+

Quick Start

Guide

HP 81110A 165/330 MHz,

HP 81104A 80 MHz

Pulse/Pattern Generators

Front Panel Display and Softkeys

Quick Start Guide

HP 81110A 165/330 MHz,

HP 81104A 80 MHz

Pulse/Pattern Generators

HP Part No. 81110-91010

Printed in Germany June 1998

Edition 1.0, E0698

NOTICE

NOTICE

Copyright

1998 Hewlett-Packard GmbH.

Herrenberger Str. 110-140

71034 Boeblingen

Federal Republic of Germany

All Rights Reserved. Reproduction, adaptation or translation without

prior written per miss ion i s p rohi bi te d, e x ce pt as al lowe d un der t h e copy right laws.

Warranty

This Hewlett-Packard produ ct has a warr anty aga inst de fects in materi al

and workmanship for a peri od of one year f rom date of ship ment. During

the warranty period, Hewlett-Pa ckard Company will , at its optio n, either

repair or replace products that prove to be defective. For warranty service or repair,this product must be returned to a service facility designated by Hewlett-Packard. The Buyer shall pay Hewlett-Packard’s

round-trip travel expenses . For pro ducts re turned t o Hewlett- Packard f or

warranty service, the Buyer shall prepay shipping charges to HewlettPackard and Hewlett-Packard shall pay shipping charges to return the

product to the Buyer. However, the Buyer sh all pay all shipping ch arge s,

duties and taxes for products returned to Hewlett-Packard from another

country. Hewlett-Packard warrants that it s software and firmware designated by Hewlett-Packard for use with an instrument will execute its

programming instructions when properly installed on that instrument.

Hewlett-Packard does not warrant that the operation of the instrument

software, or firmware, will be uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by the Buyer, Buyer-supplied software or interfacing,unauthorized modification or misuse, operation out-

6 NOTICE HP 81110/04A Quick Start

NOTICE

side of the environmen tal speci ficati ons for the product , or impro per site

preparation or maintenance.

No other warranty is exp ressed or im plied. Hewlett -Packa rd spe cifical ly

disclaims the impl ied warr antie s of mer chanta bilit y and fitnes s for a par ticular purpose.

Exclusive R emedies

The remedies supplied are the Buyer’s sole and exclusive remedies.

Hewlett-Packard shall not be liable for any direct, indirect, special, incidental, or consequentia l damages, whether ba sed on contract, to rt or any

other legal theory.

Assistance

Product maintenance agreements and other customer assistance agreements are available for Hewlett-Packard products. For any assistance,

contact your nearest Hewlett-Packard Sales Office.

Certification

Hewlett-Packard Company certifies that this product met its published

specifications at the time of shipment. Hewlett-Packard further certifies

that its calibration measurements are traceable to the United States Institute of Standards an d Technology , to the exte nt allowed by t he Institu te’s

calibrating facility, and to the calibration facilities of other International

Standards Organization members.

HP 81110/04A Quick Start NOTICE 7

About this book

About this book

This quick start guide helps you to quickly install the instrument, to get

familiar with the features, the user interface and give the set up information for some real-world signal examples which can easily be used by

varying only some parameter values.

The information is valid for HP 81104A and HP 81110A. Where

required the differences are explicitly mentioned. Possible configurations are:

Output Module for HP 81104A Mainframe:

Module Description Max Quantity

HP 81105A 10V/ max.80 MHz Output Channel 2

Output Modules for HP 81110A Mainframe:

Module Description Max Quantity

HP 81111A 10V/ max. 165 MHz Output Channel 2

Module Description Max Quantity

HP 81112A 3.8V/ max. 330 MHz Output Ch annel 2

As standard the instruments are equipped with one output channel, so,

some of the described features will not be available.

8 About this book HP 81110/04 A Quick Start

Installing

Installing the instrument. Setting Line voltage, replacing fuse and other

installation information.

Introduction

An overview of the instrument features, the user interface, and the fundamental pulse parameters.

Getting Started

A set of examples designed to demonstrate how to quickly set up a

signal.

User Interface Insight

Please refer to the Reference Guide, p/n 81110-91011.

Programming Reference

Please refer to the Reference Guide, p/n 81110-91011.

About this book

Specifications

Please refer to the Reference Guide, p/n 81110-91011.

HP 81110/04 A Quick Start About this book 9

About this book

10 About this book HP 81110/04A Quick Start

Table of Contents

NOTICE ...................................................................................................... 6

About this book ........................................................................................... 8

Output Module for HP 81104A Mainframe: ................................................ 8

Output Modules for HP 81110A Mainframe: .............................................. 8

Table of Contents ..................................................................................... 11

Chapter 1 Installation & Safety Requirements

Initial Inspection ....................................................................................... 16

Standard Deliverables: ............................................................................... 17

Options and Accessories: ........................................................................... 18

Options........................................................................................................ 18

Handle Accessory........................................................................................ 19

Rack Mounting Accessories........................................................................ 19

Table of Contents

Power Requirements ................................................................................ 20

Replacing the Fuse...................................................................................... 21

Power Cable ............................................................................................. 22

Ventilation Requirements ........................................ ...... .......................... 23

Thermal Protection ..................................................................................... 23

Overheating Detection................................................................................. 23

Fan Failure................................................................................................... 23

Battery ..................................................... ................................................. 24

Battery Replacement .................................................................................. 25

Operating Environment ........................................................................... 26

HP 81110/04A Quick Start Table of Contents 11

Table of Contents

Cleaning Recommendation ..................................................................... 27

Acoustic Noise Emission .......................................................................... 28

Acoustic Noise Emission 28

Geräuschemissionswerte 28

Declaration of Conformity ...................................................................... 29

Safety Information ............................................ ....................................... 30

Chapter 2 Introduction

Overview of this Chapter ........................................................................ 34

General Information ................................................................................ 35

Benchtop Testing........................................................................................ 35

Automated Testing...................................................................................... 35

Upgrade Capability..................................................................................... 36

User Interface Concept ............................................................................ 37

The Display ................................................................................................ 37

The Controls .............................................................................................. 38

Numerical Data Entry ................................................................................ 38

Parameter Selection and Modification ....................................................... 38

Quick Access of Menus and Parameters ................................................ 40

Additional Functions .................................................................................. 40

Select Step Size .......................................................................................... 40

Overprogramming ...................................................................................... 41

Display Modes ........................................................................................... 41

Screen Menus ............................................................................................. 42

12 Table of Contents HP 81110/04A Quick Start

Table of Contents

Special Function Keys .............................................................................. 43

Shift/Local Function Key ........................................................................... 43

Help Function Key ............................................... ...... ...... ..... ..................... 43

Store/Recall Function Key ......................................................................... 43

Default Setting............................................................................................. 44

Manual Trigger Function Key .............................. ...... ...... ..... ...... ............... 44

Screens Overview .............................. ...... ...... ........................................... 45

Available Operating/Trigger Modes ....................................................... 47

Trigger and Strobe Output........................................................................... 48

Setting Timing Parameter Formats and Values .................................... 49

Setting Level Parameter Formats and Values ....................................... 51

Internal Error Check.................................................................................... 52

Editing Pattern ......................................................................................... 54

Setting Limits ............................................................................................ 57

Thresholds and Trigger-Levels ............................................................... 59

Reading/Storing on Memory Card ......................................................... 60

Changing Configuration .......................................................................... 62

Output/Output 1 and Output 2 Parameter Grouping .......................... 64

An Overview of the Front and Rear Panel ............................................ 66

Inputs and Outputs ..................................................................................... 67

Chapter 3 Getting Started

Introduction .............................................................................................. 70

Manual Example Signals ............................................................................ 70

HP 81110/04A Quick Start Table of Contents 13

Table of Contents

Generic Signals........................................................................................... 70

Advanced Signals ....................................................................................... 70

Programming Examples ............................................................................. 70

Documentation Conventions: .................................................................... 71

Examples ................................................................................................... 72

1. Setting up a Clock Signal ....................................................................... 72

Device Command List for the Clock Signal .............................................. 77

2. Setting up a Pulse Signal ....................................................................... 79

Device Command List for the Pulse Signal ............................................... 84

3. Setting Up a Serial Data Stream Signal ................................................. 86

Device Command List for the Data Stream Signal .................................... 89

4. Setting Up an Edge-displacement Signal ............................................... 91

Device Command List for the Edge-displacement Signal ......................... 95

5. Setting Up a Dual Clock Signals ........................................................... 97

Device Command List for the Dual Clock Signal ................................... 101

6. Setting Up a Burst Signal ..................................................................... 103

Device Command List for the Burst Signal ............................................. 107

Index ........................................................................................................ 109

14 Table of Contents HP 81110/04A Quick Start

Chapter 1

1 Installation &

Safety Requirements

HP 81110/04A User’s Guide Installation & Safety Requirements 15

Installation & Safety Requirements

Initial Inspection

Initial Inspection

Inspect the shipping con tainer for dama ge. If the contai ner or cushioning

material is damaged, k eep it unt il the cont ents of the sh ipment have been

checked for completeness and the instrument has been verified both

mechanically and electrically.

WARNING: To avoid hazardous electric shock, do not perform electrical

tests when there are signs of shipping damage to any part of

the instrument’s outer covers or panels.

If the contents are incomplete, or there is mechanical damage, or if the

instrument doe s not work as expected with in its s pecificati ons, notify the

nearest Hewlett-Packard office. (please request the latest performance

tests from Hewlett Packard) Keep the shipping materials for inspection

by the carrier. The HP office will arrange for repair or replacement without awaiting settlement.

16 Installation & Safety Requirements HP 81110/04A User’s Guide

Installation & Safety Requirements

Initial Inspection

Standard Deliverables:

1 The instrument, either an HP 81110A or an HP 81104A Mainframe

with one or two channels installed.

2 This Quick Start Guid e and a Refer ence Guide

3 A power cord.

Figure 1 The Standard Deliverables

(LWKHU+3$RU+3$

7KLV)LJXUHVKRZVDQ+3$

7KLV4XLFN6WDUW*XLGH

DQGWKH5HIHUHQFH*XLGH

$3RZHU&RUG

HP 81110/04A User’s Guide Installation & Safety Requirements 17

Installation & Safety Requirements

Initial Inspection

Options and Accessories:

Options

Rear Panel Connectors Option UN2

Second Channel HP 81105A 10V/80 MHz for

1 MB SRAM Memory Card Option UFH

Figure 2 St andard Instrument’s Rear Panel

All inputs and outputs are at the rear

panel.

mainframe HP 81104A

HP 81111A 10V/165 MHz or

HP 81112A 3.8V/330 MHz for

mainframe HP 81110A

(HP part numer 0950-3880)

Figure 3 Rear Panel Connectors when Option UN2 is installed

18 Installation & Safety Requirements HP 81110/04A User’s Guide

Installation & Safety Requirements

Initial Inspection

Handle Accessory

Front Handle Kit HP part number 5063-9226

Rack Mounting Accessories

Rack Mount Kit HP part number 5063-9212

Rack Mount and Front Handle Kit HP part number 5063-9219

Rack Slide Kit HP part number 1494-0059

HP 81110/04A User’s Guide Installation & Safety Requirements 19

Installation & Safety Requirements

Power Requirements

Power Requiremen ts

CAUTION: BEFORE APPLYING AC LINE POWER TO THE

INSTRUMENT, ensure that the corr ect l ine f use is i nstal led in th e

fuse holder and the correct power cable is fitted.

NOTE: When the front panel switch is off, the Mainframe is in ’Standby’

mode. Disconnection from the AC Line Power is accomplished

only by disconnecting the power cord. Please make sure that the

power cord is easily i dentifiabl e and can quick ly be reached b y the

operator.

The following symbol is close to the ‘Standby’ switch on the front panel

of the instrument.

Figure 4 The ‘Standby’ Switch Symbol

The instrument can operate from any single-phase AC power source

supplying 100 - 240 V in the frequ ency ran ge from 50 t o 60 Hz, or 10 0 120 V at 400 Hz. The maximum power consumption is 300 VA with all

options installed. W hen the instrument is switched on the power supply

adapts automatically to the applied AC power (Auto Selection) and

monitors the AC power range during operation.

Table 1 Line Fuse

Line Voltage Fuse Type

HP Part

Number

100 - 240 V~ T 10A, 250 V 2110-0720

HP 81110/04A User’s Guide Installation & Safety Requirements 20

Installation & Safety Requirements

Power Requirements

Replacing the Fuse

1 Remove the power cord.

2 Unscrew the fuse-cap at the rear of th e instrument beside the power-

inlet socket.

Figure 5 Fuse Holder at Rear Panel

Fuse Hold er and

Fuse Cap

3 Replace the fuse with the equivalent part (see Table 1 on page 20).

4 Refit the fuse-cap.

HP 81110/04A User’s Guide Installation & Safety Requirements 21

Installation & Safety Requirements

Power Cable

Power Cable

In accordance with international safety standards, this instrument is

equipped with a three-wire power cable, see Figure 6 on page 22 for the

part numbers of the power cables available. When connected to an

appropriate AC power recepta cl e, thi s ca ble grou nds the instrument cabinet.

WARNING: To avoid the possibility of injury or death, the precautionary

Warnings given on the inside front-cover of the manual must

be followed b efore the instr ument is switch ed on.

Figure 6 Power Cables - Plug Identification

22 Installation & Safety Requirements HP 81110/04A User’s Guide

Ventilation Requirements

The instrume nt is fitted with three cooling fans. Make sure that there is

adequate clearance of 80 mm at the rear and 25 mm at the top and bottom to ensure a dequate air flow. If the air flow is restricted th e internal

operating temperature will be higher, reducing the instrument’s reliability or causing the instrument’s thermal-protection circuits to automatically switch off the instrument.

NOTE: Do not cover the ventilation holes.

Thermal Protection

Overheating Detection

Installation & Safety Requirements

Ventilatio n Requirements

The instrument monitors its internal temperature. If the temperature

exceeds approximately 80

instrument will switch on again if the temperature falls below approximately 77

°C.

°C the power supply is switched off. The

Fan Failure

If a fan is broken or prevented from operating by a blockage the temperature will increase. When the temperature exceeds approximately 80

the overheating detection switches off the instrument for safety reasons.

For reliability it is recommended to send instruments with broken or

defective fans immediately to HP Service for repair.

HP 81110/04A User’s Guide Installation & Safety Requirements 23

°C

Installation & Safety Requirements

Battery

Battery

This instrument contains a lithiu m battery. Typical life time of the battery in the HP Mainframe is about 5 years.

NOTE: Recycle or dispose used batteries according to local regulations.

Or contact your Hewlett-Packard r epresentative for in formation

on battery recycling.

(In the USA and Canada, call 1-800-333-1917)

The battery is replaceable. Replacement should only be carried out by

qualified service personnel.

NOTE: There is a danger of explosion if the battery is incorrectly r eplaced.

The battery must be replaced with the same or equivalent batter y type:

A Lithium CR2477-N type battery.

The HP replacement part number is: 1420-0557

The battery is protected against charging.

CAUTION: Do NOT crush, puncture, or incinerate the battery. Do NOT short

the battery’s external contacts.

24 Installation & Safety Requirements HP 81110/04A User’s Guide

Installation & Safety Requirements

Battery

Battery Replac eme nt

NOTE: Disconnect the power cord from ac line v oltage to avoid elect rica l

shock.

