Page 1

Service Guide

Publication Number 54856-97001

May 2005

Copyright Agilent Technologies 2004-2005

All Rights Reserved.

Agilent Model 80000 Series Infiniium

Oscilloscopes

Page 2

The Agilent Technologies Infiniium Oscilloscope at a Glance

Ease of use with h igh performance

The Agilent Techno logie s Infini ium oscillo scopes

combine unprecedented ease-of-use with highperformance digitizing oscilloscope functional ity

to simplify your design and an alysis measuremen t

tasks.

• Traditional oscillos cope front- panel interf ace

provides d irect acces s to the controls needed

for most troubleshooting tasks

• Graphical user i nterface with menus,

windows, dialo gs, and toolbars provides easy

access to dozens of configuration and

analysis tools, ensuring you can set up and

make the most complex measurements

• Agilent DSO8130 4A offers 4 channels,

20 GSa/s sampli ng rate on all four channels,

13 GHz bandwidth

• Agilent DSO8120 4A offers 4 channels,

20 GSa/s sampli ng rate on all four channels,

12 GHz bandwidth

• Agilent DSO8100 4A offers 4 channels,

20 GSa/s sampli ng rate on all four channels,

10 GHz bandwidth

• Agilent DSO8080 4A offers 4 channels,

20 GSa/s sampli ng rate on all four channels,

8 GHz bandwidth

Acquisition and general controls start and stop

the scope and do basic setup

• Run and stop controls for continuou s or

single-shot acquisitions

• Clear display before one or more acquisitions

• Default set up and Autoscale set initial

configuration

Hard disk drive and floppy disk drive for saving

and restoring setups and measurement results

• Store measurement displays for inclusion in

reports and test setup guides

• Store oscill oscope setups to rep eat tests

another time

• Hard disk stores oscilloscope operating

system

Trigger setup controls set mode and basic

parameters

• Select Edge, Glitch, or Advanced Modes

• Choose input source and slope

• Use graphical user interface to simplify

configuration of pattern, state, delay, and

violation

• Use auxiliary trigger to increase triggering

flexibility

Display shows wav eforms and graphical user

interface

• Graphical interface allows direct interaction

with waveforms, including drag-and-drop

positioning and instant waveform zoom

• Waveforms displayed in color, making

correlation easy

• Current configuration parameters displayed

near the waveform display and are colorcoded to make identification easy

• Graphical interface menus and toolbars

simplify complex measurement setups

Horizontal cont rols set swee p speed and positi on

• Main sweep speeds from 5 ps/div to 20 s/div

• Delayed sweep speeds from 1 ps/div to main

time base setting

• Intensifi ed waveforms on main sweep

window make it easy to see what will appear

in delayed sweep window

Vertical controls set attenuation, and position

• Input attenuation adjustabl e from 1 mV/div to

1 V/div

• Color-coded knobs make it easy to find the

controls that affect each waveform

Marker and quick measurements help measure

waveform parameters

• Waveform markers A and B to check voltage

or ∆−time at any point on the displayed

waveform

• Quick Meas execut es up to four predefined

measurements instantly

Service Policy

The service policy of this instrument requires

replacing defective assemblie s. Some

assemblies can be replaced on an exchange

basis.

ii

Page 3

Front panel

Display and

Graphical

Interface

Horizontal

controls

Acquisiti on and

general co ntrols

Floppy Disk Drive

Power

Rear

foot

Marker and Quick

Measurements

Rear panel without option 017

Parallel

Printer Port

LAN

and

USB

Ports

CD-RW

drive

Vertical

Controls

VGA

Interface

AutoProbe

Interface

GPIB Interface

Vertical

Inputs

Trigger

Setup

Auxiliary

Output

AC Pow e r

Input

Mouse and

Keyboard

Interface

RS232

COM

Port

Secondary

monitor

Sound In

Sound Out

Microphone

10

MHz

Ref In

(opt.)

Aux Trig

In

TTL

Trig

Out

10 MHz

Ref Out

iii

Page 4

Rear panel with option 017

Removabl e h ar d drive

iv

Page 5

In This Book

This book provides the service documentation for the Agilent Technologies DSO81304A,

DSO81204A, DSO81004A, and DSO80804A oscilloscopes. It is divided into eight chapters.

Chapter 1 provides general information and specifications.

Chapter 2 shows you how to prepare the oscilloscope for use.

Chapter 3 gives performance tests.

Chapter 4 covers calibration procedures, how to do them, and how often they need to be done.

Chapter 5 gives information on troublshooting to a faulty system.

Chapter 6 gives the procedures and techniques for replacing assemblies and other parts.

Chapter 7 includes a list of exchange assemblies and other replaceable parts, part ordering

information, and shipping information.

Chapter 8 briefly covers the internal operation of the oscilloscope.

At the back of the book you will find safety notice information.

v

Page 6

vi

Page 7

Contents

1 General Information

Oscilloscopes covered by this service guide 1-2

Accessories supplied 1-3

Accessories available 1-3

Specifications 1-5

Characteristics 1-6

Dimensions 1-12

Recommended test equipment 1-13

2 Setting Up the Oscilloscope

To inspect package contents 2-3

To inspect options and accessories 2-5

To connect power 2-7

To connect the mouse, the keyboard, a LAN cable, a printer, and a GPIB cable 2-10

To connect SMA Cables 2-12

To tilt the oscilloscope upward for easier viewing 2-13

To turn on the oscilloscope 2-14

To turn off the oscilloscope 2-15

To verify basic oscilloscope operation 2-16

Installing application programs on Infiniium 2-17

Changing Windows System Settings 2-18

To clean the oscilloscope 2-19

3Testing Performance

Before Performing Performance Verification Testing 3-3

Offset Accuracy Test 3-5

DC Gain Accuracy Test 3-12

Analog Bandwidth - Maximum Frequency Check 3-16

Performance Test Record 3-23

4 Calibration

To run the self calibration 4-3

5Troubleshooting

To install the fan safety shield 5-3

To troubleshoot the oscilloscope 5-4

Primary Trouble Isolation 5-5

Power Supply Trouble Isolation 5-12

Power Board Trouble Isolation 5-15

Display Trouble Isolation 5-19

Front Panel Display Trouble Isolation 5-21

Front Panel Trouble Isolation 5-23

Motherboard Verification 5-24

To configure the motherboard jumpers and setup BIOS 5-29

Contents–1

Page 8

Contents

POST Code Listing 5-32

Acquisition Trouble Isolation 5-34

AutoProbe Board Trouble Isolation 5-35

To check the keyboard; Trouble Isolation Procedure 5-36

To check the LEDs 5-37

Software Revisions 5-38

To check probe power outputs 5-39

To check the display board video signals 5-40

To check the backlight inverter voltages 5-41

6 Replacing Assemblies

To return the oscilloscope to Agilent Technologies for service 6-3

To remove and replace the covers 6-4

To disconnect and connect Mylar flex cables 6-6

To remove and replace the AutoProbe assembly 6-7

To remove and replace the probe power and control board 6-9

To remove and replace the front panel assembly 6-11

To remove and replace the keyboard, backlight inverter board, and flat-panel display

assemblies 6-14

To remove and replace the acquisition board assembly 6-18

To remove and replace the power regulator distribution board 6-21

To remove and replace the interface and GPIB board 6-23

To remove and replace the oscilloscope graphics board and display board 6-24

To remove and replace the floppy disk drive 6-25

To remove and replace the internal hard disk drive 6-26

To remove and replace the CD-ROM drive 6-28

To remove and replace the motherboard 6-30

To remove and replace the power supply 6-32

To remove and replace the fans 6-34

7 Replaceable Parts

Ordering Replaceable Parts 7-2

Power Cables and Plug Configurations 7-3

Exploded Views 7-5

Replaceable Parts List 7-10

8 Theory of Operation

Block-Level Theory 8-3

Acquisition Theory 8-7

Contents–2

Page 9

1

Oscilloscopes covered by this service guide 1-2

Accessories supplied 1-3

Accessories available 1-3

Specifications 1-5

Dimensions 1-11

Recommended test equipment 1-12

General Information

Page 10

General Information

This chapter of the Agilent Technologies Infiniium Oscilloscope Service Guide gives

you general information about the oscilloscope. The following topics are covered in this

chapter.

• oscilloscope identification

• Options

• Accessories

• Specifications and characteristics

• Test equipment requirements

Oscilloscopes covered by this service guide

The oscilloscope can be identified by the product number on the back panel.

On the rear panel of the oscilloscope is a serial number label and a VIN # XXX. The serial number

is composed of two parts. The first part contains two letters and two numbers that signify the

oscilloscope’s county of origin and year date code. The second part, or the last six digits from

the right, contains a rolling number that is different for each Infiniium. This manual may not

reflect changes made to the oscilloscope after the release date listed on the title page.

An oscilloscope manufactured after the printing of this manual may have a newer serial number.

This newer serial prefix indicates that the oscilloscope may be different from those described in

this manual. The manual for this oscilloscope will be revised as needed. If you have an oscilloscope

with a newer serial number, please refer to the Agilent Technologies website and download a

newer manual edition in Adobe Acrobat (pdf) format. The Agilent Technologies URL is:

“www.agilent.com”. It will be necessary to search for the product page, then click on “Manuals

& Guides” link in the Library section of the product page.

1–2

Page 11

Chapter 1: General Information

Accessories supplied

The following accessories are supplied.

• Mouse, Agilent part number 1150-7913

• Keyboard, Agilent part number 1150-7809

• Accessory Pouch, Agilent part number 54810-68701

• Front-panel cover, Agilent part number 54810-42201

• Calibration cable assembly, Agilent part number 54855-61620

• Probe De-skew and Performance Verification Kit, Agilent E2655A

• Precision 3.5 mm adapters (qty 2), Agilent part number 54855-67604

• BNC shorting cap, Agilent part number 1250-0929

• Power cord (see chapter 6, “Replaceable Parts,” for available power cords)

• User's Quick Start Guide

Accessories available

Accessories supplied

The following accessories are available for use with the oscilloscope.

