User’s and Service Guide

Agilent Technologies

85025A/B/D/E Detectors

Agilent Part Number: 85025-90063

Printed in USA

September 2002

Supersedes September 1995

© Copyright 1995, 2002 Agilent Technologies

Hewlett-Packard to Agilent Technologies Transition

This documentation supports a product that previously shipped under the Hewlett-Packard

company brand name. The brand name has now been changed to Agilent Technologies. The

two products are functionally identical, only our name has changed. The document still

includes references to Hewlett-Packard products, some of which have been transitioned to

Agilent Technologies.

ii

Certication

Agilent

at

calibration

Standards

facility

Organization

the

T

echnologies

time

of

shipment

measurements

and

,

and

to

members

T

echnology

the

DOCUMENT

THE

MATERIAL

IS

SUBJECT TO

FURTHER,

A

GILENT DISCLAIMS

WITH

HEREIN,

OF

A

REGARD

INCLUDING

MERCHANT

GILENT

SHALL

CONTAINED

BEING CHANGED

TO THE

TO

ABILITY

CONSEQUENTIAL

OR

PERFORMANCE

HEREIN.

A

GREEMENT

DOCUMENT

IN

THE

SHOULD

THA

SEP

ARA

WITH

TE

certies

calibration

from

are

,

to

that

the

traceable

the extent

facilities of

.

A

TION

W

ARRANTY

IN THIS

MAXIMUM EXTENT

ALL W

THIS MANU

NOT

D

AMA

OF

A

GILENT

W

ARRANTY

T

CONFLICT

A

GREEMENT

BUT

AND

BE

GES

THIS

NOT

LIABLE

ARRANTIES,

AL

LIMITED

FITNESS

IN

DOCUMENT

AND

WITH

this

product

factory

. Agilent

to

the

allowed by

other International

DOCUMENT

,

WITHOUT

PERMITTED

EITHER

AND

ANY

TO

FOR

A

FOR

ERRORS

CONNECTION

OR

THE

USER

TERMS

WILL

CO

THESE

CONTROL.

VERING

TERMS,

met

its published

further certies

United

States

the Institute's

IS

PRO

NOTICE,

BY

EXPRESS

INFORMA

THE

P

ARTICULAR

OR

WITH

ANY

HA

VE

TION

IMPLIED

FOR

THE

INFORMA

A

SEP

THE

THE

specications

that its

National Institute

calibration

Standards

VIDED

IN

FUTURE

\AS

APPLICABLE

OR

IMPLIED

CONT

AINED

W

ARRANTIES

PURPOSE.

INCIDENT

FURNISHING,

TION

CONT

ARA

TE

WRITTEN

MA

TERIAL

W

ARRANTY

IS,"

AND

EDITIONS.

LA

W

AL

OR

USE,

AINED

IN

THIS

TERMS

of

,

iii

Ex

clusive

THE

Remedies

REMEDIES

REMEDIES.

SPECIAL,

ON

CONTRA

INCIDENT

Assistance

PRO

A

GILENT

CT

,

TORT

VIDED

SHALL

AL,

OR

,

OR

HEREIN

NOT

ARE

BE

LIABLE

CONSEQUENTIAL

ANY

OTHER

LEGAL

BUYER'S

FOR

D

AMA

THEORY

SOLE

ANY

GES,

AND

DIRECT

WHETHER

.

EXCLUSIVE

,

INDIRECT

B

ASED

,

Product

available

your

test

Online

United

(tel)

Canada

(tel)

(fax)

Europe

(tel)

(fax)

maintenance

for

Agilent products

& measurement

Assistance:

States

1

800

452

1

877

894

(905) 206

(31

20)

547

(31

20)

547

agreements

and

.By

internet, phone

other customer

needs.

Contacting

Agilent

www.agilent.com/find/assist

Japan

(tel)

(81)

426

56

269

629

9210

7832

56

7500

7599

485

7840

5947

4844

4414

4120

2323

2390

(fax)

Latin

(tel)

(305)

(fax)

A

ustralia

(tel)

1

(fax)

(81)

426

America

(305) 269

800

(61

3)

,

or

New

(tel)

(fax)

Asia

(tel)

(fax)

assistance

fax,

get

Zealand

0

800

64

4

P

acic

(852)

(852) 2506

agreements

assistance

738

378

495

8950

3197

7777

9284

with

are

all

iv

Safety Notes

The

following

yourself

with

safety

each

instrument.

notes

of

the

are

notes

used

and

throughout

its

meaning before

this

manual. F

operating this

amiliarize

Caution

L

this

The

symbol

instruction

when

documentation.

How

to

Use

This guide

4

F

ront-P

N

N

N

N

N

anel

N

N

N

N

N

N

N

N

NN

NN

5

Key

NN

NN

N

N

Softkey

Screen

Text

Caution

that,

if

damage

beyond

understood

it

is

This

uses

the

This

represents

This

indicates

the

instrument's

This

indicates

denotes

not

to

a

caution

a

correctly

or

destruction

sign

and

met.

hazard.

documentation

necessary

for

Guide

following

a

key

a

\softkey

rmware

text

It

calls

performed

of

until

symbol.

the

user to

or

the

instrument.

the

indicated

The

refer to

conventions:

physically located

,"

a key

.

displayed

on

attention

adhered

to

to

a

,

would

Do

conditions

product

is

marked with

the instructions

on the

whose label

is determined

the instrument's

procedure

result

not

proceed

are

fully

in the

instrument.

screen.

in

by

Documentation Description

This manual contains information on operating, testing, and servicing the

Agilent 85025A/B/D/E detectors

.

v

Contents

1.

General

Product

Specications

Operating

Accessories

Storage and

Environment .

Packaging

Returning

2.

Installation

Initial

Electrostatic

Static-Safe

Static-Safe

P

ower

Mating

Connecting

3.

Operation

F

eatures

Operating

Measurement

DC Detection mode

Accurate DC Measurements

Zeroing the Detector . . . . . . . . . . . .

AC Detection Measurements

Operator's Check

Procedure .

If the Operator's Check Fails ................. 3-8

Description .

Inspection

Requirements

Connectors

Autozero .............

Manual Zero . . . . . . . . . . . . . .

Information

and

Supplemental Characteristics

Environment

..

..

Shipment .

..

..

.

.

a

Detector for

.

.

Discharge

W

ork

Station

Practices

.

the

Detector

.

.

.

..

Theory

.

System

................

...... ...... ...... ..... ..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Service

.

.

.

.

(ESD)

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

..

Conguration

.

...... ...... ...... ..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

..

..

..

..

..

..

.

.................

...... ...

............

..........

...... ...... .

.....

...... .

.

.

.

.

.

.

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

. 1-9

.

.

. 1-10

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

1-1

1-3

1-9

1-9

1-9

1-10

2-1

2-2

2-2

2-3

2-3

2-3

2-3

3-2

3-2

3-3

3-3

3-3

3-3

3-3

3-4

3-6

3-6

3-7

Agilent 85025A/B/D/E Contents-1

4.

P

erformance

Equipment

Return

Frequency

P

ower A

Power

Performance T

Loss

85025A/B/D/E

Specications

Description

Return

Calibrating

Return

only

If

This

Description

Equipment

Equipment

A

dditional

A

dditional

A

dditional

A

dditional

A

dditional

Specications

85025A/B/D/E

Conguring

Characterizing

Characterizing

Computing

ccuracy P

Specications

Description

Equipment

Procedure

Absolute

Dynamic

Accuracy, Alternate Procedure Using an 8350B (+10 dBm

maximum) . .

