Page 1

Errata

8167B/8D/8E/8F Tunable Laser Source User's Guide

08168-91031

February 1, 1998

Title & Document Type:

Manual Part Number:

Revision Date:

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. We have made no changes to this

manual copy. The HP XXXX referred to in this document is now the Agilent XXXX.

For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support your

product. This manual provides the best information we could find. It may be incomplete

or contain dated information, and the scan quality may not be idea l. If we find a better

copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available

product information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide

you to any available information. Our service centers may be able to perform calibration

if no repair parts are needed, but no other support from Agilent is available.

Page 2

User's Guide

HP 8167B/8D/8E/8F Tunable Laser Source

SERIAL NUMBERS

This guide applies to the 8167B, 8168D, 8168E and 8168F

tunable laser sources. It does not always apply to the 8167A.

Serial numbers of the 8167B begin with the letters DE.

ABCDE

HP Part No. 08168-91031

Printed in Germany

First Edition

E0298

Page 3

Notices

This document contains proprietary

information that is protected by

copyright. All rights are reserved.

No part of this document may be

photocopied, reproduced, or

translated to another language

without the prior written consent of

Hewlett-Packard GmbH.

c

Copyright 1997 by:

Hewlett-Packard GmbH

Herrenberger Str. 130

71034 Boeblingen

Germany

Subject Matter

The information in this document is

subject to change without notice.

Hewlett-Packard makes no warranty

of any kind with regard to this

printed material, including, but not

limited to, the implied warranties of

merchantability and tness for a

particular purpose.

Hewlett-Packard shall not be liable

for errors contained herein or for

incidental or consequential damages

in connection with the furnishing,

performance, or use of this material.

Printing History

New editions are complete revisions

of the guide reecting alterations in

the functionality of the instrument.

Updates are occasionally made to

the guide between editions. The

date on the title page changes when

an updated guide is published. To

nd out the current revision of the

guide, or to purchase an updated

guide, contact your Hewlett-Packard

representative.

Warranty

This Hewlett-Packard instrument

product is warranted against defects

in material and workmanship for a

period of one year (8167A and

8168D) or three years (8168E and

8168F) from date of shipment.

During the warranty period, HP will,

at its option, either repair or replace

products that prove to be defective.

For warranty service or repair, this

product must be returned to a service

facility designated by HP. Buyer shall

prepay shipping charges to HP and

HP shall pay shipping charges to

return the product to Buyer.

However, Buyer shall pay all shipping

charges, duties, and taxes for

products returned to HP from

another country.

HP warrants that its software and

rmware designated by HP for use

with an instrument will execute its

programming instructions when

properly installed on that instrument.

HP does not warrant that the

operation of the instrument,

software, or rmware will be

uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not

apply to defects resulting from

improper or inadequate maintenance

by Buyer, Buyer-supplied software or

interfacing, unauthorized

modication or misuse, operation

outside of the environmental

specications for the product, or

improper site preparation or

maintenance.

No other warranty is expressed or

Exclusive Remedies

The remedies provided herein are

Buyer's sole and exclusive remedies.

Hewlett-Packard shall not be liable

for any direct, indirect, special,

incidental, or consequential

damages whether based on contract,

tort, or any other legal theory.

Assistance

Product maintenance agreements

and other customer assistance

agreements are available for

Hewlett-Packard products.For any

assistance contact your nearest

Hewlett-Packard Sales and Service

Oce.

Certication

Hewlett-Packard Company certies

that this product met its published

specications at the time of

shipment from the factory.

Hewlett-Packard further certies

that its calibration measurements

are traceable to the United States

National Institute of Standards and

Technology, NIST (formerly the

United States National Bureau of

Standards, NBS) to the extent

allowed by the Institutes's

calibration facility, and to the

calibration facilities of other

International Standards Organization

members.

ISO 9001 Certication

Produced to ISO 9001 international

quality system standard as part of

our objective of continually

increasing customer satisfaction

through improved process control.

implied. Hewlett-Packard specically

disclaims the implied warranties of

Merchantability and Fitness for a

Particular Purpose.

08168-91031 : First Edition : 1st July 1997 : E0797 : 1st September 1997 : E0997 : 1st February 1998 : E0298

Page 4

Safety Summary

The following general safety precautions must be observed during all phases

of operation, service, and repair of this instrument. Failure to comply with

these precautions or with specic warnings elsewhere in this manual violates

safety standards of design, manufacture

, and intended use of the instrument.

Hewlett-Packard Company assumes no liability for the customer's failure to

comply with these requirements.

General

This is a Safety Class 1 instrument (provided with terminal for

protective earthing) and has been manufactured and tested according to

international safety standards.

Operation - Before applying power

Comply with the installation section.

Additionally, the following shall be observed:

Do not remove instrument covers when operating.

Before the instrument is switched on, all protective earth terminals

, extension

cords, auto-transformers and devices connected to it should be connected to a

protective earth via a ground socket. Any interruption of the protective earth

grounding will cause a potential shock hazard that could result in serious

personal injury.

Whenever it is likely that the protection has been impaired, the instrument

must be made inoperative and be secured against any unintended operation.

Make sure that only fuses with the required rated current and of the specied

type (normal blow, time delay, etc.) are used for replacement. The use of

repaired fuses and the short-circuiting of fuseholders must be avoided.

Adjustments described in the manual are performed with power supplied to

the instrument while protective covers are removed. Be aware that energy at

many points may, if contacted, result in personal injury.

Any adjustments, maintenance, and repair of the opened instrument under

voltage should be avoided as much as possible, and when unavoidable, should

be carried out only by a skilled person who is aware of the hazard involved.

Do not attempt internal service or adjustment unless another person, capable

of rendering rst aid and resuscitation is present. Do not replace components

with power cable connected.

Do not operate the instrument in the presence of ammable gases or fumes.

Operation of any electrical instrument in such an enviroment constitutes a

denite safety hazard.

Do not install substitute parts or perform any unauthorized modication to

the instrument.

Be aware that capacitors inside the instrument may still be charged even if

the instrument has been disconnected from its source of supply.

iv

Page 5

Safety Symbols

L

The apparatus will be marked with this symbol when it is

necessary for the user to refer to the instruction manual in

order to protect the apparatus against damage.

Caution, risk of electric shock.

Frame or chassis terminal.

Protective conductor terminal.

Hazardous laser radiation.

Warning

Caution

The WARNING sign denotes a hazard. It calls attention to

a procedure, practice or the like, which, if not correctly

performed or adhered to, could result in injury or loss of

life. Do not proceed beyond a WARNING sign until the

indicated conditions are fully understood and met.

The CAUTION sign denotes a hazard. It calls attention to

an operating procedure, practice or the like, which, if not

correctly performed or adhered to, could result in damage to

or destruction of part or all of the equipment. Do not proceed

beyond a CAUTION sign until the indicated conditions are fully

understood and met.

v

Page 6

Initial Safety Information for the Tunable Laser

Source

The Specications for these instruments are as follows:

HP 8167B HP 8168D HP 8168E HP 8168F

Laser Type

Fabry Fabry Fabry Fabry

Perot-Laser Perot-Laser Perot-Laser Perot-Laser

InGaAsP InGaAsP InGaAsP InGaAsP

Laser Class

According to 21 CFR 1040.20 IIIb 1 1 IIIb

(USA, Canada, Japan)

According to IEC 825-1 3A 3A 3A 3A

(Other countries)

EN 60825-1 Europe

Permissible Output Power (CW)

Beam Diameter

Numerical Aperture

Wavelength

<

9.9mW

<

1.6mW

<

1.6mW

<

9.9mW

9m 9m 9m 9m

0.1 0.1 0.1 0.1

1255-1365nm 1490-1565nm 1475-1575nm 1450-1590nm

Note

Note

vi

All Tunable Laser Source modules (8167B, 8168D/68E/68F) use

two LED devices (HLMP-1503) as indicator lamps on the front

panel. These LED devices are measured to be less than AEL

Class 1 Laser Products per EN60825-1 Standard.

USA

Class 1 laser safety warning labels, required for the 8168D

and 8168E in the USA, Canada, or Japan.

Page 7

Class IIIb stickers, required for 8167B and 8168F in the

USA, Canada, and Japan.

Caution

Note

The use of optical instruments with this product will increase

eye hazard.

Other countries

(not USA, Canada, or Japan)

Class 3A stickers, required for all Tunable Laser Sources

outside the USA, Canada, and Japan.

vii

Page 8

Class 3A Output Power stickers, required for all

Tunable Laser Sources outside the USA, Canada, and

Japan.

Note

Note

Warning

Warning

Warning

A sheet of laser safety warning labels are included with the

instrument. You

onto the outside of the instrument, in a position where they are

clearly visible to anyone using the instrument.

You

MUST

to an HP Service Center for repair and calibration.

The instrument has built in safety circuitry that will disable the

optical output in the case of a fault condition.

Use of controls or adjustments or performance of

procedures other than those specied for the laser source

may result in hazardous radiation exposure.

Refer Servicing only to qualied and authorized personnel.

Do not enable the laser when there is no ber attached to

the optical output connector.

MUST

return instruments with malfunctioning laser boxes

stick the labels in the local language

viii

Page 9

The optical output connector is at the bottom right of the

instrument front panel.

The laser is enabled by pressing the gray button beside

the optical output connector on the front panel. The laser

is enabled when the green LED on the front panel of the

instrument is lit.

Warning

Under no circumstances look into the end of an optical

cable attached to the optical output when the device is

operational.

The laser radiation is not visible to the human eye, but it

can seriously damage your eyesight.

ix

Page 10

Introduction

This guide is arranged into ve categories:

Getting Started

This section gives an introduction to the instrument, and aims to make the

instrument familiar to you: Chapter 1.

Local Control

This is the information on how to control the instrument from the front panel:

Chapters 2 and 3.

Remote Control

This is the information on how to control the instrument over the HP-IB

is made of general information for using the HP-IB

some programming examples.: Chapters 4, 5, and 6.

Additional Information

This is supporting information of a non-operational nature. This contains

installation information, accessories, specications, function tests, cleaning

procedures, and error codes: Appendices A to F.

PACT software

Appendix G gives you information about using the Passive Component Test

Spftware.

, a command reference, and

. This

Attenuator

x

Some information in this manual applies only to the tunable

laser source with the built in optical attenuator (option 003).

This paragraph is marked the way that all the passages which

only apply to the attenuator option are marked in this manual.

Page 11

Contents

1. Getting Started

What is a Tunable Laser Source? ................ 1-1

A description of the Front Panel .... ...... ...... 1-2

Starting the 8167B or 8168F .... ...... ...... .. 1-3

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Changing the Value of a Parameter ............... 1-6

Making Big Changes to a Parameter . . . . . . . . . . . . . . 1-6

Making a Small Change to a Parameter ............ 1-6

Setting a Parameter to its Default Value . . . . . . . . . . . . 1-7

If You Make a Mistake .... ...... ...... .... 1-8

If the Parameter Will Not Change . . . . . . . . . . . . . . . 1-8

A Sample Session ...... ...... ........ ... 1-8

Measuring the Power of a Modulated Signal . . . . . . . . . . 1-8

Setting the Wavelength . . . . . . . . . . . . . . . . . . . 1-9

Setting the Modulated Power . . . . . . . . . . . . . . . . 1-10

Measuring a Wavelength Characteristic ............ 1-11

Setting Up the Wavelength Sweep ............. 1-11

Performing the Wavelength Characteristic Measurement .. . 1-12

2. Setting Wavelength and Power

Setting the Wavelength . . . . . . . . . . . . . . . . . . . . . 2-2

Setting the Wavelength Directly ...... ...... ... 2-2

Setting a Relative Wavelength ...... ...... .... 2-3

Changing the Base Wavelength . . . . . . . . . . . . . . . 2-3

Performing a Wavelength Sweep ................ 2-4

Setting the Wavelength Sweep ................ 2-5

Setting the Maximum Power for the Sweep Range . . . . . . . 2-5

Executing an Automatic Sweep . . . . . . . . . . . . . . . . 2-6

Performing a Manual Sweep .... ...... ....... 2-6

Setting the Power ....................... 2-8

Setting the Output Power of a CW Signal ........... 2-8

Setting Power and Attenuation . . . . . . . . . . . . . . . 2-9

Contents-1

Page 12

What is Excessive Power? .................. 2-9

The Analog Output ..................... 2-9

Setting a Modulated Signal . . . . . . . . . . . . . . . . . . . 2-10

Using the Internal Modulation ................ 2-11

Setting the Output Power of a Modulated Signal . . . . . . . 2-11

Setting the Frequency of a Modulated Signal ........ 2-11

The Modulation Output .................. 2-12

Using External Modulation . . . . . . . . . . . . . . . . . . 2-12

Setting the Output Power of a Modulated Signal . . . . . . . 2-13

The Modulation Input ...... ........ ..... 2-13

Using Coherence Control . . . . . . . . . . . . . . . . . . . . 2-13

Setting the Output Power of a Coherence Control Signal .. .. 2-13

The Coherence Control Uncal Power ............. 2-14

3. Other Functions

Storing and Recalling Instrument Settings . . . . . . . . . . . . 3-1

Using the System Utilities ................... 3-2

Switching the Instrument into Stand-By . . . . . . . . . . . . 3-3

Increasing the Lifetime of the Display . . . . . . . . . . . . 3-3

Setting the HP-IB Address .................. 3-4

Setting the Modulation Output .... ...... ...... 3-4

Getting Information about the Instrument . . . . . . . . . . . 3-4

Setting the Date and Time ...... ...... ...... 3-4

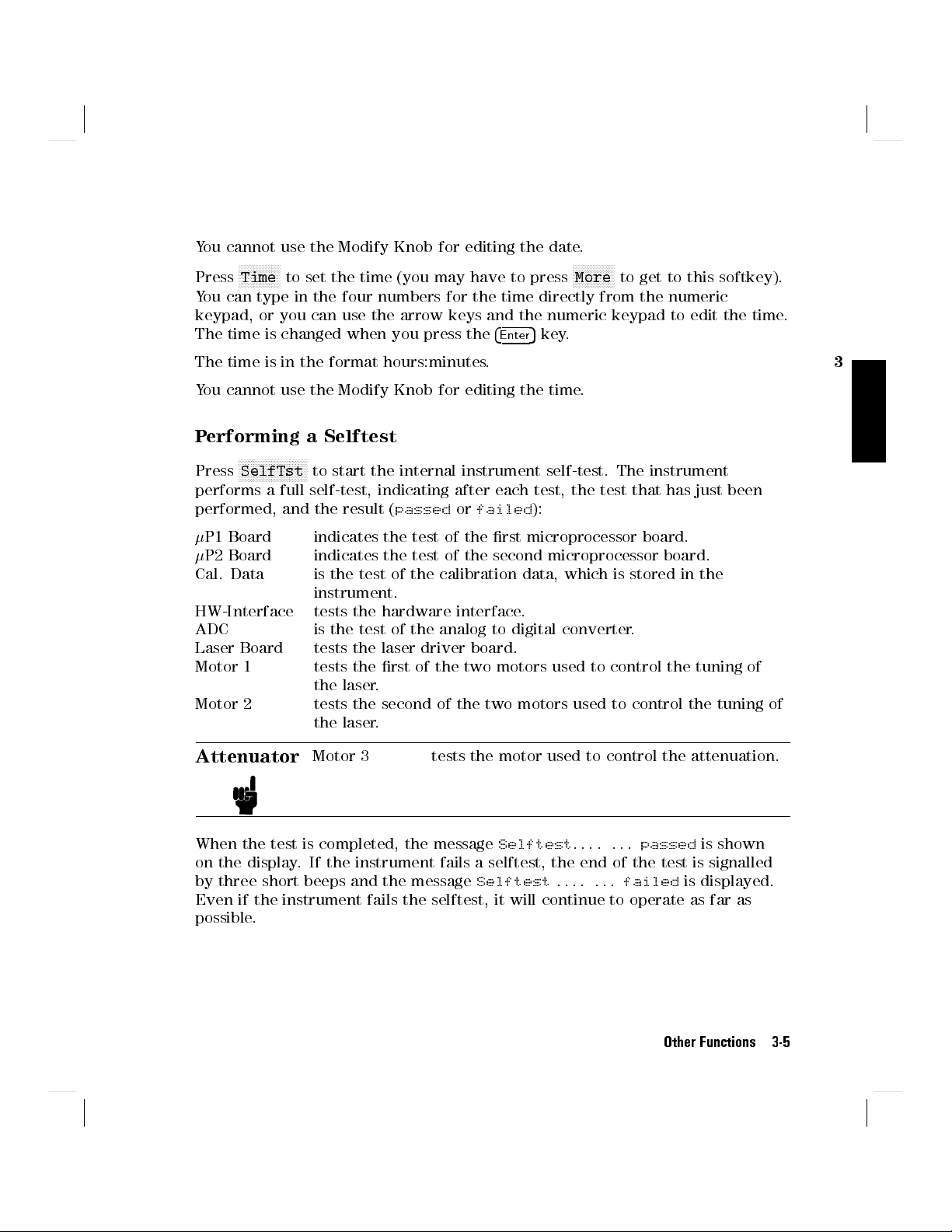

Performing a Selftest . . . . . . . . . . . . . . . . . . . . .

