Errata

8153A Lightwave Multimeter Operating and Programming Manual

08153-90011

September 1, 1999

Title & Document Type:

Manual Part Number:

Revision Date:

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. We have made no changes to this

manual copy. The HP XXXX referred to in this document is now the Agilent XXXX.

For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support your

product. This manual provides the best information we could find. It may be incomplete

or contain dated information, and the scan quality may not be idea l. If we find a better

copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available

product information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide

you to any available information. Our service centers may be able to perform calibration

if no repair parts are needed, but no other support from Agilent is available.

Operating and Programming Manual

HP 8153A Lightwave Multimeter

SERIAL NUMBERS

This manual applies to all instruments with Serial No. 2946G00476 and higher.

ABCDE

HP Part No. 08153-90011

Printed in Germany

Third Edition

E0199

This document contains proprietary

information which is protected by

copyright. All rights are reserved.

No part of this document may be

photocopied, reproduced, or

translated to another language

without the prior written consent of

Hewlett-Packard GmbH.

c

Copyright 1999 by:

Hewlett-Packard GmbH

Herrenberger Str. 130

7030 Boeblingen

Germany

Subject Matter

The information in this document is

subject to change without notice.

Hewlett-Packard makes no warranty

of any kind with regard to this

printed material, including, but not

limited to, the implied warranties of

merchantability and tness for a

particular purpose.

Hewlett-Packard shall not be liable

for errors contained herein or for

incidental or consequential damages

in connection with the furnishing,

performance, or use of this material.

Printing History

New editions are complete revisions

of the manual. Update packages,

contain additional and replacement

information to be incorporated into

the manual by the customer. The

date on the title page only changes

when a new manual is published.

When an edition is reprinted, all the

prior updates to the edition are

incorporated.

Notices

Warranty

This Hewlett-Packard instrument

product is warranted against defects

in material and workmanship for a

period of one year from date of

shipment. During the warranty

period, HP will, at its option, either

repair or replace products which

prove to be defective.

For warranty service or repair, this

product must be returned to a service

facility designated by HP. Buyer shall

prepay shipping charges to HP and

HP shall pay shipping charges to

return the product to Buyer.

However, Buyer shall pay all shipping

charges, duties, and taxes for

products returned to HP from

another country.

HP warrants that its software and

rmware designated by HP for use

with an instrument will execute its

programming instructions when

properly installed on that instrument.

HP does not warrant that the

operation of the instrument,

software, or rmware will be

uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not

apply to defects resulting from

improper or inadequate maintenance

by Buyer, Buyer-supplied software or

interfacing, unauthorized

modication or misuse, operation

outside of the environmental

specications for the product, or

improper site preparation or

maintenance.

No other warranty is expressed or

implied. Hewlett-Packard specically

disclaims the implied warranties of

Merchantability and Fitness for a

Particular Purpose.

Exclusive Remedies

The remedies provided herein are

Buyer's sole and exclusive remedies.

Hewlett-Packard shall not be liable

for any direct, indirect, special,

incidental, or consequential

damages whether based on contract,

tort, or any other legal theory.

Assistance

Product maintenance agreements

and other customer assistance

agreements are available for

Hewlett-Packard products.For any

assistance contact your nearest

Hewlett-Packard Sales and Service

Oce.Addresses are provided at

the back of this manual.

Certication

Hewlett-Packard Company certies

that this product met its published

specications at the time of

shipment from the factory.

Hewlett-Packard further certies

that its calibration measurements

are traceable to the United States

National Institute of Standards and

Technology, NIST (formerly the

United States National Bureau of

Standards, NBS) to the extent

allowed by the Institutes's

calibration facility, and to the

calibration facilities of other

International Standards Organization

members.

Control Serial Number

First Edition applies directly to all

instruments.

First Edition : E0590

Second Edition : E1191, E0492,

E1192, E1293

Third Edition : E1094, E0796, E0199

Safety Considerations

The Model HP 8153A is a Class 1 instrument (that is

, an instrument with an

exposed metal chassis directly connected to earth via the power supply cable).

The symbol used to show a protective earth terminal in the instrument is

.

Before operation, you should review the instrument and manual, including the

red safety page, for safety markings and instructions.You must follow these to

ensure safe operation and to maintain the instrument in safe condition.

Some HP 8153A circuits are powered whenever the instrument is connected to

the AC power source.To disconnect from the line power, disconnect the power

cord either at the rear power-inlet or at the AC line-power source (receptacle).

One of these must always be accessible. If the instrument is in a cabinet, it must

be disconnected from the line power by the system's line-power switch.

Warning

To avoid hazardous electrical shock, do not perform

electrical tests when there are signs of shipping damage to

any portion of the outer enclosure (covers, panels, etc.).

Line Power Requirements

The HP 8153A can operate from any single-phase A

C power source that supplies

between 100V and 240V at a frequency in the range from 40 to 60Hz. The

maximum power consumption is 55VA with all options installed.

The fuse used by this instrument is T1A / 250V (slow) (HP Part No. 2110-0007).

Changing the fuse should be carried out only by a qualied electrician or by HP

service personnel as it is necessary to open the instrument.

Line Power Cable

In accordance with international safety standards, this instrument has

a three-wire power cable. When connected to an appropriate AC power

receptacle, this cable earths the instrument cabinet. The type of power cable

shipped with each instrument depends on the country of destination. Refer to

Figure 0-1 for the part numbers of the power cables available.

iii

Figure 0-1. Line Power Cables - Plug Identication

Warning

To avoid the possibility of injury or death, you must

observe the following precautions before switching on the

instrument.

If this instrument is to be energized via an

autotransformer for voltage reduction, ensure that the

Common terminal connects to the earthed pole of the

power source.

Insert the power cable plug only into a socket outlet

provided with a protective earth contact. Do not negate

this protective action by the using an extension cord

without a protective conductor.

Before switching on the instrument, the protective

earth terminal of the instrument must be connected to a

protective conductor.You can do this by using the power

cord supplied with the instrument.

It is prohibited to interrupt the protective earth

connection intentionally.

iv

The following work should be carried out by a qualied electrician, and all local

electrical codes must be strictly observed. If the plug on the cable does not t

the power outlet, or if the cable is to be attached to a terminal block, cut the

cable at the plug end and rewire it.

The color coding used in the cable depends on the cable supplied. If you are

connecting a new plug, it should meet the local safety requirements and include

the following features:

Adequate load-carrying capacity (see table of specications).

Ground connection.

Cable clamp.

Operating Environment

Warning

Input/Output Signals

Caution

The HP 8153A is not designed for outdoor use.To prevent

potential re or shock hazard, do not expose the HP 8153A

to rain or other excessive moisture.

A maximum of 15V can be applied as an external voltage to any

of the BNC connectors.

v

Initial Safety Information for Laser Source Modules

The Specications for these modules are as follows:

HP 81551MM HP 81552SM HP 81553SM HP 81554SM

Laser Type

FP-Laser FP-Laser FP-Laser Dual FP-Laser

InGaAsP InGaAsP InGaAsP InGaAsP

Laser Class

According to IEC 825 3A 3A 3A 3A

(Europe)

According to 21 CFR 1040.10 1 1 1 1

(Canada, Japan, USA)

Output Power

Beam Diameter

Numerical Aperture

Wavelength

>

-2dBm

>

0dBm

>

0dBm

>

-1dBm

50m 9m 9m 9m

0.2 0.1 0.1 0.1

850610nm 1310620nm 1550620nm 1310/1550620nm

Note

Note

vi

Canada, Japan, USA

The laser safety warning labels are xed on the laser module.

Europe

A sheet of laser safety warning labels are included with the

laser module.You

MUST

stick the labels in the local language

onto the outside of the mainframe, in a position where they are

clearly visible to anyone using the instrument.

You

MUST

Center for repair and calibration.

The laser module has built in safety circuitry that will disable the optical output

in the case of a fault condition.

return instruments with malfunctioning laser boxes to a HP Service

Warning

Warning

Warning

Warning

Use of controls or adjustments or performance of

procedures other than those specied for the laser source

may result in hazardous radiation exposure.

Refer Servicing only to qualied and authorized personnel.

Do not enable the laser when there is no ber attached to

the optical output connector.

The optical output connector is at the bottom, on the laser

module front panel.

The laser is enabled by pressing the grey button above the

optical output connector on the front panel. The laser is

enabled when the green LED on the front panel of the laser

module is lit.

Under no circumstances look into the end of an optical

cable attached to the optical output when the device is

operational.

The laser radiation is not visible to the human eye, but it

can seriously damage your eyesight.

vii

Sicherheitsinformation fur Laser Quellen

Die Spezikationen f ur die Lasereinsch ube sind wie folgt:

HP 81551MM HP 81552SM HP 81553SM HP 81554SM

Laser Typ

FP-Laser FP-Laser FP-Laser Dual FP-Laser

InGaAsP InGaAsP InGaAsP InGaAsP

Laser Klasse

Entsprechend IEC 825 3A 3A 3A 3A

(Europa)

Ausgangsleistung

Strahldurchmesser

Numerische Apertur

Wellenl

ange

>

-2dBm

>

0dBm

>

0dBm

>

-1dBm

50m 9m 9m 9m

0.2 0.1 0.1 0.1

850610nm 1310620nm 1550620nm 1310/1550620nm

Hinweis

Europa

Ein Blatt mit Laser Warnaufklebern ist jedem Lasereinschub

beigef ugt. Die Aufkleber m ussen in der Landessprache,fur den

Anwender gut sichtbar, an der Aussenseite des Grundger ates

angebracht werden.