Table 1-1 Accessories for the Infiniium Oscilloscopes

Agilent Mode l N u mber Descrip tion

54855-67604 18 GHz BNC-compatible to APC 3.5 mm adaptor

10833A GPIB cable, 1 m

10833B GPIB cable, 2 m

10833C GPIB cable, 4 m

10833D GPIB cable, 0.5 m

11094B 75

1131A 3.5 GHz InfiniiMax Active Probe

1130A 1.5 GHz InfiniiMax Active Probe

1168A 10 GHz InfiniiMax Active Probe

1169A 12 GHz InfiniiMax Active Probe

1131A 3.5 GHz InfiniiMax Active Probe

1132A 5 GHz InfiniiMax Active Probe

1134A 7 GHz InfiniiMax Active Probe

1144A 800 MHz Active Probe

1145A 750 MHz Active Probe

1156A 1.5 GHz Active Probe

1157A 2.5 GHz Active Probe

1158A 4 GHz Active Probe

1181B Testmobile with tilt tray

1184A Testmobile w ith keyboard and mouse tray and draw er for accessories

34398A RS-232-C Printer Cable

34399A RS-232-C Adapter kit

54006A 6 GHz probe, 10:1 (500

C2950A Parallel printer cable, 2 m

Ω Feedthrough Termination

Ω) or 20:1 (1 k Ω), . 25 pf

1–3

Page 12

Chapter 1: General Information

Accessories available

Agilent Mode l N u mber Descrip tion

C2951A Parallel printer cable, 3 m

E2609B Rackmount kit

E2621A 75

E2622A 100/110/120

E2654A EZ-Probe

E2655A Additional probe deskew and performance verification kit

E2669A Differential connectivity kit

E2668A Single-ended connectivity kit

E2675A Differential browser and accessories

E2676A Single-ended browser and accessor ies

E2677A Differential solder-in probe head

E2678A Single-ended/differentia l socketed probe

E2679A Single-ended solder-in probe head

E2680A 1 MB Memory upgrade

E2681A Jitter Analysis Software for the 80000 Series Infiniium oscilloscopes

E2683A USB Test Option

E2688A Serial Bus Mask Test Option

E5850A Time-correlation fixture, integrates Infiniium oscilloscope and 16700

N1022A Adapter 113 X & 115X probes to 86100 infiniium DCA

Ω terminator

®

Positioner

logic analyzer

Ω different ial terminator

1–4

Page 13

Chapter 1: General Information

Specifications

Specifications

The following table lists the specifications for the Agilent Technologies 80000 Series Infiniium

Oscilloscopes. All specifications are warranted. Specifications are valid after a 30 minute

warm-up period, and within

Vertical

± 5 °C from the annual calibration temperature.

Analog bandwidth (-3 dB) DSO81304 A: 12 GHz

DSO81004A: 10 GHz

DC gain accuracy

Maximum input voltage ±5 V, CAT I

!

Offset accur acy

DC voltage measurement accuracy

Dual cursor

Single cursor

1

1

1

±2% of full scale at full resolution channel scale

≤3.5 V: ± (2% of channel offset +1% of full scale) + 1 mV

>3.5 V: ± (2% of channel offset +1% of full scale)

± [(DC gain accuracy)+(resolution)]

± [(DC gain accuracy)+(offset accuracy)+(resolution/2)]

1. Full scale is defined as 8 vertical divisions. Magnification is used below 5 mV/div. Below 5 mV

full scale is defined as 40 mV. The major scale settings are 5 mV, 10 mV, 20 mV,

50 mV, 100 mV, 200 mV, 500 mV and 1 V.

DSO81204 A: 12 GHz

DSO80804 A: 8 GHz

1–5

Page 14

Chapter 1: General Information

Characteristics

Characteristics

All characteristics are the typical performance values of the Infiniium oscilloscope and are not warranted.

Footnotes are located on page 10.

Vertical

Input channels 4

DSP enhanced bandwidth (-3 dB) DSO81304A: 13 GHz

Rise time (10% to 90%)

(20% to 80%)

DSO81304A

DSO81304A

9

: 33 ps DSO81204A: 36 ps DSO81004A: 42 ps DSO80804A: 54 ps

9

: 23 ps DSO81204A: 25 ps DSO81004A: 30 ps DSO80804A: 38 ps

Input impedance 50

Sensitivity

1

Ω ±3%

1 mV/div to 1 V/div

Input coupling DC

Vertical resolution

Channel to channel isolation

(any two chan nels with equal V/div

settings)

2

8 bits, ≥12 bits with averaging

DC to 3 GHz: 60 dB

3 GHz to 8 GHz: 40 dB

8 GHz to BW: 35 dB

Offset range Vertical sensitivity Available offset

0 mV to ≤ 40 mV/div ± 0.4 V

> 40 mV to ≤ 75 mV/d iv ± 0.9 V

> 75 mV to ≤ 130 mV/div ± 1.6 V

> 130 mV to ≤ 240 mV/div ± 3.0 V

> 240 mV ± 4.0 V

Dynamic range ± 4 div from center screen

RMS noise floor Vo lts/div DSO80804A DSO81004A DSO81204A DSO81304A

5 mV 280 µV 340 µV 390 µV420 µV

10 mV 310 µV 380 µV 440 µV490 µV

20 mV 470 µV 530 µV 610 µV730 µV

50 mV 1.1 mV 1.2 m V 1.4 mV 1.7 mV

100 mV 2.1 mV 2. 3 m V 2.7 mV 3.3 mV

200 mV 4.1 mV 4.7 mV 5.3 mV 6.6 mV

500 mV 11 mV 12 mV 14 mV 17 mV

1 V 21 mV 24 mV 27 mV 34 mV

Horizontal

Main sweep ti m e scale range 5 ps/div to 20 s/div real time, 5 ps/div to 500 ns/div equivalent time

Main sweep ti me delay range -200 s to 200 s real time, -25 µs to 200 s equi valent time

Delayed sweep time scale range 1 ps/div to current ma in time scale s etting

Channel deskew range ±25 µs, 100 fs resolution

Time scale accuracy

Delta-time measurement accuracy

≥ 256 Averages, rms

≥ 256 Averages, peak

Averaging disabled, rms

Averaging disabled, peak

Jitter measurement floor

Time interval error:

Period jitter:

N-cycle, cycle-cycle jitter:

3

±1 ppm pk

6,7

DSO81304A: 45 fs DSO81204A: 35 fs DSO81004A: 35 fs DSO80804A: 55 fs

500 fs peak

DSO81304A: 0.9 ps DSO81204A: 0.8 ps DSO81004A: 0.8 ps DSO80804A: 0.9 ps

5 ps peak

6

DSO81304A: 0.7 DSO81204A: 0.65 DSO81004A: 0.65 DSO80804A: 0.7 (ps rms)

DSO81304A: 0.9 DSO81204A: 0.8 DSO81004A: 0.8 DSO80804A: 0.9 (ps rms)

DSO81304A: 1.4 DSO81204A: 1.3 DSO81004A: 1.3 DSO80804A: 1.4 (ps rms)

1–6

Page 15

Acquisition

Real time sample rate per channel 40 GSa/s (2 channels simultaneously)

20 GSa/s (4 channels simul taneously)

Memory depth per channel

Standard

524,288 (2 channels) 262,144 (4 channels)

Chapter 1: General Information

Characteristics

Option 001

2,050,000 (2 channels) 1,025,000 (4 channels)

65,600,000 at 4 GSa/s (2 channels) 32,800,000 ≤ 2 GSa/s (4 channels)

Sampling modes

Real time

Real time with averaging

Real time with peak detect

Real time with hi resolution

Successive single-shot acquisitions

Selectable from 2 to 4096

2 GSa/s peak detect (4 channe ls), 4 GSa/s peak detect ( 2 channe ls)

Real time boxcar averaging reduces random noise and increases resolution.

Full bandwidth on all 4 ch annels, 262, 144 sample points maximum m em ory. Acquire s

Equivalent time

channels 1 and 3 simultaneously, fol lowed by channels 2 and 4 simultaneously on

subseque nt triggers at 40 GSa/s each. High sample rate del ivers excel lent signal

fidelity and throughput.

Filters

Sin(x)/x Interpolat ion On/off selectable FIR digital filter. Digital signal proce ssing adds points between

acquired dat a poi nts to enh anc e measu reme nt ac curacy and wavef or m displa y qua lity .

Trigger

Sensitivity

1

Interna l Lo w

Interna l Hi gh

Auxiliary

1

1

2.0 div p-p 0 to 5 GHz

0.3 div p-p 0 to 4 GHz, 1.0 div p-p 4 to 7.5 GHz

DC to 1 GHz: 200 mV p-p into 50 Ω

Level range

Internal

Auxiliary

± 4 div from center screen or ± 4 Volts, whichever is smallest

± 5 V, also limit input signal to ± 5 V

Sweep modes Auto, triggered, single

Trigge r jit te r

6,8

500 fs rms

Trigger holdoff range 100 ns to 32 0 m s

Trigger acti ons Specify an act ion to occur and the frequency of the action when a trigger condition

occurs. Actions include e-mail on trigger and QuickMeas+.

Trig ge r m o des

Edge

Triggers on a specified slo pe(rising , falling, or alternati ng between risi ng and fallin g) and

voltage level on any chan nel or auxiliary trigger.

Glitch

Triggers on glitches narrower than the other pulses in your waveform by specifying a

width less than your narrowest pulse and a polarity .

Triggers on glitches a s narrow as 500 ps. Glitch ra nge settings : < 1.5 ns to < 160 ms.

Triggers on the line voltage powering the oscilloscope.

Line

Pattern

Triggers wh en a specif ied logical comb ination of the channel s is entered, ex ited, prese nt

for a speci fied per io d of t ime o r is wi thi n a s pecif ie d time ran ge. Each ch anne l c an h ave

a value of High (H), Low (L) or Don't care (X). Triggers o n patterns as nar row as 500 ps.

Pattern trigger clocked by the rising or falling edge of one channel .

Logic type: AND or NAND.

State

The trigg er is qual ifi ed b y a n e dge. Af t er a s pec ifi ed t im e dela y b et ween 30 ns to 16 0 ms ,

a rising or falling edge on any one select ed input will generate the trigger.

Delay by time

The trigg er is q ual ifi ed by an edg e. After a sp ecifi ed dela y b etwe en 1 to 16, 000, 00 0 r isi ng

or falli ng edges, another rising or falling edge on any one selected input will generate

the trigger.

Delay by events

1–7

Page 16

Chapter 1: General Information

Characteristics

Violation triggers

Pulse width

Transition

Measurements and math

Waveform measurements

Voltage

Time

Frequency Dom ain

Trigger on a pulse that is wider or nar rower than the other pulses in your wav e form by

specifying a pulse width and a polarity. Triggers on pulse widths as narrow as 500 ps.

Pulse width range settings: 1.5 ns to 160 ms.

Trigger on pulse r ising or falling edges tha t do not cr oss two voltage lev els in > o r < the

amount of time specified.

Peak to peak, minimum, maximum, average, RM S, amplitude , base, top, overshoot,

preshoot, upper, middle, lower, area.

Period, frequency, positive widt h, negative width, duty cyc le, delta time, rise time , fall

time, Tmin, Tmax, channel-to-channel phase.

FFT frequency, FFT magnitude, FFT delt a frequency, FFT delta magnit ude, FFT phase.

Statisti cs Displays the mean, standard deviation, minimum, m aximum and number of

measurements value for the displayed automatic measurements.

Histograms Vertical ( for tim ing a nd jit te r me asureme nt s) or ho ri zo ntal (noi se and amp lit ude change )

modes, regions are defined using waveform markers. Measurements included: mean,

standard de vi ation , p eak -to- peak value , med ia n, min , max , tot al hits , peak (ar ea of mo st

hits), and mean ± 1, 2, and 3 sigma.

Eye-diagram measurements Eye-diagram measurements include eye height, eye width, eye jitter, crossing

percent age, Q factor, and duty-cycl e distortion.

Jitter measurements

(E2681A EZJIT software package)

Cycle-cycle jitter, N-cycle jitter, cycle-cycle + width, cycle-cycle - width, cycle-cycle

duty cycle, data rate , unit inter val, time i nterval e rror data, time interv al error clo ck, setup

time, hol d t ime, p has e, per io d, fr equ ency, + wi dth, - wi dth, dut y cycl e, rise tim e, f al l ti me.

Mask testi ng Allows pa ss/fail testing to user-defined or Agilent-supplied waveform templates.