Alternate Equipment

Procedure . . .

Absolute P

Dynamic A

T

ests

Required

P

erformance

Loss

Loss

from

,

to

50

T

est

F

ails

Response

Required

T

T

T

est

T

T

..

Power

Accuracy

ower A

ccuracy in A

est Record . . . . . . . . . .

.

.

.

.

.

.

T

est

.

Return

.

Measurement

the

GHz

.

.

Common

est

est

Equipment

est

est

.

Frequency

the

the

erformance

..

..

Required .

..

Loss

P

erformance

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Scalar

40

.

.

Equipment

Equipment

Equipment

Equipment

.

the

the

Maximum

..

...... ...... ...... .....

.......................

ccuracy in DC Mode

Network

MHz

for

85025D

.

.

.

P

erformance

.

.

.

.

.

to

85025A/B/D/E

.

.

.

System

Source

Detector

..

.

.

.

..

.

A

ccuracy

in

A

C

Mode

.

C Mode

to

18

only)

.

.

.

.

.

.

.

.

.

Required

Required

Required

Required

Required

.

.

.

Response

.

.

.

.

Error

T

est

.

.

.

.

.

.

..

..

.

.

.

in

DC

...................

, Alternate Procedure . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

T

est

Procedure

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Analyzer

GHz

(to

.

.

.

T

est

.

.

.

.

.

.

for

.

.

.

P

erformance

.

..

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

Mode

P

erformance

, Alternate Procedure

.

26.5

GHz

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

for

85025A

for

85025A

85025B

for

85025D

for

85025E

.

.

..

.

.

.

.

..

..

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

P

erformance

T

..........

.

.

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

est

.

.

..

..

.

.

.

..

..

.

.

.

.

..

..

..

..

.

.

.

.

.

..

.

.

.

.

.

.

for

85025B/E

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

..

..

.

.

.

.

.

.

.

.

.

..

Option

.

.

Only

Only

.

.

T

est

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

001

.

.

.

..

.

.

.

.

.

.

.

.

Procedure 4-13

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

T

est

.

.

.

..

..

. 4-3

.

.

..

.

.

..

.

.

. 4-7

.

.

.

.

.

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 4-15

.

. 4-15

..

.

.

. 4-17

.

. 4-17

.

.

..

. 4-24

4-1

4-3

4-3

4-3

4-6

4-7

4-9

4-9

4-9

4-11

4-11

4-11

4-11

4-11

4-11

4-12

4-13

4-13

4-14

4-14

4-14

4-15

4-16

4-20

4-21

4-21

4-22

4-23

4-25

Contents-2 Agilent 85025A/B/D/E

5.

A

djustments

6.

Replaceable

How

7.

Service

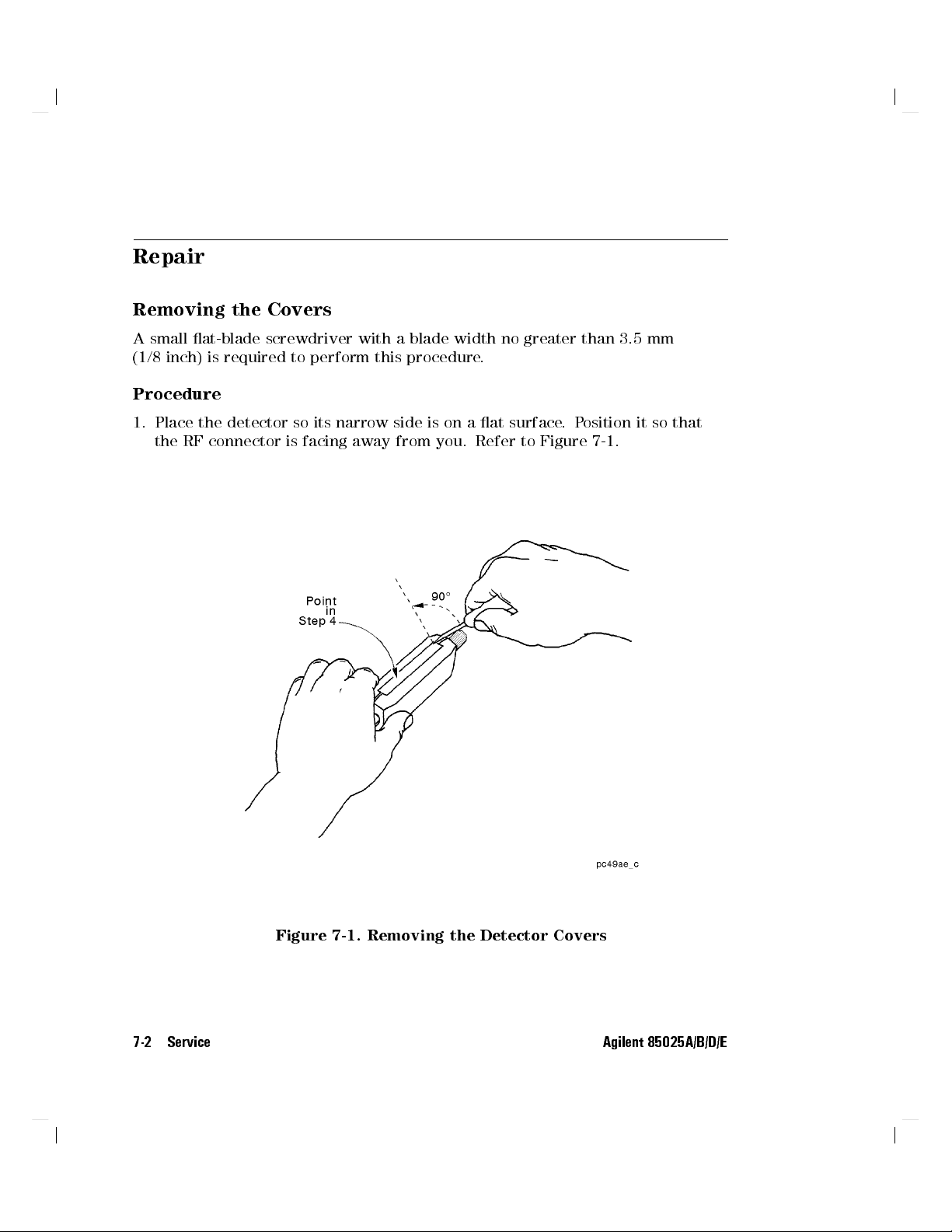

Repair

Removing

Replacing

Replacing

Replacing

8.

Detector

Mechanical

Inspecting

Visual

Cleaning

Connector

Gaging

Gaging

T

o

Order

.

.

the

Procedure

the

the

the

Maintenance

Inspection

Examination

the

Connectors

Connectors

Type-N

Precision

Precision

female

P

arts

P

arts

F

ast

.

.

.

.

.

Covers

.

.

.

.

Detector

Cable

Connectors

the

Connectors

Connectors

Cleaning

.

.

to

.

.

7

mm

.

3.5

mm

female

.

.

.

.

.

.

.

.

.

.

.

.

Assembly

.

.

.

.

.

.

.

.

Kit

.

.

.