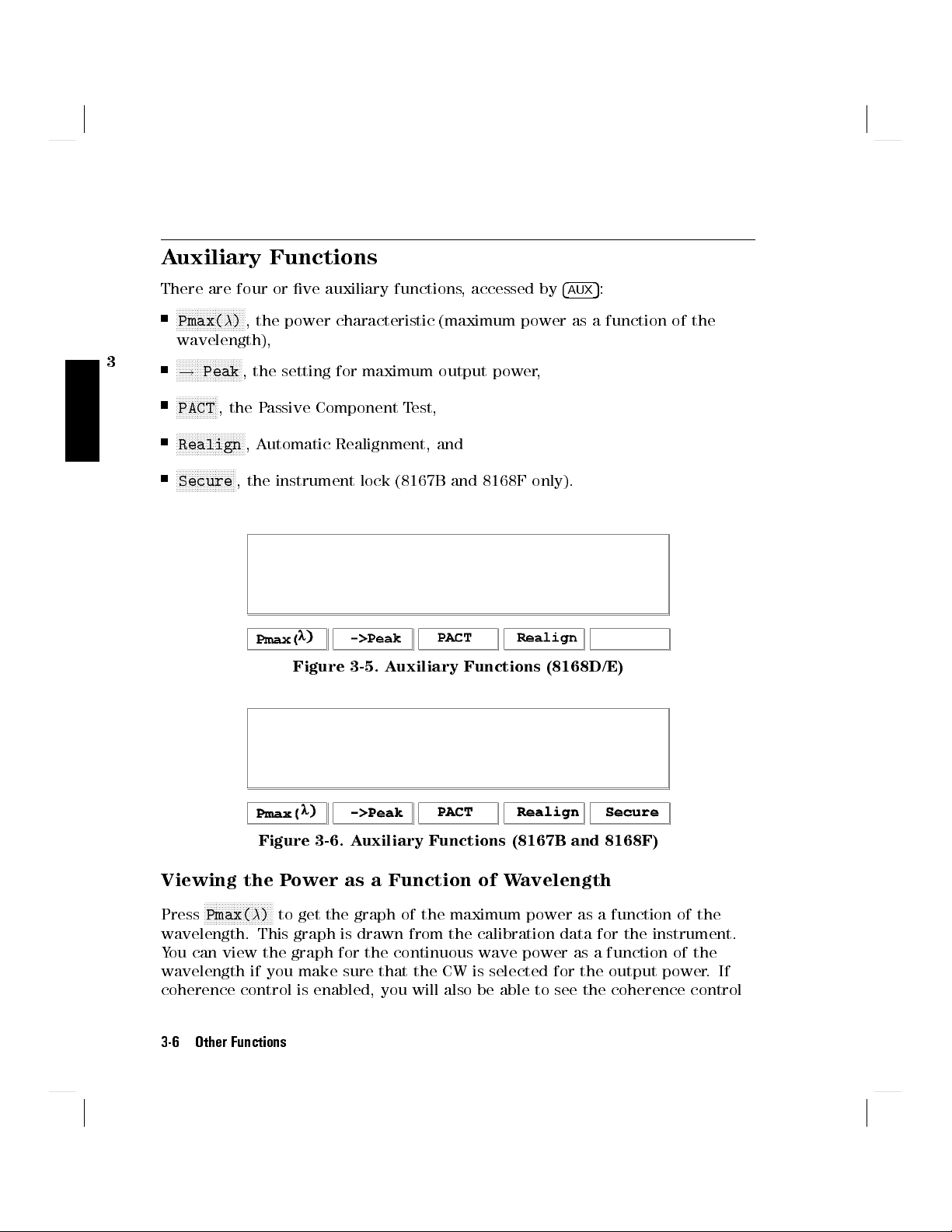

Auxiliary Functions .... ...... ........ .... 3-6

Viewing the Power as a Function of Wavelength . . . . . . . . 3-6

Setting the Peak Power ................... 3-7

Passive Component Test (PACT).. ...... ...... .. 3-7

Automatic Realignment ................... 3-7

Secure .......... ...... ...... ..... 3-9

Lock the Instrument . . . . . . . . . . . . . . . . . . . . 3-9

Change the Password .... ...... ..... .... 3-11

3-5

4. Programming the Tunable Laser Source

HP-IB Interface ........................ 4-1

Setting the HP-IB Address .... ........ ...... . 4-3

Returning the Instrument to Local Control ........... 4-3

How the Tunable Laser Source Receives and Transmits Messages . 4-3

How the Input Queue Works ................. 4-3

Clearing the Input Queue . . . . . . . . . . . . . . . . . . 4-4

The Output Queue . . . . . . . . . . . . . . . . . . . . . . 4-4

Contents-2

Page 13

The Error Queue . . . . . . . . . . . . . . . . . . . . . . . 4-4

Some Notes about Programming and Syntax Diagram Conventions 4-5

Short Form and Long Form.................. 4-5

Command and Query Syntax ................. 4-5

5. Remote Commands

Units ............................. 5-1

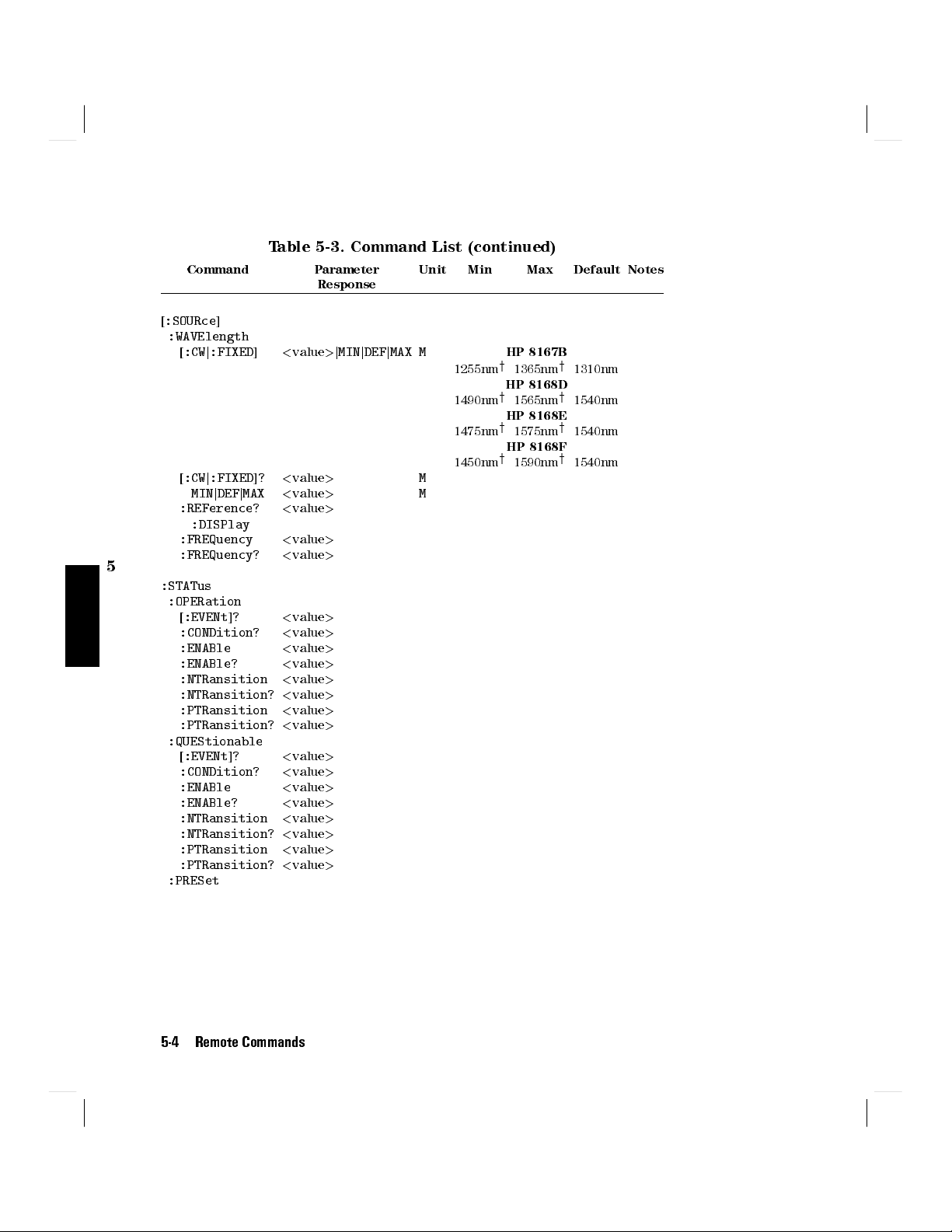

Command Summary ...................... 5-2

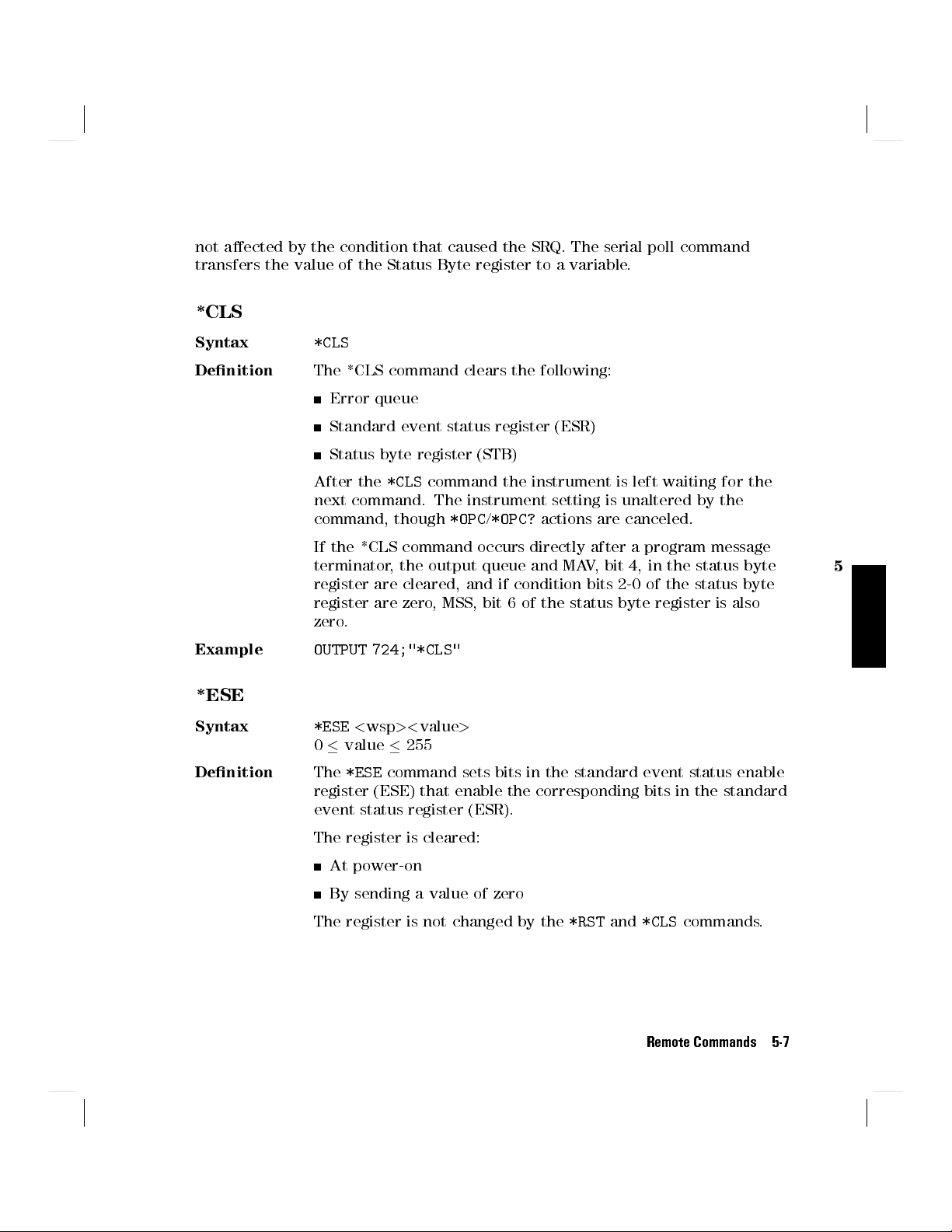

The Common Commands . . . . . . . . . . . . . . . . . . . . 5-5

Common Status Information ................. 5-5

SRQ, The Service Request ................. 5-6

*CLS ............................ 5-7

*ESE ............................ 5-7

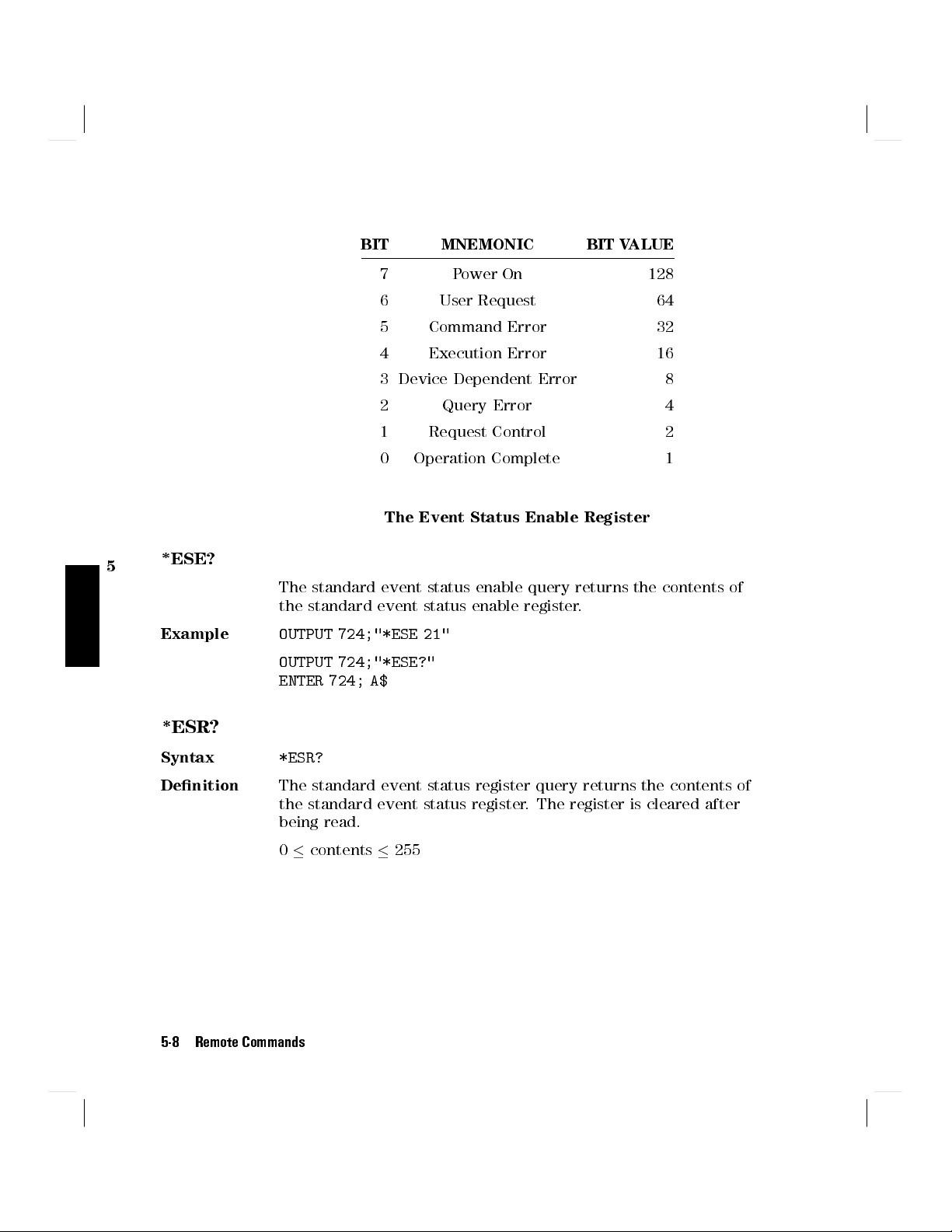

*ESE? . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

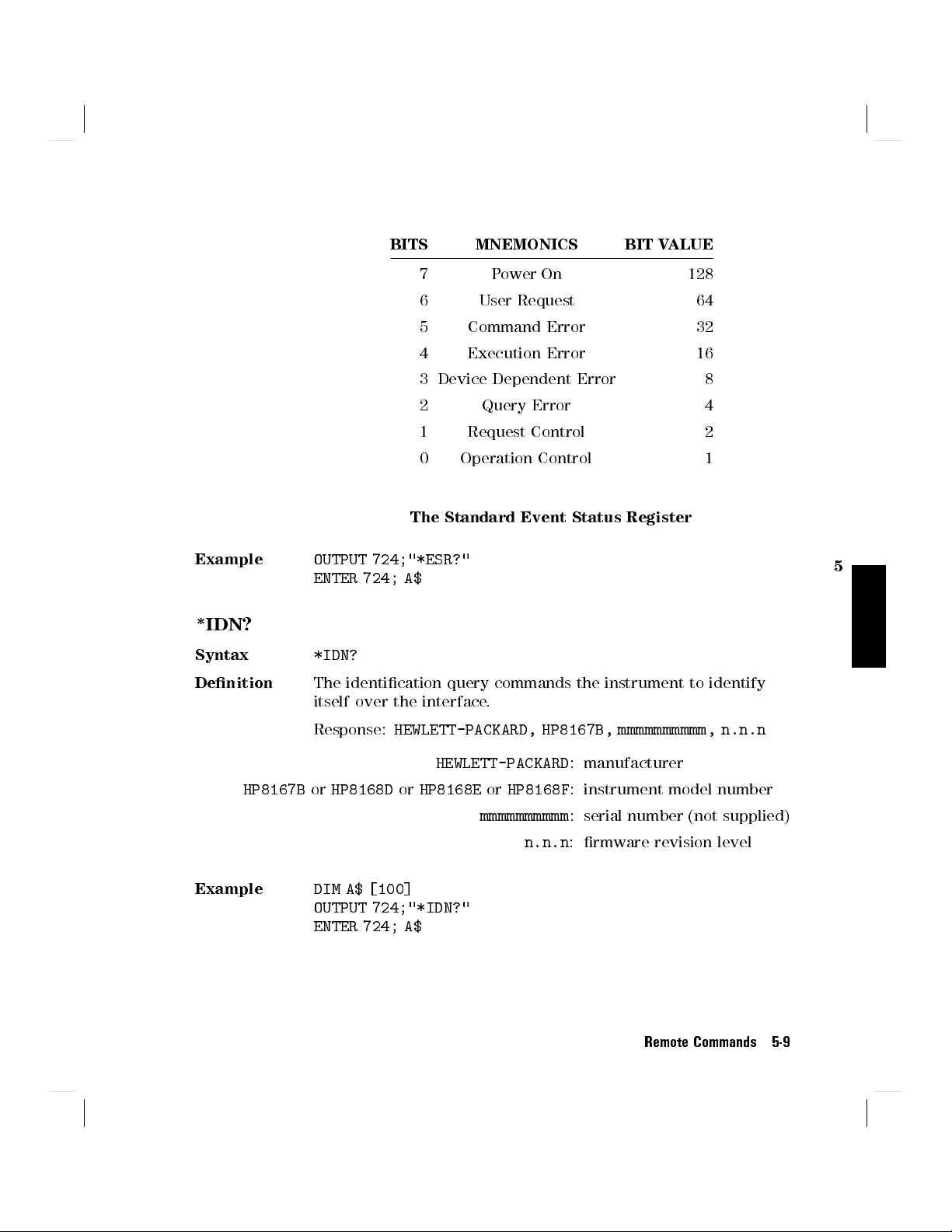

*ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

*IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

*OPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

*OPC? ........ ...... ...... ...... 5-10

*OPT? ...... ...... ...... ...... ... 5-10

*RCL ............................ 5-11

*RST ............................ 5-11

*SAV ............................ 5-12

*SRE ............................

*SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . .

*STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

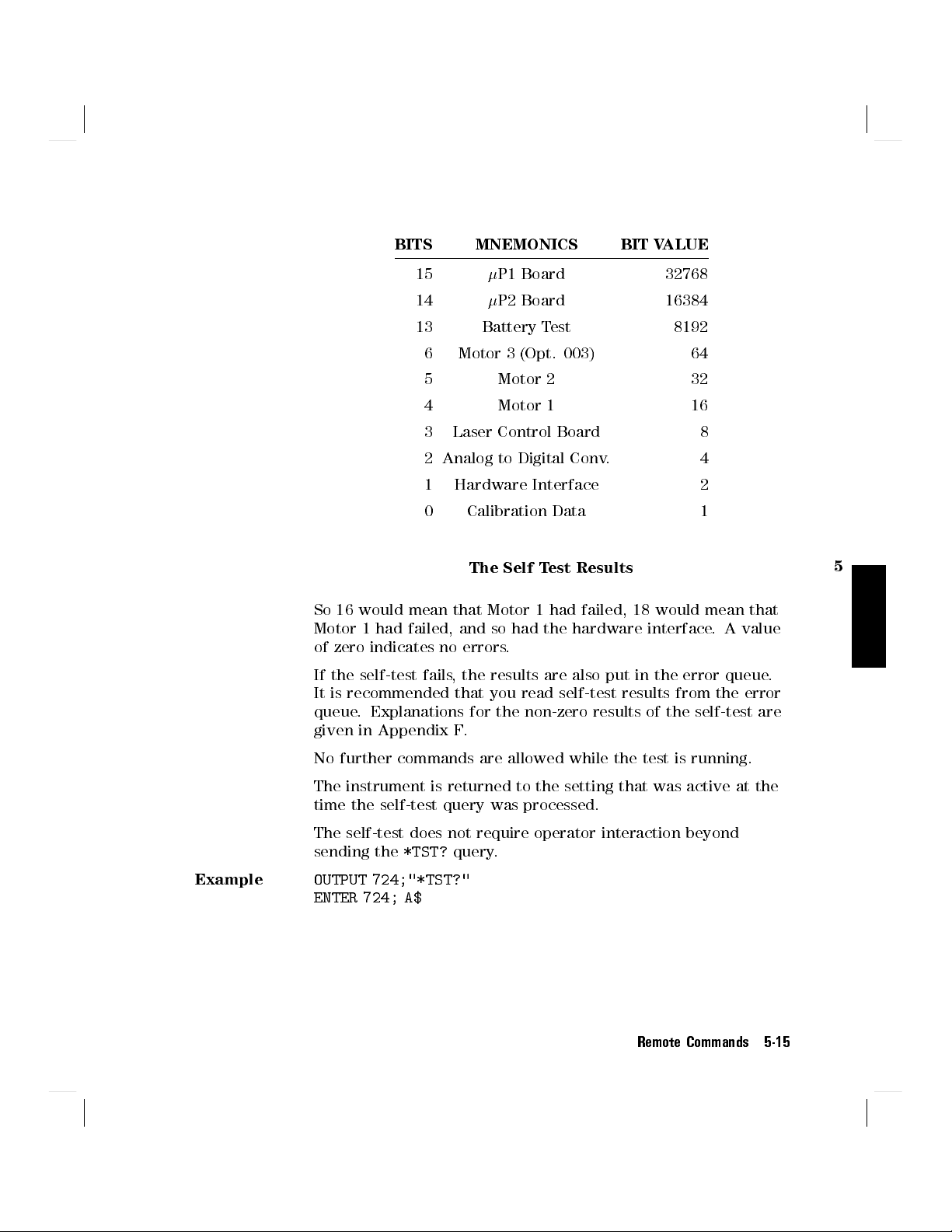

*TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

*WAI ............................ 5-16

:DISPlay Commands ...................... 5-16

:DISPlay:ENABle ...................... 5-16

:DISPlay:ENABle? . . . . . . . . . . . . . . . . . . . . . 5-16

:LOCK Commands ...... ...... ........ ... 5-17

:LOCK ........................... 5-17

:LOCK? . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

:OUTPut Commands ...... ...... ........ .. 5-17

:OUTPut[:STATe]........ ...... ...... ... 5-17

:OUTPut[:STATe]? ........ ...... ...... . 5-18

[:SOURce] Commands ..................... 5-18

[:SOURce]:AM:INTernal:FREQuency . . . . . . . . . . . . . . 5-18

[:SOURce]:AM:INTernal:FREQuency? ...... ...... 5-19

[:SOURce]:AM:SOURce . . . . . . . . . . . . . . . . . . . . 5-19

[:SOURce]:AM:SOURce? .................. 5-19

5-12

5-13

Contents-3

Page 14

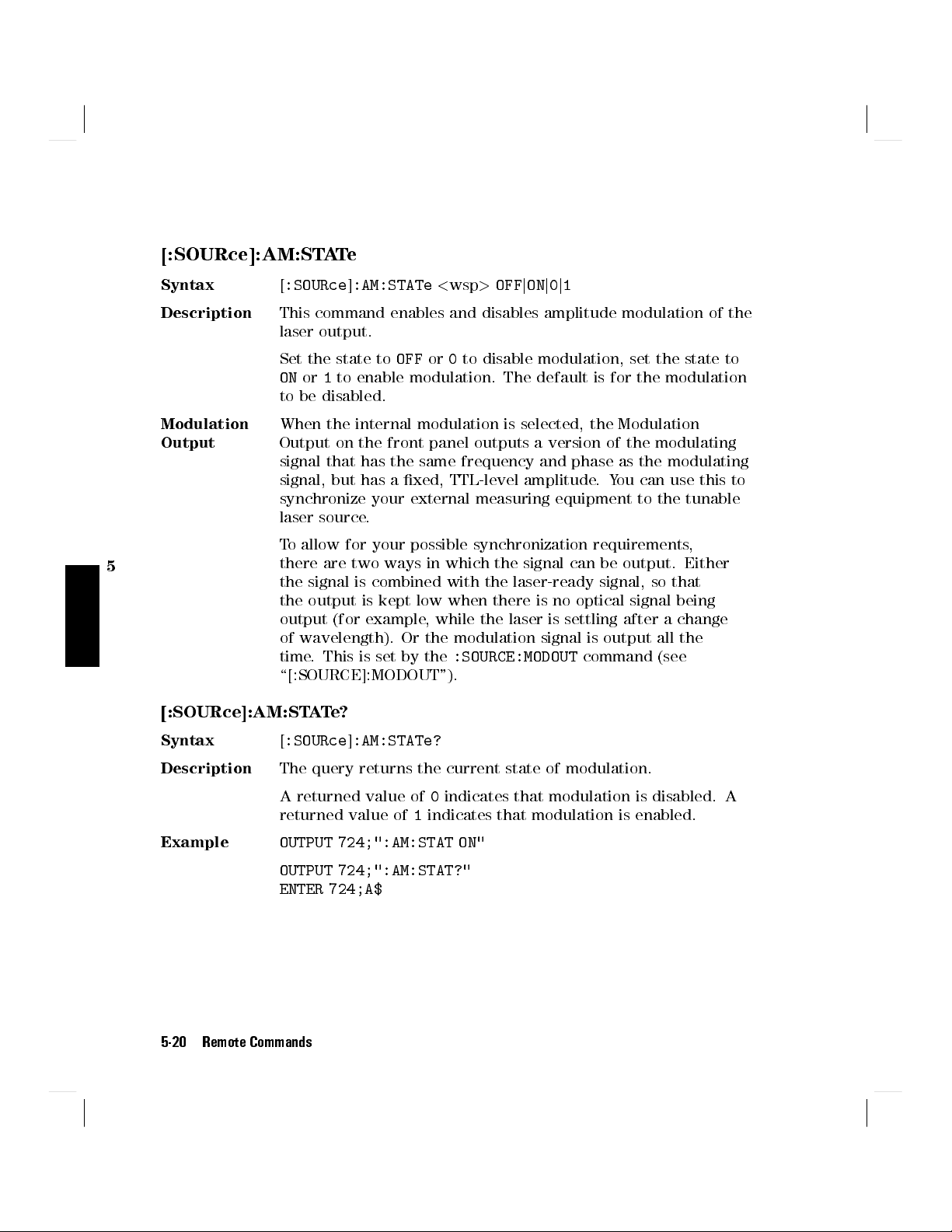

[:SOURce]:AM:STATe....... ...... ...... .. 5-20

[:SOURce]:AM:STATe? ................... 5-20

[:SOURCE]:MODOUT . . . . . . . . . . . . . . . . . . . . . 5-21

[:SOURCE]:MODOUT? ........ ........ ... 5-21

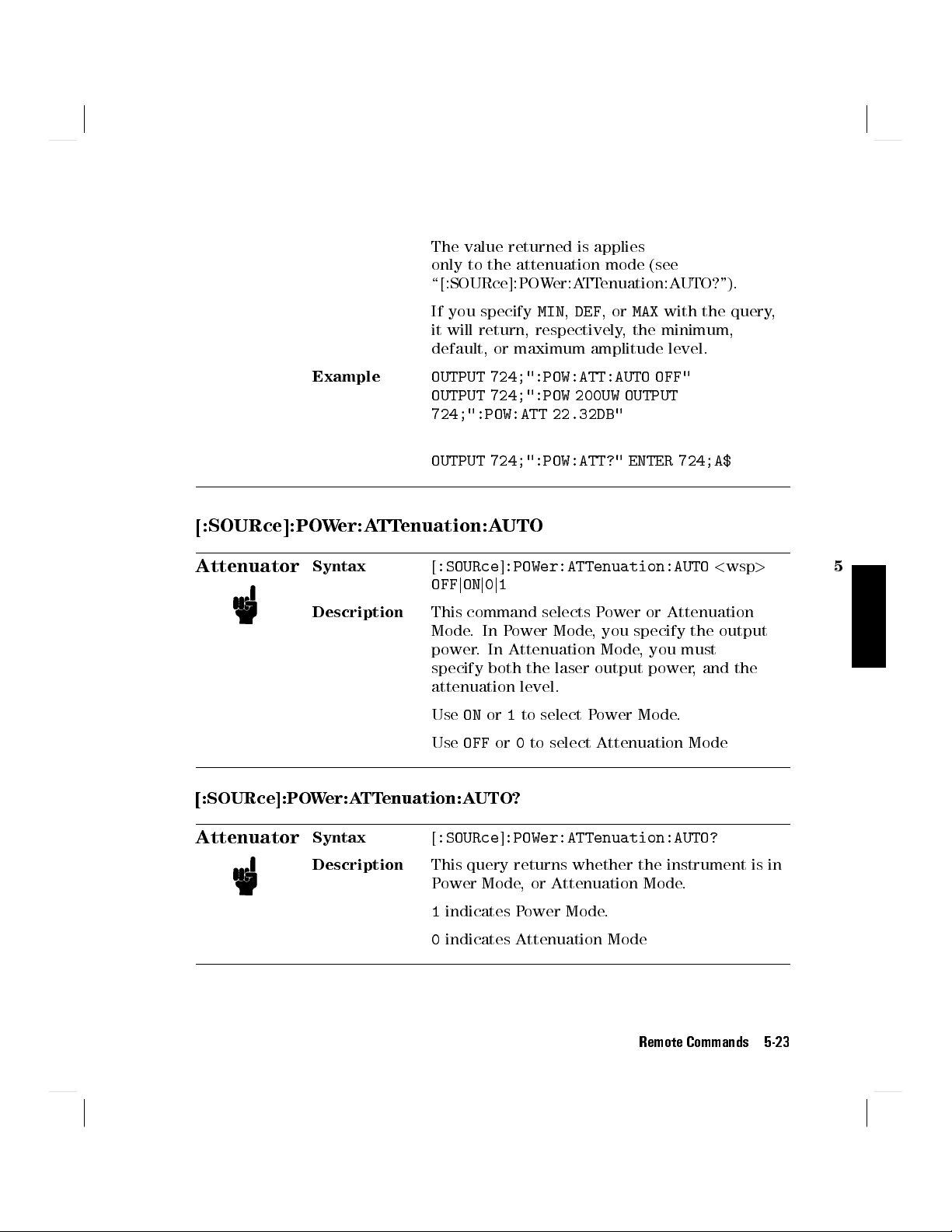

[:SOURce]:POWer:ATTenuation ........ ...... .. 5-22

[:SOURce]:POWer:ATTenuation? . . . . . . . . . . . . . . . 5-22

[:SOURce]:POWer:ATTenuation:AUTO ............. 5-23

[:SOURce]:POWer:ATTenuation:AUTO? ........... 5-23

[:SOURce]:POWer:ATTenuation:DARK............. 5-24

[:SOURce]:POWer:ATTenuation:DARK? ........... 5-24

[:SOURce]:POWer[:LEVel][:IMMediate][:AMPlitude] . . . . . . . 5-25

[:SOURce]:POWer[:LEVel][:IMMediate][:AMPlitude]? ..... 5-25

[:SOURce]:POWer:UNIT ................... 5-26

[:SOURce]:POWer:UNIT? .... ...... ...... .. 5-26

[:SOURce]:WAVElength[:CWj:FIXED] ...... ...... . 5-27

[:SOURce]:WAVElength[:CWj:FIXED]? . . . . . . . . . . . . 5-27

[:SOURce]:WAVElength:REFerence? . . . . . . . . . . . . . . 5-28

[:SOURce]:WAVElength:REFerence:DISPlay .......... 5-28

[:SOURce]:WAVElength:FREQuency . . . . . . . . . . . . . . 5-28

[:SOURce]:WAVElength:FREQuency? ............ 5-28

:STATus Commands ...................... 5-29

:STATus:OPERation:CONDition? ............... 5-30

:STATus:OPERation:ENABle .................

:STATus:OPERation:ENABle? . . . . . . . . . . . . . . . .

5-31

5-31

:STATus:OPERation[:EVENt]? . . . . . . . . . . . . . . . . . 5-31

:STATus:OPERation:NTRansition .... ...... ..... 5-32

:STATus:OPERation:NTRansition? . . . . . . . . . . . . . . 5-32

:STATus:OPERation:PTRansition ............... 5-32

:STATus:OPERation:PTRansition? . . . . . . . . . . . . . . 5-32

:STATus:QUEStionable:CONDition? .............. 5-33

:STATus:QUEStionable:ENABle . . . . . . . . . . . . . . . . 5-33

:STATus:QUEStionable:ENABle? .............. 5-33

:STATus:QUEStionable[:EVENt]? ............... 5-34

:STATus:QUEStionable:NTRansition . . . . . . . . . . . . . . 5-34

:STATus:QUEStionable:NTRansition? .... ...... .. 5-34

:STATus:QUEStionable:PTRansition . . . . . . . . . . . . . . 5-35

:STATus:QUEStionable:PTRansition? ............ 5-35

:STATus:PRESet .... ...... ...... ...... . 5-35

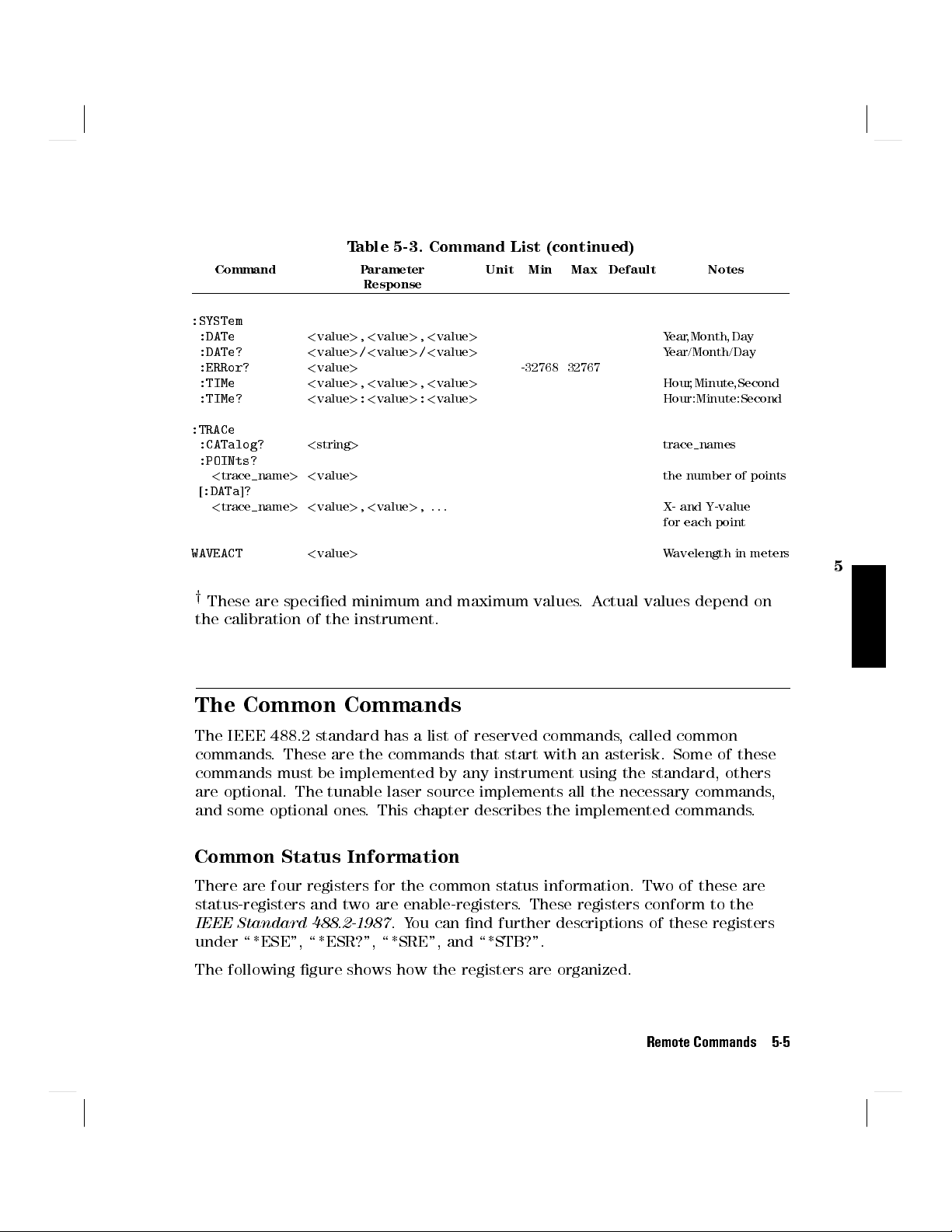

:SYSTem Commands ...................... 5-36

:SYSTem:DATe........................ 5-36

:SYSTem:DATe? ...... ...... ...... .... 5-36

Contents-4

Page 15

:SYSTem:ERRor? . . . . . . . . . . . . . . . . . . . . . . . 5-36

:SYSTem:TIMe . . . . . . . . . . . . . . . . . . . . . . . . 5-37

:SYSTem:TIMe? ...................... 5-37

:TRACe Commands . . . . . . . . . . . . . . . . . . . . . . . 5-37

:TRACe:CATalog? ...... ...... ...... .... 5-37

:TRACe:POINts?<trace name>............... 5-38

:TRACe[:DATa]?<trace name>...... ...... .... 5-38

Other Commands ....................... 5-38

WAVEACT.......................... 5-38

Passive Component Test software . . . . . . . . . . . . . . . . 5-40

BDATA?

nn

...... ...... ........ .... 5-40

DOSMODE . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

DOSMODE?

...... ...... ....... ...... 5-41

6. Programming Examples

Example 1 - Checking Communication ............. 6-2

Example 2 - Status Registers and Queues ............ 6-3

Example 3 - Measuring the Power of a Modulated Signal . . . . . 6-7

Example 4 - Measuring a Wavelength Characteristic .... ... 6-10

Example 5 - Increased Tuning Linearity . . . . . . . . . . . . . 6-12

A. Installation

Safety Considerations .....................

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . .

AC Line Power Supply Requirements .... ...... .... A-2

Line Power Cable .. ...... ...... ....... . A-2

Changing the Battery ...... ...... ...... .. A-4

Changing the Fuse . . . . . . . . . . . . . . . . . . . . . . A-4

Operating and Storage Environment .. ...... ...... A-6

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Humidity .......................... A-6

Instrument Positioning and Cooling . . . . . . . . . . . . . . A-6

Switching on the Tunable Laser Source ............. A-7

Self test . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Initializing . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Stabilizing . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Stabilizing during Operation ................ A-8

Signal Outputs. ........................ A-9

Optical Output . . . . . . . . . . . . . . . . . . . . . . . . . A-9

HP-IB Interface ........................ A-10

Connector . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

A-1

A-1

Contents-5

Page 16

HP-IB Logic Levels . . . . . . . . . . . . . . . . . . . . . . A-11

Claims and Repackaging .................... A-12

Return Shipments to HP ................... A-12

B. Accessories

Mainframe .......................... B-1

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Option 003: ........................ B-2

Option 007: ........................ B-2

Connector Interfaces and Other Accessories . . . . . . . . . B-2

Option 021, Straight Contact Connector . . . . . . . . . . B-3

Option 022, Angled Contact Connector .......... B-4

Option 023, Diamond HMS-10/HRL Angled, Non-Contact

Connector ...................... B-6

HP-IB Cables and Adapters . . . . . . . . . . . . . . . . . . . B-7

C. Specications

Denition of Terms ...................... C-1

Performance Specications . . . . . . . . . . . . . . . . . . . C-4

Supplementary Performance Characteristics . . . . . . . . . . . C-7

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . C-7

Operating Modes . . . . . . . . . . . . . . . . . . . . . . .

Internal Modulation ....................

External modulation . . . . . . . . . . . . . . . . . . . .

Coherence Control . . . . . . . . . . . . . . . . . . . . . C-7

General . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Polarization maintaining ber . . . . . . . . . . . . . . . . C-7

HP-IB Interface ...................... C-8

Passive Component Test Software . . . . . . . . . . . . . . C-8

Laser Class ........................ C-8

Environmental ........ ...... ...... .. C-8

Listed options . . . . . . . . . . . . . . . . . . . . . . . C-9

Other Specications ...................... C-9

Declaration of Conformity ................... C-10

C-7

C-7

C-7

Contents-6

Page 17

D. Performance Tests

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Equipment Required . . . . . . . . . . . . . . . . . . . . . . D-1

Test Record .......................... D-2

Test Failure .......................... D-3

Instrument Specication ...... ........ ...... D-3

Wavelength Tests ....................... D-3

Relative Wavelength Accuracy ................ D-4

Wavelength Repeatability .................. D-5

Power Tests . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Maximum Output Power ...... ...... ...... . D-7

Power Linearity . . . . . . . . . . . . . . . . . . . . . . . D-10

Power Flatness over Wavelength ............... D-14

Power Stability .. ...... ...... ........ . D-15

Source Spontaneous Emission ................. D-16

E. Cleaning Procedures

The Cleaning Kit . . . . . . . . . . . . . . . . . . . . . . . . E-1

Other Cleaning Tools . . . . . . . . . . . . . . . . . . . . . E-3

Preserving Connectors . . . . . . . . . . . . . . . . . . . . . E-4

Cleaning Instrument Housings ................. E-4

Cleaning Procedures . . . . . . . . . . . . . . . . . . . . . . E-5

Cleaning Cable Connectors . . . . . . . . . . . . . . . . . .

Cleaning Connector Adapters . . . . . . . . . . . . . . . . . E-6

Cleaning Connector Interfaces ................ E-7

Cleaning Bare Fiber Adapters . . . . . . . . . . . . . . . . . E-8

Cleaning Bare Fiber Ends .. ...... ..... ..... E-8

Cleaning Lenses . . . . . . . . . . . . . . . . . . . . . . . E-9

Cleaning Large Area Lenses and Mirrors . . . . . . . . . . . . E-10

Cleaning Fixed Connector Interfaces .......... ... E-11

Cleaning Optical Glass Plates . . . . . . . . . . . . . . . . . E-11

Cleaning Physical Contact Interfaces .... ...... ... E-11

Cleaning Recessed Lens Interfaces .............. E-12

Cleaning Fragile Optical Devices ........ ...... . E-12

Cleaning Metal Filters or Attenuator Gratings ......... E-13

E-5

Contents-7

Page 18

F. Error Messages

Display Messages .. ...... ...... ...... ... F-1

HP-IB Messages .. ........ ...... ...... .. F-3

Instrument Specic Errors .................. F-3

Command Errors . . . . . . . . . . . . . . . . . . . . . . . F-3

Execution Errors .. ...... ...... ...... .. F-6

Device-Specic Errors .................... F-7

Query Errors ........................ F-8

G. The Passive Component Test (PACT) software

Getting Started ...... ...... ....... ..... G-1

What is the Passive Component Test Software? ........ G-1

Starting the Passive Component Test Software . . . . . . . . . G-1

Getting Help while Using the System ............. G-2

Making Loss Measurements . . . . . . . . . . . . . . . . . . . G-3

Setting Up the Hardware . . . . . . . . . . . . . . . . . . . G-3

Making the Loss Measurement ................ G-4

Setting the Power Meter ...... ...... ...... . G-5

Setting the Sweep . . . . . . . . . . . . . . . . . . . . . . G-6

Measuring the Reference . . . . . . . . . . . . . . . . . . G-7

Measuring the Device Under Test ...... ...... .. G-8

Looking at the Results . . . . . . . . . . . . . . . . . . . G-8

Example, Measuring the Characteristic of a Fabry-Perot Resonator G-8

Making Return Loss Measurements .. ...... ...... . G-12

Setting Up the Hardware . . . . . . . . . . . . . . . . . . . G-12

Making the Return Loss Measurement . . . . . . . . . . . . . G-13

Setting the Power Meter ...... ...... ...... . G-15

Setting the Sweep . . . . . . . . . . . . . . . . . . . . . . G-16

Measuring the Reference Reection . . . . . . . . . . . . . G-17

Measuring the Termination Parameter . . . . . . . . . . . . G-17

Including or Excluding the Termination Parameter . . . . . G-18

Measuring the Termination Parameter . . . . . . . . . . . G-18

Measuring the Device Under Test ...... ...... .. G-18

Looking at the Results . . . . . . . . . . . . . . . . . . . G-19

Example, Measuring the Return Loss of a Fabry-Perot Resonator G-20

Making Loss Ratio Measurements . . . . . . . . . . . . . . . . G-25

Setting Up the Hardware . . . . . . . . . . . . . . . . . . . G-25

Making the Loss Ratio Measurement .... ...... ... G-26

Setting the Power Meter ...... ...... ...... . G-28

Setting the Sweep . . . . . . . . . . . . . . . . . . . . . . G-29

Measuring the Reference . . . . . . . . . . . . . . . . . . G-30

Contents-8

Page 19

Measuring the Device Under Test.... ...... .... G-30

Looking at the Results . . . . . . . . . . . . . . . . . . . G-31

Example, Measuring the Characteristic of a Wavelength Division

Multiplexer .. ...... ...... ...... ... G-32

Printing Your Results . . . . . . . . . . . . . . . . . . . . . . G-36

Setting Up the Printer ...... ........ ...... G-37

Setting Up the Hardware . . . . . . . . . . . . . . . . . . G-37

Setting Up the Printer in Software ...... ...... . G-38

Selecting the Printer . . . . . . . . . . . . . . . . . . . G-39

Setting the Layout of the Printout .......... .... G-39

Setting the X- or Y-Axis Scaling . . . . . . . . . . . . . . . G-41

Editing Text for a Result . . . . . . . . . . . . . . . . . . G-41

To Replace Text ..................... G-42

To Change the Cursor Position in the Text......... G-42

To Change between Overwriting and Inserting . . . . . . . G-42

To Put Characters into the Text.............. G-43

To End the Edit .. ...... ...... ...... . G-43

Showing the Results . . . . . . . . . . . . . . . . . . . . . G-43

Selecting the Result to Show . . . . . . . . . . . . . . . . G-43

Selecting Non-Standard Other Results . . . . . . . . . . . G-44

Previewing the Results on the Display ........... G-44

Making Readings from the Results ............ G-45

Printing the Results ....................

