S

Agilent 81130A 400/660MHz Pulse/Data Generator

Quick Start Guide

S1

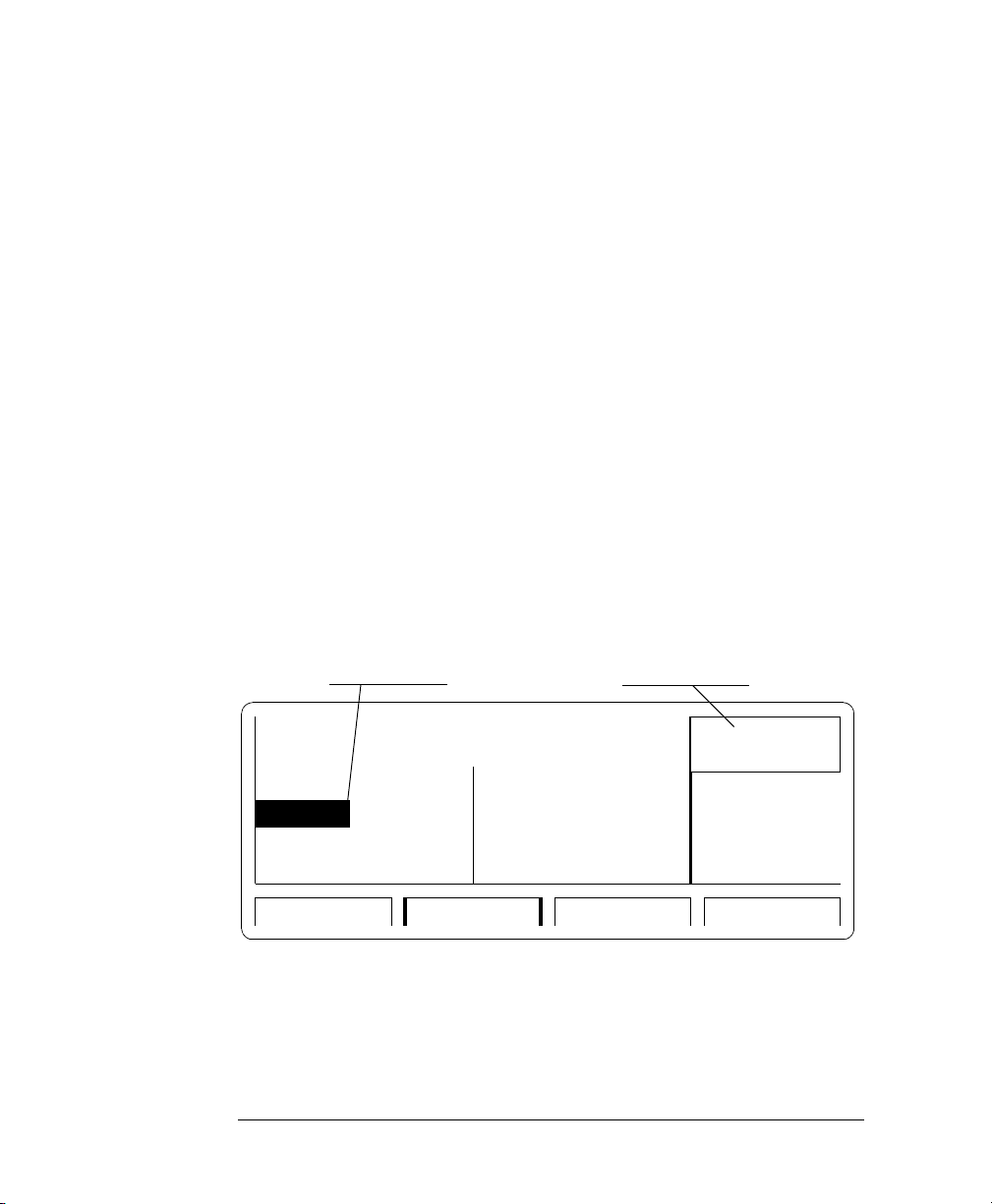

Front Panel Display and Softkeys

Mode / Parameter Area Modify / Enter Area

Use the CURSOR keys to

move the entry focus to a

mode, parameter format,

Channel 1

Column

or

parameter value

Channel 2

Column

Use the KNOB to select a

mode or modify parameters

and formats

Press ENTER or a UNIT key to

confirm parameter changes

ON Freq 50.00MHz OFF

1

OFF OFF

Entry

Focus

Delay

DtyCyc

Press a SOFTKEY to access

the required entry screen

0ps

50.0%

Screen Selection Area

Delay 0ps

Width 100.0ns

TIMING PATTERNLEVELSMODE/TRG

2

MODIFY

50.0

%

GRAPH

MORE

Press MORE key to access

the additional screen menus:

LIMITS TRG-LEV MEMCARD CONFIG

Quick Start Guide

Agilent 81130A 400/660 MHz

Pulse/Data Generator

Part No. 81130-91020

Printed in Germany March 2000

Edition 1.0, E0300

Notice

Notice

Copyright

1998 Agilent Technologies 1998, 2000. All rights reserved.

No part of this manual may be reproduced in any form or by any means

(including electronic storage and retrieval or translation into a foreign

language) without prior agreement and written consent from Agilent

Technologies Inc. as governed by United States and international

copyright laws.

Notice

The material contained in this document is subject to change without

notice. Agilent Technologies makes no warranty of any kind with regard

to this material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Agilent

Technologies shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing,

performance, or use of this material.

Warranty

This Agilent Technologies product has a warranty against defects in

material and workmanship for a period of three years from date of

shipment. During the warranty period, Agilent Technologies will, at its

option, either repair or replace products that prove to be defective. For

warranty service or repair, this product must be returned to a service

facility designated by Agilent Technologies. The Buyer shall pay Agilent

Technologies round-trip travel expenses. For products returned to

Agilent Technologies for warranty service, the Buyer shall prepay

shipping charges to Agilent Technologies and Agilent Technologies shall

pay shipping charges to return the product to the Buyer. However, the

Buyer shall pay all shipping charges, duties and taxes for products

returned to Agilent Technologies from another country.

4

Notice

Agilent Technologies warrants that its software and firmware designated

by Agilent Technologies for use with an instrument will execute its

programming instructions when properly installed on that instrument.

Agilent Technologies does not warrant that the operation of the

instrument software, or firmware, will be uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by the Buyer, Buyer-supplied

software or interfacing, unauthorized modification or misuse, operation

outside of the environmental specifications for the product, or improper

site preparation or maintenance. No other warranty is expressed or

implied. Agilent Technologies specifically disclaims the implied

warranties of merchantability and fitness for a particular purpose.

Exclusive Remedies

The remedies supplied are the Buyer's sole and exclusive remedies.

Agilent Technologies shall not be liable for any direct, indirect, special,

incidental, or consequential damages, whether based on contract, tort or

any other legal theory.

Certification

Agilent Technologies certifies that this product met its published

specifications at the time of shipment. Agilent Technologies further

certifies that its calibration measurements are traceable to the United

States Institute of Standards and Technology, to the extent allowed by

the Institute's calibrating facility, and to the calibration facilities of other

International Standards Organization members.

Services and Support

Any adjustment, maintenance, or repair of this product must be

performed by qualified personnel. Contact your customer engineer

through your local Agilent Technologies Service Center. You can find a

list of local service representatives on the Web at:

http://www.agilent.com/Service/English/index.html

5

Safety Summary

Safety Summary

The following general safety precautions must be observed during all

phases of operation of this instrument. Failure to comply with these

precautions or with specific warnings elsewhere in this manual violates

safety standards of design, manufacture, and intended use of the

instrument. Agilent Technologies Inc. assumes no liability for the

customer's failure to comply with these requirements.

General

This product is a Safety Class 1 instrument (provided with a protective

earth terminal). The protective features of this product may be impaired

if it is used in a manner not specified in the operation instructions.

All Light Emitting Diodes (LEDs) used in this product are Class 1 LEDs

as per IEC 60825-1.

Environmental Conditions

This instrument is intended for indoor use in an installation category II,

pollution degree 2 environment. It is designed to operate at a maximum

relative humidity of 95% and at altitudes of up to 2000 meters. Refer to

the specifications tables for the ac mains voltage requirements and

ambient operating temperature range.

Before Applying Power

Verify that the product is set to match the available line voltage, the

correct fuse is installed, and all safety precautions are taken. Note the

instrument's external markings described under Safety Symbols on

page 8.

