Page 1

User's/Reference Guide

HP 8509A/B LightwavePolarization

Analyzer

ABCDE

08509-90016

No.

Part

HP

Printed

in

USA

October

Supersedes:

1994

08509-90003

Page 2

Notice.

The information contained in this document is sub ject to change

without notice.

Hewlett-Packard makes no warrantyofany kind with regard to this

material, including but not limited to, the implied warranties of

merchantability and tness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental

or consequential damages in connection with the furnishing,

performance, or use of this material.

Microsoft, MS, MS-DOS, and the Microsoft logo are registered

trademarks, and Windows is a trademark, of Microsoft Corporation.

c

All

Cop

Righ

yrigh

ts

Reserv

without prior

cop

F

the

oun

taingro

under

1400

Hewlett-P

t

ed.

written

t

yrigh

e

v

ac

Repro

ermission

p

ws.

la

arkw

P

1992,

k

ard

Compan

y

duction, adaptation,

prohibited,

is

CA

a

,

y

Santa

Rosa,

1994

or

except

95403,

translation

allo

as

USA

ed

w

Page 3

Certification

Hewlett-Packard Company certies that this pro duct met its

published sp ecications at the time of shipment from the factory.

Hewlett-Packard further certies that its calibration measurements

are traceable to the United States National Institute of Standards

and Technology, to the extent allowed by the Institute's calibration

facility, and to the calibration facilities of other International

Standards Organization members.

Regulatory Information

Warranty

Chapter 9 contains regulatory information.

This Hewlett-Packard instrument product is warranted against

defects in material and workmanship for a perio d of one year from

date of shipment. During the warranty perio d, Hewlett-Packard

Company will, at its option, either repair or replace products which

b

to

e

v

pro

arran

w

or

F

service

shipping

shipping

shall

to

facilit

c

c

all

pay

Hewlett-P

Hewlett-P

Hewlett-P

y

b

programming

its

instrument.

instrumen

the

of

defectiv

e

y

t

y

harges

harges

shipping

ac

ard

k

ac

ac

Hewlett-Pac

e.

service

or

designated

Hewlett-P

to

return

to

from

ard

k

arran

w

for

ard

k

instructions

or

t,

repair,

harges,

c

another

ts

use

k

w

soft

Hewlett-P

y

b

ac

the

duties,

that

with

when

do

ard

are,

this

k

pro

its

es

or

ard

coun

an

duct

pro

ac

and

to Buy

duct

and

try

are

w

soft

instrumen

prop

w

not

are

w

rm

ust

m

ard.

k

Hewlett-P

er.

taxes

.

and

t

installed

erly

t

arran

will

b

Buy

Ho

for

rm

will

that

e

b

returned

e

shall prepa

er

ard

k

ac

er,

ev

w

ducts

pro

are

w

execute

on that

op

the

terrupted or

unin

to a

y

shall pa

er

Buy

returned

designated

eration

error-free.

y

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance byBuyer, Buyer-supplied

software or interfacing, unauthorized modication or misuse,

the

eration

op

pro

duct,

outside

or

NO OTHER W

of

improp

er

preparation

site

or

ARRANTY IS EXPRESSED OR

vironmental

en

the

HEWLETT-PACKARD SPECIFICALL

IMPLIED W

FITNESS F

ARRANTIES OF MER

OR A P

ARTICULAR PURPOSE.

CHANTABILITY

ecications

sp

tenance.

main

Y DISCLAIMS THE

for

IMPLIED.

AND

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE

CKARD

AMA

D

A

GES,

SPECIAL,

WHETHER

AND EX

NOT

CLUSIVE

LIABLE

BE

INCIDENT

AL,

REMEDIES.

ANY

OR

F

CONSEQUENTIAL

OR

HEWLETT-P

DIRECT,

INDIRECT,

SHALL

iii

Page 4

BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL

THEORY.

Assistance

Safety Notes

Caution

W

arning

Product maintenance agreements and other customer assistance

agreements are available for Hew lett-Packardproducts.

For any assistance, contact your nearest Hewlett-Packard Sales and

ServiceOce.

The following safety notes are used throughout this manual.

Familiarize yourself with each of the notes and its meaning b efore

operating this instrument.

cedure that,

pro

a

to

tion

atten

calls

Caution

not

denotes

correctly

destruction

indicated

the

til

un

correctly

Do

life.

denotes

arning

W

not

of

conditions

erformed

p

of the

performed

proceed

not

fully

are

hazard.

a

instrumen

conditions

hazard.

a

understood

It

or adhered

t.

are

calls

It

adhered

or

ond

bey

Do

a

and

fully

w

ould result

to, w

pro

not

understo

attention

could

to,

arning

met.

ceed

to

note

ey

b

d

o

procedure

a

result

until

in damage

caution

a

ond

met.

and

injury

in

indicated

the

to

which,

loss

or

sign

if

or

if

is

duct

for

the

pro

user

to

refer

to

L

ed with

mark

instructions

the

The

instruction

this sym

the

in

b

do

ol

do

cumen

when

cumen

tation

is

it

tation.

symb

necessary

ol. The

\CE" The CE mark is a registered trademark of the European

Community. (If accompanied byayear, it is when the design was

proven.)

Industrial

an

of

ol

b

a sym

is

1

This

Class

A

pro

duct.

\ISM1-A"

Group

\CSA" The CSA mark is a registered trademark of

Scien

the Canadian

Medical

and

tic

Standards Asso ciation.

iv

Page 5

General Safety Considerations

Warning

Warning

Caution

This is a Safety Class I product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall only be

inserted in a socket outlet provided with a protective earth contact.

Any interruption of the protective conductor, inside or outside the

instrument, is likely to make the instrument dangerous. Intentional

interruption is prohibited.

No operator serviceable parts inside. Refer servicing to qualified

personnel. To prevent electrical shock, do not removecovers.

Before switching on this instrument, make sure that the line voltage

selector switch is set to the voltage of the power supply and the

correct fuse is installed.

v

Page 6

Page 7

Contents

1. Getting Started

Description of the Instrument . . . . . . . . . . 1-1

Installation . . . . . . . . . . . . . . . . . . 1-1

About This Manual Set . . . . . . . . . . . . . 1-2

This guide uses the following conventions: . . . . 1-2

HP 8509A/B User's/Reference Guide Table of

Contents (this manual) . . . . . . . . . . . 1-3

The Main Menu . . . . . . . . . . . . . . . . 1-4

The Data Displays (Power, DOP, Ellipse and Poincare

Sphere) . . . . . . . . . . . . . . . . . . 1-5

.

.

.

.

.

.

.

.

.

.

.

.

.

.

y

Ellipse

unctions

F

Mark

a

Mark

a

Mark

Sphere

the

.

.

. .

.

er

er

oin

.

.

.

.

ers

ers

. .

.

t

.

.

.

.

at

at

On

P

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Curren

the

User-Sp

a

and O

.

.

.

Mark

a

on

olarization

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

ecied

.

er

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

P

Data

t

oin

P

.

.

.

.

.

.

Curren

or

Reference

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

oin

.

.

.

.

. 1-5

.

.

.

.

.

. 1-5

. .

.

.

.

.

.

.

.

.

t

. 1-7

.

.

t

.

.

.

.

.

.

t

oin

P

t

. .

.

.

.

.

. 1-10

. .

wer

Po

DOP

oincare

P

olarization

P

Mark

The

Setting

Setting

Setting

urning

T

Clearing

Cen

Tw

om and

Zo

Zoom

Displa

tering

or

o-

Display

Sphere

er

Marker

a

the

the Mark

Three-P

Rotate .

.

.

ToZoomIn . . . . . . . . . . . . . . . . 1-10

To Zoom Out . . . . . . . . . . . . . . . 1-10

The Zo om Factor Function . . . . . . . . . 1-10

Rotate . . . . . . . . . . . . . . . . . . . 1-11

To Rotate the Sphere . . . . . . . . . . . . 1-11

The

4

5

Home

4

Clea

r

4

ClearT

T

race

and

5

5

. . . . . . . . . . . . . . . . . . 1-11

race

Hold . . . . . .

45

and Cal

45

Source W

. . . . . .

. . . . . . . . . . . . . . . . .

avelength . . . . . . . . . . . . . . 1-12

Button

Hold

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

. . . . . . . . . . . . . . 1-11

. 1-12

. . . . . . . . . . . . . . . 1-12

. .

.

.

.

.

.

.

.

.

.

.