AutoMask l ets you create a mask template from a captured waveform and defi ne a

tolerance range in tim e/voltage or percent age. Test modes include te st forever, test to

specified time or event limit, and stop on failur e. Communications Mask Test Kit option

provides a set of ITU-T G.703, ANSI T1.102, and IEEE 802.3 industry-standard masks for

compliance testing.

Waveform math Four func tions, select fro m add, a verage , dif ferenti ate, d ivide, FFT magnitude , FF T pha se,

integrate, invert, magnify, min, max, multiply, subtract, versus, common mode,

smoothing, high pass filter, low pass filter.

FFT

Frequen cy range

Frequen cy resolution

Best resolution at maximum sample

rate

Frequency accuracy

Signal-to-noise ratio

4

DC to 20 GHz (at 40 GSa/s) or 10 GHz (at 20 GSa/ s).

Sample rate/memory depth = Resolution.

20 kHz.

(1/2 frequency resol u tion)+(1 x 10

5

60 dB to 100 dB depending on sett ings.

Hanning, fl attop, rectangular.

-6

)(signal frequency).

Window modes

Measurement modes

Automatic measurements

Measure menu access to all measurements, five measurem ents can be displ ayed

simultaneously.

QuickMeas

Front-panel button activates five pre-selec ted or five user-defined automatic

measurements.

Drag-and-drop measurement

toolbar

Measurement toolbar with common measurement icons tha t can be dragged and

dropped on to the displa yed w aveforms.

Marker modes Manual markers, track waveform data, track measurements.

Display

1–8

Page 17

Display

Display

Resolution

Annotation

Grids

Waveform style

Computer sy stem and peripherals, I/O por ts

8.4 inch diagonal color TFT-LCD.

640 pix els horizontally x 480 pi xe ls verti c al l y .

Up to 12 label s, wit h up to 100 charact er s each, can be i nsert ed i nto th e wavef or m are a.

Can display 1, 2 or 4 wavefor m grids.

Connecte d dots, dots, persistence (minimum, va riable, infinite), color-graded infinit e

persistence.

Chapter 1: General Information

Characteristics

Computer sy stem and peripherals

Oper at i n g sy stem

CPU

PC system memory

Drives

Peripherals

File types

Waveforms

Images

I/O por ts

LAN

GPIB

RS-2 3 2 (serial)

Parallel

PS/2

USB

Video output

Dual-monitor video output

Auxiliary output

Trigger output

Time base r e ference output

Time base reference input

Windows

Intel

512 MB.

®

XP Pro .

®

Pentium® III 1 GHz microprocessor.

≥20 GB int ern al ha rd dr ive, CD- RW dr ive on r ea r pane l, s ta ndar d 3. 5 i nc h 1.4 4 MB flop py

drive.

Logitech optical USB mouse and compact keyboard suppli ed. All Infini ium models

support any Windows-compatible input device with a serial, PS/2 or USB interface.

Compressed internal format, bin ary data, comma and tab separat ed X and Y pairs or

voltage values.

BMP, PCX, TIFF, GIF or JPEG.

RJ-45 connector, supports 10Base- T and 100Base-T. Enables Web-enabled re mote

control, e-mail on trigger or demand, data/file transfers and network printing.

IEEE 488.2, fully programmable.

COM1, printer and pointing device support.

Centronics printer port.

2 ports. Supports PS/2 pointing and input devices.

2 ports. Al lows conne ction of USB perip herals l ike stor age device s and poi nting de vices

while the oscilloscope is on.

15 pin VGA, ful l color outpu t of scope wavefor m display.

15 pin XGA, ful l color output for using thi rd-party applications.

DC (±2.4 V); square wave (~715 Hz and 456 MHz);

trigger output (255 mV p-p into 50

5 V 50

Ω back-terminated.

10 MHz filtered sine wave with all harmonics ≤ -40 dBc. Amplitude into

50 Ω is 800 mV p-p to 1.26 V p-p (4 dBm ±2 dB) if derived fr om internal reference . Tracks

external reference i nput input ampl itude ±1 dB if applied and sele ceted.

Must be 10 MHz, input Z

dBm).

O

Ω).

= 50 Ω. Minimum 360 mV p- p (-5 d Bm), ma ximum 2.0 V p- p (+10

1–9

Page 18

Chapter 1: General Information

Characteristics

General cha racterist ics

Temperatur e Operating: 5° C to +35° C.

Non-operating: -40° C to +70° C.

Humidity Operating: Up to 95% rela tive humidity (non-condensing) at +35°C.

Non-operating: Up to 90% relative humidity at +65°C.

Altitude Operating: Up to 4,600 meters (15, 000 feet).

Non-operating: Up to 15,300 meters (50,000 feet).

Vibration Operating: Random vibration 5-500 Hz, 10 minute s per axis, 0.3 g(rms).

Non-operating: Random vi bration 5- 500 Hz, 10 minutes per axis, 2.41 g(rms);

resonant search 5-500 Hz, swept sine, 1 octave/minute sweep rat e, (0.75g),

5 minute resonant dwell at 4 resonances per axis.

Power 100-240 VAC at 50 or 60 Hz; max input power 550 Watts.

Weigh t Net: 13 kg (2 8.5 lbs.).

Shippi n g : 16 kg (3 5.2 lbs.).

Dimensions (excluding handle) Height: 216 mm (8.5 in).

Width: 437 mm (17.19 in).

Depth: 44 0 m m (17.34 in).

Safety Meets IEC 61010-1 +A2, CSA certified to C2 2.2 No.1010.1, self-certified to UL 3111.

1. Full scale is defined as 8 verti cal divisions. Magnification is used below 5 mV/div. Below 5 mV full

scale is defined as 40 mV. The major scale settings are 5 mV, 10 mV, 20 mV,

50 mV, 100 mV, 200 mV, 500 mV and 1 V.

2. Vertical resolution for 8 bits = 0. 4% of full scale, fo r 12 bits = 0.024% of full s cale.

3. Within one year of previous calibration.

4. FFT amplitude readings are affe cted by scope probe and oscilloscope limitati ons and input amplifier

roll-off (e.g. -3 dB roll-off at specified bandwidth scope/probe.

5. The FFT signal to noi se rati o var ies with the v olt s/di v setti ng, th e memory dept h, and the us e of time or

frequency averaging.

6. Test signal amplitude ≥5 divisions peak-to-peak, test signal signal rise time

≤ 2 times scope rise ti me,

vertical scale ≥20 mV/div, sample rate = 40 GSa/s; sin(x )/x interpolati on enabled, measurement

threshold = fixed voltage at 50% level.

7. Between two edges on a single channel . Rms value refers to the standard deviation of 256

consecutive measurements performed using an i ndividual instrument.

8. Internal trigger. Trigger level contained within full scale display range of trigger channel.

9. 13 GHz DSP enhanced bandwidth not applicable at 5 mV/div.

CAT I and CAT II Definitions

Installation category (overvoltage category) I: Signal level, special equipment or parts of

equipment, telecommunication, electronic, etc., with smaller transient overvoltages than

installation category (overvoltage category) II.

Installation category (overvoltage category) II: Local level, appliances, portable equipment etc.,

with smaller transient overvoltages than installation category (overvoltage category) III.

1–10

Page 19

Dimensions

The following pictures shows the dimensions of the frame.

Chapter 1: General Information

Dimensions

1–11

Page 20

Chapter 1: General Information

Recommended test equipment

Recommended test equipment

The following table is a list of the test equipment required to test performance, calibrate and

adjust, and troubleshoot this oscilloscope. The table indicates the critical specification of the test

equipment and for which procedure the equipment is necessary. Equipment other than the

recommended model may be used if it satisfies the critical specification listed in the table.

Recommended Test Equipment

Equipment Required Critical Specifications Recommended Model Use

Digital Multimeter DC voltage me asureme nt accuracy bet ter than

Microwave CW

Generator

Power Splitter 2 Resistor Power Splitte r

Power Meter Agilent E-series power sensor compatibility Agilent E4418B or E4419B P

Power Sensor Maximum Frequency

Microwave Cable

Assembly

Cable Assembly

(2 required)

Adapter BNC Tee (m)(f)(f) Agilent 1250 -0781 P

Adapter BNC (f) to dual banana Agilent 1251-2277 P

Adapter 3.5 mm (f) to Precision BNC Agilent 54855-67604 P

Shorting Cap BNC (m) Agilent 1250-0929 A

Cable Assembly

(Cal Cable for

DSO80804A,

DSO81004A, and

DSO81204A)

Cable Assembly

(Cal Cable for

DSO81304A)

10 MHz Signal Source Frequency accuracy better than 0.4 ppm Agilent 53131A with

* Requires time base calibration once every 6 months

** Require s link to GPS

±0.1% of reading

Maximum Frequency

Power range: -20 dBm to +16 dBm into 50

Output resistance = 50 Ω

10 MHz Refer ence Signal Out put

Max Frequency

≥ 14 GHz

Ω

≥ 18 GHz

≥ 14 GHz

Power range: -24 dBm to +16 dBm

Ω characteristic impedance

50

3.5 mm (m) or SMA (m) connectors

Max Frequency

50

Ω characteristic impedance

BNC (m) connectors

Ω characteristic impedance

50

BNC (m) connectors

<= 12 Inch Length

NO Substitute Agilent 54855-61620 A

≥ 18 GHz

Agilent 34401 A or Agilent

3458A

Agilent E8247C with

Opt 520 or Agi lent 82712B

with Opt 1E5 or Agilent

8665B with Opt 004

Agilen t 11667B P

Agilent E4413A P

Agilent 8120-4948 or

Agilen t 11500E or

Gore EKD01D010480

Agilent 8120-1840 P

Agilent 8120-1838

or Agilent 10502A

Opt. 010 *

or Agilent 5071A or

Symmetricom 58503B **

P

P

P

A

A

Alternate Power Splitter/Power Sensor Equipment - List 1

Equipment Required Critical Specifications Recommended Model Use

Power Splitter 2 Resistor Power Splitte r

Max Frequency

Power Sensor Maximum Frequency

Power range: -24 dBm to +16 dBm

Adapters 3.5 mm (f) to Precision BNC

Type N (m) to 3.5 mm (f)

Type N (m) to 3.5 mm (m)

≥ 18 GHz

≥ 14 GHz

Agilen t 11667A P

Agilent E4412A P

Agilent 54855-67604

Agilent 1250-1744

Agilent 1250-1743

1–12

P

Page 21

Chapter 1: General Information

Recommended test equipment

Alternate Power Splitter/Power Sensor Equipment - List 2

Equipment Required Critical Specifications Recommended Model Use

Power Splitter 2 Resistor Power Splitte r

Max Frequency

Power Sensor Maximum Frequency

Power range: -24 dBm to +16 dBm

Adapters 3.5 mm (f) to Precision BNC

3.5 mm (f) to 3. 5 m m (m )

Type N (m) to 3.5 mm (m)

≥ 18 GHz

≥ 14 GHz

Agilen t 11667A P

Agilent E4412A P

Agilent 54855-67604

Agilent 1250-1748

Agilent 1250-1750

P

1–13

Page 22

Chapter 1: General Information

Recommended test equipment

1–14

Page 23

2

To inspect package contents 2-3

To inspect options and accessories 2-5

To connect power 2-7

To connect the mouse, the keyboard, a LAN cable, a printer, and a GPIB cable 2-10

To connect SMA Cables 2-12

To tilt the oscilloscope upward for easier viewing 2-13

To turn on the oscilloscope 2-14

To turn off the oscilloscope 2-15

To verify basic oscilloscope operation 2-16

Installing application programs on Infiniium 2-17

Changing Windows System Settings 2-18

To clean the oscilloscope 2-19

Setting Up the Oscilloscope

Page 24

Setting Up the Oscilloscope

This chapter shows you how to set up your Infiniium oscilloscope, connect power and

accessories, and verify general operation.

