Operating and Programming Manual

HP 81541MM Lightwave

Multimeter Source Module

SERIAL NUMBERS

This manual applies to all instruments.

ABCDE

HP Part No. 81541-90011

Printed in the Federal Republic of Germany

First Edition

E1092

Notices

This document contains proprietary

information which is protected by

copyright. All rights are reserved.

No part of this document may be

photocopied, reproduced, or

translated to another language

without the prior written consent of

Hewlett-Packard GmbH.

c

Copyright 1992 by:

Hewlett-Packard GmbH

Herrenberger Str. 130

7030 Boeblingen

Federal Republic of Germany

Subject Matter

The information in this document is

subject to change without notice.

Hewlett-Packard makes no warranty

of any kind with regard to this

printed material, including, but not

limited to, the implied warranties of

merchantability and tness for a

particular purpose.

Hewlett-Packard shall not be liable

for errors contained herein or for

incidental or consequential damages

in connection with the furnishing,

performance, or use of this material.

Printing History

New editions are complete revisions

of the manual. Update packages,

contain additional and replacement

information to be incorporated into

the manual by the customer. The

date on the title page only changes

when a new manual is published.

When an edition is reprinted, all the

prior updates to the edition are

incorporated.

Warranty

This Hewlett-Packard instrument

product is warranted against defects

in material and workmanship for a

period of one year from date of

shipment. During the warranty

period, HP will, at its option, either

repair or replace products which

prove to be defective.

For warranty service or repair, this

product must be returned to a service

facility designated by HP. Buyer shall

prepay shipping charges to HP and

HP shall pay shipping charges to

return the product to Buyer.

However, Buyer shall pay all shipping

charges, duties, and taxes for

products returned to HP from

another country.

HP warrants that its software and

rmware designated by HP for use

with an instrument will execute its

programming instructions when

properly installed on that instrument.

HP does not warrant that the

operation of the instrument,

software, or rmware will be

uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not

apply to defects resulting from

improper or inadequate maintenance

by Buyer, Buyer-supplied software or

interfacing, unauthorized

modication or misuse, operation

outside of the environmental

specications for the product, or

improper site preparation or

maintenance.

No other warranty is expressed or

implied. Hewlett-Packard specically

disclaims the implied warranties of

Merchantability and Fitness for a

Particular Purpose.

Control Serial Number: Edition 1 applies directly to all instruments.

Edition 1 : 1st March 1991 : 81541-90011 : E0391

: 1st October 1992 : 81541-90011 : E1092

Exclusive Remedies

The remedies provided herein are

Buyer's sole and exclusive remedies.

Hewlett-Packard shall not be liable

for any direct, indirect, special,

incidental, or consequential

damages whether based on contract,

tort, or any other legal theory.

Assistance

Product maintenance agreements

and other customer assistance

agreements are available for

Hewlett-Packard products.For any

assistance contact your nearest

Hewlett-Packard Sales and Service

Oce.Addresses are provided at

the back of this manual.

Certication

Hewlett-Packard Company certies

that this product met its published

specications at the time of

shipment from the factory.

Hewlett-Packard further certies

that its calibration measurements

are traceable to the United States

National Institute of Standards and

Technology, NIST (formerly the

United States National Bureau of

Standards, NBS) to the extent

allowed by the Institutes's

calibration facility, and to the

calibration facilities of other

International Standards Organization

members.

Safety Considerations

Before operation, review the instrument and manual, including the red safety

page, for safety markings and instructions

.You must follow these to ensure safe

operation and to maintain the instrument in safe condition.

Initial Inspection

Inspect the shipping container for damage. If there is damage to the container

or cushioning, keep them until you have checked the contents of the shipment

for completeness and veried the instrument both mechanically and electrically.

The Performance Tests give procedures for checking the operation of the

instrument. If the contents are incomplete, mechanical damage or defect is

apparent, or if an instrument does not pass the operator's checks, notify the

nearest Hewlett-Packard oce.

Warning

To avoid hazardous electrical shock, do not perform

electrical tests when there are signs of shipping damage to

any portion of the outer enclosure (covers, panels, etc.).

Line Power Requirements

The HP 81541MM operates when installed into the HP 8153A Lightwave

Multimeter mainframe

Operating Environment

The HP 8153A safety information summarizes the HP 81541MM operating

environment ranges. In order for the HP 81541MM to meet specications, the

operating environment must be within the limits specied for the HP 8153A.