Cal . . . . . . . . . . . . . . . . . . . . . 1-12

1-5

1-5

1-6

1-6

1-7

1-8

1-8

1-9

1-9

1-10

1-11

1-11

Contents-1

Page 8

2. Making Measurements

Conventions . . . . . . . . . . . . . . . . . 2-1

PMD Measurement: Jones Matrix Eigenanalysis

Method . . . . . . . . . . . . . . . . . . 2-2

Basic Measurement. . . . . . . . . . . . . . . 2-3

Setting up the System . . . . . . . . . . . . 2-3

External Source Preparation . . . . . . . . . . 2-4

Making the Measurement . . . . . . . . . . . 2-8

Manipulating the Measurement Results . . . . . . 2-13

The Measurement Summary Bar . . . . . . . . 2-13

The Measurement Annotation Area . . . . . . . 2-14

Using The Cursor . . . . . . . . . . . . . . 2-15

Changing The MeasurementFormat . . . . . . 2-15

Changing The Graph's Y-Scale . . . . . . . . . 2-16

Displaying and Printing Data in Tabular Format . 2-16

Displaying Data in a Statistical Format . . . . . 2-17

The File menu . . . . . . . . . . . . . . . 2-19

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Add from Selected JME Window F2

N

N

N

Add

NN

N

Add

N

N

N

Load

N

N

N

Save Statistics...F6

N

N

N

Print Bitmap

N

N

N

Print

N

NN

Exit

The

The

The Help

The

ting

Prin

ving

Sa

Saving in Database Format . . . . . . . . . . 2-23

Specialized Measurement Metho ds . . . . . . . . 2-24

Performing a Cascade Measurement . . . . . . 2-24

Setting up the System . . . . . . . . . . . 2-24

Making

Using

Using

PMD:JME Concepts

Polarization Mo de Dispersion

Polarization modes

General eects .

Mode coupling . . . . . . . . . . . . . . . 2-29

PMD units . . . . . . . . . . . . . . . . 2-30

Fiber PMD statistics . . . . . . . . . . . . . 2-30

Fitting

Enlarging

Source

Should

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

from

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

from

N

N

N

N

N

N

N

N

NN

NN

N

N

N

N

Statistics...F5

N

N

NN

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

.

Edit

ormat

F

Annotation

the

our

y

the

oltage-T

V

a

Manually-T

a

the

ectral

sp

use

I

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

Database...F3

N

N

N

NN

NN

NN

NN

N

N

N

N

N

Text

NN

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

Data

.

.

u

men

Men

menu

PMD:JME

Measurement

Measuremen

uned

Maxw

sample

the

haracteristics

c

reference

the

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

File...F4

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

N

N

N

N

N

N

.

.

.

.

.

.

.

.

.

.

.

.

u

.

.

Area

Graph

Source

uned

. . . . . . . . .

. . . . . . . .

. . . . . . . . . . . . . . 2-29

ell curv

size

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

NN

N

NN

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

.

.

. .

.

.

.

.

.

. .

.

.

.

.

.

as T

t .

source

to

e

frame?

N

N

N

N

N

N

N

N

N

.

.

.

.

.

.

.

.

N

N

N

N

N

N

.

.

.

.

.

.

. .

.

.

.

.

.

.

. .

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

ext .

.

.

.

. .

.

.

.

.

. . . . . . . . . 2-29

distribution

the

.

.

.

.

.

.

.

.

. . . . 2-19

.

.

.

.

.

.

. 2-19

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 2-22

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . . . . 2-29

. . . . . 2-29

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

2-19

2-19

2-19

2-20

2-20

2-20

2-20

2-20

2-21

2-21

2-22

2-25

2-28

2-28

2-30

2-30

2-31

2-31

Contents-2

Page 9

Cascade measurements . . . . . . . . . . . . 2-31

What is a cascade measurement? . . . . . . . 2-31

Typical applications . . . . . . . . . . . . 2-31

PMD Measurement: Wavelength-Scanning Method . 2-33

Basic Measurement. . . . . . . . . . . . . . . 2-34

Setting up the System . . . . . . . . . . . . 2-34

Making the Measurement . . . . . . . . . . . 2-35

Manipulating the Measurement Results . . . . . . 2-38

The Measurement Summary Bar . . . . . . . . 2-38

The Measurement Annotation Area . . . . . . . 2-39

Using The Cursor . . . . . . . . . . . . . . 2-39

Changing The MeasurementFormat . . . . . . 2-40

Displaying and Printing Data in Tabular Format . 2-41

Printing your Graph . . . . . . . . . . . . . 2-42

Saving your MeasurementasText . . . . . . . 2-43

Saving in Database Format . . . . . . . . . . 2-43

PMD:WS Concepts . . . . . . . . . . . . . . . 2-44

Polarization Mo de Dispersion . . . . . . . . . 2-44

2-44

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

for

range

.

.

size

Jones

.

.

. .

.

.

Matrix

. .

.

Jones

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

test

t

onen

comp

or

er

b

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

PMD

er

b

of

Matrix

.

.

. .

t

t

Results

t

t

. . . . . . . . . . . . 2-61

. . . . . . . . . . . . 2-61

.

.

.

Matrix

.

.

Metho

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . .

. . . . . . . . . . . 2-63

.

.

.

.

.

.

.

.

.

.

.

.

d

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

. . . . . . 2-62

.

.

.

.

.

.

.

.

.

Measuremen

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

t

.

.

.

.

.

2-44

2-44

2-45

2-45

2-45

2-45

2-46

2-46

2-47

2-48

2-48

2-49

2-52

2-57

2-59

2-60

2-67

2-67

2-67

2-67

Polarization

General

coupling

de

Mo

units

PMD

Optimizing

elength

v

a

W

Analysis

Minim

Statistical

Measuremen

PDL

Measuremen

Basic

Setting

External

Making the

Saving the Measurement Results . . . . . . . . 2-54

PDL Measurement: Power Max-Min Metho d . . . 2-55

Basic Measurement. . . . . . . . . . . . . . . 2-56

Setting up the System . . . . . . . . . . . . 2-56

External Source Preparation . . . . . . . . . . 2-57

Making the

Sa

Jones

Basic Measuremen

Setting up the System

External Source Preparation .

Measurement Pro cedure .

Making the Measurement . . . . . . . . . . . 2-64

Concepts

The

The

Description of

up

the

ving

Matrix

Establish the Polarization Reference Frame . . 2-63

Relativ

sign

Algorithm

modes

eects

.

the setup

tuning

de

mo

feature

um

haracterization

c

t:

t

the System

Source

.

of

Preparation

Measuremen

Measuremen

Measuremen

Measuremen

t.

.

.

.

Jones

e

.

s3

the

.

Contents-3

Page 10

Application of the Jones Matrix . . . . . . . . 2-68

Timed Measurements . . . . . . . . . . . . . . 2-69

Polarization Maintaining Fib er Launch . . . . . . 2-69

Basic Measurement. . . . . . . . . . . . . . . 2-70

Setting up the System . . . . . . . . . . . . 2-70

External Source Preparation . . . . . . . . . . 2-71

Making the Measurement . . . . . . . . . . . 2-72

Concepts . . . . . . . . . . . . . . . . . . . 2-74

Explanation of Polarization Maintaining Fiber

Launch. . . . . . . . . . . . . . . . . . 2-74

Polarization Reference Frame . . . . . . . . . . 2-75

Basic Measurement. . . . . . . . . . . . . . . 2-76

Setting up the System . . . . . . . . . . . . 2-76

External Source Preparation . . . . . . . . . . 2-77

Choosing the Polarizers . . . . . . . . . . . . 2-77

Setting the Reference Frame . . . . . . . . . . 2-78

Checking Reference Frame Quality . . . . . . . 2-78

Setting a Circular State of Polarization . . . . . 2-78

Using the

Additional

2pt

Measuremen

Device

Measuremen

In

Measuring

Surface

Concepts

Explanation

Mathematics

ransmission

T

State of

Reference F

Measuremen

3pt

and

tegrated

P

.

.

of

olarization

P

olarization

P

the

of

t

.

.

. .

Output

of

t

Circuit

olarization

.

.

.

.

.

.

.

.

olarization

P

. .

.

(3pt

Ratio

Measuremen

rame .

Applications

t

Reference

Retardance

.

.

.

.

olarization

P

.

.

.

State

.

.

.

.

.

.

.

.

Reference

.

. .

Reference

.

.

.

F

an Optical

of

.

.

.

.

.

.

a Connector

at

.

.

.

.

.

.

.

.

.

rame)

F

.

.

ts

.

.

.

.

rames

.

.

of

.

.

.

.

.

.

rame

F

.

.

.

.

.

.

.

an

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Optical

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-79

2-79

2-79

2-79

2-80

2-80

2-81

2-81

2-81

2-82

Basic Measurement. . . . . . . . . . . . . . . 2-83

Setting up the System . . . . . . . . . . . . 2-83

External Source Preparation . . . . . . . . . . 2-84

Making the Measurement . . . . . . . . . . . 2-85

Measurement Results . . . . . . . . . . . . . 2-85

. 2-86

.

.

.

.

.

Specialized

Measuring

Concepts

Degree of P

Measuremen

eectiv

.

.

.

olarization .

Electric Fields and P

hniques

ec

T

t

p

of

.

.

.

.

.

. . . . . . . . . . . 2-87

.