G-46

Example, Printing Results of Loss against Wavelength ..... G-47

Saving Your Results .. ...... ...... ....... . G-51

Formatting a Memory Card . . . . . . . . . . . . . . . . . . G-52

Saving a Measurement or Result .......... ..... G-53

Selecting the Measurement or Result to Save .. ...... G-53

Saving the Measurement or Result ............. G-54

Saving to Your Own Filename . . . . . . . . . . . . . . . . G-54

To Replace a Filename . . . . . . . . . . . . . . . . . . G-54

To Change the Cursor Position in the Filename . . . . . . . G-54

To Change between Overwriting and Inserting . . . . . . . G-55

To Put Characters into the Filename ........... G-55

To End the Edit and Save the Measurement or Result ... G-55

Loading a Measurement or Result . . . . . . . . . . . . . . . G-56

Deleting a File . . . . . . . . . . . . . . . . . . . . . . . . G-57

Example, Moving Termination Data to the DUT Data Area ... G-58

Using Data on a PC ...................... G-60

If the Data is Already On Your PC . . . .. ...... ... G-61

Contents-9

Page 20

If the Data is On the Memory Card in your Tunable Laser

Source . . . ...................... G-61

Developing Your Own Converter ........ ...... G-62

Reading .SLK Files into a Spreadsheet . . . . . . . . . . . . G-62

Microsoft Excel ..................... G-62

Borland Quattro Pro/Windows ...... ...... .. G-62

Lotus 1-2-3W ...... ...... ........ .. G-62

Error Code Descriptions .................. G-62

The Result and Measurement Data Format . . . . . . . . . . . . G-65

Backdating Information .... ...... ........ .. G-71

Index

Contents-10

Page 21

Figures

1-1. The Tunable Laser Source Front Panel ...... ...... 1-2

1-2. Starting Screen for the 8167B/8168F ............. 1-3

1-3. \Secure: Unlock Instrument" Screen ............. 1-4

1-4. \Secure" Screen . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-5. A Summary of the Help Hard- and Softkeys . . . . . . . . . . 1-5

1-6. The Help Topics Menu .................... 1-5

1-7. Connecting the Instruments for the Sample Session .. .... 1-9

1-8. Tunable Laser Source Display after Setting Up W

avelength and

Power . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9. Tunable Laser Source Display during Setting Up for the

