Page 1

Agilent 83433A

Lightwave Transmitter

User’s Guide

Page 2

© Copyright

Agilent Technologies 2000

All Rights Reserved. Reproduction, adaptation, or translation without prior written

permission is prohibited,

except as allowed under copyright laws.

Agilent Part No. 83433-90001

Printed in USA

February 2000

Agilent Technologies

Lightwave Division

1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799,

USA

(707) 577-1400

Notice.

The information contained in

this document is subject to

change without notice. Companies, names, and data used

in examples herein are fictitious unless otherwise noted.

Agilent Technologies makes

no warranty of any kind with

regard to this material, including but not limited to, the

implied warranties of merchantability and fitness for a

particular purpose. Agilent

Technologies shall not be liable for errors contained herein

or for incidental or consequential damages in connection with the furnishing,

performance, or use of this

material.

Restricted Rights Legend.

Use, duplication, or disclosure by the U.S. Government

is subject to restrictions as set

forth in subparagraph (c) (1)

(ii) of the Rights in Technical

Data and Computer Software

clause at DFARS 252.227-7013

for DOD agencies, and subparagraphs (c) (1) and (c) (2)

of the Commercial Computer

Software Restricted Rights

clause at FAR 52.227-19 for

other agencies.

Warranty.

This Agilent Technologies

instrument product is warranted against defects in

material and workmanship for

a period of one year from date

of shipment. During the warranty period, Agilent Technologies will, at its option, either

repair or replace products

which prove to be defective.

For warranty service or repair,

this product must be returned

to a service facility designated by Agilent Technologies. Buyer shall prepay

shipping charges to Agilent

Technologies and Agilent

Technologies shall pay shipping charges to return the

product to Buyer. However,

Buyer shall pay all shipping

charges, duties, and taxes for

products returned to Agilent

Technologies from another

country.

Agilent Technologies warrants that its software and

firmware designated by Agilent Technologies for use with

an instrument will execute its

programming instructions

when properly installed on

that instrument. Agilent Technologies does not warrant that

the operation of the instrument, or software, or firmware

will be uninterrupted or errorfree.

Limitation of Warranty.

The foregoing warranty shall

not apply to defects resulting

from improper or inadequate

maintenance by Buyer, Buyersupplied software or interfacing, unauthorized modification or misuse, operation

outside of the environmental

specifications for the product,

or improper site preparation

or maintenance.

No other warranty is

expressed or implied. Agilent

Technologies specifically disclaims the implied warranties

of merchantability and fitness

for a particular purpose.

Exclusive Remedies.

The remedies provided herein

are buyer's sole and exclusive

remedies. Agilent Technolo-

gies shall not be liable for any

direct, indirect, special, incidental, or consequential damages, whether based on

contract, tort, or any other

legal theory.

Safety Symbols.

CAUTION

The

caution

sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in damage to

or destruction of the product.

Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

WAR NING

The

warning

sign denotes a

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in injury or

loss of life. Do not proceed

beyond a warning sign until

the indicated conditions are

fully understood and met.

The instruction manual symbol. The product is marked with this

warning symbol when

it is necessary for the

user to refer to the

instructions in the

manual.

The laser radiation

symbol. This warning

symbol is marked on

products which have a

laser output.

The AC symbol is used

to indicate the

required nature of the

line module input

power.

The ON symbols are

|

used to mark the positions of the instrument

power line switch.

The OFF symbols

❍

are used to mark the

positions of the instrument power line

switch.

The CE mark is a registered trademark of

the European Community.

The CSA mark is a registered trademark of

the Canadian Standards Association.

The C-Tick mark is a

registered trademark

of the Australian Spectrum Management

Agency.

This text denotes the

ISM1-A

instrument is an

Industrial Scientific

and Medical Group 1

Class A product.

Typographical Conventions.

The following conventions are

used in this book:

Key type

for keys or text

located on the keyboard or

instrument.

Softkey type

for key names that

are displayed on the instrument’s screen.

Display type

for words or

characters displayed on the

computer’s screen or instrument’s display.

User type

for words or charac-

ters that you type or enter.

Emphasis

type for words or

characters that emphasize

some point or that are used as

place holders for text that you

type.

ii

Page 3

General Safety Considerations

General Safety Considerations

This product has been designed and tested in accordance with IEC Publication 61010-1, Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use, and has been supplied in a safe condition. The

instruction documentation contains information and warnings that must be

followed by the user to ensure safe operation and to maintain the product in a

safe condition.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

If this instrument is not used as specified, the protection provided by

the equipment could be impaired. This instrument must be used in a

normal condition (in which all means for protection are intact) only.

To prevent electrical shock, disconnect the Agilent 83433A from

mains before cleaning. Use a dry cloth or one slightly dampened with

water to clean the external case parts. Do not attempt to clean

internally.

This is a Safety Class 1 product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall only be

inserted in a socket outlet provided with a protective earth contact.

Any interruption of the protective conductor inside or outside of the

product is likely to make the product dangerous. Intentional

interruption is prohibited.

No operator serviceable parts inside. Refer servicing to qualified

personnel. To prevent electrical shock, do not remove covers.

Do not, under any circumstances, look into the optical output or any

fiber/device attached to the output while the laser is in operation.

Do not enable the laser when no fiber or equivalent device is attached

to the OPTICAL OUTPUT connector.

WARNING

For continued protection against fire hazard, replace line fuse only

with same type and ratings (5x20 mm,1.6 A, 250 V time-delay, low

braking capacity fuse). The use of other fuses or materials is

prohibited.

iii

Page 4

General Safety Considerations

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

This product is designed for use in Installation Category II and Pollution

Degree 2 per IEC 61010-1 and 664 respectively.

VENTILATION REQUIREMENTS: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operating

temperature of the product by 4°C for every 100 watts dissipated in the

cabinet. If the total power dissipated in the cabinet is greater than 800 watts,

then forced convection must be used.

Always use the three-prong ac power cord supplied with this instrument.

Failure to ensure adequate earth grounding by not using this cord may cause

instrument damage.

Do not

connect ac power until you have verified the line voltage is correct as

described in “GENERAL SPECIFICATIONS” on page 4-3. Damage to the

equipment could result.

This instrument has autoranging line voltage input. Be sure the supply voltage

is within the specified range.

Measurement accuracy—it’s up to you!

Fiber-optic connectors are easily damaged when connected to dirty or damaged cables

and accessories. The Agilent 83433A front-panel OPTICAL INPUT connector is no exception. When you use improper cleaning and handling techniques, you risk expensive

instrument repairs, damaged cables, and compromised measurements.

Before you connect any fiber-optic cable to the Agilent 83433A, refer to “Cleaning Con-

nections for Accurate Measurements” on page 3-6.