.

degree

e

.

olarization . . . . . . . . 2-87

.

olarization .

.

.

. .

.

.

.

.

.

.

.

.

2-86

2-87

Contents-4

Page 11

3. Accuracy Enhancement and Troubleshooting

Before You Proceed . . . . . . . . . . . . . . . 3-1

Symptoms . . . . . . . . . . . . . . . . . . . 3-3

Solutions . . . . . . . . . . . . . . . . . . . 3-3

4. Printing, Saving, and Recalling Measurement Results and

Instrument Congurations

. . . . . . . . . . . . . . . . . . . . . . . 4-1

Conventions . . . . . . . . . . . . . . . . . 4-2

For Additional Information . . . . . . . . . . 4-2

Printing Measurement Results . . . . . . . . . . 4-3

Standard Printing . . . . . . . . . . . . . . 4-3

Procedure . . . . . . . . . . . . . . . . . 4-3

Customized Printing . . . . . . . . . . . . . 4-4

Results . . . . . . . . . . . . . . . . . . 4-4

Procedure . . . . . . . . . . . . . . . . . 4-5

Saving and Recalling Measurements . . . . . . . . 4-7

Saving Measurements . . . . . . . . . . . . . 4-8

Pro

Recalling

HP

HP

ord

W

PMD:

PMD:

PDL:

Timed

and

ving

Sa

Recalling

cedure

Pro

a

ving

Sa

cedure

8509 File

8509

Numeric

the

User

.

Measuremen

Recall Pro

Recall

File

cessor,

Pro

File

Matrix Eigenanalysis

Jones

elength-Scanning

v

a

W

Jones

ormat

F

Matrix

.

Measurement

Recalling

Preset

.

.

.

Conguration .

.

.

.

ts

cedure .

Results

Spreadsheet

.

.

and

. .

As

.

Jones

.

T

t

ormat

F

.

.

Instrumen

Conguration

. .

.

.

.

.

. .

. .

. .

.

.

.

. .

.

.

.

.

.

Database

and

. .

.

.

.

e

v

Sa

ormat

F

e

v

Sa

Sa

.

.

.

ormat

F

e

v

ext

.

Matrix

.

Sa

Congurations

.

.

.

.

. .

. .

. .

.

.

. .

.

.

.

F

v

.

.

.

. .

.

.

.

.

.

.

ormat

.

e

.

.

.

.

.

.

.

.

.

.

. 4-10

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

Procedure . . . . . . . . . . . . . . . . . . 4-16

Recalling a User Conguration . . . . . . . . . . 4-17

Procedure . . . . . . . . . . . . . . . . . . 4-17

4-9

4-10

4-11

4-11

4-12

4-12

4-12

4-12

4-13

4-15

4-15

4-16

u

Men

y

Displa

The

5.

.

. .

.

.

.

.

.

.

F

The

Additional

or

PRESET

Information

Conguration

Displaying the Marker T

Displaying the P

Displaying the P

Exchanging the P

Ellipse .

oincare Sphere .

olarization Ellipse

oincare Sphere and the P

. . . . . . . . . . . . . . . .

able .

.

.

.

.

.

.

.

.

. .

.

. . . . . . . .

. . 5-3

. . . . . . . . . 5-4

. . . . . . . . 5-5

olarization

. . 5-6

.

Changing the Power Display Units . . . . . . . . 5-7

Marking the CurrentPoint . . . . . . . . . . . 5-8

Changing

Holding

Clearing

Setting

the

the

the

the

Data

Displa

Displa

race

T

Up

y

Displa

rom the

F

to

y

date

.

y

Refresh

requency

F

.

.

.

.

Sphere

Automatically

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Contents-5

5-1

5-2

5-9

5-10

5-11

5-11

Page 12

6. The System Menu

. . . . . . . . . . . . . . . . . . . . . . . 6-1

Conventions . . . . . . . . . . . . . . . . . 6-1

Optical Source . . . . . . . . . . . . . . . . . 6-2

Opening the Optical Source Setup Window . . . 6-2

Selecting an Optical Source (HP 8509A Only) . . 6-2

Selecting an Optical Source (HP 8509B Only) . . 6-3

Zero . . . . . . . . . . . . . . . . . . . . . 6-4

Initiating the Receiver Zeroing Routine . . . . . 6-4

Making Accurate Measurements . . . . . . . . 6-4

Calibration . . . . . . . . . . . . . . . . . . 6-5

Calibrating For Use With a Fixed Wavelength Source 6-7

Select the Source to be Calibrated . . . . . . 6-7

Calibrate at the Selected Wavelength . . . . . 6-8

Save and/or Apply the Calibration . . . . . . 6-10

Calibrating For Use With a Tuneable Wavelength

Source . . . . . . . . . . . . . . . . . . 6-11

Select External Source and Input Wavelength . 6-11

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

8509B

. .

.

.

.

.

.

.

.

.

.

.

.

. .

.

y

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Only)

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Calibrate at

ving

Sa

Applying

Applying

wto

Ho

Deleting

olarizers

P

ening

Op

Selecting

Selecting

out

Ab

Selecting

olarizer

P

Using the

elength

v

a

W

Calibration

A

Calibration

a

ell

T

Calibration

a

.

.

.

P

the

olarizer

P

a

an

ternal

In

an

Angles

utter

Sh

the Selected

Calibrations

Calibration

a

If

.

.

.

.

olarizers

Window

.

olarizers

P

P

ternal

In

External P

the

and

8509B

(HP

v

Wa

.

.

.

.

.

.

.

is

.

.

.

.

. .

.

.

.

.

.

.

.

olarizer

.

.

olarizer .

oincare

P

only)

elength

.

. .

Applied

.

.

.

(HP

.

Displa

.

Averaging . . . . . . . . . . . . . . . . . . . 6-21

Opening the Averaging Window . . . . . . . . 6-21

Selecting DisplayAveraging . . . . . . . . . 6-21

About Display Averaging . . . . . . . . . 6-21

Selecting MeasurementAveraging . . . . . . 6-22

t

.

.

Windo

Range

Op

About

.

ening

Measuremen

.

.

.

Range

the

. .

.

Selecting Autorange

Selecting a Specic Gain State .

About Range

Analog Outputs

. . . .

. . . . . . . . . . . . . . . . 6-24

eraging

Av

.

.

.

.

w

. . . .

. . . . . . . . . . . 6-23

.

.

.

. .

.

.

.

.

.

.

.

. .

.

.

.

.

.

. . . . . . . . 6-23

. . . . . . . 6-23

.

.

.

.

.

.

Opening the Analog Outputs Window. . . . . . 6-24

DOP and Normalized Stokes Parameters Mode . . 6-24

.

.

.

.

.

.

.

.

.

.

.

Photo

w

Ra

Reference

ening

Op

Operation

dio

rame

F

Reference

the

erication

V

de

Info

Curren

ts

.

.

.

. .

.

.

.

.

.

.

.

.

.

F

.

Information Windo

rame

.

.

.

.

.

.

.

.

w

.

.

.

.

6-12

6-14

6-15

6-15

6-16

6-17

6-18

6-18

6-18

6-18

6-19

6-19

6-19

6-20

6-22

6-23

6-23

6-25

6-26

6-26

6-28

Contents-6

Page 13

7. User Interface Reference

Main Window . . . . . . . . . . . . . . . . . 7-2

Optical Source Setup . . . . . . . . . . . . . . 7-7

Calibration . . . . . . . . . . . . . . . . . . 7-9

Operation Verication . . . . . . . . . . . . . 7-11

PMD: Jones Matrix Eigenanalysis . . . . . . . . 7-12

PMD Statistics . . . . . . . . . . . . . . . . . 7-15

PMD: Wavelength-Scanning . . . . . . . . . . . 7-18

Timed Measurements . . . . . . . . . . . . . . 7-22

PDL: Jones Matrix & Jones Matrix . . . . . . . . 7-24

PDL: Power Max - Min . . . . . . . . . . . . . 7-26

PM Fiber Launch . . . . . . . . . . . . . . . 7-28

Marker Angles . . . . . . . . . . . . . . . . . 7-29

8. Lightwave Connector Care

Introduction . . . . . . . . . . . . . . . . . . 8-1

Cleaning and Handling . . . . . . . . . . . . . 8-3

Denition of Terms . . . . . . . . . . . . . . 8-3

Connector

Adapter

Handling

Cleaning

Cleaning

Equipmen

Pro

Cleaning

Equipmen

cess

Pro

Cleaning

Storage

Making

Summary

ection

Insp

Non-Lensed

cess

Ligh

Lensed Connections

.

Connections

.

.

.

.

. .

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

Connectors

e

v

a

w

t

Ligh

.

.

. .

.

.

.

.

.

.

.

t

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

Adapters

e

v

a

w

t

.

.

.

.

.

t

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

.

.

.

.

.

.