6

Safety Summary

Ground the Instrument

To minimize shock hazard, the instrument chassis and cover must be

connected to an electrical protective earth ground. The instrument must

be connected to the ac power mains through a grounded power cable,

with the ground wire firmly connected to an electrical ground (safety

ground) at the power outlet. Any interruption of the protective

(grounding) conductor or disconnection of the protective earth terminal

will cause a potential shock hazard that could result in personal injury.

Fuses

Only fuses with the required rated current, voltage, and specified type

(normal blow, time delay, etc.) should be used. Do not use repaired fuses

or short-circuited fuse holders. To do so could cause a shock or fire

hazard.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or

fumes.

Do Not Remove the Instrument Cover

Operating personnel must not remove instrument covers. Component

replacement and internal adjustments must be made only by qualified

service personnel.

Instruments that appear damaged or defective should be made

inoperative and secured against unintended operation until they can be

repaired by qualified service personnel.

7

Safety Summary

Safety Symbols

Caution (refer to accompanying documents)

Protective earth (ground) terminal

In the manuals:

WARNING

CAUTION

The WARNING sign denotes a hazard. It calls attention to a

procedure, practice, or the like, which, if not correctly performed

or adhered to, could result in personal injury. Do not proceed

beyond a WARNING sign until the indicated conditions are fully

understood and met.

The CAUTION sign denotes a hazard. It calls attention to an operating

procedure, or the like, which, if not correctly performed or adhered to,

could result in damage to or destruction of part or all of the product. Do

not proceed beyond a CAUTION sign until the indicated conditions are

fully understood and met.

8

About this Book

About this Book

This quick start guide helps you to quickly get familiar with the features

and the user interface of the Agilent 81130A Pulse Generator.

Chapter 1 Introducing the Agilent 81130A Pulse and Data Generator

on page 15 gives a general overview of the Agilent 81130A, its features,

the user interface, and the steps required for operating the instrument.

Chapter 2 Getting Started on page 31 gives the setup information for

some real-world signal examples, which can easily be used by varying

only some parameter values.

Chapter 3 Using the Agilent 81130A on page 59 provides complete

information on the user interface screens.

Installation and maintenance are described in Appendix A Installation

& Maintenance on page 99.

For specifications and information on operating the instrument by means

of remote control, please refer to the Reference Guide, p/n 81130-91021.

9

About this Book

Conventions Used in this Book

This book uses certain conventions to indicate elements of the

Agilent 81130As user interface. The following table shows some

examples:

Softkeys Press the MODE/TRG softkey to access the Mode/

Trigger screen.

Hardkeys Press the MORE key to switch to the alternative

softkey layout.

Alternate Keys Press SHIFT + 0 (ON/OFF1) to switch on output 1.

The alternate key labelwhich is selected by

pressing the SHIFT keyis given in parentheses.

Screen Quotes Move the entry focus down to P

turn the knob to select

INTERNAL

ULSE-PERIOD

PLL.

and

Entry Focus The highlight field, that can be moved with the

cursor keys, to change modes, parameters, or

parameter formats.

10

Contents

Notice ......................................................................................... 4

Safety Summary ......................................................................... 6

About this Book ......................................................................... 9

Chapter 1

Chapter 2

Introducing the Agilent 81130A Pulse and

Data Generator

What you can do with the Agilent 81130A ............................ 16

The Front Panel ....................................................................... 18

Operating the Agilent 81130A ................................................ 20

Switching On the Instrument .............................................................. 20

The Basic Screens ................................................................................. 21

Adjusting Parameters ........................................................................... 24

Switching the Outputs On and Off ...................................................... 27

Using the Special Function Keys ........................................................ 27

Help is Available ...................................................................... 29

The Rear Panel ........................................................................ 30

Getting Started

Setting Up a Clock Signal ....................................................... 32

Setting Up a Burst Signal ....................................................... 37

Setting Up a Serial Data Stream ............................................ 41

Setting Up an Edge-Displacement Signal .............................. 46

Setting Up a Serial Data Sequence ........................................ 51

xi

Contents

Chapter 3

Using the Agilent 81130A

The Mode/Trigger Screen ....................................................... 60

Overview ................................................................................................. 60

Continuous Pulses Mode ...................................................................... 63

Continuous Burst Mode ........................................................................ 64

Continuous Pattern Mode .................................................................... 65

Started Pulses Mode ............................................................................. 66

Started Burst Mode ............................................................................... 67

Started Pattern Mode ............................................................................ 68

Gated Pulses Mode ................................................................................ 69

Gated Burst Mode ................................................................................. 70

Gated Pattern Mode .............................................................................. 71

The Timing Screen .................................................................. 72

The Levels Screen ................................................................... 76

The Pattern Screen ................................................................. 79

The Segment Editor .............................................................................. 83

Block Editing Functions ....................................................................... 85

The Limits Screen ................................................................... 86

The Trigger-Level Screen ....................................................... 87

The Memory Card Screen ....................................................... 89

The Configuration Screen ...................................................... 92

The Output Screens ................................................................ 95

Warnings and Errors .............................................................. 96

xii

Contents

Appendix A

Installation & Maintenance

Initial Inspection ................................................................... 100

Standard Deliverables ........................................................................ 101

Options and Accessories: ................................................................... 102

Power Requirements ............................................................. 104

Power Cable ........................................................................... 106

Ventilation Requirements ..................................................... 107

Thermal Protection ............................................................................. 107

Battery ................................................................................... 108

Battery Replacement .......................................................................... 109

Operating Environment ........................................................ 110

Cleaning Recommendation ................................................... 111

Acoustic Noise Emission ....................................................... 112

xiii

Contents

xiv

1Introducing the

Agilent 81130A Pulse and

1

Data Generator

The purpose of the introduction chapter is to give a general overview of

the Agilent 81130A.

The main features and use models are described in What you can do

with the Agilent 81130A on page 16.

Operating the instrument via the front panel user interface is described in

The Front Panel on page 18 and Operating the Agilent 81130A on

page 20.

Help is Available on page 29 shortly introduces the Agilent 81130As

on-line help system.

Finally, The Rear Panel on page 30 takes a look at the back of the

Agilent 81130A.

15

Introducing the Agilent 81130A Pulse and Data Generator

What you can do with the Agilent 81130A

What you can do with the

Agilent 81130A

This section introduces the basic features and use models of the

Agilent 81130A Pulse Generator.

Basic Features

The Agilent 81130A is a pulse and data generator with one or two output

channels. It is capable of generating all standard pulses, bursts, and

patterns of pulses needed to test current logic technologies (for example,

TTL, CMOS, ECL, PECL) and other digital designs up to 400 MHz/3.8V or

660 MHz/2.5V, depending on the installed output module(s).

The instrument features

placement accuracy and accurate delay and deskew even at maximum

output frequency. This contributes to reliable measurements and more

accurate and confident characterizations of the device under test (DUT).

The instrument uses an accurate and stable

For even more accuracy, it can be connected to an

reference

For programming complex

packages, 64 kbit memory are available to store individual patterns. Each

pattern can consist of up to four segments. Loops can be programmed

over single segments or groups of consecutive segments. The segments

can include

.

pseudo-randomly generated data

precision timing

data patterns

, providing highest edge

internal PLL oscillator

external frequency

, such as communication

.

.

If the Agilent 81130A is equipped with two output modules, the output

channels can be used separately or be

signals.

Complete signal setups can be stored locally (5 internal non-volatile

registers available) or on a

16

memory card

added

digitally to form complex

.

Introducing the Agilent 81130A Pulse and Data Generator

What you can do with the Agilent 81130A

Benchtop Testing

The Agilent 81130A features a graphic display showing all pulse

parameters at a glance. The cursor keys and the modify knob allow fast

and simple operation.

The user interface is designed to minimize the time invested in getting

familiar with the instrument. After familiarization, the instrument

supports quick setups of signals. This leaves you free to concentrate on

the measurement task and testing of the DUT.

Automated Testing

The Agilent 81130A features an GP-IB/SCPI-conform command structure

for all features. Using this programming interface, the instrument can be

easily integrated into all phases of test system development such as

planning rack integration and test program generation.

Programs designed for the Agilent 81130A are compatible with all other

models of the Agilent 81100 family.

NOTE

For a command reference list, please refer to the Reference Guide, part

number 81130-91021.

Upgrade Capability

It is possible to upgrade the instrument with a second channel if only one

channel has been ordered originally. There are two types of output

modules available for the Agilent 81130A. You can only use one type of

output module within one instrument.