1 Remove the bumper which is fitted to the front panel.

2 Remove the strips on the left and right side of the front panel.

3 Remove t he front panel which is secured with two screws at each side.

4 Disconnect the flat cable which connects the front panel to the

chassis.

5 On the right side of the chassis there is a cover secured with one

screw. Remove this cover.

6 Now the battery can be removed from the battery holder. It is

recommended to bush th e battery on th e top, and to pull the battery on

the bottom with one finger for easier removal.

7 Fit the new battery in the holder, take care to not short current the

battery on the chassis.

8 Fit the cover again and secure it with the screw to the chassis.

9 Re-connect the flat cable of the front panel again to the chassis

connector. Make sure th at the pin one ( red wire) is po inting to the mid

of the chassis.

10 Re-assemble the front cover.

11 Fit the strips to the sides of the front panel, again.

12 Fit the bumper to the front panel.

13 End of procedure.

HP 81110/04A User’s Guide Installation & Safety Requirements 25

Installation & Safety Requirements

Operating Environment

Operating Environment

Table 2 Operating Environment

Storage Temperature -40 °C to +70 °C

Operating Temperature 0 °C to 55 °C

Humidity 95% R.H. (at 40 °C)

Altitude Up to 2000m

Installation Category II

Pollution Degree 2

WARNING: The instrument is not design ed for outd oor use. Do not expose

the instrument to rain o r other exces sive mois ture. Pr otect t he

instrument from humidity and temperature changes which

could cause condensation within the instrument.

Do not operate the instrument in the presence of flammable

gases, fumes or powders. Operation of any electrical

instrument in such an environment constitutes a definite

safety hazard.

26 Installation & Safety Requirements HP 81110/04A User’s Guide

Installation & Safety Requirements

Cleaning Recommendation

Cleaning Recommendation

WARNING: To prevent elec trical shock, disc onnect the instrum ent from

mains before cleaning. Use a dry cloth or one slightly

dampened with water to clean external case parts. Do not

attempt to clean internally.

HP 81110/04A User’s Guide Installation & Safety Requirements 27

Installation & Safety Requirements

Acoustic Noise Emission

Acoustic Noise Emission

Acoustic Noise Emission

For ambient te mp er atures up to 30°C, under normal operation and at the

typical operator position:

LpA = 52 dBA

Measured in accordance with ISO 7779 / EN 27779.

Geräuschemissionswerte

Bei einer Umgebungstemperatur bis 30°C

LpA = 52 dBA

am Arbeitsplatz, normaler Betrieb.

Angabe ist das Ergebnis einer Typprüfung nach ISO 7779 / EN 27779.

28 Installation & Safety Requirements HP 81110/04A User’s Guide

Installation & Safety Requirements

Declaration of Conformi ty

Declaration of Conformity

Manufacturer: Hewlett-Packard GmbH

Boeblingen Verification Solutions

Herrenberger Str. 130

71034 Boeblingen Germany

We declare that the system

HP 81100 Family of Pulse/Pattern Generators

HP 81110A 165/330 MHz Pulse/Pattern Generator

HP 81104A 80 MHz Pulse/Pattern Generator

conforms to the following standards:

Safety: IEC 1010-1:1990 + A1:1992 EN61010-1:1993

EMC: EN 55011:1991/CISPR 11 Group 1, Class B

EN 61000-4-2:1995 ESD: 4kV cd, 8kV ad, 4kV cp

EN 61000-4-3:1995 Radiated Immunity: 3V/m, 80% AM

ENV 50204:1995 Radiated Immunity: 3V/m, 50% Dty

EN 61000-4-4:1995 Fast Transients/Bursts: 0.5kV, 1kV

EN 61000-4-5:1995 Surges: 1 kVdiff, 2 KV com. mode

EN 61000-4-6:1995 Conducted Immunity

EN 61000-4-8:1993 Power freq. mang. field 3A/m, 50 Hz

IEC 1000-4-11:1994 Voltage Dips and Interruptions

Supplementary Information

The product herewith complies with the requirements of the

*) Low Voltage Directive (72/23/EEC) and the

*) EMC Directive (89/336/EEC).

During the me asurement against EN 55011, the I/O ports were terminated with their n ormal im pedance, t he HP-IB co nnector wa s termina ted

with the cable HP 10833B. When the product is connected to other

devices, the user must ensure that the connecting cables and the other

devices are adequately shielded to prevent radiation.

Boeblingen, June 9th 1998 Wolfgang Fenske

Regulation Consultant

HP 81110/04A User’s Guide Installation & Safety Requirements 29

Installation & Safety Requirements

Safety Information

Safety Information

Safety

This is a Safety Class 1 instrument (p rovided with terminal for protective earthing). Before applying power, verify that the correct safety precautions are taken (s ee the following warnings). In addition, note the

external markings on the instrument that are described under Safety

Symbols. Do not operate the instrument with its covers removed.

Replace fuse only with specified type.

Warning

Before turning on the instrument, you must connect the protective earth

terminal of the instrument to the prot ective earth conductor of the

(mains) power cord. The mains plug must only be inserted in a socket

outlet with aprotect ive ear th cont act. Do n ot ne gate th e protect iv e acti on

by using an extension power cord without a protective grounding conductor. Grounding one conductor of a two-conductor outlet is not sufficient protection.

Service instructions are for trained service personnel. To avoid dangerous electric shock, do not perform any service unless qualified to do so.

Do not attempt internal service or adjustment unless another person,

capable of rendering first aid and resuscitation, is present.

If you energize this instrument using an auto-transformer (for voltage

reduction) make sure that the common ter minal is connect ed to the earth

terminal of the power source.

Whenever it is likely that the ground protection is impaired, you must

make the instrument inoperative and secure it against any unintended

operation.

Do not operate the instrument in the presence of flammable gases or

fumes. Operation of any electrical instrument in such an environment

30 Installation & Safety Requirements HP 81110/04A User’s Guide

Installation & Safety Requirements

Safety Information

constitutes a definite safe ty hazard.

Do not install subst it ute parts or perform any unauthorized modificati on

to the instrumen t.

Capacitors inside the ins trument may retain a charge even if th e instrument is disconnected from its source of supply.

Safety Symbols

Instruction Man ual symbol: The instrument is marked with this symbo l

when it is necessar y for you to r efer to the i nstru ct ion ma nual in ord er to

protect against damage to the instrument.

Protected conductor symbol.

WARNING

The Warning symbol calls attention to a procedure, practice, or the like,

which, if not correctly performed or adhered to, could result in personal

injury or loss of life. Do not pro ceed beyon d a Warning symbol until the

indicated conditions are fully understood and met.

CAUTION

The Caution symbol calls attention to a procedure, practice, or the like,

which, if not correctly performed or adhered to, could result in damage

to or destruction of part or all of the equipment. Do not proceed beyond

a Caution symbol unti l th e indi cated condit ions a re ful ly unde rsto od an d

met.

HP 81110/04A User’s Guide Installation & Safety Requirements 31

Installation & Safety Requirements

Safety Information

32 Installation & Safety Requirements HP 81110/04A User’s Guide

Chapter 2

2Introduction

HP 81110/04 A Quick Start Introduction 33

Introduction

Overview of this Chapter

Overview of this Chapter

The purpose of the Introduct io n chapter is to give a general overview of

the HP 81110A and HP 811104A, firstly regarding the features, capabilities and benefits of the instrument, see “General Information” on

page 35.

For getting familiar with the user interface, please refer to the section

“User Interface Concept” on page 37.

Various additional shortcuts and features of the user interface can be

found in the section “Q uick Access of Menus and Parameters” on

page 40.

Special function keys are described in the section “Special Function

Keys” on page 43.

More in-depth information regarding the Pulse generatio n capabilities,

details on Output Channel options and the (optional) memory card can

be found in “Screens Overview” on page 45.

A look at all connect ors o n t he fr ont pan el and the r ear pa nel i s avai lable

in the section “An Overview of the Front and Rear Panel” on page

66.

For those users unfamiliar with the terms u sed in Pulse generation there

is a comprehensive and illustrated description provided in the

HP 81110A and HP 81104A Refere nce Guide (part number 81110-

91011), in the Chapter 3, Specifications, see “Pulse Parameter Defini-

tions of Terms Used in Instrument Specifications”.

34 Introduction HP 81110/04A Quick St art

Introduction

General Information

General Information

The Pulse G enerator gen erates all st andard pulses, digital pa tterns and

multi-level waveforms needed to t est all curre nt logic technologi es (e.g.:

TTL, CMOS, ECL, PECL, LVDS, GTL) and other digital designs up to

330 MHz. The HP 81 1 10A p rovides a reliabl e and wide range of signals,

which can be used in even more applications than its predecessor, the

HP 8110A. This is due to enhancements made in the feature set and

specifications of the HP 8110A. The glitch and drop out free varying of

any timing parameter and the HP 81110A’s timing calibration feature

contributes to more accurate and confident characterizations of the

DUTs.

Benchtop Testing

The graphic display shows all pulse parameters at a glance, the Cursor

keys and the Modify knob allow fast and simple operation. The HP

811 10A is equ ipped with the familiar Use r Interface f rom the HP 81 10A,

providing no learni ng curve for those already familiar with the predecessor product. The User Interface is designed to reduce/minimize the time

invested in getting familiar with the instrument. After familiarization the

instrument supports quick set ups of signals. This leaves the user free to

concentrate on the measurement task and testing of the DUT.

Automated Testing

The HP 81110A has the same SCPI conform command structure for the

feature sets identical to the HP 8110A. As with the HP 8110A, the new

product can be easily integrated into all phases of test-system development such as planning rack integration and test program generation.

These benefits along with the low cost of ownership make the

HP 81110A an invaluable instrument in a wide range of technical applications. Programs designed for the HP 81104A can be used without any

changes for the HP 81110A with HP 81111A 10V/165 MHz outputs.

HP 81110/04 A Quick Start Introduction 35

Introduction

General Information

NOTE: Please refer to the Reference Guide, part number 81110-91011,

for the command reference list.

The HP 81110A compared to the HP 81104A has better accuracy, up to

330 MHz clock rate, 800 ps typical edges at up to 3.8 V, and a timing

auto calibration.

Upgrade Capability

It is possible to upgrade the instruments with a second channel if only

one channel was origi nall y order ed. There are t wo outp ut cha nnels avail able for the HP 81 1 10A. The sec ond channel t hat is inst alled must be the

same as channel one.

NOTE: Do not mix the output channels for the HP 81110A.

Table 1: Mainframe / Output Module Combinations

Mainframe Module Description

HP 81104A HP 81105A 10V/ max. 80 MHz Output Channel

HP 81110A HP 81111A

HP 81112A

10V/ max. 165 MHz Output Channel

3.8V/ max. 330 MHz Output Channel

36 Introduction HP 81110/04A Quick St art

Introduction

User Interface Concept

User Interface Concept

The User Interface c oncept consis ts of a disp lay and fr ont pa nel con trols

for data entry. The main principle is to progress through the setup

screens from left to right, setting the modes and parameters as required

for your signal. If this signal is a simple clock or pulse signal it is not

necessary to invoke the

Images of the front panel are available for the HP 81110A and

HP 81104A on the fold out covers, at the front and rear of this guide,

respectively.

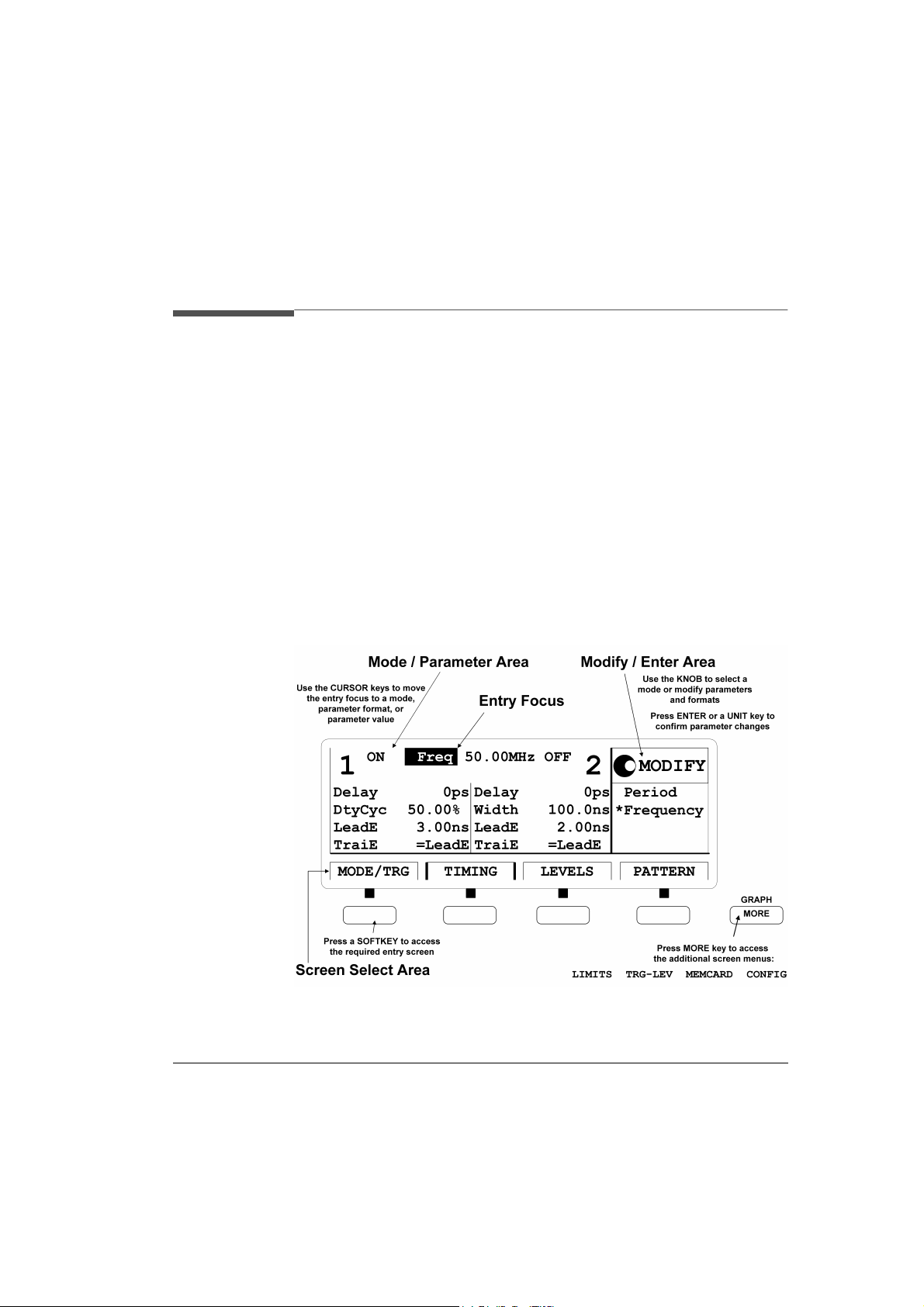

The Display

Figure 7 Display and Softkey Front Panel Section

|P ATTERN| screen.

The display contains three different areas, Mode / Parameter, Modify /

Enter and Screen Selection areas.