.

be

Mated

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

with

the 85025A/B/D/E

.

.

.

.

.

.

.

.

.

.

.

..

..

.

..

..

.

.

.

..

.

.

.

.

.

.

..

.

..

..

.

..

.

.

..

.

.

.

.

.

.

..

..

.

.

..

..

.

.

.

.

..

..

.

.

..

.

.

.

.

.

.

.

.

..

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-1

.

7-2

.

7-2

.

7-2

.

7-3

. 7-3

. 7-5

.

8-1

.

8-1

.

8-2

.

8-2

.

8-2

.

8-2

.

8-3

.

8-3

.

8-3

.

8-3

9.

Automated

A

utomating the

Cal

Running

Detector

Running

Measurement

Example

Index

Agilent 85025A/B/D/E Contents-3

Program Listing

Frequency Response

Factor

Entry Program

the Cal

Frequency Response

the

Detector

Setup .

Programs .

Factor

.

.

.

.

.

Entry

Frequency

.

.

Program .

.

.

.

.

.

.

Program

.

T

est

.

.

.

Response

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

9-1

.

.

.

.

.

.

.

.

.

.

.

.

.

9-2

.

.

.

.

.

.

.

.

.

.

.

9-2

..

.

.

.

.

.

.

.

.

.

9-3

Program

.

.

.

..

..

.

.

..

.

.

.

.

.

.

9-3

..

..

..

.

.

.

.

.

.

.

9-5

.

9-5

Figures

1-1. 85025A/B/D/E

2-1.

Example

3-1.

Detector

3-2.

Typical

3-3.

Operator's

4-1.

Setup

4-2.

85025A/B/E

4-3.

Frequency

4-4.

Absolute

4-5.

P

ower

6-1.

Module

7-1.

Removing

7-2. Cable

9-1. Typical

of

a Static-Safe

F

eatures

System Setup

Check Equipment

for 85025A/B/D/E

Response

P

ower

A

ccuracy

Exchange

the

Connections

Program

Detector

Return

A

Alternate

Detector

Output

.

W

..

.

.

for 0.01

Return Loss

Loss

0.04 GHz

Measurement

ccuracy

Program

Covers

.

.

.

.

.

.

ork

.

Test

T

est

.

.

.

.

.

.

Station

.

.

.

to 50

Setup .

to Maximum

Setup .

Setup

Setup

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

GHz

Measurements

..

..

Test

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Frequency

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1-2

.

.

.

.

.

.

.

2-2

.

.

.

.

.

.

.

3-2

.

.

.

.

3-5

.

.

.

.

.

.

.

3-7

.

.

.

.

.

.

.

4-6

.

.

.

4-8

.

.

.

.

.

.

.

4-12

.

.

.

.

.

.

.

4-17

.

.

.

.

.

.

.

4-22

.

.

.

.

.

.

.

6-3

.

.

.

.

.

.

.

7-2

.

.

.

.

.

.

.

7-5

.

.

.

.

.

.

.

9-4

Contents-4 Agilent 85025A/B/D/E

T

ables

1-1. 85025

1-2.

85025A/B/D/E

1-3.

85025A Detector

1-4.

85025B

1-5.

85025D

1-6. 85025E

Series

Detector

Detector

Detector Specications

1-7. 85025A/B/D/E

3-1. Equipment

Required for

4-1. Recommended

4-2.

85025A/B

4-3.

85025D

4-4.

85025E

4-5.

Approximate

4-6.

Approximate

6-1.

85025A/B/D/E

Return Loss

Return Loss

Return

Detector

Detector

Descriptions

General

Specications

Specications

Specications

Specications

(including

.

.

..

Detector Supplemental

Operator's

Equipment .

with

with

Loss

with

Error

Analysis

Error

Analysis

Replaceable

.

.

Measurement

Measurement

Measurement

at

18

for

the

P

arts

.

.

.

..

.

..

.

.

Characteristics

Check

.

.

.

Uncertainty

Uncertainty

GHz

for

85025D

and

A

ccessories

.

.

.

.

.

.

.

Option

..

..

.

.

.

.

.

..

..

.

.

.

.

.

.

001)

.

.

.

.

.

Uncertainty

85025A/B/E

Detector

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Detectors

.

.

.

.

.

.

.

.

.

1-1

.

1-3

.

1-4

.

1-5

.

1-6

.

1-7

.

1-8

.

3-6

.

4-2

.

4-5

.

4-5

.

4-5

4-10

.

4-10

.

6-2

Agilent 85025A/B/D/E Contents-5

1

General

This manual

Agilent

Product

The

85025A/B/D/E

series

contains

85025A/B/D/E

Description

scalar

network

Detector

85025A

85025A

Option

85025B

85025D

85025E

Information

detectors

T

able

information

detectors

analyzers

1-1.

85025

on

.

Figure

are

specically

.

Series

Type-N

001

precision

precision

precision

precision 3.5

operating,

1-1

testing,

shows

designed

the

for

Detector Descriptions

Connector

Type

(m)

7

mm

3.5

mm

(m)

2.4

mm

(m)

mm

(m)

and

servicing

detectors

use

with

Frequency

.01

.01

.01

.01

.01

.

to

to

to

to

to

the

Agilent

18

GHz

18

GHz

26.5

GHz

50

GHz

26.5

GHz

8757

Range

Agilent 85025A/B/D/E General Information 1-1

Figure

1-1.

85025A/B/D/E

Detector

1-2 General Information Agilent 85025A/B/D/E

Specications and

Supplemental

T

ables 1-2

series

performance

T

able 1-7

when

through 1-6

scalar network

standards or

lists supplemental

used with

Characteristics

list

analyzer.

one of

the

detector

limits against

(typical,

specications

These

specications

non-warranted)

which

above-mentioned

when

represent

you

can

analyzers

used

test

detector

.

with

an

8757

the

warranted

the

device

.

characteristics

,

Note

Dynamic

A

DC

Nominal

Maximum

C

mode

T

able

Range

(on

Specications

over

the

1-2.

85025A/B/D/E

all

8757

Series

describe

temperature

analyzer's

detector

the

instrument's

range

of

Detector

inputs):

C,

25

General

6

mode +16

Impedance

Input

P

ower

warranted

C.

5

performance

Specications

+16

to

0

55

dBm

to

0

50

dBm

50

+20

dBm

(100

mW),

6

10

VDC

Agilent 85025A/B/D/E General Information 1-3

85025A

Detector

T

able

1-3.

Specications

(including

Option

001)

Frequency

Return Loss

10

MHz

to 40

40

MHz

to 4

4GHz

to 18

Frequency

10

MHz

to

40

MHz

to

Absolute

Dynamic

P

P

Range

:

MHz 10

GHz 20

GHz 17

Response

40

18

ower

ower

MHz

GHz

A

ccuracy

A

ccuracy

(in

DC

mode

(in

DC

,

input

mode

power

,

50

0

MHz,

0.01

dB

dB

dB

10

dBm):

+0.25

6

0.5

calibrated

to

18

GHz

dB/

0

0.75

dB

dB

at

0

dBm)

1-4 General Information Agilent 85025A/B/D/E

T

able

1-4.

