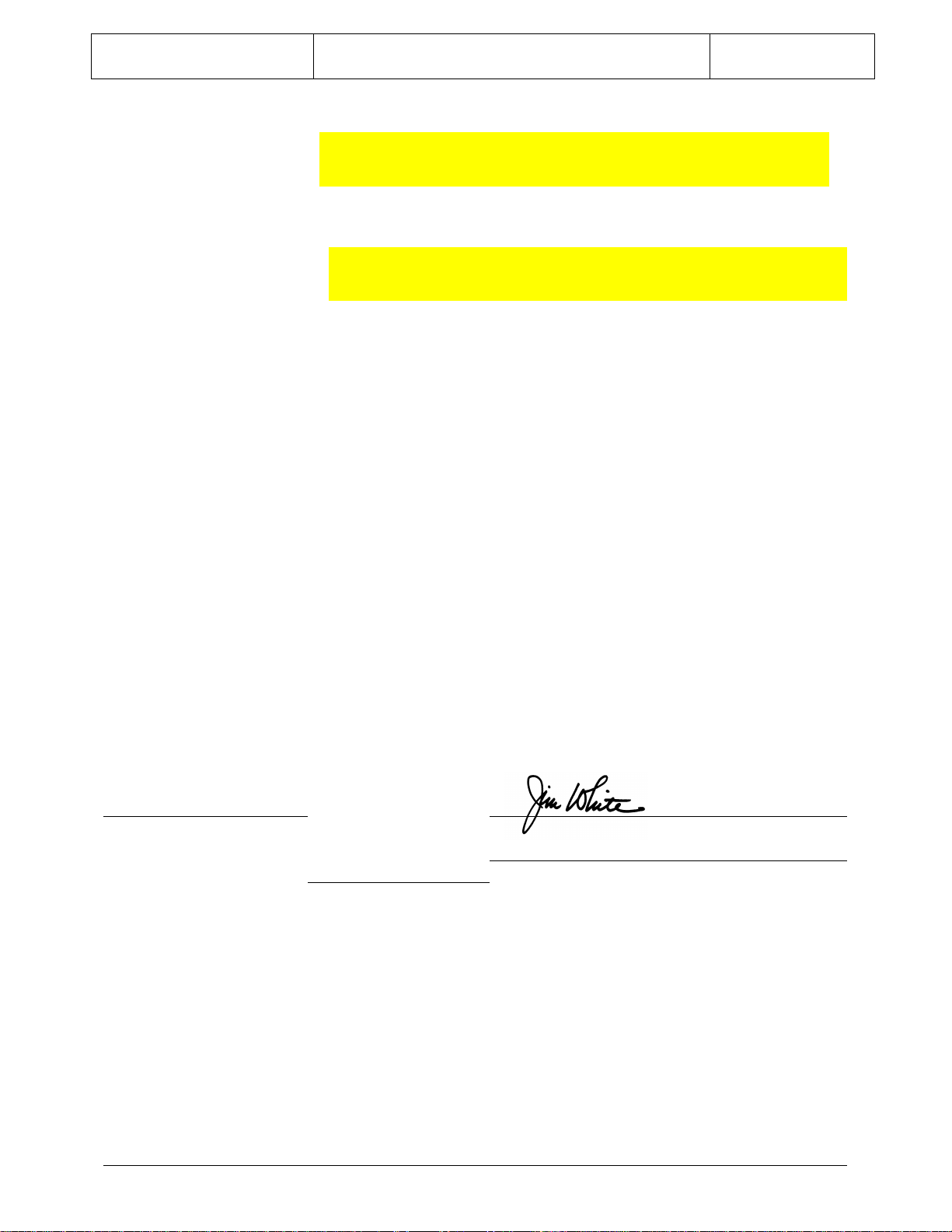

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name:

Agilent Technologies, Incorporated

Manufacturer’s Address: Measurement Product Generation Unit

815 14th ST. S.W.

Loveland, CO 80537 USA

Declares, that the product

Product Name:

Model Number:

32 Channel Form C VXI Switch

E1463A

Product Options: This declaration covers all options of the above product(s).

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC

and carries the CE Marking accordingly

Conforms with the following product standards:

EMC Standard

IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1997 +A1:1997 / EN 55011:1998

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995

IEC 61000-4-3:1995 / EN 61000-4-3:1995

IEC 61000-4-4:1995 / EN 61000-4-4:1995

IEC 61000-4-5:1995 / EN 61000-4-5:1995

IEC 61000-4-6:1996 / EN 61000-4-6:1996

IEC 61000-4-11:1994 / EN 61000-4-11:1994

Limit

Group 1 Class A

4kV CD, 8kV AD

3 V/m, 80-1000 MHz

0.5kV signal lines, 1kV power lines

0.5 kV line-line, 1 kV line-ground

3V, 0.15-80 MHz

I cycle, 100%

[1]

Canada: ICES-001:1998

Australia/New Zealand: AS/NZS 2064.1

Safety

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

UL 3111-1:1994

Supplemental Information:

[1]

The product was tested in a typical configuration with Agilent Technologies test systems.

September 5, 2000

Date Name

Quality Manager

Title

Authorized EU-representative: Agilent Technologies Deutschland GmbH, Herrenberger Straβe 130, D 71034 Böblingen, Germany

For further information, please contact your local Agilent Technologies sales office, agent or distributor.

Agilent E1463A 32-Channel, 5-Amp, Form C Switch Module Service Manual 5

Notes

6 Agilent E1463A 32-Channel, 5-Amp, Form C Switch Module Service Manual

Notes

Agilent E1463A 32-Channel, 5-Amp, Form C Swit ch Module Service Manual 7

Notes

8 Agi lent E1463A 32- Channel, 5-Amp, Form C Sw itch Module Ser vice Manual

Introduction

Chapter 1

General Info rmation

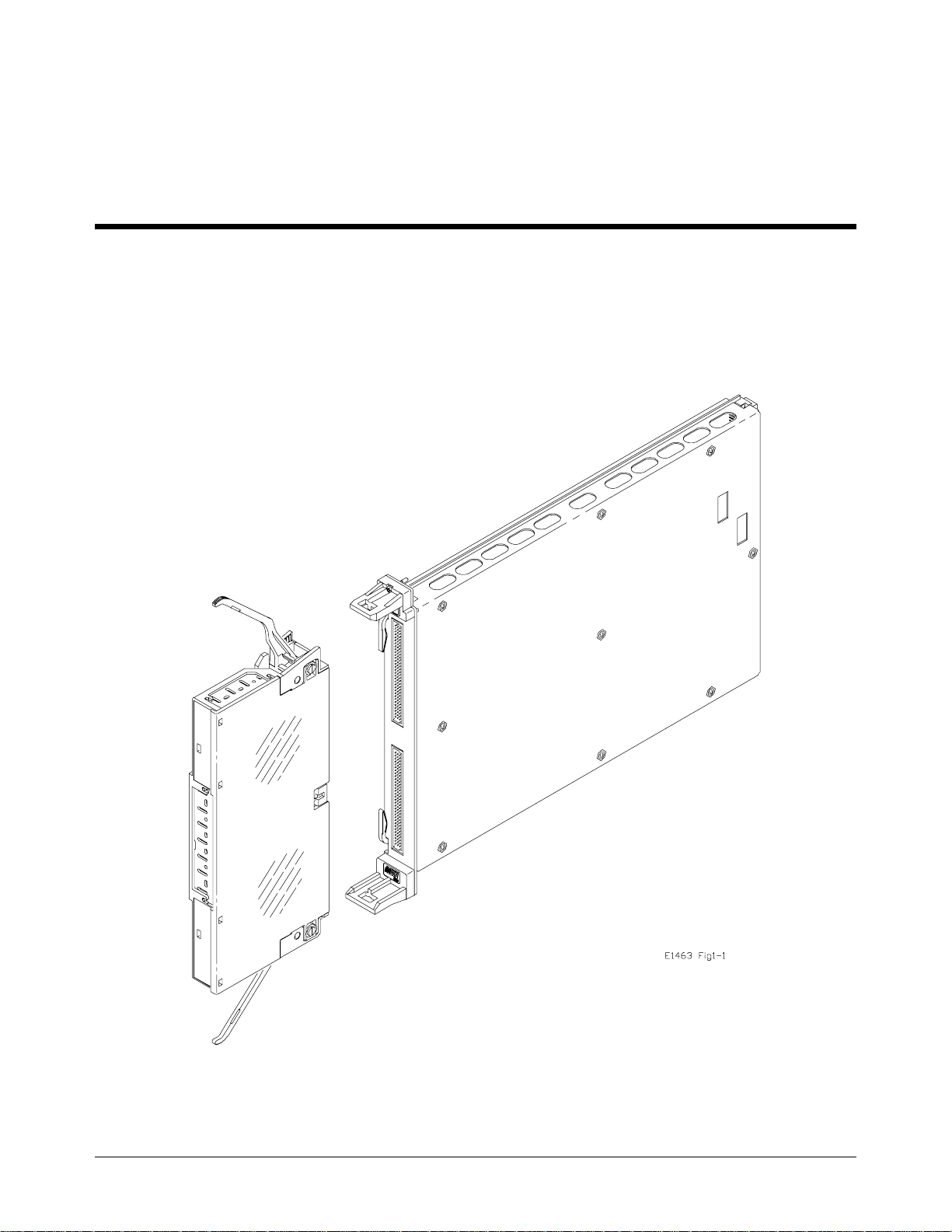

This manual contains inform at ion required to test, trouble shoot, and repai r

the Agilent E1463A 32-Channel Form C Switc h Module (see Figure 1-1).

Figure 1-1. Agilent E1463A Form C Switch

Chapter 1 General Information 9

Relay Life

Electromechanical relays are subject to normal wear-out. Relay life

depends on several factors. The effects of loading and switching

frequency are briefly discussed below:

Relay Load. In gen eral, hi ghe r powe r switching reduces relay life . In

addition, capa c it ive /inductive loa ds a nd hi gh inrush currents (e .g ., whe n

turning on a lam p or motor) reduce relay l ife . Exceeding the specified

maximum inputs can cause catastrophic failure.

Switching Frequency. Relay contacts he at up whe n switched. As the

switching frequency increases, the contacts have less time to dissipate heat.

