Page 1

HP E1422A Remote Channel

HP 75000 Series C

Multi-function DAC Module

with

HP E1529A 32ch Remote Strain Conditioning Unit and

HP E1539A Remote Channel Signal Conditioning Plug-on

User’s and SCPI Programming Manual

Where to Find it - Online and Printed Information:

System installation (hardware/software)............VXIbus Configuration Guide*

HP VIC (VXI installation software)*

Getting Started with VXI Guide**

Module configuration and wiring.......................This Manual

SCPI programming.............................................This Manual

SCPI example programs........................ .... .... ... ..This Manual, Driver Disk

SCPI command reference ..................................This Manual

VXIplug&play programm ing ............................VXIplug&play Online Help

VXIplug&play example prog ra ms.....................VXIplug&play Online Help

VXIplug&play functio n refere nce................ ... ..VXIplug&play Online Help

Soft Front Panel information..............................VXIplug&play Online Help

VISA language information...............................HP VISA User’s Guide

HP VEE programming information ...................HP VEE User’s Manual

*Supplied with HP Command Modules , Embedded Control le rs, and VXLink

** Supplied with HP VXI Mainframes and on WEB at www.tmo.hp.com then search for “getting started with

vxi”. Search result will be “Getting Started With VXI Guide

”, click on this to download .PDF file.

Manual Part Number: E1422-90003

Printed in U.S . A . E0400

Page 2

Page 3

HEWLETT-PACKARD WARRANTY STATEMENT

HP PRODUCT: HP E1422A Remote Channel Multi-func tio n DAC Modu le with DURATION OF WARRANTY: 3 years

HP E1529A Remote Strain Conditioning Module and DURATION OF WARRANTY: 3 years

1. HP warrants HP hardware, accessori es and supplies against defects in mat erials and workmanship for the perio d specified above. If

HP receives notice o f such defects during the warranty period, HP wi ll, at its option, either repair or replace products which prove to be

defective. Replacement products may be either new or like-new.

2. HP warrants that HP software will not fail to execut e its programming instructions, for the perio d specified above, due to defects in

material and workmanship when properly installed and used. If HP receives notice of such defects during the warranty period, HP will

replace software media which does not execute its programming instructions due to such defects.

3. HP does not warrant that the operation of HP products will be interrupted or error free. If HP is unable, within a reasonable time, to

repair or replace any product to a condition as warranted, customer will be entitled to a refund of the purchase price upon prompt return

of the product.

4. HP products may con tain remanufactured parts equivalent to new in performance or m a y have been subject to incidental use.

5. The warranty period begins on the date of delivery or on the date of installation if installed by HP. If customer schedules or delays HP

installation more than 30 days after delivery, warranty begins on the 31st day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or inadequate maintenance or calibration, (b) software, interfacing, parts

or supplies not supplied by HP, (c) unauthorized modification or misuse, (d) operation outside of the published environmental

specifications for the product, or (e) improper site preparation or maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE WARRANTIES ARE EXCLUSIVE AND NO OTHER

WARRANTY OR CONDITION, WHETHER WRITTEN OR ORAL, IS EXPRESSED OR IMPLIED AND HP SPECIFICALLY

DISCLAIMS ANY IMPLIED WARRANTY OR CONDITIONS OF MERCHANTABILITY, SATISFACTORY QUALITY, AND

FITNESS FOR A PARTICULAR PURPOSE.

8. HP will be liable for damage to tangible property per incident up to the greater of $300,000 or the actual amount paid for the product

that is the subject of the claim, an d for damages for bodily injury or death, to the extent that all such damages are determined by a court

of competent jurisdiction to have been directly caused by a defective HP product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS WARRANTY STATEMENT ARE CUSTOMER’S

SOLE AND EXLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE, IN NO EVENT WILL HP OR ITS SUPPLIERS BE

LIABLE FOR LOSS OF DATA OR FOR DIRECT, SP ECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDING LOST PROFIT OR

DATA), OR OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW ZEALAND: THE WARRANTY TERMS CONTAINED IN THIS

STATEMENT, EXCEPT TO THE EXTENT LAW FULLY PERM ITTED, DO NOT EXCLUDE, RESTRICT OR MODIFY AND AR E

IN ADDITION TO THE MANDATORY STATUTORY RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

HP E1539A Remote Channel Signal Conditioning Plug-on and

all other applicable Signal Conditioning Plug-ons DURATION OF WARRANTY: 3 years

U.S. Government Restricted Rights

The Software and Documentation have been developed entirely at private expense. They are delivered and licensed as "commercial

computer software" as defined in DFARS 252.227- 7013 (Oct 1988), DFARS 252.211-7015 (May 1991) or DFARS 252.227-7014 (Jun

1995), as a "commercial item" as defined i n FAR 2.101(a), or as "R estricted computer software" as define d in FAR 52.227-19 (Jun

1987)(or any equivalent agency regulation or contract clause), whichever is applicable. You have only those rights provided for such

Software and Documentation by t he applicable FAR or DFARS clause or the HP st andard software agreement for the product involved.

HP E1422A Remote Channel DAC Unit User's Manual and SCPI Programming Guide

Copyright © 1998-2000 Hewlett-Packard Company. All Rights Reserved.

Edition 4

3

Page 4

Documentation History

All Editions and Updates of t his manu al and th eir creati on da te are list ed belo w. The first Edition of the m anual is Ed ition 1. The Edition

number increments by 1 whenever the manual is revised. Updates, which are issued between Editions, contain replacement pages to

correct or add additional information to the current Edition of the manual. Whenever a new Edition is created, it will contain all of the

Update information for the previous E dition. Each new Edition or Update also inc ludes a revised c opy of this do cumentation history page.

Edition 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .May 1999

Edition 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .July 1999

Edition 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .September 1999

Edition 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . February 2000

Safety Symbols

product. Indicates that the user must refer to

the manual for specific WARNING or

CAUTION information to av oid personal

injury or damage to the product.

Indicates the field wiring te rminal that must

be connected to earth ground be fore

operating the equipmentÅprotects against

electrical shock in case of fault.

or

Frame or chassis ground terminal—

typically connects t o the e quipmen t's me tal

WARNING

CAUTION

Alternating current (AC)Instruction manual symbol affixed to

Direct current (DC).

Indicates hazardous voltages.

Calls attention to a procedure, practice, or

condition that could cause bodily injury or

death.

Calls attention to a procedure, practice, or

condition that could possibly cause damage to

equipment or perm anent loss of data.

WARNINGS

The following general safety precauti ons must be observed during all phases of operation, service, and repair of this product. Failure to

comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and

intended use of the product. Hewlett-Packard Com pany assumes no liability for the customer's failure to comply with these requirements.

Ground the equipment: For Safety Class 1 equipment (equipment having a protective earth terminal), an uninterruptible safety earth

ground must be provided from the mains power source to the product input wiring terminals or supplied power cable.

DO NOT operate the product in an explosive atmosphere or in the presence of flammable gases or fumes.

For continued protection against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current rating and type. DO NOT

use repaired fuses or short-circuited fuse holders.

Keep away from live circuits: Operating personnel must not remove equipment covers or shields. Procedures involving the removal of

covers or shields are for use by service-trained personnel only. Under certain conditions, dangerous voltages may exist even with the

equipment sw itche d off. To av oid danger ous ele ctric al sh ock, DO NOT perfor m pro cedure s inv olving cover or shi eld remova l unles s you

are qualified to do so.