iv

Page 5

General Safety Considerations

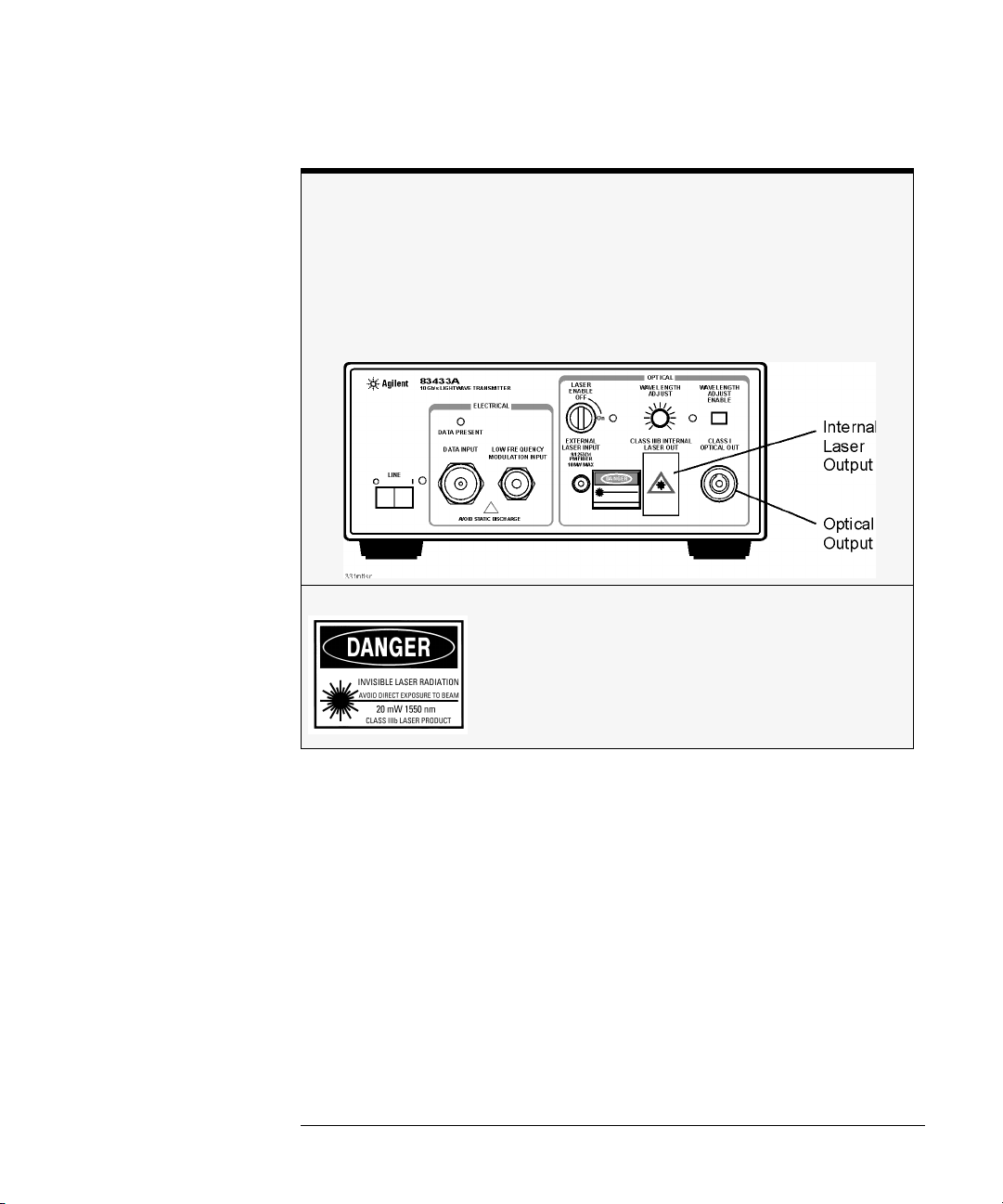

Laser classification

The Agilent 83433A is classified as an IEC LASER Class 3B according to

IEC 825-1:1999-11, and an FDA LASER class 3B according to 21CFR 1040.10. The total

power of light energy radiated out of the LASER OUT connector is 8.5 to 11 dBm. Opera-

tor precautions are necessary to maintain safety. The Agilent 83433A contains no user

serviceable parts. Removal of covers may result in hazardous radiation exposure.

v

Page 6

The Agilent 83433A—At a Glance

The Agilent 83433A—At a Glance

The Agilent 83433A lightwave transmitter is based on a lithium niobate modulator driven by an internal CW DFB 1552.52 nm laser. The laser and modulator

are inter-connected externally with a PMF fiber. The modulator can also be

used with an external laser with polarization maintaining fiber such as the Agilent 8164A, with 81680A option 071.

The Agilent 83433A is designed to produce high fidelity, low jitter waveforms

for 2.488 Gb/s STM-16/OC-48, 9.953 Gb/s STM-64/OC-192 and other transmission rates up through 10.7 Gb/s. The Agilent 83433A is intended for BER testing with error performance analyzers such as the Agilent 71612B. The MachZehnder modulator is adjusted for a fixed zero chirp. Its output waveform produces a minimum extinction ratio of 12 dB.

The internal DFB laser can be modulated at frequencies from 15 kHz to

10 MHz to increase linewidth for SBS suppression or channel identification

applications. The internal laser wavelength can be adjusted ±1.25 nm around

the 1552.52 center wavelength.

The Agilent 83433A can be combined with the Agilent 83434A 10 Gb/s lightwave receiver to create a complete optical link for system or fiber testing, or to

form a basis for substitution testing of commercial transmitters and receivers.

vi

Page 7

Contents

The Agilent 83433A—At a Glance vi

1 Getting Started

2 Using the Agilent 83433A

Front-Panel Features 2-2

Rear-Panel Features 2-4

Using a Laser Source 2-5

Performing a Quick Confidence Check 2-6

Connecting the Agilent 83433A to a Bit-Error-Ratio Test Set 2-9

Connecting the Agilent 83433A to an Oscilloscope 2-11

3 Reference

Options 3-2

Replacement Parts 3-3

Front-Panel Fiber-Optic Adapters 3-4

Power Cords 3-5

Cleaning Connections for Accurate Measurements 3-6

Returning the Instrument for Service 3-17

Agilent Technologies Service Offices 3-20

4 Specifications and Regulatory Information

Agilent 83433A Specifications and Characteristics 4-3

Regulatory Information 4-6

Contents-1

Page 8

Page 9

1

Step 1. Inspect the Shipment 1-3

Step 2. Check the Fuse 1-5

Step 3. Connect the Line-Power Cable 1-6

Step 4. Turn on the Agilent 83433A 1-8

Step 5. Avoid costly repairs 1-9

Step 6. Learn more about our products 1-10

Getting Started

Page 10

Getting Started

Setting Up the Agilent 83433A

Setting Up the Agilent 83433A

The instructions in this chapter show you how to install your lightwave transmitter. After you’ve completed this chapter, continue with Chapter 2, “Using

the Agilent 83433A”. Refer to Chapter 3, “Reference” for the following addi-

tional information:

• Tips on avoiding

techniques.

• Lists of available accessories and power cords.

• Instructions on returning your instrument to Agilent Technologies for service.

• Agilent Technologies Sales and Service Offices.

Chapter 4, “Specifications and Regulatory Information” contains information

on operating conditions, such as temperature.

costly

repairs by proper optical connection cleaning

1-2

Page 11

Step 1. Inspect the Shipment

Getting Started

Setting Up the Agilent 83433A

NOTE

The Agilent 83433A is supplied with an optical jumper cable. To avoid costly

replacement, do not misplace this cable.

❒

Inspect the shipping container for damage.

❒

Inspect the instrument.

❒

Verify that you received the options and accessories you ordered.

Keep the shipping container and cushioning material until you have inspected

the contents of the shipment for completeness and have checked the lightwave transmitter mechanically and electrically.

The lightwave transmitter is packed within a carton. Refer to “Returning the

Instrument for Service” on page 3-16, for the description and part numbers of

the packaging materials. Refer to “Options” on page 3-2, for the accessories

shipped with the lightwave transmitter.

If the shipping materials are in good condition, retain them for possible future

use. You may wish to ship the lightwave transmitter to another location or

return it to Agilent Technologies for service. Refer to “Returning the Instru-

ment for Service” on page 3-16.

1-3

Page 12

Getting Started

Setting Up the Agilent 83433A

If anything is missing or defective, or if the lightwave transmitter does not

pass the verification test, contact your nearest Agilent Technologies Sales

Office. If the shipment was damaged, contact the carrier, then contact the

nearest Agilent Technologies Sales Office. Keep the shipping materials for the

carrier’s inspection. The Agilent Sales Office will arrange for repair or replacement at Agilent Technologies’ option without waiting for claim settlement.

Serial numbers

Agilent Technologies makes frequent improvements to its products to

enhance their performance, usability, or reliability, and to control costs. Agilent service personnel have access to complete records of design changes to

each type of equipment, based on the equipment’s serial number. Whenever

you contact Agilent about your lightwave transmitter, have the complete serial

number available to ensure obtaining the most complete and accurate information possible.

A serial-number label is attached to the rear of the lightwave transmitter. It

contains the serial number and the options installed in the lightwave transmitter. Whenever you specify the serial number or refer to it in obtaining information about your lightwave transmitter, be sure to use the complete number.

1-4

Page 13

Step 2. Check the Fuse

Getting Started

Setting Up the Agilent 83433A

WARNING

1

Locate the line-input connector on the instrument’s rear panel.

2

Disconnect the line-power cable if it is connected.

3

Use a small flat-blade screwdriver to pry open the fuse holder door.

4

The fuse is housed in a small container. Insert the tip of a screwdriver on the

side of the container and gently pull outward to remove the container. A spare

fuse is stored below the line fuse.

For continued protection against fire hazard, replace line fuse only

with same type and ratings (5×20 mm,1.6 A, 250 V time-delay, low

breaking capacity fuse). The use of other fuses or materials is

prohibited.

