Agilent Technologies 83236B

PCS Interface

Operating Manual

Serial Numbers

This manual applies directly to instruments with serial

number prefix 3711J. For additional important information

about serial numbers, see Serial Numbers on page 144.

Agilent Part No. 83236-90102

Printed in Japan

April 2000

4th Edition

i

Copyright © Agilent Technologies, Inc. 1996, 1997, 2000

Notice Information contained in this document is subject to change without notice.

This document contains proprietary information that is protected by copyright. All

rights are reserved. No part of this document may be photocopied, reproduced, or,

translation to another language without the prior written consent of

Agilent Technologies, Inc.

Kobe Wireless Test Development

Agilent Technologies Japan, Limited.

1-3-2, Murotani, Nishi-ku, Kobe-shi,

Hyogo, 651-2241 Japan

ii

Manual

Printing

History

The manual printing and part number indicate its current edition. The printing date

changes when a new edition is printed. (Minor corrections and updates that are

incorporated at reprint do not cause the date to change.) The manual part number

changes when extensive technical changes are incorporated.

November 1996................................................................................ 1st Edition

March 1997 ..................................................................................... 2nd Edition

October 1997....................................................................................3rd Edition

April 2000 ........................................................................................4th Edition

iii

Certification Agilent Technologies certifies that this product met its published specifications at

the time of shipment from the factory. Agilent Technologies further certifies that

its calibration measurements are traceable to the United States National Institute of

Standards and Technology, to the extent allowed by the Institution's calibration

facility, or to the calibration facilities of other International Standards Organization

members.

Warranty This Agilent Technologies instrument product is warranted against defects in

material and workmanship for a period of one year from the date of shipment,

except that in the case of certain components listed in Specifications of this manual,

the warranty shall be for the specified period. During the warranty period, Agilent

Technologies will, at its option, either repair or replace products which prove to be

defective.

For warranty service or repair, this product must be returned to a service facility

designated by Agilent Technologies. Buyer shall prepay shipping charges to

Agilent Technologies and Agilent Technologies shall pay shipping charges to

return the product to Buyer. However, Buyer shall pay all shipping charges, duties,

and taxes for products returned to Agilent Technologies from another country.

Agilent Technologies warrants that its software and firmware designated by

Agilent Technologies for use with an instrument will execute its programming

instruction when properly installed on that instrument. Agilent Technologies does

not warrant that the operation of the instrument, or software, or firmware will be

uninterrupted or error free.

Limitation Of

Warranty

Exclusive

Remedies

The foregoing warranty shall not apply to defects resulting from improper or

inadequate maintenance by Buyer, Buyer-supplied software or interfacing,

unauthorized modification or misuse, operation outside of the environmental

specifications for the product, or improper site preparation or maintenance. No

other warranty is expressed or implied. Agilent Technologies specifically

disclaims the implied warranties of merchantability and fitness for a particular

purpose.

The remedies provided herein are buyer's sole and exclusive remedies. Agilent

Technologies shall not be liable for any direct, indirect, special, incidental, or

consequential damages, whether based on contract, tort, or any other legal theory.

Assistance Product maintenance agreements and other customer assistance agreements are

available for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales and Service

Office. Addresses are provided at the back of this manual.

iv

Safety

Summary

The following general safety precautions must be observed during all phases of

operation, service, and repair of this instrument. Failure to comply with these

precautions or with specific WARNINGS elsewhere in this manual may impair

the protection provided by the equipment. In addition it violates safety standards

of design, manufacture, and intended use of the instrument. The Agilent

Technologies assumes no liability for the customer's failure to comply with these

requirements.

NOTE: Agilent Technologies 83236B complies with INSTALLATION CATEGORY II and

POLLUTION DEGREE 2 in IEC1010-1. Agilent 83236B is an INDOOR USE product.

NOTE: LEDs in the Agilent 83236B are Class 1 in accordance with IEC 825-1.

CLASS 1 LED PRODUCT

Ground the Instrument

To avoid electric shock hazard, the instrument chassis and cabinet must be

connected to a safety earth ground by the supplied power cable with earth blade.

DO NOT Operate In An Explosive Atmosphere

Do not operate the instrument in the presence of flammable gasses or fumes.

Operation of any electrical instrument in such an environment constitutes a

definite safety hazard.

Keep Away From Live Circuits

Operating personnel must not remove instrument covers. Component replacement

and internal adjustments must be made by qualified maintenance personnel. Do

not replace components with the power cable connected. Under certain

conditions, dangerous voltages may exist even with the power cable removed. To

avoid injuries, always disconnect power and discharge circuits before touching

them.

DO NOT Service Or Adjust Alone

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation, is present.

v

DO NOT Substitute Parts Or Modify Instrument

Because of the danger of introducing additional hazards, do not install substitute

parts or perform unauthorized modifications to the instrument. Return the

instrument to a Agilent Technologies Sales and Service Office for service and

repair to ensure that safety features are maintained.

Dangerous Procedure Warnings

Warnings, such as the example below, precede potentially dangerous procedures

throughout this manual. Instructions contained in the warnings must be followed.

WARNING: Dangerous voltages, capable of causing death, are present in this instrument. Use

extreme caution when handling, testing, and adjusting this instrument.

Safety

Symbols

General definitions of safety symbols used on equipment or in manuals are listed

below.

Instruction manual symbol: the product is marked with this symbol when it is

!

necessary for the user to refer to the instruction manual.

Alternating current.

Direct current.

|

On (Supply).

Ο

Off (Supply).

In position of push-button switch.

Out position of push-button switch.

WARNING: This WARNING sign denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to, could result in

injury or death to personnel.

CAUTION: This CAUTION sign denotes a hazard. It calls attention to a procedure, practice, condition

or the like, which, if not correctly performed or adhered to, could result in damage to or

destruction of part or all of the product.

NOTE: NOTE denotes important information. It calls attention to a procedure, practice, condition

or the like, which is essential to highlight.

vi

vii

Herstellerbescheinigung

GERXUSCHEMISSION

LpA < 70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 T. 19

Manufacturer’s Declaration

ACOUSTIC NOISE EMISSION

LpA < 70 dB

operator position

normal operation

per ISO 7779

viii

In this Manual This manual describes general information, function, operation, and specifications

of the Agilent 83236B PCS Interface. The following chapters are included in this

manual.

Appendix 1, General Information

This chapter provides a product overview and describes the furnished accessories,

options, and front and rear panels.

Appendix 2, Installation

This chapter describes the steps for configuring the PCS Interface.

Appendix 3, Programming the PCS Interface using GPIB Control

This chapter describes how to control the PCS Interface using GPIB commands.

Appendix 4, GPIB Commands

This chapter describes the remote operation of the PCS Interface using GPIB.

Appendix 5, Specifications

This chapter describes the specifications of the PCS Interface.

Appendix A, Frequency Conversion Tables

Appendix A provides the frequency conversion tables used internally by the PCS

Interface’s CPU to determine the Test Set’s frequencies.

Appendix B, Manual Changes

Appendix B provides a manual change history and information about serial

numbers.

Appendix C, Error Messages

This section describes the error messages generated by the PCS Interface.

Glossary

This section defines terms used throughout this manual.

ix

x

Contents

1 General Information

Introduction 16

Incoming Inspection 18

Furnished Accessories 19

Power Cable 20

Options 22

Front Panel 24

Rear Panel 26

Other Information 29

2 Installation

Introduction 32

When Used with Agilent 8924C and Controlled via Serial Port for

CDMA Subscriber Unit Tests 34

When Used with Agilent 8924C and Controlled via GPIB for

CDMA Subscriber Unit Tests 37

When Used with Agilent 8920B and Controlled via Serial Port for

TDMA Subscriber Unit Tests 40

When Used with Agilent 8920A,B and Controlled via GPIB for

TDMA Subscriber Unit Tests 45

When Used with Agilent 8921A for CDMA Base Stations Tests 50

When Used with Agilent 8921A for TDMA Base Stations Tests 54

11

Contents

Load and Run the Connectivity Test Software (Option 001 or

002) 59

Where to go next 64

3 Programming the PCS Interface using GPIB Control

Introduction 66

Overview of Programming Issues 67

PCS Interface Programming Guide 75

Test Procedure Flow 76

Initialize the System 77

Set Up and Measure 79

4GPIB Commands

Introduction 92

The Syntax of Program Messages 94

Common Commands 98

COMPensation Subsystem 100

RF Subsystem 106

RX Subsystem 108

SYSTem Subsystem 113

TX Subsystem 114

12

Contents

GPIB Command Summary 121

5 Specifications

Introduction 124

Generator Output Path 125

Analyzer Input Path 128

Reference Specifications 131

Remote Control 131

Connectors 132

General Characteristics 135

A Frequency Conversion Tables

Frequency Conversion for Signal Generation 138

B Manual Changes

Introduction 142

Manual Changes 143

Serial Numbers 144

Change 1 145

C Error Messages

13

Contents

Error Message 154

Glossary 161

14

1G

General Information

eneral Information

What’s included in this chapter:

• Introduction

• Furnished Accessories

• Options

• Front Panel

• Rear Panel

15

Chapter 1, General Information

Introduction

Introduction

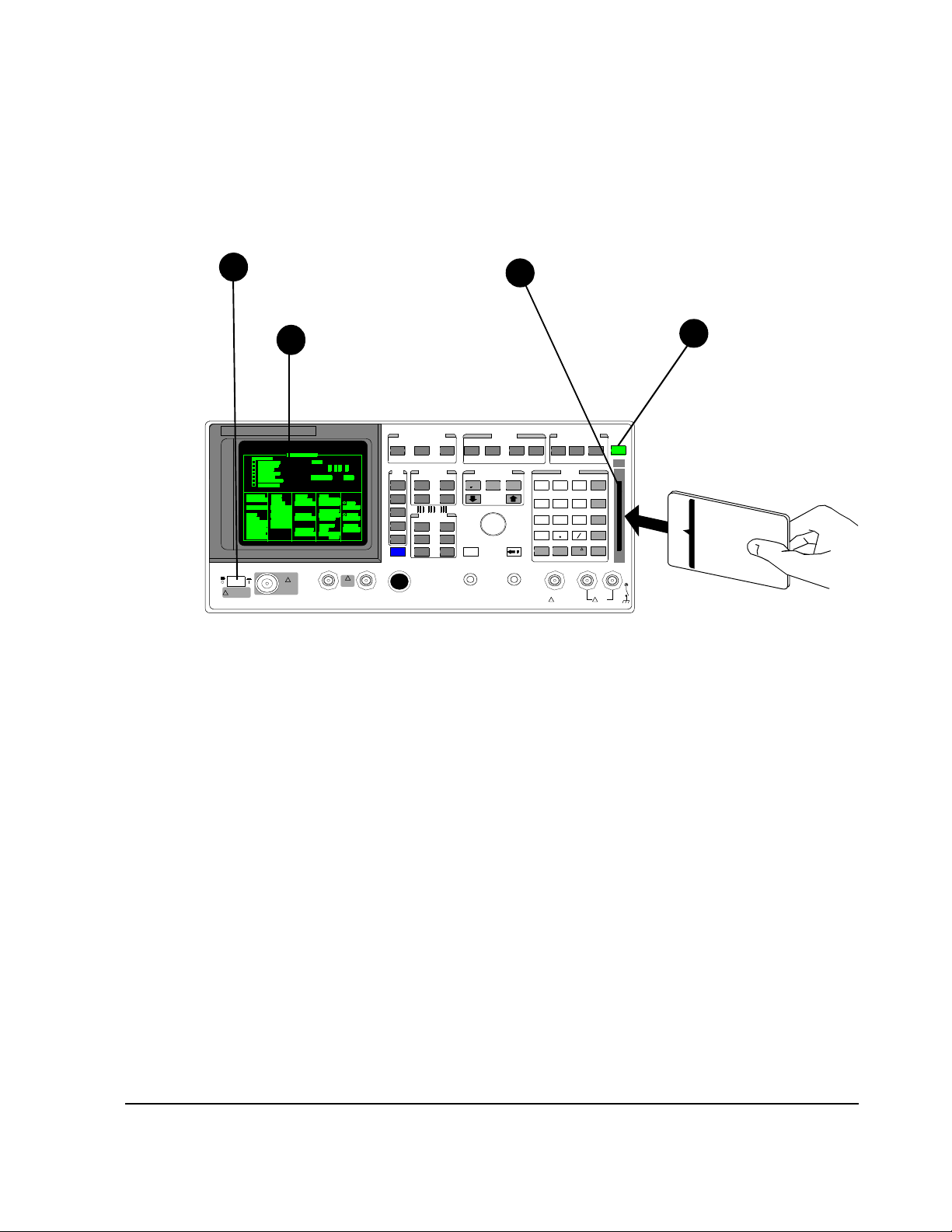

Figure 1 Agilent 83236B PCS Interface

The Agilent 83236B PCS Interface extends the time division multiple access

(TDMA) and code division multiple access (CDMA) measurement capability of

the Agilent 8920A,B, Agilent 8921A, and Agilent 8924C Test Sets to the 1710 to

1990 MHz frequency range. This frequency range covers the International (1710

to 1880 MHz), Korean (1715 to 1870 MHz), and North American (1850 to

1990 MHz) Personal Communications Service (PCS) bands. Table 1 shows the

supported equipment combinations and the type of unit-under-test (UUT).

Table 1 Supported configuration and UUTs

UUT Type Test Set

TDMA Base Station Agilent 8921A Agilent 83204A

TDMA Subscriber Unit Agilent 8920A,B Agilent 83206A

CDMA Base Station Agilent 8921A Agilent 83203B or Agilent 83205A

CDMA Subscriber Unit Agilent 8924C Not required

1.The combination of the Agilent 8921A and 83204A composes the Agilent 8921A option 500.

2.Can be used with Agilent 8920B only. The combination of the Agilent 8920B and 83206A composes

the Agilent 8920B option 800.

3.The combination of the Agilent 8920A and 83201A composes the Agilent 8920D.

4.The combination of the Agilent 8920B and 83201B composes the Agilent 8920B option 500.

5.The combination of the Agilent 8921A and 83205A composes the Agilent 8921A option 600.

International, Korea, and North

American PCS Bands

Cellular Adapter

1

2

5

North American

PCS Band only

Agilent 83201A

Agilent 83201A3,B

—

4

16

Chapter 1, General Information

Introduction

Power measurement accuracy and speed are maintained at PCS band frequencies

with an internal power meter for measurements on CW, CDMA, and TDMA

signals.

The PCS Interface has no front panel “controls” and cannot be used manually.

Control of the PCS Interface is via GPIB using an external controller or the Test

Set’s internal IBASIC controller, or via the serial port by the Agilent 8924C

whose firmware revision is A.05.00 and above or Agilent 8920B option 800

whose firmware revision is B.05.00 and above.

Most of this manual is dedicated to assisting you in the integration, GPIB

programming, and control of the PCS Interface.

NOTE: Refer to the Agilent 8924C User’s Guide or Agilent 8920B User’s Guide for the operation

of the Agilent 83236B controlled via the serial port.

Conventions Used The Agilent 83236B PCS Interface can be used with a variety of Test Sets and a

variety of Cellular Adapters.

•Test Sets

• Agilent 8920A, B

• Agilent 8921A

• Agilent 8924C

• Cellular Adapters

• Agilent 83201A,B

• Agilent 83203B

• Agilent 83204A

• Agilent 83205A

• Agilent 83206A

To simplify things, the term Test Set will be used throughout this manual to refer

to any Agilent 892NX, the term Cellular Adapter to refer to any Agilent 8320NX,

and the term PCS Interface to refer to the Agilent 83236B PCS Interface. The

combination of the Test Set, Cellular Adapter, and PCS Interface will be referred

to as the Test System.

In some instances, TX will be used in place of the word transmitter, and RX will

be used in place of the word receiver; UUT will be used as an abbreviation for

unit-under-test.

17

Chapter 1, General Information

Incoming Inspection

Incoming Inspection

WARNING: To avoid hazardous electrical shock, do not turn on the PCS Interface when there are

signs of shipping damage to any portion of the outer enclosure (for example, covers,

panel, or display).

Inspect the shipping container for damage. If the shipping container or cushioning

material is damaged, it should be kept until the contents of the shipment have

been checked for completeness and the PCS Interface has been checked

mechanically and electrically. The contents of the shipment should be as listed in

table 2 on page 19. If the contents are incomplete, if there is mechanical damage

or defect, or if the system does not pass the power-on self tests, notify the nearest

Agilent Technologies office. If the shipping container is damaged, or the

cushioning material shows signs of unusual stress, notify the carrier as well as the

Agilent Technologies office. Keep the shipping materials for the carrier's

inspection.

18

Furnished Accessories

The following accessories are furnished with the PCS Interface.

Table 2 Included Accessories

Name Qty. Part/Product Number

GPIB Cable (0.5 m) 1 Agilent 10833D

Serial Cable 1 Agilent p/n 83236-61609

N-BNC Cable 2 Agilent p/n 83236-61603

SMA-SMC Cable 1 Agilent p/n 83215-61643

Chapter 1, General Information

Furnished Accessories

SMC-SMC Cable 1 Agilent p/n 83215-61644

BNC-BNC Cable 1 Agilent p/n 8120-1839

BNC L-type adapter 2 Agilent p/n 1250-0076

BNC T-type adapter 1 Agilent p/n 1250-0781

Operation Manual (this manual) 1 Agilent p/n 83236-90102

Read Me First — Cable Connections for the

PCS Interface

Front Cover 1 Agilent p/n 83201-61013

Power Cable

1. The part number depends on where the instrument is used, see "Power Cable" on

page 20.

1

1 Agilent p/n 83236-90130

1

19

Chapter 1, General Information

Power Cable

Power Cable

In accordance with international safety standards, this instrument is equipped

with a three-wire power cable. When connected to an appropriate ac power outlet,

this cable grounds the instrument frame. The type of power cable shipped with

each instrument depends on the country of destination. Refer to figure 2 on page

21 for the part numbers of the power cables available.

20

Chapter 1, General Information

Power Cable

WARNING: For protection from electrical shock, the power cable ground must not be defeated.

The power plug must be plugged into an outlet that provides a protective earth

ground connection.