DO NOT operate damaged equipmen t: Whenever it is possible that the safety protection features built into this product have been

impaired, either through physical damage, excessive moisture, or any other reason, REMO VE POWER and do not use the product until

safe operation can be verified by service-trained personnel. If necessary, return the product to a Hewlett-Packard Sales and Service Office

for service and repair to ensure that safety features are maintained.

DO NOT service or adjust alone: Do not attempt internal service or adjustment unless another person, capable of rendering first aid and

resuscitation, is present.

DO NOT substitute parts or modify equipment: Becaus e of th e dang er of introd ucing addition al haz ards, do not i nstall subst itute pa rts

or perform any unauthorized modification to the product. Return the product to a Hewlett-Packard Sales and Service Office for service

and repair to ensure that safety features are maintained.

Operating Location: Sheltered loc a tio n whe re air tempera tu re and hu m idit y are co ntro lled within thi s pro duc t’s specifica tio ns and the

product is protected against direct exposur e to clim at ic cond itio ns such as direc t sunli ght, wind , rain, snow, sleet, and icing, water spray

or splash, hoarfrost or dew. (Typically, indoor.) Pollution envir onment for which this product may be operated is IEC 664 Pollution d egree

2.

CLEANING THE FRONT PANEL AND TOP/BOTTOM SHIELDS: Clean the outside surfaces of this module with a cloth slightly

dampened with water. Do not attempt to clean the interior of this module.

4

Page 5

Declaration of Conformity

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: Hewlett-Packard Company

Loveland Manufacturing Center

Manufacturer’s Address: 815 14th Street S.W.

Loveland, Colorado 80537

declares, that the product:

Product Names: Remote Channel Multi-function DAC Module

Remote Channel Signal Conditioning Plug-on

32-ch Remote Strain Conditioning Unit

Model Numbers: HP E1422A

HP E1539A

HP E1529A

Product Options: All options and all other applicable Signal Conditioning Plug-ons

conforms to the following Product Specifications:

Safety: IEC 1010-1 (1990) Incl. Amend 2 (1996)/EN61010-1 (1993)

CSA C22.2 #1010.1 (1992)

UL 3111-1 (1994)

EMC: CISPR 11:1990/EN55011 (1991): Group 1 Class A

EN61000-3-2:1995 Class A

EN61000-3-3:1995

EN50082-1:1992

IEC 1000-4-2:1995: 4kVCD, 8kVAD

IEC 1000-4-3:1995: 3 V/m

IEC 1000-4-4:1995: 1kV Power Line 0.5kV Signal Lines

ENV50141:1993/prEN50082-1 (1995): 3 Vrms

EN 61000-4-5:1995 1kV CM, 0.5kV DM

EN61000-4-8:1993/prEN50082-1 (1995): 3 A/M

EN61000-4-11:1994/prEN50082-1 (1995): 30%, 10mS 60%, 100mS

Supplementary Information: The product herewith complies with the requirements of the Low Voltage Directive

73/23/EEC and the EMC Directive 89/336/EEC (inclusive 93/68/EEC) and carries the "CE" mark accordingly.

May 3, 1999 Jim White, QA Manager

For Compliance In f ormation ONLY, contact:

Australia Contact

Victoria 3130, Australia

: Product Regulations Manager, Hewlett-Packard Australia Ltd., 31-41 Joseph Street, Blackburn,

European Contact:

Standards Europe, Herrenberger Straβe 130, D-71034 Boblingen (FAX: +49- 7031-14-3143)

USA Contact:

80537

Your local Hewlett-Packard Sales and Service Office or Hewlett-Packard GmbH, Department HQ-TRE,

Product Regulations Manager, Hewlett-Packard Company, P.O. Box 301, Mail Stop BU212, Loveland, CO

5

Page 6

Notes:

6

Page 7

Pl

ease fold and tape for ma

ili

ng

Reader Comment Sheet

HP E1422A Remote Channel Multifunction DAC Module User’s Manual

Edition 4

You can help us improve our manuals by sharing your commen ts and sug gestions. In appreciation of your time, we will

enter you in a quarterly drawing for a Hewlett-Packard Palmtop Personal Computer (U.S. government employees

are not eligible for the drawing).

Your Name

Company Name

Job Title

Address

City, State/Province

Country

Zip/Postal Code

Telephone Number with Area Code

Please list the system controller, operating system, programming language, and plug-in modules you are using.

fold here

BUSINESS REPLY MAIL

FIRST CLASS PERMIT NO. 37 LOVELAND, CO

POSTAGE WILL BE PAID BY ADDRESSEE

cut along this li ne

HEWLETT-PACKARD COMPANY

Measurement Systems Division

Learning Products Department

P.O. Box 301

Loveland, CO 80539-9984

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

fold here

Please pencil-in one circle for each statement below: Disagree Agree

• The documentation is well organized. OOOOO

•Instructions are easy to understand. OOOOO

The documentation is clearly written. OOOOO

•

Examples are clear and useful. OOOOO

•

•Illustrations are clear and helpful. OOOOO

The documentation meets my overall expectations. OOOOO

•

Please write any comments or suggestions below–be specific.

Page 8

Page 9

Content s

HP E1422A Remote Channel Multifunction DAC Module (Edition 3)

HEWLETT-PACKARD WARRANTY STATEMENT. . . . . . . . . . . . . . . . . . . . . 3

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

WARNINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Reader Comment Sheet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

About this Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring the HP E1422. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting the Logical Address Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installing Signal Conditioning Plug-ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Disabling the Input Protect Feature (optional) . . . . . . . . . . . . . . . . . . . . . . . 27

Disabling Flash Memory Access (optio nal) . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installing the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Instrument Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

About Example Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Verifying a Successful Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 2

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Planning Your Wiring Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SCP Positions and Channel Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Sense SCPs and Output SCPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Planning for Thermocouple Measurements . . . . . . . . . . . . . . . . . . . . . . . . . 36

Faceplate Connector Pin-Signal Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Optional Terminal and Connector Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

The SCPs and Terminal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Terminal Module Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

The RJ-45 Connector Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Spring Terminal Module Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Screw Terminal Module Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Reference Temperature Sensing with the HP E1422 . . . . . . . . . . . . . . . . . . . . . . 42

Preferred Measurement Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Contents 9

Page 10

Connecting the On-board Thermistor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Wiring and Attaching the Terminal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Removing the HP E1422 Terminal Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Attaching and Removing the HP E1422 RJ-45 Module. . . . . . . . . . . . . . . . . . . . 51

Adding Components to the Terminal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Spring and Screw Terminal Module Wiring Maps . . . . . . . . . . . . . . . . . . . . . . . 53

Chapter 3

Programming the HP E1422A & HP E1529A for Remote Strain Measurement . 55

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Instrument Setup for Remote Strain Measurements . . . . . . . . . . . . . . . . . . . . . . 56

Preparing the HP E1422A for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Preparing the HP E1529A for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Installing User Selected 1/4 Bridge Resistors (optional) . . . . . . . . . . . . . . . . 57

Connecting HP E1529As to the HP E1422A . . . . . . . . . . . . . . . . . . . . . . . . . 60

Two Interconnect Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Connecting Excitation Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Connecting the HP E1529A to Strain Gages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Channel Connector Pin-to-Signal Relationship . . . . . . . . . . . . . . . . . . . . . . 66

HP E1529A Bridge Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Connecting to the HP E1529A’s Dynamic Strain Ports. . . . . . . . . . . . . . . . . . . . 70

Extending the Dynamic Strain Connection . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Dynamic Strain Port Offset Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Remote Strain Channel Addressing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Runtime Remote Scan Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Programming for Remote Strain Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . 75

Description of Strain Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Verifying Correct Bridge Completion (Shunt Cal) . . . . . . . . . . . . . . . . . . . . . . . 87