1-5

Page 14

Getting Started

Setting Up the Agilent 83433A

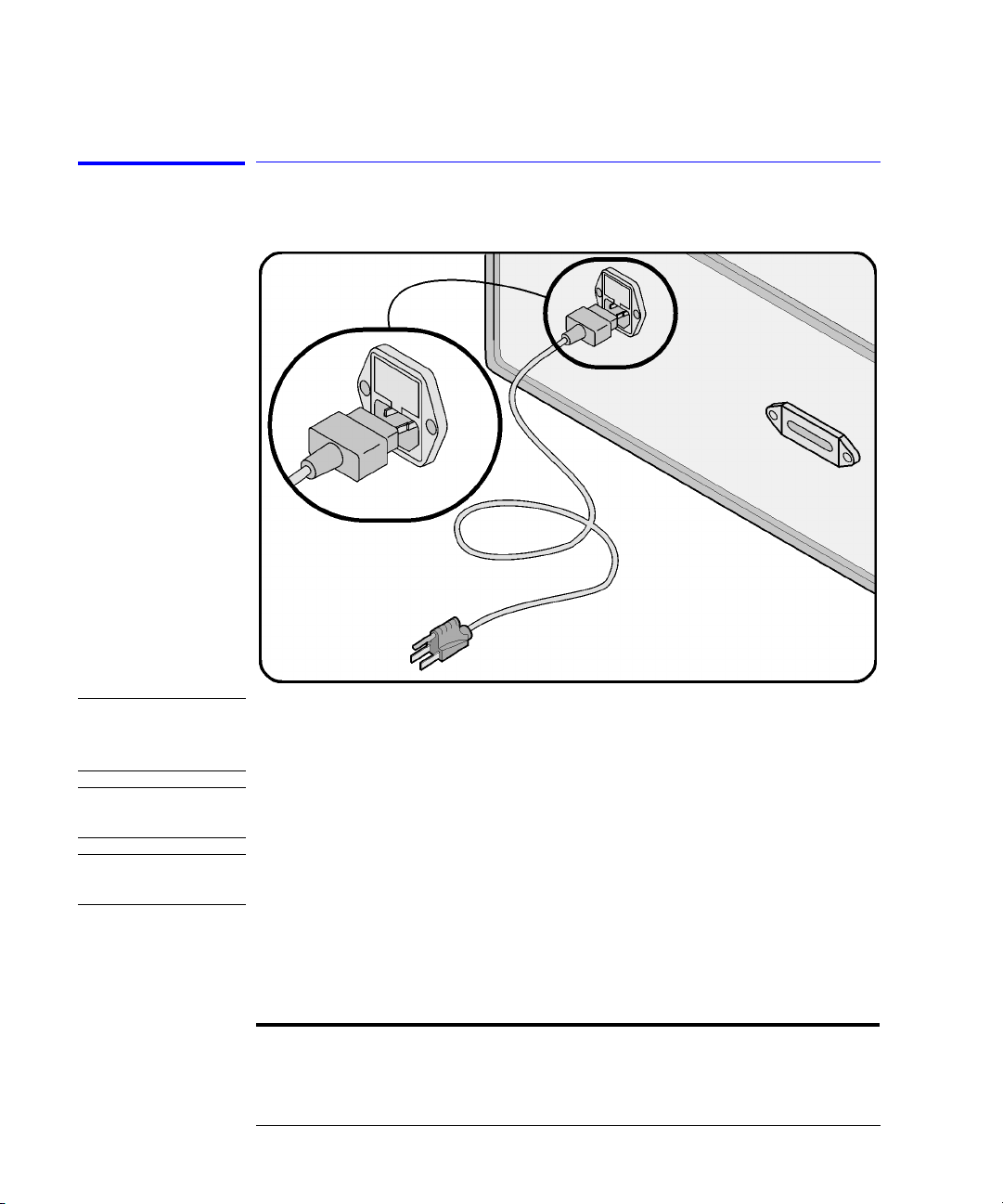

Step 3. Connect the Line-Power Cable

CAUTION

CAUTION

CAUTION

Always use the three-prong AC power cord supplied with this instrument.

Failure to ensure adequate earth grounding by not using this cord may cause

instrument damage.

not

Do

connect ac power until you have verified the line voltage is correct as

described in the following paragraphs. Damage to the equipment could result.

This instrument has autoranging line voltage input. Be sure the supply voltage

is within the specified range.

1

Verify that the line power meets the requirements shown in the following table.

Line Power Requirements

Power 115 VAC: 50 WATTS MAX

230 VAC: 50 WATTS MAX

1-6

Page 15

Getting Started

Setting Up the Agilent 83433A

Line Power Requirements

Voltage nominal: 115 VAC range: 90–132 V

nominal: 230 VAC range: 98–254 V

Frequency nominal: 50 Hz/60 Hz range: 47–63 Hz

2

Connect the line-power cord to the rear-panel connector of the instrument.

3

Connect the other end of the line-power cord to the power receptacle.

Various power cables are available to connect the Agilent 83433A to ac power

outlets unique to specific geographic areas. The cable appropriate for the area

to which the Agilent 83433A is originally shipped is included with the unit. You

can order additional ac power cables for use in different geographic areas.

Refer to “Power Cords” on page 3-5.

1-7

Page 16

Getting Started

Setting Up the Agilent 83433A

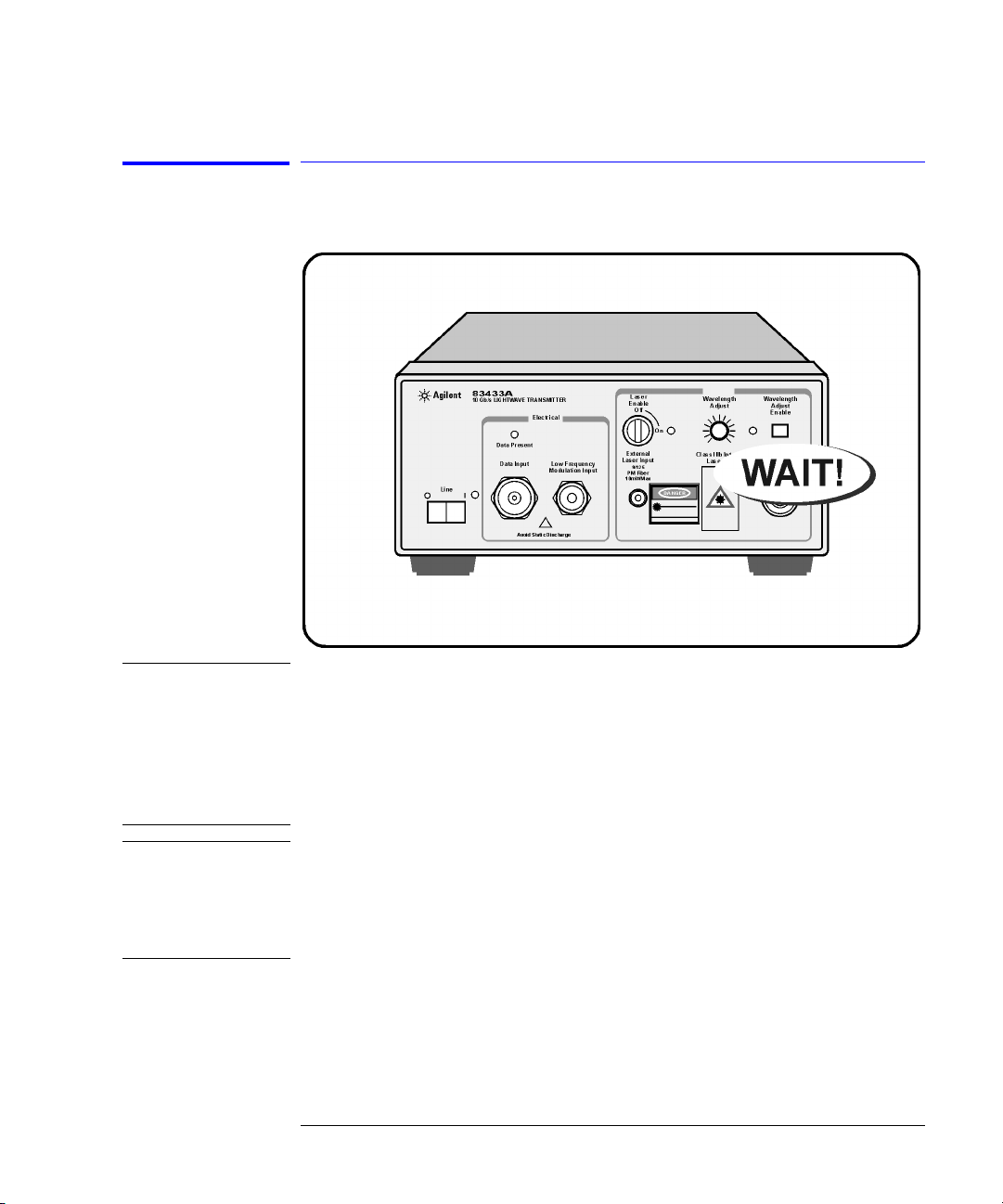

Step 4. Turn on the Agilent 83433A

NOTE

• Press the front-panel

LINE

key. All front-panel LED’s will light momentarily. The

line power indicator will remain lit.

The front panel LINE switch disconnects the mains circuit from the mains supply after

the EMC filters and before other parts of the instrument.

If the Agilent 83433A fails to turn on properly, consider the following possibilities:

❒

Is the line fuse good?

❒

Does the line socket have power?

❒

Is it plugged into the proper ac power source?

If the instrument still fails, return it to Agilent Technologies for repair. Refer to

“Returning the Instrument for Service” on page 3-17.