85025B

Detector

Specications

Frequency

Return

Loss

10

MHz

40

MHz

4

GHz

to

18

GHz

Frequency

10 MHz

40

MHz

Absolute

Dynamic

Range

:

to

40

MHz

to

4

GHz

18

GHz

to

26.5

GHz

Response

to 40

to 18

P

ower

P

ower

(in DC

mode,

input power

MHz +0.25

GHz

A

ccuracy

(in

DC

mode

,

50

MHz,

A

ccuracy

0.01

10

20

17

12

0

10

dBm):

6

calibrated

to

dB

dB

dB

dB

0.5 dB

26.5

dB/

at 0

0

dBm)

GHz

0.75

dB

Agilent 85025A/B/D/E General Information 1-5

T

able

1-5.

85025D

Detector

Specications

Frequency

Return

Loss

10

MHz

40

MHz

100

MHz

14

GHz

34

GHz

40

GHz

Frequency

10

MHz

40 MHz

20

GHz

26.5

GHz

40

GHz

Absolute

Dynamic

Range

:

to

40

MHz

to

100

MHz

to

14

GHz

to

34

GHz

to

40

GHz

to

50

GHz

Response

to 40

to 20

to

26.5

to

to

50

P

ower

P

ower

(in DC

mode,

input power

MHz +0.25

GHz

GHz

40

GHz

GHz

A

ccuracy

(in

DC

mode

,

50 MHz,

A

ccuracy

0.01

10

dB

20

dB

23

dB

20

dB

15

dB

9

dB

0

10

dBm):

6

0.5

+1/

0

+2.5/

+3.0/

calibrated at

to

50

dB/

dB

0.5 dB

0

0.5

0

0.5

GHz

0

0.75

dB

dB

0 dBm)

dB

1-6 General Information Agilent 85025A/B/D/E

T

able

1-6.

85025E

Detector

Specications

Frequency

Return

Loss

10

MHz

40

MHz

100

MHz

25

GHz

Frequency

10 MHz

40

MHz

18

GHz

Absolute

Dynamic P

Range

:

to

40

MHz

to

100

MHz

to

25

GHz

to

26.5

GHz

Response

to 40

to 18

to 26.5

P

ower

ower A

(in DC

mode,

input power

MHz +0.25

GHz

GHz

A

ccuracy

(in

DC

mode

,

50

MHz,

ccuracy

0.01

10

20

25

23

0

10

dBm):

6

6

calibrated

to

dB

dB

dB

dB

0.5 dB

0.5

dB

26.5

dB/

at

at

0

0

GHz

0.75

18

dBm)

GHz

dB

to

6

1.4

dB

at

26.5

GHz

Agilent 85025A/B/D/E General Information 1-7

85025A/B/D/E

RF

Connector Mechanical

Detector

Tolerances

T

able

1-7.

Supplemental

Characteristics

:

Recession

of the

male center

conductor from

reference plane:

85025A 0.207

85025A Option

001 0.000

85025B 0.000

85025D 0.000

85025E 0.000

Cable

Length

W

eight

(Including

cable):

Net:

Shipping:

Dimensions2(Including input

connector,

not

including

1.22

0.24

1.0

cable)

to 0.210

to

to 0.003

to 0.002

to

m

kg

kg

(2.2

0.003

0.003

(48

(0.5

inches

inches

inches

inches

inches

inches)

lb)

lb)

1

1

Because a type-N gage calibration block zeros the gage at a 0.207-inch oset, the gage

displays a 0.207- to 0.210-inch oset as 0.000 to 0.003 inches

2

The model used in this illustration is an 85025A. Because

.

of varying input connector

lengths, the overall length measurements for the other detector models covered by this

manual are:

85025A Option 001: 5 3/16 inches

85205B: 5 1/8 inches

85025D: 5

1/4 inches

85025E: 5 7/16 inches

1-8 General Information Agilent 85025A/B/D/E

Operating Environment

The

detector

performance

more

information.

T

emperature

will

is

:

not

operate

necessarily

to

+55

0

safely

C

under

warranted.

the

following

See

the

conditions,

specications

but its

section for

Humidity

Altitude

A

ccessories

The

ordered

these

Storage

T

o

keep

suggestions in

:

:

detectors

separately

detectors

your

come

and

detector

mind

Environment

Store

or ship

T

emperature

Humidity

the

:

: Up

Up

to

95%.

which

Up

to

can

4,572

with

.

T

able

.

Shipment

in

when

detectors

to

0

25

to 95%.

which

can

Protect

cause

m

(15,000

a

2-meter

6-1

lists the

proper

storing

in

environments

C

+75

Protect

cause

the detector

condensation.

ft)

cable

.

A

accessories that

working

or

condition,

shipping

the

detector

condensation.

from temperature

25-foot

and

keep

it.

within

the

from

200-foot

are

available

the

following

following

limits:

temperature

extremes

cable can

for

use

extremes

be

with

Altitude

: Up to 4,572 m (15,000 ft)

Agilent 85025A/B/D/E General Information 1-9

P

ackaging

Use

containers

packaging.

1.

Wrap

the

wrap

the

2.

Provide

layer

of

3.

Seal

the

4.

Mark

the

and

materials

If

you

ship

the

detector

detector

a

rm

in

in

cushion

the

heavy

shock-absorbing

shipping

shipping

container

container

identical

detector

original

paper

that

prevents

material

securely

FRA

or

,

follow

pouch

and

around

.

GILE

comparable

these

and

box.

use

a

strong

movement

all

sides

.

to

those

packaging

If they

shipping

inside the

of

the detector

used

in factory

instructions:

are not

available,

container

container.

.

.

Use a

Returning

When

you

by

both

model

If

you ship

blue

service tag

make

the

a

Detector

an

inquiry

number

detector

(provided

and

to

,

either

full

an

at

for

serial

Agilent

the

back

Service

by mail

number.

oce

of

or

or

this

by

telephone

service

manual),

information:

1.

Company name

Do

not

use

returned

2.

The

complete

3.

The

complete

4.

The

type

to

of

and address

an

address

a

post

phone

model

service

with

oce

number

and

required

.

a

P

box.

of

serial

(calibration,

.O

.

box

a

technical

number

number

contact

of

the

repair).

because

detector

5. Any other information that could expedite service

or cause

.

,

refer

to

the

detector

center

,

ll

out

a

and

include

products

the

following

cannot

be

person.

.

, such as failure condition

1-10 General Information Agilent 85025A/B/D/E

Installation

2

Refer to

detector

Initial

1.

2.

3.

4.

If

any

Incomplete

Mechanical

Failed

If you

material,

the

following

or

subject

Inspection

Check

Check

Check

Check

Either

the

shipping

that

connector

the

detector

perform

measurement

of

the

following conditions

shipment.

damage

electrical test.

nd damage

keep

the

in

them

information

it

to

excessive

container

shipment

,

cable

,

electrically:

the

operator's

Chapter

or

defect.

or signs

for

the

and

is

complete

and

detector

4,

\P

erformance

of stress

carrier's

when

using

mechanical

shock.

packaging

.

body

for

check

in

Chapter

T

ests

exist, notify

to

the

shipping

inspection. Agilent

the

detector

material

mechanical

3,

."

your

nearest

container

for

\Operation,"

does

claim settlement before arranging for repair or replacement.

.

Do

damage

damage.

Agilent

or

not

not

the

drop

.

or

oce:

wait

the

make

a

cushioning

for

a

Agilent 85025A/B/D/E Installation 2-1

Electrostatic Discharge

ESD

can

100

V

can

disconnect

grounding

contact

pins

damage

destroy

strap

a

device

.

the

.

