Errata

This manual may contain references to HP or Hewlett-Packard. Please note that Hewlett-Packard's former test

and measurement, semiconductor products and chemical analysis businesses are now part of Agilent

Technologies. To reduce potential confusion, the only change to product numbers and names has been in the

company name prefix: where a product number/name was HP XXXX the current name/number is now Agilent

XXXX. For example, model number HP8648 is now model number Agilent 8648.

Ce manuel peut contenir des références à <<HP>> ou <<Hewlett-Packard.>> Veuillez noter que les produits de

test et mesure, de semi-conducteur et d'analyse chimique qui avaient fait partie de la société Hewlett-Packard

sont maintenent une partie de la société Agilent Technologies. Pour reduire la confusion potentielle, le seul

changement aux noms de reference a été dans le préfixe de nom de société : là où un nom de référence était HP

XXXX, le nouveau nom de référence est maintenant Agilent XXXX. Par example, le HP 8648 s'appelle

maintenent Agilent 8648.

Diese Gebrauchsanweiseung kann Bezug nehmen auf die Namen HP oder Hewlett-Packard. Bitte beachten Sie,

dass ehemalige Betriebsbereiche von Hewlett-Packard wie HP-Halbleiterprodukte, HP-chemische Analysen

oder HP-Test- und Messwesen nun zu der Firma Agilent Technology gehören. Um Verwirrung zu vermeiden

wurde lediglich bei Produktname und - Nummer der vo laufende Firmenname geändert: Produkte mit dem

Namen/Nummer HP XXXX lauten nun mehr Agilent XXXX. Z.B, das Modell HP 8648 heißt nun Agilent 8648.

Questo manuale potrebbe contenere riferimenti ad HP o Hewlett-Packard. Si noti che le attività precedentemente

gestite da Hewlett-Packard nel campo di Test & Misura, Semiconduttori, ed Analisi Chimica sono ora diventate

parte di Agilent Technologies. Al fine di ridurre il rischio di confusione, l'unica modifica effettuata sui numeri di

prodotto e sui nomi ha riguardato il prefisso con il nome dell'azienda : dove precedentemente compariva "HP

XXXX" compare ora "Agilent XXXX". Ad esempio: il modello HP8648 è ora indicato come Agilent 8648.

Este manual puede hacer referencias a HP o Hewlett Packard. Las organizaciones de Prueba y Medición (Test

and Measurement), Semiconductores (Semiconductor Products) y Análisis Químico (Chemical Analysis) que

pertenecían a Hewlett Packard, ahora forman parte de Agilent Technologies. Para reducir una potencial

confusión, el único cambio en el número de producto y nombre, es el prefijo de la compañía: Si el producto solía

ser HP XXXX, ahora pasa a ser Agilent XXXX. Por ejemplo, el modelo HP8648 es ahora Agilent 8648.

Document Part Number 5971-2668

Printed in the UK September 2004

A

マニュアル・チェンジ

変更

本文中の「HP(YHP)」、または「(横河)ヒューレット・パッカード株式会社」とい

う語句を、「Agilent」、または「アジレント・テクノロジー株式会社」と変更して

ください。

ヒューレット・パッカード社の電子計測、半導体製品、化学分析ビジネス部門は分

離独立し、アジレント・テクノロジー社となりました。

社名変更に伴うお客様の混乱を避けるため、製品番号の接頭部のみ変更しておりま

す。

(例: 旧製品名 HP 4294A は、現在 Agilent 4294A として販売いたしておりま

す。)

Operating and Service Manual

Agilent 8480 Series Coaxial Power Sensors

This manual applies to the following models:

8481A

8482A

8483A

8485A

8487A

8481B

8482B

8481H

8482H

8487D

8485D

8481D

Manufacturing Part Number: 08481-90173

May 2004

© Copyright 2004 Agilent Technologies.

Notice

The material contained in this document is provided "as is," and is

subject to being changed, without notice, in future editions. Further, to

the maximum extent permitted by applicable law, Agilent disclaims all

warranties, either express or implied with regard to this manual and any

information contained herein, including but not limited to the implied

warranties of merchantability and fitness for a particular purpose.

Agilent shall not be liable for errors or for incidental or consequential

damages in connection with the furnishing, use, or performance of this

document or any information contained herein. Should Agilent and the

user have a separate written agreement with warranty terms covering

the material in this document that conflict with these terms, the

warranty terms in the separate agreement will control.

All Rights Reserved. Reproduction, adaptation, or translation without

prior written permission is prohibited, except as allowed under the

copyright laws.

1400 Fountaingrove Parkway, Santa Rosa CA, 95403-1799, USA

ii

War ranty

A copy of the specific warranty terms applicable to your Agilent

Technologies product can be obtained from your local Sales and Service

Office.

Manufacturer's Declaration

This statement is provided to comply with the requirements of the

German Sound Emission Directive, from 18 January 1991.

This product has a sound pressure emission (at the operator position)

< 70 dB(A).

Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

• Sound Pressure Lp < 70 dB(A).

• At Operator Position.

• Normal Operation.

• According to ISO 7779:1988/EN 27779:1991 (Type Test).

Herstellerbescheinigung

• Schalldruckpegel Lp < 70 dB(A).

•Am Arbeitsplatz.

• Normaler Betrieb.

• Nach ISO 7779:1988/EN 27779:1991 (Typprüfung).

iii

iv

Contents

1. Introduction

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Instruments Covered by Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

8480 series, B-models information . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

8480 series, Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

8485A and 8485D option 033 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Accessories Supplied. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

8483A 75 ohm sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

D-model 8480 series sensors (8481D, 8485D, 8485D-033 and 8487D).7

26.5 GHz and 33 GHz Frequency operation (8485A, 8485A-033,

8485D and 8485D-033) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

50 GHz Frequency operation (8487A and 8487D) . . . . . . . . . . . . . . . .9

Recommended Calibration Interval . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

8480 Series Power Sensor Specifications . . . . . . . . . . . . . . . . . . . . . . . . .11

Supplemental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Original Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Storage and Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Operating Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Power Meter Calibrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

1

Contents

Power Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Modulation Effects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2. General Information

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Connector Care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Standing Wave Ratio (SWR) and Reflection Coefficient (Rho)

Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3. Service

Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Thermocouple Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Diode Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Troubleshooting - Eliminating the Power Meter and Sensor Cable. . 40

Troubleshooting - Power Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

A1 Bulkhead (Thermocouple Sensors) . . . . . . . . . . . . . . . . . . . . . . . 40

A1 Bulkhead (Diode Sensors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

A2 Power Sensor Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

A1 Bulkhead Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Repair Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

A2 Power Sensor Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Repair Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2

Contents

FET Balance Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Test Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

FET Balance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Disassembly / Reassembly Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . .49

Disassembly Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Reassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

A. EPM Series Power Meter (E4418B) Modification

The Material and Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Impact on Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Modification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

B. Bulkhead Assemblies

Bulkhead Parts Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Bulkhead Exploded Graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

3

Contents

4

1 Introduction

This Operating and Service Manual contains information about initial

inspection, performance tests, adjustments, operation, troubleshooting

and repair of the Agilent 8480 Series Coaxial Power Sensors.

Chapter 1 1

Introduction

General Information

General Information

Instruments Covered by Manual

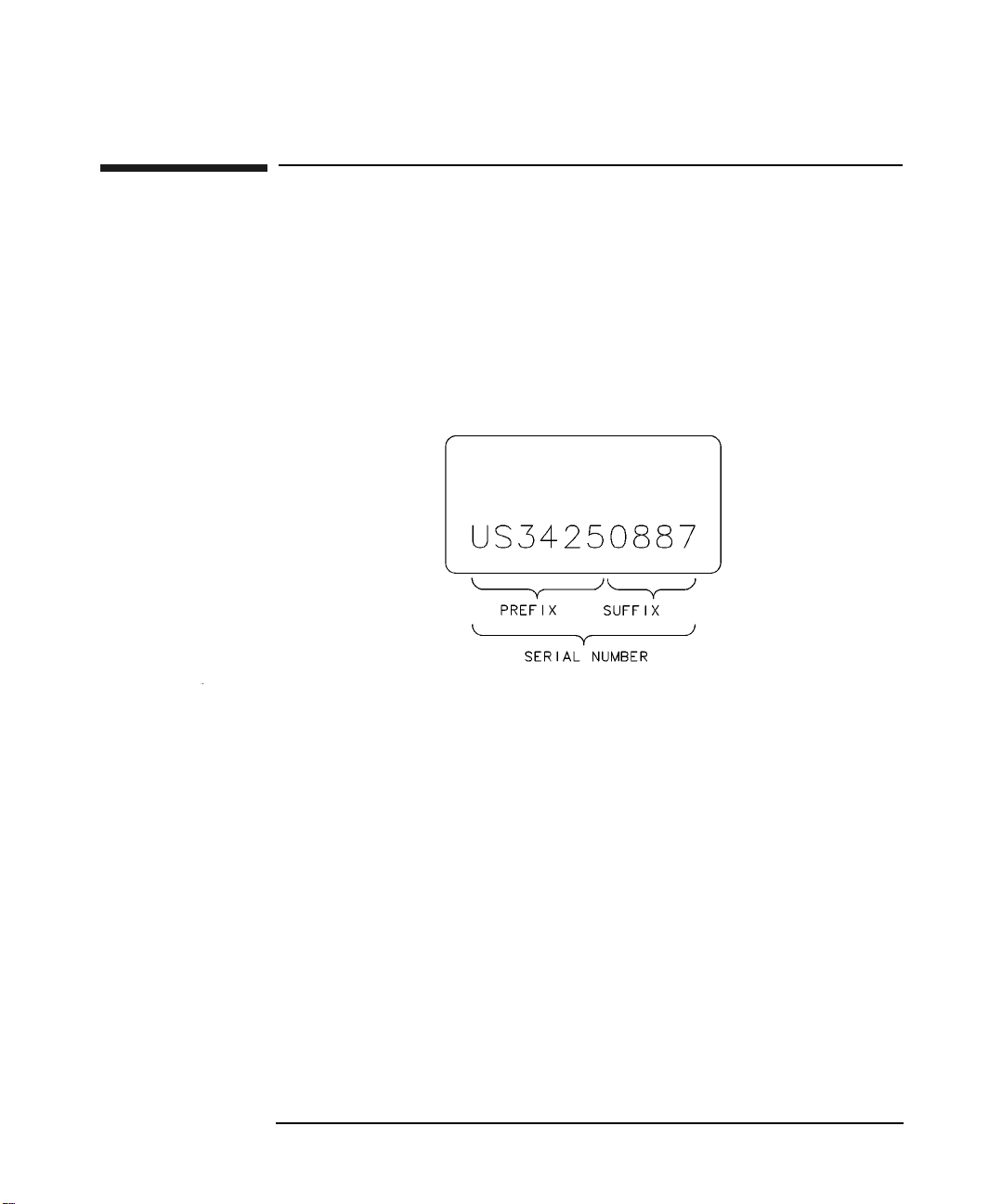

A serial number label is attached to the power sensor. The serial number

has two parts: the prefix (two letters and the first four numbers), and the

suffix (the last four numbers). Refer to the Example Serial Number

shown in Figure 1-1.

Figure 1-1 Example Serial Number

The two letters identify the country in which the unit was manufactured.

"US" represents the USA and "MY" represents Malaysia. The four

numbers of the prefix are a code identifying the date of a major design

change incorporated in your power sensor. The four digit suffix is a

sequential number and, coupled with the prefix, provides a unique

identification for each unit produced.

When seeking information about your power sensor refer to the complete

serial number and include the full prefix number and the suffix number.

For further information concerning a serial number, contact your nearest

Agilent Technologies Sales and Service office.

Chapter 12

Introduction

General Information

Description

The 8480 series power sensors are used for measuring the average power

supplied by an RF or microwave source or device-under-test (DUT). In

use, the Power Sensor is connected to the RF or microwave source and to

a compatible power meter. Suitable and compatible power meters are the

EPM series power meters (E4418B and E4419B), the EPM-P series

power meters (E4416A and E4417A) and the E1416A VXI power meter.

Discontinued and obsolete power meters that are compatible with the

8480 series sensors include the E4418A, E4419A, 435B, 436A, 437B,

438A and 70100A MMS power meter.

The 8480 series power sensors place a 50 ohm load on the RF or

microwave source, except the 8483A which has a 75 ohm load. The power

meter indicates the power dissipated in this load in mW or dBm.

The coaxial power sensors in the 8480 series measure power levels from

-70 dBm to +44 dBm (100 pW to 25 W), at frequencies from 100 kHz to

50 GHz. To cover this wide dynamic power range, both thermocouple and

diode power sensing elements are used. Both types of power sensing

elements have a maximum 50 dB dynamic range. Thermocouple sensors

have a square-law region from -30 dBm to +20 dBm, and with an

attenuator can operate up to +44 dBm. There are three model types of

thermocouple sensors in the 8480 series, covering the complete -30 dBm

to +44 dBm range.

• The A-models cover -30 dBm to +20 dBm.

• The H-models cover from -10 dBm to +35 dBm.

• The B-models cover from 0 dBm to +44 dBm.

Diode detectors (D-models) have the best sensitivity, having an operating

range from -70 dBm to -20 dBm.

Calibration factor (CAL FACTOR) data is provided on a label attached to

the power sensor's cover. Maximum uncertainties of the CAL FACTOR

data are listed in the Specifications section in page 11. This calibration

factor is used to adjust the power meter to suit the particular power

sensor and frequency being measured.

NOTE For the B-models in the 8480 series, calibration factor data is valid only

when the sensor is used with the supplied attenuator.

Chapter 1 3

Introduction

General Information

Figure 1-2 8480 Series Power Sensor Simplified Block Diagram

Cable

Balanced Chopper

Power

Input

Sensing

Element

Thermocouple

or Diode

Thermistor

AC Signal

Feedback

Autozero

Chop Signal

Chop Signal

Figure 1-2 shows a basic power sensor block diagram for both

thermocouple and diode power sensing elements. From the RF or

microwave signal input, both thermocouple and diode detector mounts

generate very low voltages, (on the order of nV or µV). The dc voltage is

proportional to the power from the RF or microwave source. As the dc

voltage is a very low-level, it requires amplification before it can be

transferred to the power meter on the standard cables.

The amplification is provided by an input amplifier assembly that

consists of a balanced chopper (sampling gate) and an AC coupled

low-noise amplifier. The dc voltage is routed on gold wires to the chopper

circuit, which converts the low-level dc voltage to an ac voltage. To do

this, the chopper is uses two field effect transistors (FET's) controlled by

a 220 Hz square-wave generated by in the power meter (the Chop

Signal). The result is an ac output signal proportional to the dc input.

The ac signal is then amplified to a relatively high-level ac signal that

can be routed to the power meter by standard cables.

The autozero signal removes residual error voltages when there is no

input RF or microwave power connected to the sensor input, and

temperature compensation is provided by a thermistor located in

amplifier feedback path.

Chapter 14

General Information

Dimensions

The physical dimensions of the power sensors differ in the model types.

This is due to the additional attenuation used to obtain the high power

performance.

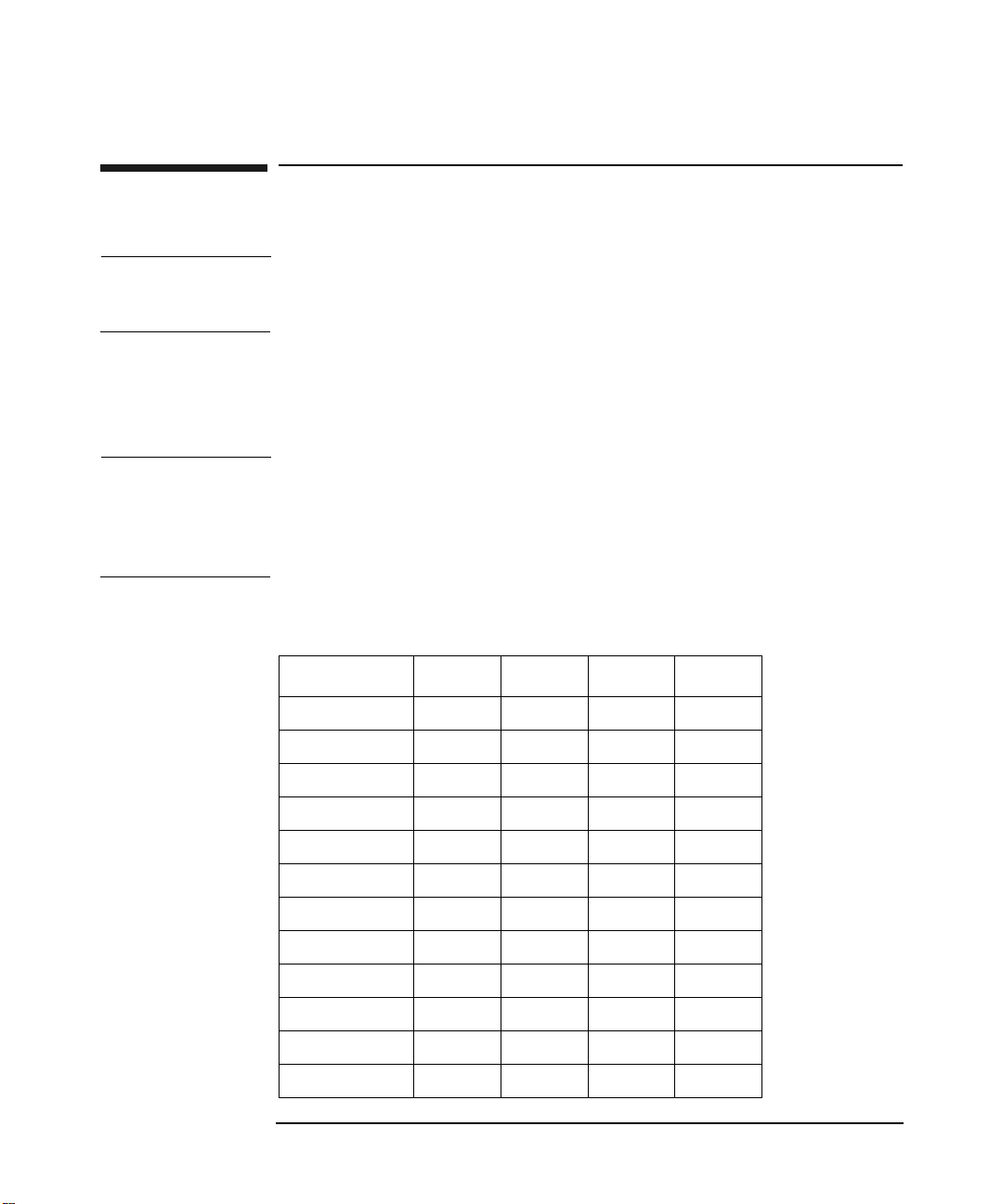

Table 1-1 8480 Series Power Sensor Dimensions (including the RF

Connector)

Introduction

8480 series power

sensor models

A-models 8481A, 8482A and 8483A:

B-models 83 mm x 114 mm x 248 mm (approx. 3.25 in. x 4.50 in. x 9.75 in.)

D-models 8481D and 8485D:

H-models 38 mm wide, 30 mm high, 149 mm long (1.5 in. x 1.2 in. x 5.9 in)

CAUTION Do not disassemble the power sensor. The 8480 series power sensors are

Dimensions

38 mm wide, 30 mm high, 105 mm long (1.5 in. x 1.2 in. x 4.1 in)

8485A and 8487A:

38 mm wide, 30 mm high, 95 mm long (1.5 in. x 1.25 in. x 3.75 in.)

38 mm wide, 30 mm high, 102 mm long (1.5 in. x 1.2 in. x 4.02 in)

8487D:

38 mm wide, 30 mm high, 94 mm long (1.5 in. x 1.2 in. x 3.7 in)

static sensitive and can be easily damaged.

8480 series, B-models information

The 25 W (+44 dBm) power sensor is a calibrated combination of a 30 dB,

25 W attenuator assembly and a sensor assembly. The attenuator and

sensor assemblies are calibrated as a set and must be used together if

specified accuracies are to be obtained.

This combination is referred to as the power sensor.

