Agilent 8703B Lightwave

Component Analyzer

User’s Guide

© Copyright

Agilent Technologies 2001

All Rights Reserved. Reproduction, adaptation, or translation without prior w r itt en

permission is prohibit ed ,

except as allowed under copyright laws.

Agilent Part No. 08703- 90 20 1

Printed in USA

July 2001

Agilent Technologies

Lightwave Division

3910 Brickway BoulevardSanta

Rosa, CA 95403, USA

Notice.

The information contained in

this document is subject to

change without notice. Companies, names, and data used in

examples herein are fictitious

unless otherwise noted. Agilent Technologies makes no

warranty of any kind with

regard to this material, including but not limited to, the

implied warranties of merchantability and fitness for a

particular purpose. Agilent

Technologies shall not be liable

for errors contained herein or

for incidental or consequential

damages in connection with

the furnishing, performance, or

use of this material.

Restricted Rights Legend.

Use, duplication, or disclosure

by the U.S. Government is subject to restrictions as set forth

in subparagrap h (c) (1 ) (i i) of

the Rights in Technical Data

and Computer Software clause

at DFARS 252.227-7013 for

DOD agencies, and subparagraphs (c) (1) and (c) (2) of

the Commercial Computer

Software Restricted Rights

clause at FAR 52.227-19 for

other agencies.

Warranty.

This Agilent Technologies

instrument product is warranted against defects in material and workmanship for a

period of one yea r fro m date of

shipment. During the warranty period, Agilent Technologies will, at its option, either

repair or replace products

which prove to be defective.

For warranty service or repair,

this product must be returned

to a service facility designated

by Agilent Technologies. Buyer

shall prepay shipping charges

to Agilent Technologies and

Agilent Technologies shall pay

shipping charges to return the

product to Buyer. However,

Buyer shall pay all shipping

charges, duties, and taxes for

products returned to Agilent

Technologies from another

country.

Agilent Technologies warrants

that its software and firmware

designated by Agilent Technologies for use with an instrument will execute its

programming instructions

when properly installed on that

instrument. Agilent Technologies does not warrant that the

operation of the instrument, or

software, or firmware will be

uninterrupted or error-free.

Limitation of Warranty.

The foregoing warranty shall

not apply to defects resulting

from improper or inadequate

maintenance by Buyer,

Buyer-supplied software or

interfacing, unauthorized modification or misuse, operation

outside of the environmental

specifications for the product,

or improper site preparation or

maintenance.

No other warranty is

expressed or implied. Agilent

Technologies specifically disclaims the implied warranties

of merchantability and fitness

for a particular purpose.

Exclusive Remedies.

The remedies provided herein

are buyer's sole and exclusive

remedies. Agilent Technologies

shall not be liable for any

direct, indirect, special, incidental, or consequential damages, whether based on

contract, tort, or any other

legal theory.

Safety Symbols.

CAUTION

The caution sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in damage to or

destruction of the product. Do

not proceed beyond a caution

sign until the indicated conditions are fully understood and

met.

WARNING

The warning sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in injury or loss

of life. Do not proceed beyond

a warning sign until the indicated conditions are fully

understood and met.

The instruction manual symbol. The product is marked with this

warning symbol when

it is necessary for the

user to refer to the

instructions in the

manual.

The laser radiation

symbol. This warning

symbol is marked on

products which have a

laser output.

The AC symbol is used

to indicate the required

nature of the line module input power.

| The ON symbols are

used to mark the positions of the instrument

power line switch.

❍ The OFF symbols

are used to mark the

positions of the instrument power line

switch.

The CE mark is a registered trademark of the

European Community.

The CSA mark is a registered trademar k of

the Canadian Standards Association.

The C-Tick mark is a

registered trademark of

the Australian Spectrum Management

Agency.

This text denotes the

ISM1-A

instrument is an Industrial Scientific and

Medical Group 1 Class

A product.

Typographical C on ve nt io ns.

The following conventions are

used in this book:

Key type for keys or text lo cated

on the keyboard or ins tr ume nt.

Softkey type for key names that

are displayed on the instrument’s screen.

Display type for words or

characters displayed on the

computer’s screen or instrument’s display.

User type for words or charac-

ters that you type or enter.

Emphasis type for words or

characters that emphasize

some point or that are used as

place holders for text that you

type.

2

Contents

1. Connector Care & ESD Information

Cleaning Connections for Accurate Measurements 1-2

Caring for Electrical Connections 1-11

Electrostatic Discharge Information 1-12

2. Making Measurements

Making Measurements 2-2

Making a Basic Measurement 2-3

Using Display Functions 2-4

Using Markers 2-17

Using the List Mode to Test a Device 2-37

Using Limit Lines to Test a Device 2-42

Using Ripple Limits to Test a Device 2-50

Using Bandwidth Limits to Test a Bandpass Filter 2-60

Using Test Sequencing 2-66

Using Test Sequencing to Test a Device 2-77

Magnitude and Phase Comparisons of Lightwave Receivers 2-83

Mathematically Combining Device Responses 2-91

Using a Coefficient Model for Device Response and Design Model Comparison 2-95

Using an External Laser 2-98

3. Optimizing Measurement Results

Optimizing Measurement Results 3-2

Taking Care of Connectors 3-3

Increasing Measurement Accuracy 3-4

Increasing Dynamic Range 3-7

Reducing Noise 3-8

Reducing Receiver Crosstalk 3-9

4. Calibrating for Increased Measurement Accuracy

Calibrating for Increased Measurement Accuracy 4-2

Calibration Considerations 4-3

Procedures for Error Correcting Your Measurements 4-9

O/O Response Calibration 4-11

O/O Response and Isolation Calibration 4-13

E/O Response Calibration 4-16

E/O Reflection Sensitivity Calibration 4-17

E/O Response and Isolation Calibration 4-18

E/O Response and Match Calibration 4-20

O/E Response Calibration 4-23

O/E Response and Isolation Calibration 4-24

O/E Response and Match Calibration 4-26

Modifying Lightwave Calibration Kits 4-29

Modifying an Electrical Calibration Kit 4-30

Ver i fy Per formance 4 - 39

Contents-1

Contents

5. Verifying Measurement Accuracy

Verifying Measurement Accuracy 5-2

Agilent Technologies Service Offices 5-8

6. Saving and Recalling Measurements and Data

Saving and Recalling Measurements and Data 6-2

Saving and Recalling Instrument States 6-3

Saving an Instrument State 6-5

Saving Measurement Results 6-6

Re-Saving an Instrument State 6-18

Deleting a File 6-19

Renaming a File 6-20

Recalling a File 6-21

Formatting a Disk 6-22

Solving Problems with Saving or Recalling Files 6-23

7. Printing Measurement Results

Printing Measurements Results 7-2

Printing or Plotting Your Measurement Results 7-3

Configuring a Print Function 7-4

Defining a Print Function 7-6

Printing One Measurement Per Page 7-8

Printing Multiple Measurements Per Page 7-9

Configuring a Plot Function 7-10

Defining a Plot Function 7-15

Plotting One Measurement Per Page Using a Pen Plotter 7-19

Plotting Multiple Measurements Per Page Using a Pen Plotter 7-20

To View Plot Files on a PC 7-22

Outputting Plot Files from a PC to a Plotter 7-23

Outputting Plot Files from a PC to an HPGL Compatible Printer 7-24

Outputting Single Page Plots Using a Printer 7-26

Outputting Multiple Plots to a Single Page Using a Printer 7-27

Plotting Multiple Measurements Per Page from Disk 7-28

Titling the Displayed Measurement 7-32

Configuring the Analyzer to Produce a Time Stamp 7-33

Aborting a Print or Plot Process 7-34

Printing or Plotting the List Values or Operating Parameters 7-35

Solving Problems with Printing or Plotting 7-36

Contents-2

1

Cleaning Connections for Accurate Measurements 1-2

Choosing the Right Connector 1-2

Inspecting Connectors 1-4

Cleaning Connectors 1-8

Caring for Electrical Connections 1-11

Electrostatic Discharge Information 1-12

Reducing ESD Damage 1-13

Connector Care & ESD Information

Connector Care & ESD Information

Cleaning Connections for Accurate Measurements

Cleaning Connections for Accurate Measurements

Today, advances in measurement capabilities make connectors and connection techniques more

important than ever. Damage to the connectors on calibration and verification devices, test ports,

cables, and other devices can degrade measurement accuracy and damage instruments. Replacing a

damaged connector can cost thousands of dollars, not to mention lost time! This expense can be

avoided by observing the simple precautions presented in this document. This document also contains

a brief list of tips for caring for electrical connectors.

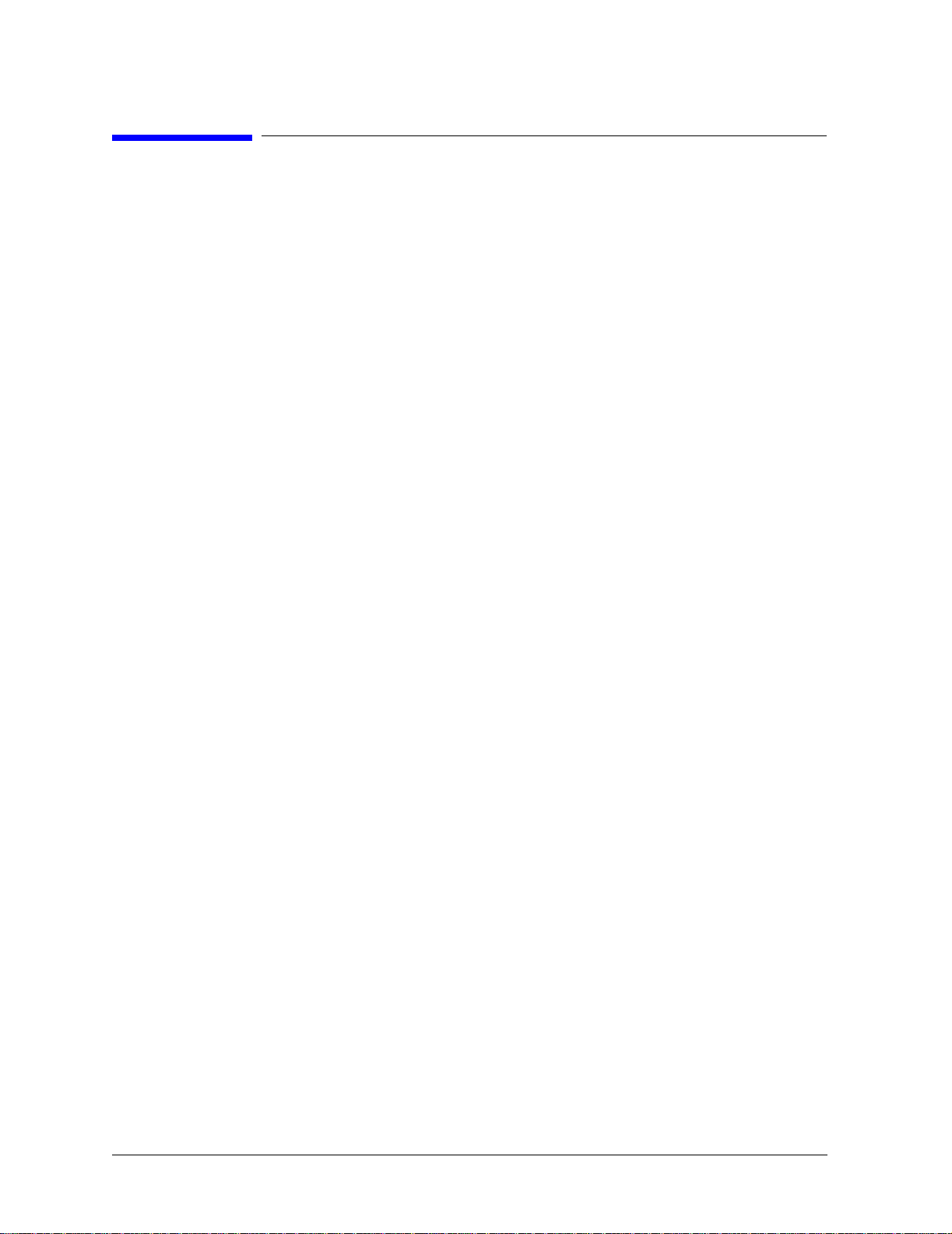

Choosing the Right Connector

A critical but often overlooked factor in making a good lightwave measurement is the selection of the

fiber-optic connector. The differences in connector types are mainly in the mechanical assembly that

holds the ferrule in position against another identical ferrule. Connectors also vary in the the polish,

curve, and concentricity of the core within the cladding. Mating one style of cable to another requires