Built-in Strain Conversion Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Chapter 4

Programming the HP E1422A for

Data Acquisition and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Overview of the HP E1422A Multifunction DAC Module. . . . . . . . . . . . . . . . . . 92

Multifunction DAC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Operational Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Detailed Instrument Operation Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Programming Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Executing the Programming Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Power-on and *RST Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Setting up Analog Input and Output Channels . . . . . . . . . . . . . . . . . . . . . . . . . 103

10 Contents

Page 11

Configuring Programmable Analog SCP Parameters . . . . . . . . . . . . . . . . 103

Linking Input Channels to EU Conversion . . . . . . . . . . . . . . . . . . . . . . . . . 105

Linking Output Channels to Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Setting up Digital Input and Output Channels. . . . . . . . . . . . . . . . . . . . . . . . . . 113

Setting up Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Setting up Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Performing Channel Calibration (Important!). . . . . . . . . . . . . . . . . . . . . . . . . . 117

Calibrationg the HP E1422A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Calibrating Remote Signal Conditioning Units . . . . . . . . . . . . . . . . . . . . . . 118

Defining an Analog Input Scan List (ROUT:SEQ:DEF). . . . . . . . . . . . . . . . . . 119

Defining C Language Algorithms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Global variable definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Algorithm definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Pre-setting Algorithm Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Defining Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Specifying th e

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Selecting the

FIFO Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Setting up the Trigger System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Arm and Trigger Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Programming the Trigger Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Setting the Trigger Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Sending Trigger Signals to

Other Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

INITiating the Module/Starting Scanning and Algorithms. . . . . . . . . . . . . . . . 126

Starting Scanning and/or Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

The Operating Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Reading Running Algorithm Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Modifying Running Algorithm Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Updating the Algorithm Variables and Coefficients . . . . . . . . . . . . . . . . . . 132

Enabling and Disabling Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Setting Algorithm Execution Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Example SCPI Command Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Example VXIplug&play Driver Function Sequence . . . . . . . . . . . . . . . . . . . . . 135

Using the Status System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Enabling Events to be Reported in the Status Byte . . . . . . . . . . . . . . . . . . 140

Reading the Status Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Clearing the Enable Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

The Status Byte Group’s Enable Register . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Reading Status Groups Directly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

HP E1422 Background Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Updating the Status System and VXIbus Interrupts . . . . . . . . . . . . . . . . . . . . . 143

Creating and Loading Custom EU Conversion Tables . . . . . . . . . . . . . . . . . . . 145

Contents 11

Page 12

Compensating for System Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Special Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Detecting Open Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

More On Auto Ranging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Settling Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Checking for Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Fixing the Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Chapter 5

Creating and Running Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Overview of the Algorithm Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Example Language Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

The Algorithm Execution Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

The Main Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

How Your Algorithms Fit In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Accessing the E1422’s Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Accessing I/O Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Accessing Remote Scan Status Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Runtime Remote Scan Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Defining and Accessing Global Variables . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Determining

First Execution (First_loop) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Initializing Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Sending Data to the CVT and FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Setting a VXIbus Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Determining Your Algorithm’s Identity (ALG_NUM) . . . . . . . . . . . . . . . . 166

Calling User Defined Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Operating Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Overall Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Algorithm Execution Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

12 Contents

Defining Algorithms (ALG:DEF). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

ALG:DEFINE in the Programming Sequence . . . . . . . . . . . . . . . . . . . . . . 170

ALG:DEFINE’s Thre e Data Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Changing an Algorithm While

it’s Running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

A Very Simple First Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Writing the Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Running the Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Modifying an Example PID Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

PIDA with digital On-Off Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Algorithm to Algorithm Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Communication Using Channel Identifiers . . . . . . . . . . . . . . . . . . . . . . . . . 175

Communication Using Global Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Page 13

Non-Control Algorithms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Process Monitoring Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Implementing Setpoint Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Algorithm Language Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Standard Reserved Keywords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Special HP E1422 Reserved Keywords . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Identifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Special Identifiers for Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Special Identifiers for Remote Scan Status . . . . . . . . . . . . . . . . . . . . . . . . . 182

Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Intrinsic Functions and Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Program Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Data Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Bitfield Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Language Syntax Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Program Structure and Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Declaring Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Assigning Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

The Operations Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Conditional Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Comment Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Overall Program Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Chapter 6

HP E1422 Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Overall Command Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Command Fundamentals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Common Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

SCPI Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Linking Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

SCPI Command Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

ABORt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

ALGorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

ALGorithm[:EXPLicit]:ARRay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

ALGorithm[:EXPLicit]:ARRay? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

ALGorithm[:EXPLicit]:DEFine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

ALGorithm[:EXPLicit]:SCALar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

ALGorithm[:EXPLicit]:SCALar? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

ALGorithm[:EXPLicit]:SCAN:RATio . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

ALGorithm[:EXPLicit]:SCAN:RATio? . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

ALGorithm[:EXPLicit]:SIZE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

ALGorithm[:EXPLicit][:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

ALGorithm[:EXPLicit][:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

ALGorithm[:EXPLicit]:TIME? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Contents 13

Page 14

ALGorithm:FUNCtion:DEFine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

ALGorithm:OUTPut:DELay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

ALGorithm:OUTPut:DELay? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

ALGorithm:UPDate[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

ALGorithm:UPDate:CHANnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

ALGorithm:UPDate:WINDow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

ALGOrithm:UPDate:WINDow? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

ARM[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

ARM:SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

ARM:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

CALibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

CALibration:CONFigure:RESistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

CALibration:CONFigure:VOLTage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

CALibration:REMote? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

CALibration:REMote:DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

CALibration:REMote:DATA? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

CALibration:REMote:STORe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

CALibration:SETup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

CALibration:SETup? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

CALibration:STORe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

CALibration:TARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

CALibration:TARE:RESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

CALibration:TARE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

CALibration:VALue:RESistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

CALibration:VALue:VOLTage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

CALibration:ZERO? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

DIAGnostic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

DIAGnostic:CALibration:SETup[:MODE] . . . . . . . . . . . . . . . . . . . . . . . . 245

DIAGnostic:CALibration:SETup[:MODE]? . . . . . . . . . . . . . . . . . . . . . . . 246

DIAGnostic:CALibration:TARE[:OTDetect]:MODE . . . . . . . . . . . . . . . . 246

DIAGnostic:CALibration:TARE[:OTDetect]:MODE? . . . . . . . . . . . . . . . 247

DIAGnostic:CHECksum? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

DIAGnostic:CONNect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

DIAGnostic:CUSTom:MXB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

DIAGnostic:CUSTom:MXB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

DIAGnostic:CUSTom:PIECewise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

DIAGnostic:CUSTom:REFerence:TEMPerature . . . . . . . . . . . . . . . . . . . 251

DIAGnostic:IEEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

DIAGnostic:IEEE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

DIAGnostic:INTerrupt[:LINe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

DIAGnostic:INTerrupt[:LINe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

DIAGnostic:OTDetect[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

DIAGnostic:OTDetect[:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

DIAGnostic:QUERy:SCPREAD? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

DIAGnostic:REMote:USER:DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

DIAGnostic:REMote:USER:DATA? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

14 Contents

Page 15

DIAGnostic:TEST:REMote:NUMber? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

DIAGnostic:TEST:REMote:SELFtest? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

DIAGnostic:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

FETCh?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

FORMat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

FORMat[:DATA] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

FORMat[:DATA]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

INITiate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

INITiate[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

INPut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

INPut:FILTer[:LPASs]:FREQuency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

INPut:FILTer[:LPASs]:FREQuency? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