2–2

Page 25

Chapter 2: Setting Up the Oscilloscope

To inspect package contents

To inspect package contents

❏ Inspect the shipping container for damage.

Keep a damaged shipping container or cushioning material until you have inspected the contents

of the shipment for completeness and have checked the oscilloscope mechanically and

electrically.

❏ Verify that you received the following items in the Infiniium Oscilloscope packaging.

• Infiniium Oscilloscope

•Mouse

• Calibration Cable

• Precision 3.5 mm Adaptors

• Accessory Pouch

• Front Panel Cover

•Keyboard

•Power cord

• Probe De-skew and Performance Verification Kit

• User’s Quick Start Guide

See Figure 2-1. (See table 2-4 for the power cord.) If anything is missing, contact your nearest

Agilent Technologies Sales Office. If the shipment was damaged, contact the carrier, then contact

the nearest Agilent Technologies Sales Office.

❏ Inspect the oscilloscope.

• If there is mechanical damage or a defect, or if the oscilloscope does not operate properly or

does not pass performance tests, notify your Agilent Technologies Sales Office.

• If the shipping container is damaged, or the cushioning materials show signs of stress, notify

the carrier and your Agilent Technologies Sales Office. Keep the shipping materials for the

carrier’s inspection. The Agilent Technologies Sales Office will arrange for repair or

replacement at Agilent’s option without waiting for claim settlement.

2–3

Page 26

Figure 2-1

Infiniium Oscilloscope

with Accessory Pouch

Calibrat ion Cable

Chapter 2: Setting Up the Oscilloscope

To inspect package contents

Probe Deskew and

Performance Verification Kit

Precision 3.5 mm Adaptors (2)

Keyboard

Mouse

User’s Quick Start Guide

Package Cont ents for the Infiniium Oscilloscopes

2–4

Page 27

Chapter 2: Setting Up the Oscilloscope

To inspect options and accessor ies

To inspect options and accessories

❏ Verify that you received the options and accessories you ordered and that none were

damaged.

If anything is missing, contact your nearest Agilent Technologies Sales Office. If the shipment

was damaged, or the cushioning materials show signs of stress, contact the carrier and your

Agilent Technologies Sales Office.

Some accessories that will enhance your work with the oscilloscopes are listed in table 2 -1.

Table 2 -1

Accessories fo r the Infiniium Oscilloscopes

Agilen t Mo de l

Number

54855-6 7604 18 GHz BNC-compatible to APC 3.5 mm adapt or

1250-2427 PC Board Mini-Probe Socket (h orizontal mo unt)

1250-2428 PC Board Mini-Probe Socket (v ertical moun t)

1250-1454 BNC to Miniature Probe Adapter

10240B BNC Blocking Capacitor

11094B 75

10024A 16-pin IC clip

10211A 24-pin IC clip

10833A GPIB cable, 1 m

10833B GPIB cable, 2 m

10833C GPIB cable, 4 m

10833D GPIB cable, 0.5 m

1131A 3.5 GHz InfiniiMax Active Probe

1132A 5 GHz InfiniiMax Active Probe

1134A 7 GHz InfiniiMax Active Probe

1156A 1.5 GHz Active Probe

1157A 2.5 GHz Active Probe

1158A 4 GHz Active Probe

1168A 10 GHz Active Probe

1169A 12 GHz Active Probe

1184A Testmobi le with keyboar d and mouse tray and drawer for accessories

34398A

34399A

54006A 6 GHz probe, 10:1 (500

C2950A Parallel printer cable, 2 m

C2951A Parallel printer cable, 3 m

E2609B Rackmount Kit

E2621A 75

E2622A 100/110/120

E2646A SQiDD Fixture for USB option

E2654A EZ-Probe

E2655A Additional probe deskew and perform ance verification kit

E2680A 1 MB Memory upgrade

Description

Ω Feedthrough Termination

RS-232-C printer cable

RS-232-C Adapter kit

Ω) or 20:1 (1 kΩ), .25 pf

Ω terminator

Ω differential terminator

®

Positioner

2–5

Page 28

Chapter 2: Setting Up the Oscilloscope

To inspect options and accessories

Agilen t Mo de l

Number

E2681A EZJIT Jit ter Analysis Software

E2682A VoiceControl Retrofit Kit

E2683A USB Test Option

E2685A Telecomm unications Mask Test Templ ate Kit

E2688A Serial Data Analysis Software Option

E5850A Time-correlation fi xture, integrates Infiniium oscilloscope and 16700 logic analyzer

N5401A EZJIT Jitter Analysis Software

Description

2–6

Page 29

Figure 2-2

Chapter 2: Setting Up the Oscilloscope

To connect power

To connect power

1 Position the oscilloscope where it will have sufficient clearance for airflow around the

top, back, and sides.

2 Position the oscilloscope so that it is not difficult to unplug the power cord.

Minimum 0 mm

Minimum 22 mm

Minimum 85 mm

both sides

Airflow requirements 250 cfm

Positionin g the Infiniium Oscilloscope w ith Sufficient Clearance

Minimum 39 mm

3 Connect the power cord to the rear of the oscilloscope, then to a suitable ac voltage

source (100 to 240 VAC ±10%, 50 and 60 Hz all models)

Maximum power dissipation: 550 W.

2–7

Page 30

Figure 2-3

Chapter 2: Setting Up the Oscilloscope

To connect power

Infiniiu m Os cilloscope Po we r Cord Connection

The oscilloscope power supply automatically adjusts for line input voltages in the range 100 to

240 VAC. Therefore, you do not need to adjust an input line voltage setting. The line cord

provided is matched by Agilent Technologies to the country of origin of the order.

4

Ensure that you have the correct line cord. See table 2-4.

2–8

Page 31

Table 2-4

Power Cords

Chapter 2: Setting Up the Oscilloscope

To connect power

Plug Type Cable Part

No.

250V 8120-1351

8120-1703

250V 8120-1369

8120-0696

250V 8120-1689

8120-1692

8120-2857

125V 8120-1378

8120-1521

8120-1992

250V 8120-2104

8120-2296

220V 8120-2956

8120-2957

250V 8120-4211

8120-4600

Plug Description Length

Straight *BS1363A

90°

Straight *NZSS198/ASC

90°

Straight *CEE7-Y11

90°

Straight (Shielded)

Straight *N EMA5-15P

90°

Straight (Medical) UL544

Straight *SEV1011

1959-24507

Type 12 90°

Straight *DHCK107

90°

Straight SABS164

90°

(in/cm)

90/228

90/228

79/200

87/221

79/200

79/200

79/200

90/228

90/228

96/244

79/200

79/200

79/200

79/200

79/200

79/200

Color Country

Gray

Mint Gray

Gray

Mint Gray

Mint Gray

Mint Gray

Coco Brown

Jade Gray

Jade Gray

Black

Mint Gray

Mint Gray

Mint Gray

Mint Gray

Jade Gray Republic of South

United Kingdom,

Cyprus, Nigeria,

Zimbabwe, Singap ore

Australia, New

Zealand

East and West

Europe, S audi A rabia,

So. Africa, India

(unpolarized in many

nations)

United Stat es,

Canada, Mexi co,

Philippines, Taiwan

Switzerland

Denmark

Africa

India

100V 8120-4753

8120-4754

* Part number shown for plug is the industry identifier for the plug only. Number shown for cable is the Agilent part number

for the complete cable including the plug.

Straight MITI

90°

90/230

90/230

Dark Gray Japan

2–9

Page 32

Chapter 2: Setting Up the Oscilloscope

To connect the mouse, the keyboard, a LAN cable, a printer, and a GPIB cable

To connect the mouse, the keyboard, a LAN cable, a printer, and a

GPIB cable

See Figure 2-5 for the location of the connectors.

Mouse. Plug the mouse into the matching connector on the back panel of the oscilloscope.

While you can operate many oscill oscope fun ctions us ing on ly the f ront-pane l keys and

knobs, you wil l need the mo use to a ccess advanc ed oscil loscope fun ctions th rough the

graphical interface, or to find out mo re about the oscilloscope through the buil t-in

information syst em.

The connectors are labeled 1 and 5.

Keyboard. Plug the keyboard cable into the connector labeled 2 on the back panel of the oscilloscope.

A keyboard cannot be plugged into the oscilloscope after the Windows operating

system has started booting.

LAN Cable. Connect your LAN cable to the RJ-45 connector labeled 3 on the back panel of the oscilloscope.

After you have co nnect ed to th e L AN ca rd, y ou must s et up t he networ k. Befor e y ou try

to setup your network, you should exit the oscilloscope application. I f you do not know

how to setup a network in Windows XP, see your network administrator or use the

Windows XP on-line help.

Printer Cable. If you have a parallel (Centronics) printer, you will need a parallel printer cable, such as an

C2950A (2 m) or C2951A (3 m) cable. Connect cable into the connector labeled 4.

If you have a serial printer, you will need a 9-pin to 25-pin serial printer cable, such as an 34398A

cable, plus the 34399A adapter kit. Some printers may require other cable configurations, but

the oscilloscope has a 9-pin serial connector. Connect cable into the connector labeled 7.

GPIB Cable. Attach the GPIB connector to the GPIB interface card connector labeled 6 on the rear of the

oscilloscope.

2–10

Page 33

Figure 2-5

Chapter 2: Setting Up the Oscilloscope

To connect the mouse, the keyboard, a LAN cable, a printer, and a GPIB cable

1

2

Back Panel

3

5

7

4

6

2–11

Page 34

Figure 2-6

Thumb screw

Chapter 2: Setting Up the Oscilloscope

To connect SMA Cables

To connect SMA Cables

You can connect an SMA cable to the Infiniium oscilloscope using precision 3.5 mm to BNC

compatible adaptors.

1

Attach the two precision 3.5 mm to BNC compatible adaptors to the ends of an SMA

cable.

2 Push the precision 3.5 mm to BNC compatible adaptors onto the oscilloscope BNC

connectors.

3 Tighten the thumbscrews until they are snug.

SMA cable

Connecting SMA to BNC Adaptors

Precision 3 .5 mm to

BNC co m p atible

adaptor

2–12

Page 35

Figure 2-7

Chapter 2: Setting Up the Oscilloscope

To tilt the oscilloscope upward for eas ier viewing

To tilt the oscilloscope upward for easier viewing

1 Lift up the front of the oscilloscope, grasp the wire bail near the center, and pull it down

and forward until it latches into place.

Latching the Oscilloscope Front Feet

2–13

Page 36

Figure 2-8

Chapter 2: Setting Up the Oscilloscope

To turn on the oscilloscope

To turn on the oscilloscope

The first time that you turn on the oscilloscope, you may need to have a keyboard

and mouse connected. The keyb oard an d mous e are ne eded to ent er the Product

Key from the Microsoft Certificate of Authenticity for Windows XP if prompted to

do so. This label is l ocated on the rear pane l of the Infiniium.