Chapter 1 5

Introduction

General Information

CAUTION Removal of the D-ring that is on the sensor assembly WILL VOID THE

WARRANTY. The input connector on the sensor has a D-ring to prevent

the sensor from being connected to a high power source when its

attenuator is not attached. The sensor must only be connected to the

power meter for calibration or to the high power attenuator for RF

measurement.

Safety Considerations

The warning that follows is related to possible personal injury.

WARNING The high power attenuator contains a substrate of beryllium

oxide. Beryllium oxide in a powder form is a hazardous material

and may be injurious to your health if inhaled. Do not perform

any operation on the beryllium oxide that might generate dust.

Defective attenuator should be returned to Agilent Technologies

for proper disposal.

8480 series, Options

8485A and 8485D option 033

The 8485A and 8485D power sensors with option 033 are calibrated to

measure power levels in the 50 MHz to 33 GHz frequency range. In all

other respects, they are the same as their respective standard power

sensor.

Accessories Supplied

Accessories are required to connect various power sensors to the power

meter's 50 ohm, Power Reference (1 mW, 50 MHz) output connector

(Type-N (f)).

Chapter 16

Introduction

General Information

8483A 75 ohm sensor

The 8483A sensor is supplied with an adapter, shown in Figure 1-3. This

accessory is a mechanical adapter only, not an impedance transformer,

therefore an impedance mismatch exists that must be taken into

consideration when calibrating the power meter and sensor. The REF

CAL FACTOR, on the power sensor label, has been adjusted for the

impedance mismatch. This REF CAL FACTOR, when used to calibrate

any power meter, will allow calibration to 1.000 mW. The CAL FACTOR,

from the data on the sensor label, should be used for any power

measurements in a 75 ohm system at 50 MHz.

CAUTION Remove the mechanical adapter from the power sensor before connecting

the sensor to a 75 ohm source.

Figure 1-3 Mechanical Adapter (8483A Only)

D-model 8480 series sensors (8481D, 8485D, 8485D-033 and 8487D)

D-model sensors are supplied with a 11708A 30 dB attenuator. To

calibrate a D-model sensor, the 1 mW 50 MHz Power Reference supplied

by the power meter must be reduced to 1µW. The reference attenuator

provides the means to do this.

Chapter 1 7

Introduction

General Information

Table 1-2 11708A 30 dB attenuator characteristics

Characteristic Limits Comments

11708A accuracy at

50 MHz, 25 °C

30 ± 0.05 dB Accuracy traceable to National Institute

of Standards and Technology (NIST),

with a temperature coefficient typically

0.003 dB per °C.

Dimensions Length: 60 mm (2.4 in)

Diameter: 20 mm (0.8 in)

NOTE The 11708A 30 dB attenuator is intended for use only at the 1 mW,

50 MHz power reference of the power meter. Its function as a calibration

reference may be compromised if used for other purposes.

26.5 GHz and 33 GHz Frequency operation (8485A, 8485A-033,

8485D and 8485D-033)

8480 series sensors that operate up to 26.5 GHz and 33 GHz are fitted

with APC-3.5mm (m) connectors as standard. To convert the

APC-3.5mm (m) connector for calibration an adapter (APC-3.5 (f) to

Type-N (m)) is included with the power sensors. Figure 1-4 shows the

parts included with your power sensor.

NOTE The APC-3.5mm to Type-N adapter is intended for use only at the 1 mW,

50 MHz power reference of the power meter. Its function as a calibration

reference may be compromised if used for other purposes.

Chapter 18

General Information

Figure 1-4 8485A, 8485A-033, 8485D, 8485D-033 Sensor Accessories

50 GHz Frequency operation (8487A and 8487D)

8480 series sensors that operate up to 50 GHz are fitted with 2.4mm (m)

connectors as standard. To convert the 2.4mm (m) connector for

calibration, adapter (2.4mm (f) to Type-N (m)) is included with the power

sensors (shown in Figure 1-5).

Introduction

NOTE The 2.4mm to Type-N adapter is intended for use only at the 1 mW,

50 MHz power reference of the power meter. Its function as a calibration

reference may be compromised if used for other purposes.

Chapter 1 9

Introduction

General Information

Figure 1-5 8487A Power Sensor with Adapter

Recommended Calibration Interval

Agilent Technologies recommends a one-year calibration cycle for the

8480 series power sensors.

War ranty

The 8480 series power sensors described in this manual are warranted

and certified as indicated on the inside cover of this manual. Power

sensors are warranted only when they are operated within their

specifications, especially the maximum power handling capability. Any

power sensor returned to Agilent Technologies under warranty will be

examined carefully to determine if the failure was possibly due to

improper use.

Do not open the power sensor. Any attempt to disassemble the power

sensor will void the warranty.

Chapter 110

Introduction

8480 Series Power Sensor Specifications

8480 Series Power Sensor Specifications

NOTE These specifications are valid with EPM and EPM-P Series of power

meters.

The 8480 series thermocouple and diode power sensors provide accuracy,

stability, and SWR over a wide range of frequencies (100 kHz to 50 GHz)

and power levels (-70 dBm to +44 dBm)

NOTE Both Table 1-3 and Table 1-4 show typical uncertainty values to help

estimate measurement uncertainty. These values are only a guideline,

and are not to be used in any accurate uncertainty calculations. Refer to

your power sensor’s specific calibration report for accurate values.

Table 1-3 Typical root sum of squares (rss) uncertainty on the calibration

factor data printed on the power sensor

Freq (MHz) 8482A 8482B 8482H 8483A

0.1 0.8 1.5 0.8 1.3

0.3 0.7 1.4 0.9 1.2

1 0.7 1.4 0.9 1.1

3 0.8 1.5 0.8 1.2

10 0.8 1.5 0.8 1.2

30 0.8 1.5 0.9 1.2

50 0.7 1.4 0.8 1.2

100 0.8 1.4 0.8 1.2

300 0.8 1.4 0.8 1.2

1000 0.8 1.5 0.9 1.2

2000 0.8 1.5 0.8 1.2

4000 0.9 1.5 0.9 -

Chapter 1 11

Introduction

8480 Series Power Sensor Specifications

Table 1-4 Typical root sum of squares (rss) uncertainty on the calibration

factor data printed on the power sensor

Freq (GHz) 8481A 8481B 8481H 8481D 8485A 8485D 8487A 8487D

1 0.7 1.4 0.8 0.8 1.4 1.4 1.4 1.3

2 0.7 1.4 0.8 0.8 1.4 1.4 1.4 1.3

4 0.8 1.5 0.8 0.8 1.7 1.7 1.4 1.4

6 0.9 1.5 0.9 0.9 1.7 1.7 1.5 1.4

8 1.0 1.5 1.0 1.0 1.7 1.7 1.5 1.4

10 1.0 1.6 1.0 1.1 1.9 1.9 1.5 1.5

12 1.1 1.6 1.1 1.2 1.9 1.9 1.6 1.5

14 1.2 1.6 1.2 1.1 2.0 2.0 1.6 1.6

16 1.2 1.7 1.2 1.5 2.0 2.1 1.7 1.7

18 1.5 1.9 1.5 1.7 2.1 2.2 1.7 1.7

22 ----2.62.71.91.9

26.5 ----2.82.82.12.2

28 ----

30 ----

33 ----

34.5 ------2.32.6

37 ------2.42.7

40 ------2.53.0

42 ------2.63.2

44 ------2.93.5

46 ------3.13.8

48 ------2.93.8

50 ------3.85.0

3.1

3.2

3.7

a

a

a

2.9

3.2

3.3

a

a

a

2.2 2.3

2.3 2.4

2.3 2.6

a. These uncertainties only apply to Option 033.

Chapter 112

8480 Series Power Sensor Specifications

Table 1-5 25 Watt sensors, 1 mW to 25 W (0 dBm to +44 dBm)

Introduction

Model Frequency

Range

8481B 10 MHz to

18 GHz

8482B 100 kHz to

4.2 GHz

a. Negligible deviation except for those power ranges noted.

b. For pulses greater than 30 W, the maximum average power (Pa) is limited by the energy per pulse (E) in

W.µs according to Pa = 30-0.02 E.

Maximum

SWR

10 MHz to

2GHz: 1.10

2GHz to

12.4 GHz: 1.18

12.4 GHz to

18 GHz: 1.28

100 kHz to

2GHz: 1.10

2GHz to

4.2 GHz: 1.18

Powe r

Linearity

+35 dBm to

+44 dBm: ±4%

+35 dBm to

+44 dBm: ±4%

a

Maximum

Powe r

0°C to 35°C:

30W avg

35°C to 55°C:

25W avg

0.01 to 5.8 GHz:

500W pk

5.8 to 18 GHz:

125W pk

500W.µs / pulse

0°C to 35°C:

30W avg

35°C to 55°C:

25W avg

0.1 to 4,2 GHz:

500W pk

500W.µs / pulse

b

b

Connector

Type

Type-N(m) Net: 0.8 kg

Type-N(m) Net: 0.8 kg

Table 1-6 3 Watt sensors, 100 µW to 3 W (–10 dBm to +35 dBm)

Wei ght

(1.75 lb)

Shipping:

1.5 kg (3.25 lb)

(1.75 lb)

Shipping:

1.5 kg (3.25 lb)

Model Frequency

Range

8481H 10 MHz to

18 GHz

8482H 100 kHz to

4.2 GHz

a. Negligible deviation except for those power ranges noted.

Maximum

SWR

10 MHz to

8GHz: 1.20

8GHz to

12.4 GHz: 1.25

12.4 GHz to

18 GHz: 1.30

100 kHz to

4.2 GHz: 1.20

Powe r

Linearity

+25 dBm to

+35 dBm: ±5%

+25 dBm to

+35 dBm: ±5%

Chapter 1 13

a

Maximum

Power

3.5W avg,

100W pk

100W.µs / pulse

3.5W avg,

100W pk

100W.µs / pulse

Connector

Type

Type-N(m) Net: 0.2 kg

Type-N(m) Net: 0.2 kg

Wei ght

(0.38 lb)

Shipping:

0.5 kg ( 1.0 lb)

(0.38 lb)

Shipping:

0.5 kg ( 1.0 lb)

Introduction

8480 Series Power Sensor Specifications

Table 1-7 100 mW sensors, 1 µW to 100 mW (–30 dBm to +20 dBm)

Model Frequency

Range

8485A 50 MHz to

26.5 GHz

Option

8485A

-033

8481A 10 MHz to

26.5 MHz to

33 GHz

18 GHz

Maximum

SWR

50 MHz to 100

MHz: 1.15

100 MHz to 2

GHz: 1.10

2 GHz to 12.4

GHz: 1.15

12.4 GHz to 18

GHz: 1.20

18 GHz to 26.5

GHz: 1.25

26.5 GHz to 33

GHz: 1.40

10 MHz to 30

MHz: 1.40

30 MHz to 50

MHz: 1.18

50 MHz to 2

GHz: 1.10

2 GHz to 12.4

GHz: 1.18

12.4 GHz to 18

GHz: 1.28

Pow er

Linearity

+10 dBm to

+20 dBm: ±3%

+10 dBm to

+20 dBm: ±3%

+10 dBm to

+20 dBm: ±3%

a

Maximum

Power

300 mW avg,

15 W pk

30 W.µs / pulse

300 mW avg,

15 W pk

30 W.µs / pulse

300 mW avg,

15 W pk

30 W.µs / pulse

Connector

Type

APC -

3.5mm(m)

APC -

3.5mm(m)

Type-N(m) Net: 0.2 kg

Weight

Net: 0.2 kg

(0.38 lb)

Shipping:

0.5 kg (1.0 lb)

Net: 0.2 kg

(0.38 lb)

Shipping:

0.5 kg (1.0 lb)

(0.38 lb)

Shipping:

0.5 kg (1.0 lb)

8482A 100 kHz to

4.2 GHz

100 kHz to 300

kHz: 1.60

300 kHz to 1

MHz: 1.20

1 MHz to 2

GHz: 1.10

2 GHz to 4.2

GHz: 1.30

+10 dBm to

+20 dBm: ±3%

300 mW avg,

15W pk

30 W.µs / pulse

Type-N(m) Net: 0.2 kg

(0.38 lb)

Shipping: 0.5

kg (1.0 lb)

Chapter 114

8480 Series Power Sensor Specifications

Table 1-7 100 mW sensors, 1 µW to 100 mW (–30 dBm to +20 dBm)

Introduction

Model Frequency

Range

8483A

(75ohm)

8487A 50 MHz to

a. Negligible deviation except for those power ranges noted.

100 kHz to

2GHz

50 GHz

Maximum

SWR

100 kHz to 600

kHz: 1.80

600 kHz to 2

GHz: 1.18

50 MHz to

100 MHz: 1.15

100 MHz to

2GHz: 1.10

2 GHz to

12.4 GHz: 1.15

12.4 GHz to

18 GHz: 1.20

18 GHz to

26.5 GHz: 1.25

26.5 GHz to

40 GHz: 1.30

40 GHz to

50 GHz: 1.50

Pow er

Linearity

+10 dBm to

+20 dBm: ±3%

+10 dBm to

+20 dBm: ±3%

a

Maximum

Power

300 mW avg,

10W pk

300 mW avg,

15W pk

30 W.µs / pulse

Connector

Type

Type-N(m)

(75 ohm)

2.4 mm (m) Net: 0.14 kg

Weight

Net: 0.2 kg

(0.38 lb)

Shipping: 0.5

kg (1.0 lb)

(0.28 lb)

Shipping: 0.5

kg (1.0 lb)

Chapter 1 15

Introduction

8480 Series Power Sensor Specifications

Table 1-8 High sensitivity sensors, 100 pW to 10 µW (–70 dBm to –20 dBm)

Model Frequency

Range

b

b

10 MHz to

18 GHz

50 MHz to

26.5 GHz

50 MHz to

33 GHz

8481D

8485D

Option

8485D

-033

Maximum SWR

10 MHz to

30 MHz: 1.40

30 MHz to 4 GHz:

1.15

4 GHz to 10 GHz:

1.20

10 GHz to

15 GHz: 1.30

15 GHz to

18 GHz: 1.35

50 MHz to

100 MHz: 1.19

100 MHz to

4GHz: 1.15

4 GHz to 12 GHz:

1.19

12 GHz to

18 GHz: 1.25

18 GHz to

26.5 GHz: 1.29

26.5 GHz to

33 GHz: 1.35

Power

Linearity

-30 dBm to

-20 dBm: ±1%

-30 dBm to

-20 dBm: ±2%

-30 dBm to

-20 dBm: ±2%

Maximum

Power

a

100 mW avg,

100 mW pk

100 mW avg,

100 mW pk

100 mW avg,

100 mW pk

Connector

Type

Type-N (m) Net: 0.16 kg

APC -

3.5mm (m)

APC -

3.5mm (m)

Weight

(0.37 lb)

Shipping:

0.5 kg (1.0 lb)

Net: 0.2 kg

(0.38 lb)

Shipping:

0.5 kg (1.0 lb)

Net: 0.2 kg

(0.38 lb)

Shipping:

0.5 kg (1.0 lb)

Chapter 116

Introduction

8480 Series Power Sensor Specifications

Table 1-8 High sensitivity sensors, 100 pW to 10 µW (–70 dBm to –20 dBm)

Model Frequency

Range

b

8487D

a. Negligible deviation except for those power ranges noted.

b. Includes 11708A 30 dB attenuator for calibrating against 0 dBm, 50 MHz power reference. The 11708A

50 MHz to

50 GHz

is factory set to 30 dB ±0.05 dB at 50 MHz, traceable to NIST. SWR < 1.05 at 50 MHz.

Maximum SWR

50 MHz to

100 MHz: 1.19

100 MHz to 2

GHz: 1.15

2 GHz to 12.4

GHz: 1.20

12.4 GHz to 18

GHz: 1.29

18 GHz to 34

GHz: 1.37

34 GHz to 40

GHz: 1.61

40 GHz to 50

GHz: 1.89

Power

Linearity

-30 dBm to -20

dBm: ±2%

Maximum

Power

a

100 mW avg,

100 mW pk

10 W.µs / pulse

Connector

Type

2.4 mm (m) Net: 0.2 kg

Weight

(0.38 lb)

Shipping:

0.5 kg (1.0 lb)

Chapter 1 17

Introduction

8480 Series Power Sensor Specifications

Supplemental Characteristics

Supplemental characteristics are intended to provide additional

information, useful in applying the power sensor by giving typical

(expected) but not warranted performance parameters.

Figure 1-6 Typical CAL FACTOR and SWR vs. Frequency

SWR

SWR

Frequency (GHz)

CF

Cal Factor (%)

Chapter 118

Introduction

Installation

Installation

Initial Inspection

Inspect the shipping container. If the container or packing material is

damaged, it should be kept until the contents of the shipment have been

checked mechanically and electrically. If there is mechanical damage or if

the instrument does not pass the performance tests, notify the nearest

Agilent Technologies office. Keep the damaged shipping materials (if

any) for inspection by the carrier and an Agilent Technologies

representative.

Original Packaging

Containers and materials identical to those used in factory packaging

are available through Agilent Technologies’ offices. If the instrument is

being returned to Agilent Technologies for servicing, attach a tag

indicating the type of service required, return address, model number,

and serial number. Also, mark the container FRAGILE to assure careful

handling. In any correspondence, refer to the instrument by model

number and serial number.

Interconnections

Refer to the power meter’s User’s Guide for interconnecting instructions.

Storage and Shipment

Environment

The instrument should be stored in a clean, dry environment. The

following limitations apply to both storage and shipment:

Temper at ure

Relative humidity <95%

Altitude < 7,600 metres (25,000 ft.)

Chapter 1 19

- 40 to +75

o

C

Introduction

Operation

Operation

Environment

The operating environment for the Power Sensor should be as follows:

Temper at ure

Relative humidity <95%

Altitude < 4,572 metres (15,000 ft.)

0 to +55

o

C

Operating Precautions

Before the Power Sensor is connected, the following precautions must be

observed.

WARNING BEFORE CONNECTING THE POWER SENSOR TO ANOTHER

INSTRUMENT, ensure that the instrument and power meter are

connected to the protective (earth) ground.

Power Meter Calibrations

Power Meter to Power Sensor calibration procedures differ with the

power meter. Follow the calibration procedure located in your power

meter’s user’s guide.

Temperature Sensitivity The sensitivity of the power sensor is

influenced by ambient temperature. The sensor should be recalibrated at

each change in temperature to obtain the most accurate results. Typical

temperature sensitivity variations are shown in Figure 1-7 for the 8481D

power sensor.

Chapter 120

Figure 1-7 Typical Influence of Temperature on Sensitivity

Temperature (oC)

01020 3040 5060

-0.5

-1.0

Sensitivity

Change (dB)

Operating Instructions

To operate the Power Sensor, refer to the operating instructions in of the

power meter’s user’s guide.

Power Measurements

To correct for varying responses at different frequencies a cal factor table

is included on the Power Sensors. To use the cal factor at the frequency of

interest, adjust the power meter’s CAL FACTOR control according to the

instructions in the power meter’s user’s guide.

Introduction

Operation

Modulation Effects

When measuring RF or microwave sources that are modulated at the

chopper frequency (nominally 220 Hz), at the first or second harmonic or

submultiples of the chopper frequency, beat notes may occur. Unless

these beat notes are exactly the chopper frequency, they can usually be

eliminated by averaging (filtering) since the amplitudes are plus and

minus the actual power. These frequencies may also be avoided by

changing the modulation frequency slightly, if possible.

Refer to the power meter’s user’s guide for information on setting the

averaging (filtering).

Chapter 1 21

Introduction

Operation

Chapter 122

2 General Information

This chapter contains information about recommended equipment,

performance tests, and replacement parts of the Agilent Coaxial Power

Sensors.

Chapter 2 23

General Information

Recommended Test Equipment

Recommended Test Equipment

Table 2-1 lists the test equipment recommended to check, adjust, and

troubleshoot the Power Sensor. If substitute equipment is used, it must

meet or exceed the critical specifications to be used in place of the

recommended instruments for servicing the Power Sensor.

NOTE Check the Power Sensor’s warranty. Opening it voids the warranty.

.