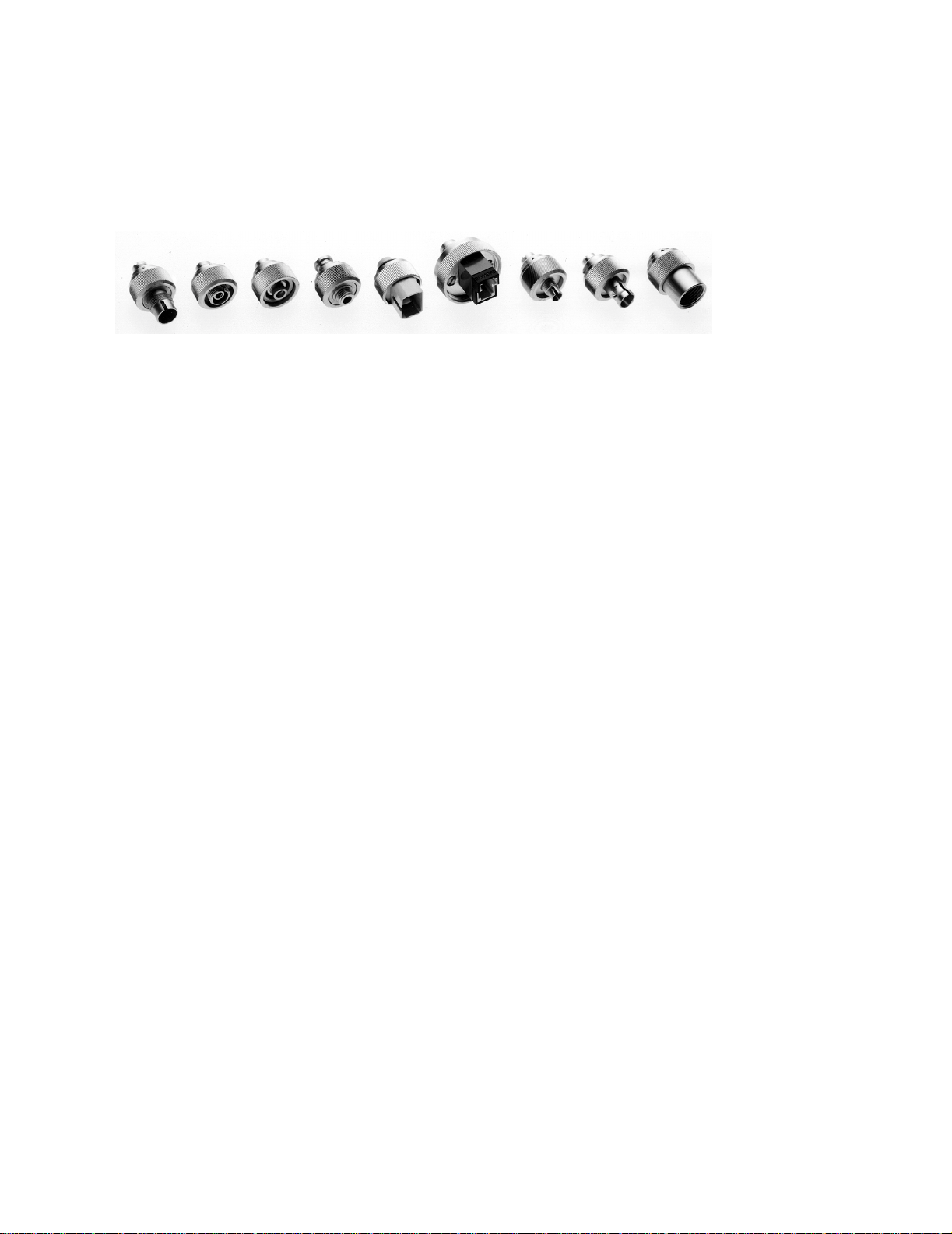

an adapter. Agilent Technologies offers adapters for most instruments to allow testing with many different cables. The Figure 1-1 on page 1-3 shows the basic components of a typical connectors.

The system tolerance for reflection and insertion loss must be known when selecting a connector from

the wide variety of currently available connectors. Some items to consider when selecting a connector

are:

• How much insertion loss can be allowed?

• Will the connector need to make multiple connections? Some connectors are better than

others, and some are very poor for making repeated connections.

• What is the reflection tolerance? Can the system take reflection degradation?

• Is an instrument-grade connector with a precision core alignment required?

• Is repeatability tolerance for reflection and loss important? Do your specifications take

repeatability uncertainty into account?

• Will a connector degrade the return loss too much, or will a fusion splice be required? For

example, many DFB lasers cannot operate with reflections from connectors. Often as

much as 90 dB isolation is needed.

1-2

Connector Care & ESD Information

Cleaning Connections for Accurate Measurements

Figure 1-1. Basic components of a connector.

Over the last few years, the FC/PC style connector has emerged as the most popular connector for

fiber-optic applications. While not the highest performing connector, it represents a good compromise

between performance, reliability, and cost. If properly maintained and cleaned, this connector can

withstand many repeated connections.

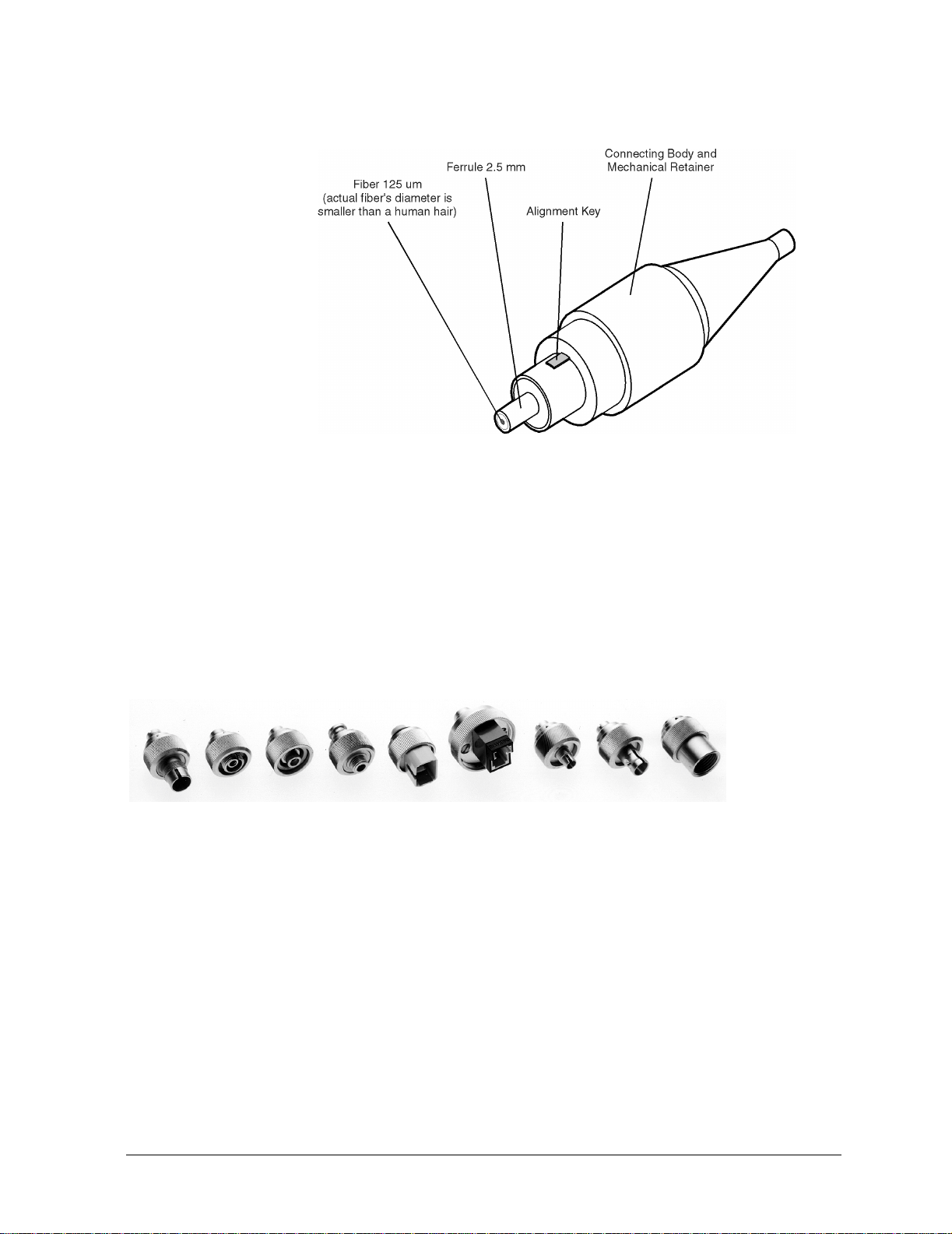

However, many instrument specifications require tighter tolerances than most connectors, including

the FC/PC style, can deliver. These instruments cannot tolerate connectors with the large non-concentricities of the fiber common with ceramic style ferrules. When tighter alignment is required,

Agilent instruments typically use a connector such as the Diamond HMS-10, which has concentric tolerances within a few tenths of a micron. Agilent then uses a special universal adapter, which allows

other cable types to mate with this precision connector. See Figure 1-2.