Output Module Description

Agilent 81131A 400 MHz, 3.8 V

Agilent 81132A 660 MHz, 2.5 V

17

Introducing the Agilent 81130A Pulse and Data Generator

The Front Panel

The Front Panel

When used for benchtop testing, the instrument is mainly operated from

the front panel.

Front Panel

Switch

NOTE

Special Function

Keys

Softkeys

front panel switch

The

When the front panel switch is off, the instrument is in standby mode.

The instrument is disconnected from the AC line power only by

disconnecting the power cord.

The four keys below the display are the

keys). The current function of each softkey is indicated in the

corresponding box on the display.

Pressing the MORE key changes the softkey layout.

The other keys (

and the

operating the instrument (see Operating the Agilent 81130A on

page 20).

rotary knob

MORE Key

is used to switch on and off the instrument.

special function keys, data entry keys, cursor keys

are used to select and modify parameters when

Data Entry

Keys

Inputs and Outputs

softkeys

Cursor

Keys

(software-controlled

Rotary

Knob

)

18

Introducing the Agilent 81130A Pulse and Data Generator

The major inputs and outputs of the instrument are available at the front

panel:

The external input (EXT INPUT) can be used to connect an external

arming source (started or gated modes). For details, please refer to

The Mode/Trigger Screen on page 60.

The clock reference input (CLK/REF INPUT) can be used to connect

either an external clock signal or a reference signal for the internal

PLL (see Pulse Period Source on page 94 and PLL Reference on

page 94).

The trigger signal (TRIGGER OUT) marks the start of the pulse

period or of parts of a pattern (see The Mode/Trigger Screen on

page 60). You can set the output levels according to the used

technology (TTL, ECL, PECL) or enter test-specific values (see The

Trigger-Level Screen on page 87).

The OUTPUT connectors provide the signal output (normal and

inverted), the indicators show the current state of the output (on or

off).

The Front Panel

NOTE

For information on the use of the memory card slot, refer to The

Memory Card Screen on page 89.

19

Introducing the Agilent 81130A Pulse and Data Generator

Operating the Agilent 81130A

Operating the Agilent 81130A

This section guides you through the first steps when operating the

Agilent 81130A via the user interface.

NOTE

For information on operating the Agilent 81130A via remote control,

please refer to the Reference Guide, part number 81130-91021.

Switching On the Instrument

After switching on the instrument the display indicates that the

instrument selftest is running. This can take several seconds to complete.

If the selftest fails, you see a flashing E at the bottom of the screen. Press

the HELP key to see a list of the selftest error messages. Use the knob or

the cursor keys to scroll through the list if necessary.

To return to normal operation press HELP again. Note that the selftest

error messages are removed from the error queue after this.

20

Introducing the Agilent 81130A Pulse and Data Generator

Operating the Agilent 81130A

The Basic Screens

The major parameters for pulse generation can be set up in 3 screens.

For setting up patterns there are two more basic screens.

Mode/Trigger screen

The

and trigger modes with respect to the signal required.

allows you to set the fundamental operating

Press the MODE/

TRG softkey to

access this screen.

CONTINUOUS

PULSES

MODIFY

*Continous

Started

Gated

TIMING PATTERNLEVELSMODE/TRG

In this screen, you can set up the signal to be gated, started or

continuous, and to be a pulse stream, a burst (several pulses followed by

a pause) or a pattern.

In the lower section you can specify the trigger source and control the

trigger output (in started and in gated mode).

21

Introducing the Agilent 81130A Pulse and Data Generator

Operating the Agilent 81130A

OFF OFF

1

OFF OFF

Delay

Width

LeadE 0.8ns

TraiE =LeadE

0ps Delay 0ps

100.0ns

TIMING PATTERNLEVELSMODE/TRG

Timing Screen

Press the TIMING

OR

LEVELS softkey

to access these

screens.

Timing screen

The

and the

Levels screen

allow you to specify timing

and level parameters for the signals to be generated.

1.000

sPer

µµµµ

Width 100.0ns

LeadE 0.8ns

TraiE =LeadE

2

MODIFY

ON OFF

1.000

1

OFF OFF

Separate Outputs

s

µµµµ

High

Low

+2.50V

+0.0MV

TIMING PATTERNLEVELSMODE/TRG

2

Offset 0.0MV

Amplit 1.00V

MODIFY

+2.50

V

M

Levels Screen

In the Timing screen you can set up the clock frequency and, for output 1

and 2, the timing for the signals (delay, pulse width, duty cycle, ...).

The Levels screen allows you to specify the level parameters for the

signals to be generated. You can select between preset values of different

technologies and/or adjust values according to individual requirements.

Set the values in terms of high/low level or offset/amplitude. If the

Agilent 81130A is equipped with two output modules, the channels can

be set as separate outputs or to be digitally added.

Pressing SHIFT + MORE (GRAPH) when the Timing or the Levels screen is

displayed, toggles between the textual display and a graphical

representation of the parameters.

1

OFF

OFF

2

OFF

OFF

TIMING PATTERNLEVELSMODE/TRG

Width

100.0

ns

In both screens, you can switch on and off the outputs. Their status (ON

or OFF) is indicated on screen and by an LED next to the output

connector.

22

Introducing the Agilent 81130A Pulse and Data Generator

Pattern screen

The

consisting of up to 4 segments. You can specify the length of each

individual segment and then compose the sequence by specifying a reentrance point (where the instrument resumes after the end of the

sequence) and/or a loop over consecutive segments.

allows you to compose a pattern sequence

Operating the Agilent 81130A

Segment

Select

Resume

Indicator

(in gated/started

mode only)

Loop

Indicator

Segment Length Loopcnt Update

1

32 1

2 0

3 0

4 0

TIMING PATTERNLEVELSMODE/TRG

To set up the data of a segment, you call the

the segment to be edited and pressing the ENTER key.

Segment 1

Address 1

CH1 Data 1 0 0 0 0 0 0

UPDATE

Length 32

1

segment editor

CH2 Data 0 0 0 0 0 0 0

Both 1 0 0 0 0 0 0

ENTER

*Edit Segm

by selecting

= ADDR

0 to Reset

1 to Set

Toggle

±±±±

TIMING PATTERNLEVELSMODE/TRG

Per channel you can select from different predefined data formats (such

as high, or low, or pseudo-random data segment), you can enter data by

using block editing functions, and you can enter the data bit by bit.

23

Introducing the Agilent 81130A Pulse and Data Generator

Operating the Agilent 81130A

Adjusting Parameters

Adjusting parameters within a screen, requires two steps:

selecting the parameter

adjusting its value

Some parameters allow different formats of their values. For example,

the pulse width can be displayed and entered as an absolute value, as

duty cycle (percentage of the period), or as the delay of the trailing edge.

The following sections show the standard procedure for adjusting

parameters, and list some features useful for the advanced user.

Standard Procedure

To experience the standard procedure for adjusting parameters, consider

the following example where the duty cycle is set to 50%.

1

Press the TIMING softkey to access the Timing screen.

2

Use the cursor keys to select the W

parameter.

IDTH

Selection Modify/Enter Area

OFF Per 1.000 µs OFF

1

OFF OFF

Delay

Width

0ps

100.0ns

Delay 0ps

Width

2

100.0ns

MODIFY

*Width

DutyCycle

TrailDel

TIMING PATTERNLEVELSMODE/TRG

The available formats for the pulse width parameter are displayed in

the Modify/Enter area.

24

Introducing the Agilent 81130A Pulse and Data Generator

Operating the Agilent 81130A

When changing the

parameter format,

the instrument

automatically

recalculates the

value.

3

Turn the knob to select D

The selected setting is indicated by an *.

4

Move the cursor to the right to select the duty cycle value.

5

Use the data entry keys or the knob to enter the required value: 50.

6

Press the ENTER key to confirm your selection.

UTYCYCLE

.

ON Per 1.000µs OFF

1

OFF OFF

Delay

DtyCyc

0ps

50.0%

Delay 0ps

Width 100.0ns

2

MODIFY

50.0

%

TIMING PATTERNLEVELSMODE/TRG

If you need to specify a unit for a parameter, simply press the appropriate

unit key (

With this small example, you have learned the basic steps required for

adjusting parameters. For a complete reference of parameters and

formats available in the individual screens, refer to Chapter 3 Using the

Agilent 81130A on page 59.

NANO, MICRO/MEGA, MILLI/KILO

) instead of the ENTER key.