Figure 2 Power Cable Supplied

21

Chapter 1, General Information

Options

Options

The following options can be used with the PCS Interface.

001

Utility Software on PCMCIA Card

002 Utility Software on EPSON Memory Card

1AB Bench Top Kit

AX4 Rack Flange Kit

Option 001 — Utility Software on PCMCIA Card

Provides the Utility Software memory card which includes the Manual Control

and Connectivity Test Programs (for Agilent 8920B and Agilent 8924C). N(f)BNC(m) adapter and N(m)-BNC(f) adapter are also provided for the Connectivity

Test Program.

Table 3 Included Accessories (Option 001)

Name Qty. Part/Product Number

Utility Software 1 Agilent p/n 83236-61002

N(f)-BNC(m) Adapter 1 Agilent p/n 1250-2789

N(m)-BNC(f) Adapter 1 Agilent p/n 1250-0780

Manual Control Software User’s Guide 1 Agilent p/n 83236-90110

Option 002 — Utility Software on EPSON Memory Card

Provides the Utility Software memory cards which include the Manual Control,

Connectivity, and CDMA/PCS Base Station Test Programs (for Agilent 8920A

and Agilent 8921A). N(f)-BNC(m) adapter and N(m)-BNC(f) adapter are also

provided for the Connectivity Test Program.

22

Table 4 Included Accessories (Option 002)

Name Qty. Part/Product Number

Utility Software 1 Agilent p/n 83236-61001

N(f)-BNC(m) Adapter 1 Agilent p/n 1250-2789

N(m)-BNC(f) Adapter 1 Agilent p/n 1250-0780

Manual Control Software User’s Guide 1 Agilent p/n 83236-90110

Chapter 1, General Information

Options

CDMA/PCS Base Station Test Software

User’s Guide

Option 1AB — Bench Top Cabinet Kit

This kit is used to stack a 19-inch-wide instrument, such as the Agilent 8924C

CDMA Mobile Station Test Set, on the Agilent 83236B. Rack mounting

hardware is included.

For the instructions on how to mount the PCS Interface, refer to the Agilent

83236A,B PCS Interface Option 1AB Bench Top Kit Installation Instruction

included with the kit.

Table 5 Included Accessories (Option 1AB)

Name Qty. Part/Product Number

Bench Top Cabinet Kit 1 Agilent p/n 83236-60022

Option AX4 — Rack Flange Kit

This kit mounts the instrument in a rack with 482.6 mm (19 in) spacing.

For the instructions on how to rack mount the PCS Interface, refer to the

Agilent 83236A,B PCS Interface Option AX4 Rack Flange Kit Rack Mount

Installation Instructions included with the kit.

1 Agilent p/n 83236-90121

Table 6 Included Accessories (Option AX4)

Name Qty. Part/Product Number

Rack Flange Kit 1 Agilent p/n 83236-60021

23

Chapter 1, General Information

Front Panel

Front Panel

1

Figure 3 Front Panel

1. Line Switch The power switch. The On position is | and the Off position is Ο. In the On

position, power is supplied and the indicator above the switch is lit.

2. FROM DUPLEX

OUT

3. TO ANT IN Connects to the ANT IN port of a Test Set. (Connector type: Type N (F))

Connects to the DUPLEX OUT port of a Test Set. (Connector type: Type N (F))

2

3

4

5

24

Chapter 1, General Information

Front Panel

Connects to the transmit/receive antenna port of a radio.

4. RF IN/OUT

CAUTION: The maximum allowable average power to the RF IN/OUT port depends on the unit-under-

(Connector type: Type N (F))

test as follows. Use an external attenuator if you are uncertain.

Subscriber Unit Test

Single carrier TDMA and FM: 10 Watts

CDMA: 5 Watts

Base Station Test

Single carrier TDMA and FM: 10 Watts

CDMA: 1 Watt

CAUTION: Peak instantaneous signals greater than 30 volts will damage internal circuitry.

Connects to the receive antenna port of a radio. (Connector type: Type N (F))

5. RF OUT only

CAUTION: Do not input a continuous signal greater than +23 dBm (200 mW). Doing so may damage

internal circuits.

25

Chapter 1, General Information

Rear Panel

Rear Panel

1234

Figure 4 Rear Panel

1. GPIB Address

Selector

2. REF IN Reference frequency input port. The REF IN port connects to the 10 MHz

3. REF OUT Reference frequency output port. The REF OUT port may be used as a 10 MHz

4. EXT TRIG IN External trigger input. EXT TRIG IN is used to trigger power measurements of

The GPIB address selector specifies the GPIB interface address. The address

selector consists of the switches A1 to A5. The switch A1 is the least significant

bit (1) and A5 the most significant bit (16). For example, you may set the switches

A1, A2, and A5 ON (1) to specify 19 as your GPIB address.

The

GPIB/Ser switch sets whether the GPIB port or SERIAL PORT is used to

control the PCS Interface.

reference source. (Connector type: BNC (F))

source for other equipment. (Connector type: BNC (F))

TDMA bursted signals. It connects to the FRAME CLK OUT port of the Cellular

Adapter when the UUT is the TDMA type. (Connector type: SMC (M))

5

678

5. DET OUT Detector output. DET OUT can be used for power measurements of CDMA

subscriber units. (Connector type: SMC (M))

26

Chapter 1, General Information

Rear Panel

6. GPIB Interface The GPIB interface connects to an external controller to enable the control of the

PCS Interface. In most cases, this control is provided by a Test Set.

NOTE: To enable this GPIB Interface, set the GPIB/Ser switch of the GPIB Address Selector to

the “GPIB” side (left side as viewed from the rear panel).

This interface conforms to IEEE 488.2 and has the following functions:

Table 7 GPIB Functions

Codes Functions

SH1 Full source handshake capability

AH1 Full accepter handshake capability

T8 Basic talker. No serial poll. No talk only mode. Unaddressed if MLA.

L4 Basic listener. No listen only mode. Unaddressed if MTA

SR0 No service request capability

RL1 Complete remote/local capability

PP0 No parallel poll capability

DC1 Full device clear capability

DT0 No device trigger capability

E2 Tri-state driver electronics

C0 No controller capability

27

Chapter 1, General Information

Rear Panel

7. SERIAL PORT This port is used for the Agilent 83236B to be controlled by the Agilent 8924C

whose firmware revision is A.05.00 and above or Agilent 8920B whose firmware

revision is B.05.00 and above.

NOTE: To enable this serial port, set the GPIB/Ser switch of the GPIB Address Selector to the

“Ser” side (right side as viewed from the rear panel).

8. Power Cord

Receptacle

The PCS Interface can operate from AC sources of 90 to 132 Vac and 198 to

264 Vac (47 to 63 Hz). No internal changes are necessary to select AC supply.

28

Other Information

Chapter 1, General Information

Other Information

Power

Requirements

The PCS Interface requires the following power source:

Voltage: 90 to 132 Vac, 198 to 264 Vac

Frequency: 47 to 63 Hz

Power: 100 VA maximum

Fuse The main fuse is located inside of the PCS Interface. The type and rating of this

fuse are as follows.

UL/CSA type, time delay, 3 A, 250 Vac

WARNING: The main fuse is not replaceable by the operator. Refer servicing to qualified

personnel.

Ventilation

Requirements

Instructions for

To ensure adequate ventilation, make sure that there is adequate clearance around

the PCS Interface.

For cleaning, wipe lightly with a soft damp cloth.

Cleaning

Calibration Cycle Contact your nearest Agilent Technologies service office.

29

Chapter 1, General Information

Other Information

30

2I

Installation

nstallation

Before attempting to make measurements or generate programs using the PCS

Interface, it is a good idea to follow the steps in this chapter. This will ensure that

the proper connections are made between the PCS Interface and other hardware

and will verify basic operation of the Test System.

Installation

31

Chapter 2, Installation

Introduction

Introduction

Chapter Overview Included in this chapter are steps for setting up the PCS Interface for the

following test configurations:

Table 8 PCS Interface Test Configurations

You will

control

the PCS

Interface

using...

Refer to...

If you are testing... And your Test Set Model is...

With Cellular

Adapter Model...

CDMA Subscriber Units Agilent 8924C

(Firmware: A.05.00 and above)

Agilent 8924C

(Firmware: Below A.05.00)

TDMA Subscriber Units Agilent 8920B

(Firmware: B.05.00 and above)

Agilent 8920B

(Firmware: Below B.05.00)

Agilent 8920A Agilent 83201A,B

CDMA Base Stations Agilent 8921A Agilent 83203B,

TDMA Base Stations Agilent 8921A Agilent 83201A,

Agilent 83206A Serial

Agilent 83201A,B,

Agilent 83206A

Agilent 83205A

Agilent 83204A

—

—GPIB

Serial

Port

Port

GPIB

page 34.

page 37.

page 40.

page 45.

page 50.

page 54.

32

Chapter 2, Installation

Introduction

The PCS Interface can be controlled by the following methods.

• Serial Port Control

The Agilent 8920B option 800 with firmware revision B.05.00 and above and Agilent

8924C with firmware revision A.05.00 and above can control the PCS Interface via

the serial port. Using this mode eliminates the need to control the PCS Interface

independently.