The resulting increase in contact temperature reduces relay life.

End-of-Life

Detection

A preventive maintenance routine can prevent problems caused by

unexpected rela y f ai lu re. The en d of the li fe of a rela y c an be determined

using one or more of the thr e e methods described bel ow. T he best me thod

(or combination of methods), as well as the failure criteria, depends on the

applicatio n in which the relay is used.

Contact Resistance. As the relay begins to wear out, its c ont act resistance

will increase. When the resistance exceeds a pre-determined value, the relay

should be replaced. Typically, a relay should be replaced when the contact

resistance exce eds 2.0 Ohm.

Stability of Co nt ac t Resistance. The stability o f the co ntac t res ista nce

decreases with age. Using this method, the contact resistance is

measured several (5-10) times, and the variance of the measurements is

determined. An increase in the variance indicates deteriorating

performance.

Number of Operations. Alternatively, relays can be replaced after a

predetermined number of contact closures. How ever, this method

requires knowledge of the applied load and life specifications for the

applied load. For the Agilent E1463A, maximum relay life is specified

at 5 X 10

worst-case rated load.

7

operations with no load and 3.5 X 104 operations at the

10 General Information Chapter 1

Replacement

Strategy

The replacement strategy also depends on the a pplication. If some

relays are used more often, or a t higher load, tha n the others, the relays

can be individually replaced as needed. If all of the relays see similar

loads and switching frequencies, the entire circuit boar d can be

replaced when the end of life a pproaches. The sensitivity of the

application should be weighed against the cost of replacing relays with

some useful life remaining.

NOTE

Relays that wear out normally or fail due to misuse should not be

considered defective and are not covered by the product’s warranty.

Safety Considerations

This pr oduct is a Saf e ty Class I instrument tha t is provided with a

prote ctive earth t e r minal when installed in th e ma inframe. Th e

instrument, mainf rame, a nd a ll r e la ted docu me ntation sho uld be revie wed

for familiarization with safety markings and instructions before operation

or service.

Refer to the WARNI NGS on pag e 4 i n thi s ma nual for a summary of safe ty

informatio n. Safety informat ion for testing a nd se rvice follows and is al so

found throughout this manual.

WARNINGS and

CAUTIONS

This section co nta i ns W A RNINGS which must be foll owe d f or your

protection and C AUTIONS whi ch must be follo w ed to a voi d da ma ge to t he

equipment when performing instrument maintenance or repair.

WARNING

SERVICE-TRAINED PERSONNEL ONLY. The information in this

manual is for service-trained personnel who are familiar with

electroni c circ u it ry and are aware of th e haz ards involved. To

avoid personal injury or damage to the instrument, do not

perform procedures in this manual or do any servic ing unless

you are qualified to do so.

CHECK MAINFRAME POWER SETTINGS. Before applying

power, verify that the main frame setting matches the line

voltage and that the correct fuse is installed. An uninterruptible

safety earth ground must be provide d from the main power

source to the supplied power cord set.

Chapter 1 General Information 11

WARNING

GROUNDING REQUIREMENTS . Interruption of the protective

(grounding) conductor (inside or outside the mainframe) or

disconnecting th e protective earth terminal will cause a

potential shock hazard that coul d result in personal injury.

(Grounding one conductor of a two-conductor outlet is not

sufficient protection.)

IMPAIRED PROTECTION. Whene ve r it is likely tha t inst ru ment

protection has been impaired, the mainframe must be made

inoperative and b e secured against any un intended operation.

REMOVE POWER IF POSSIBLE. Some procedures in this

manual may be performed with power supplied to the

mainframe while p rotective covers ar e removed. Energy

available at many points may, if contacted, result in personal

injury. (If maintenance can be performed without power

applied, the power should be removed.)

USING AUTOTRANSFORMERS. If the mainframe is to be

energized via an autotransformer (for voltage reduction) make

sure the common terminal is connected to neutra l (tha t is, the

grounded sid e of the main’s supply).

CAPACITOR VOLTAGES. Capacitors inside the mainframe

may remain charged even when the mainframe has been

disconnected from its source of supply.

USE PROPER FUSES. For continued protection ag ainst fire

hazard, rep lace th e line fuses only with fuses of the same

current rating and type (such as normal blow, time delay, etc.).

Do not use repaired fuses or short -circui ted fuseholders.

SHOCK HAZARD. Only service-trained personnel who are

aware of the hazards involved should install, remove, or

configure the Agilent E1463A 32-Cha nnel Form C Switch

Module . Before you remove any installed modul e, disconnect

AC power from the mainframe and from other modules that

may be connecte d to the Switch Module.

CHANNEL WIRING INSULATION. All channels that have a

common connection must be insulated so that the user is

protected from electrical shock. This means wiring for all

channels must be insulated as thoug h each channel carries

the voltage of the highest voltag e chann el.

12 General Information Chapter 1

CAUTION

MAXIMUM INPUTS. The maximum voltage that can be applied to

any terminal is 125 V dc (250 Vac rms). The maximum current per

channel or common is 5 A DC or ac rms. The maximum power that

can be applied to any channel or common is 150 W or 1250 VA.

STATIC ELECTRICITY. Static electricity is a major cause of

component failure. To prevent damage to the electrical components

in the Switch Module, observe anti-static techniques whenever

working on the device.

Inspection/Shipping

This section contains init ia l ( incoming) ins pe ct io n an d shi pping guideline s

for the switch module.

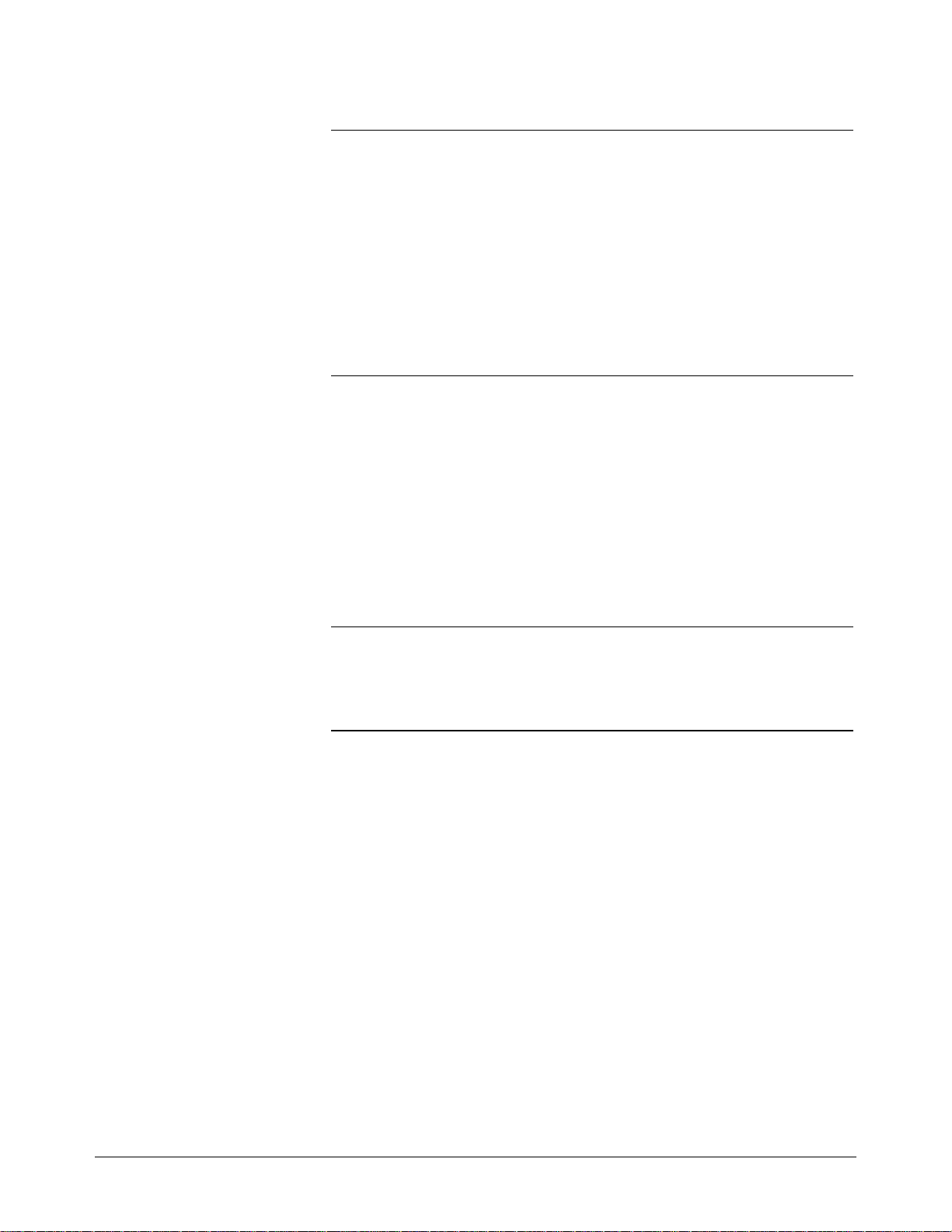

Initial Inspection Use the steps in Fi gure 1- 2 as guidelines to per fo rm initial inspe c ti on of one

of the modules. Ve ri fic a ti on Te sts are optional.

WARNING

To avoid possible hazardous electri cal shoc k, do not perform

elec t rical tests if there are signs of shipping d amage t o the

shipping container or to the instrument.

Chapter 1 General Information 13

Notify Agilent and Carrier.