Never

highly

a

detector

.

Use

this

touch

sensitive

.

ESD

detector

the

(ESD)

circuits

in

this device;

damage occurs

at

a static-safe

input connector

charges as

most often

as you

workstation and

center contacts

low as

connect or

wear a

or the

cable

Static-Safe

Figure 2-1

you

can use

illustrates

A conductive

A conductive

W

either

table

oor mat

ork

a

together

mat

Station

static-safe

or

and

and

heel-strap

station

separately:

wrist-strap

using

two

types

combination.

combination.

of

ESD

protection

that

Figure 2-1. Example of a Static-Safe W

ork Station

2-2 Installation Agilent 85025A/B/D/E

Static-Safe

Practices

Before

device

Discharge

device

the

test

protects

P

ower

The

scalar

Mating

T

able

1-7

(part

number

inspection,

cleaning,

or

test

inspecting,

port,

ground

static electricity

briey

port,

test

(through

or another

equipment

a resistor

exposed ground.

circuitry.

Requirements

network

analyzer

Connectors

lists

connector

08510-90064

and

gaging

mechanical

)

of

connectors

or

making

yourself as

from a

supplies

provides

a connection

far as

device before

of at

least 1

This discharges

power

for

tolerances

information

.

to a

possible from

connecting it.

M)

to

either

the

detector

.

Microwave

on

the

proper

static-sensitive

the test

the

static

port.

T

ouch

the

outer

shell

electricity

.

Connector

Care

maintenance

of

and

,

Connecting

1.

The

85025A/B/D/E

8757

series scalar

insert

analyzer

2. T

the multi-pin

.

o secure the DC connector in the analyzer

3. Connect the RF input to the

outer

shell clockwise

the

Detector

cables

plug

network analyzer

(DC) connector

.

into

the

connectors

.With

into the

the cable

A input

, turn the

on

the front

plug

on the

outer

panel of

key

downward,

front

panel

shell clockwise

test device by turning the male connector's

of

the

the

.

Agilent 85025A/B/D/E Installation 2-3

Operation

3

Caution

Electrostatic

circuits

your

ESD

a

wear

center

Do

than

in

this

detector

damage occurs

device

.

Use

a

grounding

contacts

not

apply

6

10

VDC

electrically

Before

discharge

on

most

large

Do

you

the

cable's

important

antenna.

not

drop the

the

discharge

device;

.

this

or

more

to

the

damage

connect

static

outer

if

detector or

(ESD)

charges

most

detector

strap

.

the

cable

than

detector

the

detector

a

RF

electricity

conductor

the

cable is

often

at

Never

+20

cable

can

damage

as

low

as

you

a

static-safe

touch

contact

dBm

RF

.

Higher

.

to

the

that

may

to

instrument

very long

subject it

the

highly

as

100

V can

connect

workstation

the

input

pins

.

power

or

power/voltage

detector

have

,

accumulated

ground.

or

connected

to mechanical

sensitive

destroy

or

disconnect

and

connector

more

can

always

This

to

shock.

is

a

Agilent 85025A/B/D/E Operation 3-1

Features

Figure

Operating

The 85025A/B/D/E

square wave

detection mode

analyzer to

In

A

C

detection

with a 27.778 MHz

this signal to produce

Theory

can detect

amplitude modulated

,the

detector provides

interpret and

mode

,

and

display.

square wave

a 27.778 MHz signal with a peak-to-peak voltage that

corresponds to the magnitude of

In DC detection mode

,no

85025A/B/D/E converts the RF signal into an

detector chops the DC voltage at a 27.778 kHz rate

is then amplied. The amplied signal simulates the signal produced by A

3-1.

Detector

either unmodulated

RF signals

a 27.778

RF

or

microwave

F

eatures

RF

in A

C

MHz

signal is

signals

mode

.

square

amplitude

in

In

wave

either

DC

mode

A

C

or

signal

modulated

or

for

. The detector demodulates (envelope detects)

the RF signal at the detector input.

modulation is required. The detector diode in the

equivalent DC voltage

.The

, and this chopped signal

C

DC

the

detection.

3-2 Operation Agilent 85025A/B/D/E

Measurement System

With

an

8757

system

of

conguration

the

analyzer

measurement.

series

scalar

requires

system

However

and

,

to

network

special

there

enable

required.

DC

Detection

mode

Conguration

analyzer

attention.

are

no

DC

using

an 85025A/B/D/E

A

C

further requirements

mode operation,

mode

is the

a series

detector,

default state

to initiate

of keystrokes

a

is

DC detection

characterize

typical

oscillator/RF plug-in

1.On

2. DC

the

detection

select

When

is automatically

A

ccurate DC

Zeroing

When

you

detector zeroing

temperature uctuations

oers

oscillators and

measurement

analyzer

N

N

N

N

N

N

N

MODE

the

the

make

mode

N

N

N

N

N

N

N

N

NN

NN

N

N

N

N

DC

N

N

N

N

N

N

N

N

N

N

N

NN

MODE

Detector

DC

,

.

N

N

procedure

greater

power

measurement

modulation-sensitive

setup

for

as the

press

4

PRESET

must

N

N

N

N

N

N

N

N

DC

softkey

switched

0.01 to

source

be

selected.

is

OFF

50 GHz,

.

5

.

Connect

selected,

.

Measurements

detection

measurements

to

compensate

.

This

zeroing

using an

the

On

the

the

source's

,

it

for

the

procedure

accuracy

devices

.

Agilent

detector(s).

analyzer

,

square

is

important

eects

eliminates

and

the

ability

Figure

3-2

8350B

press

4

SYSTEM

wave modulation

to

perform

of

DC

drift

small

DC

to

depicts

sweep

5

and

this

and

voltages

from the diode detector that would otherwise cause amplitude measurement

errors at low (

noise level with no RF signal applied (the system's noise

40 dBm) power levels

. Zeroing also establishes the displayed

oor).

a

Autozero

Pressing the autozero softkey

AUTOZRO

output and automatically zeros the detector

NNNNNNNNNNNNNNNNNNNN

NNN

switches OFF the source RF signal

.

Agilent 85025A/B/D/E Operation 3-3

The

repeat

the

autozero.

function

sweeper

autozero

Y

ou

because

to

perform

function

must

the

the

use

a

analyzer

autozeroing.

softkey

GPIB

must

N

N

N

N

N

N

N

N

N

N

NN

NN

REPT

(

interfaced

be

able

NN

NN

N

N

N

N

N

AZ

sweeper

to

switch

N

N

N

N

N

N

N

N

N

N

N

N

NN

ON/OFF

NN

NN

NN

N

)

periodically

to

take

OFF

the

repeats

advantage

RF

output

of

of

this

the

Manual

Manual

meter

1.

Remove

2.

On the

Refer

Analyzer

Analyzer

softkeys

In

the

accuracy

The

The

The

Trace

The

The source

To

increase the

N

N

N

N

N

N

N

N

DET

zeroing

1.

On the analyzer

port). Press

zero

.

to

.