Figure 1-2. Universal adapters to Diamond HMS-10

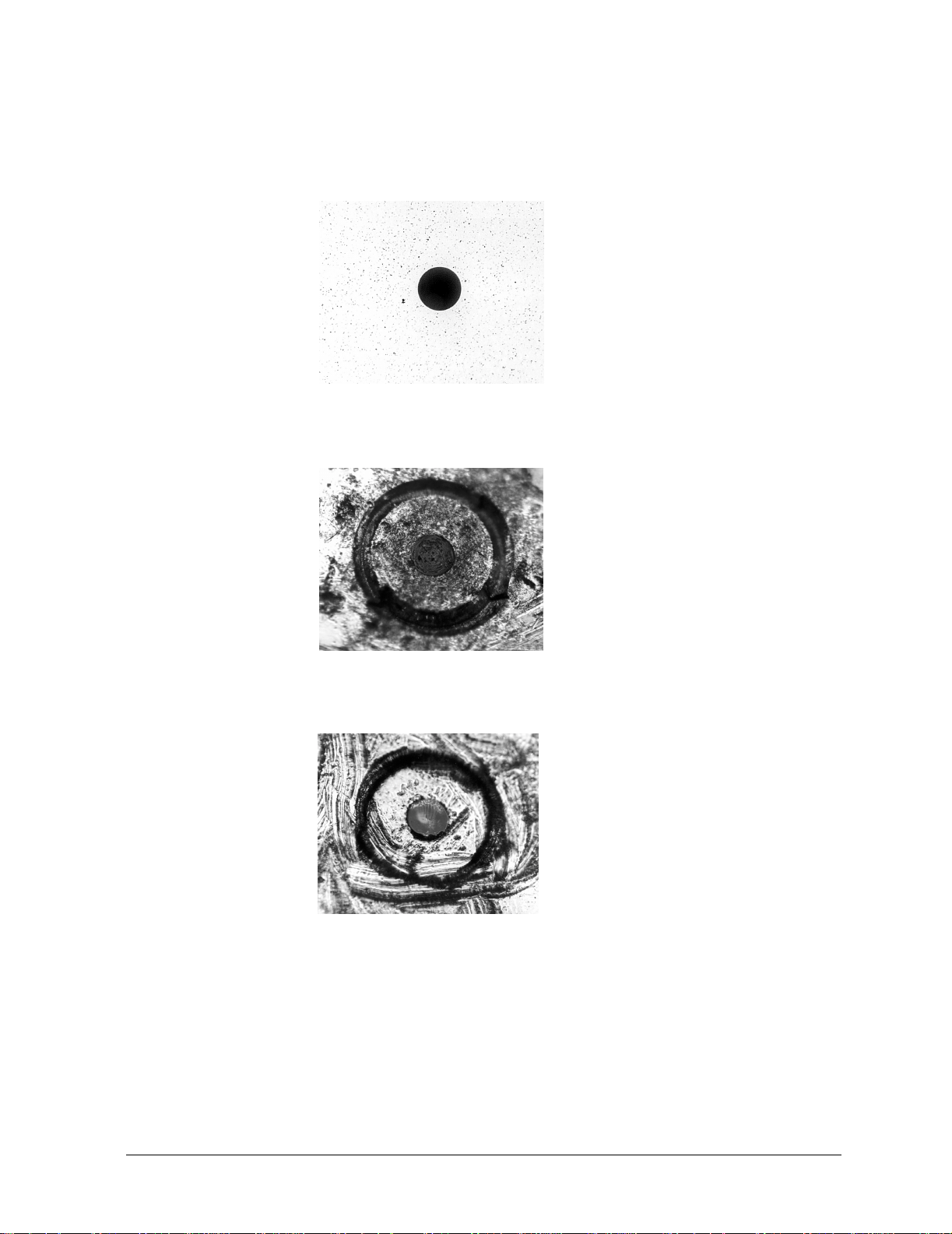

The HMS-10 encases the fiber within a soft nickel silver (Cu/Ni/Zn) center which is surrounded by a

tough tungsten carbide casing, as shown in Figure 1-3 on page 1-4.

1-3

Connector Care & ESD Information

Cleaning Connections for Accurate Measurements

Figure 1-3. Cross-section of the Diamond HMS-10 connector.

The nickel silver allows an active centering process that permits the glass fiber to be moved to the

desired position. This process first stakes the soft nickel silver to fix the fiber in a near-center loca-

tion, then uses a post-active staking to shift the fiber into the desired position within 0.2 µm. This pro-

cess, plus the keyed axis, allows very precise core-to-core alignments. This connector is found on most

Agilent lightwave instruments.

The soft core, while allowing precise centering, is also the chief liability of the connector. The soft

material is easily damaged. Care must be taken to minimize excessive scratching and wear. While

minor wear is not a problem if the glass face is not affected, scratches or grit can cause the glass fiber

to move out of alignment. Also, if unkeyed connectors are used, the nickel silver can be pushed onto

the glass surface. Scratches, fiber movement, or glass contamination will cause loss of signal and

increased reflections, resulting in poor return loss.

Inspecting Connectors

Because fiber-optic connectors are susceptible to damage that is not immediately obvious to the naked

eye, bad measurements can be made without the user even being aware of a connector problem.

Although microscopic examination and return loss measurements are the best way to ensure good

connections, they are not always practical. An awareness of potential problems, along with good

cleaning practices, can ensure that optimum connector performance is maintained. With

glass-to-glass interfaces, it is clear that any degradation of a ferrule or the end of the fiber, any stray

particles, or finger oil can have a significant effect on connector performance.

Figure 1-4 shows the end of a clean fiber-optic cable. The dark circle in the center of the micrograph is

the fiber’s 125 µm core and cladding which carries the light. The surrounding area is the soft

nickel-silver ferrule. Figure 1-5 shows a dirty fiber end from neglect or perhaps improper cleaning.

Material is smeared and ground into the end of the fiber causing light scattering and poor reflection.

Not only is the precision polish lost, but this action can grind off the glass face and destroy the connector.

1-4

Connector Care & ESD Information

Cleaning Connections for Accurate Measurements

Figure 1-6 shows physical damage to the glass fiber end caused by either repeated connections made

without removing loose particles or using improper cleaning tools. When severe, the damage on one

connector end can be transferred to another good connector that comes in contact with it.

Figure 1-4. Clean, problem-free fiber end and ferrule.

Figure 1-5. Dirty fiber end and ferrule from poor cleaning.

Figure 1-6. Damage from improper cleaning.

The cure for these problems is disciplined connector care as described in the following list and in

“Cleaning Connectors” on page 1-8.

Use the following guidelines to achieve the best possible performance when making measurements on

a fiber-optic system:

•Never use metal or sharp objects to clean a connector and never scrap e th e conn ect or.

•Avoid matching gel and oils.

1-5

Connector Care & ESD Information

Cleaning Connections for Accurate Measurements

While these often work well on first insertion, they are great dirt magnets. The oil or gel grabs and

holds grit that is then ground into the end of the fiber. Also, some early gels were designed for use

with the FC, non-contacting connectors, using small glass spheres. When used with contacting connectors, these glass balls can scratch and pit the fiber. If an index matching gel or oil must be used, apply

it to a freshly cleaned connector, make the measurement, and then immediately clean it off. Never use

a gel for longer-term connections and never use it to improve a damaged connector. The gel can mask

the extent of damage and continued use of a damaged fiber can transfer damage to the instrument.

• When inserting a fiber-optic cable into a connector, gently insert it in as straight a line as

possible. Tipping and inserting at an angle can scrape material off the inside of the

connector or even break the inside sleeve of connectors made with ceramic material.

• When inserting a fiber-optic connector into a connector, make sure that the fiber end does

not touch the outside of the mating connector or adapter.

• Avoid over tightening connections.

Unlike common electrical connections, tighter is not better. The purpose of the connector is to bring

two fiber ends together. Once they touch, tightening only causes a greater force to be applied to the

delicate fibers. With connectors that have a convex fiber end, the end can be pushed off-axis resulting

in misalignment and excessive return loss. Many measurements are actually improved by backing off

the connector pressure. Also, if a piece of grit does happen to get by the cleaning procedure, the

tighter connection is more likely to damage the glass. Tighten the connectors just until the two fibers

touch.

• Keep connectors covered when not in use.

• Use fusion splices on the more permanent critical nodes. Choose the best connector

possible. Replace connecting cables regularly. Frequently measure the return loss of the

connector to check for degradation, and clean every connector, every time.

All connectors should be treated like the high-quality lens of a good camera. The weak link in instrument and system reliability is often the inappropriate use and care of the connector. Because current

connectors are so easy to use, there tends to be reduced vigilance in connector care and cleaning. It

takes only one missed cleaning for a piece of grit to permanently damage the glass and ruin the connector.

Measuring insertion loss and return l oss

Consistent measurements with your lightwave equipment are a good indication that you have good

connections. Since return loss and insertion loss are key factors in determining optical connector performance they can be used to determine connector degradation. A smooth, polished fiber end should

produce a good return-loss measurement. The quality of the polish establishes the difference between

the “PC” (physical contact) and the “Super PC” connectors. Most connectors today are physical contact which make glass-to-glass connections, therefore it is critical that the area around the glass core

be clean and free of scratches. Although the major area of a connector, excluding the glass, may show

scratches and wear, if the glass has maintained its polished smoothness, the connector can still provide a good low level return loss connection.

If you test your cables and accessories for insertion loss and return loss upon receipt, and retain the

measured data for comparison, you will be able to tell in the future if any degradation has occurred.

Typical values are less than 0.5 dB of loss, and sometimes as little as 0.1 dB of loss with high performance connectors. Return loss is a measure of reflection: the less reflection the better (the larger the

return loss, the smaller the reflection). The best physically contacting connectors have return losses

better than 50 dB, although 30 to 40 dB is more common.

1-6

Connector Care & ESD Information

Cleaning Connections for Accurate Measurements

To Test Insertion Loss

Use an appropriate lightwave source and a compatible lightwave receiver to test insertion loss. Examples of test equipment configurations include the following equipment:

• HP/Agilent 71450A or 71451A Optical Spectrum Analyzers with Option 002 built-in white

light source.

• HP/Agilent 8702 or 8703 Lightwave Component Analyzer system.

• HP/Agilent 83420 Chromatic Dispersion Test Set with an HP/Agilent 8510 analyzer.

• HP/Agilent 8153 Lightwave Multimeter with a source and power sensor module.

To Test Return Loss

Use an appropriate lightwave source, lightwave receiver, and lightwave coupler to test return loss.

Examples of test equipment configurations include the following equipment:

• HP/Agilent 8703 Lightwave Component Analyzer.

• HP/Agilent 8702 Lightwave Component Analyzer with the appropriate source, receiver,

and lightwave coupler.

• HP/Agilent 8504 Precision Reflectometer.

• HP/Agilent 8153 Lightwave Multimeter with a source and power sensor module in

conjunction with a lightwave coupler.

• HP/Agilent 81554SM Dual Source and HP/Agilent 81534A Return Loss Module.

Visual inspection of fiber ends

Visual inspection of fiber ends can be helpful. Contamination or imperfections on the cable end face

can be detected as well as cracks or chips in the fiber itself. Use a microscope (100X to 200X magnification) to inspect the entire end face for contamination, raised metal, or dents in the metal as well as

any other imperfections. Inspect the fiber for cracks and chips. Visible imperfections not touching the

fiber core may not affect performance (unless the imperfections keep the fibers from contacting).

WARNING Always remove both ends of fiber-optic cables from any instrument, system,

or device before visually inspecting the fiber ends. Disable all optical

sources before disconnecting fiber-optic cables. Failure to do so may result

in permanent injury to your eyes.

1-7

Connector Care & ESD Information

Cleaning Connections for Accurate Measurements

Cleaning Connectors

The procedures in this section provide the proper steps for cleaning fiber-optic cables and Agilent universal adapters. The initial cleaning, using the alcohol as a solvent, gently removes any grit and oil. If a

caked-on layer of material is still present, (this can happen if the beryllium-copper sides of the ferrule

retainer get scraped and deposited on the end of the fiber during insertion of the cable), a second

cleaning should be performed. It is not uncommon for a cable or connector to require more than one

cleaning.

CAUTION Agilent Technologies strongly recommends that index matching compounds not

be applied to their instruments and accessories. Some compounds, such as gels,

may be difficult to remove and can contain damaging particulates. If you think

the use of such compounds is necessary, refer to the compound manufacturer

for information on application and cleaning procedures.

Table 1-1. Cleaning Accessories

Item Agilent Part Number

Pure isopropyl alcohol —

Cotton swabs 8520-0023

Small foam swabs 9300-1223

Compressed dust remover (non-residue) 8500-5262

Table 1-2. Dust Caps Provided with Lightwave Instruments

Item Agilent Part Number

Laser shutter cap 08145-64521

FC/PC dust cap 08154-44102

Biconic dust cap 08154-44105

DIN dust cap 5040-9364

HMS10/Agilent dust cap 5040-9361

ST dust cap 5040-9366

1-8

Connector Care & ESD Information

Cleaning Connections for Accurate Measurements

To clean a non-lensed connector

CAUTION Do not use any type of foam swab to clean optical fiber ends. Foam swabs can

leave filmy deposits on fiber ends that can degrade performance.