1 Depress the power switch in the lower left-hand corner of the oscilloscope front panel.

Turning on the Oscilloscope

After a short initialization period, the oscilloscope display appears. The oscilloscope is ready to

use.

2

Hook up all cables and accessories before applying power. You can connect and

disconnect probes while the oscilloscope is turned on.

2–14

Page 37

Chapter 2: Setting Up the Oscilloscope

To turn off the oscilloscope

To turn off the oscilloscope

1 Momentarily depress the power switch at the lower left-hand corner of

the oscilloscope front panel. The oscilloscope will go through a normal

Windows shutdown process.

2–15

Page 38

Figure 2-9

Chapter 2: Setting Up the Oscilloscope

To verify basic oscilloscope operation

To verify basic oscilloscope operation

1 Connect an oscilloscope probe to channel 1.

2 Attach the probe to the calibration output on the front panel of the oscilloscope.

Use a probe grabber tip so you do not need to hold the probe. The calibration output is marked

with a square wave symbol.

Calibration

Output

Verifying Basic Oscilloscope Operation

3 Press the Default Setup key on the front panel.

The display will pause momentarily while the oscilloscope is configured to its default settings.

Press the Autoscale key on the front panel.

4

The display will pause momentarily while the oscilloscope adjusts the sweep speed and vertical

scale. You should then see a square wave with peak-to-peak amplitude of approximately 5

divisions and a period of almost 7 divisions. If you do not see the waveform, ensure your power

source is adequate, the oscilloscope is properly powered-on, and the probe is connected securely

to the front-panel channel input BNC and to the probe calibration output.

5

Move the mouse around the mouse surface and verify that the on screen mouse pointer

follows the mouse movement.

2–16

Page 39

Chapter 2: Setting Up the Oscilloscope

Installing application programs on Infiniium

Installing application programs on Infiniium

Infiniium is an open Windows system. This allows you to install your own application software.

Agilent has verified that the following applications are compatible with the Infiniium oscilloscope

application.

• Microsoft Office 2000

•MathWorks MATLAB

• Mathsoft MathCad 2001i

• McAfee VirusScan

• Symantec Norton AntiVirus

Before install ing any software, you should exit the oscill oscope application.

If you install an application other than those which Agilent has tested, it is possible that it could

break the oscilloscope application. This would require you to reinstall the oscilloscope

application.

2–17

Page 40

Chapter 2: Setting Up the Oscilloscope

Changing Windows System Settings

Changing Windows System Settings

Before changing any Windows System settin gs outside of the oscilloscope

application you should Exit the oscilloscope appli cation.

There are several Windows System settings that can be changed to suit your own personal

preferences. However, there are some system settings that you should avoid changing because

it will interfere with the proper operation of the oscilloscope.

• Do not change the Power Options.

• Do not change the System Properties Hardware Tab settings.

• Do not change the System Properties Advanced Tab settings.

• Do not change the Regional and Language Options Advanced Tab settings.

•Do not remove Fonts.

• Display Settings

• Do not change or turn off the default screen saver. The screen saver turns off the display’s

backlights extending their life.

• Do not change the screen resolution from 640 by 480 pixels or the color quality from High (24

bit).

• Do not use the Windows XP Theme.

• Do not change “Windows and buttons” from the “Windows Classic Style”.

• Do not change the Font size to Extra Large.

• Do not use a Menu font size greater than 12 points.

• Do not modify “1. Digital Flat Panel (640x480) on Chips and Technologies (Asiliant) 65550”.

• Do not set “Intel (r) 82815 Graphics Controller” to “Use this device as the primary monitor”.

• Do not use the Administrative Tools to enable or disable Internet Information Services

(Web Server). Use the Infiniium Web Control dialog box to enable or disable the Web

Server.

• Do not delete or modify the InfiniiumAdmin user account.

2–18

Page 41

Chapter 2: Setting Up the Oscilloscope

To clean the oscilloscope

To clean the oscilloscope

• Clean the oscilloscope with a soft cloth dampened with a mild soap and water solution.

CAUTION Do not use too much liquid in cleaning the oscilloscope. Water can enter the Infiniium front

panel, damaging sensitive electronic components.

2–19

Page 42

2–20

Page 43

3

Performance Test Interval page 3-2

Performance Test Record page 3-2

Test Order page 3-2

Test Equipment page 3-2

Before Performing Performance Verification Testing page 3-3

Vertical Performance Verification page 3-4

Offset Accuracy Test page 3-5

DC Gain Accuracy Test page 3-12

Analog Bandwidth - Maximum Frequency Check page 3-17

Performance Test Record page 3-24

Testing Performance

Page 44

Testing Performance

This section documents performance test procedures. Performance verification for the

products covered by this manual consists of three main steps:

• Performing the internal product self-tests to ensure that the measurement system is

functioning properly

• Calibrating the product

• Testing the product to ensure that it is performing to specification

Performance Test Interval

The procedures in this section may be performed for incoming inspection and should be

performed periodically to verify that the oscilloscope is operating within specification. The

recommended test interval is once per year or after 2000 hours of operation. Performance

should also be tested after repairs or major upgrades.

Performance Test Record

A test record form is provided at the end of this section. This record lists performance tests,

test limits and provides space to record test results.

Test Order

The tests in this section may be performed in any order desired. However, it is recommended

to conduct the tests in the order presented in this manual as this represents an incremental

approach to performance verification. This may be useful if you are attempting to

troubleshoot a suspected problem.

Test Equipment

Lists of equipment needed to conduct each test are provided for each test procedure. The

procedures are written to minimize the number and types of oscilloscopes and accessories

required. The oscilloscopes in these lists are ones that are currently available for sale by

Agilent at the time of writing this document. In some cases, the test procedures use features

specific to the oscilloscopes in the recommended equipment list. However, with some

modification to the test procedures, oscilloscopes, cables and accessories that satisfy the

critical specifications in these lists may be substituted for the recommended models with

some modification to the test procedures.

Contact Agilent Technologies for more information about the Agilent products in these lists.

3–2

Page 45

Chapter 3: Testing Performance

Before Performing Pe rformance Verification Testing

Before Performing Performance Verification Testing

Let the oscilloscope warm up before testing

The oscilloscope under test must be warmed up (wi th the oscilloscope application running) for at least

30 minutes prior to the start of any performance test.

Equipment Required

Description Critical Specifications Recommended

Digital Multimeter DC voltage measur ement a ccurac y better than ±0. 1% of r eading Agilent 34401A

Cable Assembly 50Ω characteristi c impedance Agilent 54855-6162 0

Cable Assemby RS-232 (f)(f) Agilent 34398A

Adapter BNC Barrel (f) (f) Agilent 1250-0080

Adapter BNC shorting cap Agilent 1250-0929

Adapter Precision BNC (2) Agilent 54855-6760 4

Adapter BNC (f) to dual banana Agilent 1251-2277

1

Perform self tests

Model/

Part Numbers

Exit the oscilloscope application. From a command prompt run the oscilloscope software using

the following syntax:

c:\scope\bin\agscope.exe -servicecal

While the oscilloscope is warming up, run the self-test to ensure that the hardware is functioning

properly. To run the self-test:

a Pull down the Utilities menu and select Self Test.

b Select Scope Self Test from the Self Test list.

c Click on Start Self Test to start the self test procedure.

If any of the self-tests fail, ensure that the failure is diagnosed and repaired before

calibrating and testing performance.

2

Performance calibration.

After the warm up period, calibrate the oscilloscope.

a Connect the RS-232 cable to the Digital Multimeter RS-232 port and to the RS-232 port

on the oscilloscope.

b Set Digital Multimeter as follows:

Interface: RS-232

Baud Rate: 9600 Baud

Parity: None: 8 bits

Language: SCPI

c Pull down the Utilities menu and select Calibration.

d Uncheck to Cal Memory Protect box to allow calibration.

e Click on Start to start the calibration procedure.

Follow the on-screen instructions as calibration proceeds.

3–3

Page 46

Vertical Performance Verification

This section contains the following vertical performance verification:

• Offset Accuracy Test

• DC Gain Accuracy Test

• Analog Bandwidth Test

3–4

Page 47

Offset Accuracy Test

CAUTION Ensure that the input voltage to the oscilloscope never exceeds ±5 V.

Specifications

Offset Accuracy ≤3.5 V: ±(2% of channel offset + 1% of full scale + 1 mV)

Full scale is defined as 8 vertical divisions. Magnification is used below 5 mV/div. Below 5 mV

full scale is defined as 40 mV. The major scale settings are 5 mV, 10 mV, 20 mV,

50 mV, 100 mV, 200 mV, 500 mV and 1 V.

Equipment Required

Description Critical Specifications Recommended

Chapter 3: Testing Performance

Offset Accuracy Test

Model/

Part Numbers

Zero Error Test 1

Digital Multimeter DC voltage measur ement a ccurac y better than ±0. 1% of r eading Agilent 34401A or

Cable Assembly

(2 required)

Adapter BNC Tee (m)(f)(f) Agilent 1250-0781

Adapter BNC (f) to dual banana Agilent 1251-2277

50Ω character istic impedance, BNC (m) connect ors Agil ent 8120-1840

Agilent 3458A

The offset accuracy specification has two terms ±(offset gain + zero error) The offset gain

specification is ±2% of channel offset and the zero error specification is ±1% of full scale. The

offset accuracy test procedure tests each of these terms individually.

Procedure

Disconnect all cables from the scope channel inputs.

2 Press Default Setup, then configure the scope as follows:

a Pull down the Setup menu and select Acquisition.

3–5

Page 48

Chapter 3: Testing Performance

Offset Accuracy Test

b When the Acquisition Setup window is displayed, enable averaging and set the # of

averages to 256 as shown below.

3

V avg

measurement

Configure the scope to measure Average voltage on channel 1 as follows:

a Change the vertical sensitivity of channel 1 to 5 mV/div.

b Click the V avg measurement on the left side of the screen.