Defekte Lasereinsch ube m ussen zur Reparatur oder zur Kalibration an ein HP

Service B uro geschickt werden.

Der Lasereinschub hat eine eingebaute Sicherheitsschaltung die den

Laserausgang im Falle einer St orung abschaltet.

viii

Warnung

Bedienung, Abgleicharbeiten oder die Durchfuhrung von

Tests, die nicht im Handbuch angegeben sind, konnen zum

Austritt gefahrlicher Strahlung fuhren.

Warnung

Warnung

Warnung

Reparaturarbeiten durfen nur von qualiziertem und

bevollmachtigtem Personal durchgefuhrt werden.

Laser nicht ohne angeschlossenen Glasfaserkabel

einschalten.

Der optische Ausgang bendet sich am unteren Teil der

Einschubfrontplatte. Mit dem daruberliegenden grauen

Druckschalter wird der Laser ein- bzw. ausgeschaltet. Bei

eingeschaltetem Laser leuchtet eine grune Anzeige an der

Frontplatte des Einschubes.

Wenn der Laser eingeschaltet ist, darf unter keinen

Umstanden in das Ende des optischen Kabels oder in den

Laserausgang am Gerat geschaut werden.

Der Laserstrahl ist fur das menschliche Auge unsichtbar,

kann aber das Sehvermogen ernsthaft verletzen.

ix

Informations et Consignes de Securite Relativesa l'Utilisation

des Lasers.

Les Sp ecications des Modules Laser sont les Suivantes:

HP 81551MM HP 81552SM HP 81553SM HP 81554SM

Type de Laser

FP-Laser FP-Laser FP-Laser Dual FP-Laser

InGaAsP InGaAsP InGaAsP InGaAsP

Classe du Laser

Conforme au STD IEC 825 3A 3A 3A 3A

(Europe)

Conforme au STD CFR 1040.10 1 1 1 1

(Canada, Japan, USA)

Puissance de Sortie

Diam^etre du Faisceau

Ouverture Numerique

Longueur d'Onde

>

-2dBm

>

0dBm

>

0dBm

>

-1dBm

50m 9m 9m 9m

0.2 0.1 0.1 0.1

850610nm 1310620nm 1550620nm 1310/1550620nm

Remarque

Remarque

x

Canada, Japan, USA

Les etiquettes de s ecurit e sont ach ees sur le module laser.

Europe

Les etiquettes de s ecurit e sont incluses dans le module laser.

Il est obligatoire de coller une etiquette en langage local a

l' exterieur de l'appareil de telle sorte qu'elle soit parfaitement

visible par l'utilisateur.

Il est obligatoire de retourner tout appareil pr

de fonctionnement du laser uniquement

esentant un d efaut

a un centre de r eparation

Hewlett-Packard.

Le module laser comporte un syst eme de s ecurit e mettant hors service la sortie

optique en cas de malfonctionnement du laser.

Attention

L'utilisation du laser en dehors de ses limites de

performances et des procedures denies par HP peut

conduirea une exposition dangereuse de l'utilisateur aux

radiations.

Attention

Seul le personnel autorise par HP est qualie pour

intervenir sur le laser.

Attention

Ne pas mettre le laser sous tension sans s'^etre assure

qu'une bre optique est bien xee sur le connecteur.

Le connecteur de sortie optique est situe au bas de la face

avant du module laser.

La mise en service du laser s'eectue par la pression du

bouton gris situe au dessus de la sortie optique en face

avant du module. L'illumination de la LED verte indique que

le laser est en activite.

Attention

En aucun cas ne tenter de regarder l'extremite de la bre

optique attachee au connecteur lorsque le laser est en

activite.

Bien que la lumiereemise par le laser ne soit pas visible elle

peut cependant^etre dangereuse pour la vue.

xi

Lasersakerhet

Till HP 8153A optiska m atsystem kan man installera en lasermodul. P adetta

vis kan HP 8153A optiska m atsystem ocks a vara en laserapparat, som d a

klassiceras till laserklass 3A.

I Finland har apparatens lasers akerhet inspekterats av Institutet f or

Arbetshygien och typgodk ants av Arbetsskydstyrelsen. Vid inspektionen har

apparaten klassicerats enligt de best ammelser som anges i statsr adets beslut Nr.

472/1985 och standard SFS-IEC 825.

Om man till HP 8153A m atsystem har anlagt en lasermodul eller om man senare

installerar en lasermodul, m aste till apparaten bifogas varningsskyltar enligt

standard SFS-IEC 825:

Bruksanvisningar

Varning

Vid anv andingen av apparaten b or f oljande varningsanvisningar efterf oljas, som

pa detta s att garanterar s akerhet.

Aktivera ej lasern, om inte den optiska kapeln ar kopplad till str al oppningen.

Laserstr alen aktiveras genom att trycka p a den gr aa knoppen ovanf or

str al oppningen. D arefter informerar den gr ona indikationslampan om att

lasern ar i funktion.

xii

Om apparaten anvands pa annat sattan vad i

bruksanvisningar specicerats, kan anvandaren utsattas for

osynlig laserstralning av laserklass 3A.

Titta aldrig in i den till str al oppningen kopplade optiska kabeln eller berns

losa del, n ar lasern ar i funktion.

Underhall

I apparaten nns ej s adana delar, som anv andaren kan underh alla. N ar man

uppt acker att fel i apparaten har uppst att eller att apparaten ej fungerar

felfritt, b or apparaten s andas till HP:s verkstad f or reparering och service.

I lasermodulen nns en inbyggd s akerhetskrets, som s atter laserstr alningen ur

funktion n ar fel uppst ar i apparaten.

xiii

Laserturvallisuus

HP 8153A optiseen yleismittariin voidaan asentaa pistoyksikk on a laserl ahde.

Tall oin HP 8153A optinen yleismittari toimii laserlaitteena joka kuuluu

turvalisuusluokkaan 3A.

Laitteen on tarkastanut Suomessa laserturvallisuuden osalta Ty oterveyslaitos ja

tyypihyv aksynyt Ty osuojeluhallitus.Tarkastuksessa laitteen turvallisuusluokka

on m aaritetty valtioneuvoston p aat oksen N:o 472/1985 ja standardin SFS-IEC

825 mukaisesti.

Mik ali HP 8153A mittauslaitteeseenne on asennettu laserl ahde tai siihen

my ohemmin asennetaan em. laserl ahde, laite on varustettava laserl ahteen

mukana toimitettavilla, standardin SFS-IEC 825 mukaisilla varoitusmerkinn oill a:

Kaytto

Varoitus

Kaytt aess asi laitetta noudata seuraavia varo-ohjeita, jotka takaavat laitteen

turvallisen k ayt on:

al a aktivoi lasers adett a, ellei optinen kaapeli ole kytkettyn asateen

ulostuloliittimeen. Lasers ade aktivoidaan painamalla ulostuloliittimen

yl apuolelle sijoitettua harmaata kytkint a. T all oin vihre a merkkivalo ilmaisee

lasers ateen toimivan.

xiv

Laitteen kayttaminen muulla kuin kayttoohjeesa mainitulla

tavalla saattaa altistaa kayttajan luokan 3A nakymattomalle

lasersateilylle.

al a koskaan katso ulostuloliittimeen kytketyn optisen kaapelin tai kuidun

sis aan sen vapaana olevasta p aast a, kun laite on toiminnassa.

Huolto

Laitteessa ei ole k aytt aj an huollettavissa olevia kohteita. Laite tulee l ahett aa

korjattavaksi ja huollettavaksi HP:n huoltokorjaamoon, mik ali laite vikaantuu

tai sen havaitaan toimivan virheellisesti.

Laserl ahteess aonmyos sis aanrakennettu turvapiiri, joka est aa lasers ateen

toiminnan laitteen vikaantuessa.

xv

Introduction

This manual is arranged into four categories:

Getting Started

Descriptions of operating principles, to make you familiar with the

instrument. Chapter 1.

Quick Reference Guide

Local control and remote control programming information. Chapters 2, 3, 4,

5, 6, 7, 8, and 9.

Reference Data

Supporting information of a non-operational nature. Appendix A, B,C,D,E,

F, G, H, and I.

Customer Assistance

Sales and Service information. Appendix J.

xvi

Contents

1. Getting Started

The HP 8153A System ..................... 1-1

A Quick Overview . . . . . . . . . . . . . . . . . . . . . . . 1-2

The Keyboard . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Measure Mode . . . . . . . . . . . . . . . . . . . . . . . 1-2

Menu Mode ...... ...... ....... ..... 1-3

The Display . . . . . . . . . . . . . . . . . . . . . . . . .