. 8-3

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

Visual Inspection . . . . . . . . . . . . . . . 8-8

Optical Performance Testing . . . . . . . . . . 8-8

Introduction . . . . . . . . . . . . . . . . 8-8

Insertion Loss . . . . . . . . . . . . . . . 8-9

.

. .

.

.

.

.

.

.

.

.

.

.

. .

.

Return

Loss

8-3

8-3

8-3

8-4

8-4

8-4

8-5

8-5

8-5

8-5

8-6

8-7

8-7

8-8

8-9

Regulatory Information

and

y

Safet

9.

Regulations and Licensing .

Safety Information

Environmental Conditions .

Ventilation Requiremen

Cleaning Instructions

Instrument Conforms . . . . . . . . . . . . . 9-3

Laser Ap erture Lo cation . . . . . . . . . . . 9-4

. . . . . . . . . . . 9-1

. . . . . . . . . . . . . . 9-3

.

. . . . . . . . . . 9-3

ts . . . . . . . . . . . 9-3

. . . . . . . . . . . . . 9-3

Contents-7

Page 14

10. Programming

11. Specications and Characteristics

. . . . . . . . . . . . . . . . . . . . . . . 11-1

Warranted Specications . . . . . . . . . . . . 11-1

Polarization Mo de Dispersion (PMD) Specications,

Jones Matrix Eigenanalysis (JME) Method (HP

8509B only) . . . . . . . . . . . . . . . 11-1

Characteristics . . . . . . . . . . . . . . . . . 11-2

Jones Matrix Eigenanalysis PMD Measurement . 11-2

Wavelength Scanning PMD Measurement . . . . 11-3

Comparison Between Jones Matrix Eigenanalysis and

Wavelength Scanning Methods . . . . . . . 11-4

Receiver Characteristics . . . . . . . . . . . . 11-5

Source Characteristics . . . . . . . . . . . . . 11-6

Polarization Dependence, Jones Matrix Method . 11-7

Polarization Dependence, Power Max-Min Method 11-7

Fiber Size and Analog Output Range . . . . . . 11-7

A. Co

P

Glossary

Index

ordinate System

t

olarized

Ligh

and Generation

of

Righ

t-Hand

Circularly

Contents-8

Page 15

Figures

1-1. The HP 8509 Basic Measurement Screen . . . . 1-4

1-2. The Marker Window . . . . . . . . . . . . . 1-6

1-3. Setting a Marker . . . . . . . . . . . . . . . 1-7

1-4. Close Set Marker Window. . . . . . . . . . . 1-7

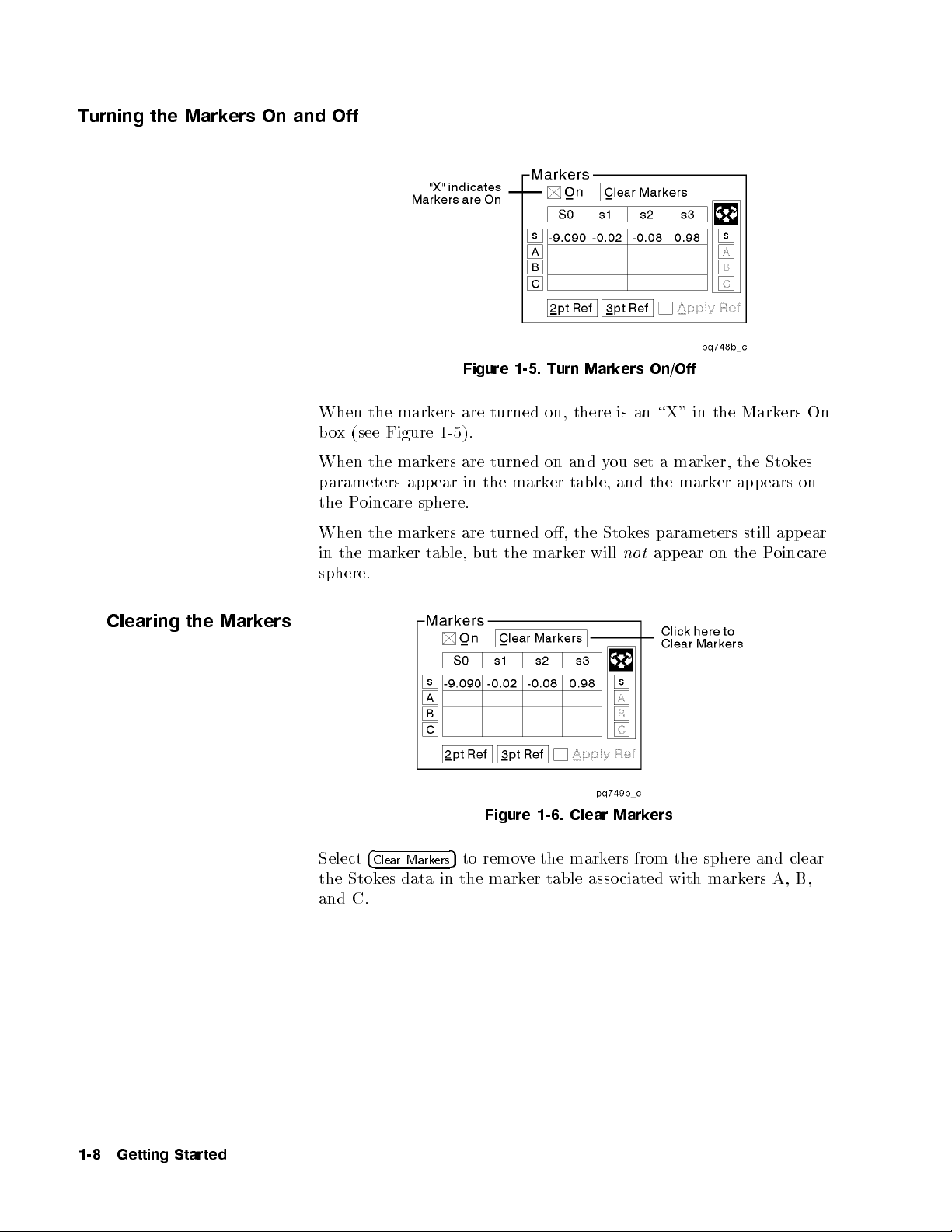

1-5. Turn Markers On/O . . . . . . . . . . . . . 1-8

1-6. Clear Markers . . . . . . . . . . . . . . . . 1-8

1-7. Center Sphere on Marker . . . . . . . . . . . 1-9

1-8. Marker Zoom and Rotate . . . . . . . . . . . 1-10

1-9. Clear Trace and Hold . . . . . . . . . . . . . 1-11

1-10.and Cal . . . . . . . . . . . . . . . . . . 1-12

Example

2-1.

Measuremen

2-2.

System

2-3.

Optical

2-4.

olarizer

P

2-5.

Polarizer

2-6.

3pt

2-7.

Circular

2-8.

JME

2-9.

2-10. JME

Segmen

2-11.

Find

2-12.

2-13. Optical

of

measuremen

Setup

t

u

Men

Source

Selection

Setup

Reference

olarization

P

Measuremen

Source

Minim

Setup

Selection

t

um

Source Setup

t .

.

.

Setup

.

.

Applied

Selection

t

of

#

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

oints

P

for PMD:

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

. .

. .

Jones Matrix

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

. .

2-2

2-3

2-4

2-5

2-5

2-6

2-6

2-7

2-8

2-9

2-10

2-10

PMD:JME

for a

y

displa

data

Eigenanalysis . . . . . . . . . . . . . . . 2-11

2-14. PMD: JME MeasurementStart . . . . . . . . 2-11

2-15. Measurement Results . . . . . . . . . . . . . 2-12

2-16. The Measurement Summary . . . . . . . . . . 2-13

2-17. The Measurement Annotation Area . . . . . . . 2-14

Cursor

The

2-18.

Changing

2-19.

2-20. Changing the Graph's Y-Scale

2-21. Displaying Data in T

2-22. Displaying Data in a Statistical

2-23. Displaying Data in a Statistical F

2-24. PMD Statistics File Men

Bar

Measuremen

the

t

abular F

u.

ormat

F

ormat .

.

. . . . . . . . 2-16

.

. . . . . . 2-16

. .

.

.

.

.

Format . . . . . 2-17

ormat . . . . . 2-18

. . . . . . . . . . 2-19

2-15

2-15

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

2-25. Printing the PMD:JME Graph . . . . . . . . . 2-22

2-26. Saveas Text . . . . . . . . . . . . . . . . . 2-22

2-23

.

.

.

.

.

.

.

.

.

.

.

. .

.

2-24

.

.

. .

.

.

.

.

.

.

.

2-25

.

.

.

. .

.

.

.

.

.

.

2-25

.

.

.

.

.

.

.

.

.

.

2-27.

2-28.

2-29.

2-30.

Database

Saving

in

.

.

.

.

Measuremen

Measuremen

.

t

t

.

.

Setup

Start

.

ormat

F

.

.

.

.

.

.