3–6

Page 49

Chapter 3: Testing Performance

Offset Accuracy Test

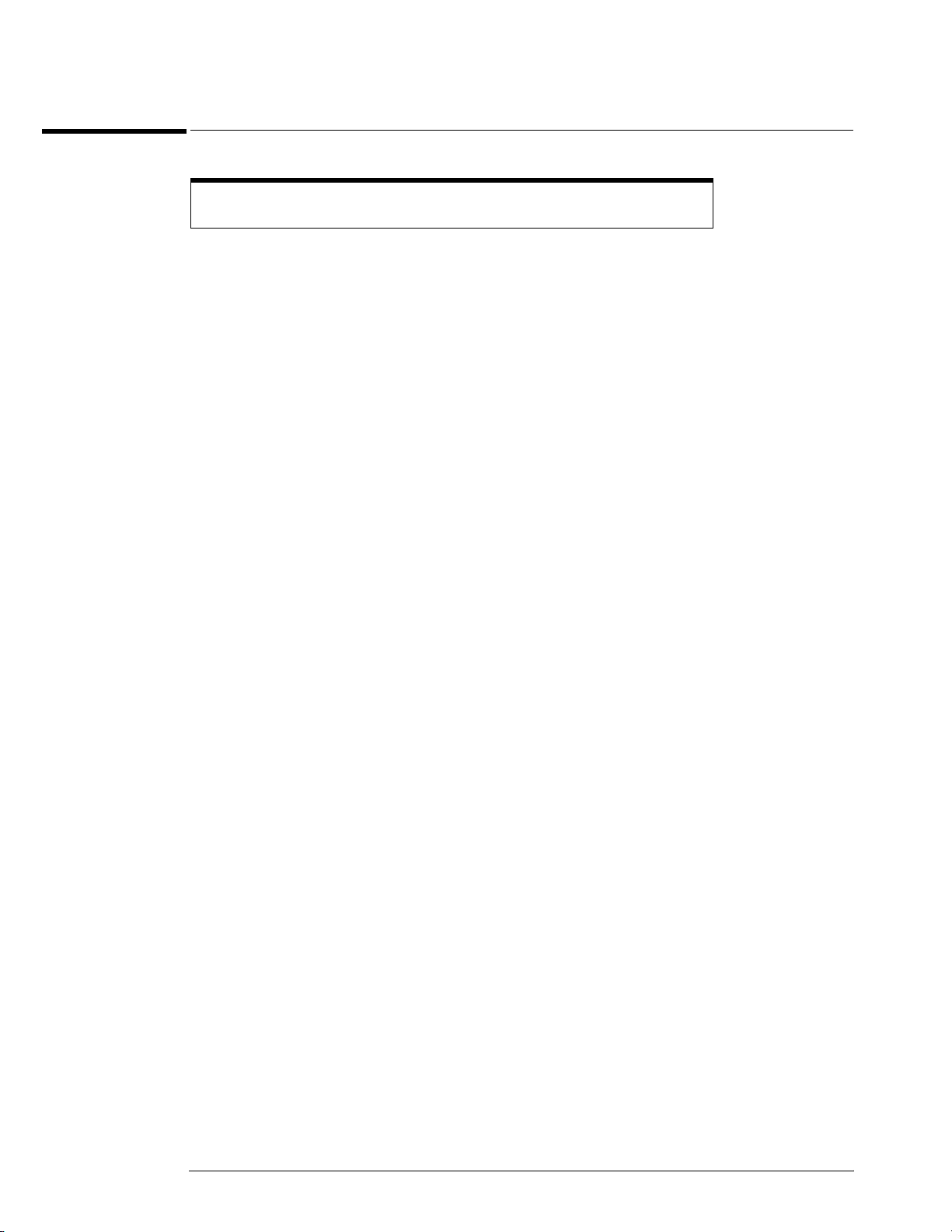

c When the Enter Measurement Info window is displayed, ensure that the V avg function

is set up as follows and then click OK:

Source = Channel 1

Measurement Area = Entire Display

4

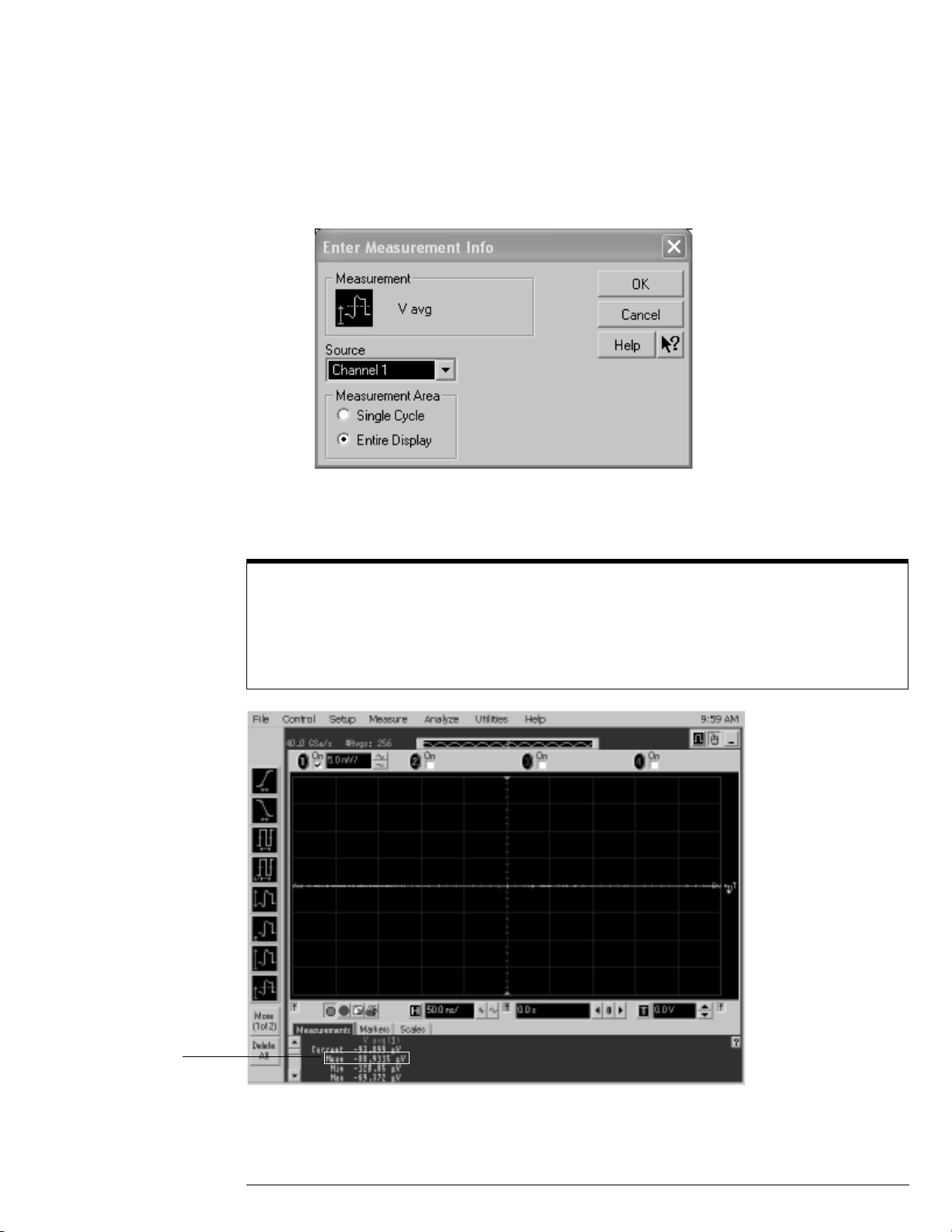

Press the Clear Display key on the scope and wait for the #Avgs value (top left corner

of screen) to return to 256. Record the scope's mean V avg reading in the Zero Error

Test section of the Performance Test Record.

Notes

• For all scope readings in this pro cedure , use the mean value i n the Measu rement s displ ay area at the

bottom of the screen.

• If a question mark is display ed in f ront of any o f the v alu es at t he bot tom o f the s creen, pr ess the Clea r

Display key on the scope, wait for the #Avg s value to ret urn to 256 and then record the scope readi ng.

Record the

mean reading

5 Change the vertical sensitivity of channel 1 to 10 mV/div, press the Clear Display key,

wait for the #Avgs value (top left corner of screen) to return to 256 and then record the

scope V avg reading in the Zero Error Test section of the Performance Test Record.

3–7

Page 50

Chapter 3: Testing Performance

Offset Accuracy Test

Repeat step 5 for the remaining vertical sensitivities for channel 1 in the Zero Error

6

Test section of the Performance Test Record.

7 Press Default Setup, then turn off channel 1 and turn channel 2 display on.

8 Configure the scope to measure V avg on Channel 2 as follows:

a Pull down the Utilities menu and select Acquisition. When the Acquisition Setup window

is displayed, enable averaging and set the # of averages to 256.

b Change the vertical sensitivity of channel 2 to 5 mV/div.

c Click the V avg measurement icon on the left side of the screen.

d When the Enter Measurement Info window is displayed, ensure that the Vavg function

is set up as follows and then click OK:

Source = Channel 2

Measurement area = Entire Display

9

Press the Clear Display key on the scope, wait for the #Avgs value to return to 256 and

then record the scope’s mean V avg reading in the Zero Error Test section of the

Performance Test Record.

10 Repeat step 9 for the remaining vertical sensitivities for channel 2 in the Zero Error

section of the Performance Test Record.

11 Repeat steps 7 through 10 for channels 3 and 4.

3–8

Page 51

Offset Gain Test

12

Make the connections to scope channel 1 as shown below.

Connections

Chapter 3: Testing Performance

Offset Accuracy Test

Notes:

• Where it is used, it i s import ant t o connect the B NC Tee adapt er direct l y to the scop e channel in put to

minimize ground potential differences between the scope and the test oscilloscopes and to ensure

that the DMM measures the input voltage to t he scope chann el as accuratel y as possibl e. Difference s

in ground potential can be a significant source of measurement error, particularly at high scope

sensitivities.

• It also helps to reduce ground potential differences if the scope and the external test os cilloscopes

are connected to the same AC supply circuit.

• A fairly large number of aver ages are used in the scope measurements of this section to reduce

measurement noise and to reduce the measurement error due to resolution.

Set up the DMM to perform DC voltage measurements.

13

14 Configure the scope to measure V avg on Channel 1 as follows:

a Press Default Setup.

b Pull down the Utilities menu and select Acquisition. When the Acquisition Setup window

is displayed, enable averaging and set the # of averages to 256.

c Change the vertical sensitivity of channel 1 to 5 mV/div.

d Click the V avg measurement icon on the left side of the screen.

e When the Enter Measurement Info window is displayed, ensure that the V avg function

is set up as follows and then click OK:

Source = Channel 1

Measurement area = Entire Display

3–9

Page 52

Channel 1

setu p i c on

Chapter 3: Testing Performance

Offset Accuracy Test

Set the channel 1 offset value to 400.0 mV. This can be done either using the front panel

15

control or:

a Pull down the Setup menu and select Channel 1 or click the Channel 1 setup icon.

b Click the Offset control arrows to change the offset value or click on the offset value

and enter 400.0 mV in the dialog box.

c Enter 400.0 mV in the Enter Offset dialog box.

16

Set the Aux Out voltage (V

a Pull down the Utilities menu and select Calibration.

b Change the Aux Output function to DC (top left corner).

c Set the Level to 400.0 mV.

d Click on Close.

17

Press the Clear Display key on the scope, wait for the #Avgs value (top left corner of

Aux Out

screen) to return to 256 and then record the DMM voltage reading as V

scope Vavg reading as V

Scope+

) to +400.0 mV as follows:

and the

DMM+

in the Offset Gain Test section of the Performance Test

Record.

3–10

Page 53

Chapter 3: Testing Performance

Offset Accuracy Test

Change the channel 1 offset value to -400.0 mV.

18

19 Set the Aux Out voltage to -400.0 mV.

20 Press the Clear Display key on the scope, wait for the #Avgs value (top left corner of

screen) to return to 256 and then record the DMM voltage reading as V

scope Vavg reading as V

in the Offset Gain Test section of the Performance Test

Scope-

DMM-

and the

Record.

21 Change the channel 1 offset value to 0 mV.

22 Set the Aux Out voltage to 0 mV.

23 Press the Clear Display key on the scope, wait for the #Avgs value (top left corner of

screen) to return to 256 and then record the DMM voltage reading as V

scope Vavg reading as V

in the Offset Gain Test section of the Performance Test

Scope0

DMM0

and the

Record.