HP 81110/04 A Quick Start Introduction 37

Introduction

User Interface Concept

The Controls

Movement of the entry focus within the Mode & Parameter section of

the display is controlled by the Cursor Keys.

Figure 8 Front Panel Controls

Numerical Data Entry

Numerical data is entered by the Data Entry keys and va lidated ei ther by

a Unit key or the key.

Parameter Selection and Modification

The Modify knob can be used in the Modify area of the display. Modes

can be selected and changed in th e Modify Area or paramet er values can

38 Introduction HP 81110/04A Quick St art

Introduction

User Interface Concept

be varied to display an immediate change at the output.

When is displayed, select a mode , a p ara me te r f or mat or modify the parameter value and validate the value with a unit key.

When is displayed, make the s elect ion an d press the

key to start a function.

HP 81110/04 A Quick Start Introduction 39

Introduction

Quick Access of Menus and Parameters

Quick Access of Menus and Parameters

Additional Func ti ons

Most keys of the front panel have an additional function. The

key provides fast access to ad dit io nal func ti ons of the Data

Entry keys and the Special Function keys.

For example, it is possible to quickly access the pulse width parameter

of output 2 by pressing , the instrument then

asks for the channel, so press (if two channels are installed).

The entry field is positioned on the output 2 width parameter editing

field.

Select Step Size

The + or + moves the cur-

sor to a different digit in the MODIFY area, so it is possible to change

step size for parameter change, then vary the value either with the up/

down cursor keys or the knob.

40 Introduction HP 81110/04A Quick St art

Introduction

Quick Access of Menus and Parameters

Overprogramming

With + it is possible to exceed specified parame-

ter ranges to utilize the instrument to its limits.

NOTE: Proper operation of the instrument outside of the specified ranges

is not guaranteed. It i s reco mmended to ha ve the o utpu ts swit ched

on when overprogramming, t o have the i nternal e rror chec k sytem

activated, which warnsyou about impossible settings.

Display Modes

In the following figure the results of pressing a sof tke y a re dis pl ayed. In

this case it is possible to toggle between textual and graphical screens.

The toggle mode is available for the

TERN|

softkeys. It is possible to alternate between a textual display and

waveform display by pressing the softkey as required.

|TIMING|, |LEVELS| and |PAT-

Figure 9 Toggling Display Mode

HP 81110/04 A Quick Start Introduction 41

Introduction

Quick Access of Menus and Parameters

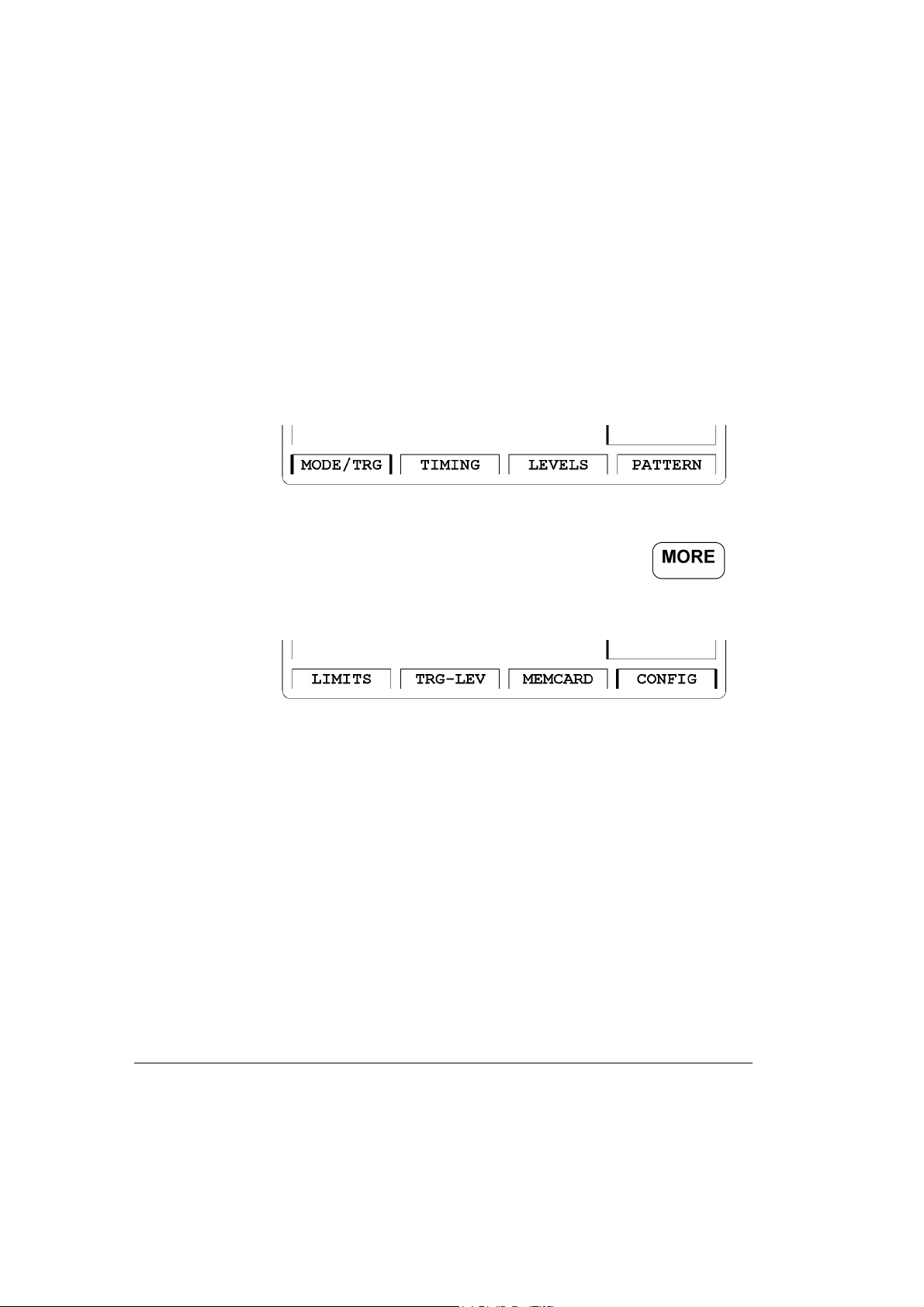

Screen Menus

The Softkeys allow access to the screen menus and can toggle betwee n

screens where applicable.

Figure 10 Screen Menus of a dual channel instrument

Additional screen menus can be accessed by pressing the

softkey leading to the following screen selection area.

Figure 11 Additional Screen Menus

42 Introduction HP 81110/04A Quick St art

Introduction

Special Function Keys

Special Function Keys

Shift/Local Function Key

The key provides fast access to additional functions.

The key can be used when, in remote control, the front

panel controls are locked. Press the key to unlock the front panel controls.

Help Function Key

The key provides access to the instru ments on-li ne help or in

Warning or Error state, access to Warning/Error Report Screen.

Store/Recall Function Key

The key can be used to store/recall from 1 to 9 individual

settings in th e instrument memory.

HP 81110/04 A Quick Start Introduction 43

Introduction

Special Function Keys

Default Setting

In the interna l memory locati on 0 there is a de fault setting stored, press

the keys to reset the instrument to

the default setting.

Manual Trigger Function Key

The key can be used in triggered or gated mode to manually

trigger the in strument if there is no other source available.

44 Introduction HP 81110/04A Quick St art

Introduction

Screens Overview

Screens Overview

The instrument is designed to create pulse streams, burst signals and

data streams, ther efore the instr ument has to be s et to the oper ating mode

required, to set the operating mode please refer to “Available Operating/

Trigger Modes” on page 47.

The instrument can be t riggere d, gated or used as a pulse si gnal reco very

instrument (external width), to set the trigger mode refer also to “Avail able Operating/Trigger Modes” on page 47.

NOTE: Triggered or gated mode is available only when int ernal Oscillator

is used as period generation source.

The instrument can be equipped with one or two output channels. It is

possible to independently program the timing and level parameters of

both channels.

If two channels are installed it is possible to select either the parameter

grouping for

for

|OUTPUT 1| and |OUTPUT 2|.

To change grouping of the parameter r ef er t o “Chang ing Conf iguration”

on page 62.

|TIMING| and |LEVELS| or all timing and level parameters

Most parameters can be entered in 2 or more different formats, e.g.

width or duty cycle or trailing delay. To select the parameter format and

to set the parameters, refer to “Setting Timing Parameter Fo rmats and

Values” on page 49.

Entering pattern for a data stream can be done in the pattern screen, refer

to “Editing Pattern” on page 54.

To protect voltage sensitive DUTs the instrument has the output voltage

limitation feature . For how to se t limits ref er to “Sett ing Limits” on pa ge

57.

HP 81110/04 A Quick Start Introduction 45

Introduction

Screens Overview

The instrument can se t thresholds and the input impedance for an external trigger signal or external high-stability clock input. For the trigger

output, available in pulse mode and the strobe output, available in burst

and pattern mode, it is possible to select between TTL or ECL output

levels. For how to set thresholds or trigger levels refer to “Thresholds

and Trigger-Levels” on page 59.

The instrument allows to read and store instrument settings from and to

a memory card. The reading and storing is done in the

|MEMCARD| menu, refer to “Reading/ Storing on Memory Card” on

page 60.

46 Introduction HP 81110/04A Quick St art

Introduction

Av ailable Operating/Trigger Modes

Available Operating/Trigger Modes

Figure 12 MODE/TRG Screen

Access the Operating/Trigger Mode (MODE/TRG) screen by pressing

the

|MODE/TRG| softkey. Move the Entry Focus with the cursor keys.

In this screen you set the fundamental operating and trigger modes with

respect to the signal required. For example, the operating mode for a

simple clock or pulse signal is the pulse stream (

Pulse Strm), PULSES

mode. Burst signals (several pulses and a pause) are easily set up in

BURST mode. Data streams (also PRBS’s) require the Pattern mode.

You can specify the pulse period source. If you have to trigger after an

external event then use the starta ble osci llator (internal Osc) which st arts

on the external signal with a fixed latency. If you do not have to trigger

but need a high accuracy freq uency, then use the interna l PLL cloc k generation circuitry. In triggered/gated mode the internal PLL can be used

as trigger sou rce.

In

Pattern mode you specify the data outp ut format in this screen, either

RZ or NRZ.

The available selecti ons are :

HP 81110/04 A Quick Start Introduction 47

Introduction

Available Operating/Trigger Modes

1 Trigger Mode - CONTINUOUS, TRIGGERED, GATED,

EXT. WIDTH

2 Operat ing Mode -

PULSES, BURST of, PATTERN of

3 Pulse Type - Single-Pulses, Double-Pulses

4 Number of Bursts - 2 to 65536

5 Data Output Format - RZ, NRZ

Can also be varied in the |PATTERN| screen.

6 Pulse Period Source -

internal Osc, internal PLL, CLK-IN

7 Trigger/Gate Sour ce - EXT INPUT, PLL, MAN KEY

8 Trig ger/Gate Even t - Rising, Falling, Both / HighLev el, LowLevel,

Always

Trigger and Strobe Output

The Trigger Output is always available and marks each pulse period

with a 50% duty cycle signal. In Ext Width the trigger output width is

5.9 ns for the HP 81104A, and 1.5 ns for the HP 81110A.

Additionally, in burst mode the Strobe output is available. The Strobe

output rises at the start of the first pulse-period and falls at the start of

the last pul se-period.

Additionally, in pattern mode the Strobe output is available. The Strobe

output is bit-programmable with NRZ data output format.

Table 2: Trigger and Strobe Output Availability

Pulse Mode Burst Mode Pattern Mode

Continuous

Triggered T T, S T, S

Gated T T, S T, S

Ext. Width Tn/an/a

1

T = Trigger Out

2

S = Strobe Out

48 Introduction HP 81110/04A Quick St art

1

T

T, S

2

T, S

Introduction

Setting Timing Parameter Formats and Values

Setting Timing Parameter Formats and

Values

Figure 13 TIMING Screen

Access the timing entry (TIMING) menu screen by pressing the

|TIMING| softkey.

In this screen you can set the timing parameters individually for both

channels. This is except for period/frequency, which defines the system

clock rate for both channels.

All parameters can be entered in different parameter formats, please

select from:

1 The System Clock Mode -

2 Delay Parameter -

3 Width Parameter - Width, DutyCycle, Trail Del

4 Leading Edge Parameter - Absolute,% of Wid

HP 81110/04 A Quick Start Introduction 49

Absolute, % of Per, Phase

Period, Frequency.

Introduction

Setting Timing Parameter Formats and Values

NOTE: For HP 81110A with HP 81112A, 3.8V/330 MHz Output channels

installed you can select between two fixed transitions, 800 ps or

1.6 ns. The trailing edge is always the same as the leading edge.

5 Trailing Edge Parameter - =

Lead E, Absolute,% of Width

6 Output Status - ON, OFF

Can also be varied in the |LEVELS| screen.

NOTE: If only one channel is installed, then all signal parameters are

grouped in an OUTPUT screen. If yo u prefe r the si gnal pa ramete r

grouping for each Output, then please refer to “Changing

Configuration” on page 62. Refer also to “Output/Output 1 and

Output 2 Parameter Grouping” on page 64.

7 Differential Output Status -

ON, OFF

Can also be varied in the |LEVELS| screen.

NOTE: Differential Outputs are available with HP 81110A with

HP 81112A, 3.8V/330 MHz Output channels installed.

Switch the output status to ON to avoid para meter conflicts, please refer

to “Internal Error Check” on page 52.

50 Introduction HP 81110/04A Quick St art

Introduction

Setting Level Parameter Formats and Values

Setting Level Parameter Formats and

Values

Figure 14 LEVELS Screen

Access the level entry (LEVELS) menu screen by pressing the

|LEVELS| softkey.

In this screen you can set the level values individually for both channels.

As with the TIMING screen you can enable or disable the outputs. All

parameters can be entered in different parameter formats, e.g. it is possible to enter the levels as current values by changing the unit to ampere.

Please select from:

1 Channel OUTPUT Status -

Can also be varied in the |TIMING| screen.

2 Differential Output Status -

Can also be varied in the |TIMING| screen.

NOTE: Differential Outputs are available with HP 81110A with

HP 81112A, 3.8V/330 MHz Output channels installed.

3 OUTPUT Mode -

HP 81110/04 A Quick Start Introduction 51

Normal, Complmnt

ON, OFF

ON, OFF

Introduction

Setting Level Parameter Formats and Values

4 Channel Output Option - Separate Outputs, Added at Output1

NOTE: Channel addition (Added at Output1) is available with HP 81104A

and HP 81110A with HP 81111A, 10V/165 MHz Output channels

installed.

5 Fixed Levels Formats -

Set TTL, Set ECL

6 Variable Level Formats - High-Low, Off-Ampl

7 Unit Format - in volt, in ampere

8 Source Impedance Values - 50 Ω ,

1

ΚΩ

NOTE: Selectable source impedance and variable load impedance is

available with HP 81104A and HP 81110A with HP 81111A,

10V/165 MHz Output channels installed.

9 Load Im pedance Values -

0.1 Ω − 1 ΜΩ

NOTE: If only one channel is installed, then all signal parameters are

grouped in an OUTPUT screen. If yo u prefe r the si gnal pa ramete r

grouping for each Output, then please refer to “Changing

Configuration” on page 62.