Contents-9

Page 16

2-31. Thru Calibration . . . . . . . . . . . . . . . 2-26

2-32. The Measurement . . . . . . . . . . . . . . 2-26

2-33. The Results . . . . . . . . . . . . . . . . . 2-27

2-34. Example of data displayforawavelength-scanning

PMD measurement . . . . . . . . . . . . 2-33

2-35. Wavelength-Scanning System Setup . . . . . . . 2-34

2-36. Wavelength-Scanning Measurement Selection . . 2-35

2-37. Optical Source Setup for PMD:Wavelength Scanning 2-36

2-38. PMD: WS Measurement Start . . . . . . . . . 2-36

2-39. Measurement Results . . . . . . . . . . . . . 2-37

2-40. The Measurement Summary . . . . . . . . . . 2-38

2-41. The Measurement Annotation Area . . . . . . . 2-39

2-42. The Cursor Bar . . . . . . . . . . . . . . . 2-39

2-43. Changing the MeasurementFormat . . . . . . . 2-40

2-44. Displaying Data in Tabular Format . . . . . . . 2-41

2-45. Printing your Graph . . . . . . . . . . . . . 2-42

2-46. Saveas Text . . . . . . . . . . . . . . . . . 2-43

2-47. Saving in Database Format . . . . . . . . . . 2-43

data

measuremen

Jones matrix

2-48. Example

Measuremen

2-49.

System

2-50.

Optical Source

2-51.

olarizer

P

2-52.

olarizer

P

2-53.

3pt

2-54.

Circular

2-55.

Jones

2-56.

Jones

2-57.

Measuremen

2-58.

Example

2-59.

2-60. Measuremen

2-61. System Menu . . . . . . . . . . . . . . . . 2-57

2-62. Optical Source Setup . . . . . . . . . . . . . 2-57

2-63. PDL Measurement Selection . . . . . . . . . . 2-58

2-64. PDL:Power Max-Min Measurement Window. . . 2-58

2-65. Measurement Results . . . . . . . . . . . . . 2-59

2-66. Example

Measuremen

2-67.

2-68. System Men

2-69. Optical Source Setup

2-70. Jones Matrix Measuremen

2-71. Jones Matrix Measuremen

2-72. Measurement Results . . . . . . . . . . . . . 2-66

2-73. Comparing the output Jones Vectors to 3 known

Jones

2-74.

Example

2-75.

Measuremen

2-76.

of a

.

.

y

displa

Setup

t

u

Men

Selection

Setup

Reference

olarization

P

Matrix

Matrix

measuremen

input

Matrix

Alignment

Measuremen

Measuremen

t Results

PDL

a

of

Setup

t

data

of

Setup

t

u . .

Jones

Application

P

a

of

Setup

t

.

.

.

.

. .

.

.

Setup

.

.

.

.

Applied

measuremen

.

displa

.

.

t

.

. . . . . . . . . . . . . . 2-62

ectors

V

olarization

displa

data

.

PDL

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

Selection

t

Windo

t

.

. .

.

.

.

for

y

. .

.

.

.

.

.

. . . . . . . . . . . . . 2-62

t Selection

t Windo

.

.

.

Maintaining

.

y

.

.

.

w

.

.

.

.

displa

data

t

.

.

.

.

matrix

Jones

a

.

.

.

.

.

.

.

w . . . . . . 2-65

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

t

. .

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

y

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. . . . . 2-64

.

.

.

.

.

.

.

. .

.

.

.

.

er

Fib

.

.

.

.

.

.

.

.

.

.

.

.

2-47

2-48

2-49

2-49

2-50

2-50

2-50

2-51

2-52

2-53

2-53

2-55

2-56

2-60

2-61

2-68

2-68

2-69

2-70

Contents-10

Page 17

2-77. System Menu . . . . . . . . . . . . . . . . 2-71

2-78. Optical Source Setup . . . . . . . . . . . . . 2-71

2-79. PM Fib er Launch Measurement Selection . . . . 2-72

2-80. PM Fib er Launch AlignmentWindow. . . . . . 2-73

2-81. How PMF cable launch extension ratio is calculated 2-74

2-82. Example of the results that can be achieved with and

without a polarization reference frame . . . . 2-75

2-83. Measurement Setup . . . . . . . . . . . . . . 2-76

2-84. System Menu . . . . . . . . . . . . . . . . 2-77

2-85. Optical Source Setup . . . . . . . . . . . . . 2-77

2-86. Example of a SOP measurement data display . . 2-82

2-87. Measurement Setup . . . . . . . . . . . . . . 2-83

2-88. System Menu . . . . . . . . . . . . . . . . 2-84

2-89. Optical Source Setup . . . . . . . . . . . . . 2-84

2-90. SOP and DOP Measurement Example . . . . . 2-85

2-91. Polarization changes with Ex(t) and Ey(t). . . . 2-87

2-92. Elliptical displays of polarization . . . . . . . . 2-88

2-93. Mathematical description of an elliptical displayof

2-88

.

.

.

.

.

.

.

.

.

.

.

.

. .

polarization

olarization

P

2-94.

Measuremen

3-1.

Men

File

The

4-1.

The Prin

4-2.

Customized

4-3.

The

4-4.

The

4-5.

The

4-6.

Viewing

4-7.

The

4-8.

The

4-9.

The

4-10.

4-11. The

4-12. The Load Menu . . . . . . . . . . . . . . . 4-17

4-13. The Load Window . . . . . . . . . . . . . . 4-17

5-1. The PRESET Conguration . . . . . . . . . . 5-2

5-2. The Show Markers Menu . . . . . . . . . . . 5-3

5-3. Marker Window Hidden . . . . . . . . . . . . 5-3

5-4. The

oincare

P

5-5.

The

5-6.

5-7. P

5-8. The Sho

5-9. Sphere and Ellipse Exc

5-10. The P

5-11. Power Display in Watts Mode . . . . . . . . . 5-7

5-12. The Mark CurrentPointMenu. . . . . . . . . 5-8

5-13.

5-14.

5-15.

5-16. The

5-17.

olarization Ellipse T

Mark

The

The

The

t

Men

e

v

Sa

As Windo

e

v

Sa

Load

a

Load

Preset Conrmation

Men

e

v

Sa

Sa

File

w

Sho

Sphere

w

Sho

w Sphere

ower Displa

Curren

Displa

Displa

Hold

Hold

. .

states

roublesho

T

t

.

u

u

Men

ting

Prin

u

u

Men

Stored

PRESET

u

As:

e

v

Sphere

T

Ellipse

oin

P

t

date

Up

y

date

Up

y

u

Men

unction

F

oincare

P

a

on

Matrix

oting

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

the

.

.

.

O .

ated

.

.

.

.

. .

.

.

P

.

File

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Example

.

.

.

.

.

.

w

.

.

.

.

on

race

T

Conguration

Window

.

.

.

.

Congure

.

u

Men

urned

Men

<->

yMen

O .

.

u

urned

Ellipse Men

hanged .

u . . . . . . . . .

Activ

t

u

Men

Box

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Sphere

.

u

.

.

.

.

w

. .

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

. .

. .

.

.

.

.

.

.

.

.

.

.

.

.

. . 5-7

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 4-15

.

.

.

.

.

.

.

.

.

. 5-10

Sphere

.

.

.

.

.

.

oincare

Men

.

Windo

.

.

.

. . . . . . . . 5-5

u . . . . . . 5-6

. . . . . . . . 5-6

.

.

.

.

.

2-89

3-2

4-1

4-3

4-4

4-8

4-9

4-10

4-11

4-15

4-16

4-16

5-4

5-4

5-5

5-8

5-9

5-9

5-10

Contents-11

Page 18

5-18. The Clear Trace Menu . . . . . . . . . . . . 5-11

5-19. The Auto Refresh Menu. . . . . . . . . . . . 5-11

6-1. The HP 8509A Optical Source Window . . . . . 6-2

6-2. The HP 8509B Optical Source Window . . . . . 6-3

6-3. The Calibration Window . . . . . . . . . . . 6-5

6-4. The Optical Source Window. . . . . . . . . . 6-7

6-5. The Calibration Window . . . . . . . . . . . 6-9

6-6. The Calibration List . . . . . . . . . . . . . 6-10

6-7. The Optical Source Window. . . . . . . . . . 6-11

6-8. The Calibration Window . . . . . . . . . . . 6-13

6-9. The Calibration List . . . . . . . . . . . . . 6-14

6-10. Calibration Applied . . . . . . . . . . . . . . 6-16

6-11. Deleting a Calibration . . . . . . . . . . . . 6-17

6-12. Conrm or Abort the Deletion Process . . . . . 6-17

6-13. The Polarizers Window . . . . . . . . . . . . 6-18

6-14. The Shutter Menu . . . . . . . . . . . . . . 6-20

6-15. The Averaging Window. . . . . . . . . . . . 6-21

6-16. The Range Window. . . . . . . . . . . . . . 6-23

6-17. The

No

6-18.