1. Apply pure isopropyl alcohol to a clean lint-free cotton swab or lens paper.

Cotton swabs can be used as long as no cotton fibers remain on the fiber end after

cleaning.

2. Clean the ferrules and other parts of the connector while avoiding the end of the fiber.

3. Apply isopropyl alcohol to a new clean lint-free cotton swab or lens paper.

4. Clean the fiber end with the swab or lens paper.

5. Do not scrub during this initial cleaning because grit can be caught in the swab and

become a gouging element.

6. Immediately dry the fiber end with a clean, dry, lint-free cotton swab or lens paper.

7. Blow across the connector end face from a distance of 6 to 8 inches using filtered, dry,

compressed air. Aim the compressed air at a shallow angle to the fiber end face.

8. Nitrogen gas or compressed dust remover can also be used.

CAUTION Do not shake, tip, or invert compressed air canisters, because this releases

particles in the can into the air. Refer to instructions provided on the

compressed air canister.

9. As soon as the connector is dry, connect or cover it for later use.

If the performance, after the initial cleaning, seems poor tr y cleaning the connector again. Often a second cleaning will restore proper performance. The second cleaning should be more arduous with a

scrubbing action.

1-9

Connector Care & ESD Information

Cleaning Connections for Accurate Measurements

To clean an adapter

The fiber-optic input and output connectors on many Agilent instruments employ a universal adapter

such as those shown in the following picture. These adapters allow you to connect the instrument to

different types of fiber-optic cables.

Figure 1-7. Universal adapters

1. Apply isopropyl alcohol to a clean foam swab.

Cotton swabs can be used as long as no cotton fibers remain after cleaning. The foam

swabs listed in this section’s introduction are small enough to fit into adapters.

Although foam swabs can leave filmy deposits, these deposits are very thin, and the risk

of other contamination buildup on the inside of adapters greatly outweighs the risk of

contamination by foam swabs.

2. Clean the adapter with the foam swab.

3. Dry the inside of the adapter with a clean, dry, foam swab.

4. Blow through the adapter using filtered, dry, compressed air.

Nitrogen gas or compressed dust remover can also be used. Do not shake, tip, or invert compressed air canisters, because this releases particles in the can into the air. Refer to instructions provided on the compressed air canister.

1-10

Connector Care & ESD Information

Caring for Electrical Connections

Caring for Electrical Connections

The following list includes the basic principles of microwave connector care. For more information on

microwave connectors and connector care, consult the Hewlett-Packard Microwave Connector Care

Manual, HP part number 08510-90064.

Handling and Storage

• Keep connectors clean

• Extend sleeve or connect or nut

• Use plastic endcaps during stor ag e

• Do not touch mating plane surfaces

• Do not set connectors contact-end down

Visual Inspection

• Inspect all connectors carefully before every connection

• Look for metal particles, scratches, and dents

• Do not use damaged connectors

Cleaning

• Try cleaning with compre ssed air first

• Clean the connector threads

• Do not use abrasives

• Do not get liquid onto the plastic support beads

Making Connections

• Align connectors carefully

• Make prelimi nary conne ct ion light ly

• To tighten, turn connector nut only

• Do not ap ply bending forc e to connection

• Do not overtighten preliminary conn ec tion

• Do not tw ist or screw in conn ec tors

• Do not tig hte n past the “break” point of the tor que wrench

1-11

Connector Care & ESD Information

Electrostatic Discharge Information

Electrostatic Discharge Information

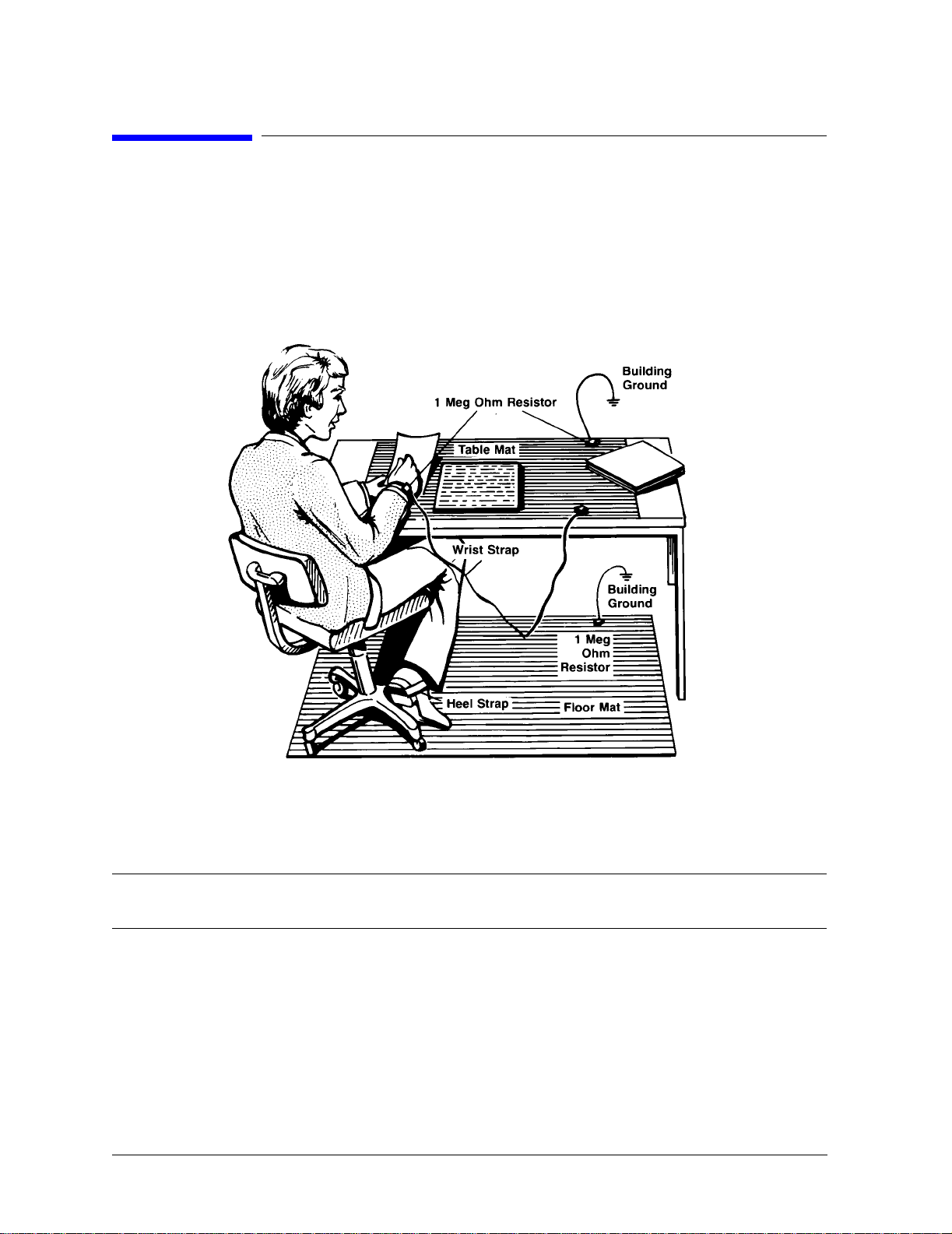

Electrostatic discharge (ESD) can damage or destroy electronic components. All work on electronic

assemblies should be performed at a static-safe work station. The following figure shows an example

of a static-safe work station using two types of ESD protection:

•Conductive table-mat and wrist-strap combination.

•Conductive floor-mat and heel-strap combination.

Both types, when used together, provide a significant level of ESD protection. Of the two, only the

table-mat and wrist-strap combination provides adequate ESD protection when used alone.

To ensure user safety, the static-safe accessories must provide at least 1 MΩ of isolation from ground.

Refer to Table 1-3 on page 1-13 for information on ordering static-safe accessories.

WARNING These techniques for a static-safe work station should not be used when

working on circuitry with a voltage potential greater than 500 volts.

1-12

Connector Care & ESD Information

Electrostatic Discharge Information

Reducing ESD Damage

The following suggestions may help reduce ESD damage that occurs during testing and servicing operations.

• Personnel should be grounded with a resistor-isolated wrist strap before removing any

assembly from the unit.

• Be sure all instruments are properly earth-grounded to prevent a buildup of static charge.

Table 1-3. Static-Safe Accessories

Agilent Part

Number

9300-0797

9300-0980 Wrist-strap cord 1.5 m (5 ft)

9300-1383 Wrist-strap, color black, stainless steel, withoutcord, has four adjustable

9300-1169 ESD heel-strap (reusable 6 to 12 months).

Description

Set includes: 3M static control mat 0.6 m

ft) ground wire. (The wrist-strap andwrist-strap cord are not included. They

must be ordered separately.)

links and a 7 mm post-type connection.

× 1.2 m (2 ft× 4 ft) and 4.6 cm (15

1-13

Connector Care & ESD Information

Electrostatic Discharge Information

1-14

2

“Making Measurements” on page 2-2

“Making a Basic Measurement” on page 2-3

“Using Display Functions” on page 2-4

“Using Markers” on page 2-17

“Using the List Mode to Test a Device” on page 2-37

“Using Limit Lines to Test a Device” on page 2-42

“Using Ripple Limits to Test a Device” on page 2-50

“Using Bandwidth Limits to Test a Bandpass Filter” on page 2-60

“Using Test Sequencing” on page 2-66

“Using Test Sequencing to Test a Device” on page 2-77

“Magnitude and Phase Comparisons of Lightwave Receivers” on page 2-83

“Mathematically Combining Device Responses” on page 2-91

“Using a Coefficient Model for Device Response and Design Model Comparison” on page 2-95

“Using an External Laser” on page 2-98

Making Measurements

Making Measurements

Making Measurements

Making Measurements

This chapter contains an outline of the process for measuring a device and example

procedures for making various measurements. This chapter also describes how to use

display, marker, and sequencing functions.

CAUTION Use of controls, or adjustment, or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

2-2

Making a Basic Measurement

There are four basic steps when you are making a measurement.

Table 2-1. Basic Measurement Sequence

Making Measuremen ts

Making a Basic Measurement

Step 1. Set Up Measurement

Step 2. Perform a Calibration

Step 3. Measure the Device Response

• Connect device under test, including

all adapters and cables.

• Select measurement type: E/O, O/O,

O/E.

• Select settings: start and stop

frequencies, power, number of

points, IF bandwidth, averaging,

sweep type, trigger.

• Select calibration type: response,

response and isolation, response and

match.

• Measure calibration standards.

• Save calibration data.

• Reconnect device under test.

Step 4. Output Measurement Results

⇐

• Analyze measurement data: markers,

limit testing.

• Perform any math operations.

• Save measurement setup and data.

• Print measurement results.

2-3

Making Measurements

Using Display Functions

Using Display Functions

This section provides information for using the display functions. These functions are helpful

for displaying measurement data so that it will be easy to read. This section covers the

following topics:

• Adding titles to your measurements

• Viewing both primary channels at the same time

• Viewing and customizing four-channel measurements

• Using the memory traces

• Using the memory math functions

• Blanking the analyzer’s display

• Changing the colors of the display

2-4

Titling the Active Channel Display

1. Press Display, MORE, TITLE to access the title menu.

Making Measuremen ts

Using Display Functions

2. Press

ERASE TITLE and enter the title you want for your measurement display.

• If you have a DIN keyboard attached to the analyzer, type the title you want from the

keyboard. Then press

ENTER to enter the title into the analyzer. You can enter a title

that has a maximum of 50 characters. (For more information on using a keyboard with

the analyzer, refer to the “Options and Accessories” chapter in the reference guide.)