• GPIB Control

All of the above Test Sets can control the PCS Interface via the GPIB. You can use the

Manual Control Software or you can make programs to control the

PCS Interface.

You will be shown how to set up the equipment, make connections, and run a

software utility that verifies the connections and the instruments’ operation.

NOTE: When you want to use the PCS Interface with the Agilent 8924C on the work bench, the

PCS Interface’s Option 1AB Bench Top Kit is required to stack the Agilent 8924C on the

PCS Interface.

33

Chapter 2, Installation

When Used with Agilent 8924C and Controlled via Serial Port for CDMA Subscriber Unit

Tests

When Used with Agilent 8924C and Controlled via Serial Port for CDMA

Subscriber Unit Tests

NOTE: To control the PCS Interface via the serial port, the firmware of the Agilent 8924C must be

A.05.00 and above. Contact your nearest Agilent Technologies sales office for firmware

upgrade information.

Unpack the PCS

Interface and

Accessories

NOTE: This product passed all applicable electrical and mechanical inspections before it was

Follow these steps to prepare the Test System for setup:

1 Unpack the test equipment and accessories.

shipped from the factory. As soon as you receive it, check that it is not damaged and that

all accessories are present (see table 2 on page 19). Should this product be damaged or any

accessories be missing, contact your local Agilent Technologies sales office or the

company from which you purchased it.

2 Mount the PCS Interface into the PCS Interface’s option 1AB bench top kit.

3 Place the Agilent 8924C Test Set on the top of the PCS Interface.

34

Chapter 2, Installation

When Used with Agilent 8924C and Controlled via Serial Port for CDMA Subscriber Unit

Tests

Cable Connections Follow these steps to prepare the test equipment for use:

1 Set the GPIB Address Selector of the rear panel of the PCS Interface as follows.

GPIB/Ser switch Ser

GPIB address Any

2 Make the front and rear panel connections shown in figure 5.

3 Turn on the PCS Interface.

NOTE: The PCS Interface must be powered on and connected before the Agilent 8924C is powered

on. If the PCS Interface is not powered on first, the Agilent 8924C will not detect it.

4 Set up the Test Set.

a Turn on the Test Set.

b Press and release the SHIFT key then the TESTS key to access the CONFIGURE

screen.

c Position the cursor in the “PCS Intrfc Control” field, and press the knob to select

“On.”

d Turn the Test Set’s power off and then back on.

5 Perform the RF Generator Level Calibration.

a Press and release the SHIFT key then the TESTS key to access the CONFIGURE

screen.

b Position the cursor in the “RF Gen Level” field, and press the knob to start the

calibration.

35

Chapter 2, Installation

When Used with Agilent 8924C and Controlled via Serial Port for CDMA Subscriber Unit

Tests

From Agilent 8924 DUPLEX OUT

To Agilent 83236 FROM DUPLEX OUT

(Cable P/N 83236-61603)

SERIAL

From Agilent 8924 SERIAL

PORT

CURR

DC

To Agilent 83236 SERIAL

PORT

(Cable P/N 83236-61609)

POWE

DO NOT

!

GPI

PROTOCO EXT

RF IN/

!

MAX PWR

POWER

ONOFF

DUPLEX

83236B

PCS INTERFACE

!

MAX

ANTENN

FROM DUPLEX OUT TO ANT IN

From Agilent 8924 ANT IN

To Agilent 83236 TO ANT IN

(Cable P/N 83236-61603)

COMP

TIME

PARALLE

CELLSITE/TRIGGERS

AUX

10 MEAS

CDMA CALL

CALL ANS

USE DA

CDMA

k1’

CELL

CALL

k1

k2’

SPECTR

GEN

k2

k3’

k3

ANALOG

ASSIG

ENCO

RF

k4

RELE

k5

SPEC

RF

TEST SET

EXT

2nd DSPMODULAUD REF

MSG

END

HELP

REF

RANG

INCR

RX

LO HI

MSRP

TX

CURSO PU SH

DECO

RX

ACP

TXAF

SCOP

DUPL

CANCSHIFT

RF IN/OUT RF OUT only

FUNCTIO

PRINT

PRINT

DATA

METE

INCR

1.8-2.0 GHz UUT

I/O CONFI

PREV TESTS

AVG

INCR

INSTRUMENT

HOLD

ADRS

SAVE

MEAS

LOCA

RECA

PRESE

MEM

789

456

123

0

YES

ON/

ENTE

dB

GHz

%

MHz

s

kHz

_

+

NO

Hzms% Ωppm

AUDIO

AUDIO SQUELVOLUMIC/

MAX

!

LHI

MAX

!

(User-supplied cable)

10

MHz1X 10X EVENCDMA DSP IF

ANT

CDMA

Subscriber

Unit

From Agilent 8924 10 MHz

REF OUTPUT

To Agilent 83236 REF IN

(Cable P/N 8120-1839)

From Agilent 8924 POWER

DET

To Agilent 83236 DET OUT

(Cable P/N 83215-61643)

Figure 5 Connection diagrams for the Agilent 8924C Test Configuration (CDMA Subscriber

Unit Tests; Serial Control)

36

Chapter 2, Installation

When Used with Agilent 8924C and Controlled via GPIB for CDMA Subscriber Unit Tests

When Used with Agilent 8924C and Controlled via GPIB for CDMA

Subscriber Unit Tests

Unpack the PCS

Interface and

Accessories

NOTE: This product passed all applicable electrical and mechanical inspections before it was

Follow these steps to prepare the Test System for setup:

1 Unpack the test equipment and accessories.

shipped from the factory. As soon as you receive it, check that it is not damaged and that

all accessories are present (see table 2 on page 19). Should this product be damaged or any

accessories be missing, contact your local Agilent Technologies sales office or the

company from which you purchased it.

2 Mount the PCS Interface into the PCS Interface’s option 1AB bench top kit.

3 Place the Agilent 8924C Test Set on the top of the PCS Interface.

37

Chapter 2, Installation

When Used with Agilent 8924C and Controlled via GPIB for CDMA Subscriber Unit Tests

Cable Connections Follow these steps to prepare the test equipment for use:

1 Set the GPIB Address Selector on the rear panel of the PCS Interface as follows.

GPIB/Ser switch GPIB

GPIB address 19 (for the manual control software and connectivity test)

2 Make the front and rear panel connections shown in figure 6.

3 Turn on the PCS Interface.

4 Turn on the Test Set.

NOTE: Make sure that the “PCS Intrfc Control” field in the CONFIGURE screen is set to “Off.”

To access the CONFIGURE screen, press and release the SHIFT key then the TESTS key.

38

Chapter 2, Installation

When Used with Agilent 8924C and Controlled via GPIB for CDMA Subscriber Unit Tests

POWE

DO NOT

!

From Agilent 8924 DUPLEX OUT

To Agilent 83236 FROM DUPLEX OUT

(Cable P/N 83236-61603)

SERIAL

From Agilent 8924 GPIB

CURR

DC

To Agilent 83236 GPIB

(Mod. No. Agilent 10833D)

RF IN/

POWER

COMP

TIME

GPI

PARALLE

CELLSITE/TRIGGERS

PROTOCO E XT

AUX

10 MEAS

CDMA CALL

CALL ANS

USE DA

k1’

CELL

CALL

k1

k2’

SPECTR

GEN

k2

k3’

k3

ASSIG

ENCO

RF

k4

RELE

k5

SPEC

RF

DUPLEX

83236B

PCS INTERFACE

!

MAX

ANTENN

FROM DUPLEX OUT TO ANT IN

TEST SET

MAX PWR

!

ONOFF

From Agilent 8924 ANT IN

To Agilent 83236 TO ANT IN

(Cable P/N 83236-61603)

EXT

2nd DSPM ODULAUD REF

CDMA

ANALOG

RANG

MSRP

DECO

SCOP

DUPL

MSG

END

HELP

REF

INCR

RX

LO HI

TX

CURSO PUSH

RX

ACP

TXAF

CANCSHIF T

RF IN/OUT RF OUT only

FUNCTIO

PRINT

PRINT

DATA

METE

INCR

1.8-2.0 GHz UUT

INSTRUMENT

I/O CONFI

ADRS

SAVE

LOCA

PREV TESTS

AVG

INCR

RECA

789

456

123

0

NO

YES

ON/

AUDIO SQUELVOLUMIC/

MAX

!

(User-supplied cable)

10

MHz1X 10X EVENCDMA DSP IF

HOLD

MEAS

PRESE

MEM

ENTE

dB

GHz

%

MHz

s

kHz

_

+

Hzms% Ωppm

AUDIO

LHI

MAX

!

ANT

CDMA

Subscriber

Unit

From Agilent 8924 10 MHz

REF OUTPUT

To Agilent 83236 REF IN

(Cable P/N 8120-1839)

Figure 6 Connection diagrams for the Agilent 8924 Test Configuration (CDMA Subscriber

Unit Tests; GPIB Control)

39

Chapter 2, Installation

When Used with Agilent 8920B and Controlled via Serial Port for TDMA Subscriber Unit

Tests

When Used with Agilent 8920B and Controlled via Serial Port for TDMA

Subscriber Unit Tests

NOTE: To control the PCS Interface via the serial port, the firmware of the Agilent 8920B must be

B.05.00 and above, and the Agilent 83206A must be used for the Test System’s Cellular

Adapter. Contact your nearest Agilent Technologies sales office for firmware upgrade

information.