Tw

6-19.

Three-P

6-20.

The Op

6-21.

Laser

9-1.

Comparison

11-1.

Analog Outputs

rame

Reference

t

Reference

t

oin

eration

.

erture

of

Optical

F

V

.

JME

.

Lo

Reference

oin

o-P

8509A

Ap

Long

for

Window

Dened

rame

F

rame Information

F

erication

.

.

.

cation

and

er

Fib

.

.

.

.

.

Windo

w

Information

the

for

Windo

.

.

.

w

.

.

.

.

.

.

.

.

.

.

WS Measuremen

.

.

.

.

est

T

.

.

.

.

.

.

Windo

Window

HP

.

.

.

.

. .

Metho

t

.

.

.

.

.

.

.

.

w

.

.

.

.

ds

.

.

6-24

6-26

6-27

6-27

6-28

9-4

11-4

Contents-12

Page 19

Tables

4-1. Summary of HP 8509 Measurement Results

Save/Recall Features . . . . . . . . . . . . 4-6

6-1. Analog Outputs for DOP and Normalized Stokes

Parameters Mo de . . . . . . . . . . . . . 6-24

6-2. Analog Outputs for Raw Dio de Currents Mode . . 6-25

7-1. Main Window . . . . . . . . . . . . . . . . 7-2

7-2. Optical Source Setup . . . . . . . . . . . . . 7-7

7-3. Calibration . . . . . . . . . . . . . . . . . 7-9

7-4. Operation Verication . . . . . . . . . . . . 7-11

7-5. PMD: Jones Matrix Eigenanalysis . . . . . . . 7-12

PMD Statistics

7-6.

7-7. PMD:

Timed

7-8.

PDL:

7-9.

PDL:

7-10.

PDL:

7-11.

Mark

7-12.

Maxim

11-1.

8509B)

11-2. PMD

Metho

Rep

11-3.

Pigtail

Repeatabilit

11-4.

v

a

W

Measuremen

Jones

w

o

P

ow

P

Angles

er

um

Measuremen

d

eatabilit

. .

elength-Scanning

.

ts

Jones

.

of

of

&

Min .

-

Min

-

.

.

.

.

Uncertain

t

8509B

JME

JME

.

.

PMD

PMD

.

DGD

.

Only)

. .

Matrix

Max

er

Max

er

Measurable

.

(HP

y

ositions .

p

y

.

.

.

.

.

.

Matrix

.

. .

.

.

.

.

.

.

.

.

Using

.

.

. .

Using

y

t

.

Measuremen

. .

. .

Measuremen

.

.

.

.

.

JME

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

the

.

.

.

.

.

.

. .

.

.

.

.

.

.

Dela

.

.

JME

.

.

with

t

.

.

with

t

.

. .

.

.

.

.

y

.

.

.

.

.

.

.

.

(HP

.

.

Fixed

.

.

. 7-22

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

. .

Randomized Pigtail Positions . . . . . . . . 11-3

11-5. Minimum Measurable PMD Using the Wavelength

Scanning Method . . . . . . . . . . . . . 11-3

11-6. Receiver Characteristics . . . . . . . . . . . . 11-5

11-7. Source Characteristics . . . . . . . . . . . . . 11-6

.

.

External Source

11-8.

Measuremen

11-9.

Only) Jones

11-10. Measuremen

Only) P

Input

olarization

P

of

t

Matrix

olarization Dependence (HP

tofP

ower Max - Min Metho d

11-11. Other Characteristics .

Characteristics

ort

P

Dep

Metho

d

. . . . .

endence (HP

.

.

.

. . . . . . 11-7

. . . . . . . 11-7

.

8509B

.

.

.

.

.

8509B

7-15

7-18

7-24

7-26

7-28

7-29

11-1

11-2

11-2

11-6

11-7

Contents-13

Page 20

Page 21

Getting Started

This chapter contains the following sections.

Description of the Instrument

Installation

About This Manual Set

The Main Menu

The Data Displays (Power, DOP, Ellipse and Poincare Sphere)

The Marker Functions

Rotate

and

om

Zo

1

Description

Installation

of

Instrument

the

4

race

T

r

Clea

45

and

HP

The

calibrated

componen

Cal

8509A/B

p

ts.

Hold

and

5

Ligh

olarization

olarization

P

e

v

a

w

t

measuremen

ts

of

optical

Analyzer

signals and

oers

high-sp

The lightwave polarization analyzer is precongured at the

factory. All that is required to install the system is to unpackthe

the

to

Refer

on.

pieces,

correctly

\Installation"

Start Guide

also pro

system to

vides instructions for unpac

the factory for service.

connect

hapter

c

of

them,

the

and turn

8509A/B

HP

for complete instructions. The \Installation" c

them

Quick

Instal

lation

and

hapter

king the system and returning the

eed,

Getting

Started

1-1

Page 22

About This Manual Set

The HP 8509A/B manual set is made up of three documents.

HP 8509A/B LightwavePolarization

Installation Quick Reference Card

Installation and Quick Start Guide

User's/Reference Guide (this manual)

This guide uses the following conventions:

4

Button

5

This represents a button that can be selected on the

computer screen to perform an action.

N

Menu

Item

This

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

NN

NN

NN

N

the

contains an installation procedure.

contains an installation procedure, and an operation

verication procedure to ensure that your analyzer is

operating prop erly.

this is the main manual for the lightwave polarization

analyzer. This manual is describ ed in detail later in this

chapter.

indicates

computer

men

a

screen.

u

item

that

can

e

b

selected

on

1-2

Getting

Started

Page 23

HP 8509A/B User's/Reference Guide Table of Contents

(this manual)

This manual contains the following chapters.

1.

Getting Started

describes the HP 8509A/B manual set, and provides a

description of the Main Menu screen of the software.

2.

Making Measurements

provides step-by-step instructions for making the following

measurements.

Polarization Mode Disp ersion: Jones Matrix Eigenanalysis

Method (PMD JME)

Polarization Mode Disp ersion: Wavelength-Scanning Metho d

(PMD WS)

Polarization Dependent Loss: Jones Matrix (PDL JM)

Polarization Dependent Loss: Power Max-Min Method

Jones Matrix

Polarization Maintaining Fiber Alignment

Polarization Reference Frame

olarization

P

of

State

olarization

P

Degree

of

3.

Accuracy

roublesho

T

ting,

Prin

4.

Measuremen

Instrumen

Displa

The

5.

System

The

6.

terface

User

Ligh

Safet

In

a

w

t

and

y

7.

8.

9.

Information

10.

Programming

11.

Specications and

Characteristics

Glossary

Index

Appendix

Enhancement

oting

ving,

Sa

Results

t

Congurations

t

Men

y

u

Men

Reference

Connector

e

v

Regulatory

and

u

and

Recalling

and

Care

measuremen

File

Displa

System

reac

to

of

u.

men

men

y

men

and

it,

h

connectors.

and

u.

u.

a

solving

vides

vides

vides

eac

ws

procedures

information

a

a

provides

and

pro

pro

pro

sho

description

information on

vides

pro

licensing,

vides

pro

measurement

description of

description

and

trol

con

h

what

of

safet

for impro

problems.

out

ab

the

the

of

displa

es.

do

it

caring for

regulatory

,

y

ving the

items

the

items

items

the

,

y

accuracy

the

in

the

in

the

in

path

the analyzer's

cleaning,

,

environmental information.

provides guidance for programming problems.

provides performance sp ecications and characteristics of the

lightwave polarization analyzer.

denitions.

their

and

terms

of

list

alphab

etized

etized

list of

terms

with

page

n

um

er

b

pro

pro

vides

vides

an alphab

an

references. This is a subject index.

provides specialized bac

kground information.