Notify Agilent

Return Module to Agilent

Figure 1-2. Initial (Incoming) Inspection Guidelines

14 General Information Chapter 1

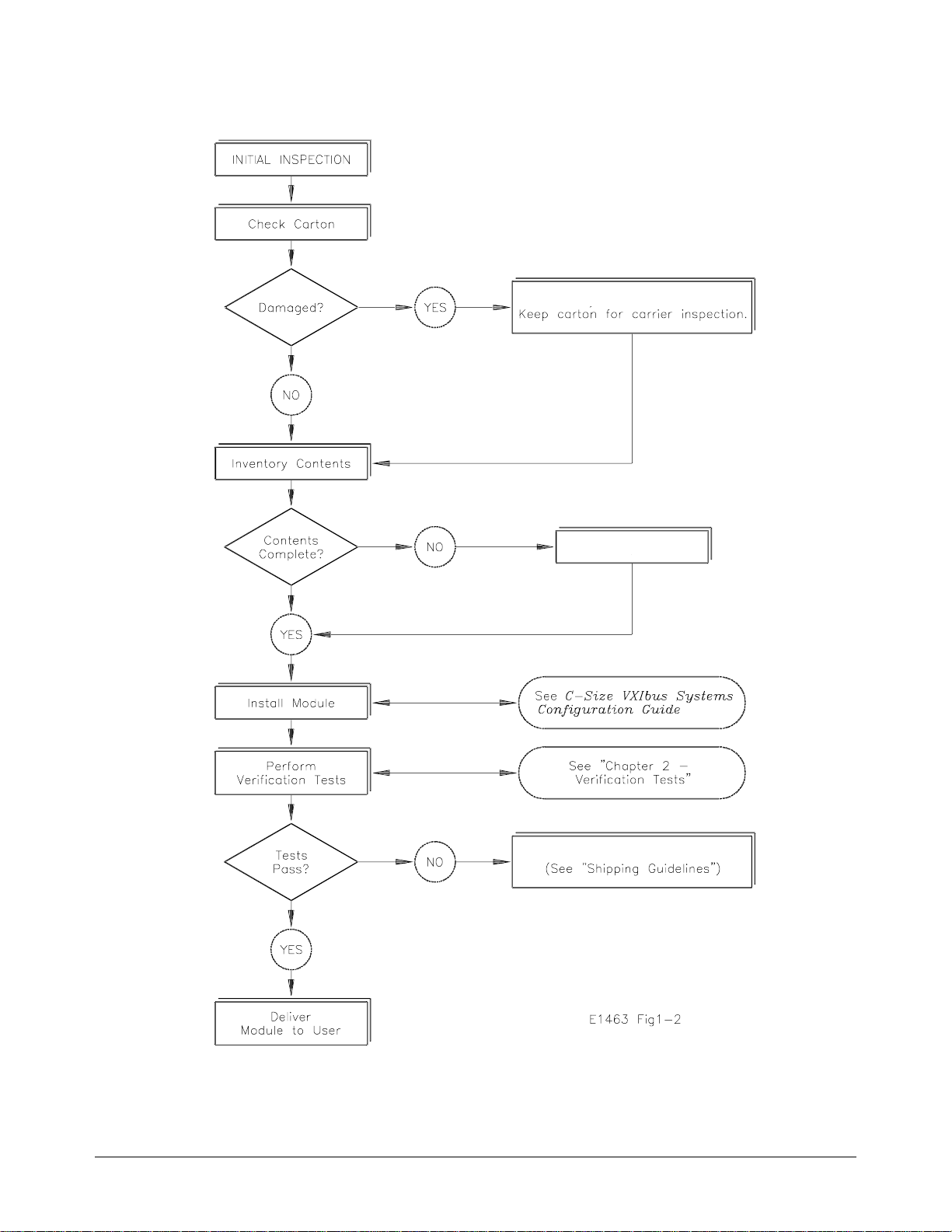

Shipping

Guidelines

Follow the steps in Figure 1-3 to retur n t he Module to an Agilent

Technologies Sales and Support Office or Service Center.

1 Prepare the Module

• Remove user wiring from terminal module

• Attach tag to module/pod that identifies

- Owner

- Model Number/Serial Number

- Service Required

• Place tagged device in approved anti-static bag

2 Package the Module

• Place packaged Module in shipping carton*

• Place 75 to 100 mm (3 to 4 inches) of shock-

absorbing material around the Module

• Seal the shipping carton securely

• Mark the shipping carton FRAGILE

3 Ship the Module to Agilent Technologies

• Place address label on shipping carton

• Send carton to Agilent Technologies

Figure 1-3. Packaging/Shipping Guidelines

* We reco m m end that you use t he s am e shipping ma t er ia l s as those used in factory packa gi ng (available fr om A gi l ent T echnologies ).

For other (com m ercially-av ailable) ship pi ng materials , us e a d oubl e wa l l- carton with mi ni mum 2.4 MPa (3 50 ps i) te st .

Chapter 1 General Information 15

Environment

The recommended operating environmen t for the Agilent E1463A 32-Channel

Form C Switch Module is:

Environment Temperature Humidity

Operating 0oC to +55oC <65% relative (0oC to +40oC)

Storage and

Shipment

Switch Module Description

The Agilent E1 463A 32-Channel Form C Switch Module is an "instrument "

in the slots of a VXIbus mainf r ame . E ach m odule is assigned an error

queue, input and output buffers, and a sta tu s regi ster.

NOTE

Agilent E1463A

Description

Instruments are based on the logical addresses of the plug-in modules. See

the C-Size VXIbus Systems Configuration Guide to set the addresses to

create an instrument.

The Agilent E1463A 32-Channel Form C Swit c h Module is a VXI-bus

C-Size register bas ed produc t. The Form C Switch Modul e prov ide s 32

channels of Form C rel a y swit c hing. Each channel includes a Comm on ( C),

a Normally Open (NO) an d a Normally Clos ed (NC) term i nal. E ach rel ay

can switch up to 5 amps.

o

-40

C to +75oC <65% relative (0oC to +40oC)

The channels ca n be indi vi dua lly controlled or ca n be scann ed . Eac h

channel uses a non- latching rel ay and al l c ha nne l Commons (C) are

connected to the Normally Closed (NC) terminals following a power

ON or a reset command.

Pads are provide d on the compo ne nt a sse mbly for the i nstallation of us er

provided protec ti on c irc uitry. The termi na l mo dule contains screw ter mi na ls

for user wiring connecti ons.

16 General Information Chapter 1

Switch Module

Specifications

Specification s are listed in Appendix A of the Agilent E1463A 32-Channel

Form C Switch Module User’s Manual. These specifications are the

performance standards or limits against which the modules may be tested.

Switch Module

Serial Numbers

Devices covered by this manual are identified by a serial number prefix

listed on the title page. Agilent Technologies uses a two-part serial number

in the form XXXXAYYYYY, where XXXX is the serial prefix, A is the

country of origin (A=USA), and YYYYY is the serial suffix. The serial

number prefix identifies a series of identical instruments. The serial number

suffix is assigned sequentially to each instrument. The serial number plate is

located on the right-hand shield near the backplane connectors.

Switch Module

Options

The Agilent E1 463A c om es sta ndar d with a terminal module consisting of

screw terminals. In addition , a ter mi na l module with solder eye termin al s is

available (Option A3G).

Sche mati cs an d

Component

Component locators and schematics for the modules are packaged with this

manual. Clear plastic sleeves are included for storage.

Locators

Recommended Test Equipment

Table 1-1 list s the te st equipment rec omm e nde d f or te sti ng a nd se r vicing the

module. Essential requirements for each piece of test equipment are

described in the Re qui r em e nts col umn.

Table 1-1. Reco mmended Test Equipment

Instrument Requirements Recommended Model Use*

Controller, GPIB GPIB compatibility as defined by IEEE

Standard 488-1988 and the iden tical

ANSI Standard MC1.1: SH1, AH1, T2,

TE0, L2, LE0, SR0, RL0, PP0, DC0,

DT0, and C1, 2, 3, 4, 5.

Mainframe Compatible with switch module Agilent E1401B/T or

Command Module Compatible with switch module Agilent E1405A/B or

Digital Multimeter 4-wire ohms

2-wire ohms (up to 1 GΩ )

HP 9000 Series 300

or

IBM Compatible PC with

BASIC

Agilent E1421B

Agilent E1406A

Agilent 3458A or

Agilent 34401A

F,O,

P,T

F,O,

P,T

F,O,

P,T

O,P, T

* F = Functiona l Verification Tests, O = Operat i on V er ification Tes t s, P = Per formance Verific at i on T e st s, T = Troublesho oting

Chapter 1 General Information 17

Notes

18 General Information Chapter 1

Introduction

Chapter 2

Verification Tests

The three levels of te st procedures described in this chapt e r ar e us ed to

verify that the Agilent E1463A 32 -Cha nne l Form C Switch Module:

• is fully functional (Functional Verification)

• meets selected testable specifications (Operation Verification)

• meets all testable specifications (Performance Verification)

Test Conditions

and Procedures

Performance Test

Record

Verification Test

Examples

See Table 1-1 for test e quipment require me nt s. You should complet e th e

Performance Verificati on tests at least once a year. Fo r hea vy us e or se ver e

operating e nv ironm e nts, pe r f orm the tests mor e often.

The verification tests assume that the person performing the tests

understands how t o ope r ate the ma inframe, the switc h module, and specified

test equipme nt. The te st procedures do not specify equip ment settings for

test equipment, except in general terms. It is assumed that a qualified,

service-trained technician will select and connect the cables, adapters, and

probes required for the test.

o

It is assumed that the temperature is no greater than 25

humidity is no gre a ter than 40% .

The results of each Performance Verification test may be recorded in the

Performance Test Re c ord (T ab le 2- 1) .

Each verification test procedure includes an example program that performs

the test. All example programs assume the following:

C and the rela tive

• Controller is an HP 9000 Series 200/300 computer

• Programming languag e is BAS IC

• Switch address is 70915

• Switch card number is 1

Chapter 2 Verification Tests 19

Switch Module Functional Verification

The Functional Verification Test for the Agilent E1 463A 32-Channel Form C

Switch Module consists of sending the

This test can be used at any time to verify that the device is connected properly and

is responding to ba sic com m ands.

Procedure 1. Verify that the Switch Module is installed in the mainframe and that

the mainframe has passed its power-on test.

2. Send the *TST? command to the device (see example following).

3. The device will return an error code . Any non-z e ro error cod e

indicates a self - te st failure. See Table 4-4 for a desc r ip tion of self-test

error codes.

Example An example follow s w hic h uses an HP 9000 Serie s 300 computer with BA S IC a nd

a Switch Module ad dre s s of 70915.

10 OUTPUT 70915;"*TST?" Send the self-test command

20 ENTER 70915;A Get response

30 PRINT A

40 END

*TST? command and checking the resp o nse.