25

Introducing the Agilent 81130A Pulse and Data Generator

Operating the Agilent 81130A

Advanced Procedures

The following features can be used to make operation more comfortable.

Selecting parameters

SHIFT

SHIFT

SHIFT

NOTE

Most keys of the front panel have an additional function. The SHIFT

key provides fast access to the additional functions of the data entry

keys and the special function keys.

For example, it is possible to quickly access the pulse width

parameter by pressing SHIFT + 6 (WIDTH). The entry focus will be

positioned on the corresponding editing field.

Changing the step size

When modifying a value in the Modify/Enter area, pressing the SHIFT

key followed by cursor left/right moves the cursor to a different digit

in the displayed number.

Thus, you can change the step size for parameter change before you

vary the value either with the up/down cursor keys or the knob.

Overprogramming

Pressing the SHIFT key while turning the knob, it is possible to exceed

specified parameter ranges to utilize the instrument to its limits.

Proper operation of the instrument outside of the specified ranges is not

guaranteed. It is recommended to have the output switched on when

overprogramming to have the internal error check system activated. This

error check system warns you about impossible settings.

26

ON/OFF1

0

Introducing the Agilent 81130A Pulse and Data Generator

Operating the Agilent 81130A

Switching the Outputs On and Off

When you switch the instrument on, the outputs and inverted outputs are

switched off to protect the device under test. The LED indicator next to

the connector indicates the output state.

For example, to switch output 1 on or off

either press SHIFT + 0 (ON/OFF1),

or move the cursor to the ON/OFF parameter in the Timing or Levels

screen and select the appropriate value by turning the knob.

To switch on or off output 2 and/or the inverted outputs, proceed in the

same way. You can use the following short cuts:

Short Cut Output

SHIFT + 0 (ON/OFF1) Normal Out 1

MAN

RECALL

STORE

SHIFT + . (decimal point) (ON/OFF1

SHIFT + +/- (ON/OFF2) Normal Out 2

SHIFT + ENTER (ON/OFF2

) Inverted Out 2

) Inverted Out 1

Using the Special Function Keys

The instrument provides the following special function keys:

The MAN key can be used to run and to stop the instrument, and, in

triggered or gated mode, to manually arm and/or trigger the

instrument if there is no other source available (see The Mode/

Trigger Screen on page 60).

The STORE key can be used to store/recall to/from 1 to 4 individual

settings in the instrument memory.

In the internal memory location 0 there is a default setting stored.

Pressing SHIFT + STORE (RECALL) and selecting 0 resets the instrument to

the default setting.

27

Introducing the Agilent 81130A Pulse and Data Generator

Operating the Agilent 81130A

SHIFT

LOCAL

HELP

The SHIFT key provides fast access to additional functions.

When the front panel controls are locked in remote control, pressing

the SHIFT key unlocks the front panel controls.

The HELP key provides access to the instruments on-line help or in

warning or error state, access to Warning/Error Report screen.

Pressing SHIFT + HELP (AUTOSET) sets the instrument to a valid

setting based on the current period setting.

28

Help

Introducing the Agilent 81130A Pulse and Data Generator

Help is Available

Help is Available

Whenever you are in doubt or the instrument signals warnings or errors,

press the HELP key.

If there are no warnings or errors pending, pressing the HELP key

displays information on the currently selected parameter, the parameter

help. More information is available within the help system:

Parameter Help

The help information gives a short description of the parameter or

setting options and the corresponding SCPI command(s) syntax for

programming the parameter or setting.

If there is more than one screen available (indicated by small arrows),

use the knob or the cursor keys to scroll through the help

information.

To access parameter help from other screens of the help system,

press the ON FIELD softkey.

Warnings and

Errors

Exit Help

Concept Help

Pressing the CONCEPT softkey within the help system displays a short

description of the instrument.

Serial Numbers and Software Revision

Pressing the SERIAL # softkey within the help system displays

information on serial numbers and software revision codes of the

instrument.

If there are warnings or errors pending (indicated by a flushing W or E),

pressing the HELP key displays a list of the current messages. Using the

ERROR QU and WARNING softkeys, you can toggle between both lists. For

more information on warnings and errors, see Warnings and Errors on

page 96.

To exit from the help system, press the HELP key again, or press the EXIT

HELP softkey.

29

Introducing the Agilent 81130A Pulse and Data Generator

The Rear Panel

The Rear Panel

The rear panel always provides two connectors:

The external input (EXT INPUT) can be used to connect an external

arming source (started or gated modes).

The input connector for external clock or PLL reference (CLOCK/

REF INPUT) can be used if a higher frequency accuracy is required.

The GP-IB connector providing the interface for remote control.

The following figure shows the rear panel view with the option UN2.

CLK/REF InputExternal Input GP-IB Connector

Inputs and Outputs

With option UN2 the major inputs and outputs of the instrument (as

described in The Front Panel on page 18) are available at the rear

panel:

external input (EXT INPUT)

clock/reference input (CLK/REF INPUT)

trigger signal (TRIGGER OUT)

signal output (OUTPUT)

30

Fuse Holder

AC Line Socket Serial Number

2

2Getting Started

The intention of this chapter is to give the necessary steps to set up

generic signals for first-time users of the Agilent 81130A.

This chapter provides examples for the following types of signals:

Setting Up a Clock Signal on page 32

Setting Up a Burst Signal on page 37

Setting Up a Serial Data Stream on page 41

Setting Up an Edge-Displacement Signal on page 46

Setting Up a Serial Data Sequence on page 51

At the end of each example, the required set of device commands is listed

to provide programming examples. For further information on the

commands and a complete command reference please refer to the

Reference Guide, p/n 81130-91021.

The examples are intended to be performed one after the other.

Therefore, the first example provides the most detailed instructions,

while the other examples are described on a higher level.

31

Getting Started

Setting Up a Clock Signal

Setting Up a Clock Signal

Ta sk

Instructions

Set up a continuous clock signal with 50 MHz frequency, a duty cycle of

50 %, a high level of 2.5 V and a low level of 0 V.

Duty Cycle = 50 %

2.5 V

0.0 V

f = 50 MHz

To set the

1

Reset all parameters and modes by pressing SHIFT + STORE (RECALL) + 0.

2

Press the MODE/TRG softkey to enter the Mode/Trigger screen.

Trigger mode CONTINUOUS and operating mode PULSES are

selected by default.

CONTINUOUS

operating mode and trigger mode

PULSES

as required:

MODIFY

*Continous

Started

Gated

32

TIMING PATTERNLEVELSMODE/TRG

Setting Up a Clock Signal

Getting Started

To set the

1

Press the TIMING softkey to enter the Timing screen.

2

Press SHIFT + 0 (ON/OFF1).

This turns on the Output 1 and activates the internal error check to

detect parameter conflicts.

3

Move the entry focus to P

4

Move the entry focus to the right (to the frequency entry field) and

enter a value of 50 MHz by pressing 5 + 0 +

A warning is displayed, indicating a potential conflict in your settings.

The conflict will be solved in the next steps.

5

If you want to view the warning message, press the HELP key. Return

by pressing the HELP key again.

6

Move the entry focus down left to W

D

7

Move the entry focus to the right and enter 50 % by typing 5 + 0 +

ENTER.

Delay

DtyCyc

timing parameters

UTYCYC

.

as required:

and turn the knob to select F

ER

ON Freq 50.00MHz OFF

1

OFF OFF

0ps

50.0%

Delay 0ps

Width 100.0ns

MICRO/MEGA

of output 1 and select

IDTH

.

2

REQUENCY

MODIFY

50.0

.

%

TIMING PATTERNLEVELSMODE/TRG

33

Getting Started

Setting Up a Clock Signal

8

Press SHIFT + MORE (GRAPH) or the TIMING softkey to see a preview of

your signal.

1

ON

OFF

2

OFF

OFF

You can modify the parameter displayed in the Modify/Enter area,

and immediately check how your changes affect the signal. Use the

cursor keys to switch to another parameter.

9

Press SHIFT + MORE (GRAPH) or the TIMING softkey to return to the

textual screen.

To set the

TIMING PATTERNLEVELSMODE/TRG

level parameters

DutyCyc1

50.0

%

as required:

1

Press the L

2

Move the entry focus to O

turn the knob to select H

3

Move the entry focus to the L

ENTER key. In the same way, enter 2.5 V for the high level.

softkey to enter the Levels screen.