Wavelength Sweep .................... 1-12

2-1. A Summary of the additional Output Power Softkeys for the

Attenuator Option .................... 2-2

2-2. Setting the Wavelength Directly .... ...... ..... 2-2

2-3. Setting a Relative Wavelength .... ...... ...... 2-3

2-4. Setting Up for a Wavelength Sweep . . . . . . . . . . . . . . 2-4

2-5. The Parameters for a Wavelength Sweep ........ ... 2-5

2-6. Performing a Manual Sweep .... ...... ...... . 2-7

2-7. Setting the Output Power of a CW Signal ........... 2-8

2-8. The Modulated Signal .................... 2-11

2-9. Setting the Output Power of an Internally Modulated Signal .. 2-11

2-10. External Modulation and Output Power . . . . . . . . . . . . 2-12

2-11. Setting the Output Power of an Externally Modulated Signal . . 2-13

2-12. Setting the Output Power of a Coherence Controlled Signal . . . 2-14

2-13. The Coherence Control Uncalibrated Power and the Maximum

Power Level ....................... 2-14

3-1. User Setting Number 1 . . . . . . . . . . . . . . . . . . . . 3-1

3-2. Summary of the Setting Hard- and Softkeys . . . . . . . . . . 3-2

3-3. The System Screen . . . . . . . . . . . . . . . . . . . . . . 3-3

3-4. Summary of the System Hard- and Softkeys . . . . . . . . . . 3-3

3-5. Auxiliary Functions (8168D/E) .......... ...... 3-6

3-6. Auxiliary Functions (8167B and 8168F) ........ .... 3-6

1-11

Contents-11

Page 22

3-7. Auto Realignment ...................... 3-8

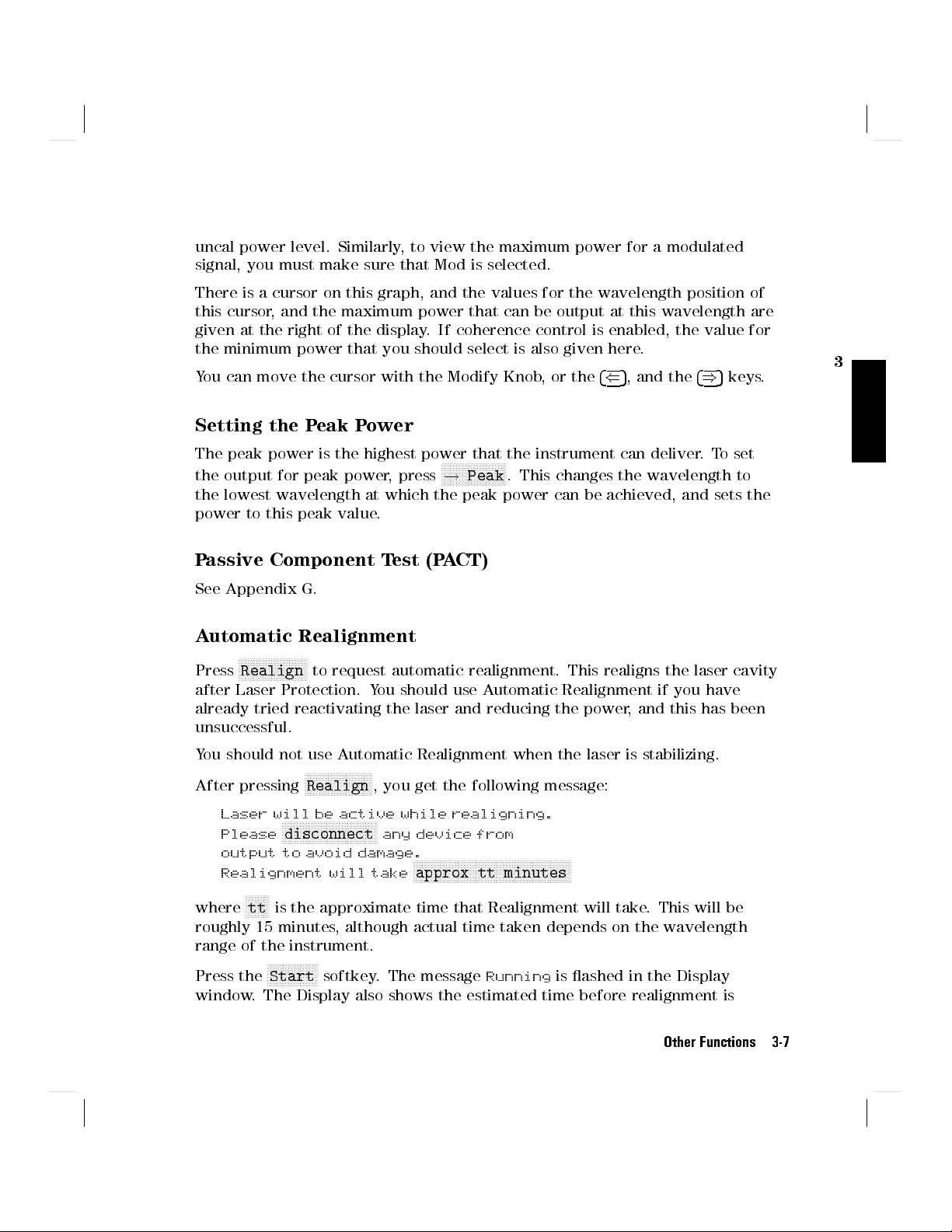

3-8. \Secure" screen . . . . . . . . . . . . . . . . . . . . . . . 3-9

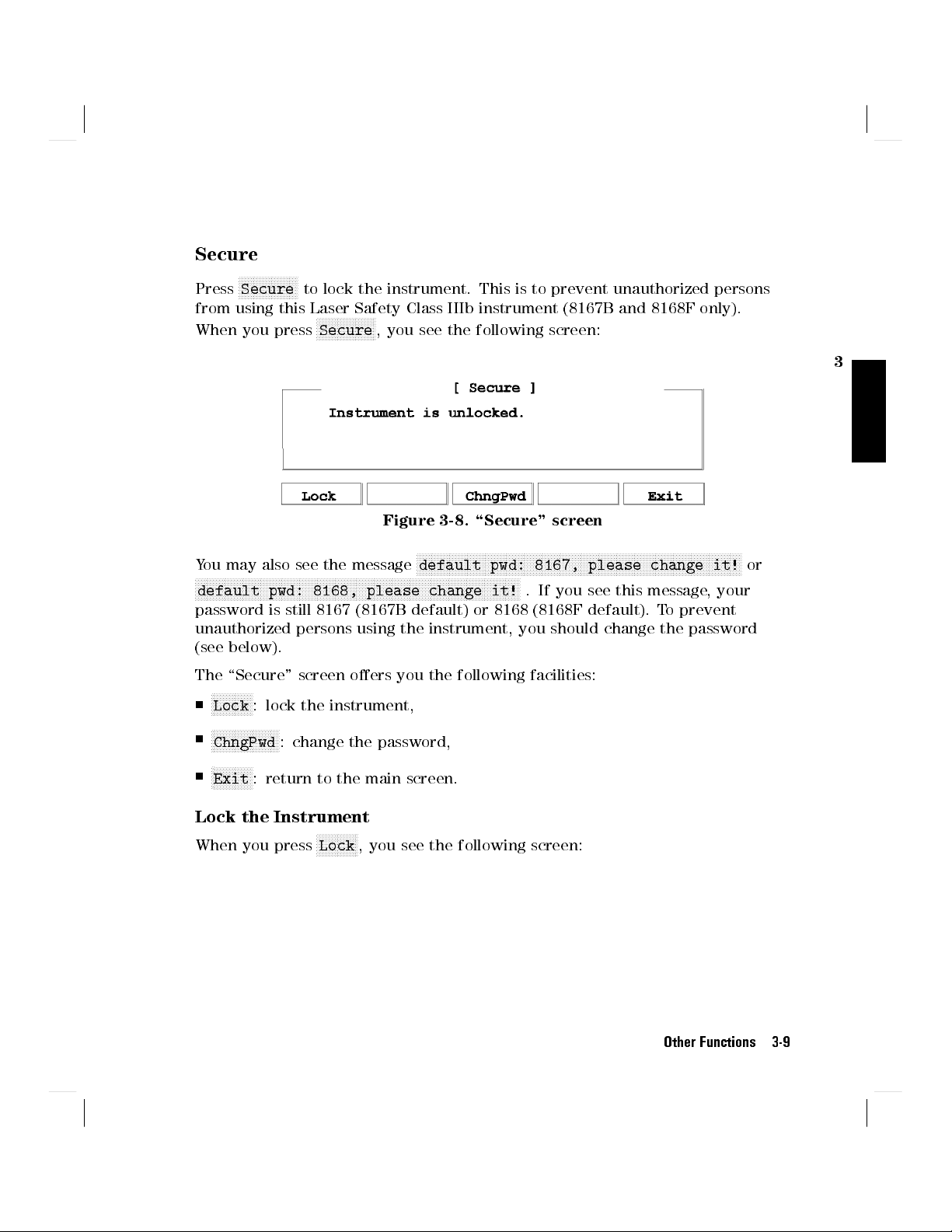

3-9. \Secure: Lock Instrument" screen .............. 3-10

3-10. \Secure" screen - instrument is locked ........ .... 3-10

3-11. \Secure: Unlock Instrument" screen ............. 3-10

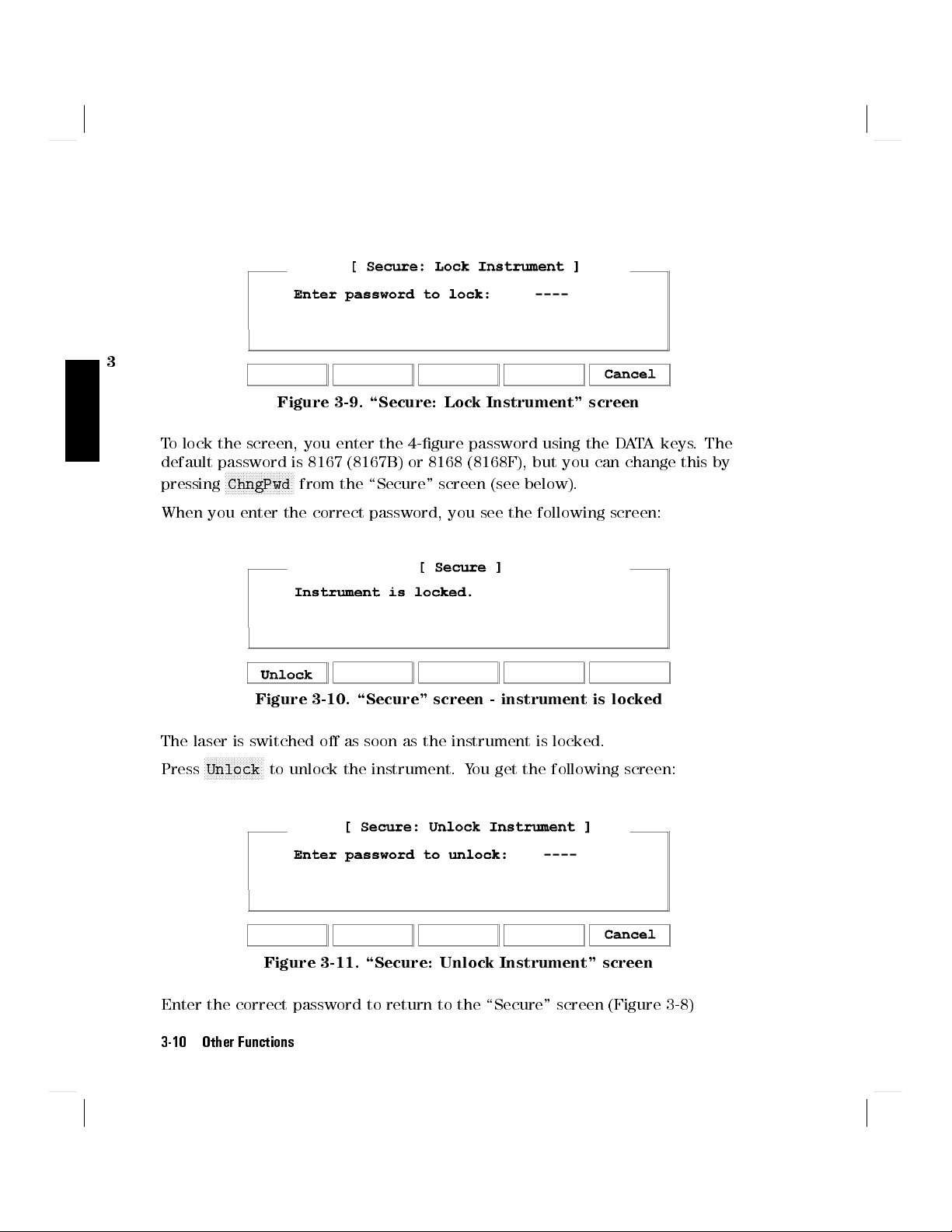

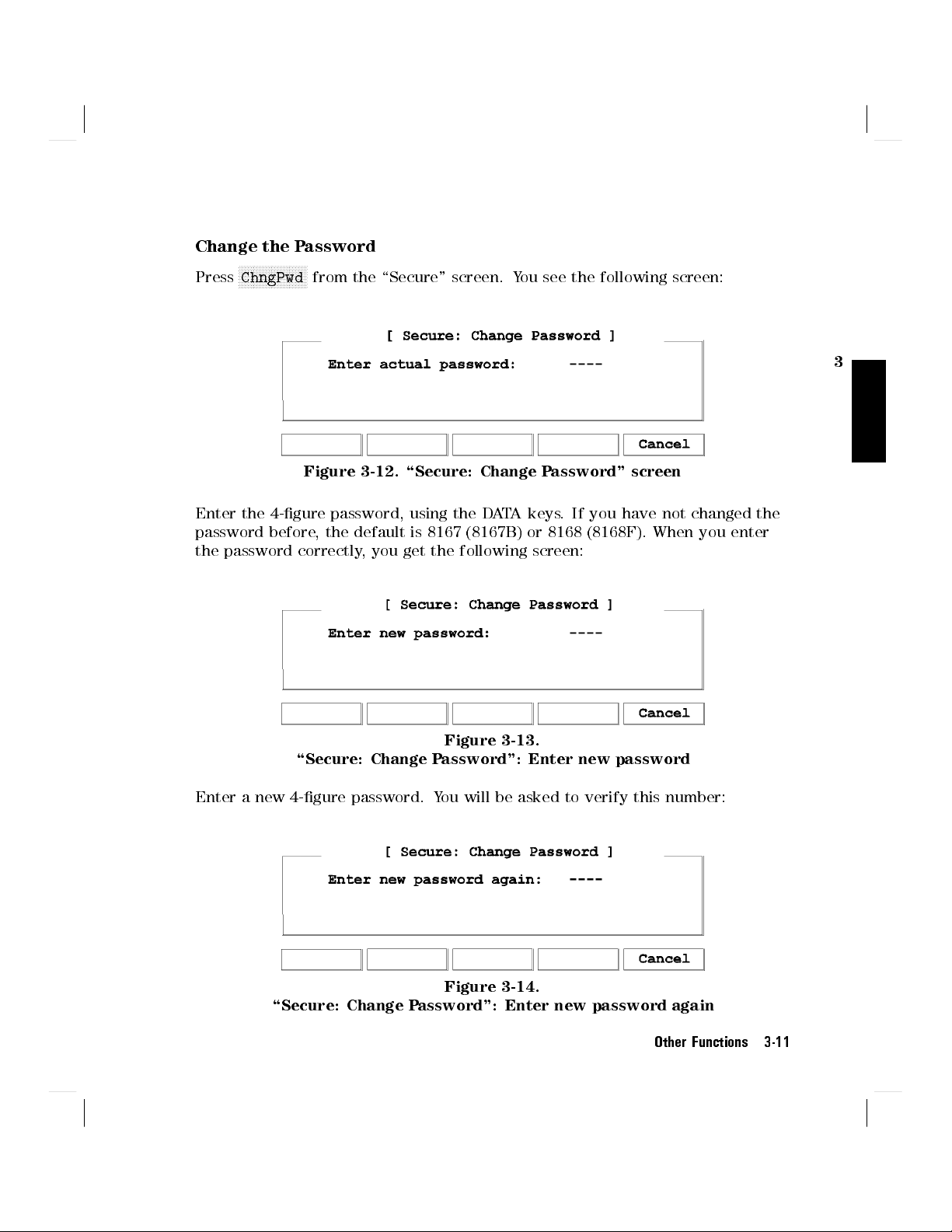

3-12. \Secure: Change Password" screen . . . . . . . . . . . . . . 3-11

3-13. \Secure: Change Password": Enter new password . . . . . . . 3-11

3-14. \Secure: Change Password": Enter new password again . . . . 3-11

5-1. Common Status Registers . . . . . . . . . . . . . . . . . . . 5-6

5-2. The Status Registers . . . . . . . . . . . . . . . . . . . . . 5-30

6-1. Connecting the Instruments for the Sample Session ...... 6-8

6-2. Measurement setup for Increased Tuning Linearity ...... 6-12

6-3. Flow chart describing Increased Tuning Linearity program. . . . 6-13

A-1. Line Power Cables - Plug Identication ............ A-2

A-2. Rear Panel Markings . . . . . . . . . . . . . . . . . . . . . A-4

A-3. Releasing the Fuse Holder .. ...... ...... .... A-5

A-4. The Fuse Holder . . . . . . . . . . . . . . . . . . . . . . . A-5

A-5. Correct Positioning of the Tunable Laser Source . . . . . . . . A-7

A-6. PMF Output . . . . . . . . . . . . . . . . . . . . . . . . . A-10

A-7. HP-IB Connector . . . . . . . . . . . . . . . . . . . . . . . A-11

B-1. Tunable Laser Source Options Overview . . . . . . . . . . . . B-2

B-2. Tunable Laser Source Option 021 Conguration ........ B-3

B-3. Tunable Laser Source Option 022 Conguration ........ B-5

B-4. Tunable Laser Source Option 023 Conguration ........ B-6

C-1. Maximum Specied Output Power for 8168D, E and F (without

options) ......................... C-1

D-1. Test Setup for the Wavelength Tests . . . . . . . . . . . . . . D-4

D-2. Test Setup for the Maximum Output Power Test (HP 8168D,E) . D-8

D-3. Test Setup for the Maximum Output Power Test (HP 8167B and

8168F) . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

D-4. Test Setup for the Power Tests (except Maximum Output Power) D-11

D-5. Test Setup for the Source Spontaneous Emission Test...... D-17

G-1. The Main Screen . . . . . . . . . . . . . . . . . . . . . . . G-2

G-2. A Summary of the Help Hard- and Softkeys . . . . . . . . . . G-2

G-3. The Help Topics Menu .... ...... ...... .... G-2

G-4. Hardware Set-Up for a Loss Measurement . . . . . . . . . . . G-3

G-5. A Summary of the Loss Softkeys ............... G-4

G-6. The Loss Measurement Display . . . . . . . . . . . . . . . . G-5

G-7. The Set Power Meter Display . . . . . . . . . . . . . . . . . G-6

G-8. The Parameters for a Wavelength Sweep ....... .... G-7

G-9. Measuring the Reference . . . . . . . . . . . . . . . . . . . G-7

Contents-12

Page 23

G-10. Test Set-Up to Characterize a Fabry-Perot Resonator . . . . . . G-9

G-11. Hardware Set-Up for a Return Loss Measurement ...... . G-13

G-12. A Summary of the Return Loss Softkeys ........... G-14

G-13. The Return Loss Measurement Display .......... .. G-14

G-14. The Set Power Meter Display . . . . . . . . . . . . . . . . . G-15

G-15. The Parameters for a Wavelength Sweep ........ ... G-16

G-16. Measuring the Reference Reection . . . . . . . . . . . . . . G-17

G-17. Measuring the Termination Parameter . . . . . . . . . . . . . G-18

G-18. Test Set-Up to Measure the Reference Reection . . . . . . . . G-20

G-19. Test Setup for Measuring the Termination Parameter . . . . . . G-23

G-20. Test Setup for Measuring the Fabry-Perot Resonator ...... G-23

G-21. Hardware Setup for a Loss Ratio Measurement ........ G-25

G-22. A Summary of the Loss Ratio Softkeys ...... ...... G-27

G-23. The Loss Ratio Measurement Display ............. G-27

G-24. The Set Power Meter Display . . . . . . . . . . . . . . . . . G-28

G-25. The Parameters for a Wavelength Sweep ........ ... G-29

G-26. Measuring the Reference . . . . . . . . . . . . . . . . . . . G-30

G-27. Test Setup to Measure the Reference for Channel A ...... G-32

G-28. Test Setup to Characterize a Wavelength Division Multiplexer . . G-35

G-29. The Show Display ...................... G-36

G-30. A Summary of the Show Softkeys . . . . . . . . . . . . . . . G-37

G-31. Printer Hardware Setup .... ...... ........ . G-38

G-32. The Show Setting Display .... ...... ...... .. G-38

G-33. The Layout of the Printout . . . . . . . . . . . . . . . . . .

G-40

G-34. The Edit Text Display .. ...... ...... ...... G-42

G-35. The Show Menu . . . . . . . . . . . . . . . . . . . . . . . G-43

G-36. Making an Absolute Reading ................. G-45

G-37. Making a Relative Reading . . . . . . . . . . . . . . . . . . G-46

G-38. Set-Up to Print Out ..................... G-47

G-39. The Memory Display . . . . . . . . . . . . . . . . . . . . . G-51

G-40. A Summary of the Memory Softkeys ............. G-52

G-41. The MemSave Display .................... G-54

G-42. The Show Text Display . . . . . . . . . . . . . . . . . . . . G-54

Contents-13

Page 24

Tables

4-1. HP-IB Capabilities .. ...... ...... ...... .. 4-2

5-1. Units and Allowed Mnemonics ................ 5-1

5-2. Common Command Summary . . . . . . . . . . . . . . . . . 5-2

5-3. Command List . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-4. Reset State (Default Setting) ................. 5-12

5-5. Specied Wavelength range . . . . . . . . . . . . . . . . . . 5-27

5-6. Command Summary .. ........ ...... ..... 5-40

6-1. Program Description: Increased Tuning Linearity ....... 6-16

A-1. Temperature . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Contents-14

Page 25

Getting Started

This chapter gives you basic information on how you can operate the tunable

laser source from the front panel.