Operation Verification

The procedure s in th is sec ti on a re used to provide a high degree of confi dence that

the Switch Modul e is me e ti ng published specific a ti ons . The O pe ration Verifica tion

tests are usually a su bset of th e Performance V e rification tests and a re suitable for

checkout aft er per forming repairs.

For the Agilent E1463A Switch Module, Operatio n Verification is performed by

completing the Closed Channel Resistance Test as described in the Performance

Verificatio n te st procedures (Tes t 2-1 ). Thi s te st is usually sufficient t o ve rif y tha t

the instr ument is meeting its specifications.

Performance Verification

The procedures in this section are used to test the module’s electrical performance

using the specific a ti ons in Ap pe ndi x A of the Agilent E1463A 32-Channel Form C

Switch Module User’s Manual as the performance standards.

20 Verification Tests Chapter 2

The performance verification tests have two parts: a closed channel resistance te st of all

relay contacts (Test 2-1) and a DC isolation test (Test 2-2). T hese tests a re sufficient t o

determine that the module is ope rat ing within sp ecificat ions. These te sts are sui table for

incoming inspection, troubleshooting, and preventive maintenance.

Wiring the Test

Fixture

A test fixture is required for the performance veri fic a ti on t ests. Figure 2-1 shows

typical connections using an Agil en t E 1463A terminal mod ule for the test fixture .

You may want to or de r an extra terminal mo dule to use as a test fixture , so yo u

don’t have to re-wire each time t he te sts are pe rformed. The A gilent E1463A

terminal module part number is E 1463-80011 (for mo dul es w ith s er ia l nu mbers

prior to 3126A01817, the terminal module part numbe r is E1 463-80001).

Figure 2-1. Agilent E1463A Test Fixture

Test 2-1:

Closed Channel

Resistance Test

This test verifies that all relay contacts meet the closed-channel resistance speci- fication

for the module. When making the Closed Channel Resistance Test, the NO and NC paths

relay contacts are tested independently. This test uses the test fixture (see Figure 2-1).

The Closed Channel resistance specification for each relay contact is 2.0 W

.

Common to NO

Measurements

1. Make Hardware Connections

• Turn mainframe power OFF

• Connect DMM le ad s as sho w n in Fi gure 2-2

Chapter 2 Verification Tests 21

• Set DMM to measure 4-wire Ohms

• Turn mainframe power ON

2. Measure Channel 0 C to NO Resistance

• Send *RST to Module

• Send CLOS (@nn00) to close channel 0, where nn = card #

(typically 01)

• Trigger the DMM with TRIG SGL and note reading

• Send OPEN (@nn00) to open channel 0, where nn = card #

(typically 01)

• Enter the result in Table 2-1 for channel 0 C to NO

3. Repeat for Channels 1 through 31 C to NO

• Repeat step 2 for channe ls 1 through 31

• Use OPEN (@nncc) and CLOS (@nncc), where nn = card # and

cc = channel # (omit leading zeroes in nn)

Figure 2-2. Common to NO Test Connections

Channel 0 C to NC

Measurements 1. Make Hardware Connections

• Turn mainframe power OFF

22 Verification Tests Chapter 2

• Set DMM to measure 4-wire Ohms

• Connect DMM leads as sh own in Figure 2-3

• Turn mainframe power ON

2. Measure Channel 0 C to NC Resistance

• Send *RST to Module

• Send CLOS (@nn00:nn31) to close all channels, where nn = card

# (typicall y 01)

• Send OPEN (@nn00) to open channel 0, where nn = card #

(typically 01)

• Trigger the DMM with TRIG SGL and note reading

• Enter the result in Table 2-1 for Channel 0 C to NC

• Send CLOS (@nn00) to close channel 0, where nn = card #

(typically 01)

3. Repeat for Channels 1 through 31

• Repeat step 2 for channel 1 through 31 C to NC

• Use OPEN (@nncc) and CLOS (@nncc), where nn = card # and

cc = channel # (omit leading zeroes in nn)

Figure 2 -3. Common to NC Test Connections

Chapter 2 Verification Tests 23

Example: Closed

Channel Resistance

Test

This example per forms a Closed Ch annel Resistance Test t o measur e

Channels 0 th rough 31 relay contact resistances. If the rela y c ontact

resistance for a channel is >2.0

Ω the program prints a message indicating

which channe l h as failed the test. Use this list in Chapter 4 whe n

troublesho oting a failing rel a y.

NOTE

This test assumes that the module is configured without protection

varistors, fuses, or resistors and that jumpers JM1 through JM8 are

installed on the Agilent E1463A Component Assembly (factory setting).

Refer to the Agilent E1463A Use r’s Manual for details and locations of

user installed protection circuits

10! RE-SAVE "CLOS_TEST"

20 ASSIGN @Dmm TO 722

30 ASSIGN @Sw TO 70915

40 DISP CHR$(129)

50 DIM Result(1,31),Path$(1)[2]

60 DATA NO,NC

70 READ Path$(*)

80 Cc$="01" ! Card number

90 Ph$="0" ! Place holder

100 !

110 !Start test

120 !

130 CLEAR SCREEN

140 PRINT "Install Component Assembly and Test Fixture "

150 PRINT

160 PRINT " 1. Turn Mainframe and Agilent 3458A DMM power OFF"

170 PRINT " 2. Connect GPIB Cable between mainframe and DMM"

180 PRINT " 3. Install E1463A Component Assembly into Mainframe"

190 PRINT " 4. Attach Test Fixture to Component Assembly"

200 PRINT " 5. Turn Mainframe and DMM power ON "

210 PRINT " 5. Press Continue when ready to begin testing "

220 PAUSE

230 CLEAR SCREEN

240 !

250 ! Start the measurements

260 !

270 FOR J = 0 TO 1

280 OUTPUT @Dmm;"PRESET NORM;FUNC OHMF"

(Continued on Next Page)

24 Verification Tests Chapter 2

290 OUTPUT @Sw;"*RST"

300 OUTPUT @Sw;"*OPC?"

310 ENTER @Sw;Opc

320 IF Opc<>1 TH EN GOTO 300

330 IF J=1 THEN

340 OUTPUT @Sw;"CLOS (@"&Cc$&"00:"&Cc$&"31)"

350 END IF

360 PRINT TABXY(1,1), "Channels 00-31 "&Path$(J)&

" measurements"

370 PRINT TABXY(1,3), "1. Connect DMM Sense and Input HI leads

to test fixture "&Path$(J)

380 PRINT TABXY(1,4), "2. Connect DMM Sense and Input LO leads

to test fi x t u r e C"

390 DISP "Press Continue when connections are complete"

400 PAUSE

410 CLEAR SCREEN

420 OUTPUT @D mm;"TRIG SGL"

430 ENTER @Dmm;Meas

440 IF Meas <1.E+6 THEN

450 PRINT "Stuck relay found"

460 PRINT "Repair problem and re-run test"

470 STOP

480 END IF

490 FOR I=0 TO 31

500 IF J<1 THEN

510 IF I <10 THEN

520 OUTPUT @Sw;"CLOS (@"&Cc$&Ph$&VAL$(I)&")"

530 ELSE

540 OUTPUT @Sw;"CLOS (@"&Cc$&VAL$(I)&")"

550 END IF

560 ELSE

570 IF I <10 THEN

580 OUTPUT @Sw;"OPEN (@"&Cc$&Ph$&VAL$(I)&")"

590 ELSE

600 OUTPUT @Sw;"OPEN (@"&Cc$&VAL$(I)&")"

610 END IF

620 END IF

630 OUTPUT @Sw;"*OPC?"

640 ENTER @Sw;Opc

650 IF Opc<>1 THEN GOTO 630

660 OUTPUT @Dmm;"TRIG SGL"

670 ENTER @Dmm;Result(J,I)

(Continued on Next Page)

! Check for stuck relays

Chapter 2 Verification Tests 25

680 IF J<1 THEN

690 IF I <10 THEN

700 OUTPUT @Sw;"OPEN (@"&Cc$&Ph$&VAL$(I)&")"

710 ELSE

720 OUTPUT @Sw;"OPEN (@"&Cc$&VAL$(I)&")"

730 END IF

740 ELSE

750 IF I <10 THEN

760 OUTPUT @Sw;"CLOS (@"&Cc$&Ph$&VAL$(I)&")"

770 ELSE

780 OUTPUT @Sw;"CLOS (@"&Cc$&VAL$(I)&")"

790 END IF

800 END IF

810 OUTPUT @Sw;"*OPC?"

820 ENTER @Sw;Opc

830 IF Opc<>1 T H EN GOTO 8 1 0

840 IF Result(J,I)<0 THEN Result(J,I)=0

850 IF Result(J,I)>2.0 THEN

860 PRINT "Resistance for Channel ";I;" "&Path$ (J)&" conta cts

is >2.0 Ohms"

870 END IF

880 NEXT I

890 PRINT "Measurements complete for Channel 00-31 "&Path$(J)&" contacts"

900 IF J<1 THEN

910 DISP "Press Continue for cha nnels 00- 31 N or ma lly Closed

measurements"

920 PAUSE

930 END IF

940 NEXT J

950 PRINT "Closed Contact Resistance measurements complete"

960 DISP "Press continue to print measu rement results"

970 PAUSE

980 CLEAR SCREEN

990 !

1000 ! Print measurement results

1010 !