Unpack the PCS

Interface and

Accessories

NOTE: This product passed all applicable electrical and mechanical inspections before it was

Follow these steps to prepare the Test System for setup:

1 Unpack the test equipment and accessories.

shipped from the factory. As soon as you receive it, check that it is not damaged and that

all accessories are present (see table 2 on page 19). Should this product be damaged or any

accessories be missing, contact your local Agilent Technologies sales office or the

company from which you purchased it.

2 Placing the equipment:

a If you are placing the Test System horizontally (on a bench top, for example) place

the Test Set (together with the Cellular Adapter) on the top of the PCS Interface.

Position the bumpers (feet) of the Test Set so that they are stably seated between

the forward and rear bumpers of the PCS Interface. Refer to figure 7.

40

Chapter 2, Installation

When Used with Agilent 8920B and Controlled via Serial Port for TDMA Subscriber Unit

Tests

Test Set Cellular Adapter

PCS Interface

Figure 7 Horizontal stacking configuration (side view) for the Agilent 8920 Test Configuration

41

Chapter 2, Installation

When Used with Agilent 8920B and Controlled via Serial Port for TDMA Subscriber Unit

Tests

b If you are placing the Test System vertically (as is often done when putting the

equipment on the floor), the PCS Interface’s rear feet must be placed on the same

surface as those of the Test Set. After placement, rotate the handle of the Test Set

downwards to provide support for the PCS Interface. Refer to figure 8.

Test Set Cellular Adapter

PCS Interface

Figure 8 Vertical configuration (side view) for the Agilent 8920 Test Configuration

42

Chapter 2, Installation

When Used with Agilent 8920B and Controlled via Serial Port for TDMA Subscriber Unit

Tests

Cable Connections Follow these steps to prepare the test equipment for use:

NOTE: You should have made all connections between the Test Set and Cellular Adapter at this

point. Refer to the User’s Guide for your particular Cellular Adapter for instructions on

connecting it to the Test Set. Verify these connections before continuing with these steps.

1 Set the GPIB Address Selector on the rear panel of the PCS Interface as follows.

GPIB/Ser switch Ser

GPIB address any

2 Make the front and rear panel connections shown in figure 9.

3 Turn on the PCS Interface.

NOTE: The PCS Interface must be powered on and connected before the Agilent 8920B is powered

on. If the PCS Interface is not powered on first, the Agilent 8920B will not detect it.

4 Turn on the Test Set.

43

Chapter 2, Installation

When Used with Agilent 8920B and Controlled via Serial Port for TDMA Subscriber Unit

Tests

PWR REF

OFF-CHANNEL

PULSE

MOD

ANALYZER ANALYZE R ANALYZER GENERATOR

UNLOCK

DATA

BASEBAND

CLOCK IN

DATA IN

TRIGGERINBASEBAND

DATA IN

From Agilent 8920 DUPLEX OUT

To Agilent 83236 FROM DUPLEX OUT

(Cable P/N 83236-61603)

Note:

Connections between

the Test Set and Cellular

Adapter are not shown

in this figure.

From Agilent 8920 SERIAL PORT

To Agilent 83236 SERIAL PORT

(Cable P/N 83236-61609)

To Agilent 83236 REF IN

(BNC “L” adapter P/N 1250-

0076)

83236B

PCS INTERFACE

POWER

ONOFF

TEST SET

FROM DUPLEX OUT TO ANT IN

From Agilent 8920 ANT IN

To Agilent 83236 TO ANT IN

(Cable P/N 83236-61603)

DIAG

GEN BB

ANL

OUT

DATA OUT

TRIG OUT

CONTROL I/O

BIT CLK

SYMBOL

OUT

CLK OUT

114.3 MHz IF IN

CW

RF IN

10 MHz REF OUT

IQ

RF OUT

FRAME

CLK OUT

REF IN

1.8-2.0 GHz UUT

RF IN/OUT RF OUT only

RF IN/OUT

EXT

IF IN

ANT

(User-supplied cable)

From Agilent 83206 REF IN

To Agilent 8920 10 MHz REF OUTPUT

(Supplied with cellular adapter)

TDMA

Subscriber

Unit

To Agilent 8920 10 MHz REF OUTPUT

(BNC “T” adapter P/N 1250-0781)

From Agilent 8920 10 MHz REF

OUTPUT

To Agilent 83236 REF IN

(Cable P/N 8120-1839)

Figure 9 Connection diagrams for the Agilent 8920 Test Configuration (TDMA Subscriber

Unit Tests; Serial Control)

44

Chapter 2, Installation

When Used with Agilent 8920A,B and Controlled via GPIB for TDMA Subscriber Unit Tests

When Used with Agilent 8920A,B and Controlled via GPIB for TDMA

Subscriber Unit Tests

Unpack the PCS

Interface and

Accessories

NOTE: This product passed all applicable electrical and mechanical inspections before it was

Follow these steps to prepare the Test System for setup:

1 Unpack the test equipment and accessories.

shipped from the factory. As soon as you receive it, check that it is not damaged and that

all accessories are present (see table 2 on page 19). Should this product be damaged or any

accessories be missing, contact your local Agilent Technologies sales office or the

company from which you purchased it.

45

Chapter 2, Installation

When Used with Agilent 8920A,B and Controlled via GPIB for TDMA Subscriber Unit Tests

2 Placing the equipment:

a If you are placing the Test System horizontally (on a bench top, for example) place

the Test Set (together with the Cellular Adapter) on the top of the PCS Interface.

Position the bumpers (feet) of the Test Set so that they are stably seated between

the forward and rear bumpers of the PCS Interface. Refer to figure 10.

Test Set Cellular Adapter

PCS Interface

Figure 10 Horizontal stacking configuration (side view) for the Agilent 8920 or Agilent 8921

Test Configuration

46

Chapter 2, Installation

When Used with Agilent 8920A,B and Controlled via GPIB for TDMA Subscriber Unit Tests

b If you are placing the Test System vertically (as is often done when putting the

equipment on the floor), the PCS Interface’s rear feet must be placed on the same

surface as those of the Test Set. After placement, rotate the handle of the Test Set

downwards to provide support for the PCS Interface. Refer to figure 11.

PCS Interface

Test Set

Cellular Adapter

Figure 11 Vertical configuration (side view) for the Agilent 8920 or Agilent 8921 Test

Configuration

47

Chapter 2, Installation

When Used with Agilent 8920A,B and Controlled via GPIB for TDMA Subscriber Unit Tests

Cable Connections Follow these steps to prepare the test equipment for use:

NOTE: You should have made all connections between the Test Set and Cellular Adapter at this

point. Refer to the User’s Guide for your particular Cellular Adapter for instructions on

connecting it to the Test Set. Verify these connections before continuing with these steps.

1 Set the GPIB Address Selector on the rear panel of the PCS Interface as follows.

GPIB/Ser switch GPIB

GPIB address 19 (for the manual control software and connectivity test)

2 Make the front and rear panel connections shown in figure 12.

Consult the User's Guide for your Cellular Adapter for further details about using

these timebase signals in your measurements.

3 Turn on the PCS Interface.

NOTE: The PCS Interface must be powered on and connected before the Agilent 8920B is powered

on. If the PCS Interface is not powered on first, the Agilent 8920A,B will not detect it.

4 Turn on the Test Set.

48

Chapter 2, Installation

When Used with Agilent 8920A,B and Controlled via GPIB for TDMA Subscriber Unit Tests

PWR REF

OFF-CHANNEL

PULSE

MOD

83236B

PCS INTERFACE

POWER

ONOFF

TEST SET

FROM DUPLEX OUT TO ANT IN

ANALYZER ANALYZE R ANALYZER GENERATOR

UNLOCK

DATA

BASEBAND

CLOCK IN

DATA IN

1.8-2.0 GHz UUT

RF IN/OUT RF OUT only

TRIGGERINBASEBAND

DATA IN

From Agilent 8920 DUPLEX OUT

To Agilent 83236 FROM DUPLEX OUT

(Cable P/N 83236-61603)

Note:

From Agilent 8920 ANT IN

To Agilent 83236 TO ANT IN

(Cable P/N 83236-61603)

RF IN/OUT

(User-supplied cable)

From Agilent 83201 or 83206 REF IN

To Agilent 8920 10 MHz REF OUTPUT

(Supplied with cellular adapter)

ANT

Connections between

the Test Set and Cellular

Adapter are not shown

in this figure.