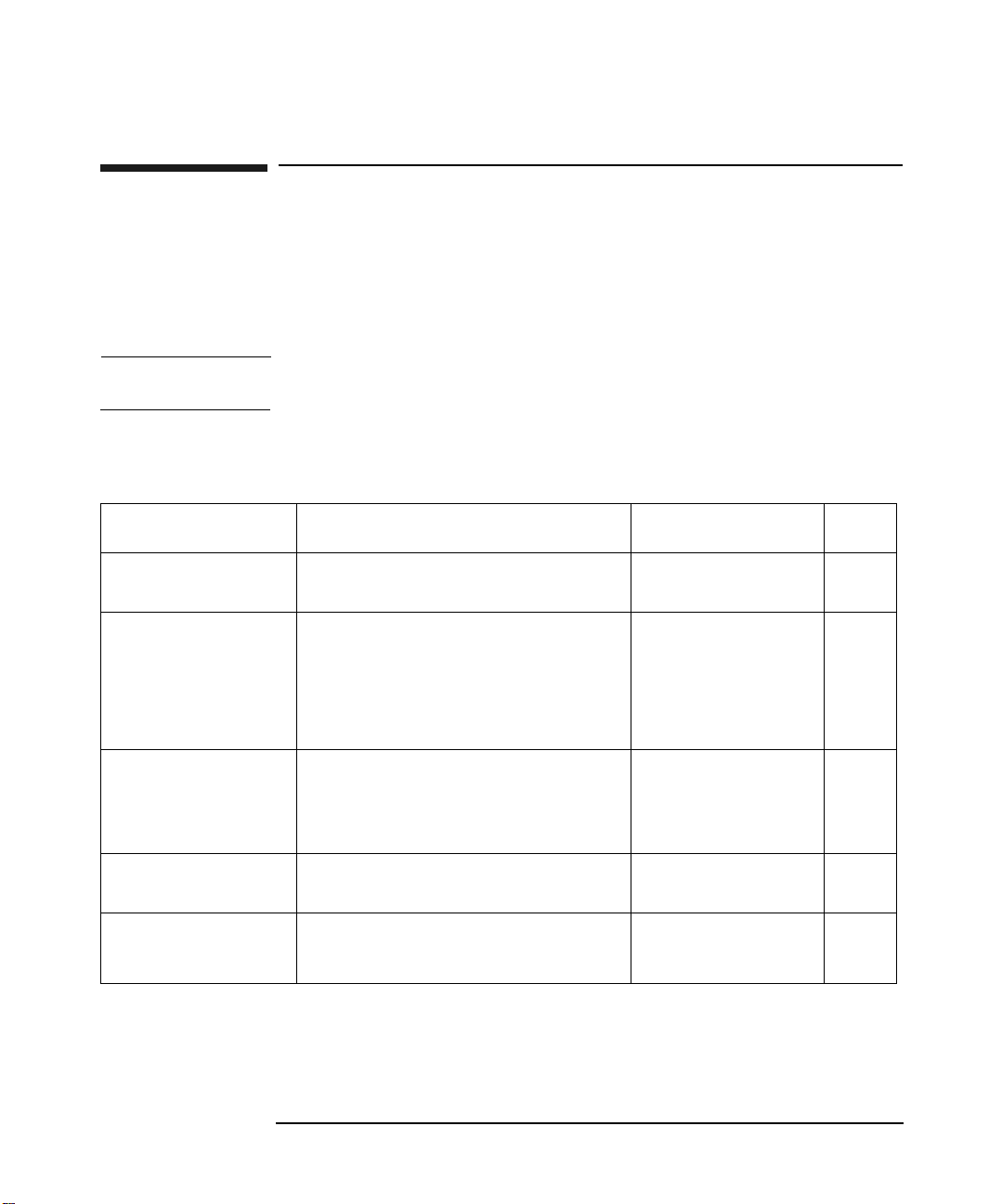

Table 2-1 Recommended Test Equipment (done)

Instrument Type Critical Specifications Suggested Model

Power meter No Substitute E4418B (Modified -

See Appendix A)

Digital Voltmeter • Range: 100 mVdc to 100 Vdc

• Input Impedance: 100 mohm;

• Resolution: 4-digit

• Accuracy: ±0.05% ±1 digit

Oscilloscope • Bandwidth: dc to 50 MHz

• Sensitivity: Vertical, 50 mV/div

• Horizontal, 500 µs/div

BNC(m) to BNC(m)

(2 required)

Ohmmeter • Range: 1 - 100,000 ohm;

•Accuracy: ±5%

a. A = Adjustment, T = Troubleshooting

34401A T

54622A A,T

10503C A

34401A T

Use

A

a

Chapter 224

General Information

Connector Care

Connector Care

Keeping in mind its flammable nature, a solution of pure isopropyl or

ethyl alcohol can be used to clean connectors.

CAUTION The RF connector bead deteriorates when contacted by any chlorinated

or aromatic hydrocarbon such as acetone, trichlorethane, carbon

tetrachloride, and benzene.

Do not attempt to clean connectors with anything metallic such as pins

or paper clips.

Clean the connector face by first using a blast of compressed air. If the

compressed air fails to remove contaminants use a cotton swab dipped in

isopropyl or ethyl alcohol. If the swab is too big, use a round wooden

toothpick wrapped in a lint free cloth dipped in isopropyl or ethyl alcohol.

Torque

For operation to 18 GHz, the newer 8480 series power sensors have a

Type-N hex nut for tightening to the device-under-test or the power

meter's 1 mW Power Reference. Older 8480 series power sensors have a

knurled portion on the connector. Turn the connector nut (or knurled

portion) only to tighten, the torque should not exceed 135 N-cm (12 in-lb)

to avoid damage to the connector.

For APC3.5 mm and 2.4mm connectors the torque should not exceed

90 N-cm (8 in-lb) to avoid damage to the connector.

CAUTION Damage can occur if torque is applied to the power sensor body.

Chapter 2 25

General Information

Performance Test

Performance Test

Standing Wave Ratio (SWR) and Reflection

Coefficient (Rho) Performance Test

This section does not provide a preset test procedure since there are

several test methods and different equipment available to make these

measurements. Therefore, when measuring this specification, the actual

accuracy of the test equipment must be taken into account in order to

determine the pass/fail condition. The Maximum SWR values (also

expressed in terms of the Reflection Coefficient [Rho]) for each model of

Power Sensor are listed in Table 2-2.

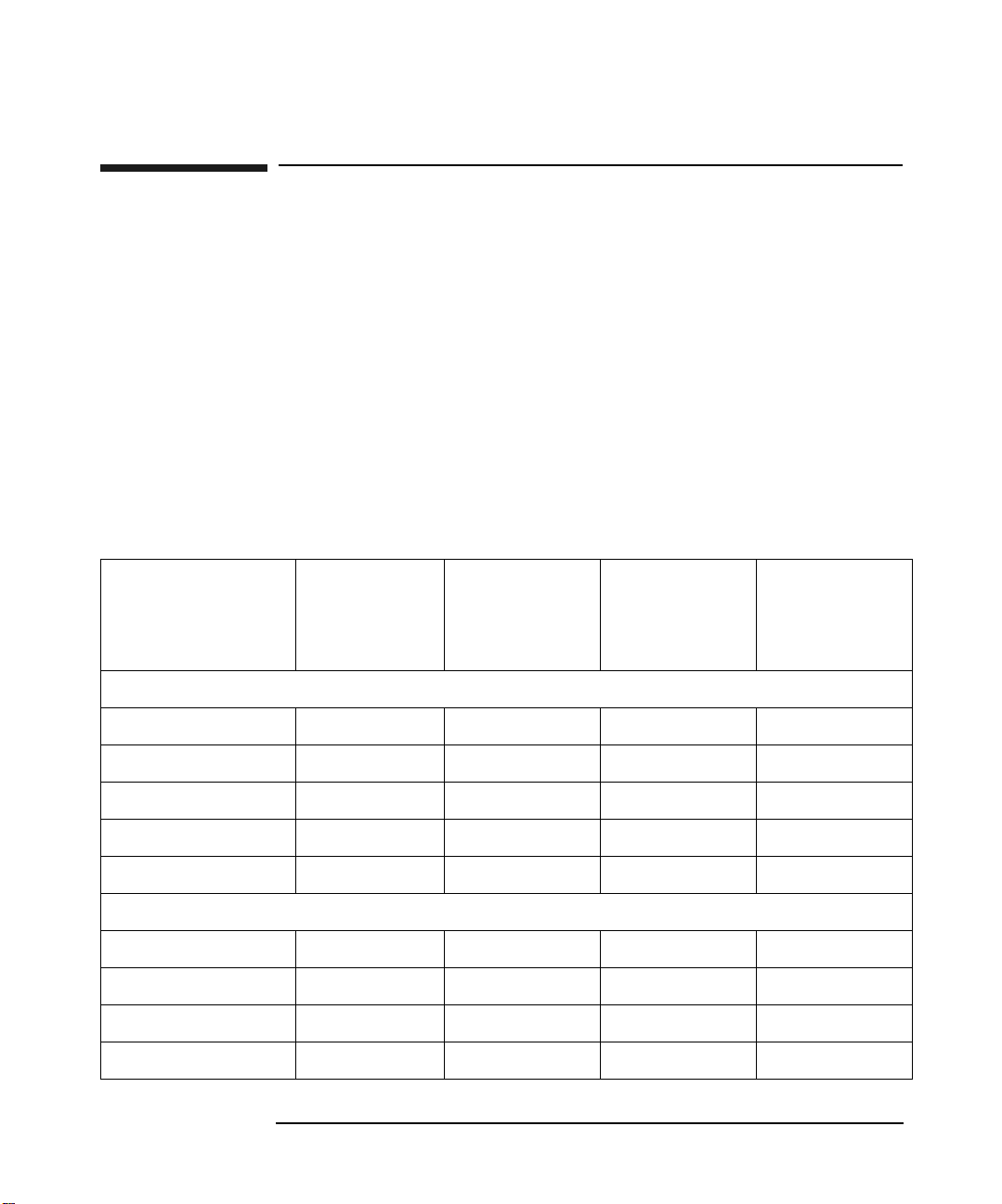

Table 2-2 Power Sensor SWR and Reflection Coefficient

Frequency Maximum

SWR

(Reflection

Coefficient)

10 to 30 MHz < 1.40 (0.166)

30 to 50 MHz < 1.18 (0.083)

50 MHz to 2 GHz < 1.10 (0.048)

2 to 12.4 GHz < 1.18 (0.083)

12.4 to 18 GHz < 1.28 (0.123)

100 kHz to 300 kHz < 1.60 (0.231)

300 kHz to 1 MHz < 1.20 (0.091)

1 MHz to 2 GHz < 1.10 (0.048)

2 to 4.2 GHz < 1.30 (0.130)

System SWR

Uncertainty

8481A

8482A

Per formance

Limit (Rho -

System Rho

Uncertainty)

Actual

Measurement

Chapter 226

Table 2-2 Power Sensor SWR and Reflection Coefficient

General Information

Performance Test

Frequency Maximum

SWR

(Reflection

Coefficient)

100 kHz to 600 kHz < 1.80 (0.286)

600 kHz to 2 GHz < 1.18 (0.083)

50 to 100 MHz < 1.15 (0.070)

0.1 to 2 GHz < 1.10 (0.048)

2 to 12.4 GHz < 1.15 (0.070)

12.4 to 18 GHz < 1.20 (0.091)

18 to 26.5 GHz < 1.25 (0.111)

26.5 to 33 GHz < 1.40 (0.166)

50 to 100 MHz < 1.15 (0.070)

System SWR

Uncertainty

8483A

8485A

8487A

Per formance

Limit (Rho -

System Rho

Uncertainty)

Actual

Measurement

0.1 to 2 GHz < 1.10 (0.048)

2 to 12.4 GHz < 1.15 (0.070)

12.4 to 18 GHz < 1.20 (0.091)

18 to 26.5 GHz < 1.25 (0.111)

26.5 to 40 GHz < 1.30 (0.130)

40 to 50 GHz < 1.50 (0.20)

Chapter 2 27

General Information

Performance Test

Table 2-2 Power Sensor SWR and Reflection Coefficient

Frequency Maximum

SWR

(Reflection

Coefficient)

10 MHz to 2 GHz < 1.10 (0.048)

2 to 12.4 GHz < 1.18 (0.083)

12.4 to 18 GHz < 1.28 (0.123)

100 kHz to 2 GHz < 1.10 (0.048)

2 to 4.2 GHz < 1.18 (0.083)

10 MHz to 8 GHz < 1.20 (0.091)

8 to 12.4 GHz < 1.25 (0.112)

12.4 to 18 GHz < 1.30 (0.130)

System SWR

Uncertainty

8481B

8482B

8481H

8482H

Per formance

Limit (Rho -

System Rho

Uncertainty)

Actual

Measurement

100 kHz to 4.2 GHz < 1.20 (0.091)

10 to 30 MHz < 1.40 (0.167)

0.03 to 4 GHz < 1.15 (0.070)

4 to 10 GHz < 1.20 (0.091)

10 to 15 GHz < 1.30 (0.130)

15 to 18 GHz < 1.35 (0.112)

8481D

Chapter 228

Table 2-2 Power Sensor SWR and Reflection Coefficient

General Information

Performance Test

Frequency Maximum

SWR

(Reflection

Coefficient)

50 to 100 MHz < 1.19 (0.085)

0.1 to 4 GHz < 1.15 (0.070)

4 to 12 GHz < 1.19 (0.085)

12 to 18 GHz < 1.25 (0.112)

18 to 26.5 GHz < 1.29 (0.127)

50 to 100 MHz < 1.19 (0.085)

0.1 to 2 GHz < 1.15 (0.069)

2 to 12.4 GHz < 1.20 (0.091)

12.4 to 18 GHz < 1.29 (0.127)

18 to 34 GHz < 1.37 (0.156)

System SWR

Uncertainty

8485D

8487D

Per formance

Limit (Rho -

System Rho

Uncertainty)

Actual

Measurement

34 to 40 GHz < 1.61 (0.234)

40 to 45 GHz < 1.86 (0.301)

45 to 50 GHz < 1.89 (0.310)