Internal Error Check

When the output status is in OFF pos ition the internal error check is

switched off and it is possible to set each parameter to any valid value.

So, it is possible to program even conflicting values between

parameters. When switching the outputs ON the instrument will

immediately show a flashing W. Pressing the Help key will list all

parameter conflicts.

Recommendation:

To avoid long lists of warnings it is recommended to:

a Check and set the output levels in the |LEVELS| screen to a va lue

52 Introduction HP 81110/04A Quick St art

Introduction

Setting Level Parameter Formats and Values

which does not damage your DUT.

b Switch the ou tput status to ON to get imm ediately res ponse if y ou try to pro -

gram a conflicting parameter combination in |LEVELS| or |TIMING|

screen.

HP 81110/04 A Quick Start Introduction 53

Introduction

Editing Pattern

Editing Pattern

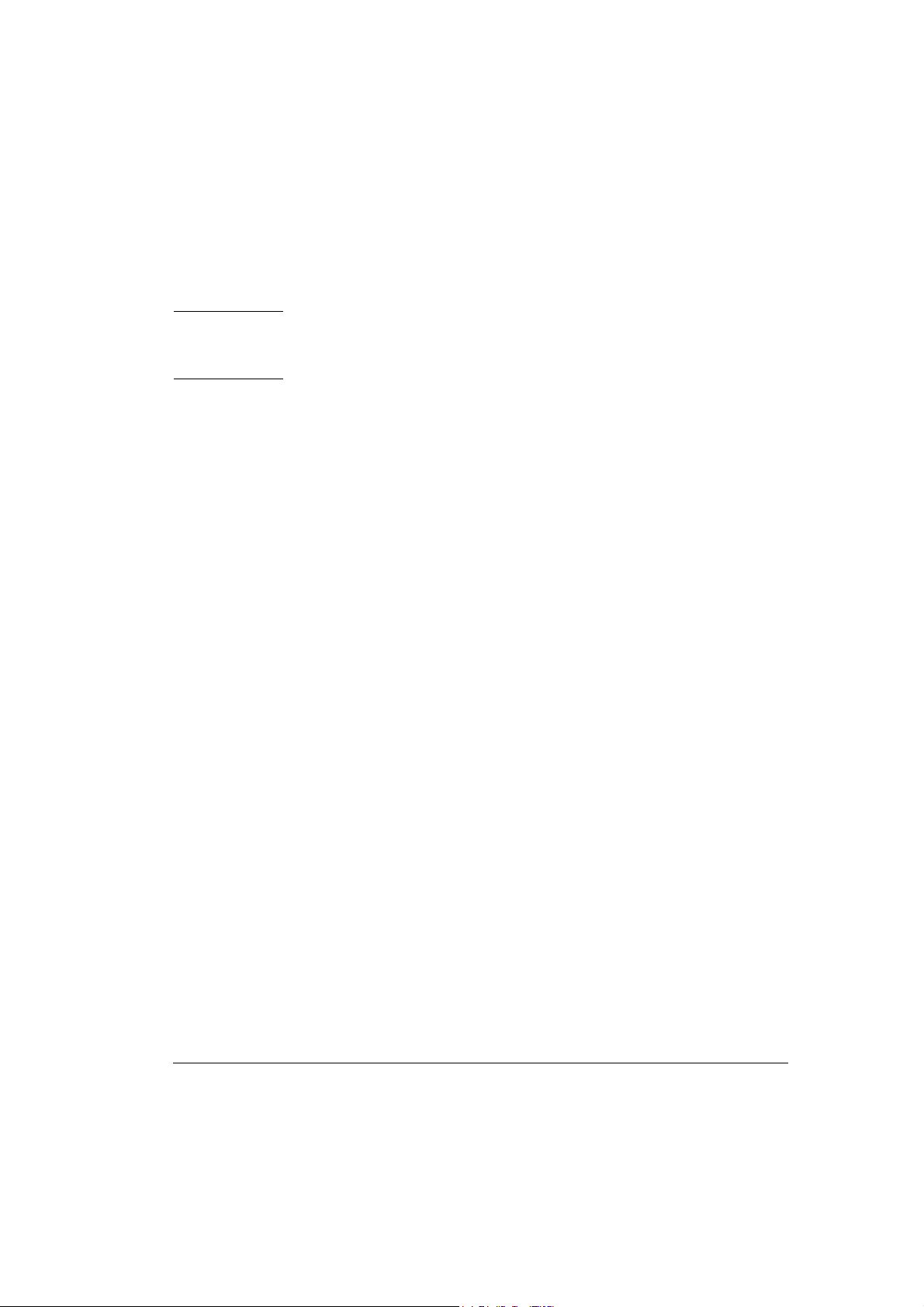

Figure 15 PATTERN Screen

Shows which memory location

can actually be edited

Bit-editing Window

Set the pattern length here

NOTE: Make sure that in the |M ODE/TRG| screen the pattern operating mo de

is selected. Please refer to “A vailable Operating/T rigger Modes” on page

47.

Access the pattern entry (PATTERN) menu screen by pressing the

|PATTERN| softkey. This screen has to be accessed for pattern entry

when data streams in Patt ern operating mode will be set up.

NOTE: A signal with a number of pulses followed by a pause is what we

would call a burst signal. Such burst signals are recommended to

be set up in the burst mode, as this is done more quic kly and easier

as it would be in the pattern mode.

54 Introduction HP 81110/04A Quick St art

Introduction

Editing Pattern

In pattern mode the Str obe output has add itional up to 1638 4 bit memory

depth with NRZ data output always. So, the Strobe output is the comfortable trigger output in patte rn mode.

In this screen you can select:

1 Update Status -

Upd Once, Update Cont

If the changes of pattern should immediately affect the output select

Upd Cont.

If you want to set up new pattern while a data stream is currently

generated select

Upd Once. Edit your new pattern, then press the

key to make the new pattern active on the output.

2 Current memory location - Addr - shows the current position of the

bit-editing window.

Move the entry field to the bit-editing window and enter the pattern.

The bit-editing window aut omatically moves one location to the right.

The bit-editing window can be moved across the pattern length by

varying the

Addr. Either change the Addr with the kn ob or by typing

in a new address with the Data Entry keys.

The range is

1-length of pattern (max 16384).

3 Length of pattern - Last - shows the last address and is equal to the

length of the data stream.

Set the required pattern length by specifying the

range is

2-16384.

Last address. The

4 Block Editing Functions for - CH1, CH2, BOTH, STRB

It is possible to manipulate each Ou tput channel sep arately

or together,

BOTH. The strobe output STRB is available and can be

CH1, CH2

programmed individually . There are block editin g functions available

to fill memory with 0 or1, to i nvert the pattern, to set a PRBS or filling

HP 81110/04 A Quick Start Introduction 55

Introduction

Editing Pattern

the memory with a divided clock pattern.- Fill 0, Fill 1, Invert,

First Bit, Last Bit, Ins Bit, Del Bit, Clock÷N, PRBS 2n-1.

NOTE: Most of the block editing functions apply from (or at) the current Addr

of the bit-editing window to the Last bit in the pattern

For further information on the block editing functions, please refer to the

HP 81110A / HP 81104A Reference Guide (p/n 81110-91010 ) Chapt er 1,

Pattern Screen.

5 Data Output Format - RZ, NRZ

Can also be varied in the |MODE/TRG| screen.

56 Introduction HP 81110/04A Quick St art

Introduction

Setting Limits

Setting Limits

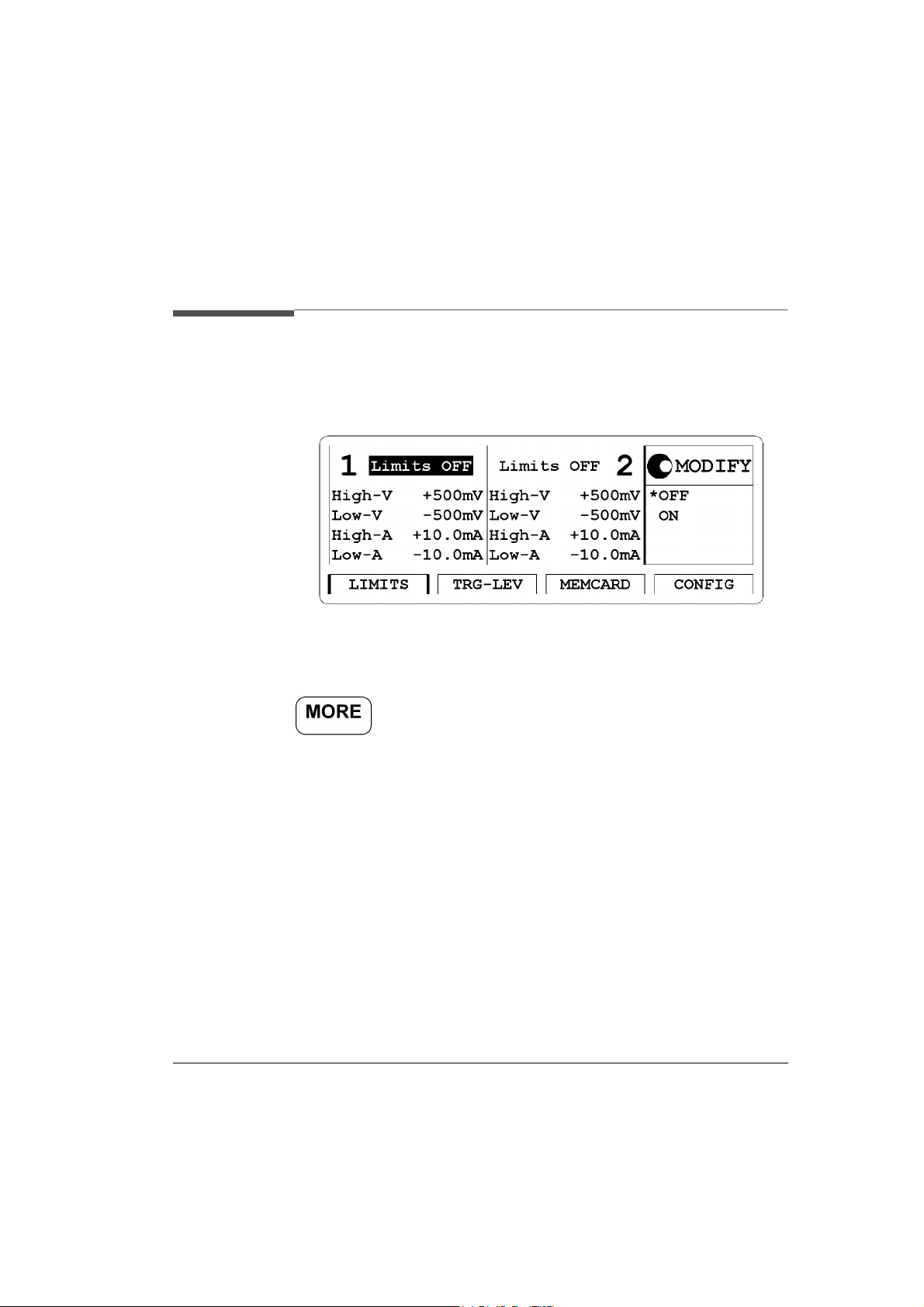

Figure 16 LIMITS Screen

Access the output limitation (LIMITS) menu screen by pressing the

softkey then pressing the

|LIMITS| softkey.

To prevent your device from being damaged by excess ive voltages it is

recommended to limit the output of the instrument. You can switch the

limit feature on, or off and set the required limits as either voltages or

currents.

Please select from:

1 Limits Status -

ON, OFF

2 High Voltage Limit - High-V

For the 10 V output channels HP 81105A and HP 81111A the range

-19.8V to +20.0V

is:

For the 3.8 V output channels HP 81112A the range is: -1.90V to

+3.80V

HP 81110/04 A Quick Start Introduction 57

Introduction

Setting Limits

3 Low Voltage Limit - Low-V

For the 10 V output channels HP 81105A and HP 81111A the range

is:

-20V to +19.8V

For the 3.8 V output channels HP 81112A the range is: -2.00V to

+3.70V

4 High Curr ent Limit - High-A

For the 10 V output channels HP 81105A and HP 81111A the range

is:

-792 mA to +800 mA

For the 3.8 V output channels HP 81112A the range is: -76.0 mA to

+152 mA

5 Low Current Limit - Low-A

For the 10 V output channels HP 81105A and HP 81111A the range

is:

-800 mA to +792 mA

For the 3.8 V output channels HP 81112A the range is: -80.0 mA to

+148 mA

58 Introduction HP 81110/04A Quick St art

Introduction

Thresholds and Trigger-Levels

Thresholds and Trigger-Levels

Figure 17 TRG-LEV Screen

Access the trigger le vel (TRG-LEV) menu screen by pressing the

softkey then pressing the

In this screen you can set the thresholds for external and clock reference

signals and the input impedanc e. For th e output tri gger and strobe signa l

specify the output levels, either TTL or ECL.

The available selecti ons are :

1 EXT-IN -

Voltage Range - -10V to +10 V

Input Resistance - 10kΩ Inp or 50Ω Inp

2 CLK-IN -

Voltage Range - -10V to +10V

Input Resistance - -10kΩ Inp or 50Ω Inp

3 Trigger-Out - TTL, ECL

4 Strobe -Out- TTL, ECL

HP 81110/04 A Quick Start Introduction 59

Set TTL, Set ECL, Voltage

Set TTL, Set ECL, Voltage

|TRG-LEV| softkey.

Introduction

Reading/Storing on Memory Card

Reading/Storing on Memory Card

Figure 18 MEMCARD Screen

Access the memory card (MEMCARD) menu screen by pressing

the softkey then pressing the |MEMCARD| softkey.

The main operations on the MEMCARD screen are:

• Store instrument settings to the memory-card

• Recall instrument settings from the memory-card

• Delete files from the memory-card

• Format the memory-card

If a memory card is plugged in the memory card slot on the front panel

you can select:

1 Dir Path- displayed if there is a plugged in memory card with a

directory created on a DOS PC.

2Filename- list of the filenames which are present on the plugged in

memory card.

3 Perform Operation -

Format

60 Introduction HP 81110/04A Quick St art

ReadCard, Recall, Store, Store All, Delete,

Introduction

Reading/Storing on Memory Card

NOTE: the HP 81110A or HP 81104A support only DOS formatted

memory-cards and you cannot create or delete directories using

the HP 81110A or HP 81104A.

The HP 81110A and HP 81104A support memory cards up to

2 MB, SRAM Type.

The filenames can be up to 8 characters long.

HP 81110/04 A Quick Start Introduction 61

Introduction

Changing Configuration

Changing Configuration

Figure 19 CONFIG Screen

NOTE: Timing Calibration is available with the HP 81110A only.

Access the Configuration (CONFIG) menu screen by pressing the

softkey then pressing the

In this screen you can vary the HP-IB address when the instrument is

used in remote control operation The factory set HP-IB address is 10. It

is possible to invoke a selftest.

With the HP 81110A the ti ming self calibration feature can be started in

this window - Perform: Timing Calibration. Apart from the factory

calibration of the instruments, the timing self calibration allows to

calibrate the instrument in respect to the actual ambient temperature.