A Sample Session ...... ...... ........ ... 1-8

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . .

Switching On and Recalling the Standard Setting ....... 1-8

Making A Power Measurement ................ 1-9

Logging Data .. ...... ........ ...... .. 1-11

Examining the Data .. ...... ........ ..... 1-12

Plotting Data ........................ 1-13

2. Measure Mode

The Chan Key . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

The Mode Key . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

The Param Key ...... ...... ...... ...... 2-2

Entry Status . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Default Values . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . 2-2

...... ...... ........ ..... .... 2-2

CAL ........ ...... ....... ...... 2-3

T............................. 2-3

REF............................ 2-5

ATT...... ...... ....... ...... ... 2-6

AUX ........................... 2-7

The Disp!RefKey....................... 2-7

ThedBKey .. ........ ...... ..... ..... 2-8

Using

4dB5

with a Two Sensor Instrument ........... 2-8

Using

4dB5

with a One Sensor Instrument ...... ..... 2-9

1-6

1-8

Contents-1

The dBm/W Key . . . . . . . . . . . . . . . . . . . . . . . . 2-9

The Zero Key ......................... 2-9

TheNDigKey......................... 2-11

The Range Keys . . . . . . . . . . . . . . . . . . . . . . . . 2-11

The AutoKey ........................ 2-13

TheUpKey......................... 2-13

The Down Key ....................... 2-13

The Analog Output ..................... 2-13

The Modify Keys . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Editing Discrete Valued Parameters . . . . . . . . . . . . . . 2-14

Editing Continuous Valued Parameters ............ 2-14

Editing Units ...... ...... ....... .... 2-14

3. Menu Mode

The Chan Key . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

The Mode Key . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

The System Key . . . . . . . . . . . . . . . . . . . . . . . . 3-2

The Modify Keys . . . . . . . . . . . . . . . . . . . . . . . . 3-2

The Loss Key ......................... 3-2

Preparation ...... ...... ........ ..... 3-2

Running the Loss Application . . . . . . . . . . . . . . . . . 3-3

The Record Key . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Preparation ...... ...... ........ .....

The Stability Application . . . . . . . . . . . . . . . . . . . .

T TOTAL .......... ...... ...... .... 3-8

AUTODUMP . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Running the Stability Application . . . . . . . . . . . . . . . 3-9

The Logging Application ...... ...... ........ 3-10

SAMPLES . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

AUTODUMP . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

START .. ...... ...... ..... ........ 3-12

THRESHLD ......................... 3-12

Running the Logging Application . . . . . . . . . . . . . . . 3-13

The Manual Logging Application ................ 3-13

Running the Manual Logging Application .... ...... . 3-13

The Plot Application . . . . . . . . . . . . . . . . . . . . . . 3-14

AUTOSCAL ......................... 3-15

Y MIN ........................... 3-15

YMAX ........................... 3-15

COMMENT ...... ...... ........ ..... 3-16

Running the Plot Application . . . . . . . . . . . . . . . . . 3-16

3-6

3-7

Contents-2

Reading the Plot . . . . . . . . . . . . . . . . . . . . . . . 3-16

The Print Application ..................... 3-19

AUTOSCAL .. ...... ...... ........ ... 3-20

Y MIN ........................... 3-20

YMAX ...... ...... ....... ...... .. 3-21

COMMENT ...... ...... ........ ..... 3-21

Running the Print Application .......... ...... 3-22

Reading the Printout . . . . . . . . . . . . . . . . . . . . . 3-22

The MinMax Applications ................... 3-25

MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

SAMPLES . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Running the MinMax Application . . . . . . . . . . . . . . . 3-27

The More Key . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

The Show Application .... ...... ........ ... 3-28

MAXIMUM ...... ...... ........ ..... 3-28

MINIMUM . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

DIFF ...... ...... ........ ..... ... 3-29

AVERAGE.......................... 3-29

#1 ...... ........ ...... ...... ... 3-29

The Alignment Application . . . . . . . . . . . . . . . . . . . 3-29

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

DELTA ...........................

MAXPOWER ........................

3-31

3-31

Running the Alignment Application . . . . . . . . . . . . . . 3-31

4. System Mode

The Mode Key . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

The Modify Keys . . . . . . . . . . . . . . . . . . . . . . . . 4-1

The System Key . . . . . . . . . . . . . . . . . . . . . . . . 4-2

RECALL .......................... 4-2

The Module Type ..................... 4-3

The Location ....................... 4-3

The Channel . . . . . . . . . . . . . . . . . . . . . . . . 4-3

STORE ........ ...... ........ ..... 4-4

The Module Type ..................... 4-5

The Channel . . . . . . . . . . . . . . . . . . . . . . . . 4-5

The Location ....................... 4-5

HPIB ............................ 4-5

ADDRESS . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Contents-3

LANGUAGE.... ........ ..... ...... . 4-6

DISPLAY ...... ...... ...... ...... .. 4-7

BRIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

DATETIME ...... ...... ...... ...... . 4-7

MM/DD/YY ........................ 4-8

HH:MM:SS . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

5. Programming the HP 8153A

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

The HP 8153A HP-IB Capabilities . . . . . . . . . . . . . . . . 5-2

HP-IB Display Indicators . . . . . . . . . . . . . . . . . . . . 5-2

The Parser .......................... 5-3

Parser Type . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Synchronization . . . . . . . . . . . . . . . . . . . . . . . 5-3

Clearing the Input Queue . . . . . . . . . . . . . . . . . . . 5-4

Accepted Characters . . . . . . . . . . . . . . . . . . . . . 5-4

HP-IB Bus Commands .................... 5-4

HP-IB Priority . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

TMSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Setting the HP-IB Address ........ ...... ..... 5-8

Syntax Diagram Conventions . . . . . . . . . . . . . . . . . . 5-9

6. Common Commands

Common Status Information .................. 6-1

SRQ, The Service Request .................. 6-3

Input Queue . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Output Queue . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Error Queue . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

*CLS .......... ...... ........ .... 6-4

*ESE ............................ 6-5

*ESE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

*ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

*IDN? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

*OPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

*OPC? ........................... 6-9

*OPT? .... ...... ....... ...... .... 6-9

*RST .......... ...... ........ .... 6-10

*SRE ...... ...... ........ ...... .. 6-11

*SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

*STB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

*TRG . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Contents-4

*TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

*WAI ............................ 6-14

7. HP-IB Status Commands

The Status Registers . . . . . . . . . . . . . . . . . . . . . . 7-1

The Condition Registers ................... 7-2

The Transition Filters .................... 7-2

The Event Registers .. ...... ........ ..... 7-2

The Enable Registers . . . . . . . . . . . . . . . . . . . . . 7-2

The Status Commands ...... ...... ........ . 7-3

STATus:PRESet ....................... 7-3

STATus:<node>:CONDition? ................. 7-4

STATus:<node>:ENABle . . . . . . . . . . . . . . . . . . . 7-5

STATus:<node>:ENABle? .................. 7-5

STATus:<node>[:EVENt]? .................. 7-5

STATus:<node>:NTRansition . . . . . . . . . . . . . . . . . 7-6

STATus:<node>:NTRansition? ................ 7-6

STATus:<node>:PTRansition . . . . . . . . . . . . . . . . . 7-6

STATus:<node>:PTRansition? ................ 7-7

The Operation Status . . . . . . . . . . . . . . . . . . . . . . 7-7

The Operation Status Commands ............... 7-9

The OPERation node . . . . . . . . . . . . . . . . . . . . . . 7-10

The OPERation:SETTling Node . . . . . . . . . . . . . . . .