INPut:FILTer[:LPASs][:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

INPut:FILTer[:LPASs][:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

INPut:GAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

INPut:GAIN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

INPut:LOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

INPut:LOW? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

INPut:POLarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

INPut:POLarity? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

MEASure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

MEASure:VOLTage:EXCitation? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

MEASure:VOLTage:UNSTrained? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

MEMory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

MEMory:VME:ADDRess . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

MEMory:VME:ADDRess? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

MEMory:VME:SIZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

MEMory:VME:SIZE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

MEMory:VME:STATe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

MEMory:VME:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

OUTPut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

OUTPut:CURRent:AMPLitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

OUTPut:CURRent:AMPLitude? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

OUTPut:CURRent[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

OUTPut:CURRent[:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

OUTPut:POLarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

OUTPut:POLarity? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

OUTPut:SHUNt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

OUTPut:SHUNt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

OUTPut:SHUNt:SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

OUTPut:SHUNt:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

OUTPut:TTLTrg:SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

OUTPut:TTLTrg:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

OUTPut:TTLTrg<n>[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

OUTPut:TTLTrg<n>[:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

OUTPut:TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Contents 15

Page 16

OUTPut:TYPE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

OUTPut:VOLTage:AMPLitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

OUTPut:VOLTage:AMPLitude? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

ROUTe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

ROUTe:SEQuence:DEFine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

ROUTe:SEQuence:DEFine? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

ROUTe:SEQuence:POINts? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

SAMPle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

SAMPle:TIMer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

SAMPle:TIMer? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

[SENSe]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

[SENSe:]CHANnel:SETTling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

[SENSe:]CHANnel:SETTling? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

[SENSe:]DATA:CVTable? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

[SENSe:]DATA:CVTable:RESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

[SENSe:]DATA:FIFO[:ALL]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

[SENSe:]DATA:FIFO:COUNt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

[SENSe:]DATA:FIFO:COUNt:HALF? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

[SENSe:]DATA:FIFO:HALF? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

[SENSe:]DATA:FIFO:MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

[SENSe:]DATA:FIFO:MODE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

[SENSe:]DATA:FIFO:PART? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

[SENSe:]DATA:FIFO:RESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

[SENSe:]FREQuency:APERture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

[SENSe:]FREQuency:APERture? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

[SENSe:]FUNCtion:CONDition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

[SENSe:]FUNCtion:CUSTom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

[SENSe:]FUNCtion:CUSTom:REFerence . . . . . . . . . . . . . . . . . . . . . . . . . . 309

[SENSe:]FUNCtion:CUSTom:TCouple . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

[SENSe:]FUNCtion:FREQuency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

[SENSe:]FUNCtion:RESistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

[SENSe:]FUNCtion:STRain:FBENding . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

[SENSe:]FUNCtion:STRain:FBPoisson . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

[SENSe:]FUNCtion:STRain:FPOisson . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

[SENSe:]FUNCtion:STRain:HBENding . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

[SENSe:]FUNCtion:STRain:HPOisson . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

[SENSe:]FUNCtion:STRain[:QUARter] . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

[SENSe:]FUNCtion:STRain:Q120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

[SENSe:]FUNCtion:STRain:Q350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

[SENSe:]FUNCtion:STRain:USER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

[SENSe:]FUNCtion:TEMPerature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

[SENSe:]FUNCtion:TOTalize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

[SENSe:]FUNCtion:VOLTage[:DC] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

[SENSe:]REFerence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

[SENSe:]REFerence:CHANnels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

[SENSe:]REFerence:TEMPerature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

[SENSe:]STRain:BRIDge[:TYPE] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

16 Contents

Page 17

[SENSe:]STRain:BRIDge:[TYPE]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

[SENSe:]STRain:CONNect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

[SENSe:]STRain:CONNect? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

[SENSe:]STRain:EXCitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

[SENSe:]STRain:EXCitation? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

[SENSe:]STRain:EXCitation:STATe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

[SENSe:]STRain:EXCitation:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

[SENSe:]STRain:GFACtor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

[SENSe:]STRain:GFACtor? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

[SENSe:]STRain:POISson . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

[SENSe:]STRain:POISson? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

[SENSe:]STRain:UNSTrained . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

[SENSe:]STRain:UNSTrained? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

[SENSe:]TOTalize:RESet:MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

[SENSe:]TOTalize:RESet:MODE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

SOURce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

SOURce:FM[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

SOURce:FM:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

SOURce:FUNCtion[:SHAPe]:CONDition . . . . . . . . . . . . . . . . . . . . . . . . . . 331

SOURce:FUNCtion[:SHAPe]:PULSe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

SOURce:FUNCtion[:SHAPe]:SQUare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

SOURce:PULM[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

SOURce:PULM:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

SOURce:PULSe:PERiod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

SOURce:PULSe:PERiod? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

SOURce:PULSe:WIDTh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

SOURce:PULSe:WIDTh? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

SOURce:VOLTage[:AMPLitude] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

STATus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

The Operation Status Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

STATus:OPERation:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

STATus:OPERation:ENABle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

STATus:OPERation:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

STATus:OPERation[:EVENt]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

STATus:OPERation:NTRansition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

STATus:OPERation:NTRansition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

STATus:OPERation:PTRansition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

STATus:OPERation:PTRansition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

STATus:PRESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

The Questionable Data Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

STATus:QUEStionable:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

STATus:QUEStionable:ENABle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

STATus:QUEStionable:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

STATus:QUEStionable[:EVENt]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

STATus:QUEStionable:NTRansition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

STATus:QUEStionable:NTRansition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

STATus:QUEStionable:PTRansition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

STATus:QUEStionable:PTRansition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Contents 17

Page 18

SYSTem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

SYSTem:CTYPe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

SYSTem:ERRor? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

SYSTem:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

TRIGger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

TRIGger:COUNt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

TRIGger:COUNt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

TRIGger[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

TRIGger:SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

TRIGger:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

TRIGger:TIMer[:PERiod] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

TRIGger:TIMer[:PERiod]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

IEEE-488.2 Common Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

*CAL? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

*CLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

*DMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

*EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

*EMC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

*ESE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

*ESE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

*ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

*GMC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

*IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

*LMC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

*OPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

*OPC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

*PMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

*RMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

*RST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

*SRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

*SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

*STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

*TRG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

*TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

*WAI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

18 Contents

Command Quick Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

HP E1422 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

HP E1529A Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

Appendix B

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

Appendix C

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 417

Page 19

Appendix D

Wiring and Noise Reduction Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 421

Separating Digital and Analog SCP Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 421

Recommended Wiring and Noise Reduction Techniques . . . . . . . . . . . . . . . . . 422

Wiring Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 422

HP E1422 Guard Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

Common Mode Voltage Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

When to Make Shield Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

Noise Due to Inadequate Card Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

HP E1422 Noise Rejection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

Normal Mode Noise (Enm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

Common Mode Noise (Ecm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

Keeping Common Mode Noise out of the Amplifier . . . . . . . . . . . . . . . . . . 424

Appendix E

Generating User Defined Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

Haversine Example.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

Appendix F

Example PID Algorithm Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

PIDA Algorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

PIDB Algorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

PIDC Algorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 445

Contents 19

Page 20

20 Contents

Page 21

About this Chapter

This chapter will expl ain hardware configuration before installation in a

VXIbus mainframe. By attending to each of the se configuration it ems, your

HP E1422 won’t have to be removed from its mainframe later. Chapter

contents include:

• Configuring the HP E1422 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

• Instrument Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

• About Example Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

• Verifying a Successful Configuration. . . . . . . . . . . . . . . . . . . . . . . 30

Configuring the HP E1422

There are several aspects to configuring the module before installing it in a

VXIbus mai nframe. They are:

Chapter 1

Getting Started

• Setting the Logical Address Switch . . . . . . . . . . . . . . . . . . . . . . . . 22

• Installing Signal Conditioning Plug-ons. . . . . . . . . . . . . . . . . . . . . 23

• Disabling the Input Protect Feature (optional) . . . . . . . . . . . . . . . . 27

• Disabling Flash Memory Access (optional) . . . . . . . . . . . . . . . . . . 27

For most applications you will only need to change the Logical Address

switch prior to installation. The other settings can be used as delivered.