1-8

Page 17

Step 5. Avoid costly repairs

Getting Started

Setting Up the Agilent 83433A

CAUTION

CAUTION

Fiber-optic connectors are easily damaged when connected to dirty or

damaged cables and accessories. The front-panel connectors of the

Agilent 83433A are no exception. When you use improper cleaning and

handling techniques, you risk expensive instrument repairs, damaged cables,

and compromised measurements. Before you connect any fiber-optic cable to

the Agilent 83433A, refer to “Cleaning Connections for Accurate

Measurements” on page 3-6.

For proper operation without an external laser, connect the supplied optical

jumper cable between the EXTERNAL LASER INPUT and the CLASS IIIB

INTERNAL LASER OUT. Be sure to position the LASER ENABLE key in the off

position before making any connection. Agilent recommends the use of Panda

PMF fiber with the EXTERNAL LASER INPUT.

1-9

Page 18

Getting Started

Setting Up the Agilent 83433A

Step 6. Learn more about our products

To learn more about this or any Agilent Technologies product, visit our website at http://www.agilent.com.

To learn more about Fiber Optic Test Equipment, go to the Agilent Technologies home page listed above, and follow this path:

1

Click Products.

2

Click Test and Measurement.

3

Under Products, click Fiber Optic Test Equipment.

This path will take you to the Fiber Optic Test Equipment page.

Or you can enter the URL for this page directly:

http://www.tm.agilent.com/tmo/Products/English/FiberOpticTestEquipment.html

1-10

Page 19

2

Front-Panel Features 2-2

Rear-Panel Features 2-4

Using a Laser Source 2-5

Performing a Quick Confidence Check 2-6

Connecting the Agilent 83433A to a Bit-Error-Ratio Test Set 2-9

Connecting the Agilent 83433A to an Oscilloscope 2-11

Using the Agilent 83433A

Page 20

Using the Agilent 83433A

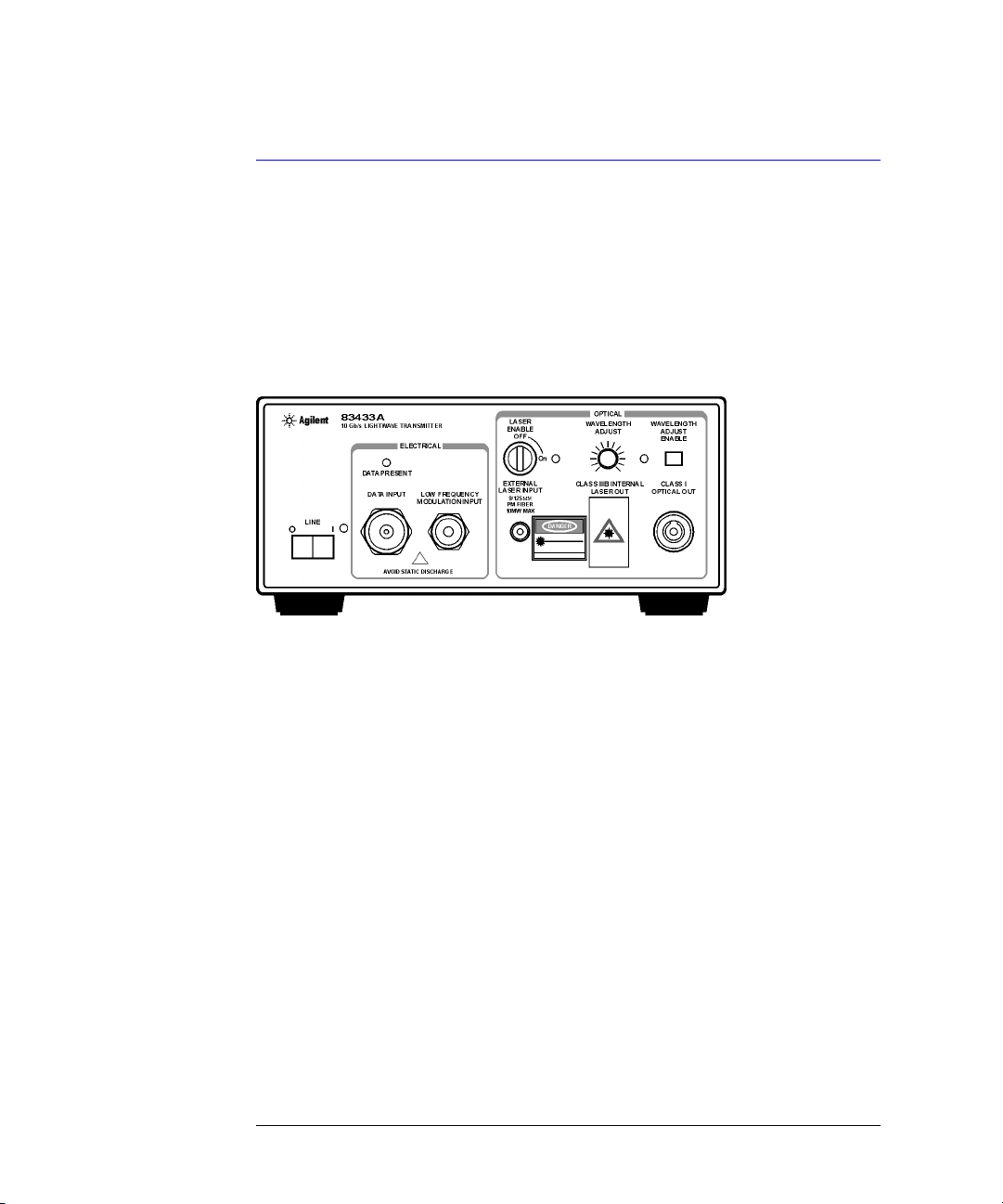

Front-Panel Features

Front-Panel Features

LASER ENABLE

DATA INPUT

DATA PRESENT INDICATOR

WAVELENGTH ADJUST

2-2

This key disables the Internal Class IIIB laser

Allows you to adjust the laser’s wavelength when

when in the OFF position. Be sure this key is in

the OFF position before making or removing any

optical connections.

Modulation input for digital signals. The input is

AC coupled.

Lights when LASER ENABLE is ON and valid

data is present.

the variable mode is activated. Press the

LENGTH ADJUST ENABLE

panel light turns on.

button so that the front-

WAVE-

Page 21

Using the Agilent 83433A

Front-Panel Features

WAVELENGTH ADJUST ENABLE

OPTICAL OUT

CLASS IIIB INTERNAL LASER OUT

EXTERNAL LASER INPUT

LOW FREQUENCY

MODULATION INPUT

Toggles between preset laser wavelength and

wavelength adjust mode. (Light turns on to indicate you can adjust the setting using the knob.).

Provides the modulated optical output for the

instrument. A universal adapter is used that can

be removed and replaced with different adapters

as needed (refer to “Front-Panel Fiber-Optic

Adapters” on page 3-4).

Provides the internal laser output for the instru-

ment. Use only Panda PMF fiber with this output. Use the supplied optical jumper cable to

connect this connector to the EXTERNAL

LASER INPUT.

Enables connection of external lasers with

Panda PMF output connectors to the internal

optical modulator.

BNC connector which allows direct, low-frequency modulation of the internal laser.

2-3

Page 22

Using the Agilent 83433A

Rear-Panel Features

Rear-Panel Features

2-4

Page 23

Using the Agilent 83433A

Using a Laser Source

Using a Laser Source

The Agilent 83433A contains an IEC LASER Class 3B according to IEC 60825.

The total power of light energy radiated out of the LASER OUT connector is

8.5 to 11 dBm. Use caution when making or breaking connections to the front

panel.

Three safety mechanisms are provided:

WARNING

WARNING

laser safety shutter

• A

nector. This shutter must be opened when attaching or removing cables.

key switch

• A

this key is turned on, the front-panel LED next to the key will light.

REMOTE SHUTDOWN connector

• A

be shorted for the laser to operate. When the short is removed from the connector, the accessible radiation does not exceed the AEL for FDA Laser

Class 1 (IEC Laser Class 1) according to IEC publication CE/IEC 8211: 1993. Use your own short, switch, or other circuitry to control the REMOTE SHUTDOWN.

To enable the laser, follow these three steps:

1

Make sure a short is connected to the rear panel REMOTE SHUTDOWN

connector. The laser will

2

Insert the key into the transmitter’s front panel.

3

Turn the key to turn the laser source on.

Do not, under any circumstances, look into the optical output or any

fiber/device attached to the output while the laser is in operation.

Do not enable the laser when no fiber or equivalent device is attached

to the OPTICAL OUTPUT connector.

on the front panel must be turned on to enable the laser. When

over the front-panel

not

operate without the short connected.

CLASS IIIB INTERNAL LASER OUT

on the rear panel. This connector

con-

must

2-5

Page 24

Using the Agilent 83433A

Performing a Quick Confidence Check

Performing a Quick Confidence Check

This procedure verifies the basic functionality of the lightwave transmitter.

The following equipment is used:

• Agilent 83433A lightwave transmitter

• Pattern generator

• Clock source

• Optical multimeter

Note

Before starting be sure to clean all connectors and optical interfaces using the procedures describe in “Cleaning Connections for Accurate Measurements” on page 3-6.