The OPERation:SETTling:LPELTier Node .......... 7-11

The OPERation:SETTling:HPELTier Node ........ .. 7-11

The OPERation:MEASuring Node . . . . . . . . . . . . . . . 7-11

The OPERation:MEASuring:POWer Node .... ...... 7-11

The OPERation:TRIGger Node .. ...... ........ 7-12

The OPERation:TRIGger:POWer Node . . . . . . . . . . . . 7-12

The OPERation:CORRecting Node . . . . . . . . . . . . . . . 7-12

The OPERation:CORRecting:ZERO Node . . . . . . . . . . . 7-12

The OPERation:AVERaging Node ............... 7-12

The OPERation:AVERaging:POWer Node . . . . . . . . . . . 7-12

The OPERation:PROGram Node . . . . . . . . . . . . . . . . 7-13

The OPERation:PROGram:<application>Node . . . . . . . . 7-13

The Questionable Status .................... 7-13

The Questionable Status Commands . . . . . . . . . . . . . . 7-15

The QUEStionable node .................... 7-16

The QUEStionable:POWer Node . . . . . . . . . . . . . . . . 7-17

The QUEStionable:POWer:OVERRange Node . . . . . . . . . 7-17

The QUEStionable:POWer:LCURRent Node .. ...... . 7-17

7-11

Contents-5

The QUEStionable:POWer:HCURRent Node ......... 7-18

The QUEStionable:POWer:LMONitor Node . . . . . . . . . . 7-18

The QUEStionable:POWer:HMONitor Node . . . . . . . . . . 7-18

The QUEStionable:POWer:ENVTemp Node . . . . . . . . . . 7-18

The QUEStionable:ISUMmary Node . . . . . . . . . . . . . . 7-19

The QUEStionable:ISUMmary:INSTrument[1j2] Node . . . . . 7-19

The QUEStionable:ISUMmary:INSTrument[1j2]:POWer Node 7-19

The Source Status ...... ...... ........ ... 7-20

The Source Status Commands The following are the source status 7-20

The SOURce node ...... ...... ........ ... 7-21

8. HP-IB Commands

ABORt Commands . . . . . . . . . . . . . . . . . . . . . . . 8-1

Specifying the Channel . . . . . . . . . . . . . . . . . . . . 8-1

ABORt ........................... 8-1

DISPlay Commands ...................... 8-2

DISPlay:BRIGhtness .... ...... ........ ... 8-2

DISPlay:BRIGhtness? . . . . . . . . . . . . . . . . . . . . . 8-2

DISPlay:STATe... ...... ...... ..... .... 8-3

DISPlay:STATe? ...... ...... ..... ...... 8-3

FETCh Commands . . . . . . . . . . . . . . . . . . . . . . . 8-4

Specifying the Channel . . . . . . . . . . . . . . . . . . . . 8-4

FETCh[:SCALar]:POWer[:DC] . . . . . . . . . . . . . . . . .

INITiate Commands ......................

Specifying the Channel . . . . . . . . . . . . . . . . . . . . 8-7

INITiate:CONTinuous ...... ........ ...... 8-7

INITiate:CONTinuous? .... ........ ...... .. 8-7

INITiate[:IMMediate] . . . . . . . . . . . . . . . . . . . . . 8-8

READ Commands ....................... 8-8

Specifying the Channel . . . . . . . . . . . . . . . . . . . . 8-8

READ[:SCALar]:POWer[:DC] ................. 8-8

SENSe Commands . . . . . . . . . . . . . . . . . . . . . . . 8-9

Specifying the Channel . . . . . . . . . . . . . . . . . . . . 8-11

SENSe:CORRection:COLLect:ZERO ........ ...... 8-11

SENSe:CORRection:COLLect:ZERO? . . . . . . . . . . . . . . 8-11

SENSe:CORRection[:LOSS[:INPut[:MAGNitude]]] . . . . . . . . 8-11

SENSe:CORRection[:LOSS[:INPut[:MAGNitude]]]? ...... . 8-12

SENSe:POWer:ATIME .................... 8-12

SENSe:POWer:ATIME? . . . . . . . . . . . . . . . . . . . . 8-13

SENSe:POWer:RANGe:AUTO ................. 8-13

SENSe:POWer:RANGe:AUTO? ...... ...... .... 8-13

8-4

8-7

Contents-6

SENSe:POWer:RANGe[:UPPER] . . . . . . . . . . . . . . . . 8-14

SENSe:POWer:RANGe[:UPPER]? ............... 8-16

SENSe:POWer:REFerence .................. 8-16

SENSe:POWer:REFerence? .................. 8-17

SENSe:POWer:REFerence:DISPlay .......... .... 8-18

SENSe:POWer:REFerence:STATe ............... 8-19

SENSe:POWer:REFerence:STATe? ............... 8-19

SENSe:POWer:REFerence:STATe:RATIo ............ 8-20

SENSe:POWer:REFerence:STATe:RATIo? . . . . . . . . . . . . 8-20

SENSe:POWer:UNIT .......... ...... ..... 8-21

SENSe:POWer:UNIT? . . . . . . . . . . . . . . . . . . . . . 8-21

SENSe:POWer:WAVElength . . . . . . . . . . . . . . . . . . 8-21

SENSe:POWer:WAVElength? ................. 8-22

SOURce Commands ...................... 8-22

Specifying the Channel . . . . . . . . . . . . . . . . . . . . 8-23

SOURce:AM[:INTernal]:FREQuency . . . . . . . . . . . . . . 8-23

SOURce:AM[:INTernal]:FREQuency? ............. 8-23

SOURce:POWer:ATTenuation ................. 8-24

SOURce:POWer:ATTenuation? . . . . . . . . . . . . . . . . . 8-24

SOURce:POWer:STATe .......... ...... .... 8-24

SOURce:POWer:STATe?.. ...... ...... ...... 8-25

SOURce:POWer:WAVElength .......... ...... . 8-25

SOURce:POWer:WAVElength? . . . . . . . . . . . . . . . . .

8-26

SYSTem Commands .... ...... ...... ...... 8-26

SYSTem:DATE........................ 8-27

SYSTem:DATE? .... ...... ...... ..... .. 8-27

SYSTem:ERRor? .... ...... ..... ........ 8-27

SYSTem:TIME . . . . . . . . . . . . . . . . . . . . . . . . 8-28

SYSTem:TIME? ...... ...... ..... ...... 8-29

9. HP-IB Application Commands

Program Commands ...................... 9-1

PROGram[:SELected]:EXECute . . . . . . . . . . . . . . . . 9-2

PROGram[:SELected]:NAME ................. 9-2

PROGram[:SELected]:NAME? . . . . . . . . . . . . . . . . . 9-3

PROGram[:SELected]:NUMBer ................ 9-3

PROGram[:SELected]:NUMBer? . . . . . . . . . . . . . . . . 9-3

PROGram[:SELected]:STATe .. ...... ...... ... 9-4

PROGram[:SELected]:STATe? ...... ...... ..... 9-4

Mainframe Applications .................... 9-5

The Logging Application .... ...... ........ .. 9-5

Contents-7

The Stability Application . . . . . . . . . . . . . . . . . . . . 9-6

10. HP-IB Programming Examples

Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Example 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Example 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Example 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

Example 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

A. Installation

Safety Considerations ..................... A-1

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . A-2

Line Power Requirements ................... A-2

Line Power Cable ...................... A-2

Operating Environment .................... A-4

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Humidity .......................... A-5

Instrument Cooling ..................... A-5

Input/Output Signals . . . . . . . . . . . . . . . . . . . . . A-5

HP-IB Interface ........................

Cables and Adapters . . . . . . . . . . . . . . . . . . . . .

Connector . . . . . . . . . . . . . . . . . . . . . . . . . .

HP-IB Logic Levels . . . . . . . . . . . . . . . . . . . . . . A-7

Removing and Fitting Modules .......... ...... . A-7

How to Remove a Module .. ...... ...... .... A-7

How to Fit a Module . . . . . . . . . . . . . . . . . . . . . A-8

Storage and Shipment .......... ..... ...... A-9

Claims and Repackaging .................... A-10

Return Shipments to HP ................... A-10

A-5

A-6

A-6

B. Accessories

Mainframe .......................... B-1

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Connector Interfaces and Other Accessories . . . . . . . . . . . B-3

Contents-8

C. Specications

Mainframe Specications . . . . . . . . . . . . . . . . . . . . C-1

Declaration of Conformity ................... C-3

Supplementary Information: ................ C-4

Acoustic Noise Emission ................... C-5

D. Function Tests

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Equipment Required . . . . . . . . . . . . . . . . . . . . . . D-1

Test Record .......................... D-2

Test Failure .......................... D-2

Instruments Specications ........ ..... ...... D-2

IA. Function Test Using the HP 81533A . . . . . . . . . . . . . D-3

Display Function and Module Interface Tests ......... D-3

Display Function Tests . . . . . . . . . . . . . . . . . . . D-3

Module Interface Tests . . . . . . . . . . . . . . . . . . . D-4

ANALOG INPUT (8152A IN) ................. D-6

P.CTRL ...... ...... ...... ...... ... D-6

IB. Function Test using a HP 81530/31/32 or HP 81536A ..... D-6

HP-IB Interface Test (Optional) . . . . . . . . . . . . . . . . . D-7

E. Cleaning Procedures

Cleaning Materials . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Fiber/Front-Panel Connectors .. ...... ..... E-2

Cleaning Connector Interfaces .. ...... ....... .. E-2

Cleaning Connector Bushings . . . . . . . . . . . . . . . . . . E-3

Cleaning Detector Windows .................. E-3

Cleaning Lens Adapters .... ...... ...... .... E-3

Cleaning Detector Lens Interfaces ........ ...... . E-4

E-1

F. Local Control Summary

Measure Mode . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Menu Mode ...... ...... ........ ..... . F-2

System Mode .... ...... ........ ...... . F-3

Contents-9

G. HP 8153A HP-IB Command Summary

The Logging Application ...... ...... ........ G-4

The Stability Application . . . . . . . . . . . . . . . . . . . . G-5

H. HP 8152A HP-IB Command Summary

Dierences .......................... H-1

Using the FETCh Command - An Example . . . . . . . . . . . . H-3

Setting the Filter .......... ..... ........ H-4

Listener Function ....................... H-5

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . H-5

Standard Parameter Set ................... H-7

Talker Function ........................ H-8

Interrogating Settings .................... H-8

Status/Error Reporting . . . . . . . . . . . . . . . . . . . . H-10

Universal Commands . . . . . . . . . . . . . . . . . . . . . . H-10

I. Error Codes

Local Operation Error Codes .................. I-1

Module Related Errors . . . . . . . . . . . . . . . . . . . . I-1

Specic Error Identiers . . . . . . . . . . . . . . . . . . . I-2

Store and Recall Errors . . . . . . . . . . . . . . . . . . . . I-2

Plot, Print, Show, and Manual Logging Errors ......... I-2

Loss Errors .... ...... ........ ...... .