EVELS

FFSET/AMPLIT

IGH-LOW

OW

in the output 1 column and

.

entry field, enter 0 and press the

ON OFF

1

OFF OFF

2

Separate Outputs

High

Low

+2.50V

+0.0MV

Offset 0.0MV

Amplit 1.00V

TIMING PATTERNLEVELSMODE/TRG

34

MODIFY

+2.50

M

V

Setting Up a Clock Signal

Getting Started

NOTE

There is also a graphical screen available for the level parameters.

Here is the signal as displayed on an Agilent 54810A Infinium

oscilloscope. Use the generators TRIGGER OUT to trigger the scope.

35

Getting Started

Setting Up a Clock Signal

Programming

Example

If you want to include this clock signal in your GP-IB program, use the

following command lines. The comment lines starting with a # are not

required.

# Reset the instrument to start from a defined, default status.

*RST

# Switch off the automatic display update to increase programming

# speed.

:DISPlay OFF

# Internal PLL has to be set as period source.

# Set the frequency to 50 MHz and the duty cycle to 50 %

:FREQuency 50 MHZ

:PULSe:DCYCle 50

# Set the high level to 2.5 Volts, the low level to 0.0 Volts.

:VOLTage:HIGH 2.5V

:VOLTage:LOW 0V

# Enable the output.

:OUTPut ON

36

Setting Up a Burst Signal

Setting Up a Burst Signal

Getting Started

Ta sk

Instructions

Set up a burst signal with a burst repetition of 4 clocks. Each burst

consists of two pulses at a period of 100 ns. The pulse width is 25 ns. The

levels are 2 Vpp amplitude and 0 V offset. On the second channel the

clock reference is generated. The signals are issued while the MAN key is

pressed.

Pulse Width = 25 ns

1 V

Output 1

Burst Signal

Output 2

Clock Signal

To set the

Trigger

Out

0 V

1 V

Pulse Period = 100 ns

1 V

0 V

1 V

Burst Period = 4 clocks

operating mode and trigger mode

as required:

1

Reset all parameters and modes by pressing SHIFT + STORE + 0.

2

Press the MODE/TRG softkey to enter the Mode/Trigger screen.

3

Move the entry focus to CONTINUOUS and turn the knob to select

G

.

ATED

4

Move to PULSES and select BURST

5

Move to PULSES OUT 1 and select 2.

6

Move to OUT 2 and select 4.

OF

.

37

Getting Started

Setting Up a Burst Signal

7

Move to BURST PERIOD and select 4 clocks.

8

Move to GATED BY and select M

9

Move right and select H

GATED

BURST of

IGHLEVEL

Pulses Out 1: 2 Out2: 4

Burst Period: 4 Clk

Gated by:

MAN Key

AN KEY

.

.

RUN

MODIFY

*HighLevel

LowLevel

TIMING PATTERNLEVELSMODE/TRG

To set the

1

Press the TIMING softkey to enter the Timing menu.

2

Switch on both outputs.

3

Enter a pulse period of 100

A warning is shown, which you may ignore because the parameter

conflict will be solved in the next steps.

4

In the output 1 column, enter a W

timing parameters

as required:

.

NS

IDTH

of 25NS.

5

In the output 2 column, move to W

value of 50 %.

ON Per 100.0ns OFF

1

OFF OFF

Delay

Width

0ps

25.00ns

Delay 0ps

DtyCyc 50.0 %

TIMING PATTERNLEVELSMODE/TRG

38

IDTH

, select D

2

UTYCYLE

, and enter a

MODIFY

50.0

%

Setting Up a Burst Signal

Getting Started

To set the

1

Press the LEVELS softkey to enter the Levels menu.

2

Enter an amplitude of 2.00 V for both outputs.

1

Offset

Amplit

The following figure shows the signals as displayed on the

Agilent 54810A Infinium Oscilloscope if the MAN key is pressed. Use the

generators TRIGGER OUT to trigger the scope.

level parameters

ON OFF

OFF OFF

Separate Outputs

+0.0MV

2.00V

as required:

Offset +0.0MV

Amplit

TIMING PATTERNLEVELSMODE/TRG

2.00V

2

MODIFY

2.00

V

39

Getting Started

Setting Up a Burst Signal

Programming

example

If you want to include this burst signal in your GP-IB program use the

following command lines. The comment lines starting with a # are not

required.

# Reset the instrument to start from a defined, default status.

*RST

# Switch off the automatic display update to increase programming

# speed.

:DISPlay OFF

# Set the instrument to gated and set burst mode by selecting a

# burst count of 4.

:ARM:SOURce MAN

:ARM:MODE:GATed

:TRIGger:COUNt 4

# Set 2 pulses per burst for channel 1 and 4 pulses per burst for

# channel 2.

:TRIGger:COUNt:PULSes1 2

:TRIGger:COUNt:PULSes2 4

# Set the pulse period 100 ns, the width of channel 1 to 25 ns

# and the duty cycle of channel 2 to 50%.

:PULSe:PERiod 100NS

:PULSe:WIDTh1 25NS

:PULSe:HOLD2 DCYCLe

:PULSe:DCYCLe2 50

# Set the output amplitudes to 2 Volts and the offsets to

# 0 Volts.

:VOLTage1 2V

:VOLTage2 2V

:VOLTage1:OFFSet 0V

:VOLTage2:OFFSet 0V

# Enable the outputs.

:OUTPut1 ON

:OUTPut2 ON

40

Setting Up a Serial Data Stream

Getting Started

Setting Up a Serial Data Stream

Ta sk

Instructions

Set up a 24 bit long pattern with NRZ data output format, 80 MBit/s, and

ECL output level.

To set the

1

Reset all parameters and modes by pressing SHIFT + STORE + 0.

2

Press the MODE/TRG softkey to enter the Mode/Trigger screen.

3

Move to PULSES and select PATTERN.

4

Move to the PULSES OUT 1 entry field and select NRZ.

5

Set T

CONTINUOUS PATTERN of

Pulses Out 1:

PRBS Polynom: 2^7-1

operating mode and trigger mode

RIGGER OUTPUT AT

NRZ

: to S

1 S

EGM

TART

Out 2: RZ

as required:

.

MODIFY

Clock

*Segment1

Segment2

Trigger Output at:

Segm1 Start

Segment3

TIMING PATTERNLEVELSMODE/TRG

41

Getting Started

Setting Up a Serial Data Stream

NOTE

To set the

1

Press the TIMING softkey to enter the Timing menu.

2

Switch on the Output 1.

3

Enter a frequency of 80 MHz.

1

Delay

Width

timing parameters

as required:

OFFON Freq 80.00MHz

OFF OFF

0ps

------

Delay 0ps

Width

100.0ns

2

MODIFY

80.00

MHz

TIMING PATTERNLEVELSMODE/TRG

You cannot enter a pulse width because of the NRZ setting. This is

indicated by the dashes in the W

To set the

1

Press the LEVELS softkey to enter the Level menu.

2

In the output 1 column, move the entry focus to OFFSET/AMPLIT and

select S

level parameters

ECL.

ET

as required:

entry field.

IDTH

42

Setting Up a Serial Data Stream

Getting Started

NOTE

To set up the

1

Press the PATTERN softkey to enter the Pattern menu.

2

Move the entry focus to the length entry of segment 1 and enter 24.

3

To start editing the data for the pattern, select 1 in the Segment

column and press the ENTER key.

4

Move to the first data of channel 1, as shown in the figure:

Segment 1 UPDATE

Address 1

CH1 Data 0 0 0 0 0 0

CH2 Data 0 1 0 0 0 0 0

Both 1 2 0 0 0 0 0

data pattern

as required:

Length 24

1

= ADDR

0 to Reset

1 to Set

Toggle

±±±±

TIMING PATTERNLEVELSMODE/TRG

5

Enter the following pattern using the 0 and 1 keys:

111001110011001001010010.

You can use the knob to scroll through the data of the segment.

43

Getting Started

Setting Up a Serial Data Stream

The following figure shows the signals as displayed on the

Agilent 54810A Infinium Oscilloscope. Use the generators

TRIGGER OUT to trigger the scope.

44

Setting Up a Serial Data Stream

Getting Started

Programming

example

If you want to include this data stream signal in your GP-IB program use

the following command lines. The comment lines starting with a # are not

required.