Switch/Jumper Setting

Logical Address Switch 208

Input Protect Jumper Protected

Flash Memory Protect Jumper PROG

Note Setting the VXIbus Interrupt Level: The HP E1422 uses a default VXIbus

interrupt level of 1. The default setting is made at power-on and after a

*RST command. You can change the interrupt level by executing the

DIAGnostic:INTerrupt[:LINe] command in your application program.

Getting Started 21Chapter 1

Page 22

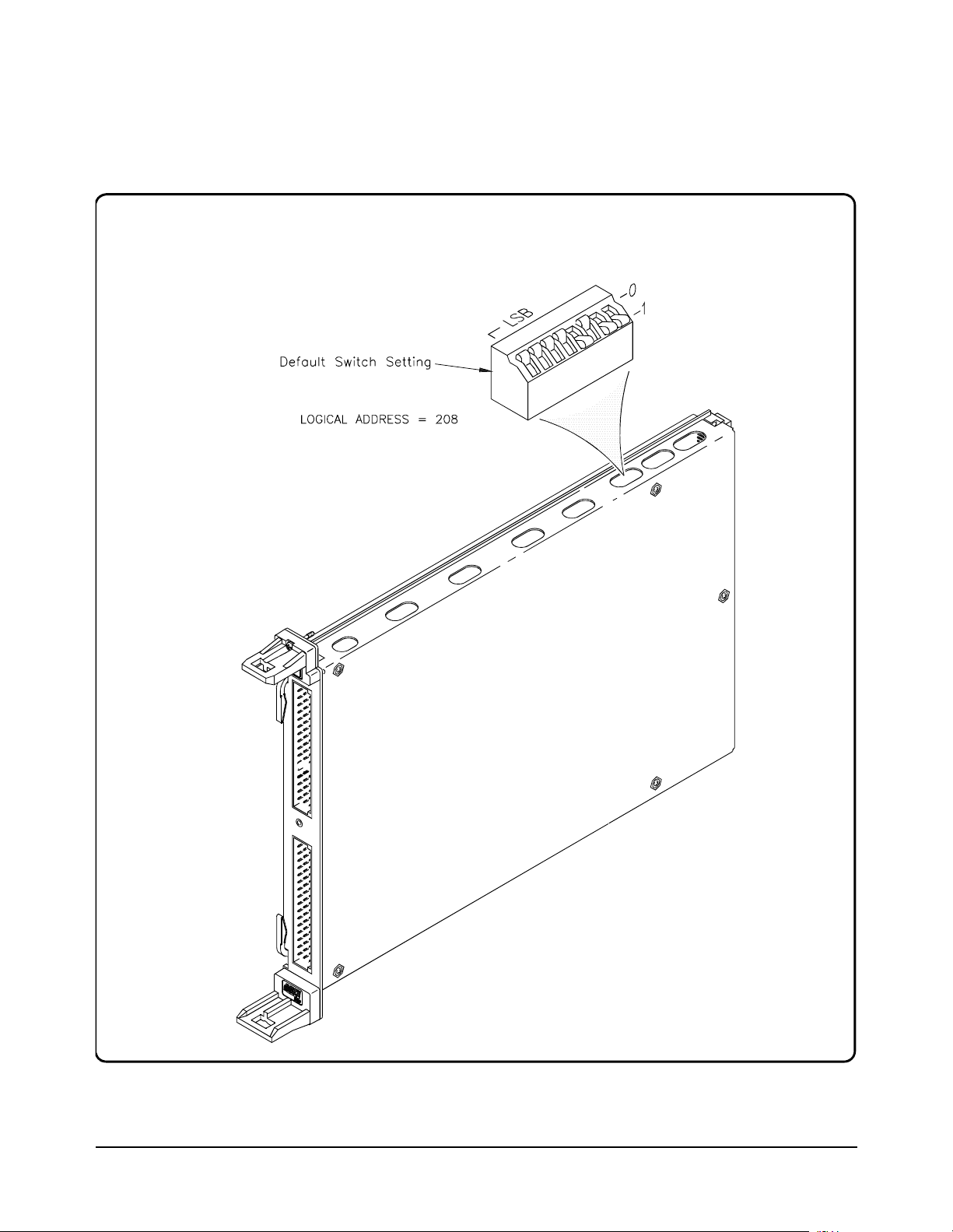

Setting the Logical

Address Switch

Follow the next figure and ignore any switch numbering printed on the

Logical Address switch. W hen installing more than one HP E1422 in a

single VXIbus Mainframe, set each instrument to a different Logical

Address.