HP-IB Errors ........................

HP-IB Error Codes . . . . . . . . . . . . . . . . . . . . . . . I-3

No Error .. ...... ........ ..... ..... I-3

Instrument Specic Errors .................. I-3

Command Errors . . . . . . . . . . . . . . . . . . . . . . . I-4

Execution Errors ........ ...... ........ I-6

Device Dependant Errors . . . . . . . . . . . . . . . . . . . I-7

Query Errors ........................ I-8

I-2

I-3

J. Sales and Service Oces

K. Backdating

Instruments with Serial Numbers 2946G00475 and Earlier .... K-1

Instruments with Serial Numbers 2946G00225 and Earlier .... K-2

The Print Application ........ ...... ...... K-2

SAMPLES . . . . . . . . . . . . . . . . . . . . . . . . . K-2

COMMENT ........................ K-2

Contents-10

Index

Contents-11

Figures

0-1. Line Power Cables - Plug Identication ............ iv

1-1. The HP 8153A System .................... 1-1

1-2. The HP 8153A Keyboard . . . . . . . . . . . . . . . . . . . 1-2

1-3. The HP 8153A Display . . . . . . . . . . . . . . . . . . . . 1-6

1-4. Hardware Set Up for the Sample Session .. ...... ... 1-8

1-5. The Display at the Start of the Sample Session . . . . . . . . .

1-6. Editing the Sensor Wavelength .... ...... ...... 1-10

1-7. Reading the Power Output by the Source ........... 1-11

1-8. Going into Menu Mode . . . . . . . . . . . . . . . . . . . .

1-9. A Plotter Connected to the HP 8153A . . . . . . . . . . . . .

2-1. Measurements with T

Average

1 second . . . . . . . . . . . . 2-4

2-2. Editing the Averaging Time Parameter .. ...... .... 2-4

2-3. The Display while Channel A is Being Zeroed ...... ... 2-10

3-1. Measuring the Reference for the Loss Application ...... . 3-3

3-2. Measuring the Loss of a Device Under Test (DUT) .... ... 3-4

3-3. The Loss Result ....................... 3-5

3-4. Setup for a Record Application . . . . . . . . . . . . . . . . 3-6

3-5. Selecting an Application : Stability . . . . . . . . . . . . . . 3-7

3-6. Editing an Application Parameter : Samples . . . . . . . . . . 3-11

3-7. Stability Plot ........................ 3-18

3-8. Logging Printout . . . . . . . . . . . . . . . . . . . . . . . 3-23

3-9. The Window and Refresh Modes ............... 3-26

3-10. Setup for an Alignment Application . . . . . . . . . . . . . . 3-30

3-11. The Display during the Alignment Application . . . . . . . . . 3-32

4-1. Making a Selection in System Mode : the Recall Function .. . 4-2

4-2. Editing a Parameter in System Mode ............. 4-4

4-3. Setting the Brightness of the Display ............. 4-7

6-1. Common Status Registers . . . . . . . . . . . . . . . . . . . 6-2

7-1. The Registers and Filters in a Node . . . . . . . . . . . . . . 7-1

7-2. The Operation Registers ................... 7-8

7-3. The Questionable Registers . . . . . . . . . . . . . . . . . . 7-14

7-4. The Source Register ........ ...... ..... .. 7-20

1-9

1-11

1-13

Contents-12

8-1. Measurements with T

8-2. Measurements with T

8-3. Measurements with T

A-1. Line Power Cables - Plug Identication ............ A-4

A-2. HP-IB Connector . . . . . . . . . . . . . . . . . . . . . . . A-6

A-3. How to Remove a Module .................. A-8

A-4. Fitting a Module . . . . . . . . . . . . . . . . . . . . . . . A-9

Average

Average

Average

1 second . . . . . . . . . . . . 8-5

>

1 second, continuous triggering. . 8-5

>

1 second, immediate triggering. . 8-6

Contents-13

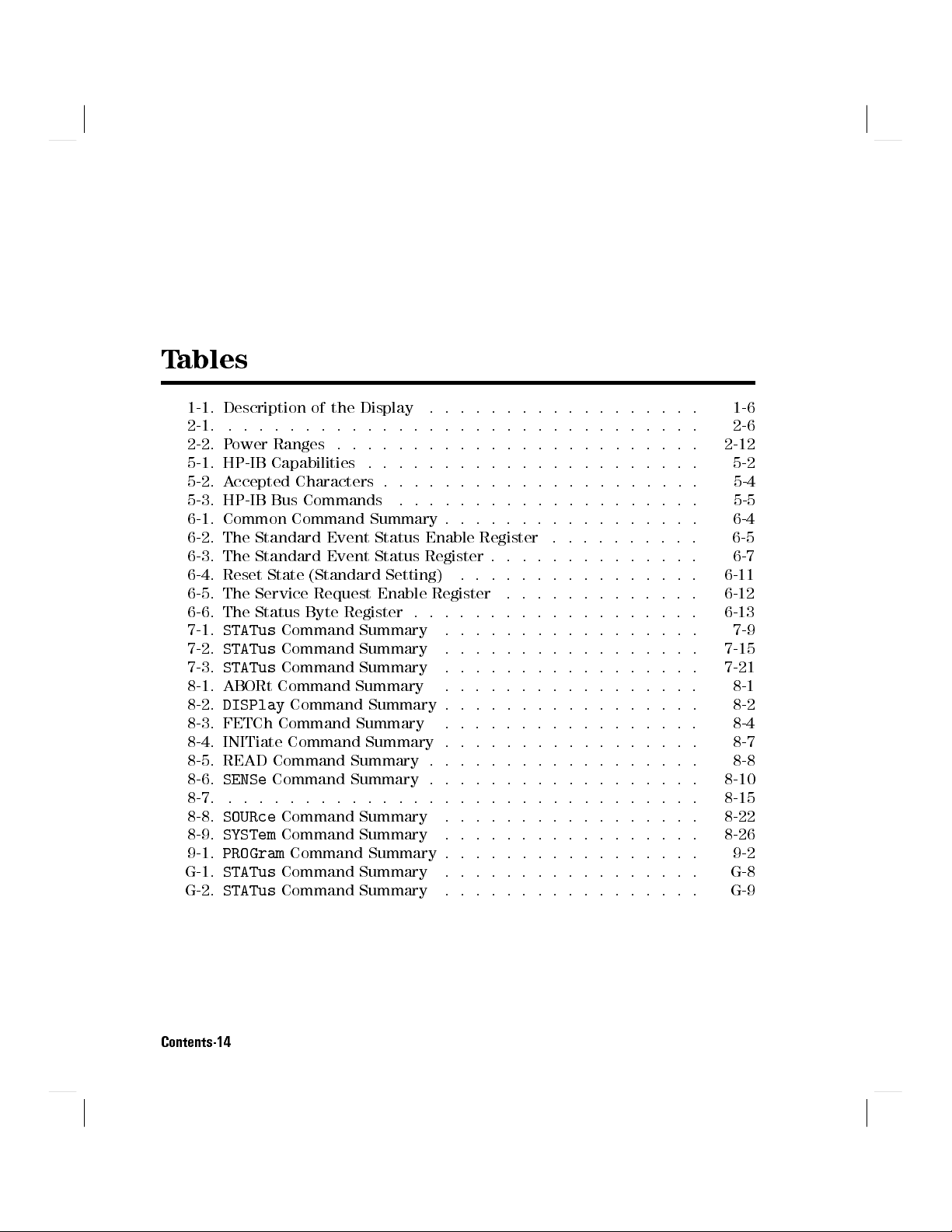

Tables

1-1. Description of the Display .......... ...... .. 1-6

2-1. ............................... 2-6

2-2. Power Ranges . . . . . . . . . . . . . . . . . . . . . . . . 2-12

5-1. HP-IB Capabilities .. ...... ...... ...... .. 5-2

5-2. Accepted Characters . . . . . . . . . . . . . . . . . . . . . 5-4

5-3. HP-IB Bus Commands .................... 5-5

6-1. Common Command Summary . . . . . . . . . . . . . . . . . 6-4

6-2. The Standard Event Status Enable Register .......... 6-5

6-3. The Standard Event Status Register . . . . . . . . . . . . . .

6-4. Reset State (Standard Setting) .. ...... ...... .. 6-11

6-5. The Service Request Enable Register .. ...... ..... 6-12

6-6. The Status Byte Register . . . . . . . . . . . . . . . . . . .

7-1.

7-2.

7-3.

STATus

STATus

STATus

Command Summary ........ ...... ... 7-9

Command Summary ........ ...... ... 7-15

Command Summary ........ ...... ... 7-21

8-1. ABORt Command Summary ................. 8-1

8-2.