Storage and Shipment

The module can be stored or shipped at temperatures between040

C and

+70C. Protect the module from temperature extremes that may cause

condensation within it.

v

Contents

C. HP 81541MM Specications

Suppelementary Performance Characteristics ...... .... C-2

Internal Digital Modulation . . . . . . . . . . . . . . . . . . C-2

Output Attenuation .... ...... ...... ..... C-2

Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

D. Performance Tests

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required . . . . . . . . . . . . . . . . . . . . . .

Test Record .......................... D-2

Test Failure .......................... D-2

Instrument Specication ...... ...... ...... .. D-2

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . D-2

Output Power and Stability Tests .... ..... ...... D-3

1. Output Power Test ................... D-3

2. Attenuation Function Test................ D-4

3. Modulation Function Test ................ D-4

4. Stability Test ...................... D-4

E. Cleaning Procedures

Cleaning Materials . . . . . . . . . . . . . . . . . . . . . . . E-1

Cleaning Fiber/Front-Panel Connectors .. ...... ..... E-2

Cleaning Connector Interfaces .. ...... ...... ... E-2

Cleaning Connector Bushings . . . . . . . . . . . . . . . . . . E-3

Cleaning Detector Windows .................. E-3

Cleaning Lens Adapters ...... ...... ...... .. E-3

Cleaning Detector Lens Interfaces ...... ...... ... E-4

D-1

D-1

Contents-1

Figures

D-1. Performance Test Setup ................... D-3

Tables

C-1. HP 81541MM Specications . . . . . . . . . . . . . . . . . . C-1

Contents-2

C

HP 81541MM Specications

Specications describe the instrument's warranted preformance. Supplementary

performance characteristics describe the instrument's non-warranted typical

performance.

Because of the modular nature of the instrument, these performance

specications apply only to this module.You should insert these pages into the

appropriate section of the manual.

Table C-1. HP 81541MM Specications

Type

Central Wavelength

[1]

Fiber Type

Spectral Bandwidth (FWHM)

Output Power

CW-Stability

[1]

LED

850nm630nm

MM 50/125m

<

90nm

>

-17dBm

Short Term (15min, T=Constant)60.003dB

Long Term (6h, T=0 to 55C61K)60.03dB

Dimensions

Weight

Recalibration Period

[1]

After a warmup time of 60min. with output enabled. If previously

75mm H, 32mm W, 335mm D

(2.8"2

1.3"2

13.2"2

)

net 0.7kg (1.5lbs), shipping 1kg (2.2lbs)

1 year

stored at the same temperature, only 20min. warmup required.

HP 81541MM Specications C-1

Suppelementary Performance Characteristics

Internal Digital Modulation

You can select internal modulation frequencies of 270HZ, 1kHz, or 2kHz. All

outputs are pulse shaped, with a duty cycle of 50%.

Output Attenuation

The output can be attenuated from 0 to 6dB, in steps of 0.1dB.

Stability

The value of the long term stability doubles with just one minute warmup time

(source enabled).

C-2 HP 81541MM Specications

D

Performance Tests

Introduction

The procedures in this section test the optical performance of the instrument.

The complete specications to which the HP 81541MM is tested are given in

Table C-1. All tests can be performed without access to the interior of the

instrument. The performance tests refer specically to tests using the Diamond

HMS-10/HP connector.

Equipment Required

Equipment required for the performance test is listed below.

Note

Instrument/Accessory Recommended Model

Power Meter Standard

#C01

Multimeter Mainframe HP 8153A

Connector Adapter

(head)

Connector Interface HP 81000AI 2ea (08154-61701)

Multimode Fiber HP 81501AC

BNC to BNC Cable 8120-1840

Oscilloscope

The LED Source module under test can be inserted into the

second channel of the Power Meter Standard. In this case, the

second multimeter mainframe is not necessary.

HP 8153A Mainframe with

HP 81533A Optical Head Interface Module with

HP 81520A Optical Head

HP 81000AA

Performance Tests D-1

Test Record

Results of the performance test may be noted in the P

The Test Record can also be used as a permanent record and may be reproduced

without written permission from Hewlett-P

Test Failure

If the HP 81541MM fails any performance test, return the instrument to the

nearest Hewlett-Packard Sales/Service Oce for repair.