1020 Format:IMAGE "CH ",DD,3X,DD.DDDD," Ohms",3X,DD.DDDD," Ohms"

1030 PRINT TABXY(1,3)," NO Contacts NC Contacts"

1040 PRINT

1050 FOR I=0 TO 31

1060 PRINT USING Format;I,Result(0,I),Result(1,I)

1070 NEXT I

1080 END

26 Verification Tests Chapter 2

Typical Result

NO Contacts NC Contacts

CH 0 .1453 Ohms .1453 Ohms

CH 1 .1616 Ohms .1661 Ohms

CH 2 .1914 Ohms .1948 Ohms

CH 3 .3491 Ohms .2657 Ohms

CH 4 .4644 Ohms .2628 Ohms

CH 5 .1226 Ohms .1389 Ohms

CH 6 .1499 Ohms .1678 Ohms

CH 7 .1547 Ohms .1817 Ohms

CH 8 .3347 Ohms .2257 Ohms

CH 9 .4932 Ohms .3096 Ohms

CH 10 .157 2 O hms .1849 O hms

CH 11 .183 6 O hms .2106 O hms

CH 12 .154 3 O hms .1317 O hms

CH 13 .286 1 O hms .2144 O hms

CH 14 .450 0 O hms .2722 O hms

CH 15 .136 6 O hms .1771 O hms

CH 16 .169 4 O hms .1639 O hms

CH 17 .184 8 O hms .1569 O hms

CH 18 .375 3 O hms .2373 O hms

CH 19 .550 8 O hms .2952 O hms

CH 20 .129 5 O hms .1257 O hms

CH 21 .164 8 O hms .1328 O hms

CH 22 .183 9 O hms .1438 O hms

CH 23 .360 9 O hms .2349 O hms

CH 24 .450 0 O hms .2808 O hms

CH 25 .173 3 O hms .1507 O hms

CH 26 .211 5 O hms .1723 O hms

CH 27 .236 2 O hms .1876 O hms

CH 28 .280 8 O hms .1874 O hms

CH 29 .414 0 O hms .2340 O hms

CH 30 .169 2 O hms .1412 O hms

CH 31 .182 2 O hms .1833 O hms

Chapter 2 Verification Tests 27

Test 2-2:

DC Isolation Test

This test veri fie s tha t sufficient DC iso la ti on e x i sts at various point s on the

Module. DC Isolation is checked from NO to NC, NO to Chassis, and NC to

Chassis. This test uses the test fixture (see Figure 2-1).

NOTE

The DMM used should be capable of measuring at least 1 G

DMM indicates an overload, record the reading as >Rmax, where Rmax is

the highest resistance that the DMM can measure. For example, if the

DMM is an Agilent 3458A, a typical return for an overload is 1.E+38 and

the entry in Table 2-1 should be >1.2 G

Ω..

NC (&C) to NO Isolation 1. Make hardware connections as sho wn in F igure 2-4

2. Set DMM to 2-wire ohms, 1 G Ω range

3. Send *RST to Module

4. Trigger the DMM with TRIG SGL

5.

Record the DMM reading in Table 2-1 (NC to NO)

Ω.. If the

Figure 2-4. NC to NO Isolation

28 Verification Tests Chapter 2

NC (&C) to Chassis

Isolation 1. Make hardware connections a s shown in Figure 2-5

2. Set DMM to 2-wire ohms, 1 G Ω range

3. Send *RST to Module

4. Trigger the DMM with TRIG SGL

5.

Record the DMM reading in Table 2-1 (NC to Chassis)

Figure 2-5. NO and NC to Chassis Isolation

NO (&C) to Chassis

Isolation 1. Make hardware connections a s shown in Figure 2-5

2. Set DMM to 2-wire ohms, 1 G Ω range

3. Send *RST to Module

4. Send CLOS (@100:131) to Module to close all channels

5. Trigger the DMM with TRIG SGL

6.

Record the DMM reading in Table 2-1 (NO to Chassis)

Chapter 2 Verification Tests 29

Example: DC Isolation

Test

This example performs DC Isolation Tests for C to chassis and NO to NC.

10! RE-SAVE "DC_ISOL"

20 ASSIGN @Dmm TO 722

30 ASSIGN @Sw TO 70915

40 DISP CHR$(129)

50 Cc$="01" ! Card number

60 DIM Result(2)

70 PRINT "Equipment Connections "

80 PRINT

90 PRINT " 1. Turn Mainframe and Agilent 3458A DMM power OFF"

100 PRINT " 2. Connect GPIB Cable between mainframe and DMM"

110 PRINT " 3. Install E1463A Component Assembly into Mainframe "

120 PRINT " 4. Attach Test Fixture to Component Assembly"

130 PRINT " 5. Turn Mainframe and Agilent 3458A power ON"

140 DISP "Press Continue when ready to begin testing "

150 PAUSE

160 OUTPUT @Dmm;"OHM 1E9"

170 CLEAR SCREEN

180 !

190 ! Measure DC isolation (NC to NO)

200 !

210 OUTPUT @Sw;"*RST"

220 OUTPUT @Sw;"*OPC?"

230 ENTER @Sw;Opc

240 IF Opc <>1 THEN GOTO 220

250 PRINT TABXY(1,1),"NC (&C) to NO DC Isolation "

260 PRINT TABXY(1,3),"1. Connect DMM Input HI lead to test fixture NO"

270 PRINT TABXY(1,4),"2. Connect DMM Input LO lead to test fixture C"

280 DISP " Press Continue when connections are complete"

290 PAUSE

300 OUTPUT @Dmm:"TRIG SGL"

310 ENTER @Dmm;Result(0)

320 CLEAR SCREEN

330 PRINT TABXY(1,1),"NC (&C) to Chassis DC Isolation"

340 PRINT TABXY(1,3),"1. Connect DMM Input HI lead to Chassis"

350 PRINT TABXY(1,4),"2. Connect DMM Input LO lead to test fixture C"

360 DISP " Press Continue when connections are complete"

370 PAUSE

380 OUTPUT @Dmm;"TRIG SGL"

390 ENTER @Dmm;Result(1)

(Continued on Next Page)

30 Verification Tests Chapter 2

400 CLEAR SCREEN

410 PRINT TABXY(1,1),"NO (&C) to Chassis DC Isolation"

420 DISP " Press Continue to make measurement"

430 PAUSE

440 OUTPUT @Sw;"CLOS (@"&Cc$&"00:"&Cc$&"31)"

450 OUTPUT @Sw;"*OPC?"

460 ENTER @Sw;Opc

470 IF Opc <>1 THEN GOTO 450

480 OUTPUT @Dmm;"TRIG SGL"

490 ENTER @Dmm;Result(2)

500 OUTPUT @Sw;"*RST"

510 PRINT "DC Isolation tests complete"

520 DISP "Press Continue to print measurement results"

530 PAUSE

540 CLEAR SCREEN

550 PRINT TABXY(1,1),"DC Isolation Tests"

560 PRINT TABXY(1,3),"NC to NO (Ohms) ";Result(0)

570 PRINT TABXY(1,4),"NC to Chassis (Ohms) ";Result(1)

580 PRINT TABXY(1,5),"NO to Chassis (Ohms) ";Result(2)

590 END

!Close all channels

Typical Result

DC Isolation Tests

NC to NO (Ohms) 1E+38

NC to Chassis (Ohm s) 1E+38

NO to Chassis (Ohm s) 1E +38

Performance Test Record

Table 2-1 is a form you can copy and use to record performance

verification test results for the Switch Module. Information

concerning test limits, measurement uncertainty, and test accuracy

ratio (TAR) is provided below.

Test Limits Test limits a r e d e f i n e d f or Closed Cha n ne l Resistan c e Test and DC

Isola tion Test using the spe c ificatio ns in Appen dix A of the Agilent

E1463A 32-Channel Form C Switch Module User’s Manual. The

speci f ic a tions are single-sided, (i.e . , there is an upper limit or a lower

limit, bu t not both). I n the Perfor ma n c e Test Record, the Minimum o r

Maximum column wi ll be blank.

Chapter 2 Verification Tests 31

Measurement

Uncertainty

For the performance verification tests in this manual, measurement

uncertainties a r e ca lculated based on th e Agile nt 3458A Digital Mu ltimeter.

The measurement uncertainty shown in Table 2-1 is the accuracy of the

Agilent 3458A usi ng 90-day specific a ti ons. The c alc ula tions follow.

Closed Channel

Resistance Test

Conditions:

• 4-wire ohms fu nction , 10 Ω range

• 90-day specifications

• Worst-case reading = 2.0 Ω

M.U. = (15 ppm of Reading + 5 ppm of Range)

= (15x10

= 8.0x10

DC Isolation Test Conditions:

• 2-wire ohms fu nction , 1 G Ω range

• 90-day specifications

• Worst-case reading = 1.2 G Ω (highest resistance that can be measured

with the Agilent 3458A)

M.U. = (0.5% of Reading + 10ppm of Range)

= (0.005 * 1.2x10

= 6.1x10

Test Accuracy

Ratio (TAR)

Test Accuracy Ratios are not defined for single-sided measurements, so all

measurements ha ve "NA" (N ot Applicable) in the TAR co lum n.

-6

* 2.0) + ( 5x10-6 * 10) Ω

-5

Ω

6

Ω

9

) + ( 10x10

-6

* 1x109) Ω

32 Verification Tests Chapter 2

Table 2-1. Performance Test Record (P age 1 of 3)

Model _______________________ Report No. __________________________ Date __________

General Informati on

Test Facility:

Name ________ ____ _________________________

Address

_____________________________________

City/State _______________________ ____________

Phone _____________________________________

Special Notes:

___________________________________________________________________________________________ __

___________________________________________________________________________________________ __

___________________________________________________________________________________________ _

___________________________________________________________________________________________ _

___________________________________________________________________________________________ _

___________________________________________________________________________________________ __

Report No. _________________________________

Date _____________________________________

Customer ___________________________________

Tested by _______________________ ___________

Test Eq uipment R e c ord

Test Equipment Used:

Description

Model No. Trace No. Cal Due Date

1. _______________________________

2. _______________________________

3. _______________________________

4. _______________________________

5. _______________________________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

______________

_______________

_______________

_______________

_______________

_______________

_______________

_______________

Chapter 2 Verification Tests 33

Table 2-1. Performance Test Record (P age 2 of 3)

Model _______________________ Report No. __________________________ Date __________

Test No/Descri ption Minimum*

Value

2-1. Contact Resistance Test (values in Ohms)

NO to C Resistance

Channel 00

Channel 01

Channel 02

Channel 03

Channel 04

Channel 05

Channel 06

Channel 07

Channel 08

Channel 09

Channel 10

Channel 11

Channel 12

Channel 13

Channel 14

Channel 15

Channel 16

Channel 17

Channel 18

Channel 19

Channel 20

Channel 21

Channel 22

Channel 23

Channel 24

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Measured V alue Maximum

Value

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

Meas

Uncert

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

Test Acc

Ratio (TAR)

