Agilent 83491/2/3/4A

Clock Recovery Modules

User’s Guide

© Copyright 2000-2004

Agilent Technologies

All Rights Reserved. Reproduction, adaptation, or translation without prior written

permission is prohibit ed ,

except as allowed under copyright laws.

Agilent Part No. 83491- 90 01 4

Printed in USA

August, 2004

Agilent Technologies

Digital Signal Analysis

1400 Fountaingrove Parkway

Santa Rosa, CA 95403, USA

Notice.

The information contained in

this document is subject to

change without notice. Companies, names, and data used

in examples herein are fictitious unless otherwise noted.

Agilent Technologies makes

no warranty of any kind with

regard to this material, including but not limited to, the

implied warranties of merchantability and fitness for a

particular purpose. Agilent

Technologies shall not be liable for errors contained herein

or for incidental or consequential damages in connection with the furnishing,

performance, or use of this

material.

Restricte d Ri ghts Legend.

Use, duplication, or disclosure by the U.S. Government

is subject to res tric tion s as se t

forth in subparagraph (c) (1)

(ii) of the Rights in Technical

Data and Computer Software

clause at DFARS 252.227-7013

for DOD agencies, and subparagraphs (c) ( 1) and (c) (2 )

of the Commercial Computer

Software Restricted Rights

clause at FAR 52.227-19 for

other agencies.

Safety Symbols.

CAUTION

The caution sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in damage to

or destruction of the product.

Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

WARNING

The warning sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in injury or

loss of life. Do not proceed

beyond a warning sign until

the indicated conditions are

fully understood and met.

The instruction manual symbol. The product is marked with this

warning symbol when

it is necessary for the

user to refer to the

instructions in the

manual.

The laser radiation

symbol. This warning

symbol is marked on

products which have a

laser output.

The AC symbol is used

to indicate the

required nature of the

line module input

power.

| The ON symbols are

used to mark the positions of the instrument

power line switch.

❍ The OFF symbols

are used to mark the

positions of the instrument power line

switch.

The CE mark is a registered trademark of

the European Community.

The CSA mark is a registered trademark of

the Canadian Standards Association.

The C-Tick mark is a

registered trademark

of the Australian Spectrum Management

Agency.

This text denotes the

ISM1-A

instrument is an

Industrial Scientific

and Medical Group 1

Class A product.

ii

Contents

1 Getting Started

Introduction 1-2

General Safety Considerations 1-4

Installation 1-5

Returning the Instrument for Service 1-12

2Operation

Introduction 2-2

Front-Panel Features 2-3

Block Diagrams 2-6

To Display a S ignal 2-9

To Compensate for Module Insertion Loss 2-10

Using Probes with an 83491A 2-11

3 Reference

Front-Panel Optical Adapters 3-2

In Case of Difficulty 3-3

Error Messages 3-5

Electrostatic Discharge Infor m ati o n 3-7

Cleaning Connections for Accurate Measurements 3-9

4 Specifications and Regulatory Information

83491A Specifications 4-3

83492A Specifications 4-4

83493A Specifications 4-6

83494A Specifications 4-8

83491/2/3/4A Operating Specifications 4-10

Regulatory Information 4-11

Contents-1

1

Introduction 1-2

General Safety Consider ations 1-4

Installation 1-5

Step 1. Inspect the shipment 1-5

Step 2. Install th e module 1-7

Step 3. Connect the front-panel cables 1-8

Step 4. Connect a modulated signal 1-10

Returning the Instrument for Service 1-12

Contacting Agilen t Technologies 1-12

Getting Started

Getting Started

Introduction

Introduction

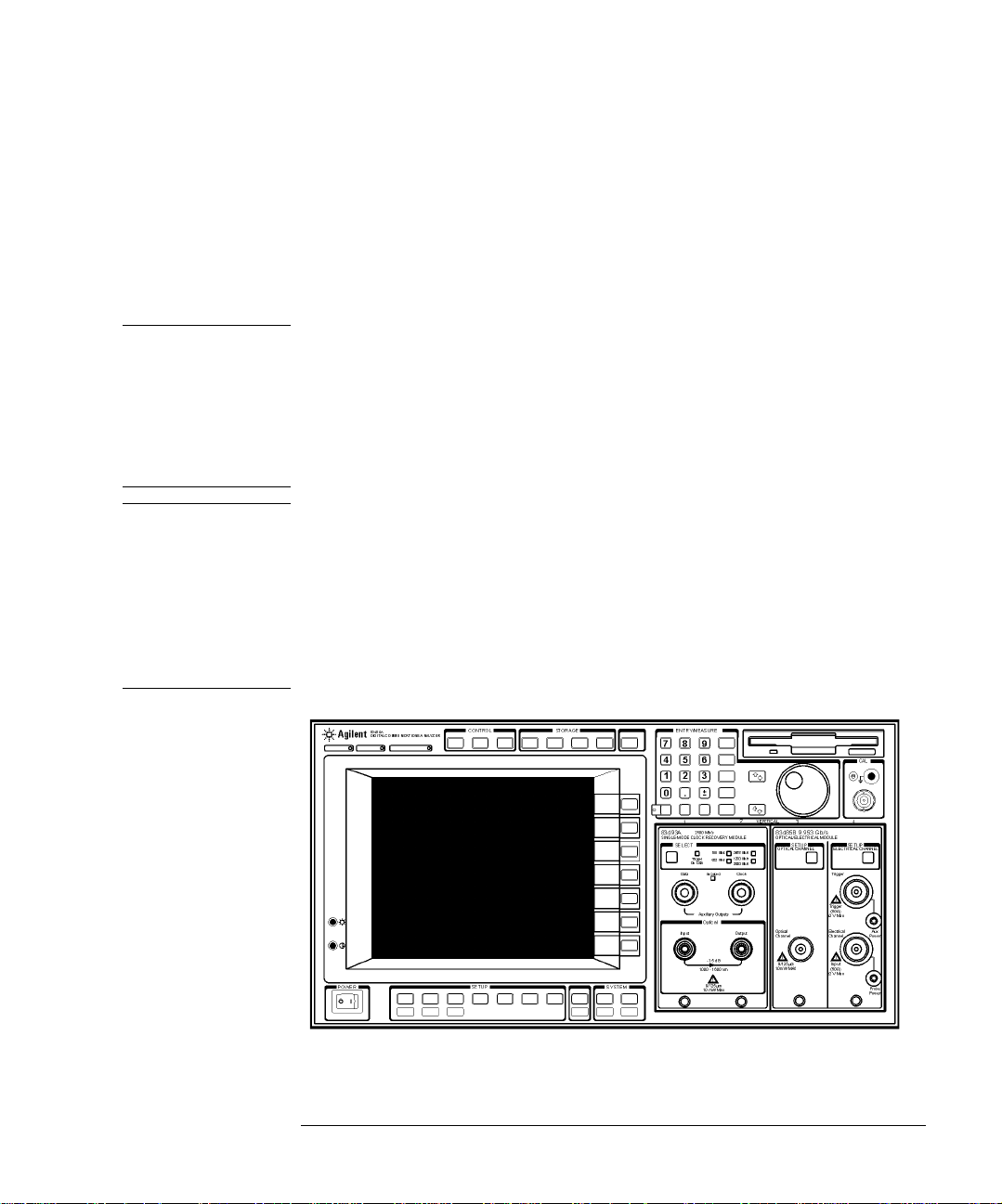

Agilent 83491/2/3/4A clock recovery modules are designed to operate in

86100-series infiniium Digital Communications Analyzers (DCA) and 83480A

DCAs. These modules recover clock and data information at standard telecom

and datacom rates. The resulting trigger signal is made available to the DCA

mainframe via a connector located on the module’s rear-panel. An external

front-pane l cable passes the data signal, with some insertion loss, to the

receiver modu le .

Table 1-1.Module Features

Agilent Module Input Connector Selectable Rates (Mb/s)

83491A

83492A

83493A

83494A

83494A Option 106

83494A Option 107

50

Ω electrical

Multimode fiber (62.5/125

Single-mode fiber (9/125

Single-mode fiber (9/125

Single-mode fiber (9/125

Single-mode fiber (9/125

µm)

µm)

µm)

µm)

155, 622, 1060, 1250, 2120, 2488, 2500

155, 622, 1060, 1250, 2120, 2488, 2500

µm)

155, 622, 1250, 2488, 2500

155, 622, 2488, 9953

155, 622, 2488, 2666, 10664

155, 622, 2488, 2666, 10709

WARNI NG Light energy can radiate from the front panel OUTPUT connectors on

83492A, 83493A, and 83494A modules. The light emitted from these

connectors is the slightly attenuated ligh t that is input to the frontpanel INPUT connector.

Online Help On 86100-series infiniium D C As, after installing the module as show n in this

chapter, you’ll find all user documentation (except programming) is located in

the instrument’s Help system. To access the Help system , complete th e installation steps, turn on the 86100C, and click Contents on the Help menu.

1-2

Getting Started

Introduction

83494A Auxiliary

Clock Output

The 83494A module’s front-panel auxiliary clock output provides the recovered clock signal, refer to “Auxiliary outpu ts” on page 2-4. To recover the

clock at data rates greater than 2.5 Gb/s, the DCA mainframe must have one of

the following trigger options installed:

• 86100C Option 001, Enhanced Trigger

• 86100A/B Option 001, Divided Trigger

• 83480A Option 100, Divided Tri g ge r

CAUTION Fiber-optic connectors are easily damaged when connected to dirty or

damaged cables and accessories. The 83492A, 83493A, and 83494A front-panel

input connectors are no exce pti o n. Whe n you use improper cleaning and

handling techniques , y o u ri sk expensive instrume nt repairs, damaged cables,

and compromised measurements. Before you connect any fiber-optic cable to

an 83492A, 83493A, or 83494A modu le, re fe r to “Cleaning Connec tions for

Accurate Measurements” on page 3-9.

CAUTION The circuits on electrical inputs and outputs can be dama g ed by electrostatic

discharge (ESD). Therefore, avoid applying static discharges to any front or

rear-panel electrical connector. Before connecting any coaxial cable to a frontpanel connector, momentarily short the center and outer conductors of the

cable together. Avoid touching the front-panel connectors without first

touching the frame of the instrument. Be sure that the instrument is properly

earth-grounded to prevent buildup of static charge. Refer to “Electros tatic

Discharge Information” on page 3-7.

Figure 1-1. An Agilent 83493A installed in an Agilent83480A mainframe

1-3

Getting Started

General Safety Considera tions

General Safety Considerations

This product has been designed and tested in accordance with the standards

listed on the Manufacturer's Declaration of Conformity, and has been supplied

in a safe condition. The documentation contains information and warni ng s

that must be followed by the user to ensure safe operation and to maintain the

product in a safe condition.

The 83491/2/3/4A modules work only with Agilent digital communication analyzer mainfram es. Refer to the mainframe documentation to ensure safe operation.

WARNI NG Light energy can radiate from the front panel OUTPUT connectors on

83492A, 83493A, and 83494A modules. The light emitted from these

connectors is the slightly attenuated ligh t that is input to the frontpanel INPUT connector.

WARNI NG If this instrument is not used as specified, the protection provided by

the equipment could be impaired. This instrument must be used in a

normal condition (in w hich all means for protection are intact) only.