Chapter 2 29

General Information

Replaceable Parts

Replaceable Parts

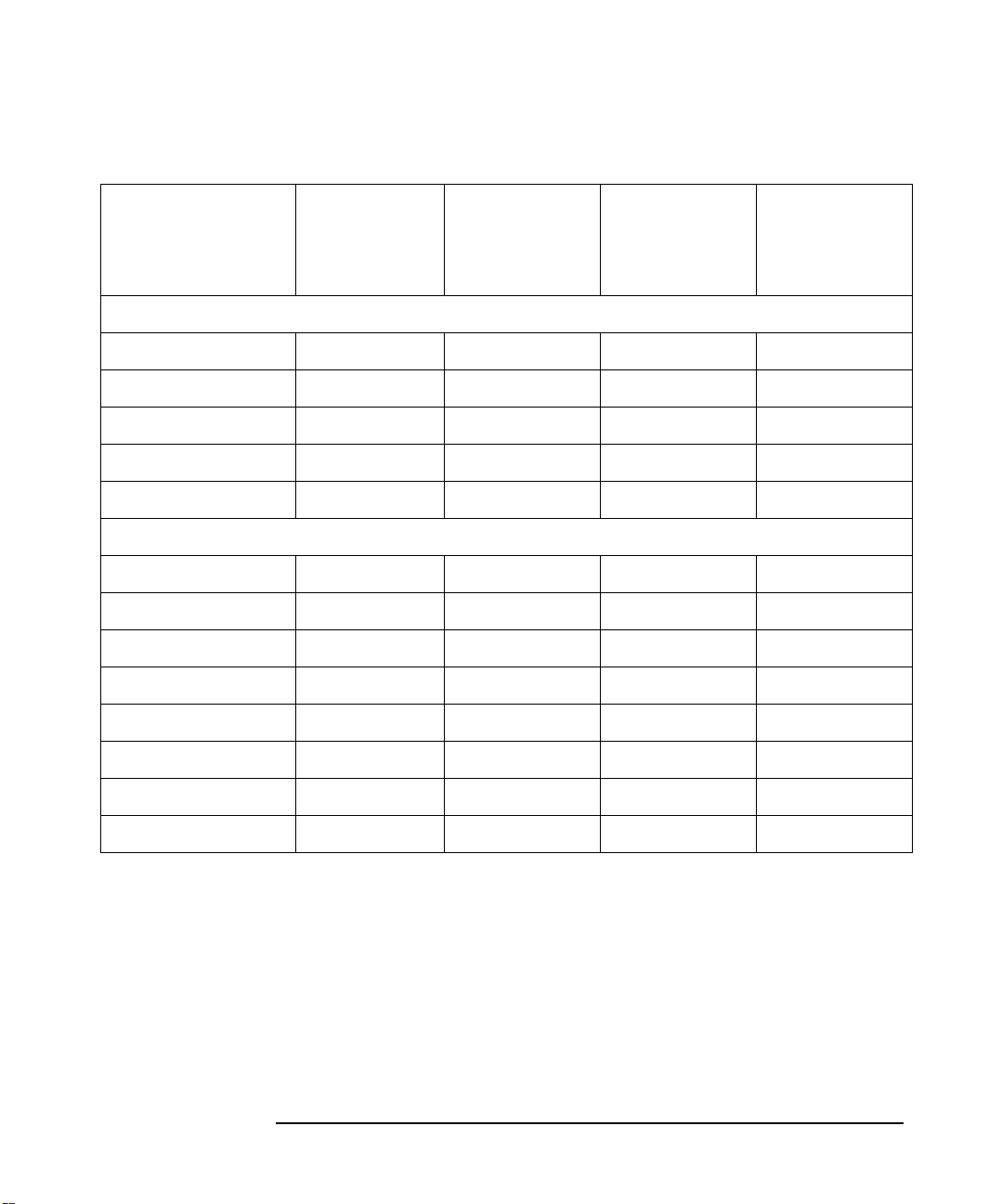

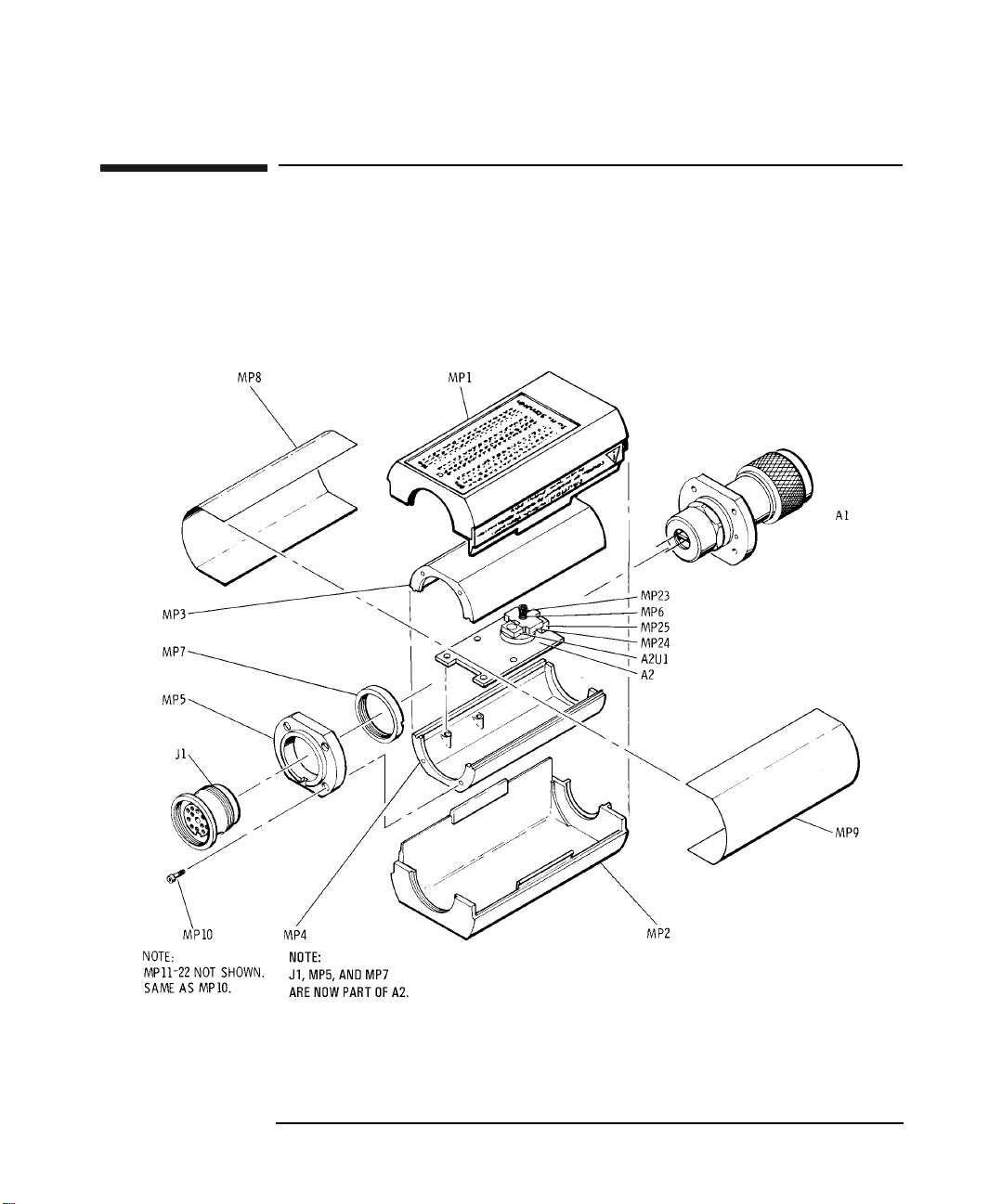

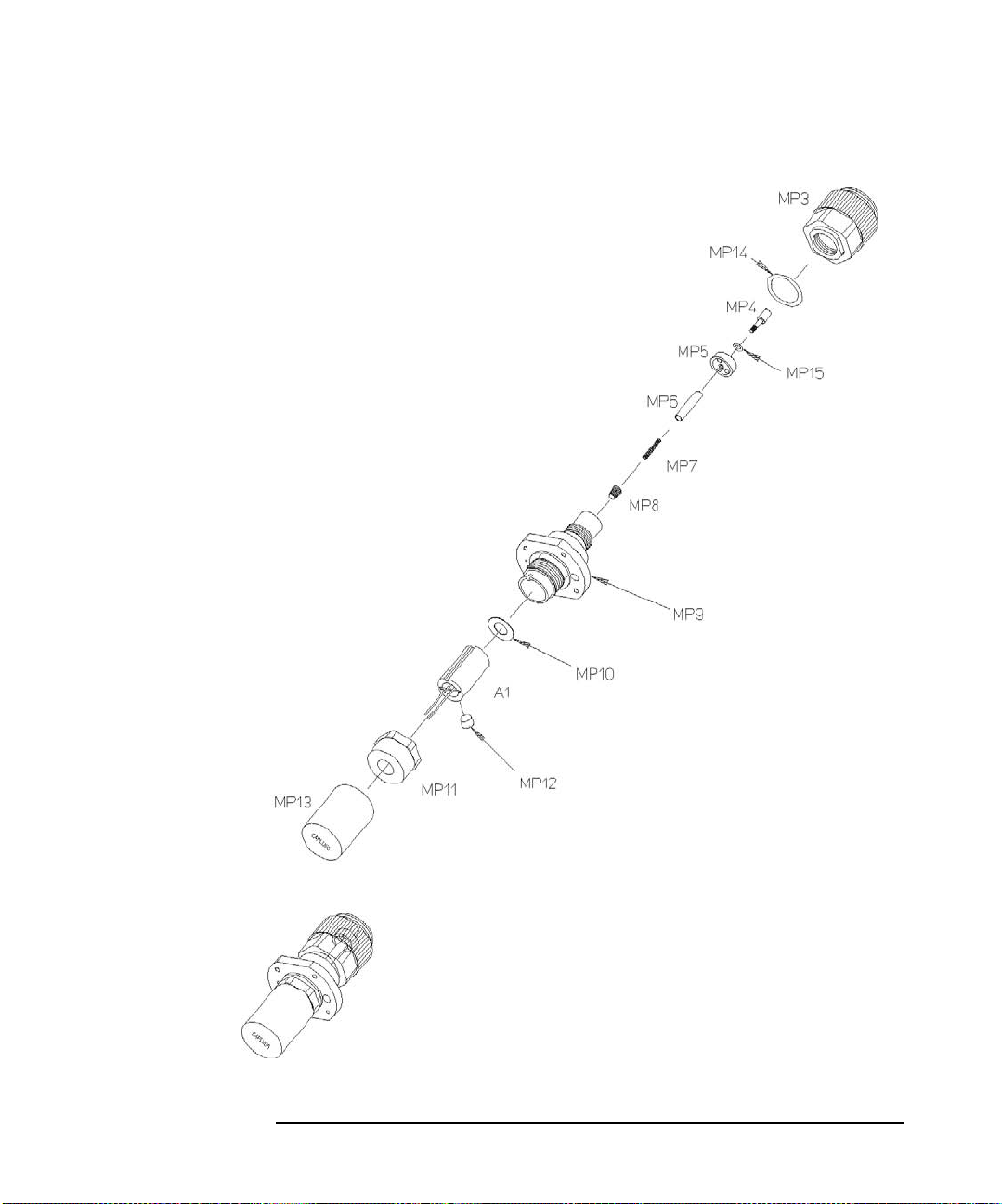

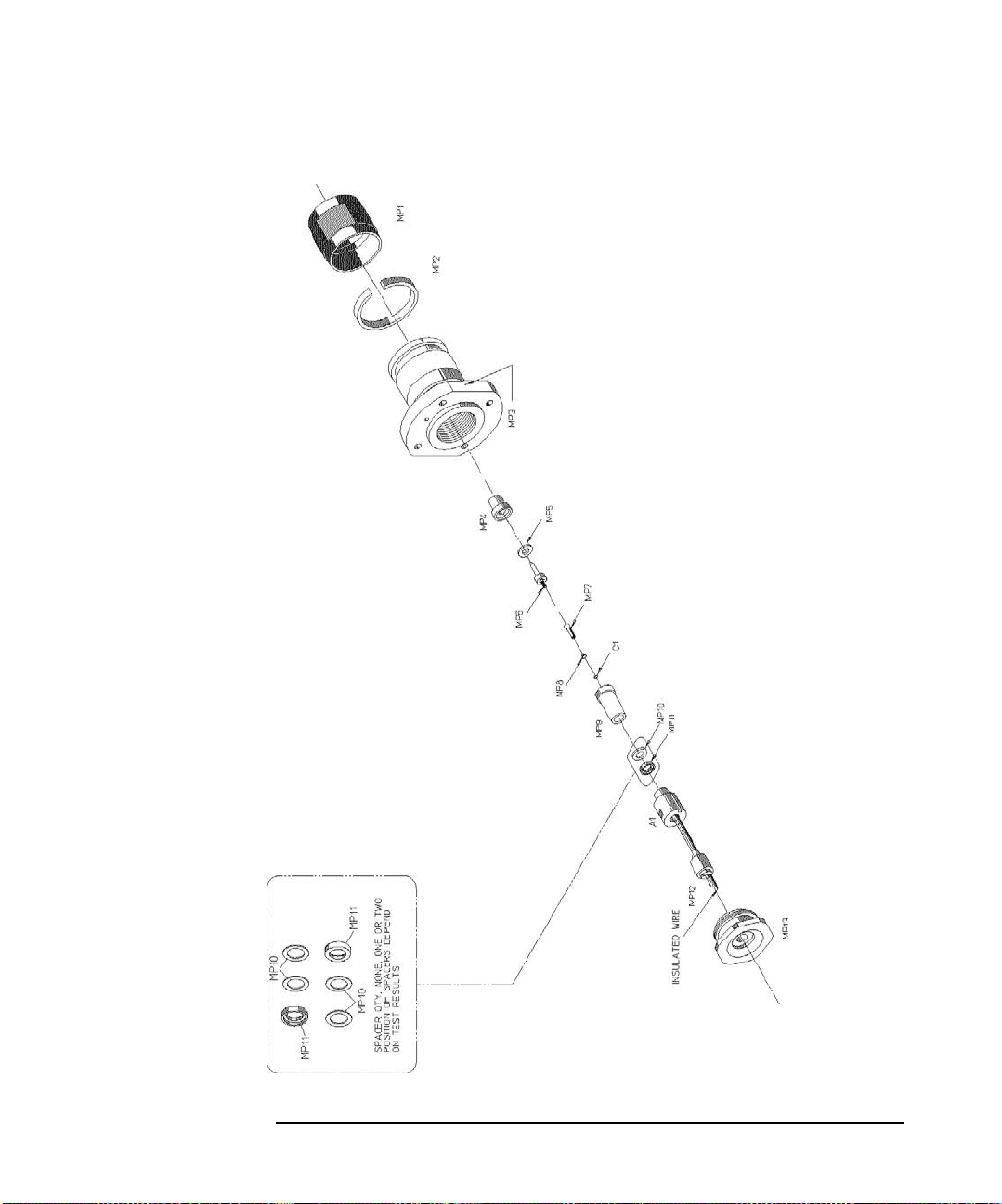

Table 2-3 to Table 2-8 are a list of replaceable parts. Figure 2-1

illustrates the major parts. To order a part listed in Table 2-3 to Table

2-8, contact your nearest Agilent Technologies Sales and Service Office.

Figure 2-1 Illustrated Major Parts Breakdown

Chapter 230

Table 2-3 Bulkhead Assembly

General Information

Replaceable Parts

Model Reference

Designator

Part

Number

Qty Description

8481A A1 08481-60004 1 Bulkhead Assembly, Type N

8481A Opt 001 A1 08481-60005 1 Bulkhead Assembly, Type APC-7

8482A A1 08482-60003 1 Bulkhead Assembly, Type N

8483A A1 08483-60003 1 Bulkhead Assembly, Type N

8485A A1 08485-60007 1 Bulkhead Assembly, 3.5mm

8485A Opt 033 A1 08485-60011 1 Bulkhead Assembly, 3.5mm

8487A A1 08487-60002 1 Bulkhead Assembly, 2.4mm

8481B A1 08481-60019 1 Bulkhead Assembly, Type N

8482B A1 08482-60011 1 Bulkhead Assembly, Type N

8481D A1 08481-60145 1 Bulkhead Assembly, Type N

8485D A1 08485-60008 1 Bulkhead Assembly, 3.5mm

8485D Opt 033 A1 08485-60012 1 Bulkhead Assembly, 3.5mm

8487D A1 08487-67002 1 Bulkhead Assembly, 2.4mm

8481H A1 08481-60014 1 20dB Bulkhead Assembly, Type N

8482H A1 08482-60009 1 20dB Bulkhead Assembly, Type N

Chapter 2 31

General Information

Replaceable Parts

Table 2-4 Power Sensor Board Assemblies

Model Reference

Designator

Part

Number

Qty Description

848xA A2 5061-0982 1 Power Sensor Board Assembly

8481B/8482B A2 08481-60039 1 Power Sensor Board Assembly

8481D/8485D/8487D A2 5061-0983 1 Power Sensor Board Assembly

8481H/8482H A2 08481-60040 1 Power Sensor Board Assembly

Table 2-5 Common Chassis Components

Reference Designator Part Number Qty Description

MP1-MP2 5040-6998 2 Plastic Shell

MP3-MP4 08481-20011 2 Chassis

MP6 1460-1978 1 Compression Spring

MP8-MP9 08481-00002 2 Shield

MP10-MP22 0515-0879 13 Screw

MP23 3030-0436 1 Screw

MP24 5040-6939 1 Clamp

MP25 5040-6940 1 Block

Chapter 232

General Information

Replaceable Parts

Table 2-6 Adapters and Attenuators

Model Part Number Qty Description

8483A 1250-0597 1 50 Ohm to 75 Ohm Coax Adapter

8485A/8485D 08485-60005 1 3.5mm to N(m) Coax Adapter

8487A/8487D 08487-60001 1 2.4mm to N(m) Coax Adapter

8481B 08498-60001 1 Coaxial Fixed 30dB Attenuator

8482B 08498-60010 1 Coaxial Fixed 30dB Attenuator

8481D/8485D/8487D 11708-60001 1 Precision 30dB Attenuator

Table 2-7 Identification Labels

Model Part Number Qty Description

8481A 08481-80002 1 8481A ID Label

8482A 08482-80002 1 8482A ID Label

8483A 08483-80001 1 8483A ID Label

8485A 08485-80002 1 8485A ID Label

8487A 08487-80001 1 8487A ID Label

8481B 08481-80004 1 8481B ID Label

8482B 08482-80003 1 8482B ID Label

8481D 08481-80011 1 8481D ID Label

8485D 08485-80003 1 8485D ID Label

8487D 08487-80004 1 8487D ID Label

8481H 08481-80003 1 8481H ID Label

8482H 08482-80001 1 8482H ID Label

Chapter 2 33

General Information

Replaceable Parts

Table 2-8 Miscellaneous Labels

Part Number Qty Description

08481-80115 1 Cal Label (Blank) - For Zebra brand printers

08486-80006 1 Cal Label (Blank) - For impact printers

08481-80005 1 Mylar Overlay - For use with Cal Label 08486-80006

08486-80005 1 Side Label - Agilent Branding

7121-2422 1 Side Label - Caution (For all models except 8487A/8487D)

08487-80002 1 Side Label - Caution (For 8487A/8487D)

00346-80011 1 Information Label (For 8481D/8485D/8487D)

Chapter 234

3 Service

This Service chapter contains information about principles of operation,

troubleshooting, and repair of the Agilent Coaxial Power Sensors.

Chapter 3 35

Service

Principles of Operation

Principles of Operation

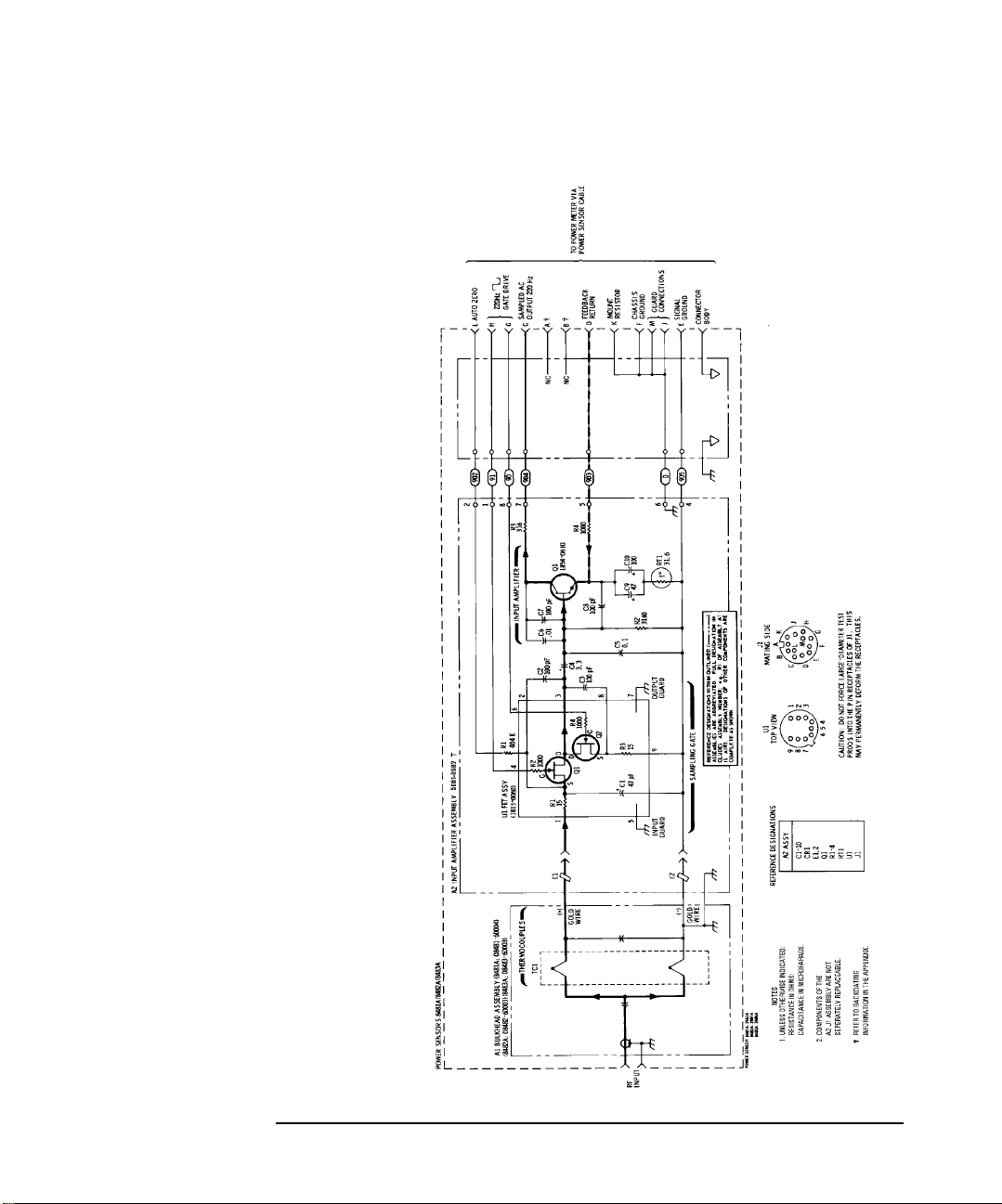

Thermocouple Sensors

The A1 Bulkhead Assembly presents a 50 Ohm load (75 Ohm for model

8483A) to the RF source.

The RF signal is coupled through a dc blocking capacitor and absorbed by

the thermocouples, generating a dc voltage proportional to the RF input

power. The dc voltage is routed from the thermocouples to the input

amplifier via gold wires reducing unwanted thermocouple effects. The

gold wires, located in the black plastic block, pass through ferrite beads

A2E1 and A2E2. The ferrite beads increase the self-inductance of the

gold wires creating an RF choke. The result is to minimize RF

feedthrough to the A2 Power Sensor Board Assembly.

The dc output from the bulkhead assembly is applied to the two field

effect transistors (FETs) in A2U1. These transistors function as a

sampling gate or chopper. The sampling rate is controlled by a 220 Hz

square wave supplied by the power meter. The amplitude of the sampling

gate output (at pin 3 of A2U1) is a 220 Hz square wave proportional to

the power input. The sampled 220 Hz ac output is applied to the input

amplifier A2Q1, which is the input stage for an operational amplifier

The Auto Zero Feedback circuit is coupled to the power sensor from the

power meter. The dc voltage used to set the zero level is applied to the

input of FET A2U1 by using A2R1 and A1TC1 as a voltage divider.

When the Power Sensor is used with a Power Meter, the resistance to

ground from J1-K (Mount Resistor) allows the Power Meter to determine

the sensor's dynamic range.

Chapter 336

Service

Principles of Operation

Diode Sensors

The A1 Bulkhead Assembly presents a 50 Ohm load to the RF source.

A diode assembly in the bulkhead rectifies the applied RF to produce a dc

voltage that varies with the square of the RF power across the 50 Ohm

load. Thus the voltage varies with the RF power dissipated in the load.

This low level DC voltage is passed on gold wires through ferrite beads

A2E1 and A2E2. The ferrite beads increase the self-inductance of the

gold wires causing this portion of the wires to provide the properties of

an RF choke. The result is to minimize RF feedthrough to the A2 Power

Sensor Board Assembly.

The dc output from the bulkhead assembly is applied to the two field

effect transistors (FETs) in A2U1. These transistors function as a

sampling gate or chopper. The sampling rate is controlled by a 220 Hz

square wave supplied by the power meter. The amplitude of the sampling

gate output (at pin 3 of A2U1) is a 220 Hz square wave proportional to

the power input. The sampled 220 Hz ac output is applied to the input

amplifier A2Q1, which is the input stage for an operational amplifier.