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

Channel 25

Channel 26

Channel 27

Channel 28

Channel 29

Channel 30

Channel 31

___________________

___________________

___________________

___________________

___________________

___________________

___________________

2.0

2.0

2.0

2.0

2.0

2.0

2.0

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

NA

NA

NA

NA

NA

NA

NA

*Single-sided specification - Minimum value does not app ly

34 Verification Tests Chapter 2

Table 2-1. Performance Test Record (P age 3 of 3)

Model _______________________ Report No. ____________ ______________ Date __________

Test No/Descri ption Minimum*

Value

2-1. Contact Resistance Test (values in Ohms)

NC to C Resistance

Channel 00

Channel 01

Channel 02

Channel 03

Channel 04

Channel 05

Channel 06

Channel 07

Channel 08

Channel 09

Channel 10

Channel 11

Channel 12

Channel 13

Channel 14

Channel 15

Channel 16

Channel 17

Channel 18

Channel 19

Channel 20

Channel 21

Channel 22

Channel 23

Channel 24

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Measured V alue Maximum

Value

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

Meas

Uncert

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

Test Acc

Ratio (TAR)

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

Channel 25

Channel 26

Channel 27

Channel 28

Channel 29

Channel 30

Channel 31

Test 2-2 DC Isolation (values in Ohms)

NO to NC

NC to Chassis

NO to Chassis

1.2E9

1.2E9

1.2E9

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

2.0

2.0

2.0

2.0

2.0

2.0

2.0

*6.1E6

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

8.000E-5

6.1E6

6.1E6

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

* Single-sided specification - Minimum/Maximum value does not apply

Chapter 2 Verification Tests 35

Notes

36 Verification Tests Chapter 2

Chapter 3

Replaceable Parts

Introduction This chapter contains information for ordering replaceable parts for the

Agilent E1463A 32-Channel Form C Swit c h Module.

Ordering

Information

To order a part list ed in this chapter, spe cif y the Agilent Technologies part

number and the qua ntity required. S en d the orde r to your nearest Agilent

Technologies Sales a nd Su ppor t Office.

Replaceable Parts List

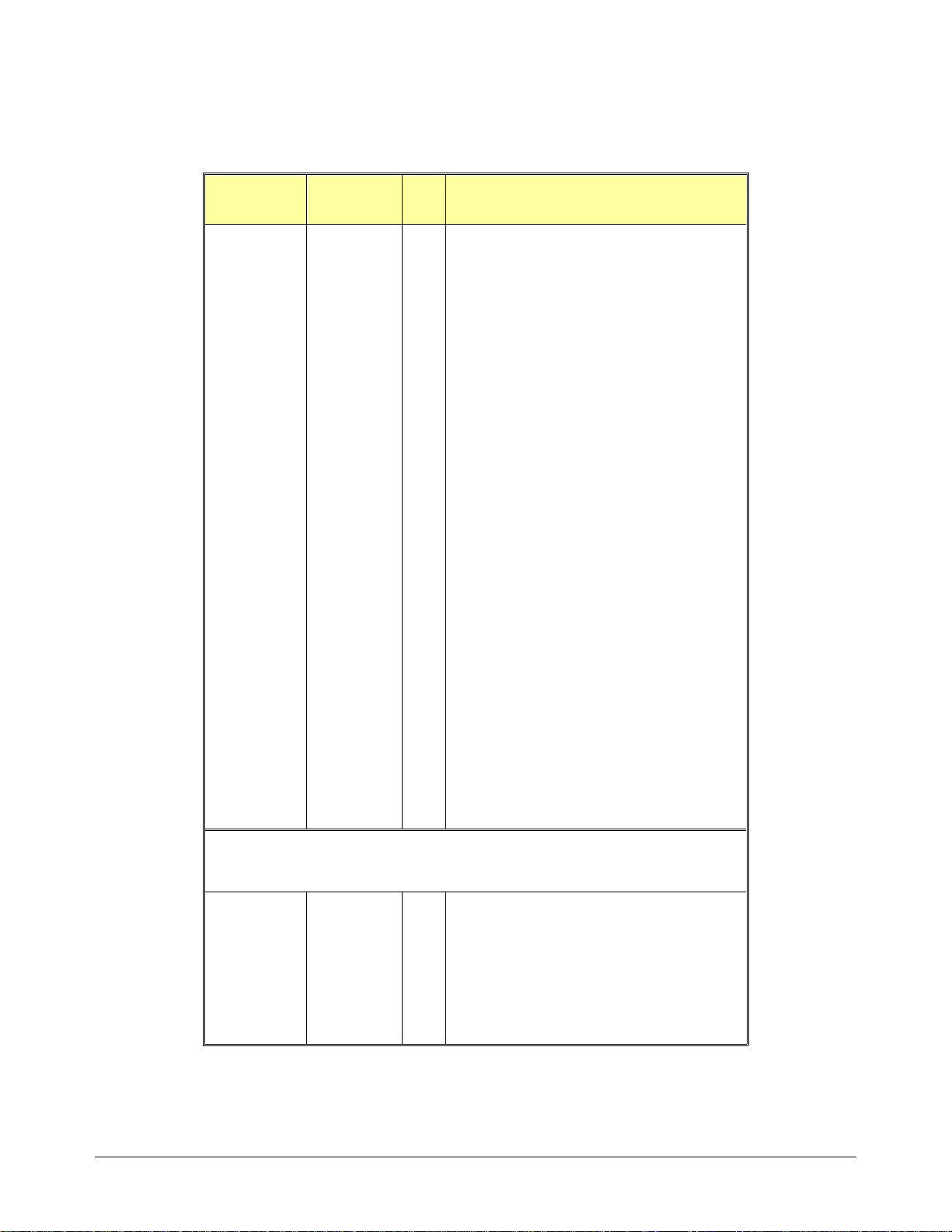

Table 3-1. Agilent E1463A Replaceable Parts

Reference

Designator

A2 E1463A† 1 GP RELAY ASSEMBLY

MP1 E1400-45101† 1 HANDLE - TOP METAL INJECTION

MP2 E1400-45102† 1 HANDLE - BOTTOM METAL INJECTION

MP3 8160-0686 1 RFI STRIP-FINGERS BE-CU TIN-PLATED

PNL1 E1463-00202† 1 FRONT PANEL

SCR1-SCR2 E1400-00610† 2 SHOULDER SCREW ASSEMBLY

SCR3-SCR8 0515-1135 9 SCREW-MACHINE M3 X 0.5 25MM-LG FLAT-HD

SCR13 0515-1375 SCREW MACHINE M2.5X0.45 6MM-LG FLAT-HD

SCR14-SCR16 0515-1135 SCREW-MACHINE M3 X 0.5 25MM-LG FLAT-HD

SHD1 E1463-00601 1 SHIELD-TOP

SHD2 E1463-00602 1 SHIELD-BOTTOM

A2A1 E1463-66501 1 PC ASSEMBLY-GP RLY BOARD

C201 0160-4835 18 CAPACITOR-FXD 0.1uF +-10% 50 V

C202 0160-4801 5 CAPACI TO R-FXD 100pF +-5% 100 V

C203-C215 0160-4835 CAP ACITOR-FXD 0.1uF +-10% 50 V

C301 0160-4822 4 CAPACITOR-FXD 1000pF +-5% 100 V

Agil e n t P ar t

Number

Qty Part Description

(See Figure 3-1)

C302 0160-4801 CAPACITOR-FXD 10 0pF +-5% 100 V

C303 0160-4822 CAPACITOR -FXD 1000pF +-5% 100 V

C304 0160-4801 CAPACITOR-FXD 10 0pF +-5% 100 V

C305-C306 0160-4835 CAP ACITOR-FXD 0.1uF +-10% 50 V

C307-C308 0160-4844 4 CAPACITOR-FXD 1uF +80% -20% 50 V

Chapter 3 Replaceable Parts 37

Table 3-1. Agilent E1463A Replaceable Parts (Continued)

Reference

Designator

C401 0160-4822 CAPACITOR -FXD 1000pF +-5% 100 V

C402 0160-4801 CAPACITOR-FXD 10 0pF +-5% 100 V

C403 0160-4822 CAPACITOR -FXD 1000pF +-5% 100 V

C404 0160-4801 CAPACITOR-FXD 10 0pF +-5% 100 V

C405-C406 0160-4835 CAP ACITOR-FXD 0.1uF +-10% 50 V

C407-C408 0160-4844 CAPACITOR-FXD 1uF +80% -20% 50 V

C601-C604 0180-1746 4 CAPACITOR-FXD 15uF +-10% 20 V

CR300-CR316 1902-0964 36 DIODE-ZENER 18V 5% PD=.4W TC=+ .09% IR=5UA

CR318-CR320 1902-0964 DIODE-ZENER 18V 5% PD=.4 W TC=+.09% IR=5UA

CR416-CR431 1902-0964 DIODE-ZENER 18V 5% PD=.4 W TC=+.09% IR=5UA

F601-F602 2110-0712 2 FUSE-SUBMINIATURE 4A 125V NTD AX

J1-J2 1252-1575 2 CONNECTOR-POST TYPE 5.08-PIN-SPCG

J101 1251-4927 2 CONNECTOR-POST TYPE .100-PIN-SPCG

J201 1251-4927 CONNECTOR-POST TYPE .100-PIN-SPCG

JM0-JM23 8159-0005 RESISTOR 0 MFS

JM25-JM31 8159-0005 33 RESISTOR 0 MFS

JM424 8159-0005 RESISTOR 0 MFS

K0-K31 0490-1773 32 RELAY 1AB 12VDC-COIL 5A 380VAC

L601-L602 9140-1354 2 INDUCTOR-FIXED 47UH +-15% .453D-INX.9LG-IN

L603 9100-1623 1 INDUCTOR-FIXED RF-CHOKE-MOLDED 27UH +-5%

Agil e n t P ar t

Number

Qty Part Description

48-CONTACT

16-CONTACT

16-CONTACT

MP1 0050-2183 1 CASTING-ZINC P.C. BOARD HOLDER

P1 1252-1596 1 CONNECTOR-POST TYPE 2.54-PIN-SPCG

P2 1252-4743 1 CONNECTOR-POST TYPE 2.54-PIN-SPCG

P101 1258-024 7 1 JUMPER-4 POSITI ONS HOUSING MATERIAL

R101 0757-0421 1 RESISTOR 825 +-1% .125W TF TC=0+-100

R201 0757-0469 1 RESISTOR 150K +-1% .125W TF TC=0+-100

R203 0757-0453 1 RESISTOR 30.1K +-1% .125W TF TC=0+-100

R204 0757-0417 1 RESISTOR 562 +-1% .125W TF TC=0+-100

R301-R302 0757-0442 4 RESISTOR 10K +-1% .125W TF TC=0+-100

R303-R304 0757-0407 4 RESISTOR 200 +-1% .125W TF TC=0+-100

R305-R306 0757-0346 4 RESISTOR 10 +-1% .125W TF TC=0+-100

R401-R402 0757-0407 RESISTOR 200 +-1% .125W TF TC=0+-100

R403-R404 0757-0442 RESISTOR 10K +-1% .125W TF TC=0+-100

96-CONTACT

64-CONTACT

38 Replaceable Parts Chapter 3

Table 3-1. Agilent E1463A Replaceable Parts (Continued)