WARNI NG To prevent electrical shock, disconnect the main frame from mains

before cleaning. Use a dry cloth or one slightly dampened with water

to clean the external case part s. Do not attempt to clean internally.

WARNI NG No operator serviceable parts inside. Refer servicing to qualified

personnel. To prevent electrical shock, do not remove covers.

CAUTION This product i s designed for use in In st allation Category II and Pollutio n

Degree 2 per IEC 10 10 and 664 re s pectively.

CAUTION Electrostatic discharge (ESD) on or near input connectors can damage circuits

inside the instrument. Repair of damage due to misuse is not covered under

warranty. Before connecting any cable to the electrical input, momentarily

short the center and outer conductors of the cable together. Personnel should

be properly grounded, and should touch the frame of the instrument before

touching any connector.

1-4

Getting Started

Installation

Installation

Although some of the figures in the following procedure show an 83480A DCA

mainframe, the procedures equal ly ap ply to installing th e m odule into an

86100-series DCA mainframe.

NOTE If an 83491/2/3/4A module is installed in an 83480A DCA , the DCA s fi rm war e

revision must be A.06.25 or later. If the module is installed in an Agilent 54750A

digitizing oscilloscope, you must first install the Agilent 83480K

communications firmware upgrade kit. To check the Agilent 83480A’ s firmware

revision code, pr ess the Utility key and then the System config softkey. The

firmware revision number is listed under the Frame sec tion of the display.

Step 1. Inspect the shipment

❒ Inspect the shipping container and instrument for damage. Keep the shipping

container and cushioning material until you have inspected the contents of the

shipment for completeness and have checked the instrument mechanically and

electrically.

❒ Locate the shipping list. Verify that you received all the accessories on this list,

and all the options that you ordered. Table 1-2 on page 1-6 shows the external

front-panel cables that are supplied for each module.

❒ Make sure that the serial number listed on the module’s rear-panel label match-

es the serial numbe r listed on the shipping document.

If your shipment is da m a g ed or incomplete, sav e the packing materi a ls and

notify both the shipping carrier and the ne a re st Agilent Technologies service

office. Agilent Technologies will arrange for repair or replacement of damaged

or incomplete shipments without waiting for a settlement from the transportation company. Notify the Agilent Technologies customer engin eer of any problems.

1-5

Getting Started

Installation

Table 1-2.Supplied External Front-Panel Cables

Supplied Cable

a

Agilent Part Number

83491A

RF cable, SMA-SMA, 9.75 cm 83491-20001

RF cable, SMA-SMA, 15.2 cm 83491-20002

83492A

Fiber-optic cable (semi-rigid), multimode, 14 cm 83492-20001

Fiber-optic cable (semi-rigid), multimode, 18.5 cm 83492-20002

83493A

Fiber-optic cable (semi-rigid), single-mode, 14 cm 83493-20001

83494A

Fiber-optic cable (semi-rigid), single-mode, 14 cm 83493-20001

a. Refer to “Step 3. Connect the front-panel cables” on page1-8 for the use of these c ables.

1-6

Getting Started

Installation

Step 2. Install the module

Up to two modules can be inserted into the 86100-series or 83480A DCA mainframe.

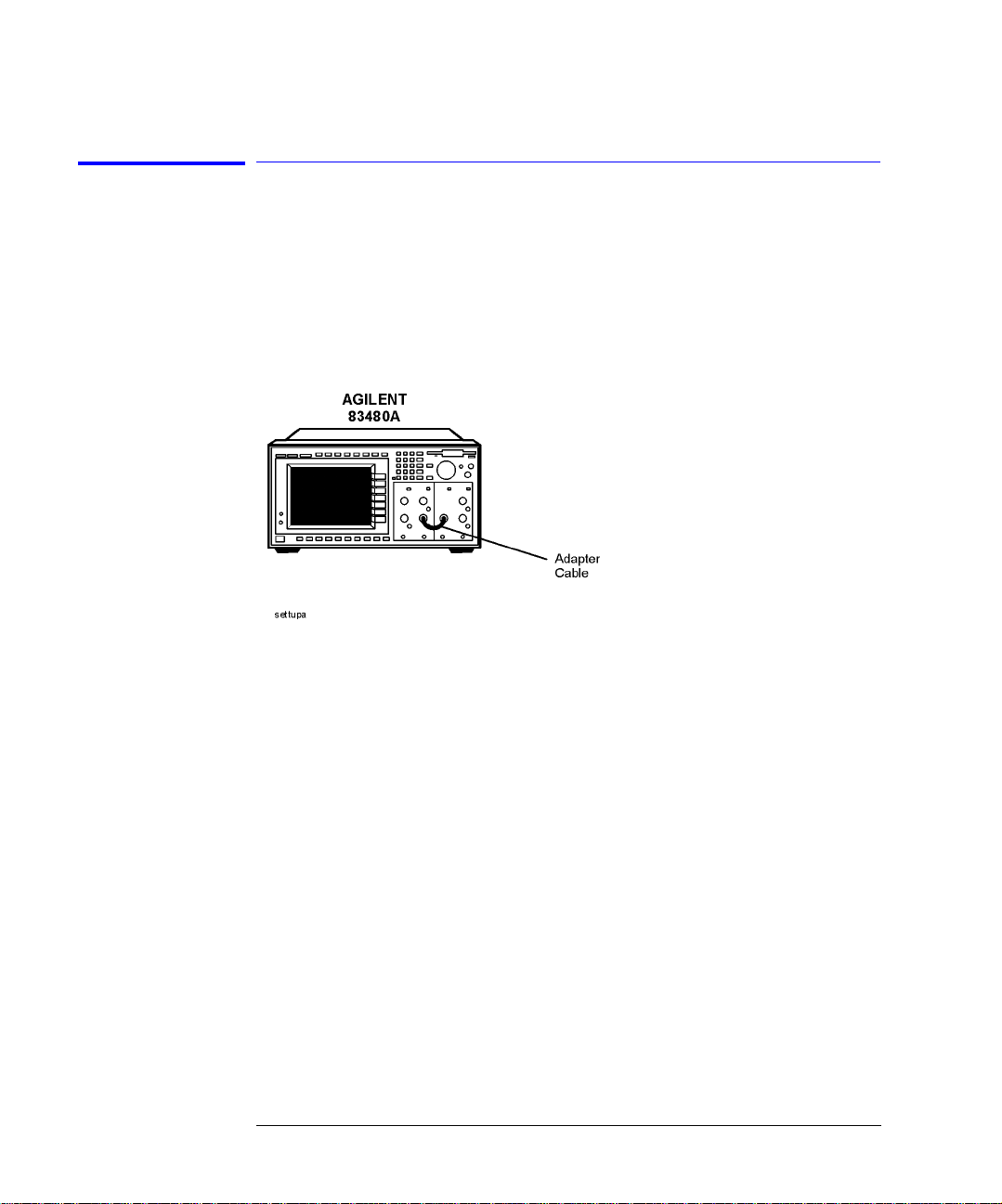

1 Install the 83491/2/3/4A module into the left slot on the mainframe. Install in g

the module into the left slot ensures that the supplied adapter cable will fit.

Finger-tighten the knur le d screw on the front panel of the plu g-in module to

ensure that the module is securely seated in the main f ra me.

Figure 1-2. Position of modules in the mainframe

2 Clean all optical interfaces as described in “Cleaning Connections for Accurate

Measurements” on page 3-9, before making measurements.

1-7

Getting Started

Installation

Step 3. Connect the front-panel cables

83491A Module Perform this step if you are installing an 83491A m odul e .

❒ Use the RF cable suppl ied with the module to conn ec t the Electrical Output

connector on the 83 491A to the input on the a dja cent measurement module.

Use the short (83491-20001) or long (83491-20002) cable depending on the location of the input on the adjacent measurement module.

Figure 1-3. The adapter cable

83493/4A Modules Perform the following steps if you are installing an 83493/4A module.

1 Because you’ll connect an FC-PC fiber-optic cable in this procedure, confirm

that the receiver module’s optical input connector has an FC-PC adapter.

Fiber-optic adapters can be removed by hand turning them in the counter-

clockwise direction. Refer to “Front-Panel Optical Adapters” on page 3-2 for a

description of available adapters.

2 If you changed the adapter in step one, you can connect the original adapter to

the 83493/4A module’s front-panel In put connector.

3 Use the FC-PC semi-rigid fiber-optic cable suppl ie d wi th the 83493/4 module

(83493-20001) to connect the Optical Output connector on the 83493/4A to the

input on the receiver module.

83492A Module Perform the following steps if you are instal ling an 83492A module.

1-8

Getting Started

Installation

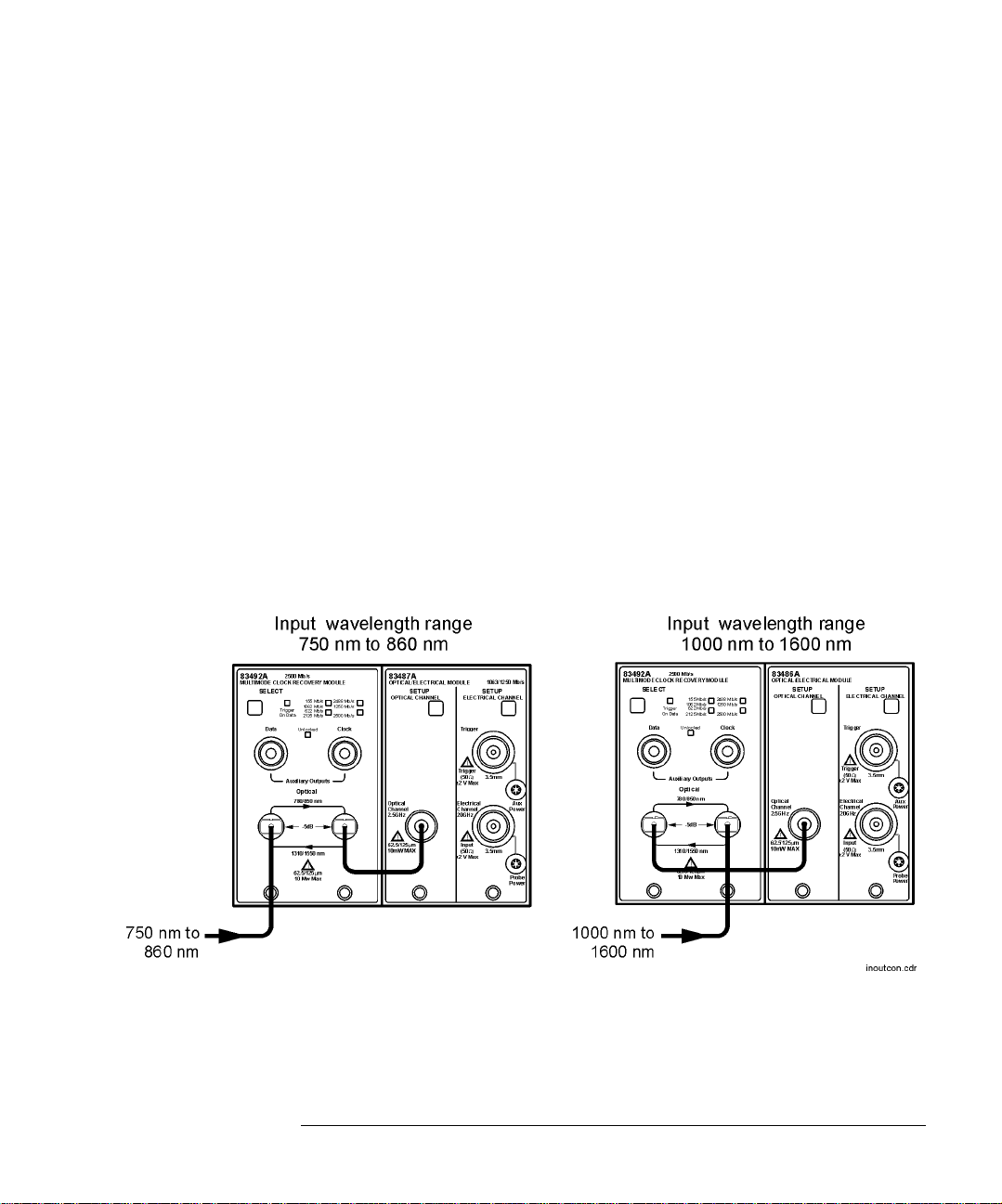

On 83492A modules, the front-panel fiber-optic connectors reverse input and

output roles depending on the wavelength of the signal. This is shown in

Figure 1-4. Signals in the 750 nm to 860 nm wavelength range are input to the

left connector and output fr om the rig ht connector. Signals in the 1000 nm to

1600 nm wavelength range are input to the ri g ht connector and output from

the left connector.