From Agilent 83201 or 83206

FRAME CLK OUT

To Agilent 83236 EXT TRIG IN

(Cable P/N 83215-61644)

From Agilent 8920 GPIB

To Agilent 83236 GPIB

(Mod. No. Agilent 10833D)

To Agilent 83236 REF IN

(BNC “L” adapter P/N 1250-0076)

DIAG

GEN BB

ANL

BIT CLK

DATA OUT

TRIG OUT

SYMBOL

OUT

CLK OUT

OUT

CONTROL I/O

114.3 MHz IF IN

REF IN10 MHz REF OUT

FRAME

CW

IQ

EXT

RF OUT

CLK OUT

RF IN

IF IN

TDMA

Subscriber

Unit

To Agilent 8920 10 MHz REF OUTPUT

(BNC “T” adapter P/N 1250-0781)

From Agilent 8920 10 MHz REF

OUTPUT

To Agilent 83236 REF IN

(Cable P/N 8120-1839)

Figure 12 Connection diagrams for the Agilent 8920 Test Configuration (TDMA Subscriber

Unit Tests; GPIB Control)

49

Chapter 2, Installation

When Used with Agilent 8921A for CDMA Base Stations Tests

When Used with Agilent 8921A for CDMA Base Stations Tests

Unpack the PCS

Interface and

Accessories

NOTE: This product passed all applicable electrical and mechanical inspections before it was

Follow these steps to prepare the Test System for setup:

1 Unpack the test equipment and accessories.

shipped from the factory. As soon as you receive it, check that it is not damaged and that

all accessories are present (see table 2 on page 19). Should this product be damaged or any

accessories be missing, contact your local Agilent Technologies sales office or the

company from which you purchased it.

2 Placing the equipment:

a If you are placing the Test System horizontally (on a bench top, for example) place

the Test Set (together with the Cellular Adapter) on the top of the PCS Interface.

Position the bumpers (feet) of the Test Set so that they are stably seated between

the forward and rear bumpers of the PCS Interface. Refer to figure 10.

Test Set Cellular Adapter

PCS Interface

Figure 13 Horizontal stacking configuration (side view) for the Agilent 8921 Test Configuration

50

Chapter 2, Installation

When Used with Agilent 8921A for CDMA Base Stations Tests

b If you are placing the Test System vertically (as is often done when putting the

equipment on the floor), the PCS Interface’s rear feet must be placed on the same

surface as those of the Test Set. After placement, rotate the handle of the Test Set

downwards to provide support for the PCS Interface. Refer to figure 11.

Test Set Cellular Adapter

PCS Interface

Figure 14 Vertical configuration (side view) for the Agilent 8921 Test Configuration

51

Chapter 2, Installation

When Used with Agilent 8921A for CDMA Base Stations Tests

Cable Connections Follow these steps to prepare the test equipment for use:

NOTE: You should have made all connections between the Test Set and Cellular Adapter at this

point. Refer to the User’s Guide for your particular Cellular Adapter for instructions on

connecting it to the Test Set. Verify these connections before continuing with these steps.

1 Set the GPIB Address Selector on the rear panel of the PCS Interface as follows.

GPIB/Ser switch GPIB

GPIB address 19 (for the manual control software and connectivity test)

2 Make the front and rear panel connections shown in figure 15.

Consult the User's Guide for your Cellular Adapter for further details about using

these timebase signals in your measurements.

3 Turn on the PCS Interface.

NOTE: The PCS Interface must be powered on and connected before the Agilent 8920B is powered

on. If the PCS Interface is not powered on first, the Agilent 8921A will not detect it.

4 Turn on the Test Set.

52

H

RF IN/OUT

TO

TEST SET

Chapter 2, Installation

When Used with Agilent 8921A for CDMA Base Stations Tests

EVEN SECOND/

CDMA

TIMEBASE IN

SYNC IN

PWR REF

UNLOCK

DIAGNOSTIC

MONITOR OUT

1.2288 MHz OUT

CHIP CLOCK

19.6608 MHz OUT

16 X CHIP CLOCK

External attenuator may be

*

required. Consult PCS

Interface Specifications.

User-supplied cables.

**

From Agilent 8921 ANT IN

To Agilent 83236 TO ANT IN

(Cable P/N 83236-61603)

83205A

CDMA CELLULAR ADA PTER

TRIGGER/

RF IN/OUT

QUALIFIER IN

MAX.PWR

60W

EVEN SECOND/

DATA

SYNC IN

IN

H

From Agilent 8921 DUPLEX OUT

To Agilent 83236 FROM DUPLEX OUT

(Cable P/N 83236-61603)

SYNTH REF IN

SYNTH REF IN 10 MHz OUT

From Agilent 83203 or 83205

10 MHz OUT

To Agilent 8921 10 MHz

REF INPUT

(supplied with cellular

adapter)

From Agilent 8921 GPIB

To Agilent 83236 GPIB

(Mod. No. Agilent 10833D)

To Agilent 83236 REF IN

(BNC “L” adapter P/N

1250-0076)

83236B

PCS INTERFACE

POWER

ONOFF

TEST SET

FROM DUPLEX OUT TO ANT IN

1.8-2.0 GHz UUT

RF IN/OUT RF OUT only

**

CDMA Base Station

RX

Base Station

RX antenna

CDMA CLOCK OUTPUTS

CONTROL I/O

114.3 MHz IF IN I BASEBAND OUT

AUX

CW

DSP IN

RF INIQRF OUT

Q BASEBAND OUT

REF OUT

**

*

**

**

10 MHz

OPTIONAL

MOD OUT

SERIAL PORT

Note:

Base Station

TX

TX port or coupler

Even Sec Clk

19.6608 MHz Clk

(or other reference)

Connections between

the Test Set and Cellular

Adapter are not shown

in this figure.

To Agilent 8921 10 MHz REF OUTPUT

(BNC “L” adapter P/N 1250-0076)

From Agilent 8921 10 MHz REF OUTPUT

To Agilent 83236 REF IN

(Cable P/N 8120-1839)

Figure 15 Connection Diagram for the Agilent 8921 Test Configuration (CDMA Base Station

Tests)

53

Chapter 2, Installation

When Used with Agilent 8921A for TDMA Base Stations Tests

When Used with Agilent 8921A for TDMA Base Stations Tests

Unpack the PCS

Interface and

Accessories

NOTE: This product passed all applicable electrical and mechanical inspections before it was

Follow these steps to prepare the Test System for setup:

1 Unpack the test equipment and accessories.

shipped from the factory. As soon as you receive it, check that it is not damaged and that

all accessories are present (see table 2 on page 19). Should this product be damaged or any

accessories be missing, contact your local Agilent Technologies sales office or the

company from which you purchased it.

2 Placing the equipment:

a If you are placing the Test System horizontally (on a bench top, for example) place

the Test Set (together with the Cellular Adapter) on the top of the PCS Interface.

Position the bumpers (feet) of the Test Set so that they are stably seated between

the forward and rear bumpers of the PCS Interface. Refer to figure 10.

Test Set Cellular Adapter

PCS Interface

Figure 16 Horizontal stacking configuration (side view) for the Agilent 8921 Test Configuration

54

Chapter 2, Installation

When Used with Agilent 8921A for TDMA Base Stations Tests

b If you are placing the Test System vertically (as is often done when putting the

equipment on the floor), the PCS Interface’s rear feet must be placed on the same

surface as those of the Test Set. After placement, rotate the handle of the Test Set

downwards to provide support for the PCS Interface. Refer to figure 11.

Test Set Cellular Adapter

PCS Interface

Figure 17 Vertical configuration (side view) for the Agilent 8921 Test Configuration

55

Chapter 2, Installation

When Used with Agilent 8921A for TDMA Base Stations Tests

Cable Connections Follow these steps to prepare the test equipment for use:

NOTE: You should have made all connections between the Test Set and Cellular Adapter at this

point. Refer to the User’s Guide for your particular Cellular Adapter for instructions on

connecting it to the Test Set. Verify these connections before continuing with these steps.

1 Set the GPIB Address Selector on the rear panel of the PCS Interface as follows.

GPIB/Ser switch GPIB

GPIB address 19 (for the manual control software and connectivity test)

2 Make the front and rear panel connections based on your UUT type:

• TDMA base station with frame clock: See figure 18.

• TDMA base station without frame clock: See figure 19.

Consult the User's Guide for your Cellular Adapter for further details about using

these timebase signals in your measurements.

3 Turn on the PCS Interface.

NOTE: The PCS Interface must be powered on and connected before the Agilent 8920B is powered

on. If the PCS Interface is not powered on first, the Agilent 8921A will not detect it.

4 Turn on the Test Set.

56

Chapter 2, Installation

When Used with Agilent 8921A for TDMA Base Stations Tests

83204A

DUAL MODE CELLULAR AD APTER

83236B

PCS INTERFACE

POWER

ONOFF

FROM DUPLEX OUT TO ANT IN

TEST SET

PWR REF

ANALYZER ANALYZER ANALYZER GENERATOR

UNLOCK

DATA

BASEBAND

CLOCK IN

DATA IN

1.8-2.0 GHz UUT

RF IN/OUT RF OUT only

TRIGGERINBASEBAND

DATA IN

*

External attenuator may be

required. Consult PCS

Interface Specifications.

**

User-supplied cables.

From Agilent 8921 ANT IN

To Agilent 83236 TO ANT IN

(Cable P/N 83236-61603)

TDMA Base Station

RX

From Agilent 8921 DUPLEX OUT

**

(RX antenna)

To Agilent 83236 FROM DUPLEX OUT

(Cable P/N 83236-61603)

From Agilent 83201 or 83204

10 MHz REF OUT

To Agilent 8921 10 MHz REF

INPUT

(supplied with cellular adapter)

REF IN

114.3 MHz IF IN

DIAG

GEN BB

ANL

OUT

DATA OUT

TRIG OUT

CONTROL I/O

BIT CLK

SYMBOL

OUT

CLK OUT

REF IN

10 MHz

CW

IQ

REF OUT EX T

RF IN

IF IN

RF OUT

FRAME CLK OUT

EXPANSION

SERIAL PORT

*

**

Note:

**

(TX port or coupler)

TX

Frame Clock (25 or 50 Hz)

(required for RX meas.)