Setting the Logical Address Switch

22 Getting Started Chapter 1

Page 23

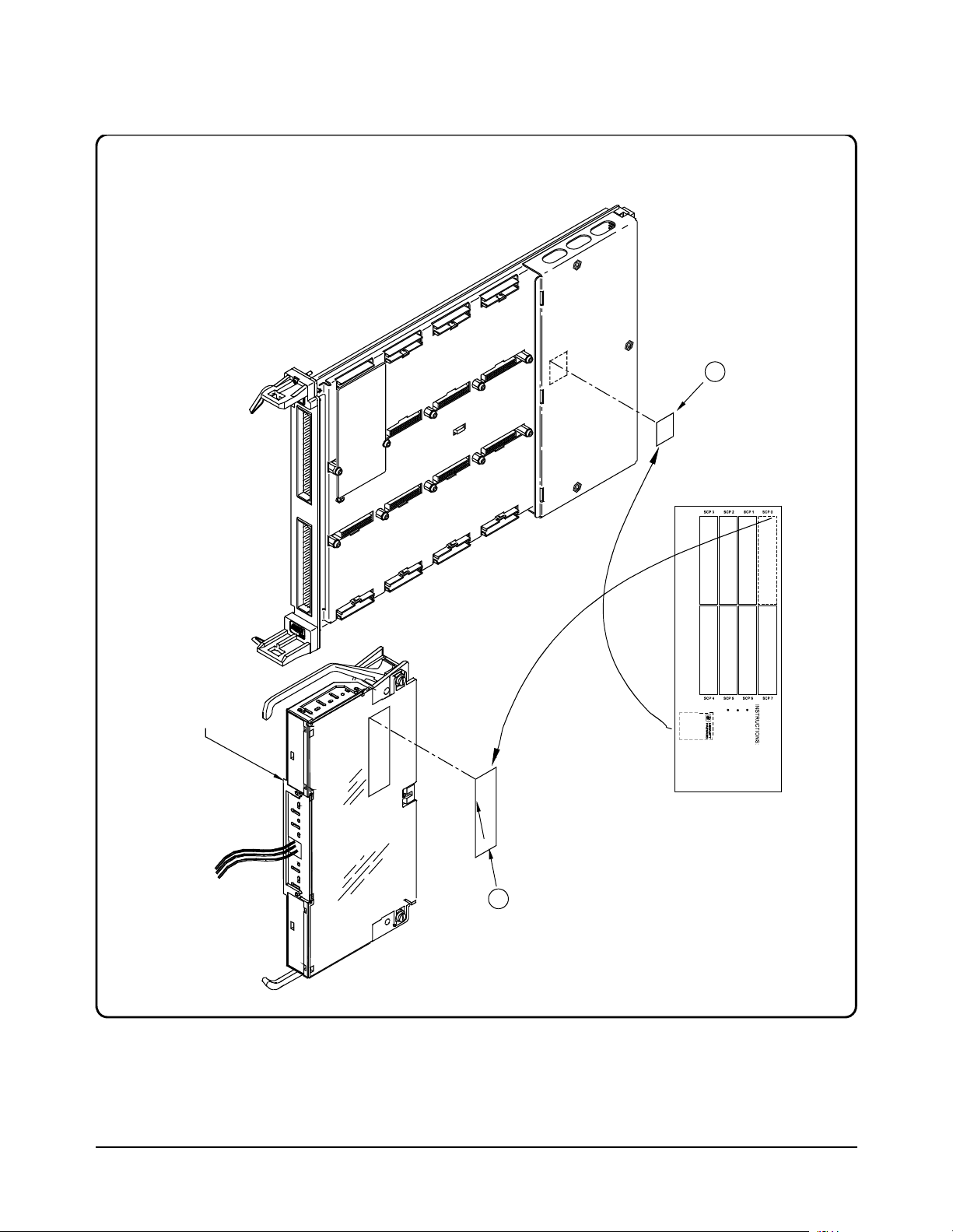

Installing Signal

Conditioning

The following illustrations show the steps you’ll use to install Signal

Conditioning Modules. Before you install your SCPs, you should read the

"Separating Digital and Analog SCP Signals" in Appendix D page 421.

Plug-ons

Caution Use approved Static Discharge Safe handling procedures

anytime you have the covers removed from the HP E1422 or are

handling SCPs.

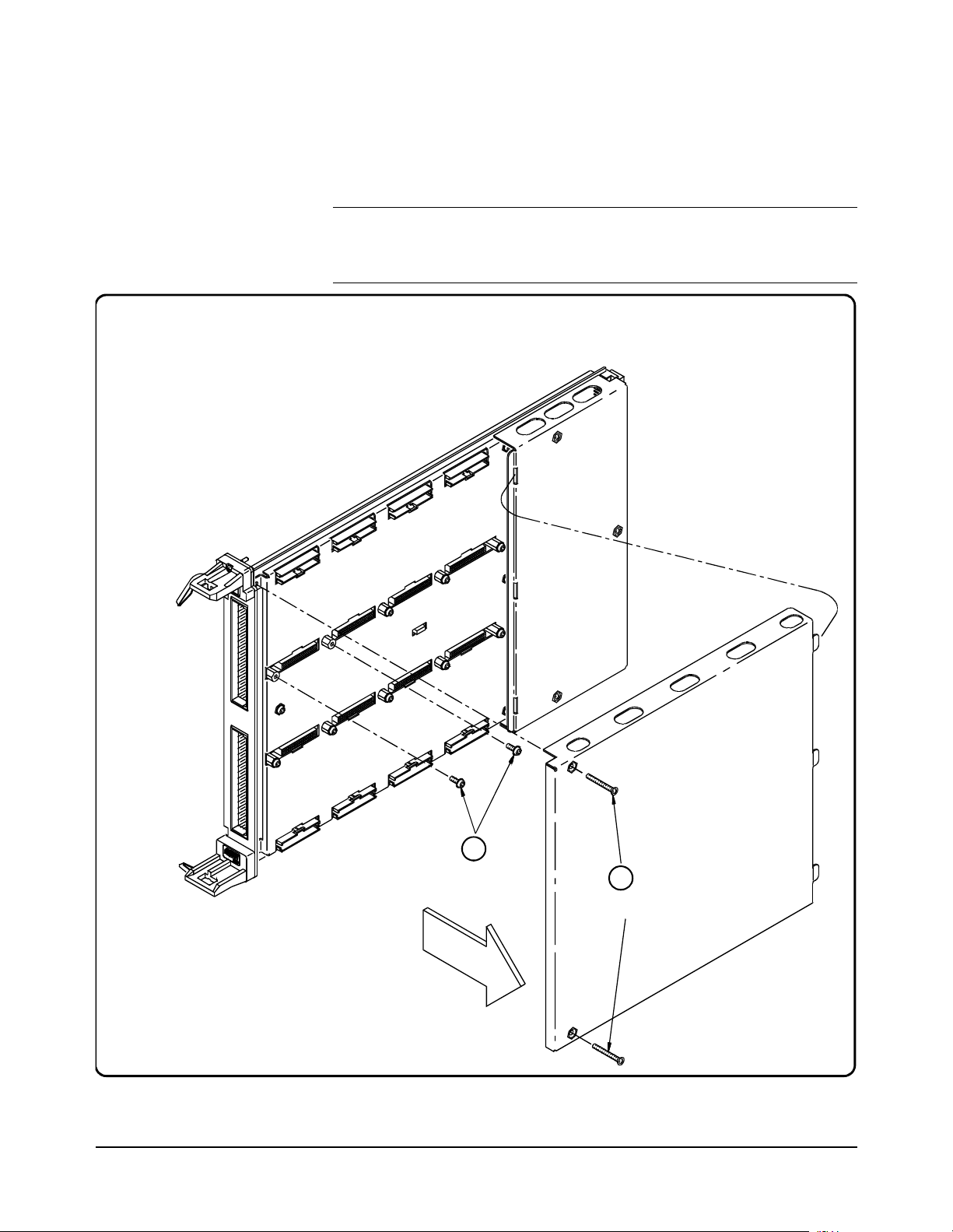

Installing SCPs: Step 1, Removing the Cover HP E1422

2

Remove the SCP

Retaining Screws

1

Remove 2 screws ( #10 Torx);