1 Because you’ll connect an FC-PC fiber-optic cable in this procedure, confirm

that the receiver module’s optical input connector has an FC-PC adapter.

Fiber-optic adapters can be removed by hand turning them in the counter-

clockwise direction. Refer to “Front-Panel Optical Adapters” on page 3-2 for a

description of available adapters.

2 If you changed the adapter in step one, you can connect the original adapter to

the 83493/4A module’s front-panel input connector. See Figure 1-3 to identify

the input connector based on input wavelength.

3 Connect the supplied adapter cable as shown in Figure 1-3. Use the short cable

(83492-20002) when operating at 750 nm to 860 nm wavelengths. Use the long

cable (83492-20001) when operating at 1000 nm to 1600 nm wavelengths.

Figure 1-4. Input and output connections versus wavel ength

1-9

Getting Started

Installation

Step 4. Connect a modulated signal

WARNI NG Light energy can radiate from the front panel OUTPUT connectors on

83492A, 83493A, and 83494A modules. The light emitted from these

connectors is the slightly attenuated ligh t that is input to the frontpanel INPUT connector.

CAUTION 83491A Modules: T o prevent damage to the module, the maximum safe signal

input level is < ±5V. The input circuits can also be damaged by electrostatic

discharge (ESD). Before connecting any coaxial cable to the connectors,

momentarily short the center and outer conductors of the cable together. A void

touching the front-pa ne l input connectors without fir st touching the frame of

the instrument. Be su re that the instrument is p ro p erly earth-grounded to

prevent buildup of static charge.

CAUTION 83492/3/4A Modules: To prevent damage to the module, th e maximum signal

input level is < +3 dBm.

1 Turn on the mainframe and connect a modulated signal to the 83491/2/3/4A

module’s Input connect or.

2 If you are using an 83480A DCA, press the Trigger key and then the Source

softkey. Then, select trigger 2 (the 83491/2/3/4A module) for the trigger source.

3 On the 83491/2/3/4A module, re pe ate dl y press the SELECT key until a front-

panel light indicates the data rate of the signal. Avoid selecting a data rate that

is a multiple of the input signal. For example, don’t select a 622 Mb/s data rate

if the signal is really at 155 Mb/s.

4 Confirm that the Unlocked light is off. If using the 83494A, confirm that the

Trigger Loss light is off. If the UNLOCKED light is on (or TRIGGER LOSS light on the

83494A), clock recovery cannot be establis hed on the signal.

5 Observe the Clock and Data outputs on DCA. Waveforms should be present. The

instrument is now ready for you to begin making measurements. If you cannot

get the clock recovery module to lock on the signal, make sure th at yo u have

selected the correct data rate and that the mainframe trigger level is adjusted

appropriately.

Signals displayed using a data trigger are less reliable than using a recovered

clock. Signals triggered on data can also vary depending upon the trigger level.

1-10

Getting Started

Installation

Green and red data-rate lights

The data-rate indicator lights on the Agilent 83491/2/3A and Agilent 83494A Option 106

change color between red and green to show which data rate is selected. A red light

does not indicate a problem. A red light shows that the adjacent red data rate label is

selected. A green light shows that the adjacent green data rate label is selected.

Repeatedly pressing the SELECT key cycles through the selections in one color before

switching to the opposite color. On Agilent83491A modules for example, the first selection cycle shows 155 Mb/s selected. The second selection cycle shows 1062 Mb/s

selected.

Agilent 83494A modules use only the green data-rate indicator light to show which data

rate is selected. Repeatedly pressing the SELECT key cycles through the available data

rates, as well as the Trigger On Data bypass mode.

Figure 1-5. Front-panel lights

1-11

Getting Started

Returning the Instrument for Servi ce

Returning the Instrument for Service

The instructions in this section show you how to properly return the instrument for repair or calibration. Always call the Agilent Technologies Instrument

Call Center fir st to initiate serv ic e before returning your instrument to a service office. This ensures that the repair (or calibrati on) can be properly

tracked and that your instrument will be returned to you as quickly as possible. Call this number regardless of where you are located.

If the instrument is still unde r warranty or is covered by an Agilen t Technologies maintenance contract, it will be repaired under the terms of the warranty

or contract (the warranty is at the front of this manual). If the instrument is

no longer under warranty or is not covered by an Agilent Technologies maintenance plan, Agilent Technologies will notify you of the cost of the repair after

examining the unit.

When an instrument is returned to a Agilent Technologies service office for

servicing, it must be adequately packaged and have a complete des cri pti on of

the failure sympt o m s a ttached. When describing the failure, please be as sp ecific as possible about the nature of the problem. Include copies of additional

failure information (such as the instrument failure settings, data related to

instrument failure, and error messages) along with the instrument being

returned.

Contacting Agilent Technologies

Call Center For technical assistance, you can contact your local Agilent Call Center.

• In the Americas, call 1 (800) 829-4444

• In other regions, visit http://www.agilent .co m/fin d/assist

Service Center Before returning an instrument for service, you must first call the Agilent

Technologies Instrument Support Center.

• In all regions, call (800) 829-4444

1-12

Getting Started

Returning the Instrument for Service

Preparing the module for shipping

1 Write a complete description of the failure and attach it to the instrument.

Include any specific performance details related to the problem. The following

information should be returned with the instrument.

• Type of ser v ice required.

• Date instrument was returned for repair.

• Description of the problem:

• Whether problem is constant or intermittent.

• Whether instrument is temperature-sensitive.

• Wheth er instrument is vibr a tion-sensitive.

• Instrument settings require d to reproduce the problem.

• Performance data.

• Company name and return address.

• Name and phone number of technical contact perso n.

• Model number of returned instrument.

• Full serial number of returned instrument.

• List of any accessories returned with instrument.

2 Cover all front or rear-panel connectors that were originally covered when you

first received the instrument.

CAUTION Cover electrical connectors to protect sensitive components from electrostatic

damage. Cover optical connectors to protect them from damage due to physical

contact or dust.

CAUTION Instrument damage can result from using packaging materials other than the

original materials. Never use styrene pellets as packaging material. They do not

adequately cus hion the instrument or prevent it from shift ing in the carton.

They may also cause instrument damage by generating static electricity.

3 Pack the instrument in the original shipping containers. Original materials are

available through any Agilent Technologies office. Or, use the following

guidelines:

• Wrap the instrument in antistatic plastic to reduce the possibility of damage

caused by electrostatic discharge.

• For instruments weighing less than 54 kg (120 lb), use a double-walled, cor-

rugated cardboard carton of 159 kg (350 lb) test strength.

• The carton must be large enough to allow approximately 7 cm (3 inches) on

1-13

Getting Started

Returning the Instrument for Servi ce

all sides of the instrument for packing material, and strong enough to accommodate the weight of the instrument.

• Surround the equipment with approximately 7 cm (3 inches) of packing material, to protect the instrument and prevent it from moving in the carton. If

packing foam is not available, the best alternative is S.D-240 Air Cap™ from

Sealed Air Corporation (Commerce, Califor nia 900 01). Air Cap look s like a

plastic sheet filled with air bubbl es . U se the pink (antistati c ) Air Cap™ to

reduce static ele ctricity. Wrapping the instrument sev eral times in this material will protect the instrument and prevent it from moving in the carton.

4 Seal the carton with strong nylon adhesive tape.

5 Mark the carton “FRAGILE, HANDLE WITH CARE”.

6 Retain copies of all shipping papers.

1-14

2

Introduction 2-2

Front-Panel Features 2-3

Block Diagra m s 2-6

To Display a S ignal 2-9

To Compensate for Module Insertion Loss 2-10

Using Probes with an 83491A 2-11

Operation

Operation

Introduction

Introduction

If you use an 83491/2/3/4A module in an 861 00- se ri e s inf in ii um DC A , information on using the clock recovery modules, along with specifi cati ons , is

included in the instrument’s help system. To acce ss the built-in infor matio n

system, referred to as Help, simply click Contents on the Help menu. GPIB

programming commands for the mo dule s are documented in the 86100-serie s

infiniium DCA p ro grammer’s guide.

If you use an 83491/2/3/4A module in an 83480A DCA, you’ll notice that, unlike

most modules designed to be used with the 834 80A, the clock recovery modules do not include Channel keys or menus. Also, there are no GPIB programming commands for these modu les when used in an 83480A mainframe.

Multimode module and single-mode reference receivers

Agilent Technologies does not recommend using the Agilent 83492A mul ti mode module with si ng le-mode referenc e re c eivers such as the

Agilent 83481A, 83482A, or 83485A,B modules. Connecti ng multi m ode to single-mode fibers cau ses large reflection s a nd insertion loss because of the

reduction of the optical fiber’s core from 62.5 µm to 9 µm.

Single-mode module and multimode reference receivers

It is acceptable to use an Agilent 834 93A or an 83494A si ng le-mo de module

with a multimode reference receiver such as the Agilent 83486A module. This

is true provided that single- m ode fiber is con nected to the Agilent 83493A or

83494A module’s front-panel INPUT connector.

2-2

Front-Panel Features

Operation

Front-Panel Features

Figure 2-1. Agilent 83491/2/3/4A front panels

2-3

Operation

Front-Panel Fe atures

SELECT key Pressing this key changes the data rate selection. The recovered and retimed

clock trigger is sent to the mainframe. The Trigger On Data selection is a bypass

mode where the data stream directly triggers the mainframe. Refer to “Blo c k

Diagrams” on page 2- 6 to view a schematic of the normal and bypass paths.

Green and red data-rate lights

The data-rate indicator lights on the Agilent 83491/2/3A and Agilent83494A Option 106

change color between red and green to show which data rate is selected. A red light

does not indicate a problem. A red light shows that the adjacent red data rate label is

selected. A green light shows that the adjacent green data rate label is selected.