• If you do not have a DIN keyboard attached to the analyzer, enter the title from the

analyzer front panel.

a. Turn the front panel knob to move the arrow pointer to the first character of the

title.

b. Press

SELECT LETTER.

c. Repeat the previous two steps to enter the rest of the characters in your title. You

can enter a title that has a maximum of 50 characters.

d. Press

DONE, to complete the title entry.

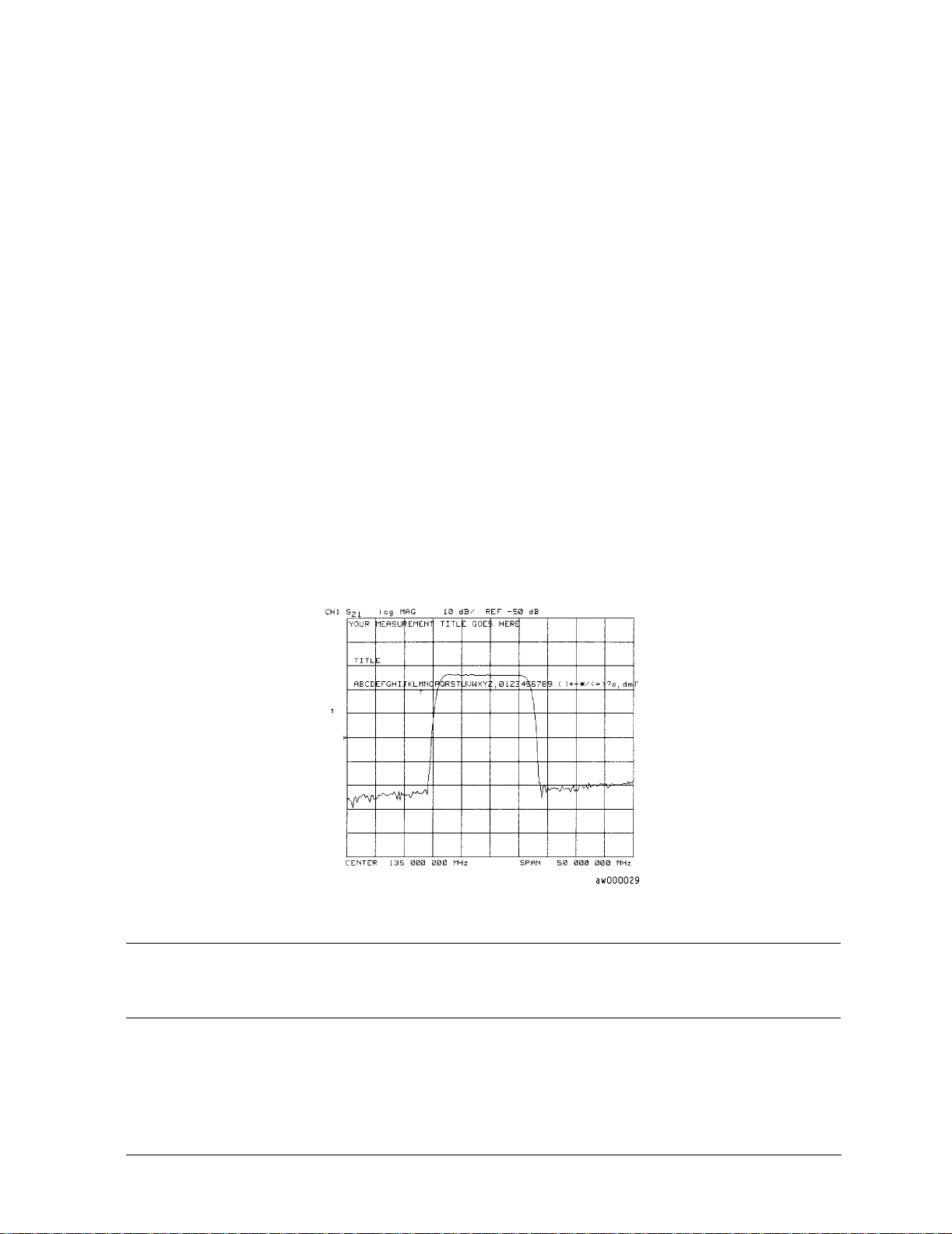

Figure 2-1. Example of a Display Title

CAUTION The NEWLINE, and FORMFEED, keys are not intended for creating display titles.

Those keys are for creating commands to send to peripherals during a sequence

program.

2-5

Making Measurements

Using Display Functions

Viewing Both Primary Measurement Channels

In some cases, you may want to view more than one measured parameter at a time.

Simultaneous gain and phase measurements, for example, are useful in evaluating stability

in negative feedback amplifiers. You can easily make such measurements using the dual

channel display.

1. To see channels 1 and 2 in the same grid, press:

Display, DUAL | QUAD SETUP

set DUAL CHAN on OFF to ON, and SPLIT DISP to 1X

Figure 2-2. Example of Viewing Channel 1 and 2 Simultaneously

2. To view the measurements on separate graticules, press: Set

SPLIT DISP to 2X. The

analyzer shows channel 1 on the upper half of the display and channel 2 on the lower half

of the display. The analyzer defaults to measuring O/O on channel 1 and channel 2.

2-6

Figure 2-3. Example Dual Channel with Split Display On

Making Measuremen ts

Using Display Functions

3. To return to a single-graticule display, press:

SPLIT DISPLAY 1X.

Dual Channel Mode with Decoupled Stimulus

The stimulus functions of the two channels can be controlled independently using

CH ON off

for each channel using

Fctn

in the sweep setup menu. In addition, the markers can be controlled independently

MARKERS: UNCOUPLED in the marker mode menu, under the Marker

key.

COUPLED

NOTE For dual channel, if channels are uncoupled and you have full 2-port

calibrations on both channels, you will not be able to select a non-ratioed

measurement. For example, you can measure S21 or B/R, but not input B.

NOTE Auxiliary channels 3 and 4 are permanently coupled by stimulus to primary

channels 1 and 2, respectively. Decoupling the primary channels’ stimulus from

each other does not affect the stimulus coupling between the auxiliar y channels

and their primary channels.

Dual Channel Mode with Decoupled Channel Power

By decoupling the channel power or port power and using the dual channel mode, you can

simultaneously view two measurements (or two sets of measurements, if both auxiliary

channels are enabled) having different power levels.

However, there are two configurations that will not sweep continuously.

1. For analyzers with source attenuators, with channel 1 having one attenuation value and

channel 2 set to a different attenuation value, then continuous sweep is disabled to avoid

2-7

Making Measurements

Using Display Functions

wear on the attenuator. A similar situation where this occurs is when a 2-port cal is active

and the port 1 attenuation value is not equal to the port 2 attenuation value. Since one

attenuator is used for both measurements, this would cause the attenuator to

continuously switch power ranges, so continuous sweep is not allowed.

2. Channel 1 is driving one test port and channel 2 is driving the other test port. This would

cause the test port transfer switch to continually cycle. The instrument will not allow the

transfer switch or attenuator to continuously switch ranges in order to update these

measurements without the direct intervention of the operator.

If one of these conditions exist, the test set hold mode will engage, and the status notation

tsH will appear on the left side of the screen. The hold mode leaves the measurement

function in only one of the two measurements. To update both measurement setups, press

Sweep Setup, MEASURE RESTART.

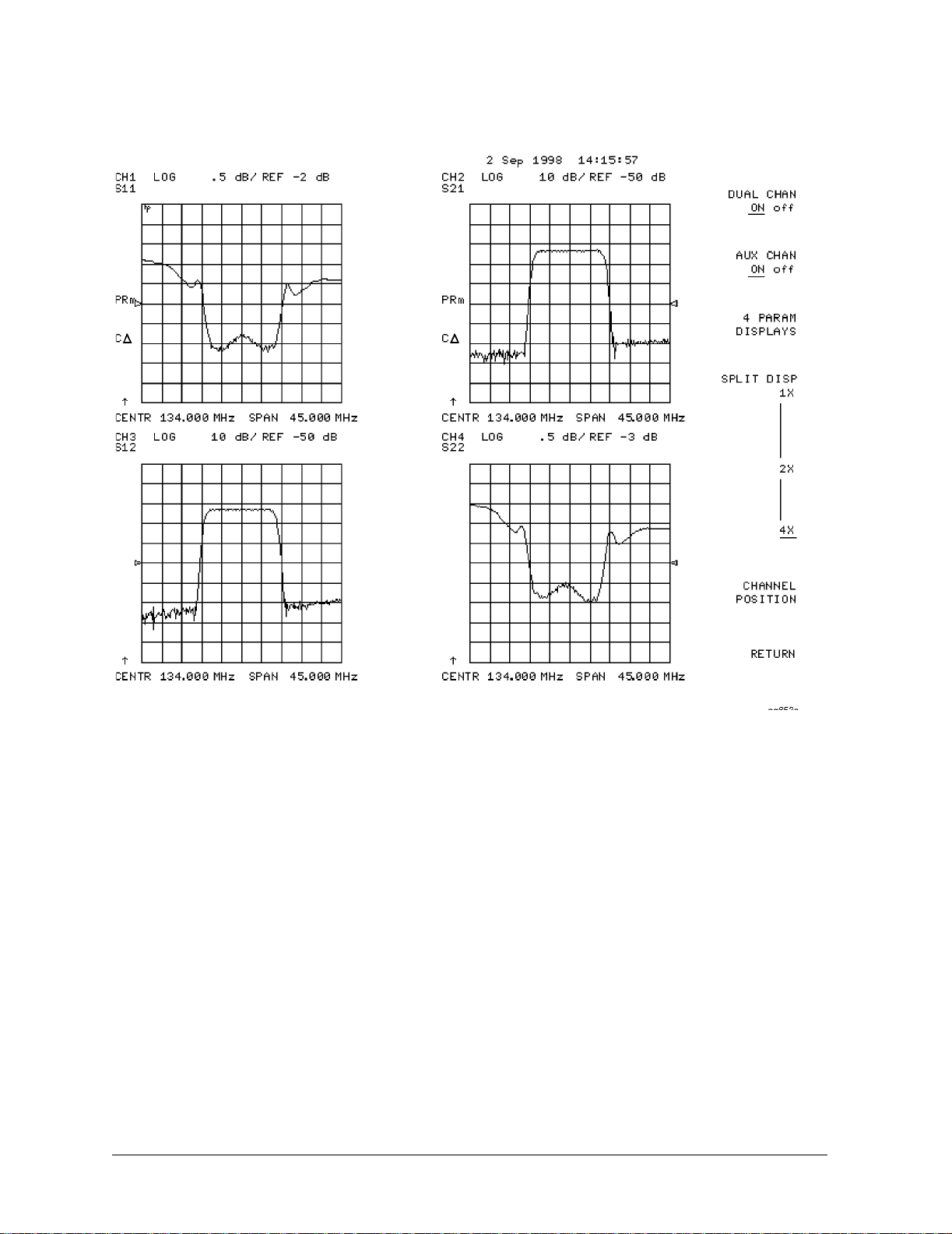

Viewing Four Measurement Channels

Four measurement channels can be viewed simultaneously by enabling auxiliary channels 3

and 4. Although independent of other channels in most variables, channels 3 and 4 are

permanently coupled to channels 1 and 2 respectively by stimulus. That is, if channel 1 is set

for a center frequency of 200 MHz and a span of 50 MHz, channel 3 will have the same

stimulus values.

NOTE Channels 1 and 2 are referred to as primary channels and channels 3 and 4 are

referred to as auxiliary channels.

Channel 3 or 4 are activated when the Chan 3 or Chan 4 keys are pressed. Alternatively, you

can enable the auxiliary channels by setting

active, pressing

AUX CHAN, to ON enables channel 3 and its trace appears on the display.