lift front and sli de out tabs

E1520 REMVLEFT

Getting Started 23Chapter 1

Page 24

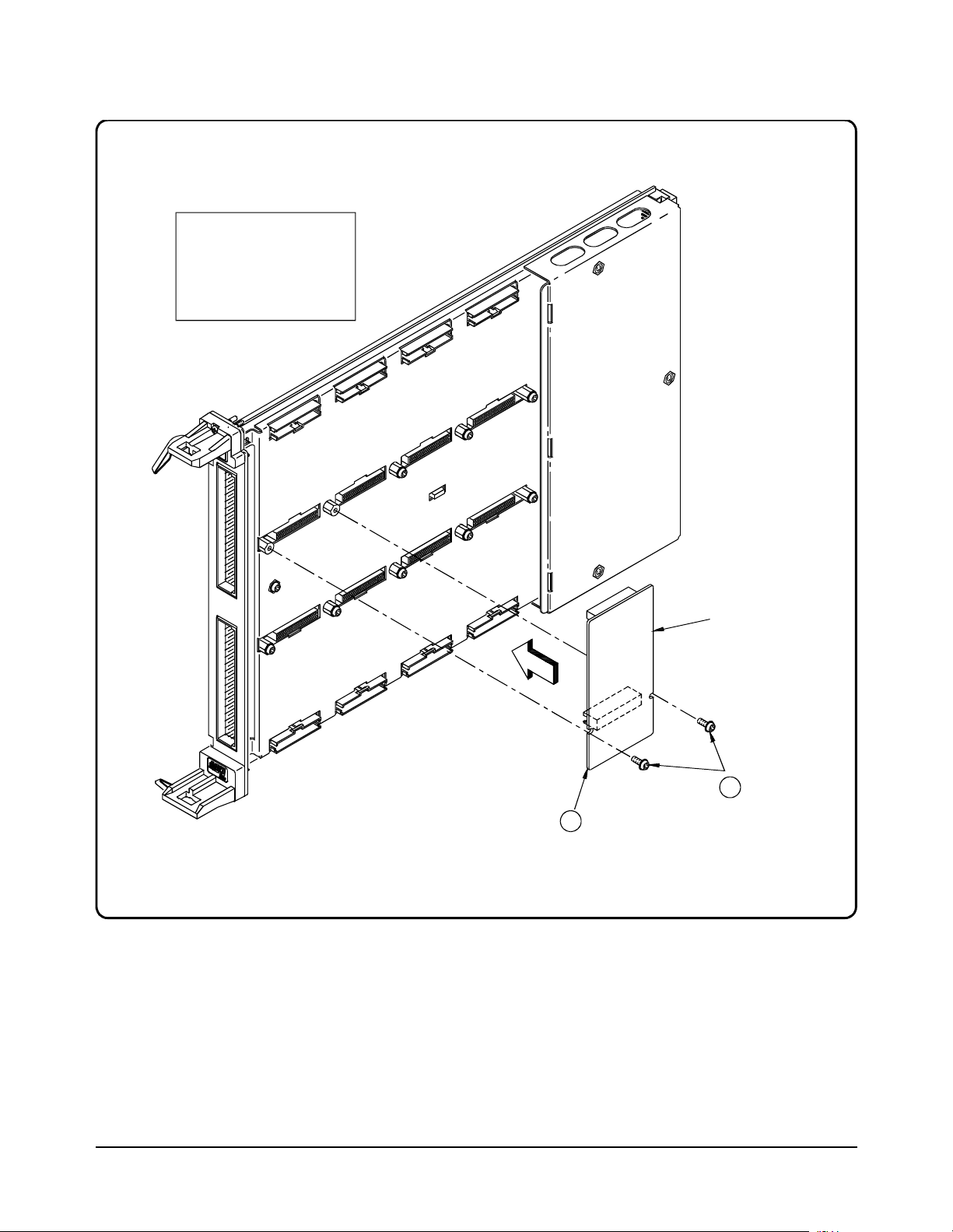

Installing SCPs: Step 2, Mounting an SCP

CAUTION

Use approved Static

Discharge handling

procedures when handling

the HP E1413 Scanning

A/D Module and the SCP s.

E1520 INSLSCP

1

Align the SCP

Connectors with the

Module Connec to rs

and then Push in

SCP

2

Tighten the SCP

Retaining Screws

24 Getting Started Chapter 1

Page 25

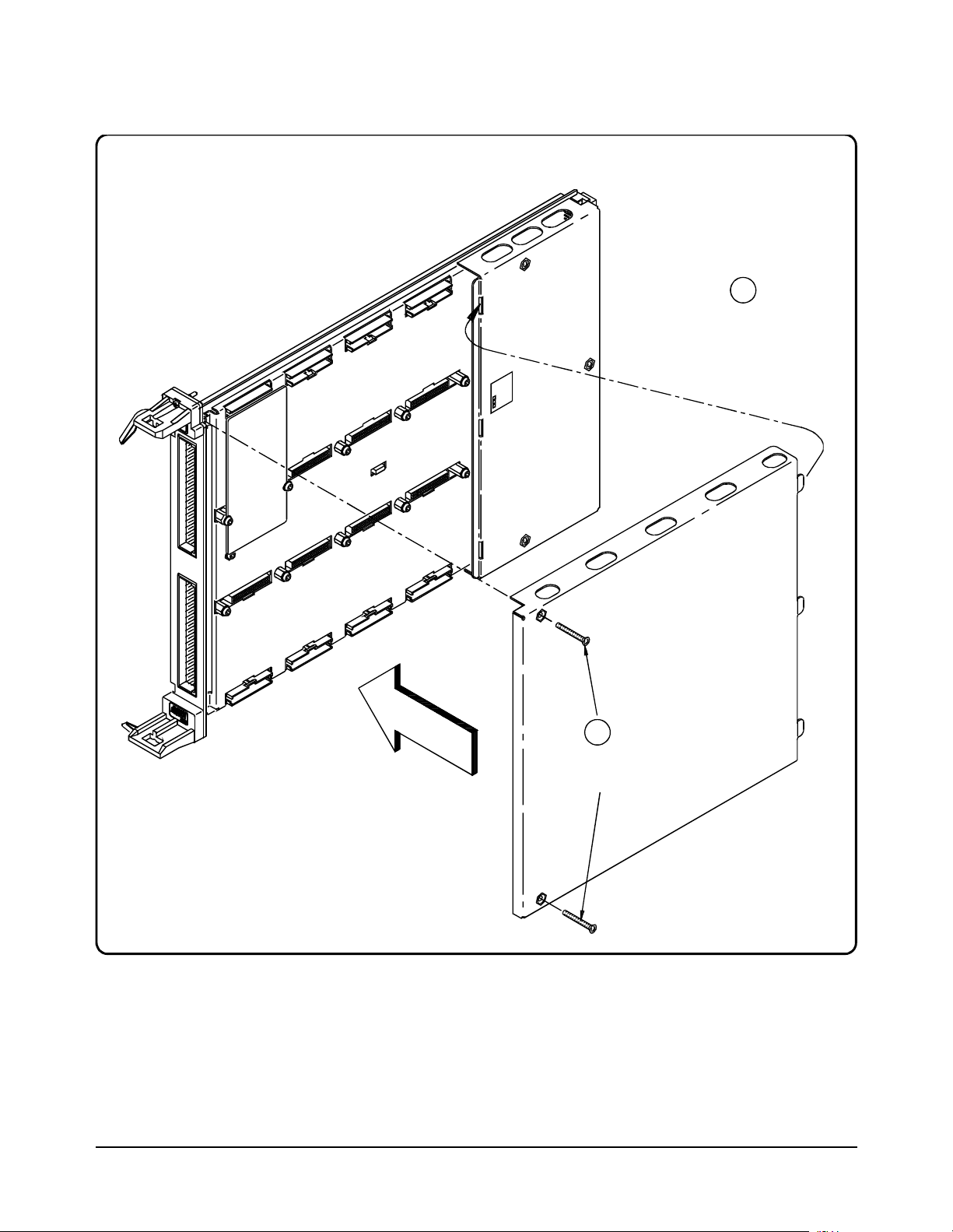

Installing SCPs: Step 3, Reinstalling the Cover HP E1422

1

Line up the 3 Tabs

with the 3 Slots;

then lower cov er

onto the Modul e

E1520 INSTLEFT

2

Tighten

2Screws

Getting Started 25Chapter 1

Page 26

Installing SCPs: Step 4, Labeling

Peel off c orrec t

Label from Card and

Stick on the

appropriate place on

the Co ver

1

Term in al Module

(Connect to A/D

Module L ater)

Stick-onLabel furnished with the SCP

(HP part number: E15xx-84304)

2

Peel off Lab el from

Card and Stick on

the Terminal

Module to be

Connected to the

A/D Module

26 Getting Started Chapter 1

Page 27

Disabling the

Input Protect

Feature

(optional)

Disabling the Input Protect feature voids the HP E1422’s warranty. The Input

Protect feature allows the HP E1422 to open all channel input relays if any input’s

voltage exceeds ±19 volts (±6 volts for digital I/O SCPs). This fe ature will help to

protect the card’s Signal Conditioning Plug-ons, input multiplexer, ranging

amplifier, and A/D from destructive voltage le vels. The le vel that trips the

protection function has been set to provide a high probability of protection. The

voltage level that is certain to cause damage is somewhat higher. If in your

application the importance of completing a measurement run outweighs the

added risk of damage to your HP E1422, you may choose to disable the Input

Protect feature.