Repeatedly pressing the SELECT key cycles through the selections in one color before

switching to the opposite color. On Agilent83491A modules for example, the first selection cycle shows 155 Mb/s selected. The second selection cycle shows 1062 Mb/s

selected.

Agilent 83494A modules use only the green data-rate indicator light to show which data

rate is selected. Repeatedly pressing the SELECT key cycles through the available data

rates, as well as the Trigger On Data bypass mode.

UNLOCKED

indicator

83491/2/3A

This light shows when clock recovery cannot be established on the signal. If a

clock rate is selected, the trigger output to the mainfram e is disabled to prevent free-run triggering . Howe ver in bypass mode (Trigger On Data selected),

triggering is not disabled. When the UNLOCKED light is on, you can establish a

trigger on the data inpu t to the reference receiver.

Trigger Loss

indicator

83494A

This light shows when clock recovery cannot be established on the signal. If a

clock rate is selected, the trigger output to the mainfram e is disabled to prevent free-run triggering . Howe ver in bypass mode (Trigger On Data selected),

triggering is not disabled. When the Trigger Loss light is on, you can estab lish a

trigger on the data inpu t to the reference receiver.

Auxiliary outputs DATA connector: This co nnector provides a fully regenerated ver sion of the

input signal. It is intended for monitoring purposes only and not for rigorous

eye mask compl iance tes ting. Th e frequenc y respons e does no t confo rm to the

requirements for eye mask testing as described in ITU-T G.957 and Bellcore

GR-253-CORE. On Agilent 83492A and 83493A modules, this port is amplitude stabilized fo r input signals greate r than approximatel y –23 dBm. On

Agilent 83494A modules, this port is amplitude stabilized for input signals

greater than approximately –10 dBm.

2-4

Operation

Front-Panel Features

CLOCK connector: This connector provides the recovered clock signal. You can

use this signal to measure jitter transfer, because this output can track and follow input data with very fast jitter; it has a wide bandwidth jitter transfer function when compared to the recovered clock signal which is routed through a

rear-panel conne ctor to the mainframe for triggering. Note that the CLOCK Aux-

iliary Output remains synchronized to input signals several dB below the onset of

errors at the DATA Auxiliary Output.

Input and Output

connectors

The input connectors pass the digitally modulated signal to the receiver module. The input signal, slightly attenuated and available at the OUTPUT connector, is connected to the input of the receiver module. The connectors on

optical modules include adapters which can e asily be chang e d to mat ch the

type of connectors that are used on your fiber-optic cables. Refer to “Fr ont-

Panel Optical Adapters” on page 3 -2 for a description of the available adapt-

ers.

Multimode and single-mode connections

Agilent 83492A modules use multimode fiber. Connecting the output to the Optical

INPUT connector on Agilent 83481/2/5 single-mode modules results in large reflections

and insertion loss.

Agilent 83493A and 83494A modules use 9/125 µm single-mode fiber. Connecting multimode fiber to the Optical Input connector results in large reflections and insertion loss.

Recovered Clock The recovered clock signal is routed directly to the 86100-series or 83480A

mainframes through the module’s rear panel. This output has a lower jitter

modulation bandwidth than the front-panel CLOCK Auxiliary Output. Because of

the reduced jitter modulation bandwidth on the mainframe trigger signal, a

more complete view of the jitter on the waveform data is obtained.

2-5

Operation

Block Diagrams

Block Diagrams

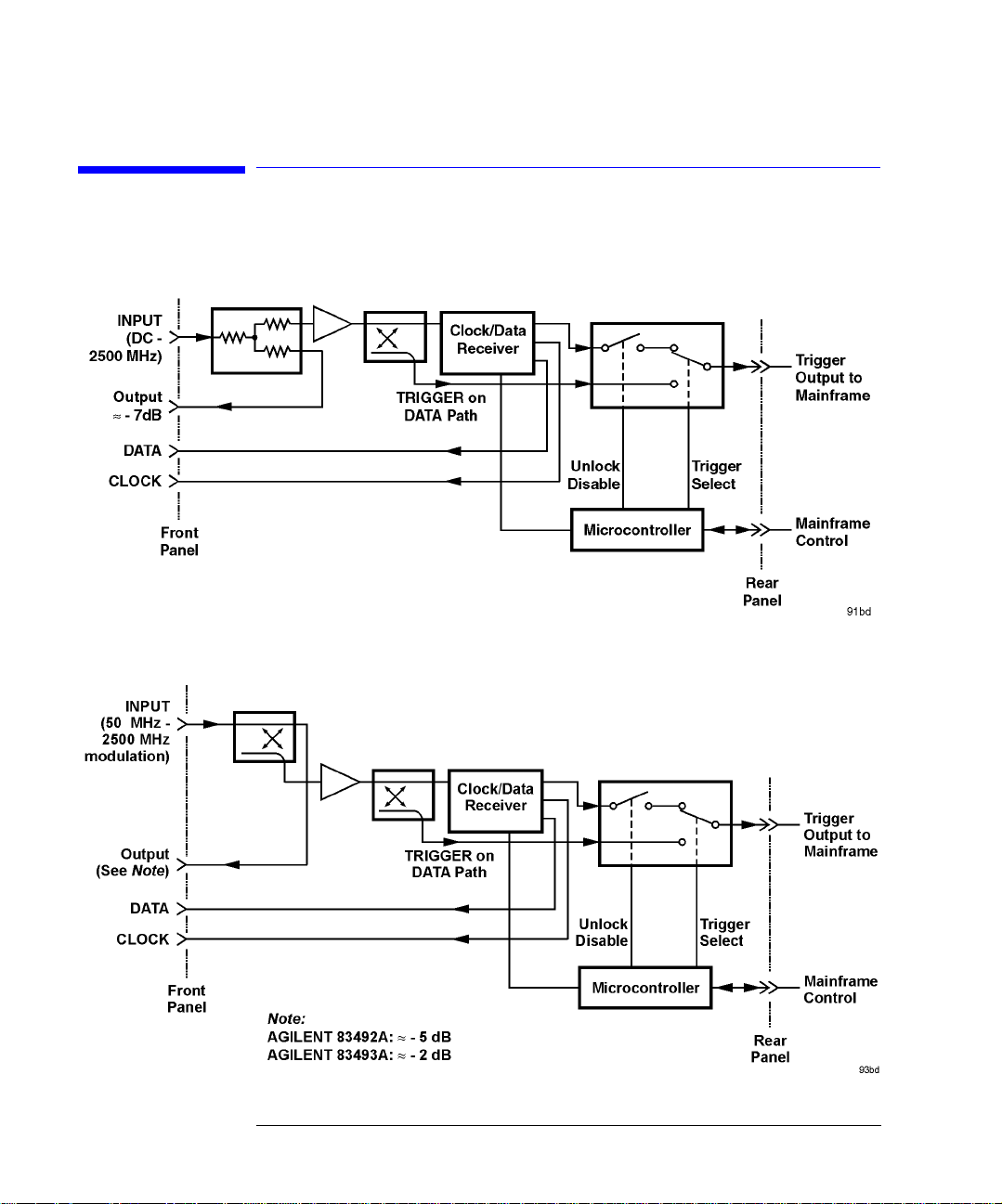

Figure 2-2. 83491A Block Diagram

Figure 2-3. 83492A and 83493A Block Diagram

2-6

Operation

Block Diagrams

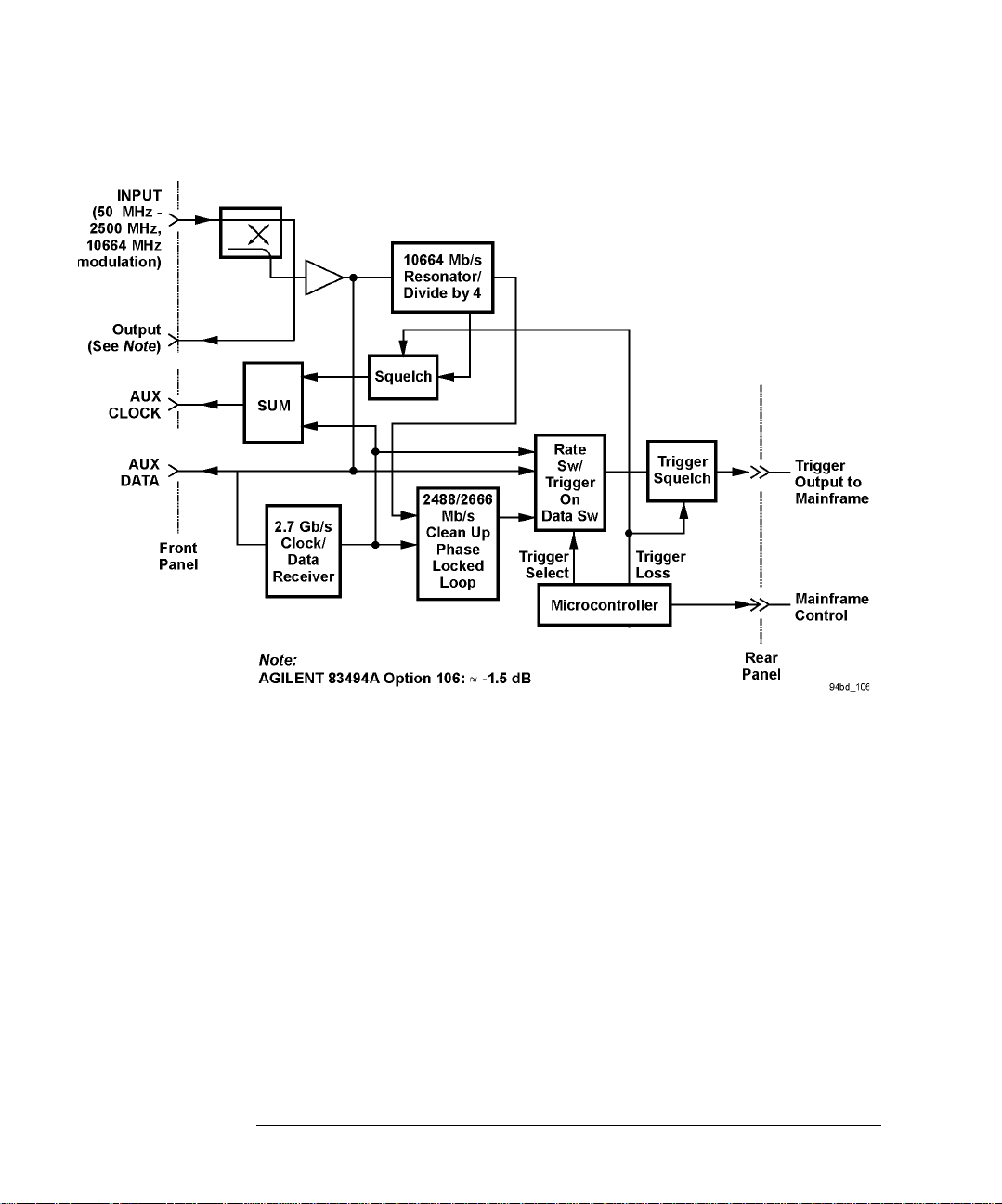

Figure 2-4. 83494A Block Diagram

2-7

Operation

Block Diagrams

Figure 2-5. 83494A Option 106 Block Diagram

2-8

Operation

T o Display a Signal

To Display a Signal

1 Install the module as described in “Installation” on page 1-5. Be sure to connect

all of the cables as described in the procedure.