DC

.

equipment

detector

oset

averaging

source

N

N

N

NN

NN

NN

NN

N

N

N

OFFSET

the

Zero

analyzer

\Operation,"

Operating

Operating

mode

In

N

N

N

N

N

N

,

represented

the

RF

signal

,

,

the

regard

has

zeroing

has

been

is

harmonics

SWR is

accuracy of

N

N

N

N

to

properly

detector

, press

4

054dB

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

by

from

N

NN

N

MANUAL

press

in

the

Manual

Manual

85025A/B/D/E

to

these

had

a

procedure

adjusted

enabled

are

1.0.

set

, follow

4

CAL

5

. This ensures the 0 dB oset.

MANUAL

the

the

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

A

gilent

or

A

gilent

for

detailed

specications

30

minute

with

on

the

below

absolute power

the

system response

these steps

NN

N

N

N

N

N

N

DET OFFSET

5

N

softkey

detector's

to

perform

T

echnologies

T

echnologies

information

is

specied

,

warmup

has

been

a

calibrated

analyzer

0

40 dBc

to set

N

N

N

N

NN

N

N

N

N

N

N

N

N

N

N

N

NN

N

RF

the

the

performed.

at

.

level

NN

N

N

N

N

N

DET A

,

is

similar

input.

zeroing.

8757C/E

for

absolute

following

period.

0 dBm,

low power

measurements

to a

the detector

N

N

N

N

N

N

N

N

N

NN

N

N

N

(or the appropriate input

8757D

on

these

conditions

50 MHz

0dBm

to

zeroing

Scalar

Scalar

power

levels,

signal. After

oset:

Network

and

level

signal

as

,

select

a

power

Network

other

apply:

applied.

required.

2. Connect the detector to the POWER REF output of a calibrated power meter

such as an Agilent 436A or 438A. Switch the POWER REF output ON.

NNNNNNNNNNNNNN

5

MORE

NNNNNNNNNNNNNNNNNNNN

5

AUTOSCALE

3.

Press

4

CURSOR

4.

Press

4

CAL

3-4 Operation Agilent 85025A/B/D/E

NNNNNNNNN

.

NNNNNNNNNNNNNN

NNNNNNNNNNNNNNNNNN

DET OFFSET

.

,

5.

Press

the

value

should

N

NN

NN

DET

now

NN

NN

N

N

N

N

N

N

N

N

A

(or

opposite

indicate

the appropriate

in

sign

to

the

a

power

reading

input port)

cursor

reading

of

0.00 dBm.

and

use

being

the

entry

displayed.

keys

to

The display

enter

Note

Pressing

to

the

4

zero,

and

oset value(s).

PRESET

the

5

on the

SA

VE/RECALL

analyzer

does

registers

not

do

reset

not

any

save

DC

or

OFFSET

recall

Figure 3-2. Typical System Setup for 0.01 to 50

GHz Measurements

Agilent 85025A/B/D/E Operation 3-5

AC

Detection Measurements

F

or

the

A

C

detection

time

and

network

provided

test

signal.

depicts

the

sweep

majority

temperature

analyzer

through

a

typical

of

oers

system

a

T

est

set

measurement

oscillator

measurements

greater

.

A

sensitivity

C

detection

require

27.778

kHz

connections

.

,

A

C detection

and

immunity

amplitude

a

modulation

square

wave amplitude

vary depending

setup

.

The 27.778

is still

the preferred

to noise

and drift

measurements with

envelope.

This envelope

modulation of

on the

source.

Figure

kHz modulation

method.

across

this scalar

is

the RF

3-2

is supplied

by

Operator's

The

following procedure

85025A/B/D/E

Check

detector.

T

able

3-1.

Equipment

provides a

Description Model/Part

Detector 85025A/B/D/E

GPIB cable 10833A/B/C/D

Bandpass

Sweep

oscillator

lter

any

within

any

compatible with

scalar

BNC

cables

(3

required)

part

number

quick

operational

Required

the

network

8120-1839

for

Operator's

frequency

the

analyzer

check

Number

range of

8757

series

of

the

Check

the sweeper

3-6 Operation Agilent 85025A/B/D/E

Procedure

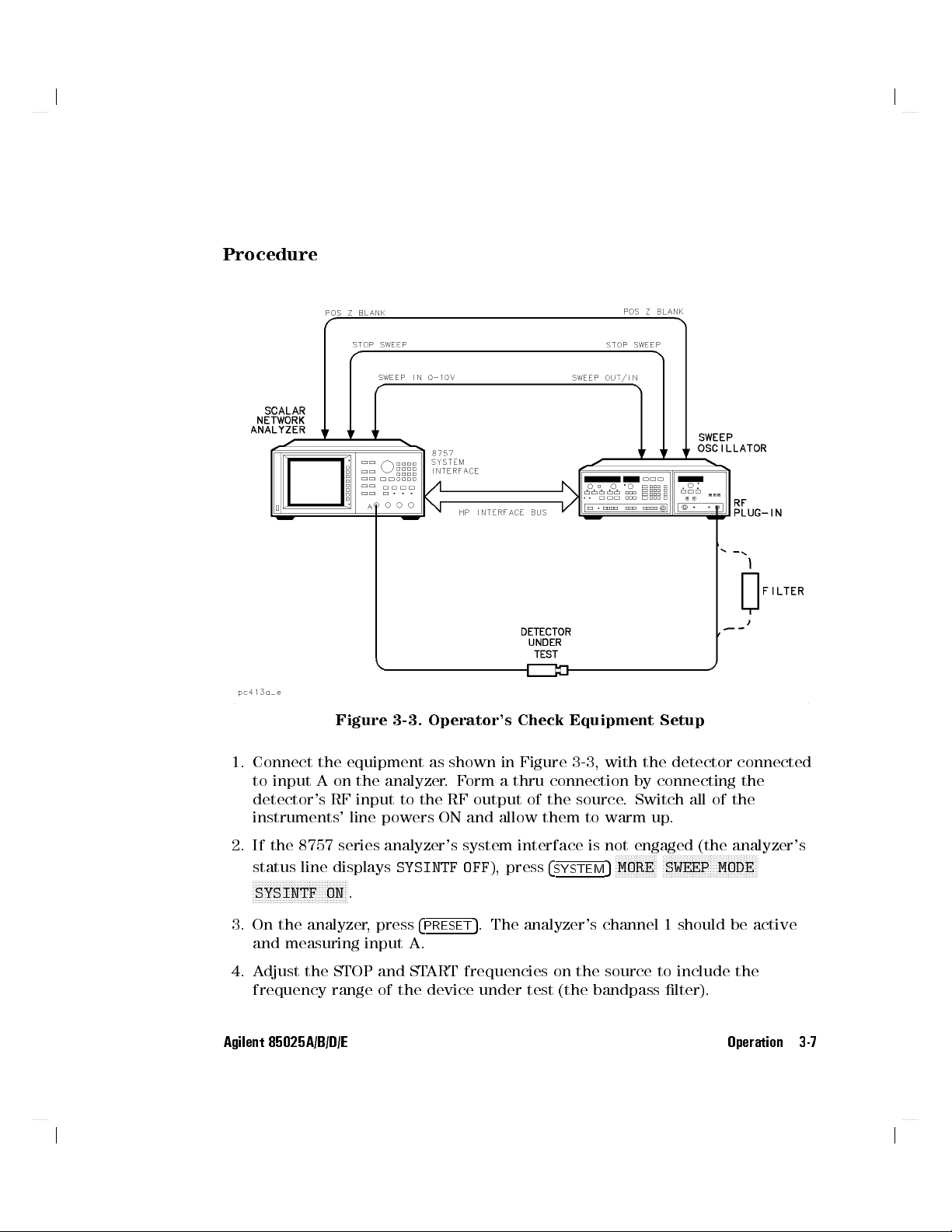

Figure

1.