Reference

Designator

R405-R406 0757-0346 RESISTOR 10 +-1% .125W TF TC=0+-100

RP101-RP103 1810-0279 3 NETWOR K- RES 10-SIP 4.7K OHM X 9

RP301- RP302 1810-0265 4 NETWORK-RES 16 -DIP 680. 0 OHM X 8

RP401- RP402 1810-0265 NETWORK-RES 16-DIP 680.0 OHM X 8

SP101 3101-2094 1 SWITCH-DIP ROCKER 8-1A 0.15A 30VDC

U101 1820-3631 2 IC COMPARATOR CMOS/HCT MAGNITUDE 8-BIT

U102 1820-3975 3 IC DRIVER CMOS/HC LINE OCTL

U103 1820-4586 1 IC DRIVER/RECEIVER CMOS/HCT BUS OCTL

U104-U105 1820-3975 IC DRIVER CMOS/HC LINE OCTL

U106 1820-3631 IC COMPARATOR CMOS/HCT MAGNITUDE 8-BIT

U107 1820-4147 1 IC LATCH CMOS/HCT TRANSPARENT OCTL

U108-U109 1820-3714 2 IC TRANSCEIVER TTL/ALS BUS OCTL

U110-U111 1820-3079 2 IC DECODER CMOS/HC BIN 3-TO-8-LINE

U112 1820-4643 2 IC GATE CMOS/HCT NOR QUAD 2-INP

U201 1820-4643 IC GATE CMOS/HCT NOR QUAD 2-INP

U203 1820-4242 1 IC SCHMITT-TRIG CMOS/HCT INV HEX

U204 1820-3081 2 IC FF CMOS/HC D-TYPE POS-EDGE-TRIG

U205 1820-4590 1 IC MV CMOS/HC MONOSTBL RETRIG DUAL

U206 1820-6731 1 IC-ASIC GATE-ARRAY CMOS

U207 1820-4057 1 IC BUFFER TTL/F NAND QUAD 2-INP

Agil e n t P ar t

Number

Qty Part Description

U208 1820-3097 1 IC GATE CMOS/HC AND QUAD 2-INP

U209 1820-3081 IC FF CMOS/HC D-TYPE POS-EDGE-TRIG

U301-U302 1820-4086 4 IC FF CMOS/HCT D-TYPE POS-EDGE-TRIG

U303-U304 1858-0069 4 TRANSISTOR ARRAY 18-PIN PLASTIC DIP

U401-U402 1820-4086 IC FF CMOS/HCT D-TYPE POS-EDGE-TRIG

U403-U404 1858-0069 TRANSISTOR ARRAY 18-PIN PLASTIC DIP

† NOTE: For modules with serial numbers prior to 3126A01817, the following

parts must be used for replacement (see inset in figure 3-1).

*A1 E1463-66201 1 GP RELAY ASSEMBLY

*MP1 E1400-84105 1 EXT HANDLE KIT-BOTTOM

*MP2 E1400-84106 1 EXT HANDLE KIT-TOP

*PNL1 E1463-00201 1 FRONT PANEL

*SCR1-*SCR2 0515-0368 2 SCREW-MACHINE ASSY M2.5 X 12MM-LG

*SCR9-*SCR10 0515-1375 3 SCREW-MACHINE M2.5 X 0.45 6MM-LG FLAT-HD

*SCR11-*SCR12 0515-1968 2 SCREW PH M2.5 X 11TX

PAN-HD

Chapter 3 Replaceable Parts 39

Figure 3-1. E1463A Mechanical Replaceable Parts

40 Replaceable Parts Chapter 3

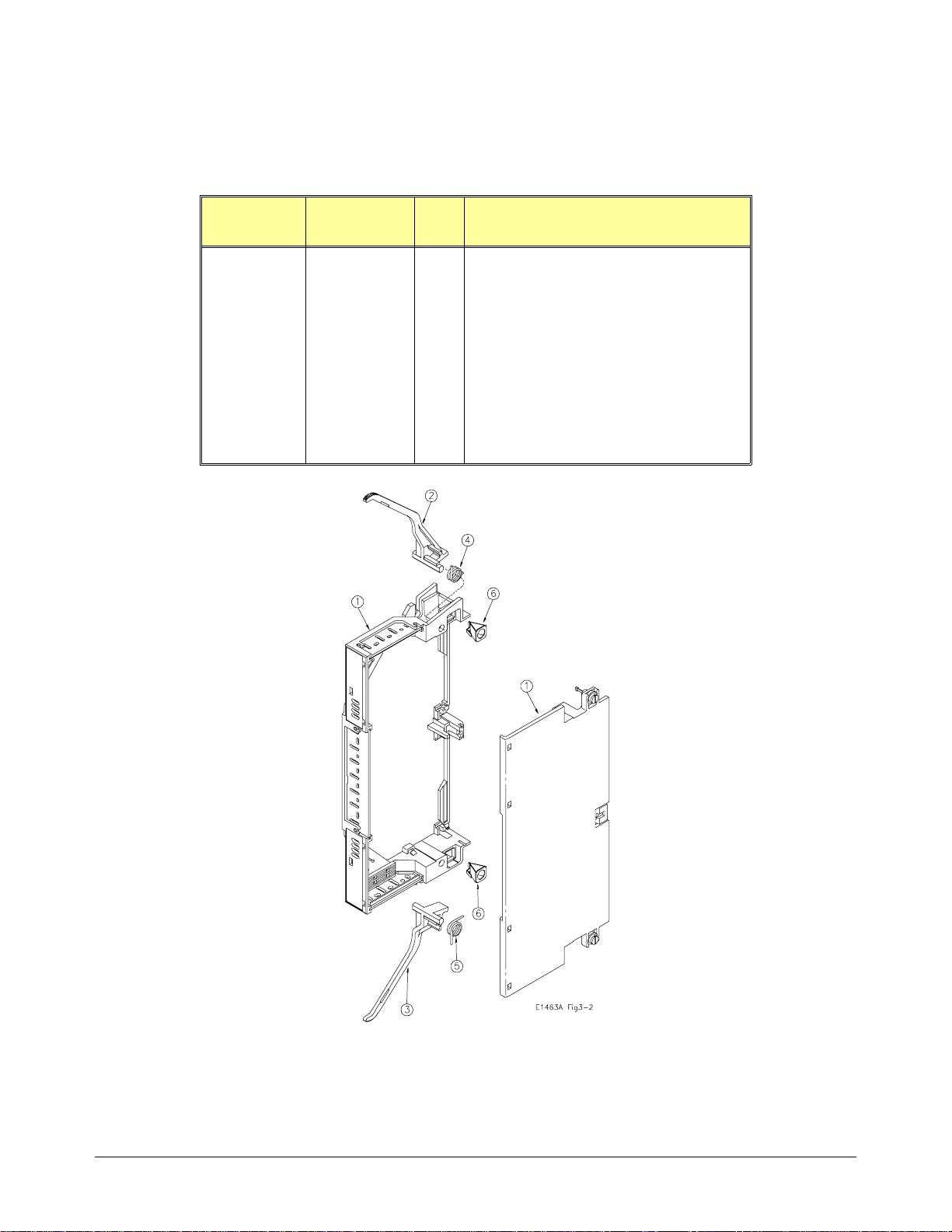

Table 3-2. Agilent E1463A Terminal Case Replaceable Parts

(for modules wit h serial numbers after 312 6A01818)

Reference

Designator

1 E1400-84405 1 Case Assembly - Terminal

2

3 E1400-45104 1 Bottom Lever

4

5 1460-2553 1 Torsion Spring - Right Hand Wound

6

PCA

Agil e n t P ar t

Number

E1400-45103

1460-2552

1390-1027

E1463-66510

1252-1574

0515-0905

E1400-21204

Qty Part Description

Top Leve r

1

Torsion Spring - Left Hand Wound

1

Receptical Quic k Fas tener

2

PC Assembly:

Screw Terminal (Standard)

1

Connector - Rcpt, 48 Pin (Option A3G)

2

Screw Pan Head 2.5 x 06 (Option A3G)

4

Crimp & Insert Connector Support (Option A3G)

4

Figure 3-2. E1463A Terminal Case Replaceable Parts

Chapter 3 Replaceable Parts 41

Table 3-3. Agilent E1463A Terminal Case Replaceable Parts

(for modules wit h serial numbers prior to 3126A01817)

Reference

Designator

A1 E1400-84401 1 TERMINAL MODULE CASE ASSY

MP1 03852-01201 1 CLAMP

MP2 03852-86701 1 PAD-CLAMP

MP3 0515-2109 1 SCREW-MACHINE 10-24 .625-IN-LG

MP4 1390-0846 2 FASTENER-CAPTIVE SCREW M2.5 X 0.45

MP5 E1300-01 20 2 1 CLAMP ST RA I N REL IE F

MP6 E1400- 44104 1 TERMINAL HOUSING-BOTTOM

MP7 E1400- 44105 1 TERMINAL HOUSING-TOP

Agilent Part

Number

Qty Part Description

(See Figure 3-1)

PAN-HD-SLT

Figure 3-3. E1463A Terminal Case Replaceable Parts

42 Replaceable Parts Chapter 3

Table 3-4. Agilent E1463A Terminal Module PCA Rep laceable Parts

Reference

Designator

A3 E1463-66510 1 TERMINAL MODULE PC ASSEMBLY

P1-P2 1252-1577 2 CONNECTOR-POST TYPE 5.08-PIN-SPCG

TB1-TB8 0360-2391 8 TERMINAL MODU LE 12 P. POLYAMIDE

Agilent Part

Number

Qty Part Description

(See Figure 3-3)

48-CONTACT

NOTE: For option A3G re placeable parts, see Table 3-2 .