AUX CHAN to ON. For example, if channel 1 is

Channel 4 is similarly enabled and viewed when channel 2 is active.

1. Press

Format to select the type of display of the data. This example uses the log mag

format.

2. If channel 1 is not active, make it active by pressing

Chan 1.

3. Press Display, DUAL | QUAD SETUP, set DUAL CHAN, to ON, set AUX CHAN, to ON, and set

SPLIT DISP, to 4X.

The display will appear as shown in Figure 2-4 on page 2-9. Channel 1 is in the upper-left

quadrant of the display, channel 2 is in the upper-right quadrant, and channel 3 is in the

lower half of the display.

2-8

Figure 2-4. Three-Channel Display

Making Measuremen ts

Using Display Functions

4. Press Chan 4 (or press

Chan 2, set AUX CHAN, to ON).

This enables channel 4 and the screen now displays four separate grids as shown in

Figure 2-5 on page 2-10. Channel 4 is in the lower-right quadrant of the screen.

2-9

Making Measurements

Using Display Functions

Figure 2-5. Four-Channel Display

5. Press

Chan 4.

Observe that the amber LED adjacent to the Chan 4 key is lit and the CH4 indicator on the

display has a box around it. This indicates that channel 4 is now active and can be

configured.

6. Press

Marker, MARKER 1, MARKER 2.

Markers 1 and 2 appear on all four channel traces. Rotating the front panel control knob

moves marker 2 on all four channel traces. Note that the active function, in this case the

marker frequency, is the same color and in the same grid as the active channel (channel

4).

7. Press

Chan 3.

Observe that the amber LED adjacent to the Chan 3 key is lit. This indicates that channel 3

is now active and can be configured.

8. Rotate the front panel control knob and notice that marker 2 still moves on all four

channel traces.

2-10

Making Measuremen ts

Using Display Functions

9. To independently control the channel markers:

Marker Fctn, MORE, MARKER MODE MENU, set MARKERS: to UNCOUPLED.

Press

Rotate the front panel control knob. Marker 2 moves only on the channel 3 trace.

Once made active, a channel can be configured independently of the other channels in most

variables except stimulus. For example, once channel 3 is active, you can change its format to

a Smith chart by pressing

Format, SMITH CHART.

Customizing the Four-Channel Display

When one or both auxiliary channels are enabled, DUAL CHAN on OFF, and SPLIT DISP 1X 2X

4X,

interact to produce different display configurations according to Table 2-2.

Table 2-2. Customizing the Display

Split Display Dual Channel Aux Channels

On

1X Don't Care Don't Care 1

1X/2X/4X Off None

2X/4X Off 3 or 4 2

2X On Don't Care

4X On 3 or 4 3

4X On Both on 4

Number of

Graticules

Channel Position Softkey

CHANNEL POSITION, gives you options for arranging the display of the channels. Press

Display, DUAL|QUAD SETUP, to use CHANNEL POSITION.

CHANNEL POSITION,

CHANNEL POSITION, gives you two choices for a two-graticule display:

works with SPLIT DISP 1X 2X 4X. When SPLIT DISP 2X, is selected,

• Channels 1 and 2 overlaid in the top graticule, and channels 3 and 4 are overlaid in the

bottom graticule.

• Channels 1 and 3 are overlaid in the top graticule, and channels 2 and 4 are overlaid in

the bottom graticule.

When

SPLIT DISP 4X, is selected, CHANNEL POSITION, gives you two choices for a

four-graticule display:

• Channels 1 and 2 are in separate graticules in the upper half of the display, channels 3

and 4 are in separate graticules in the lower half of the display.

• Channels 1 and 3 are in the upper half of the display, channels 2 and 4 are in the lower

half of the display.

2-11

Making Measurements

Using Display Functions

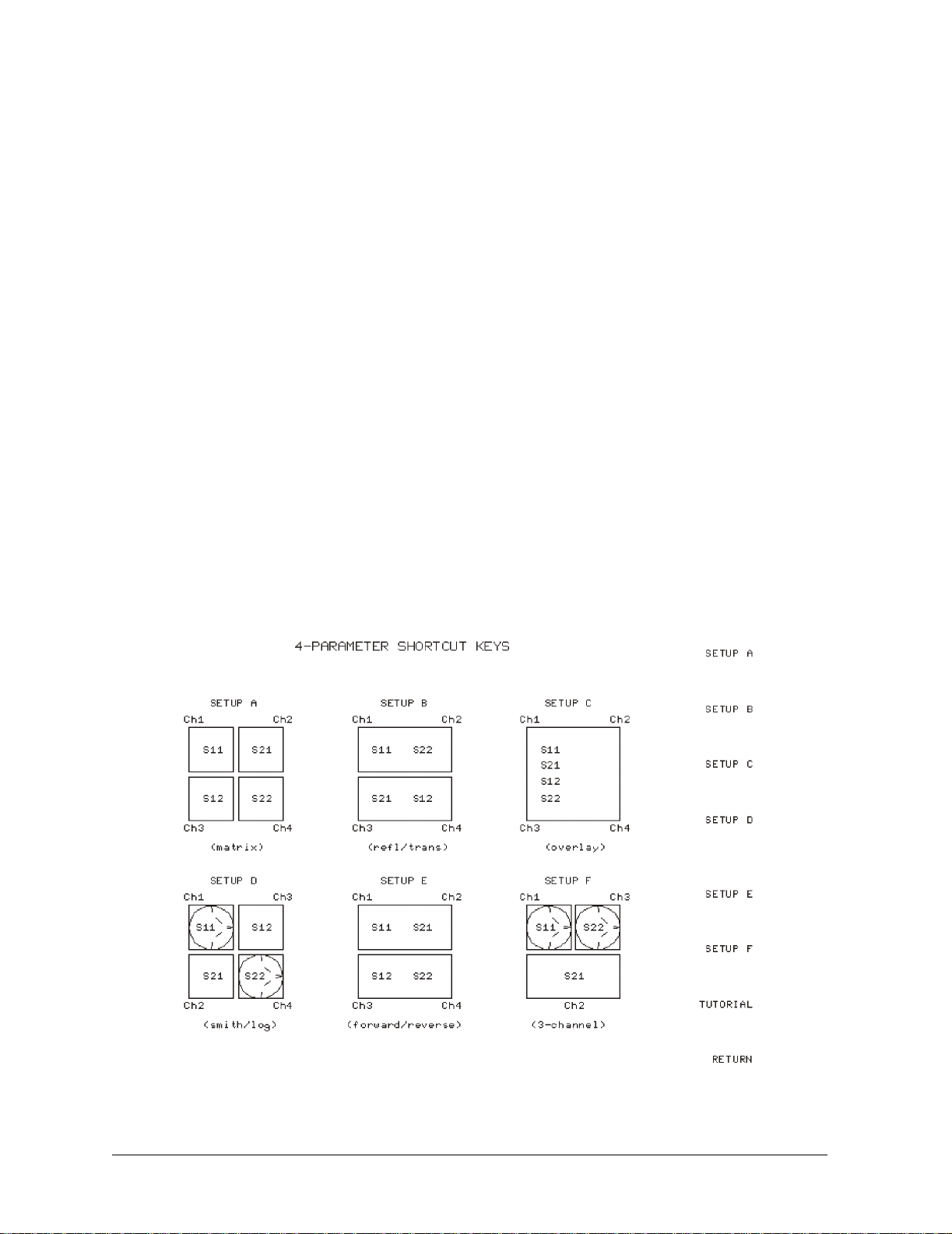

4 Param Displays Softkey

4 PARAM DISPLAYS, menu does two things:

The

• provides a quick way to set up a four-parameter display

• gives information for using softkeys in the

Figure 2-6 shows the first

softkeys

SETUP A, through SETUP F . SETUP A is a four-parameter display where each channel

4 PARAM DISPLAYS, screen. Six setup options are described with

Display, menu

is displayed on its own grid. Pressing SETUP A immediately produces a four-grid,

four-parameter display.

SETUP B, is also a four-parameter display, except that channel 1 and

channel 2 are overlaid on the upper grid and channel 3 and channel 4 are overlaid on the

lower grid. The other setup softkeys operate similarly. Notice that setups D and F produce

displays which include Smith charts.

Pressing

TUTORIAL, opens a screen which lists the order of keystrokes you would have to

enter in order to create some of the setups without using one of the setup softkeys. The

keystroke entries are listed (from top to bottom) beneath each setup and are color-coded to

show the relationship between the keys and the channels. For example, beneath the four-grid

display, [CHAN 1] and [MEAS] S11 are shown in yellow. Notice that in the four-grid graphic,

Ch1 is also yellow, indicating that the keys in yellow apply to channel 1.

Pressing

MORE HELP, opens a screen which lists the hardkeys and softkeys associated with

the auxiliary channels and setting up multiple-channel, multiple-grid displays. Next to each

key is a description of its function.

Figure 2-6. 4 Param Displays Menu

2-12

Making Measuremen ts

Using Display Functions

Using Memory Traces and Memory Math Functions

The analyzer has four available memory traces, one per channel. Memory trace 1 and

memory trace 2 can be used with either channel 1 or channel 2. Memory trace 3 is only

associated with channel 3, and memory trace 4 is only associated with channel 4.

Memory traces can be saved with instrument states: one memory trace can be saved per

channel for each saved instrument state. There are up to 31 save/recall registers available, so

the total number of memory traces that can be present is 128 including the four active for the

current instrument state. The memory data is stored as full precision, complex data. Memor y

traces must be displayed in order to be saved with instrument states.

Additional data can be stored onto 3.5-inch floppy disks using the front panel disk drive.

NOTE You may not be able to store 31 instrument states if they include a large amount

of calibration data. The calibration data contributes considerably to the size of

the instrument state file and therefore the available memory may be full prior

to filling all 31 registers. “Memory Allocation” on page 8-13 in the Reference.

The following trace math operations are implemented:

Table 2-3.

DATA/MEM MEM1/MEM2

DATA-MEM MEM1-MEM2

DATA∗MEM

DATA+MEM MEM2/MEM1

MEM/DATA MEM2-MEM1

MEM-DATA

MEM1∗MEM2

Memory traces are saved and recalled and trace math is performed immediately after

error-correction. This means that any data processing done after error-correction, including

parameter conversion, scaling, and so forth, can be performed on the memory trace. You can

also use trace math as a simple means of error-correction, although that is not its main

purpose.

All data processing operations that occur after trace math, except smoothing is identical for

the data trace and the memory trace. If smoothing is on when a memory trace is saved, this

state is maintained regardless of the data trace smoothing. If a memory trace is saved with

smoothing on, this feature can be turned on or off in the memory-only display mode.

The actual memory for storing a memory trace is allocated only as needed. The memory trace

is cleared on instrument preset, power on, or instrument state recall.

If sweep mode or sweep range is different between the data and memory traces, trace math

is allowed, and no warning message is displayed. If the number of points in the two traces is

2-13

Making Measurements

Using Display Functions

different, the memory trace is not displayed nor rescaled. However, if the number of points

for the data trace is changed back to the number of points in the memory, the memory trace

can then be displayed.

If trace math or display memory is requested and no memory trace exists, the message

CAUTION: NO VALID MEMORY TRACE is displayed.

To Save a Data Trace to the Display Memory

Press

Display, DAT A→MEMORY, to store the current active measurement data in the memory

of the active channel. The data trace is now also the memory trace. You can use a memory

trace for subsequent math manipulations.

To View the Measurement Data and Memory Trace

The analyzer default setting shows you the current measurement data for the active channel.

1. To view a data trace that you have already stored to the active channel memory, press:

Display, MEMORY

This is the only memory display mode where you can change the smoothing of the

memory trace.