2 Repeatedly press the SELECT key on the clock reco v ery module until the front-

panel light indicates the proper data rate of the signal.

Green and red data-rate lights

The data-rate indicator lights on the 83491/2/3A and 83494A Option 106 change color

between red and green to show which data rate is selected. A red light does not indicate

a problem. A red light shows that the adjacent red data rate label is selected. A green

light shows that the adjacent green data rate label is selected. Repeatedly pressing the

SELECT key cycles through the selections in one color before switching to the opposite

color. On 83491A modules for example, the first selection cycle shows 155 Mb/s

selected. The second selection cycle shows 1062 Mb/s selected.

Agilent 83494A modules use only the green data-rate indicator light to show which data

rate is selected. Repeatedly pressing the SELECT key cycles through the available data

rates, as well as the Trigger On Data bypass mode.

• If the UNLOCKED light is on (or TRIGGER LO SS light on the 83494A), clock recovery cannot be establishe d on the si gnal.

• Avoid selecting a data rate that is a multiple of the input signal. For example,

don’t select a 622 Mb/s data rate if the sign al is reall y at 155 Mb/s.

• If you cannot get the clock recovery module to lock on the signal, make sure

that you have sel ect ed th e co rrect dat a rat e and t hat the ma inf ram e tri gger

level is adju sted appropria t ely.

• Signa ls displayed us ing a data trig ger are less re liable than usin g a recovered

clock. Signals triggered on data can also vary depending upon the trigger

level.

2-9

Operation

To Compensate for Module Insertion Loss

To Compensate for Module Insertion Loss

If you are using an 86100-series in fin ii um DCA , re fe r to the instrument’s help

system for information on compensating for module insertion loss. Use the following steps on an 83480A DCA to allow you to enter an offset to compensate

for the insertion loss of the clock recovery module. This provides accurate

amplitude measu r e ments at the input to t he clock recovery module.

1 Disconnect the cable from the clock recovery module’s Input connector.

2 Measure the signal using a power meter. You can use either the 83480A’s built-

in power meter or an external power meter.

3 Reconnect the cable to the clock recovery module.

4 Disconnect the cable from the reference receiver module’s input connector.

5 Measure the signal using a power meter. You can use either the 83480A’s built-

in power meter or an external power meter.

6 Subtract the two measurements to determine the insertion loss of the module.

Insertion loss: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ____________

7 On the reference receiver module, pres s the front-panel channel SETUP key.

8 Press External scale, and set the Atten units to “decibel”.

9 Press Attenuation, and enter the value calculated in Step 6.

2-10

Operation

Using Probes with an 83491A

Using Probes with an 83491A

You can use external passive and active probes with the 83491A electrical

clock recovery module. If you are using an 86100-series infiniium DCA, refer

to the infiniium DC A’s help system; the pro c e dures in this section ar e fo r use

on an 83480A DCA.

The following probes are available for use with 83491A clock recovery modules:

• Agilent N1020A TDR probe. This passive probe (1:1, 50Ω) provides a fixture

for positioning an d holding the probe tip on the device being tested .

• Agilent 54701A 2.5 GHz active probe. This is a 100kΩ, 10:1, probe.

• Agilent 54006A 6 GHz handheld low-impedanc e probe. This passive probe

(10:1, 500Ω, 20:1, 1kΩ) has an input capacitance of 0.25 pf.

• Agilent 1163A 1 GHz resistive-divider probe. This passive 500Ω probe has an

input capacitance of 1.5 pf.

If you are using an 83480A DCA, use the procedures in this section to generate vertical scale factors. These factors are applie d to the calibr ati on of the

reference receiver module’s electrical channel. When selecting a probe, keep

in mind that the input impedance of the 83491A is 50Ω.

If the probe being calibrated has an attenu ati on factor that allows the instrument to adjust the gain to produce even steps in the vertical scale factors, the

instrument will do so. Typically, probes have standard attenuation factors such

as divide by 10, divide by 20, or divide by 100. Because the following pr ocedures include com pensation for inser tion loss of the clock re c ov ery module,

do not perform the procedur e “To Compensate for Module Insertion Loss” on

page 2-10.

To compensate for a passive probe

1 Connect the probe to the Input connector on the 83491A clock recovery module.

2 Attach the pro be ti p to th e CAL hook that is located near the floppy disk drive.

3 Press the reference receiver module’s front-panel channel SETUP key.

2-11

Operation

Using Probes with an 83491A

4 Press Calibrate and then Calibrate probe.

To compensate an 54701A active probe

1 Connect the 83491A output to the electrical measurement channel input.

2 Connect the probe to the Input connector on the 83491A clock recovery module.

3 Connect the probe po wer cable to the Probe Power connect o r on the reference

receiver modu le .

4 Attach the pro be ti p to th e CAL hook that is located near the floppy disk drive.

5 Press the reference receiver module’s front-panel channel SETUP key.

6 Press Calibrate and then Calibrate probe.

To compensate for other devices

The information in this section applies to both optical and electr ical measurements. Since the mainframe’s CAL signal is a voltage source, it cannot be used

to calibrate to the probe tip when the units are set to Ampere, Watt, or

Unknown. Instead , s et t he ext ern al gai n an d ex te rnal o ff set t o com pens ate for

the actual characteristics of the devic e. If you do not know the actual characteristics, you can refer to the typical specifications that came with the device.

1 Press the reference receiver module’s front-panel channel SETUP key.

2 Press External scale.

3 Press Atten units Ratio

, Attenuation 1:1, and then Units Ampere (Volt, Watt, or

Unknown).

4 Press Ext gain, and enter the actual gain characteristics of the device.

5 Press Ext offset, and enter the offset introduced by the device.

2-12

3

Front-Panel Optical Adapters 3-2

In Case of Difficulty 3-3

Error Messages 3-5

Electrostatic Discharge Infor m ati on 3-7

Cleaning Connections for Accurate Measurements 3-9

Reference

Reference

Front-Panel O ptical Adapter s

Front-Panel Optical Adapters

Front Panel

Fiber-Optic

Adapter

Description Agilent Part Number

Diamond HMS-10 81000AI

a

FC/PC

D4 81000GI

SC 81000KI

DIN 81000SI

ST 81000VI

Biconic 81000WI

Dust Covers

FC connector 1005-0594

Diamond HMS-10 connector 1005-0593

DIN connector 1005-0595

ST connector 1005-0596

SC connector 1005-0597

81000FI

a. The FC/PC adapter is the standard adapter supplied with the instrument.

3-2

In Case of Difficulty

In Case of Difficulty

This section provides a list of suggestions for you to follow if the plug-in module fails to operate. A list of messages that may be displayed is also included in

this chapter. Before calling Agilent Technologies or returning th e un it for service, a few minutes spent performing some simple checks may save waiting for

your instrument to be repaired.

If the mainframe does not operate

❒ Is the line fuse good?

❒ Does the line socket have power?

Reference

❒ Is the unit plugged in to the prop er ac power source?

❒ Is the mainframe tur ned on?

❒ Is the rear-panel line switch set to on?

❒ Will the mainframe po w er u p without the plug-in module installed?

If the plug-in does not operate

❒ Is the plug-in module firmly seated in the mainframe slot?

❒ Are the knurled sc rews at the bottom of the plug-in module finger-tight?

❒ Is the clock recovery module set to the modulation rate of the input signal?

❒ If other equipment, cables, and connectors are being used with the plug-in

module, are they co nnected properly and o perating correc tly?

❒ Review the procedure for the test being performed when the problem ap-

peared. Are all the settings correct? Can the problem be reproduced?

❒ Are the connectors clean? See “Clean ing Connections fo r Accurate Measur e-

3-3

Reference

In Case of Difficulty

ments” on page 3-9 for more information.

❒ Make sure that the instrument is ready to acquire data.

❒ Find any signals on the channel inputs by using the Autoscale function.

❒ See if any signals are present at the channel inputs by using Freerun triggering.

❒ Make sure Channel Display is on.

❒ Make sure the channel offset is adjusted so the waveform is not clipped off the

display.

❒ Make sure the mainframe identifies the plug-in module:

• One the 86100-series DCA, select the All Calibrati ons command on the Calibrate menu. Confirm that the Model number and Seri al Number are listed

in the displayed dialog box.

• On the 83480A DCA, press Utility, then System config. Confirm that the Model

number is listed in the box labeled “Plug-ins”. If “~known” is displayed instead of the model number of the plug-in module, remove and reinsert the

plug-in module in the same slot. If “~known” is still displayed, the mainframe

may need to have the latest operating system firmware i n stalled. Options

001 and 002 provide this firmware on a 3.5 inch diskette. To load new firmware, follow the instructions provided with this diskette. If you do not have

the optional diskette, contact your local Agilent Technologies service office

(refer to “Contacting Agilent Technologies” on page 1-12).

If the model number of the plug-in module is list ed, the mainframe ha s identified the plug-in.

3-4

Reference

Error Messages

Error Messages

This section pr o v ides description of error messages that ar e displayed if you

are using the module in an 83480A DCA. If you are using an 86100-series infiniium DCA, refer to the instrument’s help system for information on error

messages displayed on that mainframe.

Memory error occurred in plug-in_:Try

reinstalling plug-in

The mainframe could not correctly read the contents of the memory in the

plug-in.

❒ Remove and reinstall the plu g- i n mo dule. Each time a plug-in is instal le d, the

mainframe re-reads the memory in the plug-in module.

❒ Verify the plug-in module is firmly seated in the mainframe slot.

❒ Verify the knur led scr ews at the botto m of the pl ug-in mo dule ar e finger -tight .

❒ Install the plug-in in a different slot in the mainframe.

Busy timeout occurred with plug-in_:Try

reinstalling plug-in

The mainframe is having trouble communicating with the plug-in module .

Make sure there is a goo d connection between the mainframe and the plug-in

module.

❒ Remove and reinstall the plu g- i n module.

❒ Verify the plug-in module is firmly seated in the mainframe slot.

❒ Verify the knurled screws at the bottom of the plug-in module are finger-tight.

❒ Install the plug-in in a different slot in the mainframe.

3-5

Reference

Communications failure exists at slot_:Service is required

Communications failure exists at slot_:Service

is required

An illegal hardware state is detected at the mainframe-to-plug-in module

interface of the specifie d sl ot.

• If the slot is empty, there is a mainframe hardware problem. Refer to the

Agilent 83480A, Agilent 54750A Service Guide.

• If a plug-in is installed in the slot, there is a plug-in module hardware problem.

Return the plug-in module to a qualifie d service departmen t.

ID error occurred in plug-in_:Service is

required

The informatio n read from the memory of the plug-in module do e s no t m a tc h

the hardware in the plug-in module. This can be caused by a communication

problem between the mainframe and the plug-in module. Make sure there is a

good connection between the mainframe and the plug-in.

❒ Remove and re-install the plug-in module.