# Reset the instrument to start from a defined, default status.

*RST

# Switch off the automatic display update to increase programming

# speed.

:DISPlay OFF

# Enable pattern mode and set data format of channel 1 to NRZ

:DIGital:PATTern:STATe ON

:DIGital:SIGNal:FORMat NRZ

# Set data pattern of segment 1, channel 1. The leading two

# digits “#0” are control information. The data pattern

# starts at the third digit.

:DIGital:PATTern:SEGMent1:DATA1 #0111001110011001001010010

# Set frequency to 80 MHz and levels to ECL levels.

:FREQency 80MHz

:VOLTage1:HIGH -0.8V

:VOLTage1:LOW -2V

# Enable the output.

:OUTPut ON

45

Getting Started

Setting Up an Edge-Displacement Signal

Setting Up an Edge-Displacement

Signal

Ta sk

NOTE

Set up a continuous signal with one distorted pulse. The two channels

are added with NRZ at both outputs. The high level is 1 V, low level is 0 V.

The delay of output 2 is 30 ns and the bit frequency is 30 MHz.

For this example, both outputs and the channel addition feature are

required. Therefore, this type of signal can only be performed with a

Agilent 81130A with two output modules (Agilent 81131A or Agilent

81132A).

Channel 1

Channel 2

Signal at

Output 1

Signal at

Output 2

f = 30 MHz

10100010

00001000

Delay of Output 2

1.0 V

0.0 V

0.5 V

-0.5 V

NRZ Data Format

46

Setting Up an Edge-Displacement Signal

Getting Started

Instructions

To set the

1

Reset all parameters and modes by pressing SHIFT + STORE + 0.

2

Press the MODE/TRG softkey to enter the Mode/Trigger screen.

3

Move the entry focus to PULSES and select PATTERN.

4

Set P

operating mode and trigger mode

ULSES OUT

1 and OUT 2 to NRZ.

as required:

CONTINUOUS PATTERN of

Pulses Out 1:

NRZ

PRBS Polynom: 2^7-1

Out 2: NRZ

RZ

R1

*NRZ

Trigger Output at: Segm1 Start

TIMING PATTERNLEVELSMODE/TRG

To set the

1

Press the TIMING softkey to enter the Timing menu.

2

Enter a frequency of 30 MHz.

timing parameters

as required:

MODIFY

NOTE

3

Enter a D

OFF Freq 30.00MHz OFF

1

OFF OFF

Delay

Width

of 30NS for Output 2.

ELAY

0ps

------

2

Delay 30.00ns

Width ------

MODIFY

10.00

ns

TIMING PATTERNLEVELSMODE/TRG

You cannot enter a pulse width because of the NRZ setting. This is

indicated by the dashes in the W

entry field.

IDTH

47

Getting Started

Setting Up an Edge-Displacement Signal

To set the

1

Press the PATTERN softkey to enter the Pattern menu.

2

Enter a L

3

Move the entry focus to left and press the ENTER key to edit

Segment 1.

4

Enter the pattern 10100010 for Channel 1.

5

Enter the pattern 00001000 for Channel 2.

Segment 1

Address 8

CH1 Data 0 0 1 0

CH2 Data 1 0 0

Both 2 0 1 0

data pattern

of 8 for Segment 1.

ENGTH

as required:

UPDATE

Length 8

0

0 to Reset

1 to Set

±±±±

Toggle

TIMING PATTERNLEVELSMODE/TRG

To set the

1

Press the LEVELS softkey to enter the Level menu.

2

Switch on both outputs.

level parameters

as required:

= ADDR

3

Change S

4

Set H

5

Set H

1

High

Low

48

EPARATE OUTPUTS

IGHLEVEL

IGHLEVEL

to 1 V and LOWL

to 0.5 V and LOWL

to DIG.

EVEL

ADD AT OUT

to 0 V for output 1.

to 0.5 V for output 2.

EVEL

ON ON

OFF OFF

Dig. add at Out 1

+1.00V

+0.0MV

High

Low

+500mV

-500mV

TIMING PATTERNLEVELSMODE/TRG

2

1.

-500

MODIFY

V

M

Setting Up an Edge-Displacement Signal

The following figure shows the signal as displayed on the Agilent 54810A

Infinium Oscilloscope. Use the generators channel 2 to trigger the scope.

Getting Started

49

Getting Started

Setting Up an Edge-Displacement Signal

Programming

example

If you want to include this edge-displacement signal in your GP-IB

program, use the following command lines. The comment lines starting

with a # are not required.

# Reset the instrument to start from a defined, default status.

*RST

# Switch off the automatic display update to increase programming

# speed.

:DISPlay OFF

# Set the data format to NRZ for both channels, enter the

# patterns, and enable pattern mode.

:DIGital:SIGNal:FORMat1: NRZ

:DIGital:SIGNal:FORMat2: NRZ

:DIGital:PATTern:SEGMent1:DATA1 #1810100010

:DIGital:PATTern:SEGMent1:DATA2 #1800001000

:DIGital:PATTern:STATe ON

# Set the frequency and the delay for channel 2.

:FREQency 30MHz

:PULSe:DELay2 30ns

# Set the levels of outputs 1 and 2 and enable digital channel

# addition.

:VOLTage1:HIGH 1V

:VOLTage1:LOW 0V

:VOLTage2:HIGH 0.5V

:VOLTage2:LOW -0.5V

:CHANnel:MATH DIGital

# Enable the output.

:OUTPut1 ON

:OUTPut2 ON

50

Setting Up a Serial Data Sequence

Getting Started

Setting Up a Serial Data Sequence

Ta sk

NOTE

Set up a serial data sequence at 166.7 MHz, consisting of a header,

simulated payload data accompanied by a clock on output 2, and a

trailing pause.

Header Payload Trailing Pause

Output 1

Data

PRBS

Output 2

Clock

Trigger Out

For this example, both outputs are required. Therefore, this type of signal

can only be performed with a Agilent 81130A with two output modules

(Agilent 81131A or Agilent 81132A).

51

Getting Started

Setting Up a Serial Data Sequence

Instructions

To set the

1

Reset all parameters and modes by pressing SHIFT + STORE + 0.

2

Press the MODE/TRG softkey to enter the Mode/Trigger screen.

3

Move the entry focus to PULSES and select PATTERN.

4

Move to PULSES OUT 1 and select NRZ.

5

Move to OUT 2 and select RZ.

6

Set the PRBS P

7

Set T

operating mode and trigger mode

OLYNOM

RIGGER OUTPUT AT

to 215 1.

: to S

EGM

2 S

TART

as required:

.

CONTINUOUS PATTERN of

Pulses Out 1:

NRZ

PRBS Polynom: 2^15-1

Out 2: RZ

Clock

Segment1

*Segment2

Trigger Output at:

Segm2 Start

Segment3

TIMING PATTERNLEVELSMODE/TRG

MODIFY

52

Setting Up a Serial Data Sequence

Getting Started

NOTE

To set the

1

Press the TIMING softkey to enter the Timing menu.

2

Switch on both outputs.

3

Enter a period of 6

4

Enter a W

1

Delay

Width

timing parameters

NS

of 3NS for output 2.

IDTH

as required:

.

ON Per 6.000ns ON

OFF OFF

0ps

------

Delay

Width

0.00ns

3.000ns

2

MODIFY

3.000

ns

TIMING PATTERNLEVELSMODE/TRG

You cannot enter a pulse width for output 1 because of the NRZ setting.

This is indicated by the dashes in the W

To set the

1

Press the LEVELS softkey to enter the Level menu.

level parameters

as required:

entry field.

IDTH

2

Select S

TTL for both outputs.

ET

53

Getting Started

Setting Up a Serial Data Sequence

NOTE

To set the

1

Press the PATTERN softkey to enter the Pattern menu.

2

Move to U

This speeds up data setting.

3

Set the length of Segment 1 to 16 (header).

4

Set the length of Segment 2 to 32 (payload data).

5

Set the length of Segment 3 to 16 (trailing pause).

The frequency of 166.7 MHz requires a segment length resolution of 8.

See Segment/Length/Loop Control Table on page 81. Therefore, the

lengths of the segments must be set to be multiples of 8.

Segment Length Loopcnt No Upd

data pattern

and select NO U

PDATE

as required:

PDATE

.

MODIFY

1 16 1

2 32

3

16

16

4 0

TIMING PATTERNLEVELSMODE/TRG

54

Setting Up a Serial Data Sequence

Getting Started

6

Move the entry focus to 1 in the S

ENTER key to edit the segment.

7

Enter 1110101001101101 as channel 1 data.

8

Select L

OW SEG

for channel 2.

Segment 1 NO UPD

Address 16

CH1 Data

CH2

Low

Both

1

1 1 0 1

0 0 0 0

1 1 0 1

Length 16

EGMENT

column and press the

MODIFY

Data Seg

High Seg

*Low Seg

PRBS Seg

TIMING PATTERNLEVELSMODE/TRG

9

Move to the S

10

Select PRBS for channel 1 to generate pseudo-random payload data.