Connections between

the Test Set and Cellular

Adapter are not shown

in this figure.

From Agilent 8921 GPIB

To Agilent 83236 GPIB

(Mod. No. Agilent 10833D)

To Agilent 83236 REF IN

(BNC “L” adapter P/N 8120-

0076)

To Agilent 8921 10 MHz REF OUTPUT

(BNC “L” adapter P/N 8120-0076)

From Agilent 8921 10 MHz REF OUTPUT

To Agilent 83236 REF IN

(Cable P/N 8120-1839)

Figure 18 Connection Diagram for the Agilent 8921 Test Configuration (TDMA Base Station

Tests with Frame Clock)

57

Chapter 2, Installation

When Used with Agilent 8921A for TDMA Base Stations Tests

83204A

DUAL MODE CELLULAR ADAPTER

PWR REF

ANALYZER ANALYZER ANALYZER GENERATOR

UNLOCK

DATA

BASEBAND

CLOCK IN

DATA IN

TRIGGERINBASEBAND

DATA IN

*

External attenuator may be

required. Consult PCS

Interface Specifications.

**

User-supplied cables.

From Agilent 8921 ANT IN

To Agilent 83236 TO ANT IN

(Cable P/N 83236-61603)

POWER

From Agilent 8921 DUPLEX OUT

To Agilent 83236 FROM DUPLEX OUT

(Cable P/N 83236-61603)

From Agilent 83201 or 83204

10 MHz REF IN

DIAG

To Agilent 8921 10 MHz REF

GEN BB

OUT

DATA OUT

OUTPUT

(supplied with cellular adapter)

From Agilent 8921 GPIB

To Agilent 83236 GPIB

(Mod. No. Agilent 10833D)

To Agilent 83236 REF IN

(BNC “L” adapter P/N 8120-

0076)

ONOFF

TRIG OUT

83236B

PCS INTERFACE

ANL

BIT CLK

OUT

SYMBOL

CLK OUT

TEST SET

FROM DUPLEX OUT TO ANT IN

CONTROL I/O

CW

RF IN

114.3 MHz IF IN

IQ

RF OUT

10 MHz

REF OUT E XT

FRAME CLK OUT

REF IN

IF IN

SERIAL PORT

1.8-2.0 GHz UUT

RF IN/OUT RF OUT only

EXPANSION

TDMA Base Station

(RX antenna)

**

**

RX

(TX port or coupler)

TX

*

Note:

Connections between

the Test Set and Cellular

Adapter are not shown

in this figure.

To Agilent 8921 10 MHz REF OUTPUT

(BNC “T” adapter P/N 8120-0781)

From Agilent 8921 10 MHz REF OUTPUT

To Agilent 83236 REF IN

(Cable P/N 8120-1839)

Figure 19 Connection Diagram for the Agilent 8921 Test Configuration (TDMA Base Station

Tests without Frame Clock)

58

Chapter 2, Installation

Load and Run the Connectivity Test Software (Option 001 or 002)

Load and Run the Connectivity Test Software (Option 001 or 002)

The connectivity test is used to verify that the connections between the test

equipment are correct and that the cables are intact. The software also performs

basic functionality checks of each instrument in the Test System.

NOTE: The connectivity test is supplied on the memory card shipped with the Agilent 83236B

option 001, utility software on PCMCIA card, or option 002, utility software on EPSON

memory card. Use the PCMCIA card for the Agilent 8924C or Agilent 8920B; use the

EPSON memory card for the Agilent 8920A or Agilent 8921A.

1 Make proper connections between the Test Set and the PCS Interface.

2 When the PCS Interface is controlled via GPIB Interface, set the GPIB address to 19

on the rear panel of the PCS Interface.

3 When you are testing base stations, make front and rear panel connections shown in fig-

ure 20.

4 To prepare the Test Set for running the connectivity test, perform the steps shown in

figure 21.

5 To load and run the software, follow the steps of figure 22.

NOTE: Use the N(f)-BNC(m) and the N(m)-BNC(f) adapters shipped with the Agilent 83236B

options 001 and 002 when they are required to connect the cables.

59

Chapter 2, Installation

Load and Run the Connectivity Test Software (Option 001 or 002)

PWR REF

OFF-CHANNEL

PULSE MOD

OUT

ANALYZER ANALYZER ANALYZER GENERATOR

UNLOCK

DATA

BASEBAND

CLOCK IN

DATA IN

TRIGGERINBASEBAND

DATA IN

From Agilent 83236 FROM

DUPLEX OUT

To Agilent 8920,21 DUPLEX OUT

(Cable P/N 83236-61603)

Note:

Connections between

the Test Set and Cellular

Adapter are not shown

in this figure.

From Agilent 8920,21 GPIB

To Agilent 83236 GPIB

(Mod. No. Agilent 10833D)

83236B

PCS INTERFACE

POWER

ONOFF

TEST SET

FROM DUPLEX OUT TO ANT IN

1.8-2.0 GHz UUT

RF IN/OUT RF OUT only

From Agilent 83236 TO ANT IN

To Agilent 8920,21 ANT IN

(Cable P/N 83236-61603)

From Agilent 8920,21 10 MHz

114.3 MHz IF IN

10 MHz REF OUT

DIAG

GEN BB

ANL

BIT CLK

OUT

DATA OUT

TRIG OUT

CONTROL I/O

SYMBOL

OUT

CLK OUT

REF IN

FRAME

CW

IQ

EXT

RF OUT

CLK OUT

RF IN

IF IN

REF OUTPUT

To Agilent 8320NX REF IN

(Supplied with cellular adapter)

To Agilent 8920,21 10 MHz REF

OUTPUT

(BNC “T” adapter P/N 1250-0781)

From Agilent 8920,21 10 MHz

REF OUTPUT

To Agilent 83236 REF IN

(Cable P/N 8120-1839)

Figure 20 Connectivity Test Connection diagrams for the Base Station Test Configuration

60

Chapter 2, Installation

Load and Run the Connectivity Test Software (Option 001 or 002)

a

Press

POWER.

Insert the utility

c

software card.

Wait for a display to appear

b

(approximately 20 seconds).

CDMA CALL

CELL

CALL

SPECTR

ENCOD

SPEC

GEN

RF

RF

CDMA

ANALOG

RANG

MSRPT

DECOD

SCOPE

DUPLE

END

RX

TX

RX

ACP

TXAF

CALL ANS

USE DAT

k1’

k1

k2’

k2

k3’

k3

ASSIG

k4

RELEA

k5

POWE

DO NOT

!

RF IN/OUT

MAX PWR

!

DUPLEX

!

MAX

ANTENNA

FUNCTIO

I/O CONFI

MSG

PRINT

HELP

PRINT

PREV TESTS

DATA

REF

METE

AVG

INCR

INCR

INCR

LO HI

CURSO PUSH

CANCSHIFT

INSTRUMENT

ADRS

SAVE

LOCAL

RECAL

789

456

123

+

0

YES

NO

ON/

AUDIO SQUELVOLUMIC/

MAX

!

_

HOLD

MEAS

ENTER

dB

GHz

%

MHz

s

kHz

Hzms% Ωppm

AUDIO IN

MAX

!

PRESE

MEMO

LOHI

Figure 21 Turning power on and inserting the memory card.

Press

d

PRESET.

Preset returns the Test Set

to the RX Test screen.

61

Chapter 2, Installation

Load and Run the Connectivity Test Software (Option 001 or 002)

Press TESTS to display the

1

TESTS (Main Menu) screen.

If you are in the IBASIC TESTs

screen, press PRESET before

pressing TESTS.

Position cursor at Card and select it.

3 4

Position cursor at Select Procedure Location:

2

and select it.

Position cursor at Select Procedure Filename:

and select it.

Position cursor at Choices: and

select

SYS_CONN.

Figure 22 Loading and Running the Connectivity Test

62

Position cursor at Run Test and select it.

65

The software is now loading.

Loading Time:

First time:

approximately

1.5 minutes.

After first time:

approximately

10 seconds.

Chapter 2, Installation

Load and Run the Connectivity Test Software (Option 001 or 002)

Notes about GPIB

connections

Connectivity Test

guidelines

Disconnect other GPIB devices, especially system controllers, from the Test

System before running the connectivity test. The Test Set is the system controller

when the connectivity test is running and another (external) controller on the bus

will generate a bus conflict error.

The following general guidelines may be useful to you when running the

connectivity test.

Presentation of results on the Test Set’s display

The software uses the following conventions when displaying information on the

Test Set’s display:

Top display line: the very first line of text at the top of the Test Set display is used to

indicate the test being performed.

Two-line inverse text area: just below the top display line is a two-line inverse video

area that is used to prompt the user with instructions.

Main display area: below the inverse area is the main display area of the Test Set. This

large area is used to display test results and to present error messages that may occur.