DISPlay

Command Summary . . . . . . . . . . . . . . . . . 8-2

8-3. FETCh Command Summary ................. 8-4

8-4. INITiate Command Summary . . . . . . . . . . . . . . . . . 8-7

8-5. READ Command Summary . . . . . . . . . . . . . . . . . . 8-8

8-6.

SENSe

Command Summary . . . . . . . . . . . . . . . . . . 8-10

8-7. ............................... 8-15

8-8.

8-9.

9-1.

G-1.

G-2.

SOURce

SYSTem

PROGram

STATus

STATus

Command Summary ........ ...... ... 8-22

Command Summary ........ ...... ... 8-26

Command Summary . . . . . . . . . . . . . . . . . 9-2

Command Summary ........ ...... ... G-8

Command Summary ........ ...... ... G-9

6-7

6-13

Contents-14

Getting Started

This chapter introduces the features of the HP 8153A and gives you an

opportunity to familiarize yourself with the way you operate the instrument.

The HP 8153A System

The central element of the system is the HP 8153A mainframe.You customize

the instrument using plug-in modules and a changeable ber-connector

interfaces.

1

1

Figure 1-1. The HP 8153A System

Getting Started 1-1

1

A Quick Overview

The Keyboard

Most of the keys have two functions

, depending on the selected mode. Dierent

colors, or whether the legend is on the key or above it, show these dierent

functions.

Figure 1-2. The HP 8153A Keyboard

The

4

5

Chan

key, the

4

Mode

5

key, and the modify keys always have the same

function.

4

Chan

5

Select the channel. The other keys act only on the selected

channel. Channel A corresponds to the module in the left slot.

Channel B corresponds to the module in the right slot.

4

5

Mode

Modify

Keys

Switch between Measure and Menu Mode.

4(5,4)5

5

4+5,4

*

Select the digit or character to edit.

Edit the selected digit or character, or the parameter.

Measure Mode

Measure mode is the mode selected automatically when you switch on the

instrument. In this mode you can set up and make simple measurements.In

measure mode, the black writing on the key shows its function.

4

Param

5

Select the measurement-parameter that you want to view or edit.

1-2 Getting Started

4

Disp!Ref

5

Measure and record the input power-level for use as a reference.

1

4dB5

4

dBm/W

4

Zero

5

5

Display the input power-level relative to a reference.

Switch between dBm and Watt units.

Measure the electrical noise in the instrument, and compensate for

it.

4

5

N Dig

Range Keys

Select the number of decimal places shown in the result.

4

Auto

4Up5

4

Down

5

5

Start or stop automatic ranging.

Select the next higher measuring range.

Select the next lower measuring range.

Menu Mode

In this mode there are pre-programmed routines to perform some common, but

more complicated, measurements. In menu mode, the blue writing above the

key shows the function of the key.

There are some keys whose operation is common to all of the tasks you do in

menu mode.

4

5

gives you access to the parameters for editing.

Edit

5

4

Prev

5

and

step through the items in a menu. For example, these can be

4

Next

dierent types of Record applications, or the dierent parameters for the

system conguration.

4

5

to execute an application, or to nish editing a change of a system

Exec

parameter.

4

5

to pause the running application or to continue a paused application.

Pause

4

System

4

Loss

5

Select system-parameters. This allows you to view or edit the

conguration of the instrument.

5

Select the Loss application. A loss measurement tells you how

much of your optical signal you lose by passing it through a device.

Loss is calculated by the following formula:

P

Loss

=10

To measure loss you need both quantities,P

log

out

(

)

dB

P

in

in

and P

out

. The

application records Pinwhen you start the application. The

instrument expresses all the following results relative to this.

These results are loss results.

Getting Started 1-3

1

4

Record

5

Select from the Stability, Logging, Manual Logging, Plot or Print

applications.

Stability takes samples at evenly spaced intervals for a specied

period.

The parameters for this application are

T_TOTAL

Which sets the total time over which the

measurements are to be made.

AUTODUMP

Which sets whether the results are output to a

printer or plotter when the application nishes.

Logging takes a specied number of samples one immediately

after the other. That is, as soon as the rst sample has ended,

the second starts.

The parameters for this application are

SAMPLES

AUTODUMP

Which sets the number of samples to be taken.

Which sets whether the results are output to a

printer or plotter when the application nishes.

START

Which sets whether the application starts

immediately, or only after the power goes above,or

below, a specied threshold level.

THRESHLD

Which sets the threshold level to be passed before

the application begins.

Manual Logging takes a sample each time the user presses the

4

5

key.

Exec

In addition, the plot and print applications allow you to make

a graphics plot, or a printout from the samples of your record

application.

The parameters for the plot and print applications are

AUTOSCAL

Y_MIN

Y_MAX

COMMENT

4

More

5

Select from the other applications. As standard, the instrument has

Show and Alignment applications.

1-4 Getting Started

Which sets whether the axes are scaled automatically

or not.

Which sets the minimum value for the y-axis.

Which sets the maximum value for the y-axis.

Which allows you to add your own text to the

printout or plot.

The Show application lets you look at the sample values from the

most recent Stability, Logging, or Manual Logging application.

Some simple statistics for the results are also given.

The Alignment application gives you visual, and audible

feedback of the input power, to help you align two components

for the maximum transfer of optical power.

The parameters for this application are

1

TYPE

DELTA

MAXPOWER

The

4

Pause

Which sets whether the maximum transferred

power is determined automatically by the

instrument, or set manually by the user.

Which sets the size of the change in transferred

power indicated on the display, or by the tone.

Which sets expected, or required, maximum

transferred power.

5

key switches on and o the tone.

Getting Started 1-5

1

The Display

The display shows the status and the readings.

Figure 1-3. The HP 8153A Display

Table 1-1. Description of the Display

NNNNNNNN

1

Ch

annel Indicator

Description

Shows the selected channel.

NNNNNNNNNNNNNN

2

Mode

Indicator

Shows the operating mode.

3

Communications

Indicator

NNNNNNNNNNNNNNNNNNNNNNNNNN

TLK ONLY

NNNNNNNNNNNNNNNNNNNNNNNNNN

4

Low Batt

Indicator

1-6 Getting Started

NNNNNNNNNNN

RMT

NNNNNNNNNNN

SRQ

ery

Shows the state of the HP-IB communications.

Remote communications are taking place.

Talk-only selected for the HP-IB.

A service request is pending.

Indicates that the internal battery voltage is

low.

Table 1-1. Description of the Display (continued)

5

Result Field

6

Reference Indicator

A/REF

or

B/REF

A/BorB/A

7

Bar Graph

8

Operation Indicator

AUTO

APPL

EDIT

RUN

PAUSE

eter Indicator

9

NNNNNNNNNNNNNNNNN

Param

CAL

REF

ATT

AUX

10

Character Field

1

Description

This is where the results of tests or

applications are shown.

Shows the reference used for a dB result.

Results relative to a reference.

Results relative to the other channel.

Gives a linear graphical representation of the

result.

Shows the operation type.

The range is being selected automatically.

An application has been selected.

An application parameter is being edited.

An application is running.

An application has been temporarily halted.

shows the type of parameter in the character

eld.

Character eld shows wavelength.

Character eld shows the calibration factor.

T

Character eld shows the averaging time.

Character eld shows the reference level.

Character eld shows the attenuation of the

source.

Auxiliary Parameters.

Used for parameters, and error messages.

Getting Started 1-7

1

A Sample Session

In this sample session you recall the standard setting, take a power

measurement, and then do some data logging.

Hardware Setup

Figure 1-4. Hardware Set Up for the Sample Session

This session assumes that you have a multimeter congured with one source and

one sensor module. The source module is in channel B and the sensor module is

in channel A. Attach the source to the sensor with a piece of optic ber. At the

start of the session, make sure that the instrument is o.

Switching On and Recalling the Standard Setting

1. Set up the instrument as described above.

2. Switch on the instrument. All the display lights, and then the message

SELFTEST

the default power on conditions.

The current channel is channel A.

The instrument is in measure mode.

The source is inactive.

The sensor is reading the optical power at its input. Autoranging is

enabled.

1-8 Getting Started

shows in the character eld in both channels. The following are

Figure 1-5. The Display at the Start of the Sample Session

1

3. Press

4

5

. The instrument goes to menu mode. It shows the

Mode

indicator at the top of the display and the word

at the bottom of the display.

4. Press

4

System

5

. The instrument goes into system mode, it shows the

mode indicator. The character eld shows the message

the display is o.

5. Press

6. Press

4

5

Edit

the message

5

4

Exec

. The instrument shows the

RECALL 0!A

shows in the character eld.

MENU SYS EDIT

to recall the standard setting for channel A. The

indicator shows while the setting is being recalled.

5

7. Press

. The instrument shows the message

4

*

character eld.

5

8. Press

9. Press

to recall the standard setting for channel B.

4

Exec

4

5

to return the instrument to measure mode.

Mode

Making A Power Measurement

Note

Normally, the instrument is left for 20 minutes to warm up.