ts

Getting

Started

1-3

Page 24

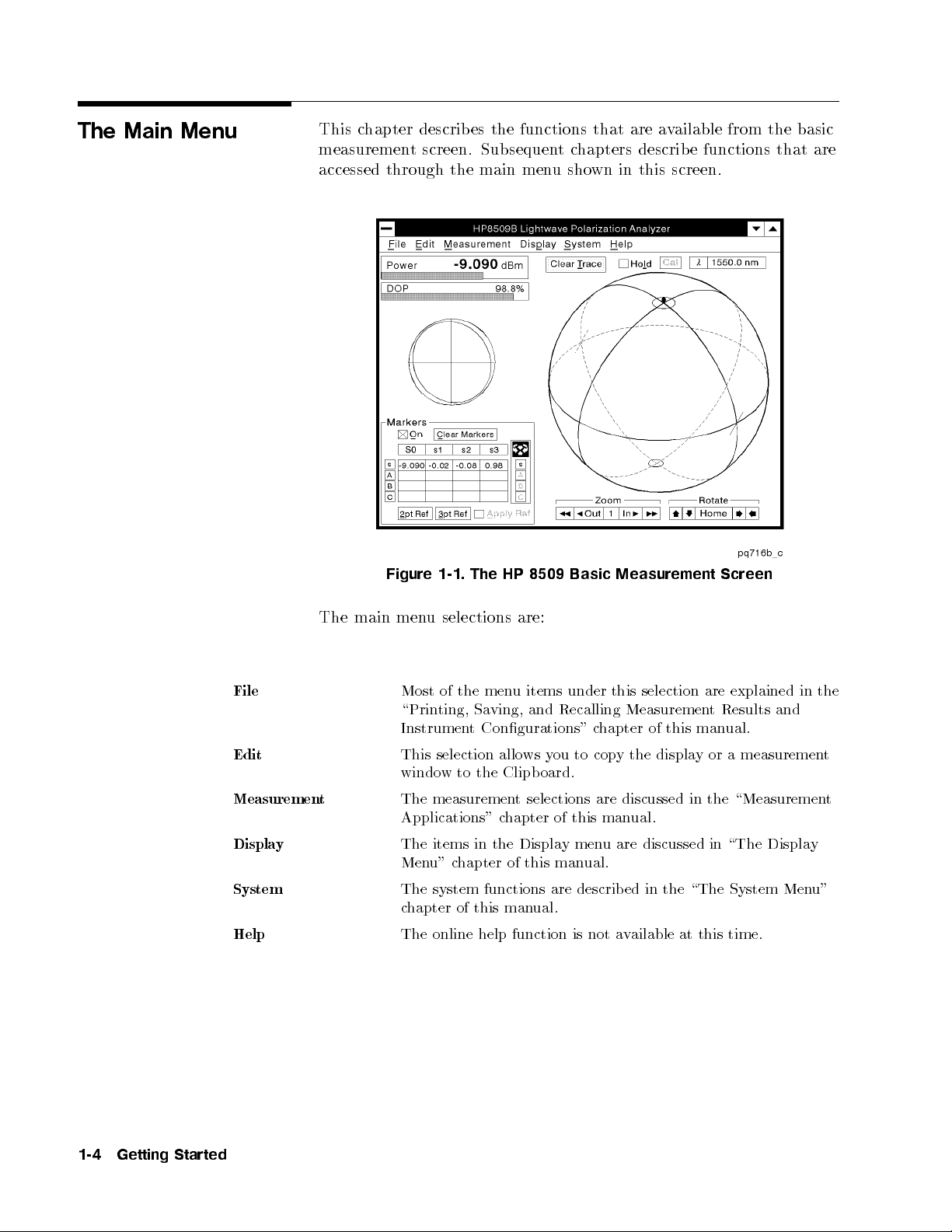

The Main Menu

This chapter describes the functions that are available from the basic

measurement screen. Subsequentchapters describe functions that are

accessed through the main menu shown in this screen.

File

Edit

Measurement

Display

System

Help

The

are

t

man

Screen

Results

ual.

Figure

main men

Most

\Prin

Instrumen

1-1.

selections

u

the

of

ting,

8509 Basic

HP

The

are:

items

u

men

and

ving,

Sa

Congurations"

t

under

Recalling

hapter

c

Measurement

selection

this

Measuremen

this

of

This selection allows you to copy the display or a measurement

window to the Clipb oard.

The measurement selections are discussed in the \Measurement

Applications" chapter of this manual.

The items in the Display menu are discussed in \The Display

ual.

man

this

hapter

c

u"

Men

system

The

chapter of this man

The online help function is not a

of

functions

ual.

are

describ

\The

in the

ed

vailable at this time.

explained

and

System

in

Men

the

u"

1-4

Getting

Started

Page 25

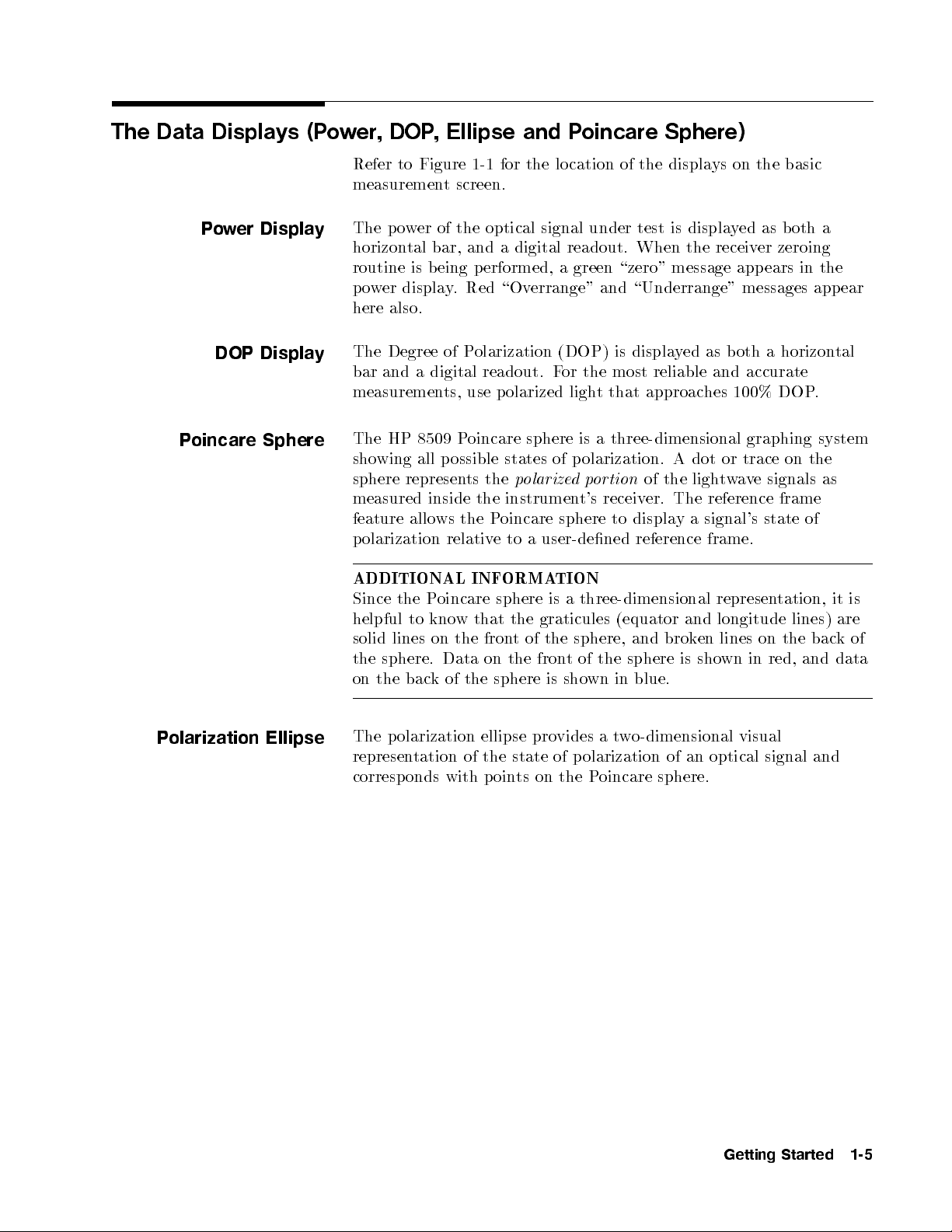

The Data Displays (Power, DOP, Ellipse and Poincare Sphere)

Refer to Figure 1-1 for the location of the displays on the basic

measurement screen.

Power Display

DOP Display

Poincare Sphere

The power of the optical signal under test is displayed as b oth a

horizontal bar, and a digital readout. When the receiver zeroing

routine is b eing performed, a green \zero" message appears in the

power display. Red \Overrange" and \Underrange" messages appear

here also.

The Degree of Polarization (DOP) is displayed as both a horizontal

bar and a digital readout. For the most reliable and accurate

measurements, use polarized light that approaches 100% DOP.

The HP 8509 Poincare sphere is a three-dimensional graphing system

showing all possible states of polarization. A dot or trace on the

sphere represen

allo

inside

ws

relativ

measured

feature

olarization

p

ADDITIONAL

oincare

P

the

Since

know

helpful

solid

the

on

to

lines

sphere.

bac

the

on

Data

k

of

ts the

the

INF

the

the

instrumen

the

oincare

P

to a

e

ORMA

sphere

that

fron

on

sphere is

ortion

p

polarize

d

t's

sphere

receiv

to

user-dened reference

TION

three-dimensional

a

is

sphere,

the

of

(equator

in

the

t

the

of

graticules

the

t

fron

shown

of

er.

displa

and

sphere

blue.

ligh

the

The

signal's state

a

y

and

en

brok

sho

is

e

v

a

w

t

reference

frame.

represen

longitude

on

lines

in red,

wn

signals

as

frame

of

tation, it

lines)

bac

the

and

is

are

of

k

data

olarization Ellipse

P

polarization

The

ellipse pro

vides

o-dimensional

w

t

a

visual

representation of the state of p olarization of an optical signal and

corresponds with points on the Poincare sphere.