2. To view both the memory trace and the current measurement data trace, press:

Display, DATA and MEMORY

To Perform a Math Function

1. You must have already stored a data trace to the active channel memory, as described in

“To Save a Data Trace to the Display Memory” on page 2-14.

2. Press

Display, MATH:DAT A/MEM to divide the data by the memory.

3. To perform other math functions on the measurement data and memory, use the menu

under the

MATH:DAT A/MEM key.

Blanking the Display

Pressing Display, MORE, ADJUST DISPLAY, BLANK DISPLAY switches off the analyzer display

while leaving the instrument in its current measurement state. This feature may be helpful in

prolonging the life of the LCD in applications where the analyzer is left unattended (such as

in an automated test system). Turning the front panel knob or pressing any front panel key

will restore normal display operation.

Pressing Display, FREQUENCY BLANK will blank the displayed frequency notation for

security purposes. The frequency labels cannot be restored except by instrument preset or

turning the power off and then on.

2-14

Adjusting the Colors of the Display

Setting Display Intensity

Making Measuremen ts

Using Display Functions

To adjust the intensity of the display, press

rotate the front panel knob, use the (

up,) (down,) keys, or use the numerical keypad to set the

Display, MORE, ADJUST DISPLAY, INTENSITY, and

intensity value between 50 and 100 percent. Lowering the intensity may prolong the life of

the LCD.

Setting Default Colors

To set all the display elements to the factory-defined default colors, press DISPLAY, MORE

ADJUST DISPLAY,

DEFAULT COLORS.

NOTE Preset, does not reset or change colors to the default color values. However,

cycling power to the instrument will reset the colors to the default color values.

The Modify Colors Menu

MODIFY COLORS softkey within the adjust display menu provides access to the modify

The

colors menu.

The modify colors menu allows you to adjust the colors on your analyzer's display. The

default colors in this instrument were chosen to maximize your ability to discern the

difference between the channel colors, and to comfortably and effectively view the colors.

Each channel’s memory trace color was chosen because the color is similar to the channels

data trace color. This allows easy association between the data trace and the memory trace

for each channel.

You may choose to change the default colors to suit environmental needs, individual

preferences, or to accommodate color deficient vision. You can use any of the available colors

for any of the display elements listed:

CH1 DATA/LIMIT LN CH3 DATA/LIMIT LN

CH1 MEM CH3 MEM

CH2 DATA/LIMIT LN CH4 DATA/LIMIT LN

CH2 MEM CH4 MEM

GRATICULE REF LINE

TEXT WARNING

RIPPLE LIM LINES

To change the color of a display element, press the softkey for that element (such as

). Then press TINT and turn the analyzer front panel knob; use the step keys or the

DATA

CH1

numeric keypad, until the desired color appears.

2-15

Making Measurements

Using Display Functions

NOTE Maximum viewing with the LCD display is achieved when primary colors or a

combination of them are selected at full brightness (100%). Table 2-4 lists the

recommended colors and their corresponding tint numbers.

Table 2-4. Display Colors with Maximum Viewing Angle

Display Color Tint Brightness Color

Red 0 100 100

Yellow 17 100 100

Green 33 100 100

Cyan 50 100 100

Blue 67 100 100

Magenta 83 100 100

White N/A 100 0

Color is comprised of three parameters:

• Tint: The continuum of hues on the color wheel, ranging from red, through green and

blue, and back to red.

• Brightness: A measure of the brightness of the color.

• Color: The degree of whiteness of the color. A scale from white to pure color.

The most frequently occurring color deficiency is the inability to distinguish red, yellow, and

green from one another. Confusion between these colors can usually be eliminated by

increasing the brightness between the colors. To accomplish this, press the

BRIGHTNESS

softkey and turn the analyzer front panel knob. If additional adjustment is needed, vary the

degree of whiteness of the color. To accomplish this, press the

COLOR, softkey and turn the

analyzer front panel knob.

NOTE Color changes and adjustments remain in effect until changed again in these

menus or the analyzer is powered off and then on again. Cycling the power

changes all color adjustments to default values. Once the colors are saved,

pressing the Preset key does not affect the color selections.

Saving Modified Colors

To save a modified color set, press

Display , MORE, ADJUST DISPLAY, SAVE COLORS. Modified

colors are not part of a saved instrument state and are lost unless saved using these softkeys.

Once modified colors are saved, they will be the colors applied until you press

Preset.

Recalling Modified Colors

To recall the previously saved color set, press

2-16

RECALL COLORS.

Making Measuremen ts

Using Markers

Using Markers

The Marker, key displays a movable active marker on the screen and provides access to a

series of menus to control up to five display markers for each channel. By using markers, you

can obtain numerical readings of measured values. Markers also provide capabilities for

reducing measurement time by changing stimulus parameters, searching the trace for

specific values, or statistically analyzing part or all of the trace.

Markers have a stimulus value (the x-axis value in a Cartesian format) and a response value

(the y-axis value in a Cartesian format). In polar format, the second part of a complex data

pair is also provided as an auxiliary response value. In Smith chart format, the real and

imaginary rectangle are both displayed, and the effective capacitance or inductance of the

imaginary part is also displayed. When a marker is activated and no other function is active,

its stimulus value is displayed in the active entry area and can be controlled with the knob,

the step keys, or the numeric keypad. The active marker can be moved to any point on the

trace, and its response and stimulus values are displayed at the top right corner of the

graticule for each displayed channel, in units appropriate to the display format. The

displayed marker response values are valid even when the measured data is above or below

the range displayed on the graticule.

• If you activate both data and memory traces, the marker values apply to the data trace.

• If you activate only the memory trace, the marker values apply to the memory trace.

• If you activate a memory math function, the marker values apply to the trace resulting

from the memory math function.

Marker values are normally continuous: that is, they are interpolated between measured

points. They can also be set to read only discrete measured points. Markers normally have

the same stimulus values for all channels, or they can be uncoupled so that each channel has

independent markers, regardless of whether stimulus values are coupled or dual channel

display is on.

To Use Continuous and Discrete Markers

The analyzer can either place markers on discrete measured points, or move the markers

continuously along a trace by interpolating the data value between measured points.

• Press

Marker Fctn, MORE, MARKER MODE MENU, and select one of the following choices:

—Choose

point on the trace, by interpolating between measured points. This default mode allows

you to conveniently obtain round numbers for the stimulus value.

—Choose

measured trace points determined by the stimulus settings. This may be the best mode

to use with automated testing, using a computer or test sequencing because the

analyzer does not interpolate between measured points.

MARKERS: CONTINUOUS, if you want the analyzer to place markers at any

MARKERS: DISCRETE, if you want the analyzer to place markers only on

2-17

Making Measurements

Using Markers

NOTE Using MARKERS: DISCRETE, will also affect marker search and positioning

functions when the value entered in a search or positioning function does not

exist as a measurement point. The marker will be positioned to the closest

adjacent point that satisfies the search or positioning value.

To Activate Display Markers

• To switch on marker 1 and make it the active marker, press:

Marker, MARKER 1

The active marker is identified on the analyzer display with the following symbol: ∇

The active marker stimulus value is displayed in the active entry area. You can modify the

stimulus value of the active marker, using the front panel knob or numerical keypad. All of

the marker response and stimulus values are displayed in the upper right corner of the

display.

Figure 2-7. Active Marker Control Example

To switch on the corresponding marker and make it the active marker, press:

MARKER 2 or MARKER 3 or MARKER 4, or MARKER 5

All of the markers, other than the active marker, become inactive and are represented on the

analyzer display as ∆. The active and inactive markers are shown in Figure 2-8.

2-18

Figure 2-8. Active and Inactive Markers Example

Making Measuremen ts

Using Markers

• To switch off all of the markers, press

ALL OFF.

To Move Marker Information Off the Grids

If marker information obscures the display traces, you can turn off the softkey menu and

move the marker information off the display traces and into the softkey menu area. Pressing

the backspace key ⇐

alternately hides and restores the current softkey menu. The softkey menu is also restored

when you press any softkey or a hardkey which leads to a menu. The following procedure

shows how you can view the marker information in the softkey area.

1. Set up a four-graticule display as described in "Viewing Four Measurement Channels" on

page 1-18.

2. Activate four markers by pressing

NOTE Observe that the markers appear on all of the grids. To activate markers on

individual grids, press Marker Fctn, MORE, MARKER MODE MENU, and set

MARKERS:, to UNCOUPLED. Then, activate the channel in which you wish to

have markers, press Marker then select the markers for that channel.

3. Turn off the softkey menu and move the marker information off the grids by pressing ⇐.

The display will be similar to Figure 2-9.

, performs this function. This is a toggle function. Pressing ⇐,

Marker, 1, 2, 3, 4.

2-19

Making Measurements

Using Markers

Figure 2-9. Marker Information Moved into the Softkey Menu Area

pg654e

4. Restore the softkey menu and move the marker information back onto the graticules:

Press ⇐

.

The display will be similar to Figure 2-10.

2-20

Figure 2-10. Marker Information on the Graticules

Making Measuremen ts

Using Markers

pg655e

You can also restore the softkey menu by pressing a hardkey which opens a menu (such as

Meas) or pressing a softkey.

To Use Delta (∆) Markers

This is a relative mode, where the marker values show the position of the active marker

relative to the delta reference marker. You can switch on the delta mode by defining one of

the five markers as the delta reference.

1. Press

2. To move marker 1 to any point that you want to reference:

3. Press

Marker, ∆ MODE MENU, ∆ REF=1, to make marker 1 a reference marker.

•Turn the front panel knob.

OR

• Enter the frequency value (relative to the reference marker) on the numeric keypad.

Marker, MARKER 2, and move marker 2 to any position that you want to measure in

reference to marker 1.

2-21

Making Measurements

Using Markers

Figure 2-11. Marker 1 as the Reference Marker Example

4. To change the reference marker to marker 2, press:

∆ MODE MENU, ∆ REF=2

To Activate a Fixed Marker

When a reference marker is fixed, it does not rely on a current trace to maintain its fixed

position. This is convenient when comparing two different measurement conditions. To

activate a fixed marker on the analyzer, press

Marker zero puts a fixed reference at the current position of the active marker.

To change to a Delta Marker to a fixed reference marker, press

∆REF=∆FIXED MKR.

Using the MKR ZERO Key to Activate a Fixed Reference Marker

Marker zero enters the position of the active marker as the ∆ reference position.

Alternatively, you can specify the fixed point with

canceled by switching delta mode off.

1. To place marker 1 at a point that you would like to reference, press:

Marker, and turn the front panel knob, or enter a value from the front panel keypad.

2. To measure values along the measurement data trace, relative to the reference point that

you set in the previous step, press:

MKR ZERO, and turn the front panel knob, or enter a value from the front panel keypad.

Marker, MKR ZERO.

Marker, ∆ MODE MENU,

FIXED MKR POSITION. Marker zero is

3. To move the reference position, press:

∆MODE MENU, FIXED MKR POSITION, FIXED MKR STIMULUS, and turn the front panel

knob, or enter a value from the front panel keypad.

2-22

Figure 2-12. Example of a Fixed Reference Marker Using MKR ZERO

Making Measuremen ts

Using Markers

Using the

∆REF=∆FIXED MKR, Key to Activate a Fixed Reference Marker

1. To set the frequency value of a fixed marker that appears on the analyzer display, press:

Marker, ∆MODE MENU, ∆REF=∆FIXED MKR, ∆MODE MENU, FIXED MKR POSITION, FIXED

MKR STIMULUS,

and turn the front panel knob, or enter a value from the front panel

keypad.

The marker is shown on the display as a small delta (∆), smaller than the inactive marker

triangles.