Maximum accuracy is only possible if the instrument is allowed

to warm up.For this sample session we do not need this

accuracy, so you can go to the next step immediately.

MENU

in the character eld

RECALL

mode indicator and

RUN

RECALL 0!B

MENU

mode

MENU SYS

. The rest of

operation

in the

Getting Started 1-9

1

5

10. Press

4

Param

until theparameter indicator for channel A lights. The

character eld on the left hand side now shows the wavelength for the

sensor. The wavelength of the source shows in the result eld on the right

side. Set the wavelength of the sensor to the wavelength of the source.

5

Use

4*5

4

(

and

5

and

4+5

to select a modiable digit. The modiable digit blinks. Use

4

)

to alter the value of this digit.

Figure 1-6. Editing the Sensor Wavelength

11. Press

4

Zero

ZEROING

5

to remove any electrical osets in the circuitry. The message

is shown in the character eld and

----

shows blinking in the

result eld.

12. Enable the source by pressing the button on its front panel. The green LED

lights to show that the source is now active.

13. The instrument shows the power of the source in the result eld of channel

A, in Watts.

1-10 Getting Started

Figure 1-7. Reading the Power Output by the Source

Logging Data

You will now set up the instrument to record 250 consecutive power readings.

The instrument starts this part with the settings used after the section \Making

aPower Measurement".

1

5

14. Press

MENU.MENU

to change to menu mode. The mode indicator changes to show

4

Menu

is displayed in the character eld.

Figure 1-8. Going into Menu Mode

15. Press

4

Record

5

to choose a record application. The

switches on. The character eld shows

that the character eld shows

LOGGING

STABILTY

.

APPL

operation indicator

. Press

4

Record

Getting Started 1-11

5

again, so

1

5

, the

EDIT

16. Press

the left shows

4

Edit

SAMPLES

operation indicator lights and the character eld on

. The other character eld shows the setting for the

number of samples to be taken.

Use the Modify keys to set the number of samples to 250.

17. Press

18. Press

4

5

Next

it is not, use

4

5

Next

to

IMMEDIAT

, the character eld shows

4*5or4+5

to switch it

. The character eld shows

AUTODUMP

OFF

.

START

. Make sure that it is

Use

4*5or4+5

to set the state

. This means that the logging starts immediately when you

OFF

execute it.

19. Press

4

5

again to get back to the display with

Edit

LOGGING

in the character

eld.

You have now set the parameters for the application. The application takes

a just under a minute to record the values

. While it is running try moving

and twisting the ber to change the power received at the sensor.

20. Press

to start the application. The instrument shows the

4

Exec

RUN

operation

5

indicator. While the application is running, the character eld shows the

number of the sample that is being taken. When the application nishes,

the

RUN

indicator goes out.

Examining the Data

After you have run the Logging application, you can look at the data that has

been recorded. You do this using the Show application.

21. Press

22. Press

. The character eld shows the word

4

More

4

5

. The character eld now shows

Edit

SHOW

MAXIMUM

.

and the value of the

5

highest reading taken during the logging.

.If

23. Press

4

5

. The character eld now shows

Next

lowest reading taken during the logging.

5

24. Press

. The character eld shows

4

Next

highest and lowest readings.

25. Press

4

5

. The character eld shows

Next

readings.

26. Press

4

5

. The character eld shows

Next

To examine all the readings, use the

1-12 Getting Started

DIFF

AVERAGE

#1

4*5

and

MINIMUM

and the value of the

and the dierence between the

and the average of the

and the value of the rst reading.

4+5

.

1

27. When you have nished examining the readings

the display with

SHOW

in the character eld.

, press

5

to get back to

4

Edit

Plotting Data

Now that you have recorded the data, you can plot it on a plotter using the

Hewlett-Packard|Interface Bus (HP-IB).

28. Attach the instrument to a graphics-plotter that has HP-GL capabilities.

Attach the plotter to the HP-IB connector. Do not attach any other device

to this connector at the same time as the plotter. Make sure that the plotter

is congured at address 5.

29. Make sure that the instrument is in T

is in Talk Only mode, the

NNNNNNNNNNNNNNNNNNNNNNNNNN

TLK ONLY

alk Only mode. When the instrument

shows at the top of the display. If the

instrument is not in Talk Only mode use the following procedure to put it

into Talk Only mode

a. Press

b. Press

4

5

System

4

Edit

repeatedly until

5

. The character eld shows the message

HPIB

shows in the character eld.

ADDRESS

and the

HP-IB address of the HP 8153A.

c. Press

d. Use the modify keys to set the HP-IB state to

4

Next

TLK LSTN

5

. The character eld shows the message

is blinking.

TLK ONLY

MODE

.

. The word

e. Press

4

5

to return to the display with

Edit

HPIB

in the character eld.

Figure 1-9. A Plotter Connected to the HP 8153A

Getting Started 1-13

1

30. Press

4

Record

repeatedly, until the message

PLOT

shows in the character

5

eld.

31. Press

4

5

. The character eld shows

Edit

AUTOSCAL

. Use the modify keys to set

this parameter toON. This means that the instrument automatically scales

the plot.

32. Press

4

5

. The character eld shows

Next

COMMENT

. The comment is a message

that prints on the plot. Use the modify keys to enter a comment. Use

and

4)5

to select a character position in your comment. Use

letter and

33. Press

34. Press

The

RUN

4+5

to select a number for your comment.

4

5

to get back to the display with

Edit

4

5

to plot the readings.

Exec

Mode indicator shows while the graph of the results plots

plot has nished the

RUN

indicator switches o.

PLOT

in the character eld.

4*5

. When the

This ends the sample session.

4(5

to select a

1-14 Getting Started

Measure Mode

The default mode at switch-on is Measure Mode. When the instrument is in

measure mode, the mode-indicator shows

MEAS

. In measure mode, the function

of key is shown by the black legend on the key.

The Chan Key

4

5

selects the channel. This can be A or B. The channel- indicator, at the top

Chan

of the display, shows the selected channel.

2

2

Note

When the instrument is under remote operation, this key acts as

Functions in Measure mode apply only to the selected channel.

5

. That is,

4

Local

it returns the instrument to local operation (unless Local Lockout is active).

The Mode Key

4

5

changes the operating mode. If you press this key in measure mode,it

Mode

changes the instrument into menu mode (the next chapter gives a description of

menu mode).

Note

The commands described in this chapter can only be used when

the instrument is in Measure mode.

Local Control - Measure Mode 2-1

2

The Param Key

Use

4

5

to select a measurement-parameters for editing. The parameter-

Param

indicator shows the selected parameter, the character eld shows the value of

the parameter.You can select the next parameter by pressing

4

Param

5

again.

When the hardware does not use a particular parameter, you cannot select it.

When you have selected a parameter, you can edit it using the Modify keys

(described later in this chapter). Some parameters are set by the instrument,

these cannot be edited.

The Applications in Menu mode also use the parameters set in Measure mode.

Entry Status

When you select a parameter, the editable part blinks. The editable part can be

one digit or character, or the whole parameter.You can only edit a parameter,or

a part of a parameter, while it is blinking.

If you do not press any more keys within 10 seconds, the blinking stops and you

are prevented from editing the value.You can enable editing again if you press

any of the Modify keys.

Note

The instrument holds the parameter information in memory

until you edit it. Switching the instrument o does not aect

the parameters.

Default Values

5

If you hold down

4

for 2 seconds or longer, the parameter is set to its

Param

default value.

Parameter List

The parameters and their specications are as follows:

This is the wavelength value. Sometimes, you can set the wavelength to any

value within limits set by the module (for example, for a power sensor). For

other modules, you can choose one wavelength from two possibilities (for

2-2 Local Control - Measure Mode

example, multi-wavelength sources). In other cases, the module sets this value

and you can display the value but you cannot edit it.

2

Display Format

nnnn.n

nm

Limits Depends on the module used.

Resolution 0.1nm

Default Depends on the module used.

CAL

This is a calibration oset that you can enter to compensate for external optical

circuitry. This value is automatically subtracted from the input signal.

P

measured

(

dBm)=P

input

(

dBm)0

CAL(dB

)

Where,

P

measured

P

is the adjusted value of the signal read,

is the input signal level, and

input

CAL is the calibration oset.

Display Format6nnn.nnn

dB

Limits -200.000dBnnn.nnn+200.000dB

Resolution .001dB

Default 0.000dB

When the calibration factor is not set to zero, the

CAL

parameter- indicator stays

on at half brightness.

T

This is the length of time over which a signal is averaged. Longer averaging

times increase the accuracy and improve the noise rejection of the

measurement. Longer averaging times also decrease sensitivity and increase the

length of time between updates of the results on the display.

For averaging times of 1 second or less, a new measurement is shown on the

display at the end of each averaging time. This is drawn in Figure 2-1. A new

measurement is shown on the display at each x.

Local Control - Measure Mode 2-3

2

Figure 2-1. Measurements with T

Average

1 second

For averaging times of more than 1 second, the x value is given by the formula

x

new

=

10T

x

old

T

sample

avg

+

Sample

T

sample

T

avg

Where

x

x

new

old

is the new, displayed result,

is the previously displayed result,

Sample is the value read by the hardware,

T

avg

T

sample

is the averaging time (as set by the user), and

is the time taken, by the hardware, to make a reading.