Getting

Started

1-5

Page 26

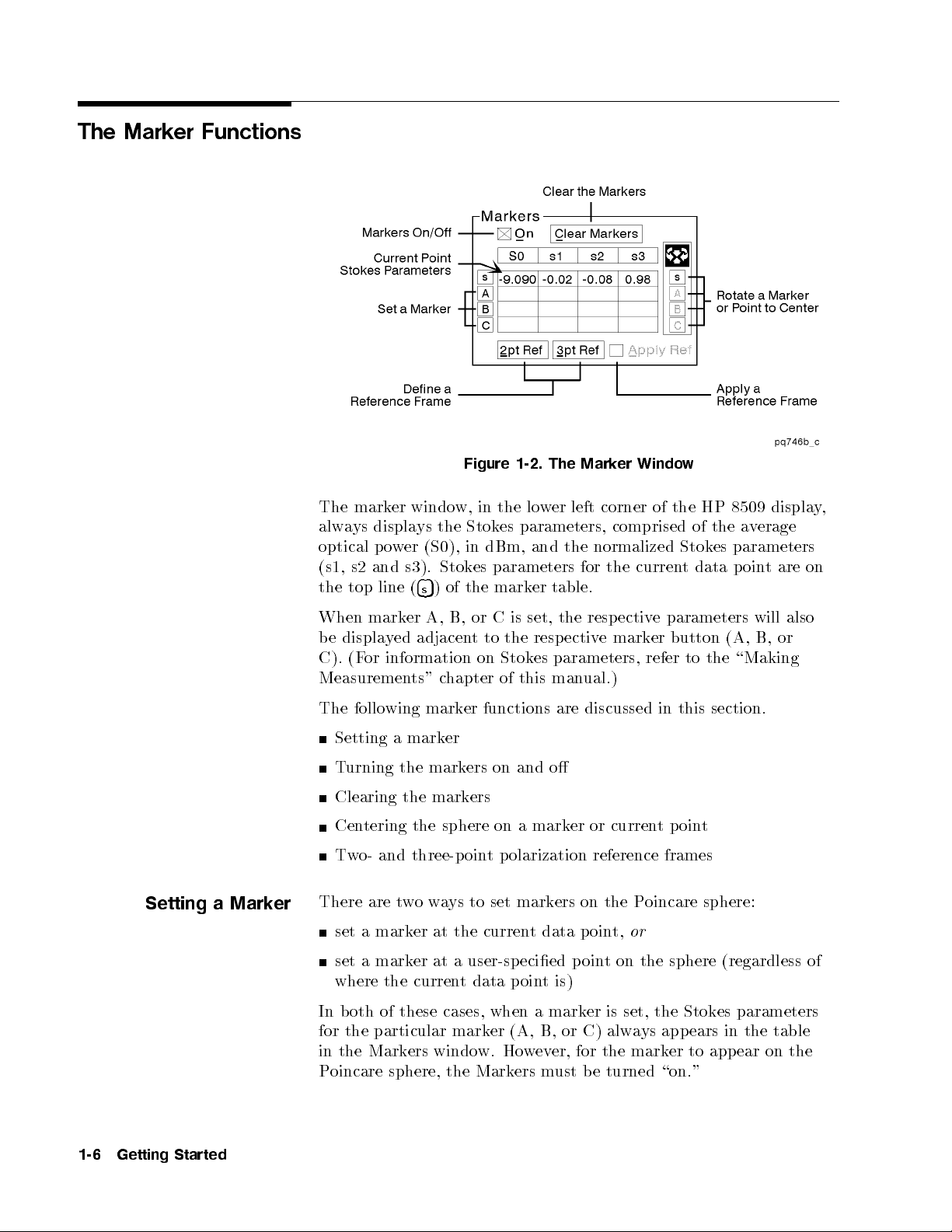

The Marker Functions

The mark

displa

ys

a

alw

s2

top

p

and

line

optical

(s1,

the

er windo

ys

(S0),

er

w

o

s3).

4

(

5

s

the

Stok

of

)

Figure

the

w, in

es

Stok

dBm,

in

parameters for

es

mark

the

Mark

The

1-2.

left

er

w

lo

parameters,

the

and

table.

er

Windo

er

corner

of

comprised

normalized

curren

the

w

the

of

Stokes

data

t

8509

HP

the

parameters

p

v

a

oin

displa

erage

are

t

on

,

y

Setting a Mark

A,

adjacen

ed

y

information

hapter

c

ts"

mark

wing

marker

to

t

on

of

functions

er

resp

the

es

Stok

this man

mark

e

ectiv

parameters,

ual.)

discussed in

are

button

er

to

refer

this section.

the

displa

e

marker

or

(F

When

b

C).

Measuremen

follo

The

Setting a

parameters

e

ectiv

resp

the

set,

is

C

or

B,

Turning the markers on and o

Clearing the markers

Centering the sphere on a marker or currentpoint

frames

oincare sphere:

or

er

p

t

o- and

Tw

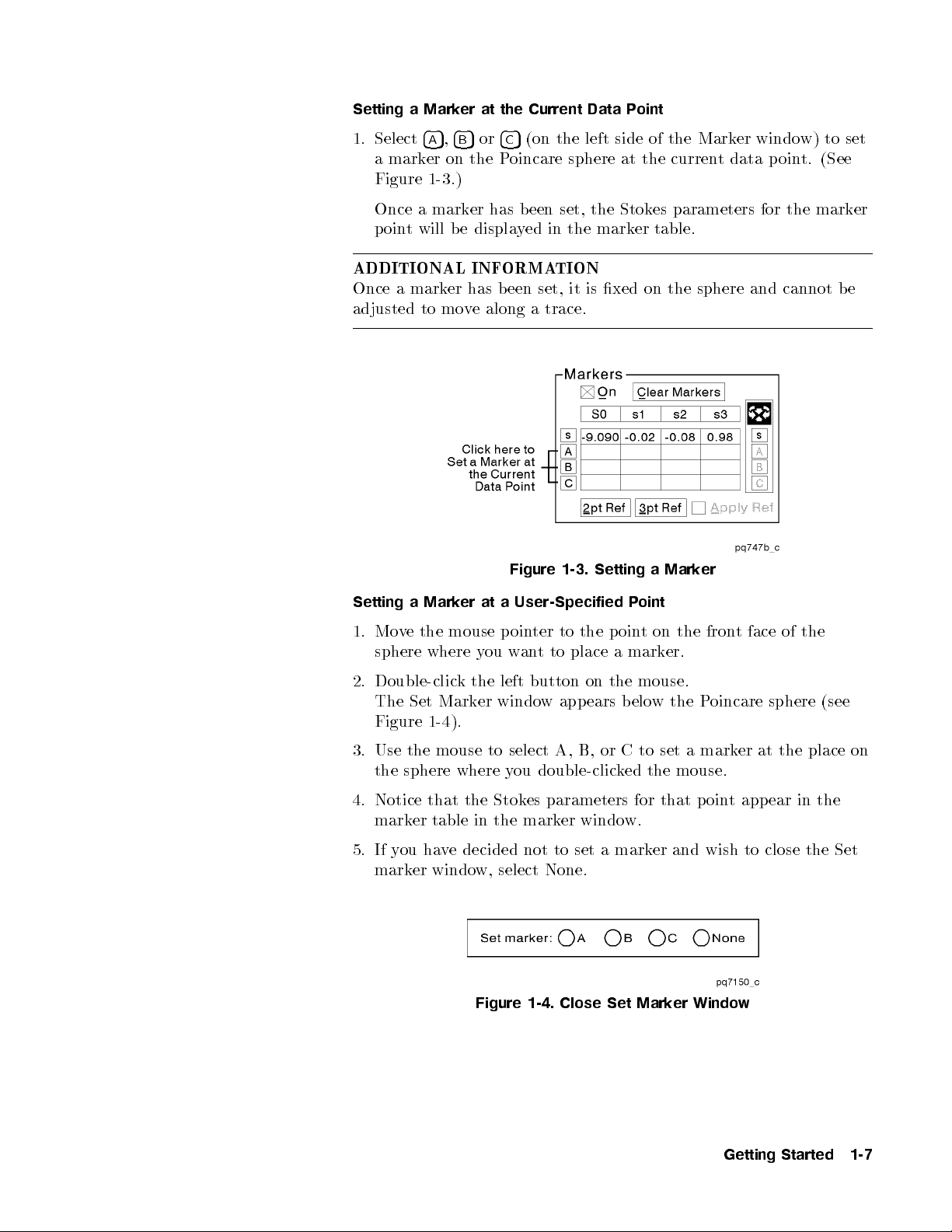

There are t

set a mark

a marker at a user-specied poin

set

three-p

wow

er at the curren

where the curren

oin

to set mark

ays

t data poin

olarization

ers on the P

t data poin