❒ Verify the plug-in module is firmly seated in the mainframe slot.

❒ Verify the knurled screws at the botto m of the plug-in module ar e fi nger tight.

❒ The standard Agilent 54750A mainframe does not accept the Agilent 83491/2/

3/4A module. To use the module, a firm ware upgrade must first be installed.

Order the Agilent 8348 0K communi cati ons firmware kit and install according

to the instruct ions.

❒ The Agilent 83480A, Agilent 54750A mainframes do not accept plug-in mod-

ules designed for use with the Agilent 54710A, 54720A.

Plug-in is not supported:System firmware

upgrade is needed

The mainframe ma y need to have the latest o perating system firmware

installed. Options 001 and 002 provide this firmware on a 3.5 inch diskette. T o

load the new firmware, follow the instructions provided with the diskette. If

you do not have the optional diskette, contact your local Agilent Technologies

service office.

3-6

Reference

Electrostatic Discharge Information

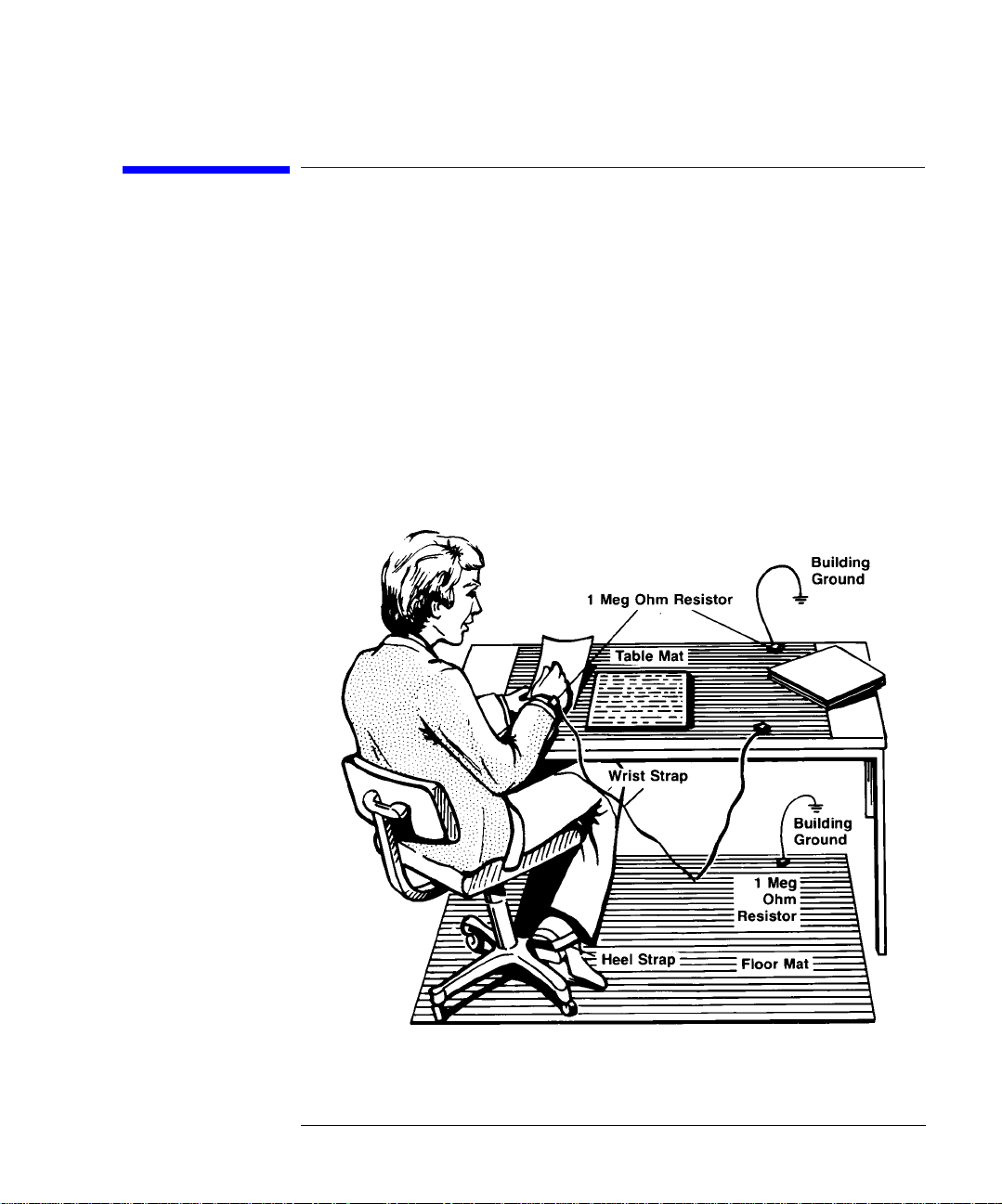

Electrostatic Discharge Information

Electrostatic dis c h arge (ESD) can damage or destro y electronic components .

All work on electronic assemblies should be performed at a static-safe work

station. The following figure shows an example of a static-safe work station

using two types of ESD protecti on:

• Conductive table-mat and wrist-strap combination.

• Conductive floor-mat and heel-strap combination.

Figure 3-1. Static-safe work station

3-7

Reference

Electrostatic Discharge Informa tio n

Both types, when used together, provide a significant level of ESD protection.

Of the two, only the table-mat and wrist-strap combination provides adequate

ESD protection when used alone.

T o ensure user safety, the static-safe accessories must provide at least 1 MΩ of

isolation from ground. Refer to Table 3-1 for information on ordering staticsafe accessories.

WARNI NG These techniques for a static-safe work station should not be used

when working on circuitry with a voltage potential greater than 500

volts.

Reducing ESD Damage

The following suggestions ma y he lp reduce ESD damag e that occurs during

testing and servic ing operations.

• Personnel shoul d be grounded with a resi stor-isolated wrist strap before removing any assembly from the unit.

• Be sure all instrument s are properly earth-grounded to prevent a buildup of

static charge.

Table 3-1.Static-Safe Accessories

Agilent Part

Number

9300-0797

9300-0980 Wrist-strap cord 1.5 m (5 ft)

9300-1383 Wrist-strap, color black, st ainless steel, without cord, has fo ur adjustable

9300-1169 ESD heel-strap (reusable 6 to 12 months).

3-8

Description

Set includes: 3M static control mat 0.6 m

ft) ground wire. (The wrist-strap and wrist-strap cord are not included. They

must be ordered separately.)

links and a 7 mm post-type connection.

× 1.2 m (2 ft× 4 ft) and 4.6 cm (15

Reference

Cleaning Connections for Accurate Measurements

Cleaning Connections for Accurate

Measurements

Today, advances in measurement capabilities make connectors and connection techniques more important than ever. Damage to the connectors on calibration and verification devices, test ports, cables , and ot her device s can

degrade measurement accuracy and damage instruments. Replacing a damaged connector can cost thousands of dollars, not to mention lost time! This

expense can be avoided by observing the simple precautions presented in this

book. This book also contains a brief list of tips for caring for electrical connectors.

Choosing the Right Connector

A critical but often overlooked factor in making a good lightwave measure ment is the selection of the fiber-optic connector. The differences in connector types are mainly in the mechanic a l a ssembly that holds th e fe rrule in

position against another identical ferrule. Connectors also vary in the polish,

curve, and conce ntricity of the core within the cladding. Mating one style of

cable to another requires an adapter. Agilent T echnologies offers adapters for

most instruments to allow testin g w i th many different c ables. Figure 3-2 on

page 3-10 shows the basic componen ts of a ty pica l conn ect ors .

The system tole ranc e for reflection and in se rtion loss must be kn ow n w he n

selecting a connector from the wide variety of currently available connectors.

Some items to consider when selecting a connector are:

• How much insertion loss can be allowed?

• Will the connector need to make multiple connections? Some connectors are

better than others, and some are very poor for making repeate d connections.

• What is the reflection tolerance? Can the system take reflection degradation?

• Is an instrument-grade connector with a preci sion core alig nmen t re qu ir ed ?

• Is repeatability tolerance for reflection and loss important? Do your specifica-

3-9

Reference

Cleaning Connections for Accurate Measurements

tions take repeatability uncertain ty into account?

• Will a connector degrade the return loss too much, or will a fusion splice be required? For example, many DFB lasers cannot operate with reflections from

connectors. Often as much as 90 dB isolation is needed.

Figure 3-2. Basic components of a connector.

Over the last few ye a rs, the FC/PC style c onnector has emerge d as the most

popular connector for fiber-optic applications. While not the highest performing connector, it represents a good compromise between performance, reliability, and cost. If properly maintained and cleaned, this connector can

withstand many repeated connections.

However, many instrument specifications require tighter tolerances than most

connectors, including the FC/PC style, can deliver. These instruments cannot

tolerate connectors with the l arge non-concentricities of the fiber common

with ceramic style ferrules. When tighter alignme n t is required, Agi lent

Technologies instru ments typi cally use a connector such as the Diamond

HMS-10, which has concentric tolerances within a few tenths of a micron. Agilent Technologies then uses a special unive rsal adapter, which allows oth er

cable types to mate with this precision connector. See Figure 3-3.

3-10

Reference

Cleaning Connections for Accurate Measurements

Figure 3-3. Universal adapters

The HMS-10 enca se s the fiber within a soft nickel silver (C u/Ni/Zn) center

which is surrounded by a tough tungsten carbide casing, as shown in

Figure 3-4.

Figure 3-4. Cross-section of the Diamond HMS-10 connector.

The nickel silver allows an active centering process that permits the glass fiber

to be moved to the desired positi on. This process first stakes the soft n ickel

silver to fix the fiber in a near-center location, then uses a post-active staking

to shift the fiber into the desired position within 0.2 µm. This process, plus the

keyed axis, allo ws very precise core-to-core alignments. This conne c to r is

found on most Agilent Technologies lightwave instruments.

3-11

Reference

Cleaning Connections for Accurate Measurements

The soft core, wh ile allowing precise c entering, is also th e c h ief liability of the

connector. The soft material is easily damaged. Care must be taken to minimize excessive scratching and wear. While minor wear is not a problem if the

glass face is not affected, scratches or grit can cause the glass fiber to move

out of alig nment. Also, if unkeye d co nnecto rs ar e used , the nicke l sil ver ca n be

pushed onto the glass surface. Scratches, fiber movement, or glass contamination will cause lo s s of sign al and increa sed re flect ion s, resu ltin g in p oor retu rn

loss.

Inspecting Connectors

Because fiber-optic connectors are susceptible to damage that is not immediately obvious to the naked eye, poor measurements result without the user

being aware. Microscopic examination and return loss measure men ts are the

best way to ensure good measurements. Good cleaning practices can help

ensure that optim u m c onnector performanc e is maintained. With glass - to glass interface s, any degradatio n of a ferrule or the end of the fi ber, any stray

particles, or finger oil can have a significant effect on connector performance.

Where many repeat connections are required, use of a connector saver or

patch cable is recommended.

Figure 3-5 shows the end of a clean fiber-optic cable. The dark circle in the

center of the micrograph is the fiber’s 125 µm core and cladding which carries

the light. The surrounding area is the soft nickel-silver ferrule. Figure 3-6

shows a dirty fiber end from neglect or perhaps improper cleaning. Material is

smeared and gr ou nd i nto t he end o f t he f ib er cau si ng l igh t sc att erin g an d po or

reflection. Not only is the precision polish lost, but this action can grind off the

glass face and destroy the connector.