Instrument Specication

Specications are the performance characteristics of the instrument that are

certied. These specications, listed in Table C-1, are the performance standards

or limits against that the HP 81541MM can be tested. Appendix C also lists some

supplemental characteristics of the HP 81541MM and should be considered as

additional information.

Any changes in the specications due to manufacturing changes, design, or

traceability to the National Bureau of Standards will be covered in a manual

change supplement or revised manual. The specications listed in such a change

supercede any previously published.

ackard

erformance Test Record.

Performance Tests

The performance tests given in this section are separated into Output Power

Test and Stability Test. Perform each step in the tests in the order they are

given, using the corresponding test equipment.

Note

D-2 Performance Tests

Make sure that all optical connections in the test setups given in

the procedure are dry and clean.

Output Power and Stability Tests

Specications:

Optical output power of 50/125

Stability over 15 minutes at constant temperature:

Stability over 6h and61K env. temp. window:

m ber:

>

-17dBm

6

0.003dB

6

0.02dB

1. Output Power Test

a. Make sure that cable connectors and detector windows are clean.

b. Turn instruments on, enable the LED output of the HP 81541MM and allow

instruments to warm up for at least 60 minutes.

c. On the power meter:

i. Setto the wavelength displayed for the HP 81541MM source channel.

ii. Make sure that the CAL parameter on the power meter is set to zero

iii. With the connector adapter, on the optical head, covered with a plastic

5

cap, press

to zero the power meter.