24 Calculate the offset gain error using the following expressions and record the value in

the Offset Gain Test section of the Performance Test Record. The offset gain error is

the greater (maximum magnitude) of either:

V

------------------------------------------

V

scope+

DMM+

– V

– V

scope0

DMM0

1–

100

or

V

-----------------------------------------

V

scopeDMM-

– V

– V

scope0

DMM0

1–

100

25 Repeat steps 15 to 21 for the remaining channel 1 vertical sensitivities in the Offset

Gain Test section of the Performance Test Record. For each measurement, set both

the Aux Out voltage (V

Aux Out

value and then to the negative V

) and the Channel offset voltage to the positive V

Aux Out

value in the "V

Aux Out

Setting" column of the

Aux Out

Offset Gain Test table in the Performance Test Record for each of the vertical

sensitivities.

26 Move the Tee connector to the next channel input and repeat steps 18 to 22 for the

channels 2 to 4.

3–11

Page 54

Chapter 3: Testing Performance

DC Gain Accuracy Test

DC Gain Accuracy Test

CAUTION Ensure that the input voltage to the oscilloscope never exceeds ±5 V.

Specifications

DC Gain Accura cy ±2% of full scale at full resolution channel scale

Full scale is defined as 8 vertical divisions. Magnification is used below 5 mV/div. Below 5 mV

full scale is defined as 40 mV. The major scale settings are 5 mV, 10 mV, 20 mV,

50 mV, 100 mV, 200 mV, 500 mV and 1 V.

Equipment Required

Description Critical Specifications Recommended

Digital Multimeter DC voltage measur ement a ccurac y better than ±0. 1% of r eading Agilent 34401A or

Cable Assembly

(2 required)

Adapter BNC Tee (m)(f)(f) Agilent 1250-0781

Adapter BNC (f) to dual banana Agilent 1251-2277

50Ω character istic impedance, BNC (m) connect ors Agil ent 8120-1840

Model/

Part Numbers

Agilent 3458A

Procedure

Disconnect all cables from the scope channel inputs.

1

2 Press Default Setup, then configure the scope as follows:

a Pull down the Setup menu and select Acquisition.

3–12

Page 55

Chapter 3: Testing Performance

DC Gain Accuracy Test

b When the Acquisition Setup window is displayed, enable averaging and set the # of

averages to 256 as shown below.

3

Set the Aux Out voltage (V

a Pull down the Utilities menu and select Calibration.

b Change the Aux Output function to DC (top left corner).

c Set the Level to 15 mV.

d Click on Close.

4

Set the channel 1 vertical sensitivity value to 5 mV/div. This can be done either using

Aux Out

) to +15 mV as follows:

the front panel control or:

a Pull down the Setup menu and select Channel 1 or click the Channel 1 setup icon.

b Change the vertical sensitivity of channel 1 to 5 mV/div.

3–13

Page 56

V avg

measurement

Chapter 3: Testing Performance

DC Gain Accuracy Test

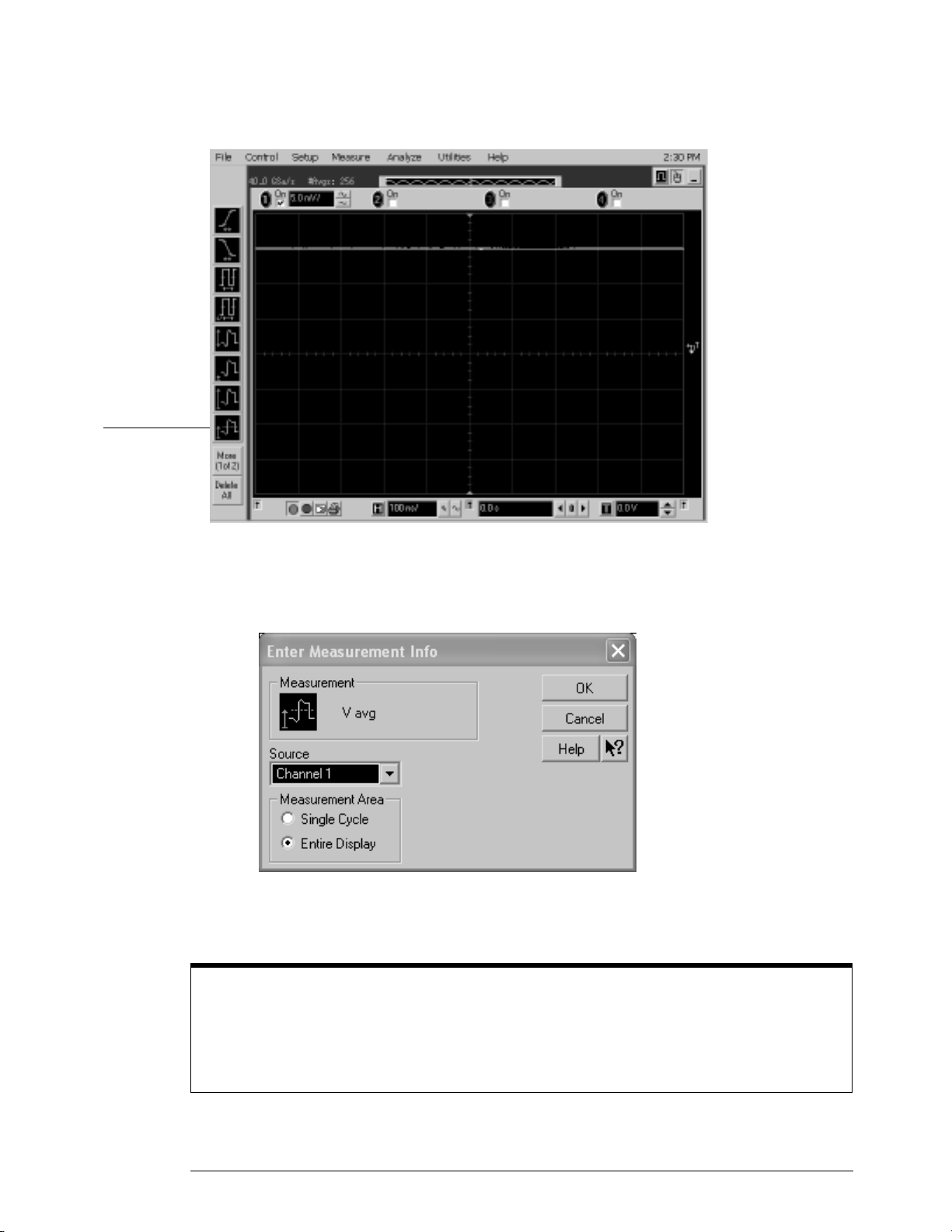

c Select the Vavg measurement as shown below.

d When the Enter Measurement Info window is displayed, ensure that the V avg function

is set up as follows and then click OK:

Source = Channel 1

Measurement Area = Entire Display

5

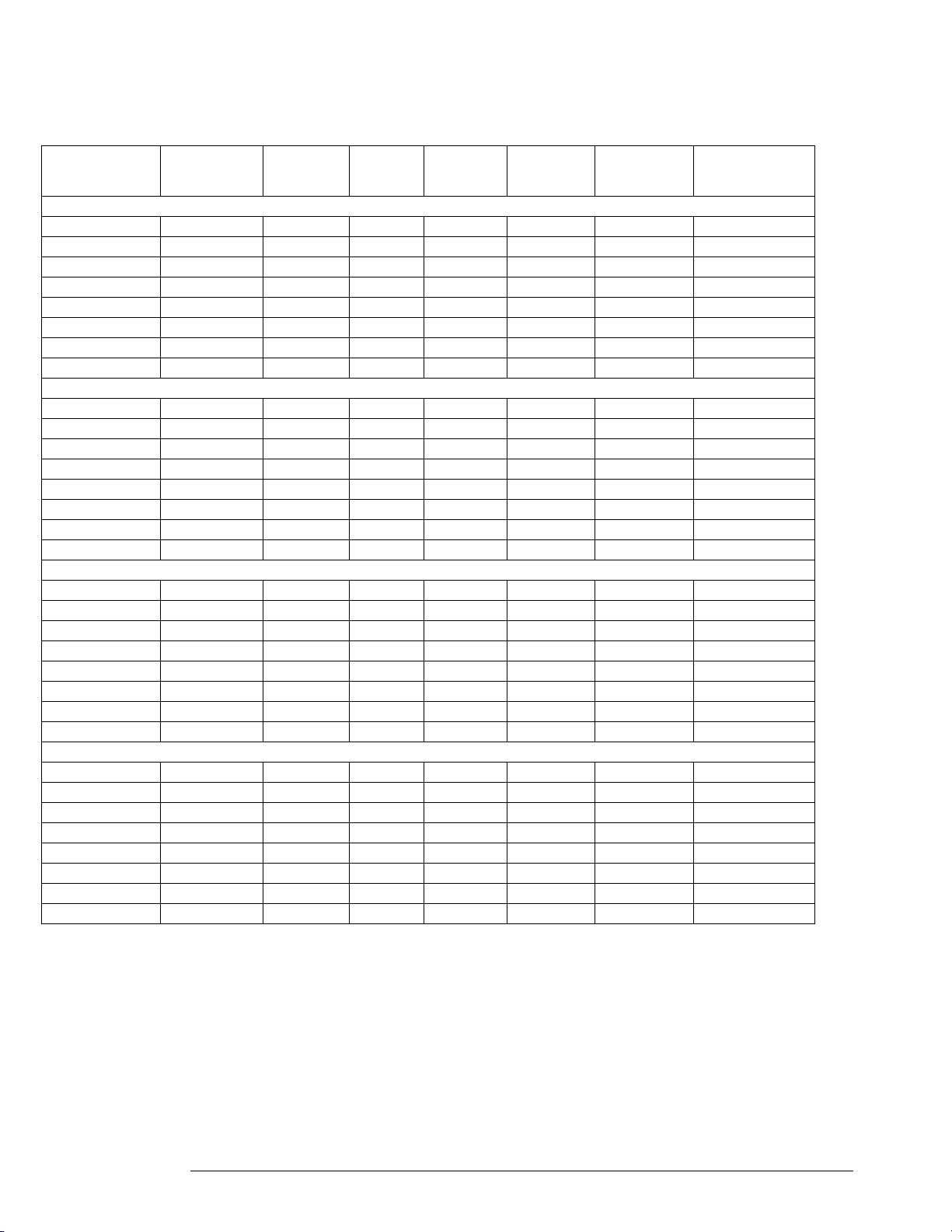

Press the Clear Display key on the scope, wait for the #Avgs value (top left corner of

screen) to return to 256 and then record the scope's mean V avg reading in the DC Gain

Test page 3-26 section of the Performance Test Record.

Notes

• For all scope readings in this pro cedure , use the mean value i n the Measu rement s displ ay area at the

bottom of the screen.

• If a question mark is display ed in f ront of any o f the v alu es at t he bot tom o f the s creen, press the Clea r

Display key on the scope, wait for the #Avg s value to return to 25 6 and then record the sco pe reading.

3–14

Page 57

Record the

mean reading

Chapter 3: Testing Performance

DC Gain Accuracy Test

Change the the Aux Out voltage to -15 mV.