1

Connect the equipment as shown in Figure 2-1.

Figure 2-1. Setup to perform a quick confidence check.

2

Turn on the Agilent 83433A and let it warm up for 30 minutes.

3

Turn on the pattern generator and clock source and let them warm up

according to their specifications.

4

Connect the output of the clock source to the clock input of the pattern

generator.

2-6

Page 25

Using the Agilent 83433A

Performing a Quick Confidence Check

5

Connect the data output of the pattern generator to the

DATA INPUT

of the

83433A.

6

Use the ruggedized optical cable with Panda polarization maintaining fiber to

connect the 83433A

INPUT

.

7

Connect the 83433A

8

Set the pattern generator as follows:

CLASS IIIB INTERNAL LASER OUTPUT

CLASS I OPTICAL OUT

to the

to the input of an optical multimeter.

EXTENAL LASER

Clock output frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9953.28 MHz

Data output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . External AC coupled

Data amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 V

Pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

9

On the 83433A, ensure the wavelength adjust feature is disabled (front-panel

31

LED is off).

10

Turn the

11

Measure the optical power at the output of the 83433A. It will show a minimum

LASER ENABLE

key to the ON position.

of zero dBm.

–1 PRBS

2-7

Page 26

Using the Agilent 83433A

Performing a Quick Confidence Check

If the verification check fails

If the lightwave transmitter does not pass the verification check, you should

review the procedure being performed when the problem occurred. A few

minutes spent performing some simple checks may save waiting for your

instrument to be repaired. Before calling Agilent Technologies or returning

the unit for service, please make the following checks:

1

Is the line fuse good?

2

Does the line socket have power?

3

Is the unit plugged in to the proper ac power source?

4

Is the unit turned on? Verify the green light-emitting diode (LED) next to the

line switch is on, indicating that the power supply is on.

5

If other equipment, cables, and connectors are being used with the lightwave

transmitter, are they connected properly and operating correctly?

6

Review the procedure for the test being performed when the problem

appeared. Are all the settings correct?

7

Are the connectors clean? Refer to“Cleaning Connectors” on page 3-12 for

more information about cleaning the connectors.

WARNING

If the lightwave transmitter still fails, you can:

Return the lightwave transmitter to Agilent Technologies for repair. If the

lightwave transmitter is still under warranty or is covered by an Agilent Technologies maintenance contract, it will be repaired under the terms of the warranty or contract (the warranty is at the front of this manual). If the lightwave

transmitter is no longer under warranty or is not covered by an Agilent Technologies maintenance plan, Agilent Technologies will notify you of the cost of

the repair after examining the unit. Refer to “Returning the Instrument for

Service” on page 3-16 for more information.

No operator serviceable parts inside. Refer servicing to qualified

personnel. To prevent electrical shock do not remove covers.

2-8

Page 27

Using the Agilent 83433A

Connecting the Agilent 83433A to a Bit-Error-Ratio Test Set

Connecting the Agilent 83433A to a

Bit-Error-Ratio Test Set

The following procedure describes how to connect the lightwave transmitter

to a bit-error-ratio test set (BERT). The following equipment is used:

• Agilent 83433A lightwave transmitter

• Lightwave receiver or Agilent 83434A

• Bit error ratio tester or Agilent 71612B error performance analyzer

• Optical attenuator

1

Connect the equipment as shown in Figure 2-2.

2-9

Page 28

Using the Agilent 83433A

Connecting the Agilent 83433A to a Bit-Error-Ratio Test Set

Figure 2-2. Connecting the Agilent 83433A to a bit-error-ratio test system.

2

Use the optical cable with Panda polarization maintaining fiber to connect the

Agilent 83433A

3

Adjust the optical attenuator so the power to the receiver is between 0 dBm

CLASS IIIb INTERNAL LASER

output to the

EXTERNAL LASER INPUT

and –16 dBm.

2-10

.

Page 29

Using the Agilent 83433A

Connecting the Agilent 83433A to an Oscilloscope

Connecting the Agilent 83433A to an

Oscilloscope

The following procedure describes how to connect the lightwave transmitter

to an oscilloscope. The following equipment is used:

• Agilent 83433A lightwave transmitter

• Pattern generator

• Clock source

• Optical multimeter

• Optical oscilloscope

Note

Before starting, be sure to clean all connectors and optical interfaces using the procedures describe in “Cleaning Connections for Accurate Measurements” on page 3-6.

1

Follow the procedure described in “Performing a Quick Confidence Check” on

page 2-6.

2

After completing this check, connect the

to the optical input of the oscilloscope.

3

Connect the trigger output of the pattern generator to the trigger input of the

oscilloscope.

4

Evaluate the

filters and eye mask selected.

OPTICAL OUTPUT

of the Agilent 83433A with the OC-192/STM-64

OPTICAL OUTPUT

of the Agilent 83433A

2-11

Page 30

Page 31

3

Options 3-2

Replacement Parts 3-3

Front-Panel Fiber-Optic Adapters 3-4

Power Cords 3-5

Cleaning Connections for Accurate Measurements 3-6

Returning the Instrument for Service 3-17

Agilent Technologies Service Offices 3-20

Reference

Page 32

Reference

Options

Options

Accessories supplied

The Agilent 83433A lightwave transmitter is shipped with:

• FC/PC connector adapter on the optical output of the lightwave transmitter

unless a different option was ordered. Refer to Table 3-1, “Agilent 83433A

Options,” on page 3-2 for a complete list of the available connector interfaces.

• Optical jumper cable, Agilent part number 5022-1843.

Agilent 83433A Lightwave Receiver User’s Guide,

•

83434-90001.

Agilent part number

Available

seperately

Fiber Optics Handbook

The

tion and reference for fiber-optic measurements.

, Agilent part number 5952-9654, is an introduc-

Options

Table 3-1. Agilent 83433A Options

Option Description

Option 011 Diamond (HMS-10) connector interface on

the optical output of the lightwave

transmitter

Option 013 DIN connector interface on the optical

output of the lightwave transmitter

Option 014 ST connector interface on the optical

output of the lightwave transmitter

Option 017 SC connector interface on the optical

output of the lightwave transmitter

3-2

Page 33

Replacement Parts

Table 3-2. Replaceable Parts

Description Agilent Part Nmmber

APC 3.5 F-to-F (connector saver) 5061-5311

APC 3.5 50 ohm termination 1810-0118

Optical jumper cable 5022-1843

FC/PC connector interface 81000FI

Reference

Replacement Parts

3-3

Page 34

Reference

Front-Panel Fiber-Optic Adapters

Front-Panel Fiber-Optic Adapters

Front Panel

Fiber-Optic

Adapter

Description Agilent Part Number

Diamond HMS-10 81000AI

a

FC/PC

D4 81000GI

SC 81000KI

DIN 81000SI

ST 81000VI

Biconic 81000WI

Dust Covers

FC connector 1005-0594

Diamond HMS-10 connector 1005-0593

DIN connector 1005-0595

ST connector 1005-0596

SC connector 1005-0597

81000FI

a. The FC/PC adapter is the standard adapter supplied with the instrument.

3-4

Page 35

Power Cords

Reference

Power Cords

Plug Type Cable Part No. Plug Description

250V 8120-1351

8120-1703

250V 8120-1369

8120-0696

250V 8120-1689

8120-1692

8120-2857p

125V 8120-1378

8120-1521

8120-1992

250V 8120-2104

8120-2296

220V 8120-2956

8120-2957

Straight *BS1363A

90°

Straight *NZSS198/ASC

90°

Straight *CEE7-Y11

90°

Straight (Shielded)

Straight *NEMA5-15P

90°

Straight (Medical) UL544

Straight *SEV1011

1959-24507

Type 12 90°

Straight *DHCK107

90°

Length

(in/cm)

90/228

90/228

79/200

87/221

79/200

79/200

79/200

90/228

90/228

96/244

79/200

79/200

79/200

79/200

Color Country

Gray

Mint Gray

Gray

Mint Gray

Mint Gray

Mint Gray

Coco Brown

Jade Gray

Jade Gray

Black

Mint Gray

Mint Gray

Mint Gray

Mint Gray

United Kingdom,

Cyprus, Nigeria, Zimbabwe, Singapore

Australia, New Zealand

East and West Europe,

Saudi Arabia, So.

Africa, India (unpolarized in many nations)

United States, Canada,

Mexico, Philippines,

Tai wa n

Switzerland

Denmark

250V 8120-4211

8120-4600

100V 8120-4753

8120-4754

* Part number shown for plug is the industry identifier for the plug only. Number shown for cable is the Agilent

Technologies part number for the complete cable including the plug.