4

Zero

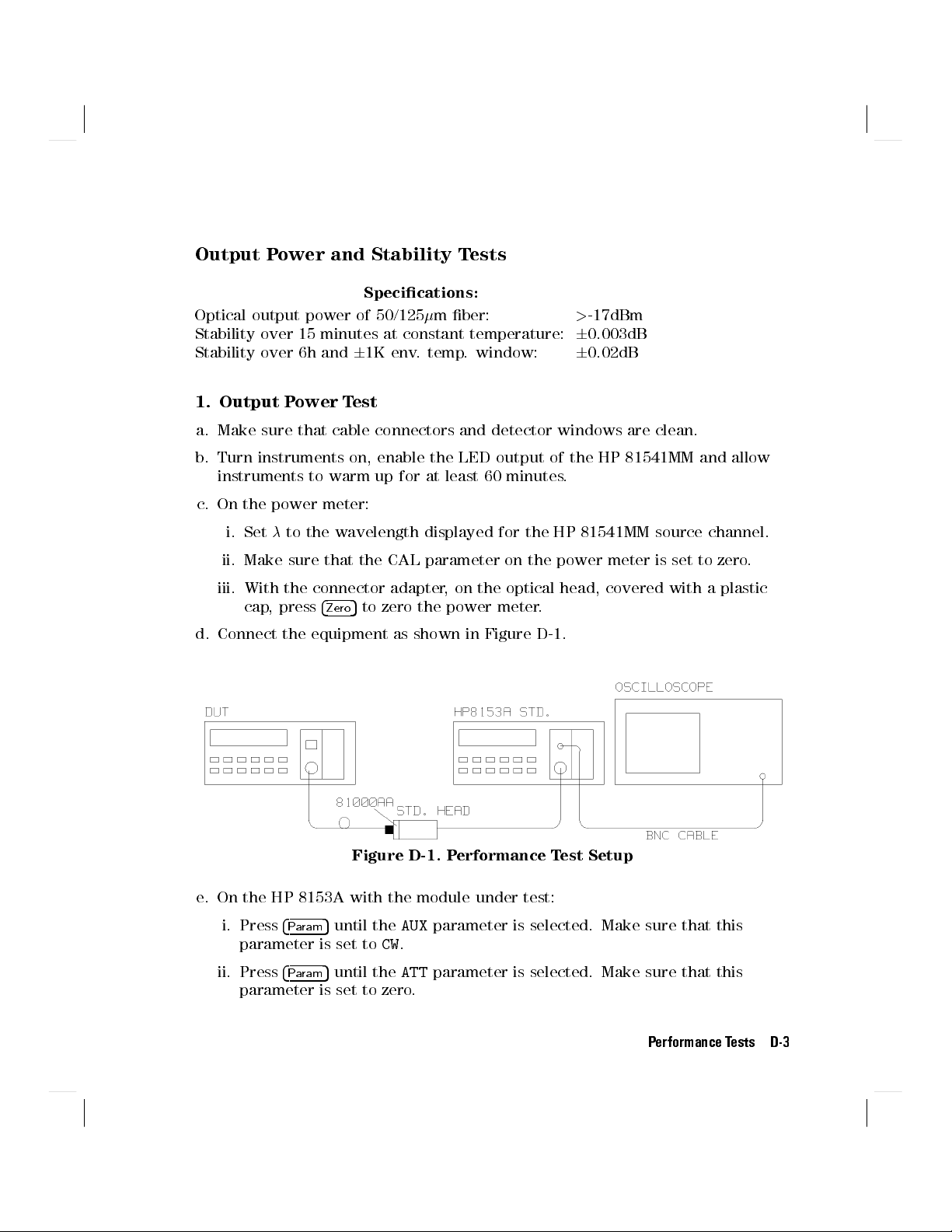

d. Connect the equipment as shown in Figure D-1.

Figure D-1. Performance Test Setup

e. On the HP 8153A with the module under test:

i. Press

4

Param

5

until the

AUX

parameter is selected. Make sure that this

parameter is set toCW.

ii. Press

4

Param

5

until the

ATT

parameter is selected. Make sure that this

parameter is set to zero.

.

Performance Tests D-3

f. Measure the output power and note the result in the Test Record.

2. Attenuation Function Test

g. On the power meter, press

4

Disp!Ref

5

. Press

4dB5

to select a display in dB.

h. Using the modify keys on the HP 8153A with the module under test, increase

the attenuation and check that the output power changes.

Note the reaction on the Test Record.

i. Set the attenuation to 0.0dB.

3. Modulation Function Test

j. Using a BNC cable, connect the power meter transducer output to the

oscilloscope input and set the oscilloscope as follows: 0.5V/DIV DC coupled,

1ms/DIV.

k. On the power meter, switch the autoranging o and select the -20dBm range.

l. On the HP 8153A with the module under test, press

4

Param

5

to select the

AUX

parameter. Monitor the frequency change on the oscilloscope as you set the

5

modulation to 270Hz, 1kHz, and then to 2kHz. Use

5

and

4

*

to modify the

4

+

modulation.

Note the reaction on the Test Record.

4. Stability Test

a. Enable the HP 81541MM LED output and allow the instruments to warm up

for 60 minutes.

b. Select the channel with the source.

i. Press

ii. Press

4

Param

4

Param

5

to select the

5

to select the

AUX

parameter. Set this parameter toCW.

ATT

parameter. Set this parameter to zero.

c. On the power meter:

i. Cover the input to the sensor with a plastic cap and press

the meter.

5

ii. Press

4

Param

to select theparameter. Set this parameter to the value

displayed for the source.

iii. Press

4

Param

5

to select theTparameter. Set this parameter to1s.

D-4 Performance Tests

4

Zero

5

to zero

d. Using the HP 81501A

C cable, connect the output of the source to the input

of the sensor. Make sure that the cable is xed and that it cannot be moved

during the measurement.

e. Select the

i. Press

ii. Press

MENU

mode on the power meter.

5

4

Record

4

5

and select the

Edit

to select

STABILTY

T_TOTAL

.

parameter. Set the

to 15 minutes.

iii. Press

f. When the stability test has completed, press

application. Press

4

Edit

5

and then

4

Edit

4

Exec

5

and then

5

to run the stability application.

5

to select the

4

More

5

4

Next

5/4

to display the

Prev

Divide this result by 2 to obtain the value for the stability:

DIF F

=

2

Stabil ity(dB

)

Note the result on the Test Record.

g. Repeat the stability measurement (steps e and f) with

T_TOTAL

DIFF

T_TOTAL

parameter

SHOW

result.

set to 6 hours.

Performance Tests D-5

Performance Test for the HP 81541MM

Test Facility:

Model HP81541MM Source Module

Page 1 of 3

Report No.