What is a Tunable Laser Source?

A tunable laser source is a laser source for which the wavelength is not xed.

The Hewlett-Packard tunable laser sources also allow you to set the output

power, and to choose between continuous wave or modulated output power

.

1

1

Note

The single greatest factor aecting the performance of the

tunable laser source, as with all ber optic measurements, is the

cleanliness of the connectors. Ensure that your connectors are

always clean. For cleaning instructions, see Appendix E.

Getting Started 1-1

Page 26

1

A description of the Front Panel

Figure 1-1. The Tunable Laser Source Front Panel

A softkey is a key whose function changes depending on the keys that you have

pressed before. The function of a softkey is shown on the display above the

softkey.

The memory card drive allows you to load replacement, or additional, software

to increase the capabilities of your tunable laser source.

There are six function keys. These allow you

to set the wavelength, or to perform a wavelength sweep.

to set the output power,

to save the wavelength and output power setting,

to check or change the system conguration: to test the instrument, to switch

o the laser and display, to change the HP-IB Address, to select whether the

internal modulation signal is available at the Modulation Output constantly,

or only when the power is being output, or to get information about the

instrument and the software revision,

to get help information (see \Getting Help" in the next section of this

chapter), or

to perform an auxiliary application such as examine the power characteristic,

or to set the instrument for maximum power output.

The numeric keypad, the cursor keys, and the modify knob are used to edit

parameters.

1-2 Getting Started

Page 27

The modulation output gives a TTL level signal of the same frequency as the

internal modulating signal.

The modulation input allows you to input a signal to modulate the power of the

optical output.

The analog output gives a dc-signal proportional to the output power. The

relationship between this voltage level and the output power is not calibrated,

but is approximately 1mV for each 1W.

At the back of the 8167B and 8168F, you also have a Remote Interlock

Connector. This is to protect the user from injury. If the short-circuit at this

BNC connector is opened, the laser is switched o immediately and cannot be

switched on until it is closed again.

Starting the 8167B or 8168F

When you turn on the 8167B or the 8168F, the instrument is locked. This is to

prevent unauthorized persons from using this Laser Safety Class IIIb instrument.

The Starting screen for the 8167B/8168F is shown below:

1

Figure 1-2. Starting Screen for the 8167B/8168F

If you have not set a new password, you also see the message:

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

default pwd: 8167, please change it!

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

default pwd: 8168, please change it!

(8167B), or

(8168F).

This message appears in the \Secure" screen until you set a new password (see

\Secure" in Chapter 3).

To unlock the instrument, press

Unlock

.You see the following screen:

NNNNNNNNNNNNNNNNNNN

N

Getting Started 1-3

Page 28

1

Figure 1-3. \Secure: Unlock Instrument" Screen

Enter the 4-gure password using the DATA keys. The default password is 8167

(8167B) or 8168 (8168F), although you can change this from the AUX menu (see

\Secure" in Chapter 3).

When you enter the correct password, the instrument is unlocked, and you see

the following screen:

NNNNNNNNNNNNNN

Press

Exit

, or any of the function keys, to view the main screen.

1-4 Getting Started

Figure 1-4. \Secure" Screen

Page 29

Getting Help

Press

4

5

to get help.

HELP

When you press this key, the rst help screen is displayed, this is either the last

screen that was used, or the screen with the limit values for the parameters.

Figure 1-5. A Summary of the Help Hard- and Softkeys

NNNNNNNNNNNNNNNNNNNN

Press

Search

to get the help topics menu.

1

Figure 1-6. The Help Topics Menu

Choose a topic using

NNNNN

"

and

NNNNN

#

, or the Modify Knob. Press

NNNNNNNNNNNNNNNNNNNN

Select

,or

4

ENTER

to get the information.

NNNNNNNNNNNNNNNNN

Press

Close

Many of the help texts are longer than one screen. You move between screens

of information using

to close the help topics menu without selecting a topic.

NNNNN

"

and

NNNNN

#

.

Getting Started 1-5

5

Page 30

1

Changing the Value of a Parameter

What follows is a description of the various methods of changing the value of

parameters on the tunable laser source

values are changed are given with the parameter descriptions

. Examples in which actual parameter

.

Making Big Changes to a Parameter

If you are changing the value of a parameter completely, you can directly type

in the value on the keypad, and press

4

ENTER

5

.

Example

To change the output power from 200W to 1025W.

1. Press

4

OUTPUT POWER

5

. The cursor moves to P on the right

hand side of the display.

:1540.000nm

P

: 200W

2. Type the new value for the output power on the numeric

keypad.

3. Press

4

ENTER

:1540.000nm P:1025

5

to end the editing.

W

Making a Small Change to a Parameter

For small changes to a parameter use

4

5

, or the Modify Knob.

EDIT

Select the parameter and then:

1. Press

4

EDIT

5,4

(

)

5

, or turn the Modify Knob slightly. If you start with

5.4

Modify Knob the cursor moves to the digit that was most recently changed.

If no digit was changed before, or if you started with another key, the cursor

moves to the position of the most signicant digit of the parameter.

2. If you want to move the cursor and select another digit to edit, use

4)5

.

1-6 Getting Started

4(5

and

Page 31

3. Enter the new value for the digit at the cursor on the keypad, or by turning

the Modify Knob. If you have entered the value from the keypad, the cursor

moves to the next digit.

4. Repeat steps 2 and 3 to continue editing the value.

5

5. When you have nished editing the value, press

4

ENTER

. The edited value

becomes the new value of the parameter.

1

Example

To change the wavelength from 1540.000nm to 1542.500nm.

5

1. Press

4

WAVELENGTH

. The cursor moves toon the left hand

side of the display.

:1540.000nm P: 200W

2. Press

4

5

. The cursor moves to the most signicant digit of

EDIT

the wavelength value.

:1

540.000nm P: 200W

3. Press

4)5

digit. Press

three times to move to the cursor to the units

425

on the numeric keypad. The units digit

changes, and the cursor moves to the next digit.

:1542.000nm P: 200W

4. Press

Press

455

on the numeric keypad, to change the tenths digit.

5

4

ENTER

to end the editing.

:1542.500nm P: 200W

Setting a Parameter to its Default Value

There is a default softkey that you can use to set a parameter to its default

value.

1. Press

2.

Press

4

5

.

EDIT

NNNNNNNNNNNNNNNNNNNNNN

N

Default

.

Getting Started 1-7

Page 32

1

If You Make a Mistake

If you make a mistake while you are editing a parameter, you can cancel the

editing, and get the previous value for the parameter back by pressing

Alternatively, you can press

NNNNNNNNNNNNNNNNN

Clear

and type in the parameter again.