Figure 3-7 shows physical damage to the glass fibe r end caused by either

repeated connections made without removing loose particles or using

improper cleaning tools. When severe, the damage of one connector end can

be transferred to another good connector en dface that comes in contact with

the damaged one. Periodic checks of fiber ends, and replacing connecting

cables after many connections is a wise practice.

The cure for these p roblems is discipline d c o nnector care as described in the

following list and in “Cleaning Connectors” on page3-16.

3-12

Reference

Cleaning Connections for Accurate Measurements

Use the following guidelines to achieve the best possible performance when

making measurements on a fiber-optic system:

• Never use metal or sharp objects to clean a connector and never scrape the

connector.

• Avoid matching gel and oils.

Figure 3-5. Clean, problem-free fiber en d and f errule.

Figure 3-6. Dirty fiber end and ferrule from poor cleaning.

3-13

Reference

Cleaning Connections for Accurate Measurements

Figure 3-7. Damage from improper cleaning.

While these often work well on first insertion, they are great dirt magnets. The

oil or gel grabs and holds grit that is then ground into the end of the fiber.

Also, some early ge ls were designed fo r use with the FC, non-con t ac ting connectors, using small glass spheres. When used with contacting connectors,

these glass balls can scratch and pit the fiber. If an index matching gel or oil

must be used, apply it to a freshly cleaned connector, make the measurement,

and then immed ia tely clean it off. Never us e a gel for longer- term connections

and never use it to improve a damaged connector. The gel can mask the extent

of damage and continued use of a damaged fiber can trans fer damage to the

instrument.

• When inserting a fiber-optic c able into a connector, gently inse rt i t in a s

straight a line as possible. Tipping and inserting at an angle can scrape material

off the inside of the connector or even break the inside sleeve of connectors

made with ceramic material.

• When inserting a fiber-optic connector into a connector, make sure that the fiber end does not touch the outside of the mating connec tor or adapter.

• Avoid over tightening connections.

Unlike common electrical connections, tighte r is not better. The purpose of

the connector is to bring two fiber ends together. Once they touch, tightening

only causes a greater force to be applied to the delicate fibers. With connectors that have a convex fiber end, the end can be pushed off-axis resulting in

misalignmen t a nd e xc essive return lo ss. Many measurem ents are actually

improved by backing off the connector pressu re . Also, if a piece of grit does

happen to get by the cleaning procedure, the tighter connection is more likely

to damage the glass. Tighten the connectors just until the two fibers touc h.

3-14

Reference

Cleaning Connections for Accurate Measurements

• Keep connectors covered when not in use.

• Use fusion splices on the more permanent critical nodes. Choose the best connector possible. Replace connecting cables regularly. Frequently measure the

return loss of the connector to check for degradation, and clean every connector, every time.

All connectors should be treated like the high-quality lens of a good camera.

The weak link in instrument and syste m reliability is of te n the inappropriate

use and care of the connector. Because current connectors are so easy to use,

there tends to be reduced vigilance in connector care and cleaning. It takes

only one missed cle a ning for a piece of grit to permanently dama g e the glass

and ruin the conne c to r.

Measuring insertion loss and return loss

Consistent measurements with your lightwave equipme nt are a good indication that you have good connections. S ince return loss and insertion loss are

key factors in determining optical connector performance they can be used to

determine connector degradation. A smooth, polished fiber end should produce a good return- loss measurement. The quality of the polish establishes

the difference between the “PC” (physical contact) and the “S upe r PC” connectors. Most connectors today are physical contact which make glass-to-glass

connections, therefore it is critical that the area around the glass core be clean

and free of scratches. Altho ug h the major area of a connector, excluding the

glass, may show scra tc hes and wear, if the glass has maintained its polished

smoothness, the connector can st ill provide a good low lev el return loss connection.

If you test your cables and acces so ries for insertion loss and re turn loss upon

receipt, and retain the measured data for comparison, you will be able to tell in

the future if any degradation has occurred. Typical values are less than 0.5 dB

of loss, and somet im es as little as 0.1 dB of lo ss with high performanc e connectors. Return loss is a measure of reflection: the less reflection the bett er

(the larger the return loss, the smaller the reflection). The best physically

contacting connectors have return losses better than 50 dB, although 30 to

40 dB is more common.

3-15

Reference

Cleaning Connections for Accurate Measurements

Visual inspection of fiber ends

Visual inspection of fiber ends can be helpful. Contamination or imperfections

on the cable end face can be detected as well as cracks or chips in the fiber

itself. Use a microscope (100X to 200X magni fi cati on) to in spect the entire

end face for contam ina tion, raised meta l , o r de nts in the metal as well a s an y

other imperfections. Inspect the fiber for cracks and chips. Visible imperfections not touching the fibe r cor e m ay no t affe ct pe rformance (unless the

imperfections keep the fibers from contacting).

WARNI NG Always remove both ends of fiber-optic cables from any instrument,

system, or device before visually inspecting the fiber ends. Disable all

optical sources before disconnecting fiber-optic cables. Failure to do

so may result in permanent injury to your eyes.

Cleaning Connectors

The procedures in this section provide the proper steps for cleaning fiberoptic cables and Agilent Technologies universal adapter s. The initi al cleani ng ,

using the alcohol as a solvent, gently removes any grit and oil. If a caked-on

layer of material is still present, (this can happen if the beryllium-copper sides

of the ferrule retainer get scraped and deposited on the end of the fiber during

insertion of the cable), a second cleaning should be performed. It is not

uncommon for a cable or connector to require more than one cleanin g.

CAUTION Agilent Technologies strongly recommends that index matching compounds

not be applied to their instruments and accessories. Some compounds, such as

gels, may be difficult to remove and can contain damaging particulates. If you

think the use of such compounds is necessary, refer to the compound

manufacturer for infor mat ion on application and cleaning procedures.

Table 3-2.Cleaning Accessories

Item AgilentPart Number

Any commercially available denatured alcohol —

Cotton swabs 8520-0023

Small foam swabs 9300-1223

Compressed dust remover (non-resi due) 8500-5262

3-16

Reference

Cleaning Connections for Accurate Measurements

Table 3-3. Dust Caps Provided with Lightwave Instruments

Item AgilentPart Number

Laser shutter cap 08145-64521

FC/PC dust cap 08154-44102

Biconic dust cap 08154-44105

DIN dust cap 5040-9364

HMS10/dust cap 5040-9361

ST dust cap 5040-9366

To clean a non-lensed connector

CAUTION Do not use any type of foam swab to clean optical fiber ends. Foam swabs can

leave filmy deposits on fiber e nds that can degrade performance.

1 Apply pure isopropyl alcohol to a clean lint-free cotton swab or lens paper.

Cotton swabs can be used as long as no cotton fibers remain on the fiber end

after cleaning.

2 Clean the ferrules and o the r parts of the connector while avoidi ng the end of

the fiber.

3 Apply isopropyl alcohol to a new clean lint-free cotton swab or lens paper.

4 Clean the fiber end with the swab or lens paper.

Do not scrub durin g this initial clea ning because grit c a n be c a ught in the

swab and become a gouging element.

5 Immediately dry the fiber end with a clean, dry, lint-free cott on swab or len s

paper.

6 Blow across the connector end face from a distance of 6 to 8 inches using

filtered, dry, compressed air. Aim the compressed air at a shallow angle to the

fiber end face. Nitrogen gas or compressed dust remover can also be used.

3-17

Reference

Cleaning Connections for Accurate Measurements

CAUTION Do not shake, tip, or invert compressed air canisters, because this releases

particles in the can into the air. Refer to instructions provided on the

compressed air canister.

7 As soon as the connec tor is dry, connect or cover it for later use.

If the performance, after the initial cleaning, seems poor try cleaning the connector again. Often a second cleaning will restore proper performance. The

second cleaning should be more arduous with a scrubbing action.

To clean an adapter

The fiber-optic input and output connectors on many Agilent Technologies

instruments employ a universal adapter such as those shown in the following

picture. These adapters allow you to connect the instrument to different types

of fiber-optic cables.

Figure 3-8. Universal adapters.

1 Apply isopropyl alcohol to a clean foam swab.

Cotton swabs can be used as long as no cotton fibers remain after cleaning. The

foam swabs listed in this section’s int roduction are smal l en ough to fit into

adapters.

Although foam swabs can leave filmy deposits, these deposits are very thin, and

the risk of other conta m ination buildup on the inside of adapte rs greatly outweighs the risk of contamination by foam swabs.

2 Clean the adapter with the foam swab.

3 Dry the inside of the adapter with a clean, dry, foam swab.

4 Blow through the adapter using filtered, dry, compressed air.

Nitrogen gas or compressed dust remover can also be used. Do not shake, tip,

or invert compressed air canisters, because this releases particles in the can

into the air. Refer to instructions provided on the compressed air canister.

3-18

4

83491A Specifications 4-3

83492A Specifications 4-4

83493A Specifications 4-6

83494A Specifications 4-8

83491/2/3/4A Operating Specifications 4-10

Regulatory Information 4-11

Specifications and Regulatory Information

Specifications and Regulatory Information

Specifications and Regulatory Information

Specifications and Regulatory Information

This chapter lists specifications and characteristics of the clock recovery modules. Specifications apply over the temperature range +15°C to +35°C (unless

otherwise noted) after the instrument’s temperature has been stabilized after

60 minutes of continuous operation.

Specifications Specifications described warranted performance.

Characteristics Characteristics provide useful, nonwarranted, information about the func-

tions and performance of the instrument. Characteristics are printed in

italics.

Calibration cycle Agilent Technologies warrants instrument specifications over the recom-

mended calibrat ion interv al. T o ma intain speci fications , periodic re calibrati ons

are necessary. We recommend that the Agilent 83491/2/3/4A be calibrated at

an Agilent Technologies service facility eve ry 24 months.

4-2

Specifications and Regulat ory Information

83491A Specifications

83491A Specifications

Table 4-1.83491A Specifications

Clock Recovery Phase Locked Loop Bandwidth (characteristic)

Internal Path Triggering

External Output

Clock recovery rates (NRZ coding)

155.52 Mb/s

622.08 Mb/s

1062.50 Mb/s

1250 Mb/s

2125.00 Mb/s

2488.32 Mb/s

2500.00 Mb/s

Data triggering (character istic) 50 Mb/s to 2500 Mb/s

Operatin g in put power level

a b

Triggering operati on, all rates

–10

10

BER, all rates

c

50 to 70 kHz

4 to 5 MHz

±0.1%

±0.1%

±0.1%

±0.1%

±0.1%

±0.1%

±0.1%

–10 dBm to 3 dB m

–10 dBm to 3 dB m

Insertion loss (through path)

DC through 2500 MHz

Output jitter, all rates

d

≤ 7 dB

0.0125 UI

Maximum continuous electrical power bef or e damage (characteristic) 1W peak

DATA and CLO CK output amplitude, all rates (characteristic) 0.5Vp- p

INPUT electrical return loss

DC through 1250 MHz (characteristic)

1250 MHz through 2500 MHz (character ist ic)

≥ 20 dB

≥ 15 dB

DATA and CLOCK electrical return loss

50 MHz through 2000 MHz (charact er istic)

2000 MHz through 2500 MHz (character ist ic)

a. Source extinction ratio ≥ 8.2 dB when measured per TIA/EIA OFSTP-4A.

b. Operating power level applies over temperature range 25

c. Better than 10

d. Measured on an oscilloscope eye diagram with PRBS 223–1 test pattern.