2. To set the response value (dB) of a fixed marker, press:

FIXED MKR VALUE, and turn the front panel knob, or enter a value from the front panel

keypad.

In a Cartesian format, the setting is the y-axis value. In polar or Smith chart format, with

a magnitude/phase marker, a real/imaginary marker, an R+jX marker, or a G+jB marker,

the setting applies to the first part of the complex data pair. (Fixed marker response

values are always uncoupled in the two channels.)

3. To set the auxiliary response value of a fixed marker when you are viewing a polar or

Smith format, press:

FIXED MKR AUX VALUE, and turn the front panel knob, or enter a value from the front

panel keypad.

This value is the second part of complex data pair, and applies to a magnitude/phase

marker, a real/imaginary marker, an R+jX marker, or a G+jB marker. (Fixed marker

auxiliary response values are always uncoupled in the two channels.)

2-23

Making Measurements

Using Markers

Figure 2-13. Example of a Fixed Reference Marker Using (∆)REF=(∆)FIXED MKR

To Couple and Uncouple Display Markers

At a preset state, the markers have the same stimulus values on each channel, but they can

be uncoupled so that each channel has independent markers.

Press

• Choose

Marker Fctn, MORE, MARKER MODE MENU, and select from the following keys:

MARKERS: COUPLED, if you want the analyzer to couple the marker stimulus

values for the display channels.

• Choose

MARKERS: UNCOUPLED, if you want the analyzer to uncouple the marker

stimulus values for the display channels. This allows you to control the marker stimulus

values independently for each channel.

Figure 2-14. Example of Coupled and Uncoupled Markers

2-24

Making Measuremen ts

Using Markers

To Use Polar Format Markers

The analyzer can display the marker value as magnitude and phase, or as a real/imaginary

pair: LIN MKR, gives linear magnitude and phase, LOG MKR, gives log magnitude and phase,

Re/Im, gives the real value first, then the imaginary value.

You can use these markers only when you are viewing a polar display format. (The format is

available from the

NOTE For greater accuracy when using markers in the polar format, it is

1. To access the polar markers, press:

Format, POLAR, Marker Fctn, MORE, MARKER MODE MENU, POLAR MKR MENU

2. Select the type of polar marker you want from the following choices:

Format, key.)

recommended to activate the discrete marker mode. Press

MKR MODE MENU, MARKERS:DISCRETE.

Marker Fctn, MORE,

•Choose

LIN MKR, if you want to view the magnitude and the phase of the active marker.

The magnitude values appear in units and the phase values appear in degrees.

•Choose

LOG MKR, if you want to view the logarithmic magnitude and the phase of the

active marker. The magnitude values appear in dB and the phase values appear in

degrees.

•Choose

Re/Im MKR, if you want to view the real and imaginary pair, where the complex

data is separated into its real part and imaginary part. The analyzer shows the real

part as the first marker value (M cos Θ), and the second value is the imaginary part (M

sin Θ, where M = magnitude).

Figure 2-15. Example of a Log Marker in Polar Format

2-25

Making Measurements

Using Markers

To Use Smith Chart Markers

To avoid displaying marker data interpolated between measured points when using markers

in the Smith chart format, activate the discrete marker mode. Press

MODE MENU,

interpolate between points.)

MARKERS:DISCRETE. (Discrete markers will display only measured data and do not

To use Smith chart format:

Marker Fctn, MORE, MKR

1. Press

Format, SMITH CHART.

2. Press Marker Fctn, MORE, MARKER MODE MENU, SMITH MKR MENU, and turn the front

panel knob, or enter a value from the front panel keypad to read the resistive and reactive

components of the complex impedance at any point along the trace. This is the default

Smith chart marker.

The marker annotation tells that the complex impedance is capacitive in the bottom half

of the Smith chart display and is inductive in the top half of the display.

•Choose

LIN MKR, if you want the analyzer to show the linear magnitude and the phase

of the reflection coefficient at the marker.

•Choose

LOG MKR, if you want the analyzer to show the logarithmic magnitude and the

phase of the ref lection coefficient at the active marker. This is useful as a fast method

of obtaining a reading of the log magnitude value without changing to log magnitude

format.

•Choose

Re/Im MKR, if you want the analyzer to show the values of the reflection

coefficient at the marker as a real and imaginary pair.

•Choose

R+jX MKR, to show the real and imaginary parts of the device impedance (the

series resistance and reactance, in ohms) at the marker. Also shown is the equivalent

series inductance or capacitance.

•Choose

G+jB MKR, to show the complex admittance values of the active marker in

rectangular form. The active marker values are displayed in terms of conductance (in

Siemens), susceptance, and equivalent parallel circuit capacitance or inductance.

Siemens are the international unit of admittance and are equivalent to mhos (the

inverse of ohms).

2-26

Figure 2-16. Example of Impedance Smith Chart Markers

To Set Measurement Parameters Using Markers

Making Measuremen ts

Using Markers

The analyzer allows you to set measurement parameters with the markers, without going

through the usual key sequence. You can change certain stimulus and response parameters

to make them equal to the current active marker value.

Setting the Start Frequency

1. Press

Marker Fctn, and turn the front panel knob, or enter a value from the front panel

keypad to position the marker at the value that you want for the start frequency.

2. Press

MARKER→START, to change the start frequency value to the value of the active

marker.

Figure 2-17. Example of Setting the Start Frequency Using a Marker

2-27

Making Measurements

Using Markers

Setting the Stop Frequency

1. Press

Marker Fctn, and turn the front panel knob, or enter a value from the front panel

keypad to position the marker at the value that you want for the stop frequency.

2. Press

MARKER→STOP, to change the stop frequency value to the value of the active

marker.

Figure 2-18. Example of Setting the Stop Frequency Using a Marker

Setting the Center Frequency

1. Press

Marker Fctn, and turn the front panel knob, or enter a value from the front panel

keypad to position the marker at the value that you want for the center frequency.

2. Press

MARKER→CENTER, to change the center frequency value to the value of the active

marker.

Figure 2-19. Example of Setting the Center Frequency Using a Marker

2-28

Making Measuremen ts

Using Markers

Setting the Frequency Span

You can set the span equal to the spacing between two markers. If you set the center

frequency before you set the frequency span, you will have a better view of the area of

interest.

1. Press

Marker, ∆MODE MENU, ∆REF=1, MARKER 2.

2. Turn the front panel knob, or enter a value from the front panel keypad to position the

markers where you want the frequency span.

Iterate between marker 1 and marker 2 by pressing

MARKER 1, and MARKER 2,

respectively, and turning the front panel knob or entering values from the front panel

keypad to position the markers around the center frequency. When finished positioning

the markers, make sure that marker 2 is selected as the active marker.

NOTE Step 2 can also be performed using MKR ZERO, and MARKER 1. However, when

using this method, it will not be possible to iterate between marker zero and

marker 1.

3. Press Marker Fctn, MARKER→SPAN, to change the frequency span to the range between

marker 1 and marker 2.

Figure 2-20. Example of Setting the Frequency Span Using Marker

Setting the Display Reference Value

1. Press

Marker Fctn, and turn the front panel knob, or enter a value from the front panel

keypad to position the marker at the value that you want for the analyzer display

reference value.

2. Press

MARKER→REFERENCE, to change the reference value to the value of the active

marker.

2-29

Making Measurements

Using Markers

Figure 2-21. Example of Setting the Reference Value Using a Marker

Setting the Electrical Delay

This feature adds phase delay to a variation in phase versus frequency, therefore it is only

applicable for ratioed inputs.

1. Press

Format, PHASE.

2. Press Marker Fctn, and turn the front panel knob, or enter a value from the front panel

keypad to position the marker at a point of interest.

3. Press

MARKER→DELAY, to automatically add or subtract enough line length to the

receiver input to compensate for the phase slope at the active marker position. This

effectively flattens the phase trace around the active marker. You can use this to measure

the electrical length or deviation from linear phase.

Additional electrical delay adjustments are required on devices without constant group

delay over the measured frequency span.

2-30

Figure 2-22. Example of Setting the Electrical Delay Using a Marker

Setting the CW Frequency

Making Measuremen ts

Using Markers

1. To place a marker at the desired CW frequency, press:

Marker, and either turn the front panel knob or enter the value, followed by a unit

terminator.

2. Press

Seq, SPECIAL FUNCTIONS, MKR→CW.

You can use this function to set the marker to a gain peak in an amplifier. After pressing

MKR→CW FREQ, activate a CW frequency power sweep to look at the gain compression

with increasing input power.

2-31

Making Measurements

Using Markers

To Search for a Specific Amplitude

These functions place the marker at an amplitude-related point on the trace. If you switch on

tracking, the analyzer searches every new trace for the target point.

Searching for the Maximum Amplitude

1. Press

2. Press

Marker Search, to access the marker search menu.

SEARCH: MAX, to move the active marker to the maximum point on the

measurement trace.

Figure 2-23. Example of Searching for the Maximum Amplitude Using a Marker

Searching for the Minimum Amplitude

1. Press

2. Press

Marker Search, to access the marker search menu.

SEARCH: MIN, to move the active marker to the minimum point on the measurement

trace.

2-32

Making Measuremen ts

Figure 2-24. Example of Searching for the Minimum Amplitude Using a Marker

Searching for a Target Amplitude

Using Markers

1. Press

2. Press

Marker Search, to access the marker search menu.

SEARCH: TARGET, to move the active marker to the target point on the

measurement trace.

3. If you want to change the target amplitude value (default is −3 dB), press

TARGET, and

enter the new value from the front panel keypad. You may also press Marker Search,

TARGET VALUE, to enter the new value.

4. If you want to search for multiple responses at the target amplitude value, press

and SEARCH RIGHT.

LEFT,

Figure 2-25. Example of Searching for a Target Amplitude Using a Marker

SEARCH

2-33

Making Measurements

Using Markers

Searching for the 3 dB Bandwidth of a Lowpass Device

The analyzer can search for the 3 dB bandwidth, locating the rolloff on the high side of a

device’s passband.

1. Press

Marker, Marker 1.

2. Move marker 1 to any point that you want to reference:

•Turn the front panel knob.

OR

• Enter the frequency value on the numeric keypad.

5. Press Marker Search, 3 DB BANDWIDTH.

Searching for the Bandwidth and Related Information of a Bandpass Device

The analyzer can automatically calculate and display the bandwidth (BW:), center frequency

(CENT:), Q, and loss of the device under test at the center frequency. (Q stands for “quality

factor,” defined as the ratio of a circuit's resonant frequency to its bandwidth.) These values

are shown in the marker data readout.

1. Press

Marker Search, and SEARCH: MAX, to place the marker near the center of the filter

passband.

2. Press Marker,

3. Press

Marker Fctn, MORE, BANDWIDTH VALUE and enter the amplitude value (default

MKR ZERO, if you want the bandwidth relative to the maximum.

is −3 dB) that defines the passband or reject band.

4. If you want to change the amplitude value (default is −3 dB) that defines the passband or

reject band, press

WIDTH VALUE, and enter the new value from the front panel keypad.

5. Press BANDWIDTH for the analyzer to calculate the center stimulus value, bandwidth,

and the Q of a bandpass or band reject shape on the measurement trace.

Figure 2-26. Example of Searching for the Bandwidth of a Bandpass Device

2-34

Making Measuremen ts

Using Markers

Tracking the Amplitude that You Are Searching

1. Set up an amplitude search by following one of the previous procedures in “To Search for

a Specific Amplitude” on page 2-32.

2. Press

Marker Search, TRACKING ON, to track the specified amplitude search with every

new trace and put the active marker on that point.

When tracking is not activated, the analyzer finds the specified amplitude on the current

sweep and the marker remains at same stimulus value, regardless of changes in the trace

response value with subsequent sweeps.