When the HP 81110A is switched off and on again, the factory

calibration data are va lid again.

You can select the parameter grouping from either TIMING and

LEVELS or OUTPUT 1 and OUTPUT 2. You can also define what the

62 Introduction HP 81110/04A Quick St art

|CONFIG| softkey.

Introduction

Changing Configur ati on

PLL reference source is, eit her the internal on-board refer ence or a much

more stable external reference.

Please select from:

1 HP-IB Addr ess Range -

1 to 30

2 Perform Option- Selftest, Timing Calibration (HP 81110A only)

3 Group Parameters by - TIMING/LEVELS, OUTPUT 1/2

4 PLL Refe re nce Sour ce - Internal, CLK-IN: Freq 5 MHz or 10 MHz

HP 81110/04 A Quick Start Introduction 63

Introduction

Output/Output 1 and Output 2 Parameter Grouping

Output/Output 1 and Output 2

Parameter Grouping

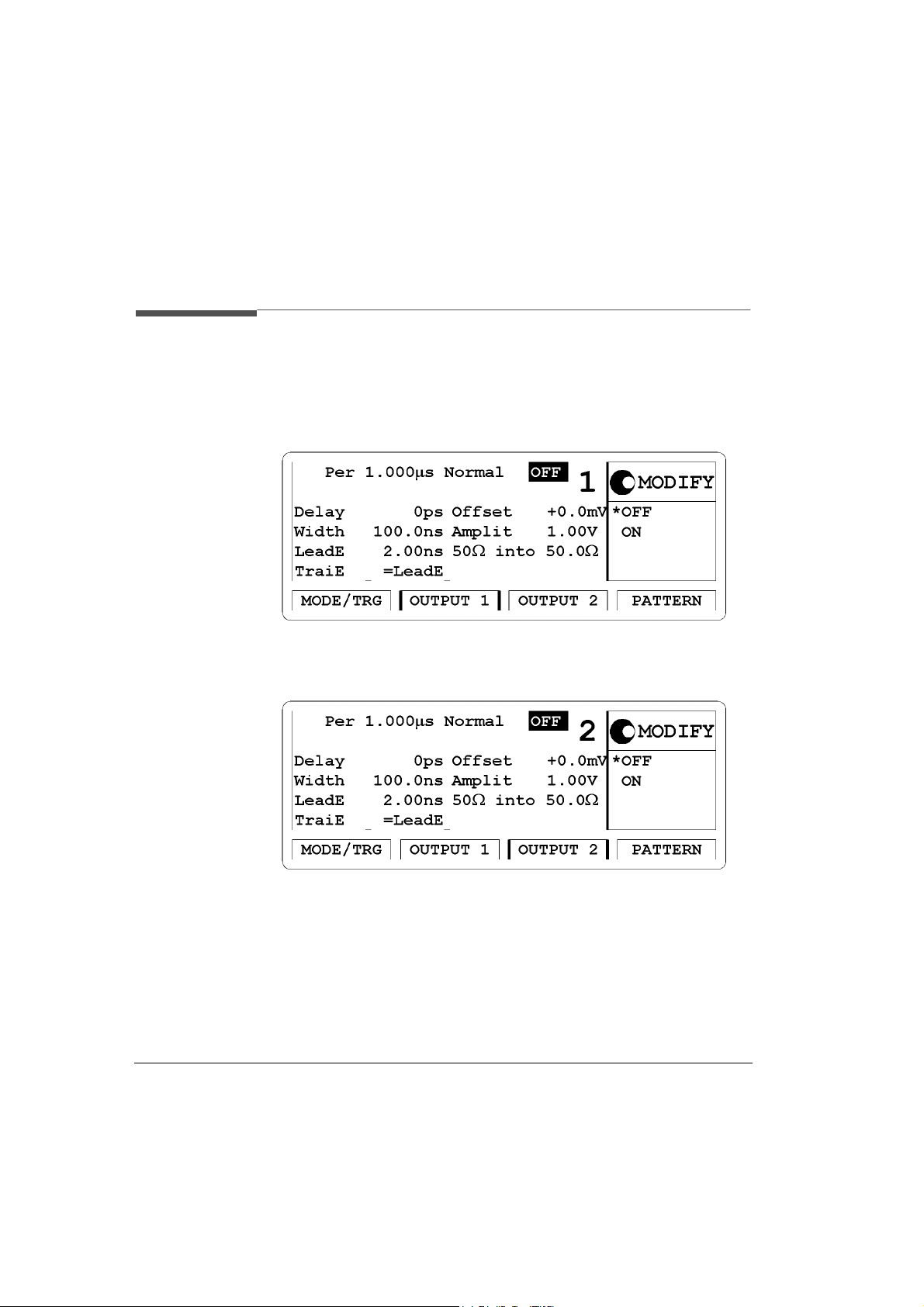

Figure 20 OUTPUT 1 Screen of a dual channel instrument

Figure 21 OUTPUT 2 Screen

64 Introduction HP 81110/04A Quick St art

Introduction

Output/Output 1 and Output 2 Parameter Grouping

Figure 22 Output Screen of a single channel instrument

The |OUTPUT| screen is standard for a single channel instrument. The

|OUTPUT 1| and |OUTPUT 2| timing and level grouping is configurable

for dual channel instruments.

After selecting

Group Params by: OUTPUT 1/2 in the |CONFIG| screen,

see “Changing Configura tion” on pa ge 62, the 2 Output Sof tkey options

are available. The timing and level parameters are grouped together for

each output.With the exception of period/frequency all parameters can

be individually set for each output.

All parameters can be entered in different formats. For the available

parameter and format selections, please refer to “Setting Timing

Parameter Formats and Values” on page 49. Refer also to “Setting

Level Parameter Formats and Values” on page 51.

HP 81110/04 A Quick Start Introduction 65

Introduction

An Overview of the Front and Rear Panel

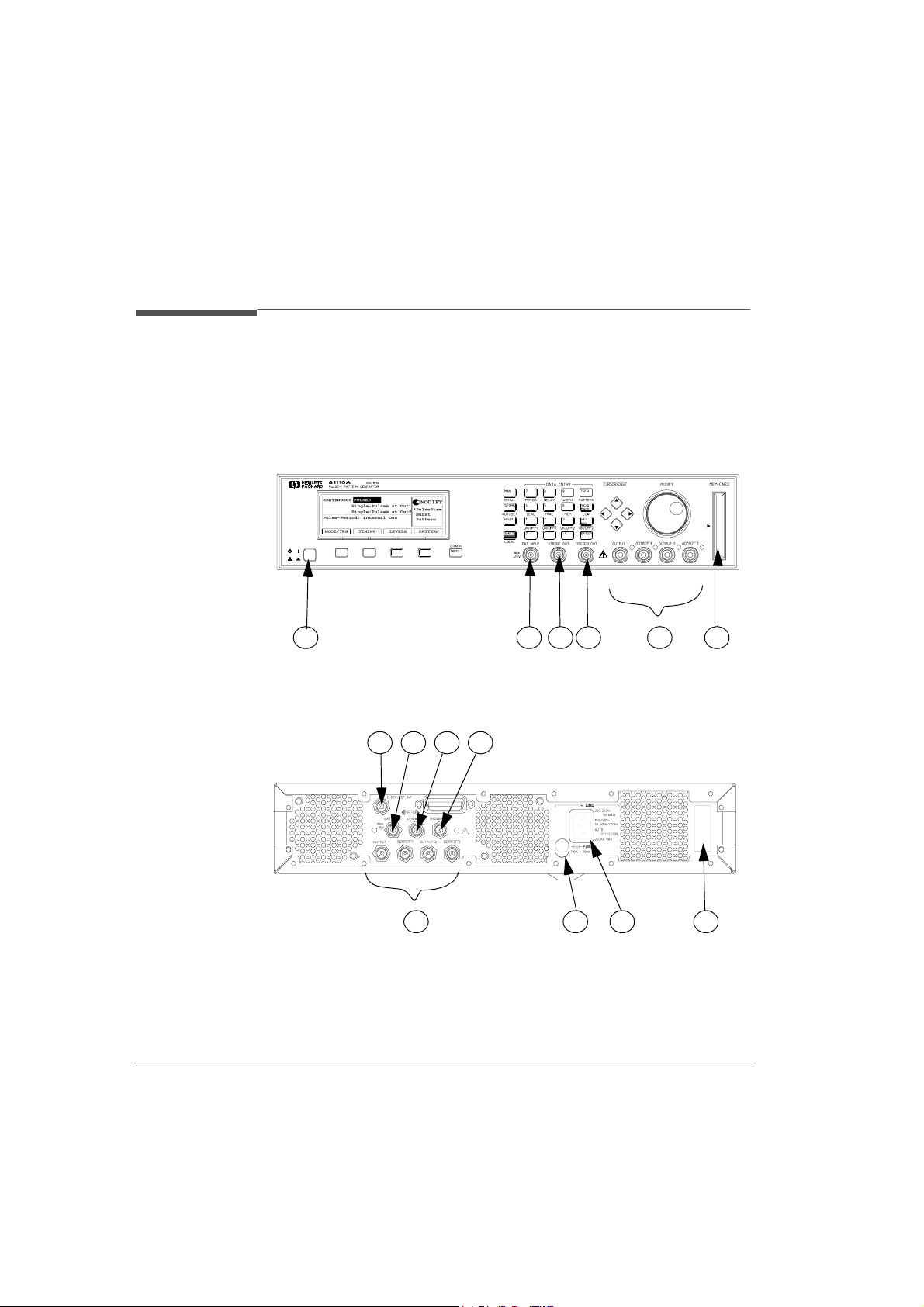

An Overview of the Front and Rear Panel

Figure 23 Front Panel View

1

Figure 24 Rear Panel View with Option UN2

5

6

2

3

4

4

5

3

8

2

9

7

10

The numbers in the Figures correspond to the numbers in the following

list.

66 Introduction HP 81110/04A Quick St art

Introduction

An Overview of the Front and Rear Panel

Inputs and Outputs

1 Standby Switch

NOTE: When the front panel switch is off, the Mainframe is in ’Standby’

mode. Disconnection from the AC Line Power is accomplished

only by disconnecting the power cord.

2 OUTPUT 1/2 - Signal outputs, channel 2 optional.

OUTPUT 1/2

with HP 81112A 3.8V/330 MHz Output channels installed.

3 TRIGGER OUT

A signal with risin g edge ma rking the st art of each pu lse- period . For

further informati on r ef er to “Trigger and Strobe Output” on page 48.

4 STROBE OUT

• The Strobe output rises at the start of the first pulse-period and falls

at the start of the last pulse-per iod mar kin g start a nd e nd of th e burst

in Burst mode.

• Bitwise programmable in Pattern mode. NRZ data format.

• Not used in Pulses mode.

• For further information refer to “Trigger and Strobe Output” on

page 48.

5 EXT INPUT - Connect an external t rigger or gate si gnal here, or use

EXT -WIDTH mode to perform pulse recovery.

NOTE: When rear panel option UN2 is ordered the connectors 2), 3), 4)

and 5) are at the rear panel.

6 PLL REF IN/CLK IN - Connect an exter nal fr equency re fere nce or

clock signal here, if a higher frequency accuracy than 0.01% is

required, or if you need fr equency locking.

- Differential signal outputs available with HP 81110A

7 Memory Card slot

HP 81110/04 A Quick Start Introduction 67

Introduction

An Overview of the Front and Rear Panel

8 Fuse Holder

9 AC Line Socket

10 Serial Number Label

68 Introduction HP 81110/04A Quick St art

Chapter 3

3Getting Started

HP 81110/04A Quick Start Getting Started 69

Getting Started

Introduction

Introduction

The intention of this chapter is to give the necessary steps to set up

generic signals for fi rst time users of the HP 81110A or HP 81104A.

Additionally, advanced signals are also described step by step to enable

even experienced users to set up signals more quickly.

When using this product for the first time it is recommended t o read

Chapter 2, Introduction to get familiar with the user Interf ace concept

and the fundam entals of puls e parameters, fo r User Interface Concept

description see page 37 .

Manual Example Signals

Generic Signals

1 How to set up a Clock Signal (see page 72 )

2 How to set up a Pulse Signal (see page 79 )

3 How to set up a Serial Data Stream Signal (see page 86 )

Advanced Signals

4 How to set up an Edge-displacement Signal (see page 91 )

5 How to set up a Dual Clock Signal (see page 97 )

6 How to set up Burst Signals (see page 103 )

Programming Examples

At the end of each manual example signal, the required set of device

commands are listed. For further information of the commands and a

complete command reference see Chapter 2 of the Reference Guide, p/n

81110-91011.

70 Getting Started HP 81110/04A Quick Start

Getting Started

Introduction

Documentation Conventions:

|TIMING| Press the |TIMING| softkey to access the

TIMING parameter screen.

Entry Focus The highlight field, can be moved with the

cursor keys, to either change a mode or

parameter.

24 ns Enter this value and unit with the DATA

ENTRY keys

Freq Select the mode or parameter name with

the knob.

Keys to press in the DATA ENTRY area

on the front panel.

MODIFY \

CURSOR > Use the front panel controls.

DATA ENTRY /

:VOLTage:HIGH 3V Full command for pattern, 3V high level.

The upper case letters represent the short

form of the command, which results in

faster programming times.

*RST Common IEE 488 command, to reset

instrument to d efault status

:DISPlay OFF Switch off the au tomatic update of the

display, when instrument is used in remote

control operations. This increases the

programming speed.