Figure 3-4. E1463A Termin al Board

Chapter 3 Replaceable Parts 43

Table 3-5. Agilent E1463A Reference Designators

Reference Designators

A .................. assembly P.................. electrical connector (plug)

BRK... ........ .. bra c ket PCB ............ printed circu it board

C.................. capacitor PNL ............ panel

CR................ diode Q ...... ........ ...t ransis t o r

CS................case R .................resistor

CVR............. cover RP.......... ..... resistor pa c k

F................... fuse RT ...............thermistor probe

J............... .... electric al con n e c tor (ja c k ) SC R............ .screw

JM................ jumper SHD ............ shield

K ..................relay SW .............. switch

MNL.............manual TB ............... termina l b lock (mo d ule)

MP ...............mechanical part U ................. integrated circuit

44 Replaceable Parts Chapter 3

Introduction

Chapter 4

Service

This chapter contains service information for the Agilent E1463A

Form C Switch Mod ule , inc luding trouble shooting tech niques

and repair and maintenance guideli ne s.

WARNING

Repair Strategy

Equipment

Required

Do not perform any of the service procedures shown unless

you are a qualified, service-trained technic ian, and have read

the WARNINGS and CAUTIONS in Cha pter 1.

Agilent Technologies recommends component replacement for the

Agilent E1463A. Proc e dure s in this chapter describe troubleshoo ting

techniques. Schematics and Component Locators are located at the back of

this manual. Component- level replaceable parts lists are contained in

Chapter 3, "Replaceable Parts." See Chapter 1, "General Information," for a

description o f rela y life factors.

Equipment req uir e d f or the Agilent E1463A Form C S witch Module

troublesho oting and repair is l isted in Table 1-1 , "Re c ommended Test

Equipment. " Any equipment t ha t sa ti sf ie s the requirements given in the

table may be su bstituted.

To avoid damage to the screw head slots, use a T8 Tor x dr ive r to r e move

the front panel handles and a T10 To rx d rive r to r emove the shields.

Service Aids See Chapter 3, "Replaceable Parts," for descriptions and locations of

Agilent E1463A replaceable parts. Service notes, manual updates, and

service lite rat ur e for the swi tc h module may be available through Agilent

Technologies . For infor mation, contact your ne a rest Agil e nt Te c hnologies

Sales and Support Offi ce.

Chapter 4 Service 45

Troubleshooting

To troublesh oot a switch module problem you must f irst identify th e

problem and then isolate the cause of the problem to a replaceable part. See

Chapter 3, "Replaceable Parts," and the component locators at the back of

this manual for descriptions and locations of Agilent E1463A replaceable

parts.

Identifying the

Problem

Problem

Type Symptom

Self-test Errors Non-zero error code in response to

Operator Errors Non-zero error code in response to

Catastrophic

Failures

Performance Out

of Specification

Table 4-1 list s som e common problem s, along with symptom s and possible

solutions. If the problem persists, pe rform component-le ve l troubleshooting

using the compone nt locator and schematics.

Table 4-1. Agilent E1463A Common Problems

Possible

Solutions

See Table 4-4 for information on

the *TST? comman d.

the SYST:ERR? command.

Not responding to commands. Check logical address setting.

Failing Closed Channel R esist ance

Test (see Test 2-1 in Chapter 2).

Failing DC Isolation test (See Test

2-2 in Chapter 2)

self-test errors.

See Appendix C of the the Agilent

E1463A User’s Manual for Switch

Module errors and causes.

See Appendix B of the

Agilent E1405 User’s Manual for

additional information on ope rator

errors.

Check GPIB cables and connections.

See "Testing the Assembly" in this

chapter.

Check user wiring, test connections,

and installed protection devices.

Replace relays that corre spon d to the

channels that are failing (see Table

4-3).

If most of the channels are near or

above the test limit (2.0 Ohms),

replace entire printed circuit board

(Agilent part number E1463-66501)

Check user wiring, test connections,

and installed protection devices.

Remove dust from relay module and

terminal module printed circuit board.

46 Service Chapter 4

Testing the

Assembly

You can use the test s an d checks in Table 4-2 t o isolate the proble m. Se e

Figures 3-1, 3-2, and 3- 3 in Chapter 3 for locati ons of me c ha ni cal parts.

See the component locator included with this manual for locations of

electrical components.

Table 4-2. Agilent E1463A Tests/Checks

Test/Check Reference Designator Check:

Heat Damage - - - - - - - - - - Discolored PC boards

Damaged insulation

Evidence of arcing

Switch/Jumper

Settings

Switch Module

PCA

J101, J201

SP101

F601, F602

P1, P2, J1, J2

K0-K31

IRQ Level setting

LADDR setting

Fuse continuity

Connector contacts

Test 2-1, Closed Channel

Resistance Test

Checking for Heat Damage

Inspect the asse mbly for signs of a bnor m al internally generated heat su ch as

discolored pr inted circuit boa r ds or co mponents, dam ag ed insulation, or

evidence of arcing.

Checking Switches/Jumpers

Verify that the logical address swit c h is se t correctly (factor y se t a t 120).

Verify that the interrupt priority jumpers are set correctly (factory set at

level 1).

Checking the Switch Module PCA

Check the followi ng:

• Verify that fuses F601 and F602 are good.

• Check connectors J1, J2, P1, an d P2 for da ma ge .

• Perform Test 2-1 in Chapter 2.

Chapter 4 Service 47

Matching Relays to Channels

Use Table 4-3 to help match channel numbers to relay and drive circuit

reference designators.

Table 4-3. Channel Relays/Referen ce Designators

Channel Relay Driver Driver Register

00 K00

01 K01

02 K02

03 K03

04 K04

05 K05

06 K06

07 K07

08 K08

09 K09

10 K10

11 K11

12 K12

13 K13

14 K14

15 K15

16 K16

17 K17

18 K18

19 K19

20 K20

21 K21

22 K22

23 K23

24 K24

25 K25

26 K26

27 K27

28 K28

29 K29

30 K30

31 K31

U303 U301

U304 U302

U403 U401

U404 U402

48 Service Chapter 4

Self-Test

Error Codes

Table 4-4 shows the se lf - te st err or co de s fo r th e Swit c h Module. The

meaning of each code is given in the right-hand column. If a self-test failure

occurs, cycle power and repeat the test. If the problem reoccurs, the device

may need repair.

Table 4-4. Self-test E rror Codes

Error* Description

+0

+ss01

+ss02

+ss03

+ss10

+ss11

Self-test passes

Firmware er ro r

Bus error (communica tions problem with car d)

Bad ID information in ID register

Interrupt expected but not recei ved

Busy bit was not held ≈10.5 to 18.5 msec

*ss = card number (with leading zero deleted)

Disassembly Use the following procedures to disassemble the Agi le nt E1463A Switch

Module. For dis as sembly refer to Figure 4-1.

Switch Module

Disassembly 1. To remove the covers:

• Remove the nine T10 Tor x sc r e ws from the top cover as shown.

• Lift the to p co ve r off of the module.

• Turn the assembly over and lift off the bottom cover.

2. To remove the front panel:

• Remove the two T8 Tor x sc r ews from the fron t pa ne l ha ndles as

shown.

• Remove the T8 To rx screw holding the panel t o the A1 PC

Assembly as shown.

• Lift the front panel from the A1 assembly.

Chapter 4 Service 49

Figure 4-1. Agilent E1463A Disassembly

50 Service Chapter 4

Repair/Maintenance Guidelines

This sectio n provides guideli ne s fo r re pa iring and mainta ining the

Agilent E1463A S witch Module, including:

• ESD precautions

• S oldering printed circuit boards

• Po st-repair safety checks

ESD Precautions Electrostatic disc ha r ge (E SD) ma y da ma ge static-sensi tive devices in the

switch mod ule s. T his damage can range f ro m slight parame te r deg rada tion

to catastrophic failure. When handling the switch module assemblies, follow

these guideli ne s to avoid damaging components:

• Always use a static-free work stati on wi th a pa d of con ductive rubber or

similar ma te r ial whe n ha ndling electr oni c com ponents.

• Do not use pliers to remove a MOS or CMOS device from a hi gh-gr ip

socket. Instead, use a small sc rewdr i ve r to pr y the de vice up from one

end. Slowly lift the device up, one pair of pins at a time.

Sold e rin g Pr i n t ed

Circuit Boards

• After you remove a MOS or CMOS device from a module, place the

device onto a pad of conductive foam or ot he r suitable holdi ng ma t eri al .

• If a device requires soldering, be sur e the ass embly is placed on a pad of

conductiv e mat e ria l. Also, be sure that you, the pa d, an d the soldering

iron tip are grounded to the assembly.

The etched circu it boards in the switch module have pla ted- through holes

that allow a solder path to bo th si de s of the insulating ma te r ial. Soldering

can be done from eit he r side of the boa rd with equally goo d results. When

soldering to an y ci rcu it board, keep in mind the following guidelines:

• The relays used on these printed circuit boards require special soldering

techniques and e quipment. The use of a sol de r-p ot is recommended for

relay removal and replacement.

• Do not use a high power soldering iron on e tc he d cir c uit boa r ds, as

excessive heat m ay lift a conductor or damage the boa r d.

• Use a suc t ion de vice or wooden t oothpick to re move so lder from

component mounting holes. Wh en using a suction de vic e , be su re the

equipment is pr operly grounded.

Chapter 4 Service 51

Post-Repair

Safety Checks

After making repa irs to the module, inspect the devi c e for an y signs of

abnormal int erna lly generated he a t, suc h a s dis colored printed c ir c uit boa r ds

or components, dama ge d insulation, or evi de nc e of arci ng. De te r mi ne and

correct the cause of the condition. Then pe r fo rm the Functional Verific a ti o n