6

7 Press the Clear Display key on the scope, wait for the #Avgs value to return to 256 and

then record the DMM voltage reading and the scope V avg reading in the DC Gain Test

section of the Performance Test Record.

8 Repeat step 7 for the remaining vertical sensitivities for channel 1 in the DC Gain Test

section of the Performance Test Record.

9 Press Default Setup, then turn off channel 1 and turn channel 2 display on.

10 Set the Aux Out voltage (V

11 Configure the scope to measure V avg on Channel 2.

a Pull down the Utilities menu and select Acquisition. When the Acquisition Setup window

is displayed, enable averaging and set the # of averages to 256.

b Change the vertical sensitivity of channel 2 to 5 mV/div.

c Click the V avg measurement icon on the left side of the screen.

d When the Enter Measurement Info window is displayed, ensure that the Vavg function

is set up as follows and then click OK:

Source = Channel 2

Measurement area = Entire Display

12

Press the Clear Display key on the scope, wait for the #Avgs value to return to 256 and

Aux Out

) to +15 mV as follows:

then record the DMM voltage reading and the scope V avg reading in the DC Gain Test

section of the Performance Test Record.

13 Repeat step 12 for the remaining vertical sensitivities for channel 2 in the DC Gain

section of the Performance Test Record.

14 Repeat steps 9 through 13 for channels 3 and 4.

3–15

Page 58

Chapter 3: Testing Performance

DC Gain Accuracy Test

Calculate the offset gain using the following expression and record this value in the

15

DC Gain Test section of the Performance Test Record.

For vertical sensitivities of less than 1 volt use the following equation:

DCGainError =

∆V

out

--------------

∆V

V

scope+

=

----------------------------------------- 1–

V

in

DMM+

– V

– V

scopeDMM-

For vertical sensitivity = 1 V use the following equation:

DCGainError =

∆V

out

--------------

∆V

V

scope+

=

----------------------------------------- 1–

V

in

DMM+

– V

– V

scopeDMM-

0.75⋅

0.6⋅

3–16

Page 59

Analog Bandwidth - Maximum Frequency Check

Analog Bandwidth - Maximum Frequency Check

CAUTION Ensure that the input voltage to the oscilloscope never exceeds ±5 V.

Specification

Analog Bandwidth (-3 dB)

DSO81304A 12.0 GHz

DSO81204A 12.0 GHz

DSO81004A 10.0 GHz

DSO80804A 8.0 GHz

Equipment Required

Chapter 3: Testing Performance

Description Critical Specifications Recommended Model/

Microwave CW

Generator

Power Splitter 2 Resistor Power Splitter

Power Meter Agilent E-series w ith power sensor compatibility Agilent E4418B or E4419B

Power Sensor Maximum Frequency ≥ 14 GHz

Microwave Cab le 50Ω Characteristic Impedance

SMA Adapters 3.5 mm (m) to 3.5 mm ( m ) SM A Agilent E2655-83202

SMA to BNC Adapter 3.5 mm (f) SMA to Precision BNC (No Substitute) Agilent 54855-67604

Maximum Frequency ≥ 14 GHz

Power range: -20 dBm to +16 dBm into 50Ω

Output resistance = 50Ω

Max Frequency ≥18 GHz

Power range: -24 dBm to +16 dB m

3.5 mm (m) to 3.5 mm (m) SMA connector s

Max Frequency ≥18 GHz

Part Numbers

Agilent E8257D with Opt 520

Agilent 11667B

Agilent E4413A

Agilent 8120-4948

3–17

Page 60

Chapter 3: Testing Performance

Analog Bandwidth - Maximum Frequency Check

Connections

Power meter

E4418A or E4419A

Power sensor

cable

Microwave CW

Generator E8257D

Power splitter

11667B

SMA to BNC adapter

SMA adapter

Power sensor

E4413A

Microwave cable

Notes

• Connect output 1 of the 11667B splitter to the scope Channel n input directly using th e 54855-67604

adapter, without any additional cabling or adapters.

• Connect the power sensor directly to output 2 of the power splitter without any additional cabling or

adapters.

• Minimize the use of other adapters.

• Ensure that SMA and 3.5 mm connectors are tightened properly:

8 in-lbs (90 N-cm) for 3.5 mm

5 in-lbs (56 N-cm) for SMA

Procedure

Preset the power meter.

1

2 Ensure that the power sensor is disconnected from any source and zero the meter.

3 Connect the power sensor to the power meter's Power Ref connector and calibrate the

meter.

4 Make the connections to scope channel 1 as shown in the connection diagram above.

5 Set up the Power Meter to display measurements in units of Watts.

6 Press Default Setup, then configure the scope as follows:

a Ensure Channel 1 is displayed and all other channels are turned off.

b Set the vertical sensitivity of channel 1 to 5 mV/div.

3–18

Page 61

Chapter 3: Testing Performance

Analog Bandwidth - Maximum Frequency Check

c Set the horizontal scale to 16 ns/div (to display 8 cycles of a 50 MHz waveform).

Click here and enter 16E-9

d Pull down the Setup menu, select Acquisition and then set up the acquisition parameters

as follows:

Memory Depth = Automatic

Sampling rate = Maximum (40 GSa/s)

Sin(x)/x Interpolation filter enabled

Averaging = Disabled

e Pull down the Measure menu, select Voltage and then select V rms.

3–19

Page 62

Chapter 3: Testing Performance

Analog Bandwidth - Maximum Frequency Check

f When the RMS voltage measurement setup window is displayed, configure this

measurement as follows:

Source = Channel 1

Measurement Area = Entire Display

RMS Type = AC

7

Set the generator to apply a 50 MHz sine wave with a peak-to-peak amplitude of about

4 divisions.

• Use the following table to determine the approximate required signal amplitude.

The amplitude values in the table below are not absolutely required. If your generator is

unable to produce the recommended amplitude, then set the generator to the highest

value that does not produce a vertically clipped signal on the scope.

Table 3-1. Nominal Generator Amplitude Settings

Scope

Vertical Sensitivity

5 mV/div 0.02 -30

10 mV/div 0.04 -24

20 mV/div 0.08 -18

50 mV/div 0.20 -10

100 mV/div 0.40 -4

200 mV/div 0.80 +2

500 mV/div 2.0 +10

1 V/div 4.0 +16

8

Measure the input power to the scope channel and convert this measurement to Volts

Gener a tor Signal

Amplitude (Vp-p)

Generator Si gnal

Amplitude (dBm)

RMS using the expression:

V

in

For example, if the power meter reading is 4.0 µW, then Vin = (4.0*10-6 * 50Ω)

Record the RMS voltage in the Analog Bandwidth - Maximum Frequency Check section of the

Performance Test Record (Vin @ 50 MHz).

P

meas

50Ω×=

1/2

= 14.1 mVrms.

3–20

Page 63

Chapter 3: Testing Performance

Analog Bandwidth - Maximum Frequency Check

Press the Clear Display key on the scope and record the scope V rms reading in the

9

Analog Bandwidth - Maximum Frequency Check section of the Performance Test

Record (Vout @ 50 MHz). For all scope readings in this procedure, use the mean value

in the Measurements display area at the bottom of the screen.

Notes

• For all scope readings in this pro cedure , use the mean value i n the Measu rement s displ ay area at the

bottom of the screen.

• If a question mark is display ed in f ront of any o f the v alu es at t he bot tom o f the s creen, pr ess the Clea r

Display key on the scope, wait for the #Avgs val ue to return to 16 and then record the scope reading.

Record the

mean reading

10 Calculate the reference gain as follows:

V

Gain

50 MHz

Record this value in the Calculated Gain @50 MHz column in the Analog Bandwidth - Maximum

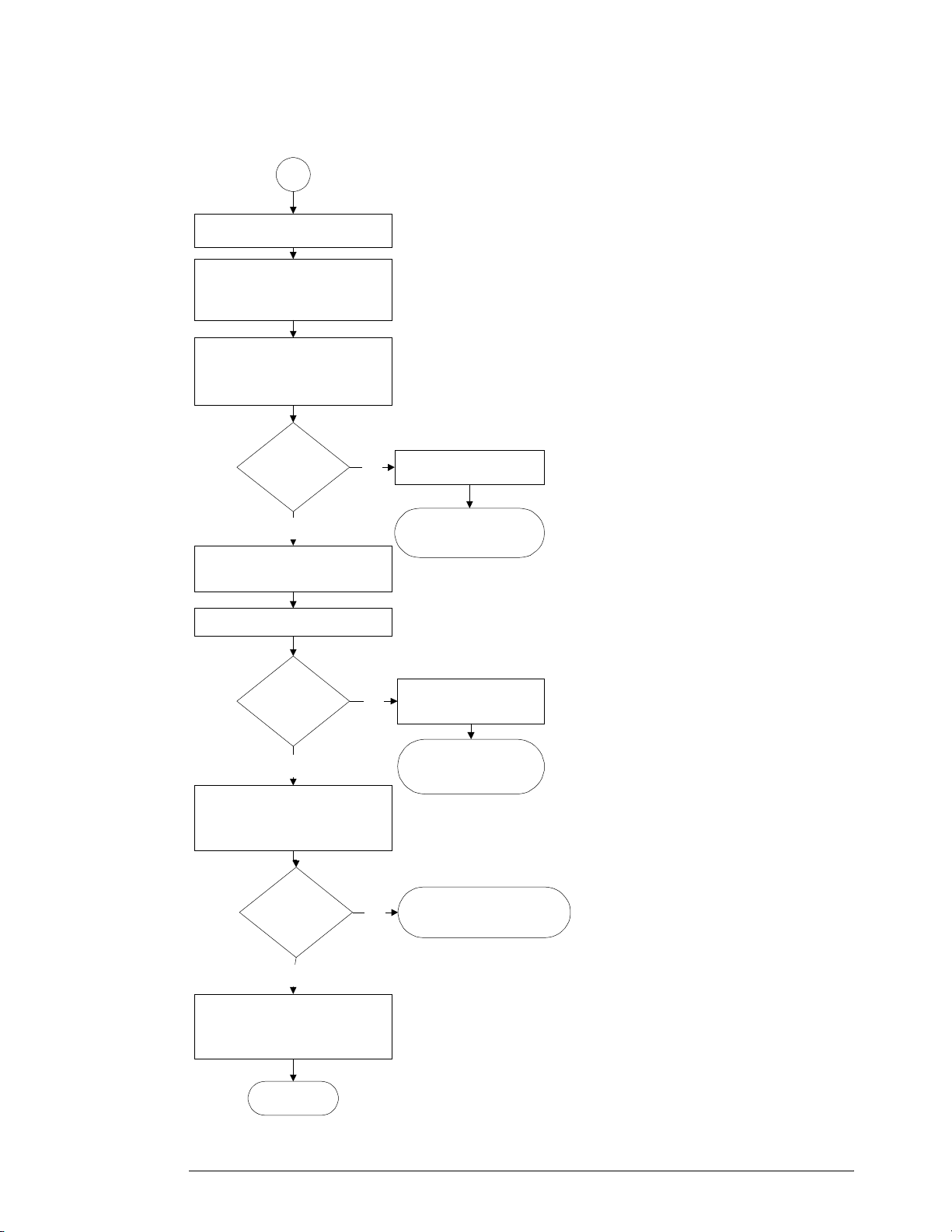

Frequency Check section of the Performance Test Record.