HP 81110/04A Quick Start Getting Started 71

Getting Started

Examples

Examples

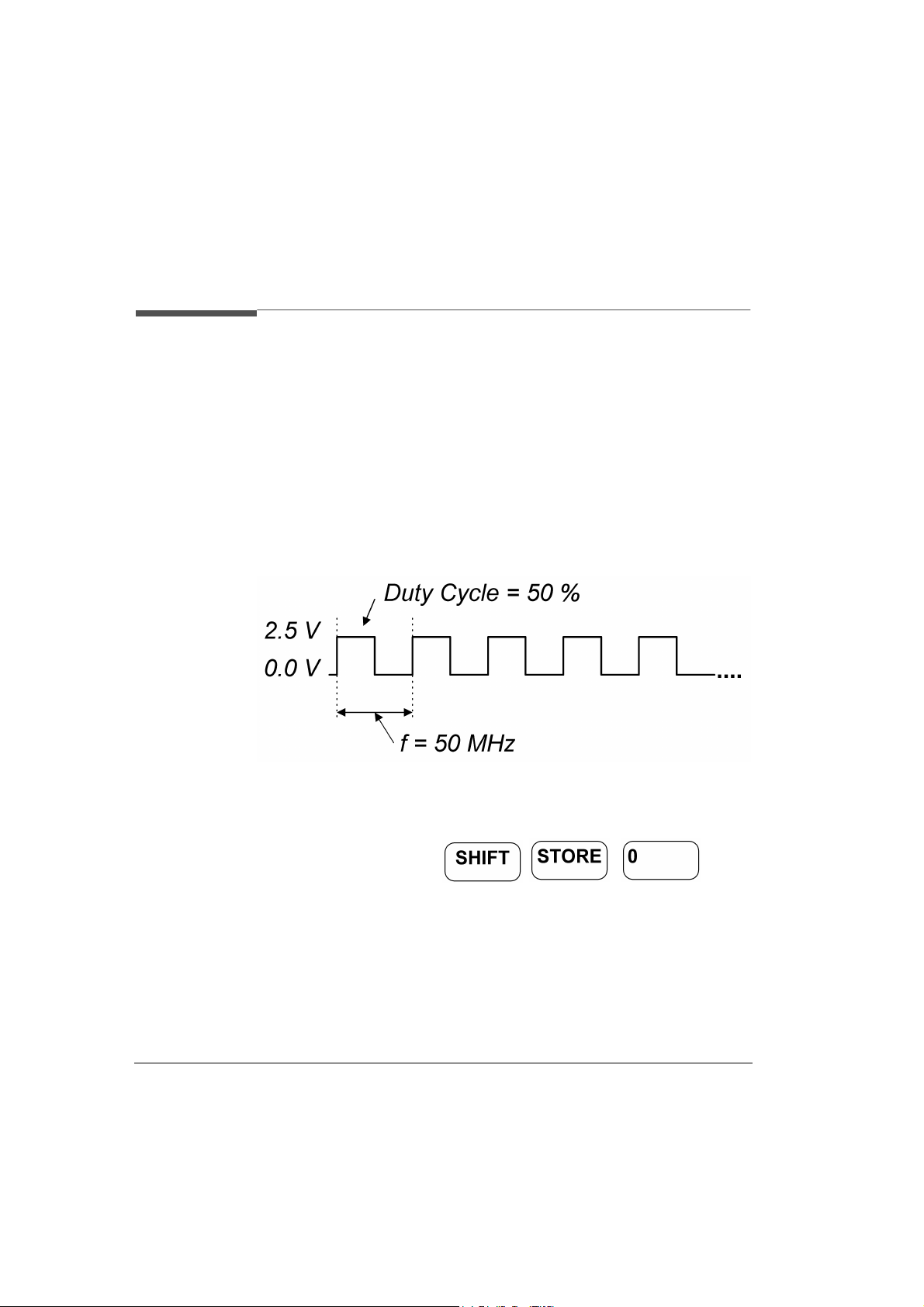

1. Setting up a C l ock Signal

Here, a continuous clock signal with 50 MHz frequency with PLL accuracy, a duty cycle of 50%, 3 ns tr ansition times , a h igh l evel of 2.5 V and

low level of 0 V, will be set up.

Figure 25 Clock Signal Diagram

1 Before setting up the signal it is recommended to reset all parameters

and modes by pressing .

72 Getting Started HP 81110/04A Quick Start

Getting Started

Examples

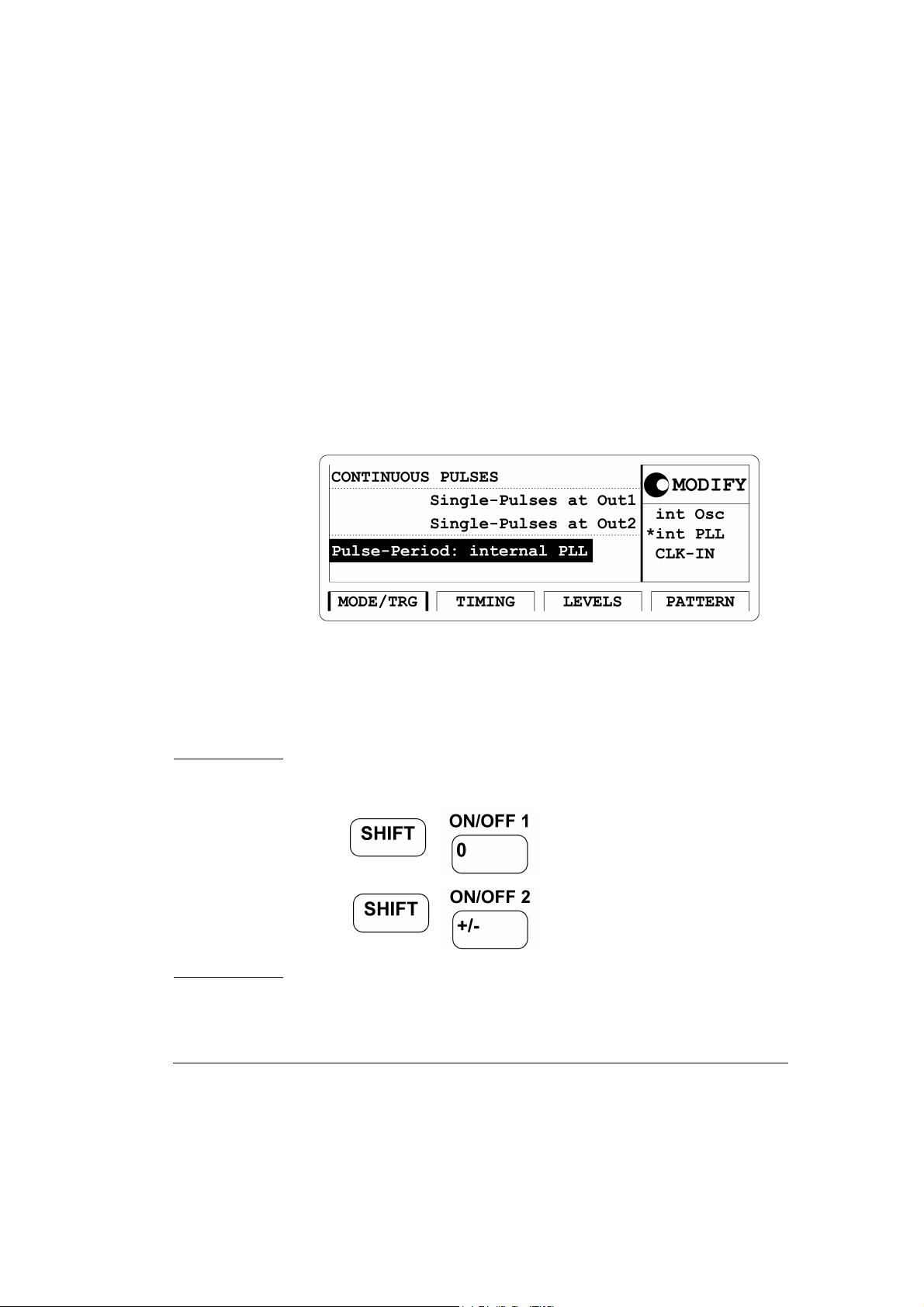

2 Press the |MODE/TRG| softkey to enter the Operatin g/Trigger Mode

menu. Use the cursor keys to move the Entry Focus to the Trigger

mode

CONTINUOUS. Move the Entry Focus to the right and select

PULSES. Move the Entry Focus down to select Single-Pulses at Out1

and then

Figure 26 Current MODE/TRG Screen

Pulse-Period: internal PLL.

3 Press the |TIMING| softkey to enter the Timing menu.

• Move the Entry Focus to the Output 1 status with the cursor keys.

ON in the Modify area to turn on the Output 1.

Select

NOTE: The Output channel can be turned on and off in either the

|LEVELS| or |TIMING| screens or by the following: pressing

for Output 1 and

for Output 2. Repeated pressing of

the keys toggles the output state from on to off and vise versa.

• Move the Entry Focus to

HP 81110/04A Quick Start Getting Started 73

Per and select Freq.

Getting Started

Examples

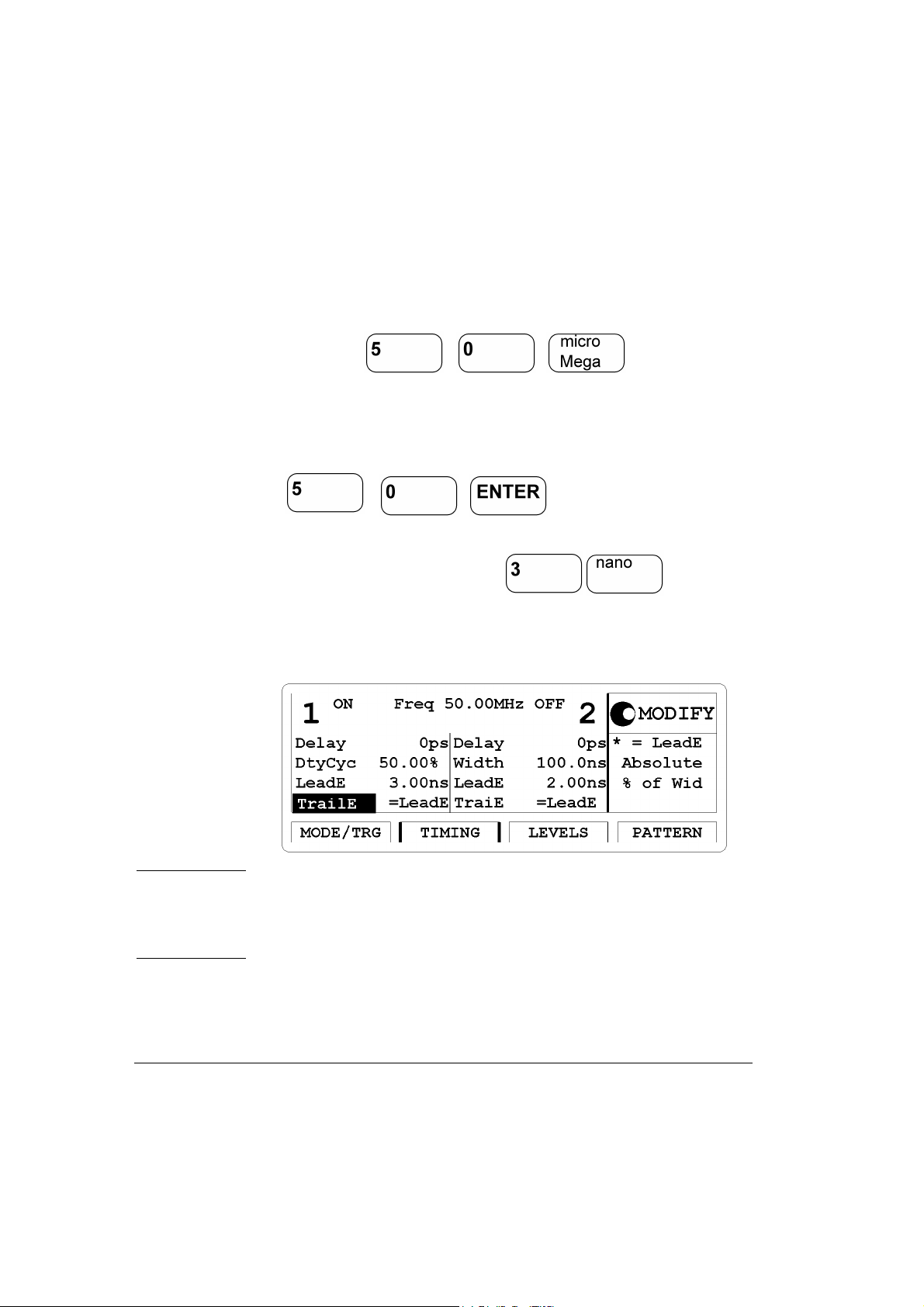

• Move the Entry Focus to Freq ent ry field and e nter a valu e of 50 MHz

by pressing

• Move the Entry Focus down to the width of Output 1 and select

tyCyc

.

Du-

Move Entry Focus to the right and enter 50% by typing

• Move Entry Focus down to enter for the leading edge. Trailing edge should be the sa me as leading ed ge. (

Lead E

Figure 27 Current TIMING Screen

)

Trail E =

NOTE: With HP 81110A with HP 81112A 3.8V/330 MHz Output

channels installed the transition times can be either 800 ps or 1.6

ns, trailing edge is equal to leading edge. The minimum transition

times for the HP 81104A are 3 ns.

74 Getting Started HP 81110/04A Quick Start

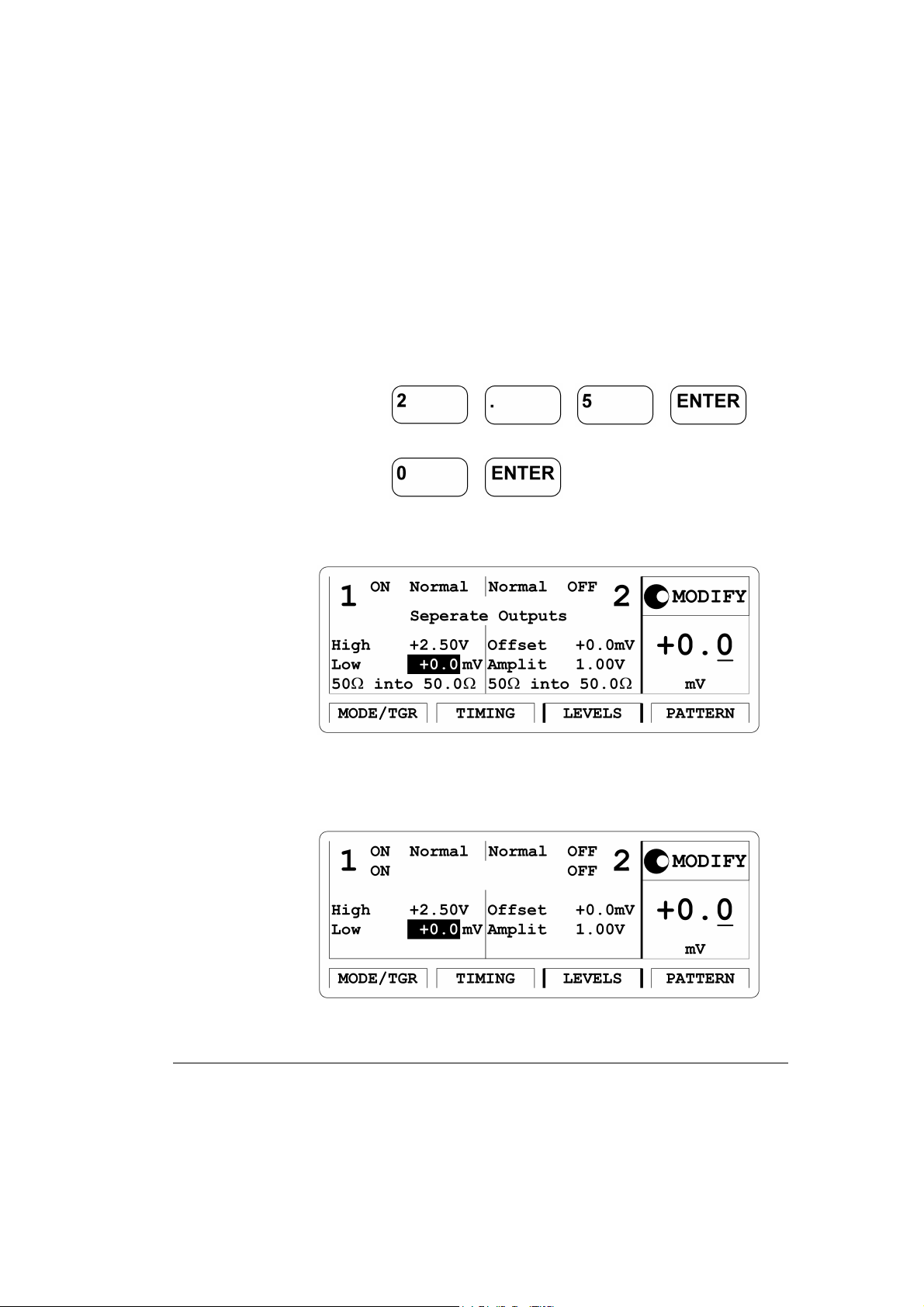

4 Press the |LEVELS| softkey to enter the Levels menu.

Getting Started

Examples

• Move the Entry Focus to

IFY area

High-Low, then move Entry Focus to high level entry field

Offset and Amplitude and select in the MOD-

and press for

high level and move down the Entry Focu s to the low level entry field

and press .