Date

Customer

Tested By

Serial No. Ambient temperature

Options Relative humidity %

Firmware Rev. Line frequency Hz

Special Notes:

C

D-6 Performance Tests

Performance Test for the HP 81541MM

Page 2 of 3

Test Equipment Used:

Description Model No. Trace No. Cal. Due Date

1. Lightwave Multimeter (Std.) HP 8153A

#C01

2. Opt. Head Interface Module HP 81533A

3. Optical Head 850nm HP 81520A

4. Lightwave Multimeter (DUT) HP 8153A

5. Connector Interface HP 81000AI N/A N/A

6. Connector Adapter HP 81000AA N/A N/A

7. Multimode Fiber HP 81501AC N/A N/A

8. BNC to BNC Cable P/N 8120-1840 N/A N/A

9. Oscilloscope

10.

11.

12.

13.

14.

15.

16.

17.

Performance Tests D-7

Performance Test for the HP 81541MM

Page 3 of 3

Model HP 81541MM LED Source Module No. Date

Test Minimum Maximum Measurement

No.Test Description Spec. Result Spec. Uncertainty

I.

Output Power Test

Output Power -17dBm

II.

Attenuation Function Test

Passed (P)/Failed (F)

III.

Modulation Function Test

Passed (P)/Failed (F)

IV.

Stability Tests

Stability (15min.) -0.003dB +0.003dB

Stability (6h.) -0.02dB +0.02dB

6

0.5dB (610.14%)

D-8 Performance Tests

Cleaning Procedures

E

In general,

connectors may be used dry or wet. Dry means without index matching

compound. If there is a need to use an index matching compound, use only HP

index matching oil (part number 8500-4922). Clean the connectors, interfaces

and bushings carefully each time after use.

Cleaning Materials

Lens Cleaning Paper 9300-0761

Special Cleaning Tips 9300-1351

Blow Brush 9300-1131

Adhesive Cleaning tape 15475-68701

Isopropyl Alcohol Not available from HP. This should be available from

Pipe Cleaner

whenever possible use physically contacting dry connectors

HP P/N

any local pharmaceutical supplier.

. Fiber

Cleaning Procedures E-1

Cleaning Fiber/Front-Panel Connectors

1. In order to clean the instrument front panel connector remove the connector

interface.

2. Apply some isopropyl alcohol to the lens cleaning paper and clean the

surface and the ferrule of the connectors.

3. Using a new dry piece of cleaning paper wipe the connector surface and

ferrule until they are dry and clean.

4. Lightly press the adhesive tape several times against the connector surface to

remove any remaining particles. After use store the tape in the container.

5. Protect the connector surface with a cap.

Cleaning Connector Interfaces

Apply some isopropyl alcohol to the pipe cleaner and wash the inside of the

connector interface.

Using a new dry pipe cleaner, dry the inside of the connector interface.

Remove the brush part from the blow brush and blow air through the inside

of the interface to remove any remaining particles.

Note

E-2 Cleaning Procedures

If any index matching compound was used, use an ultrasonic

bath with isopropyl alcohol to clean the connector interfaces.

Cleaning Connector Bushings

As used on the HP 8158B and HP 81000AS/BS.

Normally the connector bushings require no cleaning. However

that cleaning is necessary, use only the blow brush with the brush part

removed.

Caution

Cleaning Detector Windows

As used on the HP 81520A and HP 81521B

1. Use the blow brush to remove any particles from the surface

2. Wipe the surface with cleaning paper or special cleaning tips

Cleaning Lens Adapters

NEVER insert any cleaning tool into the bushing as this may

aect the optical system.

NEVER use any index matching compound, cleaning uid or

cleaning spray.

.

, if it appears

.

.

Caution

1. Using the blow brush, remove dust.

2. Wipe the surfaces with the special cleaning tips.

Do not use any cleaning uid or cleaning spray.

Cleaning Procedures E-3

Cleaning Detector Lens Interfaces

As used on the HP 81522A and HP 8140A and HP 8153A detector modules

.

Normally, the lens interface can be cleaned by using the blow brush. If adhesive

dirt must be removed perform as follows:

1. Using the blow brush, remove the dust from the lens surface.

2. Press the special cleaning tip to the lens surface and rotate the tip.

Note

Use alcohol for cleaning only then when above procedure does

not help or if the dirt is caused by oil or fat.

E-4 Cleaning Procedures

Loading...

Loading...