11

Select H

EGMENT

IGH SEG

Segment 2 NO UPD

Address

1

CH1 PRBS 15

CH2

entry field and select segment 2.

for channel 2 to generate the clock pulse.

Length 32

MODIFY

Data Seg

1 1 1 1 1 1 1High

*High Seg

Low Seg

PRBS Seg

TIMING PATTERNLEVELSMODE/TRG

55

Getting Started

Setting Up a Serial Data Sequence

12

Move to the Segment entry and select segment 3.

13

Select L

Segment 3 NO UPD

Address 1

CH1 Low

CH2

Both

for both channels.

OW

1

Low

Length 16

0 0 0 0 0 0 0

0 0 0 0 0 0 0

0 0 0 0 0 0 0

MODIFY

Data Seg

High Seg

*Low Seg

PRBS Seg

TIMING PATTERNLEVELSMODE/TRG

14

Move to NO UPD and press the ENTER key.

The following figure shows the signals as displayed on the

Agilent 54810A Infinium Oscilloscope. Use the generators

TRIGGER OUT to trigger the scope.

56

Setting Up a Serial Data Sequence

Getting Started

Programming

example

If you want to include this data sequence in your GP-IB program, use the

following command lines. The comment lines starting with a # are not

required.

# Reset the instrument to start from a defined, default status.

*RST

# Set the trigger output to start of segment 1

:SOUR:PULS:TRIG:MODE START

:SOUR:PULS:TRIG:POS 1

# Program segment 1

:DIG:PATT:SEGM1:DATA1 #01110101001101101

:DIG:PATT:SEGM1:TYPE2 LOW

# Set the length of segments 2 and 3

:DIG:PATT:SEGM2:LENG 32

:DIG:PATT:SEGM3:LENG 16

# Program segment 2

:DIG:PATT:SEGM2:TYPE1 PRBS

:DIG:PATT:SEGM2:TYPE2 HIGH

# Program segment 3

:DIG:PATT:SEGM3:TYPE1 LOW

:DIG:PATT:SEGM3:TYPE2 LOW

# Set the pulses format at output 1 to NRZ, the format at

# output 2 to RZ

:DIG:SIGN1:FORM NRZ

:DIG:SIGN2:FORM RZ

# Set the levels of outputs 1 and 2 to TTL levels.

:VOLTage1:HIGH 2.5V

:VOLTage1:LOW 0V

:VOLTage2:HIGH 2.5V

:VOLTage2:LOW 0V

# Program a period of 6 ns

:SOUR:PULS:HOLD2 DCYC

:SOUR:PULS:PER 6ns

57

Getting Started

Setting Up a Serial Data Sequence

# Enable pattern mode

:DIG:PATT ON

# Enable the outputs

:OUTP1 ON

:OUTP2 ON

58

3

3Using the Agilent 81130A

This chapter provides complete reference information for using the

Agilent 81130A by means of the user interface screens.

Each screen is described in detail. To access the individual screens, use

the softkeys below the screen. There are two softkey layouts:

the default layout

TIMING PATTERNLEVELSMODE/TRG

the alternative layout displayed after pressing the MORE key

TRG-LEV CONFIGMEMCARDLIMITS

At the end of this chapter, Warnings and Errors on page 96 provides

details on the instruments warning and error messaging system.

NOTE

NOTE

For general information on using the Agilent 81130A and information on

the instruments hardkeys, please refer to Chapter 1 Introducing the

Agilent 81130A Pulse and Data Generator on page 15.

For information on using the Agilent 81130A via remote control, please

refer to the Reference Guide, part number 81130-91021.

59

Using the Agilent 81130A

The Mode/Trigger Screen

The Mode/Trigger Screen

This section describes the Mode/Trigger screen, starting with an

overview of the available parameter combinations, followed by detailed

descriptions of each combination.

Overview

To access the Mode/Trigger screen, press the MODE/TRG softkey.

The following figure shows a typical Mode/Trigger screen, where the

individual parameters are indicated. The parameter combinations are

listed in the table on the next page.

➃

➄

➀

STARTED

Pulses Out 1:RZ Out 2: RZ

PRBS Polynom:

Trg'd by:

Trigger Output at: Segm1 Start

PATTERN of

TIMING PATTERNLEVELSMODE/TRG

➁

2^7-1

➂

EXT-IN

Run/Stop Indicator

STOP

Continuous

*Started

Gated

MODIFY

➅

In this screen, you can start and stop the instrument and set up the signal

to be continuous, started or gated and to be a pulse stream, a burst

(several pulses followed by a pause) or a pattern.

60

Using the Agilent 81130A

The Mode/Trigger Screen

Furthermore, you can specify the trigger input and the trigger output

behavior.

The following table provides a list of possible parameter combinations.

The rows refer to the numbers in the figure.

Tri gg er

➀

Mode

Pulse Mode Pulses Burst Pattern Pulses Burst Pattern Pulses Burst Pattern

➁

Pulse

➂

PRBS

➃

Polynom/

Burst

Period

Arming

➄

Source/

Tri gg ere d

by

Tri g g er O u t

➅

Continuous Started Gated

marks

each pulse

period

265504 RZ

265504

clocks

marks

start of

burst

R1

NRZ

2

2

each pulse

7

1 to

15

1

marks

period or

start of

segment

14

MAN

Ext. Input

each pulse

key

marks

period

265504 RZ

265504

clocks

marks

start of

burst

R1

NRZ

7

2

1 to

15

1

2

marks

each pulse

period or

start of

segment

14

MAN

Ext. Input

marks

each pulse

period

key

265504 RZ

265504

clocks

marks

start of

burst

Run/Stop Indicator

In started and gated mode, the Run/Stop indicator shows the current

function of the MAN key:

if the indicator shows RUN, pressing the MAN key starts the

instrument, that is: trigger/gate is armed

R1

NRZ

7

2

1 to

15

1

2

marks

each pulse

period or

start of

segment

14

if the indicator shows STOP, pressing the MAN key stops the

instrument, that is: generating of the current signal is aborted and the

trigger/gate is not armed

61

Using the Agilent 81130A

The Mode/Trigger Screen

Pattern Formats

NOTE

In pattern mode, the

from RZ, R1, and NRZ. The timing of the different formats is shown in the

diagram:

111001

RZ

R1

NRZ

To generate DNRZ (Delayed NRZ) signals, program NRZ pulses with a

delay. See Pulse Delay Parameter on page 74.

pulse output format

of a pattern can be selected

Random Pattern

To g e n e rate

can be selected as a pulse type. To determine the repetition length of the

PRBS sequence, specify the parameter n of the PRBS Polynom 2

The value range is 7 to 15. This allows to specify repetition lengths

between 2

random data, PRBS

7

1 = 127 and 215 1 = 32767.

(Pseudo Random Binary Sequence)

n

1.

NOTE

The sequence is stored in the memory. This reduces the available

memory for data patterns.

The instrument always cycles completely through the PRBS sequence.

When used multiple times or by different segments, the sequence is not

restarted at the beginning of another segments execution.

62

Characteristics

Using the Agilent 81130A

The Mode/Trigger Screen

Continuous Pulses Mode

The following figure shows typical timings for trigger mode

CONTINUOUS and pulse mode PULSES.

Period

Output

Trigger Out

Pulse periods are generated continuously.

TRIGGER OUT marks each pulse period.

63

Using the Agilent 81130A

The Mode/Trigger Screen

Continuous Burst Mode

The following figure shows typical timings for trigger mode

CONTINUOUS and pulse mode BURST.

Output A

3 pulses per burst

Output B

2 clocks per burst

Trigger Out

Characteristics

A burst of pulse periods is repeated continuously.

You can select the burst periods (total of pulse periods per burst) in

the range of 265504.

You can select the number of pulses per burst in the range of 265504

up to the burst period.

Burst Period 4 Clocks

Period

TRIGGER OUT marks each start of a burst.

64

Using the Agilent 81130A

The Mode/Trigger Screen

Continuous Pattern Mode

The following figure shows typical timings for trigger mode

CONTINUOUS and pulse mode PATTERN.

Period

Output A

RZ

1

0

1

Characteristics

Output B

Output C

NRZ

R1

1

10

0

1

1

Trigger Out

A pattern of pulses is repeated continuously.

You can select between RZ, R1 and NRZ data pulses for each output.