Straight SABS164

90°

Straight MITI

90°

79/200

79/200

90/230

90/230

Jade Gray Republic of South

Africa

India

Dark Gray Japan

3-5

Page 36

Reference

Cleaning Connections for Accurate Measurements

Cleaning Connections for Accurate Measurements

Today, advances in measurement capabilities make connectors and connection techniques more important than ever. Damage to the connectors on calibration and verification devices, test ports, cables, and other devices can

degrade measurement accuracy and damage instruments. Replacing a damaged connector can cost thousands of dollars, not to mention lost time! This

expense can be avoided by observing the simple precautions presented in this

book. This book also contains a brief list of tips for caring for electrical connectors.

Choosing the Right Connector

A critical but often overlooked factor in making a good lightwave measurement is the selection of the fiber-optic connector. The differences in connector types are mainly in the mechanical assembly that holds the ferrule in

position against another identical ferrule. Connectors also vary in the polish,

curve, and concentricity of the core within the cladding. Mating one style of

cable to another requires an adapter. Agilent Technologies offers adapters for

most instruments to allow testing with many different cables. Figure 3-1 on

page 3-7 shows the basic components of a typical connectors.

The system tolerance for reflection and insertion loss must be known when

selecting a connector from the wide variety of currently available connectors.

Some items to consider when selecting a connector are:

• How much insertion loss can be allowed?

• Will the connector need to make multiple connections? Some connectors are bet-

ter than others, and some are very poor for making repeated connections.

• What is the reflection tolerance? Can the system take reflection degradation?

• Is an instrument-grade connector with a precision core alignment required?

• Is repeatability tolerance for reflection and loss important? Do your specifications

take repeatability uncertainty into account?

• Will a connector degrade the return loss too much, or will a fusion splice be required? For example, many DFB lasers cannot operate with reflections from connectors. Often as much as 90 dB isolation is needed.

3-6

Page 37

Reference

Cleaning Connections for Accurate Measurements

Figure 3-1. Basic components of a connector.

Over the last few years, the FC/PC style connector has emerged as the most

popular connector for fiber-optic applications. While not the highest performing connector, it represents a good compromise between performance, reliability, and cost. If properly maintained and cleaned, this connector can

withstand many repeated connections.

However, many instrument specifications require tighter tolerances than most

connectors, including the FC/PC style, can deliver. These instruments cannot

tolerate connectors with the large non-concentricities of the fiber common

with ceramic style ferrules. When tighter alignment is required, Agilent

Technologies instruments typically use a connector such as the Diamond

HMS-10, which has concentric tolerances within a few tenths of a micron. Agilent Technologies then uses a special universal adapter, which allows other

cable types to mate with this precision connector. See Figure 3-2.

Figure 3-2. Universal adapters to Diamond HMS-10.

3-7

Page 38

Reference

Cleaning Connections for Accurate Measurements

The HMS-10 encases the fiber within a soft nickel silver (Cu/Ni/Zn) center

which is surrounded by a tough tungsten carbide casing, as shown in

Figure 3-3.

Figure 3-3. Cross-section of the Diamond HMS-10 connector.

The nickel silver allows an active centering process that permits the glass fiber

to be moved to the desired position. This process first stakes the soft nickel

silver to fix the fiber in a near-center location, then uses a post-active staking

to shift the fiber into the desired position within 0.2µm. This process, plus the

keyed axis, allows very precise core-to-core alignments. This connector is

found on most Agilent Technologies lightwave instruments.

The soft core, while allowing precise centering, is also the chief liability of the

connector. The soft material is easily damaged. Care must be taken to minimize excessive scratching and wear. While minor wear is not a problem if the

glass face is not affected, scratches or grit can cause the glass fiber to move

out of alignment. Also, if unkeyed connectors are used, the nickel silver can be

pushed onto the glass surface. Scratches, fiber movement, or glass contamination will cause loss of signal and increased reflections, resulting in poor return

loss.

3-8

Page 39

Inspecting Connectors

Because fiber-optic connectors are susceptible to damage that is not immediately obvious to the naked eye, bad measurements can be made without the

user even being aware of a connector problem. Although microscopic examination and return loss measurements are the best way to ensure good connections, they are not always practical. An awareness of potential problems, along

with good cleaning practices, can ensure that optimum connector performance is maintained. With glass-to-glass interfaces, it is clear that any degradation of a ferrule or the end of the fiber, any stray particles, or finger oil can

have a significant effect on connector performance.

Figure 3-4 shows the end of a clean fiber-optic cable. The dark circle in the

center of the micrograph is the fiber’s 125 µm core and cladding which carries

the light. The surrounding area is the soft nickel-silver ferrule. Figure 3-5

shows a dirty fiber end from neglect or perhaps improper cleaning. Material is

smeared and ground into the end of the fiber causing light scattering and poor

reflection. Not only is the precision polish lost, but this action can grind off the

glass face and destroy the connector.

Figure 3-6 shows physical damage to the glass fiber end caused by either

repeated connections made without removing loose particles or using

improper cleaning tools. When severe, the damage on one connector end can

be transferred to another good connector that comes in contact with it.

The cure for these problems is disciplined connector care as described in the

following list and in “Cleaning Connectors” on page 3-12.

Use the following guidelines to achieve the best possible performance when

making measurements on a fiber-optic system:

Reference

Cleaning Connections for Accurate Measurements

• Never use metal or sharp objects to clean a connector and never scrape the connector.

• Avoid matching gel and oils.

3-9

Page 40

Reference

Cleaning Connections for Accurate Measurements

Figure 3-4. Clean, problem-free fiber end and ferrule.

Figure 3-5. Dirty fiber end and ferrule from poor cleaning.

Figure 3-6. Damage from improper cleaning.

While these often work well on first insertion, they are great dirt magnets. The

oil or gel grabs and holds grit that is then ground into the end of the fiber.

Also, some early gels were designed for use with the FC, non-contacting con-

3-10

Page 41

Reference

Cleaning Connections for Accurate Measurements

nectors, using small glass spheres. When used with contacting connectors,

these glass balls can scratch and pit the fiber. If an index matching gel or oil

must be used, apply it to a freshly cleaned connector, make the measurement,

and then immediately clean it off. Never use a gel for longer-term connections

and never use it to improve a damaged connector. The gel can mask the extent

of damage and continued use of a damaged fiber can transfer damage to the

instrument.

• When inserting a fiber-optic cable into a connector, gently insert it in as straight

a line as possible. Tipping and inserting at an angle can scrape material off the inside of the connector or even break the inside sleeve of connectors made with ceramic material.

• When inserting a fiber-optic connector into a connector, make sure that the fiber

end does not touch the outside of the mating connector or adapter.

• Avoid over tightening connections.

Unlike common electrical connections, tighter is

not

better. The purpose of

the connector is to bring two fiber ends together. Once they touch, tightening

only causes a greater force to be applied to the delicate fibers. With connectors that have a convex fiber end, the end can be pushed off-axis resulting in

misalignment and excessive return loss. Many measurements are actually

improved by backing off the connector pressure. Also, if a piece of grit does

happen to get by the cleaning procedure, the tighter connection is more likely

to damage the glass. Tighten the connectors just until the two fibers touch.

• Keep connectors covered when not in use.

• Use fusion splices on the more permanent critical nodes. Choose the best connec-

tor possible. Replace connecting cables regularly. Frequently measure the return

loss of the connector to check for degradation, and clean every connector, every

time.

All connectors should be treated like the high-quality lens of a good camera.

The weak link in instrument and system reliability is often the inappropriate

use and care of the connector. Because current connectors are so easy to use,

there tends to be reduced vigilance in connector care and cleaning. It takes

only one missed cleaning for a piece of grit to permanently damage the glass

and ruin the connector.

Measuring insertion loss and return loss

Consistent measurements with your lightwave equipment are a good indication that you have good connections. Since return loss and insertion loss are

key factors in determining optical connector performance they can be used to

determine connector degradation. A smooth, polished fiber end should pro-

3-11

Page 42

Reference

Cleaning Connections for Accurate Measurements

duce a good return-loss measurement. The quality of the polish establishes

the difference between the “PC” (physical contact) and the “Super PC” connectors. Most connectors today are physical contact which make glass-to-glass

connections, therefore it is critical that the area around the glass core be clean

and free of scratches. Although the major area of a connector, excluding the

glass, may show scratches and wear, if the glass has maintained its polished

smoothness, the connector can still provide a good low level return loss connection.

If you test your cables and accessories for insertion loss and return loss upon

receipt, and retain the measured data for comparison, you will be able to tell in

the future if any degradation has occurred. Typical values are less than 0.5 dB

of loss, and sometimes as little as 0.1 dB of loss with high performance connectors. Return loss is a measure of reflection: the less reflection the better

(the larger the return loss, the smaller the reflection). The best physically

contacting connectors have return losses better than 50 dB, although 30 to

40 dB is more common.