NNNNNNNNNNNNNNNNNNNN

Cancel

If the Parameter Will Not Change

5

If, when you press

4

ENTER

immediately to the previous value for the parameter

enter is outside the calibrated range. Press

after editing, the tunable laser source returns

, then the value you tried to

4

5

, and select the

HELP

Input Limits

help topic to see the calibrated range.

A Sample Session

There are two short tasks in this sample session. The rst is to measure the

power of a modulated signal at a single wavelength, and then a wavelength

characteristic at a xed power.

The sample session is written for an HP 8168E/F Tunable Laser Source, and

an HP 8153A Lightwave Multimeter with an HP 81532A Power Sensor (It

is assumed that the power sensor is inserted in channel A). To perform the

sample session as described here, you also need a connector interface for the

multimeter (for example, an HP 81000AI), and a patchcord (if you are using

the HP 81000AI, then a Diamond HMS-10/HP/HRL to Diamond HMS-10/HP

patchcord, HP 81109AC).

.

These same procedures are repeated in \Example 3 - Measuring the Power of

a Modulated Signal" in Chapter 6 and \Example 4 - Measuring a Wavelength

Characteristic" in Chapter 6, where they are performed using the HP-IB.

Measuring the Power of a Modulated Signal

We want to measure the power of a 1540nm signal, modulated by a 100kHz

square wave, at 500W.

1. Make sure that all your connectors and connector interfaces are clean.

2. Make sure that the Optical Output on the laser source is not Active.

1-8 Getting Started

Page 33

3. Connect the output of the laser source to the input of the power sensor (as

shown in the gure below). Make sure that the connector with the orange

strain-relief sleeve is connected to the tunable laser source (the orange

sleeve indicates an angled connector).

Figure 1-7. Connecting the Instruments for the Sample Session

Typically, you would connect a component to test between the tunable laser

source and the power meter.

1

4. Make sure that both instruments are powered up

Note

Normally you also need to be sure that the instruments are

properly warmed up before using the source, or making any

measurements. Here, because the measurements are not critical,

it is okay to proceed immediately to the next step.

Setting the Wavelength

5. On the tunable laser source:

a. Press

b. Make sure that you are setting the wavelength directly.

(Press

4

WAVELENGTH

NNNNNNNNNNNNNNNNNNNN

nm/GHz

5

.

if necessary until there is only one parameter () shown

on the left side of the display).

c.

Press

4

EDIT

5

and then

NNNNNNNNNNNNNNNNNNNNNNN

Default

to set the wavelength to 1540.000nm.

.

Getting Started 1-9

Page 34

1

6. On the multimeter set the wavelength for the power sensor to 1540.0nm,

set the measurement averaging time to 1s

(

4

Chan

5!A;

4

Mode

5!MEAS;4

5!!1540.0nm;

Param

4

Param

5!T!1s).

Setting the Modulated Power

7. On the tunable laser source:

a. Press

b. Make sure that you have a modulated signal selected

c. Make sure that

4

OUTPUT POWER

5

.

NNNNNNNNNNNNNNNNNNNN

(Press

FREQ

Mod/CW

if necessary until there are two parameters (

) shown on the right side of the display).

POWER

is selected

POWER

(the label of the selected parameter is displayed in inverse, press

if it is not selected).

d. Make sure that the power is being shown inWatts

(if necessary, press

e. Type 500 on the keypad and press

NNNNNNNNNNNNNNNNN

W/dBm

to change the units).

5

4

ENTER

.

8. On the multimeter, make sure that Watts are selected and that the

instrument is autoranging

(

4

dBm/W

5!W;

4

Auto

5!AUTO

).

9. On the tunable laser source:

NNNNNNNNNNNNNN

a. Press

Freq

.

b. Type in 100 on the keypad.

c. Make sure that the units are set to kHz

(If necessary, press

d. Press

4

ENTER

5

.

NNNNNNNNNNNNNNNNNNNN

Hz/kHz

to change the units).

and

NNNNNNNNNNNNNNNNN

Power

1-10 Getting Started

Page 35

Figure 1-8.

Tunable Laser Source Display after Setting Up Wavelength and Power

10. Press the button beside the Optical Output, the green LED should be lit to

indicate that the laser is now active.

You should notice that the power reading on the multimeter is approximately

half the value set on the laser source. This is because the output is modulated

by a square wave with a 50% duty cycle.

Measuring a Wavelength Characteristic

1

For the second part, we assume that the instruments are in the state given after

the rst task (see Figure 1-8).

We now want to measure the wavelength characteristic by measuring the power

at 1nm steps between 1535nm and 1545nm, at the highest power level possible

that is available over the full sweep range.

11.

On the laser source, press

NNNNNNNNNNNNNNNNNNNN

Mod/CW

to return the laser source to CW

operation.

Setting Up the Wavelength Sweep

12. On the laser source:

NNNNNNNNNNNNNNNNNNNNNNN

5

a. Press

4

WAVELENGTH

,and then

b. Type in 1535 on the keypad and press

-Sweep

.

4

ENTER

5

to set the start wavelength

for the sweep.

c. Type in 1545 on the keypad and press

4

ENTER

5

to set the stop wavelength

for the sweep.

d. Type in 1 on the keypad and press

4

ENTER

5

to set the size of the

wavelength step for the sweep.

Getting Started 1-11

Page 36

1

Figure 1-9.

Tunable Laser Source Display during Setting Up for the Wavelength

Sweep

Press

NNNNN

#

to skip over the dwell parameter.

4

ENTER

5

to set the number of times

e.

f. Type in 1 on the keypad and press

that the sweep is to be performed.

13.

On the laser source, press

value that can be maintained for the full sweep range

NNNNNNNNNNNNNNNNNNNNNN

Pmax!P

to set the output power to the highest

.

14. On the power meter:

a. Setto 1535nm

5!!1535.0nm).

(

4

Param

b. Make sure that the parameter cursor is in the units position (that is,at

the second \5").

Performing the Wavelength Characteristic Measurement

15. Make sure that the laser source is still active.

NNNNNNNNNNNNNNNNNNNN

16. On the laser source, press

Manual

.

17. Read the value for the power at 1535nm on the multimeter.

18. Repeat the following steps at each wavelength in the sweep range

a.

On the laser source, press

b. On the multimeter, increment(press

NNNNNNNNNNNNNN

Next

.

5

).

4

*

c. Read the value for the power at the wavelength on the multimeter.

19.

On the laser source, press

NNNNNNNNNNNNNN

Stop

to end the sweep.

1-12 Getting Started

Page 37

This procedure can be used in practice to measure the wavelength characteristic

of a component.

1

Getting Started 1-13

Page 38

Page 39

2

Setting Wavelength and Power

This chapter describes how to set the wavelength and the power of the output.

2

A Summary of the Wavelength and Output Power Hard- and

Softkeys

Setting Wavelength and Power 2-1

Page 40

2

Figure 2-1.

A Summary of the additional Output Power Softkeys for the

Attenuator Option

Setting the Wavelength

There are three ways to set the wavelength of the tunable laser source.

You can set the wavelength () directly,

You can set the wavelength from a base wavelength and an oset in the

frequency domain, or

You can set a range of wavelengths for the instrument to \sweep"

5

Press

Use

Use

4

WAVELENGTH

NNNNNNNNNNNNNNNNNNNN

nm/GHz

NNNNNNNNNNNNNNNNNNNNNNN

-Sweep

to select how you set the wavelength.

to select the wavelength parameter.

to perform a wavelength sweep.

Setting the Wavelength Directly

You can set the wavelength directly if the display looks like this:

Figure 2-2. Setting the Wavelength Directly

2-2 Setting Wavelength and Power

Page 41

Press

4

WAVELENGTH

5

and

nm/GHz

as necessary to get this display.

See \Changing the Value of a Parameter" in Chapter 1 if you need details on

how to edit parameters.

NNNNNNNNNNNNNNNNNNNN

2

Example

To set the wavelength to 1505.500nm (on an HP 8168E/F)

1. Press

2.

Press

4

WAVELENGTH

NNNNNNNNNNNNNNNNNNNN

nm/GHz

, if necessary, until the display looks as shown

5

in Figure 2-2

3. Type in 1505.5 on the numeric keypad, and press

4

ENTER

Setting a Relative Wavelength

You use a relative wavelength for heterodyning, for example, when you are

measuring the linewidth of DFB (distributed feedback) lasers.

You can set a relative wavelength if the display looks like this:

Figure 2-3. Setting a Relative Wavelength

NNNNNNNNNNNNNNNNNNNN

5

and

Press

4

WAVELENGTH

nm/GHz

The output wavelength () is set from the base wavelength (

as necessary to get to this display.

0) and the

frequency oset (df). The formula for calculating the output wavelength is:

=

c

(

0)df+

0

c

5

.

where c is the speed of light in a vacuum (2.9982108ms-1).

You can edit only the value ofdfdirectly. See \Changing the Value of a

Parameter" in Chapter 1 if you need details on how to edit parameters.

Changing the Base Wavelength

If you want to change

0,

1. setto the value to which you want to set the base wavelength (by

calculatingdf, or by setting the wavelength directly) and then

Setting Wavelength and Power 2-3

Page 42

press

NNNNNNNNNNNNNNNN

!

0

.

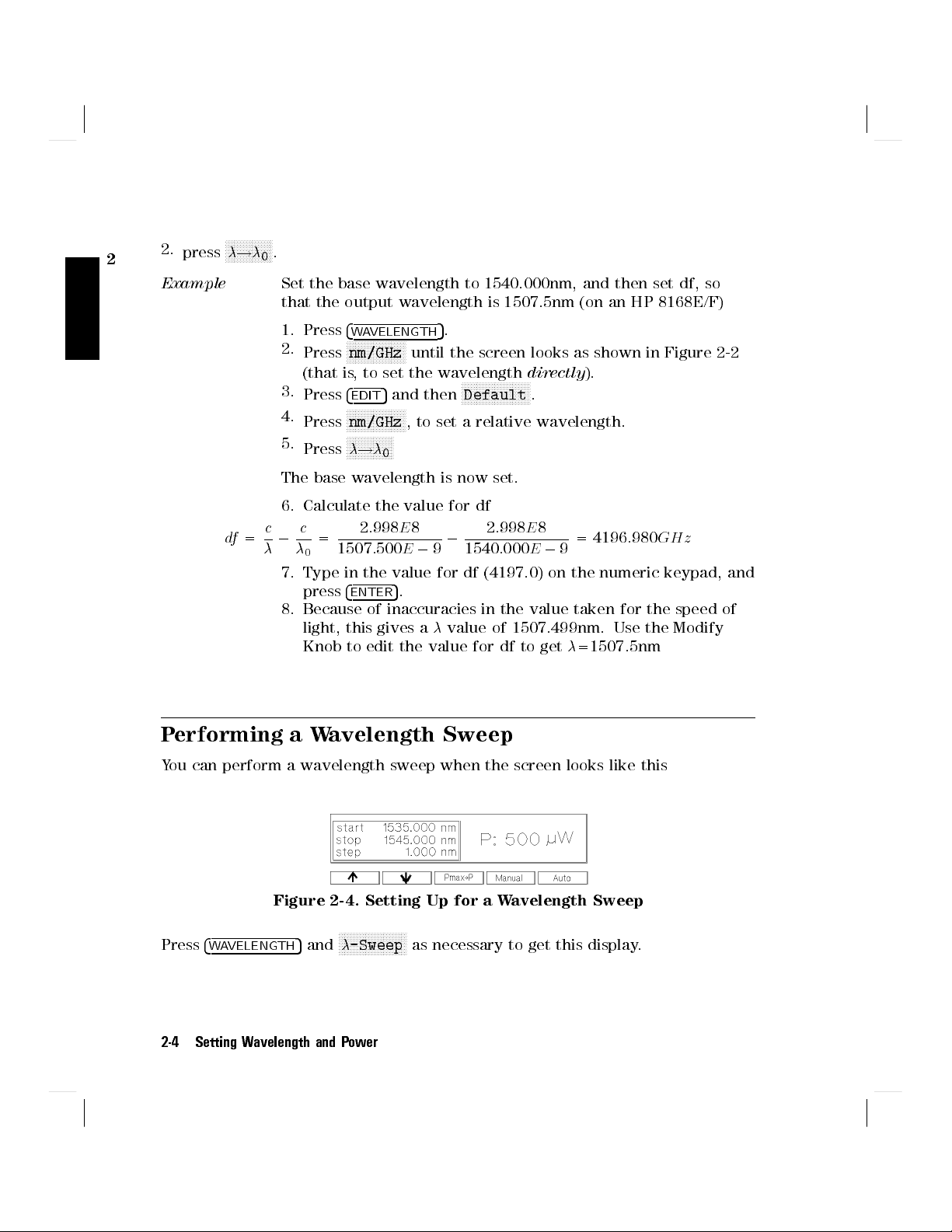

Set the base wavelength to 1540.000nm, and then set df, so

2

2.

Example

that the output wavelength is 1507.5nm (on an HP 8168E/F)

1. Press

2.

3.

4.

5.

4

WAVELENGTH

NNNNNNNNNNNNNNNNNNN

N

Press

nm/GHz

(that is, to set the wavelength

4

EDIT

5

Press

5

.

until the screen looks as shown in Figure 2-2

NNNNNNNNNNNNNNNNNNNNNNN

and then

Default

NNNNNNNNNNNNNNNNNNNN

Press

nm/GHz

, to set a relative wavelength.

NNNNNNNNNNNNNNNN

Press

!

0

directly

.

).

The base wavelength is now set.

6. Calculate the value for df

c

df

=

c

0

0

2:998E8

=

1507:500E0

0

9

1540:000E0

2:998E8

= 4196:980

9

7. Type in the value for df (4197.0) on the numeric keypad, and

5

press

4

ENTER

.

8. Because of inaccuracies in the value taken for the speed of

light, this gives avalue of 1507.499nm. Use the Modify

Knob to edit the value for df to get=1507.5nm

Performing a Wavelength Sweep

You can perform a wavelength sweep when the screen looks like this

GH z

Figure 2-4. Setting Up for a Wavelength Sweep

NNNNNNNNNNNNNNNNNNNNNNN

Press

4

WAVELENGTH

5

and

-Sweep

2-4 Setting Wavelength and Power

as necessary to get this display.