–10

BER when tested with PRBS 223–1 pattern.

°C ± 5°.

≥ 10 dB

≥ 6 dB

rms

4-3

Specifications and Regulatory Information

83492A Specification s

83492A Specifications

Table 4-2.83492A Specifications (1 of 2)

Wavelength range (characterist ic) 750 nm to 860 nm and

1000 nm to 1600 nm

Optical INPUT and OUTPUT fiber (characteristic) 62.5/125 multimode

Optical insertion loss (th rough path)

750 nm to 860 nm

1000 nm to 1600 nm

Optical return loss

b

a

≤ 5.0 dB

≤ 5.0 dB

≥ 28 dB

Clock Recovery Phase Locked Loop Bandwidth (characteristic)

Internal Path Triggering

External Output

50 to 70 kHz

4 to 5 MHz

Clock recovery rates (NRZ coding)

155.52 Mb/s

622.08 Mb/s

1062.50 Mb/s

1250 Mb/s

2125.00 Mb/s

2488.32 Mb/s

2500.00 Mb/s

±0.1%

±0.1%

±0.1%

±0.1%

±0.1%

±0.1%

±0.1%

Data triggering (character istic) 50 Mb/s to 2500 Mb/s

Operating input power level

c d

750 nm to 860 nm

Triggering op e r a t io n, all rates

–10

BER, all rates

10

e

–10 dBm to 3 dB m

–10 dBm to 3 dB m

1000 nm to 1600 nm

Triggering op e r a t io n, all rates

–10

BER, all rates

10

Output jitter, all rates

f

g

–13 dBm to 3 dB m

–13 dBm to 3 dB m

0.0125 UI

rms

4-4

Specifications and Regulat ory Information

83492A Specifications

Table 4-2.83492A Specifications (2 of 2)

Maximum continuous optical power bef or e damage (characteristic) 10 mW peak

DATA and CLO CK output amplitude, all rates (characteristic) 0.5Vp- p

DATA and CLOCK electrical return loss

50 MHz through 2000 MHz (charact er istic)

2000 MHz through 2500 MHz (character ist ic)

a. Minimum loss in 850 nm window.

b. Single-mode backreflection tested with FC/PC adapter and single-mode fiber. Optical output terminated

with > 33 dB return lo ss. R etur n loss with fully filled 62.5

c. Source extinction ratio

d. Operating power level applies over temperature range 25

e. Better than 10

f. Better than 10

g. Measured on an oscilloscope eye diagram with PRBS 2

≥ 8.2 dB when measured per TIA/EIA OFSTP-4A.

–10

BER when tested with PR BS 223–1 pattern.

–10

BER when tested with PR BS 223–1 pattern.

µm core multimode fiber may be sl igh tly lower .

°C ± 5°.

23

–1 test pattern.

≥ 10 dB

≥ 6 dB

4-5

Specifications and Regulatory Information

83493A Specification s

83493A Specifications

Table 4-3.83493A Specifications

Wavelength range (characteristic) 1000 nm to 1600 nm

Optical INPUT fiber (characteristic) 9/125 s ingle mode

Optical insertion loss (through path)

Optical return loss

a

≤ 1.5 dB

≥ 28 dB

Clock Recovery Phase Locked Loop Bandwidth (characteristic)

Internal Path Triggering

External Output

50 to 70 kHz

4 to 5 MHz

Clock recovery rates (NRZ coding)

155.52 Mb/s

622.08 Mb/s

1250 Mb/s

2488.32 Mb/s

2500.00 Mb/s

±0.1%

±0.1%

±0.1%

±0.1%

±0.1%

Data triggering (character istic) 50 Mb/s to 2500 Mb/s

Operating input power level

Triggering operation, all rates

–10

10

BER, all rates

Output jitter, all rates

b c

–20 dBm to 3 dB m

d

e

–17 dBm to 3 dB m

0.0125 UI

rms

Maximum continuous optical power bef or e damage (characteristic) 10 mW peak

DATA and CLO CK output amplitude, all rates (characteristic) 0.5Vp- p

DATA and CLOCK output electrical return loss

50 MHz through 2500 MHz (characteristic)

2.5 GHz through 10 GHz (characteristic)

≥ 10 dB

≥ 8 dB

a. Tested with FC/PC adapter. Optical output terminated without > 33 dB return loss.

4-6

Specifications and Regulat ory Information

b. Source extinction ratio ≥ 8.2 dB when measured per TIA/EIA OFSTP-4A.

c. Operating power level applies over temperature ra nge 25

d. Better than 10

–10

BER when tested with PR BS 223–1 pattern.

e. Measured on an oscilloscope eye diagram with PRBS 2

°C ± 5°.

23

–1 test pattern.

83493A Specifications

4-7

Specifications and Regulatory Information

83494A Specification s

83494A Specifications

Table 4-4.83494A Specifications (1 of 2)

Wavelength range (characteristic) 1200 nm to 1600 nm

Optical INPUT fiber (charact er istic) 9/125 single mode

Optical insertion loss (through path) 1.5 dB

Optical return loss

Clock Recovery Phase Locked Loop Ban dwidth (characteristic)

Internal Path Triggering

External Output

a

≥ 28 dB

90 kHz

4 to 5 MHz

Clock recovery rates (NRZ coding)

155.52 Mb/s

622.08 Mb/s

2488.32 Mb/s

2666.06 Mb/s (Options 106 and 107)

9953.00 Mb/s (Standard)

10312.500 Mb/s (Option 103)

10664.228 Mb/s (Option 106)

10709.225316 Mb/s (Option 107)

±0.1%

±0.1%

±0.1%

±0.1%

±0.03%

±0.03%

±0.03%

±0.03%

Data triggering (charact eristic) 50 Mb/s to 2500 Mb/s

Operating input power level

b c

Triggering operation

9953.00 Mb/s, 10312.500 Mb /s, 10664.228 Mb/s, and

–8 dBm to 3 dBm

10709.225316 Mb/s

Triggering operation, all other rates

-12 dBm to 3 dBm

-14 dBm to 3 dBm (t y pical)

–10

10

BER, all rates

d

0 dBm

4-8

Specifications and Regulat ory Information

83494A Specifications

Table 4-4.83494A Specifications (2 of 2)

Output jitter e

all rates

155.52 Mb/s

622.08 Mb/s

2488.32 Mb/s

Maximum continuous optical power before damage (characteristic) 10 mW peak

DATA and CLOCK output amplitude, all rates (characteristic) 0 .5Vp-p

DATA and CLOCK output electrical return loss

50 MHz through 2500 MHz (characteristic)

2.5 GHz through 10 GHz (characteristic)

0.02 UI

0.01 UI

0.01 UI

0.01 UI

≥ 10 dB

≥ 8 dB

rms

(typical)

rms

(typical)

rms

(typical)

rms

a. Tested with FC/PC adapter. Optical output terminated without > 33 dB return loss.

b. Source extinction ratio

c. Operating power level applies over temperature range 25

d. Better than 10

e. Measured on an oscilloscope eye diagram with P RBS 2

≥ 8.2 dB when mea sured per TIA/EI A OFSTP-4A.

–10

BER when tested with PRBS 223–1 pattern.

°C ± 5°.

23

–1 test pattern.

4-9

Specifications and Regulatory Information

83491/2/3/4A Operating S pecifications

83491/2/3/4A Operating Specifications

Table 4-5. Operating Specifications

Use Indoor

Temperature

Operating

Non-operating

Altitude

Operating

Non-operating

0°C to +55°C

–40

°C to +70°C

4600 m (15,000 ft)

15,300 m (50,000 ft)

Humidity

Operating

Non-operating

Net weight appr ox i mately 1.2 kg (2.6 lb.)

Shipping weight approximately 2.1 kg (4.6 lb.)

Dimensions H x W x D 131.66 mm x 80.14 mm x 266.9 mm

Power Requirements Supplied by mainframe

4-10

up to 90% relative humidity at <35

up to 90% relative humidity at <35

(5.18 in x 3.15 in x 10.5 i n )

°C

°C

Specifications and Regulat ory Information

Regulatory Information

Notice for Germany: Noise Declaration

Acoustic Noise Emission Geraeuschemission

LpA < 70 dB LpA < 70 dB

Operator position am Arbeitsplatz

Normal position normaler Betrieb

per ISO 7779 nach DIN 45635 t.19

Regulatory Information

Notice for Canada: Compliance with Canadian EMC Requirements

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme a la norme NMB du Canada.

4-11

Specifications and Regulatory Information

Regulatory Information

4-12

Index

Numerics

83494A, 4-8

A

adapter cable, 1-9

Agilent 54701A active probe, 2-12

Agilent 83492A

maximum input level, 1-10

Agilent Technologies, contacting, 1-12

B

Bellcore GR-253-CORE, 2-4

block diagram, 2-6

built-in information system, 2-2

bypass mode, 2-4

C

cabinet, cleaning, 1-4

calibration cycle, 4-2

care

of cabinet, 1-4

care of fiber optics, 1-3

channel

key, 1-3

setup, 1-3

Channel key, 2-2

characteristics, defined, 4-2

cleaning

adapters, 3-18

cabinet, 1-4

fiber-optic connections, 3-9, 3-17

non-lensed connectors, 3-17

CLOCK Auxiliary Output connector, 2-5

compensation

Agilent 54701A active probe, 2-12

insertion loss, 2-10

other devices, 2-12

passive probe, 2-11

compressed dust remover, 3-16

connector

care, 3-9

Contents topic, 2-2

cotton swabs, 3-16

customer assistance, 1-4

D

damaged shipment, 1-5

DATA Auxiliary Output connector, 2-4, 2-5

data rate

indicator lights, 1-11

data rates, 1-2

multiple of, 1-10, 2-9

declaration of conformity, 1-4

dust caps, 3-17

E

electrostatic discharge, 1-3, 3-7

EMC requirements, 4-11

ESD

reducing damage caused by ESD, 3-8

static-safe work station, 3-8

extender cables, 1-7

F

fiber

adapters, 3-2

care of, 1-3

multimode, 1-2

reflections, 2-5

single-mode, 1-2

single-mode connections, 2-5

fiber optics

cleaning connections, 3-9

connectors, covering, 1-13

firmware

upgrade kit, 1-5

version required, 1-5

foam swabs, 3-16

front panel, 2-3

adapters, 3-2

features, 2-3

G

GPIB programming, 2-2

green light, 1-11

H

Help, 2-2

Index-1

Index

I

input

connector, 3-9

Input connector, 1-3, 1-9

input connector, 1-2

input signal, maximum safe, 1-10

insertion loss, 2-2, 2-5

compensation, 2-10

instrument

returning for service, 1-12

ITU-T G.957, 2-4

M

mainframe troubleshooting, 3-3

maximum input level, 1-10