Visual inspection of fiber ends

Visual inspection of fiber ends can be helpful. Contamination or imperfections

on the cable end face can be detected as well as cracks or chips in the fiber

itself. Use a microscope (100X to 200X magnification) to inspect the entire

end face for contamination, raised metal, or dents in the metal as well as any

other imperfections. Inspect the fiber for cracks and chips. Visible imperfections not touching the fiber core may not affect performance (unless the

imperfections keep the fibers from contacting).

WARNING

Always remove both ends of fiber-optic cables from any instrument,

system, or device before visually inspecting the fiber ends. Disable all

optical sources before disconnecting fiber-optic cables. Failure to do

so may result in permanent injury to your eyes.

Cleaning Connectors

The procedures in this section provide the proper steps for cleaning fiberoptic cables and Agilent Technologies universal adapters. The initial cleaning,

using the alcohol as a solvent, gently removes any grit and oil. If a caked-on

layer of material is still present, (this can happen if the beryllium-copper sides

of the ferrule retainer get scraped and deposited on the end of the fiber during

insertion of the cable), a second cleaning should be performed. It is not

uncommon for a cable or connector to require more than one cleaning.

3-12

Page 43

Reference

Cleaning Connections for Accurate Measurements

CAUTION

Agilent Technologies strongly recommends that index matching compounds

not

be applied to their instruments and accessories. Some compounds, such as gels,

may be difficult to remove and can contain damaging particulates. If you think the

use of such compounds is necessary, refer to the compound manufacturer for

information on application and cleaning procedures.

3-13

Page 44

Reference

Cleaning Connections for Accurate Measurements

Table 3-3. Cleaning Accessories

Item Agilent Part Number

Any commercially available denatured alcohol —

Cotton swabs 8520-0023

Small foam swabs 9300-1223

Compressed dust remover (non-residue) 8500-5262

Table 3-4. Dust Caps Provided with Lightwave Instruments

Item Agilent Part Number

Laser shutter cap 08145-64521

FC/PC dust cap 08154-44102

CAUTION

Biconic dust cap 08154-44105

DIN dust cap 5040-9364

HMS10/dust cap 5040-9361

ST dust cap 5040-9366

To clean a non-lensed connector

Do not use any type of foam swab to clean optical fiber ends. Foam swabs can

leave filmy deposits on fiber ends that can degrade performance.

1

Apply pure isopropyl alcohol to a clean lint-free cotton swab or lens paper.

Cotton swabs can be used as long as no cotton fibers remain on the fiber end

after cleaning.

2

Clean the ferrules and other parts of the connector while avoiding the end of the

fiber.

3

Apply isopropyl alcohol to a new clean lint-free cotton swab or lens paper.

4

Clean the fiber end with the swab or lens paper.

3-14

Page 45

Reference

Cleaning Connections for Accurate Measurements

not

Do

scrub during this initial cleaning because grit can be caught in the

swab and become a gouging element.

5

Immediately dry the fiber end with a clean, dry, lint-free cotton swab or lens

paper.

6

Blow across the connector end face from a distance of 6 to 8 inches using filtered,

dry, compressed air. Aim the compressed air at a shallow angle to the fiber end

face.

Nitrogen gas or compressed dust remover can also be used.

CAUTION

Do not shake, tip, or invert compressed air canisters, because this releases

particles in the can into the air. Refer to instructions provided on the compressed

air canister.

7

As soon as the connector is dry, connect or cover it for later use.

If the performance, after the initial cleaning, seems poor try cleaning the connector again. Often a second cleaning will restore proper performance. The

second cleaning should be more arduous with a scrubbing action.

To clean an adapter

The fiber-optic input and output connectors on many Agilent Technologies

instruments employ a universal adapter such as those shown in the following

picture. These adapters allow you to connect the instrument to different types

of fiber-optic cables.

Figure 3-7. Universal adapters.

1

Apply isopropyl alcohol to a clean foam swab.

Cotton swabs can be used as long as no cotton fibers remain after cleaning. The

foam swabs listed in this section’s introduction are small enough to fit into

adapters.

Although foam swabs can leave filmy deposits, these deposits are very thin, and

the risk of other contamination buildup on the inside of adapters greatly outweighs the risk of contamination by foam swabs.

2

Clean the adapter with the foam swab.

3-15

Page 46

Reference

Cleaning Connections for Accurate Measurements

3

Dry the inside of the adapter with a clean, dry, foam swab.

4

Blow through the adapter using filtered, dry, compressed air.

Nitrogen gas or compressed dust remover can also be used. Do not shake, tip,

or invert compressed air canisters, because this releases particles in the can

into the air. Refer to instructions provided on the compressed air canister.

3-16

Page 47

Returning the Instrument for Service

The instructions in this section show you how to properly return the instrument for repair or calibration. Always call the Agilent Technologies Instrument

Support Center first to initiate service

service office. This ensures that the repair (or calibration) can be properly

tracked and that your instrument will be returned to you as quickly as possible. Call this number regardless of where you are located. Refer to “Agilent

Technologies Service Offices” on page 3-20 for a list of service offices.

Agilent Technologies Instrument Support Center. . . . . . . . . . . (800) 403-0801

If the instrument is still under warranty or is covered by an Agilent Technologies maintenance contract, it will be repaired under the terms of the warranty

or contract (the warranty is at the front of this manual). If the instrument is

no longer under warranty or is not covered by an Agilent Technologies maintenance plan, Agilent Technologies will notify you of the cost of the repair after

examining the unit.

When an instrument is returned to a Agilent Technologies service office for

servicing, it must be adequately packaged and have a complete description of

the failure symptoms attached. When describing the failure, please be as specific as possible about the nature of the problem. Include copies of additional

failure information (such as the instrument failure settings, data related to

instrument failure, and error messages) along with the instrument being

returned.

Returning the Instrument for Service

before

returning your instrument to a

Reference

3-17

Page 48

Reference

Returning the Instrument for Service

Preparing the instrument for shipping

1

Write a complete description of the failure and attach it to the instrument. Include

any specific performance details related to the problem. The following

information should be returned with the instrument.

• Type of service required.

• Date instrument was returned for repair.

• Description of the problem:

• Whether problem is constant or intermittent.

• Whether instrument is temperature-sensitive.

• Whether instrument is vibration-sensitive.

• Instrument settings required to reproduce the problem.

• Performance data.

• Company name and return address.

• Name and phone number of technical contact person.

• Model number of returned instrument.

• Full serial number of returned instrument.

• List of any accessories returned with instrument.

2

Disconnect the optical jumper cable from the front panel of the instrument. Place

protective wrap around the cable and tape it to the top panel of the instrument.

CAUTION

CAUTION

3

Cover all front or rear-panel connectors that were originally covered when you

first received the instrument.

Cover electrical connectors to protect sensitive components from electrostatic

damage. Cover optical connectors to protect them from damage due to physical

contact or dust.

Instrument damage can result from using packaging materials other than the

original materials. Never use styrene pellets as packaging material. They do not

adequately cushion the instrument or prevent it from shifting in the carton. They

may also cause instrument damage by generating static electricity.

4

Pack the instrument in the original shipping containers. Original materials are

available through any Agilent Technologies office. Or, use the following guidelines:

• Wrap the instrument in antistatic plastic to reduce the possibility of damage

caused by electrostatic discharge.

• For instruments weighing less than 54 kg (120 lb), use a double-walled, cor-

3-18

Page 49

Returning the Instrument for Service

rugated cardboard carton of 159 kg (350 lb) test strength.

• The carton must be large enough to allow approximately 7 cm (3 inches) on

all sides of the instrument for packing material, and strong enough to accommodate the weight of the instrument.

• Surround the equipment with approximately 7 cm (3 inches) of packing material, to protect the instrument and prevent it from moving in the carton. If

packing foam is not available, the best alternative is S.D-240 Air Cap™ from

Sealed Air Corporation (Commerce, California 90001). Air Cap looks like a

plastic sheet filled with air bubbles. Use the pink (antistatic) Air Cap™ to

reduce static electricity. Wrapping the instrument several times in this material will protect the instrument and prevent it from moving in the carton.

5

Seal the carton with strong nylon adhesive tape.

6

Mark the carton “FRAGILE, HANDLE WITH CARE”.

7

Retain copies of all shipping papers.

Reference

3-19

Page 50

Agilent Technologies Service Offices

Before returning an instrument for service, call the Agilent Technologies

Instrument Support Center at (800) 403-0801, visit the Test and Measurement

Web Sites by Country page at http://www.tm.agilent.com/tmo/country/English/

index.html, or call one of the numbers listed below.