Voids Waranty! Disabling the Input Protection Feature voids the HP E1422’s warranty.

To disable the Input Prote ction feature, locat e and cut JM2202. Make a singl e cut in

the jumper and bend the adjace nt ends ap art. Se e foll owing i llust ration for locat ion

of JM2202.

Disabling

Flash Memory

Access

(optional)

The Flash Memory Protect Jumper (JM2201) is shipped in the “PROG” position.

We recommend that you leave the jumper in this position so that all of the

calibration commands can function. Changing the jumper to the protect position

will mean you won't be able to execute:

•The SCPI calibration command CAL:STORE ADC | TARE

•The register-based calibration commands STORECAL, and STORETAR

•Any application that installs firmware-updates or makes any other

modification to Flash Memory through the A24 window.

With the jumper in the “PROG” po sition, you ca n completely ca librate one or mor e

HP E1422s without removing them from the application system. An HP E1422

calibrated in its working environment will in general be better calibrated than if it

were calibrated separate from its application system.

The multimeter you use dur ing the per i odi c ca li bra ti on c ycl e should be considered

your calibration transfer standard. Have your Calibration Organization control

unauthorized access to its calib ration cons tants. See the HP E1422 Service Manual

for complete information on HP E1422 periodic calibration.

If you must limit access to the HP E1422's calibration constants, you can place

JM2201 in the protected position and cover the shield retaining screws with

calibration stickers. See following illustration for location of JM2201.

Getting Started 27Chapter 1

Page 28

Accessing and Locating JM2201 and JM2202 HP E1422

Flash MemoryProtect Jumper

Default = PROG

(recommended)

JM2201

E1413 FIG1-3

JM2202

1 Locate

2Cut

3 Bend

Input Protect Jump er

Warning: Cutting this Jumpe r

Voids Your Warranty!

28 Getting Started Chapter 1

Page 29

Installing the Module

Installation of the HP E1422 VXI module is covered in your HP Mainframe manual.

WARNING All instruments within the VXI mainframe are gr ounded thro ugh

the mainframe chassis. During insta llation, tighten the

instrument’ s retaining screws to secure the instrument to

the mainframe and to make the ground connection.

WARNING SHOCK HAZARD. Only qualified, service-trained personnel who

are aware of the hazards involved should install, configure, or

remove the VXI Module. Disconnect all power sources from the

mainframe, the Terminal Modules, and installed modules before

installing or removing a module.

Instrument Drivers

Two driver types are supplied on the HP Universal Drivers CD that comes with your

Instrument. There is a VXIpl ug&pl ay driver which includes a front panel program

and help file. In addition there is also a down-loadable driver for the HP E1406A

Command Module. Follow the instructions that are presented by the CD setup

program. Also view the readme .txt file pro vided wit h the VXIplug&pl ay driver for

possible update information.

About Example Programs

Examples on CD All example programs mentioned by file name in this manual are available on the

HP Universal Drivers CD supplied with your HP E1422. Again see the readme.txt

file for the specific file locations of these examples.

Example

Command

Sequences

Typical Example

program

Where programming concept s ar e discussed in this manual, the commands to send

to the HP E1422 are shown in the form of command sequences. These are not

example programs because t hey are not written in a ny computer language. Th ey are

meant to show the HP E1422 SCPI commands in th e sequ ence the y shoul d be se nt.

Where necessary th ese sequences include comments to describ e program flow and

control such as loop - end loop, and if - end if. See “Example SCPI Command

Sequence” on page 134. for an example. For VXIplug&play users, there is an

“Example VXIplug&play Driver Function Sequence” on page 135.

The Verify program (file name ve rif.cpp) is printed below to show a typical

VXIplug&play program for the HP E1422.

Getting Started 29Chapter 1

Page 30

Verifying a Successful Configuration

An example ’C’ progra m source is s hown on th e fol lowing p ages. T his pr ogram is

included on your HP Universal Drivers CD that comes with your HP E1422A (file

name verif.cpp). The program uses the *IDN? query command to verify the HP

E1422 is operational and r esponding t o commands. The program also has an error

checking function ( check( )). It is important to include an instrument error checking

routine in your programs, particularly your first trial programs so you get instant

feedback while you are learning about the HP E1422. Compile this program

according to the plug&play help file (hpe1422.hlp) topics "Introduction to

Programming"

Environments".

/*******************************************************************************

verif.cpp

This example program verifies your instrument installation by reading the

instrument IDs and then querying for and printing the SCP types found.

Use the "Copy Button" in the Help File’s "Example" window to place this code

into the clipboard, then paste this code text into your development tool’s

editor window. Similarly, "Copy" the actual example code from the help file’s

"Example" window and paste it into the location provided below.

This program should be compiled in the ’large’ memory model.

→"Compiling and Linking Programs Using Integrated

link with the hpe1422_32.lib - library file

*******************************************************************************

*/

#include <stdio.h>

#include <stdlib.h>

#include <string.h>

#include <hpe1422.h> /* include the driver header file */

/* GPIB-VXI addressing (0 is the interface number, 208 is the */

/* instrument logical address, INSTR is a VISA resource type) */

#define INSTR_ADDRESS "GPIB-VXI0::208::INSTR"

ViSession addr;

ViStatus errStatus;

/* Function Prototypes */

void main (void); /* Main function */

void rst_inst(void); /* Resets the instrument and sends a device clear */

void reads_instrument_id(void); /* reads instrument software revision */

void check (ViSession addr, ViStatus errStatus); /* checks module errors */

/*******************************************************************************/

void main (void) /* Main function */

{

ViChar err_message[256];

/* Set the session and status variables */

#if defined(__BORLANDC__) && !defined(__WIN32__)

_InitEasyWin();

#endif

30 Getting Started Chapter 1

Page 31

/* open device session and reset the instrument; check if successful */

errStatus = hpe1422_init(INSTR_ADDRESS,0,0,&addr);

if( VI_SUCCESS > errStatus)

{

hpe1422_error_message( addr, errStatus, err_message);

printf("Unable to open %s\n", INSTR_ADDRESS);

printf("hpe1422_init() returned error message %s\n", err_message);

return;

}

rst_inst(); /* Resets the instrument and sends a device clear */

reads_instrument_id(); /* Reads instrument software revision */

/* close the device session */

hpe1422_close(addr);

}

/****************************************************************************/

void rst_inst(void)

/* Function to set the interface timeout period, resets the instrument, */

/* waits for completion of reset, and sends a device clear to enable */

/* the instrument to receive a new command */

{

ViInt32 result;

/* set timeout to allow completion of reset */

errStatus = hpe1422_timeOut(addr, 5000);

check(addr, errStatus);

/* reset the instrument */

errStatus = hpe1422_reset(addr);

check(addr, errStatus);

/* wait for completion of *RST */

errStatus = hpe1422_cmdInt32_Q(addr,"*OPC?",&result);

check(addr, errStatus);

/* send a device clear to enable new commands to be sent to the instrument */

errStatus = hpe1422_dcl(addr);

check(addr, errStatus);

/* enables automatic error checking after each driver call */

errStatus = hpe1422_errorQueryDetect( addr, VI_TRUE);

}

/****************************************************************************/

void reads_instrument_id(void)

/* Function uses a hpe1422__revision_query to read the software revision */

/* string. */

{

ViChar driver_rev[256];

ViChar instr_rev[256];

/* Query the instrument for its firmware revision */

errStatus = hpe1422_revision_query(addr, driver_rev, instr_rev);

/* Print the results */

printf("The instrument driver’s revision is %s\n", driver_rev);

printf("The instrument’s firmware revision is %s\n", instr_rev);