In the pattern screen (see The Pattern Screen on page 79) you can

select the pattern length and the data values for each output

divide your pattern into individual, repeatable segments.

You can select TRIGGER OUT to mark each pulse period, or the start

of a selected segment.

65

Using the Agilent 81130A

The Mode/Trigger Screen

Started Pulses Mode

The following figure shows typical timings for trigger mode STARTED

and pulse mode PULSES. The pulses are triggered by the rising edge of

the arming source.

Arming Source

Trg'd by: Ext Input or MAN Key

Trg'd by:

Output

Trigger Out

Characteristics

Pulse periods are triggered by (T

RG'D BY

) an active edge at the

selected arming source:

MAN key on front panel, triggered by pressing or releasing.

EXT INPUT triggered by rising or falling edges.

TRIGGER OUT marks each pulse period.

NOTE For the delay between trigger in to output refer to Agilent 81130A

Reference Guide, Chapter 3 Specifications.

66

Using the Agilent 81130A

The Mode/Trigger Screen

Started Burst Mode

The following figure shows a typical timing for trigger mode STARTED

and pulse mode BURST. The bursts are triggered by the rising edge of the

arming source.

Arming Source

(Trg'd by:) EXT INPUT

3 pulses per burst

2 pulses per burst

Trigger Out

or MAN Key

Output A

Output B

Trg'd b y:

Period

Burst Period of 4 clocks

Characteristics

A burst of pulse periods is triggered by an active edge at the selected

arming source

MAN key on front panel, triggered by pressing or releasing.

EXT INPUT triggered by rising or falling edges.

You can select the burst periods (total of pulse periods per burst) in

the range of 265504.

You can select the number of pulses per burst in the range of 265504

up to the burst period.

TRIGGER OUT marks each start of a burst.

67

Using the Agilent 81130A

The Mode/Trigger Screen

Started Pattern Mode

The following figure shows typical timings for trigger mode STARTED

and pulse mode PATTERN. The patterns are triggered by the rising edge

of the arming source.

Arming Source

(Trg'd by:) EXT INPUT

or MAN Key

Output A

Trg'd by:

Loop Restart

Period

1

RZ

Pattern of 3

0

1

Characteristics

Output B

Output C

NRZ

R1

1

101

0

1

Trigger Out

The pattern is repeated only if it is embedded in a loop.

A pattern of pulses is triggered by an active edge at the selected

arming source

MAN key on front panel, triggered by pressing or releasing.

EXT INPUT triggered by rising or falling edges.

You can select between RZ, R1 and NRZ data pulses for each output.

In the pattern screen (see The Pattern Screen on page 79) you can

select the pattern length and the data values for each output

divide your pattern into individual, repeatable segments.

You can select TRIGGER OUT to mark each pulse period or the start

of a selected segment.

68

Using the Agilent 81130A

The Mode/Trigger Screen

Gated Pulses Mode

The following figures show typical timings for trigger mode GATED and

pulse mode PULSES.

Gated by:

Arming Source

(Gated by:) EXT INPUT

or MAN Key

Output

Trigger Out

Characteristics

Pulse periods are gated by (enabled by) an active level at the selected

arming source:

MAN key on the front panel, gated while pressed.

EXT INPUT (external signal) gated by high or low.

TRIGGER OUT marks each pulse period.

69

Using the Agilent 81130A

The Mode/Trigger Screen

Gated Burst Mode

The following figure shows typical timings for trigger mode GATED and

pulse mode BURST.

Arming Source

(Gated by:) EXT INPUT

3 pulses per burst

2 pulses per burst

Trigger Out

Gated by:

or MAN Key

Burst Period of 4 clocks

Period

Output A

Output B

Characteristics

Bursts of pulse periods are gated by (enabled by) an active level at

the selected arming source:

MAN key on the front panel, gated while pressed or released.

EXT INPUT (external signal) gated by high or low.

You can select the burst periods (total of pulse periods per burst) in

the range of 265504.

You can select the number of pulses per burst in the range of 265504

up to the burst period.

TRIGGER OUT marks each start of a burst.

NOTE When the gate signal is deasserted, the burst generation will be

interrupted immediately and resume with the next phase after the gate

signal is asserted again.

70

Using the Agilent 81130A

The Mode/Trigger Screen

Gated Pattern Mode

The following figure shows typical timings for trigger mode GATED and

pulse mode PATTERN.

Characteristics

Arming Source

(Gated by:) EXT INPUT

or MAN Key

Output A

Output B

Output C

NRZ

Period

RZ

R1

110

11

10

Gated by:

Pattern of 3

0

0

Trigger Out

A pattern of pulses is gated by an active level at the selected arming

source

MAN key on front panel, gated while pressed or released

EXT INPUT (external signal) gated by high or low.

You can select between RZ, R1 and NRZ data pulses for each output.

In the pattern screen (see The Pattern Screen on page 79) you can

select the pattern length and the data values for each output

divide your pattern into individual, repeatable segments.

You can select Trigger out to mark each pulse period or the start of a

segment.

NOTE When the external gate signal is deasserted, the pattern generation will

be interrupted immediately and resume with the next phase after the gate

signal is asserted again (with the MAN key, pattern generation will always

start from the beginning).

71

Using the Agilent 81130A

The Timing Screen

The Timing Screen

To access the Timing screen press the TIMING softkey.

You can use the left part of the Timing screen to view and control the

pulse timing parameters of channel 1, the right part for those of

channel 2.

OFF OFF

1

OFF OFF

Delay

Width

LeadE 0.8ns

TraiE =LeadE

The individual timing parameters are described in more detail in the

following. Parameters can be entered in different formats. The

L

E and T

EAD

output module only.

If you prefer to set the timing parameters per output together with the

level parameters of that output, switch the type of parameter grouping.

See Parameter Grouping on page 93.

NOTE If only one channel is installed, Timing and Levels screens are grouped in

an Output screen automatically.

0ps Delay 0ps

100.0ns

E parameters are available with the AGILENT 81131A

RAI

1.000

TIMING PATTERNLEVELSMODE/TRG

µµµµ

sPer

Width 100.0ns

LeadE 0.8ns

TraiE =LeadE

2

1.000

MODIFY

µµµµ

s

72

Using the Agilent 81130A

The Timing Screen

When you press SHIFT + MORE (GRAPH) or the TIMING softkey again, you will

see a graphical representation of the timing parameters of both channels.

The currently selected parameter is displayed in the Modify/Enter area

and is indicated by dashed or bold lines in the graphical display.

1

OFF

OFF

2

OFF

OFF

TIMING PATTERNLEVELSMODE/TRG

1

OFF

OFF

2

OFF

OFF µs

Use the left/right cursor keys to move to an individual timing parameter.

NOTE Note that in graphics mode you can only adjust the values of each

parameter, not the parameter format. If you want to change the format of

a parameter, for example W

select the parameter name with the cursor.

Press SHIFT + MORE (GRAPH) or the TIMING softkey again to toggle between

textual and graphical display.

Width

100.0

ns

TIMING PATTERNLEVELSMODE/TRG

to DTYCYC, you must be in text mode to

IDTH

Period

1.000

73

Using the Agilent 81130A

The Timing Screen

Output ON/OFF Parameter

Switch on and off the normal output and the inverted output of each

channel.

NOTE If a channel is switched on, this also activates the internal error check to

detect parameter conflicts.

OFF OFF

1

OFF OFF

You can use short cuts as described in Switching the Outputs On and

Off on page 27.

normal

inverted

2

Pulse Period Parameter

Set the pulse period as either P

ERIOD

or F

REQUENCY

.

Pulse Delay Parameter

Set the delay of the leading edge within the pulse period. There are three

delay formats available:

D

(select A

ELAY

D

is the absolute delay from the start of a pulse period to the

ELAY

start of the leading edge of the pulse.

% (select % OF P

D

ELAY

The delay from the start of the pulse period to the start of the leading

edge expressed as a percentage of the pulse period.

P

(select P

HASE

The phase delay in degrees from the start of the pulse period to the

start of the leading edge (360° = 1 pulse period).

BSOLUTE

HASE

)

)

ERIOD

)

74

Using the Agilent 81130A

The Timing Screen

Pulse Width Parameter

Set the width of the output pulse. There are three width formats

available:

W

IDTH

(select W

The absolute pulse width measured from the start of the leading edge

to the start of the trailing edge. In this format, the pulse width is

independent of changes in pulse period and delay.

IDTH

)

D

TYCYC