The A2 Power Sensor Board Assembly also contains various components

that comprise a shaping network. This network brings about a linear

change in the amplitude of the square wave output as RF input power

changes. A shaping network is necessary in diode power sensors to

compensate for the characteristics of the thermocouple type shaping in

the power meter, and to make minor diode corrections. In order to bring

about a linear change in amplitude, the components in this network are

factory selected to match variations of the diode assembly in the

bulkhead.

The Auto Zero Feedback circuit is coupled to the power sensor from the

power meter. The dc voltage used to set the zero level is applied to the

input of FET A2U1 by using A2R1 and A1TC1 as a voltage divider.

When the Power Sensor is used with a Power Meter, the resistance to

ground from J1-K (Mount Resistor) allows the Power Meter to determine

the sensor's dynamic range.

Chapter 3 37

Service

Principles of Operation

Figure 3-1 Schematic Diagram

Chapter 338

Service

Troubleshooting

Troubleshooting

Troubleshooting information is intended to first isolate the Power Sensor

or the Power Meter as the defective component. When the Power Sensor

is isolated, troubleshooting information is intended to identify the A1

Bulkhead Assembly or the A2 Power Sensor Board Assembly as the

defective component.

Before you open the Power Sensor to continue with the troubleshooting

procedures, try the substitution method of elimination. Use another

power meter, known to be in good operating condition, with the suspected

power sensor and cable. If the same problem occurs with the “known

good” power meter, substitute a “known good” power sensor cable.

Troubleshooting should be performed with the Power Sensor opened, and

the printed circuit board exposed. Refer to the “Disassembly /

Reassembly Procedures” on page 49.

When a failed assembly has been identified, refer to the repair section in

either the “A1 Bulkhead Assembly” on page 43 or the “A2 Power Sensor

Board Assembly” on page 44.

NOTE The FETs in A2U1 are light sensitive, and dc levels are shifted slightly

when the FETs are exposed.

CAUTION Excessive power damages the Power Sensor.

CAUTION Electrostatic discharge renders the Power Sensor inoperative.

Troubleshooting and Repair procedures must be carried out at a static

free workstation.

Chapter 3 39

Service

Troubleshooting

Troubleshooting - Eliminating the Power Meter and

Sensor Cable

Where a “known good” power meter and/or sensor cable is unavailable,

another means must be used to isolate the fault to the Power Sensor.

This is done by ensuring the power meter is providing the correct 220Hz

drive signal. Check the following levels of the square wave with an

oscilloscope.

• At the black/white wire: -0.05 ± 0.05 Vdc (top of square wave).

• At the brown/white wire: -9Vdc (bottom of square wave).

If the levels are incorrect, then the power meter or sensor cable is at

fault. Refer to the power meter service manual for troubleshooting

information.

If the levels are correct then the Power Sensor is at fault. Continue by

troubleshooting the A1 Bulkhead Assembly.

Troubleshooting - Power Sensors

The most common cause of Power Sensor failure is the application of

power levels beyond the specified tolerance. The second most common

cause of failure is applying torque to the body of the Power Sensor. Either

of these common causes damages the bulkhead cartridge unit (which

holds the thermocouples/diodes). If this happens, the fault causes a short

or an open between the two gold wires.

A1 Bulkhead (Thermocouple Sensors)

CAUTION Disconnect the gold wires from the A2 assembly before measuring the

resistance. Be extremely careful when measuring across the gold wires.

They are delicate and can be damaged easily.

Step 1. Disconnect all cables from the Power Sensor.

Step 2. Remove the clamp holding the two gold wires.

Step 3. Resistance measured between the two gold wires from the A1 Bulkhead

Assembly is listed in Table 3-1.

Chapter 340

Service

Troubleshooting

Table 3-1 Bulkhead Assembly Resistance

Model Measured Resistance

8481A, 8481B, 8481H, 8485A, 8487A: 200 Ohms ± 10 Ohms

8482A, 8482B, 8482H: 245 Ohms ± 12.5 Ohms

8483A: 375 Ohms ± 17.5 Ohms

If the resistance value is incorrect (failure is usually indicated by an

open circuit), then the A1 Bulkhead Assembly is defective. If the

resistance is correct then continue to test the A2 Power Sensor Board

Assembly.

A1 Bulkhead (Diode Sensors)

CAUTION Disconnect the gold wires from the A2 assembly before measuring the

voltage. Be extremely careful when measuring across the gold wires.

They are delicate and can be damaged easily.

Step 1. Disconnect all cables from the Power Sensor.

Step 2. Remove the clamp holding the two gold wires.

Step 3. Connect the Precision 30dB Attenuator to the 1mW Power Reference

connector on the power meter.

Step 4. Connect the Power Sensor to the Precision 30dB Attenuator.

NOTE Models 8485A and 8487A require 3.5mm and 2.4mm adapters

respectively.

Step 5. Turn on the 1mW Power Reference, and measure the voltage across the

two gold wires. The voltage should be between 0.9mV and 1.5mV. If the

voltage is incorrect, then the A1 Bulkhead Assembly is defective. If the

voltage is correct then continue to test the A2 Power Sensor Board

Assembly.

Chapter 3 41

Service

Troubleshooting

A2 Power Sensor Board Assembly

It is extremely rare for the A2 Assembly to fail. Eliminate the power

meter, the sensor cable, and the A1 Bulkhead Assembly before

suspecting the A2 Assembly.

In most cases, the operational amplifier (made up of A2Q1 and the first

amplifier of the power meter,) is operating correctly if the dc voltage on

the metal cover of A2Q1 (collector) is -70 ±30 mV dc.

Chapter 342

Repair

Power Sensor repair consists of replacing either the A1 Bulkhead

Assembly, or the A2 Power Sensor Board Assembly.

A1 Bulkhead Assembly

Repair Strategy

The recommended repair strategy for the A1 Bulkhead Assembly is to

completely replace it. The replacement Bulkhead is calibrated at the

factory, and is supplied with a calibration report and a new calibration

sticker for the Power Sensor.

Procedure

Step 1. Order your new or restored A1 Bulkhead Assembly from Table 2-3,

“Bulkhead Assembly,” on page 31.

Service

Repair

Step 2. Follow the disassembly and reassembly procedures for Bulkhead

removal and replacement. See “Disassembly / Reassembly Procedures”

on page 49.

Step 3. Check the FET balance using the procedure described in “FET Balance

Adjustment” on page 45. If you did not disturb the wires, it is likely that

no adjustment is necessary.

Step 4. Place the new calibration sticker on the plastic shell of the Power Sensor.

NOTE Although the recommended Bulkhead strategy is to completely replace

it, we are aware that some customers have both the ability and

experience that enables them to disassemble and repair Bulkheads to a

lower level. For this reason, Appendix B provides exploded views of the

various Bulkheads, and tables listing the parts.

Lower level Bulkhead repair can be more economical than replacement,

although this may be offset by the need to invest in sensor calibration

equipment and a SWR test set-up.

Chapter 3 43

Service

Repair

A2 Power Sensor Board Assembly

Repair Strategy

The recommended repair strategy for the A2 Power Sensor Board

Assembly is to completely replace it. Replacing this assembly is usually

less costly than the time it takes to troubleshoot and replace faulty

components.

Procedure

When replacing the A2 Power Sensor Board Assembly, some soldering is

required in order to remove and replace the wires from connector J1.

Remember that the Power Sensor is a highly sensitive device. As such, it

is affected by very small temperature differences between its

components. After performing any soldering in the unit, wait several

hours for the unit to reach thermal equilibrium before using or testing it.

1. Use a temperature controlled 600F (311C) with a zero crossover tip.

2. Use a low temperature RMA flux SN 62 solder.

3. Do not attempt to remove flux residue from around solder joints.

Using a cleaning solution may spread the flux over the entire

assembly in a thin sticky layer.

Chapter 344

FET Balance Adjustment

FET Balance Adjustment

The FET balance adjustment should be performed if the wires

connecting J1 (the sensor cable connector) to A2 (the power sensor board

assembly) have been moved. If you have replaced A2 assembly or moved

the wires during troubleshooting you need to perform this adjustment.

NOTE You do not need to perform a FET balance adjustment after an A1

bulkhead assembly replacement, if the wires between J1 and A2 have

not been disturbed.

Equipment Required

• Oscilloscope

•BNC cables (2 required)

• Power Meter (Modified as described in Appendix A)

Service

Test Description

This test applies to both thermocouple and diode power sensors. Among

the required equipment is a modified E4418B Power Meter. The High

Gain output of the power meter is connected to Channel 1 of an

oscilloscope, and the Chop Output (220Hz square wave) of the power

meter is connected to the oscilloscope trigger - the High Gain output is

the amplified version of the Power Sensor chopped signal. Ideally, when

no RF power is applied to the power sensor, the High Gain output signal

displayed on the oscilloscope is a straight line. If there is a sensor offset,

the offset signal is visible on the oscilloscope as a square wave (chopped

signal). Also, a switching transient (spike) usually occurs at the edge of

the chopped signal, due to the switching of the FET in the Power Sensor.

Sensor offset and spike balance are affected by the relative positions of

the wires connected to pins G and H of connector J1. One wire is black

and white; the other is brown and white. Moving the black and white

wire adjusts the amplitude of the switching transient (spike). Moving the

brown and white wire changes the offset. Once positioned, care must be

taken not to displace these wires. To correctly position these wires,

perform the “FET Balance Procedure” on page 46.

Chapter 3 45

Service

FET Balance Adjustment

FET Balance Procedure

Step 1. Set the Power Meter as follows:

CAL FACTOR 100%

POWER REF ON

Step 2. Connect the HIGH GAIN OUTPUT on the modified Power Meter to

CHANNEL 1 on the Oscilloscope and set it up as follows:

POSITION 0 Volts (centered)

COUPLING AC

PROBE 1:1

DISPLAY AVERAGE

AVERAGE 8

VECTORS ON

GRID ON

MAIN/DELAYED MAIN

TIME REF CENTER

TIME/DIV 500us

VOLTS/DIV 50 mV

Step 3. Connect the CHOP OUTPUT on the modified Power Meter to

CHANNEL 2 on the Oscilloscope and set it up as follows:

MODE AUTO LEVEL

TRIGGER SOURCE CHANNEL 2

VOLTS/DIV 5V

POSITION -5V

Chapter 346

Service

FET Balance Adjustment

Step 4. Connect the Power Sensor to channel A of the Power Meter.

NOTE Heat can affect the adjustments so handle the sensor as little as possible.

Step 5. Adjust the black/white and brown/white wires until the waveform shown

on the oscilloscope is similar to that shown in Figure 3-2. This shows an

example of a High Gain output signal with acceptable sensor offset and

spike balance settings.

Figure 3-2 Example of an Acceptable Waveform

Step 6. Allow no more than 50mV variance on the sensor offset step (i.e. from

top-to-top or bottom-to-bottom of the waveform). Figure 3-3 shows an

example of a High Gain output signal with an unacceptably high sensor

offset setting.

Chapter 3 47

Service

FET Balance Adjustment

Figure 3-3 Example of an Unacceptable Waveform

TIP You will find that positioning the wire for switching transients affects

the offset. Go back and forth between the two wires, positioning and

repositioning, until both adjustments are deemed acceptable.

Step 7. Reassemble the Power Sensor, ensuring that the waveform shown on the

oscilloscope does not change. If the waveform has changed, remove the

cover and readjust the black/white and brown/white wires again.

Chapter 348

Service

Disassembly / Reassembly Procedures

Disassembly / Reassembly Procedures

Disassembly Procedure

Disassemble the Power Sensor by performing the following steps:

CAUTION Disassembly must be performed in sequence described in the following

procedure, otherwise damage may be caused to the two gold wires

between the bulkhead assembly and the Power Sensor Board Assembly.

If these wires are damaged, the A1 Bulkhead Assembly must be

replaced.

NOTE Every Power Sensor has an individually prepared label on the housing. If

more than one power sensor is disassembled at a time, be sure to mate

the correct Power Sensor and housing when reassembling.

Step 1. Insert the blade of a large screwdriver between the two-piece plastic

shell at the rear of the Power Sensor. Gently pry the sections apart. (See

Figure 3-4.)

Chapter 3 49

Service

Disassembly / Reassembly Procedures

Figure 3-4 Removing the Power Sensor’s Cover

Step 2. At the other side of the sensor, again pry the cover shell sections apart.

Remove the shells and the inner magnetic shields.

Step 3. Position the Power Sensor as shown in Figure 3-5 (top). The small hole 5

should be on the left side of the RF input connector. Remove the allen cap

screws 1, 2, 10, and 13. Loosen 11 and 12. Remove the upper chassis

from the Power Sensor.

Step 4. Remove the spring clamp cap screw 7 to free the gold leads which come

from the Bulkhead Assembly.

Step 5. Remove cap screws 3, 4, and 5.

Step 6. Slide the Bulkhead Assembly straight out from the chassis.

Step 7. Remove cap screws 8, 9, 11, 12, 14, and 15.

Step 8. Lift the A2 Input Amplifier and J1 connector out of the chassis.

Chapter 350

Figure 3-5 Power Sensor Hardware Locations

Service

Disassembly / Reassembly Procedures

Reassembly Procedures

CAUTION The gold wires connecting the A1 Bulkhead Assembly and the A2 Power

Sensor Board Assembly are extremely delicate and may be easily broken.

Be careful when working around them.

Step 1. Set the printed circuit board and connector into place as shown in Figure

3-5, bottom view.

Chapter 3 51

Service

Disassembly / Reassembly Procedures

Step 2. Insert cap screws 8, 9, 11, 12, 14, and 15 but do not tighten.

Step 3. Center the circuit board so there is equal air gap between each side and

the chassis. Tighten 8, 9, 14, and 15.

Step 4. Insert screw 3, 4, and 5. Tighten only screw 5.

Step 5. With small hole 5 to the left, carefully insert the gold leads on A1

bulkhead assembly through the holes in the black plastic guide on A2

input amplifier.

Step 6. Using tweezers, position the ends of the gold wires over the electrical

pads.

CAUTION DO NOT tighten clamp screw 6 excessively or the FET circuit may be

broken.

Step 7. Place and hold plastic clamp 16 over the gold wires. As you tighten the

clamp screw, watch the compression spring. Tighten the clamp screw 7

only until the spring coils touch. Any further tightening could damage

the FET circuit.

Step 8. Place the upper chassis in position and insert cap screws 1, 2, 10, and 13.

Step 9. Tighten 1, 2, 3, and 4.

Step 10. Tighten 10, 11, 12, and 13.

Step 11. Place the plastic shells, magnetic shields, and the chassis together as

shown in Figure 2-1. Snap the plastic shells together.

Chapter 352

A EPM Series Power Meter

(E4418B) Modification

This Appendix describes the modification procedure for adapting an

E4418B Power Meter to allow it to be used for the 8480 Series Power

Sensor FET Balance Adjustment.

Appendix A 53

EPM Series Power Meter (E4418B) Modification

The Material and Tools Required

The Material and Tools Required

The following material and tools are required for this modification:

• A T-15 torque screwdriver.

• A Razor blade or Craft Knife.

• Three 30 cm lengths of AWG 20 single core wire.

• Three screw-fit BNC Female connectors

(Agilent Part Number 1250-0118).

• A fine tip marker pen and adhesive labels.

• A 10-20 Watt pencil tip soldering iron.

• 60/40 0.8 mm rosin activated core solder wire.

• A Wire stripper.

• 25 lb/in Torque Wrench - Size 7/16 in. AF.

Impact on Warranty

NOTE Please be aware that doing this modification requires you to open the

power sensor. Therefore, as stated earlier, any attempt to disassemble

the power sensor will void the warranty.

Appendix A54

EPM Series Power Meter (E4418B) Modification

Modification Procedure

Modification Procedure

CAUTION Precautions must be taken to protect the Power Meter’s PCBs from

Electrical Static Damage (ESD).

Step 1. Using the T-15 torque screwdriver, remove the two screws shown in

Figure A-1.

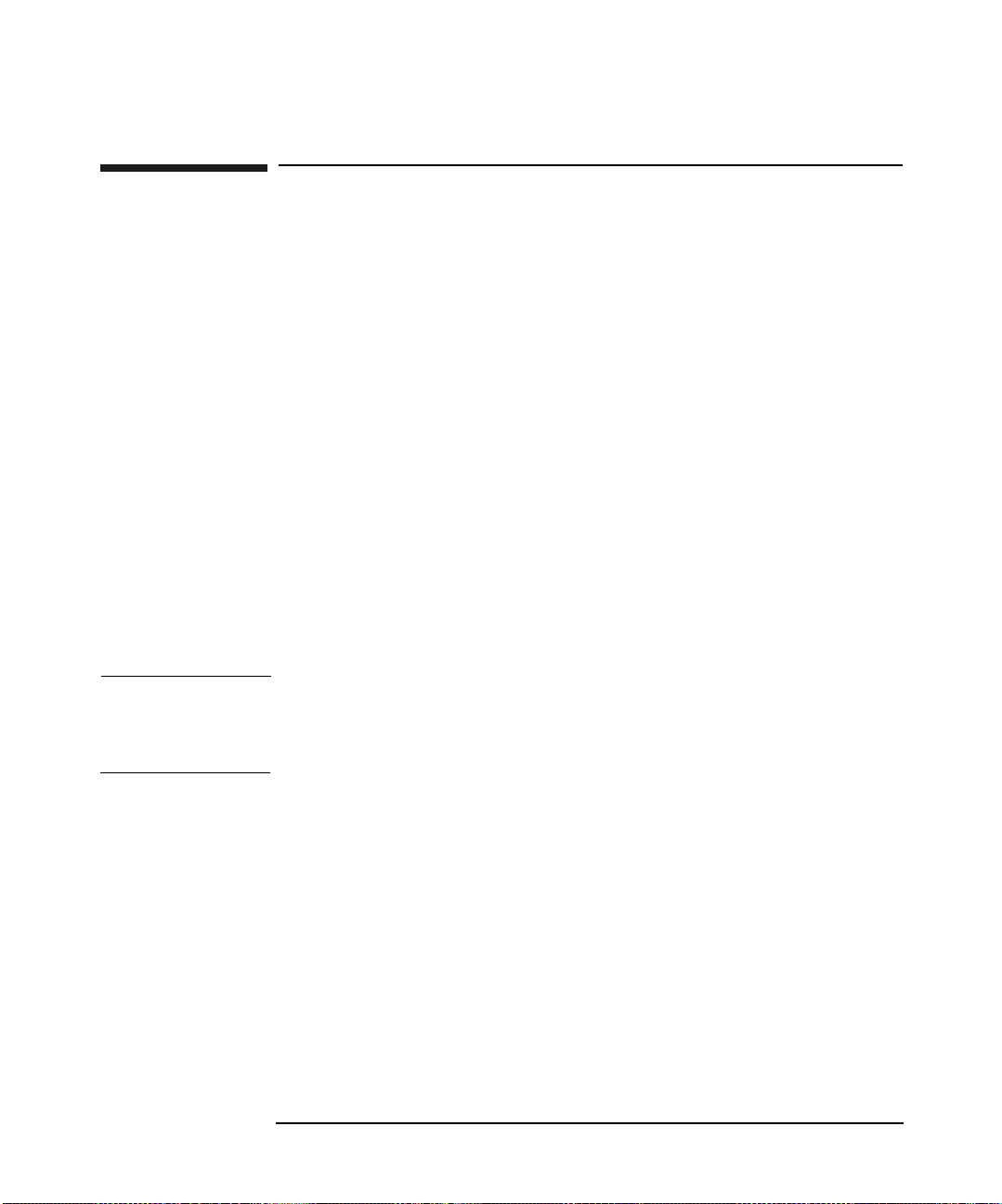

Figure A-1

Remove these 2 screws

Appendix A 55

Figure A-2

EPM Series Power Meter (E4418B) Modification

Modification Procedure

Step 2. Remove the power meter handle. To remove the handle, pull the 2 ends

as shown in Figure A-2.