If the measurement conditions are changed (for example, by a range change in

autoranging) x

is reset, and the averaging starts again. This is why the display

old

update seems faster in autoranging.

Display Format

nnnms,s,

min

Values 20, 50, 100, 200, 500ms, 1, 2, 5, 10, 20, 30s, 1, 2, 5, 10, 15, 20,

30, 60min

Default 200ms

Figure 2-2. Editing the Averaging Time Parameter

2-4 Local Control - Measure Mode

REF

dB results are shown relative to a reference-level. This parameter sets the

reference-level. You can choose the units for the reference using

4

dBm W

5

.

Setting, or changing, the reference only aects results that are displayed in dB.

2

P

display

(dB)=

P

measured

0

REF

Where,

P

display

P

measured

is the displayed, relative power,

is the absolute power-level (see \CAL"), and

REF is the reference.

Logarithmic Units

Display Format6nnn.nnn

dBm

Limits -200.000dBmnnn.nnn+200.000dBm

Resolution 0.001dBm

Default 0.000dBm

Linear Units

Display Format 5 digits pW,nW,W,mW.

Limits 0.001pWn9999.9mW

Resolution see Table 2-1

Default 1000.0W

Local Control - Measure Mode 2-5

2

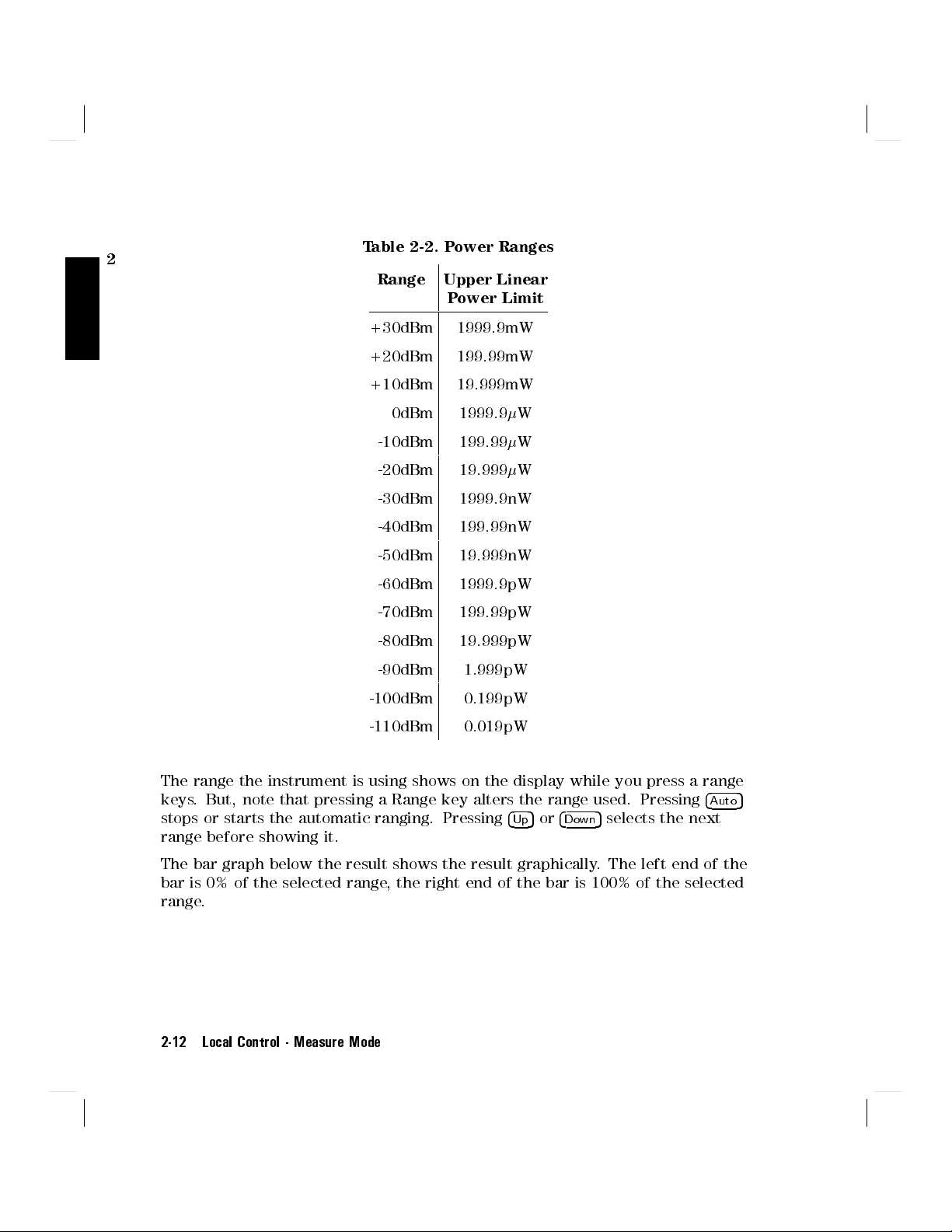

Range Upper Limit

Table 2-1.

Linear Power

Resolution

@T100ms

+30dBm 1999.9mW 100W

+20dBm 199.99mW 10W

+10dBm 19.999mW 1W

0dBm 1999.9W 100nW

-10dBm 199.99W 10nW

-20dBm 19.999W 1nW

-30dBm 1999.9nW 100pW

-40dBm 199.99nW 10pW

-50dBm 19.999nW 1pW

-60dBm 1999.9pW 0.1pW

-70dBm 199.99pW 0.01pW

-80dBm 19.999pW 0.001pW

ATT

The amount of power that is output from a source can be controlled. This

parameter sets the attenuation of an output.

P

output

=

P

source

0

AT T(dB

)

Where,

P

P

is the power-level at the output of the module,

output

is the power-level at the output of the source, and

source

ATT is the attenuation parameter.

Display Format6n.n

dB

Limits 0.0dBn.n6.0dB

Resolution 0.1dB

Default 0.0dB

2-6 Local Control - Measure Mode

AUX

The output amplitude of a source can be modulated by a square wave. This

parameter sets the frequency of the modulation. The modulation can be one of

CW (continuous wave, that is no modulation), 270Hz, 1kHz, or 2kHz.

Values CW, 270Hz, 1, 2kHz

Default CW

The Disp!Ref Key

2

Pressing this key takes the input power-level and stores it as the reference

.

Setting, or changing, the reference in this way only aects results displayed in

dB.

If the display is in dBm or Watts, the measured power-level is stored as the

reference, that is

REF=P

measured

Where,

REF is the reference, and

P

measured

is the absolute power-level (see \CAL").

If the display is in dB, this value is converted to dBm or Watts before being

stored as a reference, that is

REF

new

=

P

display

(dB)+

REF

old

Where,

REF

P

display

REF

is the reference after the key press,

new

is the displayed, relative power, and

is the reference before the key press.

old

Local Control - Measure Mode 2-7

2

The dB Key

This key switches the display to show results in dB

given with respect to another power-level. This can be a stored reference

. Results in dB are always

,orit

can be a second power-level.

Using

4dB5

with a Two Sensor Instrument

For an instrument with two sensors, the dB result can be with respect to the

reference stored for the channel, or it can be with respect to the power-level of

the other channel.

If the result is in dB with respect to the power-level of the other channel,

4dB5

changes the result to dB with respect to the stored reference. The

reference-indicator shows

set the reference you use

A/REForB/REF

5or4

4

Param

P

display

Disp!Ref

(dB)=

.To see the reference , use

5

.

0

P

measured

REF

4

Param

5

.To

Where,

P

display

P

measured

is the displayed, relative power,

is the absolute power-level (see \CAL"), and

REF is the reference.

If the result is in dB with respect to the reference,

4dB5

changes the result to dB

with respect to the power-level in the other channel. The reference-indicator

shows

A/BorB/A

. When the result is with respect to the power-level in the

other channel, the stored reference is also used in the calculation of the

displayed result.

P

display

(dB)=

P

measured

Where,

P

display

P

measured

is the displayed, relative power,

is the absolute power-level (see \CAL"), and

REF is the reference.

If the result is in dBm or Watts,

2-8 Local Control - Measure Mode

0

P

1stChan

5

changes the result to dB.

4

dB

measured

2ndChan

0

REF

Using

4dB5

the stored reference. The reference-indicator shows

reference, use

4dB5

with a One Sensor Instrument

changes the display to show the result as a relative value with respect to

A/REForB/REF

4

5

.To set the reference, use

Param

4

Param

5or4

Disp!Ref

5

.

2

.To see the

P

display

(dB)=

P

measured

0

REF

Where,

P

display

P

measured

is the displayed, relative power,

is the absolute power-level (see \CAL"), and

REF is the reference.

The dBm/W Key

This key changes the display to show results in dBm or in W

5

If the results are in dB,

4

dBm W

changes the display to showing the result as

dBm or Watts.