Connect

to

detector's

input A

the

equipment

on

RF input

instruments'

2. If the 8757 series analyzer's system interface is not engaged (the analyzer's

status line displays

NNNNNNNNNNNNNNNNNNN

NNNNNNNNNNNNN

SYSINTF ON

3. On the analyzer

3-3. Operator's

the

analyzer

to

line

powers

SYSINTF OFF

.

, press

as

shown

.

the

RF

ON

4

PRESET

Check Equipment

in

Figure

F

orm

a

thru

output

and

allow

), press

5

. The analyzer's channel 1 should be active

3-3,

connection

of

the

them

4

SYSTEM

with

source

to

warm

5

by

.

Switch

NNNNN

NNNNNNNNN

MORE

Setup

the

detector

connecting

all

up

.

NNNNN

NNNNNNNNNNNNNNNNNNNNNNNNN

SWEEP MODE

connected

of

the

the

NN

and measuring input A.

4. A

djust the STOP and ST

ART frequencies on the source to include the

frequency range of the device under test (the bandpass lter).

Agilent 85025A/B/D/E Operation 3-7

5.

Switch

6.

On

the

value of

of the

cursor value

attainable on

of the

7.

Press

message

OFF

analyzer

the

analyzer

analyzer

4

DISPLA

line

the

analyzer's

,

press

trace

.

A

on

the

all

sources).

.

N

NN

N

N

N

MEAS

5

Y

displays

.

The

djust

analyzer

N

N

N

N

N

N

N

N

N

N

N

!

CHAN

4

CURSOR

CRSR

the

N

N

N

N

N

NN

NN

NN

MEM

channel

N

N

MAX

5

value

output

reads

This

value

to

store

1

MEAS TO

N

N

N

N

N

N

power

2

by

N

N

N

to

is

displayed

+16

is

the

trace

MEMORY

pressing

place

the

of

the

dBm

(this

the

upper

in

.

CHANNEL

cursor

in

the

active

RF

plug-in

power

limit

of

memory

at

.

level

The

5

4

2

the

entry

until

the

dynamic

analyzer's

twice

.

maximum

area

the

may

not

be

range

8.

Disconnect

N

N

N

N

N

N

N

NN

N

N

N

N

N

AVG

ON

W

ait

a

9.

Press

displayed

power

10.

Insert

detector

11. Press

in

the

test

device

12.

Press

to

settle

however

has

increased

If

the

Operator's

Since

the

be due to the source

well as the

can vary considerably from

the

N

N

N

N

N

N

to

few seconds

4

CURSOR

level.

the

.

4

CURSOR

active

4

SYSTEM

.

detector

bandpass lter waveform are accurate

detector

activate

N

N

N

N

N

MAX

5

in

the

active

bandpass

W

ait

a

few

N

N

N

NN

MAX

5

entry

.

V

erify

N

N

N

N

N

MODE

5

The trace

the

noise

more

is

, rather than the detector

the

to allow

N

N

NN

NN

.

A

lter

seconds

N

N

N

N

N

N

to

area

that

N

N

N

N

N

N

N

N

N

N

N

AC/DC

should look

oor

than

Check

measuring

from

averaging

the trace

cursor

entry

area.

between

to

nd

the

now

represents

the

bandpass

N

N

NN

NN

N

N

N

N

N

N

N

N

N

N

until

may

be up

5

dB,

F

ails

the

unit to unit.

the

RF

function.

value

This

the

allow

trace

the

similar to

to 5

zero the

output

OUTPUT

The

to settle

of

0

55 dBm

value

RF

output

the

trace

maximum.

the

minimum

lter

shape

DC

mode

the trace

dB higher

detector.

of

an

external source

.V

erify that the source output as

of

the

source

. Press

averaging

.

or

lower

represents

of

the

to

settle

The

is

as

is

activated.

observed

.

If

. Note that bandpass lters

value

should

the

source

.

CRSR

value

insertion

expected.

the

noise

,

4

A

will

be

noise

oor

and

the

displayed

loss

of

Allow

the

in

step

oor

problems

V

G

be

your

11,

level

5

8.

trace

may

If the average noise oor

detector. The instructions for zeroing

chapter.

3-8 Operation Agilent 85025A/B/D/E

is not below

0

50 dBm in DC mode

the detector can be found earlier in this

, try zeroing the

P

erformance T

4

ests

Use the

to

access

T

o

1. return

2. frequency

3. absolute

procedures

the

specications

to the

completely

loss

detector's

test

response

power/dynamic accuracy

Note

Equipment

Preceding

that

critical

each

particular

specications

Note

in

this

listed

interior

each

detector

F

or

information

P

erformance

chapter

in

to

test

\General

.

, three

on automating

T

est,

see

the

the

detector's

Information."

tests are

required:

the

chapter

electrical

None

Frequency

titled

\Program

of

these

Response

performance

tests

Listing."

Required

test

is

a

list

that

test.

Y

ou

may

.

See

T

Before you

input

connector

Performance T

describes the

substitute

able

4-1

for an

proceed with

on

the

est R

ecord

detector

equipment required

any equipment

overall list

the performance

and

enter

at the end of \P

that meets

of required

tests,

the

results

erformance T

to perform

the indicated

equipment.

gage the

For instructions on gaging the detector's input connector

\Detector Maintenance

."

require

in

the

ests."