Softkey (USER key) label area: at the upper right of the Test Set’s display are five

inverse video labels that are used to indicate the function of the corresponding softkey

(k1 to k5). These keys are used to run the software, continue it at key points, and for

other assorted functions.

Pauses during connectivity test execution

As the testing is done to verify connectivity, the software will display abbreviated

results on the main screen of the Test Set’s display. If the program pauses and

gives a prompt before the testing is complete, it is typically to communicate that it

has found a problem. In this case the program will suggest cable paths (and

cables) to check before going on with the testing.

63

Chapter 2, Installation

Where to go next

Where to go next

If you have run the

connectivity

software with a pass

result

If you encountered

failures when

running the

connectivity

software

Now that the Test System’s operation has been verified, you will want to start

making tests on radio equipment.

• If you are planning to test CDMA subscriber units using the Agilent 8924C with the

serial port control, refer to the Agilent 8924C User’s Guide.

• If you are planning to test TDMA subscriber units using the Agilent 8920B with the

serial port control, refer to the Agilent 8920B User’s Guide.

• If you are planning to test CDMA base stations using the Agilent 8921A, refer to the

CDMA/PCS Base Station Test Software User’s Guide.

• If you are planning to test radio equipment using the Agilent 8920A,B, Agilent 8921A,

or Agilent 8924C with the GPIB interface control, refer to the Manual Control Soft-

ware User’s Guide for the next steps in making tests using the manual control software.

If it finds problems, the connectivity software will prompt you to check various

connections in the Test System. The software will then repeat the testing to verify

that the problem has been corrected.

If failures persist after running the Test System connectivity software, you may

have a failure in one of the pieces of test equipment in the Test System. The

connectivity software will attempt to identify the failed unit. Once the suspected

failed unit is identified, contact your nearest Agilent Technologies Service Center

for instructions on servicing the unit.

In North America you may call, toll-free, 1-800-827-3848 (between 9 am and

5 pm, Pacific time) for instructions on further troubleshooting and how to proceed

if repairs are needed. Refer to the last page of this manual for service center

addresses and locations.

64

3P

rogramming the PCS Interface using GPIB

Control

What’s included in this chapter:

• Introduction

• Overview of programming issues

• PCS Interface programming guide

65

Programming the

PCS Interface

Chapter 3, Programming the PCS Interface using GPIB Control

Introduction

Introduction

The PCS Interface extends the frequency range of the Test Set to the 1710 to

1785 MHz, 1805 to 1910 MHz, and 1930 to 1990 MHz PCS band. Since the PCS

Interface has no front-panel user controls, its only available control interface is

through GPIB.

NOTE: To control the PCS Interface over GPIB, some form of control software must be used. The

software can run on either an external controller or in the Test Set’s IBASIC controller. No

“manual” front panel controls of the PCS Interface are provided.

The information in this chapter does not apply when an Agilent 8924C is controlling the

PCS Interface over the serial port.

Purpose This chapter is designed to assist Software Application Designers who will be

integrating the PCS Interface into their own testing system and who as a result,

will need to develop their own software. It provides task flow diagrams,

programming examples, and recommends a testing theory to help guide the

development of control software.

When integrating the PCS Interface into a custom test system, there are a few

topics which must be considered. The following discussions provide general

overviews of these topics. The remaining sections of this chapter then provide

more specific procedures for making the various settings and measurements with

the PCS Interface.

66

Chapter 3, Programming the PCS Interface using GPIB Control

Overview of Programming Issues

Overview of Programming Issues

Features The basic features of the PCS Interface include:

• A PCS frequency RF generator for receiver testing

• A PCS frequency signal analyzer for transmitter testing

• A power detector for direct power measurements

• A temperature sensor for accuracy compensations

The PCS Interface takes the signal generated by the Test Set (810 to 995 MHz) at

its FROM DUPLEX OUT port and upconverts it to a PCS frequency band

(1710 to 1785 MHz, 1805 to 1910 MHz, or 1930 to 1990 MHz) signal at the unitunder-test (UUT) port.

Conversely, the PCS Interface takes the UUT’s transmitted signal (1710 to

1785 MHz, 1805 to 1910 MHz, or 1910 to 1990 MHz), downconverts it to a

frequency the Test Set is capable of analyzing (650 to 940 MHz), and applies it to

the Test Set’s ANT IN port. Both the PCS Interface’s generator and analyzer

paths include variable attenuators for controlling signal levels in the Test System.

The power detector inside the PCS Interface provides direct measurements of the

UUT’s transmitter power.

In order to provide the best possible accuracy and confidence in measurements,

the PCS Interface has built-in temperature sensing circuitry which is used to

determine whether re-calibration is needed. Three compensations are available for

re-calibration and will be discussed in detail later in this chapter.

67

Chapter 3, Programming the PCS Interface using GPIB Control

Overview of Programming Issues

System

Connections

NOTE: It is assumed that all connections between the Test Set and Cellular Adapter have been

made. Refer to the User’s Guide for your Cellular Adapter for instructions on connecting

it to the Test Set.

For connections between the Test Set and PCS Interface, refer to chapter 2,

"Installation".

UUT Port Selection The PCS Interface has two ports available for UUT connection; the RF IN/OUT

port and the RF OUT only port. Use the PCS Interface’s RF IN/OUT port for

single-port devices (for example, a subscriber unit) or its RF OUT only port for

devices with separate RX and TX ports (for example, a base station).

Frequency Setting The PCS Interface provides a PCS frequency generator by upconverting the Test

Set’s generator signal with a stepped local oscillator (LO) and mixer. It downconverts a PCS frequency transmitter signal for analysis by the Test Set using a

fixed frequency LO and mixer. For convenience, conversion bypass paths are also

provided which eliminate any connection changes when testing devices in the 800

to 960 MHz band.

68

Agilent 83236B

Chapter 3, Programming the PCS Interface using GPIB Control

Overview of Programming Issues

EXT TRIG IN

(Frame C lk from

Agilent 8320NX)

ADC CPU GPIB

GPIB (to Agilent 892NX)

Serial (to Agilent 8924C)

DET OUT (to Agilent 8924C)

REF IN (from Agilent 892NX)

REF OUT

To ANT IN

650 to 940 MHz

(to Agilent 892NX)

FROM DUPLEX OUT

810 to 995 MHz

(from Agilent 892NX)

RF IN/OUT

1710 to 1990 MHz

(to UUT)

RF OUT only

1710 to 1990 MHz

(to UUT)

Serial

TEMP Sense

1050 or 1060 MHz

SW1

1

0

1

0

SW2

Pwr Det

TX ATTEN

0 to 40 dB

1 dB step

RX ATTEN

0 to 70 dB

10 dB step

790, or 990 MHz to 1110 MHz

10 MHz step

REF

Figure 23 PCS Interface block diagram

NOTE: The frequency conversion tables, used internally by the PCS Interface’s CPU to determine

the Test Set’s frequencies, are shown in Appendix A, Frequency Conversion Tables on

page 137.

The frequencies desired at the UUT’s ports are set using GPIB commands. When

the PCS Interface receives the generator or analyzer frequency settings over

GPIB, its CPU automatically controls the conversion/bypass and internal LO

settings in its generator and analyzer paths. In addition, the PCS Interface’s CPU

determines the frequencies required for the Test Set’s RF generator and analyzer.

These values are returned over GPIB and are then used by the controlling

software to set the Test Set’s generator and analyzer frequencies.

69

Chapter 3, Programming the PCS Interface using GPIB Control

Overview of Programming Issues

Generator level

Setting

The PCS Interface’s generator path has a 0 to 70 dB attenuator with 10 dB steps

which provide coarse level settings of the RF generator. Fine level control is

provided by the 0.1 dB resolution of the Test Set’s DUPLEX OUT port.

The output signal level desired at the UUT’s port is set using an GPIB command.

When the PCS Interface’s generator level setting is received over GPIB, the CPU

of the PCS Interface automatically determines the appropriate generator path

attenuator setting, and computes a level which should be set at the Test Set’s

DUPLEX OUT port. This level is returned over GPIB and is then used by the

controlling software to set the Test Set’s RF generator level.

The automatic attenuator and level computations performed by the PCS

Interface’s CPU include two factors which are stored internally; a temperature (of

the PCS Interface) factor and an attenuation step accuracy factor. The temperature

correction factor is updated during the generator level temperature compensation

which is discussed later. The attenuator step accuracy correction factor is

established as part of the factory calibration. Both factors are also a function of

the current generator frequency. Therefore, the generator level setting should be

done after setting the desired RF generator frequency.

70

Chapter 3, Programming the PCS Interface using GPIB Control

Overview of Programming Issues

Analyzer

Attenuator Setting

The PCS Interface’s analyzer path has a 0 to 40 dB attenuator with 1 dB steps.

This attenuator is adjusted to optimize the signal level through the PCS

Interface’s downconverter to the Test Set’s ANT IN port.

After the UUT’s transmitter signal is applied to the PCS Interface’s RF IN/OUT

port, the setting of the analyzer path attenuator can be automatically set using an

GPIB command. When the command is received, the PCS Interface uses the

internal peak detector to measure the peak power at its RF IN/OUT port, then

computes and sets the analyzer path attenuator accordingly.