Page 43

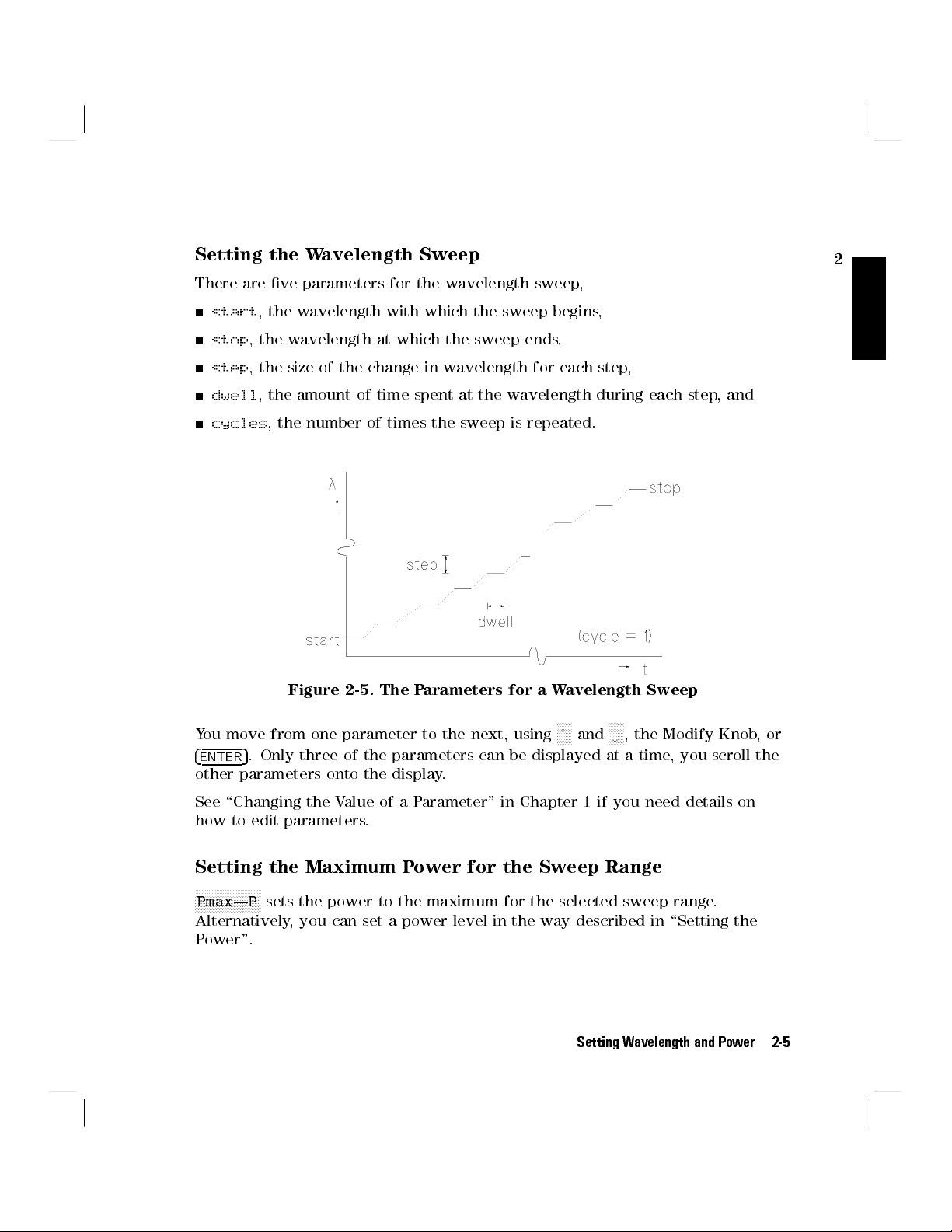

Setting the Wavelength Sweep

There are ve parameters for the wavelength sweep,

start

, the wavelength with which the sweep begins

stop

, the wavelength at which the sweep ends,

step

, the size of the change in wavelength for each step,

dwell

, the amount of time spent at the wavelength during each step, and

2

,

cycles

, the number of times the sweep is repeated.

Figure 2-5. The Parameters for a Wavelength Sweep

You move from one parameter to the next, using

4

5

ENTER

. Only three of the parameters can be displayed at a time, you scroll the

NNNNN

"

and

NNNNN

#

, the Modify Knob,or

other parameters onto the display.

See \Changing the Value of a Parameter" in Chapter 1 if you need details on

how to edit parameters.

Setting the Maximum Power for the Sweep Range

NNNNNNNNNNNNNNNNNNNNNN

Pmax!P

sets the power to the maximum for the selected sweep range.

Alternatively, you can set a power level in the way described in \Setting the

Power".

Setting Wavelength and Power 2-5

Page 44

2

Note

If coherence control is enabled, and the uncal power level

cannot be exceeded for the full wavelength range chosen, the

wavelength range is reduced as necessary.

Executing an Automatic Sweep

NNNNNNNNNNNNN

You can perform an automatic sweep if you press

sweep parameters, or if you press

NNNNNNNNNNNNN

N

Cont

during a manual sweep.

N

Auto

after setting up the

NNNNNNNNNNNNNNNNN

Press

Pause

to interrupt the sweep. The instrument switches to a manual

sweep (see \Performing a Manual Sweep").

NNNNNNNNNNNNN

N

Press

Stop

to end the sweep.

Example

Set the instrument to sweep the range 1495nm to 1555nm,

three times, in 1nm steps, stopping for half a second at

each wavelength, at the highest power level available at all

wavelengths.

1.

Press

4

WAVELENGTH

5

and then

2. Make sure you are at the

3. Type in 1495 and then

4. Type in 1555 and then

5. Type in 1 and then

6. Type in 0.5 and then

7. Type in 3 and then

8.

9. Enable the optical output, if necessary.

10.

Press

Press

NNNNNNNNNNNNNNNNNNNNNN

Pmax!P

N

NNNNNNNNNNNNN

Auto

, to set the power.

, to run the application.

4

ENTER

4

ENTER

4

ENTER

4

4

Performing a Manual Sweep

You can perform a manual sweep if you press

sweep parameters, or if you press

NNNNNNNNNNNNNNNNN

Pause

during an automatic sweep. During a

manual sweep the display looks as follows:

NNNNNNNNNNNNNNNNNNNNNNN

-Sweep

start

5

ENTER

ENTER

, to set the start wavelength.

5

, to set the stop wavelength.

5

, to set the step size.

5

, to set the dwell time.

5

, to set the number of cycles.

.

parameter.

NNNNNNNNNNNNNNNNNNNN

Manual

after setting up the

2-6 Setting Wavelength and Power

Page 45

Press

Press

Press

Press

NNNNNNNNNNNNNN

Next

NNNNNNNNNNNNNN

Prev

NNNNNNNNNNNNN

N

Cont

NNNNNNNNNNNNNN

Stop

Figure 2-6. Performing a Manual Sweep

to move on to the next wavelength step

to move back to the previous wavelength step.

to continue with an automatic sweep, from the current wavelength.

to end the sweep.

.

2

Setting Wavelength and Power 2-7

Page 46

2

Setting the Power

The laser output can be either

a continuous wave (CW), xed-amplitude signal,

a modulated signal, or

a signal with increased linewidth (coherence control).

Attenuator

If you have the built in attenuator, there are two power modes

for both the xed-amplitude, the modulated, and the increased

linewidth signals.You can either

specify the output power (Power Mode), or

specify the laser power and the attenuation (Attenuation

Mode).

The two modes are separate, the values set in one mode do not

aect the values set in the other.

NNNNNNNNNNNNNNNNNNNN

Press

4

OUTPUT POWER

5

to select the output power parameter. Use

Mod/CW

choose CW, modulated, or coherence control.

NNNNNNNNNNNNNNNNNNNNNNN

Attenuator

If you have the optional attenuator installed, use

PowMode

choose between Power Mode (specifying the output power) and

Attenuation Mode (specifying the laser power and attenuation).

Setting the Output Power of a CW Signal

You can set the output power of a CW signal if the display looks like this:

to

to

Figure 2-7. Setting the Output Power of a CW Signal

NNNNNNNNNNNNNNNNNNNN

Press

4

OUTPUT POWER

5

,

Mod/CW

2-8 Setting Wavelength and Power

and

NNNNNNNN

CW

as necessary to get to this display.

Page 47

See \Changing the Value of a Parameter" in Chapter 1 if you need details on

how to edit parameters.

NNNNNNNNNNNNNNNNN

You can change the units by pressing

W/dBm

.

2

Attenuator

If you have the optional attenuator installed, you may need to

NNNNNNNNNNNNNNNNNNNNNNN

press

PowMode

to get the display shown above.

Setting Power and Attenuation

Attenuator

If you have the optional attenuator installed, you can also set

the output power by setting rst the laser output power, and

then setting the amount of attenuation.

NNNNNNNNNNNNNNNNNNNNNNN

Press

PowMode

from the screen shown in Figure 2-7 to change

to the Attenuation Mode.

Press

NNNNNNNNNNN

Att

to select the attenuation parameter. Press

NNNNNNNNNNNNNN

Pref

to

select the laser output power.

What is Excessive Power?

An

EXCESSIVE

message indicates that the value you have set for the output

power is larger than the laser diode is capable of producing at this wavelength.

The instrument sets the output power as high as possible; it is this actual output

power that is shown as part of the

Note

If the chosen value is simultaneously too low for the coherence

control, if you are also using this, the

to

EXC

.

EXCESSIVE

message.

EXCESSIVE

is shortened

The Analog Output

The Analog Output, on the front panel of the instrument, outputs a dc level

that is proportional to the laser output power. The relationship between this

voltage level and the output power is not calibrated, but is approximately 1mV

for each 1W.

Setting Wavelength and Power 2-9

Page 48

2

Attenuator

If you have the optional attenuator installed, the Analog Output

signal depends on the power mode you have chosen.

In Power Mode the laser output power, and therefore the

Analog Output signal, is not linearly proportional to the output

power. This is because the actual output optical power is

derived by the optimum combination of the laser output power

and the attenuation.

In Attenuation Mode the relationship between the Pref and

the voltage level is approximately 1.35mV for each 1W. (The

dierence between this value and that of the tunable laser

source without the attenuator is due to the insertion loss of the

attenuator). This value is only proportional to the output power

if the attenuation remains constant. Here, the attenuator adds a

constant oset to the voltage level.

Example

To set the power to -10dBm.

5

1. Press

2.

3.

4

OUTPUT POWER

NNNNNNNNNNNNNNNNNNNN

Press

Mod/CW

as shown in Figure 2-7.

NNNNNNNNNNNNNNNNN

Press

W/dBm

, and

, if necessary, so that the power is displayed in

NNNNNNNN

CW

.

if necessary, so that the display looks

dBm.

4. Type -10 on the numeric keypad, and press

4

ENTER

Setting a Modulated Signal

There are two ways of modulating the amplitude of the optical output.

Using the internal modulation, and

using external modulation.

5

.

2-10 Setting Wavelength and Power

Page 49

Using the Internal Modulation

The internal modulating source is a square wave with a 50% duty-cycle.You can

set both the amplitude and the frequency of this signal. The amplitude is set by

the power parameter. This is the maximum output power of the output signal;

at the minimum, nothing is output.

Figure 2-8. The Modulated Signal

Setting the Output Power of a Modulated Signal

You can set the output power of a modulated signal if the display looks like this:

Figure 2-9. Setting the Output Power of an Internally Modulated Signal

2

Press

4

OUTPUT POWER

NNNNNNNNNNNNNNNNNNNN

Mod/CW

5

,

, and

NNNNNNNNNNN

Int

as necessary to get to this display.

See \Changing the Value of a Parameter" in Chapter 1 if you need details on

how to edit parameters.

NNNNNNNNNNNNNNNNN

You can change the units by pressing

W/dBm

.

The notes above about excessive power, and the analog output apply also to the

power of a modulated signal.

Setting the Frequency of a Modulated Signal

You can also set the frequency of a modulated signal from the display shown

above. Press

NNNNNNNNNNNNN

N

Freq

to select the parameter. See \Changing the Value of a

Parameter" in Chapter 1 if you need details on how to edit parameters.

NNNNNNNNNNNNNNNNNNNN

You can change the units by pressing

The new units come into eect when you press

Hz/kHz

while you are editing the value.

5

4

ENTER

.

Setting Wavelength and Power 2-11

Page 50

2

The Modulation Output

The Modulation Output on the front panel outputs a version of the modulating

signal that has the same frequency and phase as the modulating signal, but has

a xed, TTL-level amplitude.You can use this to synchronize your external

measuring equipment to the tunable laser source.

To allow for your possible sychronization requirements, there are two ways

in which the signal can be output. Either the signal is combined with the

laser-ready signal, so that the output is kept low when there is no optical

signal being output (for example, while the laser is settling after a change of

wavelength). Or the modulation signal is output all the time. This is set by the

4

System

NNNNNNNNNNNNNNNNNNNN

5

MODOUT

parameter (see \Setting the Modulation Output" in Chapter 3).

Example

Set the frequency of the modulated output to 300Hz.

5

1. Press

2.

3.

4. Type 300 on the numeric keypad.

5.

4

OUTPUT POWER

NNNNNNNNNNNNNNNNNNN

N

Press

Mod/CW

looks as shown in Figure 2-9.

NNNNNNNNNNNNNN

Press

Freq

, and

.

NNNNNNNNNNNNNNNNNNNN

Press

4

ENTER

Hz/kHz

5

.

, if necessary, to set the units to Hz, and press

.

NNNNNNNNNN

N

Int

if necessary, so that the display

Using External Modulation

The external modulating source can be any signal of up to 5Vpp.A5Vppsignal

causes 15% modulation of the power of the optical output signal.

Figure 2-10. External Modulation and Output Power

2-12 Setting Wavelength and Power

Page 51

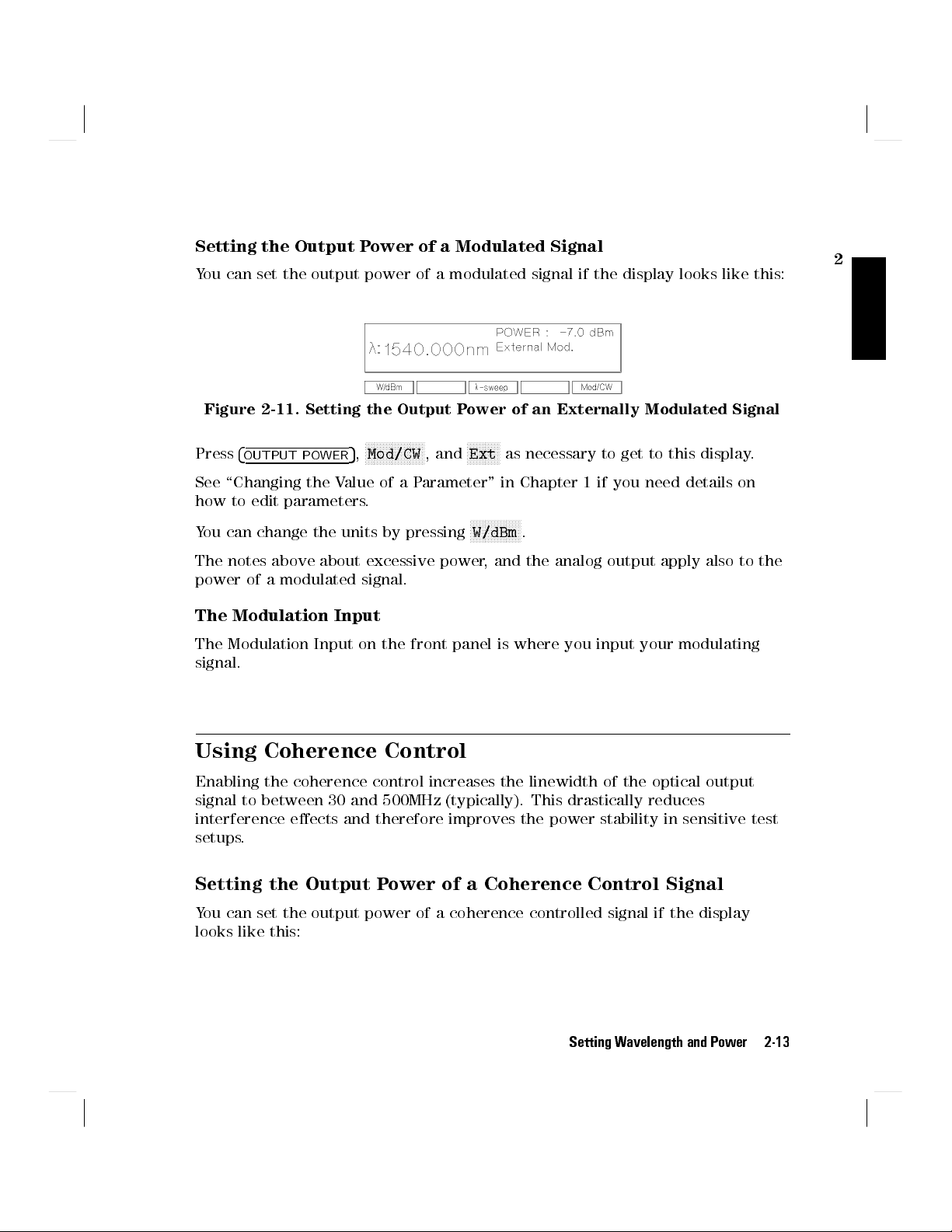

Setting the Output Power of a Modulated Signal

You can set the output power of a modulated signal if the display looks like this:

Figure 2-11. Setting the Output Power of an Externally Modulated Signal

2

Press

4

OUTPUT POWER

NNNNNNNNNNNNNNNNNNNN

5

,

Mod/CW

, and

NNNNNNNNNNN

Ext

as necessary to get to this display.

See \Changing the Value of a Parameter" in Chapter 1 if you need details on

how to edit parameters.

NNNNNNNNNNNNNNNNN

You can change the units by pressing

W/dBm

.