PullPull

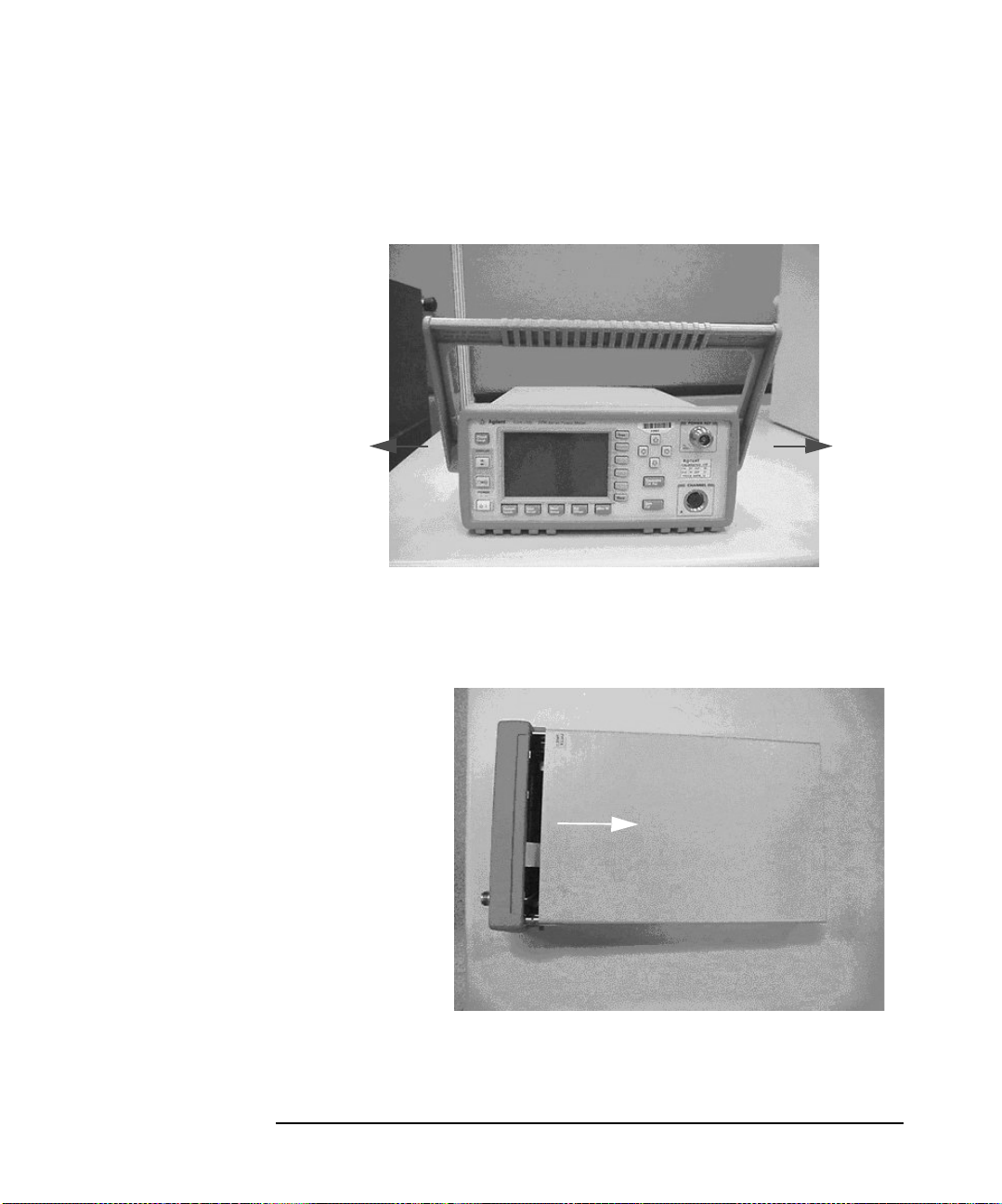

Step 3. Remove the power meter cover. To remove the cover, slide it open as

shown in Figure A-3.

Figure A-3

Slide cover this direction

Appendix A56

Figure A-4

EPM Series Power Meter (E4418B) Modification

Modification Procedure

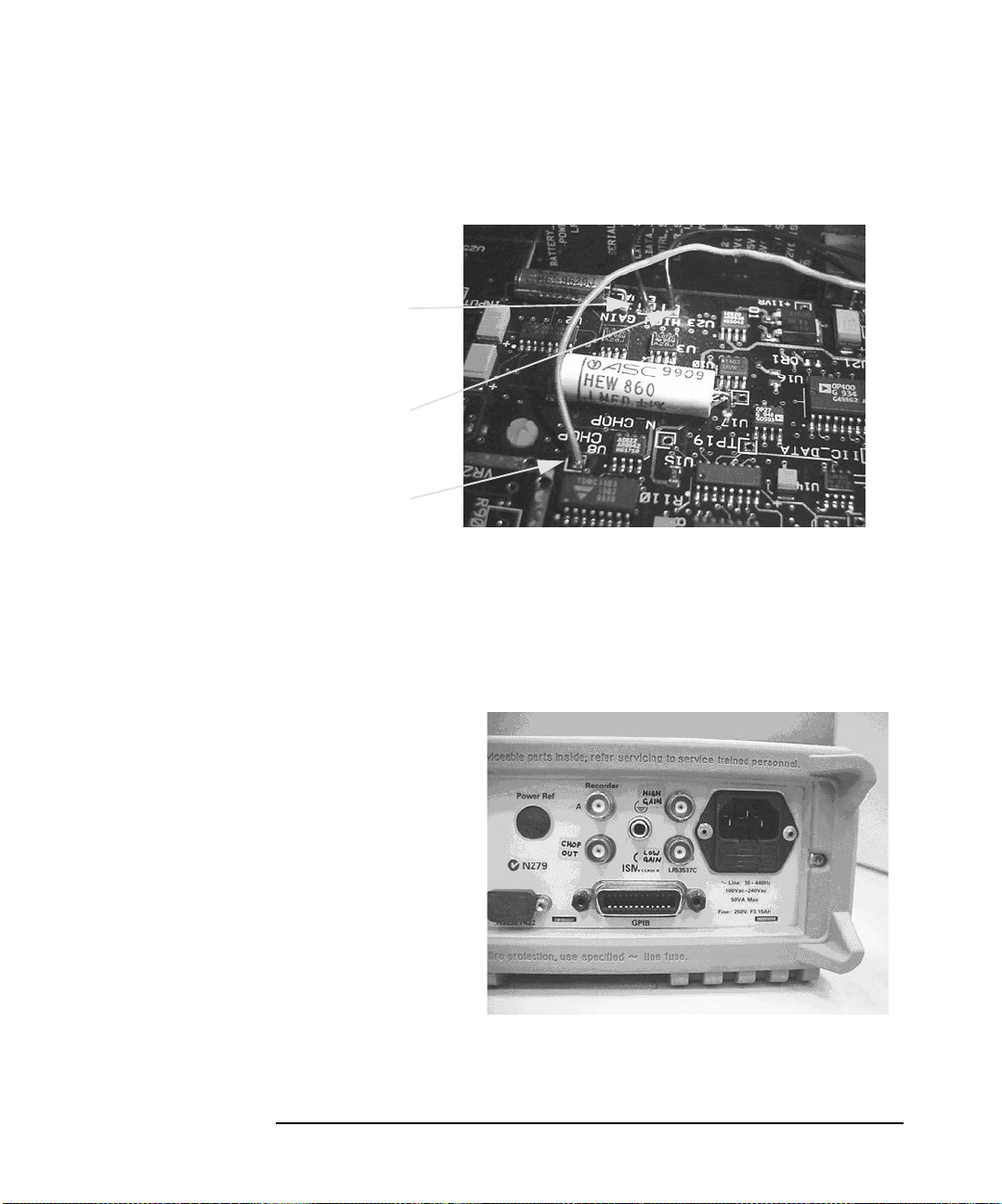

Step 4. Figure A-4 shows the power meter with its cover removed.

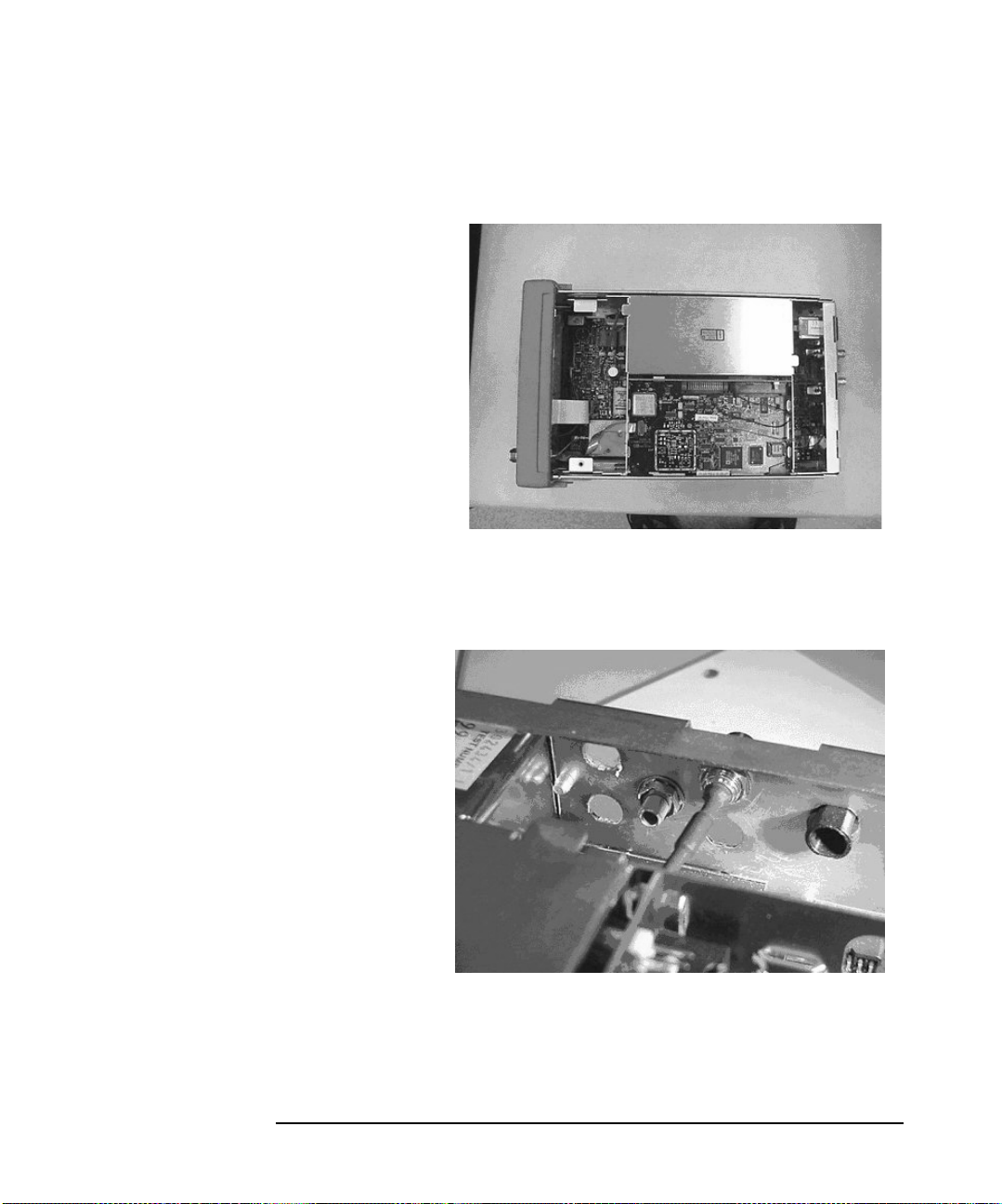

Step 5. Use the razor blade or craft knife to remove three hole plugs in the rear

panel, as shown in Figure A-5.

Figure A-5

Appendix A 57

Figure A-6

EPM Series Power Meter (E4418B) Modification

Modification Procedure

Step 6. Figure A-6 shows a different view of the holes in the rear panel.

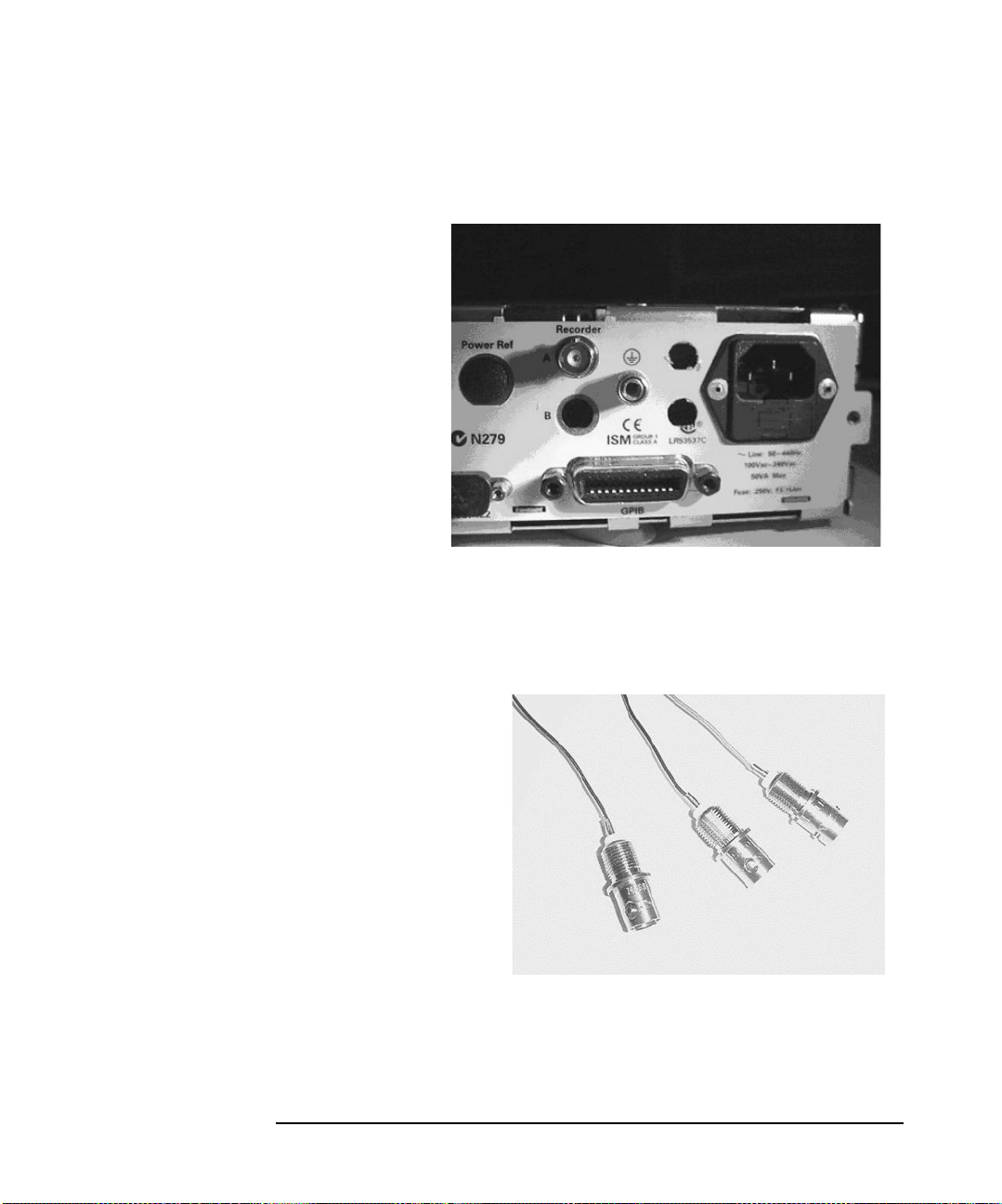

Step 7. Using the three lengths of AWG 20 wire, strip away 2cm from each end of

the wires. Solder an end of each wire onto the screw-fit BNC female

connectors, as shown in Figure A-7.

Figure A-7

Appendix A58

Figure A-8

EPM Series Power Meter (E4418B) Modification

Modification Procedure

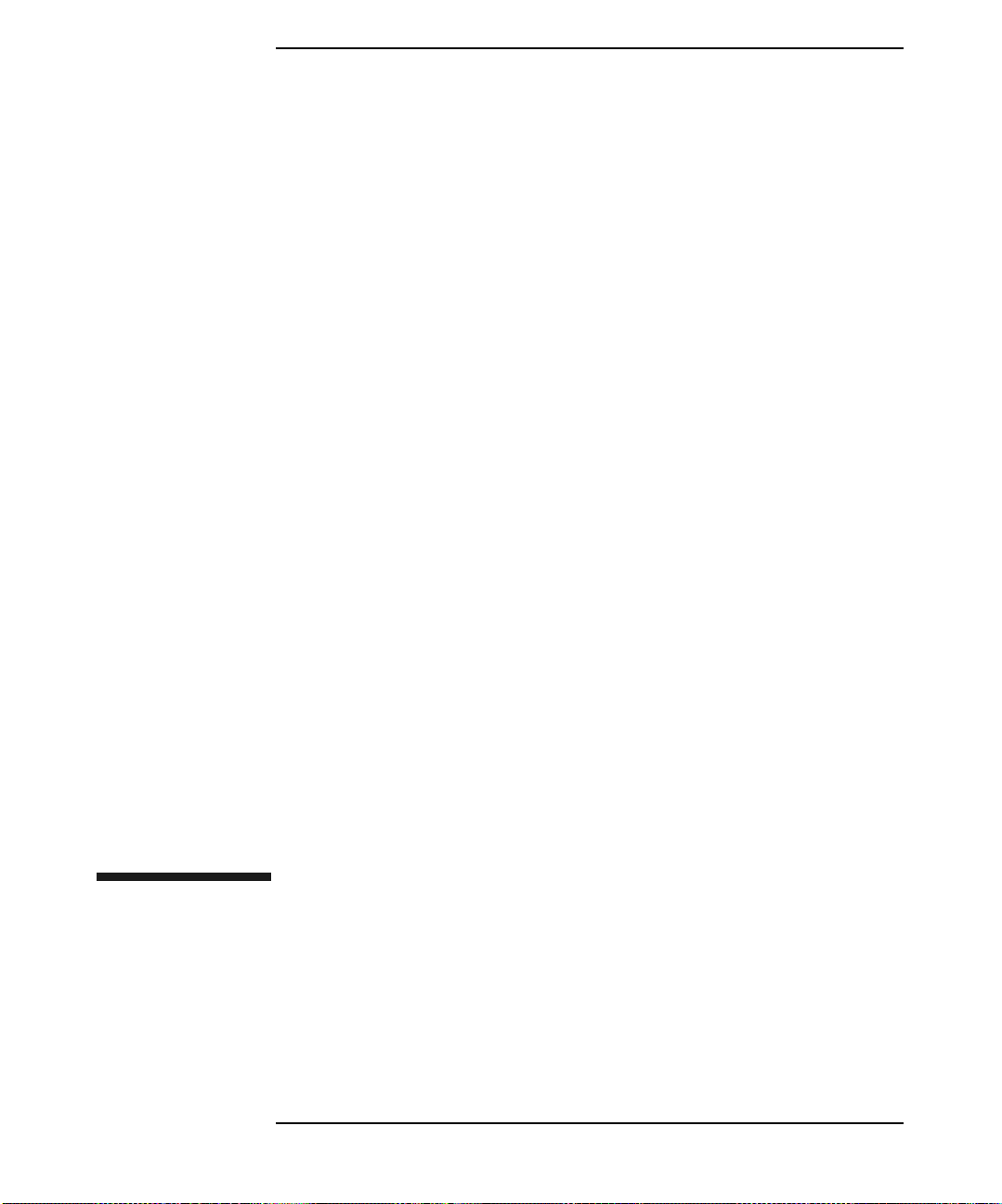

Step 8. Securely fit the three BNC connectors into the three holes in the rear

panel, as shown in Figure A-8. Use the 25 lb/in torque wrench to tighten

the nuts.

Step 9. The Measurement PCB (A6) must now be modified. The call outs in

Figure A-9 show where the three wires need to be soldered. Solder a wire

into each hole (Chop, Low Gain, and High Gain Outputs). Take care not

to over heat the PCB, as this may damage the trace.

Figure A-9

Chop Output

Appendix A 59

High Gain Output

Low Gain Output

Step 10. Figure A-10 shows a different view of the modified Measurement PCB.