Agilent Technologies Service Numbers

Austria 01/25125-7171

Belgium 32-2-778.37.71

Brazil (11) 7297-8600

China 86 10 6261 3819

Denmark 45 99 12 88

Finland 358-10-855-2360

France 01.69.82.66.66

Germany 0180/524-6330

India 080-34 35788

Italy +39 02 9212 2701

Ireland 01 615 8222

Japan (81)-426-56-7832

Korea 82/2-3770-0419

Mexico (5) 258-4826

Netherlands 020-547 6463

Norway 22 73 57 59

Russia +7-095-797-3930

Spain (34/91) 631 1213

Sweden 08-5064 8700

Switzerland (01) 735 7200

United Kingdom 01 344 366666

United States and Canada (800) 403-0801

Page 51

4

Agilent 83433A Specifications and Characteristics 4-3

Regulatory Information 4-6

Specifications and Regulatory Information

Page 52

Specifications and Regulatory Information

Specifications and Regulatory Information

Specifications and Regulatory Information

This chapter lists specification and characteristics of the instrument. The distinction between these terms is described as follows:

• Specifications describe warranted performance over the temperature range

0°C to +45°C and relative humidity <95% non-condensing (unless otherwise

noted). All specifications apply after the instrument’s temperature has been

stabilized after 30 minutes of continuous operation.

• Specifications pertaining to the use of the internal laser require the use of the

supplied PMF jumper cable.

Characteristics

•

ed, performance parameters.

provide useful information by giving functional, but nonwarrant-

Characteristics are printed in this typeface.

Calibration cycle

This instrument requires periodic verification of performance. The instrument

should have a complete verification of specifications at least once every two

years.

4-2

Page 53

Specifications and Regulatory Information

Agilent 83433A Specifications and Characteristics

Agilent 83433A Specifications and

Characteristics

OPERATING SPECIFICATIONS

Digital Data Input

Data rate compatibility

Amplitude

a

Return loss

0.1 to 5000 MHz

5000 to 10,700 MHz

Impedance

Mark density

Maximum run of consecutive “ones” or “zeros”

Polarity

Maximum Safe Input Level

Digital data input

Low-frequency modulation input

External optical modulator input

b

Low-Frequency Modulation Input

Frequency range 3 dB points

Amplitude for 5% mod index

a

Impedance

Polarity

Internal Laser Output

CW power

Wavelength

c

d

Wavelength adjustment range

Spectral width at –20 dBc (Full Width Half Maximum)

Side-mode suppression ratio

Optical Modulator Input

Wavelength

Optical power input

b

Input return loss

2.4 to 10.7 Gb/s

0.5 to 1.5 V pk-pk

12 dB minimum

9 dB minimum

Ω

50

45 to 55%

100 bits

non-inverting

2.0 V pk-pk; +2.0, –2.0 V dc

2.0 V pk-pk

+14 dBm

0.015 to 10 MHz

0.5 to 1.5 V pk-pk; 1 V pk-pk nominal

Ω

50

inverting

+8.5 to +11.5 dBm; +10 dBm nominal

1552.42 to 1552.62 nm; 1552.52 nominal

–1 to +1 nm

10 MHz maximum

30 dB minimum

1530 to 1565 nm

+2 to +12 dBm

27 dB minimum

4-3

Page 54

Specifications and Regulatory Information

Agilent 83433A Specifications and Characteristics

Modulated Optical Output

Modulator insertion loss

Optical power output

Output return loss

Extinction ratio

Jitter generation

OC-192 data rate

e

f

g

f

Eye mask

OC-192 data rate

OC-48 data rate

3 to 7 dB

0 to +5.5 dBm

27 dB minimum

12 dB minimum

0.15 UI pk-pk max.

Meets GR-253-CORE (scaled to data

rate)

Meets GR-253-CORE

GENERAL SPECIFICATIONS

Temperature

Operating

Storage

°

0 to +45

–40 to +70

C

°

C

Power Requirements 100/120/220/240 VAC (±10%), 47 to 63

Hz

Weight (characteristic) 3.5 kg (7.8 lb)

Dimensions 102mm (4 in) height, 216 mm (8.5 in)

width, 444 mm (17.5 in) depth (Agilent

System II, half-width case)

FRONT-PANEL INPUT / OUTPUT

Digital data input connector APC-3.5 male

Low frequency modulation input connector BNC female

Internal laser output connector

Optical modulator input connector

Modulated optical output connector

h

FC/PC

h

FC/PC

Diamond HMS-10/HP

i

Optical jumper cable Includes semi-rigid, polarization

maintaining fiber to connect internal

laser output and optical modulator input

SAFETY

Safety

General safety

Meets or exceeds

CAN/CSA-C22.2 NO.1010 and

EN 61010/IEC 61010-1 and all

Laser classification

amendments

4-4

FDA Laser Class IIIb according to

21 CFR 1040.10

IEC Laser Class 3B according to

IEC 60825

Page 55

Specifications and Regulatory Information

Agilent 83433A Specifications and Characteristics

EMI Radiated and conducted emissions are

in compliance with the requirements of

CISPR Publication 11, Class A and

immunity in compliance with

IEC 61326-1

a. AC coupled.

b. Input power greater than +10 dBm may cause modulated optical output power to exceed Class I level.

c. Class IIIB laser output.

d. Wavelength adjustment disabled.

e. Average power with internal laser modulated with 2

f. Measured with 1 V pk-pk data input signal and 2

g. Applies over the temperature range 0

h. Panda polarization-maintaining fiber with slow axis aligned to key.

i. Standard instrument has FC/PC adapters.Other adapters available as options.

C to 30°C.

°

31

-1 PRBS.

31

-1 PRBS on an 83480A, 83485B with OC-192 filter.

4-5

Page 56

Specifications and Regulatory Information

Regulatory Information

Regulatory Information

• Laser Classification: This product contains an IEC LASER Class 3B according

to IEC 60825-1 Title 21 Part 1040.

• This product contains an FDA laser Class IIIb according to 21CFR 1040.10.

• This product is designed for use in INSTALLATION CATEGORY II and POLLU-

TION DEGREE 2, per IEC 61010-1 and 664 respectively.

Notice for

Germany: Noise

Declaration

This is to declare that this instrument is in conformance with the German Regulation on Noise Declaration for Machines (Laermangabe nach der Maschinenlaermrerordnung –3.GSGV Deutschland).

Acoustic Noise Emission Geraeuschemission

LpA < 70 dB

Operator position

Normal position

per ISO 7779

LpA < 70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 t.19

4-6

Page 57

Declaration of Conformity

Specifications and Regulatory Information

Regulatory Information

4-7

Page 58

Page 59

Index

A

accessories, 3-2

adapters, 2-3

fiber optic, 3-4

adjusting

wavelength, 2-2

Agilent offices, 3-20

B

BERT

connecting to, 2-9

bit-error-ratio test set, 2-9

C

cabinet, cleaning, iii

calibration

cycle, 4-2

care

of cabinet, iii

class IIIB internal laser out, 2-3

classification

laser, v, 4-6

product, iii

cleaning

adapters, 3-15

cabinet, iii

fiber-optic connections, 3-6, 3-14

non-lensed connectors, 3-14

compressed dust remover, 3-14

connecting to a BERT

bit-error-rate test set, 2-9

connecting to an oscilloscope, 2-11

connector

care, 3-6

connector interface

front-panel, 3-2

cotton swabs, 3-14

D

DATA, 2-2

data input connector, 2-2

declaration of conformity, 4-7

dust caps, 3-14

E

external laser input, 2-3

F

fiber optics

adapters, 2-3, 3-4

cleaning connections, 3-6

connectors, covering, 3-18

fiber optics handbook, 3-2

foam swabs, 3-14

front panel

adapters, 3-4

connector interface, 3-2

fuse, 1-5

I

input

connector, 3-6

inspecting, instrument, 1-3

installing, 1-2

instrument

returning for service, 3-17

K

key, 2-5

L

laser

aperture, v

classification, v, 4-6

laser enable key, 2-2

laser safety shutter, 2-5

laser source, using, 2-5

line fuse, safety, iii, 1-5

LINE key, 1-8

line-power

cable, 1-6

cables, 3-5

input connector, 1-5

requirements, 1-6

low frequency modulation input, 2-3

Index-1

Page 60

Index

M

maintenance contract, 2-8

measurement

accuracy, iv

N

noise declaration, 4-6

O

optical out connector, 2-3

oscilloscope

connecting to, 2-11

P

packaging for shipment, 3-18

power cable requirements, 1-6

preset wavelength, 2-3

Q

quick confidence check, 2-6

R

radiation exposure, v

rear panel short, 2-5

regulatory

duration, 4-2

information, 4-6

remote shutdown connector, 2-5

repair options, 2-8

returning for service, 3-17

sales and service offices, 3-20

shipping

procedure, 3-18

spare fuse, 1-5

specifications

definition of terms, 4-2

swabs, 3-14

U

using a laser source, 2-5

V

verification test

failing, 2-8

verifying operation, 2-6

W

warranty, 2-8

wavelength

adjustment, 2-3

wavelength adjust enable button, 2-3

wavelength adjust knob, 2-2

S

safety, iii, v

laser classification, iii

line fuse, iii, 1-5

sales and service offices, 3-20

SDH/SONET

compliance, vi

serial numbers, 1-4

service, 3-17

options, 2-8

returning for, 3-17

Index-2

Loading...

Loading...