Figure 28 Current LEVELS Screen for HP 81104A and HP 81110A

with HP 81111A installed

Figure 29 Current LEVELS Screen for HP 81110A with HP 81112A in-

stalled

HP 81110/04A Quick Start Getting Started 75

Getting Started

Examples

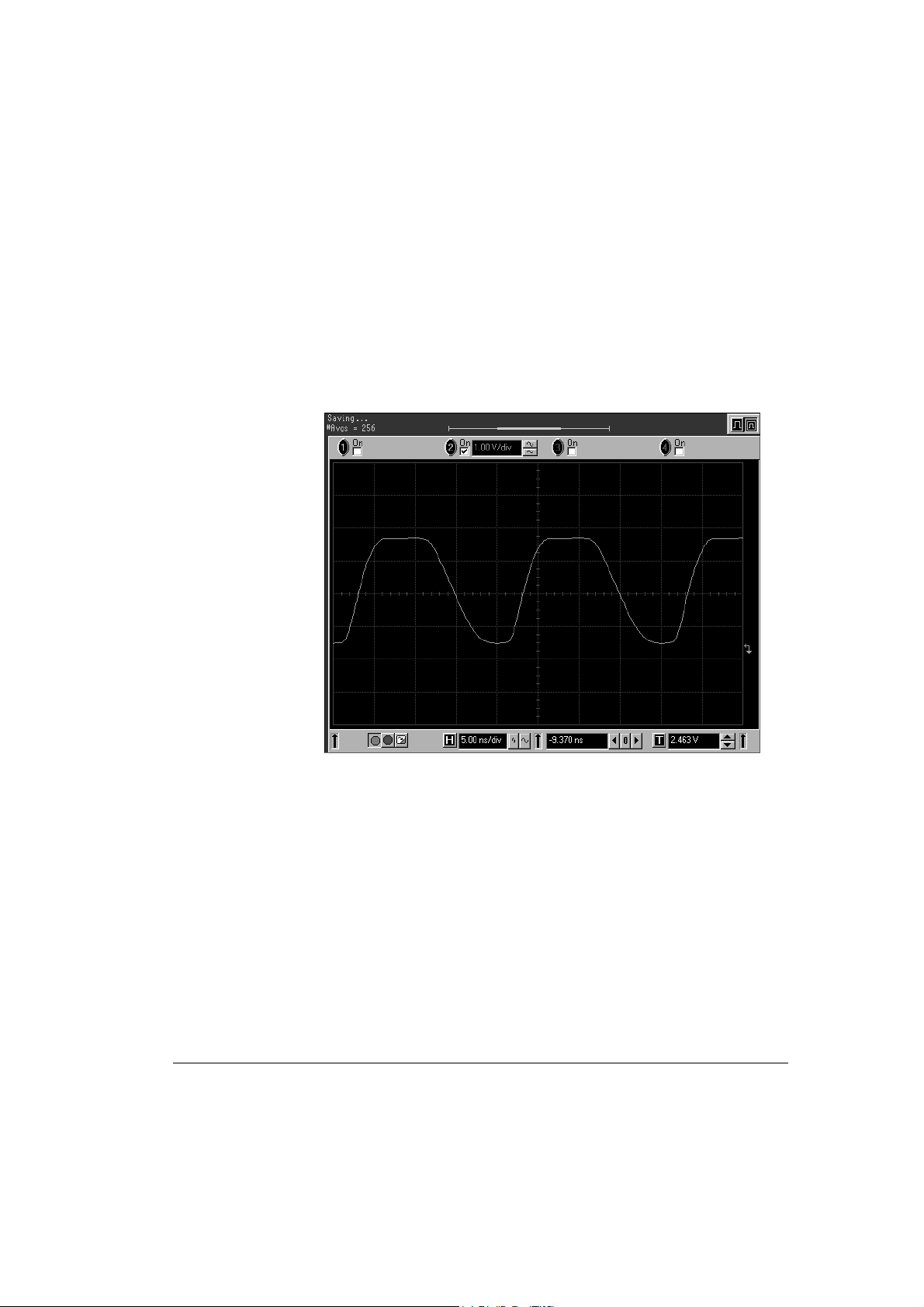

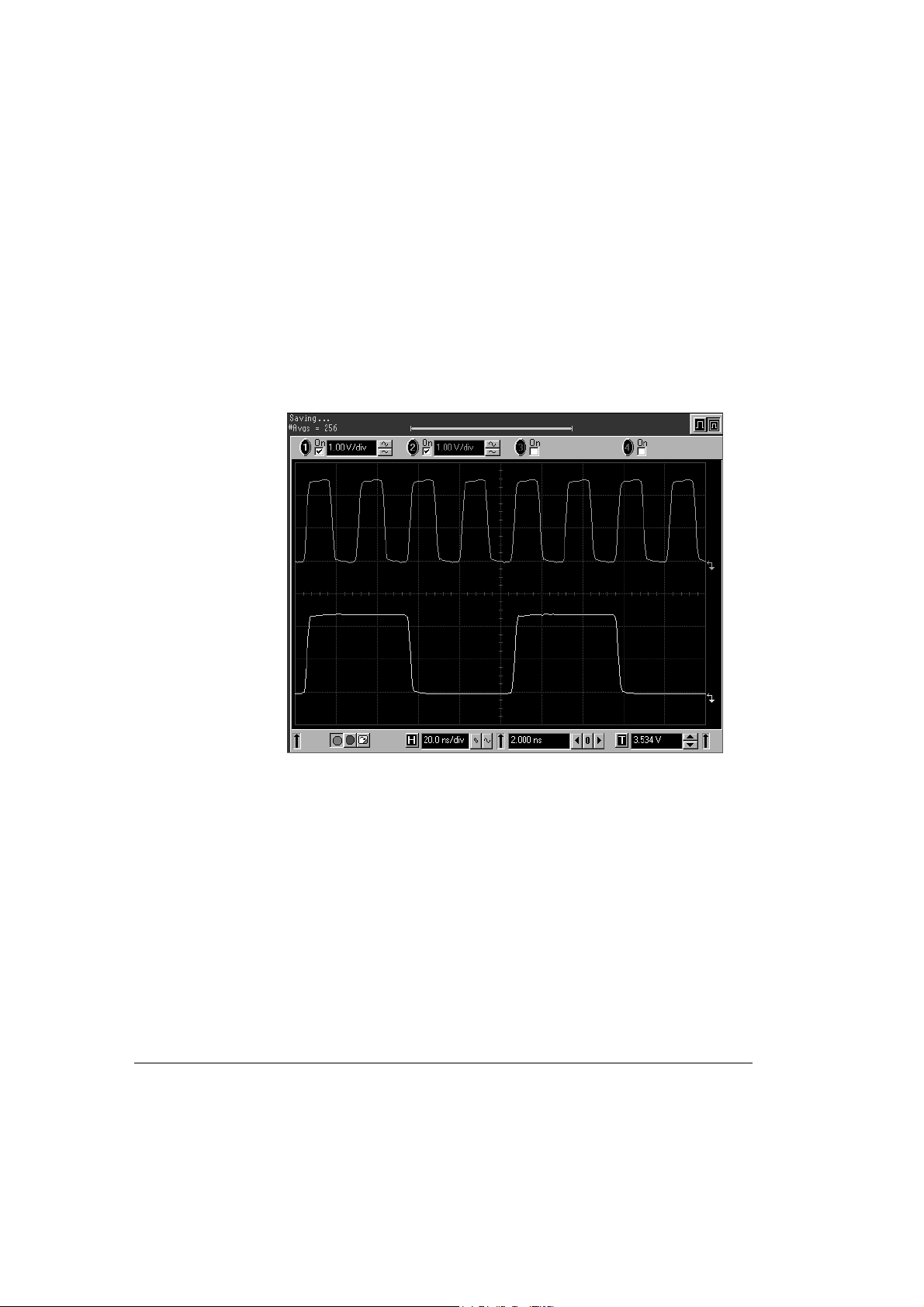

5 Here is the signal as displayed on an HP 54810A Infinium

oscilloscope. Use the generator’s TRIGGER OUT to trigger the

scope.

Figure 30 Resulting Signal

76 Getting Started HP 81110/04A Quick Start

Getting Started

Examples

Device Command List for the Clock Signal

• If you want to include this Clock Signal in your program use the

following command lines in boldface font. The comment lines starting with a # are not required.

• The commands are listed with the channel specifier for channel 1, if

there is a second channel install ed and you want to program it with a

similar signal, use the same commands and replace 1 by 2 for the

second channel, where required.

# Reset the instrument to start from a defined, default status.

*RST

# Switch off the automatic display update to increase programming

# speed.

:DISPlay OFF

# Internal PLL has to be set as period source.

:ARM:SOURce INT2

# Set the frequency to 50 MHz, the duty cycle to 50% and the leading

# and trailing edge to 3 ns. Settings are to program for output 1.

:FREQuency 50MHZ

:PULSe:DCYCle1 50

:PULSe:TRANsition1 3NS

# For example, the same settings for the optional second channel will

# look like as follow s:

:PULSe:DCYCle2 50

HP 81110/04A Quick Start Getting Started 77

Getting Started

Examples

:PULSe:TRANsition2 3NS

# Set the high level to 2.5 Volts, the low level to 0.0 Volts.

:VOLTage1:HIGH 2.5V

:VOLTage1:LOW 0V

# Enable the output 1 and the complement output 1 (HP 81110A

# with HP 81112A 3.8V/330 M Hz output channel installed, only).

:OUTPut1 ON

:OUTPut1:COMPlement ON

78 Getting Started HP 81110/04A Quick Start

Getting Started

Examples

2. Setting up a Pulse Signal

Here a continuous pul se si gnal wi th 20 ns p eriod , a pul se widt h of 1 0 ns,

a leading edge of 3 ns, a tr ai ling edge of 5 ns, an amplitude of 3.3 V and

an offset of 1.65 V (high level 3.3 V, low level 0.0 V) will be set up.

Figure 31 Pulse Signal Diagram

1 Before setting up the signal it is recommended to reset all parameters

and modes by pressing .

HP 81110/04A Quick Start Getting Started 79

Getting Started

Examples

2 For reference the current |MODE/TRG| screen is displayed.There is

nothing to change.

Figure 32 Current MODE/TRG Menu

3 Press the |TIMING| softkey to enter the Timing menu.

•Switch

• Enter a period of

ON the Output Channel 1.

20 ns. Enter a pulse width of 10 ns.

•Enter 3 ns for leading edge. Se lect Absolute for trailing edge and enter

a value of

5 ns.

NOTE: With HP 81110A with HP 81112A 3.8V/330 MHz Output

channels installed the transition times can be either 800 ps or 1.6

ns, trailing edge is equal to leading edge. The minimum transition

times for the HP 81104A are 3 ns.

80 Getting Started HP 81110/04A Quick Start

Getting Started

Figure 33 Current TIMING Screen

NOTE: The Output channel can be turned on and off in either the

|LEVELS| or |TIMING| screens or by the following: pressing

for Output 1 and

Examples

for Output 2. Repeated pressing of

the keys toggles the output state from on to off and vise versa.

HP 81110/04A Quick Start Getting Started 81

Getting Started

Examples

4 Press the |LEVELS| softkey to enter the Levels menu.

Enter an offset of 1.65 V and an amplitude of 3.30 V.

Figure 34 Current LEVELS Screen for HP 81104A and HP 81110A

with HP 81111A installed

Figure 35 Current LEVELS Screen for HP 81110A with HP 81112A in-

stalled

82 Getting Started HP 81110/04A Quick Start

Getting Started

5 Here is the figure as displayed on the HP 54810A Infinium

oscilloscope. Use the generator’s TRIGGER OUT to trigger the

scope.

Figure 36 Resulting Display

Examples

HP 81110/04A Quick Start Getting Started 83

Getting Started

Examples

Device Command List for the Pulse Signal

• If you want to include this Pulse Signal in your program use the fol-

lowing command lines in boldface font. The comment lines starting

with a # are not required.

• The commands are listed with the channel specifier for channel 1, if

there is a second channel install ed and you want to program it with a

similar signal, use the same commands and replace 1 by 2 for the

second channel, where required.

# Reset the instrument to start from a defined, default status.

*RST

# Switch off the automatic display update to increase programming

# speed.

:DISPlay OFF

# Pulse stream operating mode is required, but as we start from a

# default status it is not necessary to send a command for setting the

# instrument into pulse stream operating mode.

# Set the period to 20 ns, the pulse width to 10 ns, the leading edge to

# 3 ns and the trailing edge to 5 ns.

:PULSe:PERiod 20NS

:PULSe:WIDTh1 10NS

:PULSe:TRANsition1 3NS

:PULSe:TRANsition1:TRAiling:AUTO OFF

:PULSe:TRANsition1:TRAiling 5NS

84 Getting Started HP 81110/04A Quick Start

Getting Started

Examples

NOTE: For HP 81110A with HP 81112A 3.8V/330 MHz Output channel

installed the transitions can be selected either 800 ps or 1.6 ns.

Leading and trailing edge are equal.

# Set the amplitude to 3.3 Volts, the offset to 1.65 Volts.

:VOLTage1 3.3V

:VOLTage1:OFFSet 1.65V

# Enable the output 1 and the complement output 1 (HP 81110A

# with HP 81112A 3.8V/330 M Hz output channel installed, only).

:OUTPut1 ON

:OUTPut1:COMPlement ON

HP 81110/04A Quick Start Getting Started 85

Getting Started

Examples

3. Setting Up a Serial Data Stream Signal

Here a continuous 24 bit long pattern signal with NRZ data output format at 80 MBit/s and ECL output level will be set up. The pattern is

‘111001110011001001010010’.

1 Before setting up the signal it is recommended to reset all parameters

by pressing .