,see

Agilent 85025A/B/D/E Performance Tests 4-1

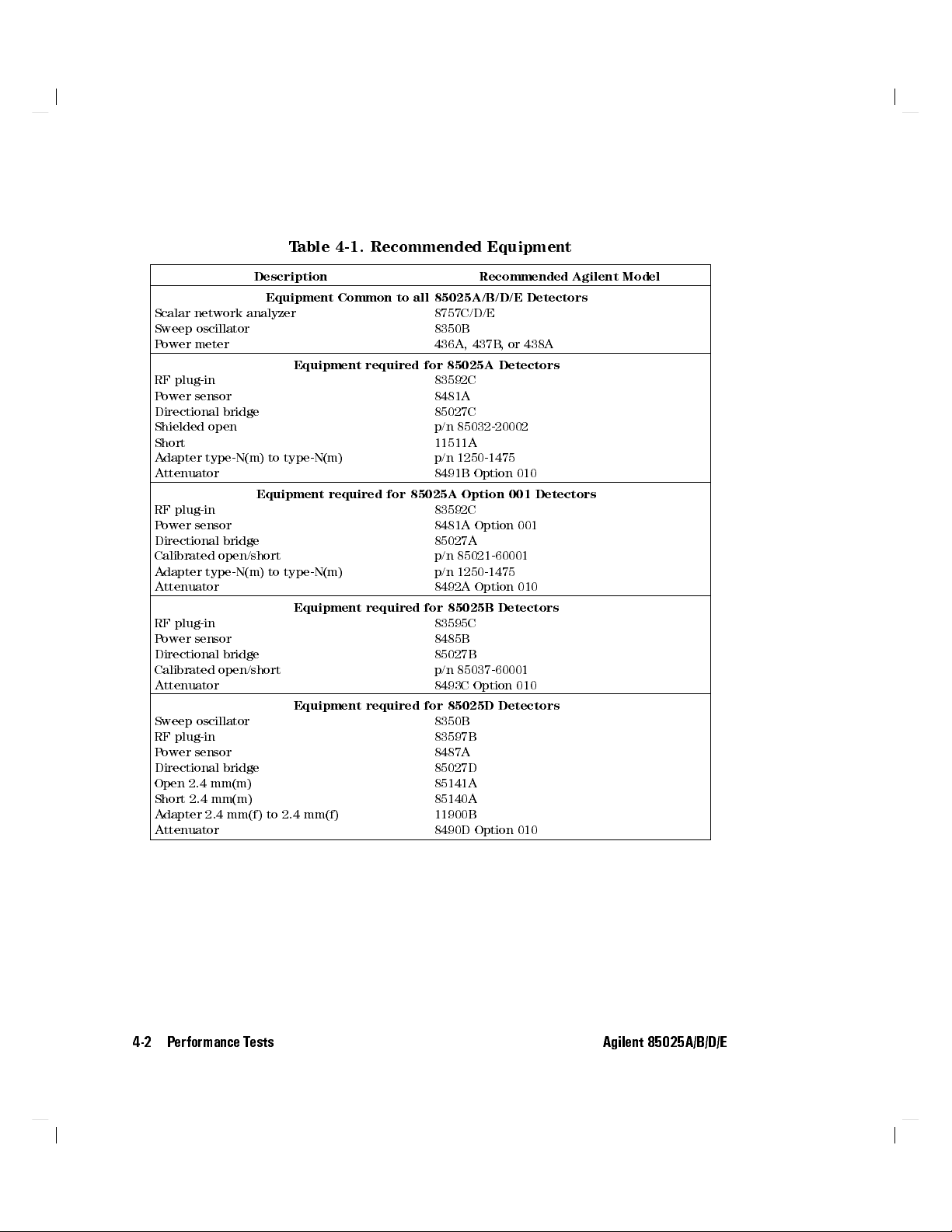

T

able

4-1.

Recommended

Equipment

Description

Scalar

network analyzer

Sweep

oscillator

P

ower

meter

RF

plug-in

P

ower

sensor

Directional

Shielded

bridge

open

Short

A

dapter

type-N(m)

Attenuator

RF

plug-in

P

ower

sensor

Directional bridge

Calibrated

A

dapter

open/short p/n

type-N(m)

Attenuator

RF

plug-in

P

ower

sensor

Directional

Calibrated

bridge

open/short

Equipment

to

type-N(m)

Equipment required

to

type-N(m)

Common

Equipment

Equipment

to

required

for 85025A

required

all

85025A/B/D/E Detectors

8757C/D/E

8350B

436A,

for

85025A

83592C

8481A

85027C

p/n

11511A

p/n

8491B

83592C

8481A

85027A

p/n

8492A

for

85025B

83595C

8485B

85027B

p/n

Attenuator 8493C

Sweep

oscillator 8350B

RF

plug-in

P

ower

sensor

Directional

Open

Short

A

dapter 2.4

bridge 85027D

2.4

mm(m) 85141A

2.4

mm(m)

mm(f)

to

2.4

mm(f)

Attenuator

Equipment

required

for

83597B

8487A

85140A

11900B

8490D

85025D

Recommended

437B

,

or 438A

Detectors

85032-20002

1250-1475

Option

010

Option

001

Option

85021-60001

1250-1475

Option

Detectors

85037-60001

Option

010

Detectors

Option

Detectors

001

010

010

Agilent

Model

4-2 Performance Tests Agilent 85025A/B/D/E

T

able

4-1.

Recommended

Equipment

(continued)

Description

RF

Equipment

plug-in

Power

sensor 8485A

Directional

Calibrated

bridge

open/short

required

Attenuator 8493C

Return

This

measure

85025A/B/D/E

Loss P

performance

the

return

erformance T

test

uses

an

8757C/D/E

loss

of

the

detector

Return

Loss

P

erformance

Specications

Specications

return

loss

apply

at

specications

a

temperature

,

refer

to

T

ables

range

Description

The

return

described

minimize

then

on

the

loss

in

this

frequency

connected

analyzer

of

the

procedure

response

to

the

.

85025A/B/D/E

.

The

test

and

phasing

TEST

PORT

can be

of

setup

the

for

85025E

83595C

85027B

p/n

85037-60001

Option

est

scalar

.

of

25

1-2

through

measured using

is calibrated

errors

bridge,

Recommended

Detectors

010

network

analyzer

T

est Procedure

C

C.

6

5

1-6.

using an

.

The

detector under

and its

return loss

Model

system to

F

or

the

the test

open/short to

detector's

system

test is

is measured

The return

1-6.

There

loss should

is

a

certain

be greater

amount

of

than the

limits listed

measurement

in T

uncertainty

ables

in

any scalar

1-2

through

network analyzer system. The return loss uncertainty for each detector is given

in T

ables 4-2 through 4-4. Conformance to specication cannot be assured

unless the return loss of the detector is equal to the specied return loss

plus the measurement uncertainty

proven unless measured return loss equals the

measurement uncertainty

. The measurement uncertainty is

case specications for the test devices in the

.F

ailure to meet specication cannot be

specied return loss minus the

based on the worst

measurement.

Agilent 85025A/B/D/E Performance Tests 4-3

Example

The

specied

A:

measurement

If

the

detector's

detector

If

the

is

denitely

measured

measurement

One

way

to

using

a

vector

return

uncertainty

measured

return

uncertainty

reduce

the

network

loss

for

an

is

6

return

within

specication.

loss

is

,

the

measurement

analyzer

85025A

1.4

dB

loss

within

detector

.

detector

.

is

20

dB

the

specied

may

or

uncertainties

at

+1.4

return

may

1

not

is

GHz

dB

to

is

20

(21.4

dB

loss

plus-or-minus

be

within

measure

dB

.

The

or

higher),

specication.

the

detector

the

the

Example

If

the

it

cannot

If

the

measurement

Example

If

the

or

less),

The

three

Bridge

Source

Dynamic

The

rst two

measured

T

ables 4-2,

85025D

B:

85025A

be

determined

measured

C:

85025A

the

detector

main

directivity

match of

accuracy of

vary with

return loss

4-3,

, and

85025E

in

uncertainty

in

sources

and

the corresponding

example,an

85027A bridge with an 85025A detector

Example

return

Example

A

if

loss

,

the

A

is

denitely

of

error

measures

it

is

or

is

less

detector

and

20

dB

6

1.4

is

not

within

than

the

is

B

measured

out

of specication.

in

these measurements

specication.

specied

denitely

less

dB

return

out

than

(i.e

.

from

loss minus

of

specication.

20

dB

come from:

the bridge

the analyzer

frequency while

dynamic

accuracy

varies

amplitude.

4-4

show

detectors

measurement

,

respectively

uncertainty

.

The

tables

for

the

assume

connector-compatible Agilent directional bridges

.

18.6

0

1.4 dB

with

85025A/B

you

.F

to

the

(18.6

are

or

21.4 dB)

dB

the

,

using

,

4-4 Performance Tests Agilent 85025A/B/D/E

85025A/B

Return

Loss

T

able

with

4-2.

Measurement

Uncertainty