Figure A-10

Step 11. Label each of the BNC connectors using the permanent marker and

EPM Series Power Meter (E4418B) Modification

Modification Procedure

Low Gain Output

High Gain Output

Chop Output

adhesive labels, as shown in Figure A-11. Refit the cover, handle, and the

rear bumper to the power meter. Tighten both screws with the T-15

torque screwdriver.

Figure A-11

Appendix A60

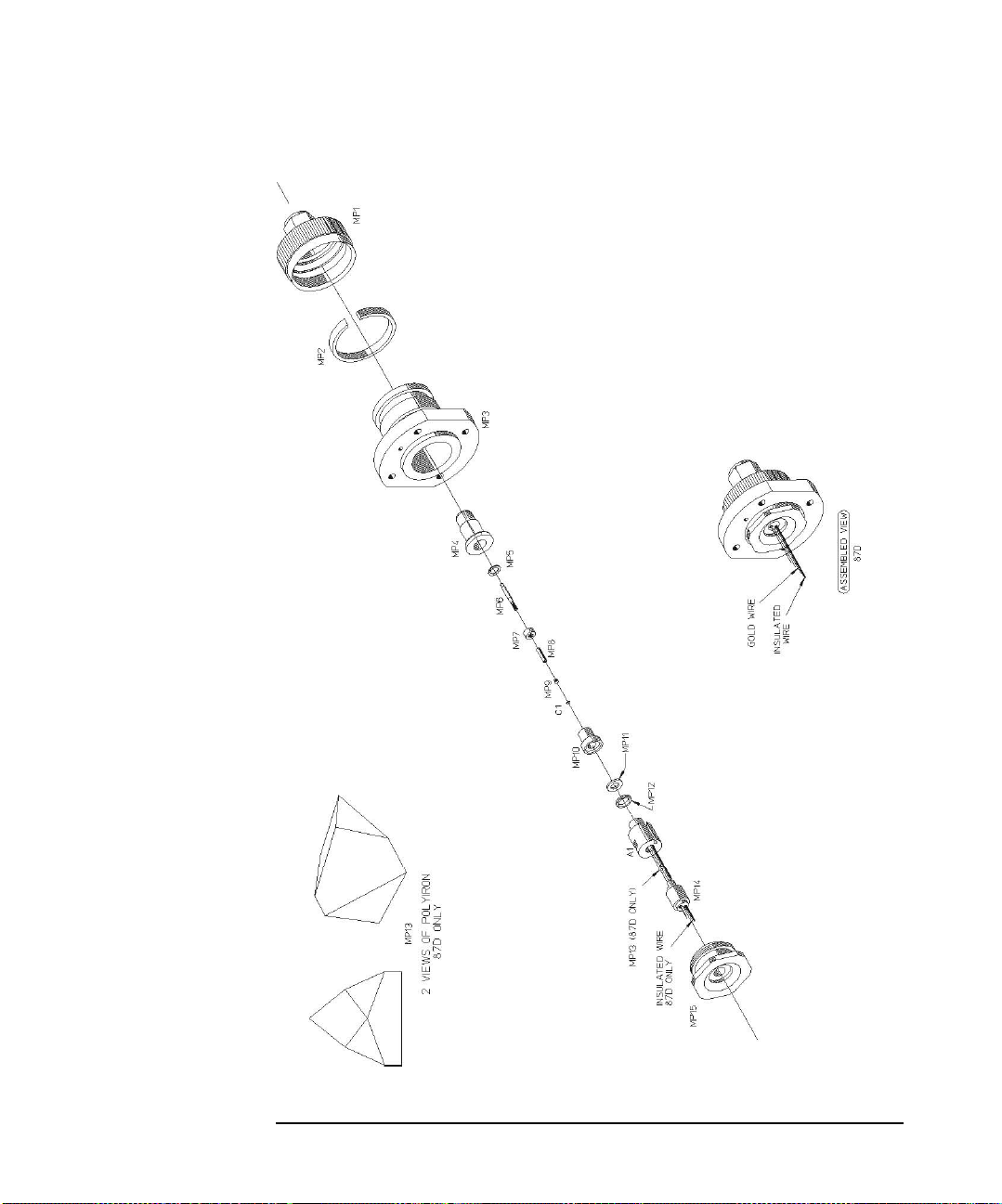

B Bulkhead Assemblies

This Appendix contains the material lists and exploded graphics of the

Bulkhead Assemblies.