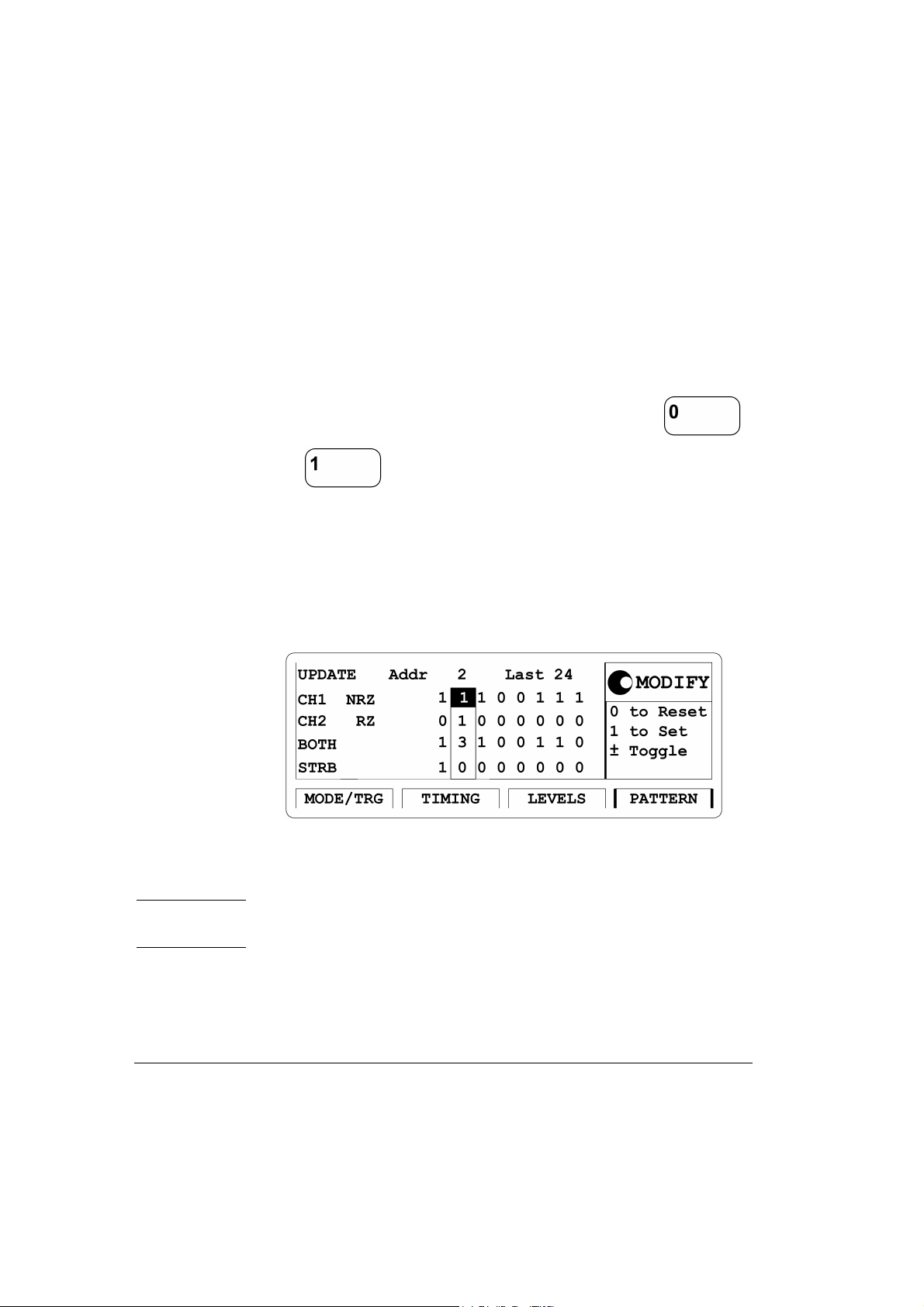

2 Press the

menu. Select

Out 1

Figure 37 Current MODE/TRG Screen

|MODE/TRG| softkey to enter the Operating/Trigger Mode

CONTINUOUS PATTERN of. Highlight RZ- Pulses at

and select NRZ.

86 Getting Started HP 81110/04A Quick Start

Getting Started

Examples

3 Press the |TIMING| softkey to enter the Timing menu. Switch ON the

Output 1.

Enter frequency of 80 MHz.

NOTE: It is recommended to set the width for channel 2 to 6.250 ns to

avoid a parameter conflict when switching on this channel.

The

‘-------’ in the output 1 width ent ry field relate to the NRZ dat a

output format selection.

Figure 38 Current TIMING Screen (for HP 81110A)

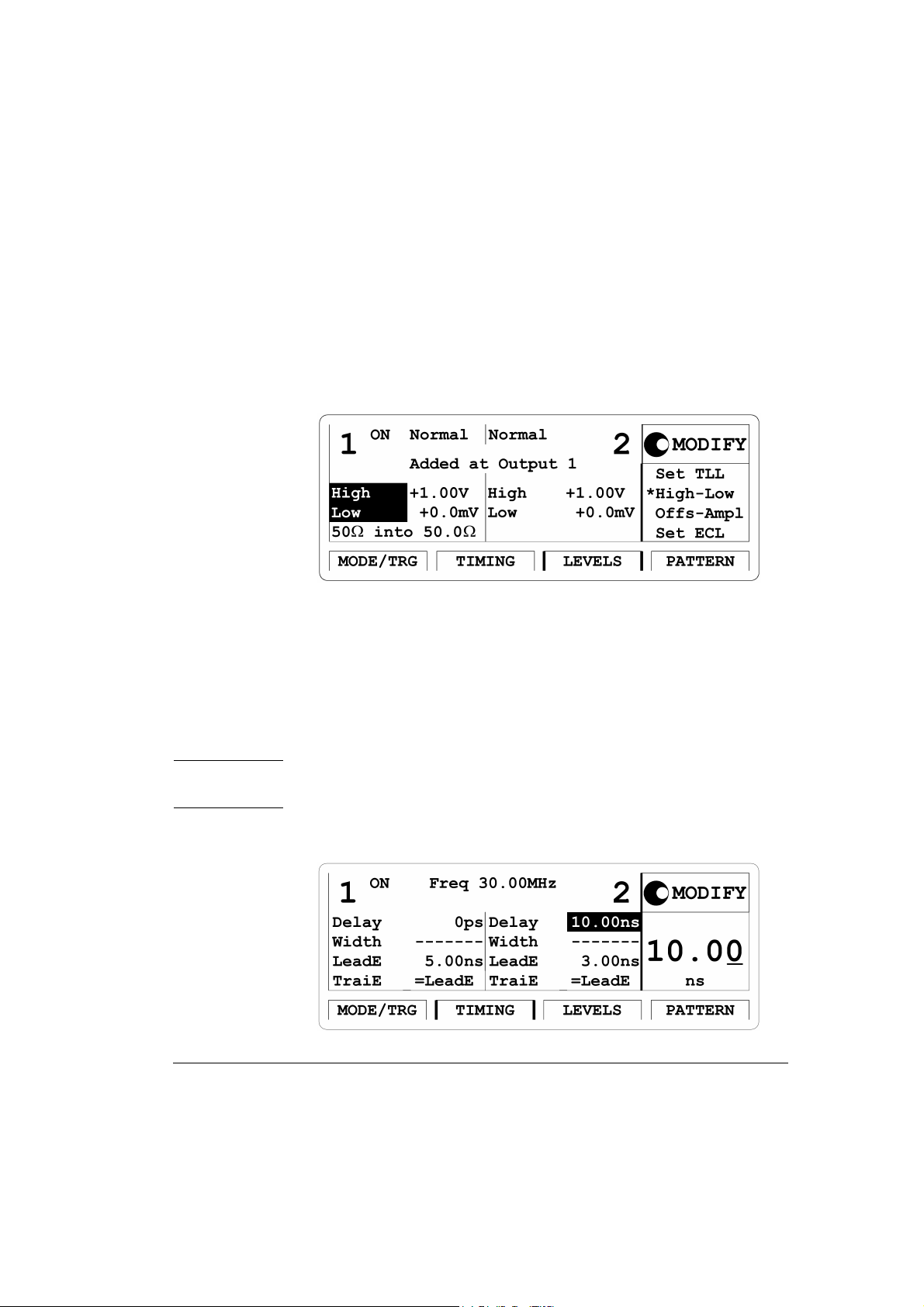

4 Press the |LEVELS| softkey to enter the Levels menu. Change Offset

and

Amplitude mode to ECL levels by selecting Set ECL in the

Modify Area.

Figure 39 Current LEVELS Screen

NOTE: HP 81110A with HP 81112A 3.8V/330 MHz Output channels

installed have fixed 50

Ω source impedance and does not offer to

adjust for a load impedance different then 50 Ω.

HP 81110/04A Quick Start Getting Started 87

Getting Started

Examples

5 Press the |PATTERN| softkey to enter the Pattern menu.

• Move the Entry Field to

Last and input a value of 24.

• Move the Entry Fie ld to the b it-editing wi ndow for CH1 and enter the

pattern ‘111001110011001001010010’ by pressing th e

or key, respecively. When entering the pattern the bitediting window moves automatically one location to the right. By

turning the knob c ount er cl ockwise you can move th e bi t -editing window back. The actual memory location on which the the bit-editing

window is pointing is shown by Addr.

Figure 40 Current PATTERN Screen

NOTE: To get a stable displa y of th e pattern str eam on a n os cill oscope set

1 bit of the Strobe (STRB) and trigger the scope.

88 Getting Started HP 81110/04A Quick Start

Getting Started

Examples

Device Command List for the Data Stream Signal

• If you want to include this Data Stream Signal in your program use

the following command lines in boldface font. The comment lines

starting with a # are not required.

• The commands are listed with the channel specifier for channel 1, if

there is a second channel install ed and you want to program it with a

similar signal, use the same commands and replace 1 by 2 for the

second channel, where required.

# Reset the instrument to start from a defined, default status.

*RST

# Switch off the automatic display update to increase programming

# speed.

:DISPlay OFF

# Set the instrument to pattern mode and select NRZ data output format

# for output 1.

:DIGital:PATTern ON

:DIGital:SIG Nal1:FORMat NRZ

# For example the command to set NRZ data fo rmat for the optional

# second channel is:

# :DIGital:SIGNal2:FORMat NRZ

# Define a pattern length of 24 bit and program the pattern:

# ‘111001110011001 00101 0010’.

:TRIGger:COUNt 24

HP 81110/04A Quick Start Getting Started 89

Getting Started

Examples

:DIGital:PATTern:DATA1 #224111001110011001001010010

# Set the frequency to 80 MHz, and output 2 width to 6.25 ns to avoid a

# parameter conflict.

:FREQuency 80MHZ

:PULSe:WIDTh2 6.25NS

# Set the output voltage to fixed ECL levels.

:VOLTage1:HIGH -0.85V

:VOLTage1:LOW -1.8V

# Enable the output 1 and the complement output 1 (HP 81110A

# with HP 81112A 3.8V/330 M Hz output channel installed, only).

:OUTPut1 ON

:OUTPut1:COMPlement ON

90 Getting Started HP 81110/04A Quick Start

Getting Started

Examples

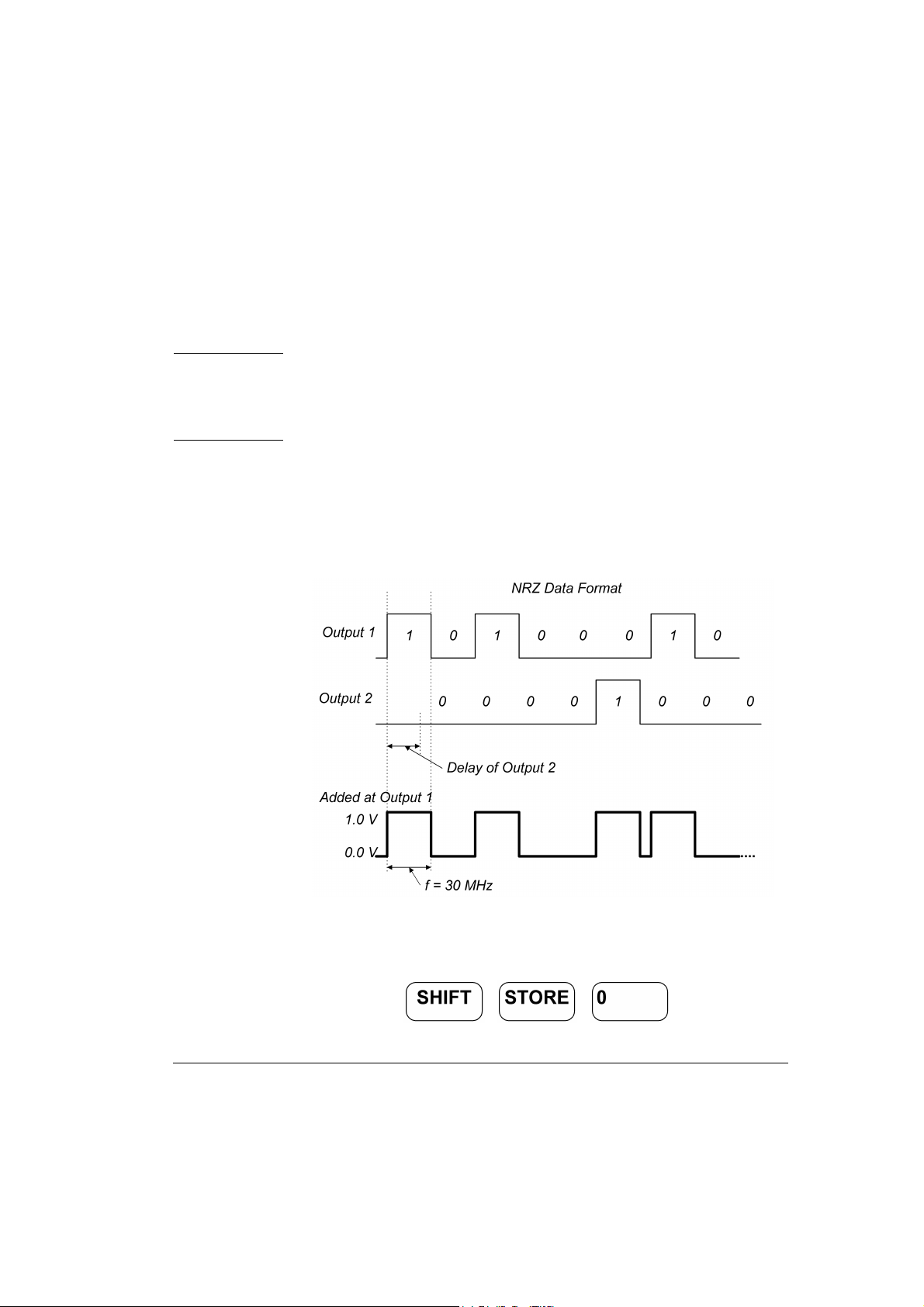

4. Setting Up an Edge-displacement Signal

NOTE: Two Outputs are required for this example. The channel addition

feature is used for this example. Therefore, this type of signal can

be performed by HP 81104A and HP 81110A with HP 81111A

10V/165 MHz Outputs.

Here a continuous pattern signal, with one distorted pulse will be set up.

The two channels are added with NRZ (Non Return to Zero) pulses at

both outputs, high level of 1 V and low level of 0 V and Channel 2 delay

of 10 ns. The bit frequency is 30 MHz.

Figure 41 Edge-displacement Signal Diagram

1 Before setting up the signal it is recommended to reset all parameters

by pressing .

HP 81110/04A Quick Start Getting Started 91

Getting Started

Examples

2 Press the |MODE/TRG| softkey to enter the Operating/Trigger Mode

Menu. Select

1 and

NRZ-Pulses at Out 2 using the MODIFY knob.

Figure 42 Current MODE/TRG Screen

CONTINUOUS PATTERN of. Select NRZ-Pulses at Out

3 Pres s the |PATTERN| softkey t o enter t he Patter n menu. Set up the bit

pattern as follows. Enter 8 for Last.