Appendix B 61

Bulkhead Assemblies

Bulkhead Parts Lists

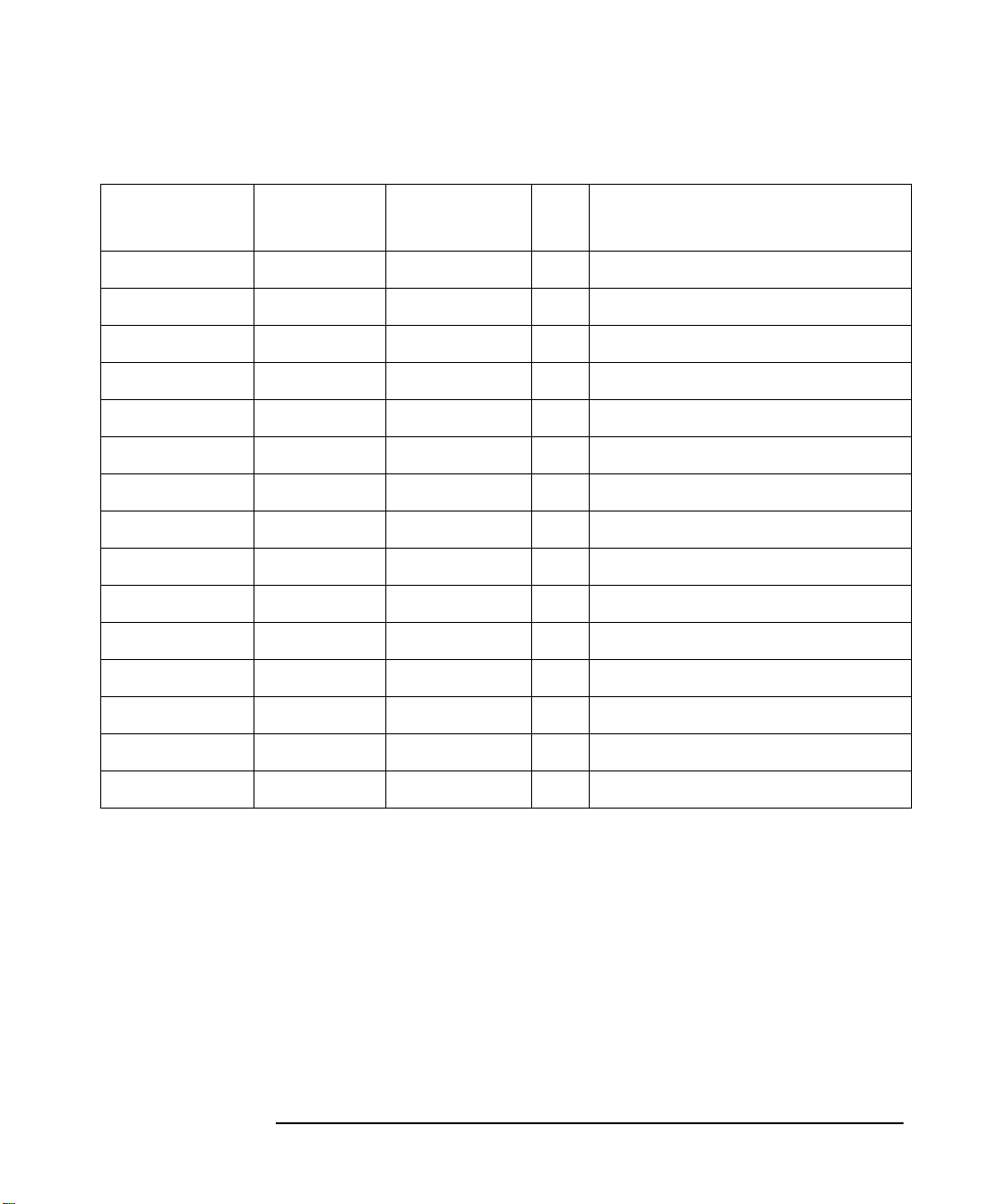

Bulkhead Parts Lists

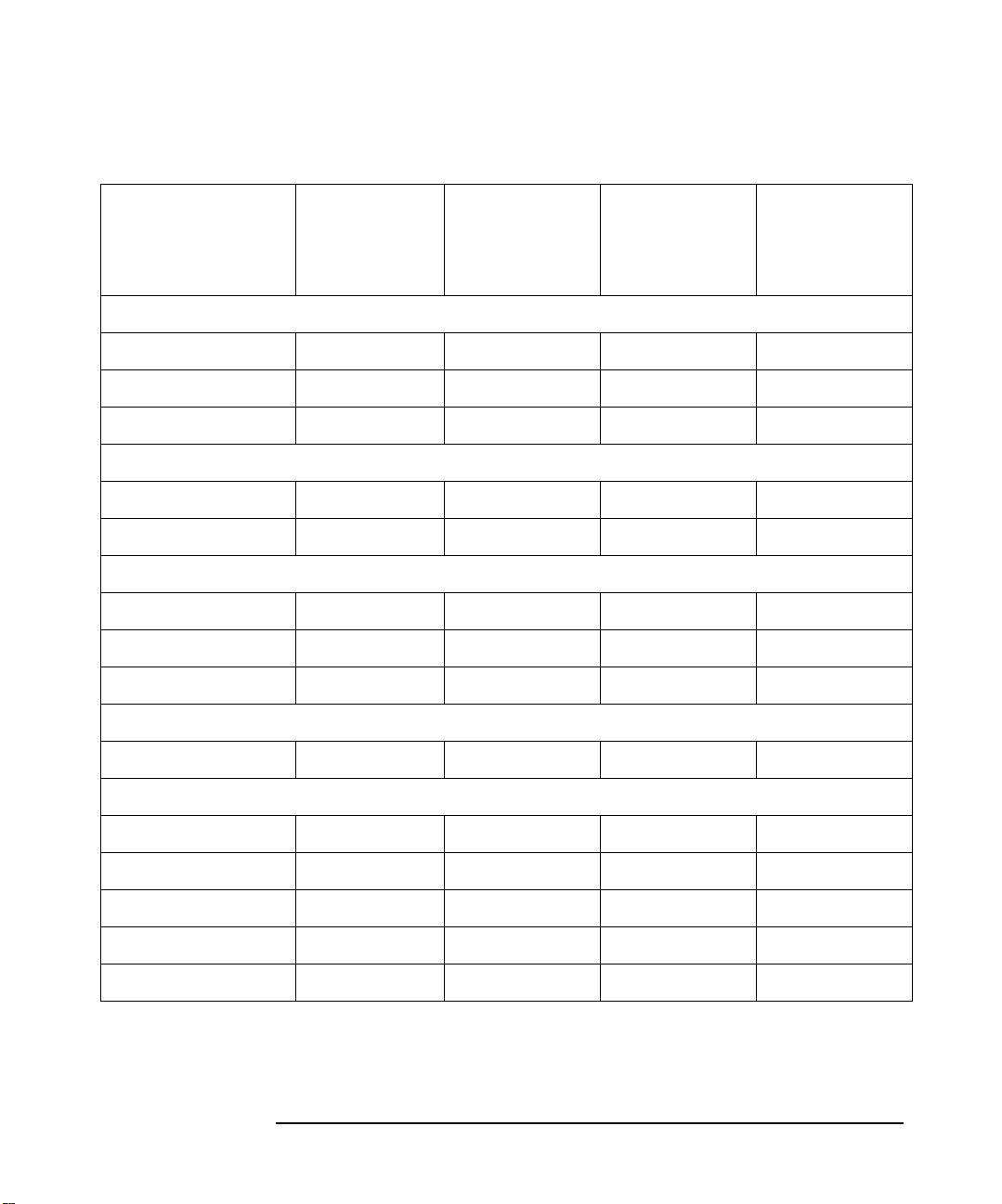

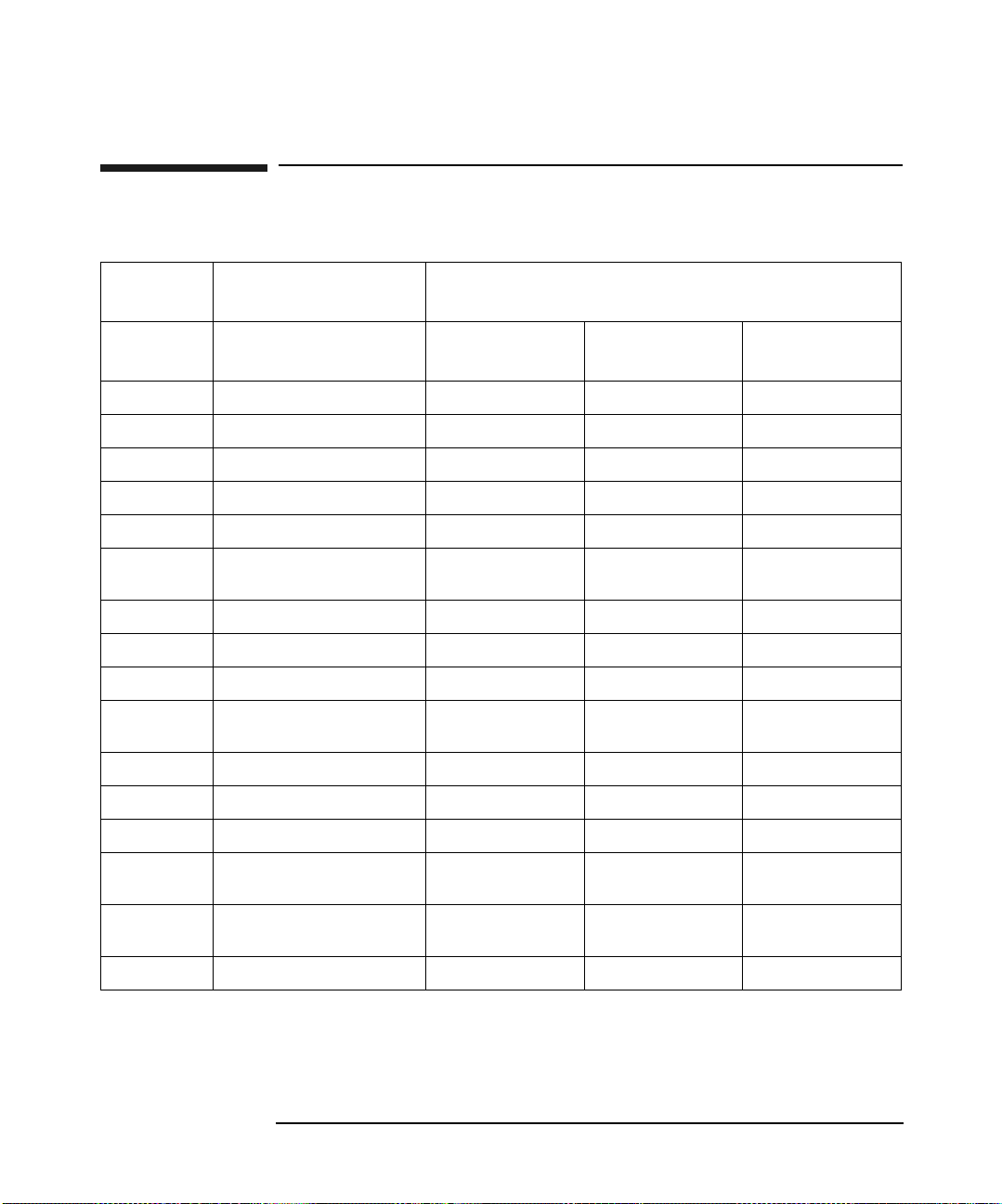

Table B-1 Bulkhead Parts for the 8481A, 8481B, 8482B, and 8482B Models

Reference

Designator

MP1 Connector Nut 5021-7255 - 5021-7255

MP2 Connector Component 1250-0016 - 1250-0016

MP3 Connector Body 1250-2132 1250-1466 1250-2132

MP4 Contact Assembly 1250-0917 1250-0816 1250-0917

MP5 Insulator 5040-0306 5040-0306 5040-0306

MP6 Center Conductor -

MP7 Compression Spring 1460-0977 1460-0977 1460-0977

MP8 Sliding Contact 5020-3297 5020-3297 5020-3297

MP9 Bulkhead 08481-20015 08481-20015 08481-20015

MP10 Flat Washer 2190-0831 or

MP11 Cap Nut 08481-20016 08481-20016 08481-20016

MP12 Polyiron 08481-40006 08481-40006 -

Part Description Sensor Model

8481A

8481B

5020-3296 5020-3296 5020-3296

Cartridge Adapter

3050-0622

8481A

Opt 001

2190-0831 or

3050-0622

8482A

8482B

-

MP13 Protective Cap 1401-0099 1401-0099 1401-0099

MP14 Outer Conductor Spacer 5021-0830 or

08742-0006

MP15 Inner Conductor Spacer 5020-8540 or

08742-0005

A1 Cartridge 08481-60042 08481-60042 08482-60019

5021-0830 or

08742-0006

5020-8540 or

08742-0005

5021-0830 or

08742-0006

5020-8540 or

08742-0005

Appendix B62

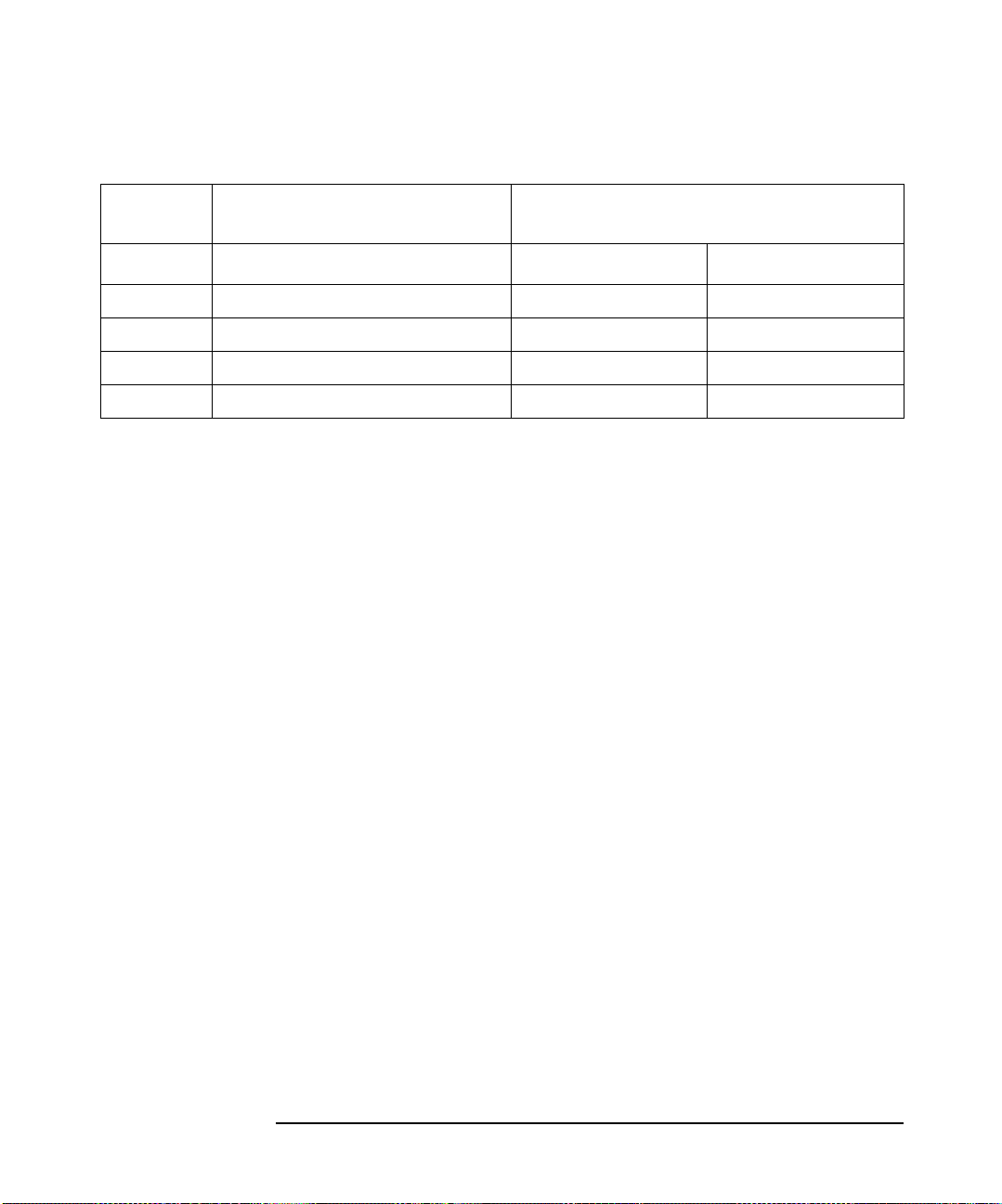

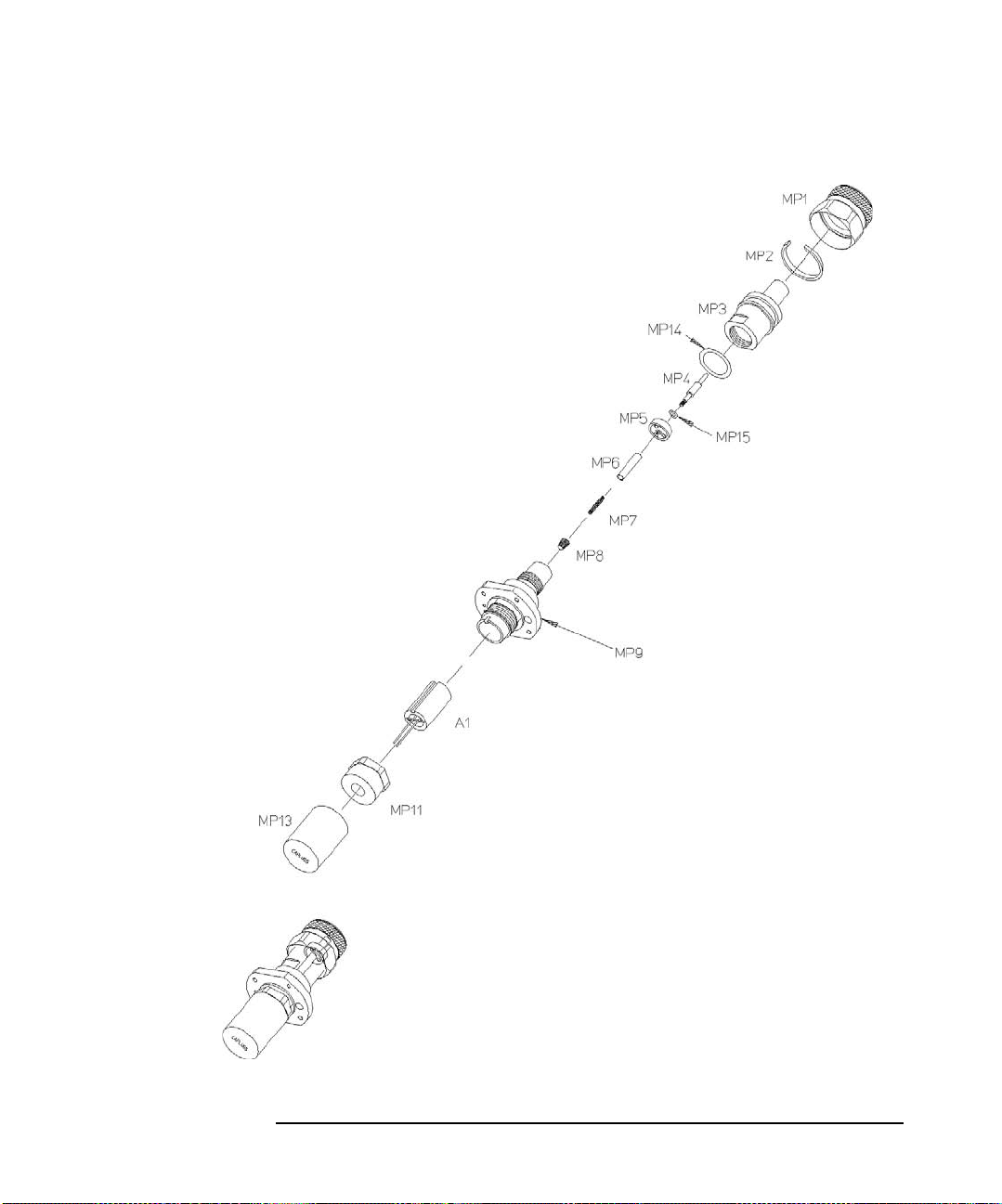

Table B-2 Bulkhead Parts for the 8481D Model

Bulkhead Assemblies

Bulkhead Parts Lists

Reference

Designator

MP1 Connector Nut 5021-7255

MP2 Connector Component 1250-0016

MP3 Connector Body 1250-2132

MP4 Contact Assembly 1250-0917

MP5 Insulator 5040-0306

MP6 Center Conductor - Cartridge Adapter 5020-3296

MP7 Compression Spring 1460-0977

MP8 Sliding Contact 5020-3297

MP9 Adapter Connector 08481-20034

MP10 Center Conductor Contact 08481-20032

MP11 Insulator 5040-0306

MP12 Stepped Center Conductor 08481-20033

MP13 Rear Spacer 08481-20029

MP14 Bellows 0955-0238

Part Description Sensor Model

8481D

MP15 Feed Thru Insulator 08486-40001

MP16 Rear Housing 08481-20028

MP17 Cap Nut 08486 20007

MP18 Compensation Washer 08481-20031

MP19 Outer Conductor Spacer 5021-0830

MP20 Inner Conductor Spacer 5020-8540

MP21 Inner Conductor Spacer 08742-0005

MP22 Outer Conductor Spacer 08742-0006

A1 Cartridge 08481-60041

H1 Flat Washer 2190-0831 or 3050-0622

Appendix B 63

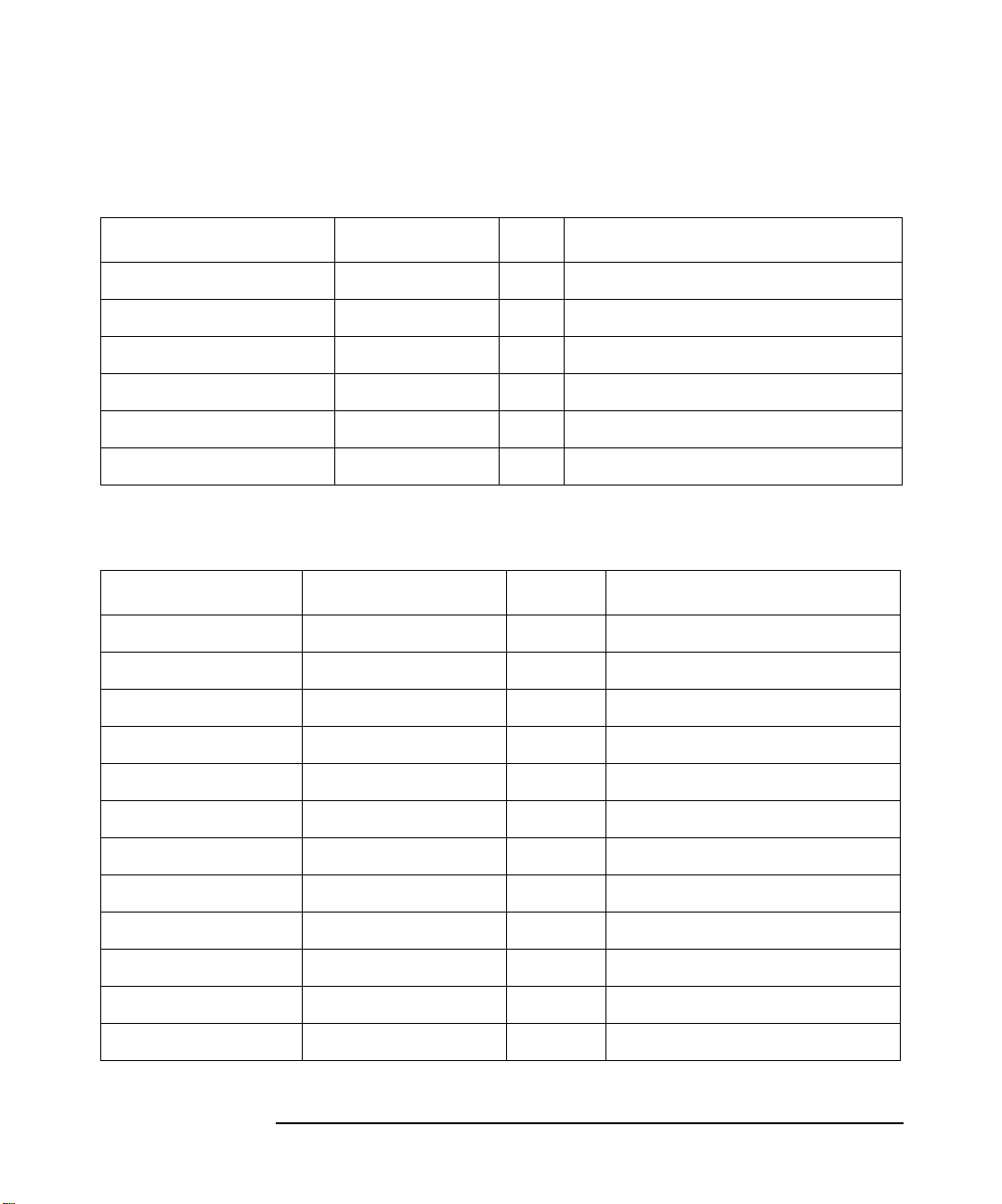

Bulkhead Assemblies

Bulkhead Parts Lists

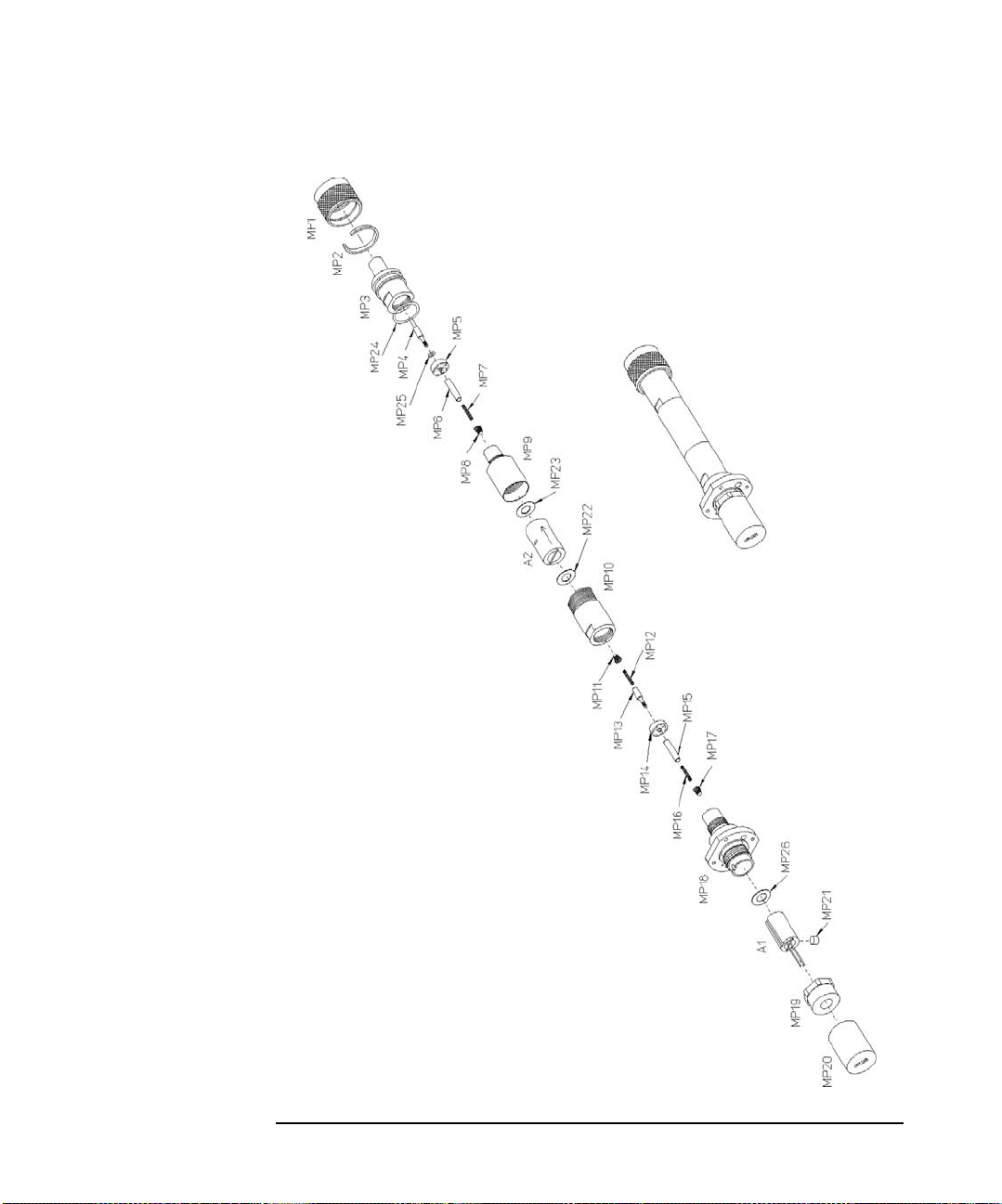

Table B-3 Bulkhead Parts for the 8481H and 8482H Models

Reference

Designator

MP1 Connector Nut 5021-7255 5021-7255

MP2 Connector Component 1250-0016 1250-0016

MP3 Connector Body 1250-2132 1250-2132

MP4 Contact Assembly 1250-0917 1250-0917

MP5 Insulator 5040-0306 5040-0306

MP6 Center Conductor - Cartridge Adapter 5020-3296 5020-3296

MP7 Compression Spring 1460-0977 1460-0977

MP8 Sliding Contact 5020-3297 5020-3297

MP9 Housing 08492-2000 08492-2000

MP10 Attenuator Adapter 5021 0154 5021 0154

MP11 Sliding Contact 5020-3297 5020-3297

MP12 Compression Spring 1460-1547 1460-1547

MP13 Contact Holder 5021-0157 5021-0157

MP14 Insulator 5040-0306 5040-0306

Part Description Sensor Model

8481H 8482H

MP15 Center Conductor - Cartridge Adapter 5020-3296 5020-3296

MP16 Compression Spring 1460-0977 1460-0977

MP17 Sliding Contact 5020-3297 5020-3297

MP18 Bulkhead 08481-20015 08481-20015

MP19 Cap Nut 08481-20016 08481-20016

MP20 Protective Cap 1401-0099 1401-0099

MP21 Polyiron 08481-40006 -

MP22 Flat Washer 3050-0622 3050-0622

MP23 Flat Washer 3050-0622 3050-0622

MP24 Outer Conductor Spacer 5021-0830 or 08742-0006 5021-0830 or 08742-0006

Appendix B64

Table B-3 Bulkhead Parts for the 8481H and 8482H Models

Bulkhead Assemblies

Bulkhead Parts Lists

Reference

Designator

MP25 Inner Conductor Spacer 5020-8540 or 08742-0005 5020-8540 or 08742-0005

MP26 Flat Washer 2190-0831 or 3050-0622 -

A1 Cartridge 08481-60042 08482-60019

A2 Cartridge Assembly 08481-60011 08481-60011

Part Description Sensor Model

8481H 8482H

Appendix B 65

Bulkhead Assemblies

Bulkhead Parts Lists

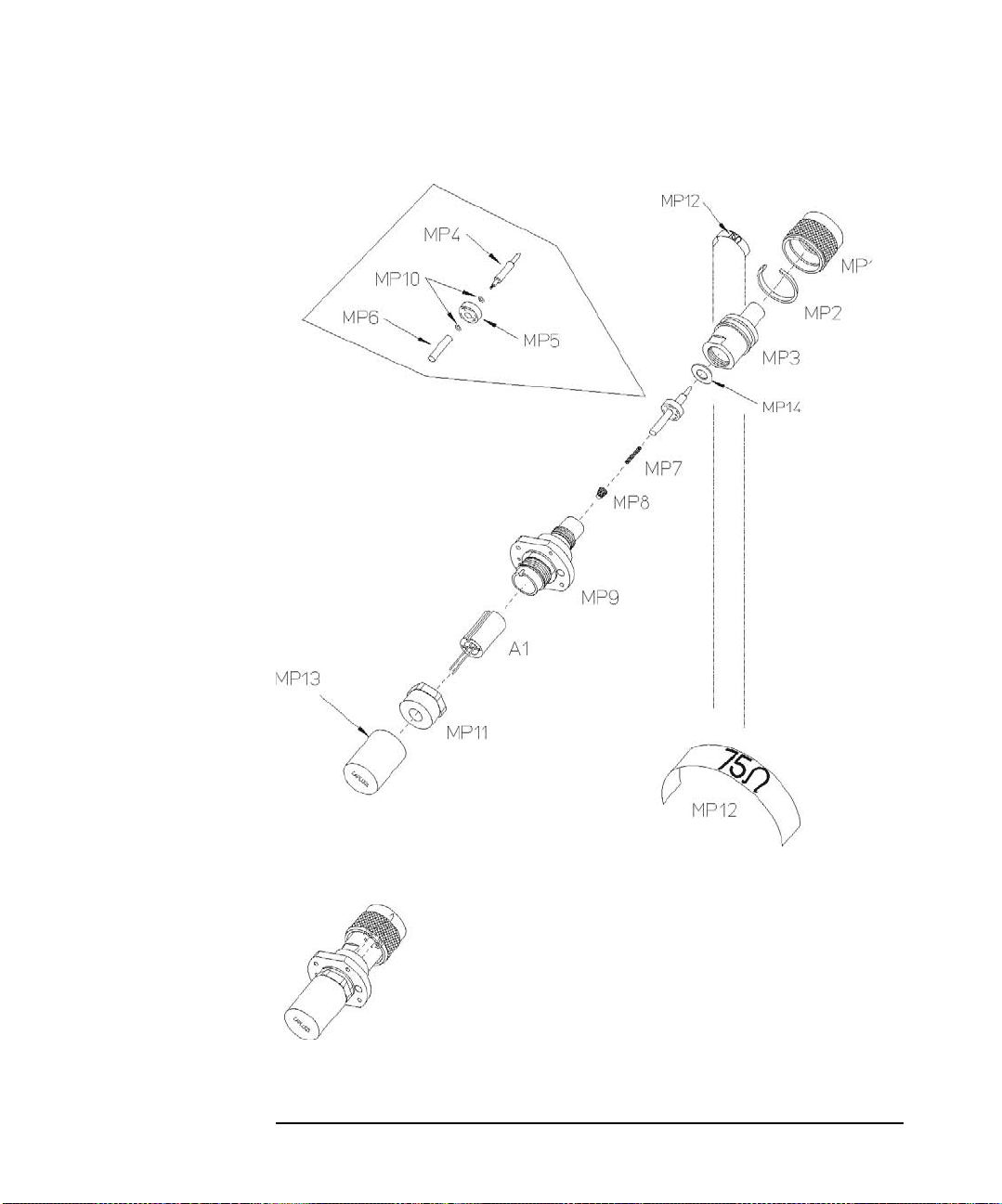

Table B-4 Bulkhead Parts for the 8483A Model

Reference

Designator

MP1 Connector Nut 5021-7255

MP2 Connector Component 1250-0016

MP3 Connector Body 1250-2132

MP4 Center Conductor, 75 Ohm 08483-20003

MP5 Insulator 5020-8593

MP6 Center Contact, 75 Ohm 08483-20002

MP7 Compression Spring 1460-0526

MP8 Sliding Contact 08491-2009

MP9 Bulkhead 08481-20015

MP10 Inner Conductor Spacer 00909-20006

MP11 Cap Nut 08481-20016